Application Research on Cable Force Optimization of Cable-Stayed Bridge Based on Improved Grey Wolf Algorithm

Abstract

1. Introduction

2. Improved Grey Wolf Algorithm Cable Force Optimization Theory

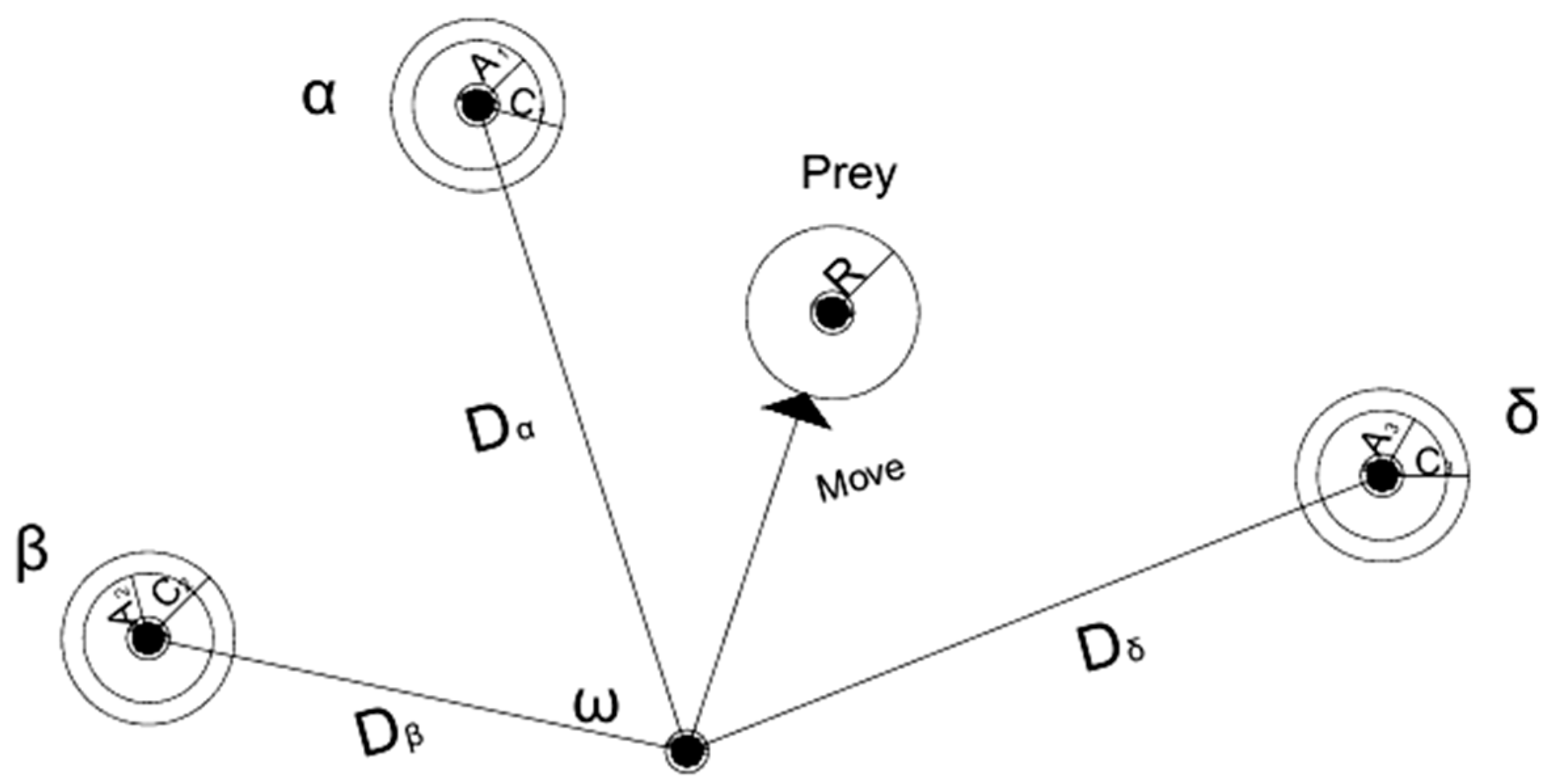

2.1. Standard Grey Wolf Algorithm

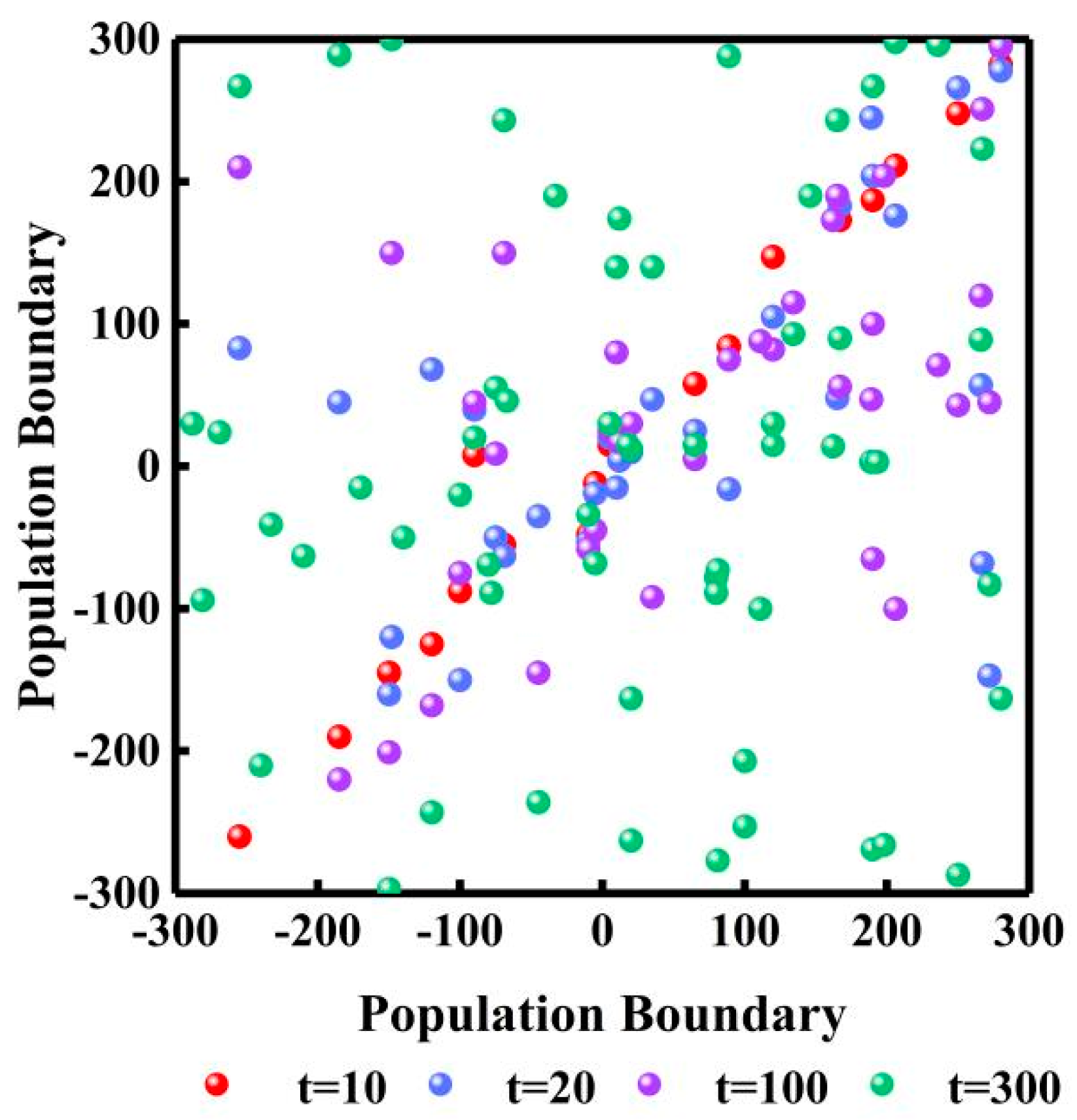

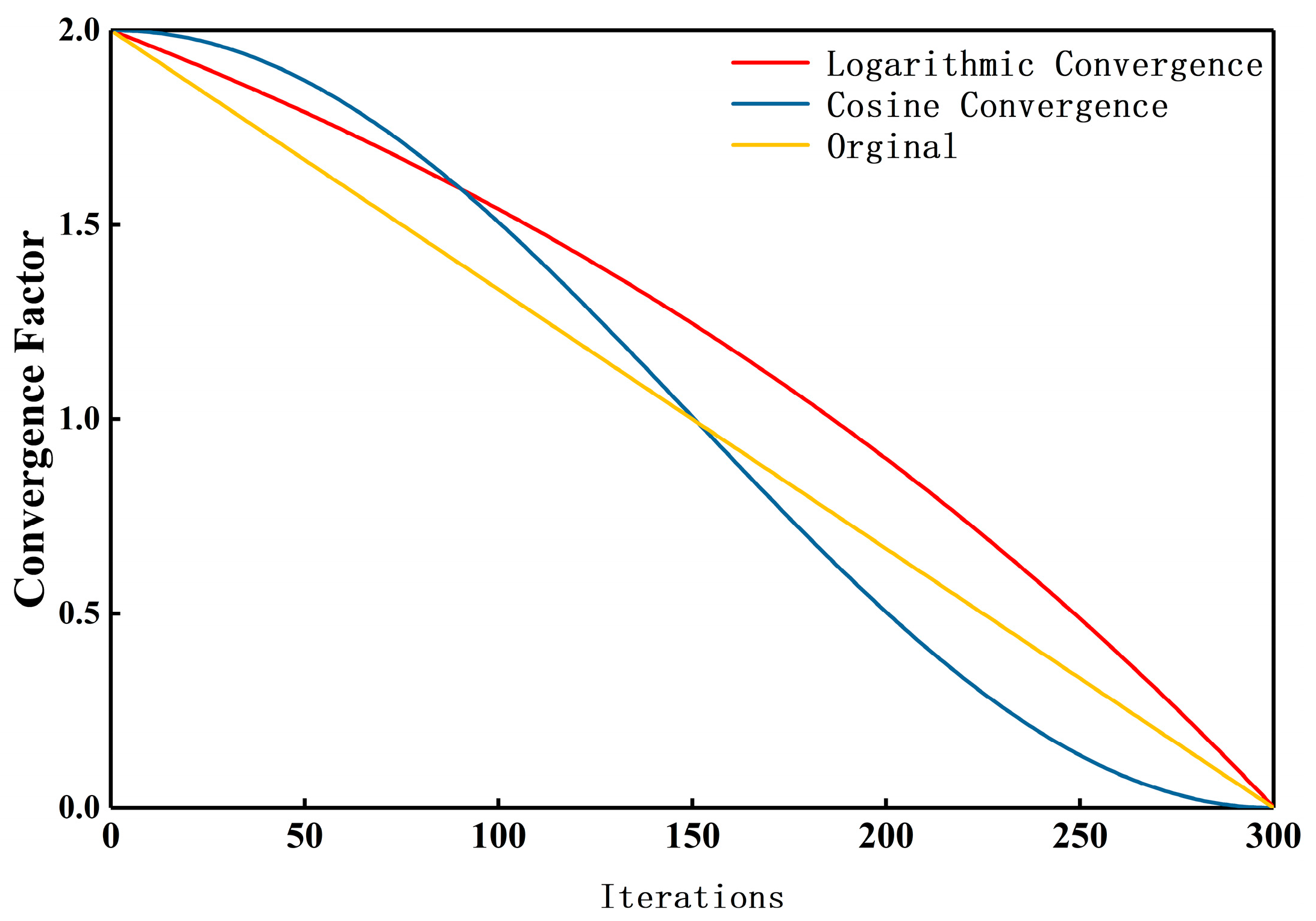

2.2. Improvement of Grey Wolf Algorithm

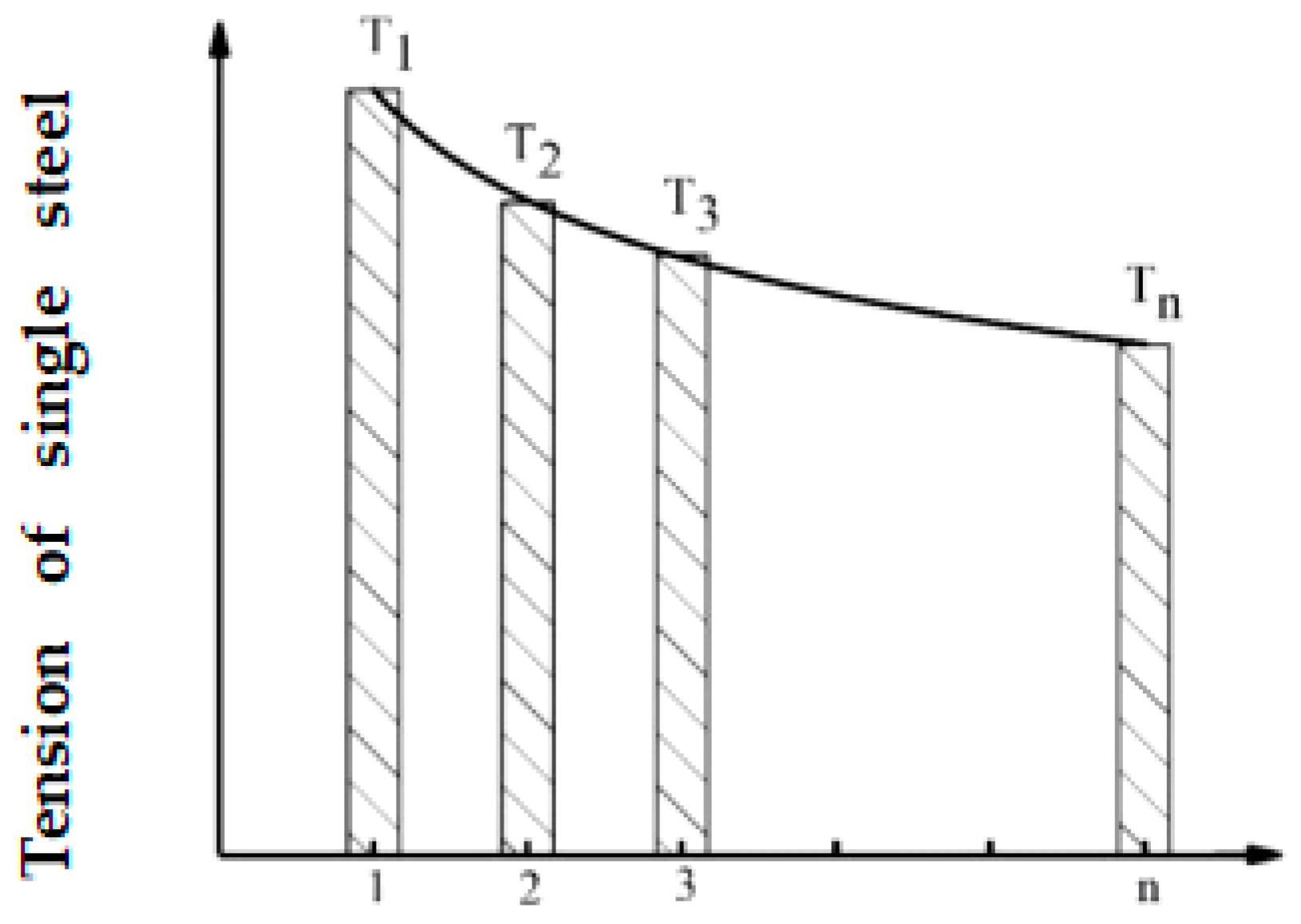

2.3. Improved Grey Wolf Algorithm Cable Force Optimization Method for Cable-Stayed Bridges

- (1)

- The mathematical model for optimizing cable forces in a low-pylon cable-stayed bridge has been established. Structural modeling and stress analysis during construction are conducted using Midas Civil 2023, in accordance with the structural design parameters, to extract relevant data for the mathematical model.

- (2)

- The coding method has been selected, and an optimization model for the key parameters of the support vector machine (SVM) linear prediction has been established. The parameters (c, g) of the vector machine to be optimized are converted into the coordinates of grey wolf individuals within the search space. Sixty-two groups of cable force combination data are randomly generated within the reasonable upper and lower limits of the designed cable tensions. These datasets are then substituted into the finite element program of the low-pylon cable-stayed bridge to calculate the computed elevation of the main girder at each elevation control point.

- (3)

- The IGWO parameters for the SVM parameter optimization model have been initialized. The size of the grey wolf population is set at , and the maximum number of iterations is set at . The parameters (c, g) to be optimized are encoded into the coordinates of the wolf group, and the grey wolf population is evenly distributed within the search space according to Equation (9).

- (4)

- The convergence factor is updated according to Equation (11). The fitness values of the grey wolf population are calculated, and the optimal fitness is assigned to the alpha wolf.

- (5)

- The algorithm’s completion is assessed by determining whether it has reached the maximum number of iterations. If it has not, the process returns to Step 4; if it has, the optimal parameter combination for the support vector machine (SVM) is output. The prediction accuracy of the updated SVM parameters is evaluated using cable force linear training samples. Prediction accuracy is defined as the mean squared error of the deviations between the predicted and actual linear shapes, as shown in Equation (12):where ffit denotes the individual fitness value of the grey wolf; xi signifies the predicted linear elevation of the i-th sample; represents the calculated linear elevation of the i-th sample.

- (6)

- The accuracy of the SVM with updated parameters is evaluated. If the requirements are not met, the process returns to Step (3) for re-optimization. If the requirements are satisfied, the optimization of the SVM linear prediction model is considered complete.

- (7)

- The parameters of the IGWO combination optimization model are initialized, with the parameters to be optimized defined as the cable force combination T in the mathematical model represented by Equation (13). The population size of grey wolves is designated as , and the maximum number of iterations is defined as . The cable force combination T is incorporated into the coordinates of the wolf group. The constraints on the cable force affecting the grey wolf population are established, and the chaos of the grey wolf population is mapped into the search space in accordance with Equation (9).where T represents the cable force input vector to be optimized; xi represents the actual elevation value of the i-th sample; ui represents the theoretical elevation design value of the i-th sample.

- (8)

- The cosine convergence factor is updated according to Equation (11), while the positions of the wolves in the search space are updated based on Equations (7) and (8).

- (9)

- The coordinates of the wolves are decoded, a linear prediction is made using the input vector of the support vector machine (SVM), and the fitness value of the grey wolf population is updated according to the calculation method of the objective function outlined in Equation (13).

- (10)

- It is assessed whether the termination condition of the algorithm—specifically, the maximum number of iterations—has been reached. If the maximum number of iterations has not been reached, the process returns to Step (7). If the maximum number of iterations is attained, the coordinates of the alpha wolf are output, decoded into the cable force combination T, and the results are imported into finite element software for the analysis of the bridge’s completion state. If the target bridge completion state meets the specified requirements, the target cable force for the bridge completion is obtained. If the requirements are not met, relevant parameters are modified, and the process is recalculated.

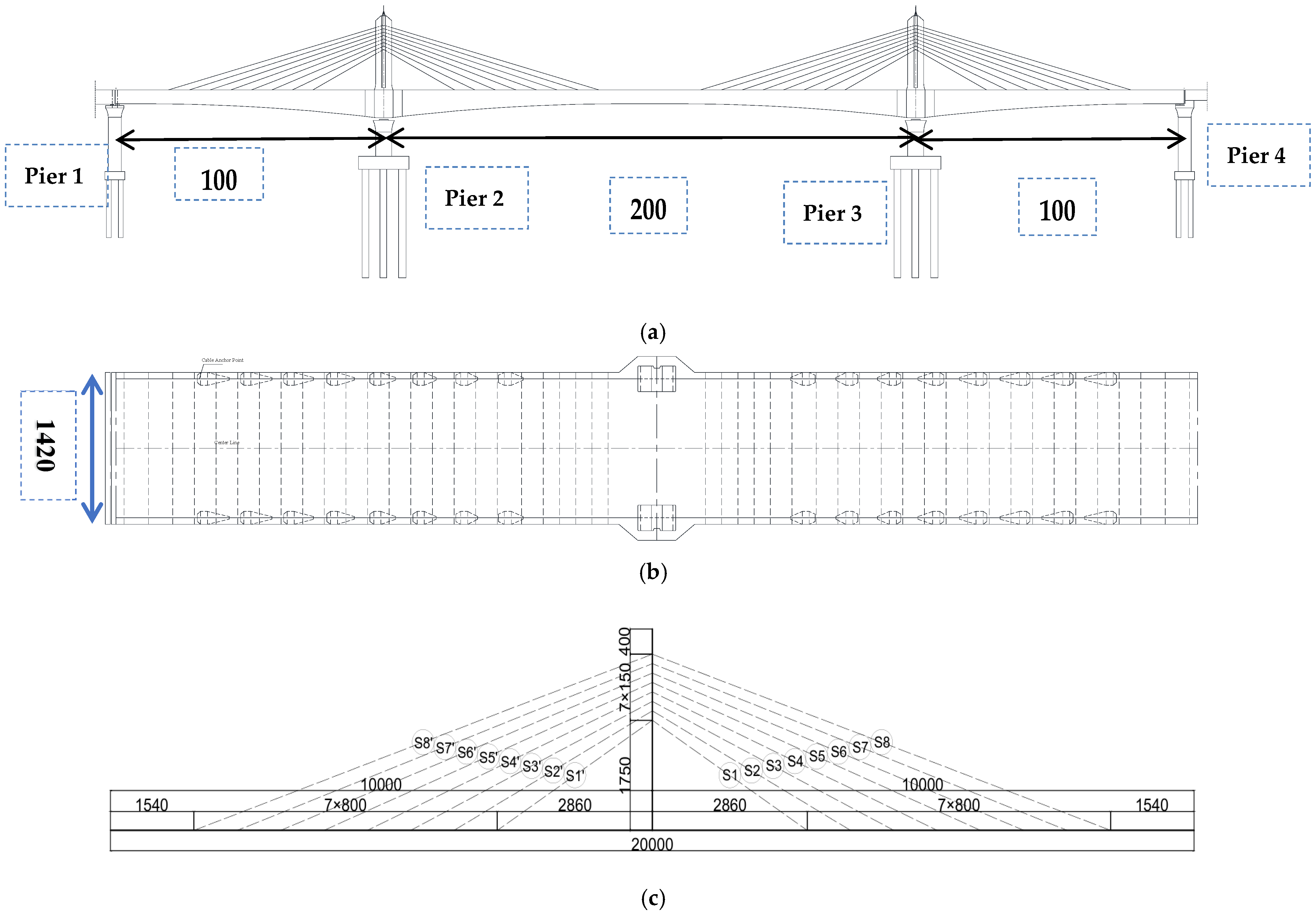

3. Applied Research

3.1. Project Overview

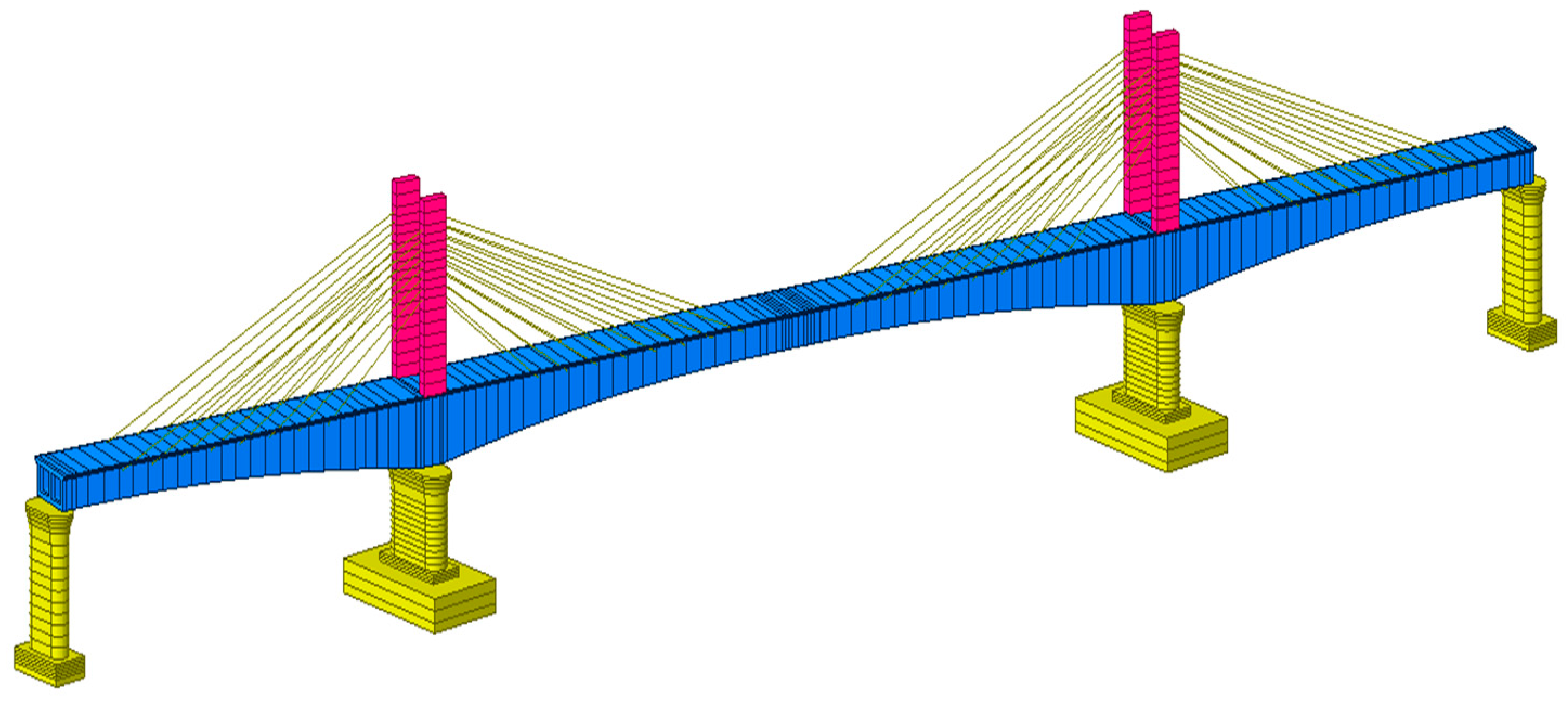

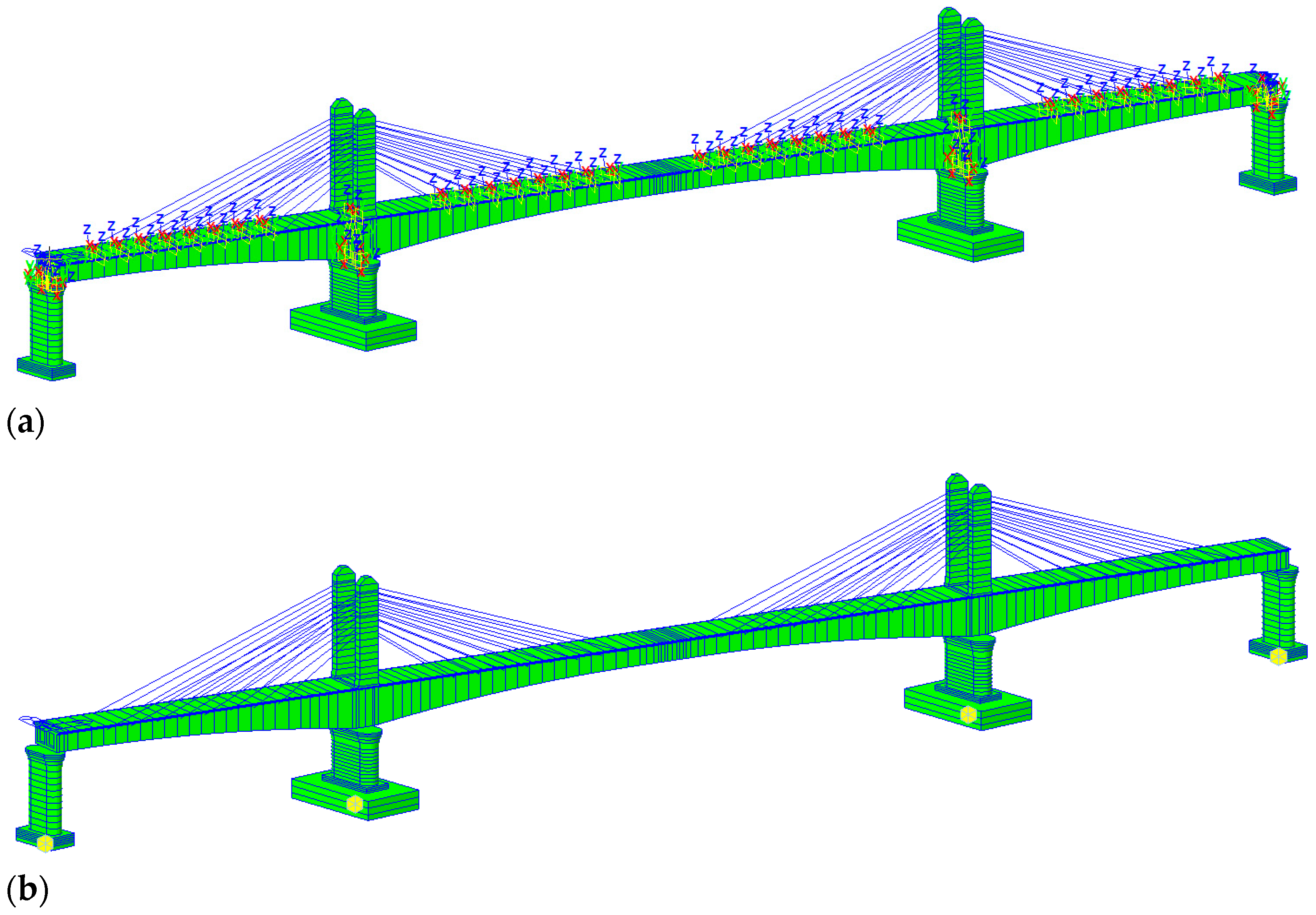

3.2. Simulation of Main Bridge of Lanjiang Bridge

3.3. Field Monitoring Results

3.4. Improved Grey Wolf Algorithm Cable Force Optimization Analysis

3.4.1. Other Cable Force Optimization Methods

| Variable | Meaning |

| u | The displacement value of the control point for the beam, obtained after optimization. |

| dis | The displacement vector of the control points under the influence of the initial tension value X0 for the suspenders. |

| X | The optimized cable force increment vector. |

| m | The real-time corrected weight vector of the grid beam represents the difference between the actual weight and the design weight for each segment of the grid beam. |

| dest | The target displacement vector of the control points on the bridge deck during the bridge completion stage. |

| A | The influence matrix for the unit force of a stay cable on the displacement of the main girder control points. |

| Am | The influence matrix for the weight correction value on the displacement in the completed section of the bridge. |

| delta | The difference vector between the optimization value and the target value. |

| The influence value of the tension unit force of the i-th stay cable on the displacement of the main girder control points. | |

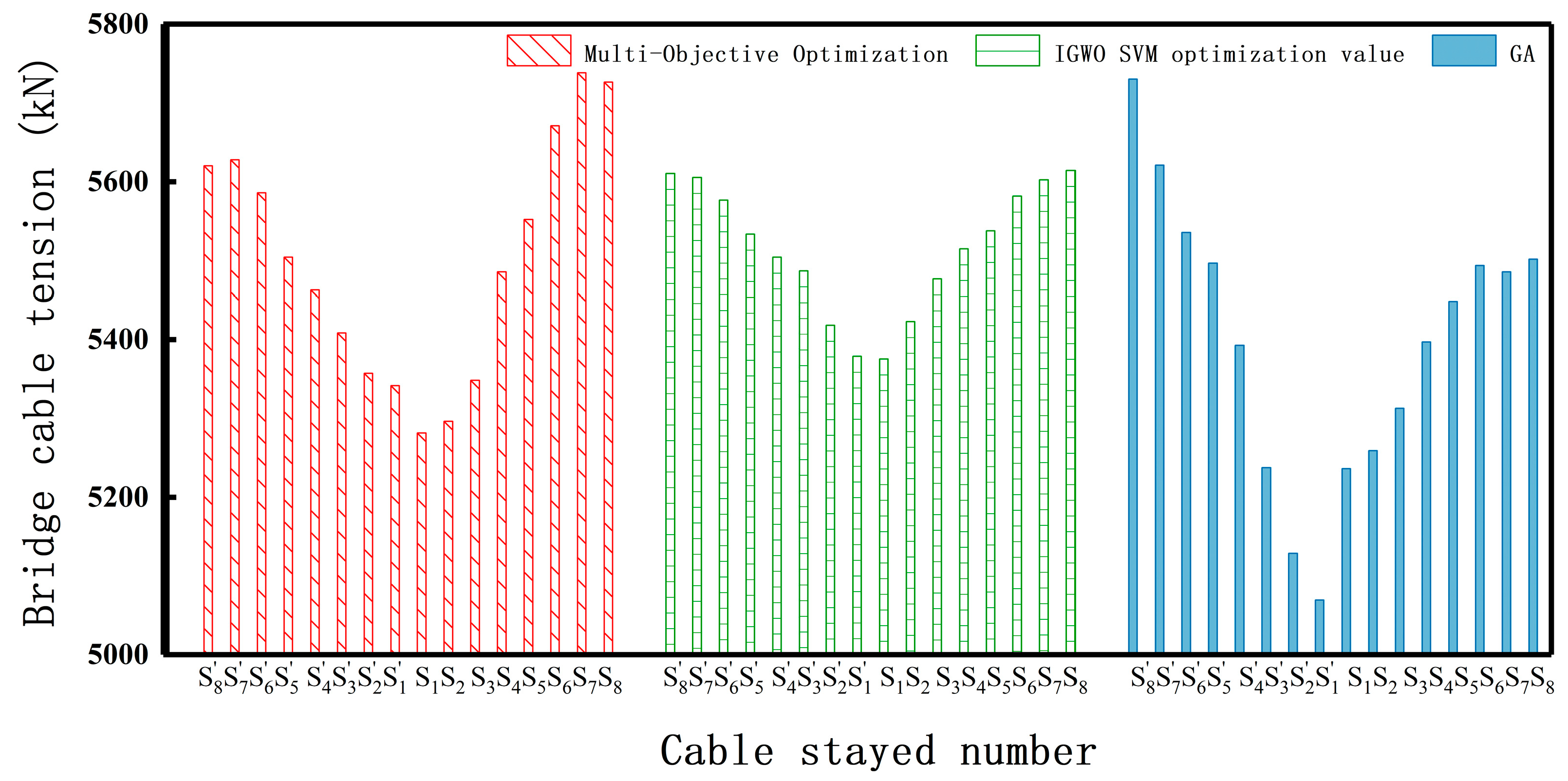

3.4.2. Advantages of Cable Force Optimization Method Based on Improved Grey Wolf Algorithm

- (1)

- Dead load cable force of completed bridge

- (2)

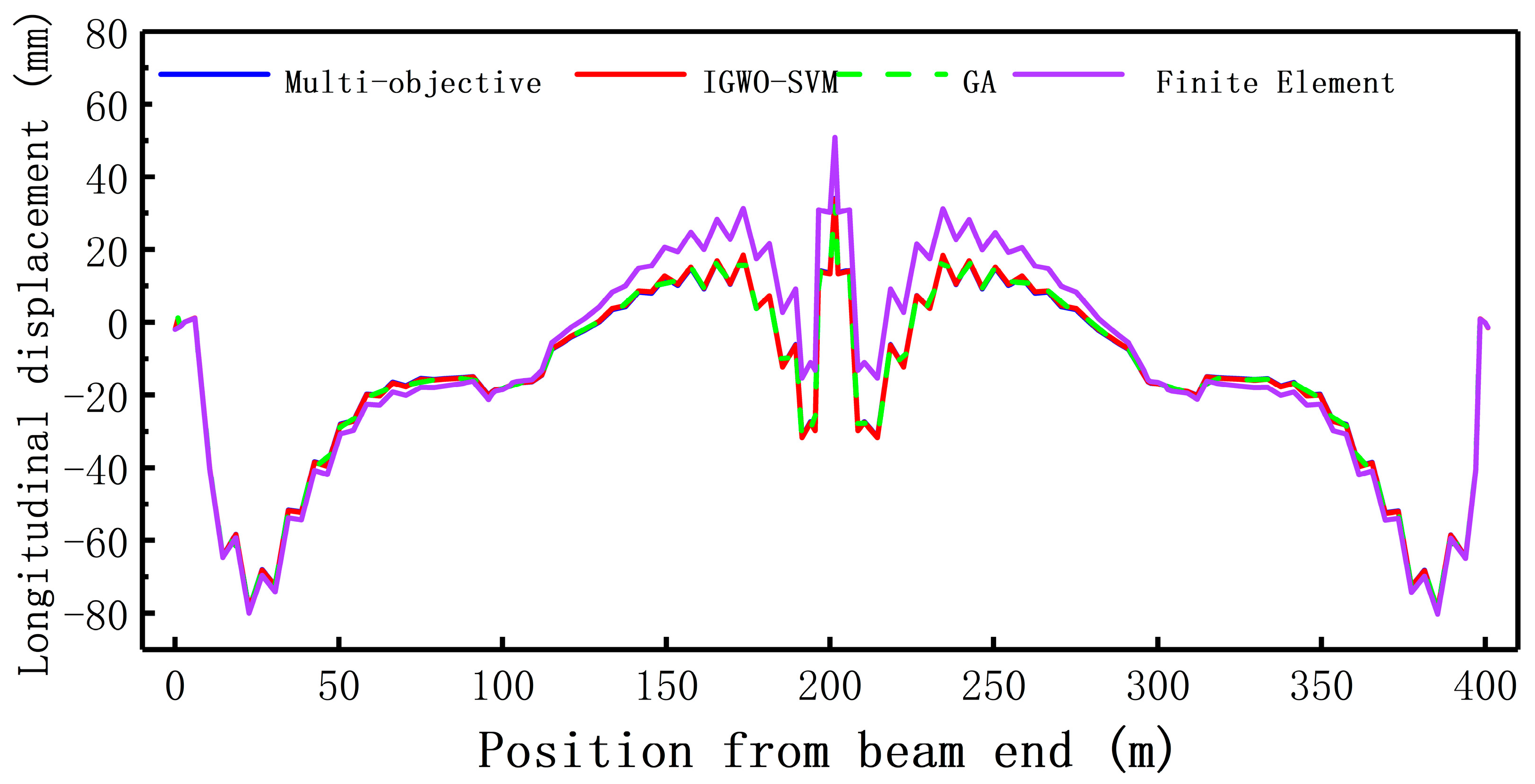

- Main girder deflection change

- (3)

- The change of bending moment under dead load when the bridge is completed

- (4)

- Stress analysis of the main beam under dead load.

- (5)

- Calculation efficiency evaluation

3.5. Verification of Cable Force Optimization Method

4. Conclusions

- (1)

- After optimizing the IGWO-SVM prediction model, the linear mapping relationship between cable force and girder elevation in long-span low-pylon cable-stayed bridges can be accurately simulated, minimizing prediction error and demonstrating strong generalization capabilities. Utilizing the combined optimization model, the maximum deflection of the main girder in the middle span is reduced from 50.89 mm to 33.85 mm, representing a decrease of 33.48%. Additionally, the maximum negative bending moment is reduced by 16.74%, while the maximum positive bending moment decreases by 13.92%. The calculated cable force results are more uniform, with a variance of 19.96, which is lower than that obtained through multi-objective optimization and the improved genetic algorithm.

- (2)

- This method comprehensively accounts for the dynamic changes in cable force during the construction phase, enabling accurate predictions of cable force distribution and main girder displacement from bridge closure to completion. This provides a solid foundation for effective construction control. Additionally, the optimization method ensures the stability of main girder displacement throughout the construction process, aligning the structural integrity of the completed bridge with predetermined control objectives. Based on measured data, this method also allows for the timely adjustment and optimization of key parameters, ensuring that the final state of the completed bridge adheres to design specifications.

- (3)

- A guiding framework is established for low-pylon cable-stayed bridges with varying spans, demonstrating high practicality and a broad range of applications. During the actual construction process, real-time modifications of design parameters and optimization of calculation methods allow for timely corrections of process deviations, ensuring that the completed bridge meets the specified design requirements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Fan, L.; Du, G.; Jiang, L. Cable force optimization and nonlinear ideal regression analysis of cable-stayed bridges. J. Chongqing Jiaotong Univ. 1992, 11, 1–12. [Google Scholar]

- Xiao, R.; Gong, H. Influence matrix of cable force optimization of cable-stayed bridges. J. Tongji Univ. 1998, 26, 235–240. [Google Scholar]

- Xiao, R.; Xiang, H. Cable force optimization of cable-stayed bridge and its engineering application. J. Comput. Mech. 1998, 15, 120–128. [Google Scholar]

- Yan, D. Determination of Reasonable Design State and Construction Control of Cable-stayed Bridges. Ph.D. Dissertation, Hunan University, Changsha, China, 2001. [Google Scholar]

- Yan, D.; Li, X.; Liu, G.; Yi, W. Step-by-step algorithm for determining reasonable completed state of concrete cable-stayed bridge. China J. Highw. Transp. 2003, 16, 43–46. [Google Scholar]

- Liang, P.; Xiao, R.; Zhang, X. Practical method for cable force optimization of cable-stayed bridges. J. Tongji Univ. (Nat. Sci. Ed.) 2003, 31, 1270–1274. [Google Scholar]

- Baldomir, A.; Hernandez, S.; Nieto, F.; Jurado, J. Cable optimization of a long span cable stayed bridge in La Corua (Spain). Adv. Eng. Softw. 2010, 41, 931–938. [Google Scholar] [CrossRef]

- Martins, A.M.B.; Simes, L.M.C.; Negro, J.H.J.O. Optimization of cable forces on concrete cable-stayed bridges including geometrical nonlinearities. Comput. Struct. 2015, 155, 18–27. [Google Scholar] [CrossRef]

- Miao, C.; Wang, Y.; Li, S. Cable force optimization of low-pylon concrete cable-stayed bridge. J. Southeast Univ. (Nat. Sci. Ed.) 2012, 42, 526–530. [Google Scholar]

- Chen, C. Research on cable force optimization of low-pylon cable-stayed bridge based on the principle of minimum cost. Eng. Mech. 2012, 29, 141–146. [Google Scholar]

- Hassan, M.M.; El Damatty, A.A.; Nassef, A.O. Database for the optimum design of semi-fan composite cable-stayed bridges based on genetic algorithms. Struct. Infrastruct. Eng. 2015, 11, 1054–1068. [Google Scholar] [CrossRef]

- Song, C.; Xiao, R.; Sun, B.; Wang, Z.; Zhang, C. Optimization of cable pre-tension forces in long-span cable-stayed bridges considering the counterweight. Eng. Struct. 2018, 283, 115856. [Google Scholar] [CrossRef]

- Cao, H.; Li, H.; Zhou, Y.; Li, Z.; Feng, L. Biobjective Optimization of Cable Force for Concrete Cable-Stayed Bridges Considering the Requirements of the Serviceability and Ultimate Limit State. J. Bridge Eng. 2024, 29, 04024026. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Y.; Sheng, H.; Sun, H. Practical method for cable force optimization of cable-stayed bridges based on MALTAB optimization toolbox. For. Eng. 2006, 22, 35–37. [Google Scholar] [CrossRef]

- Guo, Z.; Xie, Z.; Zhao, K.; Xie, L.; Lin, X. Cable force optimization of cable-stayed bridge based on feasible region method. J. Jiangxi Univ. Sci. Technol. 2012, 33, 10–13. [Google Scholar]

- Liu, Y.; Liu, D.; Liu, S. Cable force optimization of cable-stayed bridge under dead load based on MATLAB combined with ANSYS. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2013, 32, 1111–1114+1194. [Google Scholar]

- Zhang, J.; Au, F.T.K. Calibration of initial cable forces in cable-stayed bridge based on Kriging approach. Finite Elem. Anal. Des. 2014, 92, 80–92. [Google Scholar] [CrossRef]

- Yin, X.; Wang, G.; Xue, Z. Research on cable force optimization of cable-stayed bridge based on new strongly sub-feasible SQR method. World Bridges 2016, 44, 33–37. [Google Scholar]

- Wang, Z.; Zhang, N.; Du, X.; Wang, S.; Sun, Q. Multiobjective Optimization of Cable Forces and Counterweights for Universal Cable-Stayed Bridges. J. Adv. Transp. 2021, 2021, 6615746. [Google Scholar] [CrossRef]

- Wu, X.; Xiao, R. Cable force optimization of long-span hybrid beam cable-stayed bridge based on genetic algorithm. J. Jiangsu Univ. (Nat. Sci. Ed.) 2014, 35, 722–726. [Google Scholar]

- Jiang, Z.; Zhu, B. Cable Force Optimization of Asymmetric Cable-stayed Bridge Based on Improved Particle Swarm Optimization. Highw. Eng. 2018, 43, 117–121. [Google Scholar]

- Wang, J.; Liu, L.; Ren, X. Cable force optimization of long-span cable-stayed bridge based on improved imperial competition algorithm. J. Jiangsu Univ. (Nat. Sci. Ed.) 2019, 40, 94–101. [Google Scholar]

- Ma, G. Research on Cable Force Optimization of Four-wire Steel Truss Cable-stayed Bridge Based on Hybrid Genetic Algorithm. Railw. Stand. Des. 2020, 64, 85–89. [Google Scholar]

- Kan, B. Cable Force Optimization of Cable-stayed Bridge Based on Improved Particle Swarm Optimization. Chin. Foreign Highw. 2021, 41, 133–137. [Google Scholar] [CrossRef]

- Li, B. Cable Force Optimization and Construction Simulation Analysis of Low-Pylon Cable-Stayed Bridge. Master’s Thesis, Sichuan Agricultural University, Ya’an, China, 2022. [Google Scholar] [CrossRef]

- Wang, T.; Hu, Y.; Zhang, X.; Wang, L. Research on cable force optimization of cable-stayed bridge based on genetic algorithm. J. Chongqing Jiaotong Univ. (Nat. Sci. Ed.) 2023, 42, 9–17+23. [Google Scholar]

- Xiong, H.-Z.; Yang, X.; He, Y.-N.; Huang, Y. Optimization of cable-stayed force for asymmetric single tower cable-stayed bridge formation based on improved particle swarm algorithm. Int. J. Struct. Integr. 2024, 15, 873–890. [Google Scholar] [CrossRef]

- Wang, L.; Xiao, Z.; Li, M.; Fu, N. Cable Force Optimization of Cable-Stayed Bridge Based on Multiobjective Particle Swarm Optimization Algorithm with Mutation Operation and the Influence Matrix. Appl. Sci. 2023, 13, 2611. [Google Scholar] [CrossRef]

- Yue, F.; Cheng, L.; Briseghella, B.; Fenu, L.; Zordan, T. Cable optimization of a cable-stayed bridge based on genetic algorithms and the influence matrix method. Eng. Optim. 2020, 54, 20–39. [Google Scholar]

- Ha, M.H.; Vu, Q.A.; Truong, V.H. Optimum Design of Stay Cables of Steel Cable-stayed Bridges Using Nonlinear Inelastic Analysis and Genetic Algorithm. Structures 2018, 16, 288–302. [Google Scholar] [CrossRef]

- Zarbaf, S.E.H.A.; Norouzi, M.; Allemang, R.J.; Hunt, V.J.; Helmicki, A. Stay Cable Tension Estimation of Cable-Stayed Bridges Using Genetic Algorithm and Particle Swarm Optimization. J. Bridge Eng. 2017, 22, 05017008. [Google Scholar] [CrossRef]

- Zhang, D.; Jun, X.; Zhou, B.; Yuan, S. Research on cable force optimization of multi-tower cable-stayed bridge based on BP neural network-GSL&PS-PGSA. Highw. Eng. 2022, 47, 34–39. [Google Scholar]

- Guo, J.; Guan, Z. Optimization of the cable forces of completed cable-stayed bridges with differential evolution method. Structures 2023, 47, 1416–1427. [Google Scholar] [CrossRef]

- Huang, K.; Chai, S.; Wang, X. Crossing cable design optimization of multi-tower cable-stayed bridge based on joint analytical method and genetic algorithm. Structures 2024, 69, 107335. [Google Scholar] [CrossRef]

- Zhong, Z. Research on Cable Force Optimization and Construction Control of Asymmetric Single-Tower Wide Concrete Box Girder Cable-Stayed Bridge. Master’s Thesis, Sichuan Agricultural University, Ya’an, China, 2024. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalil, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Kohli, M.; Arora, S. Chaotic grey wolf optimization algorithm for constrained optimization problems. J. Comput. Des. Eng. 2018, 5, 458–472. [Google Scholar] [CrossRef]

- Teng, Z.; Lv, J.; Guo, L.; Xu, Y. An improved algorithm for hybrid grey wolf optimization based on Tent map. J. Harbin Inst. Technol. 2018, 50, 40–49. [Google Scholar] [CrossRef]

- Guo, Z.; Liu, R.; Gong, C.; Zhao, L. Research on improvement based on grey wolf algorithm. Comput. Appl. Res. 2017, 34, 3603–3610. [Google Scholar]

- Cui, J.; Lin, H.; Lyu, X.; Zhang, W. Chaotic Opposition learning and differential evolution grey wolf algorithm based on individual disturbance. Comput. Eng. Des. 2022, 43, 587–595. (In Chinese) [Google Scholar]

- Wang, Q.; Wang, M.; Wang, X. Grey Wolf Optimization Algorithm with Improved Convergence Factor and Proportional Weight. Comput. Eng. Appl. 2019, 55, 60–65+98. [Google Scholar] [CrossRef]

- Duan, J.; Wang, H.; Hao, T.; Liang, Q. Cable Force Optimization Model of Arch Bridge Based on Improved Grey Wolf Algorithm and Support Vector Machine. Comput. Eng. Des. 2023, 44, 457–465. [Google Scholar] [CrossRef]

- Hashemi, M.; Javaheri, D.; Sabbagh, P.; Arandian, B.; Abnoosian, K. A multi-objective method for virtual machines allocation in cloud data centres using an improved grey wolf optimization algorithm. IET Commun. 2021, 15, 2342–2353. [Google Scholar] [CrossRef]

- Niu, Y. Analysis on the application of equivalent tension method in the construction of steel strand stay cables. Anhui Archit. 2022, 29, 148–149+170. [Google Scholar] [CrossRef]

- Wang, J.; Yang, J.; Zeng, Z.; Pei, Z. Error analysis of cable tension measurement by frequency method and optimization of cable tension calculation formula. Ind. Saf. Environ. Prot. 2021, 47, 27–31. [Google Scholar]

- Yu, M.; Yao, X.; Deng, N.; Hao, T.; Wang, L.; Wang, H. Optimal Cable Force Adjustment for Long-Span Concrete-Filled Steel Tube Arch Bridges: Real-Time Correction and Reliable Results. Buildings 2023, 13, 2214. [Google Scholar] [CrossRef]

| Component Part | Material | Elastic Modulus (Mpa) | Linear Expansion Coefficient (1/°C) | Poisson’s Ratio | |

|---|---|---|---|---|---|

| Mean Beam | C55 | 0.2 | 26.5 | ||

| Main Tower | C50 | 0.2 | 26 | ||

| Stay Cable | Prestressed Steel Strand | 0.3 | 78.5 |

| Cable Number | Measured Value of Tower 1 (kN) | Measured Value of Tower 2 (kN) | ||

|---|---|---|---|---|

| The Left Side | Right | The Left Side | Right | |

| S8’ | 4049.81 | 4052.56 | 4042.33 | 4052.56 |

| S7’ | 4063.58 | 4063.58 | 4066.54 | 4063.19 |

| S6’ | 4064.17 | 4064.17 | 4063.58 | 4063.58 |

| S5’ | 4063.58 | 4063.02 | 4065.35 | 4065.55 |

| S4’ | 4053.07 | 4063.36 | 4065.65 | 4065.65 |

| S3’ | 4062.60 | 4062.60 | 4071.45 | 4071.45 |

| S2’ | 4057.68 | 4042.73 | 4076.18 | 4077.95 |

| S1’ | 4056.30 | 4049.55 | 4051.78 | 4048.83 |

| S1 | 4052.23 | 4055.12 | 4038.59 | 4055.12 |

| S2 | 4060.83 | 4045.48 | 4053.75 | 4076.18 |

| S3 | 4062.60 | 4062.60 | 4062.60 | 4071.45 |

| S4 | 4059.09 | 4056.69 | 4065.65 | 4065.65 |

| S5 | 4071.85 | 4067.72 | 4063.58 | 4067.72 |

| S6 | 4064.17 | 4064.17 | 4063.58 | 4063.58 |

| S7 | 4063.58 | 4063.58 | 4064.57 | 4062.40 |

| S8 | 4053.55 | 4043.12 | 4052.56 | 4052.56 |

| Cable Number | Measured Value of Tower 1 (kN) | Measured Value of Tower 2 (kN) | ||

|---|---|---|---|---|

| The Left Side | Right | The Left Side | Right | |

| S8’ | 3860.93 | 3929.05 | 4344.87 | 4316.4 |

| S7’ | 3722.67 | 3899.57 | 4275.73 | 4190.33 |

| S6’ | 3824.33 | 3694.2 | 4190.33 | 4133.4 |

| S5’ | 3903.63 | 3887.37 | 4228.97 | 4292 |

| S4’ | 3694.2 | 3791.8 | 4241.17 | 4165.93 |

| S3’ | 3663.7 | 3806.03 | 4163.9 | 4115.1 |

| S2’ | 3736.9 | 3816.2 | 4094.4 | 4011.03 |

| S1’ | 3662.97 | 3740.23 | 3941.17 | 3888.3 |

| S1 | 3765.93 | 3609.37 | 3733.4 | 3625.63 |

| S2 | 3798.83 | 3741.9 | 3778.5 | 3784.6 |

| S3 | 3941.53 | 3856.13 | 3988.3 | 3880.53 |

| S4 | 4063.9 | 3974.43 | 4055.77 | 3980.53 |

| S5 | 4133.03 | 3996.8 | 4037.47 | 3960.2 |

| S6 | 3994.77 | 3895.13 | 4076.1 | 3960.2 |

| S7 | 4072.77 | 4143.93 | 4155.4 | 4122.87 |

| S8 | 3903.63 | 4021.57 | 4240.8 | 4244.87 |

| Stay Cable Number | Multi-Objective Optimization of Cable Force | IGWO-SVM Optimization Value | Improved Genetic Algorithm |

|---|---|---|---|

| S8’ | 5620.3 | 5610.3 | 5730 |

| S7’ | 5627.6 | 5605.23 | 5620.8 |

| S6’ | 5585.7 | 5576.4 | 5535.3 |

| S5’ | 5504.3 | 5533.43 | 5496.3 |

| S4’ | 5462.7 | 5504.12 | 5392.7 |

| S3’ | 5408.5 | 5486.59 | 5237.5 |

| S2’ | 5357.4 | 5418.23 | 5128.6 |

| S1’ | 5341.6 | 5378.85 | 5069.3 |

| S1 | 5281.4 | 5375.5 | 5236.2 |

| S2 | 5296.3 | 5422.81 | 5259 |

| S3 | 5348.2 | 5476.54 | 5312.9 |

| S4 | 5485.3 | 5514.77 | 5397 |

| S5 | 5552.1 | 5537.45 | 5448.4 |

| S6 | 5670.8 | 5581.42 | 5493.7 |

| S7 | 5738.2 | 5602.28 | 5485.5 |

| S8 | 5726.5 | 5614.33 | 5501.4 |

| Average value | 5500.43 | 5514.91 | 5402.79 |

| Variance | 36.58 | 19.96 | 40.57 |

| Kolmogorov–Smirnov test | 0.351 | 0.394 | 0.591 |

| Cable Number | IGWO-SVM Optimization Value (kN) | No. 1 Left Tower | No. 1 Right Tower | ||

|---|---|---|---|---|---|

| Measured Value (kN) | Error (%) | Measured Value (kN) | Error (%) | ||

| S8’ | 4112.3 | 3860.93 | 6.5 | 3929.05 | 4.7 |

| S7’ | 3981.7 | 3722.67 | 7.0 | 3899.57 | 2.1 |

| S6’ | 3952.7 | 3824.33 | 3.4 | 3694.2 | 7.0 |

| S5’ | 3943.4 | 3903.63 | 1.0 | 3887.37 | 1.4 |

| S4’ | 3807.1 | 3694.2 | 3.1 | 3791.8 | 0.4 |

| S3’ | 3768 | 3663.7 | 2.8 | 3806.03 | −1.0 |

| S2’ | 3656.5 | 3736.9 | −2.2 | 3816.2 | −4.2 |

| S1’ | 3545.3 | 3662.97 | −3.2 | 3740.23 | −5.2 |

| S1 | 3580.1 | 3765.93 | −4.9 | 3609.37 | −0.8 |

| S2 | 3608.9 | 3798.83 | −5.0 | 3741.9 | −3.6 |

| S3 | 3739.4 | 3941.53 | −5.1 | 3856.13 | −3.0 |

| S4 | 3820 | 4063.9 | −6.0 | 3974.43 | −3.9 |

| S5 | 3882.1 | 4133.03 | −6.1 | 3996.8 | −2.9 |

| S6 | 3974.1 | 3994.77 | −0.5 | 3895.13 | 2.0 |

| S7 | 4036.7 | 4072.77 | −0.9 | 4143.93 | −2.6 |

| S8 | 3911.3 | 3903.63 | 0.2 | 4021.57 | −2.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Zhu, L.; Zhang, Y.; Guo, H. Application Research on Cable Force Optimization of Cable-Stayed Bridge Based on Improved Grey Wolf Algorithm. Buildings 2025, 15, 1309. https://doi.org/10.3390/buildings15081309

Guo J, Zhu L, Zhang Y, Guo H. Application Research on Cable Force Optimization of Cable-Stayed Bridge Based on Improved Grey Wolf Algorithm. Buildings. 2025; 15(8):1309. https://doi.org/10.3390/buildings15081309

Chicago/Turabian StyleGuo, Jian, Li Zhu, Yuzhong Zhang, and Hongzhe Guo. 2025. "Application Research on Cable Force Optimization of Cable-Stayed Bridge Based on Improved Grey Wolf Algorithm" Buildings 15, no. 8: 1309. https://doi.org/10.3390/buildings15081309

APA StyleGuo, J., Zhu, L., Zhang, Y., & Guo, H. (2025). Application Research on Cable Force Optimization of Cable-Stayed Bridge Based on Improved Grey Wolf Algorithm. Buildings, 15(8), 1309. https://doi.org/10.3390/buildings15081309