1. Introduction

Reactive Powder Concrete (RPC), as a new generation of ultra-high-performance cementitious material, achieves compressive strengths of 150–200 MPa and exceptional durability through optimized particle gradation (maximum particle size < 2 mm), the incorporation of steel fibers (1–3% by volume), and high-temperature curing (60–90 °C) [

1]. Its dense microstructure not only endows RPC with superior frost resistance [

2] and chloride ion penetration resistance but also makes it particularly advantageous in harsh environments such as marine zones and cold regions [

3]. Currently, RPC has been successfully applied in power engineering [

4], bridge construction, marine structures, and high-rise buildings [

5]. Its lightweight nature and high durability significantly reduce the life-cycle cost of structures [

6], positioning RPC as a key material for advancing low-carbon development in civil engineering [

7]. In practical engineering applications, steel–RPC systems are subjected to coupled environmental effects. For instance, studies in Ref. [

8] demonstrate that chloride ion erosion in marine environments accelerates bond degradation in conventional concrete, whereas RPC’s dense matrix delays this process. Furthermore, pull-out tests in Ref. [

9] confirm that RPC retains over 90% of its bond strength after freeze–thaw cycles, significantly outperforming traditional concrete.

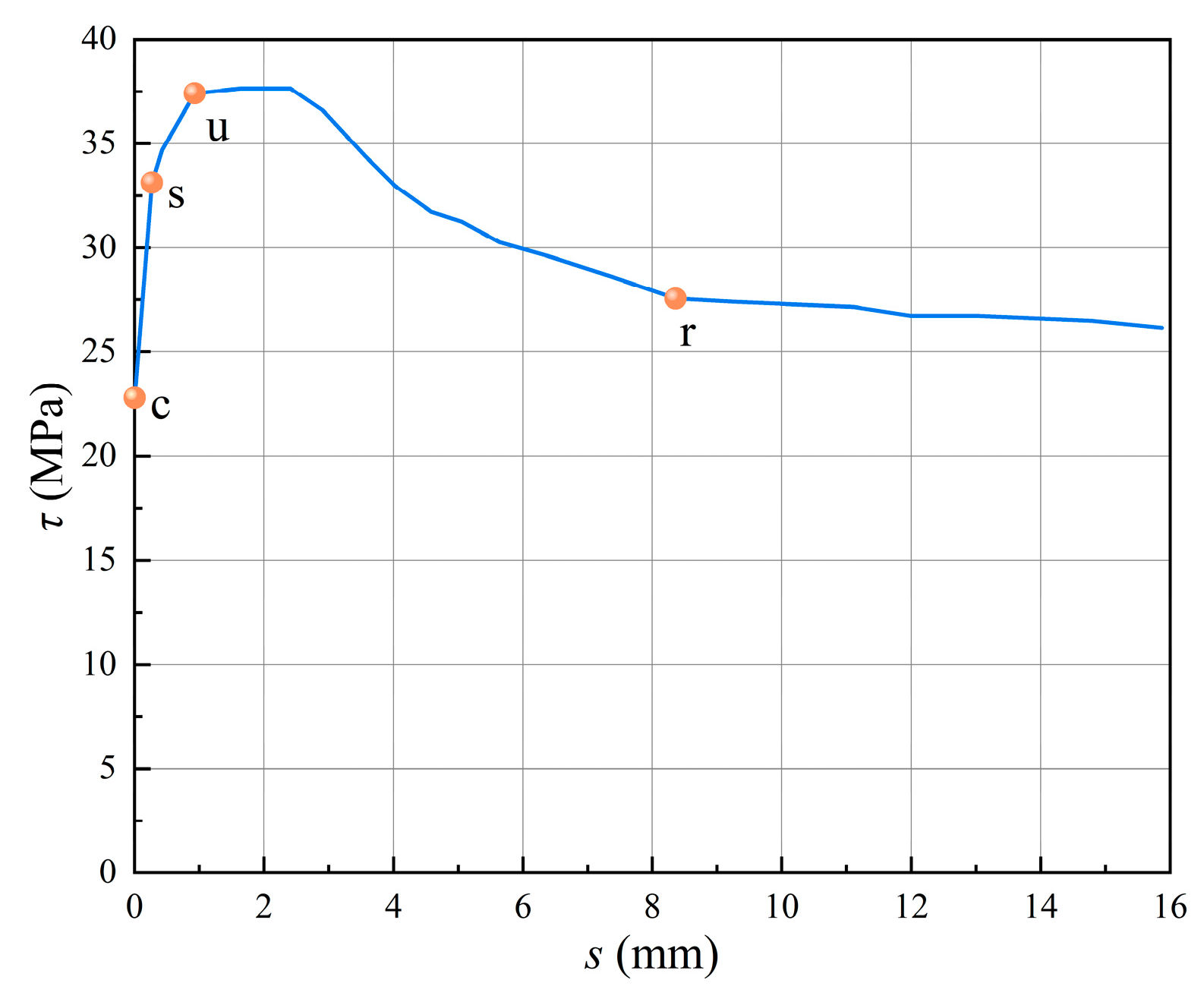

In reinforced concrete structures, the bond behavior between steel bars and concrete is a key mechanism ensuring their collaborative work and structural ductility [

10,

11]. Research on the bond behavior of traditional concrete (NC) has established classical theories covering concrete properties, concrete cover thickness [

8], steel bar properties, and shape [

12]. Due to the significantly lower water-to-binder ratio of RPC (0.16–0.2) compared to NC, and the bridging effect of steel fibers in the RPC matrix [

13], the bond behavior between steel bars and RPC is fundamentally different from that of NC [

14].

Existing research primarily investigates the bond characteristics between steel bars and RPC through static pull-out tests. It is widely recognized that bond length has the greatest impact on bond performance, followed by concrete strength, cover thickness, and steel bar diameter [

15]. Piccinini et al. [

16] conducted concentric pull-out tests on steel bars and RPC, showing that bond strength increases up to 28 days, following a similar trend to compressive strength. Qi et al. [

17] conducted 96 pull-out tests, revealing that insufficient concrete cover thickness leads to splitting failure, while short bond lengths result in concrete cone failure. Wang et al. [

18] found that due to the non-uniform distribution of bond stress over a large range, bond strength is inversely proportional to the ratio of bond length to steel bar diameter (

l/d). Regarding the influence of steel fibers on bond strength, Bae et al. [

19] demonstrated that RPC with 1% steel fiber volume fraction has twice the ultimate bond strength of plain RPC, but further increases in steel fiber content do not significantly enhance bond strength. Wang et al. [

18] found that RPC with 2% and 2.5% steel fiber volume fractions exhibited similar bond performance, consistent with Bae’s findings. Alkaysi et al. [

20] suggested that the variation in bond strength due to steel fiber content depends on the number of fibers bridging cracks rather than the compressive strength differences caused by fiber volume.

However, in practical engineering, the steel–concrete interface is often subjected to repeated loads such as traffic loads, wind vibrations, and earthquakes [

21]. These loads can lead to bond stiffness degradation and increased slip [

22], threatening the overall safety of structures [

23]. Lemcherreq et al. [

24] found that under repeated loading, the distribution of bond stress in NC along the bond length changes. Zhang et al. [

25] designed 29 eccentric pull-out specimens of steel bars in ordinary concrete, conducting monotonic, repeated, and post-fatigue monotonic loading tests. The results showed that fatigue loading history increases bond stiffness and peak slip, and a bond stress-slip model considering fatigue loading history was proposed. Wu et al. [

26] found that after repeated loading, the stiffness of the descending branch of the monotonic bond stress-slip curve of fiber-reinforced concrete generally decreases. Shang et al. [

27] demonstrated that higher stress levels in repeated loading reduce the bond strength of steel bars in ordinary concrete. Shao et al. [

28] used the beam-end test method recommended by ACI Committee 408 to study the effect of repeated loading on the bond behavior of steel bars in ultra-high-performance concrete (UHPC). The study showed that repeated loading accelerates the degradation of bond strength after bond softening. Gong et al. [

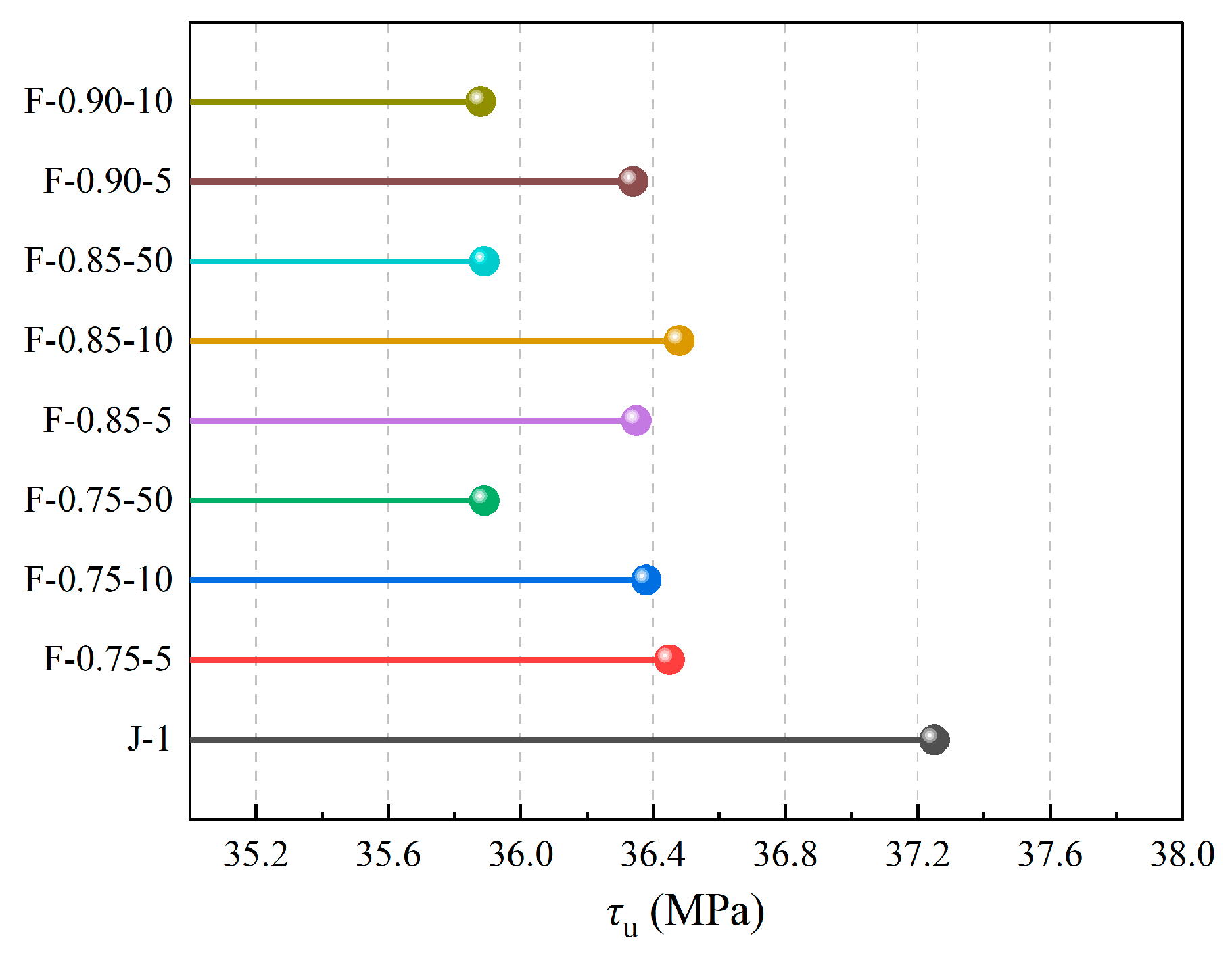

29] conducted concentric pull-out tests to investigate the effects of loading patterns and concrete cover thickness on the bond behavior of steel bars in RPC. The results indicated that repeated loading significantly reduces the bond strength of steel bars, but increasing bond length or concrete cover thickness can mitigate this effect. These studies demonstrate that the bond behavior between steel bars and concrete is significantly influenced by load type (whether subjected to repeated loading), stress level, and the number of repeated loading cycles [

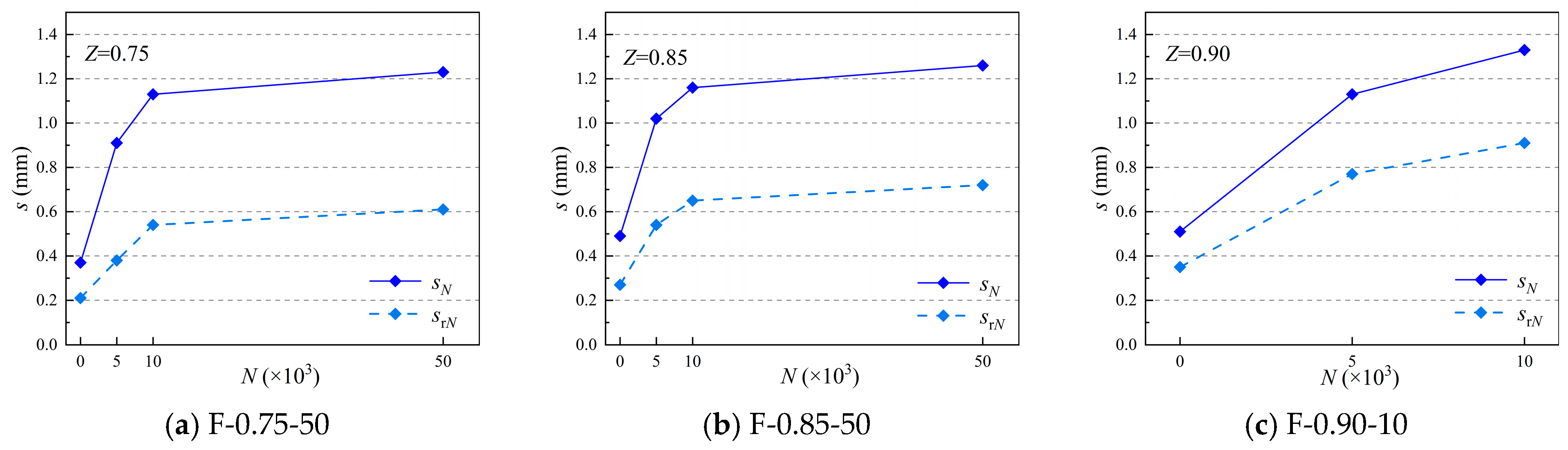

30]. The service load conditions of steel–RPC structures are more complex than those of NC structures. However, there is limited research on the mechanisms by which stress levels and loading cycles affect the bond strength and slip development of steel–RPC interfaces. Moreover, the lack of constitutive models considering the coupling effects of stress levels and loading cycles hinders the refined design of RPC structures in repeated loading environments.

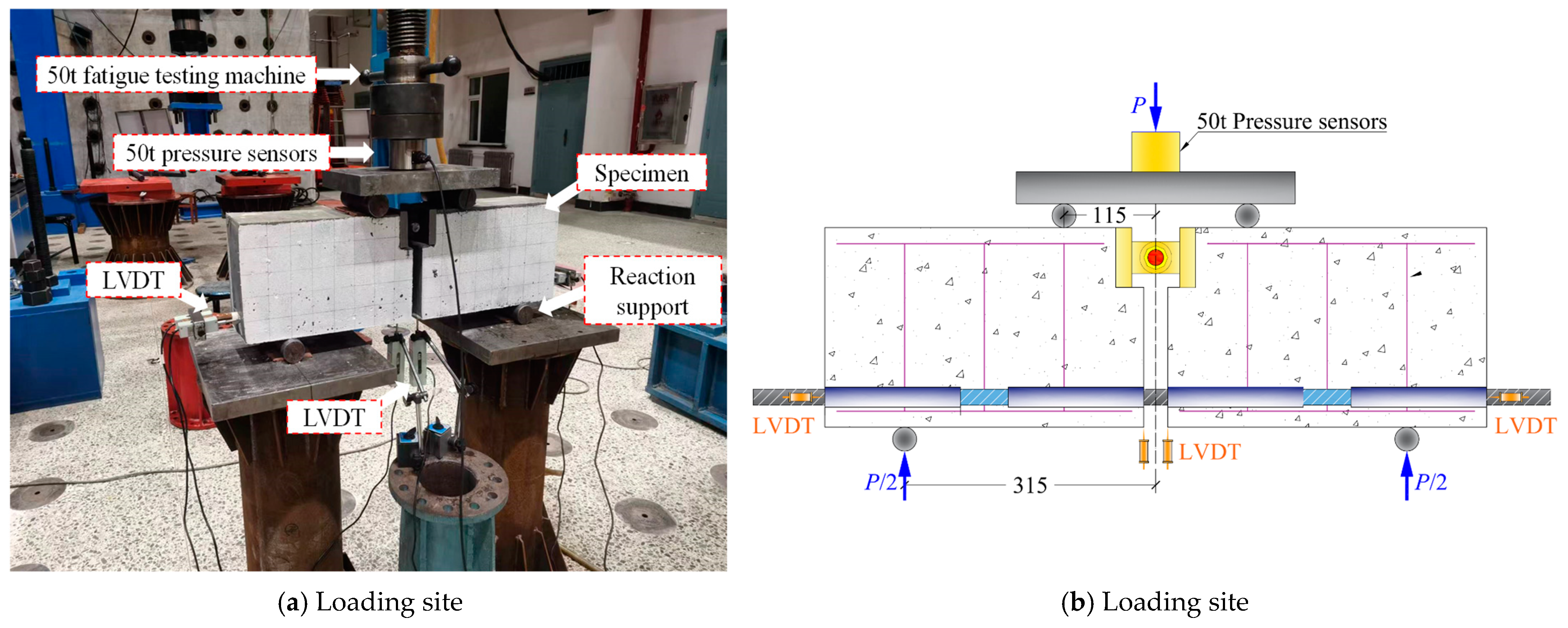

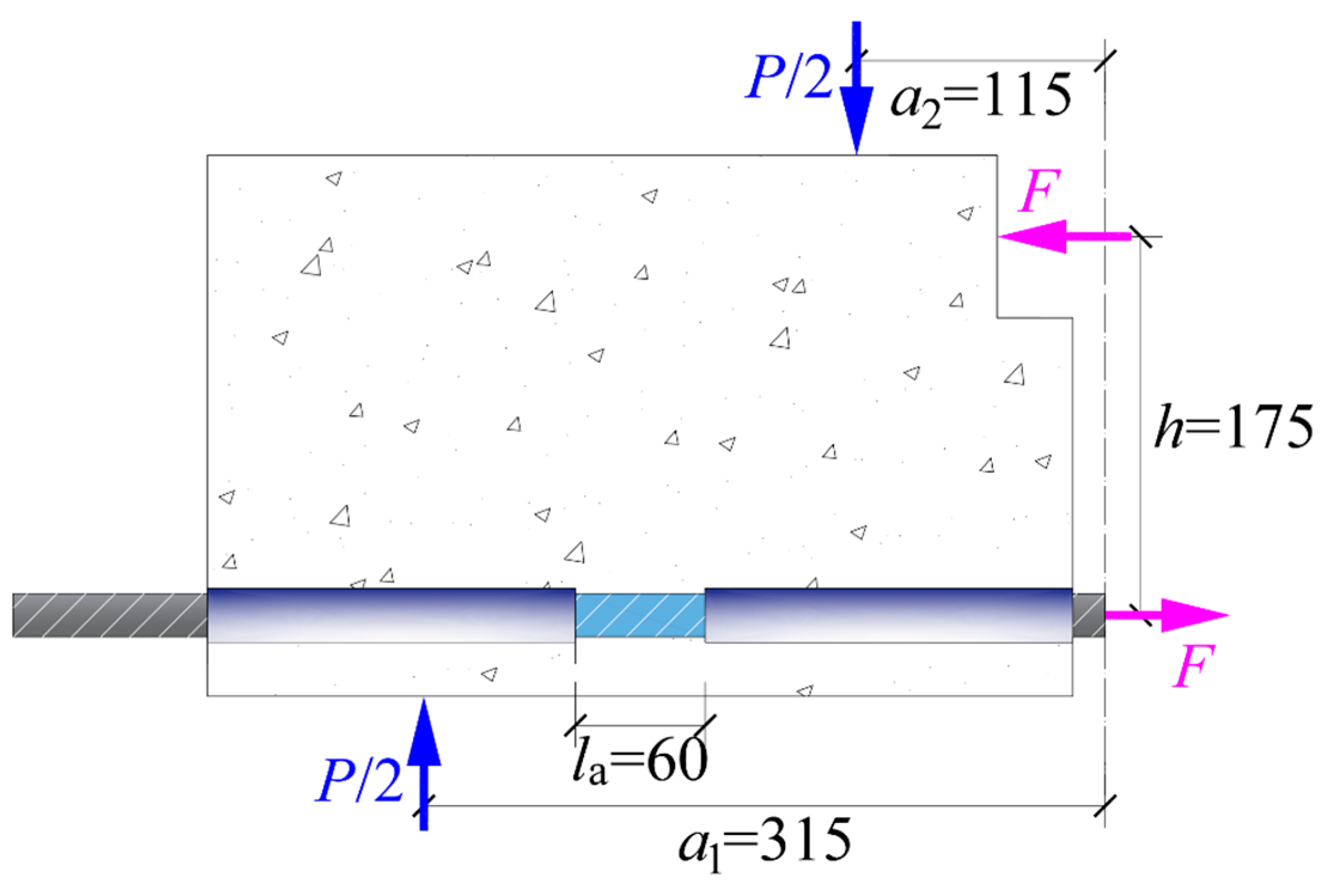

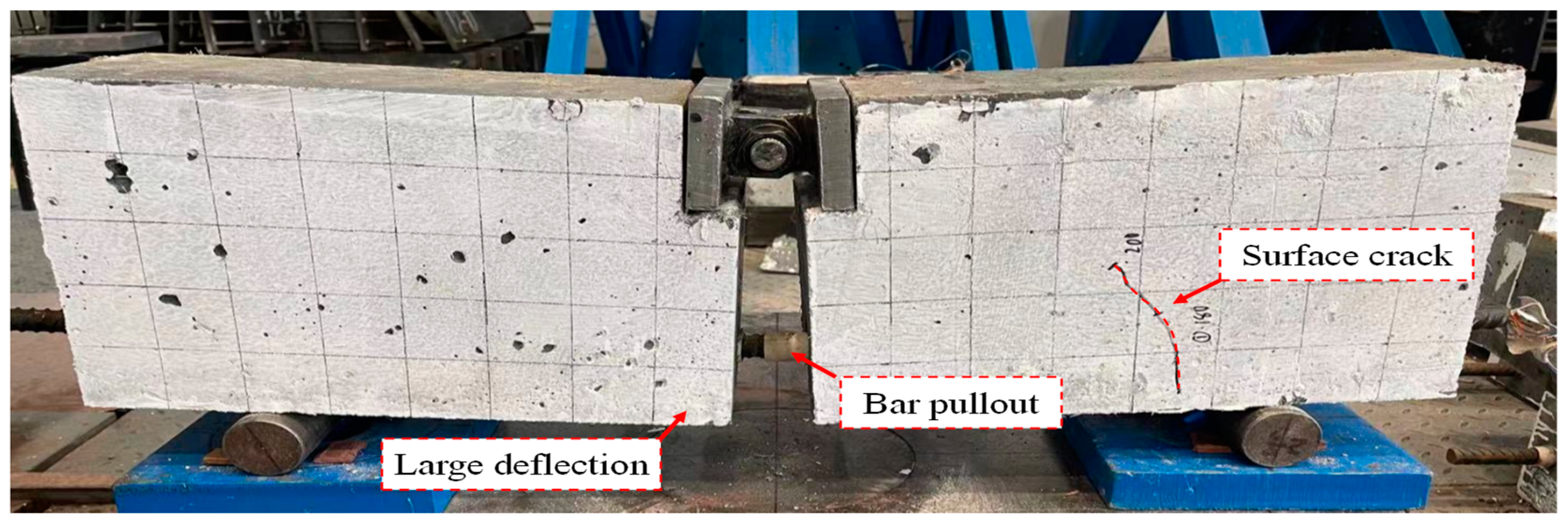

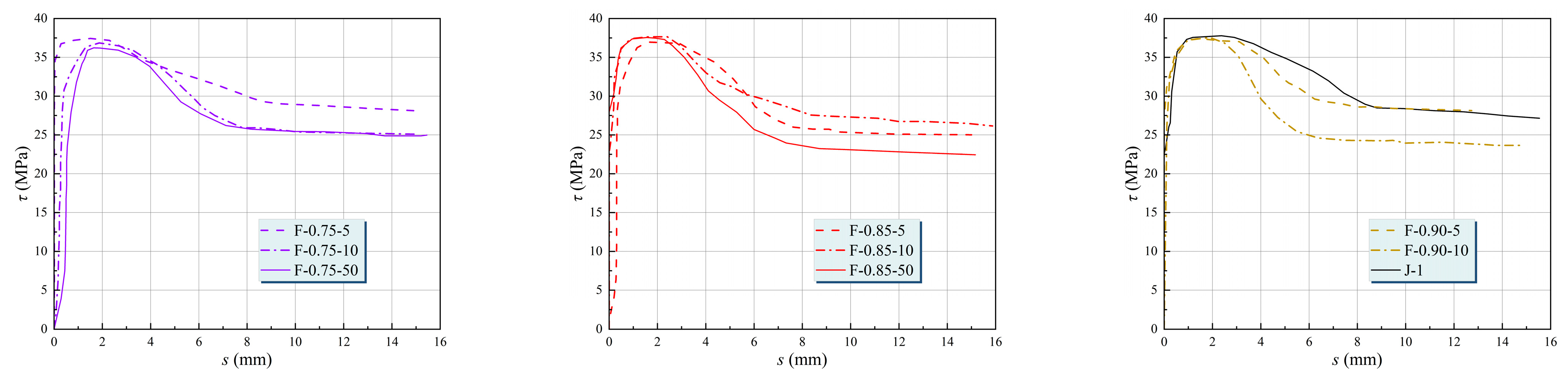

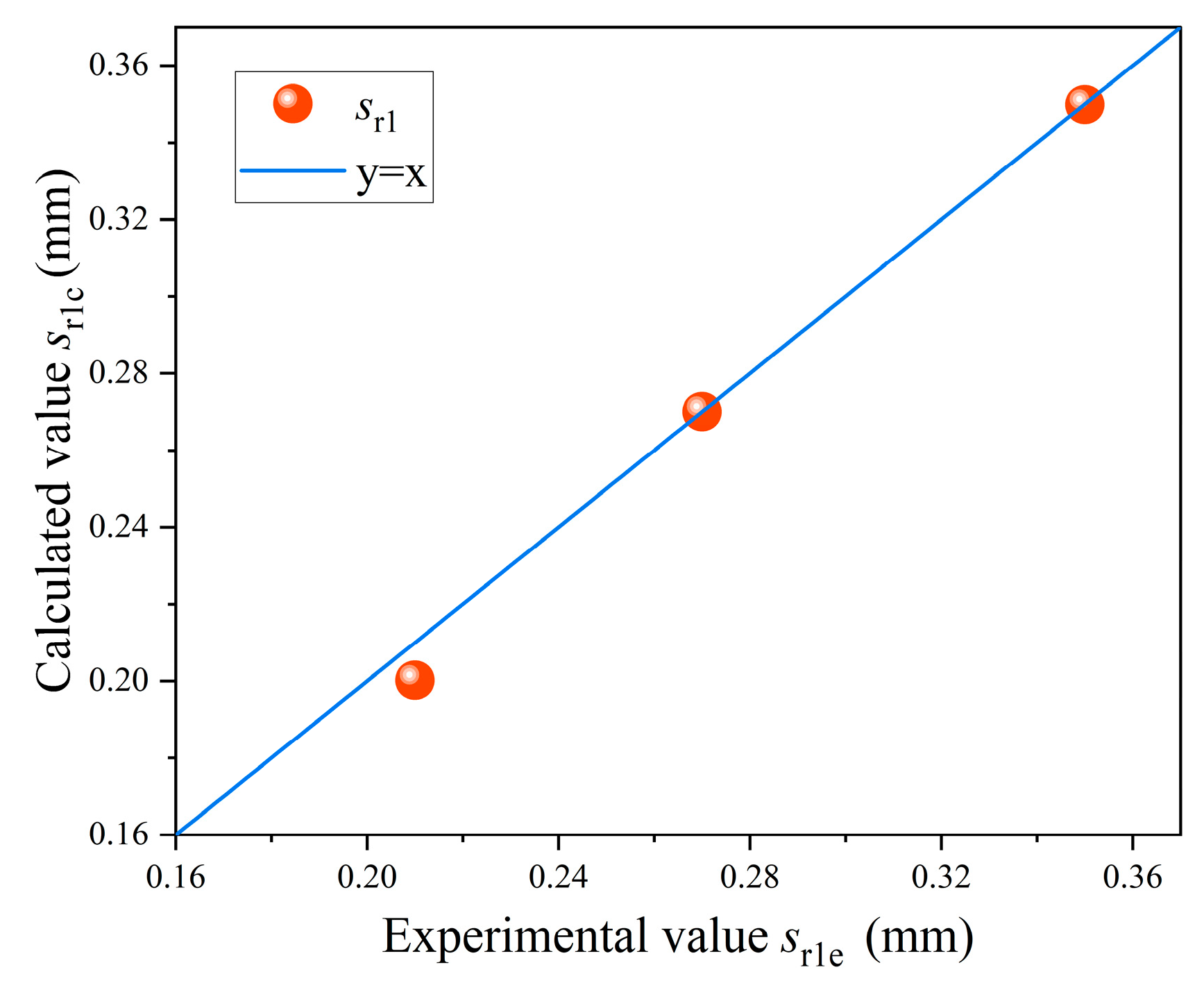

This study conducted multi-level repeated loading tests (stress levels 0.75–0.9, loading cycles 5 × 103–5 × 104) on eight beam specimens to investigate the influence of repeated loading on the bond behavior between steel bars and RPC. The multi-stage response characteristics of the bond stress-slip curve under repeated loading were revealed, and the effects of stress levels and loading cycles on ultimate bond strength were analyzed. A residual slip prediction model considering loading history was established, and a constitutive equation for the bond–slip behavior of steel–RPC under repeated loading was proposed. The research findings provide a theoretical basis for the design of RPC structures in fatigue-sensitive areas such as long-span bridges, high-rise buildings, and railway facilities.