1. Introduction

High-strength steel can effectively reduce the component section, thus decreasing the structural deadweight as well as the amount of steel, with such benefits on economy and society. In recent years, it has been widely used in practical engineering [

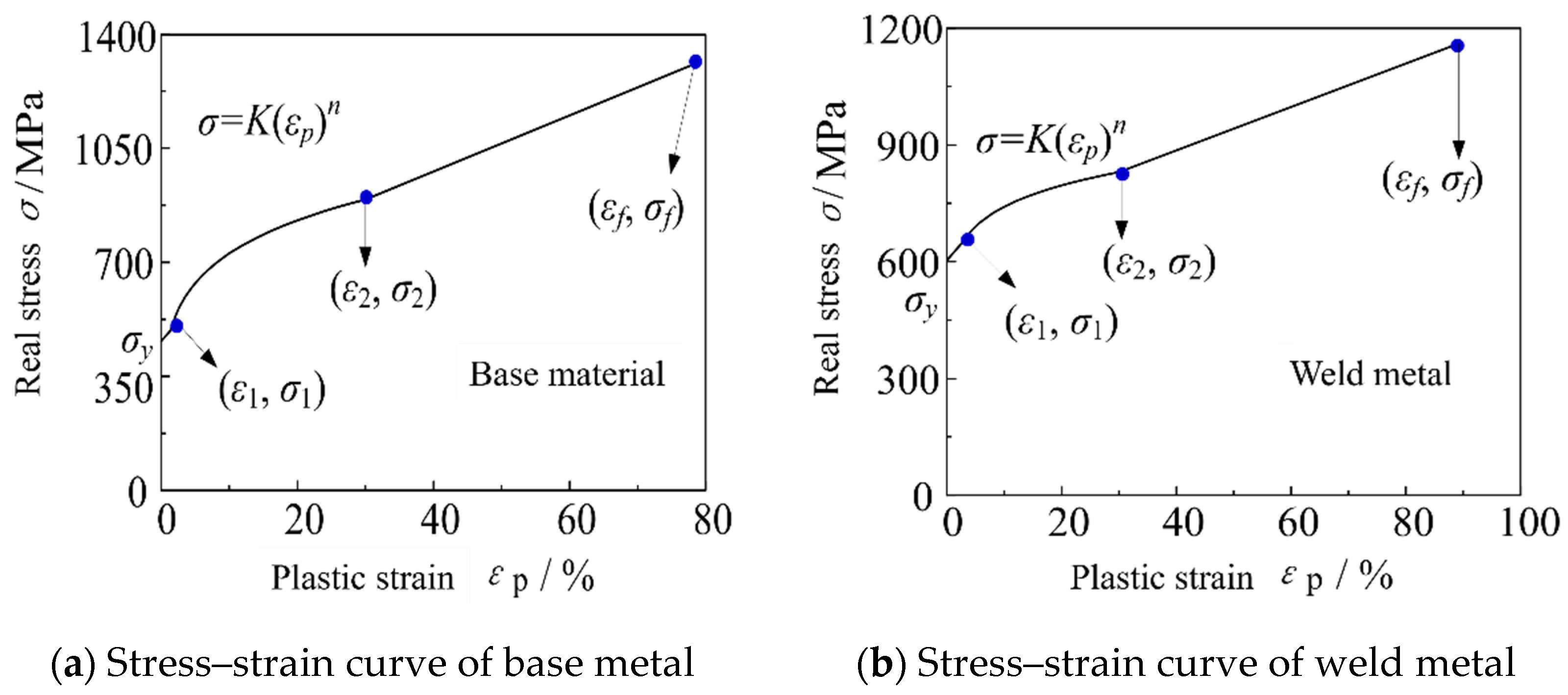

1,

2]. The strength of high-strength steel is superior to conventional-strength steels [

3,

4,

5], but from the perspective of fracture mechanics [

6], high-strength steel structures will be more susceptible to crack defects and more prone to brittle fracture damage [

7,

8,

9]. At the same time, the effect of welding on the fracture behavior of high-strength steels is significant [

10].

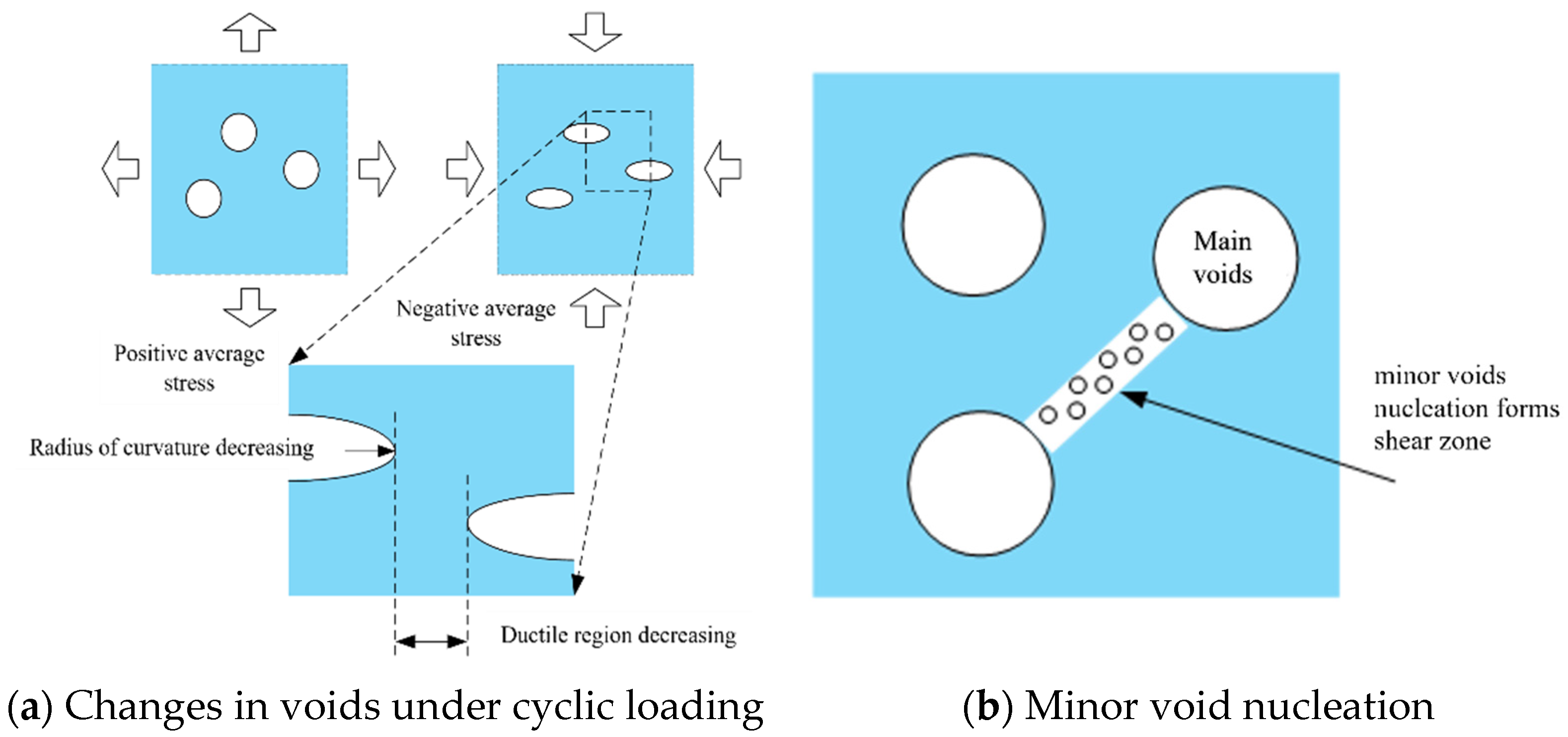

Recently, the fracture mechanism of structural steel has been studied, and good progress has been made. The fracture process of structural steel primarily involves two stages: crack nucleation and crack propagation. During the crack nucleation stage, internal defects within the metal, such as dislocations and second-phase particles, lead to localized stress concentration. In the crack propagation stage, plastic deformation occurs at the crack tip, accompanied by the formation of microvoids [

11]. The crack propagation process can be divided into the following steps: (i) void nucleation, (ii) void growth, and (iii) void coalescence, as illustrated in

Figure 1. The mechanism of fracture under cyclic loading is shown in

Figure 2. The fracture mechanism under low-cycle fatigue loading is similar to that under monotonic loading [

12,

13] but with the following two differences: (i) voids experience alternating expansion and contraction after nucleation due to cyclic tensile and compressive stresses; (ii) due to the accumulation of damage under cyclic loading, aggregation can occur even at a lower percentage of void volume.

The fracture initiation mechanisms can be captured by micromechanical facture models, and therefore, these models can be used for figuring out the fracture behavior of steel materials as well as to predict their service life [

14,

15,

16,

17,

18]. Guo et al. [

19] and Chi et al. [

20], based on Rice and Tracey [

21] and Hancock and Mackenzie [

22], systematically developed a stress-modified critical strain model (SMCS) and a void growth model (VGM) to predict monotonic loading fracture. Furthermore, the degeneration effective plastic strain model (DSPS) and cyclic void growth model (CVGM) were developed to predict fracture under low cyclic loading. Two types of structural steel, A572-Grade 50 (345 MPa grade) and HPS70W (480 MPa grade), were subjected to 12 tensile plate tests and finite element analyses by Kanvinde and Deierlein [

12,

23], and the validity and accuracy of the SMCS and VGM for predicting ductile cracking of structural steel joints under monotonic loading were verified. Meanwhile, some scholars [

24,

25,

26] also calibrated the CVGM and DSPS models for predicting fractures under ultra-low cyclic fatigue and verified the accuracy of the CVGM and DSPS models for predicting fractures under ultra-low cyclic fatigue based on cyclic loading tests and finite element analyses. In addition, Liao et al. [

27,

28] and Zhou et al. [

13] calibrated the toughness parameters of the SMCS, VGM, DSPS, and CVGM for three types of materials, namely the base material, weld metal, and heat-affected zone of Q345 steel, using the weldment as specimens. Their models have been applied in the prediction of ductile crack initiation in the welded joints of steel structures.

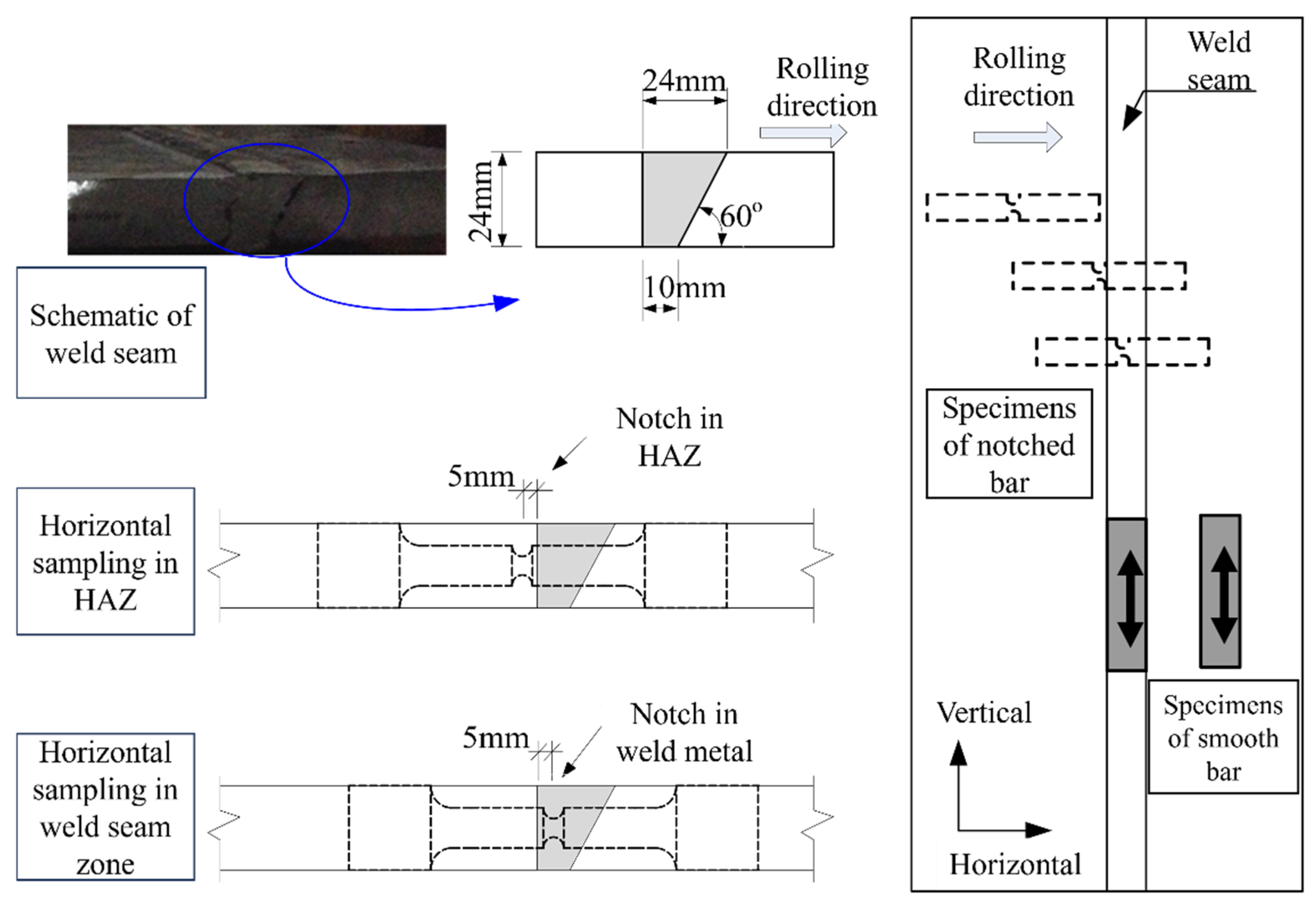

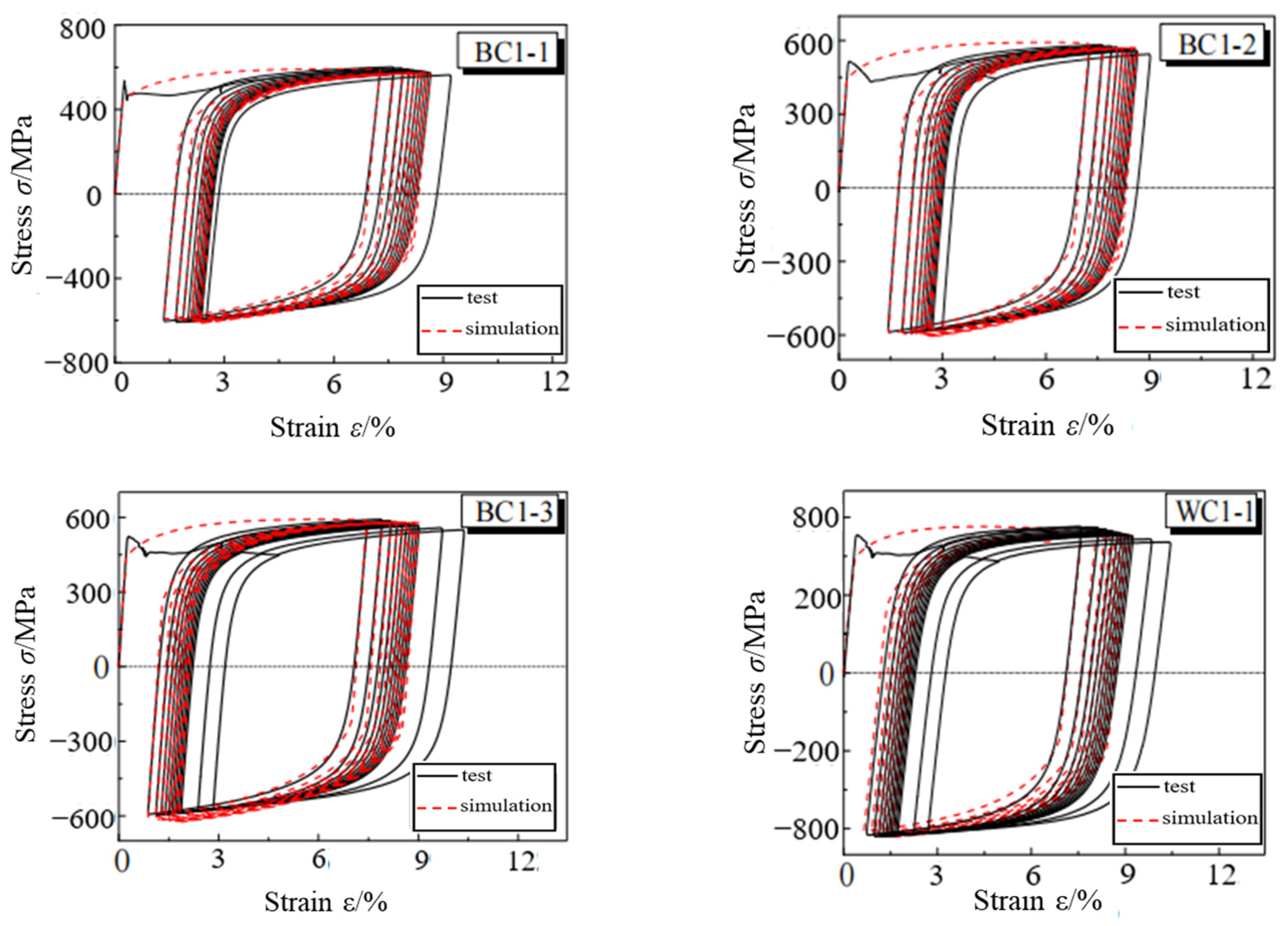

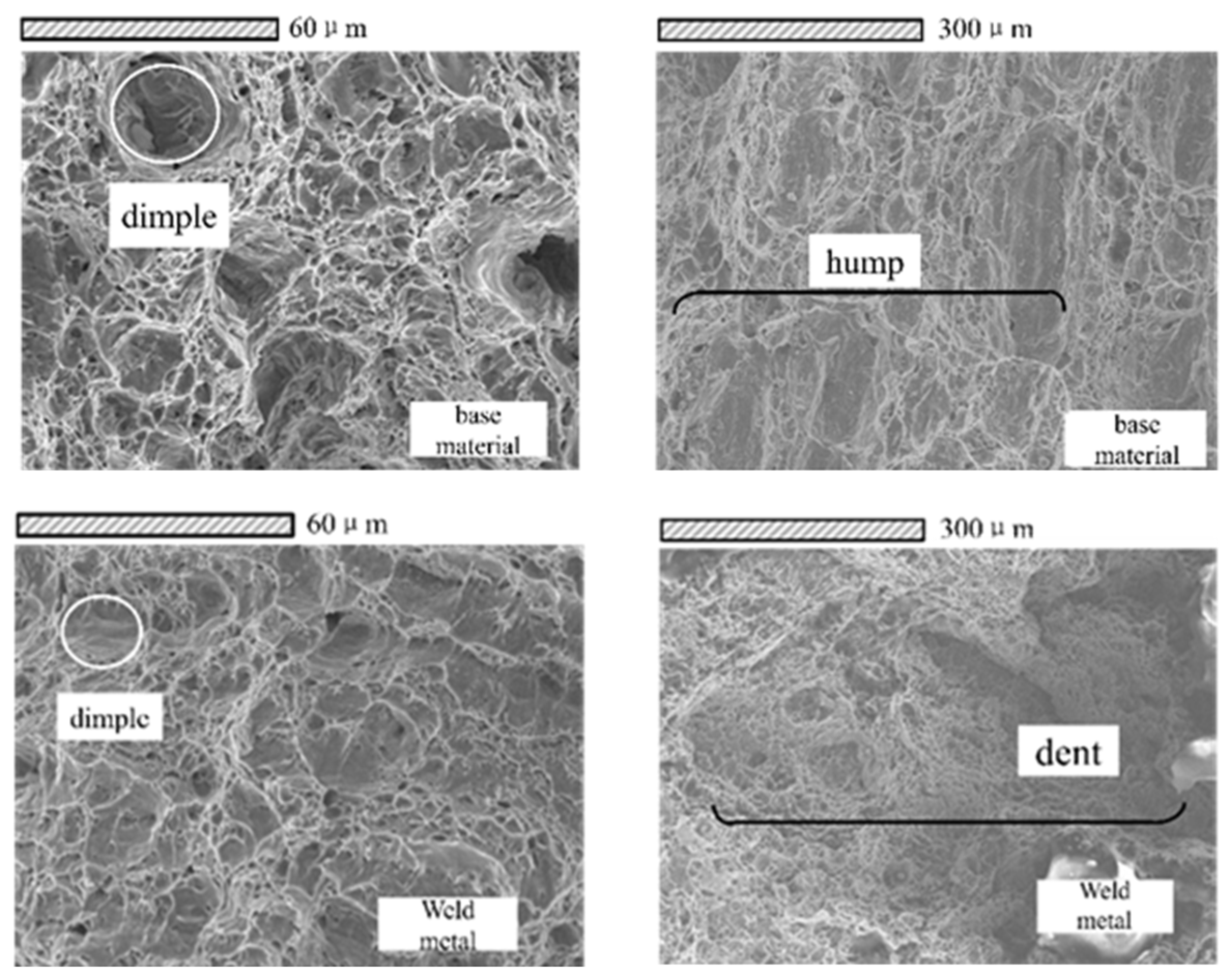

The aim of this paper is to validate the applicability of the VGM, SMCS, and CVGM micromechanical fracture models for the high-strength steel Q460C and its butt-welded joints, which are widely used in engineering. The hysteretic behavior, damage degradation mechanisms, failure progression, and cyclic material hardening models were systematically investigated through a comprehensive experimental program involving tensile and cyclic loading tests on smooth round bar specimens, complemented by detailed finite element analyses. Subsequently, the micromechanical fracture mechanisms were systematically investigated through a series of notched round bar specimens subjected to monotonic and cyclic loading, complemented by scanning electron microscopy (SEM) characterization and computational fracture mechanics simulations. The calibrated micromechanical models were then implemented to predict the fracture behavior of welded steel joints under low-cycle fatigue (LCF) loading conditions, demonstrating excellent predictive capability through comprehensive experimental validation.

4. Fracture Behavior Analysis Based on Micromechanical Model

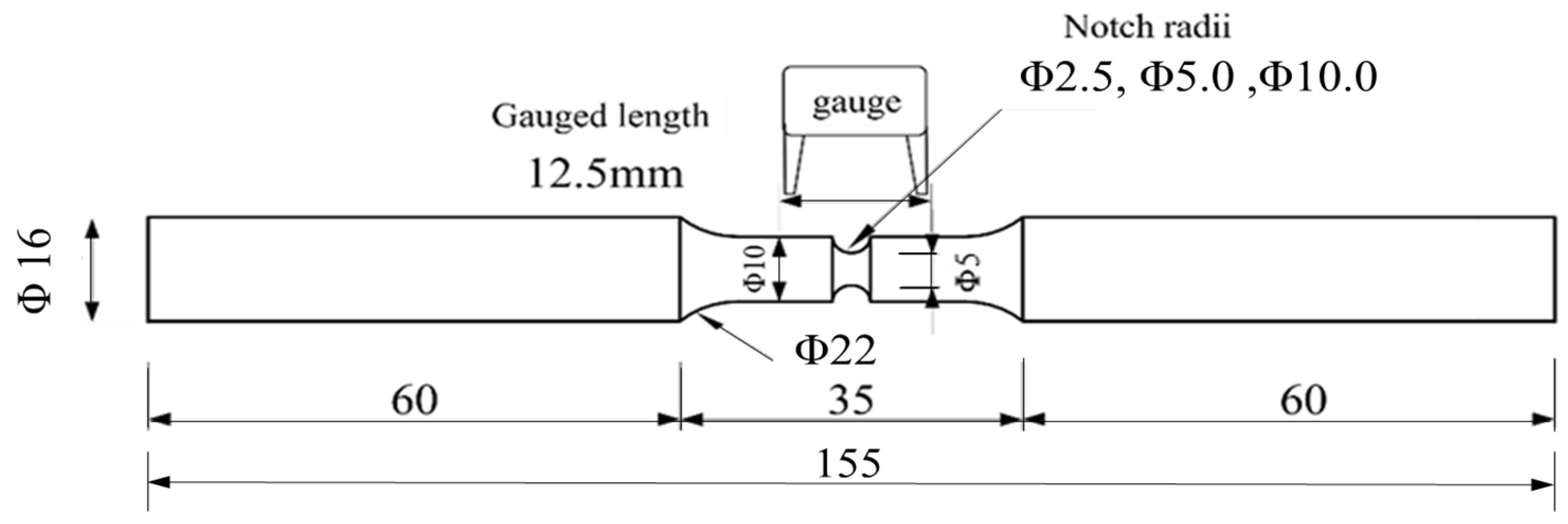

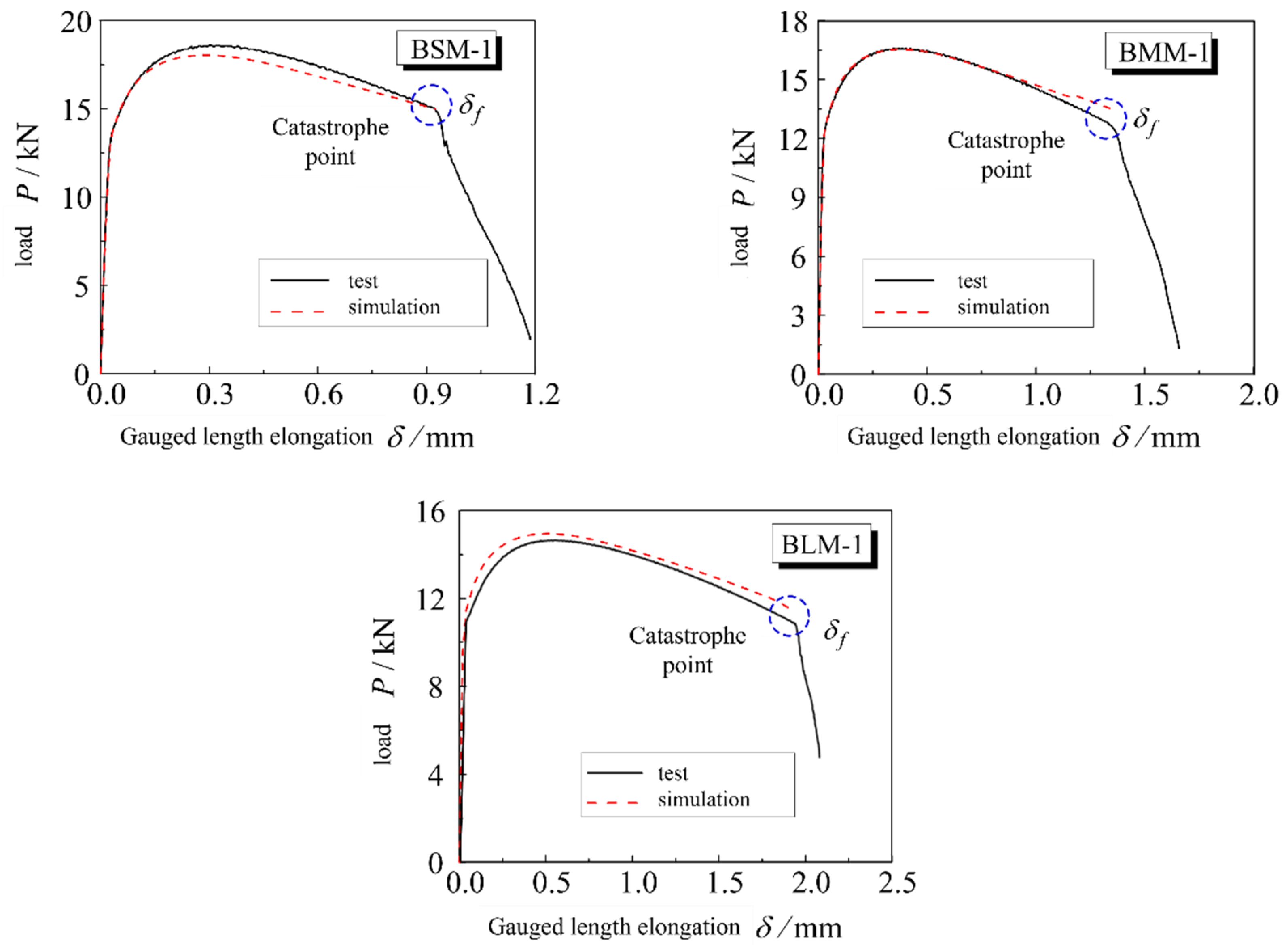

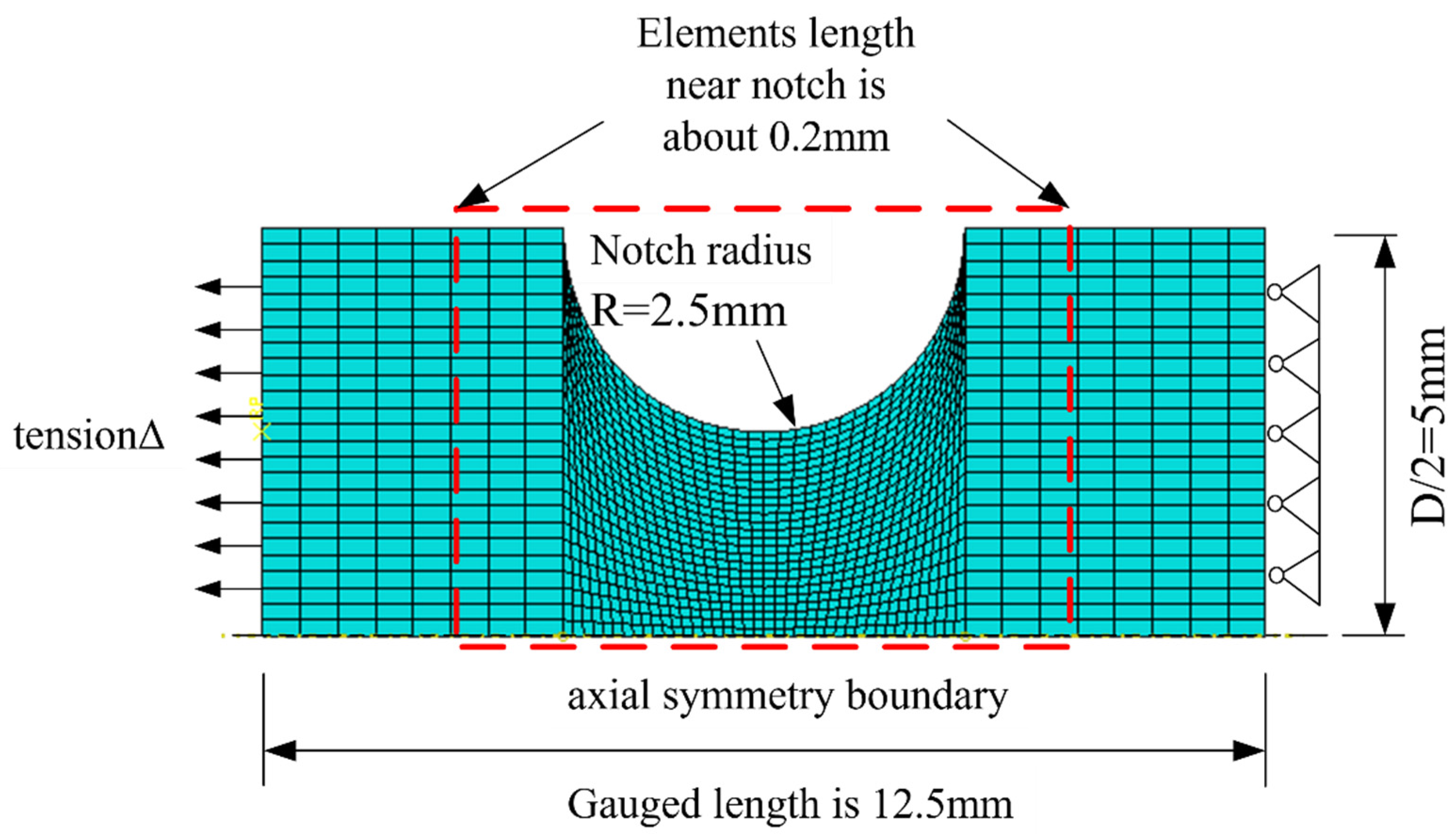

Based on the results from the notched round bar tests and corresponding finite element numerical simulations, the micromechanical fracture model parameters for the monotonic tensile fracture of each material were calibrated. This provides a foundation for calibrating the micromechanical fracture model under cyclic loading. Using the symmetry of the specimens, the finite element software ABAQUS 6.14 is used to establish an axisymmetric finite element model of the gauged part of the specimen, as shown in

Figure 14. The selected element type is CAX4, with reference to the characteristic length, and the element size in the region near the notch is approximately 0.2 mm. Axisymmetric boundary conditions are applied at the center axis of the round bar; one end is set as hinged joint, and the other end is subjected to displacement load. Material property data obtained from the standard round bar’s monotonic tensile test were utilized to simulate the loading process through the finite element model. The load–deformation curves of the specimens obtained were in good agreement with the test results, and the results of the typical base material specimens are shown in

Figure 13.

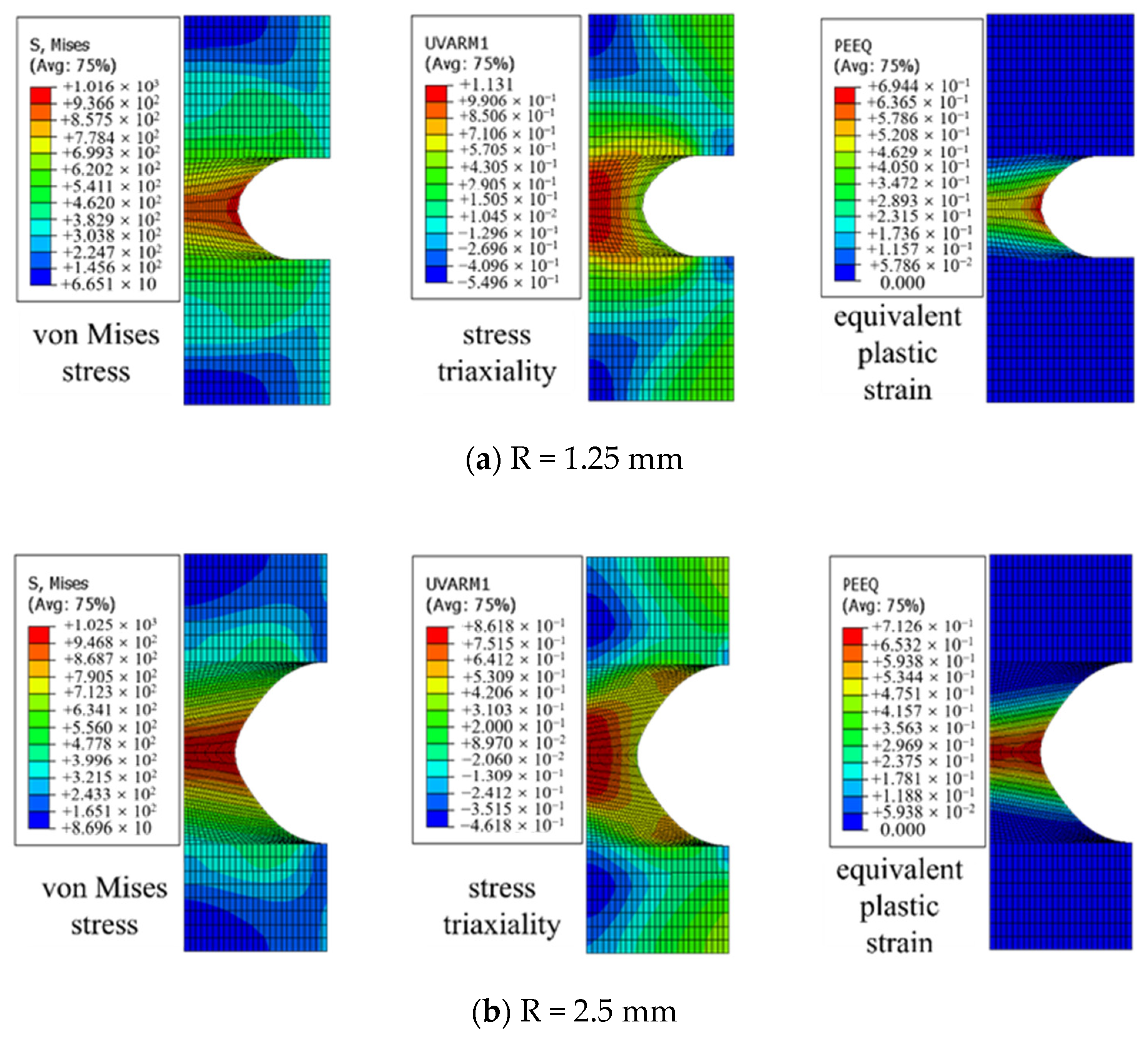

The finite element loading simulation of the specimen was analyzed, and based on the test results, the fracture elongation

δf corresponding to the ductile initial fracture point of the material shown in

Figure 13 is used as the control deformation to ensure that the material reaches the critical state of fracture, and the toughness parameters

η and

γ for both the VGM and the SMCS were calculated. The distribution of the local stress–strain field of the section with different notch radii when the specimen reaches the critical elongation is shown in

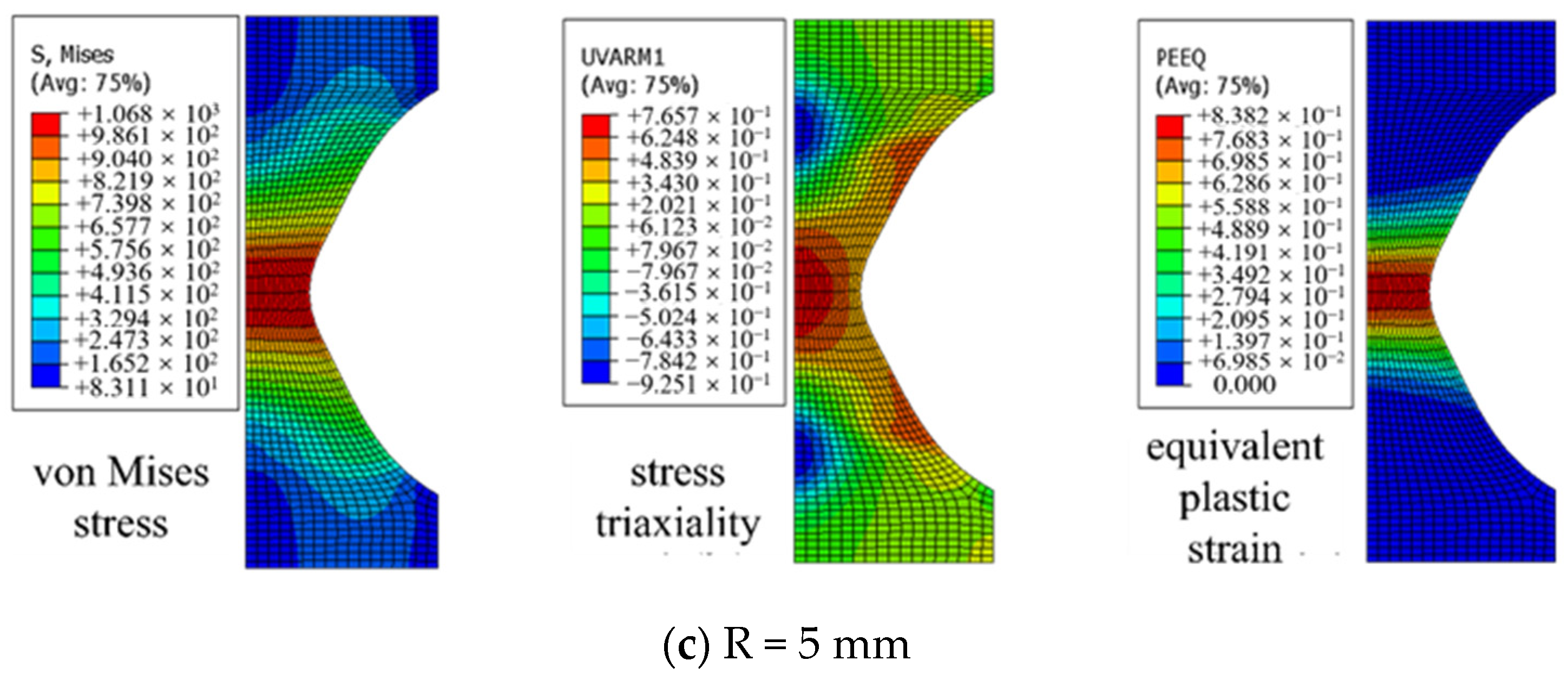

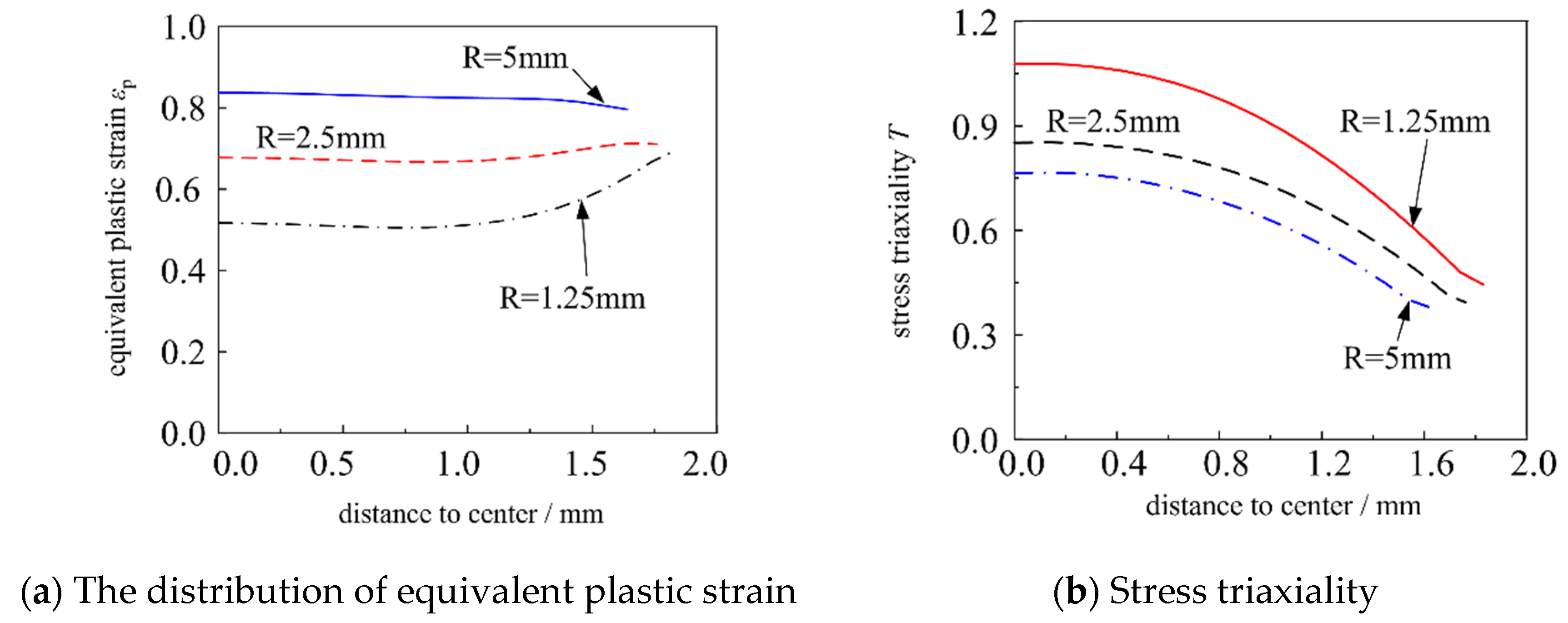

Figure 15.

Figure 16 shows the distribution of equivalent plastic strain and stress triaxiality along the notched section of the specimen. The results indicate that for a notch radius of R = 5 mm, its equivalent plastic strain

εp is nearly uniformly distributed along this section. However, for smaller notch radii (R = 2.5 mm or 1.25 mm), the equivalent plastic strain reaches its maximum at the notched surface. The larger the notch radius is, the smaller the stress triaxiality

T is, with the maximum stress triaxiality value appearing at the center of the specimen, contrary to the distribution law of equivalent plastic strain, while the fracture index in the micromechanical model depends on both the stress triaxiality and equivalent plastic strain. Consequently, under a triaxial stress state, the fracture prediction cannot be made to only rely on the plastic strain index.

When the specimen reaches the critical elongation of initial fracture, the stress–strain state or history of the center point was input into Equations (9) and (10), so the toughness parameters

ηmon and

γ in the VGM and the SMCS were calculated, as listed in

Table 10.

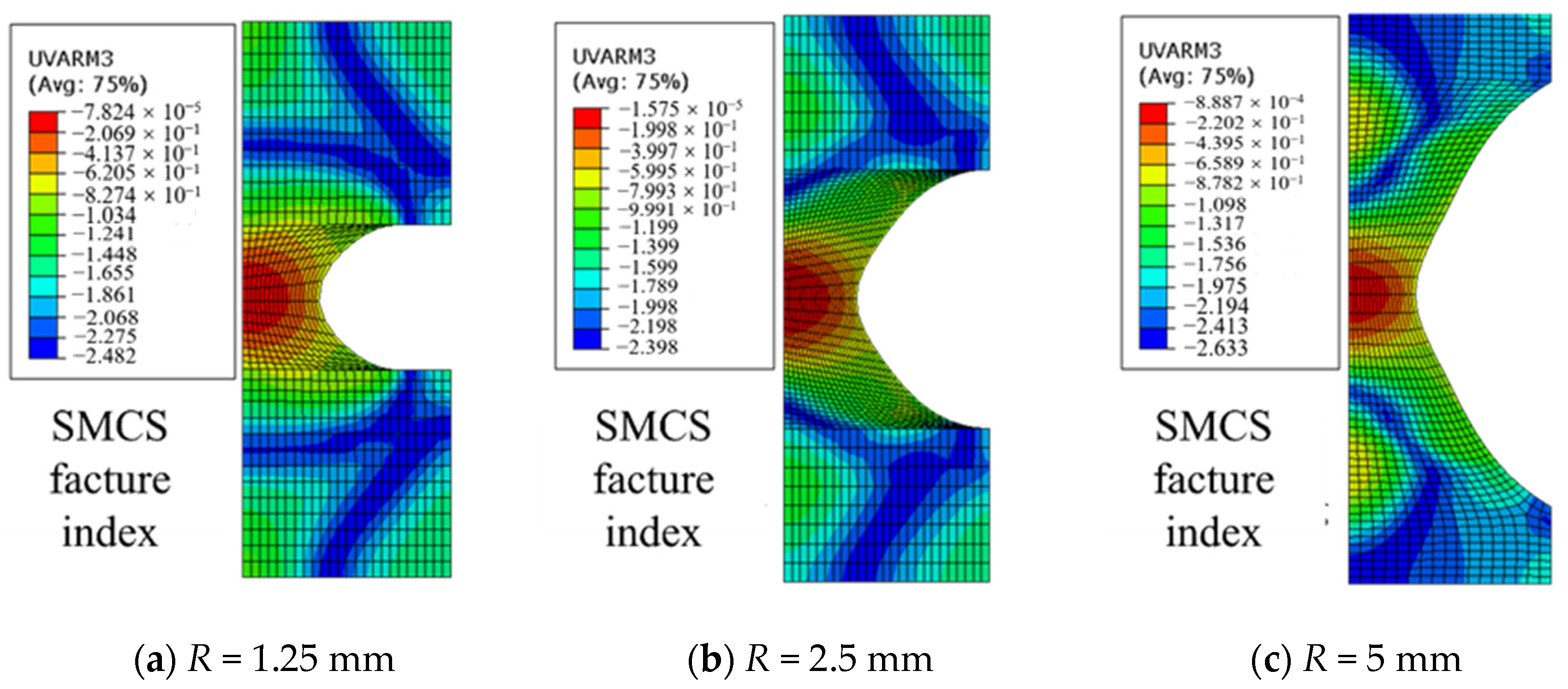

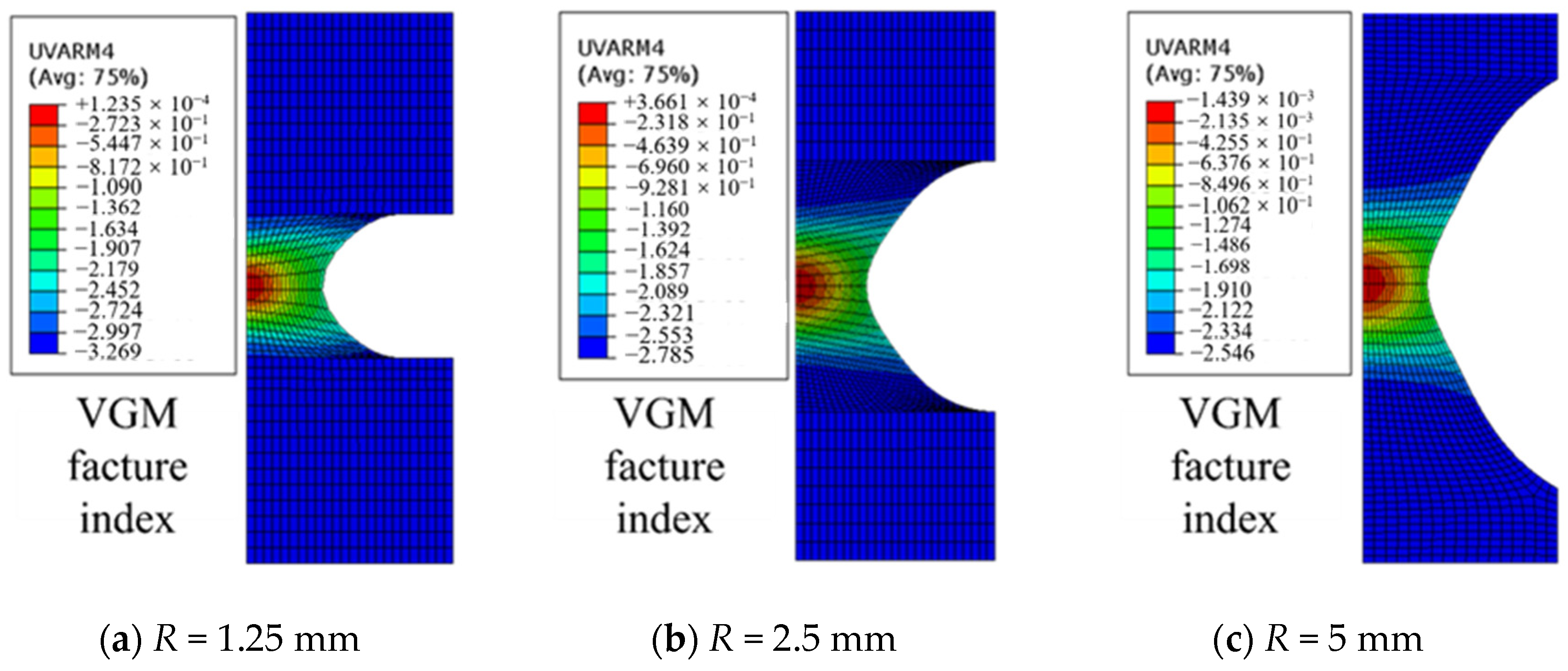

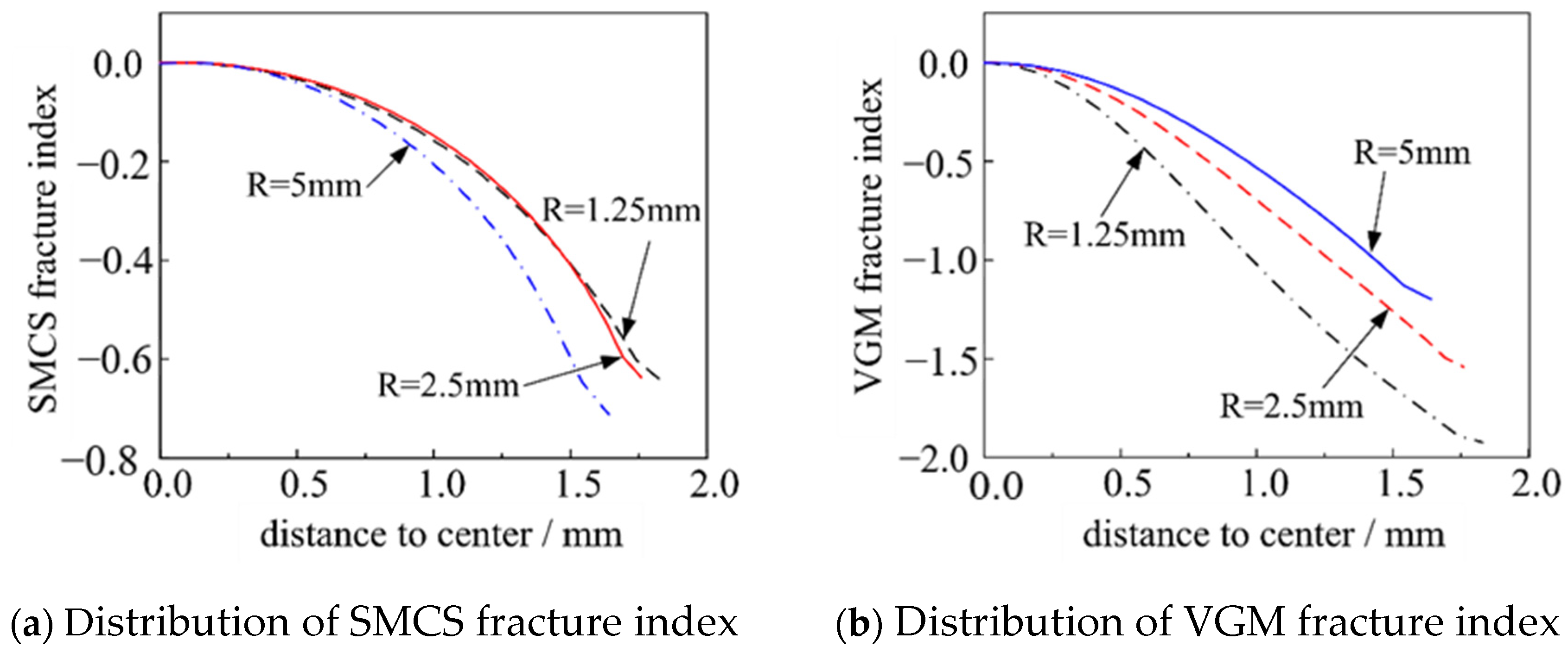

When the toughness index was determined, the fracture indexes of the VGM and SMCS can be calculated according to Equation (11) and Equation (12), respectively, and the output variables were recorded through a subroutine.

The distribution of fracture index when the elongation of the specimen is

δf is shown in

Figure 17 and

Figure 18. As can be seen from the figures, the fracture index reaches maximum at the center of the specimen, indicating that the specimens’ initial fracture at the center point, which is consistent with the test phenomenon.

Figure 19 shows the distribution curves of the fracture indexes in the notched section for three specimens with different notched radii. For each of the three different stress states, the distribution patterns of fracture indexes along the notched section are consistent between the SMCS and the VGM. Both show a decreasing trend from the center of the specimen to the notched surface, with only minor gradient changes observed within certain ranges. This indicates that the characteristic length based on the material’s microstructure does not significantly influence fracture prediction for the notched round bar specimens. Furthermore, there is an absence of evident correlation between the characteristic length and toughness indexes. The consistency on the distribution pattern of fracture indexes for the SMCS and the VGM also verifies their applicability to high-strength steels under various stress states.

Through the monotonic tensile test of the notched round bar specimens, corresponding finite element numerical simulations were conducted to obtain the toughness parameters

ηmon,

γ and other relevant parameters during the calibration process for the microfracture model, as listed in

Table 10. In the table, the equivalent plastic strain

εp,cr, the equivalent stress

σe, the average stress

σm, and the stress triaxiality

T are the stress–strain values corresponding to the critical elongation

δf. Comparing the calibrated toughness parameters for the base material, weld metal, and heat-affected zone, it was observed that the toughness parameters of the heat-affected zone are somewhat lower. However, the average values of the three materials are similar, and the low coefficient of variation (COV) of the calibrated results indicates that the VGM and the SMCS are suitable for the prediction of the ductile fracture of high-strength steels and their weld materials under different stress states.

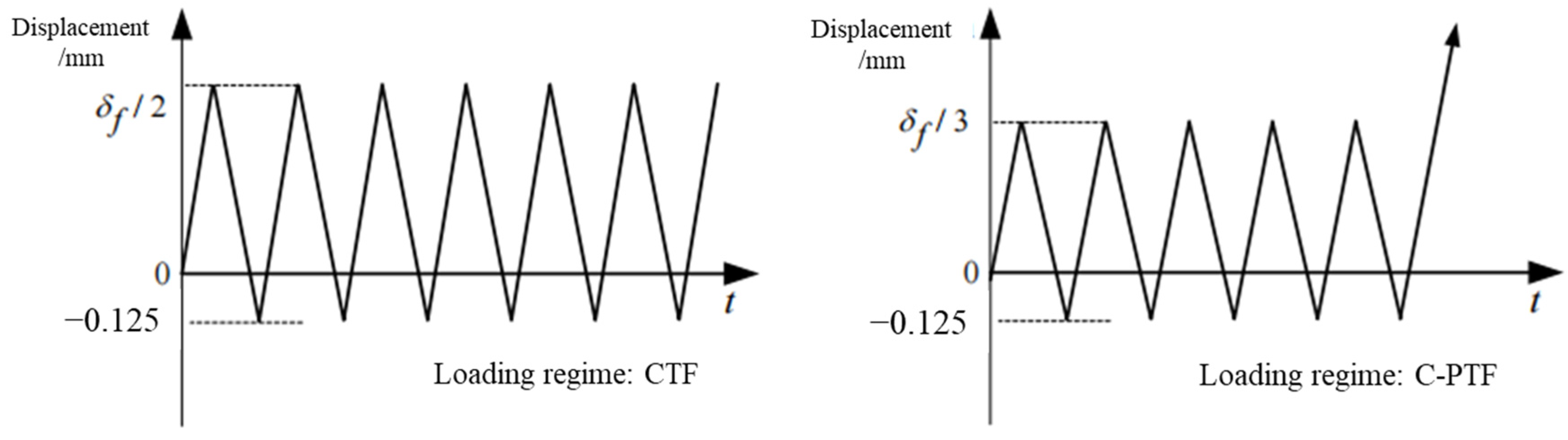

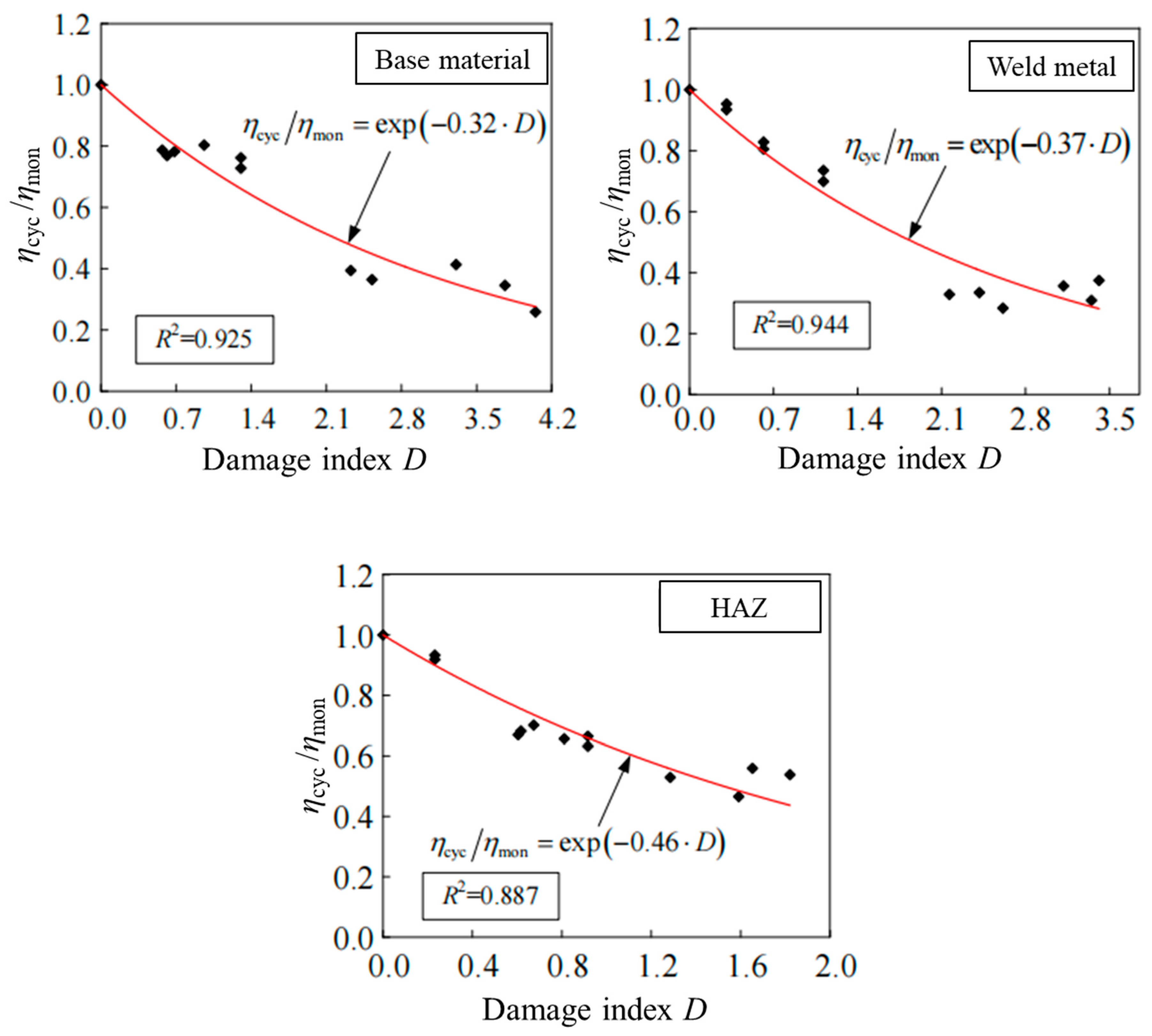

For the calibration of CVGM model parameters under large-strain low-cycle fatigue loading, the stress–strain history at the fracture hazardous point of the notched round bar specimen undergoing cyclic loading is monitored up to failure. Using the number of cycles

Nf and the critical elongation

δf obtained from notched round bar cyclic loading test at the time of the initial fracture via the Equation (13), the critical expansion of the material voids of the specimen at the point of cracking under cyclic loading is calculated as

ηcyc, i.e., the demanded toughness under cyclic loading.

The material damage ratio is obtained by comparing it with the toughness index

ηmon under monotonic loading, as mentioned above. The equivalent plastic strain

εp at the beginning of the last tensile cycle of the specimen is employed as the damage variable D. An exponential function fit, detailed in Equation (14), establishes the relationship between the damage ratio and damage variable and obtains the damage coefficient

λ.

The material damage coefficient

λCVGM obtained from the fitting data of Q460C base material, weld seam, and heat-affected zone are shown in

Table 11, while the damage coefficient fitting curve is shown in

Figure 20.

The fracture toughness parameters of Q460C high-strength steel and its welded joints were comparatively analyzed with reference to Q345 steel [

28] and seven structural steels from American and Japanese sources [

12], as detailed in

Table 12.

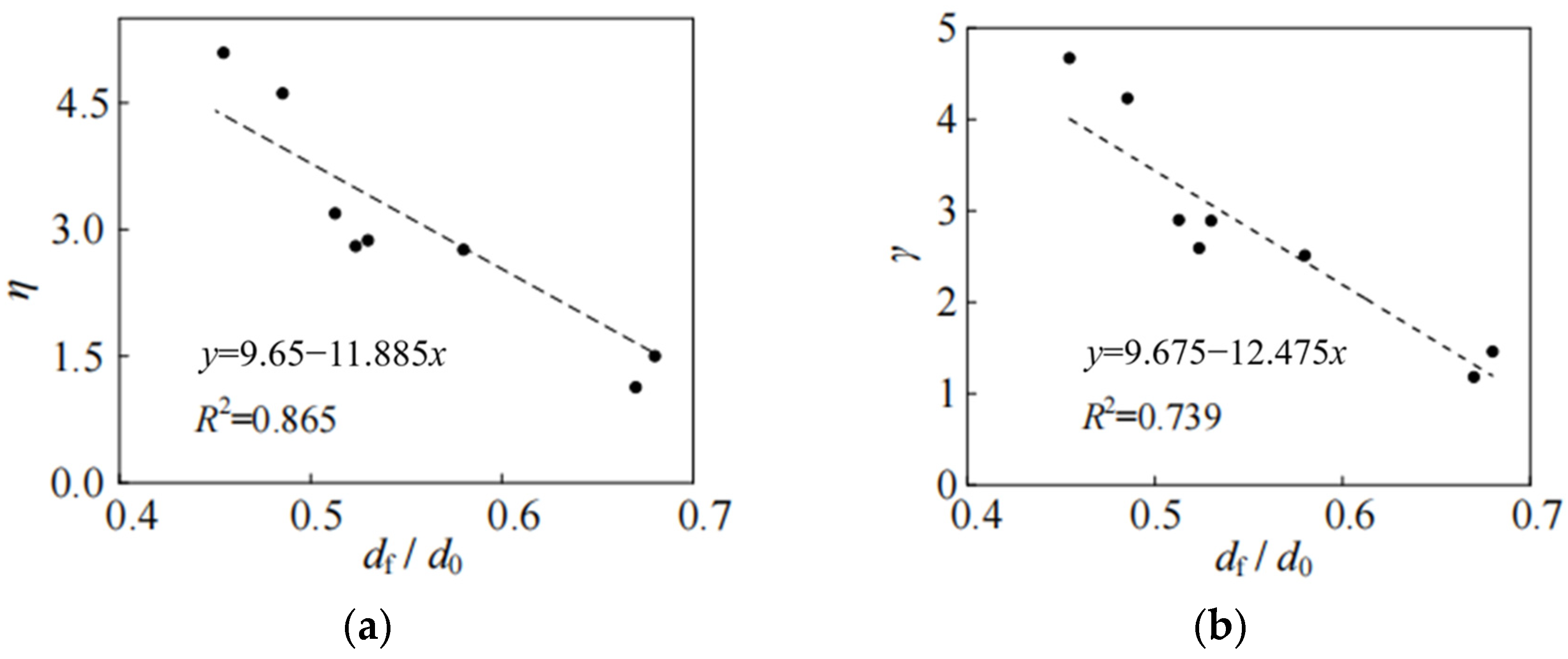

The comparison results of toughness parameters of steel with different strengths show that the toughness parameters

γ and

ηmon of the material under monotonic tensile do not exhibit a significant correlation with material strength index and yield ratio. However, there is a certain relationship with the specimen plasticity index, i.e., the section shrinkage ratio. The better the plasticity is, the greater the toughness parameters is. The damage degradation coefficient

λCVGM under cyclic loading shows little relationship with the material mechanical property index.

Figure 21 illustrates the correlation between toughness and plasticity indexes across various fracture prediction models. The micromechanical toughness parameter exhibits an inverse correlation with section shrinkage, demonstrating a strong dependence (

R2 = 0.865) between the

η parameter in the VGM and experimental measurements, as determined by the regression analysis. Therefore, when the micromechanical model calibration is limited by the actual conditions, the formula in

Figure 21 can be used to make an approximate conversion of the plasticity indexes, such as the elongation after the fracture.