System Dynamics Simulation of Intervention Strategies for Unsafe Behaviors Among Prefabricated Building Construction Workers

Abstract

1. Introduction

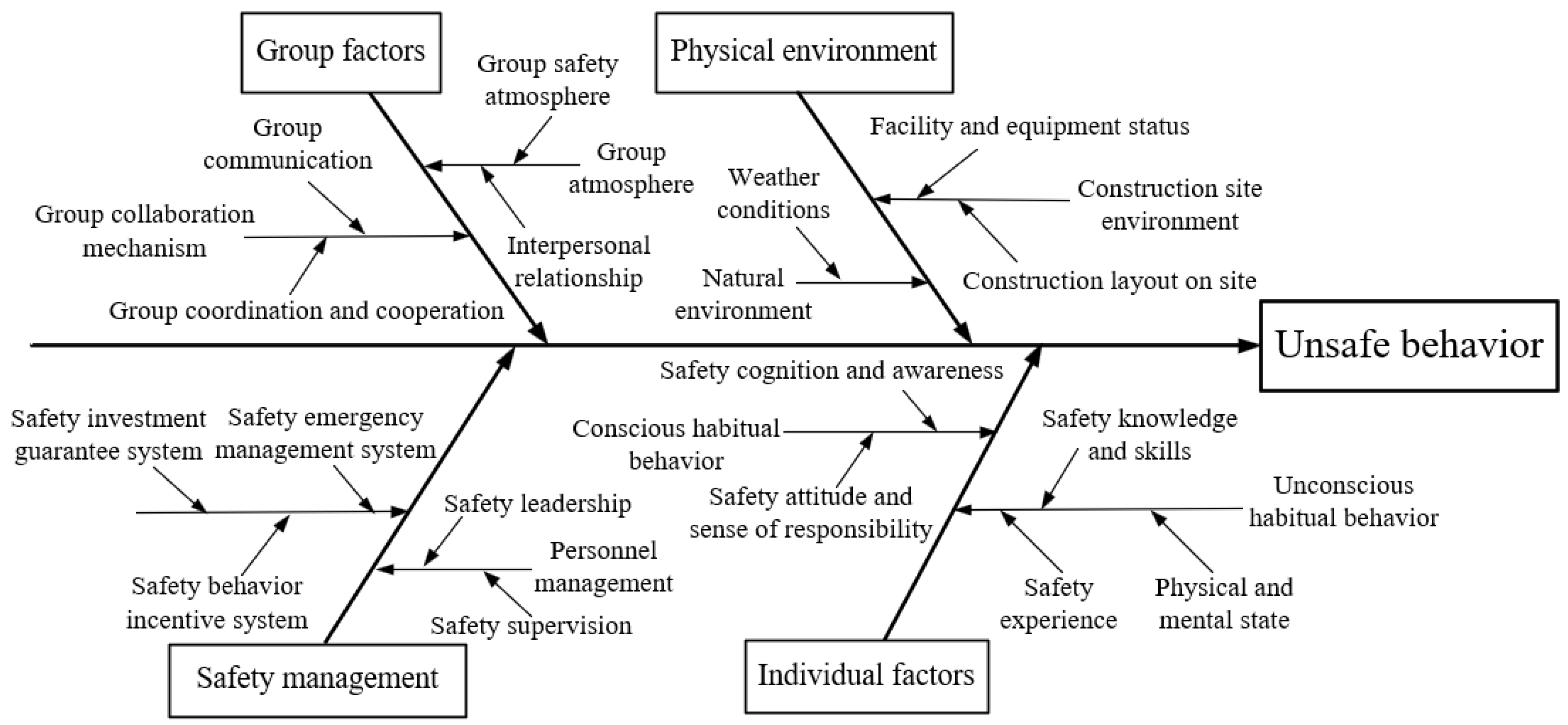

2. Identification of Factors Influencing Unsafe Behaviors of Construction Personnel

2.1. Physical Environment

2.2. Individual Factors

2.3. Group Factors

2.4. Security Management

3. Determination of the Weighting of Factors Influencing Unsafe Behaviors

3.1. Data Sources

3.2. Calculation of the Weights of the Indicators of Impact Factors

3.2.1. Entropy Weighting Method to Determine Weights

3.2.2. Weight Determination by Using the Coefficient of Variation Method

3.2.3. Combined Weight Calculation by Entropy Weighting Method of Coefficient of Variation

4. Simulation of Intervention Strategies for Construction Workers’ Unsafe Behaviors

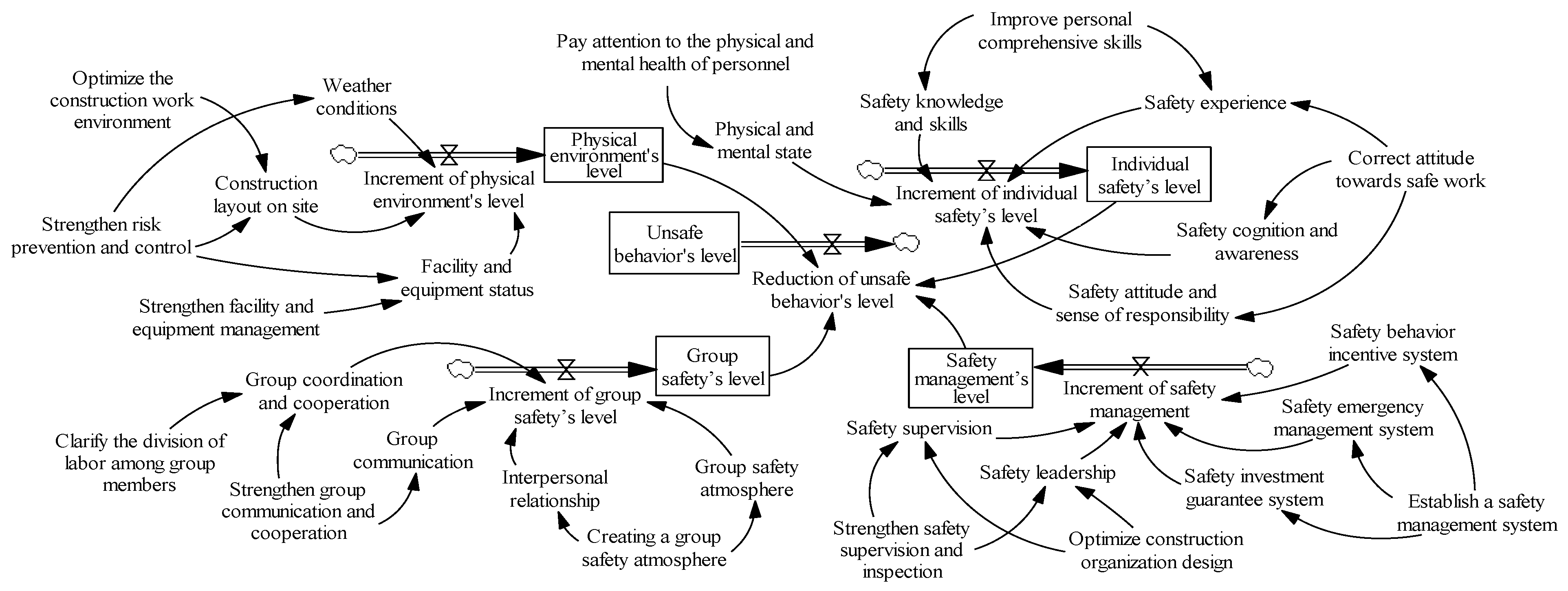

4.1. SD Intervention Model

4.2. Intervention Simulation

5. Results

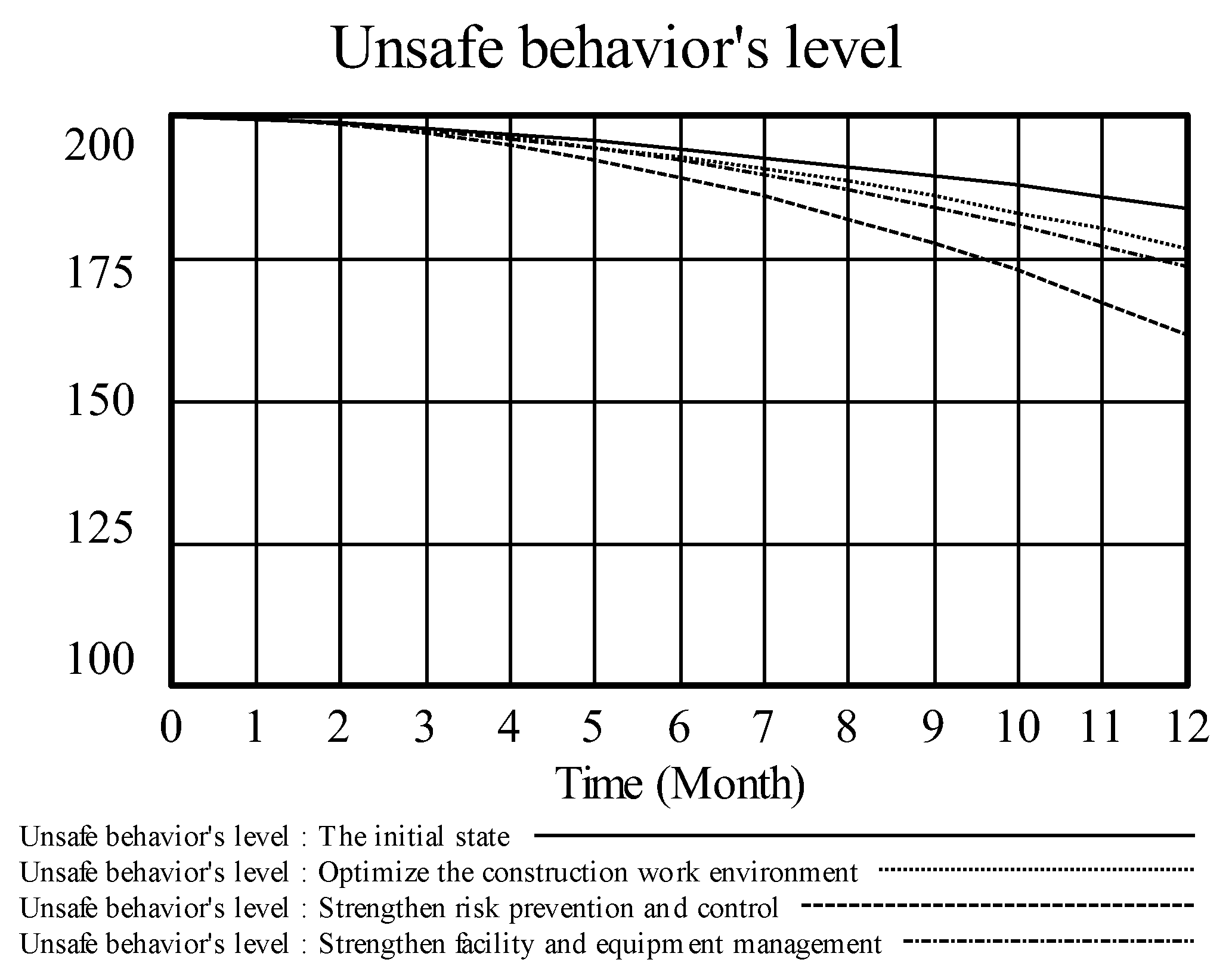

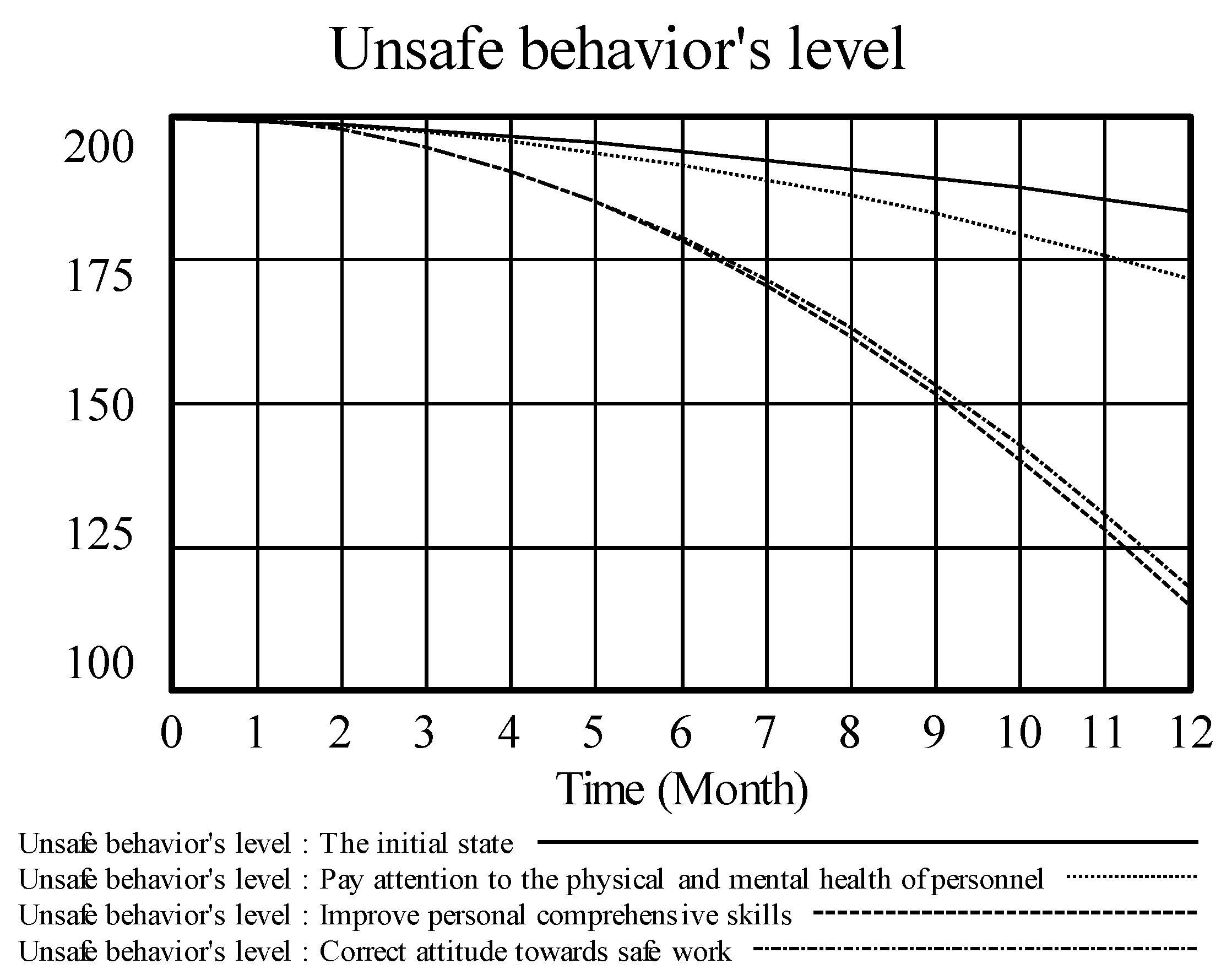

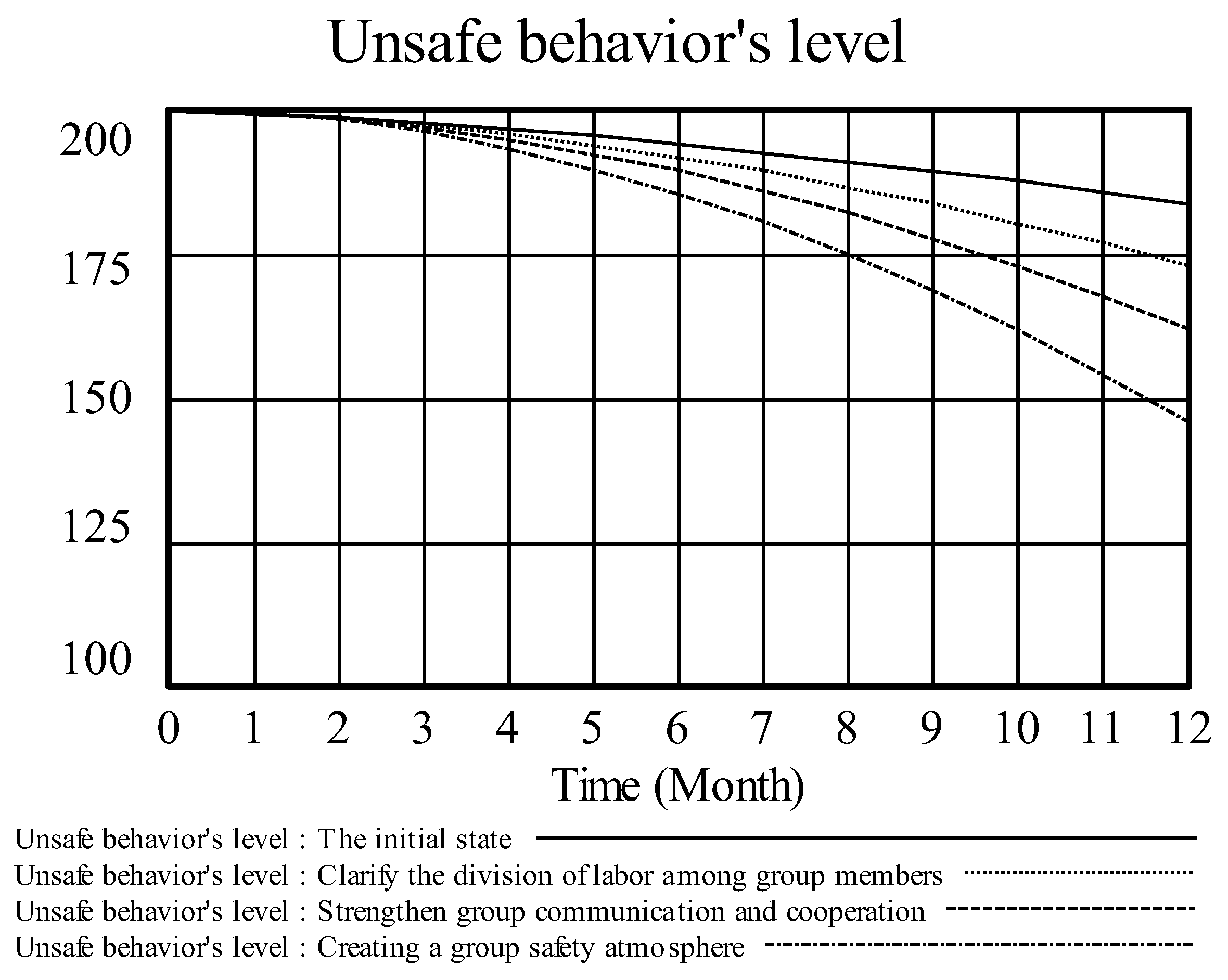

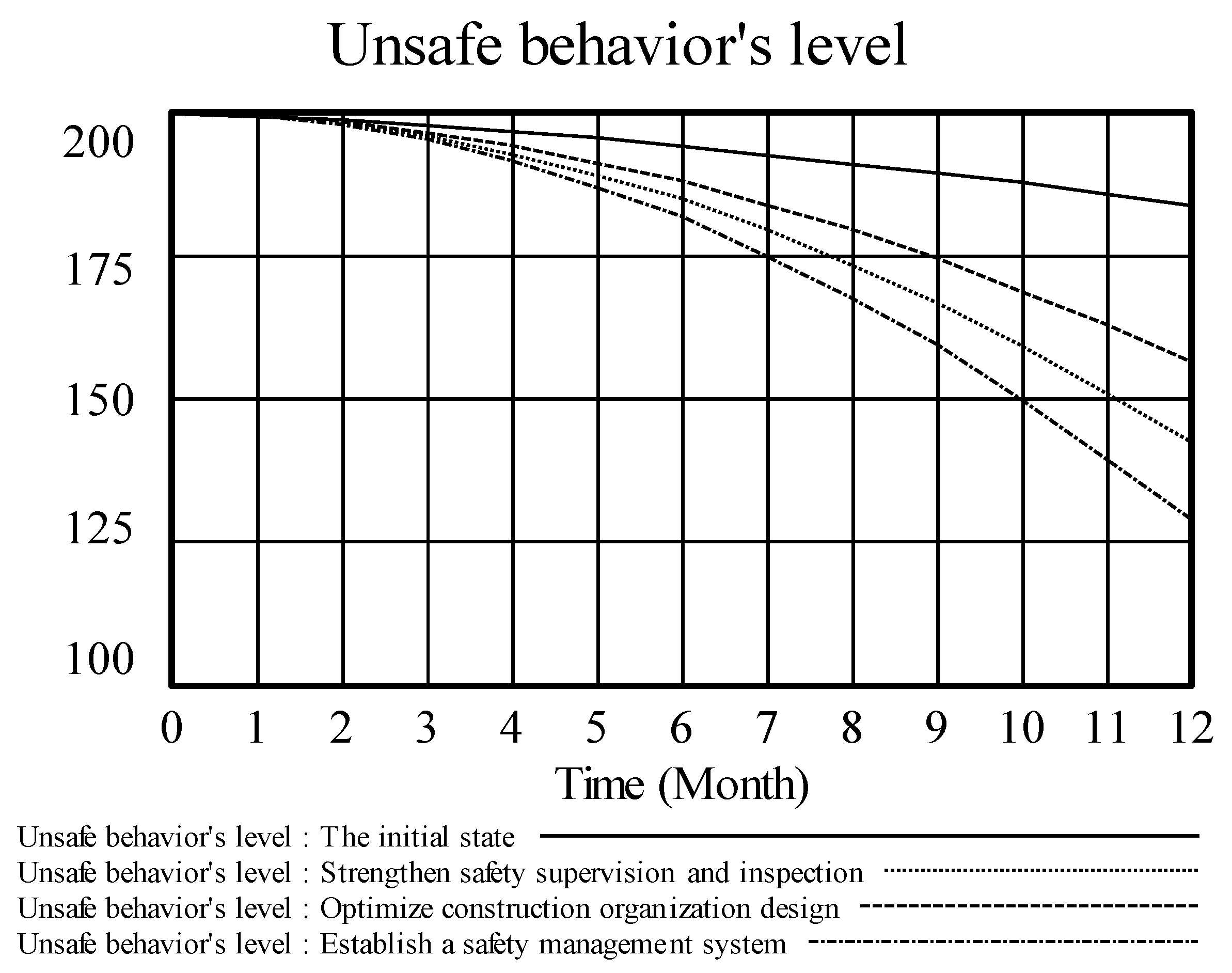

5.1. Analysis of Single Intervention Results

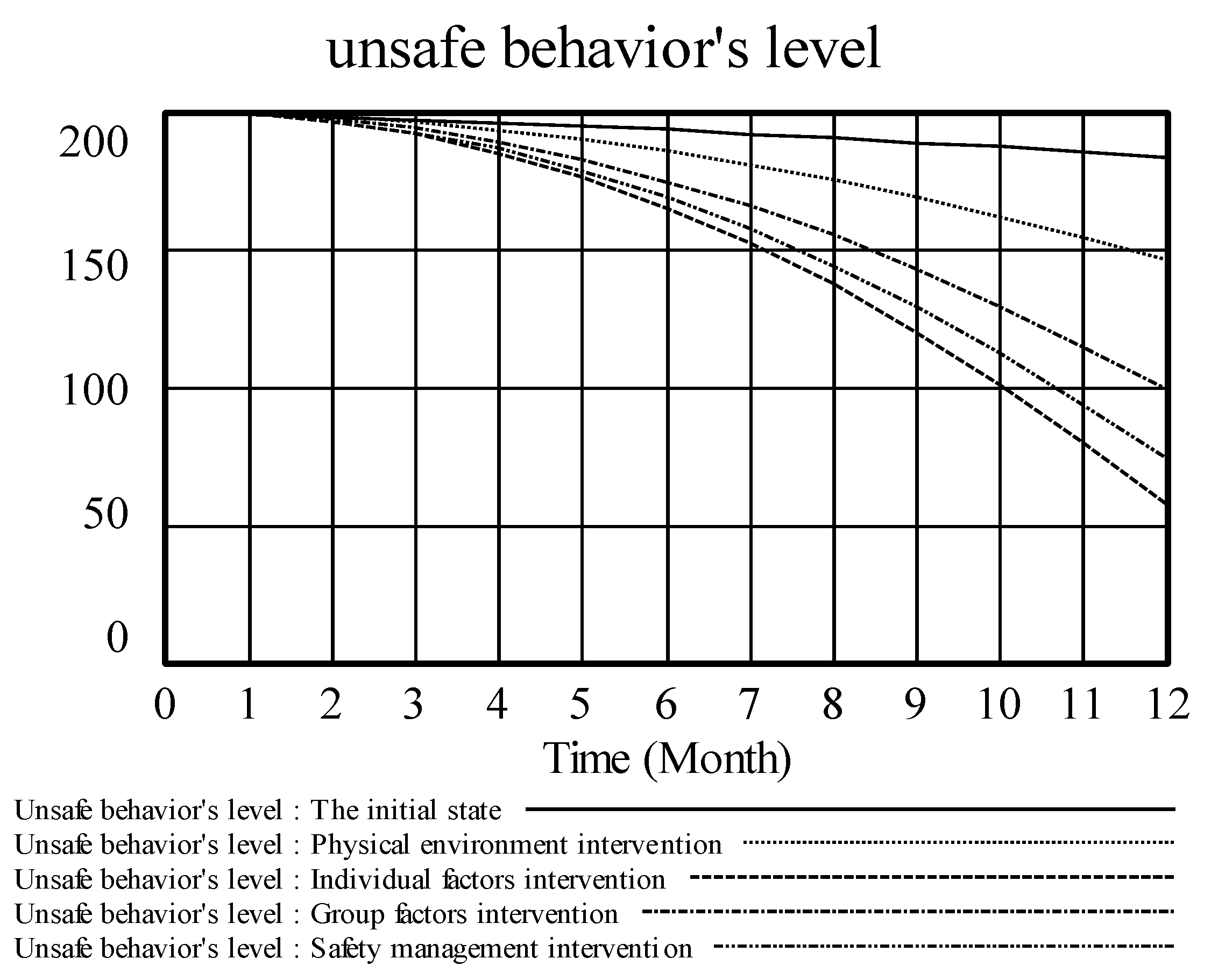

5.2. Analysis of Combined Intervention Results

6. Discussion on Intervention Strategies

7. Conclusions

- (1)

- An intervention simulation model for unsafe behaviors of prefabricated building construction workers was developed from four aspects: physical environment, individual factors, team factors, and safety management. The simulation results indicate that implementing a single intervention measure can reduce the level of unsafe behaviors among prefabricated building construction workers. Among them, enhancing individual comprehensive skills had the most significant effect, with a reduction of 37.78%. Although the decrease is considerable, it still falls short of the expected goal of significantly reducing unsafe behaviors. This indicates that single intervention measures have a limited impact on reducing the level of unsafe behaviors among prefabricated building workers.

- (2)

- Implementing combined interventions can significantly enhance the control effect on unsafe behaviors. The intervention effects of applying combined interventions to the four subsystems for prefabricated building construction workers, ranked in descending order, are as follows: individual factor intervention (68.87% reduction), safety management intervention (59.93% reduction), team factor intervention (46.32% reduction), and physical environment intervention (20.71% reduction). This demonstrates that combined interventions have a significant advantage in terms of intervention effectiveness.

- (3)

- In the prefabricated building construction process, priority should be given to strengthening individual factors and safety management interventions. This mainly includes enhancing training interventions and institutional development. In terms of training interventions, safety skill levels of construction workers can be improved through customized specialized training systems, the promotion of intelligent training tools (such as VR and AR), and the implementation of phased skill certification and mandatory licensing systems. In terms of institutional development, a comprehensive safety management model involving all personnel can be established through behavioral guidance mechanisms, emergency response mechanisms, supervision and management mechanisms, and a leadership-driven positive reinforcement system to enhance safety awareness and execution.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, K.; Yuan, Y. Geographic distribution and influencing factor analysis of green residential buildings in China. Sustainability 2021, 13, 12060. [Google Scholar] [CrossRef]

- Liu, H.; Chen, X. Research on coordination degree evaluation of construction waste governance system from the perspective of complex systems. J. Saf. Environ. 2022, 22, 3379–3386.s. [Google Scholar]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for applying the circular economy to prefabricated buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Alashwal, A.; Bora, S. Game analysis on prefabricated building evolution based on dynamic revenue risks in China. J. Clean. Prod. 2020, 267, 121730. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Liu, S.; Li, Z.; Teng, Y.; Dai, L. A dynamic simulation study on the sustainability of prefabricated buildings. Sustain. Cities Soc. 2022, 77, 103551. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, Y. Study on Large-Scale Promotion of Prefabricated Buildings in Anhui Province Based on SEM and IoT. Sci. Program. 2022, 2022, 6947365. [Google Scholar] [CrossRef]

- Lee, J.; Jeong, J.; Soh, J.; Jeong, J. Quantitative analysis of the accident prevention costs in korean construction projects. Buildings 2022, 12, 1536. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Development. Announcement on the Development of Prefabricated Buildings in China in 2020. Available online: https://www.mohurd.gov.cn/gongkai/zc/wjk/art/2022/art_17339_768565.html (accessed on 1 March 2025).

- Wang, J.; Chen, Z.; Song, Y.; Liu, Y.; He, J.; Ma, S. Data-driven dynamic bayesian network model for safety resilience evaluation of prefabricated building construction. Buildings 2024, 14, 570. [Google Scholar] [CrossRef]

- Ding, Y.; Tian, Y.F. Research on Quality and Safety Risk Evaluation of Prefabricated Building Assessment. Constr. Econ. 2019, 40, 80–84. [Google Scholar]

- Heinrich, H. Industrial Accident Prevention. A Scientific Approach, 2nd ed.; McGraw-Hill Book Company: New York, NY, USA, 1941; pp. 102–128. [Google Scholar]

- China Building Energy Efficiency Association Building Energy Consumption and Carbon Emission Data Specialised Committee. China Building Energy Consumption and Carbon Emission Research Report; China Building Energy Efficiency Association Building Energy Consumption and Carbon Emission Data Specialised Committee: Chongqing, China, 2022; Volume 12. [Google Scholar]

- Fard, M.M.; Terouhid, S.A.; Kibert, C.J.; Hakim, H. Safety concerns related to modular/prefabricated building construction. Int. J. Inj. Control Saf. Promot. 2017, 24, 10–23. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.-H.; Zhou, Z.-H.; Tang, Y.-C.; Lu, Y.; Xiahou, X.-E.; Li, Q.-M. Scene-oriented Statistical Analysis of Safety Accidents in Prefabricated Construction. Constr. Technol. 2022, 51, 51–57. [Google Scholar]

- Fu, H.; Tan, Y.; Xia, Z.; Feng, K.; Guo, X. Effects of construction workers’ safety knowledge on hazard-identification performance via eye-movement modeling examples training. Saf. Sci. 2024, 180, 106653. [Google Scholar]

- Chi, C.F.; Lin, S.Z.; Dewi, R.S. Graphical fault tree analysis for fatal falls in the construction industry. Accid. Anal. Prev. 2014, 72, 359–369. [Google Scholar] [CrossRef]

- Li, L. Research on Formation Mechanism and Combination Intervence of Coal Miners’ Unsafe Behaviors. Ph.D. Thesis, Xi’an University of Science and Technology, Xi’an, China, 2014. [Google Scholar]

- Wang, C.; Wang, J.; Wang, X.; Yu, H.; Bai, L.; Sun, Q. Exploring the impacts of factors contributing to unsafe behavior of coal miners. Saf. Sci. 2019, 115, 339–348. [Google Scholar]

- Tong, R.P.; Fan, B.Q.; Sun, N.H.; Yao, J.T.; Dong, B.Y. Targeted intervention method for unsafe behaviors of subway construction workers. China Saf. Sci. J. 2022, 32, 10–16. [Google Scholar]

- Ni, G.D.; Li, H.K.; Cao, M.X.; Wang, K.D. Inducing Factors of and Intervention Countermeasures against Unsafe Behavior of New Generation of Construction Workers. Saf. Environ. Eng. 2022, 29, 8–16. [Google Scholar]

- Zhang, M.Y.; Xu, Q. Analysis on propagation model and intervention effects of unsafe behaviors of construction workers. China Saf. Sci. J. 2021, 31, 1–9. [Google Scholar]

- Mazlina Zaira, M.; Hadikusumo, B.H.W. Structural equation model of integrated safety intervention practices affecting the safety behaviour of workers in the construction industry. Saf. Sci. 2017, 98, 124–135. [Google Scholar]

- James, J.; Ikuma, L.H.; Nahmens, I.; Aghazadeh, F. The impact of Kaizen on safety in modular home manufacturing. Int. J. Adv. Manuf. Technol. 2014, 70, 725–734. [Google Scholar]

- Xin, Y.Y.; Yang, D.L.; Fang, Q.C. Application of improved GRA-TOPSIS model in risk assessment of prefabricated building construction. J. Saf. Environ. 2023, 23, 2212–2222. [Google Scholar]

- Chang, L.; Zhao, S. Risk evaluation of prefabricated building construction based on PTF-VIKOR of prospect theory. Alex. Eng. J. 2025, 115, 147–159. [Google Scholar] [CrossRef]

- Chu, W.; Han, S.; Luo, X.; Zhu, Z. Monocular vision–based framework for biomechanical analysis or ergonomic posture assessment in modular construction. J. Comput. Civ. Eng. 2020, 34, 4020011–4020018. [Google Scholar] [CrossRef]

- Shen, Y.; Xu, M.; Lin, Y.; Cui, C.; Shi, X. Safety Risk Management of Prefabricated Building Construction Based on Ontology Technology in the BIM Environment. Buildings 2022, 12, 765. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, M.M.; Wang, B.Y.; Liang, H.; He, W.Y. Research on construction safety management of assembled building based on BIM technology and risk assessment system. Build. Struct. 2023, 53, 2089–2093. [Google Scholar]

- Wang, X.X. Research on Intentional Unsafe Behavior in Prefabricated Building Construction. Master’s Thesis, North China University of Technology, Beijing, China, 2021. [Google Scholar]

- Yuan, X. Research on Intervention Mechanism of Unsafe Behaviors of Crane Workers in Prefabricated Buildings. Master’s Thesis, Suzhou University of Science and Technology, Suzhou, China, 2023. [Google Scholar]

- Xu, G. Analysis of safety behavior of prefabricated building workers’ hoisting operation based on computer vision. Math. Probl. Eng. 2022, 2022, 1715332. [Google Scholar] [CrossRef]

- Zhang, Y. Thoughts and Views on Safety of Prefabricated Buildings based on the Computer Technology. J. Phys. Conf. Ser. 2021, 1744, 022090. [Google Scholar] [CrossRef]

- Ye, G.; Yang, L.J.; Wang, H.X.; Fu, Y.; Tang, X.Y. Study on Influencing Factors of Construction Workers’ Unsafe Behavior Based on Multi Level Hierarchical Structure Model. Saf. Environ. Eng. 2019, 26, 129–134. [Google Scholar]

- Shen, Q.Y.; Chen, Z.; Li, Z. A Study on the quality and Ability Requirements of on-site construction Talents and training approaches for prefabricated buildings: A case study of Guangzhou. Constr. Econ. 2021, 42, 189–192. [Google Scholar]

- Yu, K.; Cao, Q.; Xie, C.; Qu, L.; Zhou, L. Analysis of intervention strategies for coal miners’ unsafe behaviors based on analytic network process and system dynamics. Saf. Sci. 2019, 118, 145–157. [Google Scholar] [CrossRef]

- Fan, Z.Z.; Wang, N.F. On the unsafe or reckless behaviors of the seafarer based on the structural equation model (SEM). J. Saf. Environ. 2021, 21, 682–687. [Google Scholar]

- Ju, J.; Yang, G.S.; Yang, P. Analysis of Influencing factors and control Measures of Unsafe Behavior of Construction workers. China Work Saf. Sci. Technol. 2013, 9, 179–184. [Google Scholar]

- Qi, S.J.; Yao, M.L.; Cheng, J.L.; Chen, M.; Zhang, Y.B. Effect of safety incentive on unsafe behavior of construction workers with conformity motivation. China Prod. Saf. Sci. Technol. 2018, 14, 186–192. [Google Scholar]

- Zhu, L.; Xiong, K. Identification of key factors influencing unsafe behavior of decoration workers. Int. J. Occup. Saf. Ergon. 2024, 30, 936–945. [Google Scholar] [PubMed]

- Huang, Y.; Xiong, W.W.; Liu, M.R.; Wei, J.G. Fall risk assessment of prefabricated building construction based on improved evidence Theory. J. Xi ’an Univ. Archit. Technol. (Nat. Sci. Ed.) 2022, 54, 11–17. [Google Scholar]

- Huang, Q.Q.; Qi, S.J.; Zhang, Y.B.; Cheng, J.L. SD model of intervention strategies for habitual unsafe behavior of construction workers. China Saf. Sci. J. 2018, 28, 25–31. [Google Scholar]

- Chen, T.H.; Chang, J.L.; LI, H.X. Study on the influencing factors and paths of miners’ pressure of safety production responsibility. J. Xi’an Univ. Sci. Technol. 2025, 45, 98–107. [Google Scholar]

- Guo, H.L.; Zhang, Z.T.; Yu, R. Unsafe Behavior assessment of Construction workers based on risk factor. J. Tsinghua Univ. (Nat. Sci. Ed.) 2019, 59, 873–879. [Google Scholar]

- Li, G.L.; Zhang, M.; Li, Y.L. Research on the influence mechanism of construction workers’ safety behavior based on Meta-SEM. J. Saf. Environ. 2024, 24, 626–635. [Google Scholar]

- Yang, X.G.; Sun, X.J.; Ren, G.Y. Analysis of the conscious unsafe behavior of construction workers in multi-party games. Saf. Secur. 2020, 41, 70–74. [Google Scholar]

- Wang, Y.; Cui, J.; Zhang, Y.; Geng, X. Study and Action Plan on the Key Factors Influencing Unsafe Behaviors by Construction Workers. J. Build. 2024, 14, 1973. [Google Scholar] [CrossRef]

- Hu, X.F. A Cross-Level Study on Miners’ Performance Assessment, SafetyConsciousness and Unsafe Behavior. Master’s Thesis, Xi’an University of Science and Technology, Xi’an, China, 2017. [Google Scholar]

- Mitropoulos, P.; Memarian, B. Team processes and safety of workers: Cognitive, affective, and behavioral processes of construction crews. J. Constr. Eng. Manag. 2012, 138, 1181–1191. [Google Scholar] [CrossRef]

- Liu, R.; Cheng, W.; Yu, Y.; Xu, Q.; Jiang, A.; Lv, T. An impacting factors analysis of miners’ unsafe acts based on HFACS-CM and SEM. Process Saf. Environ. Prot. 2019, 122, 221–231. [Google Scholar] [CrossRef]

- Gu, B.T.; Cao, S.H.; Wang, Y.; Huang, Y.C.; Fang, D.P. Types and characteristics of unsafe behaviors in construction teamwork. J. Tsinghua Univ. (Sci. Technol.) 2023, 63, 160–168. [Google Scholar]

- Liu, B.; Xie, F.T.; Meng, Q.C. The Influence Mechanism of Team Climate on Team Performance: An Empirical Study Based on the Data of 164 Teams in Shandong Province. China Soft Sci. 2011, 2011, 133–140. [Google Scholar]

- Liang, L.Y. Study on Effect of Construction Group Safety Climate on Construction Worker’s Unsafe Behavior. Master’s Thesis, Chongqing University, Chongqing, China, 2021. [Google Scholar]

- Cao, L.L.; Liu, Y. Research on relationship between unsafe psychology and behavior of workers in confined space. China Saf. Sci. J. 2021, 31, 70–75. [Google Scholar]

- Chen, W.K.; Chen, R.R. Study on the mechanism of bad occupational psychology and unsafe behavior of Construction Site workers. China Work Saf. Sci. Technol. 2016, 12, 118–123. [Google Scholar]

- Yang, S.G.; Yao, Y.J.; Pang, S.Y.; Zhou, J. Analysis of Coal Mine Accidents Based on Trace Intersecting Theory. Coal Eng. 2019, 51, 177–180. [Google Scholar]

- Zhu, Y.Q. Study on Mechanism and Intervention Strategy of Prefabricated Construction Workers’ Unsafe Behavior. Master’s Thesis, Southeast University, Nanjing, China, 2022. [Google Scholar]

- Hu, Z.; Hu, H.X.F.; Wang, W. Research on personalized safety management for construction workers considering personality traits. J. Saf. Environ. 2023, 23, 1194–1201. [Google Scholar]

- Feng, L.X.; Lin, X.C.; Gu, Y.F.; Wang, X.L. Studying relationship between safety inputs and safety performance of construction by agent-based model. China Saf. Sci. J. 2017, 27, 163–168. [Google Scholar]

- Huang, J.H. Research on Common Problem and Preventive Measure in Prefabricated Building Construction. Eng. Technol. Res. 2025, 10, 166–168. [Google Scholar]

- Li, J.T.; Zheng, M.Z.; Sai, Y.X. A Simulation Research on Intervention of Strategies in Construction Workers’ Unsafe Behaviors. Ind. Eng. J. 2021, 24, 111–116. [Google Scholar]

- Zhang, J. Research on the Mechanism of Unsafe Behavior of Construction Workers and Management Strategy. Ph.D. Thesis, Chongqing University, Chongqing, China, 2021. [Google Scholar]

- Lu, R.; Wang, X.; Yu, H.; Li, D. Multiparty evolutionary game model in coal mine safety management and its application. Complexity 2018, 2018, 9620142. [Google Scholar] [CrossRef]

- Qi, S.J.; Cheng, J.L.; Huang, Q.Q.; Zhuang, Y.B. Occurrence Mechanism of Safety Attitude, Safety Capability and Unsafety Motivation to Unsafe Behavior for Construction Workers. J. Huaqiao Univ. (Nat. Sci.) 2018, 39, 669–674. [Google Scholar]

- Li, L.; Li, H.; Li, R.H.; Zhi, M.; Fang, Z.H.; Wang, Y.Q. Study on causes of coal miners’ unsafe behavior based on informal organization. Saf. Coal Mines 2024, 55, 241–249. [Google Scholar]

- Mattila, M.; Hyttinen, M.; Rantanen, E. Effective supervisory behaviour and safety at the building site. Int. J. Ind. Ergon. 1994, 13, 85–93. [Google Scholar] [CrossRef]

- Langford, D.; Rowlinson, S.; Sawacha, E. Safety behaviour and safety management: Its influence on the attitudes of workers in the UK construction industry. Eng. Constr. Archit. Manag. 2000, 7, 133–140. [Google Scholar] [CrossRef]

- Chen, H.; Li, H.; Goh, Y.M. A review of construction safety climate: Definitions, factors, relationship with safety behavior and research agenda. Saf. Sci. 2021, 142, 105391. [Google Scholar] [CrossRef]

- Wu, B.; Chen, H.H.; Huang, W. Safety risk assessment for the railway gas tunnel construction based on the fuzzy-entropy method. J. Saf. Environ. 2021, 21, 2386–2393. [Google Scholar]

- Yan, Z.G.; Li, J.Q. Assessment of ecosystem in giant panda distribution area based on entropy method and coefficient of variation. Chin. J. Appl. Ecol. 2017, 28, 4007–4016. [Google Scholar]

- Chen, H.G.; Li, X.N.; Li, C.Y. Resilience Evaluation of Water Resource System Based on Coefficient of Variation-Entropy Weight Method: A Case Study of Water Resources in Heilongjiang Province from 2007 to 2016. Ecol. Econ. 2021, 37, 179–184. [Google Scholar]

- Ai, C.M.; Miao, Q.; Zhang, X.; Wang, F.S. Risk assessment of filling pipeline blockage based on AHP entropy weight combination method and the cloud model. J. Lanzhou Univ. (Nat. Sci.) 2024, 60, 684–690+699. [Google Scholar]

- Wang, D.; Ji, Y. Research on influencing factors of unsafe behavior diffusion of construction workers under MOA framework: Based on system dynamics method. J. Saf. Sci. Technol. 2023, 19, 39–45. [Google Scholar]

- Shin, M.; Lee, H.S.; Park, M.; Moon, M.; Han, S. A system dynamics approach for modeling construction workers’ safety attitudes and behaviors. Accid. Anal. Prev. 2014, 68, 95–105. [Google Scholar]

- Cheng, L.H.; Zhuang, X.; Guo, H.M.; Cao, D.Q. Impact of miners’risk perception levels on unsafe behaviors in the context of intelligent mining. J. Xi’an Univ. Sci. Technol. 2024, 44, 1041–1049. [Google Scholar]

- Zhou, Y.J.; He, H.G.; Du, Y.K.; Ge, Q.G.; Guo, C.R.; Fang, X.H.; Wang, J. Research on the Correlation Between Physical-Psychological Factors and Unsafe Behavior Risks in Coal Miners Based on System Dynamics Model. Labour Prot. 2024, 64–66. [Google Scholar]

- Ai, X. Simulation Study on Intervention of Strategies in Tunnel Workers’ Unsafe Behaviors. Master’s Thesis, Southwest Jiaotong University, Chengdu, China, 2022. [Google Scholar]

- Wang, Y.G.; Li, X.C.; Song, Z.Z.; Zhang, X.Y. Study on Unsafe Behavior Intervention Strategy of Airport Security Inspectors Based on SD. Saf. Environ. Eng. 2020, 27, 187–191+200. [Google Scholar]

- Li, N.W.; Ji, Y.H.; Tang, S.Q.; Niu, L.X. Simulation of factors influencing miners’ counterproductive workplace behavior based on system dynamics. China Saf. Sci. J. 2018, 28, 13–18. [Google Scholar]

- Zhang, M.C.; Fang, D.P. Cognitive causes of construction worker’s unsafe behaviors and management measures. China Civ. Eng. J. 2012, 45, 297–305. [Google Scholar]

- Liu, Y.; He, J.; Shi, J.H. Study on combined intervention strategies for unsafe behavior of metro drivers. J. Saf. Sci. Technol. 2020, 16, 157–162. [Google Scholar]

- Xu, R.H.; Luo, F. Simulation on Combination Intervention Strategies in Civil Aviation Maintenance Personnels’ Job Burnout Based on System Dynamics. Saf. Environ. Eng. 2019, 26, 120–126. [Google Scholar]

- Ye, M.Z. Research on Cost Influencing Factors of Assembly Building Based on System Dynamics. Master’s Thesis, Guangxi University, Nanning, China, 2022. [Google Scholar]

- Ajzen, I. The theory of planned behavior. Organ. Behav. Hum. Decis. Process. 1991, 50, 179–211. [Google Scholar]

- Gatti, U.C.; Schneider, S.; Migliaccio, G.C. Physiological condition monitoring of construction workers. Autom. Constr. 2014, 44, 227–233. [Google Scholar]

- Aryee, S.; Hsiung, H.H. Regulatory focus and safety outcomes: An examination of the mediating influence of safety behavior. Saf. Sci. 2016, 86, 27–35. [Google Scholar]

- Liu, H.; Miao, X.; Shi, C.; Xu, T. Exploring the acceptance of virtual reality training systems among construction workers: A combined structural equation modeling and artificial neural network approach. Front. Public Health 2024, 12, 1478615. [Google Scholar]

| Categories | Influence Factors | Source | Weight Coefficient 1 |

|---|---|---|---|

| Physical environment (0.14) | Weather conditions | [36,37] | 0.04 |

| Construction layout on site | [38,39] | 0.05 | |

| Facility and equipment status | [11,40] | 0.05 | |

| Individual factors (0.35) | Safety knowledge and skills | [42,43] | 0.11 |

| Physical and mental state | [34,43,44] | 0.03 | |

| Safety experience | [19,44] | 0.11 | |

| Safety attitude and sense of responsibility | [34,45] | 0.05 | |

| Safety cognition and consciousness | [47,48] | 0.05 | |

| Group factors (0.24) | Group communication | [35,50,51] | 0.06 |

| Group coordination and cooperation | [35,50,51] | 0.04 | |

| Group safety atmosphere | [45,53] | 0.10 | |

| Interpersonal relationship | [54,55] | 0.04 | |

| Safety management (0.27) | Safety behavior incentive system | [48,50] | 0.08 |

| Safety investment guarantee system | [50,59] | 0.07 | |

| Safety emergency management system | [60,61] | 0.03 | |

| Safety supervision | [47,62,63] | 0.05 | |

| Safety leadership | [36,64] | 0.04 |

| Information | Classification | Frequency | Percentage |

|---|---|---|---|

| Gender | Men | 129 | 84.31% |

| Women | 24 | 15.69% | |

| Educational background | Primary school | 12 | 7.84% |

| Junior high school | 25 | 16.34% | |

| High school | 33 | 21.57% | |

| Junior college | 29 | 18.95% | |

| Bachelor’s degree or above | 54 | 35.29% | |

| Age | 18–25 | 19 | 12.42% |

| 26–35 | 40 | 26.14% | |

| 36–45 | 63 | 41.18% | |

| 45–55 | 23 | 15.03% | |

| 55 or above | 8 | 5.23% | |

| Nature of Work | Construction personnel | 67 | 43.79% |

| Site management personnel | 36 | 23.53% | |

| Architectural designers | 24 | 15.69% | |

| University and enterprise researchers | 26 | 16.99% |

| Variable Categories | Variables |

|---|---|

| State variable | Unsafe behavior level, physical environment level, individual safety level, group safety level, and safety management level. |

| Rate variable | Reduction in unsafe behavior level, increment in physical environment level, increment in individual safety level, increment in group safety level, and increment in safety management level. |

| Auxiliary variables | Weather conditions, construction layout on site, facility and equipment status, safety knowledge and skills, physical and mental state, safety experience, safety attitude and sense of responsibility, safety cognition and consciousness, group communication, group coordination and cooperation, group safety atmosphere, interpersonal relationship, safety behavior incentive system, safety investment guarantee system, safety emergency management system, safety supervision, and safety leadership. |

| Constant | Optimize the construction work environment, strengthen risk prevention and control, strengthen facility and equipment management, pay attention to the physical and mental health of personnel, improve personal comprehensive skills, correct attitude towards safe work, strengthen group communication and cooperation, clarify the division of labor among group members, creating a group safety atmosphere, establish a safety management system, strengthen safety supervision and inspection, and optimize construction organization design. |

| Intervention Subsystem | Intervention Measures | Unsafe Behavior Level | Drop Rate % |

|---|---|---|---|

| Physical environment | Strengthen risk prevention and control | 161.41 | 12.08% |

| Optimize the construction work environment | 176.48 | 3.88% | |

| Strengthen facility and equipment management | 173.25 | 5.64% | |

| Individual factors | Pay attention to the physical and mental health of personnel | 171.71 | 6.47% |

| Improve personal comprehensive skills | 114.23 | 37.78% | |

| Correct attitude towards safe work | 117.38 | 36.07% | |

| Group factors | Strengthen group communication and cooperation | 161.86 | 11.84% |

| Clarify the division of labor among group members | 172.73 | 5.92% | |

| Creating a group safety atmosphere | 145.57 | 20.71% | |

| Safety management | Establish a safety management system | 128.59 | 29.96% |

| Optimize construction organization design | 156.09 | 14.98% | |

| Strengthen safety supervision and inspection | 142.06 | 22.63% | |

| Combination intervention | Physical environment intervention | 145.57 | 20.71% |

| Individual factor intervention | 57.15 | 68.87% | |

| Group factor intervention | 98.55 | 46.32% | |

| Security management intervention | 73.58 | 59.93% |

| Categories | Intervention Strategies | Detailed Contents |

|---|---|---|

| Physical environment | Strengthen risk prevention and control | Take safety precautions against severe weather: temporary suspension measures are implemented for on-site construction activities such as installation and dismantling of lifting machinery and equipment, component hoisting, and outdoor high-altitude operations. Isolate hazardous sources and build security lines of defense: post hazard warning signs and installing safety facilities, including edge and opening protections. |

| Optimize the construction work environment | Ensure smooth and safe roads: the roads within the construction site should be level and unobstructed to meet the transportation requirements of prefabricated components. Plan the location of tower cranes scientifically to ensure the safety and efficiency of hoisting: the location of loading and unloading of components should be within the radius of the tower crane, reserving space for the use of component turnover. Strengthen on-site construction management to ensure a clean and safe environment. | |

| Strengthen facility and equipment management | Use qualified operating equipment: select transport and hoisting equipment, support devices, and hoisting tools that match the specifications and dimensions of prefabricated components and have good working performance. Ensure on-site safety protection: all personnel entering the construction site must wear safety helmets correctly, and high-altitude workers must use safety belts and be equipped with safety protection equipment that meets their job requirements. Improve equipment management systems: regularly organize inspections and maintenance of large lifting machinery such as tower cranes and external wall protection frames, replace worn parts in time, and keep equipment inspection records. | |

| Individual factors | Pay attention to the physical and mental health of personnel | Focus on physical health and enhance happiness: establish a comprehensive health monitoring system for all personnel, implement flexible working arrangements, and create a diversified platform for cultural and sports activities. Build a dedicated mental health team to boost employee engagement: improve employee psychological income through psychological counseling, emotional counseling, psychological training, and other measures. |

| Improve personal comprehensive skills | Develop a customized training system to optimize job competency alignment: set up corresponding training programs for specialized trades in prefabricated construction, such as welding, lifting, grouting, and component assembly workers. Promote intelligent training tools to enhance interaction and effectiveness: conduct immersive safety training using VR technology to enhance workers’ vigilance and safety awareness. Implement a phased skills certification system and a mandatory certificate system: strict practice with access standards to ensure that construction workers have the corresponding professional abilities. | |

| Correct attitude towards safe work | Conduct systematic capacity building and behavioral interventions to enhance safety literacy: develop a scale for unsafe behavior tendencies and implement behavioral correction measures for construction personnel at risk of unsafe behaviors. Deepen risk awareness through case-based education and reshape safety values. | |

| Group factors | Strengthen group communication and cooperation | Conduct regular daily work communication and safety production technical briefings: organize specialized safety production technical exchanges before high-altitude and hoisting operations for large and complex components to ensure safe operation. Establish a safety collaboration mechanism: clarify the cooperation relationships and work coordination requirements among various professional trades, and ensure effective work coordination and collaboration. |

| Clarify the division of labor among group members | Divide labor clearly and implement responsibilities to promote the construction of cross operations orderly. | |

| Create a group safety atmosphere | Improve safety publicity to create a safe construction atmosphere. Regularly organize team-building activities to enhance team cohesion. | |

| Safety management | Establish a safety management system | Develop safety operating procedures to standardize construction behaviors: establish safety operating procedures for PC component hoisting, mold assembly, product transfer, storage, and loading, and improve safety management systems. Establish a safety performance evaluation system: establish a safety behavior reward fund to incentivize safe practices, while also disciplining those who violate regulations, thereby guiding the standardization of safety behaviors. Develop emergency plans and response processes and conduct regular emergency drills. Develop a safety investment guarantee system: based on the characteristics of prefabricated building construction, ensure and rationally allocate the investment of human resources, material resources, and financial resources. |

| Optimize construction organization design | Improve the process flow to ensure smooth and safe construction: establish standardized construction process workflows, and develop reasonable transportation, storage, and hoisting sequences, as well as construction schedules, based on component specifications, types, and usage locations. Develop specialized hoisting plans and support schemes: select representative units for trial installation of prefabricated components to refine the construction plan. | |

| Strengthen safety supervision and inspection | Use drone monitoring to ensure the implementation of safety systems: monitor and provide real-time warnings for worker behavior in critical construction site areas (e.g., component hoisting zones, grouting operation zones). Establish a safety management team to conduct regular safety inspections: develop a key safety issue checklist, promptly address identified problems, and eliminate potential safety hazards. Set up a leadership behavior positive conduction system: leaders at all levels set an example by consciously observing all safety systems, leading their groups to follow suit. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Gao, Y.; Chen, R.; Huang, B.; Ma, L. System Dynamics Simulation of Intervention Strategies for Unsafe Behaviors Among Prefabricated Building Construction Workers. Buildings 2025, 15, 996. https://doi.org/10.3390/buildings15070996

Chen X, Gao Y, Chen R, Huang B, Ma L. System Dynamics Simulation of Intervention Strategies for Unsafe Behaviors Among Prefabricated Building Construction Workers. Buildings. 2025; 15(7):996. https://doi.org/10.3390/buildings15070996

Chicago/Turabian StyleChen, Xiaohong, Yujie Gao, Ronghong Chen, Bolong Huang, and Lingyan Ma. 2025. "System Dynamics Simulation of Intervention Strategies for Unsafe Behaviors Among Prefabricated Building Construction Workers" Buildings 15, no. 7: 996. https://doi.org/10.3390/buildings15070996

APA StyleChen, X., Gao, Y., Chen, R., Huang, B., & Ma, L. (2025). System Dynamics Simulation of Intervention Strategies for Unsafe Behaviors Among Prefabricated Building Construction Workers. Buildings, 15(7), 996. https://doi.org/10.3390/buildings15070996