The Influence of the Addition of Multi-Scale Zirconia on the Properties of Ultra-High-Performance Concretes

Abstract

1. Introduction

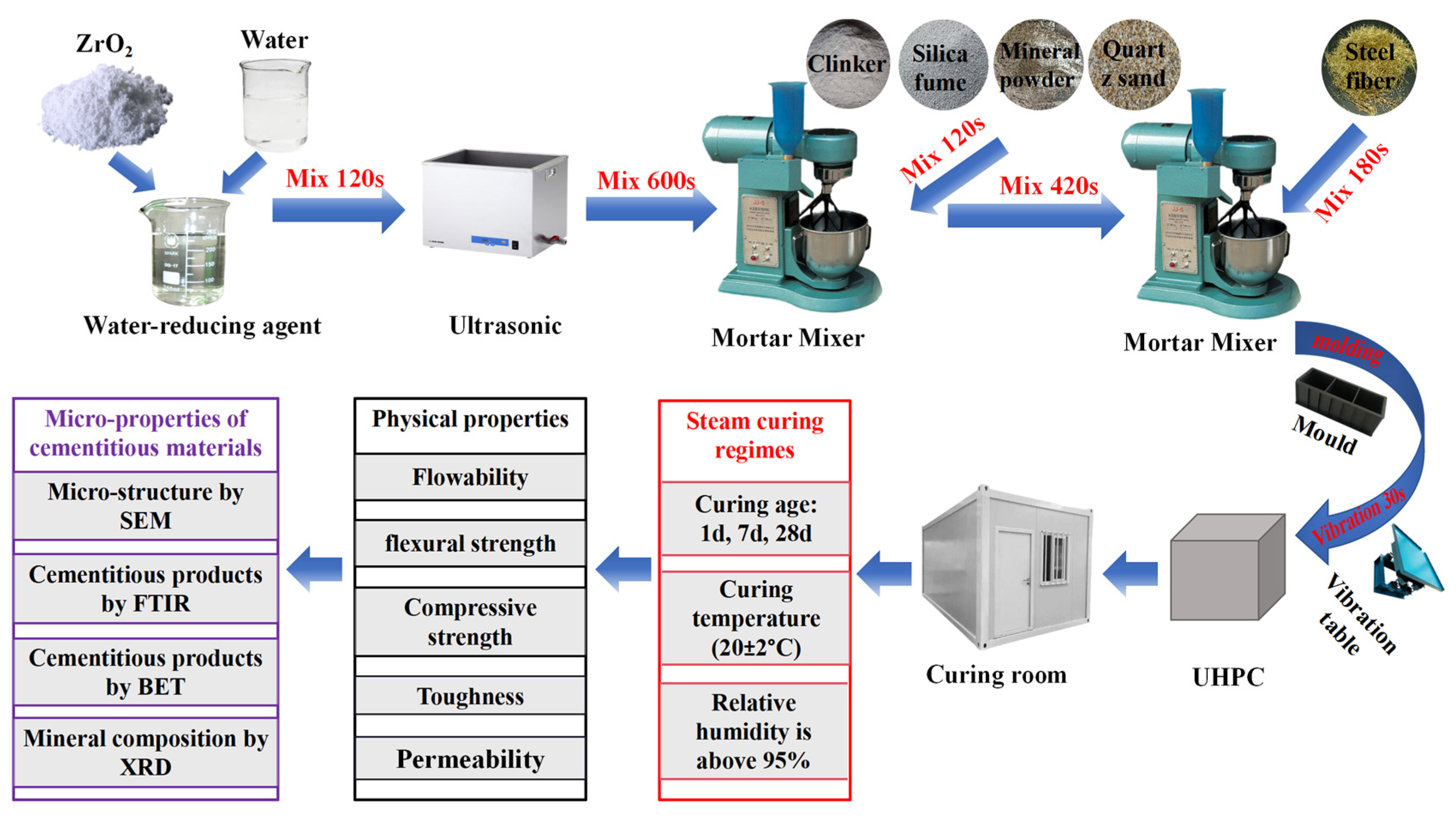

2. Materials and Methods

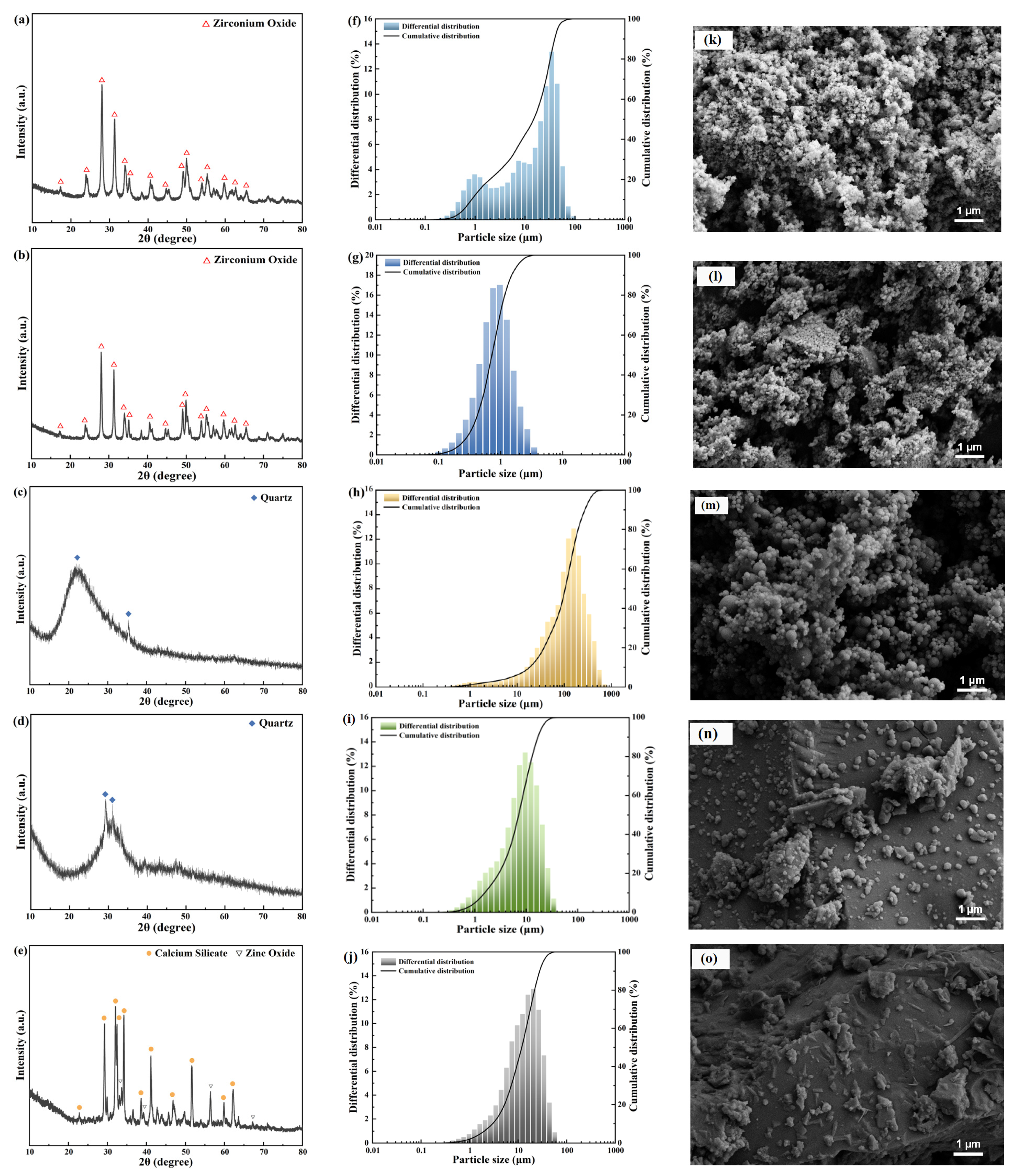

2.1. Raw Materials

2.2. Mixture Design and Sample Preparation

2.3. Methods

2.3.1. Mechanical Properties

2.3.2. Fresh Behavior

2.3.3. Microscopic Characteristics Determination

3. Results and Discussions

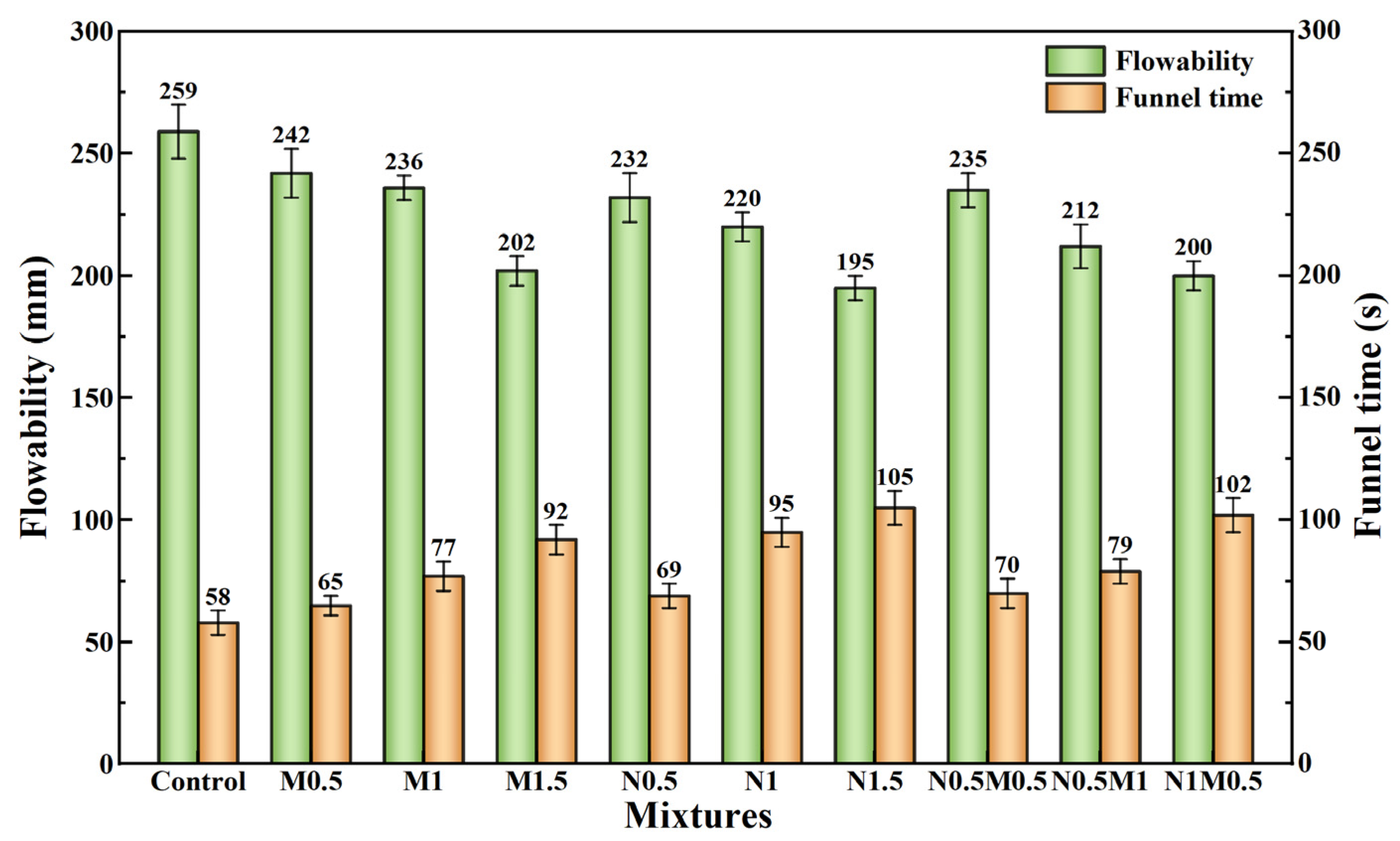

3.1. Fresh Behavior

3.1.1. Workability

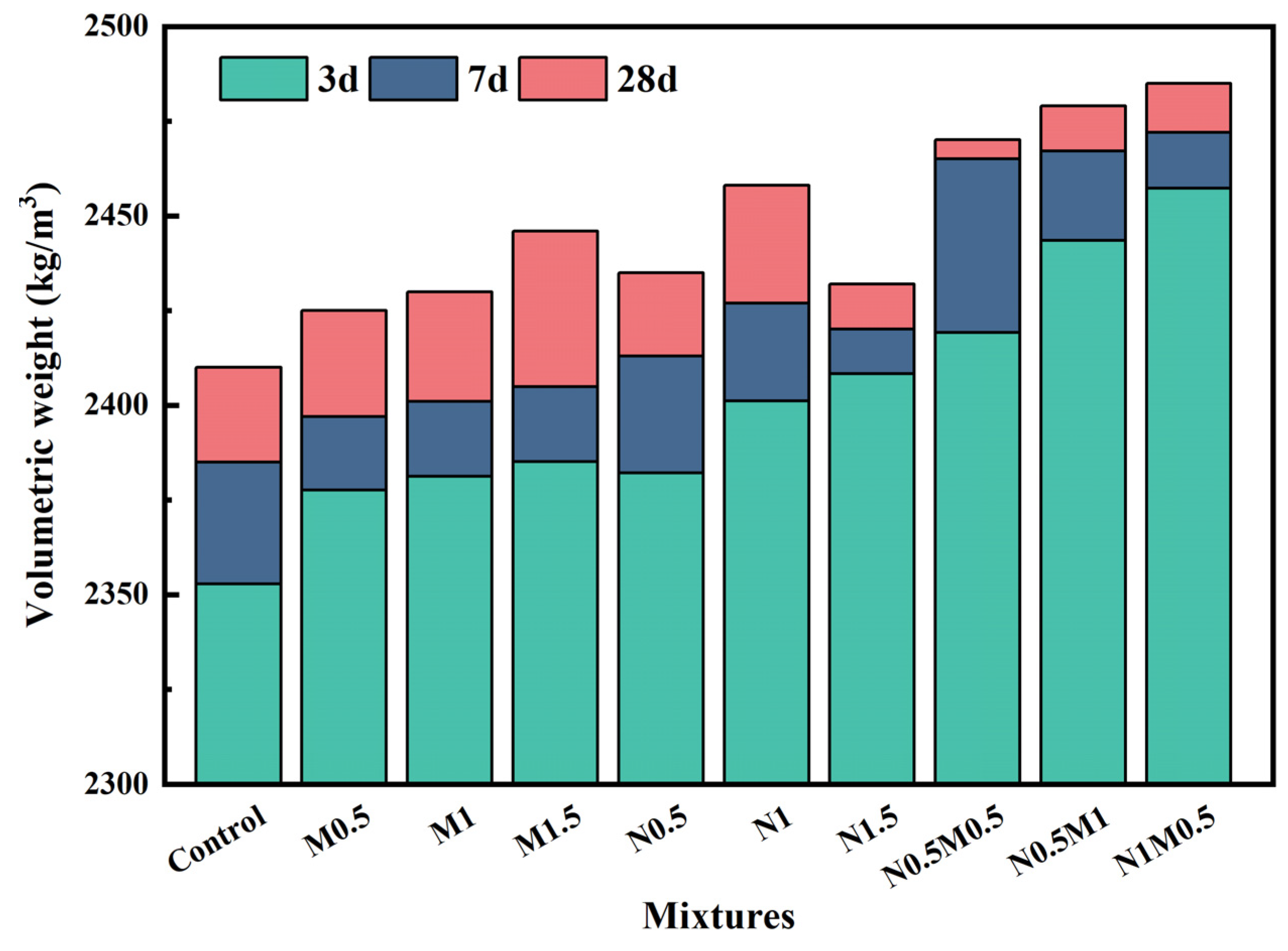

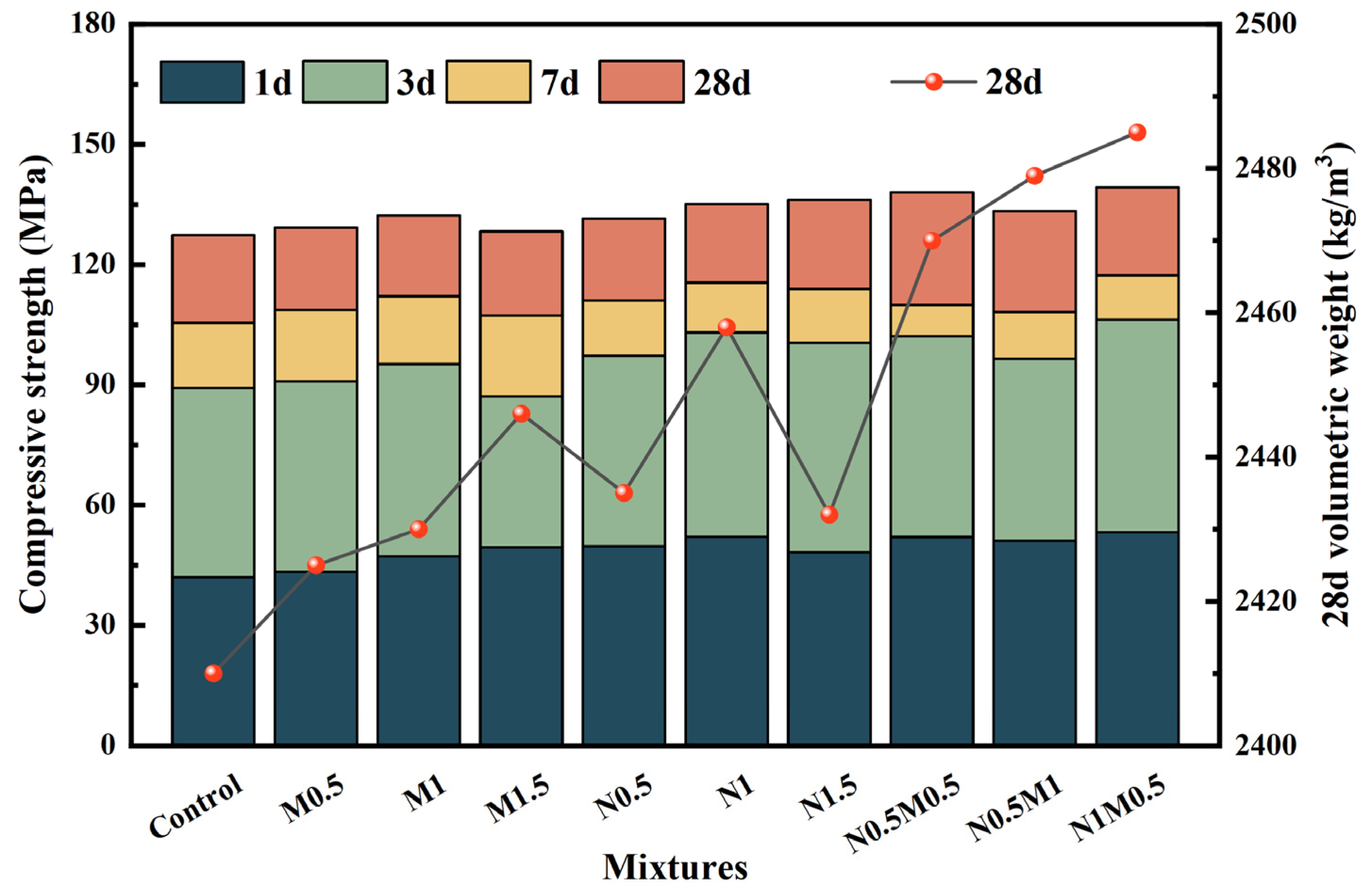

3.1.2. Bulk Density

3.2. Mechanical Properties

Compressive Strength

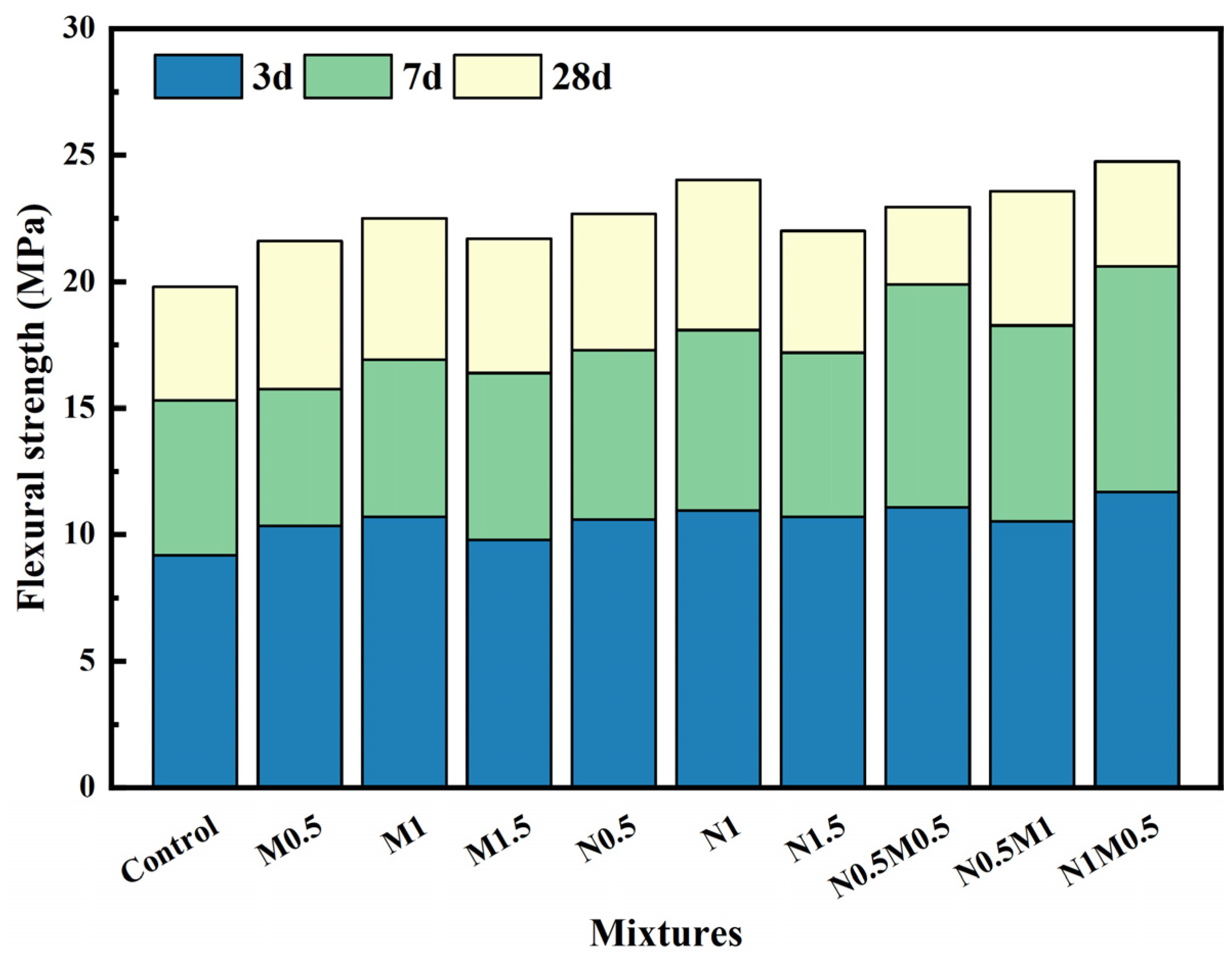

3.3. Flexural Strength

3.4. Mechanism Analysis

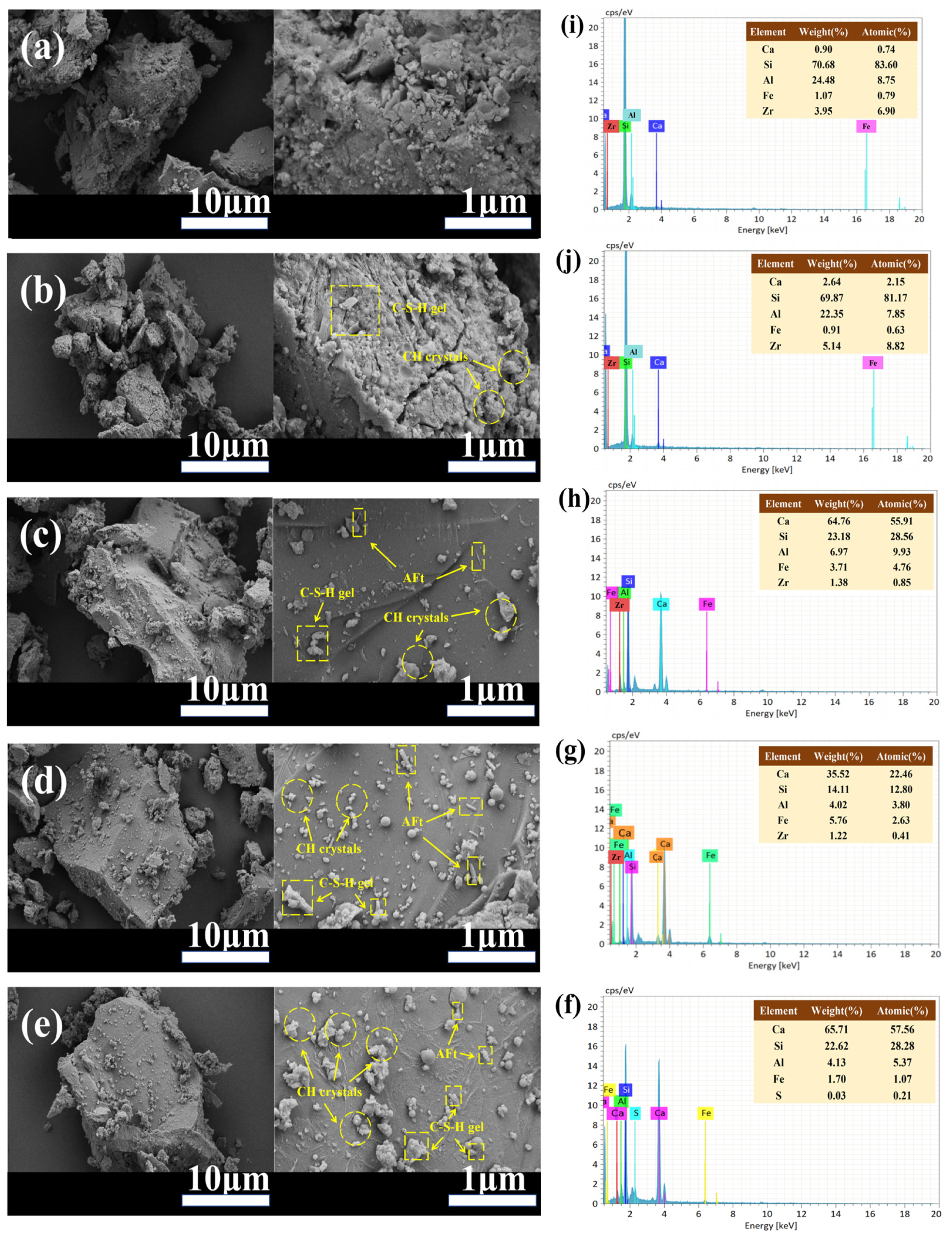

3.4.1. SEM Microstructure

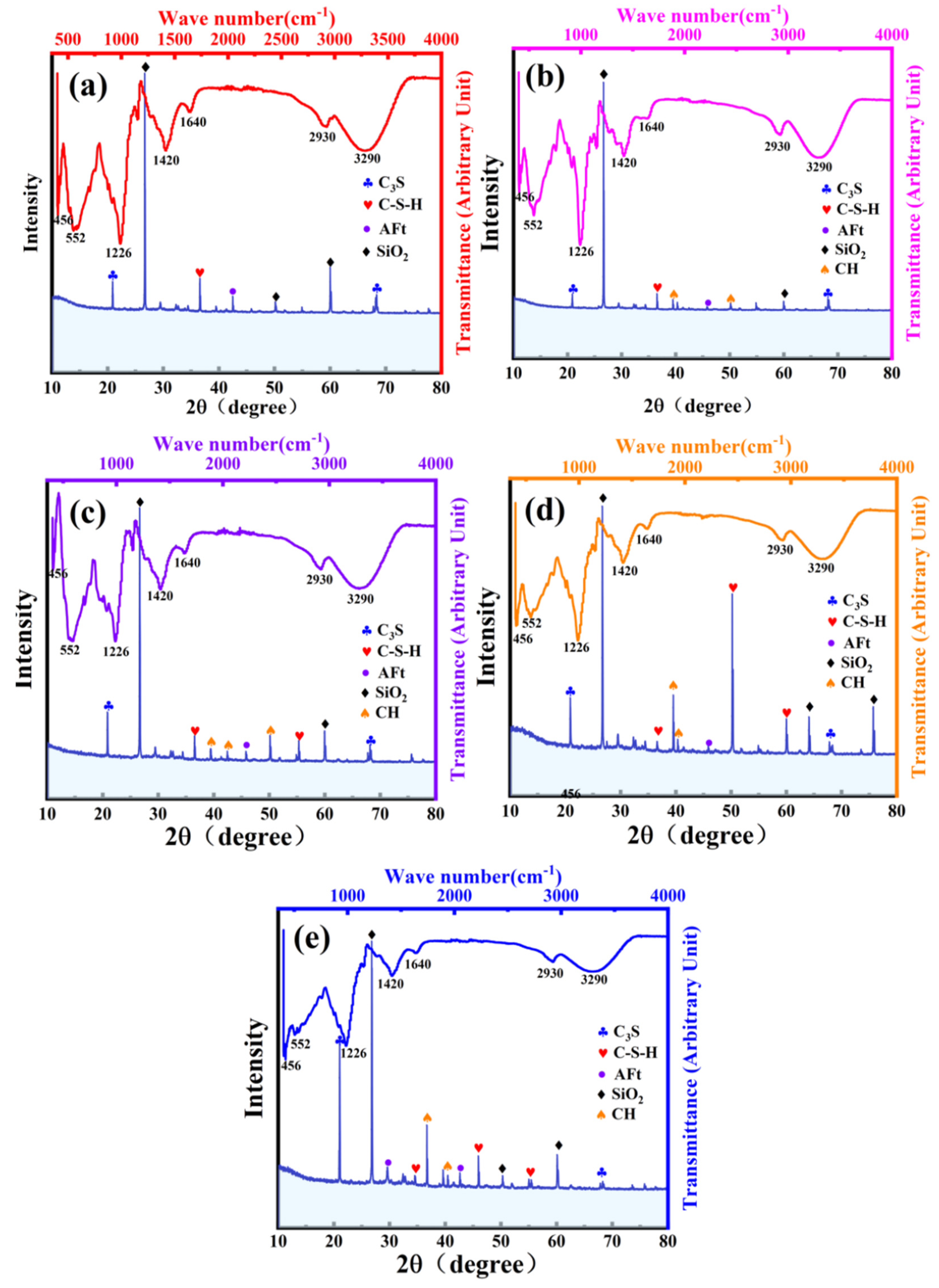

3.4.2. XRD

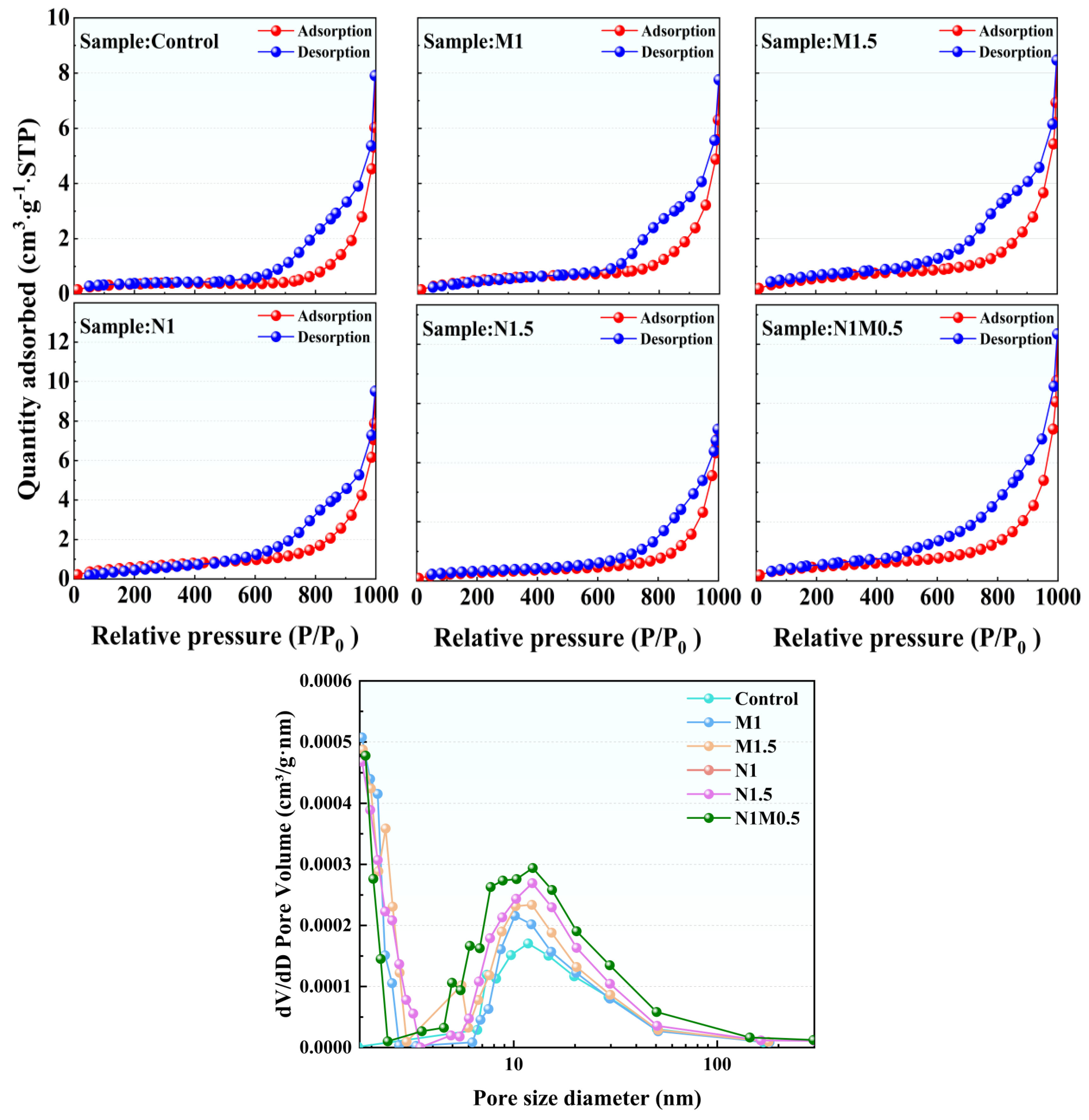

3.4.3. BET Pore Structure Analysis

3.4.4. FTIR Analysis

3.5. Innovation and Limitations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yoo, D.-Y.; Oh, T.; Banthia, N. Nanomaterials in ultra-high-performance concrete (UHPC)—A review. Cem. Concr. Compos. 2022, 134, 104730. [Google Scholar]

- Han, Y.; Shao, S.; Fang, B.; Shi, T.; Zhang, B.; Wang, X.; Zhao, X. Chloride ion penetration resistance of matrix and interfacial transition zone of multi-walled carbon nanotube-reinforced concrete. J. Build. Eng. 2023, 72, 106587. [Google Scholar]

- Wakjira, T.G.; Kutty, A.A.; Alam, M.S.; Materials, B. A novel framework for developing environmentally sustainable and cost-effective ultra-high-performance concrete (UHPC) using advanced machine learning and multi-objective optimization techniques. Constr. Build. Mater. 2024, 416, 135114. [Google Scholar]

- Fan, J.; Shao, Y.; Bandelt, M.J.; Adams, M.P.; Ostertag, C.P. Sustainable reinforced concrete design: The role of ultra-high performance concrete (UHPC) in life-cycle structural performance and environmental impacts. Eng. Struct. 2024, 316, 118585. [Google Scholar]

- Yu, R.; Liu, K.; Yin, T.; Tang, L.; Ding, M.; Shui, Z. Comparative study on the effect of steel and polyoxymethylene fibers on the characteristics of Ultra-High Performance Concrete (UHPC). Cem. Concr. Compos. 2022, 127, 104418. [Google Scholar]

- Yin, T.; Yu, R.; Liu, K.; Wang, Z.; Fan, D.; Wang, S.; Feng, Y.; Shui, Z. Precise mix-design of Ultra-High Performance Concrete (UHPC) based on physicochemical packing method: From the perspective of cement hydration. Constr. Build. Mater. 2022, 352, 128944. [Google Scholar]

- Pyo, S.; Kim, H.-K. Fresh and hardened properties of ultra-high performance concrete incorporating coal bottom ash and slag powder. Constr. Build. Mater. 2017, 131, 459–466. [Google Scholar]

- Hakeem, I.Y.; Amin, M.; Abdelsalam, B.A.; Tayeh, B.A.; Althoey, F.; Agwa, I.S. Effects of nano-silica and micro-steel fiber on the engineering properties of ultra-high performance concrete. J. Build. Eng. 2022, 82, 295–312. [Google Scholar]

- Divya, S.; Praveenkumar, S.; Tayeh, B.A. Performance of modified nano carbon blended with supplementary materials in cement composite–An interpretive review. Constr. Build. Mater. 2022, 346, 128452. [Google Scholar] [CrossRef]

- Shaban, W.M.; Heniegal, A.M.; Amin, M.; Zeyad, A.M.; Agwa, I.S.; Hassan, H.H. Effect of agricultural wastes as sugar beet ash, sugarcane leaf ash, and sugarcane bagasse ash on UHPC properties. J. Build. Eng. 2024, 98, 111359. [Google Scholar]

- Esmaeili, J.; Romouzi, V.; Kasaei, J.; Andalibi, K. An investigation of durability and the mechanical properties of ultra-high performance concrete (UHPC) modified with economical graphene oxide nano-sheets. J. Build. Eng. 2023, 80, 107908. [Google Scholar]

- Guo, D.; Guo, M.; Zhou, Y.; Zhu, Z. Use of nano-silica to improve the performance of LC3-UHPC: Mechanical behavior and microstructural characteristics. Constr. Build. Mater. 2024, 411, 134280. [Google Scholar]

- Wu, Z.; Shi, C.; Khayat, K.H.; Wan, S. Effects of different nanomaterials on hardening and performance of ultra-high strength concrete (UHSC). Cem. Concr. Compos. 2016, 70, 24–34. [Google Scholar]

- Li, L.; Wang, B.; Hubler, M.H. Carbon nanofibers (CNFs) dispersed in ultra-high performance concrete (UHPC): Mechanical property, workability and permeability investigation. Cem. Concr. Compos. 2022, 131, 104592. [Google Scholar]

- Rawat, G.; Gandhi, S.; Murthy, Y.I. Influence of nano-TiO2 on the chloride diffusivity of concrete. Emerg. Mater. Res. 2022, 11, 495–505. [Google Scholar]

- Luo, Z.; Zhi, T.; Liu, X.; Yin, K.; Pan, H.; Feng, H.; Song, Y.; Su, Y. Effects of different nanomaterials on the early performance of ultra-high performance concrete (UHPC): C–S–H seeds and nano-silica. Cem. Concr. Compos. 2023, 142, 105211. [Google Scholar]

- Soleymani, F. The effects of ZrO2 nano powders on compressive damage and pore structure properties of lightweight concrete specimens. J. Am. Sci. 2012, 8, 232–239. [Google Scholar]

- Shekari, A.; Razzaghi, M.S. Influence of nano particles on durability and mechanical properties of high performance concrete. Procedia Eng. 2011, 14, 3036–3041. [Google Scholar]

- Nazari, A.; Riahi, S.; Riahi, S.; Shamekhi, S.F.; Khademno, A. Embedded ZrO2 nanoparticles mechanical properties monitoring in cementitious composites. J. Am. Sci. 2010, 6, 86–89. [Google Scholar]

- Nazari, A.; Riahi, S. Limewater effects on properties of ZrO2 nanoparticle blended cementitious composite. J. Compos. Mater. 2011, 45, 639–644. [Google Scholar]

- Han, B.; Wang, Z.; Zeng, S.; Zhou, D.; Yu, X.; Cui, X.; Ou, J. Properties and modification mechanisms of nano-zirconia filled reactive powder concrete. Constr. Build. Mater. 2017, 141, 426–434. [Google Scholar] [CrossRef]

- GB/T 31387-2015; Reactive Powder Concrete. Standardization Administration of the People’s Republic of China: Beijing, China, 2015.

- GB/T 17671-2021; Method for Strength of Cement Mortar (ISO Method). Standardization Administration of the People’s Republic of China and the State Administration for Market Regulation: Beijing, China, 2021.

- Meng, W.; Khayat, K.H. Effect of graphite nanoplatelets and carbon nanofibers onrheology, hydration, shrinkage, mechanical properties, and microstructure of UHPC. Cement Concr. Res. 2018, 105, 64–71. [Google Scholar]

- Kwan, K.H.; Fung, W.W.S. Packing density measurement and modelling of fine aggregate and mortar. Cement Concr. Compos. 2009, 31, 349–357. [Google Scholar] [CrossRef]

- Piao, R.; Oh, T.; Kim, G.W.; Choi, H.-J.; Banthia, N.; Yoo, D.-Y. Enhanced microstructure and mechanical properties of cementless ultra-high-performance fiber-reinforced alkali-activated concrete with silicon dioxide nanoparticles. Constr. Build. Mater. 2023, 398, 132514. [Google Scholar] [CrossRef]

- Rajasekar, A.; Arunachalam, K.; Kottaisamy, M. Assessment of strength and durability characteristics of copper slag incorporated ultra high strength concrete. J. Clean. Prod. 2019, 208, 402–414. [Google Scholar] [CrossRef]

- Shi, J.; Pan, W.; Kang, J.; Yu, Z.; Sun, G.; Li, J.; Zheng, K.; Shen, J. Properties of Ultra-High Performance Concrete incorporating iron tailings powder and iron tailings sand. Constr. Build. Mater. 2024, 83, 108442. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S.; Riahi, S.; Shamekhi, S.F.; Khademno, A. An investigation on the Strength and workability of cement based concrete performance by using ZrO2 nanoparticles. Environ. Sci. 2010, 6, 29–33. [Google Scholar]

- Liu, J.; Fu, J.; Ni, T.; Yang, Y. Fracture toughness improvement of multi-wall carbon nanotubes/graphene sheets reinforced cement paste. J. Build. Eng. 2019, 200, 530–538. [Google Scholar] [CrossRef]

- Chen, S.J.; Wang, W.; Sagoe-Crentsil, K.; Collins, F.; Zhao, X.L.; Majumder, M.; Duan, W.H. Distribution of carbon nanotubes in fresh ordinary Portland cement pastes: Understanding from a two-phase perspective. J. Am. Sci. 2016, 6, 5745–5753. [Google Scholar] [CrossRef]

- Karkhaneh, S.; Tarighat, A.; Jahromi, S.G. Kinetics behavior of delayed ettringite in limestone calcined clay cement (LC3) by thermodynamic approach and consideration of the time factor. Constr. Build. Mater. 2023, 367, 129143. [Google Scholar] [CrossRef]

- Liu, B.; Lu, X.; Meng, H.; Pan, G.; Li, D. Dispersion of in-situ controllably grown nano-SiO2 in alkaline environment for improving cement paste. RSC Adv. 2023, 369, 130460. [Google Scholar] [CrossRef]

- Yeluri, M.; Ertugral, E.G.; Sharma, Y.; Fodor, P.S.; Kothapalli, C.R.; Allena, S. Revolutionizing ultra-high performance concrete: Unleashing metakaolin and diatomaceous earth as sustainable fly ash alternatives. Constr. Build. Mater. 2025, 460, 139822. [Google Scholar]

- Wang, W.; Xiong, Z.; Yu, Y.; Chen, D.; Wu, C. Residual behaviour and damage assessment of UHPC-filled double-skin steel tubular columns after lateral impact. Thin-Wall. Struct. 2024, 205, 112602. [Google Scholar]

- Mi, Y.; Wang, W.; Yu, Y. Residual Load-Carrying Capacity of Hybrid FRP-UHPC-Steel Double-Skin Tubular Column after Lateral Impact. J. Compos. Constr. 2024, 28, 04024033. [Google Scholar]

| Properties | PC | SF | MP | QP |

|---|---|---|---|---|

| Physical | ||||

| Specific gravity | 2.98 | 2.06 | 2.61 | 2.39 |

| Specific area (cm2/gm) | 506 | 18,230 | 2832 | - |

| Color | Grey | Light Grey | White | White |

| Chemical composition (%) | ||||

| SiO2 | 32.79 | 98.12 | 35.17 | 96.58 |

| Al2O3 | 6.22 | 0.97 | 15.92 | - |

| Fe2O3 | 2.99 | 0.36 | 0.71 | - |

| CaO | 52.29 | 0.14 | 32.58 | 0.35 |

| MgO | 1.28 | 0.10 | 11.60 | 0.14 |

| SO3 | 2.06 | 0.07 | 1.00 | - |

| K2O | 0.81 | 0.06 | 0.26 | 0.62 |

| Na2O | 0.85 | 0.04 | 0.24 | 0.16 |

| Sample | Mix Proportion/(kg·m−3) | |||||||

|---|---|---|---|---|---|---|---|---|

| ZrO2 | Nano-ZrO2 | PC | SF | MP | QZ | Water | Steel Fiber | |

| Control | 0 | 0 | 880 | 240 | 160 | 798 | 216 | 156 |

| M0.5 | 6.4 | 0 | 873.6 | 240 | 160 | 798 | 216 | 156 |

| M1 | 12.8 | 0 | 868.2 | 240 | 160 | 798 | 216 | 156 |

| M1.5 | 19.2 | 0 | 860.8 | 240 | 160 | 798 | 216 | 156 |

| N0.5 | 0 | 6.4 | 873.6 | 240 | 160 | 798 | 216 | 156 |

| N1 | 0 | 12.8 | 868.2 | 240 | 160 | 798 | 216 | 156 |

| N1.5 | 0 | 19.2 | 860.8 | 240 | 160 | 798 | 216 | 156 |

| N0.5M0.5 | 6.4 | 6.4 | 868.2 | 240 | 160 | 798 | 216 | 156 |

| N0.5M1 | 12.8 | 6.4 | 860.8 | 240 | 160 | 798 | 216 | 156 |

| N1M0.5 | 6.4 | 12.8 | 860.8 | 240 | 160 | 798 | 216 | 156 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Liu, H.; Zhang, Y.; Chen, P.; Gong, J.; Zhong, Y.; Gao, R.; Lei, J.; Yu, H.; Tang, L. The Influence of the Addition of Multi-Scale Zirconia on the Properties of Ultra-High-Performance Concretes. Buildings 2025, 15, 1207. https://doi.org/10.3390/buildings15071207

Wang Q, Liu H, Zhang Y, Chen P, Gong J, Zhong Y, Gao R, Lei J, Yu H, Tang L. The Influence of the Addition of Multi-Scale Zirconia on the Properties of Ultra-High-Performance Concretes. Buildings. 2025; 15(7):1207. https://doi.org/10.3390/buildings15071207

Chicago/Turabian StyleWang, Qilin, Haifeng Liu, Yongtao Zhang, Peishuai Chen, Jianwu Gong, Yu Zhong, Ran Gao, Jinnan Lei, Haiyang Yu, and Lingya Tang. 2025. "The Influence of the Addition of Multi-Scale Zirconia on the Properties of Ultra-High-Performance Concretes" Buildings 15, no. 7: 1207. https://doi.org/10.3390/buildings15071207

APA StyleWang, Q., Liu, H., Zhang, Y., Chen, P., Gong, J., Zhong, Y., Gao, R., Lei, J., Yu, H., & Tang, L. (2025). The Influence of the Addition of Multi-Scale Zirconia on the Properties of Ultra-High-Performance Concretes. Buildings, 15(7), 1207. https://doi.org/10.3390/buildings15071207