Experimental and Numerical Investigation on the Effect of Different Types of Synthetic Fibers on the Flexure Behavior and Mechanical Properties of 3D Cementitious Composite Printing Provided with Cement CEM II/A-P

Abstract

1. Introduction

2. Research Significance

3. Experimental Program

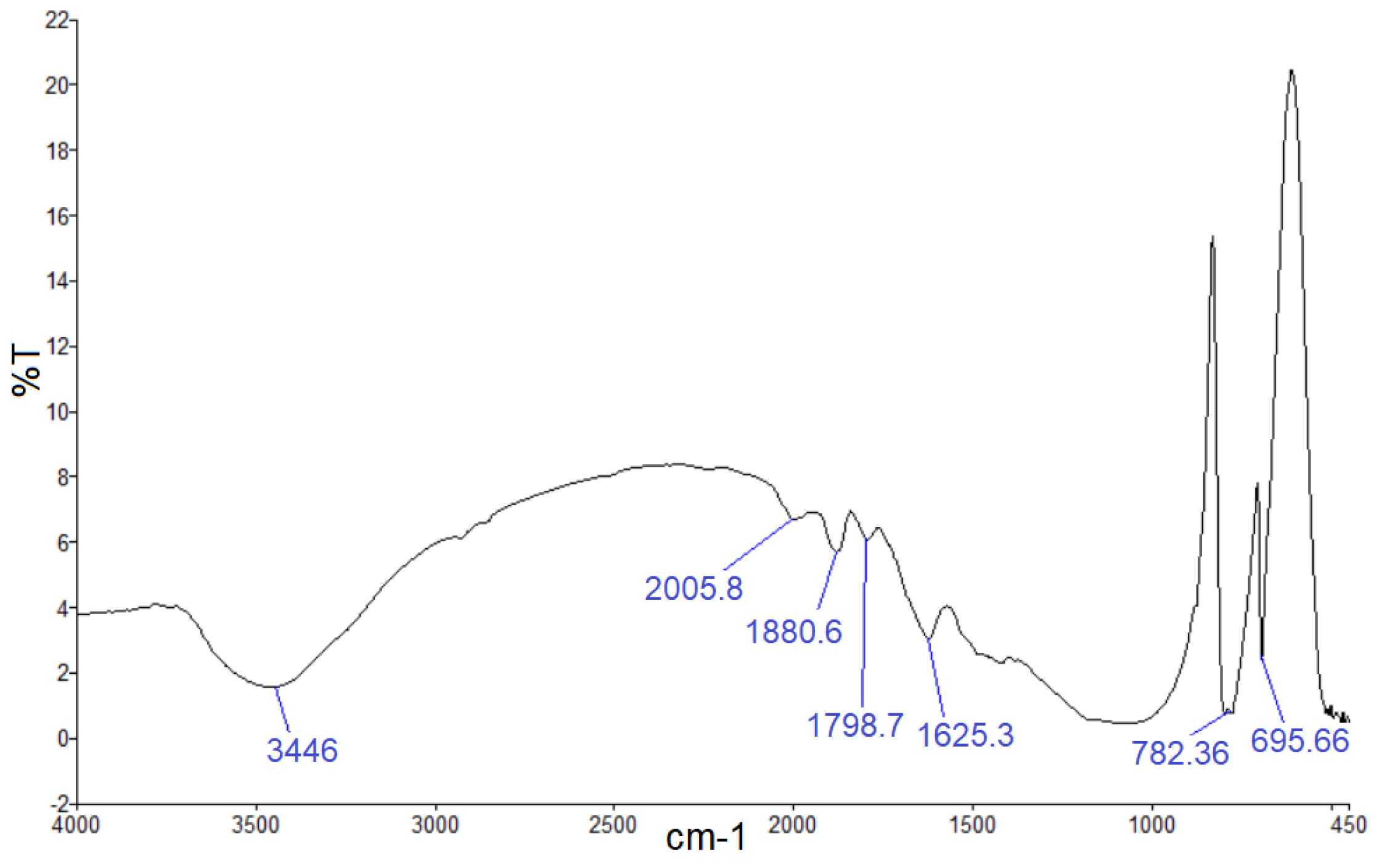

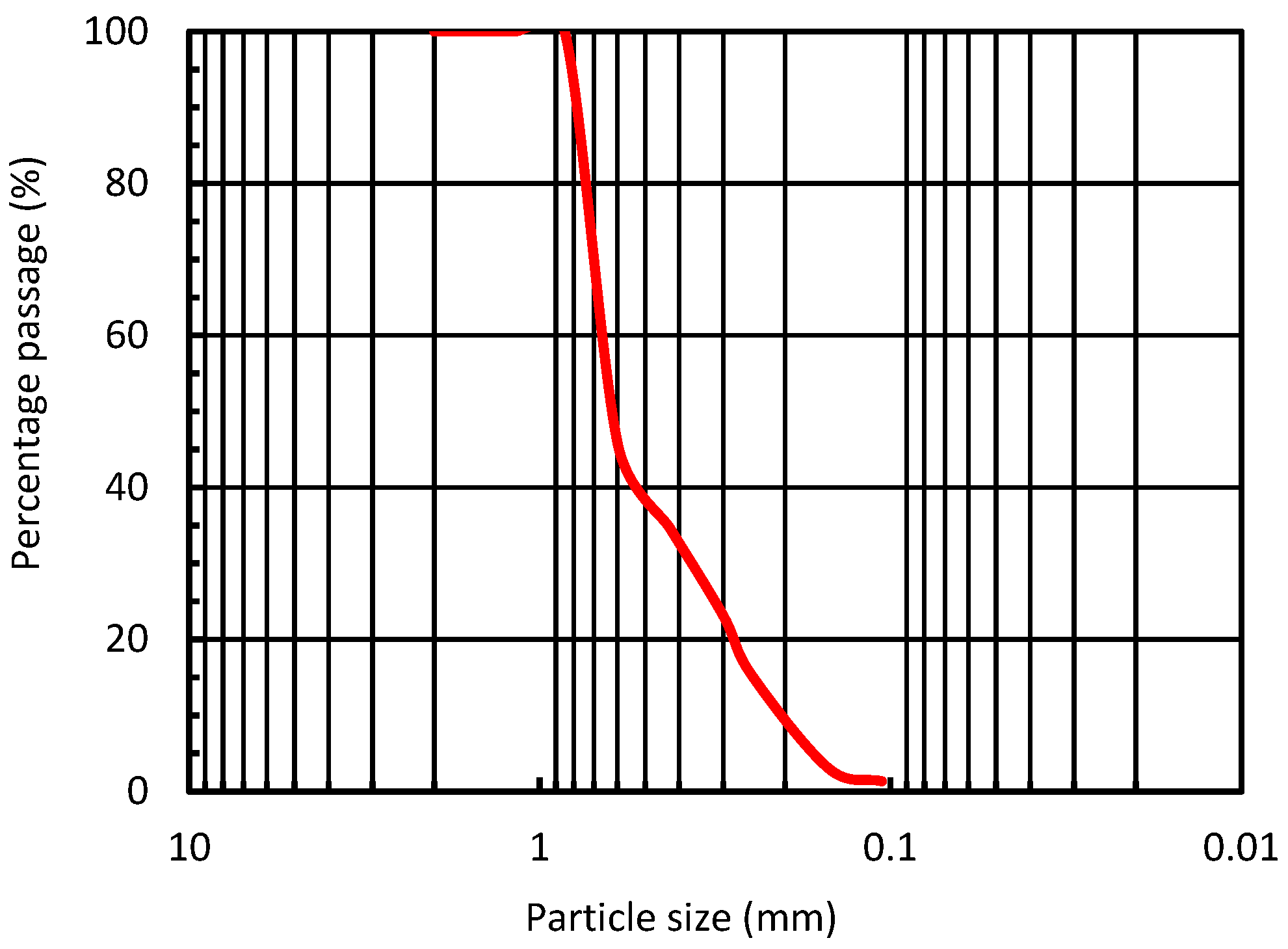

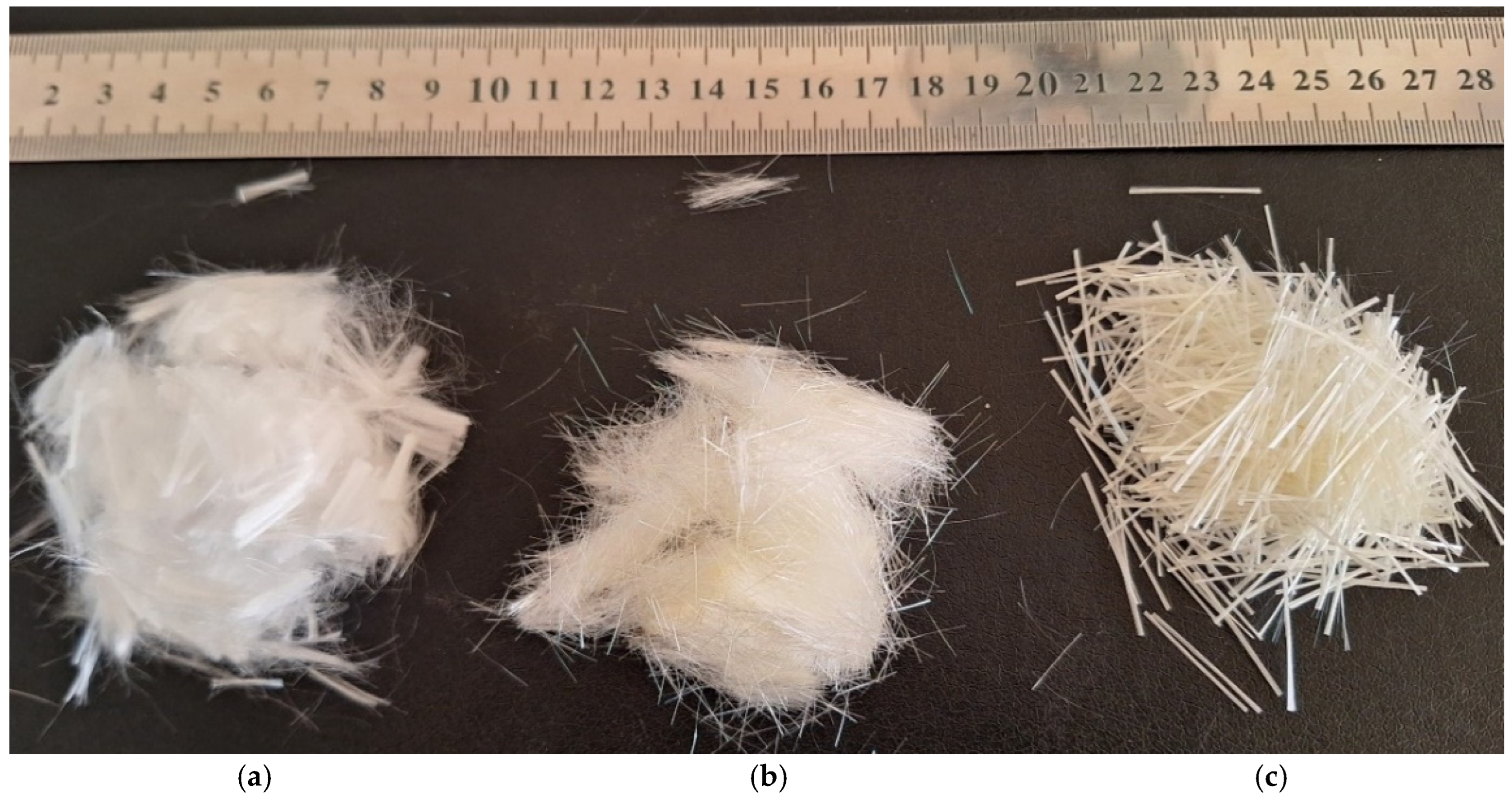

3.1. Materials and Mix Proportions

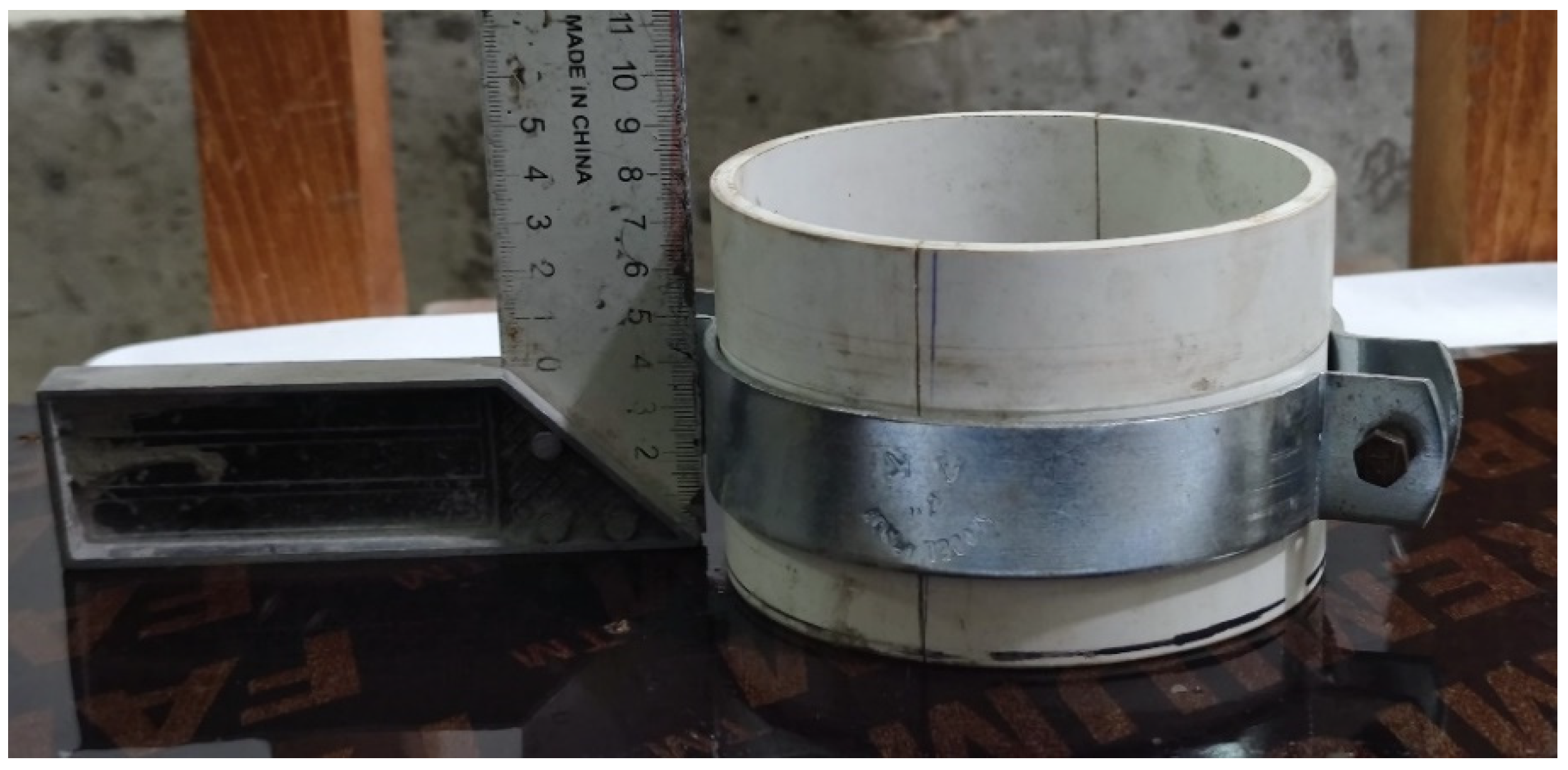

3.2. Mixing Procedure and Test Specimens

3.3. Testing Methods

3.3.1. Fresh Property Evaluation

3.3.2. Hardened Property Evaluation

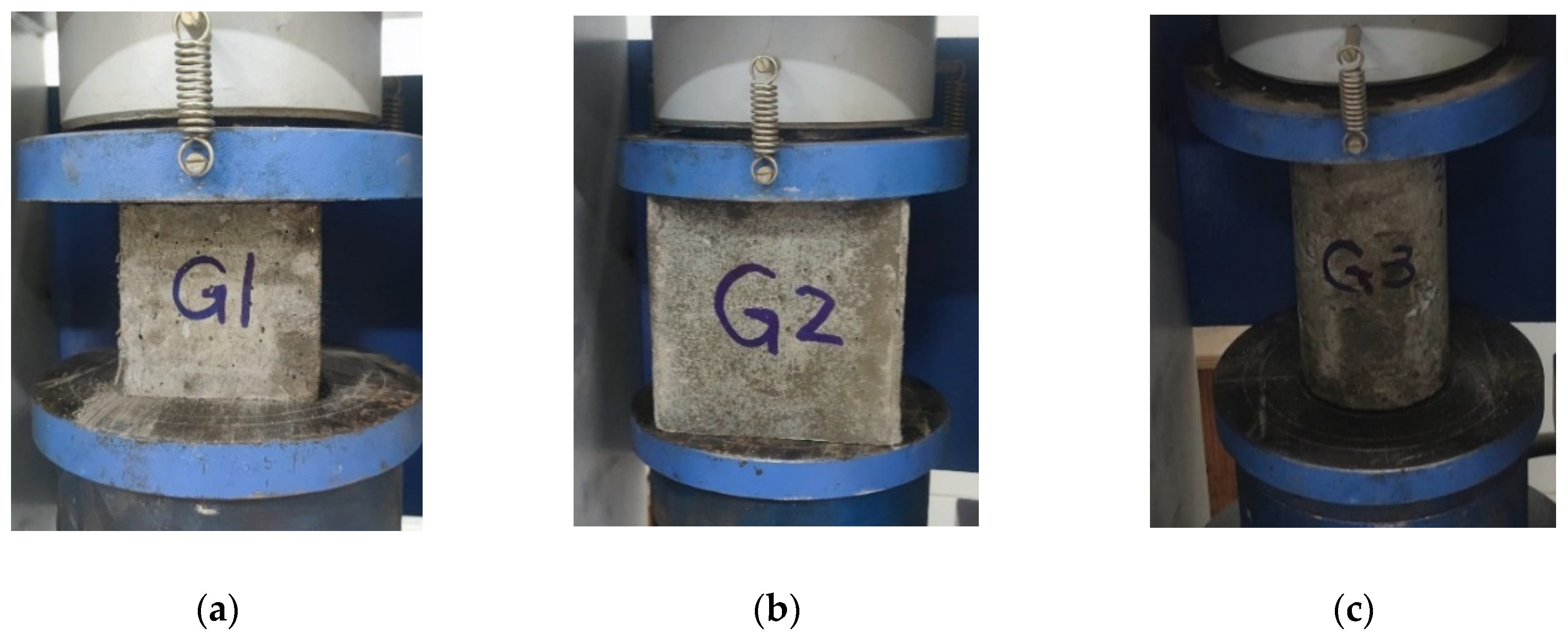

Compression Test

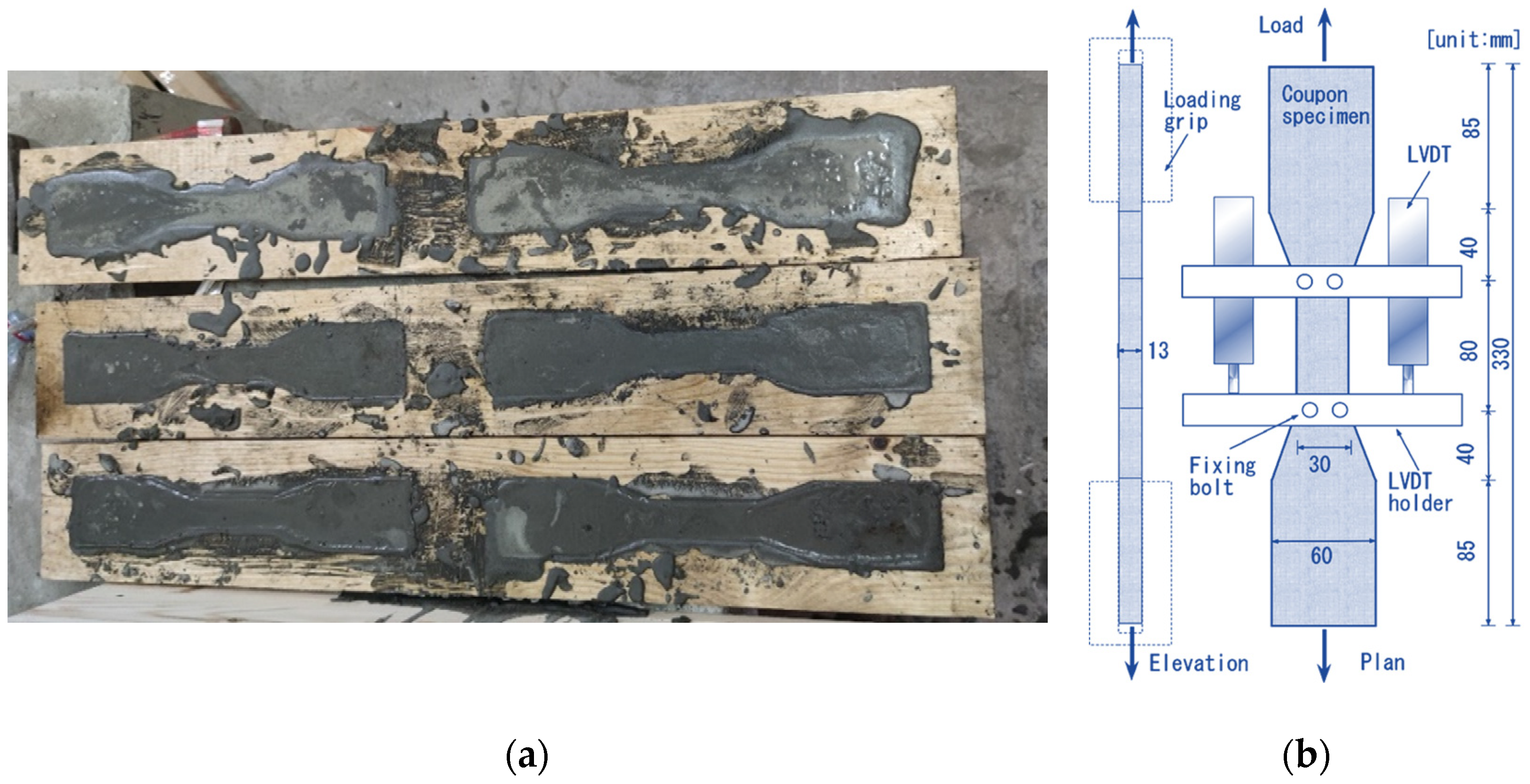

Uniaxial Direct Tensile Test

Splitting Tensile Test

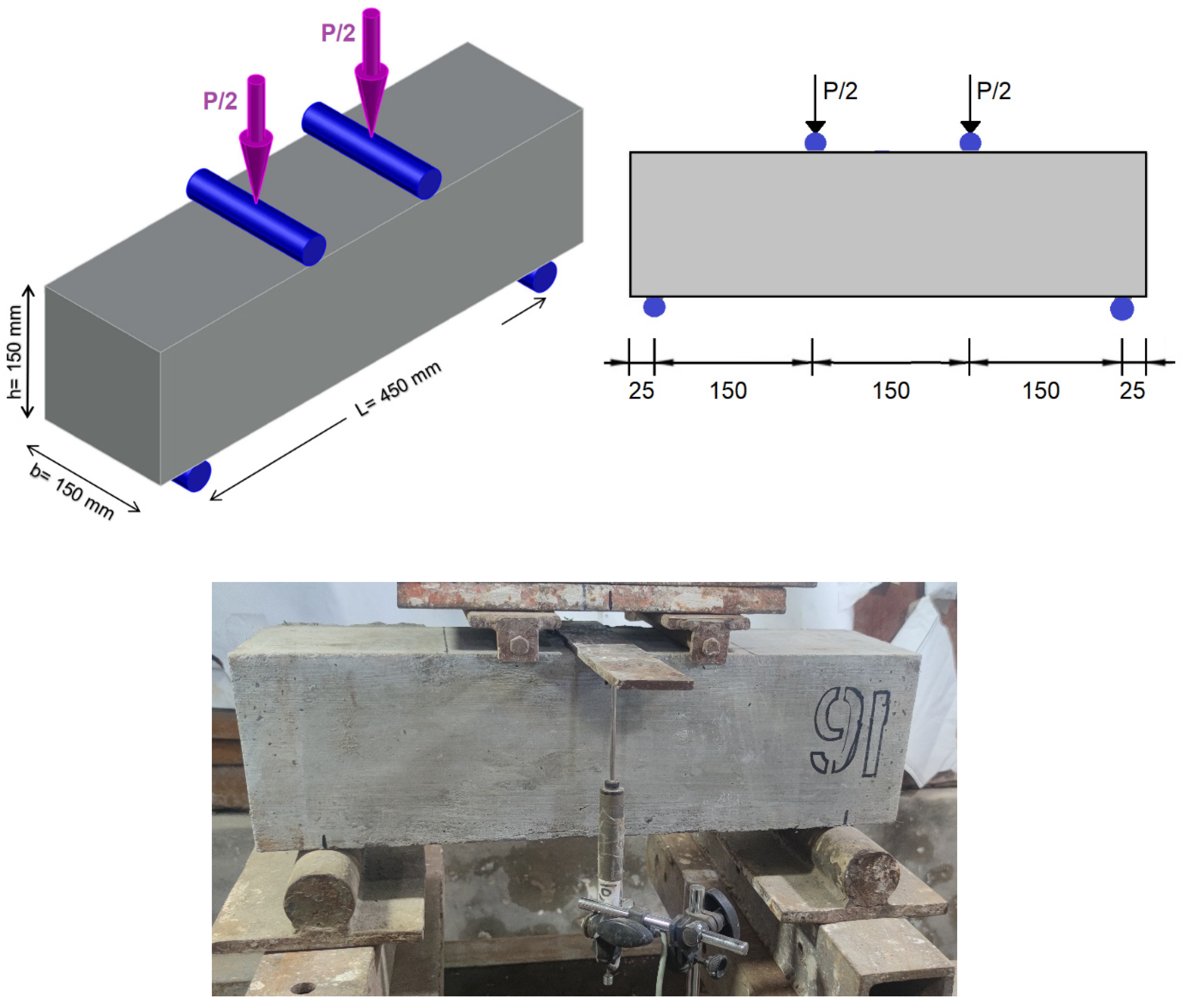

Flexural Bending Test

4. Results and Discussions

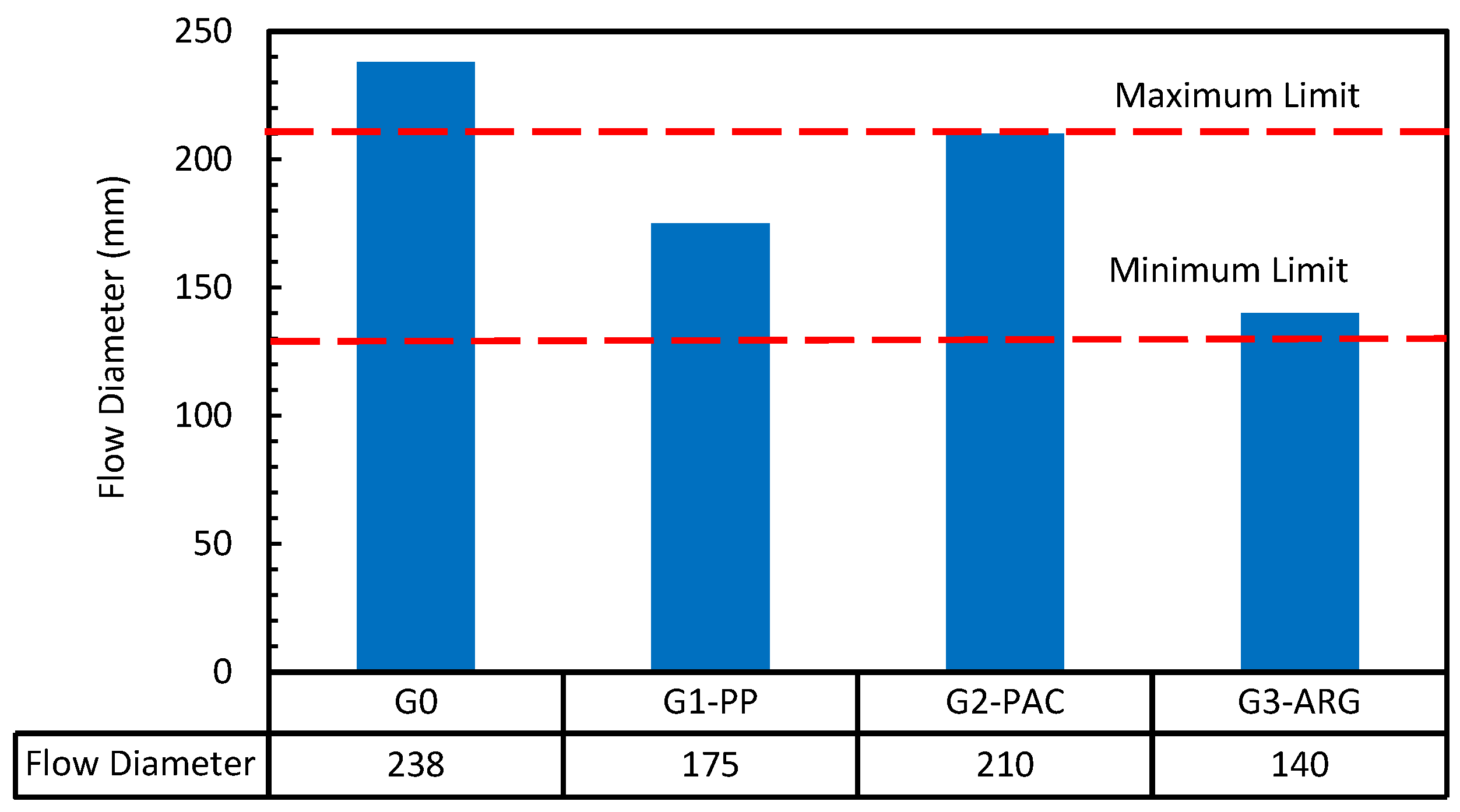

4.1. Workability

4.2. Shape Stability

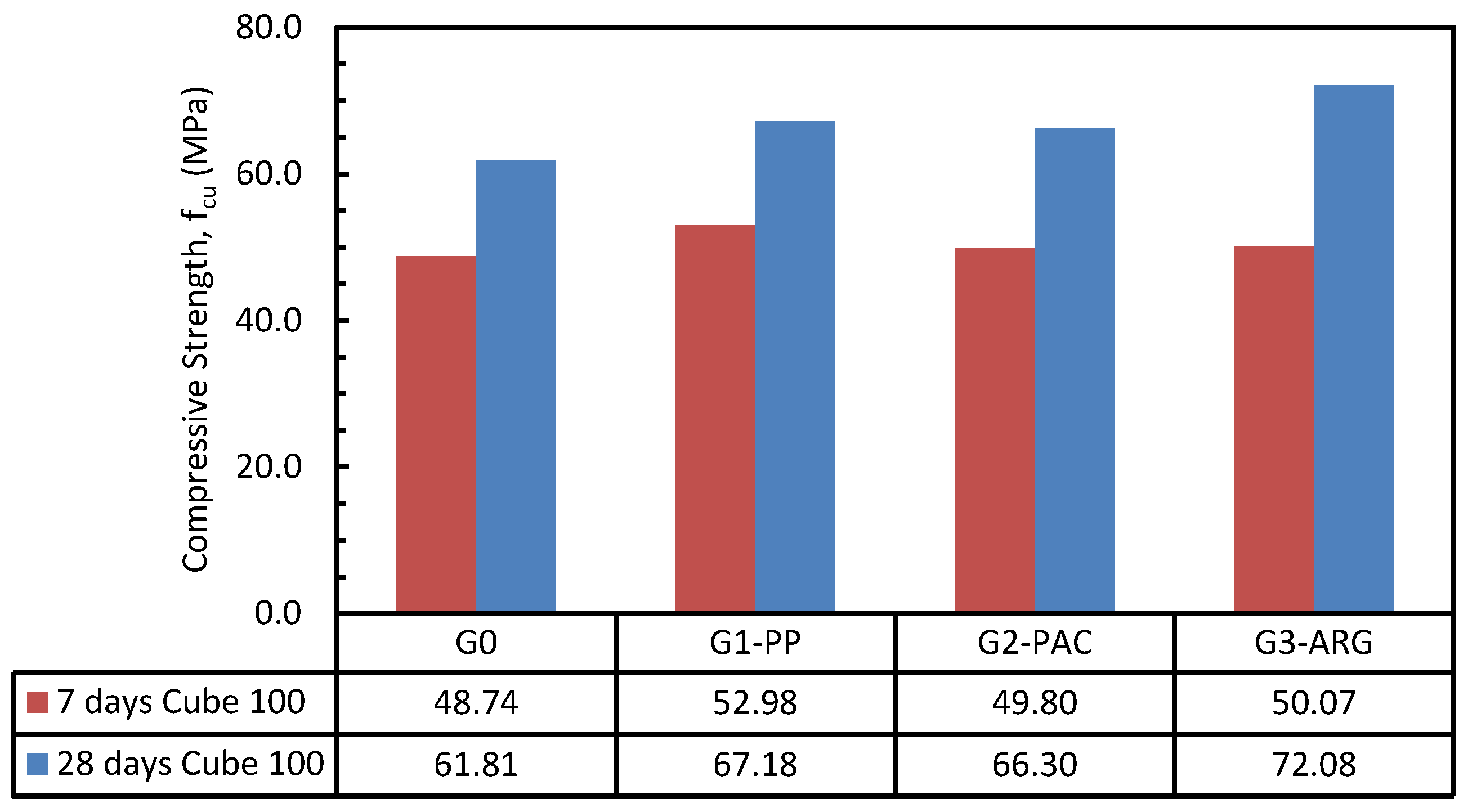

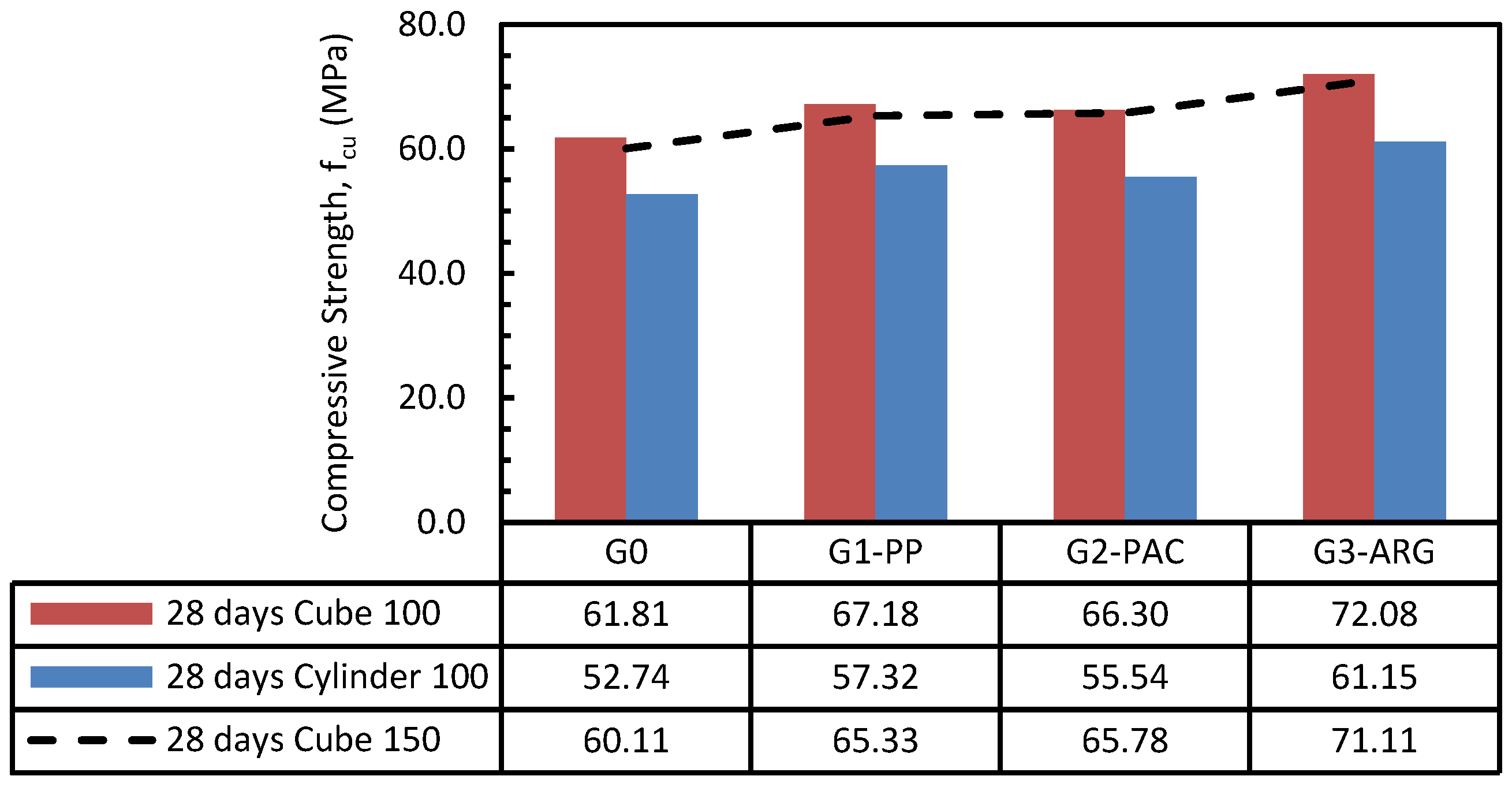

4.3. Compressive Strength

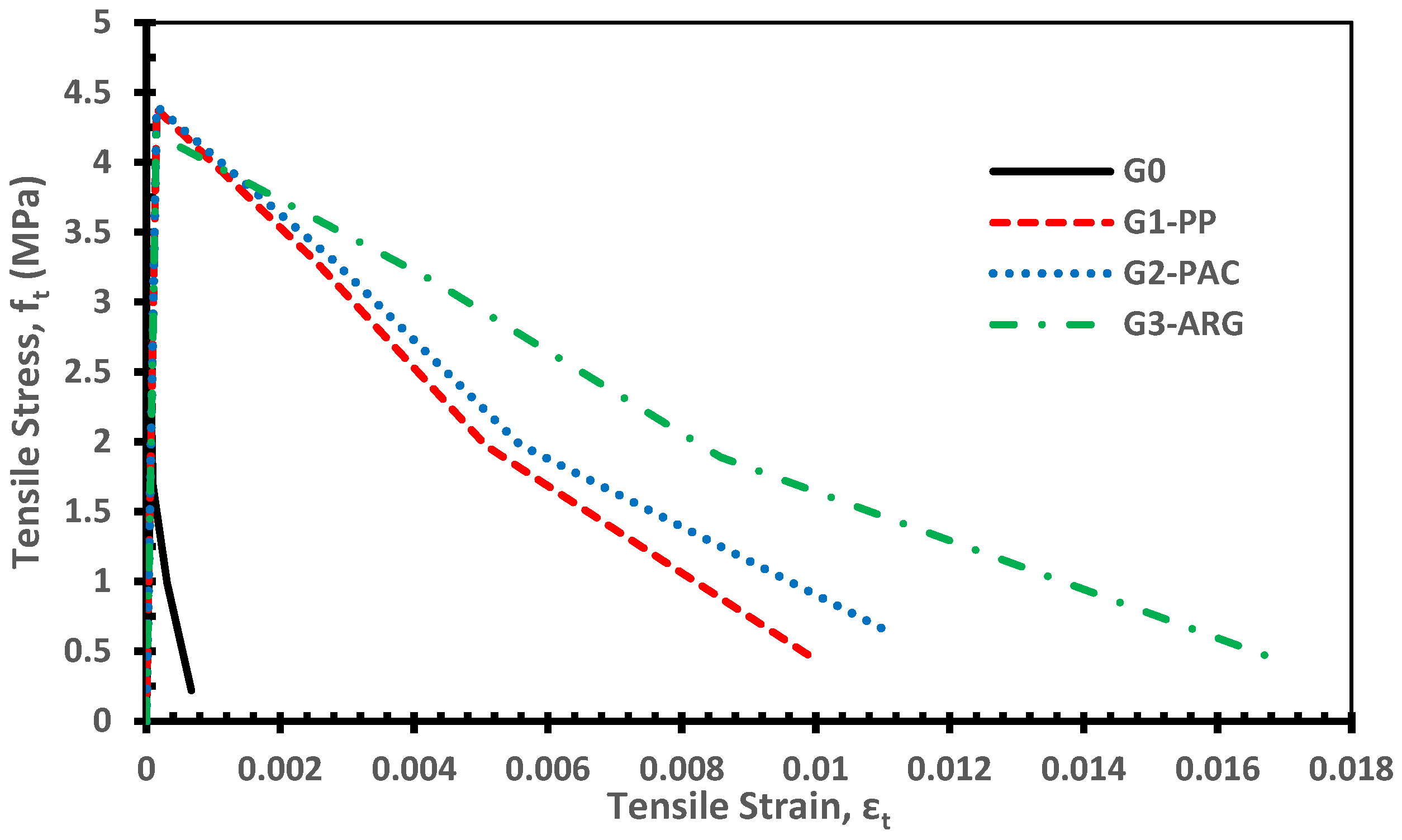

4.4. Uniaxial Tensile Strength

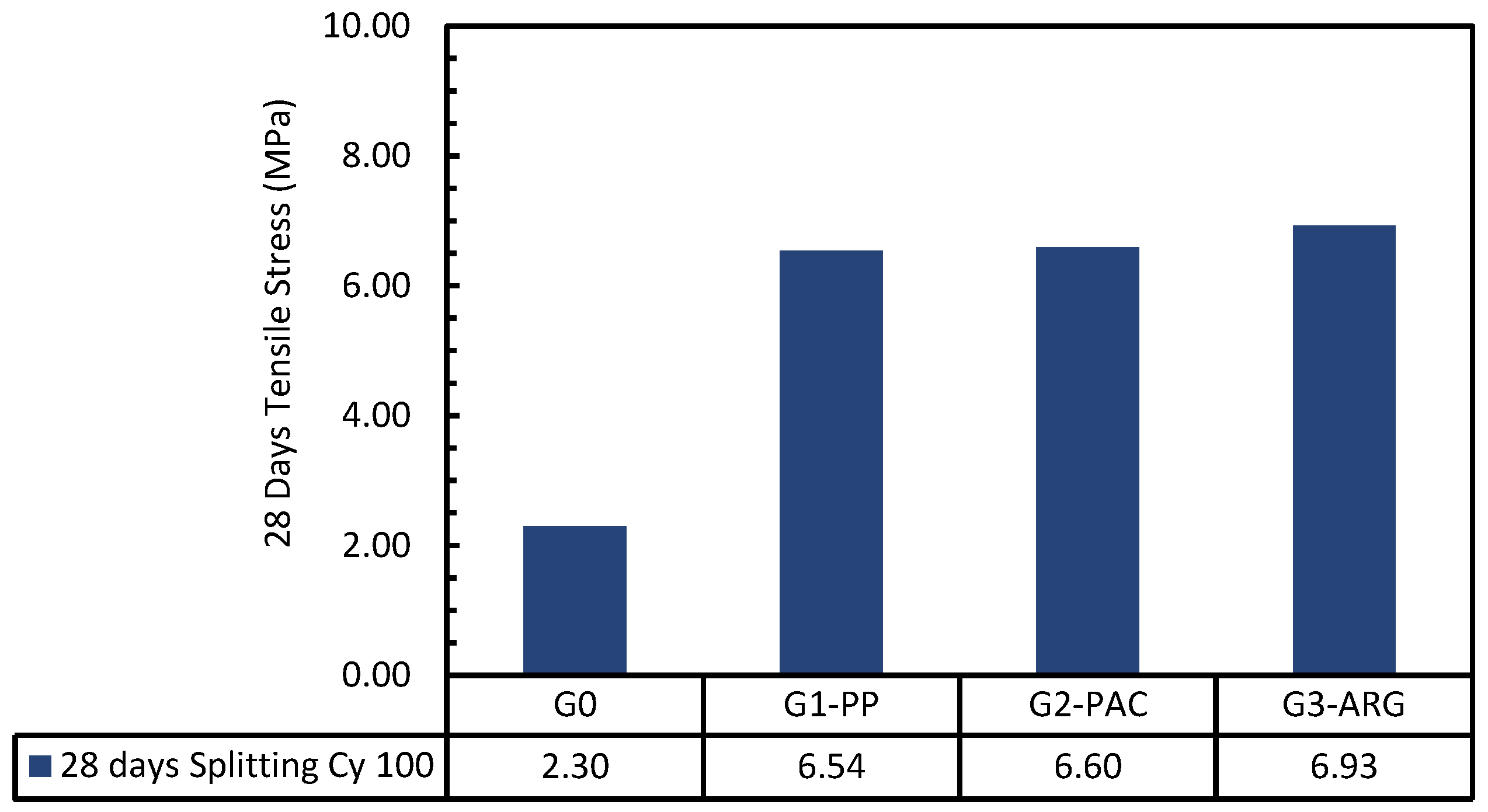

4.5. Tensile Splitting Strength

4.6. Flexural Tensile Strength

5. Finite Element Modeling of the Flexural Beam Test

5.1. FEM Elements

5.2. Concrete Modeling

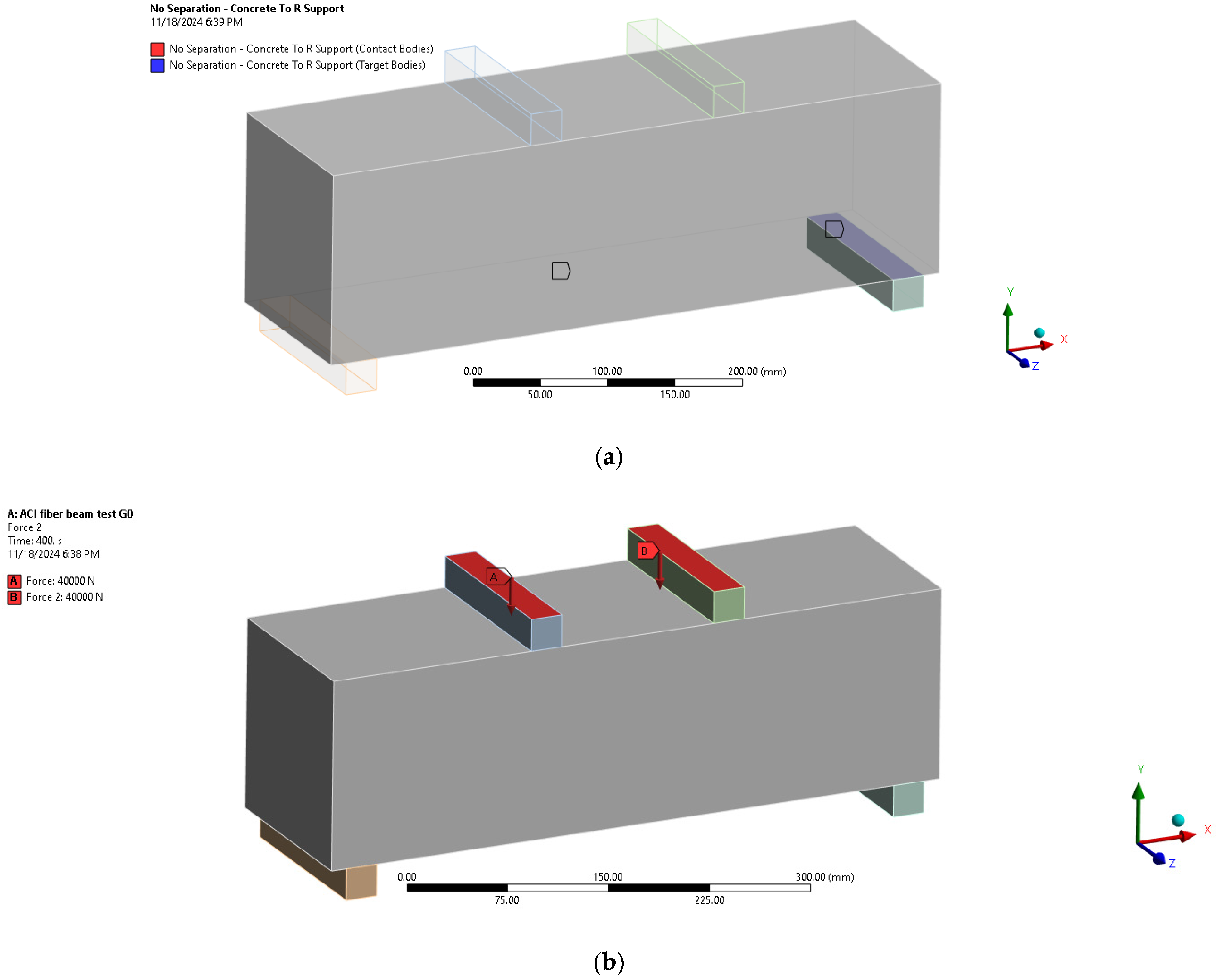

5.3. Supports and Loading Plates Modeling

5.4. Constraints and Interactions

5.5. Loads and Boundary Conditions

5.6. Type of Analysis and Result Outputs

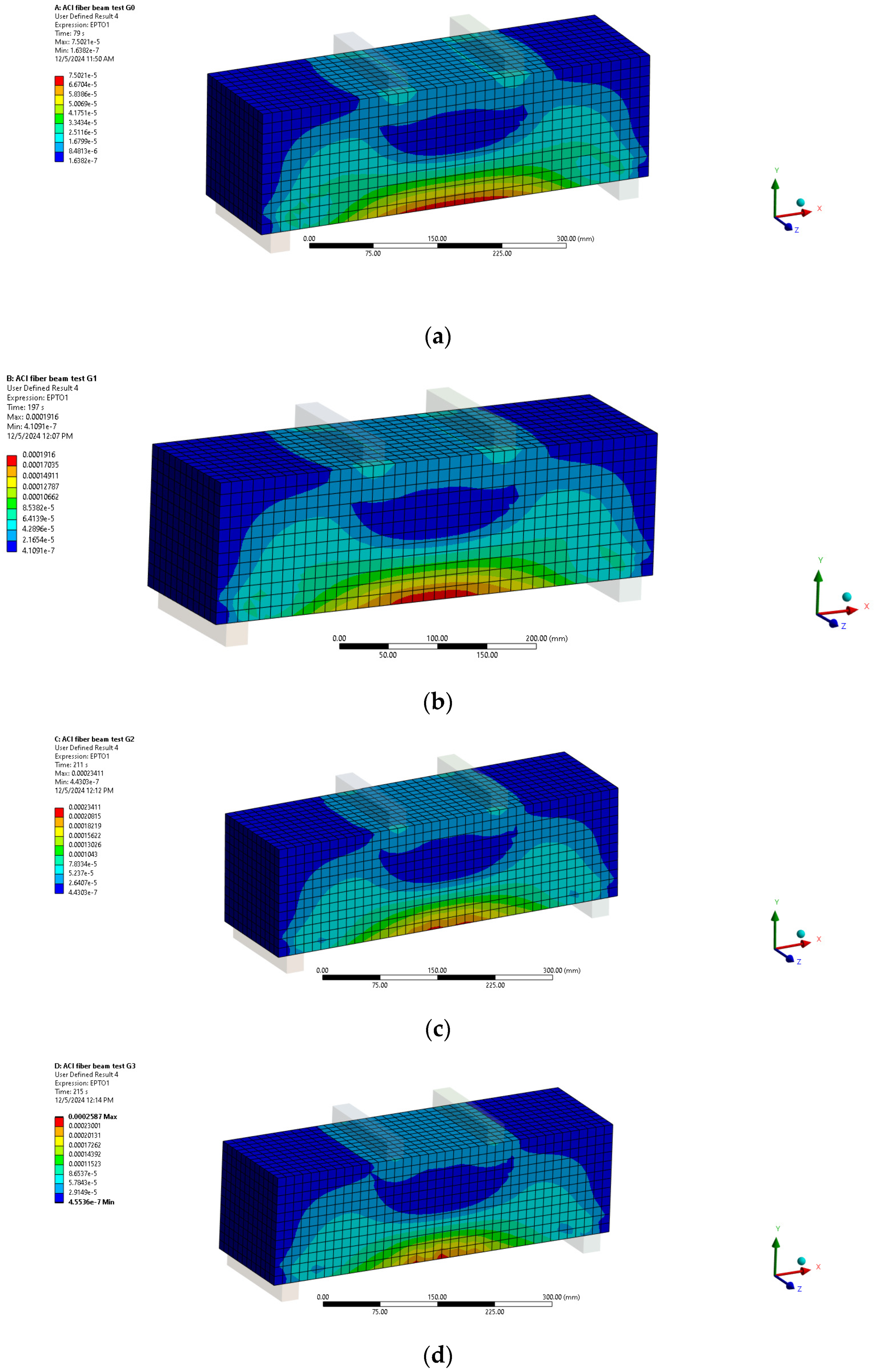

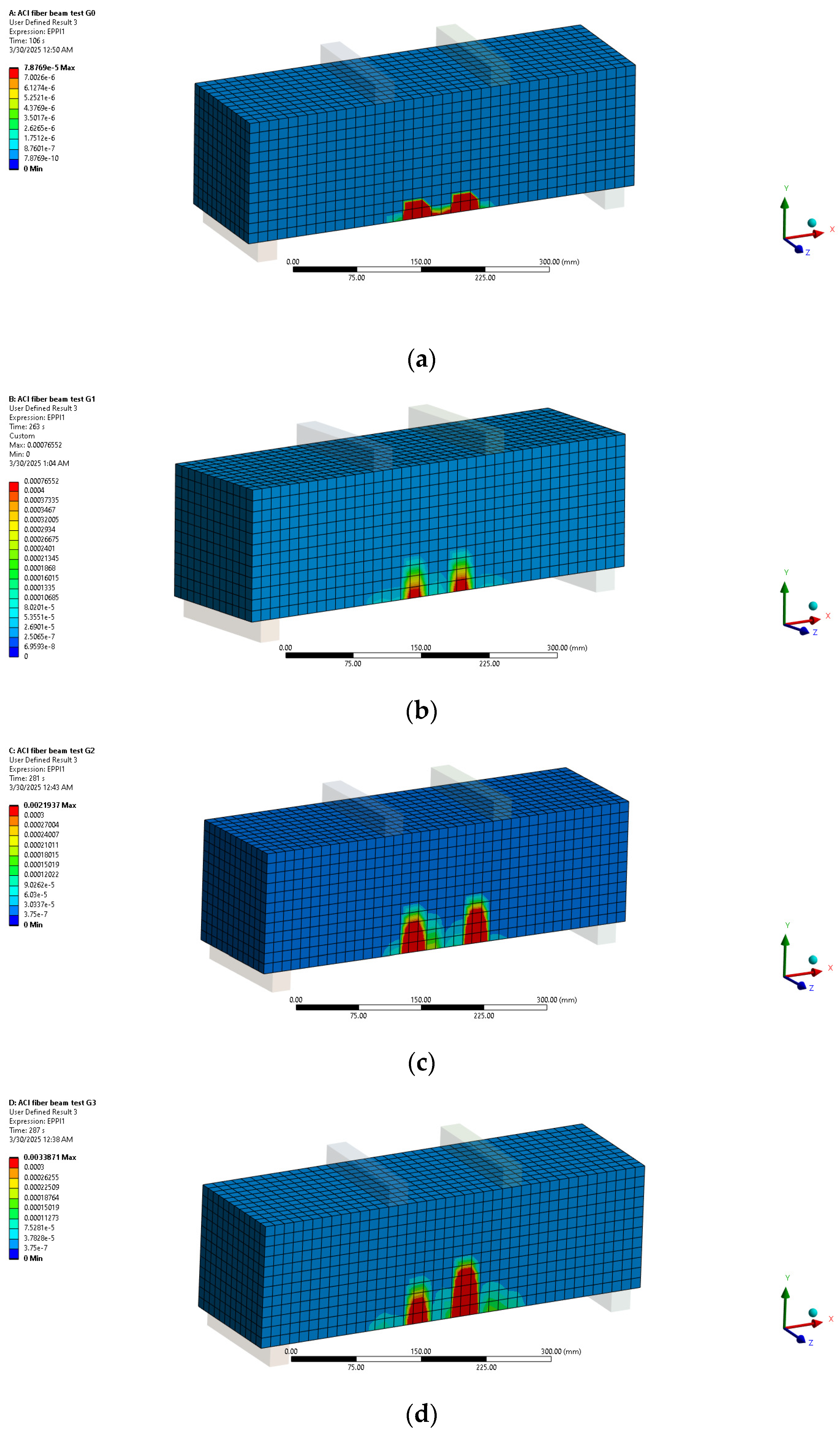

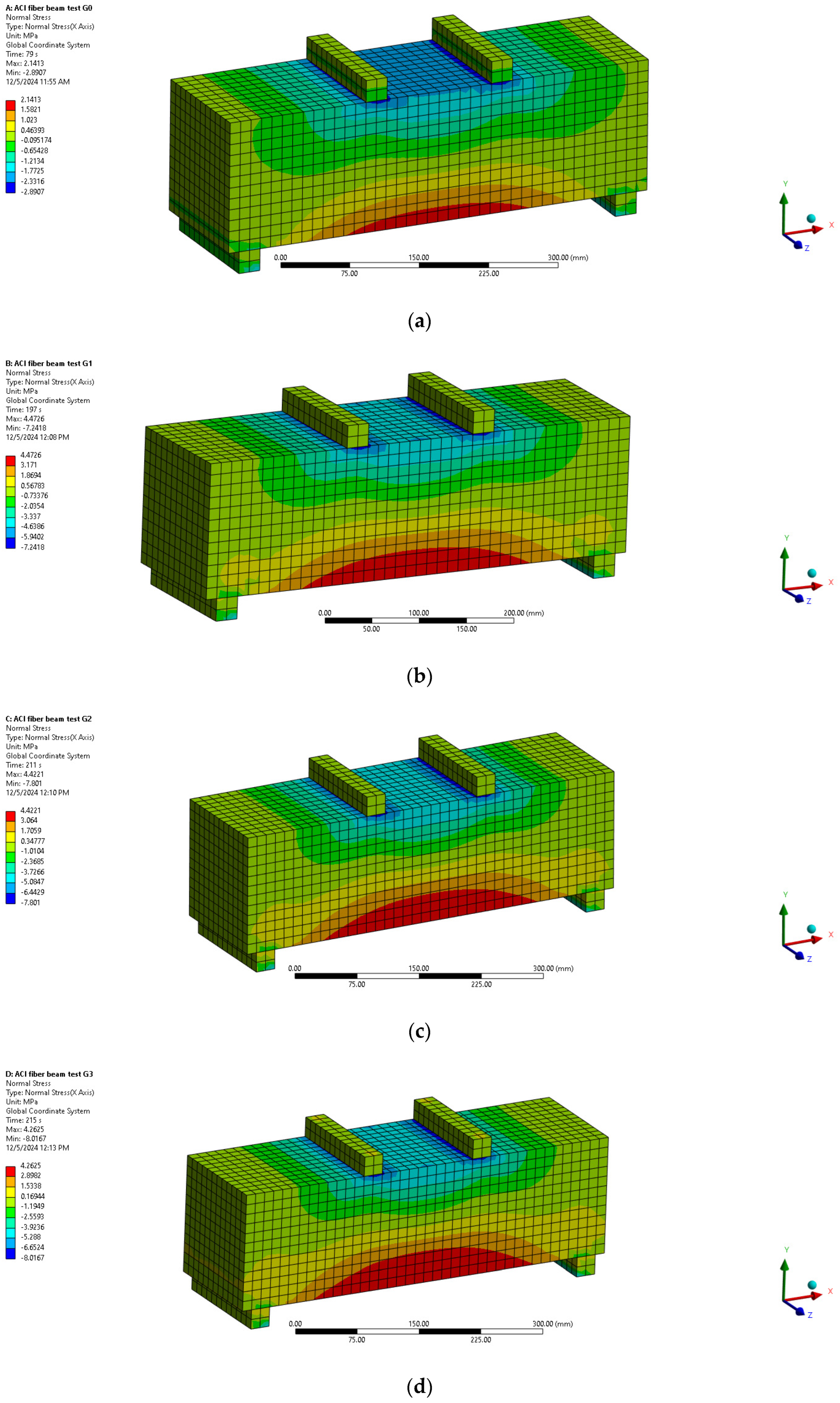

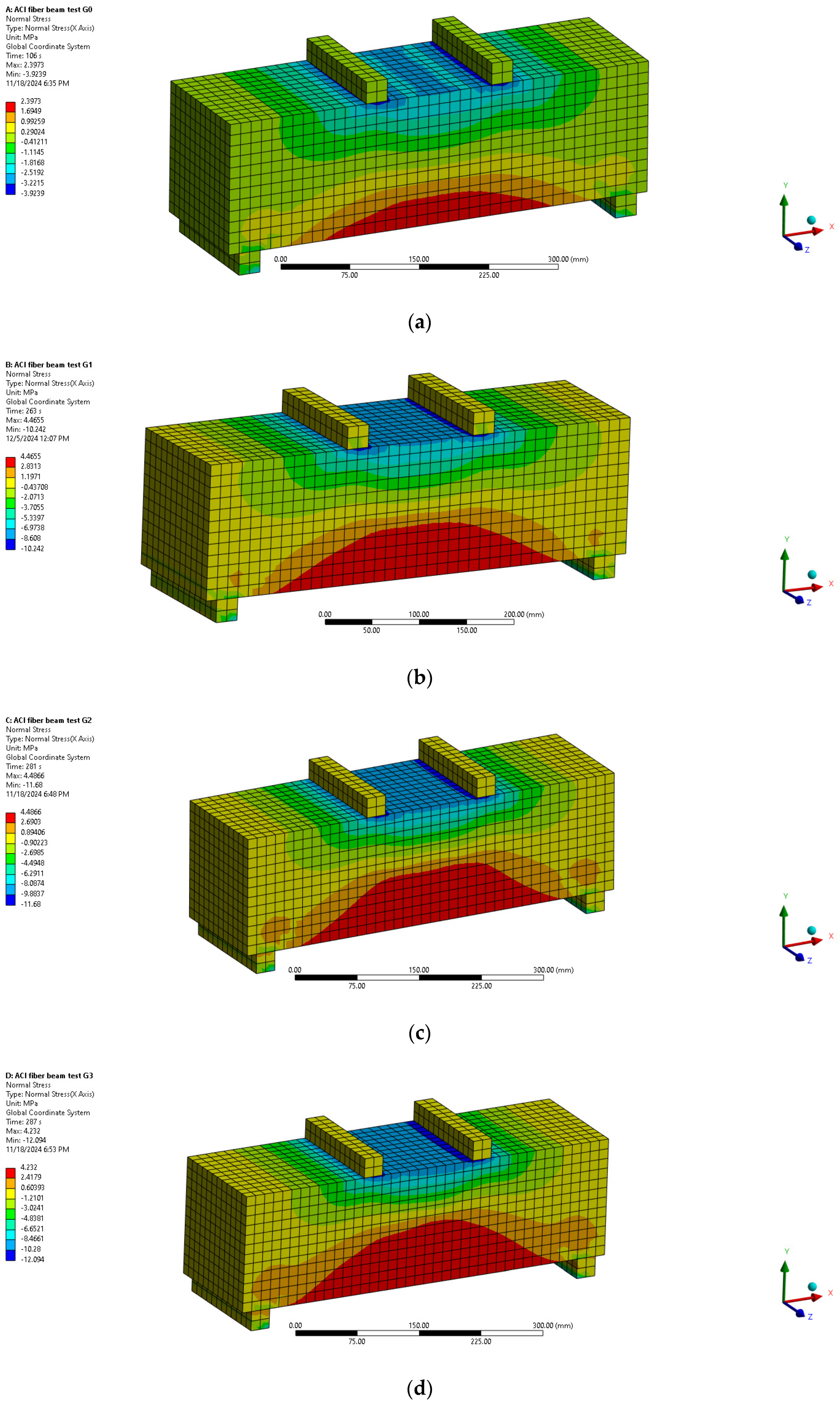

5.7. FEM Results and Validation

6. Conclusions

- The obtained results showed that adding the fibers decreased the flow diameter. Also, the flow diameter of all types of fibers used in this study was within the accepted limit, and the mixture provided with alkali-resistant glass fibers had the lowest flow diameter of all mixtures.

- For all 3DPFCC mixtures, the cylinder stability test was performed to evaluate the shape stability, and the obtained results indicate that the fiber addition enhanced the shape stability of the 3DPFCC mixtures, and the best performance was for the mixture provided with glass fiber (G3-ARG).

- Generally, the obtained results showed a conservative increase in the compressive strength for mixtures with fiber compared to those without fiber (G0). The results indicate that using the PP, PAC, and ARG fiber with a volume content of 1% increased the 28 days compressive strength (fcu) compared to the mixture without fiber G0 (fcu,G0) by 9%, 7%, and 17%, respectively.

- For all tested specimens, the ratio of the 28 days compressive strength between the cubes 150 mm (fcu,150) and the cubes 100 mm (fcu) ranged from 97 to 99%. For the cylinder specimens, the concrete compressive strengths showed the same trends and behavior as the cube specimens. In addition, the ratio of the cylinder compressive strength 100 × 200 (fc′) to the concrete compressive strength (fcu) was about 85%.

- The crack pattern of the tested dog-bone specimens for the 3DPFCC mixtures showed that the addition of fibers changed the uniaxial tensile behavior of the mixtures and transferred it from brittle failure (G0) to ductile failure (G1-PP, G2-PAC, and G3-ARG).

- The uniaxial tensile strength for all specimens with fibers is almost equal, but the mixture with glass fiber (G3-ARG) shows more ductile behavior than the other mixtures with other types of fibers (G1-PP and G2-PAC); this may be due to the higher aspect ratio of the used glass fiber. Also, the mixtures of G1-PP and G2-PAC show almost the same trends and behavior. In addition, the increase of the uniaxial tensile strength for the 3DPFCC mixtures G1-PP, G2-PAC, and G3-ARG were 99%, 100%, and 91% compared to the mixture without fibers (G0).

- The tensile splitting strength of the fiber-reinforced mixtures (G1-PP, G2-PAC, and G3-ARG) was superior to that of the mixture without fibers (G0). The tensile splitting strength of the 3DPFCC mixtures G1-PP, G2-PAC, and G3-ARG increased by 184%, 187%, and 201%, respectively, compared to the mixture without fiber (G0). The results indicated that the alkali-resistant glass fiber tensile splitting strength was approximately 5% greater than that of the polypropylene and polyacrylonitrile high-modulus fibers.

- The flexural tensile strength of the specimens containing polypropylene, polyacrylonitrile, and alkali-resistant glass fibers (G1-PP, G2-PAC, and G3-ARG) exceeded that of the fiberless specimen (G0) by 132%, 139%, and 155%, respectively. The results indicated that the greatest enhancement in flexural tensile strength occurred with the use of alkali-resistant glass fibers, which may be attributable to the fiber aspect ratio.

- The findings revealed that the ratio of tensile splitting strength (fsp) to flexural tensile strength (fctr) varied from 0.75 to 0.92, exceeding the 0.72 value suggested by ECP203-2020.

- The FEM results, utilizing the Menetrey–Willam constitutive model with a linear softening yield function, accurately predicted the ultimate loads for the tested 3DPFCC beams, with the ratio of experimental to FEM values approximating 1.00.

- The results demonstrate the compatibility of the crack patterns between experimental and FEM outcomes. It can be concluded that the Menetrey–Willam constitutive model, featuring a linear softening yield function, effectively simulates the flexural behavior of 3DPFCC beams with CEM II/A-P.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Menna, C.; Mata-Falcón, J.; Bos, F.P.; Vantyghem, G.; Ferrara, L.; Asprone, D.; Salet, T.; Kaufmann, W. Opportunities and challenges for structural engineering of digitally fabricated concrete. Cem. Concr. Res. 2020, 133, 106079. [Google Scholar] [CrossRef]

- Lee, S. Properties of Waste Incineration Ash Added Cementitious Material for Possible Usage in 3D Printing. Master’s Dissertation, Yonsei University, Department of Structural Engineering, Faculty of Engineering, Seoul, Republic of Korea, 2017. [Google Scholar]

- Nerella, V.N.; Krause, M.; Mechtcherine, V. Direct printing test for buildability of 3D-printable concrete considering economic viability. Autom. Constr. 2020, 109, 102986. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Dutton, R. Innovative rapid prototyping process makes large sized, smooth surfaced complex shapes in a wide variety of materials. Mater. Technol. 1998, 13, 53–56. [Google Scholar] [CrossRef]

- Heidarnezhad, F.; Zhang, Q. Shotcrete based 3D concrete printing: State of art, challenges, and opportunities. Constr. Build. Mater. 2022, 323, 126545. [Google Scholar] [CrossRef]

- Aboelhassan, M.G. Future of Sustainable Construction Industry: A Review of Research, Practice and Applications of 3D Concrete Printing. Adv. Civ. Eng. Technol. 2023, 5, 1–8. [Google Scholar] [CrossRef]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Liu, G.; Bai, E.; Xu, J.; Wang, T.; Chang, S. Research Status and Development Prospect of 3D Printing Concrete Materials. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 032014. [Google Scholar]

- Khan, M. Mix suitable for concrete 3D printing: A review. Mater. Today Proc. 2020, 32, 831–837. [Google Scholar] [CrossRef]

- Krishnaraja, A.; Guru, K. 3D Printing Concrete: A Review. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; p. 012033. [Google Scholar]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Ahmed, Z.Y.; Bos, F.P.; Wolfs, R.J.; Salet, T.A. Design considerations due to scale effects in 3D concrete printing. In Proceedings of the 8th Arab Society for Computer Aided Architectural Design, London, UK, 7–8 November 2016. [Google Scholar]

- Bos, F.P.; Ahmed, Z.Y.; Wolfs, R.J.; Salet, T.A. 3D Printing Concrete with Reinforcement. In Proceedings of the High Tech Concrete: Where Technology and Engineering Meet, Maastricht, The Netherlands, 12–14 June 2017. [Google Scholar]

- Gebhard, L.; Mata-Falcón, J.; Anton, A.; Dillenburger, B.; Kaufmann, W. Structural behaviour of 3D printed concrete beams with various reinforcement strategies. Eng. Struct. 2021, 240, 112380. [Google Scholar] [CrossRef]

- Kloft, H.; Empelmann, M.; Hack, N.; Herrmann, E.; Lowke, D. Reinforcement strategies for 3D-concrete-printing. Civ. Eng. Des. 2020, 2, 131–139. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Valentine, P.J.; Piker, D.; Austin, S.A.; De Kestelier, X. Modelling curved-layered printing paths for fabricating large-scale construction components. Addit. Manuf. 2016, 12, 216–230. [Google Scholar] [CrossRef]

- Nishiwaki, T.; Miyata, Y.; Furue, S.; Fukatsu, S.; Kajita, H. Reinforcing interlayers of three-dimensional-printed mortar using metal fiber insertion. ACI Mater. J. 2021, 118, 331–340. [Google Scholar]

- Hack, N.; Bahar, M.; Hühne, C.; Lopez, W.; Gantner, S.; Khader, N.; Rothe, T. Development of a robot-based multi-directional dynamic fiber winding process for additive manufacturing using shotcrete 3D printing. Fibers 2021, 9, 39. [Google Scholar] [CrossRef]

- Jo, J.H.; Jo, B.W.; Cho, W.; Kim, J.-H. Development of a 3D printer for concrete structures: Laboratory testing of cementitious materials. Int. J. Concr. Struct. Mater. 2020, 14, 1–11. [Google Scholar] [CrossRef]

- Şahin, H.G.; Mardani-Aghabaglou, A. Assessment of materials, design parameters and some properties of 3D printing concrete mixtures; a state-of-the-art review. Constr. Build. Mater. 2022, 316, 125865. [Google Scholar] [CrossRef]

- Antoni, A.; Agraputra, A.; Teopilus, D.; Sunaryo, A.; Mulyadi, M.; Pudjisuryadi, P.; Chandra, J.; Hardjito, D. Investigation of the material mixtures and fiber addition for 3D concrete printing. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; p. 012011. [Google Scholar]

- Yuan, Q.; Zuo, S.; Li, Z.; Shi, C.; Wu, Q. Optimizing Three-Dimensional Printing Binder Composed of Ordinary Portland Cement and Calcium Sulfoaluminate Cement with Retarders. ACI Mater. J. 2021, 118, 155–165. [Google Scholar]

- Ko, L.; Moro, S.; Bury, J.; Vickers, T.; Sachsenhauser, B.; Mönnig, S. Rheology and Setting Control of Concrete for Digital Construction. ACI Mater. J. 2021, 118, 167–175. [Google Scholar]

- Murcia, D.H.; Abdellatef, M.; Genedy, M.; Taha, M. Rheological Characterization of Three-Dimensional-Printed Polymer Concrete. ACI Mater. J. 2021, 118, 189–201. [Google Scholar]

- Sonebi, M.; Dedenis, M.; Amziane, S.; Abdalqader, A.; Perrot, A. Effect of Red Mud, Nanoclay, and Natural Fiber on Fresh and Rheological Properties of Three-Dimensional Concrete Printing. ACI Mater. J. 2021, 118, 97–110. [Google Scholar]

- Douba, A.; Kawashima, S. Use of nanoclays and methylcellulose to tailor rheology for three-dimensional concrete printing. ACI Mater. J. 2021, 118, 275–289. [Google Scholar]

- Tao, Y.; Vantyghem, G.; Lesage, K.; Yuan, Y.; De Corte, W.; Van Tittelboom, K.; De Schutter, G. Adhesion properties of printable polymer-modified concrete for rock tunnel linings. ACI Mater. J. 2021, 118, 61–73. [Google Scholar]

- Kruger, J.; Cho, S.; van den Heever, M.; Bester, F.; van Rooyen, A.; van Zij, G. Nanotechnology for Improved Three-Dimensional Concrete Printing Constructability. ACI Mater. J. 2021, 118, 19–28. [Google Scholar]

- Kruger, J.; Zeranka, S.; van Zijl, G. 3D concrete printing: A lower bound analytical model for buildability performance quantification. Autom. Constr. 2019, 106, 102904. [Google Scholar] [CrossRef]

- Liu, C.; Yue, S.; Zhou, C.; Sun, H.; Deng, S.; Gao, F.; Tan, Y. Anisotropic mechanical properties of extrusion-based 3D printed layered concrete. J. Mater. Sci. 2021, 56, 16851–16864. [Google Scholar] [CrossRef]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious materials for construction-scale 3D printing: Laboratory testing of fresh printing mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability region for 3D concrete printing using slump and slump flow test. Compos. Part B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Wi, K.; Hong, J.; Wang, K. Determining printable zone of three-dimensional-printable mortar using flow table tests. ACI Mater. J. 2021, 118, 75–85. [Google Scholar]

- Zareiyan, B.; Khoshnevis, B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom. Constr. 2017, 83, 212–221. [Google Scholar] [CrossRef]

- Xu, J.; Ding, L.; Cai, L.; Zhang, L.; Luo, H.; Qin, W. Volume-forming 3D concrete printing using a variable-size square nozzle. Autom. Constr. 2019, 104, 95–106. [Google Scholar] [CrossRef]

- Seo, E.-A.; Kim, W.-W.; Kim, S.-W.; Kwon, H.-K.; Lee, H.-J. Mechanical properties of 3D printed concrete with coarse aggregates and polypropylene fiber in the air and underwater environment. Constr. Build. Mater. 2023, 378, 131184. [Google Scholar] [CrossRef]

- Aramburu, A.; Calderon-Uriszar-Aldaca, I.; Puente, I.; Castano-Alvarez, R. Effects of 3D-printing on the tensile splitting strength of concrete structures. Case Stud. Constr. Mater. 2024, 20, e03090. [Google Scholar] [CrossRef]

- Arif, M.; Jan, F.; Rezzoug, A.; Afridi, M.A.; Luqman, M.; Khan, W.A.; Kujawa, M.; Alabduljabbar, H.; Khan, M. Data-driven models for predicting compressive strength of 3D-printed fiber-reinforced concrete using interpretable machine learning algorithms. Case Stud. Constr. Mater. 2024, 21, e03935. [Google Scholar] [CrossRef]

- Cai, J.; Wang, J.; Zhang, Q.; Du, C.; Meloni, M.; Feng, J. State-of-the-art of mechanical properties of 3D printed concrete. Case Stud. Constr. Mater. 2024, 21, e03847. [Google Scholar] [CrossRef]

- Luo, S.; Jin, W.; Wu, W.; Zhang, K. Rheological and mechanical properties of polyformaldehyde fiber reinforced 3D-printed high-strength concrete with the addition of fly ash. J. Build. Eng. 2024, 98, 111387. [Google Scholar] [CrossRef]

- Sun, J.; Liu, S.; Ma, Z.; Wang, D.; Wang, Y.; Zhao, H.; Huang, B.; Saafi, M.; Wang, X. 3D printed lightweight concrete containing surface pretreated coal gangue. Case Stud. Constr. Mater. 2024, 20, e02906. [Google Scholar] [CrossRef]

- Wang, L.; Wang, F.; Li, R.; Wang, Q. Interfacial constitutive model of 3D printed fiber reinforced concrete composites and its experimental validation. Case Stud. Constr. Mater. 2024, 20, e02807. [Google Scholar] [CrossRef]

- Ma, W.; Wang, G.; Zhou, Y.; Xu, Q.; Dai, Y. Polyacrylonitrile fiber reinforced 3D printed concrete: Effects of fiber length and content. J. Build. Eng. 2024, 97, 110869. [Google Scholar] [CrossRef]

- Shoukry, M.E.; Tarabia, A.M.; Yassin, A.M. Punching shear strength of ultra-high-performance fibre concrete slab–column connections. Proc. Inst. Civ. Eng. Struct. Build. 2022, 175, 13. [Google Scholar] [CrossRef]

- Yassin, A.M.; Mohie Eldin, M.; Hafez, M.A.; Elnaggar, M.A. The Flexural Behavior and Mechanical Properties of Super High-Performance Concrete (SHPC) Reinforced Using the Hybridization of Micro Polypropylene and Macro Steel Fibers. Buildings 2024, 14, 1887. [Google Scholar] [CrossRef]

- Yassin, A.M.; Eldin, M.M.; Omar, M.S.; Hafez, M.A.; Elnaggar, M.A. A new approach to calculate the shear strength of high-performance reinforced concrete beams fibered with micro polypropylene (experimental and analytical study). Eng. Struct. 2024, 314, 118347. [Google Scholar] [CrossRef]

- Yassin, A.M.; Eldin, M.M.; Omar, M.S.; Hafez, M.A.; Elnaggar, M.A. Effect of nano-silica on the flexural behavior and mechanical properties of self-compacted high-performance concrete (SCHPC) produced by cement CEM II/A-P (experimental and numerical study). Case Stud. Constr. Mater. 2024, 21, e03490. [Google Scholar] [CrossRef]

- ECP 203-2020; Egyptian Code for Design and Construction of Reinforced Concrete Structures, ECP 203-2020. Egyptian Code Committee for Design and Construction of Reinforced Concrete Structures: Egypt, 2020.

- Japan Society of Civil Engineers. Concrete Engineering Series 82. In Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks (HPFRCC); Japan Society of Civil Engineers (JSCE), Concrete Committee: Tokyo, Japan, 2008. [Google Scholar]

- Fédération Internationale du Béton (fib). Fib Model Code for Concrete Structures 2010; Fédération Internationale du Béton (fib): Lausanne, Switzerland, 2013. [Google Scholar]

- ACI Committee 544. Guide for Specifying, Proportioning, and Production of Fiber-Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2008; p. 16. [Google Scholar]

- ACI Committee 363. Report on High-Strength Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2010. [Google Scholar]

- ACI Committee 544. Report on Indirect Method to Obtain Stress-Strain Response of Fiber-Reinforced Concrete (FRC); American Concrete Institute: Farmington Hills, MI, USA, 2016; p. 28. [Google Scholar]

- ACI Committee 544. Report on the Measurement of Fresh State Properties and Fiber Dispersion of Fiber-Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2017; p. 24. [Google Scholar]

- ACI Committee 544. Report on Measuring Mechanical Properties of Hardened Fiber-Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2017; p. 52. [Google Scholar]

- BSI. BS EN 206: 2013+ A1: 2016: Concrete. Specification, Performance, Production and Conformity; BSI: London, UK, 2013. [Google Scholar]

- ANSYS, Inc. ANSYS Mechanical APDL 2023/R2 (Material Reference); ANSYS, Inc.: Canonsburg, PA, USA, 2023; Available online: https://ansyshelp.ansys.com/public/account/secured?returnurl=/Views/Secured/corp/v242/en/ans_mat/ans_mat.html (accessed on 3 April 2025).

- Yassin, A.M.; Hafez, M.A.; Mohie Eldin, M. The Flexural Behavior of Reinforced Ultra-High Performance Engineering Cementitious Composite (UHP-ECC) Beams Fabricated with Polyethylene Fiber (Numerical and Analytical Study). Buildings 2024, 14, 3484. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar]

- Available online: https://classes.engineering.wustl.edu/2009/spring/mase5513/abaqus/docs/v6.6/books/usb/default.htm?startat=pt05ch18s05abm36.html (accessed on 3 April 2025).

| Chemical Composition (%) | ||||

|---|---|---|---|---|

| Materials | CEM I 42.5N | CEM II/A-P 42.5N | Silica Fume | Calcium Oxide |

| SiO2 | 18.32 | 22.68 | 95.20 | - |

| TiO2 | - | - | 0.05 | 0.01 |

| Al2O3 | 4.31 | 5.96 | 0.44 | - |

| Fe2O3 | 3.32 | 6.86 | 0.70 | 0.11 |

| MnO | - | - | 0.01 | - |

| MgO | 3.76 | 4.10 | 0.10 | 0.11 |

| CaO | 61.39 | 53.94 | 1.01 | 99.23 |

| Na2O | 0.84 | 1.11 | 0.10 | 0.02 |

| K2O | 0.28 | 0.32 | <0.01 | - |

| P2O5 | - | - | <0.01 | - |

| Lol | 3.66 | 1.86 | 2.19 | - |

| SO3 | 2.44 | 2.04 | - | - |

| Cl | 0.04 | 0.04 | - | - |

| Cr2O3 | - | - | - | - |

| Free Cao | 1.76 | 1.44 | - | - |

| Insoluble residue | 2.53 | - | - | - |

| Hexavalent Chromium | 1.91 (ppm) | 1.81 (ppm) | - | - |

| Physical properties | ||||

| Specific gravity | 3.15 | 3.15 | 2.23 | 3.30 |

| Average particle size | 1–10 μm | 1–10 μm | 0.11 μm | <10 μm |

| Specific surface area | 0.385 | 0.392 | 18 | 4.34 |

| Fiber | PP12 | PAC 251-60-12 | ARG24 |

|---|---|---|---|

| Material | polypropylene | polyacrylonitrile high modulus | alkali-resistant fiberglass |

| Shape | straight | straight | straight |

| Length, lf (mm) | 12 | 12 | 24 |

| Thickness (mm) | 0.03–0.032 | 0.084 | 0.015–0.017 |

| Cross section | rounded | kidney shaped | rectangular |

| Density (kg/m3) | 910 | 1180 | 2700 |

| Modulus of elasticity (N/mm2) | 5500–5700 | 8000–11,000 | 80,000 |

| Tensile strength (N/mm2) | 350 | 400 | 2500 |

| Mix | Mix Proportion (kg/m3) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Binder | Calcium Oxide | Sand | Water | SP * | Fiber ** | W/B *** | ||||

| Cement | Silica Fume | Weight | Vf (%) | Type | ||||||

| G0 | 1058.40 | 117.60 | 105 | 1100 | 294 | 11.76 | 0 | 0 | Without fiber | 0.25 |

| G1-PP | 9.10 | 1 | PP12 | |||||||

| G2-PAC | 11.80 | PAC 251-60-12 | ||||||||

| G3-ARG | 27.00 | ARG24 | ||||||||

| Mix | Fiber Type | Compressive Strength (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| At 7 Days | At 28 Days | ||||||||

| fcu | fcu,150 | fc′ | fcu/fcu,G0 | fcu | fcu,150 | fc′ | fcu/fcu,G0 | ||

| G0 | without fiber | 48.74 | 46.44 | 40.11 | 1.00 | 61.81 | 60.11 | 52.74 | 1.00 |

| G1-PP | PP12 | 52.98 | 48.89 | 44.59 | 1.09 | 67.18 | 65.33 | 57.32 | 1.09 |

| G2-PAC | PAC 251-60-12 | 49.80 | 48.13 | 40.76 | 1.02 | 66.30 | 65.78 | 55.54 | 1.07 |

| G3-ARG | ARG24 | 50.07 | 48.40 | 42.04 | 1.03 | 72.08 | 71.11 | 61.15 | 1.17 |

| Mix | Uniaxial Tensile Strength (MPa) | Tensile Splitting Strength (MPa) | Flexure Tensile Strength (MPa) | fsp/fctr | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ft | ft/ft,G0 | fsp | fsp/fsp,G0 | fctr | fctr/fctr,G0 | |||||

| G0 | 2.20 | 1.00 | 0.28 | 2.30 | 1.00 | 0.29 | 3.08 | 1.00 | 0.39 | 0.75 |

| G1-PP | 4.38 | 1.99 | 0.53 | 6.54 | 2.84 | 0.80 | 7.13 | 2.32 | 0.87 | 0.92 |

| G2-PAC | 4.40 | 2.00 | 0.54 | 6.60 | 2.87 | 0.81 | 7.36 | 2.39 | 0.90 | 0.90 |

| G3-ARG | 4.20 | 1.91 | 0.49 | 6.93 | 3.01 | 0.82 | 7.86 | 2.55 | 0.93 | 0.88 |

| Denotation | The Proposed Value |

|---|---|

| Concrete parameters according to the Menetrey–Willam constitutive model | |

| Modulus of elasticity, Ec (N/mm2) | Based on experimental findings |

| Poisson’s ratio, νc | Based on experimental findings |

| Uniaxial compressive strength (Rc), fc′ (N/mm2) | Based on experimental findings |

| Uniaxial tensile strength (Rt), ft (N/mm2) | Based on experimental findings |

| Biaxial compressive strength (Rb) (N/mm2) | 1.2 fc′ |

| Dilatancy angle (), (Degrees) | 30° |

| Plastic strain at uniaxial compressive strength (kcm) | Based on experimental findings |

| Ultimate effective plastic strain in compression (kcr) | Based on experimental findings |

| Relative stress at the start of nonlinear hardening (ci) | Based on experimental findings |

| Residual compressive relative stress (cr) | Based on experimental findings |

| Plastic strain limit in tension (ktr) | Based on experimental findings |

| Residual tensile relative stress (tr) | Based on experimental findings |

| Material parameters for the steel loading plate and steel supports | |

| Poisson’s ratio, us | 0.3 |

| Modulus of elasticity, Es (N/mm2) | 200,000 |

| Yield stress, fy (N/mm2) | 500 |

| Mix | Fiber Type | Ultimate Load; Pu (MPa) | Modulus of Rupture; fctr (MPa) | ||||

|---|---|---|---|---|---|---|---|

| Experimental (1) | FEM (2) | (1)/(2) | Experimental (3) | FEM (4) | (3)/(4) | ||

| G0 | without fiber | 23.10 | 22.20 | 1.04 | 3.08 | 2.96 | 1.04 |

| G1-PP | PP12 | 53.50 | 52.60 | 1.02 | 7.13 | 7.01 | 1.02 |

| G2-PAC | PAC 251-60-12 | 55.20 | 56.20 | 0.98 | 7.36 | 7.49 | 0.98 |

| G3-ARG | ARG24 | 58.94 | 57.40 | 1.03 | 7.86 | 7.65 | 1.03 |

| Mean | 1.02 | ||||||

| Standard deviation (STD.) | 0.02 | ||||||

| Coefficient of variation (COV); % | 2.45 | ||||||

| Coefficient of determination (R2) | 1.00 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yassin, A.M.; Hafez, M.A.; Aboelhassan, M.G. Experimental and Numerical Investigation on the Effect of Different Types of Synthetic Fibers on the Flexure Behavior and Mechanical Properties of 3D Cementitious Composite Printing Provided with Cement CEM II/A-P. Buildings 2025, 15, 1201. https://doi.org/10.3390/buildings15071201

Yassin AM, Hafez MA, Aboelhassan MG. Experimental and Numerical Investigation on the Effect of Different Types of Synthetic Fibers on the Flexure Behavior and Mechanical Properties of 3D Cementitious Composite Printing Provided with Cement CEM II/A-P. Buildings. 2025; 15(7):1201. https://doi.org/10.3390/buildings15071201

Chicago/Turabian StyleYassin, Ahmed M., Mohamed Ahmed Hafez, and Mohamed Gamal Aboelhassan. 2025. "Experimental and Numerical Investigation on the Effect of Different Types of Synthetic Fibers on the Flexure Behavior and Mechanical Properties of 3D Cementitious Composite Printing Provided with Cement CEM II/A-P" Buildings 15, no. 7: 1201. https://doi.org/10.3390/buildings15071201

APA StyleYassin, A. M., Hafez, M. A., & Aboelhassan, M. G. (2025). Experimental and Numerical Investigation on the Effect of Different Types of Synthetic Fibers on the Flexure Behavior and Mechanical Properties of 3D Cementitious Composite Printing Provided with Cement CEM II/A-P. Buildings, 15(7), 1201. https://doi.org/10.3390/buildings15071201