Study on Composition Design and Performance Characteristics of Warm-Mixed Rubber–Asphalt Mixture for Cold-Region Stress Absorption Layers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Generation of Rubber–Asphalt

2.1.2. Selection of Aggregates

2.1.3. Ascertainment of Aggregate Gradation

2.1.4. Determination of the Optimum Amount of Asphalt

2.1.5. Determination of the Optimal Blending and Compaction Temperatures

2.2. Methods

2.2.1. Design Ideas of Processing Technology and Flow of WMRA Mix

2.2.2. General Design Method of WMRA Mix

2.2.3. Performance Test and Research Method of WMRA Mix

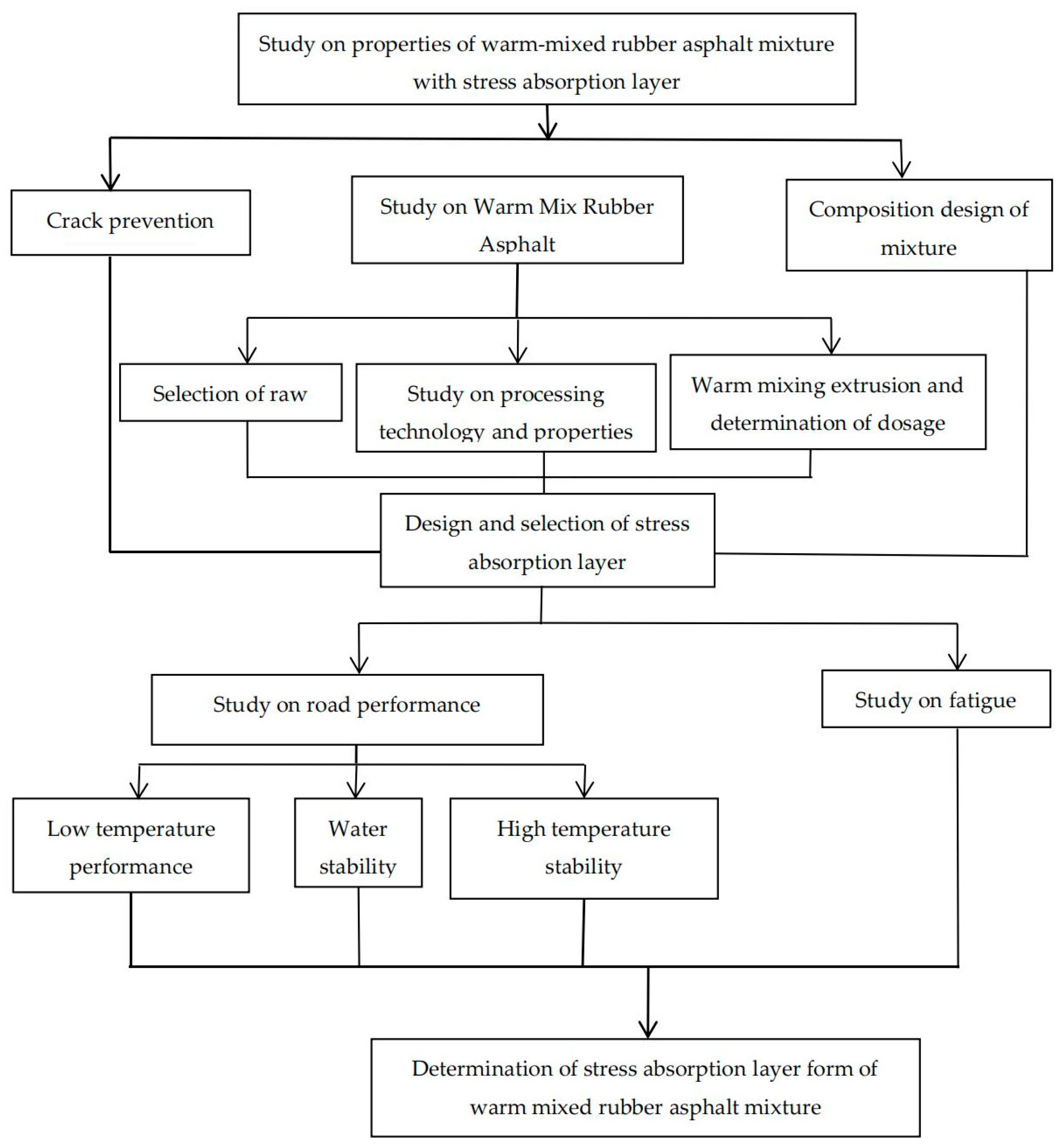

2.2.4. Flow Chart for Performance Study of WMRA Mix

3. Results

3.1. Performance Study and Comparative Analysis of SAK-III WMRA Mix for Stress Absorption Layer in Cold Regions

3.1.1. High Temperature Stability

Rutting Test Results and Comparative Study

Structural Rutting Test Results and Comparative Study

3.1.2. Low-Temperature Performance

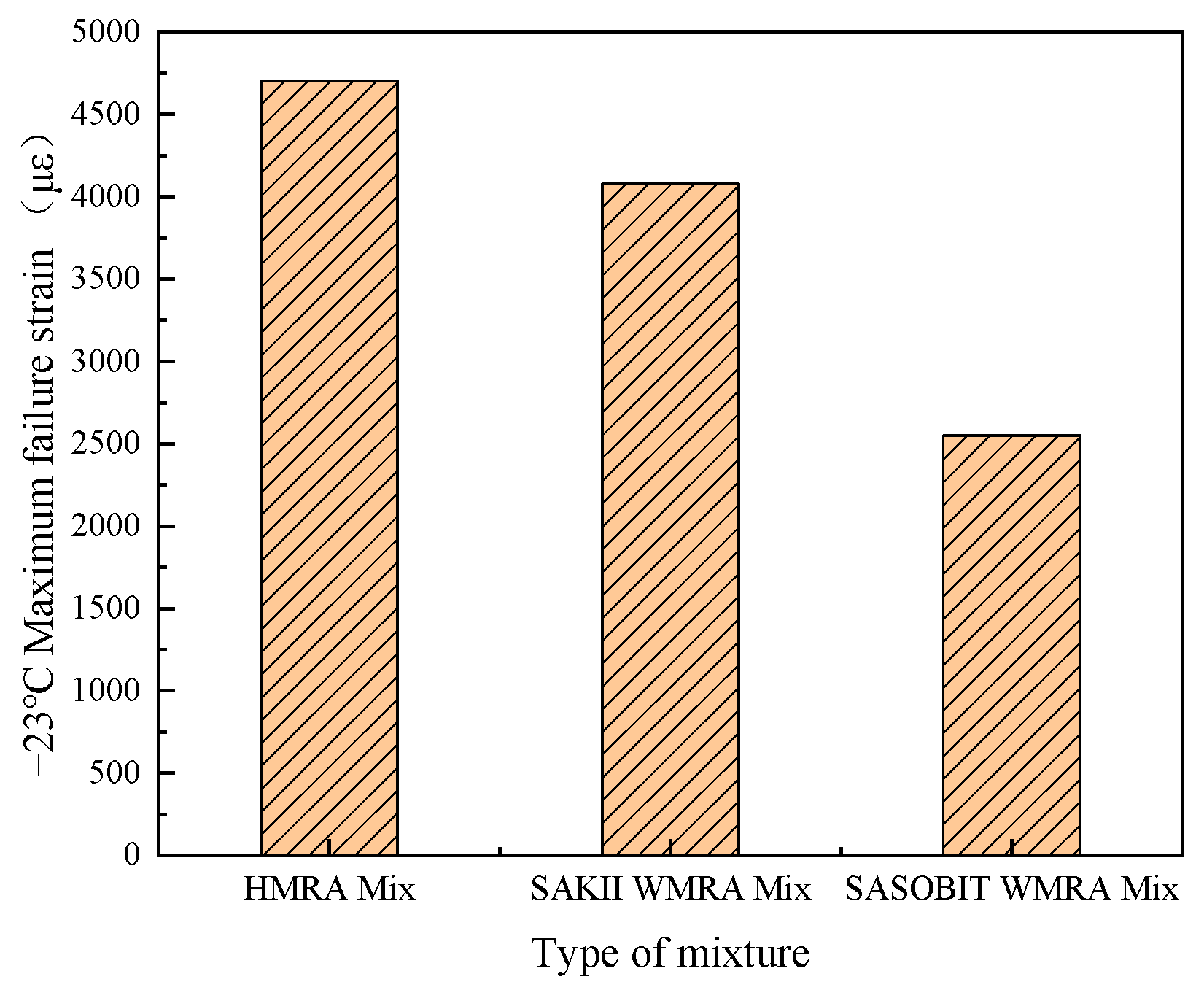

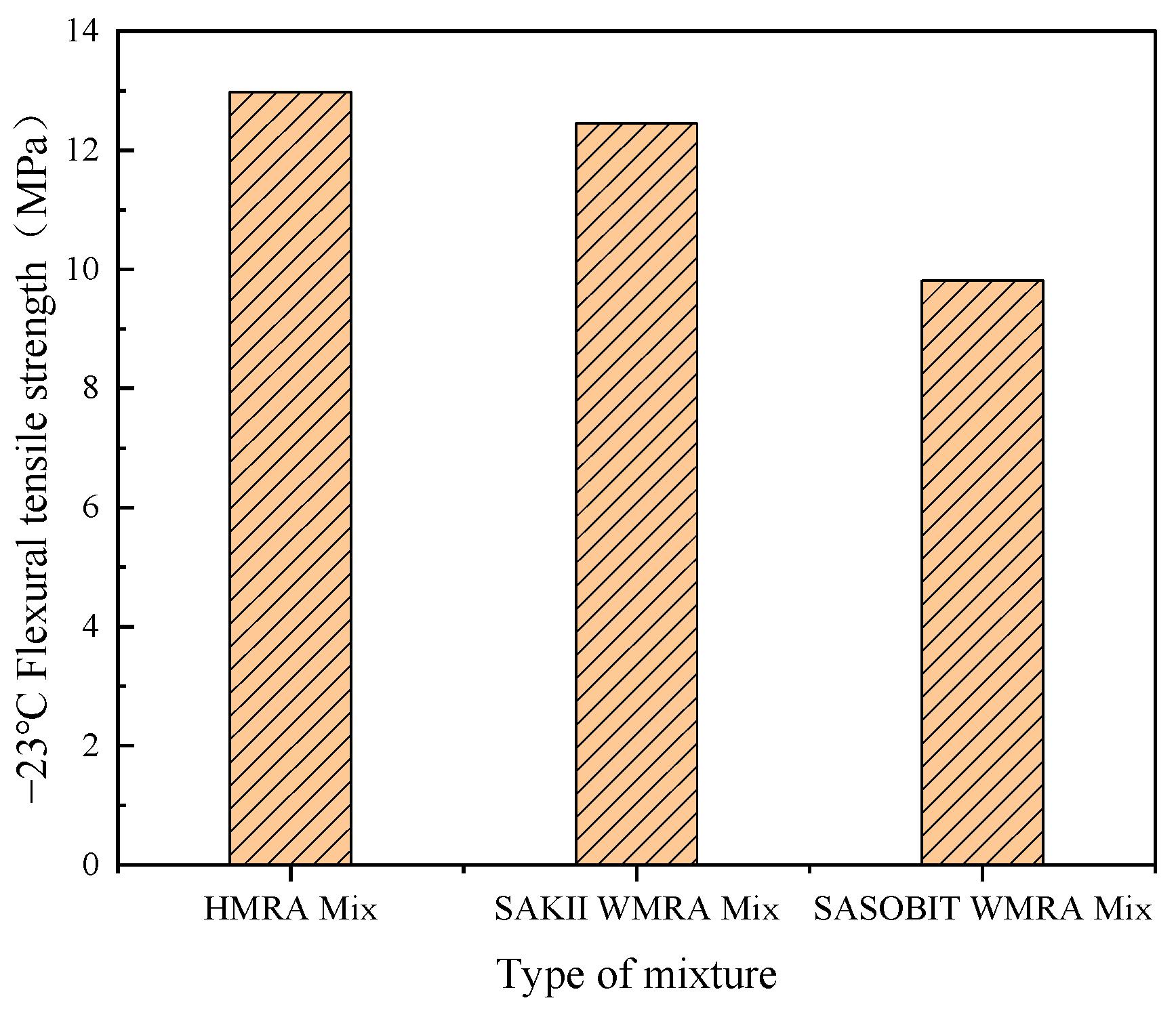

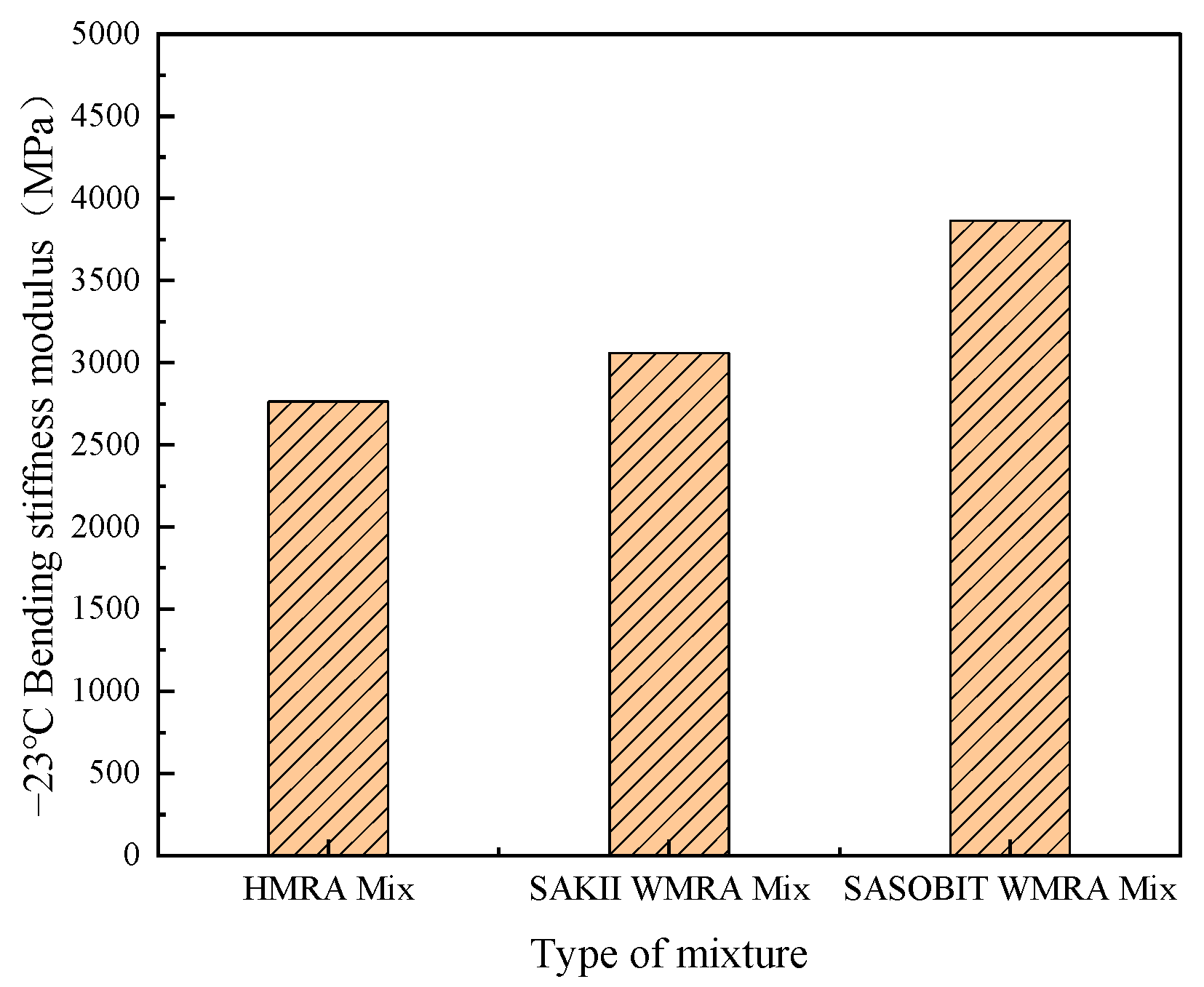

Comparative Research on the Outcomes of Low-Temperature Bending Tests

- Tmin is the lowest pavement design temperature, °C;

- Tair is the average annual minimum temperature, °C.

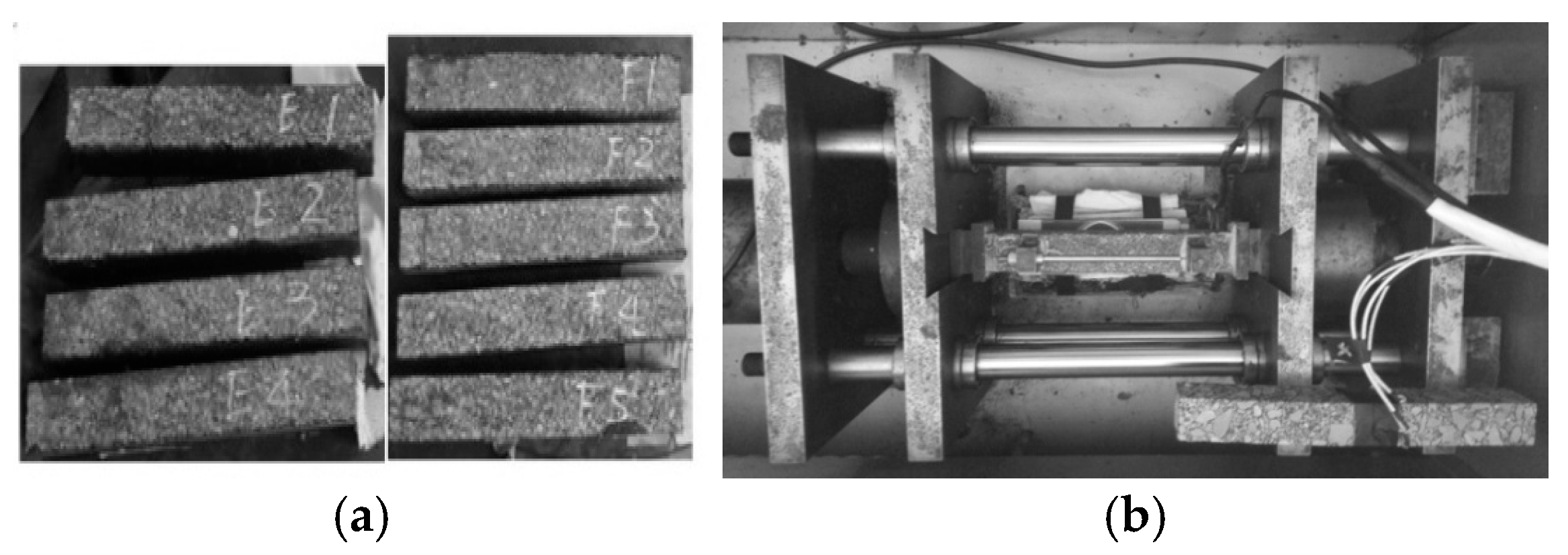

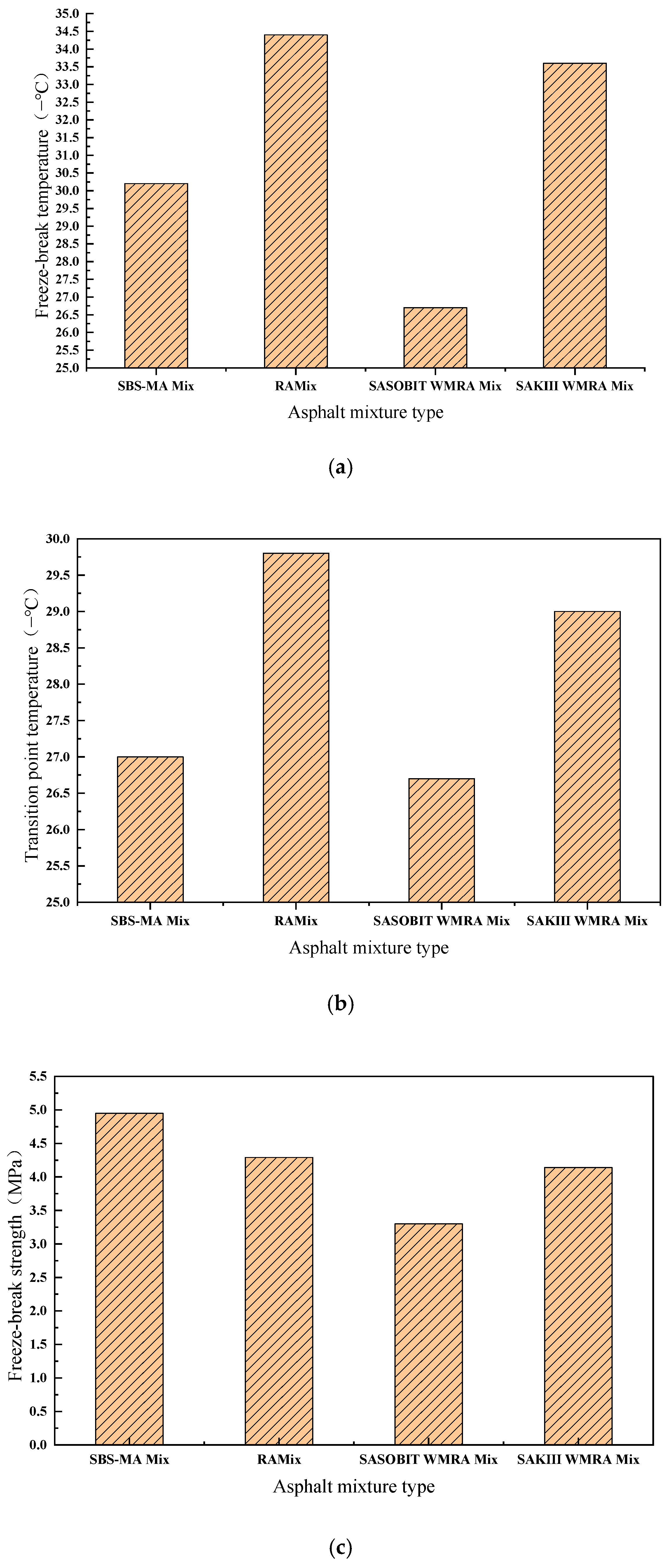

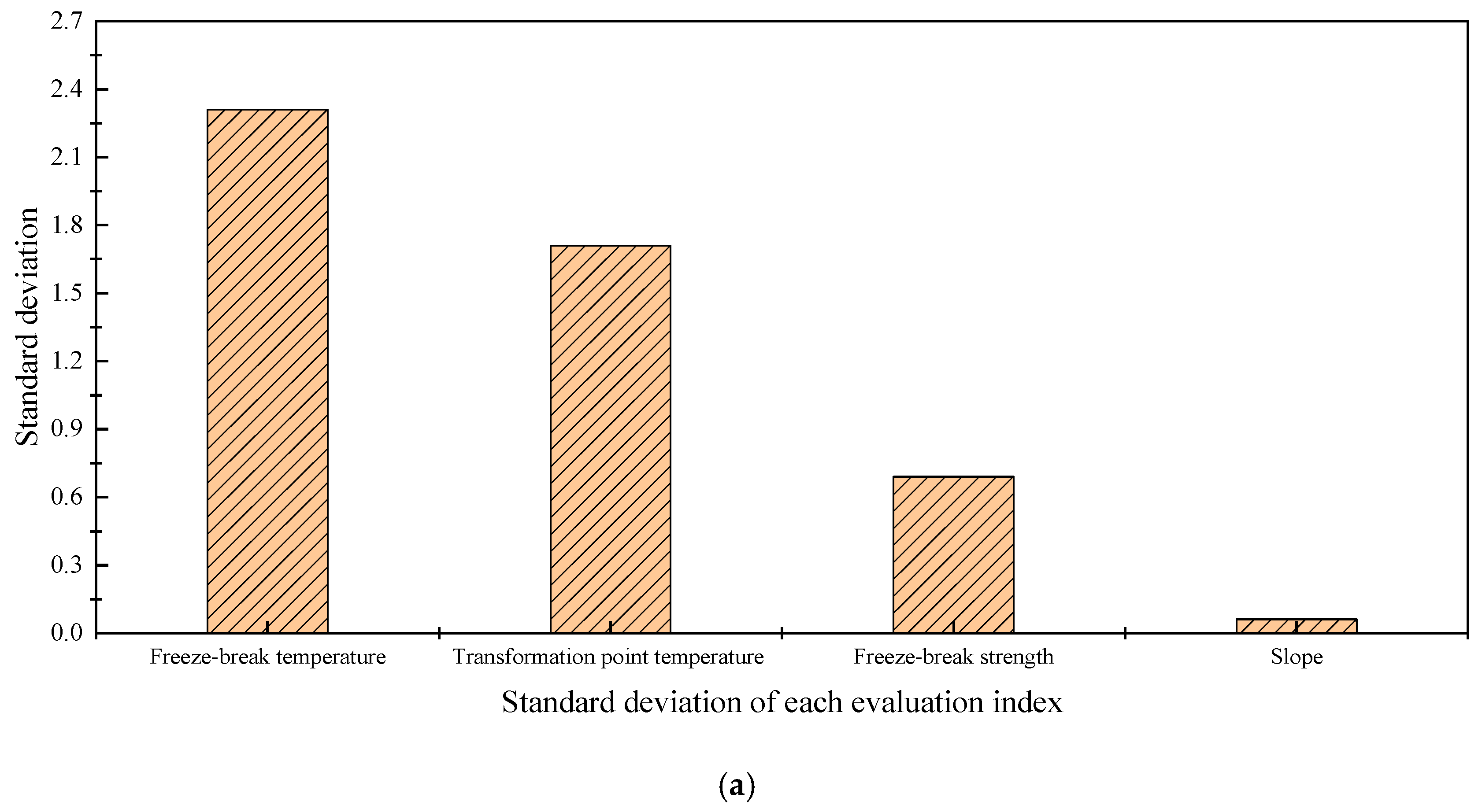

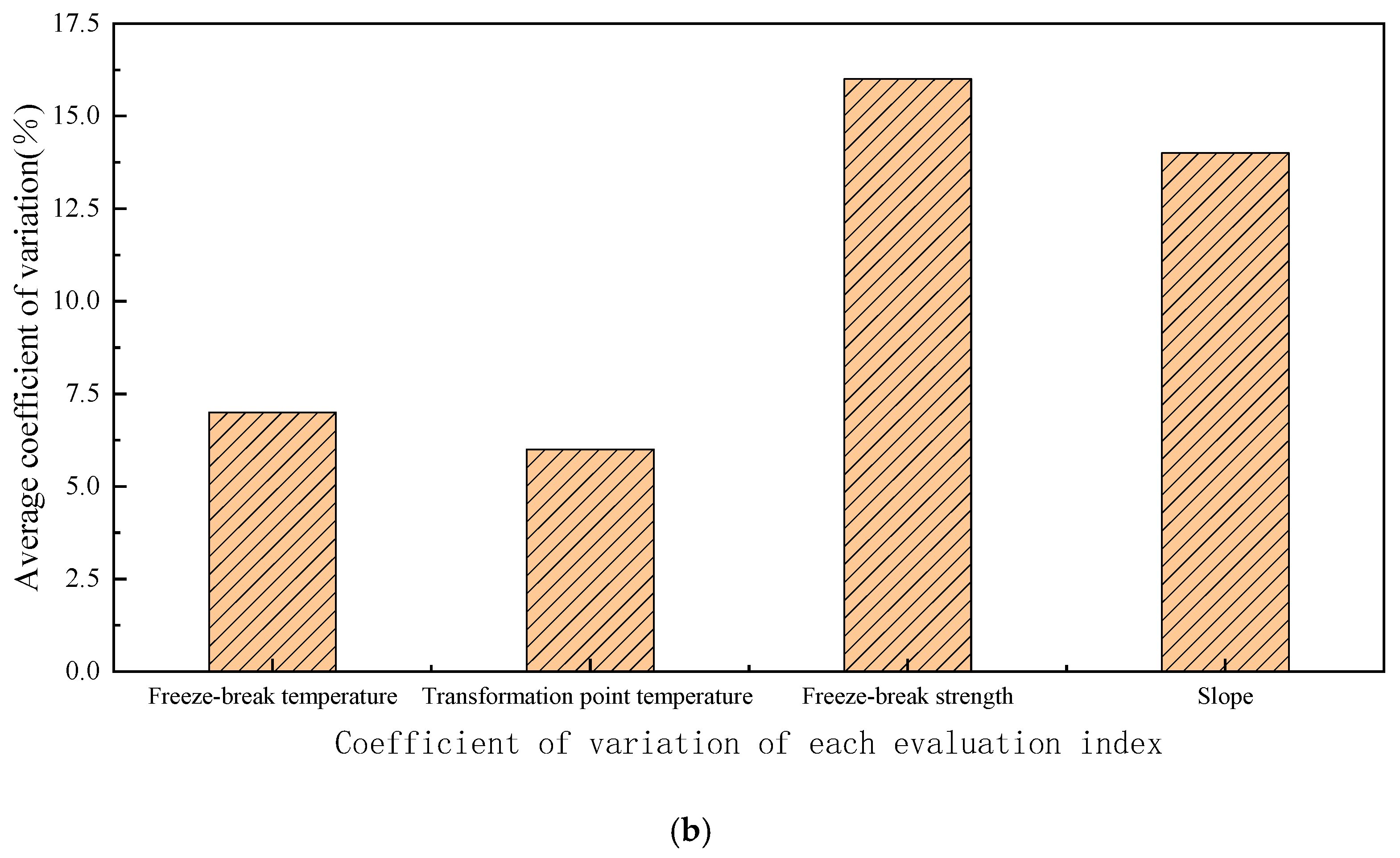

Results and Comparative Study of Freeze-Break Test

3.1.3. Water Stability

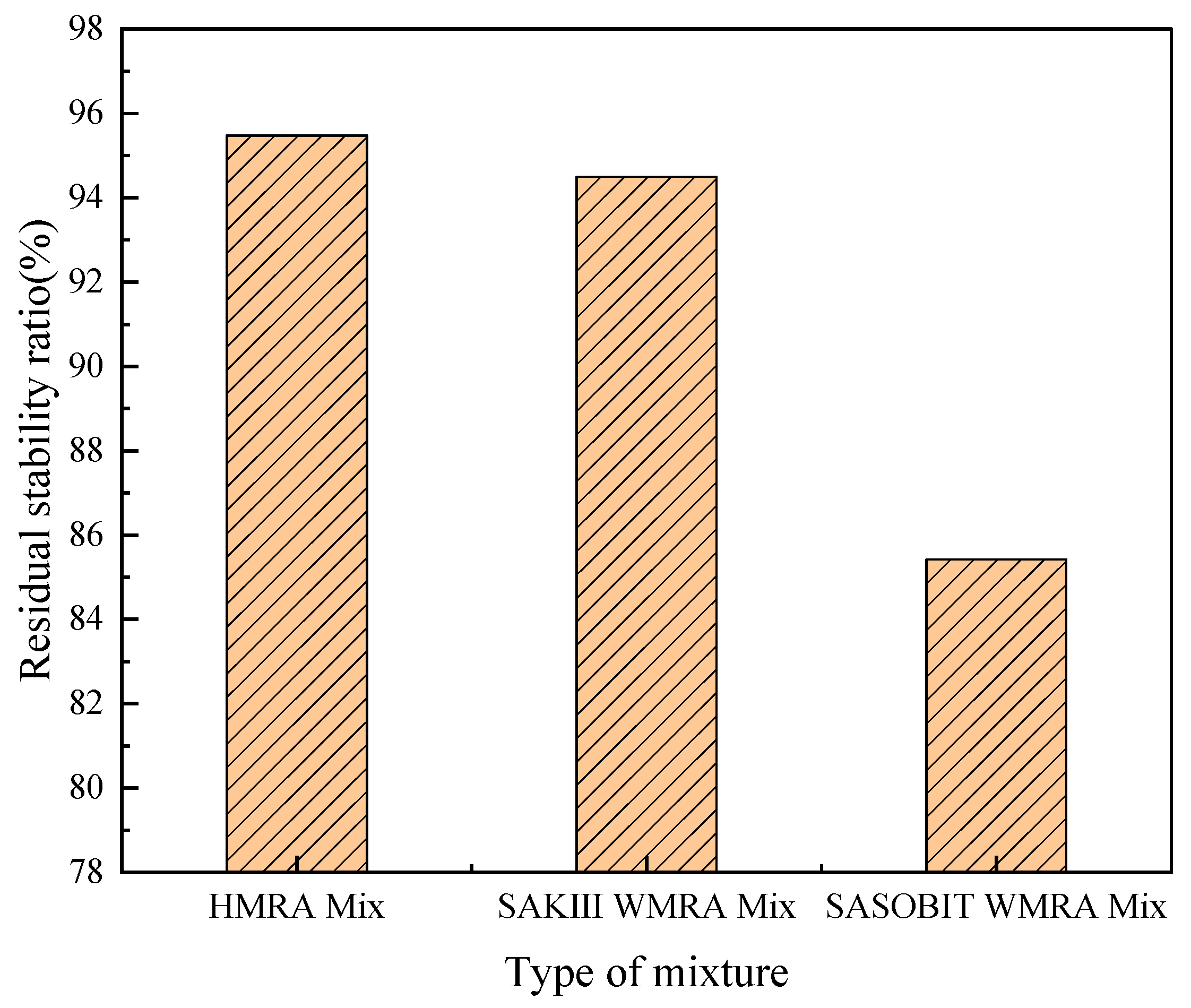

Experimental Results and Comparative Study of Immersed Marshall Stability

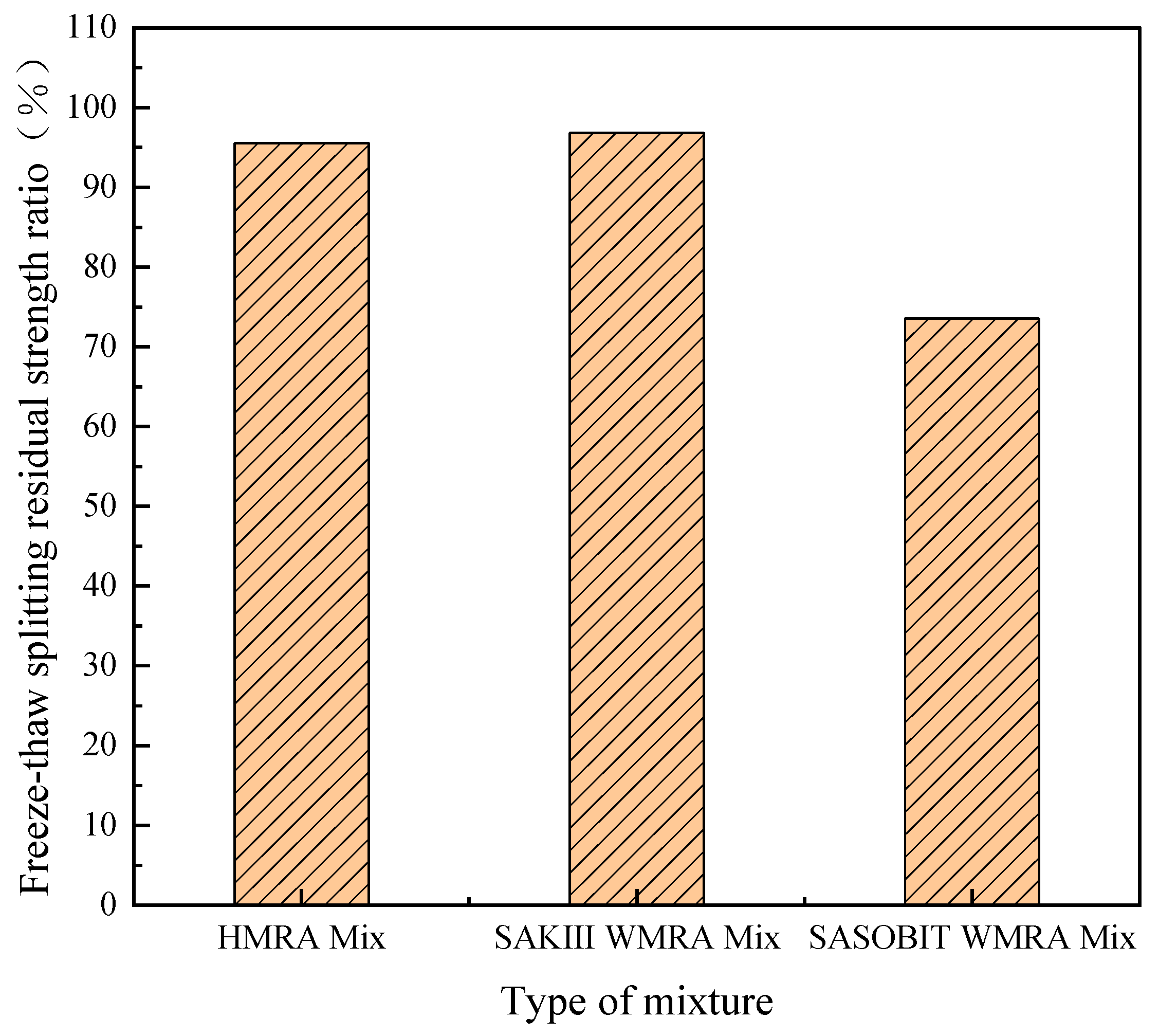

Freeze–Thaw Splitting Test Results and Comparative Study

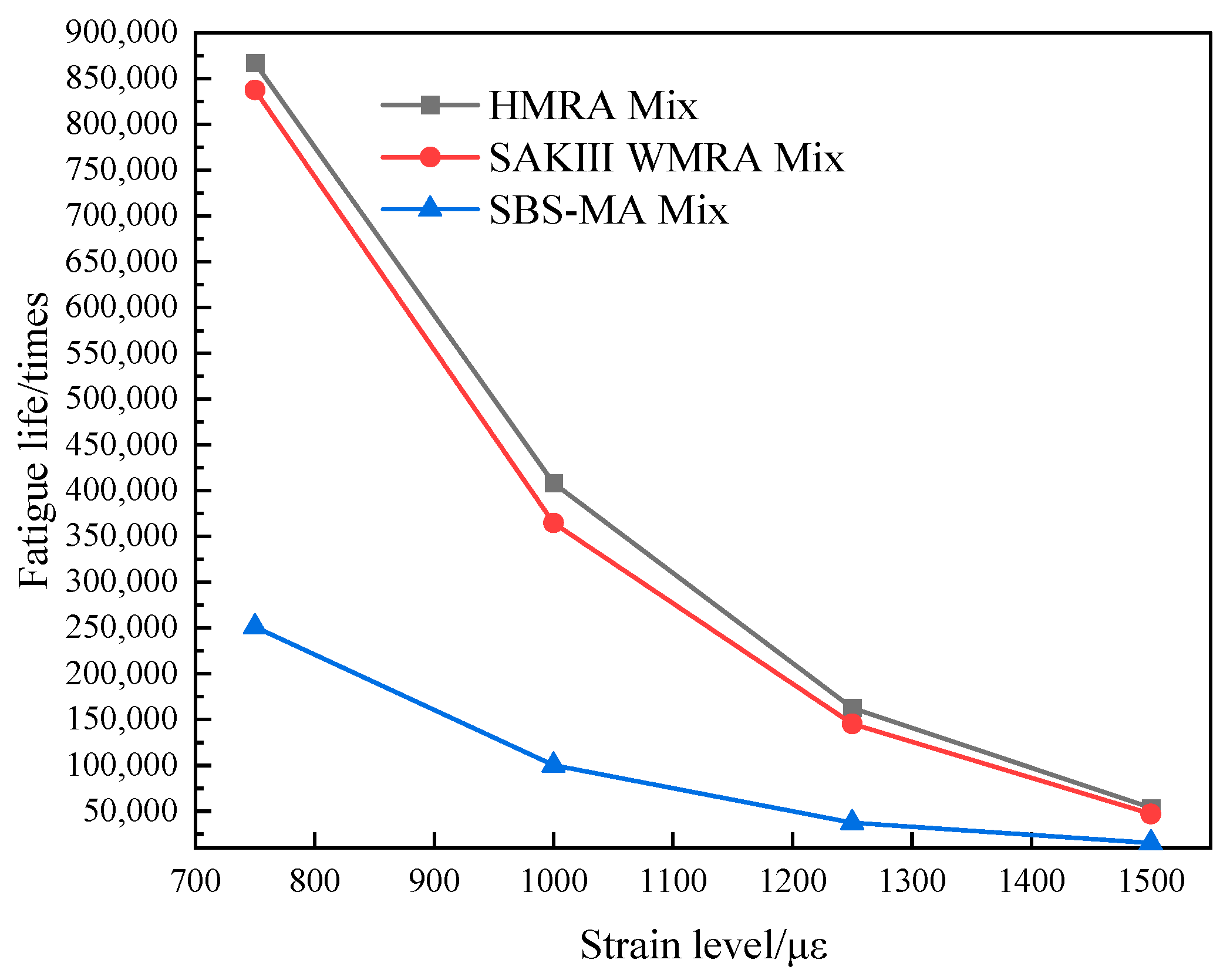

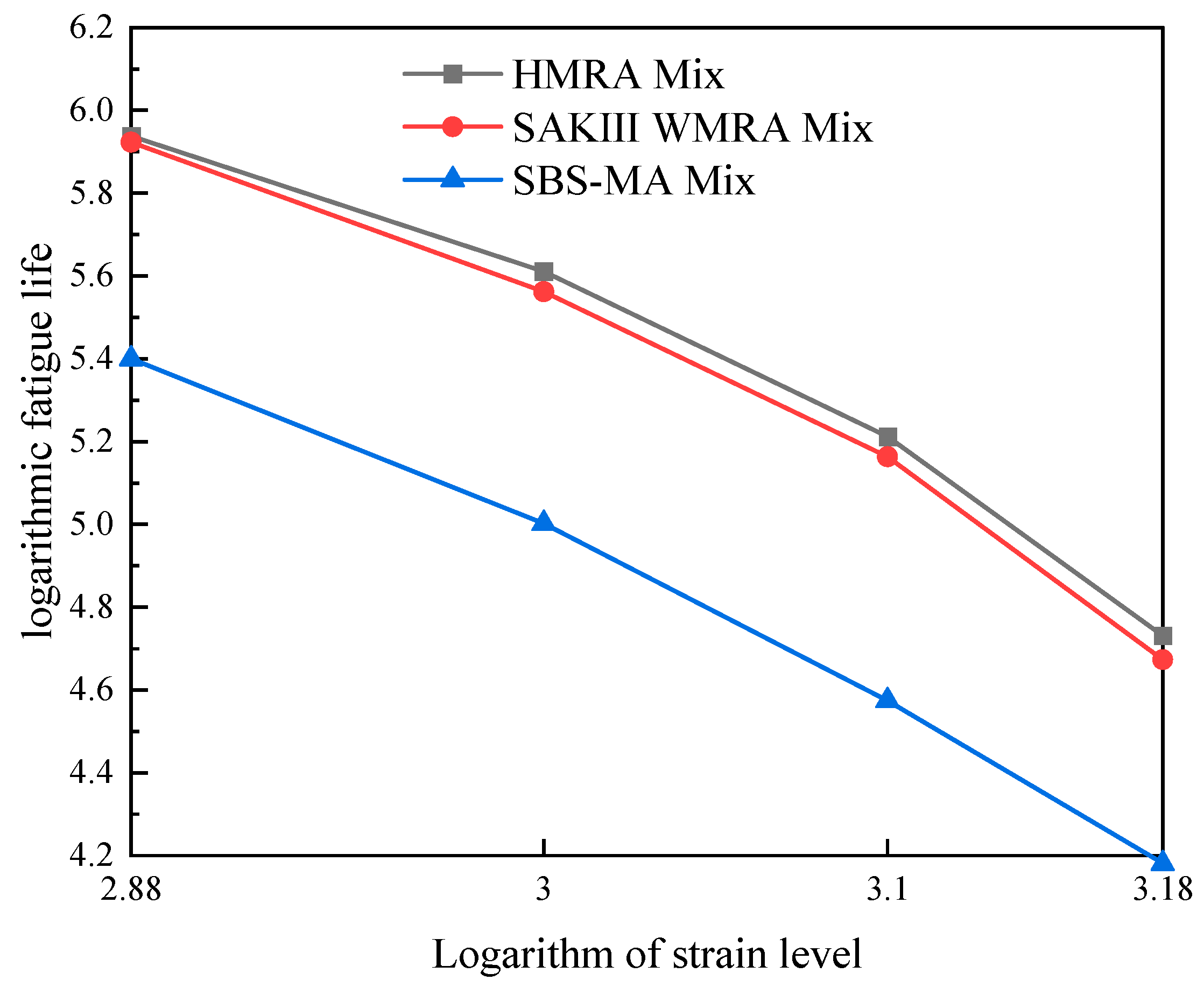

3.2. Analysis of the Fatigue-Resistance Comparison for Three Sorts of Asphalt Mixtures Serving as Stress Absorption Layers in Cold Regions

3.3. Comparative Study on Road Performance of SAKIII WMRA Mix and SBS-MA Mix Used as Stress Absorption Layer in Cold Regions

4. Discussion

4.1. Comparison of Cost and Environmental Impact Between WMRA Mix and Traditional RAMix

4.2. Analysis of the Influence of the Reduction in Compaction Temperature on Energy Consumption and Emission

- Energy consumption

- 2.

- Environmental emissions

4.3. Analysis on the Implications of Stress Absorption Layer Technology of WMRA Mix in Cold-Region Infrastructure

5. Conclusions

- (1)

- The application of SAKIII warm-mixing additive significantly improves the dynamic stability of RAMix, reduces the mixing and compaction temperature, thus improving the performance and durability of the mixture, and achieving energy saving and consumption reduction. Compared with HMRA Mix and SASOBIT WMRA Mix, the high-temperature stability of SAK-III WMRA Mix is outstanding, which far exceeds the requirements of construction technical specifications.

- (2)

- When contrasted with the other two types of rubber–asphalt mixtures, SAKIII WMRA Mix exhibits superior low-temperature crack resistance. Its low temperature performance is equivalent to that of a traditional rubber–asphalt mixture. Even if the temperature for mixing and compaction is decreased by 30 °C, it can still maintain good low-temperature performance, showing strong anti-deformation ability and stress relaxation ability. Freeze-break temperature can evaluate the low temperature anti-crack capacity of WMRA Mix more accurately than freeze-break strength, transformation point temperature, and slope of thermal stress growth.

- (3)

- In comparison to HMRA Mix and SASOBITWMRA Mix, SAKIII WMRA Mix demonstrates superior water stability. Consequently, SAKIII warm-mixing additive is more apt to function as a modifier for the rubberized asphalt. This application can effectively safeguard the long-term stability and durability of pavement performance.

- (4)

- The linear relationship between fatigue and strain in three distinct asphalt mixtures designated as stress absorption layers is remarkably evident. When analyzing the coefficient within the fatigue curve equations, it becomes clear that the k value of WMRA Mix is somewhat lower than that of HMRA Mix. However, it is substantially greater than the k value of SBS-MA Mix. This disparity implies that the fatigue resistance capabilities of WMRA Mix closely approximate those of HMRA Mix, while clearly outperforming SBS-MA Mix. Shifting the focus to the n value in the fatigue curve equations, WMRA Mix presents a value that is slightly elevated compared to HMRA Mix. Conversely, it is significantly lower than that of SBS-MA Mix. Such a difference suggests that the fatigue life of WMRA Mix is more responsive to variations in the strain level when contrasted with HMRA Mix. In contrast, it is far less sensitive than SBS-MA Mix. Evidently, SBS-MA Mix displays an especially high degree of sensitivity to the strain level. These findings offer profound insights into the fatigue-related behaviors of these materials, which can be instrumental in guiding material selection and design strategies in road-building projects. Understanding the fatigue characteristics of the above materials will provide important theoretical support and reference for road construction in cold regions, especially for the application of WMRA Mix.

- (5)

- Even when the temperatures for both mixing and compaction are cut down by 30 °C, RAMix blended with SAKIII warm-mixing additive is able to maintain its outstanding road-performance capabilities. This temperature reduction, which is a key feature of the SAKIII warm-mixing technology, does not compromise the quality of RAMix. Instead, it allows for the production of a high-performance asphalt mixture that can meet the demanding requirements of modern road construction. The unique properties of SAKIII warm-mixing additive enable RAMix to achieve a fine balance between workability at lower temperatures and long-term durability, making it a viable option for various road-building applications. When employed as a stress absorption layer in cold regions, WMRA Mix presents distinct advantages over SBS-MA Mix. It features better road performance, a longer service life, and lower energy consumption along with reduced carbon emissions, all of which align with the demands of sustainable development.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gao, Y.; Wang, W.; Zhao, Q. Crack Reflection of Semi-rigid Base Asphalt Pavement Based on Analytical Method. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2018, 37, 49–54+68. [Google Scholar]

- Cheng, P.; Li, H. Based on Abaqus of Paving Asphalt Layer Structure of Old Cement Concrete Pavement Mechanics. Highw. Eng. 2017, 42, 9–12. [Google Scholar]

- Gkyrtis, K.; Pomoni, M. An Overview of the Recyclability of Alternative Materials for Building Surface Courses at Pavement Structures. Buildings 2024, 14, 1571. [Google Scholar] [CrossRef]

- Feng, Z. Research on the Application of Rubberized Asphalt Aggregate Stress Absorbing Layer in Pavement Maintenance and Repair. Transpo World 2023, 100–101. [Google Scholar]

- Deng, H.; Ma, X.; Deng, D.; Tan, L. Research on Application of Rubber Asphalt Composite Seal in Renovation Project of Cement Pavement. North. Commun. 2021, 50–53. [Google Scholar]

- Wang, Q.; Tan, Q.; Chen, H. Study on influencing factors of construction temperature of rubber asphalt stress absorbing layer. Shanxi Archit. 2021, 64–68. [Google Scholar]

- Yang, J. Engineering Experimental Study on Stress Absorbing Layer of Stable asphalt rubber Mixture. Transpo World 2019, 27–29. [Google Scholar]

- Shi, Z.; Wand, B. Analysis on the advantages of popularizing warm mix rubber asphalt in Heilongjiang Province. Shanxi Archit. 2020, 46, 95–97. [Google Scholar]

- Thives, L.P.; Pais, J.C.; Pereira, P.A.A. Performance of Asphalt Rubber Mixture Overlays to Mitigate Reflective Cracking. Materials 2022, 15, 2375. [Google Scholar] [CrossRef]

- Sukhija, M.; Saboo, N. A comprehensive review of warm mix asphalt mixtures—Laboratory to field. Constr. Build. Mater. 2021, 274, 121781. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, S.; Wang, X.; Dong, Z.; Han, H.; Wang, H.; Liu, J. Study on the Influence of Sasobit Warm Mixing Agent on the Performance of SBS Modified Asphalt and Mixture. J. Wuhan Univ. Technol. 2024, 48, 974–978. [Google Scholar]

- Mao, S. Study on Performances of Warm Minxing Rubber Modified Asphalt Mixture in Cold Regins. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2019; pp. 20–26. [Google Scholar]

- Li, F.; Zhang, X.; Wang, L.; Zhai, R. Economic and environmental analysis of crumb rubber modified asphalt. Constr. Build. Mater. 2022, 335, 127468. [Google Scholar]

- Cao, X. Study influencing factors of rubber asphalt performance based on orthogonal experimental design. China Build. Mater. Sci. Technol. 2021, 10, 78–81. [Google Scholar]

- Pan, R.; Cheng, P. Grading design and road use performance of warm mix rubber asphalt mixture suitable for stress absorbing layer in cold region. World Earthq. Eng. 2015, 31, 161–166. [Google Scholar]

- Li, Q.; Meng, Y.; Li, N.; Li, G.; Wang, J. Characterization of fatigue performance of the warm-mix recycled asphalt mixture using different models. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 175–186. [Google Scholar] [CrossRef]

- Ma, T. Application of high performance stress absorbing layer in highway engineering. Transpo World 2024, 27–30. [Google Scholar]

- Chu, Y.; Wang, A.; Zhu, Y.; Wang, H.; Liu, K.; Ma, R.; Guo, L.; Sun, D. Enhancing the performance of basic magnesium sulfate cement—Based coral aggregate concrete through gradient composite design technology. Compos. Part B Eng. 2021, 227, 109382. [Google Scholar] [CrossRef]

- Tang, H.; Yuan, W.; Bian, J.; Wang, J.; Sun, H.; Li, S.; Feng, Z.; Li, J. Comparative Experimental Study on the Effects of Superpave and Marshall Design Methods on the Performance of AC-20 Asphalt Mixture. Tianjin Constr. Sci. Technol. 2024, 34, 25–28. [Google Scholar]

- Ji, X.; Song, X.; Shao, J. Research on the construction technology of composite modified rubber asphalt mixture. Qinghai Transp. Sci. Technol. 2022, 34, 63–67. [Google Scholar]

- Ma, Z.B. Research on the Anti-permanent Deformation Asphalt Mixture with Different Ability of Warm-recycled Rap Content. North. Commun. 2022, 38–40. [Google Scholar]

- Yang, Y. Study on the Performance of Warmly MixHigh Adhesive Asphalt Mixture Based on Water Damage. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2021; pp. 58–65. [Google Scholar]

- Liu, X. Test on rutting resistance of rubber powder modified asphalt pavement. China Highw. 2022, 106–109. [Google Scholar]

- Shen, C.; Wu, Z.; Xiao, P. Experimental Research on the Anti-Reflection Crack Performance of Basalt Fiber Modified Rubber Asphalt Stress-Absorbing Layer. Materials 2024, 17, 2013. [Google Scholar] [CrossRef]

- Yan, M. Research on construction technology of Superpave asphalt pavement of expressway. Constr. Mater. Decor. 2018, 212–213. [Google Scholar]

- Nan, X.; Zhu, J.; Wang, F. Analysis of Road Performance of the Asphalt-foam and Foaming Asphalt Warm Mixture. Sci. Technol. Eng. 2019, 19, 221–233. [Google Scholar]

- Rangan, P.R.; Tumpu, M. Marshall Test Characteristics of AC-BC Mixture to Determination of Optimum Asphalt Content and Marshall Immersion Index Using Portland Composite Cement As Filler. ARPN J. Eng. Appl. Sci. 2023, 17, 1666–1673. [Google Scholar]

- Rahbar-Rastegar, R.; Pouranian, M.R. Superpave 5: Improving Asphalt Mixture Performance. In ISBM 2020, Proceedings of the RILEM International Symposium on Bituminous Materials, Lyon, France, 14–16 December 2020; Springer: Berlin/Heidelberg, Germany, 2021; pp. 2235–2243. [Google Scholar]

- Kassab, T. Comparative Study of Hot Asphalt Mixtures Properties Designed by Marshall and Superpave Methods. Mansoura Eng. J. 2021, 46, 40–51. [Google Scholar] [CrossRef]

- Gao, C. Study on temperature of construction of warm mixed asphalt mixture in low temperature environment. Commun. Sci. Technol. Heilongjiang 2023, 46, 42–44. [Google Scholar]

- Li, C.; Li, B.; Cai, J.; Ji, Y. Modified Temperature Calculation Model of Asphalt Pavement BearingCapacity Based on Measured Data. Constr. Qual. 2023, 41, 34–40. [Google Scholar]

- Niu, Z. Low Temperature Crack Resistance of Large DoseRubber/Polyester Fiber SMA Asphalt Mixes. Master’s Thesis, AnHui University of Science and Technology, Chongqing, China, 2022; pp. 29–51. [Google Scholar]

- Xu, J.; Yang, E.; Wang, S. Study on Low Temperature Performance Evaluation Indicator of Sasobit Warm Mix Asphalt. J. Highw. Transp. Res. Dev. 2020, 37, 8–14+39. [Google Scholar]

- Chen, H.; Ao, F.; He, Q.; Yan, C. Preparation and Performance of Warm Mix Crack Filling Materialfor Bituminous Pavement in Alpine Region. J. Civ. Eng. Manag. 2021, 38, 95–100. [Google Scholar]

- Praveen, K.; Chauhan, M.S. Experimental Investigation on Warm Mix Using Zycotherm as a Chemical Additive with PMB 40 in Mix Design of Flexible Pavement. Des. Eng. 2015, 2, 8–14+39. [Google Scholar]

- Wang, Z.; Guo, K.; Liu, D.; Meng, H.; Wang, G. Factors influencing the cracking resistance of rubber asphalt mixture and sensitivity analysis. New Build. Mater. 2023, 50, 151–155. [Google Scholar]

- Zhang, L. Asphalt Mixture Low-Temperature Cracking and Relaxation Characteristic Research. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2010; pp. 50–64. [Google Scholar]

- Xu, J. Study on Evaluation Index of Low Temperature Performance of Rubber Asphalt. J. Lanzhou Inst. Technol. 2018, 25, 34–38. [Google Scholar]

- Yuan, Y.; Gao, B. The analysis of volume characteristics for warm rubber asphalt mixture based on gyratory compaction method. Shanxi Archit. 2020, 46, 102–103. [Google Scholar]

- Xu, J.-Y.; Ma, B.; Mao, W.-J. Review of interfacial adhesion between asphalt and aggregate based on molecular dynamics. Constr. Build. Mater. 2023, 362, 129642. [Google Scholar] [CrossRef]

- Li, Z.; Hao, Y.; Yuan, X.; Zhuang, C. Fatigue Performance of Qingchuan Rock Modified Asphalt Mixtureunder Accelerated Loading Test. J. China Foreign Highw. 2024, 44, 78–84. [Google Scholar]

- Lu, H. Discussion on engineering technology of modified asphalt pavement. Transp. Constr. Manag. 2023, 107–109. [Google Scholar]

- Ahematiniazi, A. Research on Road Performance and Construction Technology of Asphalt Mixture Based on Rubber. Constr. Mach. Maint. 2023, 259–261. [Google Scholar]

- Wei, X. Analysis of Construction Technology of Warm Mixed Rubber Asphalt Mixture. Constr. Des. Eng. 2023, 182–184. [Google Scholar]

- Wei, X. Energy Saving and Emission Reduction of Warm Mix Rubber Asphalt Mixture. Road Mach. Constr. Mech. 2018, 35, 68–71+76. [Google Scholar]

- Lai, H.; Zhai, J.; Liang, M.; Xiong, R. Research progress on characterization means of asphalt smoke emission and smoke suppression technology. In Proceedings of the 2023 World Transportation Conference (WTC2023) (Part I), Wuhan, China, 14–17 June 2023; pp. 61–66. [Google Scholar]

- Liu, J. Study on Water Stability of Asphalt Rubber Mixture in Seasonal Frost Region. Master’s Thesis, Shenyang jianzhu university, Shenyang, China, 2021; pp. 8–13. [Google Scholar]

- Zhang, C. Prediction and Evolvement Rules of Transverse Cracking for Asphalt Pavement in High Altitude Cold Regions Based on the Regional Characteristics. Ph.D. Thesis, Chang’an University, Xi’an, China, 2018; pp. 1–5. [Google Scholar]

- Qin, L.; Luo, C.; Huancu, Z.; Li, J. Effect of Different Warm Mixing Agent on Properties of Rubber Asphalt Mixture. Sci. Technol. Ind. 2023, 23, 149–154. [Google Scholar]

- Hu, D. Study on Influencing Factors of High Performance Stress Absorbing Layer in Highway Engineering. Constr. Mach. Maint. 2022, 269–271. [Google Scholar]

| Testing Element | Penetration (0.1 mm) | Ductility (cm) | Softening Point (°C) | Viscosity (Pa·s) | Elastic Recovery (%) |

|---|---|---|---|---|---|

| Measured value | 67 | 18.0 | 62.9 | 2.398 | 88 |

| Gradation | The Rate of Passing Through Each Sieve Opening | |||||||

|---|---|---|---|---|---|---|---|---|

| 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| Gradation I | 100.0 | 98.0 | 62.4 | 43.2 | 29.6 | 18.5 | 12.9 | 8.40 |

| Gradation II | 100.0 | 98.9 | 71.6 | 49.7 | 34.2 | 21.8 | 15.4 | 10.2 |

| Gradation III | 100.0 | 99.1 | 73.9 | 51.7 | 35.8 | 23.0 | 16.4 | 11.0 |

| Rubber–Asphalt Mixture Type | Mixing Compaction (°C) | Compaction Temperature (°C) | Dynamic Stability (times/mm) | Specification Requirements (times/mm) (China’s Design Standards for Highway Asphalt Pavements) |

|---|---|---|---|---|

| HMRA Mix | 200 | 180 | 3810 | >2400 |

| SAKIII WMRA Mix | 170 | 150 | 4875 | >2400 |

| SASOBIT WMRA Mix | 180 | 160 | 4060 | >2400 |

| Scheme Type | Structural Form | Dynamic Stability (times/mm) |

|---|---|---|

| Scheme A | 12.5 cm asphalt mixture | 4780 |

| Scheme B | 10 cm asphalt mixture + stress absorption layer of 2.5 cm HMRA Mix | 4595 |

| Scheme C | 10 cm asphalt mixture + stress absorption layer of 2.5 cm SAKIII WMRA Mix | 4715 |

| Scheme D | 10 cm asphalt mixture + stress absorption layer of 2.5 cm SASOBIT WMRA Mix | 4630 |

| Type of Mixture | Maximum Failure Load (kN) | Maximum Damage Deflection (mm) | Flexural Tensile Strength (MPa) | Maximum Failure Strain (με) | Bending Stiffness Modulus (MPa) |

|---|---|---|---|---|---|

| HMRA Mix | 1590.00 | 1.36 | 13.00 | 4701.9 | 2764.8 |

| SAKIII WMRA Mix | 1515.01 | 1.165 | 12.48 | 4079.9 | 3058.9 |

| SASOBIT WMRA Mix | 1140.01 | 0.80 | 9.85 | 2549.9 | 3862.9 |

| Type of Mixture | Freeze-Break Temperature (°C) | Transition Point Temperature (°C) | Freeze-Break Strength (MPa) | Slope |

|---|---|---|---|---|

| SBS-MA Mix | −30.2 | −27.0 | 4.95 | 0.367 |

| RAMix | −34.4 | −29.8 | 4.29 | 0.481 |

| SASOBIT WMRA Mix | −26.7 | −26.7 | 3.30 | 0.363 |

| SAKIII WMRA Mix | −33.6 | −29.0 | 4.14 | 0.412 |

| Mixture Specimen Type | Residual Stability Ratio (%) | Specification Requirements (times/mm) (Highway Asphalt Pavement Design Code in CHINA) |

|---|---|---|

| HMRA Mix | 95.48 | >85 |

| SAKIII WMRA Mix | 94.50 | >85 |

| SASOBIT WMRA Mix | 85.42 | >85 |

| Mixture Specimen Type | Freeze–Thaw Splitting Residual Strength Ratio (%) | Specification Requirements (/mm) (China’s Design Standards for Highway Asphalt Pavements) |

|---|---|---|

| HMRA Mix | 95.52 | >75 |

| SAKIII WMRA Mix | 96.80 | >75 |

| SASOBIT WMRA Mix | 73.52 | >75 |

| Mixture Specimen Type | Asphalt Content (%) | Dynamic Stability (time/mm) | Bending Strain (με) | Freeze–Thaw Splitting Strength Ratio (%) |

|---|---|---|---|---|

| SAKIII WMRA Mix | 8.9 | 4875 | 4081 | 96.80 |

| SBS-MA Mix | 6.3 | 4550 | 3215 | 89.21 |

| Comparative Term | WMRA Mix | Traditional Method |

|---|---|---|

| cost | ||

| initial investment | Relatively high | higher |

| operating costs | Relatively low | higher |

| energy consumption | lower | higher |

| Comprehensive cost | medium | higher |

| environmental effect | ||

| energy consumption | lower | higher |

| CO2 emission | lower | higher |

| Scrap/waste | lower | higher |

| Pollution of soil/water sources | lower | higher |

| noise pollution | lower | higher |

| Visual influence | lower | higher |

| Mixture Type | Reduce the Value of Compaction Temperature (°C) | Energy Saving Situation |

|---|---|---|

| RAMix | None (conventional high temperature construction) | As a comparison benchmark, energy consumption is at a high level, and there is no energy-saving effect brought by reducing compaction temperature. |

| FOAM WMRA mix | Compared with the hot-mixed rubber–asphalt mixture, it is significantly reduced. | The production of 1000 m3 FOAM WMRA mix can save about 1.69 t of heavy oil, which is equivalent to 2.4 t of standard coal. |

| SMC WMRA mix | 30–60 | It can save fuel by 20–30%. |

| FOAM WMRA mix | Around 30 | Compared with a hot-mixed asphalt mixture, it can save 30% of energy consumption. |

| SAK WMRA mix | 25–35 | Under the same construction scale, compared with the conventional HMRA Mix, the energy consumption is reduced by about 22%, which means that the energy equivalent to 1.8 t standard coal can be saved for every certain amount of mixture (for example, 1000 m3). |

| SASOBIT WMRA mix | 20–30 | Using the SASOBIT warm-mixing additive can save energy equivalent to 2 t of standard coal for every 1000 m3 mixture produced. After the construction temperature is lowered, the energy consumption in the mixing process is obviously reduced. |

| Mixture Type | Reduce the Value of Compaction Temperature (°C) | Major Emission Reductions and Their Reduction. |

|---|---|---|

| RAMix | None (conventional high temperature construction) | Emissions of a large number of pollutants, such as the production of 1000 m, CO emissions are large, and there is no emission reduction advantage, which is a high emission reference for the comparison of various warm mix types. |

| FOAM WMRA mix | Compared with the hot-mixed rubber–asphalt mixture, it is significantly reduced. | Production of 1000 m3 foam warm-mixed rubber–asphalt mixture can reduce CO by about 6.3 t, CO by about 317 kg and NOx by about 107 kg; The emission reduction efficiency of CO2 is 8.1%, and the emission reduction efficiencies of CO, NOx and SO2 are 65.0%, 73.3% and 75.0%, respectively. |

| WMRA mix | 40–60 | Reduce greenhouse gas emissions such as carbon dioxide by more than 50%, and reduce toxic gas emissions such as asphalt smoke by more than 80%. |

| SAK WMRA mix | 25–35 | Compared with the traditional hot-mixed rubber–asphalt mixture, when producing 1000 m3 mixture, the CO2 emission reduction is about 5.5 t, and the emission reduction efficiency reaches 7.5%. CO emission reduction is about 280 kg, and the emission reduction efficiency is about 60%; NOx emission reduction is about 95 kg, and the emission reduction efficiency is about 68%. |

| SASOBIT WMRA mix | 20–30 | When producing 1000 m3 mixture, CO2 emission reduction is about 5 t, and the emission reduction efficiency is about 7%. CO emission reduction is about 250 kg, and the emission reduction efficiency is about 55%; NOx emission reduction is about 85 kg, and the emission reduction efficiency is about 65%, which effectively reduces harmful gas emissions. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, R.; Chang, J.; Chen, Y. Study on Composition Design and Performance Characteristics of Warm-Mixed Rubber–Asphalt Mixture for Cold-Region Stress Absorption Layers. Buildings 2025, 15, 1164. https://doi.org/10.3390/buildings15071164

Pan R, Chang J, Chen Y. Study on Composition Design and Performance Characteristics of Warm-Mixed Rubber–Asphalt Mixture for Cold-Region Stress Absorption Layers. Buildings. 2025; 15(7):1164. https://doi.org/10.3390/buildings15071164

Chicago/Turabian StylePan, Rui, Jifeng Chang, and Yu Chen. 2025. "Study on Composition Design and Performance Characteristics of Warm-Mixed Rubber–Asphalt Mixture for Cold-Region Stress Absorption Layers" Buildings 15, no. 7: 1164. https://doi.org/10.3390/buildings15071164

APA StylePan, R., Chang, J., & Chen, Y. (2025). Study on Composition Design and Performance Characteristics of Warm-Mixed Rubber–Asphalt Mixture for Cold-Region Stress Absorption Layers. Buildings, 15(7), 1164. https://doi.org/10.3390/buildings15071164