Abstract

This study investigates the effects of incorporating recycled coarse aggregates (RCAs) at different substitution rates on the mechanical and fracture properties of recycled aggregate concrete (RAC). Four concrete mixtures were prepared: a reference mixture using natural coarse aggregates (NCAs) and three RAC mixtures in which 30%, 60%, and 100% of the NCA mass was replaced with RCAs. The RAC mixtures were compared to natural aggregate concrete (NAC) in terms of compressive strength, splitting tensile strength, modulus of elasticity, hydration rate, water-accessible porosity, pore size distribution, post-peak behavior, and fracture energy. The results show that as the RCA substitution rate increases, the RAC porosity rises and its modulus of elasticity decreases. However, the compressive strength and splitting tensile strength remain comparable to, or even exceed, those of NAC, with optimal performance observed at a 60% substitution rate. This optimal behavior can be attributed to a more favorable pore distribution and an increased hydration rate. For an equivalent strength class, RAC with up to 60% RCA substitution exhibits post-peak behavior and fracture energy comparable to NAC. However, at a 100% substitution rate, the behavior becomes more brittle, and fracture energy decreases by 23.20%.

1. Introduction

The use of construction and demolition waste as recycled coarse aggregates (RCAs) in concrete production, replacing natural coarse aggregates (NCAs), effectively addresses two major challenges: the depletion of natural resources and the accumulation of concrete waste. This approach is crucial for enhancing the sustainability of the construction industry [1,2].

The main difference between NCAs and RCAs lies in the presence of adhered mortar on the surface of RCAs [3]. Depending on the shape and amount of adhered mortar, RCAs can be classified into three categories: aggregates with partially adhered mortar, aggregates fully covered with mortar, and aggregates primarily composed of residual mortar [4,5].

The characteristics of RCA are strongly influenced by the quantity and quality of the residual mortar attached to them [4,6]. The mortar content depends on three main factors: the properties of the original concrete, the crushing method employed, and the size fraction produced (with larger aggregates generally containing less adhered mortar) [4,7,8]. Compared to NCAs, RCAs exhibit distinct characteristics, including lower bulk density, higher porosity, greater water absorption capacity, and lower mechanical strength [3].

The presence of adhered mortar results in the formation of two distinct interfacial transition zones (ITZs) in RAC: an old ITZ between the original aggregate and the adhered mortar, and a new ITZ between the existing mortar and the new cement matrix. Nanoindentation measurements have revealed that the thickness of the old ITZ typically ranges from 40 to 50 µm, while the new ITZ measures between 55 and 65 µm [9,10].

These two ITZs exhibit distinct characteristics, particularly the high porosity and presence of initial microcracks in the old ITZ, which significantly influence the properties of RAC. The high porosity and microcracking in the old ITZ increase water demand and reduce water availability in the new ITZ, potentially impeding the initial hydration process. However, this absorbed water can later promote hydration through an internal curing mechanism, contributing to the long-term densification of both ITZs [10].

The characteristics of the ITZs are influenced by several factors. The quality of the mortar attached to the RCA plays an important role, while the quantity of this mortar has no significant effect on these characteristics [10]. Additionally, the moisture state of the RCA also affects the properties of the ITZs [11,12,13].

Previous studies have examined the impact of the moisture state of RCAs on the properties of the ITZs [11,12,13]. However, the conclusions of these studies are divergent. Leite et al. [12] found that concretes made with dry RCAs developed a distinct network of macropores around the RCA particles, which was not observed in concretes using saturated surface-dry RCAs. Zhao et al. [13] observed that the ITZs in concrete made with saturated surface-dry RCAs were more porous and exhibited lower micromechanical properties compared to the ITZs in concrete made with dry RCAs. Djerbi [11] suggested that the microstructure of the ITZs in concrete containing RCAs is influenced by the pre-saturation water, which can be released into the new cement paste, thereby disrupting its microstructure (new ITZ). This mechanism leads to increased porosity in concrete made with RCA.

Various techniques have been developed to improve the properties of the ITZs in RAC, which can be grouped into two main categories. The first focuses on removing the adhered mortar from the surface of RCAs, which can be achieved through water cleaning, thermal treatment, or pre-soaking in an acidic solution. The second aims to enhance the quality of the adhered mortar, including coating the RCA with pozzolanic materials or polymer emulsions, using specific mixing methods, or applying carbonation [10,14,15,16,17,18].

In general, RAC exhibits lower mechanical performance and durability than NAC [3,19,20]. Kim et al. [19] reported that full substitution with RCA reduces compressive strength by 31%, splitting tensile strength by 14%, and modulus of elasticity by 15%. Moreover, Tran et al. [20] found that this substitution increases porosity by 37% and permeability by 85%.

To enhance RAC performance, various RCA treatment methods have been investigated. Several studies [21,22,23] have examined carbonation’s effect on improving mechanical and durability properties. Jamil et al. [22] reported that RCA carbonation increases compressive strength by 30% and splitting tensile strength by 42%, while reducing water absorption by 20% compared to concrete with non-carbonated RCA. Other studies [24,25,26] have explored calcium carbonate biodeposition. Deverajan and Sivamani [25] demonstrated that this technique enhances compressive strength by 30% and reduces water absorption and sorptivity by 33% and 15%, respectively. It also improves resistance to carbonation and chloride penetration by 15% and 29% compared to concrete with untreated RCA. Additionally, pozzolanic treatments for RCAs have been extensively studied [27,28,29]. Shaban et al. [29] proposed coating RCAs with three types of slurry: fly ash and silica fume, fly ash and cement, and nano-silica. This treatment improves compressive strength by 25–45%, flexural strength by 22–30%, modulus of elasticity by 16–30%, and resistance to chloride ion migration by 22–30% compared to concrete with untreated RCA. Optimized mixing techniques have also been developed [30,31,32]. Zhang et al. [30] introduced an optimized triple-mixing method for producing RAC, which enhances compressive strength by 14% and water impermeability by 13%.

Numerous studies have examined the impact of incorporating RCA on the fracture behavior of concrete [33,34,35]. These works have shown that concrete becomes more brittle with RCA addition, and this brittleness increases with higher substitution rates. Moreover, RCA incorporation reduces fracture energy, with the extent of this reduction depending on the RCA type, proportion, and concrete maturity. Ghorbel and Wardeh [34] observed that fracture energy decreased progressively as the RCA substitution rate increased, with a 40% reduction at full replacement. This decline was attributed to the increased porosity of the concrete. Xiao et al. [35] demonstrated that the incorporation of recycled aggregates, particularly RCA, led to a reduction in fracture energy, while the addition of recycled powder (RP) had a limited effect. Fully recycled aggregate concrete (FRAC) showed the largest decrease (39.90%), followed by concrete containing RCA (35.30%) and concrete with recycled fine aggregate (RFA) (26.40%), with a slight reduction ranging from 3.90% to 8.20% as the content of RP increased. Fallahnejad et al. [33] found that RAC exhibited lower fracture energy than NAC across various ages. They observed that while both types showed improvement over time, NAC demonstrated greater enhancement (58% increase from 3 to 90 days) compared to RAC (25% increase).

To improve the fracture energy of RAC, various treatments of RCAs have been explored. Ahmed et al. [36] pretreated RCAs by soaking them in a pozzolan slurry with the addition of basalt fibers. This treatment increased the fracture energy by 91% for concrete containing 20% of these pretreated RCAs and 1% fibers, and by 56% for concrete containing 100% of these pretreated RCAs and 1% fibers. Luo et al. [37] combined pressure carbonation with pre-soaking in a calcium hydroxide solution, resulting in a 5.38% improvement in fracture energy compared to concrete with untreated RCAs. Tang et al. [18] observed that the carbonation of recycled aggregates (RFA and RCAs) significantly enhanced fracture energy, with increased values of 19.50% for FRAC, 10.10% for concrete with RFA, and 8.10% for concrete with RCAs.

The fracture behavior of RAC when its strength is comparable to that of NAC remains relatively unexplored. Existing studies [34,38] indicate that, within the same strength class, fracture energy decreases as the RCA substitution rate increases, with reductions of 24–40% at full substitution. This strength equivalence was achieved by increasing the cement content.

However, no research has examined the fracture behavior of RAC with strengths comparable to or exceeding those of NAC without increasing the cement content. This raises a key question: can RAC achieve a strength equivalent to or greater than that of NAC if the RCA is sourced from parent concrete made with the same constituents and similar proportions as NAC?

This study aims to address this question by experimentally evaluating the mechanical and fracture behavior of RAC incorporating various proportions of RCAs. Four concrete mixtures were studied: one control mixture made with NCA and three RAC mixtures, where 30%, 60%, and 100% of the NCA mass was replaced with RCAs. Three-point bending tests, under crack mouth opening displacement (CMOD) control, were conducted on pre-notched beams with dimensions of 10 × 10 × 40 cm, in accordance with RILEM recommendations [39], to determine the fracture properties of the different concrete mixtures.

2. Experimental Program

2.1. Materials Used

The NAC and RAC mixes were made with:

- Portland composite cement (CEM II/B-L 42.5 N) from the Lafarge Oggaz cement plant, located in Mascara, Algeria, with an absolute density of 3100 kg/m3 and a Blaine specific surface area of 4450 cm2/g.

- Crushed limestone aggregates from the National Aggregates Company in Sidi Abdelli, Tlemcen, Algeria, consisting of sand (0–3.15 mm fraction, fineness modulus of 2.72) and NCA (4–8 mm and 8–16 mm fractions).

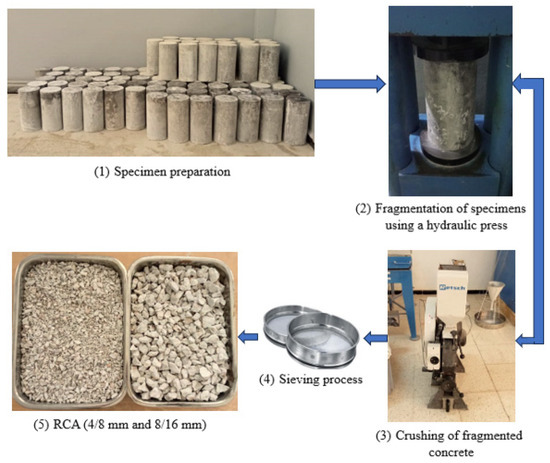

- RCAs with 4–8 mm and 8–16 mm fractions, produced by laboratory crushing of one-year-old concrete samples (Figure 1). These samples were originally formulated using the same constituents and proportions as the reference concrete made exclusively with NCA.

Figure 1. Process for preparing RCA.

Figure 1. Process for preparing RCA.

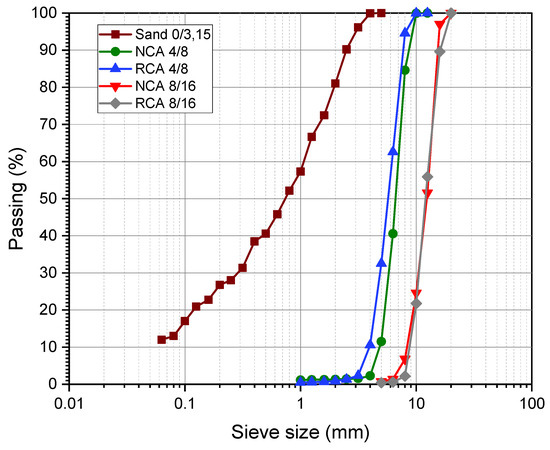

Figure 2 shows the particle size distribution of the NCA and RCAs, determined in accordance with EN 933-1 [40]. The physical properties of the aggregates, including bulk density (measured in accordance with EN 1097-3 [41]), as well as absolute density, water absorption, and porosity (measured in accordance with EN 1097-6 [42]), are presented in Table 1. The RCAs exhibit lower bulk and absolute densities, higher water absorption, and greater porosity compared to the NCA, primarily due to the presence of adhered mortar on their surfaces.

Figure 2.

Grading curves of aggregates.

Table 1.

Physical properties of used aggregates.

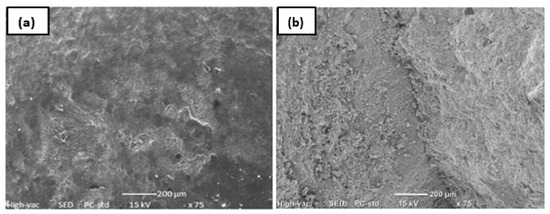

To examine the microstructure of the aggregates, a scanning electron microscopy (SEM) analysis was performed. The SEM image (Figure 3) shows that the RCA has a rougher and more irregular surface than the NCA, with remnants of attached cement paste. These characteristics explain the differences in physical properties.

Figure 3.

Microstructure of aggregates: (a) NCA; (b) RCA.

2.2. Concrete Mixtures

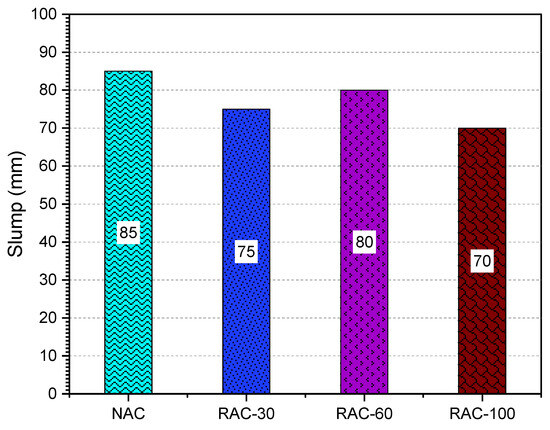

Four concrete mixtures were designed for this study: a control mix using NCA and three RAC mixtures, designated as RAC-30, RAC-60, and RAC-100. In the RAC mixtures, 30%, 60%, and 100% of the NCA, by mass, were replaced with RCA, respectively. All concrete mixtures were designed with a plastic slump (Figure 4). The mix proportions of the concretes are shown in Table 2.

Figure 4.

Slump of the studied concretes.

Table 2.

Mixture proportions (kg/m3).

The NCA was used in a dry state, while the RCAs were prepared in a saturated surface-dry (SSD) condition due to their high water absorption capacity. The RCAs were pre-saturated by immersion in water for 24 h before mixing, and their surfaces were carefully dried with a cloth to achieve the SSD state.

The selection of these RCA substitution rates is based on normative considerations [43] and a review of existing studies [44,45,46,47,48]. A 30% substitution rate allows for assessing the impact of a moderate replacement, which is generally recommended to maintain mechanical properties comparable to those of NAC [46,48]. A 60% substitution rate, identified as optimal in several studies, represents a balance where the increase in porosity is partially offset by the reactivity of residual cement [44,45]. This rate also corresponds to the upper limit set by EN 206+A2/CN [43], which allows up to 60% RCA in certain exposure classes. Finally, a 100% substitution rate enables the evaluation of concrete fully made with RCA, providing insights into the feasibility of total replacement and its effects on mechanical and fracture properties.

Concrete specimens were demolded 24 h after casting and cured in water at room temperature until testing at 28 days. Three specimens were tested for each concrete mixture and test type.

2.3. Tests Methodology

2.3.1. Density

The density of the prepared mixtures, both in the fresh state and at 28 days, was measured in accordance with NF EN 12350-6 [49] on cylindrical specimens with a diameter of 16 cm and a height of 32 cm.

2.3.2. Mechanical Properties

The compressive strength and splitting tensile strength tests were conducted on cylindrical specimens with dimensions of 11 × 22 cm and 16 × 32 cm, respectively, in accordance with EN 12390-3 [50] and EN 12390-6 [51].

The dynamic modulus of elasticity was determined according to EN 12504-4 [52] by measuring the ultrasonic pulse velocity on prismatic specimens with dimensions of 10 × 10 × 40 cm. The dynamic modulus of elasticity (Ed) was calculated using Equation (1):

where: ρ is the density (kg/m3), ν is the Poisson’s ratio, assumed to be 0.2, and Vp is the wave propagation velocity (m/s).

2.3.3. Bound Water

Thermogravimetric analysis (TGA) was used to quantify the bound water in concrete, following the methodology adapted from Tran et al. [20]. The analyses were performed on concrete powder oven-dried at 40 °C and sieved to 80 µm, then heated to 1050 °C at a rate of 10 °C/min. The bound water content was determined based on the mass loss recorded between 105 °C and 550 °C.

2.3.4. Water-Accessible Porosity

The water-accessible porosity tests were carried out in accordance with NF P18-459 [53], on 10 × 10 × 5 cm specimens. First, to determine the dry mass, the samples were dried in an oven at 60 °C until their mass stabilized. Subsequently, they were degassed for 24 h and then saturated for 72 h in a desiccator connected to a vacuum pump. After saturation, the specimens were removed from the desiccator and weighed both in air and in water using hydrostatic weighing. Finally, concrete porosity was calculated using Equation (3):

where: Md is the mass of the sample in the dry state (g), Mair is the mass of the sample in air (g), and Mw is the mass of the sample in water (g).

2.3.5. Pore Size Distribution

Mercury intrusion porosimetry (MIP) was used to determine the pore size distribution. The tests were conducted using a Micromeritics AutoPore IV 9500 porosimeter, manufactured by Micromeritics Instrument Corporation, headquartered in Norcross, GA, USA, which can reach a maximum pressure of 400 MPa and measure pore diameters ranging from 3 nm to 378 µm. The analyses were performed on samples with maximum dimensions between 16 mm and 20 mm, which were freeze-dried for 48 h to remove water by sublimation.

2.3.6. Fracture Properties

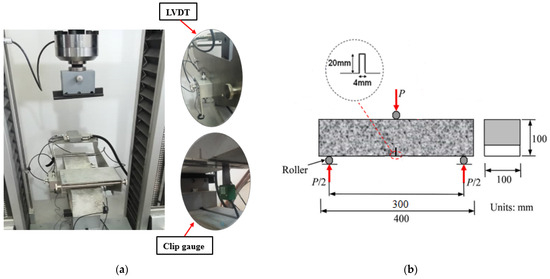

Three-point bending tests were performed on pre-notched beams with dimensions of 10 × 10 × 40 cm using an electromechanical testing machine with a 50 kN capacity (Figure 5). The tests were conducted under CMOD control. A notch of 4 mm width and 20 mm depth was created using a diamond saw. Testing was carried out at a loading rate of 0.05 µm/s. The crack opening at the notch was measured using a CMOD clip gauge (±4 mm stroke) mounted across the notch, while mid-span deflection was monitored with a linear variable differential transformer (LVDT) sensor, following the procedure described in ref. [39]. The CMOD clip gauge was installed by positioning its two blades on either side of the notch on metal plates bonded at the specimen’s center with a high-strength adhesive.

Figure 5.

Three-point bending test: (a) experimental setup used; (b) geometry of the tested specimen.

To enhance test reproducibility, several measures were implemented: notches were precisely cut to ensure uniform geometry and depth, the low loading rate was maintained to promote stable crack propagation, and at least three specimens were tested to ensure result representativeness and minimize experimental variability.

2.3.7. SEM

SEM analysis of concrete microstructures was performed using a Hitachi TM-1000 tabletop mini-SEM, manufactured by Hitachi High-Tech Corporation, headquartered in Tokyo, Japan, on parallel-piped samples of approximately 20 mm per side. No prior treatment was required, and the analysis focused on the ITZ.

3. Results and Discussion

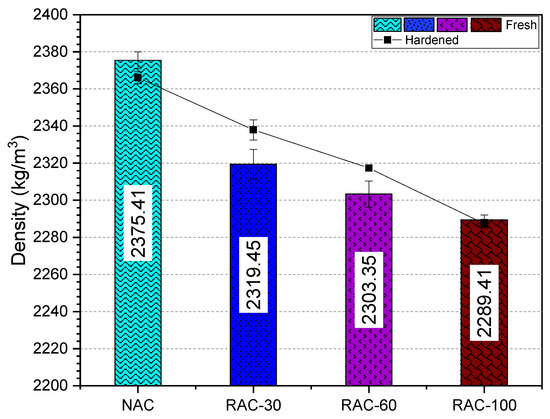

3.1. Density

Figure 6 presents the evolution of concrete density in the fresh state and at 28 days. The results indicate that incorporating RCA leads to a progressive density reduction proportional to the substitution rate, with decreases of 3.62% and 3.32% in the fresh and hardened states, respectively, at 100% substitution. This reduction is attributed to the lower density of RCA. These findings align with those reported in refs. [48,54,55,56].

Figure 6.

Density of the studied concretes.

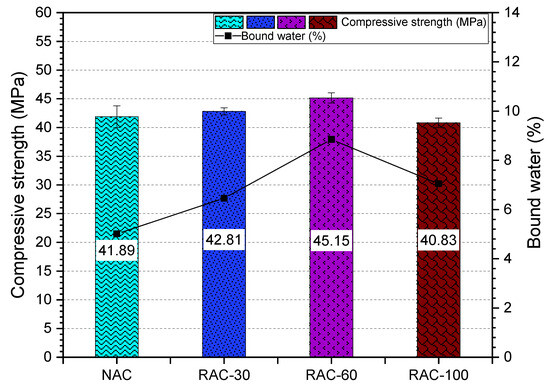

3.2. Compressive Strength

Figure 7 illustrates the evolution of compressive strength and bound water in concrete as a function of the RCA substitution rate. It is observed that the incorporation of RCA positively affects the compressive strength of RAC. A substitution rate of 30% or 100% of RCA results in a compressive strength comparable to that of NAC, while a 60% substitution rate leads to an improvement of 7.75%. Among the three substitution rates analyzed, the 60% rate is found to be optimal, offering the best performance in terms of compressive strength.

Figure 7.

Correlation between compressive strength and bound water.

The improvement in strength can be attributed to the continued hydration of unhydrated cement residues present on the RCA surface. When these residues come into contact with water, they participate in secondary hydration reactions, generating additional hydration products that contribute to the solidification of the new cement paste. The bound water measurements confirm variations in the hydration rate, which directly correlate with the observed evolution in compressive strength, highlighting the positive effect of these interactions on RAC performance.

Several studies [19,57,58,59,60] indicate that the compressive strength of RAC decreases as the RCA substitution rate increases, with a reduction of up to 25% in the case of total substitution. However, other research [44,47,61] suggests that RAC can exhibit strengths equivalent to, or even exceeding, those of conventional concrete. For instance, Elansary et al. [47] report that a 50% substitution rate optimizes compressive strength, with an increase of up to 12%. Similarly, Aït Mohamed Amer et al. [44] identified an optimal substitution rate of 60%, resulting in a strength improvement of approximately 18%. Their work also demonstrates that total substitution can yield performance comparable to that of conventional concrete.

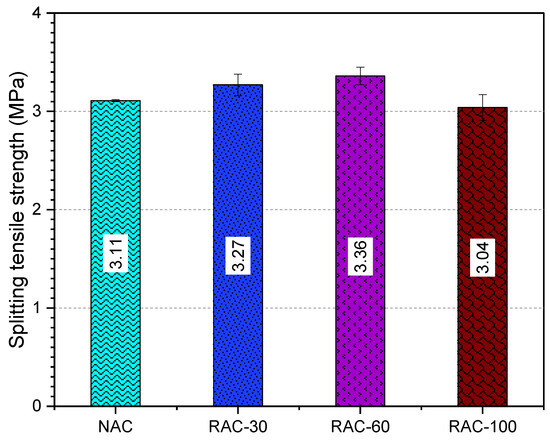

3.3. Splitting Tensile Strength

Figure 8 shows the splitting tensile strengths of the concretes. Consistent with the trend observed for compressive strength, the incorporation of RCA demonstrates a beneficial effect on splitting tensile strength. Concrete mixtures with 30% and 100% RCA substitution exhibit splitting tensile strengths comparable to those of NAC, while the 60% substitution ratio results in an 8.55% increase. Among the three replacement ratios investigated, the 60% replacement proves to be optimal, yielding the highest splitting tensile strength performance.

Figure 8.

Splitting tensile strength of the tested concretes.

The improvement in strength can be attributed to two main factors: first, the rougher surface texture of RCA compared to NCA; and second, the compositional similarity between the old mortar and the new paste, which reduces stress concentrations at the new ITZ. The combination of these factors results in a higher-quality ITZ, leading to an increase in splitting tensile strength.

Several studies [19,62,63] show a decrease in splitting tensile strength as the RCA substitution rate increases, with reductions of up to 14% observed in cases of full replacement. In contrast, other research [46,61,64,65] indicates that RAC can achieve splitting tensile strength comparable to, or even exceeding, that of conventional concrete. For instance, Pani et al. [46] found that a 50% substitution rate of RCA optimizes this strength, resulting in a 7% increase compared to the reference concrete. Similarly, Etxeberria et al. [61] observed that full substitution with RCA can enhance splitting tensile strength by 10% compared to conventional concrete.

3.4. Compressive-to-Splitting Tensile Strength Ratio

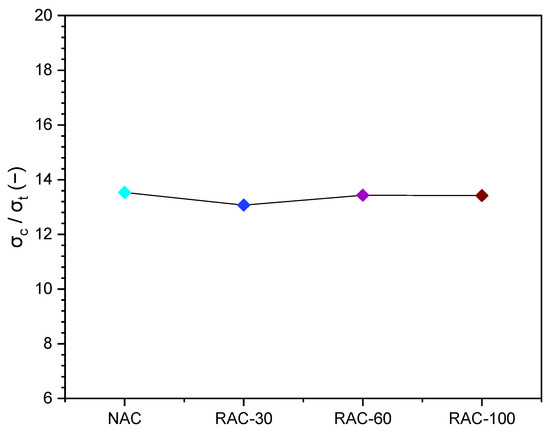

Figure 9 presents the relationship between compressive strength and splitting tensile strength as a function of the RCA substitution rate. The results indicate that incorporating RCA at substitution rates of 30%, 60%, and 100% does not significantly alter the ratio between these two strengths, which remains nearly constant.

Figure 9.

Ratio of compressive strength to splitting tensile strength for the tested concretes.

This stability can be attributed to two main mechanisms:

- RCA homogeneity: The RCA originates from parent concrete with similar mechanical properties and maturity. Consequently, their intrinsic characteristics influence both compressive strength and splitting tensile strength in a comparable manner across all mixtures.

- Compensatory microstructural mechanisms: The rough surface texture of RCA and the presence of unhydrated cement particles help mitigate potentially adverse effects, such as increased porosity and the lower quality of the old ITZ. These mechanisms counterbalance each other, maintaining an almost constant ratio between compressive and splitting tensile strength.

In conclusion, using RCA derived from parent concrete with similar mechanical properties and maturity, produced with the same cement and natural aggregates as the reference concrete, maintains a stable relationship between compressive and splitting tensile strength, even at high substitution rates.

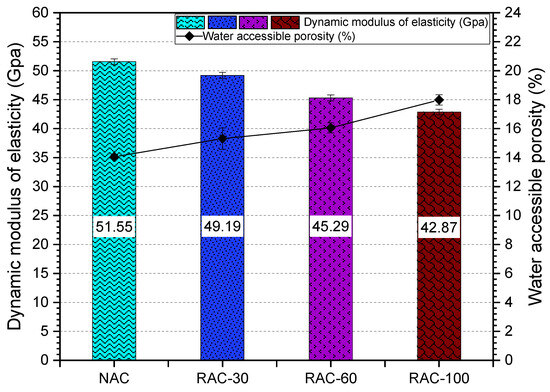

3.5. Dynamic Modulus of Elasticity

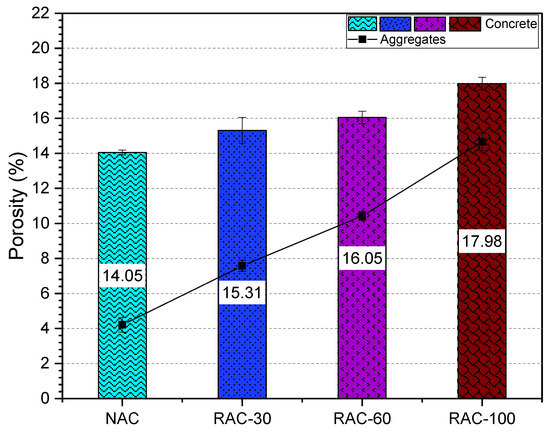

Figure 10 illustrates the correlation between the modulus of elasticity and water-accessible porosity of the concretes. The modulus of elasticity decreases as the RCA substitution rate increases. Compared to NAC, the incorporation of 30%, 60%, and 100% RCA results in reductions of 4.57%, 12.14%, and 16.84% in the modulus of elasticity, respectively. At a 30% substitution rate, the variation in the modulus of elasticity remains negligible; however, beyond this threshold, a significant decrease is observed, primarily due to the substantial amount of residual mortar. This reduction in the modulus of elasticity is directly associated with the increase in porosity, which reaches 8.95%, 14.25%, and 28.01% for substitution rates of 30%, 60%, and 100%, respectively. This rise in porosity is attributed to the inherently high porosity of RCA (Figure 11).

Figure 10.

Correlation between the dynamic modulus of elasticity and water-accessible porosity.

Figure 11.

Water-accessible porosity of the tested concretes and aggregate mixtures.

Several studies [19,63,66] report that the modulus of elasticity decreases as the RCA substitution rate increases, with a reduction of up to 16% in the case of total substitution. A decrease in both compressive and tensile strengths is also observed as the RCA content increases. However, Etxeberria et al. [61] demonstrate that, for equivalent compressive strength, the use of RCA enhances splitting tensile strength while reducing the modulus of elasticity. At 100% substitution, the tensile strength increases by 10%, whereas the modulus of elasticity decreases by 15%.

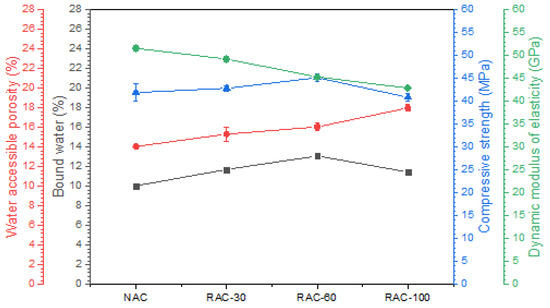

3.6. Correlation Between Mechanical Properties, Porosity, and Hydration Rate

Figure 12 presents the relationship between compressive strength, modulus of elasticity, water-accessible porosity, and hydration rate. As the RCA substitution rate increases, the porosity of the RAC increases, leading to a reduction in its modulus of elasticity. However, the compressive strength remains comparable to, or even exceeds, that of NAC. This divergence between compressive strength and modulus of elasticity in response to increased porosity can be attributed to two compensatory mechanisms. First, the rough surface texture of RCA enhances the bond between residual mortar and new cement paste. Second, unhydrated cement particles present on the RCA surface continue to hydrate upon contact with water, generating additional hydration products that strengthen the new paste. Hydration rate analyses confirm this beneficial effect on compressive strength.

Figure 12.

Correlations among porosity, bound water, compressive strength, and the dynamic modulus of elasticity.

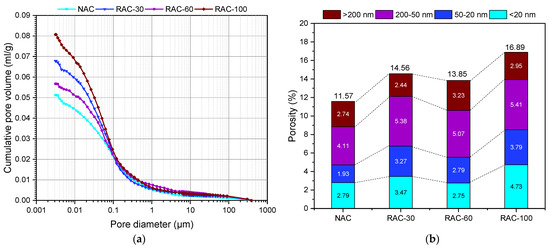

3.7. Pore Size Distribution

Figure 13a shows the evolution of cumulative pore volume as a function of the RCA substitution rate, while Figure 13b illustrates the pore distribution across different size ranges. According to Chen et al. [67], concrete contains four categories of pores: non-harmful pores (<20 nm), slightly harmful pores (20–50 nm), harmful pores (50–200 nm), and highly detrimental pores (>200 nm).

Figure 13.

Evolution of concrete porosity as a function of the RCA substitution rate: (a) cumulative pore volume; (b) pore size distribution.

In the macropore region (>0.1 µm), all concrete mixtures exhibit comparable behavior. However, in the micropore region (<0.1 µm), notable differences are observed. RAC-60 displays a pore distribution comparable to that of NAC, whereas RAC-30 and RAC-100 exhibit significantly higher pore volumes. Furthermore, RAC-60 has the lowest volume of pores smaller than 20 nm among all studied concretes.

This characteristic at a 60% substitution rate can be attributed to the release of reactive hydrates and fine particles from the residual cement in the RCA, which contribute to partially filling the pores and densifying the ITZs. Bound water measurements confirm this beneficial effect, indicating an increased degree of hydration at this substitution rate.

The discrepancy between the volume of small pores and water-accessible porosity arises from the redistribution of pores and their connectivity. Water-accessible porosity increases continuously with the substitution rate due to the increased pore connectivity induced by the RCA. At a 60% substitution rate, the RAC may reach an equilibrium between the reactivation of residual cement and the densification of the ITZs, mitigating the impact of micropores on mechanical strength [48]. Moreover, pore interconnectivity does not significantly affect its performance. This could explain why, despite the increase in water-accessible porosity, the compressive strength at this substitution rate remains higher than that of NAC.

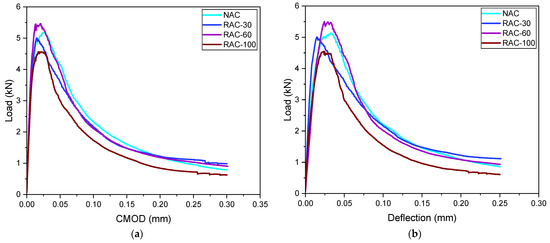

3.8. Load–Displacement Curve

Figure 14 shows the average load–displacement curves for the various concrete mixes studied. The behavior of all concrete specimens initially exhibits a linear elastic relationship, followed by a nonlinear phase, indicating progressive damage development within the material. The incorporation of 30% and 60% RCA does not significantly affect the maximum load compared to NAC. However, complete replacement with RCA reduces this load by approximately 11.50%. In the post-peak region, RAC-100 displays distinct behavior compared to NAC, RAC-30, and RAC-60, exhibiting more brittle failure characteristics. Meanwhile, RAC-30 and RAC-60 demonstrate post-peak behavior comparable to that of NAC.

Figure 14.

Load–displacement curves of concretes (average values): (a) load–CMOD; (b) load–deflection.

It can be concluded that, for a comparable strength class, RAC exhibits similar post-peak behavior to NAC when the RCA substitution rate is up to 60%. However, its behavior becomes more brittle at a 100% substitution rate.

According to refs. [34,38], RAC exhibits greater brittleness than conventional concrete for the same strength class. This brittleness tends to increase with higher substitution rates of RCA. The increased brittle behavior is attributed to the limited crack bridging effects and reduced crack branching during the fracture process [35].

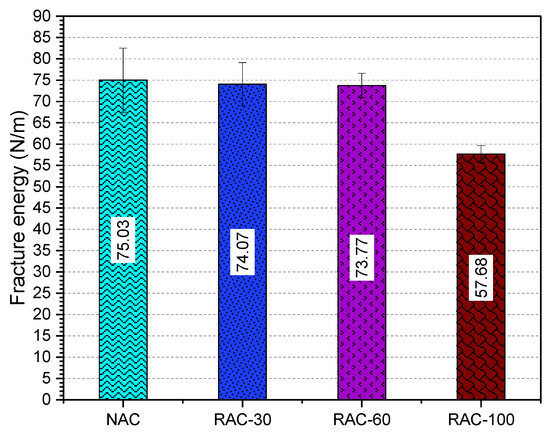

3.9. Fracture Energy

The fracture energy is determined according to the procedure described by RILEM [25], from the load–deflection curve, using the following expression:

in which W0 is the area under the load–deflection curve; mg is the self-weight of the specimen between supports (kg); is the maximum displacement (m); Alig is the ligament area (m2); b and D are the height and width of the beam, respectively (m); and a0 is the notch depth (m).

Figure 15 shows the fracture energy of the different concrete mixes studied. The incorporation of 30% and 60% RCA maintains fracture energy comparable to that of NAC. However, a complete substitution with RCA results in a significant decrease in fracture energy, with a reduction of 23.20%.

Figure 15.

Fracture energy of the tested concretes.

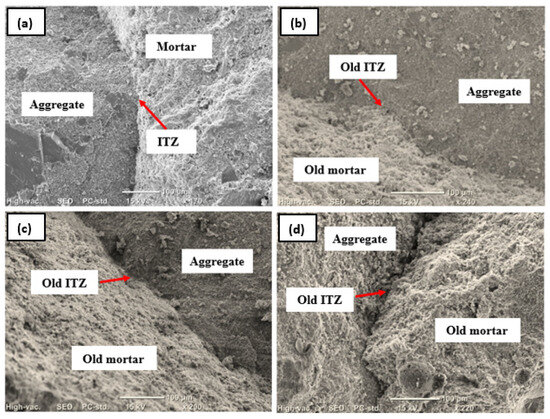

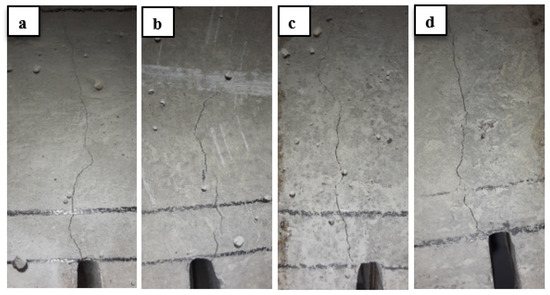

It can be concluded that, for an equivalent strength class, the fracture energy of RAC remains comparable to that of NAC for RCA substitution rates up to 60%. However, it decreases when the substitution rate reaches 100%. This reduction can be attributed to the fact that, at a 100% substitution rate, the surface area of the old ITZ exceeds a critical threshold (Figure 16). The old ITZ is considered the weakest phase of RAC due to its high porosity and the presence of pre-existing microcracks.

Figure 16.

ITZ of concretes: (a) NAC; (b) RAC-30; (c) RAC-60; (d) RAC-100.

According to refs. [34,38], the fracture energy of RAC progressively decreases as the RCA substitution rate increases, with a reduction of 40% at a 100% substitution rate for an equivalent strength class. This reduction is primarily attributed to the brittleness of the old ITZ and the initial damage to the RCA caused by the crushing process. Consequently, crack branching and meandering during fracture are limited (Figure 17), leading to lower energy consumption.

Figure 17.

Failure modes of concrete: (a) NAC; (b) RAC-30; (c) RAC-60; (d) RAC-100.

4. Conclusions

In this article, an experimental study was conducted to investigate the effect of incorporating RCA at various substitution rates on the mechanical and fracture properties of RAC. Based on the results, the main conclusions of this study are as follows:

- The incorporation of RCA at substitution rates of 30%, 60%, and 100% achieves compressive strength and splitting tensile strengths equivalent to, or even exceeding, those of NAC, with optimal performance at 60%.

- The dynamic modulus of elasticity of RAC decreases as the RCA substitution rate increases due to the higher porosity of RCA.

- Increased porosity affects compressive strength and modulus of elasticity differently: the rougher texture of RCA and the continued hydration of unhydrated cement residues mitigate its impact on compressive strength, whereas the modulus of elasticity is more significantly affected.

- The discrepancy between the volume of small pores and water-accessible porosity results from pore redistribution and their connectivity. Water-accessible porosity progressively increases with the RCA substitution rate due to the enhanced pore connectivity induced by RCA.

- The optimal performance at a 60% substitution rate can be attributed to a more favorable pore distribution, characterized by a lower proportion of pores smaller than 20 nm and an increased hydration rate.

- For the same strength class, RAC with an RCA substitution rate of up to 60% exhibits post-peak behavior comparable to that of NAC. However, at 100% substitution, it becomes more brittle.

- For equivalent strength classes, the fracture energy of RAC remains comparable to that of NAC for RCA substitution rates up to 60% but decreases by 23.20% at 100% substitution.

The proposed RACs can be used in a wide range of applications depending on the substitution rate. At up to 60%, they are suitable for structural elements subjected to moderate loads, such as slabs, precast components, and certain reinforced concrete structures. At 100%, their use is limited to non-structural applications, including sidewalks, curbs, lightly loaded foundations, and compacted concrete backfills.

Moreover, the industrialization of these RACs remains challenging due to the variability of concrete waste. Unlike the controlled experimental conditions of this study, such variability can affect concrete quality and performance. Therefore, implementing rigorous protocols for the selection, sorting, and treatment of RCA is essential to stabilize its properties and ensure consistent concrete performance.

However, a limitation of this study is the difference in moisture content between NCA and RCA, with the latter used in an SSD state. Further research could focus on direct comparisons under equivalent moisture conditions to better assess their impact on concrete properties.

Author Contributions

Conceptualization, M.H., Z.D., H.M. and W.M.; methodology, M.H., Z.D., H.M. and W.M.; software, M.H., Z.D., H.M. and W.M.; validation, M.H., Z.D., H.M. and W.M.; formal analysis, M.H., Z.D., H.M. and W.M.; investigation, M.H., Z.D., H.M. and W.M.; resources, Z.D.; data curation, M.H. and Z.D.; writing—original draft preparation, M.H.; writing—review and editing, Z.D., H.M. and W.M.; methodology, M.H., Z.D., H.M. and W.M.; software, M.H., Z.D., H.M. and W.M.; visualization, Z.D., H.M. and W.M.; software, M.H., Z.D., H.M. and W.M; supervision, Z.D., H.M. and W.M.; project administration, Z.D., H.M. and W.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bahraq, A.A.; Jose, J.; Shameem, M.; Maslehuddin, M. A Review on Treatment Techniques to Improve the Durability of Recycled Aggregate Concrete: Enhancement Mechanisms, Performance and Cost Analysis. J. Build. Eng. 2022, 55, 104713. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, H.; Liang, Y.; Shen, J.; Yang, H. Study on Fracture Characteristics and Fracture Mechanism of Fully Recycled Aggregate Concrete Using AE and DIC Techniques. Constr. Build. Mater. 2024, 419, 135540. [Google Scholar] [CrossRef]

- Berredjem, L.; Arabi, N.; Molez, L. Mechanical and Durability Properties of Concrete Based on Recycled Coarse and Fine Aggregates Produced from Demolished Concrete. Constr. Build. Mater. 2020, 246, 118421. [Google Scholar] [CrossRef]

- Kim, J. Influence of Quality of Recycled Aggregates on the Mechanical Properties of Recycled Aggregate Concretes: An Overview. Constr. Build. Mater. 2022, 328, 127071. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, G.J. Recycled Concrete Aggregate Classification Based on Quality Parameters and Performance. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 47, 3211–3232. [Google Scholar] [CrossRef]

- Muhammad, F.; Harun, M.; Ahmed, A.; Kabir, N.; Khalid, H.R.; Hanif, A. Influence of Bonded Mortar on Recycled Aggregate Concrete Properties: A Review. Constr. Build. Mater. 2024, 432, 136564. [Google Scholar] [CrossRef]

- Bai, G.; Zhu, C.; Liu, C.; Liu, B. An Evaluation of the Recycled Aggregate Characteristics and the Recycled Aggregate Concrete Mechanical Properties. Constr. Build. Mater. 2020, 240, 117978. [Google Scholar] [CrossRef]

- Fang, H.Y.; Liu, F.L.; Yang, J.H. High-Quality Coarse Aggregate Recycling from Waste Concrete by Impact Crushing. J. Mater. Cycles Waste Manag. 2020, 22, 887–896. [Google Scholar] [CrossRef]

- de Andrade Salgado, F.; de Andrade Silva, F. Recycled Aggregates from Construction and Demolition Waste towards an Application on Structural Concrete: A Review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Wang, R.; Yu, N.; Li, Y. Methods for Improving the Microstructure of Recycled Concrete Aggregate: A Review. Constr. Build. Mater. 2020, 242, 118164. [Google Scholar] [CrossRef]

- Djerbi, A. Effect of Recycled Coarse Aggregate on the New Interfacial Transition Zone Concrete. Constr. Build. Mater. 2018, 190, 1023–1033. [Google Scholar] [CrossRef]

- Leite, M.B.; Monteiro, P.J.M. Microstructural Analysis of Recycled Concrete Using X-Ray Microtomography. Cem. Concr. Res. 2016, 81, 38–48. [Google Scholar] [CrossRef]

- Zhao, Y.; Zeng, W.; Zhang, H. Properties of Recycled Aggregate Concrete with Different Water Control Methods. Constr. Build. Mater. 2017, 152, 539–546. [Google Scholar] [CrossRef]

- Mistri, A.; Bhattacharyya, S.K.; Dhami, N.; Mukherjee, A.; Barai, S.V. A Review on Different Treatment Methods for Enhancing the Properties of Recycled Aggregates for Sustainable Construction Materials. Constr. Build. Mater. 2020, 233, 117894. [Google Scholar] [CrossRef]

- Sai Trivedi, S.; Snehal, K.; Das, B.B.; Barbhuiya, S. A Comprehensive Review towards Sustainable Approaches on the Processing and Treatment of Construction and Demolition Waste. Constr. Build. Mater. 2023, 393, 132125. [Google Scholar] [CrossRef]

- Shaban, W.M.; Yang, J.; Su, H.; Mo, K.H.; Li, L.; Xie, J. Quality Improvement Techniques for Recycled Concrete Aggregate: A Review. J. Adv. Concr. Technol. 2019, 17, 151–167. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. Quality Improvement of Recycled Concrete Aggregate by Removal of Residual Mortar: A Comprehensive Review of Approaches Adopted. Constr. Build. Mater. 2021, 288, 123066. [Google Scholar] [CrossRef]

- Tang, Y.; Xiao, J.; Zhang, H.; Wang, D.; Zhang, M.; Zhang, J. Effect of Accelerated Carbonation of Fully Recycled Aggregates on Fracture Behaviour of Concrete. Cem. Concr. Compos. 2024, 148, 105442. [Google Scholar] [CrossRef]

- Kim, J.; Grabiec, A.M.; Ubysz, A. An Experimental Study on Structural Concrete Containing Recycled Aggregates and Powder from Construction and Demolition Waste. Materials 2022, 15, 2458. [Google Scholar] [CrossRef]

- Tran, D.L.; Mouret, M.; Cassagnabère, F.; Phung, Q.T. Effects of Intrinsic Granular Porosity and Mineral Admixtures on Durability and Transport Properties of Recycled Aggregate Concretes. Mater. Today Commun. 2022, 33, 104709. [Google Scholar] [CrossRef]

- Zhang, T.; Cui, J.; Chen, M.; Yang, J.; Yan, Z.; Zhang, M. Durability of Concrete Containing Carbonated Recycled Aggregates: A Comprehensive Review. Cem. Concr. Compos. 2025, 156, 105865. [Google Scholar] [CrossRef]

- Jamil, S.; Idrees, M.; Akbar, A.; Ahmed, W. Investigating the Mechanical and Durability Properties of Carbonated Recycled Aggregate Concrete and Its Performance with SCMs. Buildings 2025, 15, 201. [Google Scholar] [CrossRef]

- Russo, N.; Lollini, F. Effect of Carbonated Recycled Coarse Aggregates on the Mechanical and Durability Properties of Concrete. J. Build. Eng. 2022, 51, 104290. [Google Scholar] [CrossRef]

- Wang, J.; Pang, S.; Zhan, X.; Wei, W.; Li, X.; Wang, L.; Huang, X.; Zhang, L. Improving Recycled Concrete Aggregate Performance via Microbial-Induced Calcium Carbonate Precipitation: Effects of Bacterial Strains and Mineralization Conditions. Buildings 2025, 15, 825. [Google Scholar] [CrossRef]

- Deverajan, A.; Sivamani, J. Influence of Bio-Deposited Recycled Aggregate on the Concrete Properties. Eur. J. Environ. Civ. Eng. 2024, 28, 2080–2098. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Neelakantan, T.R.; Jagan, S. Microbial Technique to Treat Recycled Aggregates from Construction Waste for Its Effective Reutilization in Concrete. Glob. Nest J. 2023, 25, 148–155. [Google Scholar] [CrossRef]

- Siletani, A.H.; Asayesh, S.; Shirzadi Javid, A.A.; Habibnejad Korayem, A.; Ghanbari, M.A. Influence of Coating Recycled Aggregate Surface with Different Pozzolanic Slurries on Mechanical Performance, Durability, and Micro-Structure Properties of Recycled Aggregate Concrete. J. Build. Eng. 2024, 83, 108457. [Google Scholar] [CrossRef]

- Singh, P.K.; Rajhans, P. Optimizing Mechanical and Durability Properties of Recycled Aggregate Concrete Using Pozzolanic Slurries and Modified Mixing Approach. Eur. J. Environ. Civ. Eng. 2024, 28, 3661–3685. [Google Scholar] [CrossRef]

- Shaban, W.M.; Elbaz, K.; Yang, J.; Thomas, B.S.; Shen, X.; Li, L.H.; Du, Y.; Xie, J.; Li, L. Effect of Pozzolan Slurries on Recycled Aggregate Concrete: Mechanical and Durability Performance. Constr. Build. Mater. 2021, 276, 121940. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, S.; Zhao, P.; Lu, L.; Cheng, X. Effect of the Optimized Triple Mixing Method on the ITZ Microstructure and Performance of Recycled Aggregate Concrete. Constr. Build. Mater. 2019, 203, 601–607. [Google Scholar] [CrossRef]

- Rajhans, P.; Panda, S.K.; Nayak, S. Sustainable Self Compacting Concrete from C&D Waste by Improving the Microstructures of Concrete ITZ. Constr. Build. Mater. 2018, 163, 557–570. [Google Scholar] [CrossRef]

- Kong, D.; Lei, T.; Zheng, J.; Ma, C.; Jiang, J.; Jiang, J. Effect and Mechanism of Surface-Coating Pozzalanics Materials around Aggregate on Properties and ITZ Microstructure of Recycled Aggregate Concrete. Constr. Build. Mater. 2010, 24, 701–708. [Google Scholar] [CrossRef]

- Fallahnejad, H.; Davoodi, M.R.; Nikbin, I.M. The Influence of Aging on the Fracture Characteristics of Recycled Aggregate Concrete through Three Methods. Struct. Concr. 2021, 22, E74–E93. [Google Scholar] [CrossRef]

- Ghorbel, E.; Wardeh, G. Influence of Recycled Coarse Aggregates Incorporation on the Fracture Properties of Concrete. Constr. Build. Mater. 2017, 154, 51–60. [Google Scholar] [CrossRef]

- Xiao, J.; Tang, Y.; Chen, H.; Zhang, H.; Xia, B. Effects of Recycled Aggregate Combinations and Recycled Powder Contents on Fracture Behavior of Fully Recycled Aggregate Concrete. J. Clean. Prod. 2022, 366, 132895. [Google Scholar] [CrossRef]

- Ahmed, W.; Lim, C.W. Evaluating Fracture Parameters of Basalt Fiber Reinforced and Pozzolana Slurry Modified Recycled Concrete Produced from Waste. Structures 2023, 50, 1476–1492. [Google Scholar] [CrossRef]

- Luo, S.; Lin, Q.; Lin, T.; Wang, D.; Wang, S. Effects of Pressurized Carbonation with Presoaking in Calcium Hydroxide Solution on the Fracture Behaviours of Recycled Coarse Aggregate Concrete. Constr. Build. Mater. 2023, 397, 132386. [Google Scholar] [CrossRef]

- Li, T.; Xiao, J.; Zhang, Y.; Chen, B. Fracture Behavior of Recycled Aggregate Concrete under Three-Point Bending. Cem. Concr. Compos. 2019, 104, 103353. [Google Scholar] [CrossRef]

- Anonymous. Determination of the Fracture Energy of Mortar and Concrete by Means of Three-Point Bend Tests on Notched Beams. Mater. Struct. 1985, 18, 287–290. [Google Scholar] [CrossRef]

- Standard NF EN 933-1. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-en-9331/tests-for-geometrical-properties-of-aggregates-part-1-determination-of-part/fa163900/39221 (accessed on 7 August 2024).

- Standard NF EN 1097-3. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-en-10973/tests-for-mechanical-and-physical-properties-of-aggregates-part-3-determina/fa039534/10658 (accessed on 17 November 2024).

- Standard NF EN 1097-6. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-en-10976/tests-for-mechanical-and-physical-properties-of-aggregates-part-6-determina/fa192181/321395 (accessed on 17 November 2024).

- Standard NF EN 206+A2/CN. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-en-206-a2-cn/concrete-specification-performance-production-and-conformity-national-addit/fa203976/336018 (accessed on 11 March 2025).

- Ait Mohamed Amer, A.; Ezziane, K.; Adjoudj, M.H. Evaluation of Coarse Recycled Concrete Aggregates Effect on the Properties of Fresh and Hardened Concrete. Asian J. Civ. Eng. 2021, 22, 1173–1184. [Google Scholar] [CrossRef]

- Ait Mohamed Amer, A.; Ezziane, K.; Bougara, A.; Adjoudj, M. Rheological and Mechanical Behavior of Concrete Made with Pre-Saturated and Dried Recycled Concrete Aggregates. Constr. Build. Mater. 2016, 123, 300–308. [Google Scholar] [CrossRef]

- Pani, L.; Francesconi, L.; Rombi, J.; Mistretta, F.; Sassu, M.; Stochino, F. Effect of Parent Concrete on the Performance of Recycled Aggregate Concrete. Sustainability 2020, 12, 9399. [Google Scholar] [CrossRef]

- Elansary, A.A.; Ashmawy, M.M.; Abdalla, H.A. Effect of Recycled Coarse Aggregate on Physical and Mechanical Properties of Concrete. Adv. Struct. Eng. 2020, 24, 583–595. [Google Scholar] [CrossRef]

- Verian, K.P.; Ashraf, W.; Cao, Y. Properties of Recycled Concrete Aggregate and Their Influence in New Concrete Production. Resour. Conserv. Recycl. 2018, 133, 30–49. [Google Scholar] [CrossRef]

- Standard NF EN 12350-6. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-en-123506/testing-fresh-concrete-part-6-density/fa190562/83423 (accessed on 11 March 2025).

- Standard NF EN 12390-3. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-en-123903/testing-hardened-concrete-part-3-compressive-strength-of-test-specimens/fa190566/83462 (accessed on 7 August 2024).

- Standard NF EN 12390-6. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-en-123906/testing-hardened-concrete-part-6-tensile-splitting-strength-of-test-specime/fa043001/19053 (accessed on 7 August 2024).

- Standard NF EN 12504-4. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-en-125044/testing-concrete-part-4-determination-of-ultrasonic-pulse-velocity/fa048399/24971 (accessed on 7 August 2024).

- Standard NF P18-459. Available online: https://www.boutique.afnor.org/en-gb/standard/nf-p18459/concrete-testing-hardened-concrete-testing-porosity-and-density/fa160729/34961 (accessed on 18 November 2024).

- Silva, R.V.; de Brito, J.; Dhir, R.K. Fresh-State Performance of Recycled Aggregate Concrete: A Review. Constr. Build. Mater. 2018, 178, 19–31. [Google Scholar] [CrossRef]

- Lavado, J.; Bogas, J.; de Brito, J.; Hawreen, A. Fresh Properties of Recycled Aggregate Concrete. Constr. Build. Mater. 2020, 233, 117322. [Google Scholar] [CrossRef]

- Ibrahim, M.; Alimi, W.; Assaggaf, R.; Salami, B.A.; Oladapo, E.A. An Overview of Factors Influencing the Properties of Concrete Incorporating Construction and Demolition Wastes. Constr. Build. Mater. 2023, 367, 130307. [Google Scholar] [CrossRef]

- Arora, S.; Singh, B.; Bhardwaj, B. Strength Performance of Recycled Aggregate Concretes Containing Mineral Admixtures and Their Performance Prediction through Various Modeling Techniques. J. Build. Eng. 2019, 24, 100741. [Google Scholar] [CrossRef]

- Devi, S.V.; Gausikan, R.; Chithambaranathan, S.; Jeffrey, J.W. Utilization of Recycled Aggregate of Construction and Demolition Waste as a Sustainable Material. Mater. Today Proc. 2021, 45, 6649–6654. [Google Scholar] [CrossRef]

- Patra, I.; Al-Awsi, G.R.L.; Hasan, Y.M.; Almotlaq, S.S.K. Mechanical Properties of Concrete Containing Recycled Aggregate from Construction Waste. Sustain. Energy Technol. Assess. 2022, 53, 102722. [Google Scholar] [CrossRef]

- Wang, X.; Yang, X.; Ren, J.; Han, N.; Xing, F. A Novel Treatment Method for Recycled Aggregate and the Mechanical Properties of Recycled Aggregate Concrete. J. Mater. Res. Technol. 2021, 10, 1389–1401. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of Amount of Recycled Coarse Aggregates and Production Process on Properties of Recycled Aggregate Concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of Moisture Conditioning of Recycled Aggregates on the Properties of Fresh and Hardened Concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural Concrete with Simultaneous Incorporation of Fine and Coarse Recycled Concrete Aggregates: Mechanical, Durability and Long-Term Properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Lu, L. Optimal Replacement Ratio of Recycled Concrete Aggregate Balancing Mechanical Performance with Sustainability: A Review. Buildings 2024, 14, 2204. [Google Scholar] [CrossRef]

- Safiuddin, M.; Alengaram, U.J.; Salam, M.A.; Jumaat, M.Z.; Jaafar, F.F.; Saad, H.B. Properties of High-Workability Concrete with Recycled Concrete Aggregate. Mater. Res. 2011, 14, 248–255. [Google Scholar] [CrossRef]

- Lahmar, N.; Bouziadi, F.; Boulekbache, B.; Meziane, E.H.; Hamrat, M.; Haddi, A.; Djelal, C. Experimental and Finite Element Analysis of Shrinkage of Concrete Made with Recycled Coarse Aggregates Subjected to Thermal Loading. Constr. Build. Mater. 2020, 247, 118564. [Google Scholar] [CrossRef]

- Chen, X.; Mao, J.; Wu, Q.; Liu, J.; Cheng, S.; Liu, Z. Study of the Effect of Pretreatment on Coarse Recycled Aggregate in Self-Compacting Concrete: Rheology, Mechanical Properties, and Microstructures. J. Build. Eng. 2025, 101, 111744. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).