Design and Experimental Study of a Prefabricated Building Thermoelectric Power Generation–Wall System for Severe Cold Climates

Abstract

1. Introduction

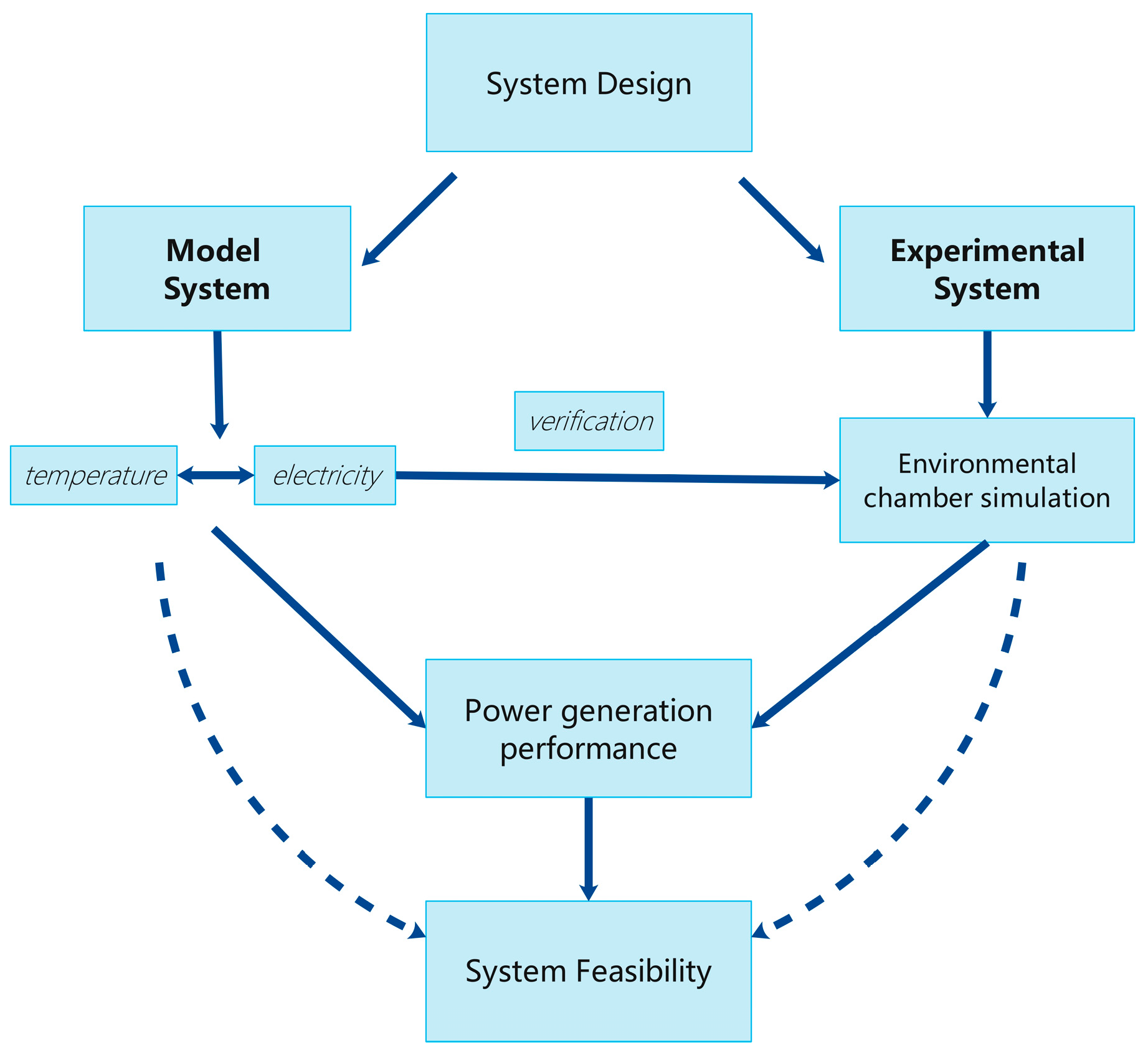

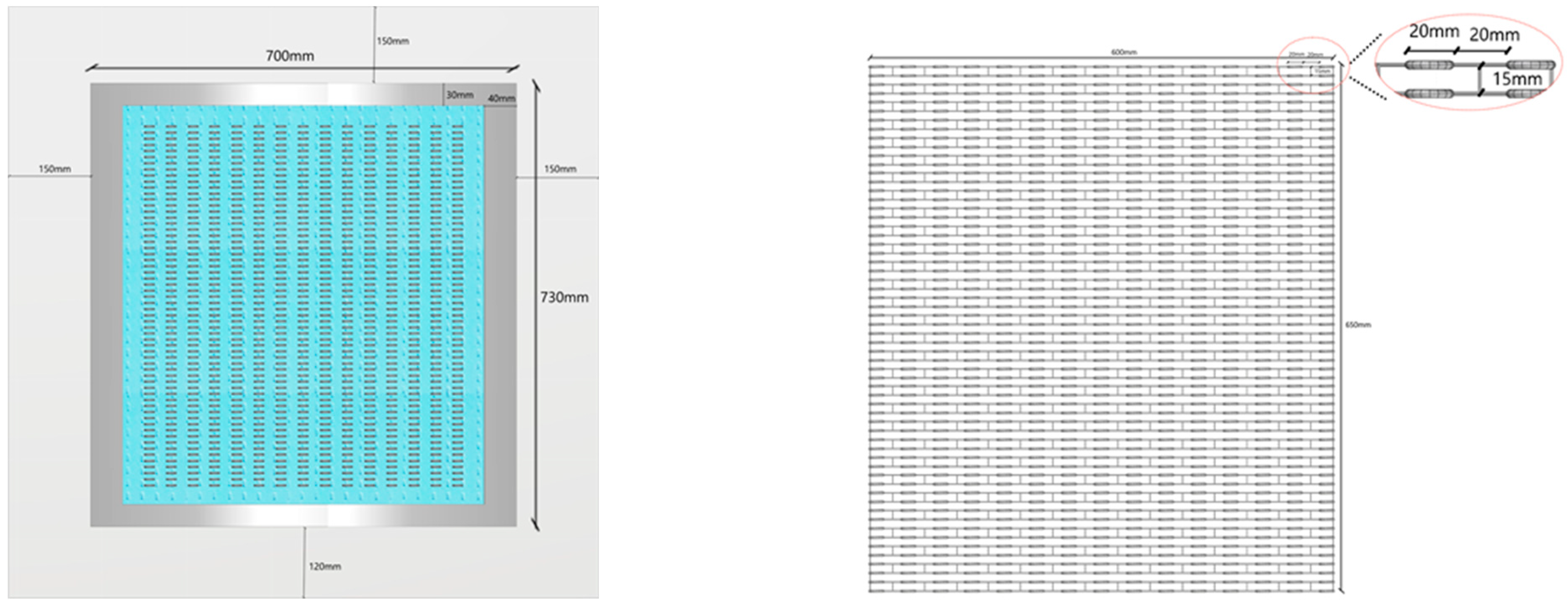

2. Materials and Methods

2.1. Thermoelectric Power Generation–Wall System Design

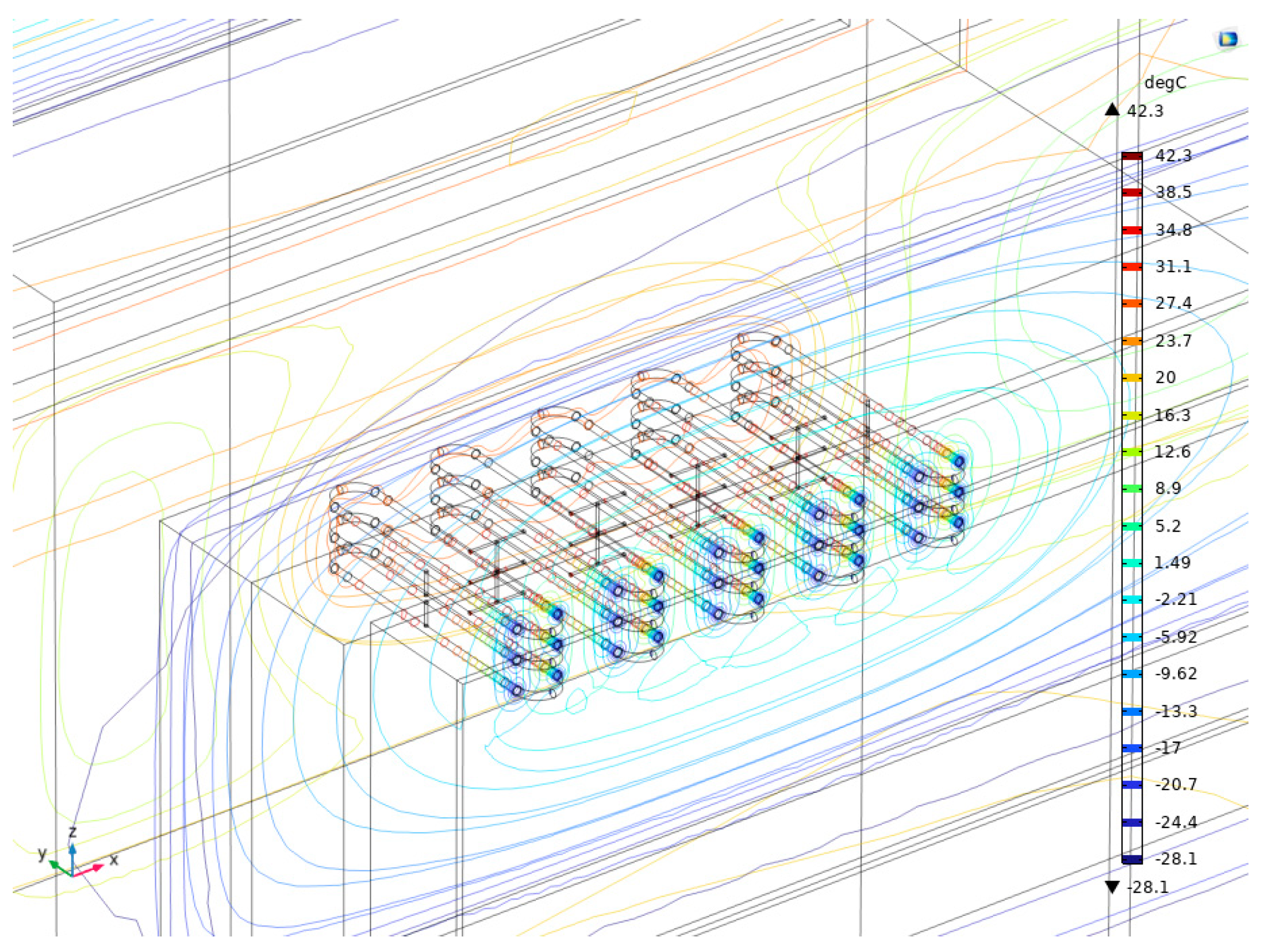

2.2. Software Simulation

2.2.1. Boundary Conditions and Principles

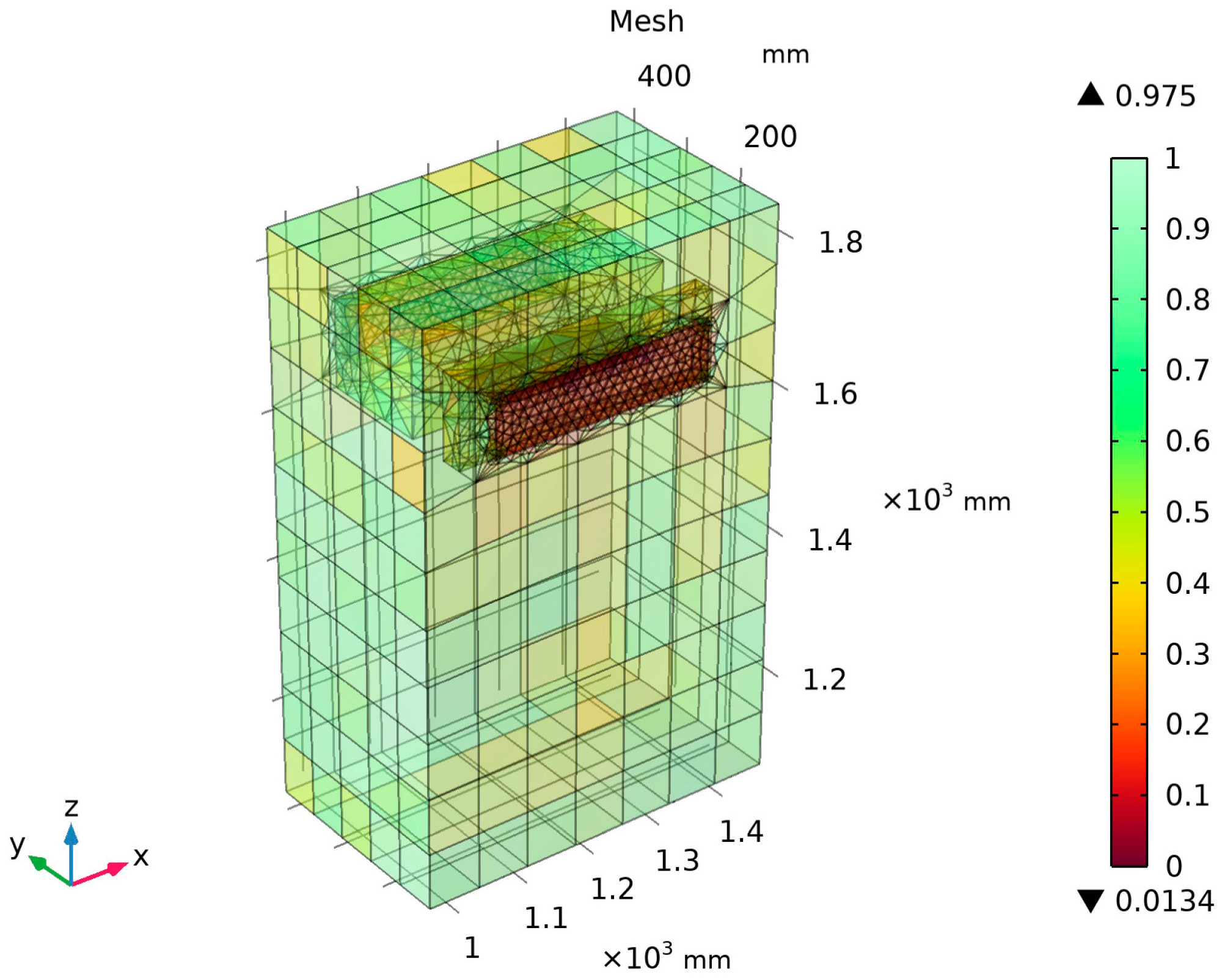

2.2.2. COMSOL Model

2.2.3. Simulation Process

2.3. Experimental Research

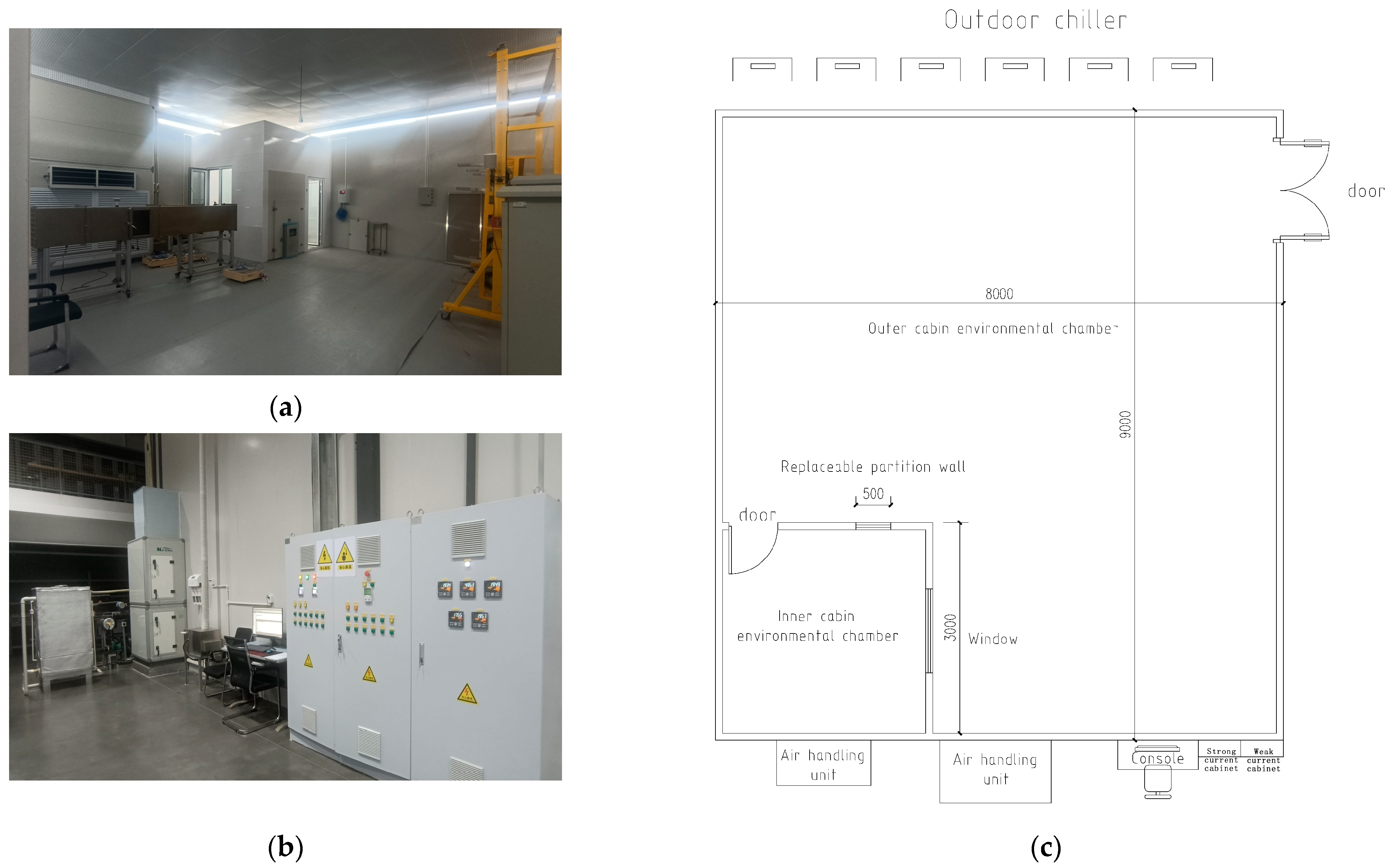

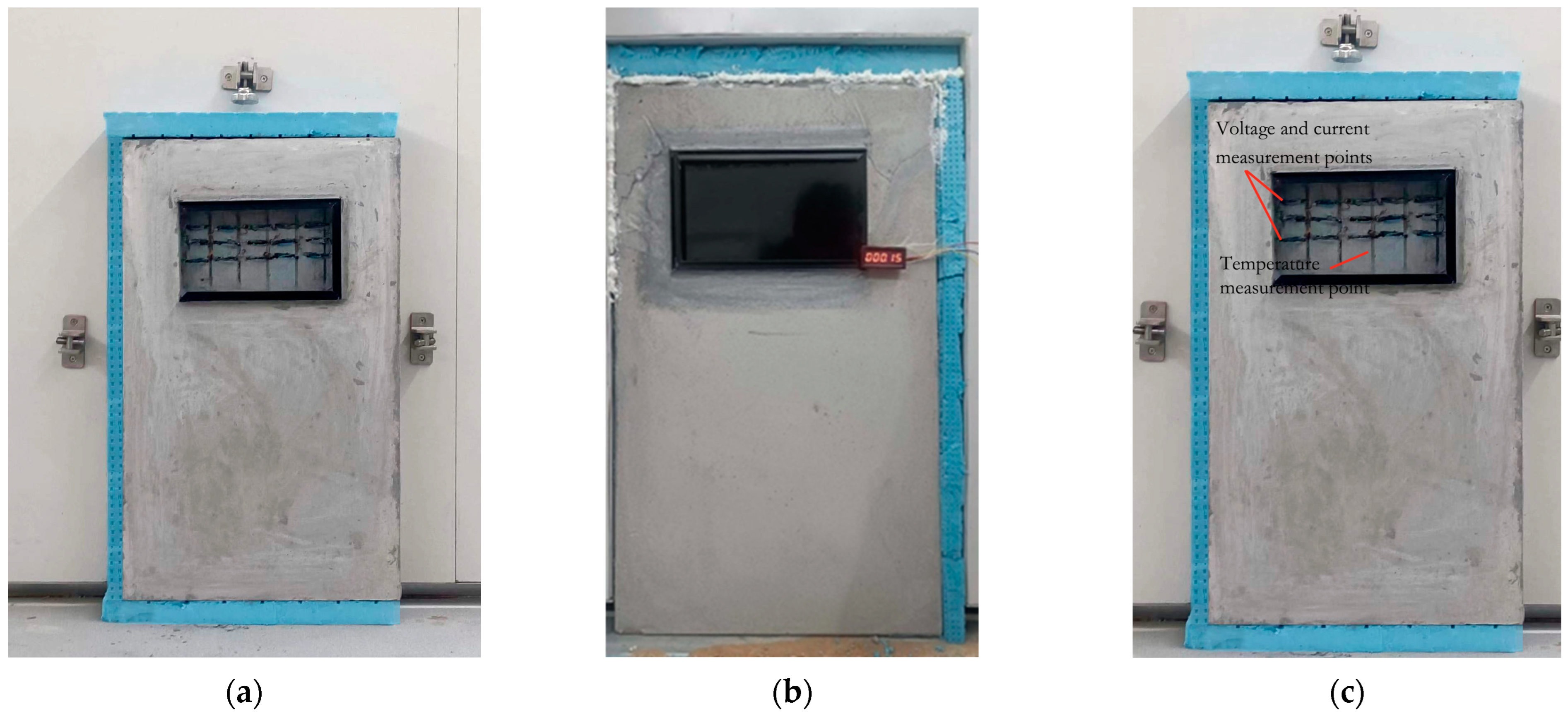

2.3.1. Experimental Setup

2.3.2. Experimental Procedure

3. Results

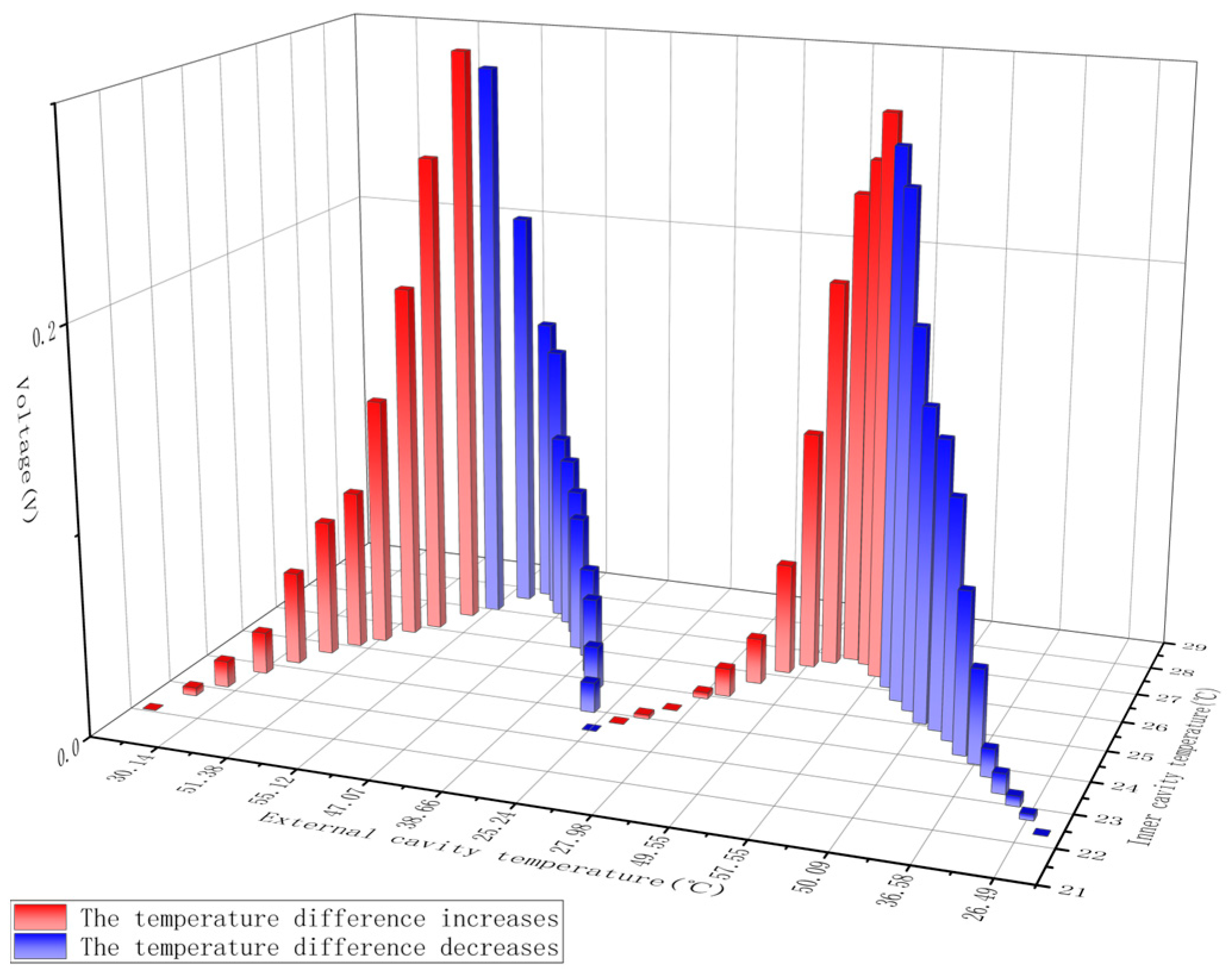

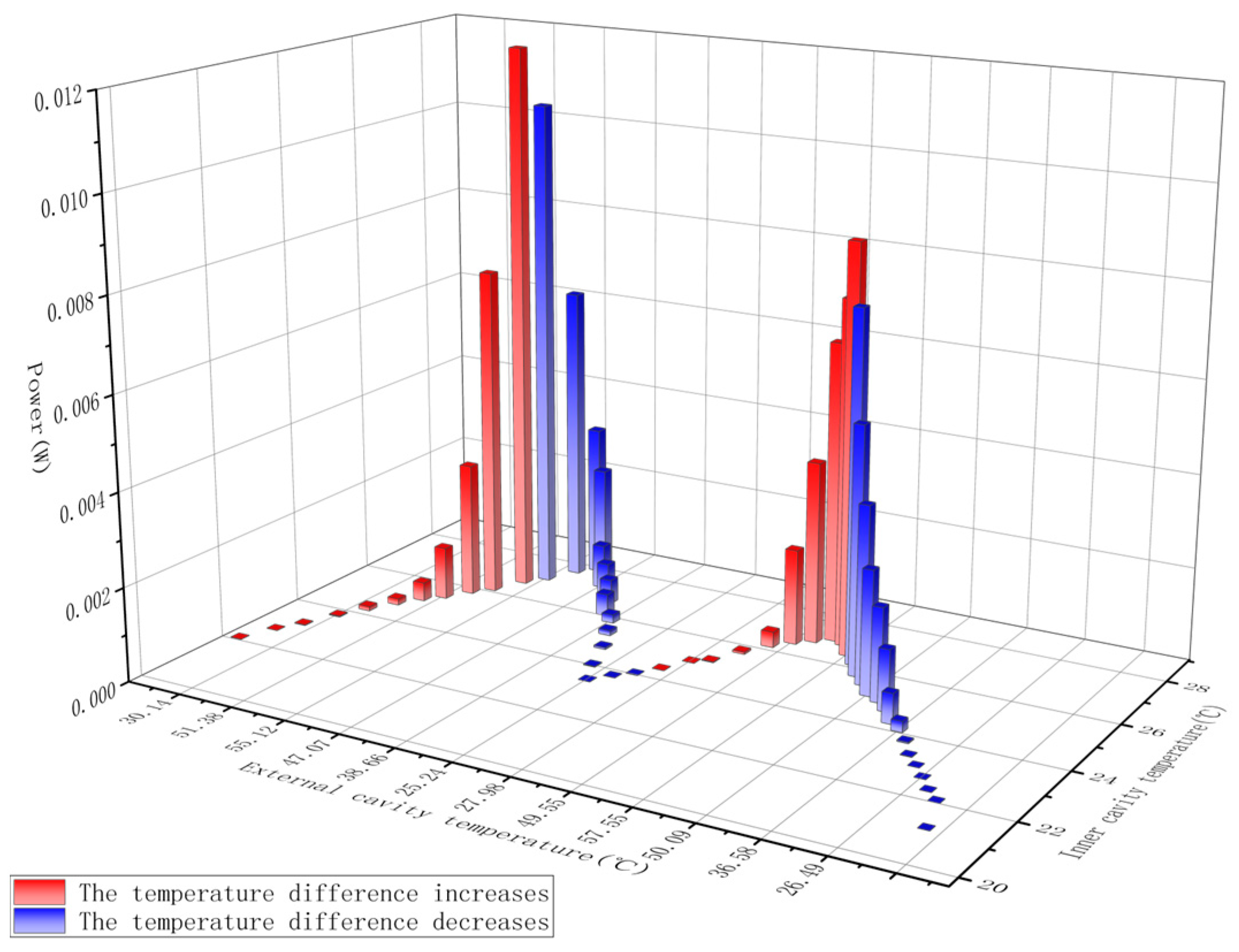

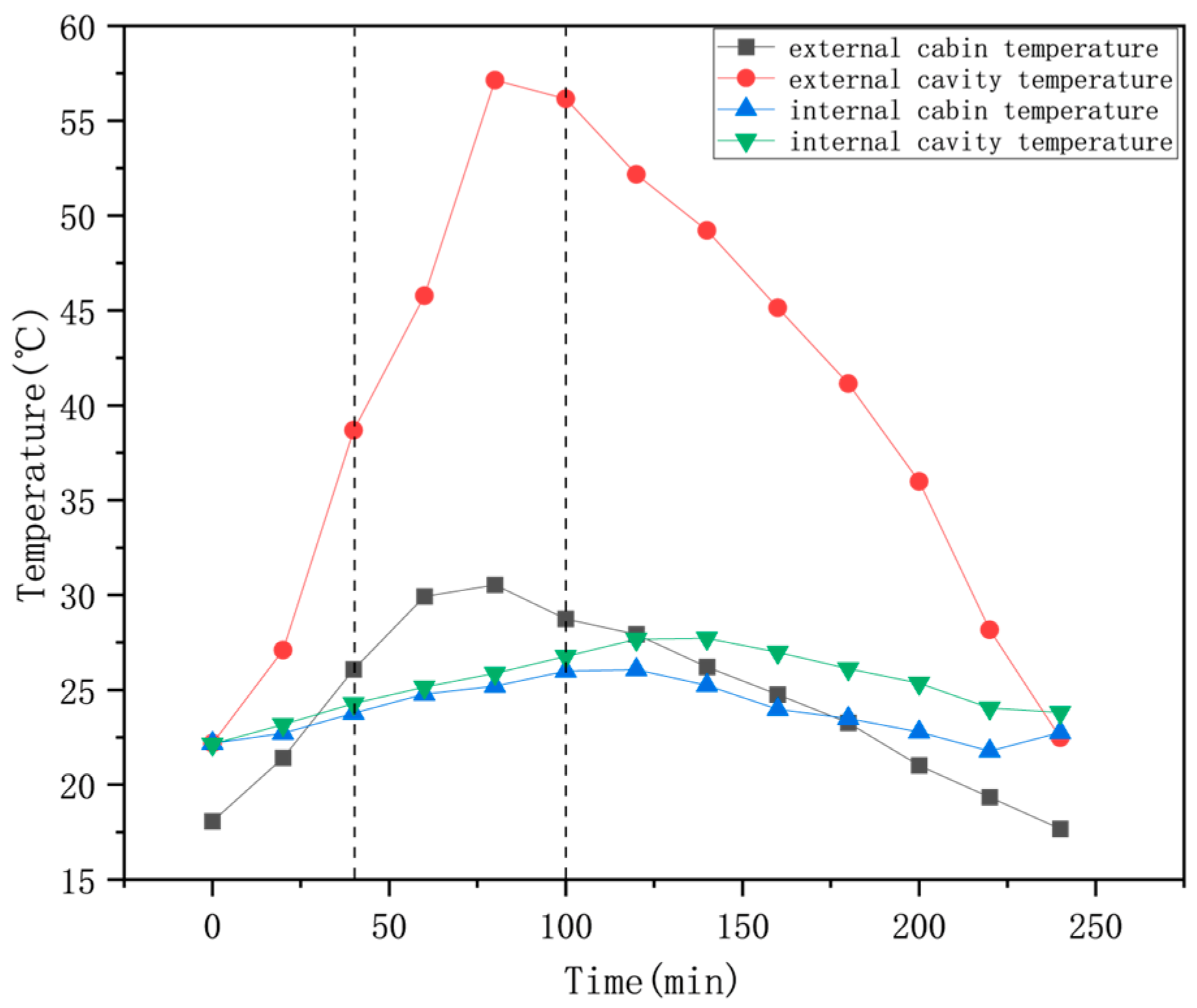

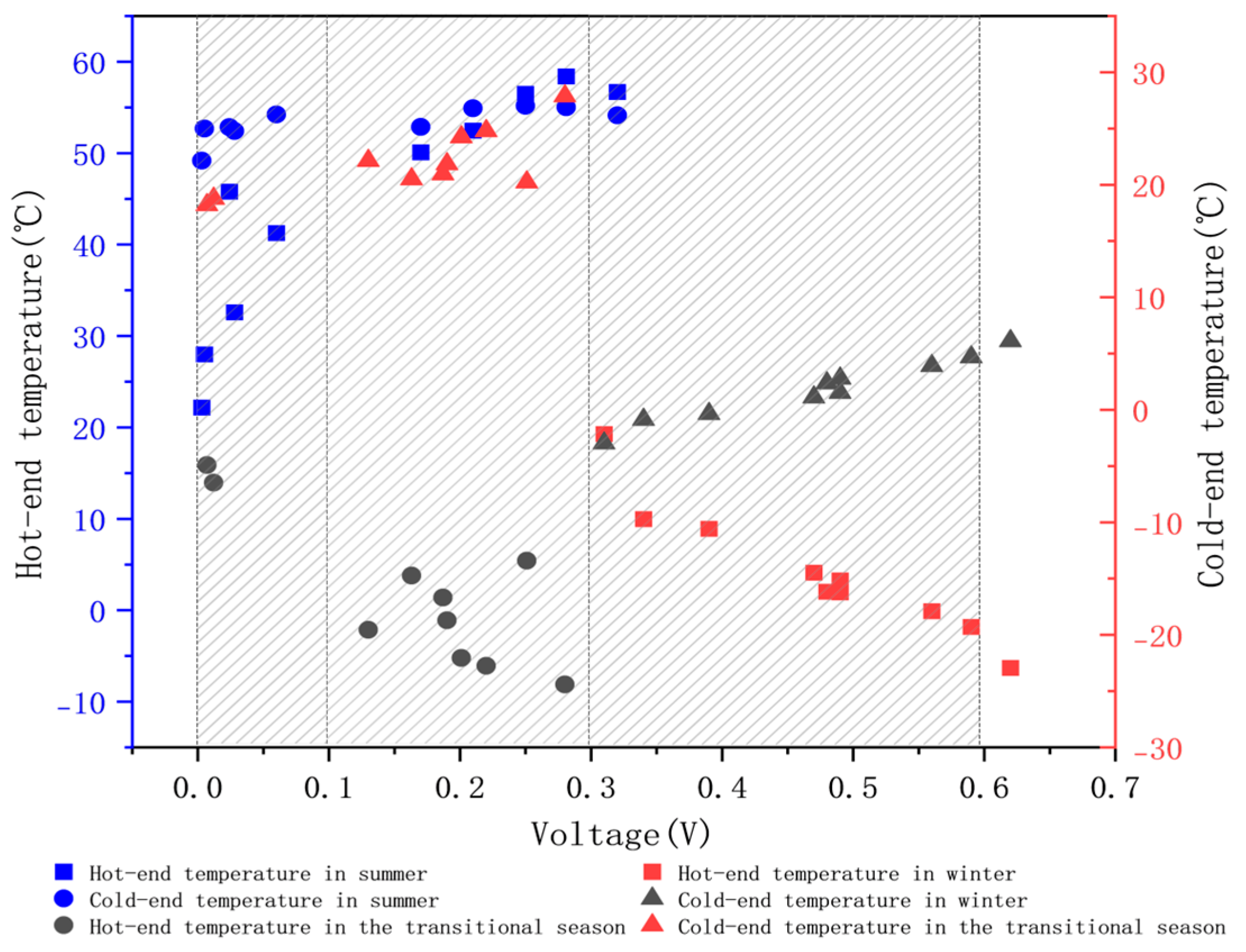

3.1. Summer Power Generation Performance

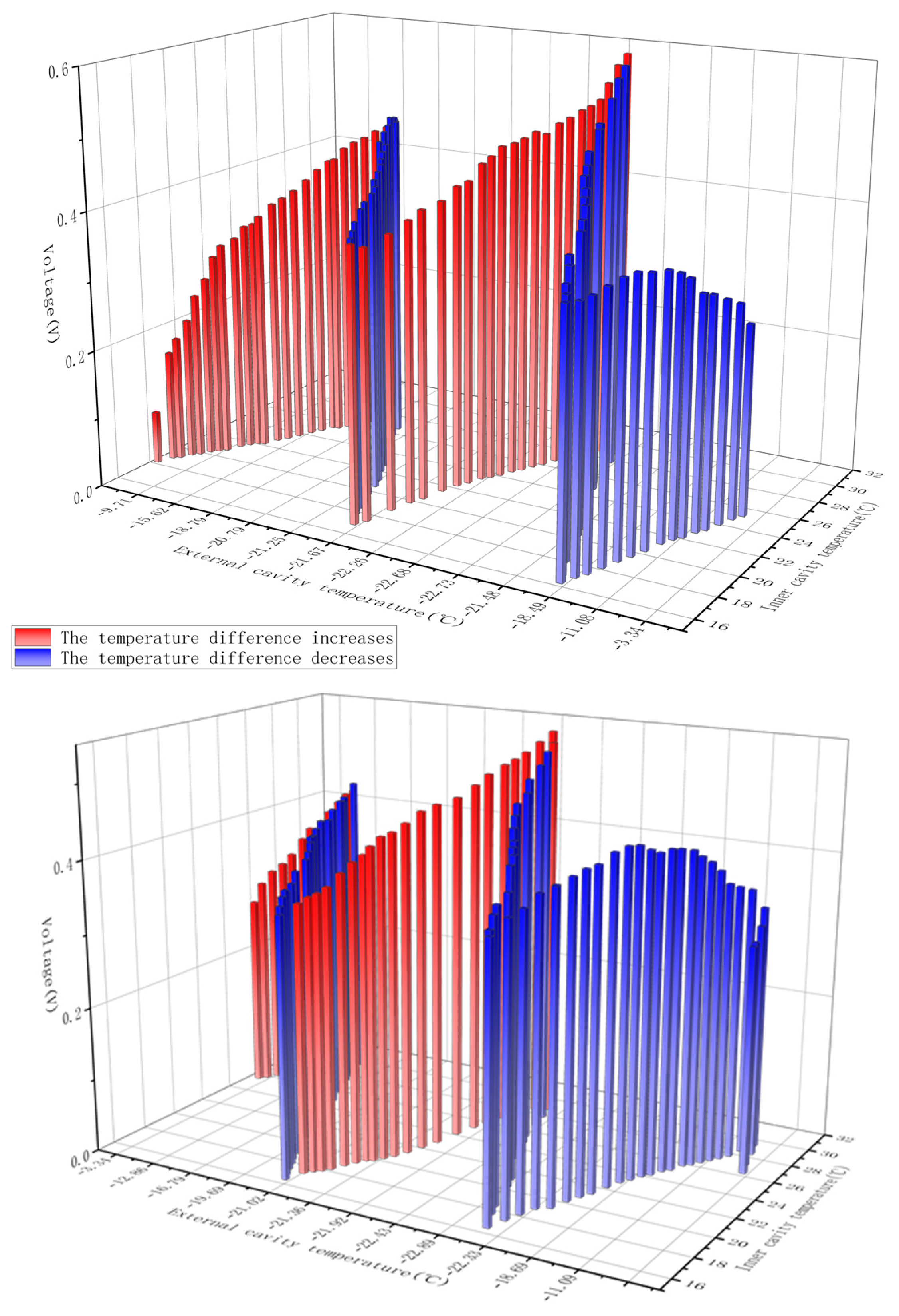

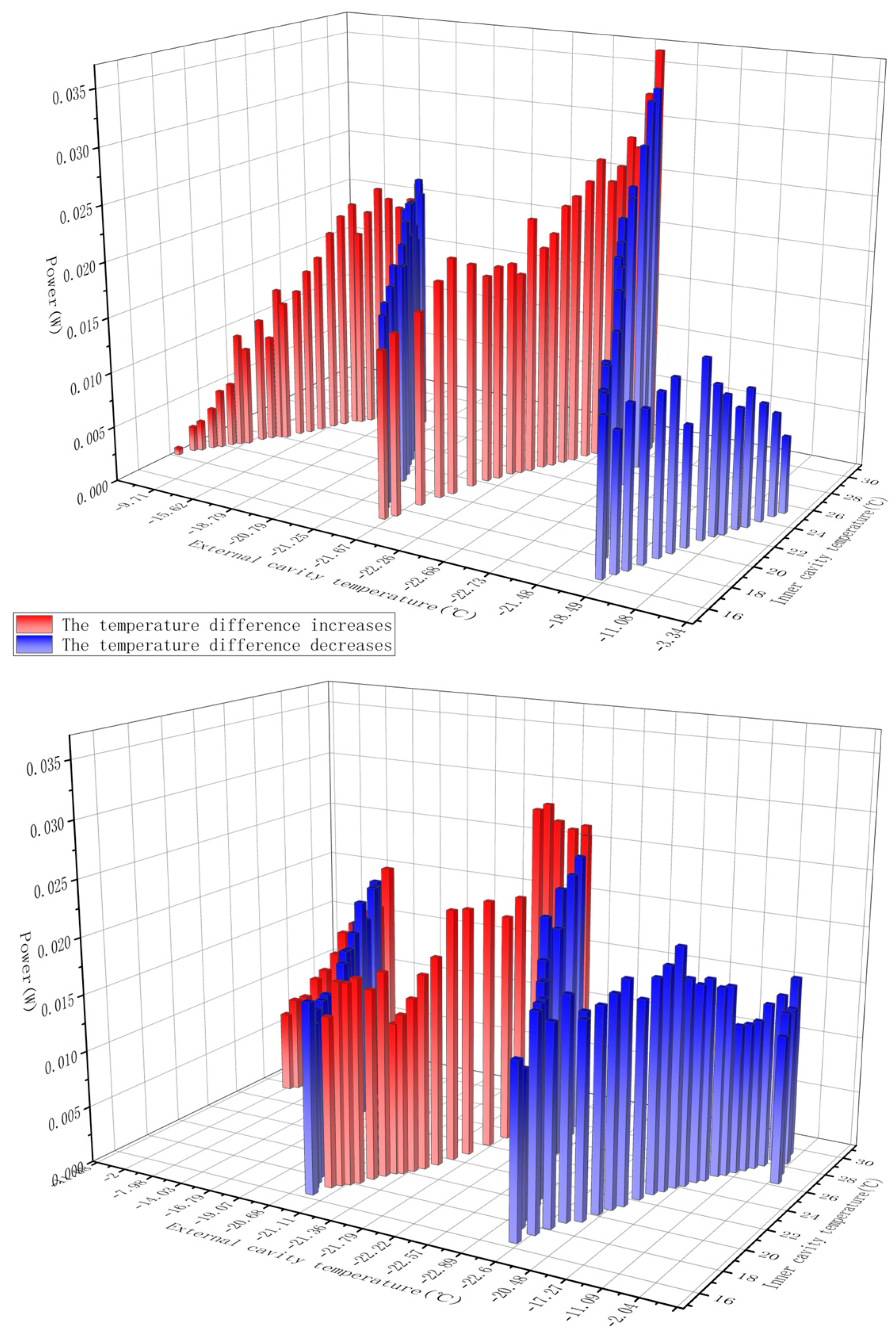

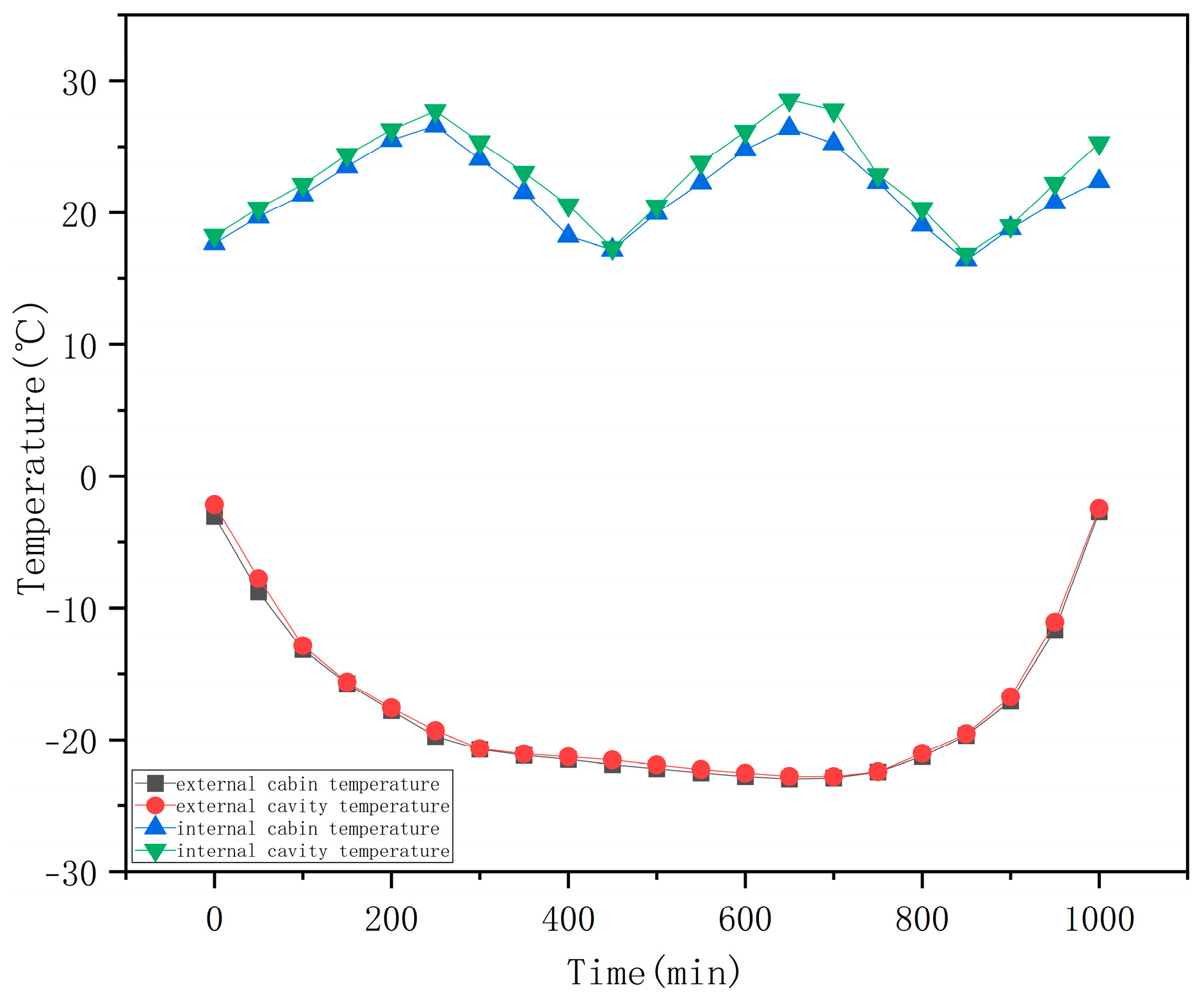

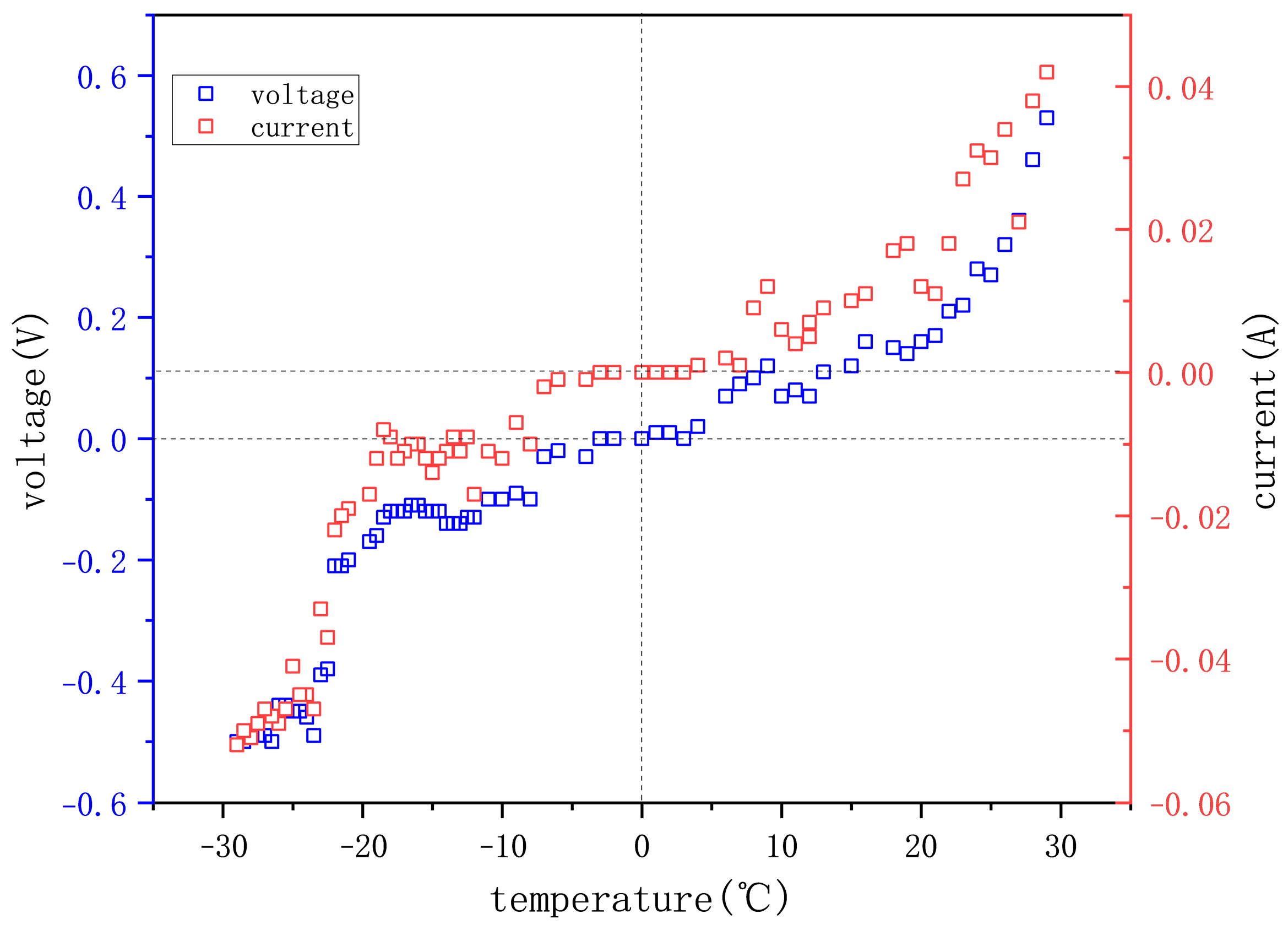

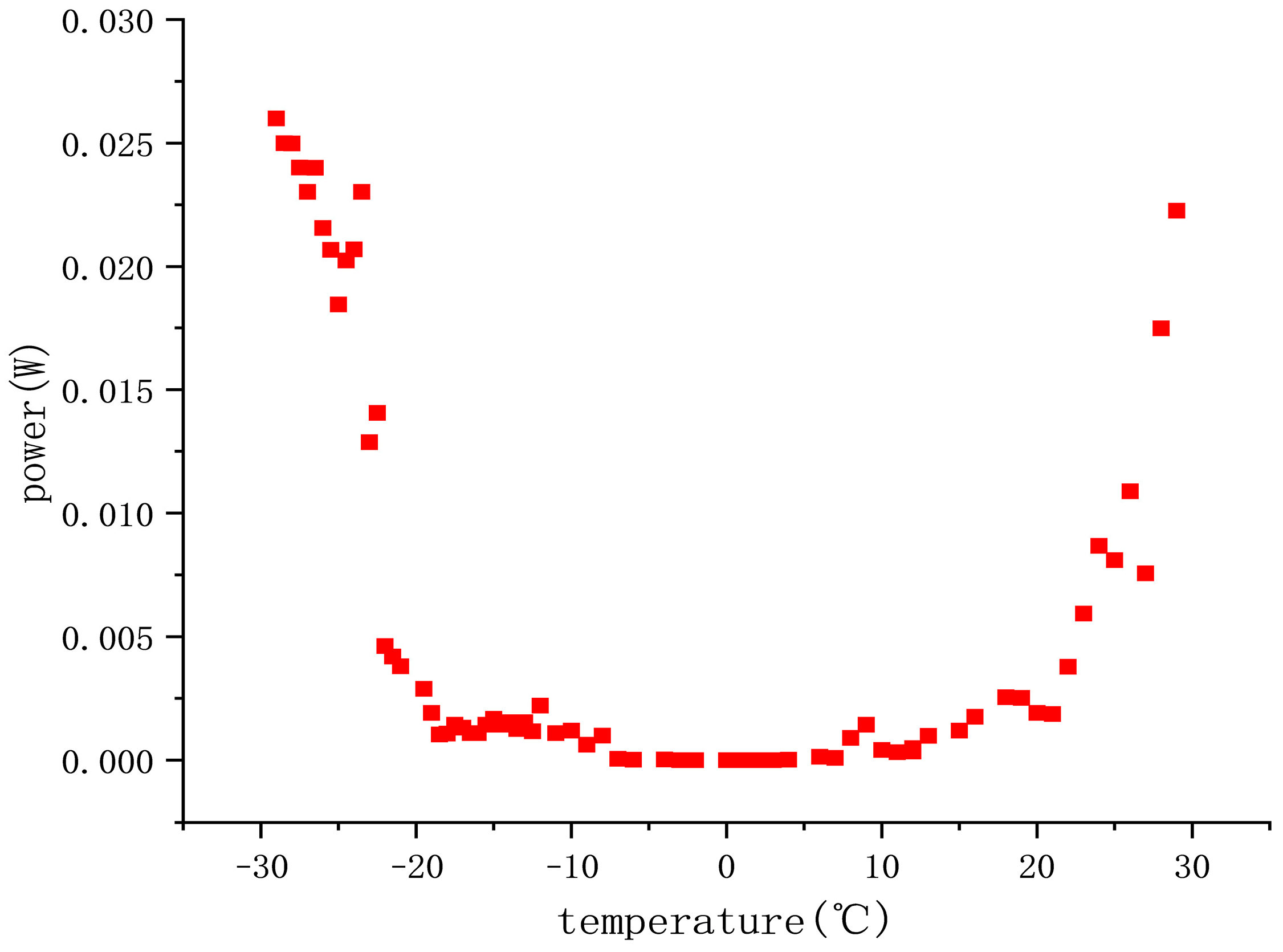

3.2. Winter Power Generation Performance

3.3. Power Generation Performance in the Transition Season

4. Discussion

4.1. Thermal Behavior of the System

4.1.1. Heat Collection Performance of the System Collector

4.1.2. Temperature Field Distribution in the System

4.2. Electrical Behavior of the System

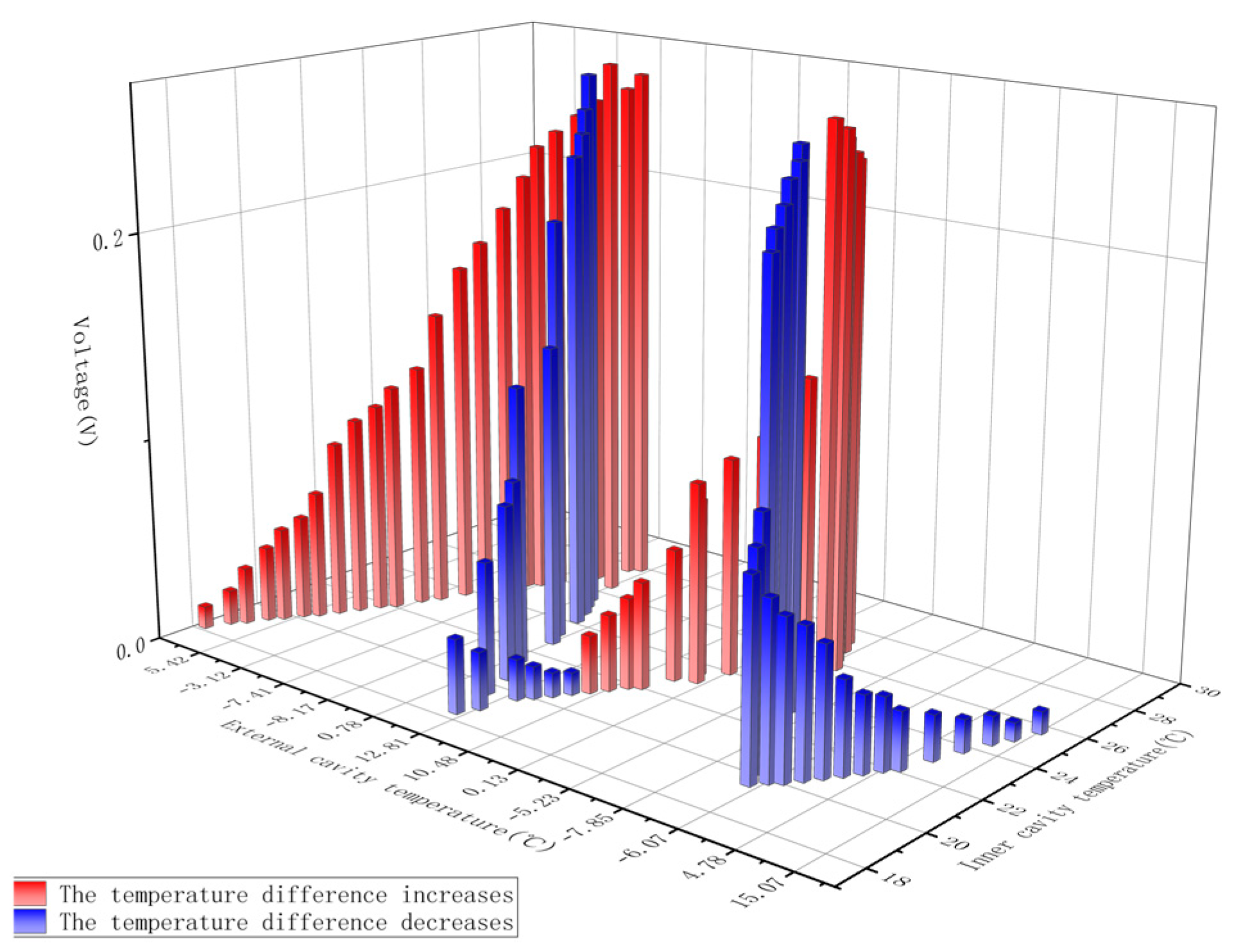

4.2.1. Voltage Variation Characteristics

4.2.2. Power Variations at a Single Point of the System Device

4.3. Thermoelectric Behavior of the System

4.3.1. Summer

4.3.2. Winter

4.3.3. Transition Season

4.3.4. Annual Thermoelectric Power Generation Performance

4.3.5. Power Generation Performance of the TEPG–Wall System per Unit Area

4.4. Significance

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TEPG–Wall | Thermoelectric power generation–wall system |

| TEPG | Thermoelectric power generation |

| PCMs | Phase-change materials |

| CTEG | Concentrating thermoelectric generator |

| TEG | Thermoelectric generator |

Appendix A

| External Cabin Temperature/°C | External Cavity Temperature/°C | Internal Cabin Temperature/°C | Internal Cavity Temperature/°C | Temperature Difference in the Cavity/°C | Voltage/V | Current/A |

|---|---|---|---|---|---|---|

| 18.07 | 22.18 | 22.18 | 22.14 | 0.04 | 0 | 0 |

| 19.36 | 23.12 | 22.25 | 22.76 | 0.36 | 0.004 | 0.000 |

| 21.42 | 27.10 | 22.72 | 23.18 | 3.92 | 0.013 | 0.001 |

| 24.36 | 30.14 | 23.48 | 23.79 | 6.35 | 0.021 | 0.001 |

| 26.08 | 38.68 | 23.77 | 24.28 | 14.40 | 0.047 | 0.002 |

| 27.82 | 41.42 | 24.01 | 24.76 | 16.48 | 0.069 | 0.002 |

| 29.92 | 45.78 | 24.78 | 25.15 | 20.63 | 0.081 | 0.005 |

| 30.21 | 51.38 | 24.92 | 25.44 | 25.94 | 0.127 | 0.009 |

| 30.54 | 57.14 | 25.20 | 25.87 | 31.27 | 0.182 | 0.016 |

| 29.37 | 58.11 | 25.59 | 26.18 | 31.93 | 0.247 | 0.029 |

| 28.74 | 56.15 | 25.99 | 26.76 | 29.39 | 0.298 | 0.040 |

| 28.81 | 55.12 | 26.39 | 27.10 | 28.02 | 0.288 | 0.037 |

| 27.93 | 52.17 | 26.07 | 27.67 | 24.50 | 0.207 | 0.031 |

| 27.07 | 50.87 | 25.76 | 27.95 | 22.92 | 0.149 | 0.022 |

| 26.21 | 49.21 | 25.24 | 27.72 | 21.49 | 0.137 | 0.018 |

| 25.34 | 47.07 | 24.57 | 27.26 | 19.81 | 0.096 | 0.010 |

| 24.76 | 45.14 | 23.98 | 26.98 | 18.16 | 0.088 | 0.008 |

| 23.91 | 42.21 | 24.06 | 26.65 | 15.56 | 0.076 | 0.007 |

| 23.27 | 41.14 | 23.49 | 26.11 | 15.03 | 0.069 | 0.007 |

| 21.89 | 38.66 | 23.01 | 25.87 | 12.79 | 0.046 | 0.004 |

| 21.01 | 35.98 | 22.78 | 25.35 | 10.63 | 0.038 | 0.003 |

| 20.17 | 32.59 | 22.29 | 24.78 | 7.81 | 0.022 | 0.002 |

| 19.34 | 28.17 | 21.78 | 24.04 | 4.13 | 0.015 | 0.001 |

| 18.42 | 25.24 | 22.44 | 23.47 | 1.77 | 0 | 0 |

| 17.67 | 22.48 | 22.76 | 23.81 | −1.33 | 0 | 0 |

| 18.17 | 21.67 | 23.01 | 24.08 | −2.41 | 0.002 | 0 |

| 19.46 | 24.88 | 23.49 | 24.47 | 0.41 | 0 | 0 |

| 21.52 | 27.98 | 23.88 | 24.99 | 2.99 | 0.003 | 0 |

| 24.26 | 31.76 | 24.17 | 25.17 | 6.59 | 0.014 | 0.001 |

| 26.18 | 36.19 | 24.55 | 25.74 | 10.45 | 0.023 | 0.002 |

| 27.92 | 41.26 | 25.00 | 26.24 | 15.02 | 0.056 | 0.006 |

| 29.82 | 49.55 | 25.38 | 26.56 | 22.99 | 0.121 | 0.017 |

| 30.43 | 52.46 | 25.77 | 26.79 | 25.67 | 0.196 | 0.020 |

| 30.94 | 56.48 | 26.14 | 27.01 | 29.47 | 0.239 | 0.027 |

| 29.97 | 58.38 | 25.89 | 26.89 | 31.49 | 0.257 | 0.029 |

| 28.94 | 57.55 | 25.66 | 26.52 | 31.03 | 0.283 | 0.031 |

| 28.61 | 56.69 | 25.34 | 26.18 | 30.51 | 0.270 | 0.028 |

| 27.94 | 55.44 | 25.07 | 25.77 | 29.67 | 0.254 | 0.021 |

| 27.27 | 53.17 | 24.69 | 25.49 | 27.68 | 0.191 | 0.020 |

| 26.31 | 50.09 | 24.22 | 25.14 | 24.95 | 0.157 | 0.017 |

| 25.42 | 48.22 | 23.76 | 24.98 | 23.24 | 0.144 | 0.014 |

| 24.76 | 45.89 | 23.44 | 24.71 | 21.18 | 0.120 | 0.011 |

| 23.93 | 41.77 | 23.18 | 24.32 | 17.45 | 0.081 | 0.008 |

| 23.17 | 36.58 | 22.94 | 24.12 | 12.46 | 0.047 | 0.005 |

| 22.66 | 32.11 | 22.66 | 23.79 | 8.32 | 0.014 | 0.002 |

| 21.87 | 30.24 | 22.47 | 23.36 | 6.88 | 0.010 | 0.001 |

| 21.00 | 28.27 | 22.11 | 23.07 | 5.2 | 0.005 | 0 |

| 20.18 | 26.49 | 21.84 | 22.74 | 3.75 | 0.003 | 0 |

| 19.36 | 24.24 | 22.07 | 22.38 | 1.86 | 0 | 0 |

| 18.43 | 21.88 | 22.39 | 22.10 | −0.22 | 0 | 0 |

| 17.68 | 19.19 | 22.88 | 21.21 | −2.02 | 0 | 0 |

Appendix B

| External Cabin Temperature/°C | External Cavity Temperature/°C | Internal Cabin Temperature/°C | Internal Cavity Temperature/°C | Temperature Difference in the Cavity/°C | Voltage/V | Current/A |

|---|---|---|---|---|---|---|

| −3.04 | −2.15 | 17.68 | 18.27 | 20.42 | 0.076 | 0.008 |

| −4.29 | −3.12 | 18.25 | 18.98 | 22.1 | 0.161 | 0.014 |

| −5.33 | −3.97 | 18.48 | 19.19 | 23.16 | 0.182 | 0.015 |

| −6.61 | −4.87 | 18.88 | 19.64 | 24.51 | 0.207 | 0.018 |

| −7.80 | −6.21 | 19.09 | 19.92 | 26.13 | 0.243 | 0.022 |

| −8.80 | −7.77 | 19.67 | 20.33 | 28.1 | 0.266 | 0.022 |

| −9.58 | −8.94 | 19.93 | 20.61 | 29.55 | 0.298 | 0.035 |

| −10.44 | −9.71 | 20.28 | 20.85 | 30.56 | 0.314 | 0.029 |

| −11.86 | −10.58 | 20.56 | 21.49 | 32.07 | 0.321 | 0.036 |

| −12.47 | −11.66 | 20.88 | 21.85 | 33.51 | 0.337 | 0.029 |

| −13.16 | −12.85 | 21.36 | 22.13 | 34.98 | 0.340 | 0.042 |

| −13.71 | −13.26 | 21.85 | 22.24 | 35.5 | 0.351 | 0.037 |

| −14.13 | −14.02 | 22.19 | 22.88 | 36.9 | 0.366 | 0.038 |

| −14.61 | −14.47 | 22.26 | 23.30 | 37.77 | 0.373 | 0.042 |

| −15.18 | −15.15 | 22.73 | 23.79 | 38.94 | 0.382 | 0.044 |

| −15.74 | −15.62 | 23.49 | 24.38 | 40 | 0.395 | 0.048 |

| −16.03 | −16.17 | 23.98 | 24.85 | 41.02 | 0.408 | 0.050 |

| −16.79 | −16.22 | 24.03 | 25.37 | 41.59 | 0.419 | 0.051 |

| −17.06 | −16.78 | 24.77 | 25.45 | 42.23 | 0.422 | 0.044 |

| −17.55 | −17.07 | 24.93 | 25.84 | 42.91 | 0.437 | 0.047 |

| −17.76 | −17.56 | 25.49 | 26.27 | 43.83 | 0.444 | 0.051 |

| −18.11 | −17.89 | 25.98 | 26.74 | 44.63 | 0.449 | 0.048 |

| −18.52 | −18.24 | 26.37 | 27.21 | 45.45 | 0.457 | 0.045 |

| −19.07 | −18.79 | 26.88 | 27.75 | 46.54 | 0.461 | 0.046 |

| −19.34 | −19.00 | 27.06 | 27.99 | 46.99 | 0.472 | 0.048 |

| −19.73 | −19.29 | 26.57 | 27.70 | 46.99 | 0.471 | 0.045 |

| −19.99 | −19.67 | 25.76 | 27.29 | 46.96 | 0.480 | 0.048 |

| −20.27 | −19.98 | 25.24 | 26.89 | 46.87 | 0.484 | 0.049 |

| −20.41 | −20.19 | 24.57 | 26.66 | 46.85 | 0.479 | 0.047 |

| −20.58 | −20.48 | 23.98 | 25.87 | 46.35 | 0.491 | 0.038 |

| −20.71 | −20.66 | 24.06 | 25.35 | 46.01 | 0.484 | 0.042 |

| −20.83 | −20.79 | 23.49 | 24.68 | 45.47 | 0.479 | 0.044 |

| −20.90 | −20.90 | 23.03 | 23.98 | 44.88 | 0.470 | 0.048 |

| −20.98 | −20.97 | 22.69 | 24.06 | 45.03 | 0.466 | 0.050 |

| −21.11 | −21.01 | 22.17 | 23.49 | 44.50 | 0.460 | 0.051 |

| −21.17 | −21.07 | 21.53 | 23.03 | 44.10 | 0.454 | 0.044 |

| −21.22 | −21.10 | 21.07 | 22.66 | 43.76 | 0.449 | 0.047 |

| −21.29 | −21.13 | 20.46 | 22.07 | 43.20 | 0.444 | 0.051 |

| −21.33 | −21.18 | 19.79 | 21.43 | 42.61 | 0.438 | 0.048 |

| −21.40 | −21.25 | 19.18 | 21.17 | 42.42 | 0.431 | 0.045 |

| −21.49 | −21.29 | 18.22 | 20.56 | 41.85 | 0.427 | 0.046 |

| −21.58 | −21.33 | 17.79 | 19.69 | 41.02 | 0.422 | 0.048 |

| −21.66 | −21.38 | 17.21 | 19.08 | 40.46 | 0.418 | 0.045 |

| −21.71 | −21.41 | 16.89 | 18.32 | 39.73 | 0.407 | 0.044 |

| −21.80 | −21.47 | 16.36 | 17.80 | 39.27 | 0.400 | 0.043 |

| −21.88 | −21.52 | 17.17 | 17.32 | 38.84 | 0.395 | 0.037 |

| −21.94 | −21.59 | 18.25 | 16.97 | 38.56 | 0.391 | 0.038 |

| −22.00 | −21.67 | 18.79 | 17.47 | 39.14 | 0.384 | 0.042 |

| −22.08 | −21.78 | 19.28 | 18.85 | 40.63 | 0.392 | 0.044 |

| −22.14 | −21.86 | 19.69 | 19.88 | 41.74 | 0.404 | 0.048 |

| −22.20 | −21.91 | 19.97 | 20.47 | 42.38 | 0.415 | 0.051 |

| −22.28 | −21.97 | 20.38 | 21.55 | 43.52 | 0.420 | 0.048 |

| −22.36 | −22.08 | 20.84 | 22.34 | 44.42 | 0.436 | 0.043 |

| −22.42 | −22.14 | 21.37 | 22.82 | 44.96 | 0.441 | 0.044 |

| −22.49 | −22.21 | 21.93 | 23.47 | 45.68 | 0.462 | 0.042 |

| −22.52 | −22.26 | 22.25 | 23.79 | 46.05 | 0.471 | 0.039 |

| −22.60 | −22.30 | 22.72 | 24.21 | 46.51 | 0.483 | 0.048 |

| −22.66 | −22.38 | 23.48 | 24.78 | 47.16 | 0.485 | 0.042 |

| −22.70 | −22.42 | 23.77 | 25.17 | 47.59 | 0.490 | 0.044 |

| −22.74 | −22.48 | 24.01 | 25.69 | 48.17 | 0.497 | 0.048 |

| −22.79 | −22.54 | 24.78 | 26.13 | 48.67 | 0.492 | 0.050 |

| −22.82 | −22.59 | 24.92 | 26.79 | 49.38 | 0.504 | 0.051 |

| −22.85 | −22.62 | 25.20 | 27.27 | 49.89 | 0.510 | 0.054 |

| −22.90 | −22.68 | 25.59 | 27.84 | 50.52 | 0.518 | 0.049 |

| −22.95 | −22.74 | 25.99 | 28.17 | 50.91 | 0.523 | 0.051 |

| −22.98 | −22.77 | 26.39 | 28.54 | 51.31 | 0.531 | 0.055 |

| −23.02 | −22.82 | 26.77 | 28.76 | 51.58 | 0.554 | 0.051 |

| −23.05 | −22.90 | 27.07 | 29.14 | 52.04 | 0.579 | 0.057 |

| −23.01 | −22.93 | 26.54 | 29.47 | 52.4 | 0.594 | 0.062 |

| −22.96 | −22.84 | 25.76 | 28.83 | 51.67 | 0.581 | 0.058 |

| −22.90 | −22.79 | 25.24 | 27.76 | 50.55 | 0.569 | 0.058 |

| −22.81 | −22.73 | 24.57 | 26.73 | 49.46 | 0.547 | 0.054 |

| −22.78 | −22.68 | 23.68 | 25.27 | 47.95 | 0.522 | 0.051 |

| −22.66 | −22.60 | 23.46 | 24.76 | 47.36 | 0.518 | 0.050 |

| −22.58 | −22.52 | 22.78 | 23.45 | 45.97 | 0.497 | 0.050 |

| −22.44 | −22.43 | 22.29 | 22.86 | 45.29 | 0.483 | 0.048 |

| −22.29 | −22.39 | 21.78 | 22.18 | 44.57 | 0.475 | 0.047 |

| −22.11 | −22.28 | 21.44 | 21.87 | 44.15 | 0.461 | 0.047 |

| −21.87 | −21.89 | 20.76 | 21.31 | 43.2 | 0.454 | 0.042 |

| −21.55 | −21.48 | 19.78 | 20.97 | 42.45 | 0.447 | 0.044 |

| −21.27 | −21.03 | 19.07 | 20.28 | 41.31 | 0.434 | 0.048 |

| −21.06 | −20.86 | 18.31 | 19.69 | 40.55 | 0.425 | 0.042 |

| −20.76 | −20.37 | 17.97 | 18.38 | 38.75 | 0.406 | 0.040 |

| −20.47 | −20.09 | 17.28 | 17.98 | 38.07 | 0.397 | 0.041 |

| −20.10 | −19.88 | 16.69 | 17.27 | 37.15 | 0.381 | 0.039 |

| −19.66 | −19.54 | 16.38 | 16.84 | 36.38 | 0.373 | 0.040 |

| −19.18 | −19.13 | 17.27 | 16.33 | 35.46 | 0.368 | 0.037 |

| −18.54 | −18.49 | 17.65 | 16.97 | 35.46 | 0.366 | 0.033 |

| −18.21 | −17.88 | 17.99 | 17.46 | 35.34 | 0.370 | 0.038 |

| −17.68 | −17.20 | 18.37 | 18.21 | 35.41 | 0.376 | 0.035 |

| −17.07 | −16.73 | 18.79 | 18.99 | 35.72 | 0.382 | 0.037 |

| −16.31 | −16.07 | 19.28 | 19.64 | 35.71 | 0.384 | 0.039 |

| −15.49 | −15.29 | 19.69 | 20.35 | 35.64 | 0.379 | 0.028 |

| −14.20 | −14.13 | 19.97 | 21.27 | 35.40 | 0.375 | 0.042 |

| −12.96 | −12.88 | 20.38 | 21.83 | 34.71 | 0.368 | 0.036 |

| −11.67 | −11.08 | 20.76 | 22.19 | 33.27 | 0.359 | 0.034 |

| −10.08 | −9.37 | 21.07 | 22.88 | 32.25 | 0.334 | 0.032 |

| −9.21 | −8.77 | 21.38 | 23.27 | 32.04 | 0.330 | 0.037 |

| −7.88 | −7.14 | 21.86 | 24.03 | 31.17 | 0.318 | 0.033 |

| −5.37 | −5.22 | 22.20 | 24.76 | 29.98 | 0.307 | 0.030 |

| −2.68 | −2.45 | 22.36 | 25.27 | 27.72 | 0.275 | 0.025 |

| −2.39 | −2.00 | 22.93 | 25.63 | 27.63 | 0.271 | 0.027 |

| −3.04 | −2.89 | 23.57 | 25.93 | 28.82 | 0.298 | 0.029 |

| −4.07 | −3.34 | 23.97 | 26.39 | 29.73 | 0.314 | 0.028 |

| −5.13 | −4.01 | 24.13 | 26.87 | 30.88 | 0.323 | 0.032 |

| −6.21 | −5.21 | 24.67 | 27.24 | 32.45 | 0.336 | 0.033 |

| −7.80 | −6.78 | 24.95 | 27.77 | 34.55 | 0.357 | 0.035 |

| −9.00 | −7.98 | 25.39 | 28.04 | 36.02 | 0.372 | 0.039 |

| −9.98 | −9.17 | 25.84 | 28.56 | 37.73 | 0.381 | 0.040 |

| −11.44 | −10.59 | 26.27 | 28.84 | 39.43 | 0.394 | 0.039 |

| −12.86 | −11.67 | 26.88 | 29.27 | 40.94 | 0.407 | 0.040 |

| −13.47 | −12.86 | 27.23 | 29.53 | 42.39 | 0.418 | 0.038 |

| −14.16 | −13.27 | 27.48 | 29.76 | 43.03 | 0.423 | 0.045 |

| −14.61 | −14.03 | 26.97 | 29.44 | 43.47 | 0.436 | 0.047 |

| −15.19 | −14.48 | 25.86 | 28.27 | 42.75 | 0.423 | 0.041 |

| −15.84 | −15.16 | 25.34 | 27.76 | 42.92 | 0.420 | 0.048 |

| −16.23 | −15.63 | 24.77 | 27.35 | 42.98 | 0.424 | 0.047 |

| −16.78 | −16.18 | 23.78 | 26.86 | 43.04 | 0.427 | 0.047 |

| −17.16 | −16.23 | 23.36 | 25.91 | 42.14 | 0.421 | 0.042 |

| −17.76 | −16.79 | 22.76 | 25.04 | 41.83 | 0.407 | 0.044 |

| −18.10 | −17.17 | 22.27 | 24.87 | 42.04 | 0.414 | 0.048 |

| −18.42 | −17.58 | 21.79 | 23.98 | 41.56 | 0.418 | 0.042 |

| −19.06 | −17.89 | 21.47 | 23.26 | 41.15 | 0.413 | 0.040 |

| −19.37 | −18.24 | 20.73 | 22.66 | 40.90 | 0.408 | 0.041 |

| −19.63 | −18.79 | 19.74 | 22.13 | 40.92 | 0.410 | 0.039 |

| −19.98 | −19.07 | 19.09 | 21.75 | 40.82 | 0.406 | 0.032 |

| −20.17 | −19.39 | 18.51 | 21.27 | 40.66 | 0.397 | 0.033 |

| −20.40 | −19.69 | 17.98 | 20.73 | 40.42 | 0.391 | 0.035 |

| −20.59 | −19.99 | 17.27 | 19.64 | 39.63 | 0.383 | 0.039 |

| −20.75 | −20.20 | 16.68 | 19.00 | 39.20 | 0.372 | 0.040 |

| −20.84 | −20.47 | 16.37 | 18.31 | 38.78 | 0.367 | 0.039 |

| −20.91 | −20.68 | 17.28 | 17.88 | 38.56 | 0.373 | 0.040 |

| −20.97 | −20.69 | 17.64 | 17.37 | 38.06 | 0.369 | 0.038 |

| −21.12 | −20.94 | 17.93 | 16.86 | 37.8 | 0.361 | 0.045 |

| −21.18 | −20.98 | 18.38 | 16.47 | 37.45 | 0.354 | 0.047 |

| −21.23 | −21.02 | 18.89 | 17.38 | 38.4 | 0.363 | 0.041 |

| −21.30 | −21.08 | 19.38 | 17.73 | 38.81 | 0.370 | 0.048 |

| −21.34 | −21.11 | 19.79 | 17.97 | 39.08 | 0.374 | 0.047 |

| −21.41 | −21.14 | 19.94 | 18.28 | 39.42 | 0.381 | 0.047 |

| −21.50 | −21.19 | 20.34 | 18.89 | 40.08 | 0.396 | 0.042 |

| −21.58 | −21.26 | 20.77 | 19.38 | 40.64 | 0.408 | 0.044 |

| −21.64 | −21.28 | 21.17 | 19.79 | 41.07 | 0.416 | 0.032 |

| −21.70 | −21.33 | 21.48 | 19.94 | 41.27 | 0.427 | 0.033 |

| −21.79 | −21.36 | 22.23 | 20.34 | 41.70 | 0.438 | 0.035 |

| −21.87 | −21.43 | 22.56 | 20.77 | 42.20 | 0.442 | 0.039 |

| −21.94 | −21.46 | 23.77 | 21.38 | 42.84 | 0.451 | 0.041 |

| −22.01 | −21.51 | 23.93 | 22.17 | 43.68 | 0.463 | 0.048 |

| −22.08 | −21.58 | 24.43 | 22.98 | 44.56 | 0.468 | 0.047 |

| −22.13 | −21.66 | 24.87 | 24.22 | 45.88 | 0.471 | 0.047 |

| −22.19 | −21.79 | 25.17 | 25.27 | 47.06 | 0.483 | 0.042 |

| −22.25 | −21.87 | 25.39 | 25.93 | 47.8 | 0.495 | 0.044 |

| −22.31 | −21.92 | 25.84 | 26.87 | 48.79 | 0.504 | 0.058 |

| −22.40 | −21.98 | 26.27 | 27.31 | 49.29 | 0.510 | 0.058 |

| −22.47 | −22.10 | 26.88 | 27.78 | 49.88 | 0.518 | 0.054 |

| −22.53 | −22.15 | 27.23 | 28.56 | 50.71 | 0.529 | 0.051 |

| −22.61 | −22.22 | 26.64 | 29.27 | 51.49 | 0.541 | 0.050 |

| −22.67 | −22.27 | 25.76 | 28.84 | 51.11 | 0.528 | 0.050 |

| −22.71 | −22.31 | 25.33 | 27.86 | 50.17 | 0.521 | 0.048 |

| −22.75 | −22.39 | 24.74 | 26.79 | 49.18 | 0.509 | 0.047 |

| −22.79 | −22.43 | 23.76 | 25.37 | 47.8 | 0.498 | 0.047 |

| −22.82 | −22.48 | 23.35 | 24.75 | 47.23 | 0.484 | 0.042 |

| −22.85 | −22.57 | 22.77 | 23.46 | 46.03 | 0.478 | 0.044 |

| −22.90 | −22.60 | 22.29 | 22.87 | 45.47 | 0.467 | 0.048 |

| −22.94 | −22.67 | 21.74 | 22.28 | 44.95 | 0.455 | 0.042 |

| −22.97 | −22.71 | 21.48 | 21.89 | 44.6 | 0.442 | 0.040 |

| −23.02 | −22.77 | 20.72 | 21.33 | 44.1 | 0.438 | 0.041 |

| −23.04 | −22.83 | 19.64 | 20.99 | 43.82 | 0.431 | 0.039 |

| −23.01 | −22.89 | 19.19 | 20.26 | 43.15 | 0.424 | 0.040 |

| −22.93 | −22.93 | 18.52 | 19.67 | 42.6 | 0.395 | 0.032 |

| −22.82 | −22.84 | 17.95 | 18.37 | 41.21 | 0.390 | 0.033 |

| −22.79 | −22.79 | 17.21 | 17.67 | 40.46 | 0.384 | 0.035 |

| −22.68 | −22.73 | 16.63 | 16.95 | 39.68 | 0.372 | 0.039 |

| −22.54 | −22.68 | 16.36 | 16.53 | 39.21 | 0.368 | 0.041 |

| −22.48 | −22.60 | 17.29 | 17.46 | 40.06 | 0.385 | 0.048 |

| −22.30 | −22.52 | 17.65 | 18.21 | 40.73 | 0.392 | 0.044 |

| −22.14 | −22.33 | 17.94 | 18.99 | 41.32 | 0.406 | 0.047 |

| −21.82 | −22.19 | 18.88 | 19.84 | 42.03 | 0.411 | 0.042 |

| −21.57 | −21.28 | 18.69 | 19.36 | 40.64 | 0.414 | 0.041 |

| −21.29 | −20.89 | 19.48 | 20.24 | 41.13 | 0.421 | 0.042 |

| −21.16 | −20.48 | 19.89 | 20.87 | 41.35 | 0.427 | 0.043 |

| −20.66 | −20.03 | 20.34 | 21.39 | 41.42 | 0.430 | 0.045 |

| −20.37 | −19.86 | 20.87 | 22.27 | 42.13 | 0.441 | 0.039 |

| −20.08 | −19.37 | 21.19 | 22.98 | 42.35 | 0.445 | 0.042 |

| −19.46 | −18.69 | 21.47 | 23.44 | 42.13 | 0.444 | 0.044 |

| −18.54 | −17.89 | 22.22 | 23.97 | 41.86 | 0.436 | 0.048 |

| −18.22 | −17.27 | 22.57 | 24.32 | 41.59 | 0.431 | 0.042 |

| −17.69 | −16.73 | 23.64 | 24.89 | 41.62 | 0.433 | 0.040 |

| −17.09 | −16.08 | 23.91 | 25.20 | 41.28 | 0.432 | 0.041 |

| −16.32 | −15.30 | 24.53 | 25.87 | 41.17 | 0.427 | 0.039 |

| −15.50 | −14.14 | 24.88 | 26.13 | 40.27 | 0.418 | 0.040 |

| −14.21 | −12.87 | 25.27 | 26.56 | 39.43 | 0.409 | 0.032 |

| −12.86 | −11.09 | 25.50 | 26.95 | 38.04 | 0.396 | 0.033 |

| −11.57 | −9.38 | 25.85 | 27.34 | 36.72 | 0.377 | 0.035 |

| −10.00 | −8.75 | 26.27 | 27.79 | 36.54 | 0.371 | 0.039 |

| −9.11 | −7.17 | 26.76 | 28.53 | 35.70 | 0.363 | 0.041 |

| −7.89 | −5.28 | 27.24 | 29.37 | 34.65 | 0.334 | 0.048 |

| −5.87 | −2.47 | 26.65 | 28.46 | 30.93 | 0.317 | 0.044 |

| −3.78 | −2.04 | 25.79 | 27.19 | 29.23 | 0.306 | 0.047 |

| −1.69 | −2.90 | 26.01 | 26.37 | 29.27 | 0.308 | 0.042 |

Appendix C

| External Cabin Temperature/°C | External Cavity Temperature/°C | Internal Cabin Temperature/°C | Internal Cavity Temperature/°C | Temperature Difference in the Cavity/°C | Voltage/V | Current/A |

|---|---|---|---|---|---|---|

| 15.92 | 15.88 | 17.88 | 18.21 | 2.33 | 0.011 | 0 |

| 12.66 | 13.96 | 18.24 | 18.78 | 4.82 | 0.017 | 0 |

| 9.86 | 11.10 | 18.49 | 19.07 | 7.97 | 0.028 | 0.001 |

| 7.55 | 9.14 | 18.87 | 19.54 | 10.4 | 0.037 | 0.001 |

| 5.65 | 6.68 | 19.07 | 19.82 | 13.14 | 0.046 | 0.002 |

| 4.20 | 5.42 | 19.66 | 20.23 | 14.81 | 0.051 | 0.003 |

| 2.69 | 3.78 | 19.92 | 20.51 | 16.73 | 0.063 | 0.005 |

| 1.35 | 1.38 | 20.27 | 20.94 | 19.56 | 0.087 | 0.009 |

| 0.22 | 0.14 | 20.55 | 21.39 | 21.25 | 0.098 | 0.012 |

| −1.00 | −1.11 | 20.89 | 21.84 | 22.95 | 0.104 | 0.019 |

| −2.03 | −2.15 | 21.37 | 22.14 | 24.29 | 0.113 | 0.011 |

| −3.07 | −3.12 | 21.84 | 22.76 | 25.88 | 0.121 | 0.017 |

| −3.83 | −3.97 | 22.18 | 23.18 | 27.15 | 0.147 | 0.011 |

| −4.65 | −4.87 | 22.25 | 23.79 | 28.66 | 0.169 | 0.022 |

| −5.34 | −5.21 | 22.72 | 24.24 | 29.45 | 0.181 | 0.018 |

| −6.11 | −6.07 | 23.48 | 24.79 | 30.86 | 0.197 | 0.016 |

| −6.74 | −7.14 | 23.77 | 25.25 | 32.39 | 0.212 | 0.020 |

| −7.14 | −7.41 | 24.01 | 25.48 | 32.89 | 0.227 | 0.022 |

| −7.08 | −7.58 | 24.78 | 25.88 | 33.46 | 0.234 | 0.021 |

| −6.89 | −7.66 | 24.92 | 26.38 | 34.04 | 0.241 | 0.022 |

| −7.62 | −7.85 | 25.24 | 26.78 | 34.63 | 0.248 | 0.024 |

| −7.88 | −7.96 | 24.57 | 27.66 | 35.62 | 0.252 | 0.025 |

| −7.94 | −8.12 | 23.98 | 27.88 | 36.00 | 0.259 | 0.026 |

| −8.00 | −8.17 | 23.46 | 26.48 | 34.65 | 0.268 | 0.026 |

| −6.46 | −7.68 | 22.94 | 25.45 | 33.13 | 0.266 | 0.024 |

| −5.06 | −6.29 | 22.57 | 25.04 | 31.33 | 0.251 | 0.020 |

| −3.78 | −5.47 | 22.00 | 24.67 | 30.14 | 0.241 | 0.022 |

| −2.62 | −4.89 | 21.54 | 24.15 | 29.04 | 0.232 | 0.021 |

| −1.67 | −2.56 | 21.08 | 23.21 | 25.77 | 0.205 | 0.019 |

| 0.12 | 0.78 | 20.49 | 22.77 | 21.99 | 0.147 | 0.015 |

| 2.46 | 1.97 | 19.78 | 21.39 | 19.42 | 0.135 | 0.014 |

| 4.53 | 4.48 | 19.07 | 20.98 | 16.5 | 0.093 | 0.010 |

| 6.45 | 6.69 | 18.21 | 20.48 | 13.79 | 0.085 | 0.009 |

| 8.21 | 8.84 | 17.77 | 19.57 | 10.73 | 0.064 | 0.006 |

| 9.91 | 10.77 | 18.35 | 18.37 | 7.6 | 0.036 | 0.004 |

| 11.47 | 12.81 | 18.99 | 18.85 | 6.04 | 0.028 | 0.003 |

| 13.01 | 14.14 | 19.28 | 19.77 | 5.63 | 0.020 | 0.002 |

| 15.12 | 16.07 | 19.59 | 20.06 | 3.99 | 0.016 | 0.002 |

| 16.47 | 17.11 | 19.87 | 20.41 | 3.3 | 0.012 | 0.001 |

| 15.62 | 16.58 | 20.28 | 20.78 | 4.2 | 0.011 | 0.001 |

| 12.96 | 13.21 | 20.56 | 21.11 | 7.9 | 0.028 | 0.003 |

| 9.78 | 10.48 | 20.99 | 21.48 | 11 | 0.037 | 0.004 |

| 7.65 | 8.34 | 21.21 | 21.86 | 13.52 | 0.044 | 0.005 |

| 5.45 | 6.76 | 21.55 | 22.04 | 15.28 | 0.052 | 0.005 |

| 4.30 | 5.46 | 21.87 | 22.88 | 17.42 | 0.064 | 0.006 |

| 2.79 | 3.77 | 22.19 | 23.46 | 19.69 | 0.086 | 0.008 |

| 1.45 | 1.37 | 22.98 | 23.11 | 21.74 | 0.097 | 0.009 |

| 0.32 | 0.13 | 23.64 | 23.98 | 23.85 | 0.105 | 0.010 |

| −1.07 | −1.10 | 24.11 | 24.88 | 25.98 | 0.112 | 0.011 |

| −2.05 | −2.16 | 24.77 | 25.34 | 27.50 | 0.123 | 0.012 |

| −3.08 | −3.13 | 24.91 | 25.84 | 28.97 | 0.138 | 0.014 |

| −3.85 | −3.98 | 25.23 | 27.18 | 31.16 | 0.237 | 0.023 |

| −4.67 | −4.89 | 24.56 | 26.73 | 31.62 | 0.242 | 0.024 |

| −5.44 | −5.23 | 23.97 | 26.11 | 31.34 | 0.251 | 0.025 |

| −6.21 | −6.09 | 23.47 | 25.74 | 31.83 | 0.257 | 0.026 |

| −6.84 | −6.77 | 22.93 | 24.98 | 31.75 | 0.264 | 0.027 |

| −7.32 | −7.43 | 22.56 | 23.46 | 30.89 | 0.258 | 0.026 |

| −7.04 | −7.57 | 22.07 | 23.11 | 30.68 | 0.252 | 0.025 |

| −5.93 | −7.69 | 21.55 | 22.47 | 30.16 | 0.247 | 0.024 |

| −6.87 | −7.85 | 21.18 | 21.99 | 29.84 | 0.238 | 0.023 |

| −7.43 | −7.99 | 20.59 | 21.38 | 29.37 | 0.231 | 0.023 |

| −7.75 | −7.96 | 19.98 | 20.96 | 28.92 | 0.223 | 0.022 |

| −7.91 | −8.12 | 19.47 | 20.48 | 28.60 | 0.115 | 0.014 |

| −8.08 | −8.17 | 18.61 | 20.01 | 28.18 | 0.103 | 0.011 |

| −6.86 | −7.56 | 17.74 | 19.55 | 27.11 | 0.095 | 0.010 |

| −5.21 | −6.07 | 18.37 | 19.87 | 25.94 | 0.084 | 0.009 |

| −3.79 | −4.29 | 18.89 | 20.06 | 24.35 | 0.076 | 0.008 |

| −2.67 | −3.07 | 19.29 | 20.42 | 23.49 | 0.071 | 0.007 |

| −1.57 | −2.58 | 19.67 | 20.77 | 23.35 | 0.062 | 0.006 |

| 0.13 | 0.88 | 20.28 | 21.13 | 20.25 | 0.045 | 0.005 |

| 2.48 | 2.97 | 20.57 | 21.49 | 18.52 | 0.037 | 0.004 |

| 4.56 | 4.78 | 21.19 | 21.87 | 17.09 | 0.035 | 0.003 |

| 6.47 | 6.99 | 21.61 | 22.14 | 15.15 | 0.028 | 0.003 |

| 8.28 | 8.94 | 21.95 | 22.98 | 14.04 | 0.022 | 0.002 |

| 9.96 | 10.87 | 22.37 | 23.76 | 12.89 | 0.016 | 0.002 |

| 11.57 | 12.08 | 22.89 | 24.48 | 12.40 | 0.014 | 0.001 |

| 13.21 | 13.86 | 23.28 | 24.97 | 11.11 | 0.009 | 0.001 |

| 15.17 | 15.07 | 23.79 | 25.66 | 10.59 | 0.011 | 0 |

References

- Sun, J.; Li, S.; Dong, Y. Multi-objective optimization of nearly zero energy building shape in cold regions with carbon neutrality orientation. J. Hum. Settl. West China 2024, 39, 87–95. [Google Scholar]

- Li, Z.Y.; Liu, J.S. Research on the development and countermeasures of green buildings under the dual carbon target. J. Southwest Financ. 2021, 55–66. (In Chinese) [Google Scholar]

- Wang, Y.Y.; Zhang, X.; Zhang, Y.F.; Zhang, H.; Xiong, B.; Shi, X.P. Multi-Objective Analysis of Visual, Thermal, and Energy Performance in Coordination with the Outdoor Thermal Environment of Productive Facades of Residential Communities in Guangzhou, China. Buildings 2023, 13, 1540. [Google Scholar] [CrossRef]

- Zhao, Y.H. Features and Construction of Prefabricated Buildings. In Proceedings of the 4th International Conference on Civil Engineering, Architecture and Building Materials (CEABM), Haikou, China, 24–25 May 2014. [Google Scholar]

- Chen, Y.; Hou, X.N.; Ma, C.Y.; Dou, Y.K.; Wu, W.T. Review of Development Status of Bi2Te3-Based Semiconductor Thermoelectric Power Generation. Adv. Mater. Sci. Eng. 2018, 2018, 1210562. [Google Scholar] [CrossRef]

- Seebeck, T.J. Ueber die magnetische Polarisation der Metalle und Erze durch Temperatur-Differenz. Ann. Phys. 1822, 82, 133–160. [Google Scholar] [CrossRef]

- Sommerfeldt, N.; Madani, H. Review of solar PV/thermal plus ground source heat pump systems for European multi-family houses. In Proceedings of the 11th ISES EuroSun Conference, Palma, Spain, 11–14 October 2016. [Google Scholar]

- Zhang, J.H.; Ming, H.W.; Li, D.; Qin, X.Y.; Zhang, J.; Huang, L.L.; Song, C.J.; Wang, L. Ultralow Thermal Conductivity and High Thermoelectric Performance of N-type Bi2Te2.7Se0.3-Based Composites Incorporated with GaAs Nanoinclusions. ACS Appl. Mater. Interfaces 2020, 12, 37155–37163. [Google Scholar] [CrossRef]

- Han, G.; Chen, Z.G.; Yang, L.; Hong, M.; Drennan, J.; Zou, J. Rational Design of Bi2Te3 Polycrystalline Whiskers for Thermoelectric Applications. ACS Appl. Mater. Interfaces 2015, 7, 989–995. [Google Scholar] [CrossRef]

- Win, S.L.Y.; Liao, C.T.; Chang, H.Y.; Lai, C.M. Experimental observations on electricity generation and thermal characteristics of TEG façades. Energy Build. 2023, 294, 113225. [Google Scholar] [CrossRef]

- Byon, Y.S.; Jeong, J.W. Annual energy harvesting performance of a phase change material-integrated thermoelectric power generation block in building walls. Energy Build. 2020, 228, 110470. [Google Scholar] [CrossRef]

- Hong, B.H.; Huang, X.Y.; He, J.W.; Cai, Y.; Wang, W.W.; Zhao, F.Y. Round-the-clock performance of solar thermoelectric wall with phase change material in subtropical climate: Critical analysis and parametric investigations. Energy 2023, 272, 127128. [Google Scholar] [CrossRef]

- Chandel, R.; Singh Chandel, S.; Prasad, D.; Prakash Dwivedi, R. Review on thermoelectric systems for enhancing photovoltaic power generation. Sustain. Energy Technol. Assess. 2022, 53, 102585. [Google Scholar] [CrossRef]

- Faheem, M.; Abu Bakr, M.; Ali, M.; Majeed, M.A.; Haider, Z.M.; Khan, M.O. Evaluation of Efficiency Enhancement in Photovoltaic Panels via Integrated Thermoelectric Cooling and Power Generation. Energies 2024, 17, 2590. [Google Scholar] [CrossRef]

- Sun, Q.; Du, C.; Chen, G. Thermoelectric materials and applications in buildings. Prog. Mater. Sci. 2025, 149, 101402. [Google Scholar]

- Bel-Hadj, I.; Bougrioua, Z.; Ziouche, K. Planar Micro-thermoelectric Generators Based on Cu55Ni45 and Ni90Cr10 Thermocouples for IoT Applications. In Advanced Computational Techniques for Renewable Energy Systems; Springer: Cham, Switzerland, 2023. [Google Scholar]

- Wu, J.; Liu, M.; Xu, X.; Zhang, Y.; Lao, X.; Li, K. Preparation and thermal properties of SiC based solar heat absorbing ceramic. J. Chin. Ceram. Soc. 2012, 40, 1685–1692. (In Chinese) [Google Scholar]

- Luo, Y.; Zhang, L.; Wu, J.; Liu, Z.; Wu, Z.; He, X. Dynamical simulation of building integrated photovoltaic thermoelectric wall system: Balancing calculation speed and accuracy. Appl. Energy 2017, 204, 887–897. [Google Scholar]

- Lamba, R.; Kaushik, S.C. Modeling and performance analysis of a concentrated photovoltaic–thermoelectric hybrid power generation system. Energy Convers. Manag. 2016, 115, 288–298. [Google Scholar]

- Liao, T.; Lin, B.; Yang, Z. Performance characteristics of a low concentrated photovoltaic–thermoelectric hybrid power generation device. Int. J. Therm. Sci. 2014, 77, 158–164. [Google Scholar]

- Yin, E.; Li, Q.; Xuan, Y. Feasibility analysis of a tandem photovoltaic-thermoelectric hybrid system under solar concentration. Renew. Energy 2020, 162, 1828–1841. [Google Scholar]

- Huq, M.; Jasi, A.M.; Poure, P.; Jovanovic, S.; Revol, I.; Lenoir, B. Critical analysis of optimized energy harvesting at small-scale by thermally coupled photovoltaic-thermoelectric systems. Renew. Sustain. Energy Rev. 2024, 195, 114331. [Google Scholar]

- Nyandang, A.N.; Singh, B.; Remeli, F.M.; Oberoi, A. Power Generation using Thermoelectric Power Generator with Parabolic Solar Dish Concentrator. J. Phys. Conf. Ser. 2021, 2013, 012004. [Google Scholar]

- Pintanel, M.T.; Martínez-Gracia, A.; Galindo, M.P.; Bayod-Rújula, A.A.; Uche, J.; Tejero, J.A.; del Amo, A. Analysis of the Experimental Integration of Thermoelectric Generators in Photovoltaic-Thermal Hybrid Panels. Appl. Sci. 2021, 11, 2915. [Google Scholar] [CrossRef]

- Fan, H.N.; Singh, R.; Akbarzadeh, A. Electric Power Generation from Thermoelectric Cells Using a Solar Dish Concentrator. J. Electron. Mater. 2011, 40, 1311–1320. [Google Scholar]

- Liu, Z.B.; Zhang, L.; Gong, G.C.; Luo, Y.Q.; Meng, F.F. Evaluation of a prototype active solar thermoelectric radiant wall system in winter conditions. Appl. Therm. Eng. 2015, 89, 36–43. [Google Scholar]

- An, Q.Q.; Zhang, T.T.; Han, D.L.; Tan, Y.F. Experimental study on thermoelectric performance of photovoltaic solar thermal wall in severe cold area. Gas Heat 2022, 42, 9–13. (In Chinese) [Google Scholar]

| Thermal Conductivity/W/(m·K) | Conductivity/(S/m) | Seebeck Coefficient/(V/K) | Density/(kg/m3) | Constant-Pressure Heat Capacity J/(kg·K) | |

|---|---|---|---|---|---|

| Ni45Cu55 | 20 | 2.04 × 106 | −3.5 × 10−5 | 8900 | 205.9 |

| Ni90Cr10 | 11 | 1.42 × 106 | 2.5 × 10−5 | 8400 | 4.6 |

| Al2O3 | 39 | / | / | 3500 | 765 |

| Copper | 400 | 5.998 × 107 | 1.5 × 10−6 | 8960 | 385 |

| Aluminum alloy frame | 231 | / | / | 2850 | 896 |

| XPS | 0.041 | / | / | 34 | 1450 |

| Concrete | 1.8 | / | / | 2300 | 880 |

| Variable | Temperature | Voltage | Current |

|---|---|---|---|

| Measurement accuracy | ±3 °C | ±0.05% | ±0.5% |

| Uncertainty | ±5% | ±2% | ±3% |

| Equipment Name | Material | Number | Dimension | Temperature Difference | Output Power |

|---|---|---|---|---|---|

| CTEG | Bi2Te3 | 127 | 40 mm(L) × 40 mm(W) × 3 mm(T) | 127 °C | 4.9 W |

| TEPG–Wall System | Ni90Cr10–Ni45Cu55 | 15 | 80 mm(L) × 2 mm(D) | 55 °C | 0.012 W |

| Study | Seasonal Coverage | ΔT Range (°C) | Key Limitations Addressed in This Work |

|---|---|---|---|

| Lamba and Kaushik [19] | Summer/Winter | 30–100 | No transitional season analysis |

| Liao et al. [20] | Summer | 20–60 | Limited to stable lighting conditions |

| Huq et al. [22] | Laboratory-Simulated ΔT | 10–50 | Lack of real-world transitional data |

| This study | Summer/Winter/Transition | 2–55 | Quantified nonlinear ΔT–voltage relationships in transitional climates |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, Z.; Hu, R.; Gao, Y.; Liu, J.; Su, X. Design and Experimental Study of a Prefabricated Building Thermoelectric Power Generation–Wall System for Severe Cold Climates. Buildings 2025, 15, 1076. https://doi.org/10.3390/buildings15071076

Hao Z, Hu R, Gao Y, Liu J, Su X. Design and Experimental Study of a Prefabricated Building Thermoelectric Power Generation–Wall System for Severe Cold Climates. Buildings. 2025; 15(7):1076. https://doi.org/10.3390/buildings15071076

Chicago/Turabian StyleHao, Zhanguo, Ribo Hu, Yi Gao, Jinyuan Liu, and Xiaoming Su. 2025. "Design and Experimental Study of a Prefabricated Building Thermoelectric Power Generation–Wall System for Severe Cold Climates" Buildings 15, no. 7: 1076. https://doi.org/10.3390/buildings15071076

APA StyleHao, Z., Hu, R., Gao, Y., Liu, J., & Su, X. (2025). Design and Experimental Study of a Prefabricated Building Thermoelectric Power Generation–Wall System for Severe Cold Climates. Buildings, 15(7), 1076. https://doi.org/10.3390/buildings15071076