Abstract

A quick method to access the tensile strength of concrete is often required during surveys. However, it is not always clear which method is the most effective or whether a certain method can be simplified or adjusted. Recently, pull-off tests on floors and walls have become more common for measuring the tensile strength of concrete, although the results can be interpreted in different ways. This research compares different types of pull-off testing with the standard tensile splitting strength test, which is considered destructive. This study revealed differences between the pull-off and tensile splitting strength test results. Among the three pull-off methods, the standard method showed the least deviation and appeared to be most closely with uniaxial tensile strength. The rectangular method resulted in 33% to 35% lower strength, likely due to increased stress concentration compared to the standard circular method. The straight-to-surface method proved unreliable, as strength depended on the failure area size. Additionally, a high correlation was found between concrete density, ultrasonic pulse velocity (UPV) (r = 0.81–0.88), and rebound hardness, indicating that the pull-off test results closely reflect changes in concrete density and UPV.

1. Introduction

The correct design of concrete and subsequent assessment of its durability requires the determination of both compressive and tensile strengths. While both methods are destructive, conducting non-destructive, timely, efficient, and high-precision evaluations remains a challenge. Although modern pull-off testing devices are compact, portable, and provide real-time data, reducing the necessity to perform destructive testing, the variability in tensile strength results and the adequate application of test methods on site are still critical factors in accessing the durability of infrastructure when compared to destructive testing. Considering that concrete is a heterogeneous material and it is exposed to a wide range of environmental conditions through its service life, accurately assessing its current condition during testing becomes significantly more complex. This makes it challenging to obtain a precise and consistent description of the concrete infrastructure’s condition at the time of evaluation. Furthermore, the dynamic nature of these conditions and changes in concrete microstructure over time means that a comprehensive assessment requires careful consideration of multiple variables to achieve an accurate reflection of the material’s true state.

The pull-off test method has gained its importance due to the rising focus on quality control, evaluation of repair techniques, and the durability assessment of the structures [1]. In general, it is used extensively to test the adhesion of protective coatings on concrete and other materials, which is crucial for maintenance and quality control. Formalized in the 1960s, the pull-off test introduced a standardized approach to measuring the strength of concrete surfaces, resulting in more accurate and repeatable results. However, questions still arise when comparing the results during surveys. Standards established by ASTM [2] and EN [3,4] provide guidelines for conducting pull-off tests, ensuring consistency and reliability in the results. The pull-off method involves bonding circular cross-section steel pull-head plates to the concrete surface using epoxy adhesive. Before that, tested concrete shall be cored or cut using a core drilling machine or a saw, as appropriate. The cutting depth shall reach at least 5 mm into the concrete. The pull-head plates shall be boned centrally on the test areas. By increasing the tensile force that is applied perpendicular to the test area through the pull-head plates, the concrete fails, assuming that the adhesive bond is stronger than the concrete. The failure area can be calculated through the layer where the rupture occurs. The concrete’s tensile strength based on the applied force at failure can be calculated as well.

The correlation between the pull-off test results and other tensile strength determination methods, such as (a) uniaxial (direct) tensile strength achieved using specifically manufactured dog bone specimens or cored cylinder specimens with a circumambient groove located at mid-height of the specimen [5]; (b) splitting cylindrical or cubic specimens; and (c) bending prismatic specimens, is still not well defined. For, instance, studies [6,7] show that the splitting tensile strength is 5–70% higher than the direct tensile strength. At the same time, Le and Hoang [8] obtained that the bending and tensile splitting test results are significantly higher than those of the direct tensile and double punch tests. A specific relationship exists between the tensile strength of concrete and its bond strength [9]. Based on the experimental results, researchers conclude that the direct tensile test offers more accurate findings of tensile strength than the tensile splitting test [10]. However, the execution of a uniaxial tensile strength test (direct tensile strength) for concrete is a rather complex and challenging process that often does not ensure high precision in the obtained results.

Therefore, indirect test methods―the tensile splitting strength test method using cylindrical or cubic specimens and the flexural strength test using prismatic specimens―are commonly chosen for their both relative simplicity and reliability in assessing the tensile behavior of concrete. However, the results presented by Słowik and Akram [11] indicate a notable concern regarding the reliability of these methods in accurately determining tensile strength. It is well established that the shape and size of concrete specimens significantly impact the tensile strength [12,13,14], w/c ratio, and age of concrete [15]. Cylinder specimens are generally recommended for testing, as their results typically differ from cubic specimens, avoiding an increase in values by approximately 10%. The experimental evidence indicates that the diameter of cylindrical specimens, ranging from 100 to 500 mm, notably affects the measured tensile strength and its variability [12,13,14]. According to EN 12390-1:2021 [16], the standard recommended cylindrical specimen dimensions are 150 mm in diameter and 300 mm in length, which are commonly used in laboratory testing. However, many test laboratories and on-site coring typically involve cylinders with smaller dimensions, often 100 mm in diameter and 200 mm in length.

Recently, pull-off tests on floors and walls have become a more common approach for measuring concrete’s tensile strength. International standards primarily focus on laboratory tests, with limited documentation available for in situ measurements, which are not fully suited for the wide variety of components used in facades, for example [17]. Variations in factors like surface preparation (curing process, roughening techniques, and type of adhesive used), test execution (failure modes―cohesive one in concrete and one in the top layer of the concrete), and the way the results are analyzed can lead to differences in the interpretation of the concrete’s actual tensile strength (in terms of local material properties or as a general measure of the concrete’s structural behavior) [18].

A key limitation of the pull-off test is its low precision, as evidenced by the high variability in the results across different equipment [19]. For given concrete strength, pull-off failure requires a higher load in concrete with a low elastic modulus. Bungey and Madandoust [20] concluded that a pull-head plate with a thickness of at least 20 mm for steel and 30 mm for aluminum is needed to uniform stress in concrete. Increasing the disc thickness to 30 mm improves stress uniformity, with less influence from the elastic modulus. However, for adhesion testing of repairs, the pull-head plate’s thickness is less critical, as stress is more evenly distributed through the repair material. In general, the pull-off strength measured with steel pull-head plates is higher than that measured with aluminum discs; however, this difference tends to decrease with increased pull-head plate rigidity [21]. A core depth beyond 20 mm yields comparable results regardless of the pull-head plate’s material, with a 30 mm pull-head plate giving consistent results at shallower depths. Moisture conditions during testing have a minor effect, aside from influencing adhesive strength, but inaccuracies in partial coring can reduce measured bond strength due to eccentricity. Several surface roughening techniques are commonly used in practice to ensure a strong adhesion between the concrete surfaces and glued pull-head steel plates. These techniques include using a surface cast against steel formwork (which acts as a reference surface), preparing the surface with a steel brush, partially chipping the surface, and treating the surface through sandblasting. According to Julio et al. [18], among all the techniques considered, the sandblasting method provided the highest bond results, both in shear and in tension. Environmental conditions like time of placement, workmanship, and temperature might be of influence on the durability of bonding [22]. In addition to the composition and concrete properties, the variation on the rupture surface is also influenced by factors such as the orientation and position of the aggregate under the pull-head plate [23]. The maximum aggregate size between 10 and 20 mm has minimal impact on the pull-off test results, as the average pull-off strength for 20 mm aggregate concrete is only 1% higher than for 10 mm aggregates in plain SCC, for example [21].

It is known that the simplest type of pull-off test involves direct gluing of the pull-head plates to the concrete surface without any preliminary preparation and then pulling them off sequentially. Naturally, this approach creates a complex stress distribution at the moment of tearing off. However, how can the results be compared to those obtained using the standard method? Similarly, square-notch cutting is also a common practice in pull-off testing. The question is whether the results obtained using this method can be reliably analyzed and correctly interpreted. Existing research does not provide a clear understanding of how these variations in pull-off testing methods impact the accuracy and consistency of the results, particularly in comparison to the standard tensile splitting strength test. Although pull-off tests are increasingly used in the field due to their simplicity, there is a lack of comprehensive studies that evaluate their reliability and correlation with standard testing methods. In order to answer these questions and to determine whether the results of pull-off tests are similar to the tensile splitting strength, the corresponding experimental investigation was carried out in this research study. This study aims to address the gap in existing research by experimentally comparing different pull-off testing methods with the standard tensile splitting strength method to evaluate their effectiveness and reliability in assessing the tensile strength of concrete.

2. Materials and Methods

The object of the research was an experimental investigation of two concrete slabs with dimensions 560 × 580 × 50 mm3, which were manufactured specifically for this experiment, following the standard EN 13892-8:2002 [4] with required minimum dimensions of 300 × 300 × 50 mm3. The experimental concrete mix design for two concrete slabs is shown in Table 1.

Table 1.

Concrete mix design [kg/m3].

As detailed before, the concrete of these two slabs differed in the water content: slab No. 1 was made using 20% less water than slab No. 2. Additionally, a plasticizer was also added to the concrete of slab No. 1.

For the first two days, the concrete slabs were kept at room temperature in waterproof plywood formwork, and the surfaces of the slabs were covered by polyethylene film. After two days, the slabs were released from the formwork and placed in water until reaching the age of 28 days. From the age of 28 days until the start of testing, the concrete slabs were cured at room conditions.

The dimensions of the slabs were designed to accommodate pull-off tests at 16 different areas. This ensured that the minimum distance between specimens’ test areas, as specified in the standard EN 13892-8:2002 [4] (the test areas shall be at least 50 mm apart from each other and at least 50 mm away from the edge of the test specimens), was maintained, as shown in Figure 1.

Figure 1.

Test areas of pull-off tests for both slabs (see circular areas). Dimensions are given in mm. The numbers highlighted in red indicate the designations of the pull-of test areas.

Three different methods were chosen to carry out the pull-off tests for the following:

- Cylindrical specimens with a circular cutting depth, to the surface of which metal pull-head plates were glued, following the standard EN 13892-8:2002 [4]—standard method;

- Rectangular specimens with a square sawing depth, onto which metal pull-head plates were glued—rectangular method;

- Circular specimens bonded directly to a concrete surface without prior preparation, thereby not defining a regular failure zone—straight-to-surface method.

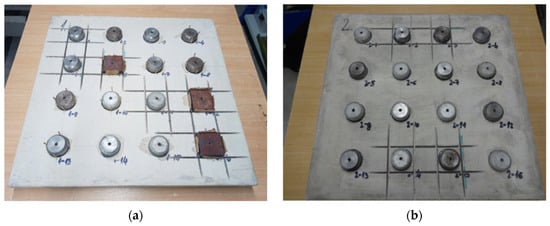

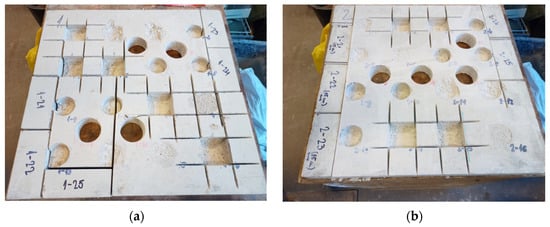

It should be emphasized that for both slabs, the test areas for the last two pull-off test methods were different, as shown in Figure 2. The numbers of tests for both concrete slabs tested with different pull-off test methods are listed in Table 2.

Figure 2.

Test areas of different pull-off test methods for two slabs: (a) No. 1 and (b) No. 2.

Table 2.

The number of performed tests for two concrete slabs.

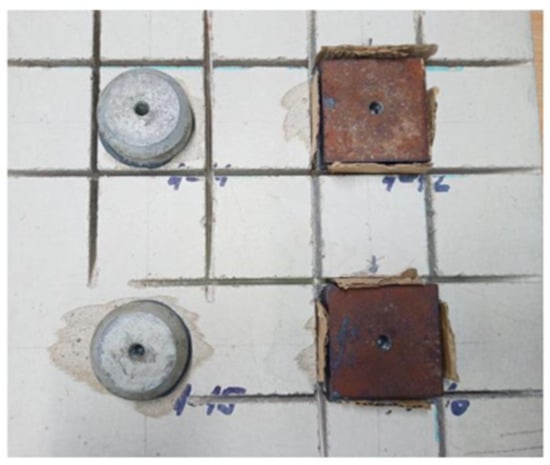

Additionally, it should be noted that it was decided to glue square steel plates at 3 test areas of the rectangular cutouts on slab No. 1 to investigate whether the results differed from those where the circular pull-head plates were glued (see Figure 2a and Figure A1 (in Appendix A)).

Pull-off tests were performed using an adhesion tester “Controls” No. 58-C0215/T. The load capacity of this equipment is 16 kN.

As previously described, three different methods were chosen for this purpose. In this research study, the first one will be referred to as the standard method, the second one as the rectangular method, and the third one as the straight-to-surface method. Before the pull-off testing, some preparatory works were carried out. The test areas on both slabs, where the standard method would be applied, were cored using a core drilling device with a 50 mm diamond barrel to a depth of 17–19 mm into the concrete. In turn, for the rectangular method, the test areas were cut transversely through the concrete of the slabs to the same depth using a diamond sawing machine. As mentioned before, no such preparatory works were carried out for the straight-to-surface method. It should also be noted that in all test areas, the concrete surface was ground to ensure better adhesion of the adhesive. The prepared test areas for all three pull-off methods are shown in Figure 3.

Figure 3.

Differently prepared test areas for pull-off tests: (a) the standard method with a circular cutting depth; (b) the rectangular method with a square sawing depth; (c) the straight-to-surface method without defining a regular failure zone.

After the preparation of the test areas, circular pull-head and square steel plates were glued to the surface of both concrete slabs using two-component epoxy adhesive, as shown in Figure 4 and Figure A1 (in Appendix A). Once the adhesive layer had hardened over a few days, the pull-off tests were carried out. First, a screw-type element was screwed into metal plates, which is the connecting element between the plates and the tension system of the adhesion tester. The tester’s mechanical tension system was then attached to the metal plates (see Figure 4). Applying a loading handle connected to a hydraulic piston, the tensile system of the adhesion tester was uniformly tensioned following a loading rate of 0.05 ± 0.01 N/mm2·s, as specified in the standard EN 13892-8:2002 [4]. The ultimate tensile force achieved at the moment of failure was recorded on the electronic display of the measuring device. By relating the obtained ultimate force to the area of the failure zone, the corresponding tensile strength was calculated. It should be noted that since the straight-to-surface method resulted in the fracture surface areas having an irregular shape, for each test, those were determined using the square grid method, with the area being divided into mm2 units.

Figure 4.

The adhesion tester connected to the test specimen 1-1 using a screw-type element screwed into the steel pull-head plate.

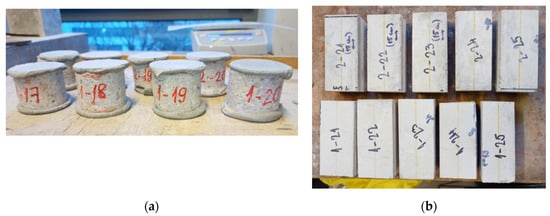

A total of 25 specimens were obtained from each slab: 16 for the pull-off tests and 4 and 5 for determining compressive strength and tensile splitting strength, respectively. For the testing of the compressive strength, cylindrical specimens with a diameter of ~50 mm were drilled, while to determine the tensile splitting strength, prismatic specimens with dimensions of ~150 × 70 × 45 mm3 were cut. In the specimen designations, the first digit indicates the slab number, and the numbers following the dash indicate the corresponding tests: 1 to 16 for pull-off, 17 to 20 for compressive strength, and 21 to 25 for tensile splitting strength. Destructive tests were carried out on a hydraulic press “Controls” No. 50-C4320 with a load capacity of 4000 kN. Areas for pull-off tests and locations where specimens were obtained for destructive testing for both concrete slabs are shown in Figure A2 (in Appendix A).

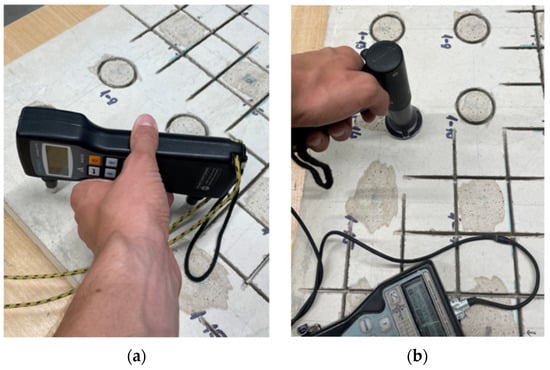

Along with the previously mentioned semi-destructive and destructive tests, non-destructive testing methods were also applied in the research. In particular, the ultrasonic pulse velocity (UPV) and rebound hardness (RH) for the concrete of both slabs were determined using the UK-1401 tester and the IPS MG-4.03 sclerometer, respectively, as shown in Figure 5.

Figure 5.

Carrying out measurements of the concrete slab using (a) an ultrasonic tester and (b) a sclerometer.

Non-destructive tests were performed prior to pull-off testing. They were performed to avoid damage caused by semi-destructive tests. The results obtained made it possible to establish differences in the density and compressive strength properties of concrete in both slabs. It should be noted that in relation to the vibration of concrete in formworks, the tests were carried out on the bottom (smooth) surface of the concrete slabs.

It is important to note that UPV is one of the most widely applicable non-destructive tests for accessing concrete homogeneity and estimating compressive strength and elastic modulus. UPV depends on the material’s elastic properties (elastic modulus and Poisson’s ratio) and density, which enables correlations for determining concrete strength. However, as Popovics et al. [24] pointed out, UPV as the one and only indicator cannot provide a highly accurate strength determination due to the lack of a direct theoretical relationship. This is why other non-destructive testing methods, such as RH, were used in this research study.

The RH method is mostly used as a non-destructive method that measures concrete surface hardness to estimate compressive strength. However, it is sensitive to local variations like aggregates, holes, surface roughness, carbonation, and moisture. The test localizes the hardness to about 20–30 mm in depth [25] and generally provides a satisfactory relationship between the rebound number and compressive strength, though the accuracy is ±20% with a 10% variation [23].

3. Results

The testing began when the concrete was approximately 2 months old. Initial tests were carried out using an ultrasonic tester and a sclerometer. For both slabs, measurements were carried out at 16 test areas, where pull-off tests were subsequently performed. At each test area, four measurements were performed with each device. As a result, a total of 128 measurements were carried out with each device to obtain the homogeneity and rebound hardness of the concrete in both slabs. The density of concrete was achieved by weighing and determining the volume of prismatic specimens, which were cut from the slabs. The results obtained for UPV and RH, as well as for the density of both slabs, including the main statistical parameters, are shown in Table 3.

Table 3.

UPV, RH, and density results of concrete for both slabs.

As can be seen in Table 3, the obtained data for all properties exhibited a low dispersion, which is indicated by both the narrow measurement ranges and the low correlation coefficient values. It was observed that for all properties, the concrete in slab No. 1 showed higher values compared to slab No. 2. And, namely, for the concrete of the No. 1, UPV, RH, and density values were 5%, 22%, and 3% higher, respectively. This emphasizes the previously mentioned correlation between the density of concrete and the UPV, as the differences in these two properties between the two slabs were very similar.

After the non-destructive testing, the pull-off tests were carried out.

The results obtained from all three pull-off test methods for two concrete slabs are listed in Table A1, Table A2, Table A3, Table A4, Table A5 and Table A6 in Appendix A. In turn, a summary of the results, including the main statistical parameters, is presented in Table 4.

Table 4.

Tensile strength results for all three pull-off test methods for both slabs.

The obtained results did not reveal any significant difference in the tensile strength of the two concrete slabs using the standard method (see Table 4). The rectangular method showed the lowest tensile strength values, and the differences for the concrete of both slabs are almost the same (on average −33…−35%) when compared to the standard method, as listed in Table 5. In turn, the straight-to-surface method showed slightly higher tensile strength results, with differences of around 5–6% in comparison to the standard method. Moreover, the results of the straight-to-surface method showed significantly greater variation.

Table 5.

Comparison of the pull-off test results for all three methods.

Additionally, as shown in Table A3 and Table A6 (in Appendix A), in the case of the straight-to-surface method, a lower tensile strength was obtained with a larger failure area. Furthermore, for the rectangular method, there is no significant difference between using cylindrical pull-head or rectangular steel plates, as evidenced by the average tensile strengths of 2.01 MPa and 1.96 MPa, respectively (see Table A2 in Appendix A). The failure types observed in the different pull-off test methods are shown in Figure 6 and Figure A3 (in Appendix A).

Figure 6.

Failure types for the different pull-off tests: (a) the standard method with a circular cutting depth; (b) the rectangular method with a square sawing depth; (c) the straight-to-surface method without defining a regular failure zone.

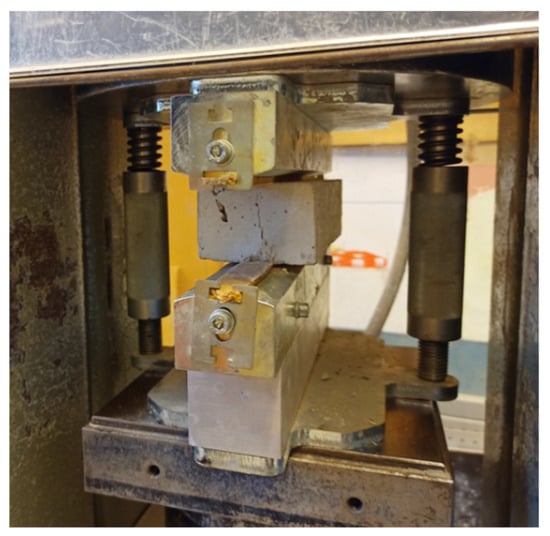

Simultaneously, four and five specimens were obtained from each slab to determine the compressive and tensile splitting strength, respectively. The specimens prepared for these tests are shown in Figure A4 (in Appendix A). To determine the splitting tensile strength, a jig was used for positioning the prismatic specimens. The specimen captured in the hydraulic press jig system is shown in Figure 7.

Figure 7.

Performing a tensile splitting strength test for a prismatic specimen in the hydraulic press.

When determining the results of destructive tests, the shape and size factors of concrete specimens were taken into account according to the standard [26]. The summary of the compressive and tensile splitting strengths results is provided in Table 6.

Table 6.

Destructive test results for all three pull-off test methods for both slabs.

It can be seen that the values of both strength properties are higher for the concrete of slab No. 1. In turn, for the concrete of both slabs, the standard pull-off test method shows practically identical tensile strength results (Table 4). It should also be noted that a significantly higher deviation was observed in the results of the tensile splitting strength. This indicates that the pull-off test data are more reliable than the tensile splitting strength test data. This is probably influenced by the complex stress state that occurs when testing specimens with a splitting method to achieve tensile strength.

4. Discussions

Comparing the results of pull-off tests for the three types of testing methods―the standard, the rectangular, and the straight-to-surface―it was found that the closest results to the tensile splitting strength were determined for the standard and straight-to-surface methods. However, the least dispersion had a standard method. At the same time, an important observation should be noted: although the water content for slab No. 2 was more than 20%, the change in the pull-off test strength was minimal compared to variations in the tensile splitting and compressive strengths, as shown in Table 7.

Table 7.

Summary and comparison of different properties determined for both concrete slabs.

As mentioned before, the results of pull-off tests were closer to the uniaxial tensile strength than the results of tensile splitting strength tests, where a complex stress state occurred. Thus, it can be concluded that changes in the tensile splitting strength results for different concrete mixes do not necessarily guarantee the same changes in uniaxial tensile strength. Namely, the results of the tensile splitting strength may provide an inaccurate interpretation of the results regarding the uniaxial tensile properties of concrete. In this research study, it was found that the average values of the tensile splitting strength were 14% to 37% higher in comparison to the pull-off test results for the standard method, which is consistent with the literature.

Table 7 shows a comparison of all the research methods discussed earlier. It can be concluded that despite a relatively large increase in compressive and tensile splitting strengths, the change in tensile strength obtained from pull-off tests (which is related to uniaxial tensile strength) was lower. And, namely, the largest differences in the properties of the concrete slabs were observed in rebound hardness, compressive, and tensile splitting strengths―22%, 27%, and 18%, respectively. In turn, these changes in tensile strength obtained by the pull-off method were only 1%. The correlation between the UPV in concrete and the density of the two concrete slabs was very high because the differences in these two properties were very similar.

5. Conclusions

This study aimed to evaluate and compare different pull-off test methods for determining the tensile strength of concrete, along with the standard tensile splitting strength test. The findings demonstrated that the standard pull-off method appeared to be the most reliable for assessing tensile strength, while other methods, such as the rectangular and straight-to-surface approaches, have limitations. Additionally, variations in water content in concrete mixes showed different effects on the pull-off and tensile splitting test results. The key conclusions from this study are as follows:

- The standard pull-off method showed the lowest deviation and may be much closer to the uniaxial tensile strength, making it the most reliable method for determining concrete’s tensile properties.

- The rectangular method produced tensile strength results that were 33% to 35% lower than the standard method. This is likely due to increased stress concentration at the corners of the rectangular pull-off region, which is less uniform compared to the circular method. Therefore, this method is not suitable for tensile strength determination.

- The straight-to-surface method was found to be unreliable, as the strength readings were highly dependent on the failure area size—larger failure areas resulted in lower strength readings. Moreover, the results of this method showed significantly greater dispersion.

- The average values of the tensile splitting strength were 14% to 37% higher in comparison to the pull-off test results for the standard method.

- Regarding the effect of increased water content, when the water content in the concrete mix was increased by 20%, only minor changes were observed in the pull-off test results. However, tensile splitting strength dropped by 20% to 54%, with higher deviations due to the complex stress state in the splitting test.

- Regarding the correlation between density, UPV, and rebound hardness, a high correlation (r = 0.81–0.88) was found between concrete density and ultrasonic pulse velocity (UPV). A strong correlation was also observed between rebound hardness and results from destructive testing methods.

In summary, the pull-off test method appeared to be more consistent with uniaxial tensile strength and closely aligned with changes in concrete density and UPV, especially when the water content was varied. To determine whether the results of the pull-off test method are closer to those of uniaxial tensile strength than the results of tensile splitting strength, studies are needed in which all three methods are used together, including the manufacturing of dogbone-type specimens.

Author Contributions

Conceptualization, U.L.; data curation, U.L., A.U., and E.Z.; investigation, A.U.; methodology, U.L. and A.U.; project administration, A.K.; resources, U.L. and P.K.D.M.; software, U.L. and A.K.; supervision, A.K.; validation, A.U. and P.K.D.M.; writing—original draft preparation, U.L. and P.K.D.M.; writing—review and editing, A.K., A.U., and E.Z. All authors have read and approved the final version of the manuscript.

Funding

This research study is supported by research and development grant No. RTU-PA-2024/1-0036 within the EU RRF project No. 5.2.1.1.i.0/2/24/I/CFLA/003.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

Figure A1.

Circular pull-head plates (see specimens 1-11 and 1-15) and square steel plates (see specimens 1-12 and 1-16) glued to the surface of concrete slab No. 1.

Figure A2.

Pull-off test areas and locations where specimens were obtained for destructive testing of two slabs: (a) No. 1 and (b) No. 2.

Figure A3.

View of (a) slab No. 1 after all pull-off tests have been carried out; (b) all specimens torn from slab No. 2 from the bottom side.

Figure A4.

Specimens for destructive testing obtained from two concrete slabs: (a) surfaces of the drilled cylindrical concrete specimens leveled with mortar for the testing of compressive strength; (b) sawn prismatic specimens for testing of tensile splitting strength.

Table A1.

Results obtained using the standard pull-off test method for the concrete of slab No. 1.

Table A1.

Results obtained using the standard pull-off test method for the concrete of slab No. 1.

| Specimen Designation | Diameter of Specimen d, mm | Tensile Area A, mm2 | Ultimate Tensile Force F, kN | Tensile Strength B, MPa | Minimum Drilling Depth, mm | Depth of Failure, mm |

|---|---|---|---|---|---|---|

| 1-4 | 44.8 | 1576 | 4.869 | 3.09 | 18.0 | 10.5–19.0 |

| 1-7 | 44.9 | 1583 | 4.601 | 2.91 | 17.4 | 8.5–20.5 |

| 1-8 | 44.7 | 1569 | 4.473 | 2.85 | 17.3 | 13.0–19.0 |

| 1-9 | 44.7 | 1569 | 4.374 | 2.79 | 17.5 | 16.0–22.5 |

| 1-10 | 44.7 | 1569 | 4.653 | 2.97 | 18.1 | 13.0–20.0 |

| 1-13 | 44.9 | 1583 | 4.917 | 3.11 | 17.0 | 13.0–18.0 |

| on average | 2.95 | - | - |

Table A2.

Results obtained using the rectangular pull-off test method for the concrete of slab No. 1.

Table A2.

Results obtained using the rectangular pull-off test method for the concrete of slab No. 1.

| Specimen Designation | Dimensions of the Sawn Rectangular Section, mm | Tensile Area A, mm2 | Ultimate Tensile Force F, kN | Tensile Strength B, MPa | Minimum Sawing Depth, mm | Depth of Failure, mm | |

|---|---|---|---|---|---|---|---|

| a | b | ||||||

| 1-1 | 59.1 | 56.2 | 3321 | 7.448 | 2.24 | 16.8 | 15.5–30.5 |

| 1-5 | 59.1 | 60.8 | 3593 | 6.659 | 1.85 | 20.0 | 8.0–31.0 |

| 1-6 * | 61.2 | 60.5 | 3703 | 7.233 | 1.95 | 18.9 | 18.0–34.0 |

| 1-11 | 61.1 | 61.1 | 3733 | 7.243 | 1.94 | 21.6 | 19.0–31.0 |

| 1-12 * | 60.3 | 59.3 | 3576 | 6.754 | 1.89 | 21.3 | 0.5–2.0 |

| 1-16 * | 59.5 | 61.3 | 3647 | 7.397 | 2.03 | 21.0 | 20.0–35.0 |

| on average | 1.98 | - | - | ||||

Table A3.

Results obtained using the straight-to-surface pull-off test method for the concrete of slab No. 1.

Table A3.

Results obtained using the straight-to-surface pull-off test method for the concrete of slab No. 1.

| Specimen Designation | Tensile Area A, mm2 | Ultimate Tensile Force F, kN | Tensile Strength B, MPa | Depth of Failure, mm |

|---|---|---|---|---|

| 1-2 | 3139 | 7.344 | 2.34 | 0.2–11.0 |

| 1-3 | 2588 | 8.395 | 3.24 | 0.2–7.5 |

| 1-14 | 2214 | 8.278 | 3.74 | 0.1–7.5 |

| 1-15 | 2205 | 6.921 | 3.14 | 0.1–0.3 |

| on average | 3.12 | - |

Table A4.

Results obtained using the standard pull-off test method for the concrete of slab No. 2.

Table A4.

Results obtained using the standard pull-off test method for the concrete of slab No. 2.

| Specimen Designation | Diameter of Specimen d, mm | Tensile Area A, mm2 | Ultimate Tensile Force F, kN | Tensile Strength B, MPa | Minimum Drilling Depth, mm | Depth of Failure, mm |

|---|---|---|---|---|---|---|

| 2-4 | 44.9 | 1583 | 4.989 | 3.15 | 19.1 | 17.0–29.5 |

| 2-7 | 45.0 | 1590 | 4.939 | 3.11 | 18.5 | 8.0–23.0 |

| 2-8 | 45.0 | 1590 | 4.262 | 2.68 | 17.0 | 15.0–20.5 |

| 2-9 | 45.0 | 1590 | 4.488 | 2.82 | 18.8 | 17.0–22.0 |

| 2-10 | 45.0 | 1590 | 4.782 | 3.01 | 18.0 | 13.0–22.0 |

| 2-13 | 44.9 | 1583 | 4.467 | 2.82 | 18.3 | 16.0–25.5 |

| on average | 2.93 | - | - |

Table A5.

Results obtained using the rectangular pull-off test method for the concrete of slab No. 2.

Table A5.

Results obtained using the rectangular pull-off test method for the concrete of slab No. 2.

| Specimen Designation | Dimensions of the Sawn Rectangular Section, mm | Tensile Area A, mm2 | Ultimate Tensile Force F, kN | Tensile Strength B, MPa | Minimum Sawing Depth, mm | Depth of Failure, mm | |

|---|---|---|---|---|---|---|---|

| a | b | ||||||

| 2-2 | 55.5 | 55.3 | 3069 | 5.603 | 1.83 | 19.6 | 18.5–29.0 |

| 2-3 | 56.3 | 58.6 | 3299 | 6.532 | 1.98 | 18.7 | 19.5–31.5 |

| 2-14 | 59.1 | 62.5 | 3694 | 6.951 | 1.88 | 19.2 | 19.0–30.5 |

| 2-15 | 57.8 | 59.0 | 3410 | 6.445 | 1.89 | 20.4 | 20.0–31.0 |

| on average | 1.89 | - | - | ||||

Table A6.

Results obtained using the straight-to-surface pull-off test method for the concrete of slab No. 2.

Table A6.

Results obtained using the straight-to-surface pull-off test method for the concrete of slab No. 2.

| Specimen Designation | Tensile Area A, mm2 | Ultimate Tensile Force F, kN | Tensile Strength B, MPa | Depth of Failure, mm |

|---|---|---|---|---|

| 2-1 | 2117 | 7.454 | 3.52 | 1.0–7.5 |

| 2-5 | 2177 | 6.385 | 2.93 | 0.5–9.0 |

| 2-6 | 2274 | 7.995 | 3.52 | 0.1–4.0 |

| 2-11 | 2902 | 7.974 | 2.75 | 0.3–10.5 |

| 2-12 | 3243 | 8.135 | 2.51 | 0.5–8.5 |

| 2-16 | 2241 | 7.231 | 3.23 | 0.1–4.0 |

| on average | 3.08 | - |

References

- Bai, Y.; Basheer, P.A.M.; Cleland, D.J.; Long, A.E. State-of-the-art applications of the pull-off test in civil engineering. Int. J. Struct. Eng. 2009, 1, 93–103. [Google Scholar] [CrossRef]

- ASTM D4541; Standard Test Method for Pull-Off Strength of Coating Using Portable Adhesion Testers. American Society for Testing and Materials: West Conshohocken, PA, USA, 2002.

- EN 1542; Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Measurement of Bond Strength by Pull-Off. European Committee for Standardization: Brussels, Belgium, 1999.

- EN 13892-8:2002; Methods of Test for Screed Materials—Part 8: Determination of Bond Strength. European Committee for Standardization: Brussel, Belgium, 2002.

- Nilimaa, J.; Nilforoush, R. A Direct tensile strength testing method for concrete from existing structures. CivilEng 2023, 4, 333–344. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, J.; Yu, H.; Wu, Q.; Da, B. Computer-aided investigation of the tensile behavior of concrete: Relationship between direct and splitting tensile strength. Structures 2023, 55, 453–467. [Google Scholar] [CrossRef]

- Olesen, J.F.; Østergaard, L.; Stang, H. Nonlinear fracture mechanics and plasticity of the split cylinder test. Mater. Struct. 2006, 39, 421–432. [Google Scholar] [CrossRef]

- Le, A.-T.; Hoang, A.L. Comparisons of flexural, split tensile, double punch, and direct tension tests on high-performance concrete reinforced with different fiber types. Case Stud. Constr. Mater. 2023, 19, e02413. [Google Scholar] [CrossRef]

- Rozsypalova, I.; Danek, P.; Karel, O. The bond strength by pull-off and direct tensile strength of concrete damaged by elevated temperatures. IOP Conf. Ser. Mater. Sci. Eng. 2018, 385, 012047. [Google Scholar] [CrossRef]

- Goaiz, H.A.; Yu, T.; Hadi, M.N.S. Quality evaluation tests for tensile strength of reactive powder concrete. J. Mater. Civil Eng. 2018, 30, 04018070. [Google Scholar] [CrossRef]

- Słowik, M.; Akram, A. Length effect at testing splitting tensile strength of concrete. Materials 2022, 15, 250. [Google Scholar] [CrossRef]

- Hasegawa, T.; Shioya, T.; Okada, T. Cracking and size effect in concrete—Splitting tensile strength of large concrete cylinder. J. Cem. Concr. 1986, 474, 6–20. [Google Scholar]

- Bazant, Z.P.; He, S.; Plesha, M.E.; Gettu, R.; Rowlands, R.E. Rate and size effect in concrete fracture: Implications for dams. In Proceedings of the International Conference on Dam Fracture, Denver, CO, USA, 11–13 September 1991; University of Colorado: Boulder, CO, USA, 1991; pp. 413–425. [Google Scholar]

- Kanos, A.; Kanos, A.; Perdikaris, P. Size effect on concrete splitting tensile strength and modulus of elasticity. In Measuring, Monitoring and Modeling Concrete Properties; Konsta-Gdoutos, M.S., Ed.; Springer: Dordrecht, The Netherlands, 2006; pp. 239–246. [Google Scholar] [CrossRef]

- Al-Abdaly, N.M.; Seno, M.E.; Thwaini, M.A.; Imran, H.; Ostrowski, K.A.; Furtak, K. Advanced ensemble machine-learning models for predicting splitting tensile strength in silica fume-modified concrete. Buildings 2024, 14, 4054. [Google Scholar] [CrossRef]

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. European Committee for Standardization: Brussels, Belgium, 2021.

- Ramos, N.M.M.; Simões, M.L.; Delgado, J.M.P.Q.; de Freitas, V.P. Applicability of the pull-off test: Teachings from a large sample of in situ tests. In Hygrothermal Behavior, Building Pathology and Durability; de Freitas, V.P., Delgado, J.M.P.Q., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 165–181. [Google Scholar]

- Julio, E.N.B.S.; Branco, F.A.B.; Silva, V.D. Concrete-to-concrete bond strength. Influence of the roughness of substrate surface. Constr. Build. Mater. 2004, 18, 675–681. [Google Scholar] [CrossRef]

- Vaysburd, A.M. An Evaluation of Equipment and Procedures for Tensile Bond Testing of Concrete Repairs; Report REMR-CS-61; U.S. Army Corps of Engineers: Washington, DC, USA, 1999; Available online: https://apps.dtic.mil/sti/tr/pdf/ADA366843.pdf (accessed on 6 October 2024).

- Bungey, J.H.; Madandoust, R. Factors influencing pull-off tests on concrete. Mag. Concr. Res. 1992, 44, 21–30. [Google Scholar] [CrossRef]

- Ghavidel, R.; Madandoust, R.; Ranjbar, M.M. Reliability of pull-off test for steel fiber reinforced self-compacting concrete. Measurement 2015, 73, 628–639. [Google Scholar] [CrossRef]

- Das, K.K.; Lam, E.S.-S.; Ip, C.T.; Chau, Y.K.; Jang, J.G. Modified pull-off test evaluation of bond properties in preplaced aggregate concrete incorporating silica fume. J. Build. Eng. 2024, 82, 108264. [Google Scholar] [CrossRef]

- Pereira, E.; de Medeiros, M.H.F. Pull off test to evaluate the compressive strength of concrete: An alternative to Brazilian standard techniques. Rev. IBRACON Estrut. Mater. 2012, 5, 757–780. [Google Scholar] [CrossRef]

- Popovics, J.S.; Song, W.-J.; Ghandshari, M.; Subramaniam, K.V.; Achenbach, J.D.; Shah, S.P. Application of surface wave transmission measurements for crack depth determination in concrete. ACI Mater. J. 2000, 97, 127–135. [Google Scholar]

- ACI Committee 228. ACI 228.1R-19 Report on Methods for Estimating In-Place Concrete Strength; American Concrete Institute: Farmington Hills, MI, USA, 2019; Available online: https://www.scribd.com/document/606239231/ACI-228-1R-19-Report-on-Methods-for-Estimating-In-Place-Concrete-Strength (accessed on 6 October 2024).

- GOST 28570-2019; Concrete. Methods for Determining the Strength of Samples Taken from Structures. Russian Institute of Standardization, Russian Federation: Moscow, Russia, 2019. Available online: https://internet-law.ru/gosts/gost/70846/ (accessed on 12 March 2025). (In Russian)

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).