1. Introduction

Karst is the most distinctive geological process and phenomenon in carbonate rock distribution areas. Influenced by the chemical dissolution and mechanical erosion of water, karst forms grooves, cavities, and fissures in rock masses, which exhibit a highly complex distribution and morphology [

1]. These features are often concealed underground, making them difficult to detect. For pile foundation engineering, karst landforms such as caves, fissures, grooves (trenches), underground rivers, and soil caves developed in bedrock pose significant geological hazards [

2]. The randomness and unpredictability of these karst landforms can lead to frequent risks during construction, including borehole collapse, slurry leakage, and ground subsidence. These risks not only threaten construction safety but may also cause project delays and cost overruns. The primary risk in bridge pile foundation construction in karst regions is karst collapse. However, due to the influence of numerous interrelated factors, the assessment and prediction of pile foundation construction risks in these areas are highly complex. The risks associated with pile foundation construction in karst regions are multi-source and coupled [

3]. In addition to the predominant risk of karst-induced ground collapse, the following risk types are also significant: (1) Hydrogeological Risks: These include the thickness of the overburden, the degree of fissure development in the rock layers, and the intensity of groundwater activity. For example, insufficient stability in the cave roof may lead to pile-bearing capacity failure, loose overburden can cause borehole wall collapse, and fluctuations in groundwater levels may result in sudden drops in slurry levels, exacerbating the risk of borehole collapse [

4,

5,

6]. (2) Technical Risks: These encompass risks related to pile foundation construction techniques, cave treatment technologies, and concrete-pouring processes [

7,

8]. (3) Environmental and External Risks: These include risks to adjacent structures, ecological impacts, and water source contamination. For instance, vibrations from pile foundation construction may cause cracking in nearby buildings, and the infiltration of chemically treated slurry into karst conduits may pollute groundwater [

9,

10,

11]. (4) Management and Design Risks: These arise from deficiencies in geological surveys and design, as well as lapses in construction management [

12,

13]. The complexity and interdependence of these factors make risk assessment and management in pile foundation construction in karst regions a challenging yet critical task.

Early research on risk assessment primarily relied on empirical judgment and qualitative analysis. For instance, geological experts assessed risk levels through field surveys and drilling data [

1]. However, such approaches struggled to quantify risk probabilities, heavily depended on expert experience, and lacked systematic rigor, making them inadequate for addressing the complexity and uncertainty of karst geology. In recent years, scholars both domestically and internationally have gradually introduced quantitative analysis tools, such as probabilistic statistics, numerical simulation techniques, and the Analytic Hierarchy Process (AHP) [

2,

9,

10,

14,

15,

16,

17]. Nevertheless, these methods still fall short in effectively handling the inherent fuzziness and data deficiencies in risk assessment. To address these limitations, the concept of fuzzy mathematics and multi-criteria decision-making methods have been increasingly integrated into the field of risk assessment. For example, Perrin et al. proposed a multi-criteria approach based on weight-of-evidence analysis for predicting karst geological hazards [

18]. Zhang et al. [

19] developed a system for assessing surface stability in karst regions using an improved fuzzy comprehensive evaluation method, with the results showing good agreement with historical records of ground subsidence. Wei et al. [

20] combined the Analytic Hierarchy Process, catastrophe theory, and entropy models to evaluate susceptibility to karst collapse. Lou et al. [

21] introduced a high-precision risk assessment method specifically tailored to thermokarst hazards in permafrost regions. Zhang et al. [

22] established a risk assessment system for ground subsidence along tunnels in karst areas by refining and extending evaluation methods. Additionally, Lu et al. [

23] enhanced the network structure analysis method, addressing the inherent subjectivity in weight allocation.

In summary, although existing studies have established multi-level risk assessment frameworks for construction in karst regions, they often analyze individual risks in isolation and fail to adequately consider the interactions among geological, technical, and managerial factors. Furthermore, most assessments are conducted based on regional engineering projects, and a unified standard system has yet to be established. The establishment of a unified standard system can improve the accuracy and credibility of risk assessment. To address these issues, this paper proposes a risk assessment model for bridge pile foundation construction in karst areas based on the Fuzzy Analytic Hierarchy Process (FAHP). By utilizing fuzzy mathematics to quantify the uncertainty of expert judgment and incorporating a dynamic weight adjustment mechanism, the model enables the collaborative assessment of multi-source risks. This research is expected to provide more accurate risk prediction and decision-making support for bridge engineering in complex geological conditions.

3. Application Case

3.1. Project Overview

The research is based on the Qinghua Expressway project located in Guangdong Province, China. The route generally runs from north to south, starting in Taiping Town, Qingxin District, Qingyuan City, and ending in Tanbu Town, Huadu District, Guangzhou City. The total length of the route is approximately 53.728 km, with 45 mainline bridges spanning a total of 29,774.1 m. Among these, there are 11 extra-large bridges totaling 14,153.6 m, 28 large bridges totaling 15,175.5 m, and 6 medium bridges totaling 445.0 m. The bridge-to-total-length ratio is approximately 55.42%.

The Qinghua Expressway project traverses a variety of geomorphological types, primarily including tectonically denuded hills interspersed with inter-hill valleys, alluvial plains, and local low-relief hills and low-mountainous areas. The project area is influenced by the Qinhuang River, Beijiang River, its tributary the Dayan River, and the Baini River, which have formed extensive alluvial plains. The plain regions are characterized by flat and open terrain, offering relatively convenient transportation conditions. The primary adverse geological conditions in the project area include concealed karst, collapses, and sand liquefaction. According to the geological survey results of the Qinghua Expressway project, karst regions are widely distributed along the route, with a cumulative length of approximately 34.8 km, accounting for 64% of the total route length. The borehole encounter rate of cavities at bridge sites ranges from 34.8% to 100%, while the linear dissolution rate varies between 5.0% and 42.4%. The geologic overview of the study area is shown in

Figure 1.

The groundwater in the study area exhibits significant annual variations, with one to two peak water levels occurring between April and September, and a low water level observed in January. Additionally, the water table of the Quaternary unconsolidated porous aquifers is relatively shallow, with the thickness of the Quaternary strata generally ranging from 5 to 60 m. Following heavy rainfall, the water level rises rapidly, typically reaching its peak within about 10 h. The annual fluctuation range of the water level is between 1 and 4 m.

3.2. Evaluation Content

3.2.1. Determination of Evaluation Indicators

The methods for determining evaluation indicators include theoretical analysis, expert interviews, questionnaire surveys, and analysis of practical engineering cases. In this study, the risk assessment indicator system was established by reviewing the distribution characteristics of karst in Guangdong, researching disaster mechanisms, and consulting experts. The assessment indicators and scoring guidelines are shown in

Table 4,

Table 5 and

Table 6.

3.2.2. Calculation of Indicator Weights

The weights of the indicators were determined using the FAHP method, and the calculation process is as follows: Firstly, it is necessary to collect the importance evaluation results of each factor independently provided by five experts in related fields (the criteria for selecting experts here are that at least five professors or experts from different fields should be selected and these experts should include, for example, geological engineers, geotechnical engineers, construction technicians, etc. These experts should have high recognition and a good reputation in the industry, to ensure the comprehensiveness and accuracy of the evaluation). Then, a fuzzy positive reciprocal matrix A is established using fuzzy theory. For the first-level factor set (A

1, A

2, A

3, A

4), matrix A can be decomposed into three matrices.

We calculate the geometric mean of the columns:

The same reasoning leads to

The fuzzy weights are then calculated:

i.e.,

. Similarly, the fuzzy weights of the remaining factors can be obtained as follows:

The regularization of the fuzzy weight values using the geometric mean method gives the relative weights of the first-level factors:

The remaining indicators were calculated in the same way as above, and the results are shown in

Table 7. The target level weights (WTL) are equal to the weight of each level 2 indicator multiplied by the weight of the corresponding level 1 indicator.

In addition to consistency checks, the results of the calculations need to ensure that the sum of the weights of the indicators at each level is 1, thus guaranteeing the homogeneity of the system.

3.3. Evaluation Results

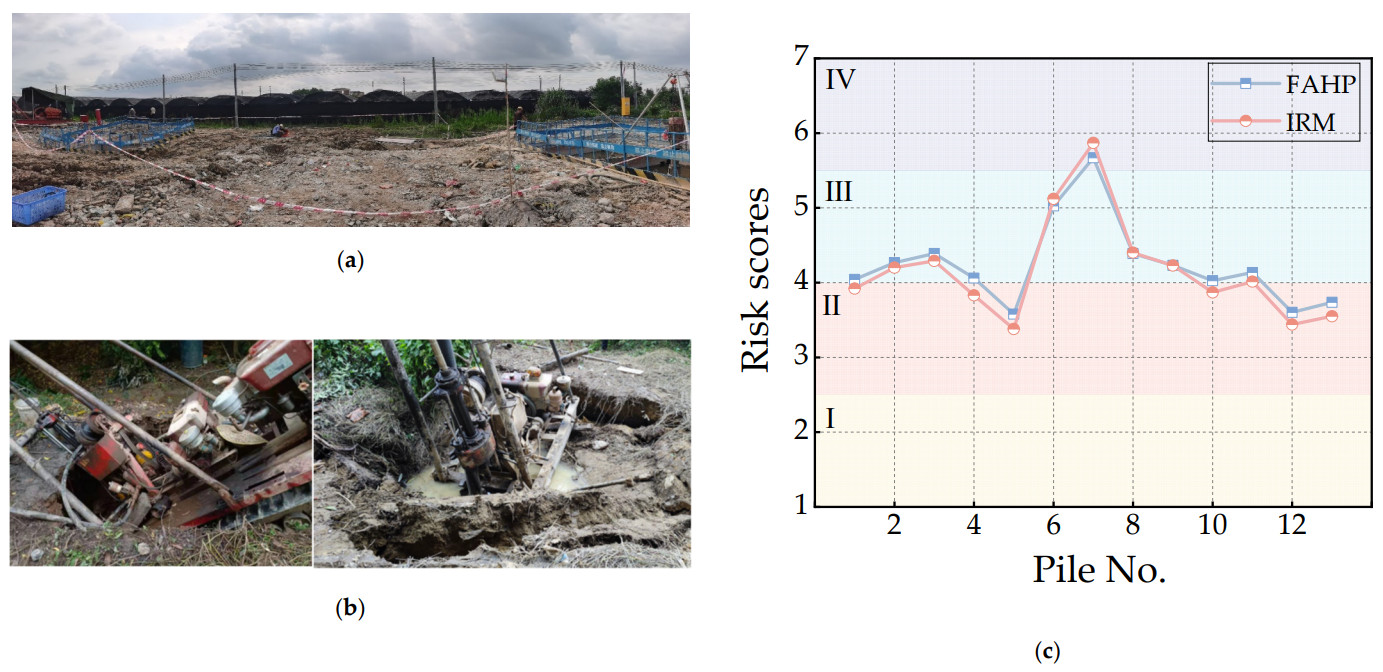

According to the construction ground investigation report of the Qinghua Expressway section, some pile foundations were involved in accidents such as ground collapse and borehole collapse during the investigation and construction stages, as shown in

Table 8. Based on the determined index system, the weight coefficients of each factor were calculated by the FAHP and IRM (refer to

Appendix A for the calculation methodology) methods, respectively (e.g.,

Table 7), and then the risk assessment of accidental pile foundations in

Table 8 was carried out. The scoring criteria for the indicators are shown in

Table 6 (on a 10-point scale).

The evaluation results are shown in

Figure 2c, where the scores for the accident pile foundations are generally consistent between the two methods. Specifically, when the score is greater than 4.4, the IRM yields a higher score than the FAHP method. When the score is lower than 4.4, the FAHP method yields a higher score than the IRM. Based on the weight coefficient values of the two methods presented in

Table 7, this outcome arises because the IRM, in comparison to the FAHP method, assigns slightly larger weights to the higher-ranked factors and smaller weight coefficients to the lower-ranked factors. This may be due to the IRM not adequately taking into account the correlation between the indicators and the systematic nature of the indicators. For pile foundations 1, 4, and 10, the evaluation levels differ between the two methods, with the FAHP method assigning a Level III rating and the IRM assigning a Level II rating. Since all evaluated pile foundations are accident pile foundations, a higher risk evaluation score indicates greater reliability for high-risk pile foundations. Therefore, it can be concluded that the FAHP method provides a more accurate assessment in this case, as the evaluation results are more in line with the actual situation and are thus more reasonable.

Finally, the risk of pile foundation construction for four different types of bridge in the Qinghua Expressway section was evaluated using the FAHP method, and the relevant parameters of the bridges are shown in

Table 9.

The evaluation results are illustrated in

Figure 3. As can be observed from the results, among the four bridges, Class II piles constitute the largest proportion: 40.48% for the Baini River Grand Bridge, 53.33% for the Hengbei Bridge, 60% for the main bridge of the Dayan River Grand Bridge, and 64.44% for the Beijiang Grand Bridge. The proportions of Class I and Class IV piles are relatively smaller. Specifically, Class I piles account for 21.43%, 33.33%, 0%, and 0%, respectively, while Class IV piles account for 6.55%, 0%, 7.32%, and 4.44%, respectively. Notably, besides the Hengbei Bridge, the other three bridges have pile foundations with Class IV construction risks. This is attributed to the relatively stable site conditions and weaker karst development (the linear karst rate is 12.3%) in the bridge area of the Hengbei Bridge. The mean risk scores for four bridges are all in the range of 3–4, and the standard deviation of the scores was around 1.000, The specific values are shown in

Table 10. This result indicates that the overall construction risk of bridge pile foundations in the area is average to high, with small differences in risk between bridges. Based on the evaluation results and actual construction survey data, the risk level assessments of the four bridges are generally consistent with the actual working conditions. Therefore, the evaluation results can serve as an important reference for subsequent construction activities.

4. Conclusions and Future Prospects

A risk assessment model for bridge pile foundation construction in karst areas based on the Fuzzy Analytic Hierarchy Process (FAHP) is proposed, establishing a comprehensive evaluation index system. This model employs fuzzy mathematical concepts to quantify the subjective experiences inherent in traditional evaluations while incorporating a dynamic weight adjustment mechanism to enable the synergistic assessment of multi-source risks.

The construction risk scores of accident pile foundations were calculated based on the weight coefficients of each factor obtained using the FAHP method and the IRM, respectively. The results indicate that the scores derived from the FAHP method are relatively higher. Higher scores signify greater pile foundation risks, which aligns with the initial assumptions, thereby demonstrating that the weight coefficients calculated by the FAHP method are more reasonable. Finally, the FAHP method was employed to assess the construction risks of pile foundations for four different types of bridges within the working area. The results show that the average risk values of the bridges are all in the range of 3 to 4 points, and the standard deviations are all around 1.000. The evaluation conclusions are largely consistent with actual working conditions.

There are many risk factors affecting the pile foundation construction of bridges in karst regions, and different regions have corresponding local characteristics. This evaluation was conducted based on the area along the Qinghua Expressway in Guangdong Province, where the project is located. The selection of risk factors may have certain limitations. Further research can be conducted in the future to identify more representative risk factors, thereby expanding the scope of application.