Optimizing of Self-Compacting Concrete (SCC): Synergistic Impact of Marble and Limestone Powders—A Technical and Statistical Analysis

Abstract

1. Introduction

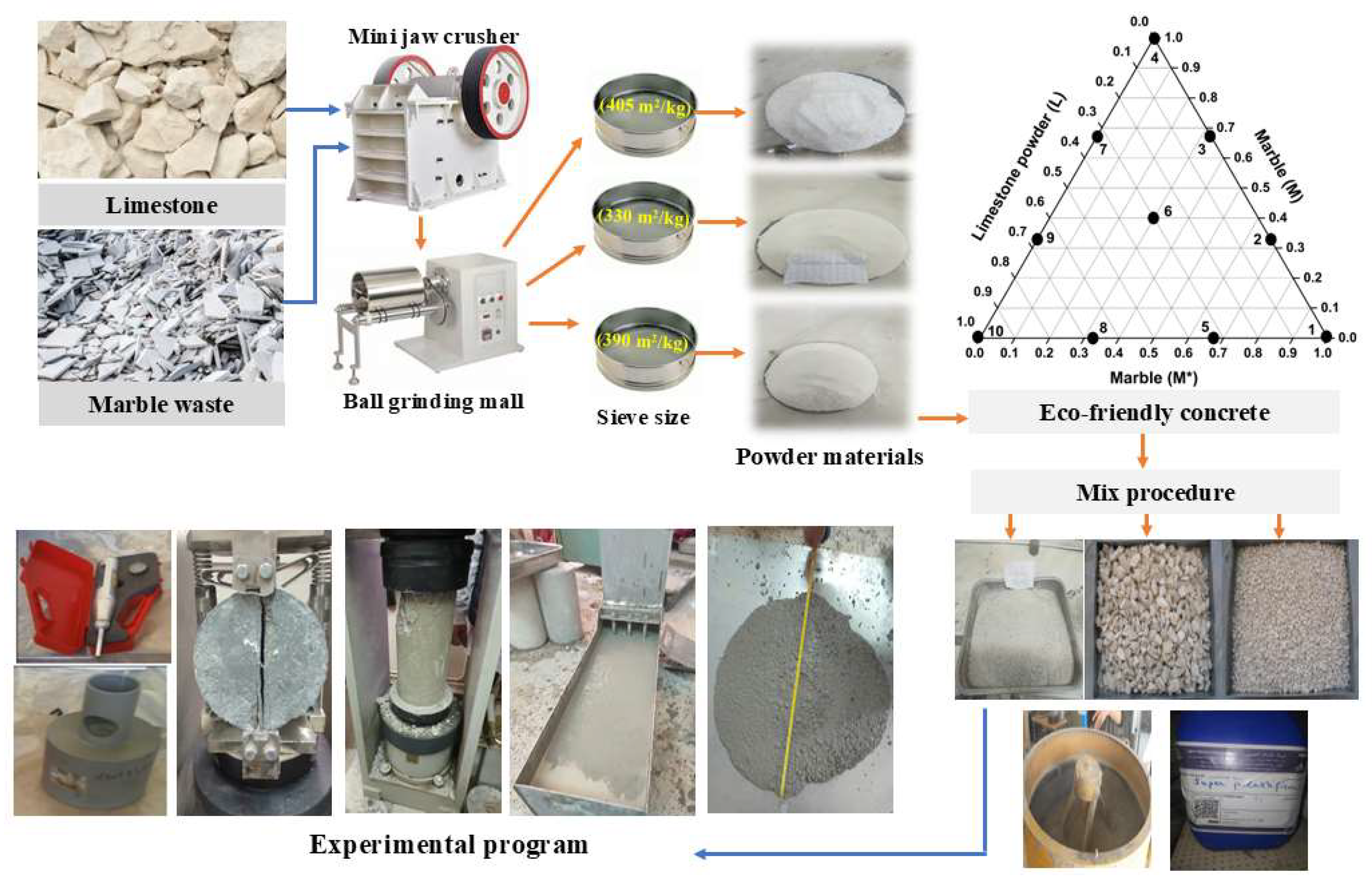

2. Materials and Methods

- G/S ratio ≈ 1, according to AFGC recommendations;

- Binder B dose = cement + filler = 480 kg/m3;

- SP = 1.8%.

3. Results and Discussion

3.1. Bulk Density

3.2. Fresh-State Properties

3.3. Hardened State Properties

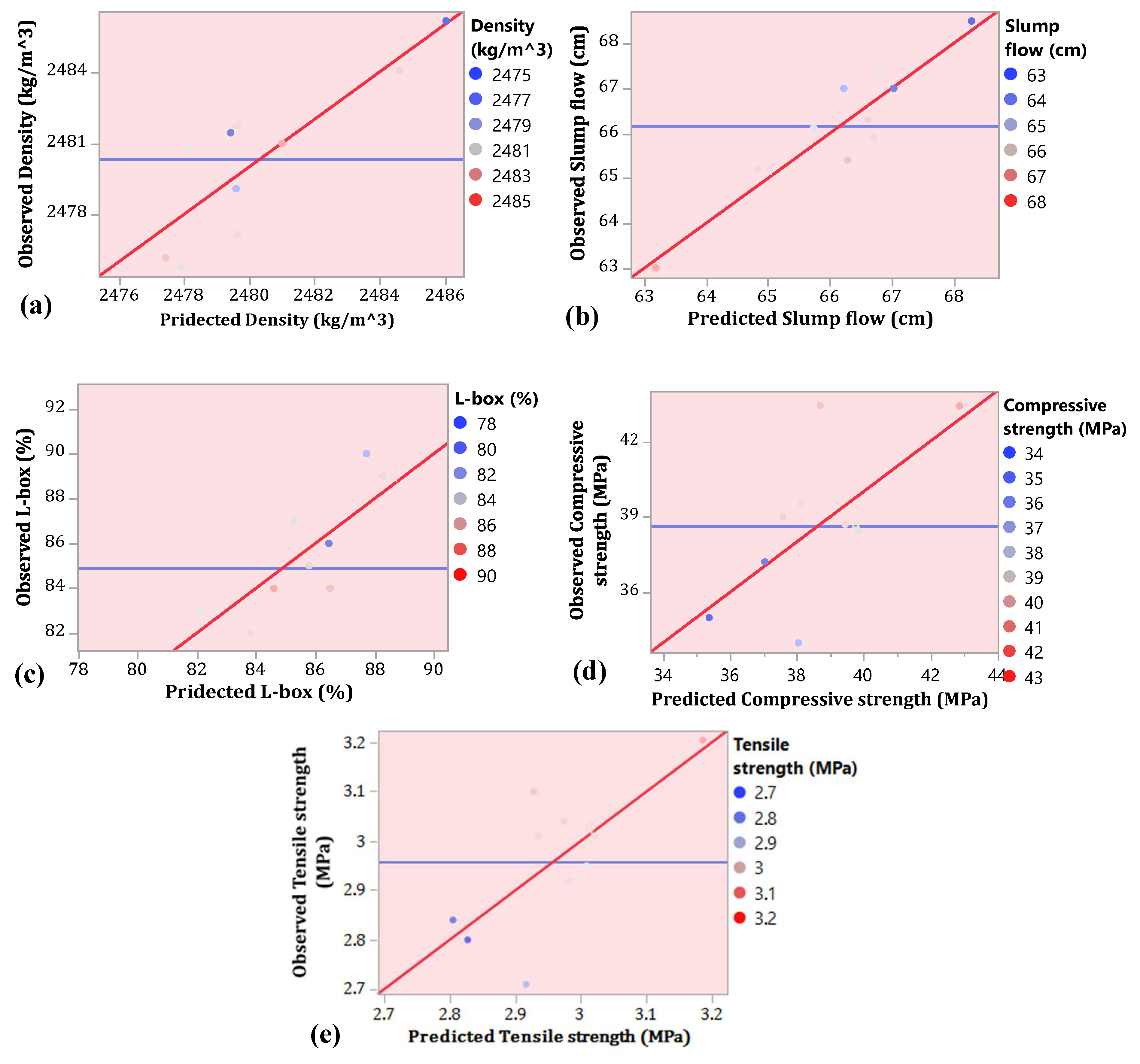

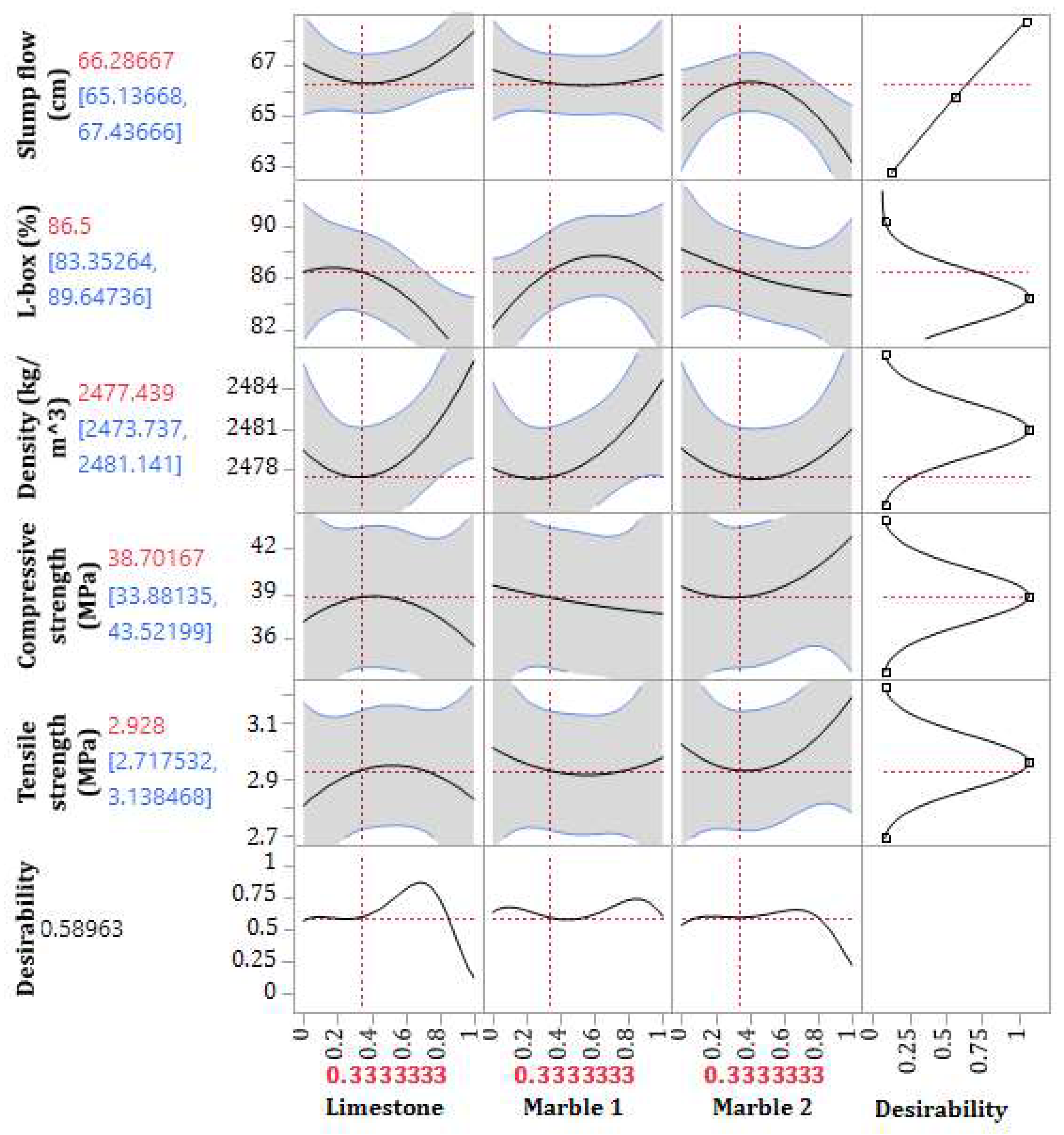

3.4. Statistical Analysis

4. Conclusions

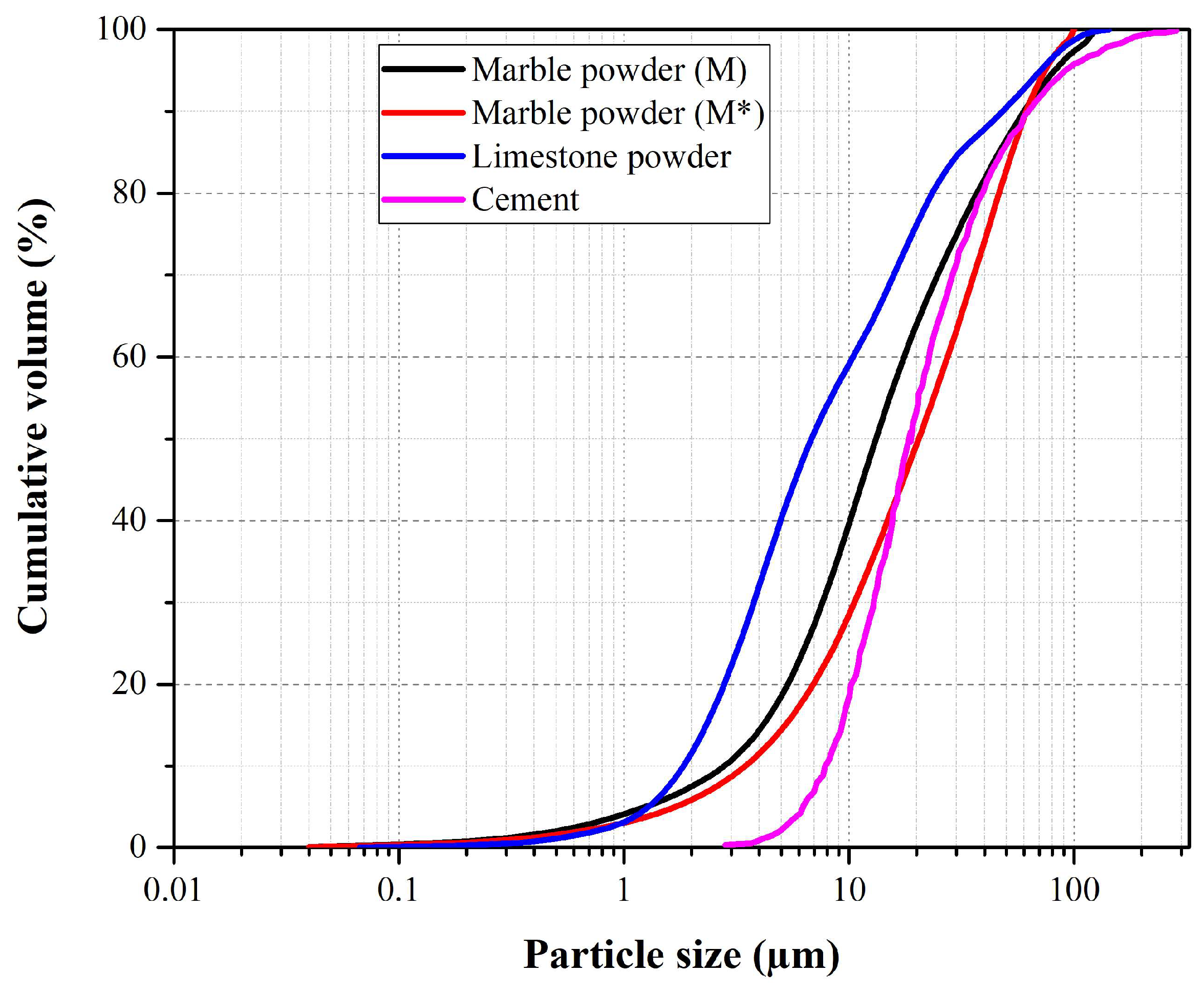

- Mixtures containing pure limestone powder (1L) achieve a density up to 5 kg/m3 higher than those incorporating pure marble powder (1M and 1M*), attributed to the finer granulometry and smoother morphology of limestone powder, which improves packing efficiency by reducing void spaces. Ternary mixtures have an average density of approximately 2477 kg/m3 but show density reductions of up to 4–10 kg/m3 compared to binary and single-powder mixtures;

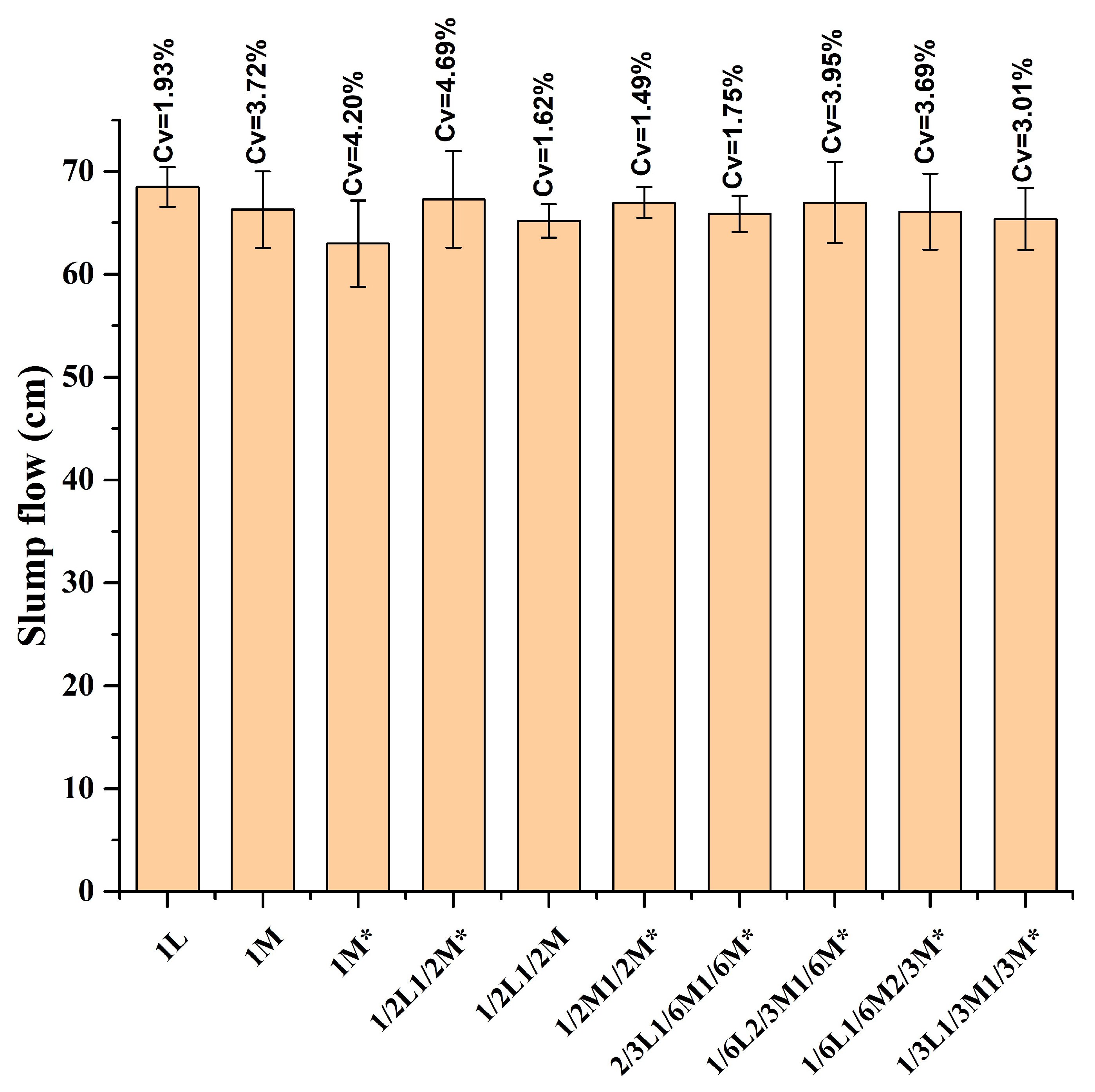

- Mixtures incorporating limestone powder exhibit a significant improvement in slump flow, with an increase of up to 8%, reaching 69 cm, compared to marble powder mixtures, which show an average flow of 66 cm. This enhancement can be attributed to the finer particle size and smoother morphology of limestone, which reduce friction between particles and improve workability. In contrast, binary and ternary mixtures containing marble powder demonstrate only marginal improvements, with the angular particle morphology of marble powder contributing to increased resistance to flow;

- The fill capacity of the SCC ranged from 0.79 to 0.9, with mixtures containing marble powder achieving a fill capacity 5% higher than those incorporating limestone powder;

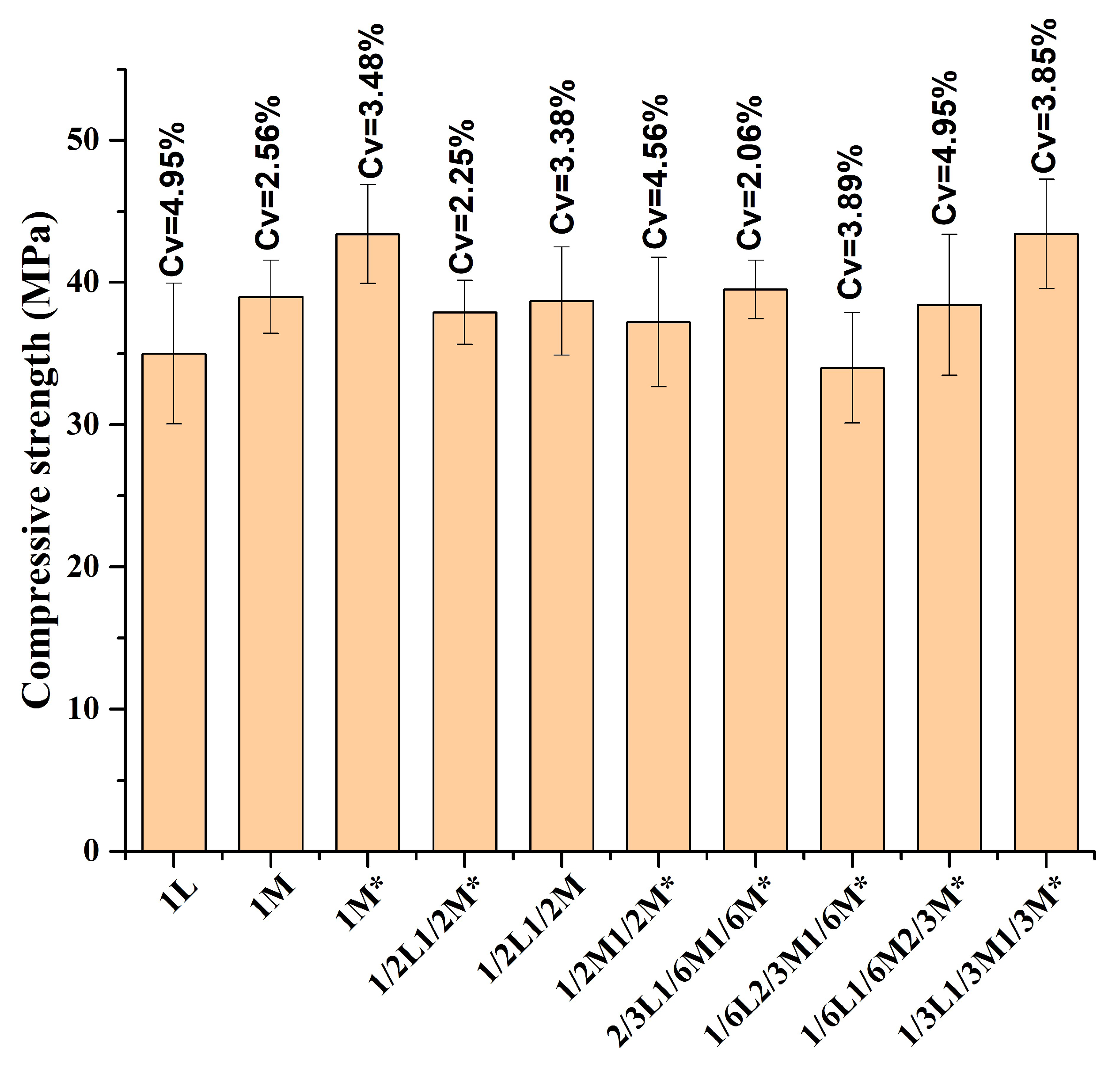

- The compressive strength of the concretes studied ranged from 34 to 45 MPa. However, mixtures containing marble powder with an SSA of 330 m2/kg exhibited a significant improvement in compressive strength, with increases ranging from 10% to 19% compared to other mixtures. Furthermore, concrete mixes incorporating a combination of fillers, particularly limestone and marble powders, achieved an average compressive strength of 38 MPa;

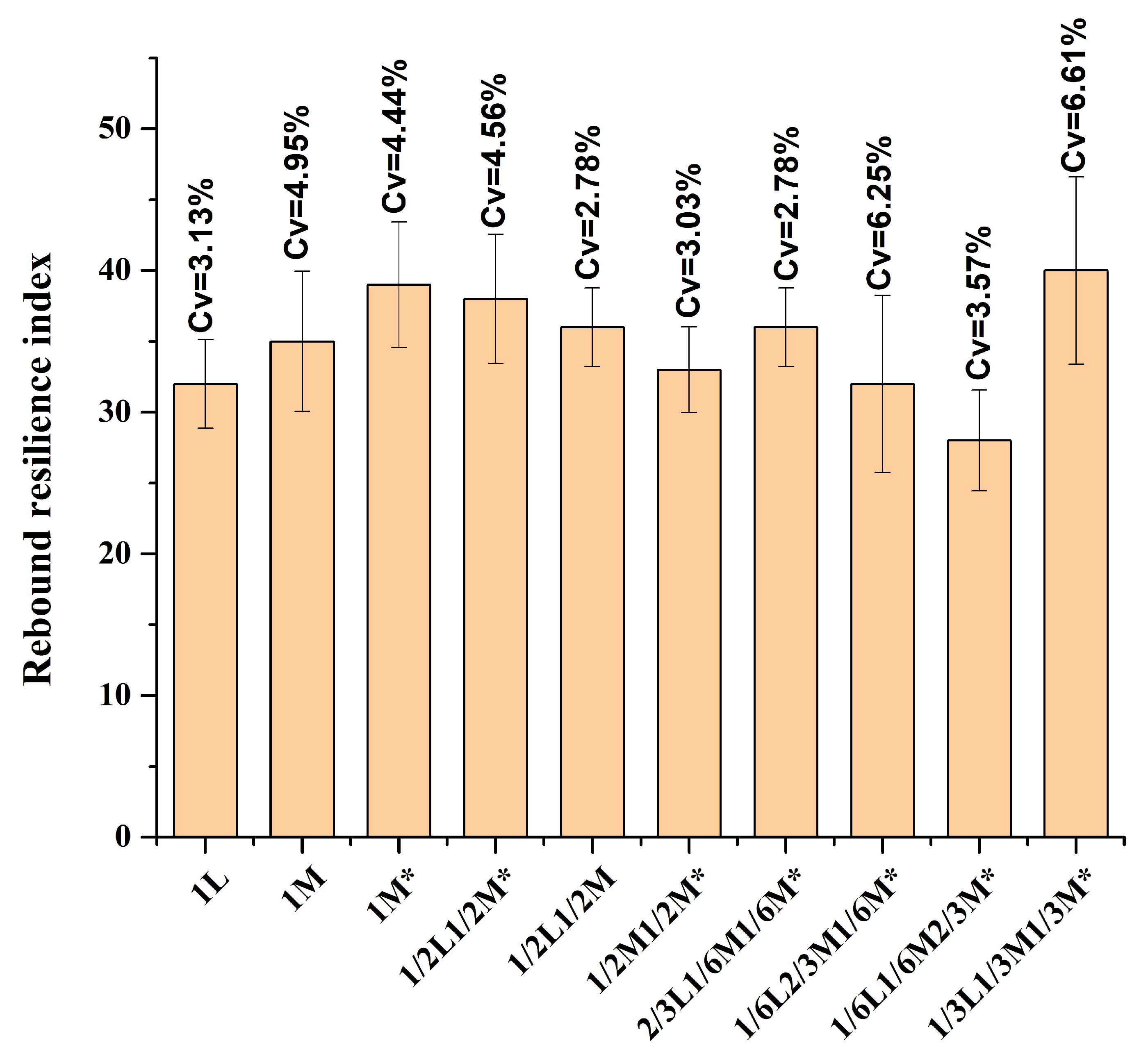

- The correlation between compressive strength and rebound index was effectively modeled using a first-order polynomial equation, with an R2 value of 0.97, demonstrating a strong predictive relationship. This correlation highlights the potential of using rebound testing as a non-destructive method to estimate the compressive strength of concrete. The high value of R2 indicates that the rebound index is a reliable indicator of concrete strength, offering a practical tool for quality control and in situ testing;

- The mixture design method was proven to be an effective tool for optimizing and analyzing the properties of SCC, enabling efficient investigation of the complex interactions between the input variables (fillers L, M, and M*) and their impact on the various responses. Statistical analysis of the results demonstrates that the polynomial equations obtained accurately predicted responses, with a p-value less than 0.05 and an R2 value exceeding 0.94, indicating a strong correlation and high prediction precision.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Choudhary, R.; Gupta, R.; Nagar, R. Impact on fresh, mechanical, and microstructural properties of high strength self-compacting concrete by marble cutting slurry waste, fly ash, and silica fume. Constr. Build. Mater. 2020, 239, 117888. [Google Scholar]

- Jain, A.; Gupta, R.; Chaudhary, S. Sustainable development of self-compacting concrete by using granite waste and fly ash. Constr. Build. Mater. 2020, 262, 120516. [Google Scholar]

- Saleh, R.D.; Hilal, N.; Sor, N.H. The impact of a large amount of ultra-fine sunflower ash with/without polypropylene fiber on the characteristics of sustainable self-compacting concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2022, 46, 3709–3722. [Google Scholar]

- Güneyisi, E.; Gesoğlu, M.; Algin, Z. Performance of self-compacting concrete (SCC) with high-volume supplementary cementitious materials (SCMs). Eco-Effic. Concr. 2013, 198–217. [Google Scholar]

- Hilal, N.; Hadzima-Nyarko, M. Improvement of eco-efficient self-compacting concrete manufacture by recycling high quantity of waste materials. Environ. Sci. Pollut. Res. 2021, 28, 53282–53297. [Google Scholar]

- Gautam, L.; Jain, J.K.; Jain, A.; Kalla, P. Valorization of bone-china ceramic powder waste along with granite waste in self-compacting concrete. Constr. Build. Mater. 2022, 315, 125730. [Google Scholar]

- Alizadeh, S.M.M.; Rezaeian, A.; Rasoolan, I.; Tahmouresi, B. Compressive stress-strain model and residual strength of self-compacting concrete containing recycled ceramic aggregate after exposure to fire. J. Build. Eng. 2021, 38, 102206. [Google Scholar]

- Sadek, D.M.; El-Attar, M.M.; Ali, H.A. Reusing of marble and granite powders in self-compacting concrete for sustainable development. J. Clean. Prod. 2016, 121, 19–32. [Google Scholar]

- Taherlou, A.; Asadollahfardi, G.; Salehi, A.M.; Katebi, A. Sustainable use of municipal solid waste incinerator bottom ash and the treated industrial wastewater in self-compacting concrete. Constr. Build. Mater. 2021, 297, 123814. [Google Scholar]

- Alani, N.Y.; Al-Jumaily, I.A.; Hilal, N. Effect of nanoclay and burnt limestone powder on fresh and hardened properties of self-compacting concrete. Nanotechnol. Environ. Eng. 2021, 6, 20. [Google Scholar]

- Ren, Q.; Xie, M.; Zhu, X.; Zhang, Y.; Jiang, Z. Role of limestone powder in early-age cement paste considering fineness effects. J. Mater. Civ. Eng. 2020, 32, 04020289. [Google Scholar]

- Hilal, N.; Al Saffar, D.M.; Ali, T.K.M. Effect of egg shell ash and strap plastic waste on properties of high strength sustainable self-compacting concrete. Arab. J. Geosci. 2021, 14, 291. [Google Scholar]

- Soroka, I.; Setter, N. The effect of fillers on strength of cement mortars. Cem. Concr. Res. 1977, 7, 449–456. [Google Scholar]

- Poppe, A.-M.; De Schutter, G. Cement hydration in the presence of high filler contents. Cem. Concr. Res. 2005, 35, 2290–2299. [Google Scholar]

- Esping, O. Effect of limestone filler BET (H2O)-area on the fresh and hardened properties of self-compacting concrete. Cem. Concr. Res. 2008, 38, 938–944. [Google Scholar]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production—Present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar]

- Dhir, R.; Limbachiya, M.; McCarthy, M.; Chaipanich, A. Evaluation of Portland limestone cements for use in concrete construction. Mater. Struct. 2007, 40, 459–473. [Google Scholar]

- Tsivilis, S.A.; Chaniotakis, E.; Kakali, G.; Batis, G. An analysis of the properties of Portland limestone cements and concrete. Cem. Concr. Compos. 2002, 24, 371–378. [Google Scholar]

- Hornain, H.; Marchand, J.; Duhot, V.; Moranville-Regourd, M. Diffusion of chloride ions in limestone filler blended cement pastes and mortars. Cem. Concr. Res. 1995, 25, 1667–1678. [Google Scholar]

- Bentz, D.P.; Irassar, E.F.; Bucher, B.E.; Weiss, W.J. Limestone fillers conserve cement; part 2: Durability issues and the effects of limestone fineness on mixtures. Concr. Int. 2009, 31, 35–39. [Google Scholar]

- Bentz, D. Modeling the influence of limestone filler on cement hydration using CEMHYD3D. Cem. Concr. Compos. 2006, 28, 124–129. [Google Scholar]

- Ghrici, M.; Kenai, S.; Said-Mansour, M. Mechanical properties and durability of mortar and concrete containing natural pozzolana and limestone blended cements. Cem. Concr. Compos. 2007, 29, 542–549. [Google Scholar]

- Güneyisi, E.; Gesoglu, M.; Özturan, T.; Mermerdas, K.; Özbay, E. Properties of mortars with natural pozzolana and limestone-based blended cements. ACI Mater. J. 2011, 108, 493. [Google Scholar]

- Pandey, S.; Sharma, R. The influence of mineral additives on the strength and porosity of OPC mortar. Cem. Concr. Res. 2000, 30, 19–23. [Google Scholar]

- Bonavetti, V.; Donza, H.; Rahhal, V.; Irassar, E. Influence of initial curing on the properties of concrete containing limestone blended cement. Cem. Concr. Res. 2000, 30, 703–708. [Google Scholar]

- Helal, M. Effect of curing time on the physicomechanical characteristics of the hardened cement pastes containing limestone. Cem. Concr. Res. 2002, 32, 447–450. [Google Scholar]

- Tsivilis, S.; Tsantilas, J.; Kakali, G.; Chaniotakis, E.; Sakellariou, A. The permeability of Portland limestone cement concrete. Cem. Concr. Res. 2003, 33, 1465–1471. [Google Scholar]

- Kore, S.D.; Vyas, A.; Kabeer KI, S.A. A brief review on sustainable utilisation of marble waste in concrete. Int. J. Sustain. Eng. 2020, 13, 264–279. [Google Scholar]

- Kabeer, K.S.A.; Bisht, K.; Saravanan, T.J.; Vyas, A.K. Effect of marble slurry on the microstructure of cement mortars subjected to salt crystallization and alternate wetting and drying cycles. J. Build. Eng. 2021, 44, 103342. [Google Scholar]

- Sufian, M.; Ullah, S.; Ostrowski, K.A.; Ahmad, A.; Zia, A.; Śliwa-Wieczorek, K.; Siddiq, M.; Awan, A.A. An experimental and empirical study on the use of waste marble powder in construction material. Materials 2021, 14, 3829. [Google Scholar] [CrossRef]

- Demirel, B.; Alyamaç, K.E. Waste marble powder/dust. In Waste and Supplementary Cementitious Materials in Concrete; Elsevier: Amsterdam, The Netherlands, 2018; pp. 181–197. [Google Scholar]

- Meko, B.; Ighalo, J.O.; Ofuyatan, O.M. Enhancement of self-compactability of fresh self-compacting concrete: A review. Clean. Mater. 2021, 1, 100019. [Google Scholar] [CrossRef]

- Long, G.; Gao, Y.; Xie, Y. Designing more sustainable and greener self-compacting concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Khatib, J. Performance of self-compacting concrete containing fly ash. Constr. Build. Mater. 2008, 22, 1963–1971. [Google Scholar]

- Celik, K.; Meral, C.; Gursel, A.P.; Mehta, P.K.; Horvath, A.; Monteiro, P.J. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar]

- Danish, P.; Ganesh, G.M. Study on influence of Metakaolin and waste marble powder on self-compacting concrete–a state of the art review. Mater. Today Proc. 2021, 44, 1428–1436. [Google Scholar] [CrossRef]

- Azarhomayun, F.; Haji, M.; Shekarchi, M.; Kioumarsi, M. Investigating the effectiveness of the stable measurement tests of self-compacting concrete. Constr. Build. Mater. 2023, 383, 131262. [Google Scholar]

- Benaicha, M.; Jalbaud, O.; Roguiez, X.; Alaoui, A.H.; Burtschell, Y. Prediction of Self-Compacting Concrete homogeneity by ultrasonic velocity. Alex. Eng. J. 2015, 54, 1181–1191. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Kocabağ, M.E.; Bayram, V.; Mermerdaş, K. Fresh and hardened characteristics of self compacting concretes made with combined use of marble powder, limestone filler, and fly ash. Constr. Build. Mater. 2012, 37, 160–170. [Google Scholar]

- Alyamac, K.E.; Ghafari, E.; Ince, R. Development of eco-efficient self-compacting concrete with waste marble powder using the response surface method. J. Clean. Prod. 2017, 144, 192–202. [Google Scholar]

- Belaidi, A.; Azzouz, L.; Kadri, E.; Kenai, S. Effect of natural pozzolana and marble powder on the properties of self-compacting concrete. Constr. Build. Mater. 2012, 31, 251–257. [Google Scholar]

- Boukhelkhal, A.; Azzouz, L.; Belaïdi, A.S.E.; Benabed, B. Effects of marble powder as a partial replacement of cement on some engineering properties of self-compacting concrete. J. Adhes. Sci. Technol. 2016, 30, 2405–2419. [Google Scholar] [CrossRef]

- Aidjouli, Y.; Belebchouche, C.; Hammoudi, A.; Kadri, E.-H.; Zaouai, S.; Czarnecki, S. Modeling the Properties of Sustainable Self-Compacting Concrete Containing Marble and Glass Powder Wastes Using Response Surface Methodology. Sustainability 2024, 16, 1972. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of limestone powder to improve the properties of self-compacting concrete incorporating high volumes of untreated rice husk ash as fine aggregate. Constr. Build. Mater. 2013, 38, 455–464. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, J.; An, X.; Qi, B.; Shen, D.; Lv, M. Effects of fly ash and limestone powder on the paste rheological thresholds of self-compacting concrete. Constr. Build. Mater. 2021, 281, 122560. [Google Scholar] [CrossRef]

- Zhu, W.; Gibbs, J.C. Use of different limestone and chalk powders in self-compacting concrete. Cem. Concr. Res. 2005, 35, 1457–1462. [Google Scholar] [CrossRef]

- Ahmed, Y.H.; Babikir, K.S.E. Effects of Limestone Powder on Self-compacting Concrete Properties. FES J. Eng. Sci. 2020, 9, 14–20. [Google Scholar]

- Zamir Hashmi, S.R.; Khan, M.I.; Khahro, S.H.; Zaid, O.; Shahid Siddique, M.; Md Yusoff, N.I. Prediction of strength properties of concrete containing waste marble aggregate and stone dust—Modeling and optimization using RSM. Materials 2022, 15, 8024. [Google Scholar] [CrossRef]

- Hammoudi, A.; Moussaceb, K.; Belebchouche, C.; Dahmoune, F. Comparison of artificial neural network (ANN) and response surface methodology (RSM) prediction in compressive strength of recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 425–436. [Google Scholar] [CrossRef]

- Ghafari, E.; Costa, H.; Júlio, E. RSM-based model to predict the performance of self-compacting UHPC reinforced with hybrid steel micro-fibers. Constr. Build. Mater. 2014, 66, 375–383. [Google Scholar]

- ISO 13320; 2020 Particle Size Analysis—Laser Diffraction Methods. iTeh Standards: Etobicoke, ON, Canada, 2020; p 59.

- EN 196-6; Methods of Testing Cement. Determination of fineness. British Standards Institute: London, UK, 2010.

- L’Association Française de Génie Civil. Recommandations Pour L’emploi des Bétons Auto-Plaçants: Ecommendations for Use of Self-Compacting Concrete; AFGC: Dublin, Ireland, 2008. [Google Scholar]

- EN 12350-8:2019; Testing Fresh Concrete—Part 8: Self-Compacting Concrete—Slump-Flow Test. iTeh Standards: Etobicoke, ON, Canada, 2019; p 10.

- EN 12350-10:2010; Testing Fresh Concrete—Part 10: Self-Compacting Concrete—L Box Test. iTeh Standards: Etobicoke, ON, Canada, 2010; p 10.

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019; p 20.

- EN 12390-6:2023; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2023.

- EN 12504-2; Essais pour béton dans les structures—Partie 2: Essais non destructifs—Détermination de l’indice de rebondissement. AFNOR: Saint-Denis, France, 2021; p 10.

- Raju, M.R.; Ahmad, S.I.; Hasan, M.M.; Hasan, N.M.S.; Islam, M.M.; Basit, M.A.; Hossain, I.T.; Santo, S.A.; Alam, M.S.; Rahman, M.J.H. Machine learning for predicting strength properties of waste iron slag concrete. Heliyon 2025, 11, e42133. [Google Scholar]

- Pelánek, R. Metrics for Evaluation of Student Models. J. Educ. Data Min. 2015, 7, 1–19. [Google Scholar]

- Hammouche, R.; Belebchouche, C.; Hammoudi, A.; Douadi, A.; Czarnecki, S. Modeling and Optimizing the Durability of Self-Compacting Mortars Incorporating Cement Kiln Dust and Glass Powder: A Box-Behnken Design Study. J. Clean. Prod. 2025, 145282. [Google Scholar]

- Liu, C.; Li, Z.; Bezuijen, A.; Chen, L.; Cachim, P.J.C.; Materials, B. Optimizing the shield tunnel backfilling grouts with supplementary cementitious materials by response surface methodology. Constr. Build. Mater. 2024, 421, 135575. [Google Scholar]

- Ehrenberg, S.; Eberli, G.; Keramati, M.; Moallemi, S. Porosity-permeability relationships in interlayered limestone-dolostone reservoirs. AAPG Bull. 2006, 90, 91–114. [Google Scholar]

- Elgalhud, A.A.; Dhir, R.K.; Ghataora, G. Limestone addition effects on concrete porosity. Cem. Concr. Compos. 2016, 72, 222–234. [Google Scholar]

- Singh, A.; Thakare, A.A.; Chaudhary, S. A case study on examining the fresh-state behavior of self-compacting mortar containing waste powders from various sources. Case Stud. Constr. Mater. 2023, 19, e02684. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Hilal, N.; Hamah Sor, N.; Hadzima-Nyarko, M.; Radu, D.; Tawfik, T.A.J. The influence of nanosunflower ash and nanowalnut shell ash on sustainable lightweight self-compacting concrete characteristics. Sci. Rep. 2024, 14, 9450. [Google Scholar]

- Orkoula, M.G.; Koutsoukos, P.G. Dissolution effects on specific surface area, particle size, and porosity of pentelic marble. J. Colloid Interface Sci. 2001, 239, 483–488. [Google Scholar]

- Mohammed, A.A.; Tawfik, T.A.; Aadi, A.S.; Hamah Sor, N. Ultra-high performance of eco-friendly self-compacting concrete incorporated cement Kiln dust with/without waste plastic and polypropylene fiber. Innov. Infrastruct. Solut. 2023, 8, 94. [Google Scholar]

- Kendall, K.; Howard, A.J.; Birchall, J.D. The relation between porosity, microstructure and strength, and the approach to advanced cement-based materials. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Sci. 1983, 310, 139–153. [Google Scholar]

- Boukendakdji, O.; Kenai, S.; Kadri, E.; Rouis, F.J.C.; Materials, B. Effect of slag on the rheology of fresh self-compacted concrete. Constr. Build. Mater. 2009, 23, 2593–2598. [Google Scholar]

- Said-Mansour, M.; Kadri, E.-H.; Kenai, S.; Ghrici, M.; Bennaceur, R.J.C. Influence of calcined kaolin on mortar properties. Constr. Build. Mater. 2011, 25, 2275–2282. [Google Scholar]

- Sua-iam, G.; Sokrai, P.; Makul, N.J.C. Novel ternary blends of Type 1 Portland cement, residual rice husk ash, and limestone powder to improve the properties of self-compacting concrete. Constr. Build. Mater. 2016, 125, 1028–1034. [Google Scholar]

- Yahia, A.; Tanimura, M.; Shimoyama, Y.J.C. Rheological properties of highly flowable mortar containing limestone filler-effect of powder content and W/C ratio. Cem. Concr. Res. 2005, 35, 532–539. [Google Scholar]

- Qasim, M.; Lee, C.; Zhang, Y.J.C.; Materials, B. An experimental study on interfacial bond strength between hybrid engineered cementitious composite and concrete. Constr. Build. Mater. 2022, 356, 129299. [Google Scholar]

- Kanellopoulos, A.; Savva, P.; Petrou, M.F.; Ioannou, I.; Pantazopoulou, S.J.C. Assessing the quality of concrete–reinforcement interface in Self Compacting Concrete. Constr. Build. Mater. 2020, 240, 117933. [Google Scholar]

- Chahour, K.; Mechakra, H.; Safi, B.; Dehbi, N.-M.; Chaibet, C. Rheological and mechanical behavior study of eco-friendly cement mortar made with marble powder. Int. J. Appl. Mech. Eng. 2024, 29, 19–35. [Google Scholar]

- Talah, A.; Kharchi, F.; Chaid, R. Influence of marble powder on high performance concrete behavior. Procedia Eng. 2015, 114, 685–690. [Google Scholar]

- Sahraoui, M.; Bouziani, T. ANN modelling approach for predicting SCC properties-Research considering Algerian experience. Part III. Effect of mineral admixtures. J. Build. Mater. Struct. 2021, 8, 128–138. [Google Scholar]

- Shi, J.; Zhang, F.; Zhuang, J.; Wu, Z.; Chen, R.; Li, H. Study on the Influence of SAP on Properties of White Fair-Faced Concrete with Limestone Powder. Adv. Mater. Sci. Eng. 2023, 2023, 4994299. [Google Scholar]

- Alrawashdeh, A.; Eren, O. Mechanical and physical characterisation of steel fibre reinforced self-compacting concrete: Different aspect ratios and volume fractions of fibres. Results Eng. 2022, 13, 100335. [Google Scholar]

- Bashaveni, B.; Pannem, R.M.R. Development of self-healing property in self compacting concrete. Case Stud. Constr. Mater. 2024, 20, e02942. [Google Scholar]

| References | Powder Used | Main Results |

|---|---|---|

| [39] | Limestone and marble powder | The use of marble or limestone fillers resulted in an increased dose of superplasticizer to maintain the target slump flow and an increase in viscosity. |

| [40] | Marble powder | The addition of marble powder enhanced the fresh properties of SCC. With an M/C ratio increasing to 0.43, the slump flow decreased, the T-50 increased, and the V-funnel value remained stable. |

| [41] | Marble powder | The inclusion of marble powder (5–30%) improved the rheological properties of both mortar and concrete. However, a decrease in compressive strength was observed with marble powder addition compared to the control mix. |

| [42] | Marble powder | Substituting cement with marble powder reduced both yield stress and plastic viscosity. |

| [43] | Marble powder | Response surface methodology can be used to model the properties of self-compacting concrete incorporating waste marble and glass powder. |

| [8] | Marble powder | The use of waste powders as mineral additives in SCC improved its physical, mechanical, and durability-related properties compared to the control mix. |

| [44] | Limestone powder | SCCs containing limestone powder showed superior hardening properties. Furthermore, the fresh and hardened properties of the SCCs improved significantly when the limestone powder was combined with the pozzolanic powder. |

| [45] | Limestone powder | The paste rheological thresholds showed only slight variation with an increase in the substituted content of limestone powder in the self-compacting concrete mix. |

| [46] | Limestone powder | The strength of SCC mixes containing limestone powder was significantly higher than that of reference concrete. Specifically, the compressive strengths of the cubes for limestone powder mixes were 60 to 80% higher at 7 days and 30 to 40% higher at 28 days. |

| [47] | Limestone powder | The quantity of limestone powder (LSP) is a crucial factor affecting the properties of SCC. For a higher free water content, LSP had a less significant effect on slump flow compared to lower water content. Obtaining compressive strengths of (35–50) MPa is easily possible with up to 15% cement replacement by LSP. |

| Compounds (%) | Cement | Marble | Limestone |

|---|---|---|---|

| SiO2 | 22.7 | 7.44 | 1 |

| Al2O3 | 5.4 | 0.83 | 0.3 |

| Fe2O3 | 2.7 | 0.75 | 0.3 |

| CaO | 65.7 | 49.73 | 53.3 |

| MgO | 0.7 | 0.66 | 1.1 |

| SO3 | 0.6 | 0.01 | 0.07 |

| K2O | 0.4 | 0.02 | 0.04 |

| Na2O | 0.7 | 0.008 | 0.06 |

| Loss of ignition | 0.3 | 39.79 | 43.63 |

| SSA (m2/kg) | 326 | 330 for M* 390 for M | 405 |

| Specific gravity (g/cm3) | 3.15 | 2.75 | 2.72 |

| Mixes | Designation | Limestone (L) | Marble 1 (M) | Marble 2 (M*) |

|---|---|---|---|---|

| M1 | 1L | 1 | 0 | 0 |

| M2 | 1M | 0 | 1 | 0 |

| M3 | 1M* | 0 | 0 | 1 |

| M4 | 1/2L1/2M* | 0.50 | 0 | 0.50 |

| M5 | 1/2L1/2M | 0.50 | 0.50 | 0 |

| M6 | 1/2M1/2M* | 0 | 0.50 | 0.50 |

| M7 | 2/3L1/6M1/6M* | 0.66 | 0.16 | 0.16 |

| M8 | 1/6L2/3M1/6M* | 0.16 | 0.66 | 0.16 |

| M9 | 1/6L1/6M2/3M* | 0.16 | 0.16 | 0.66 |

| M10 | 1/3L1/3M1/3M* | 0.33 | 0.33 | 0.33 |

| Components (kg/m3) | Additives (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Mix | Cement | Water | SP | Sand | Gravel | Limestone | Marble | ||

| (3/8) | (8/16) | M | M* | ||||||

| M1 | 400 | 178.56 | 7.2 | 826.5 | 429.52 | 429.52 | 80 | 0 | 0 |

| M2 | 0 | 80 | 0 | ||||||

| M3 | 0 | 0 | 80 | ||||||

| M4 | 40 | 0 | 40 | ||||||

| M5 | 40 | 40 | 0 | ||||||

| M6 | 0 | 40 | 40 | ||||||

| M7 | 52.8 | 13.4 | 13.4 | ||||||

| M8 | 13.4 | 52.8 | 13.4 | ||||||

| M9 | 13.4 | 13.4 | 52.8 | ||||||

| M10 | 26.66 | 26.66 | 26.66 | ||||||

| Density | Slump Flow | L-Box | CS | TS | |

|---|---|---|---|---|---|

| R2 | 0.94 | 0.98 | 0.97 | 0.99 | 0.97 |

| Adjusted R2 | 0.86 | 0.96 | 0.93 | 0.97 | 0.92 |

| Root-Mean-Square-Error (RMSE) | 1.24 | 0.31 | 0.01 | 0.56 | 0.04 |

| Mean response | 2480.34 | 66.17 | 0.85 | 38.66 | 2.96 |

| Observations (or weighted sums) | 10 | 10 | 10 | 10 | 10 |

| Source | df | Sum of Squares | Mean Squares | F-Ratio | |

|---|---|---|---|---|---|

| Density | Model | 5.00 | 94.91 | 18.98 | 12.26 |

| Error | 4.00 | 6.19 | 1.55 | Prob. > F | |

| Uncorrected total | 9.00 | 101.11 | 0.008 | ||

| Slump flow | Model | 5.00 | 19.37 | 3.87 | 39.69 |

| Error | 4.00 | 0.39 | 0.10 | Prob. > F | |

| Uncorrected total | 9.00 | 19.76 | 0.0022 | ||

| L-box | Model | 5.00 | 0.0094 | 0.0019 | 25.58 |

| Error | 4.00 | 0.0003 | 0.0001 | Prob. > F | |

| Uncorrected total | 9.00 | 0.0097 | 0.0017 | ||

| CS | Model | 5.00 | 82.55 | 16.51 | 53.15 |

| Error | 4.00 | 1.24 | 0.31 | Prob. > F | |

| Uncorrected total | 9.00 | 83.79 | 0.0039 | ||

| TS | Model | 5.00 | 0.188 | 0.04 | 22.25 |

| Error | 4.00 | 0.007 | Prob. > F | ||

| Uncorrected total | 9.00 | 0.195 | 0.0013 |

| Mix 1 | Mix 2 | Mix 3 | Mix 4 | |

|---|---|---|---|---|

| (A) L | 0.214 | 0.059 | 0.132 | 0.177 |

| (B) M | 0.76 | 0.871 | 0.47 | 0.779 |

| (C) M* | 0.026 | 0.071 | 0.398 | 0.044 |

| Slump flow (cm) | 66.567 | 66.577 | 67.281 | 66.879 |

| L-box | 89.739 | 88.946 | 87.289 | 88.166 |

| Density (min) | 2484.932 | 2484.473 | 2486.336 | 2485.395 |

| CS (MPa) | 44.195 | 43.522 | 41.899 | 48.955 |

| TS (MPa) | 3.135 | 3.183 | 3.135 | 3.066 |

| Desirability | 1 | 0.994 | 0.956 | 0.793 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boutlikht, M.; Douadi, A.; Khitas, N.E.H.; Messai, A.; Hebbache, K.; Belebchouche, C.; Smarzewski, P.; Tawfik, T.A. Optimizing of Self-Compacting Concrete (SCC): Synergistic Impact of Marble and Limestone Powders—A Technical and Statistical Analysis. Buildings 2025, 15, 1043. https://doi.org/10.3390/buildings15071043

Boutlikht M, Douadi A, Khitas NEH, Messai A, Hebbache K, Belebchouche C, Smarzewski P, Tawfik TA. Optimizing of Self-Compacting Concrete (SCC): Synergistic Impact of Marble and Limestone Powders—A Technical and Statistical Analysis. Buildings. 2025; 15(7):1043. https://doi.org/10.3390/buildings15071043

Chicago/Turabian StyleBoutlikht, Mourad, Abdellah Douadi, Nour El Houda Khitas, Abderraouf Messai, Kamel Hebbache, Cherif Belebchouche, Piotr Smarzewski, and Taher A. Tawfik. 2025. "Optimizing of Self-Compacting Concrete (SCC): Synergistic Impact of Marble and Limestone Powders—A Technical and Statistical Analysis" Buildings 15, no. 7: 1043. https://doi.org/10.3390/buildings15071043

APA StyleBoutlikht, M., Douadi, A., Khitas, N. E. H., Messai, A., Hebbache, K., Belebchouche, C., Smarzewski, P., & Tawfik, T. A. (2025). Optimizing of Self-Compacting Concrete (SCC): Synergistic Impact of Marble and Limestone Powders—A Technical and Statistical Analysis. Buildings, 15(7), 1043. https://doi.org/10.3390/buildings15071043