1. Introduction

With the completion of the Three Gorges Reservoir and its subsequent water storage, the water level in the reservoir area exhibits prolonged periods of high water levels and brief intervals of low water levels. This phenomenon results in the overhead vertical wharf experiencing more complex and variable water pressure during operation. Additionally, the shore geological conditions and complex topography of the Three Gorges Reservoir area make the traditional overhead vertical wharf go through a lot of changes in construction, use, and hydrological conditions, making it difficult to meet the construction and development needs. The large-scale steel cashing-reinforced concrete pile composite member can significantly accelerate the construction speed during the dry water period, and it is not affected by the changes in water level rise and fall in the reservoir area. Thus, it prolongs the overall construction time and makes it widely applicable in overhead vertical wharfs designed for significant water level differences [

1,

2]. In addition to being used in overhead vertical wharfs with significant water level differences, steel casing is widely used in highland canyon reservoir bridges, karst areas, offshore wind power piles, and so on due to their advantages of anti-sliding stability, foundation reinforcement, and construction convenience. There is a significant difference in the lateral working performance of large-scale steel casing-reinforced concrete pile composite members under complex hydrological conditions compared to traditional reinforced concrete column (concrete-filled steel tube) composite structures. In the context of ship–wave–current–structure interactions, this combined structure is subjected to low-frequency ship impacts, resulting in ship crashes that damage piers from time to time, which have serious impacts on the structure’s strength, stiffness, deformation, and energy consumption. Therefore, studying the interfacial force transfer, damage mechanisms, and energy dissipation modes [

3,

4] of the wharf-combined structure under low-frequency lateral loading [

5,

6,

7] is of great theoretical and practical significance.

Steel casings are often required to be embedded to a certain depth within the rock strata as part of the construction of rock-socketed piles over water. Due to the difficulty of removing the steel casing after construction, it is typically not considered a stressed member. However, a steel casing exhibits significant flexural stiffness, which inevitably results in load-bearing under horizontal loading conditions [

8]. As research on composite piles has deepened, scholars both domestically and internationally have increasingly focused on the influence of steel casings on the overall performance of the structure. The AASHTO LRFD Bridge Design Specifications [

9] indicate that the steel casing can be regarded as participating in the load-bearing capacity when the wall thickness of the steel casing exceeds 3 mm. Mu et al. [

10] investigated the displacement and internal force distribution of foundation piles under cast-in-place conditions, considering and ignoring the effects of the steel casing. The study found that the pile top displacement can be reduced by half when accounting for the effect of the steel casing. Zhu et al. [

11,

12,

13] investigated the lateral bearing behavior of steel-socketed piles. They found that the steel casing significantly improved the bearing capacity of rock-socketed piles and facilitated the local backfill of steel tube pile computational technology. Zhou et al. [

14] investigated the impact behavior of steel casing composite piles by performing pendulum impact tests on specimens and found that the damage of short steel casing piles transferred from bending to bending-shear as the impact velocity increased. Wang et al. [

15] investigated the displacement depth and buckling characteristics of super-large-diameter steel casings under axial impact loads, etc. The results showed that for thin walls, the resulting axial stresses are high, and buckling deformation is likely to occur, making it difficult to drive the SLDSC to the design depth. Chen et al. [

16] carried out vertical bearing tests and horizontal bearing tests on common precast piles and steel casing precast piles, respectively, to compare and analyze the effects of the depth of rock embedded in the pile body on the bearing performance of the pile foundation under the conditions of with and without steel casings. Xiong et al. [

17] analyzed the relationship between the circumferential strain and displacement of thin-walled steel casings under axial loads by constructing the equilibrium differential equations, geometric equations, and the intrinsic equations of the micrometric body.

From the above literature, it can be seen that existing studies mainly focus on the structural bearing capacity under vertical as well as horizontal loading of steel casing members; however, large-scale steel casing-reinforced concrete pile composite members are often subjected to more complex loads, such as low circumferential cyclic loads. The current studies on large-scale steel-reinforced concrete columns and steel link-braced composite structures are still limited [

18], and most of the studies focus on the lateral load-bearing characteristics and hysteresis performance of concrete-filled steel tubes. For instance, Bradford et al. [

19,

20,

21,

22,

23] investigated rectangular concrete-filled steel tubular columns, revealing their cross-section strain and stress patterns under vertical loading and exploring the applicable conditions for these columns. Huang et al. [

24,

25,

26,

27,

28,

29,

30,

31] found that the thickness and strength of steel tubes significantly influence the concrete bearing capacity by studying the compression performance of square concrete-filled steel tubes (CFSTs), rectangular reinforced concrete-filled steel tubes (RACFSTs), and slender columns. Hajjar et al. [

32,

33,

34,

35,

36,

37] developed a theoretical model for the hysteretic performance of square concrete-filled steel tubes by investigating the constitutive relationship of concrete-filled steel tubes and proposed a corresponding theoretical framework for axial compression members made of average-strength and high-strength concrete-filled steel tubes. Additionally, a study by Dong [

38] showed that concrete-filled steel tubes with internal structures have fuller hysteresis return curves, a higher load-bearing capacity, better energy dissipation capacity and ductility, and better seismic performance. Zhang Y et al. [

39] explored the effect of axial load levels on the hysteretic performance of concrete-filled steel tubes through experimental tests. Alva et al. [

40,

41] found that both the structural design and the magnitude of the axial load significantly influence the energy dissipation capacity of concrete-filled steel tubes in their study. Given that large-scale steel and reinforced concrete composite members share similarities with concrete-filled steel tubes, this paper aims to further investigate the mechanical properties and working mechanisms of steel casing-reinforced concrete pile composite members, leveraging the existing research findings on concrete-filled steel tubes.

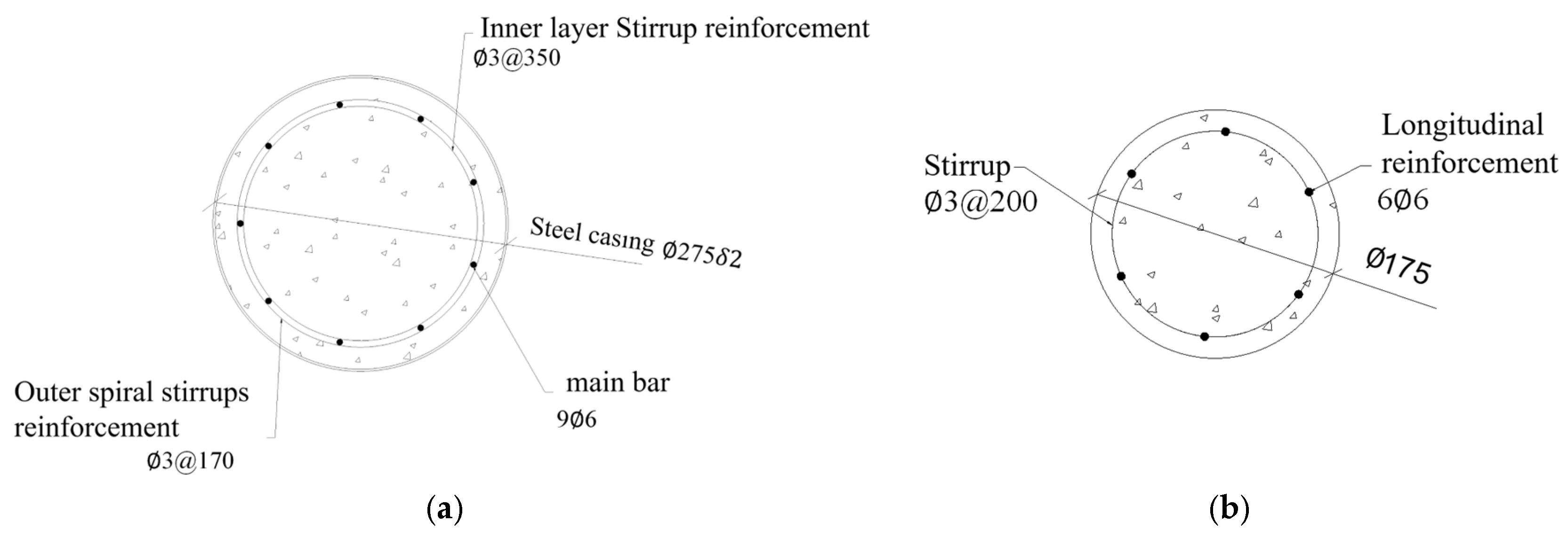

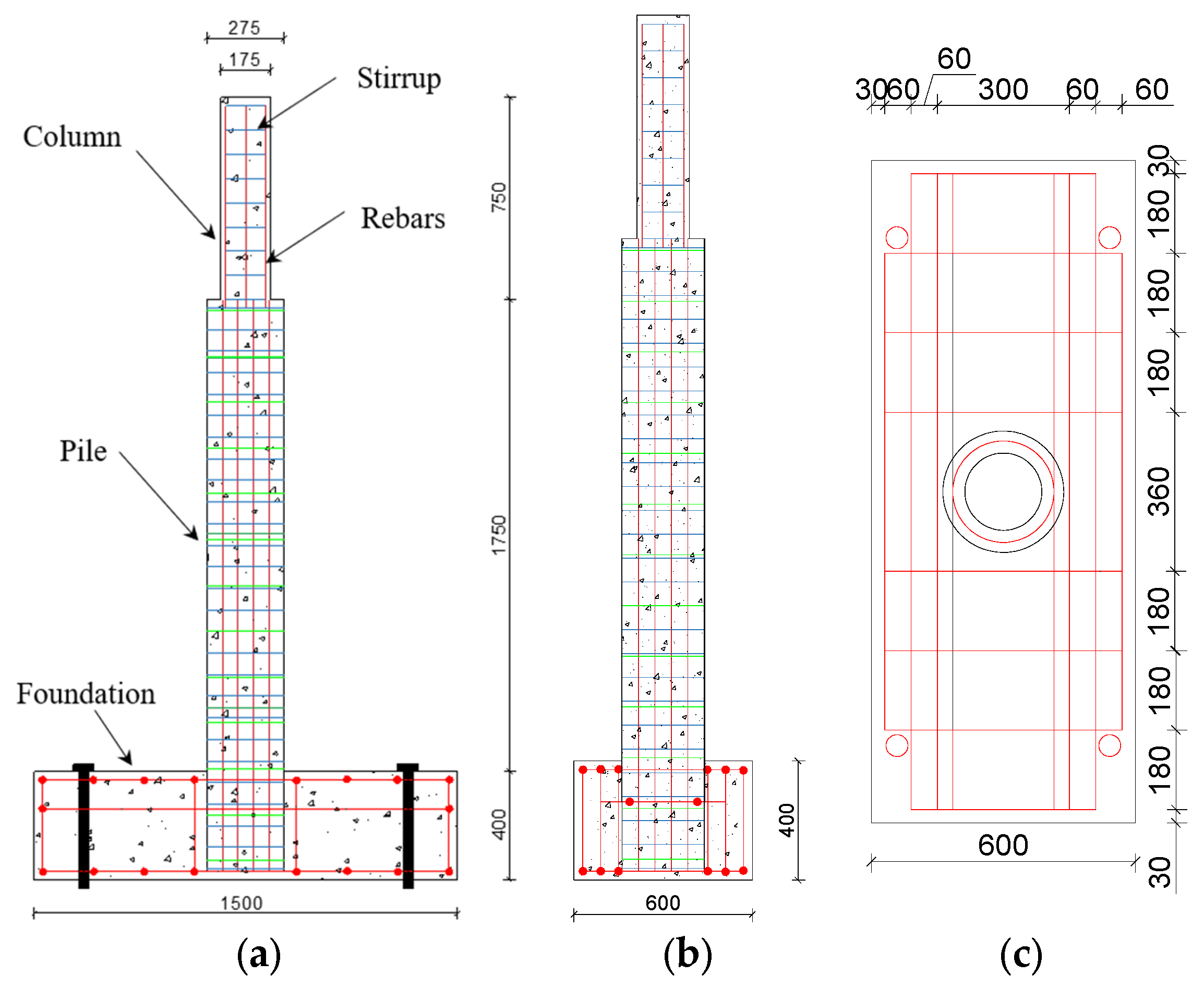

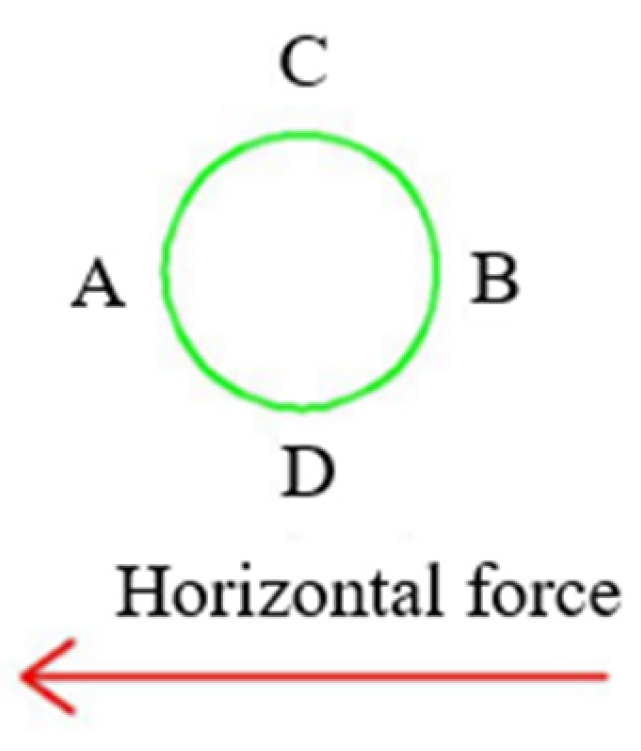

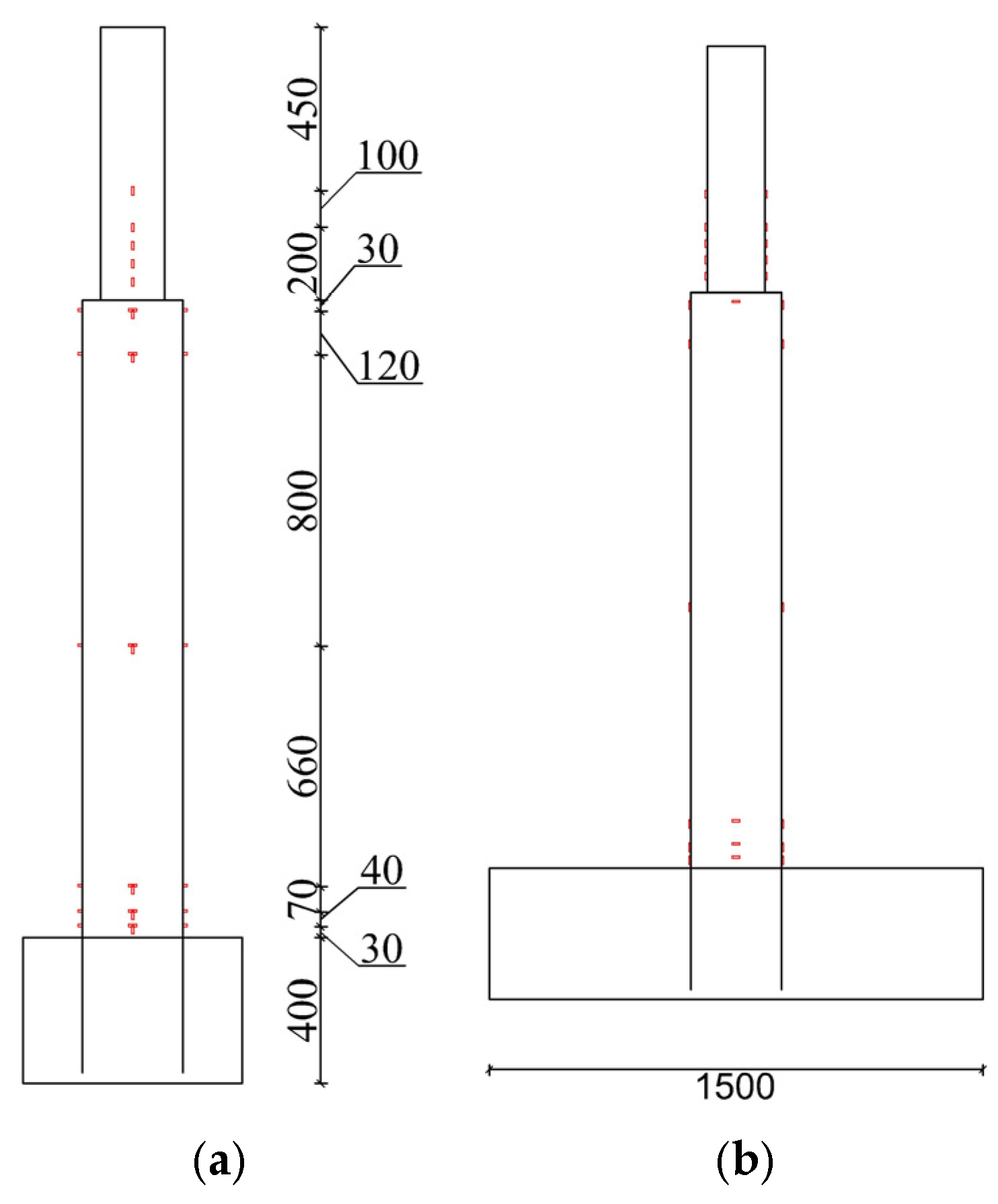

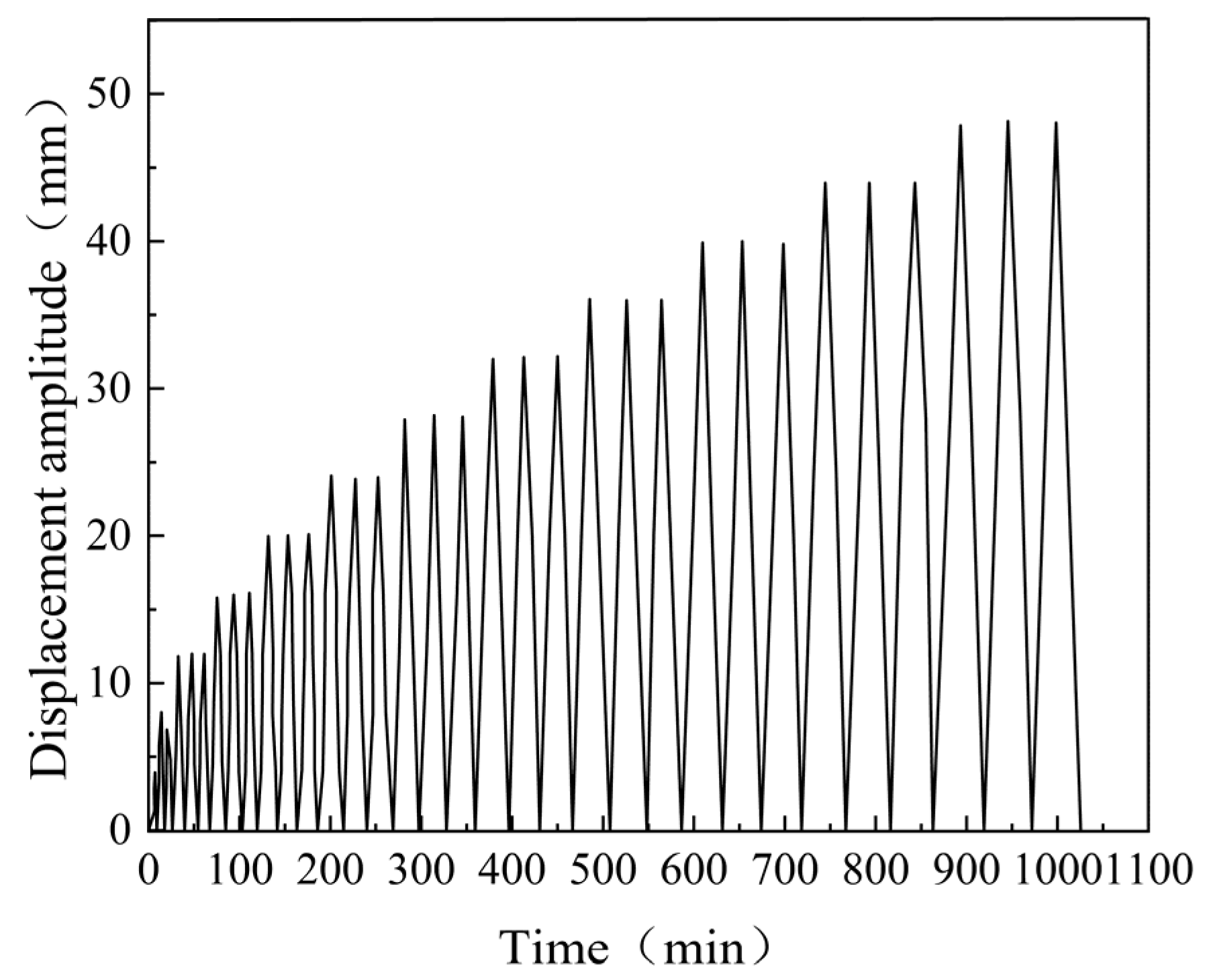

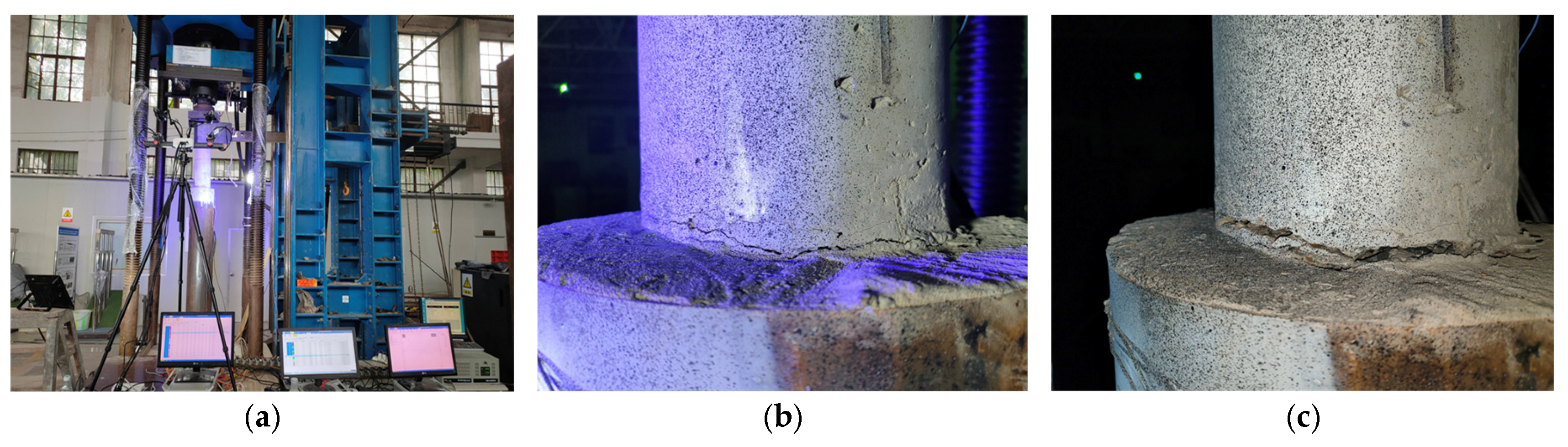

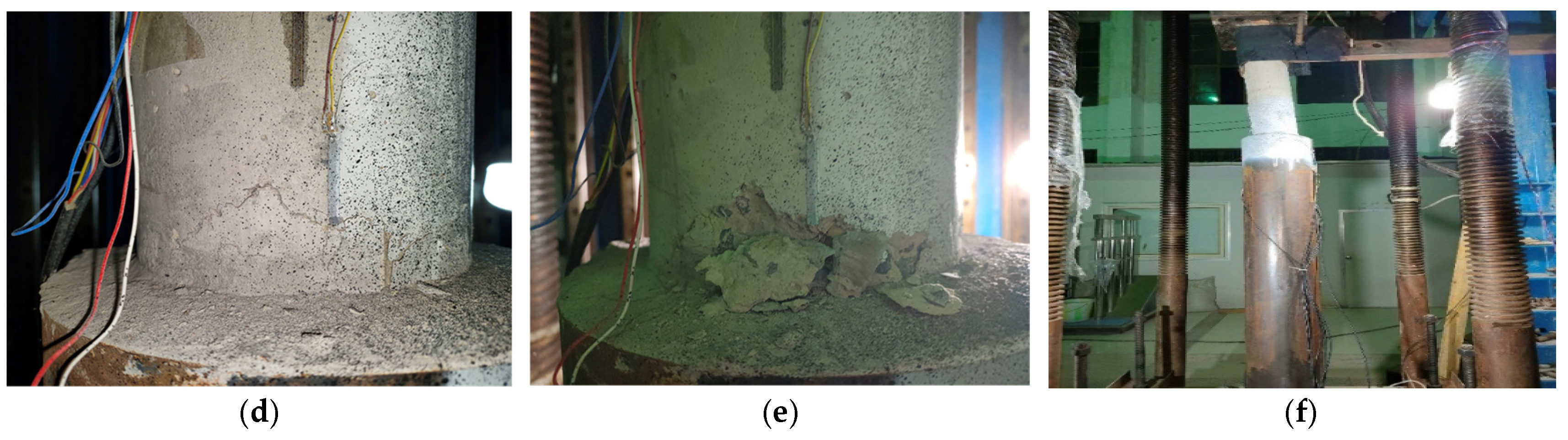

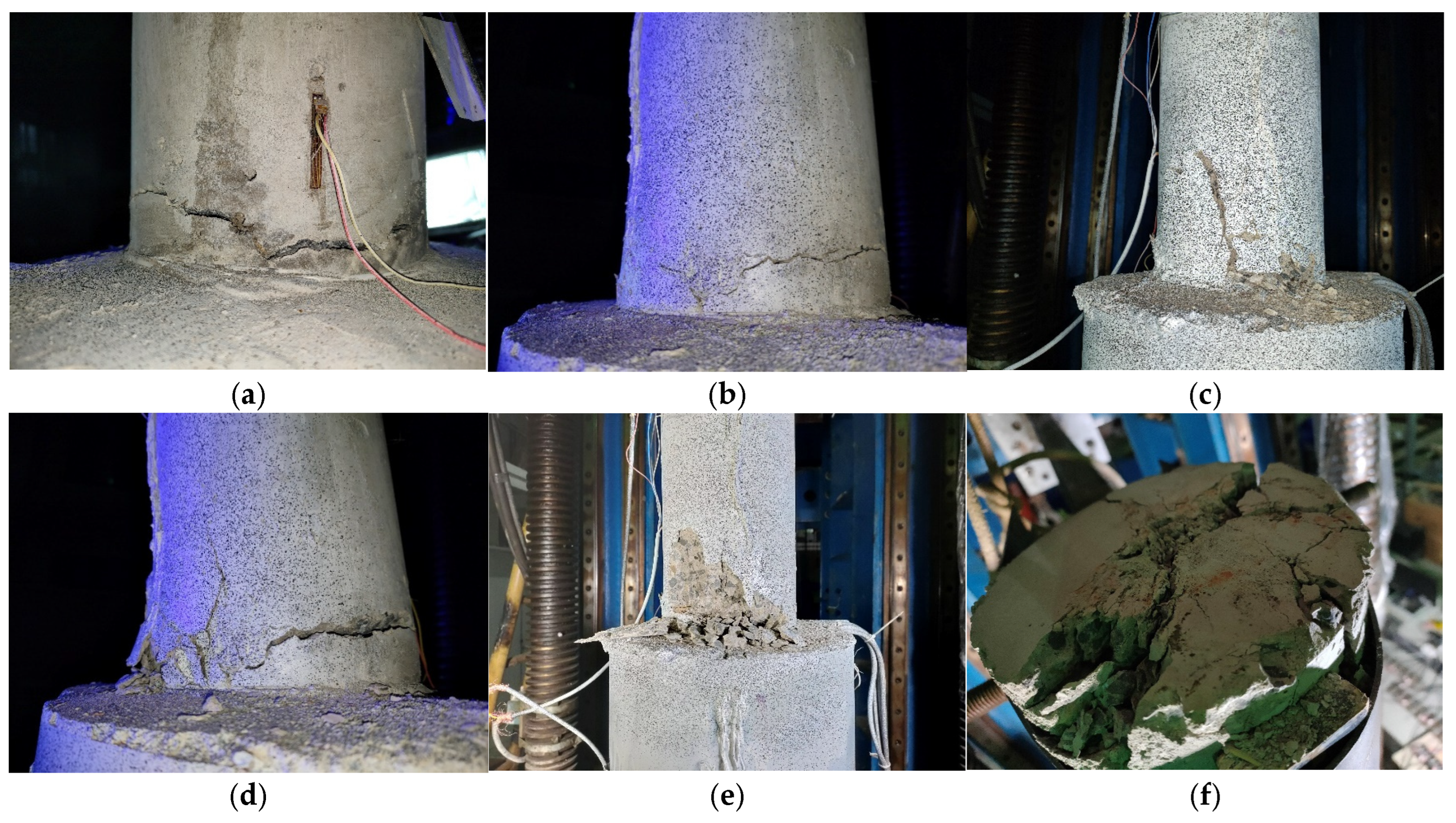

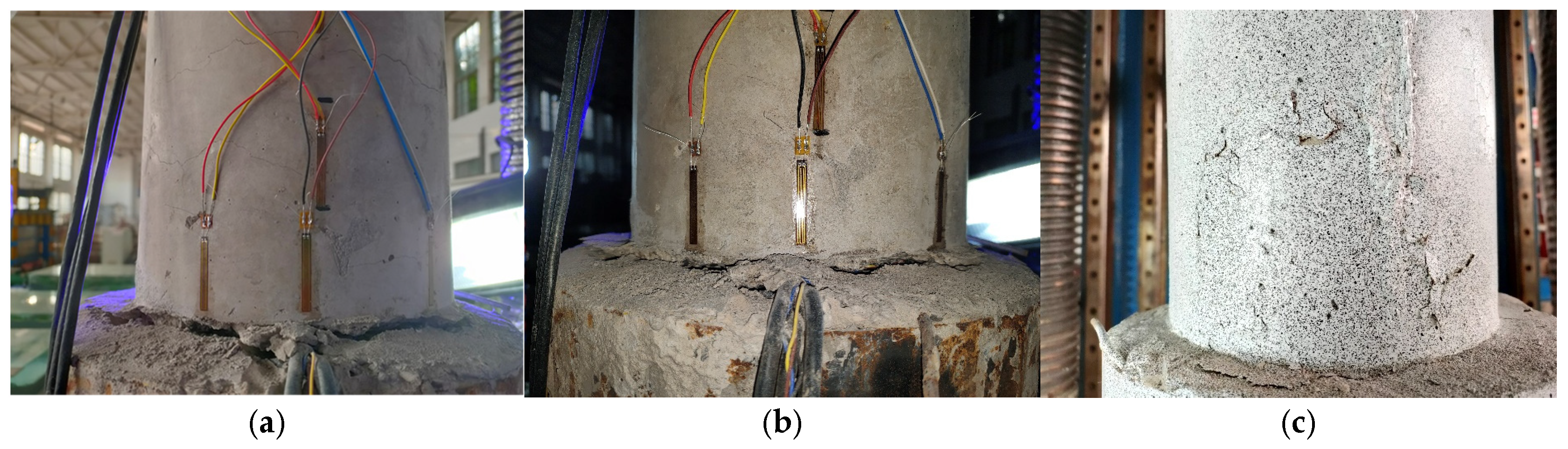

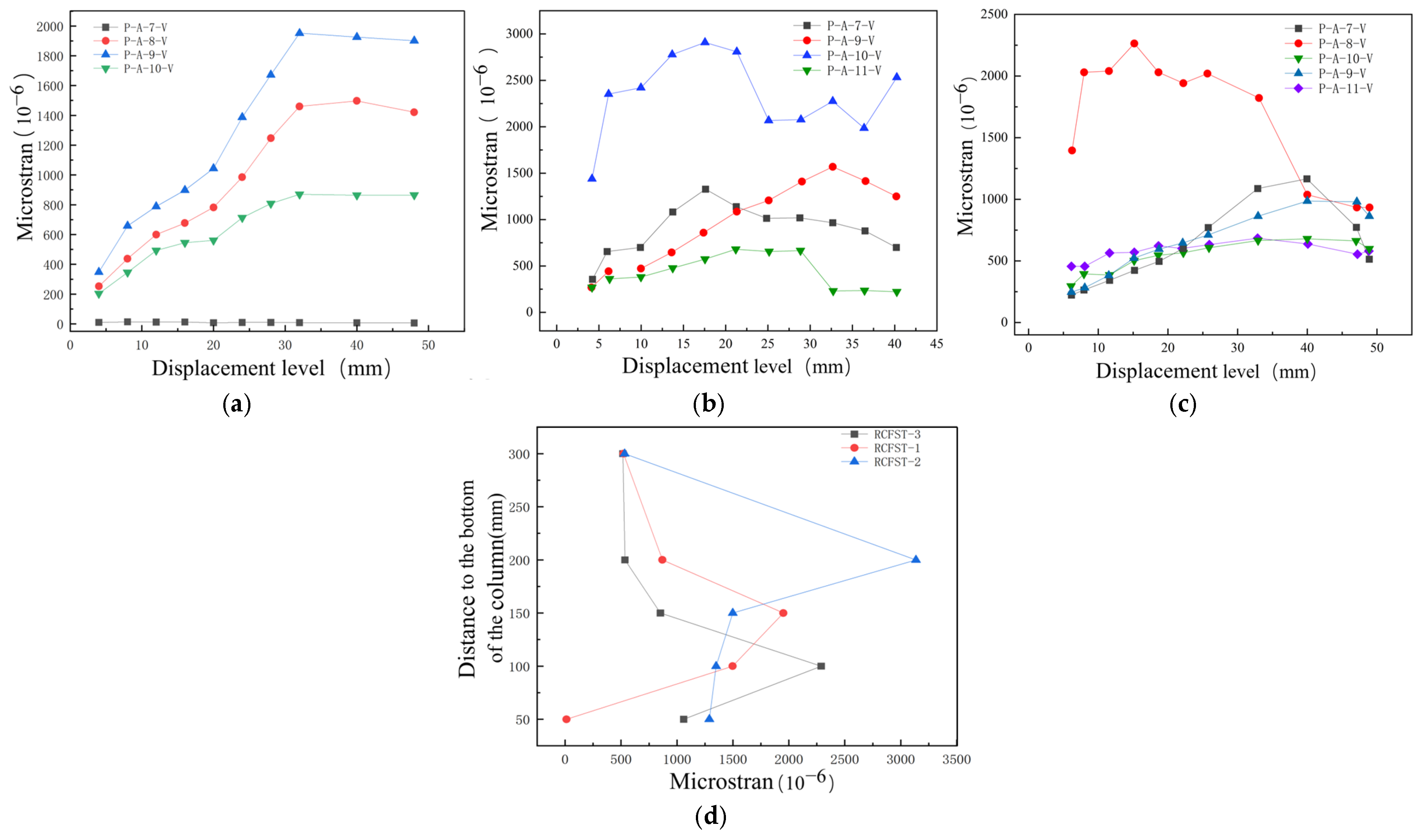

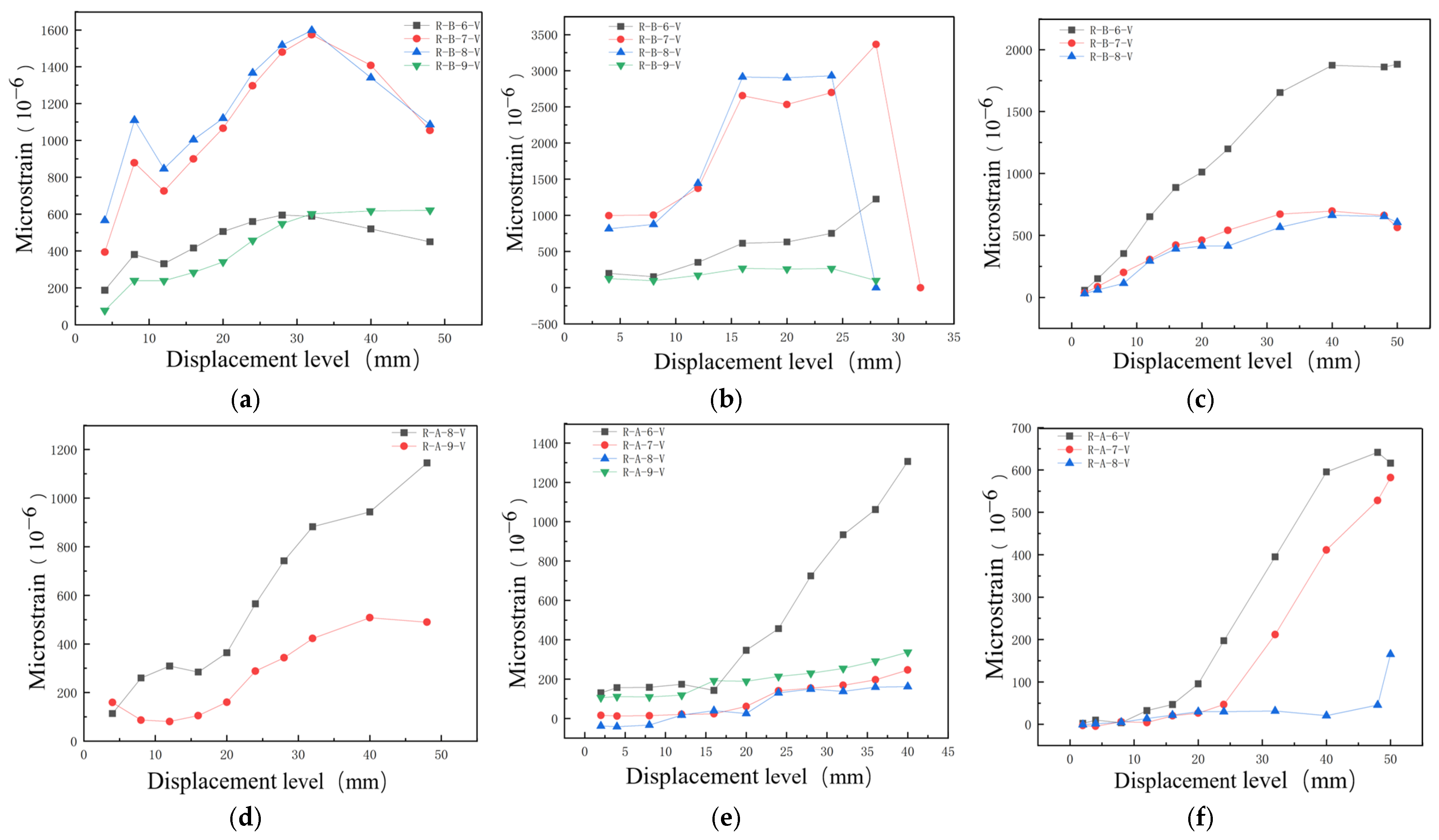

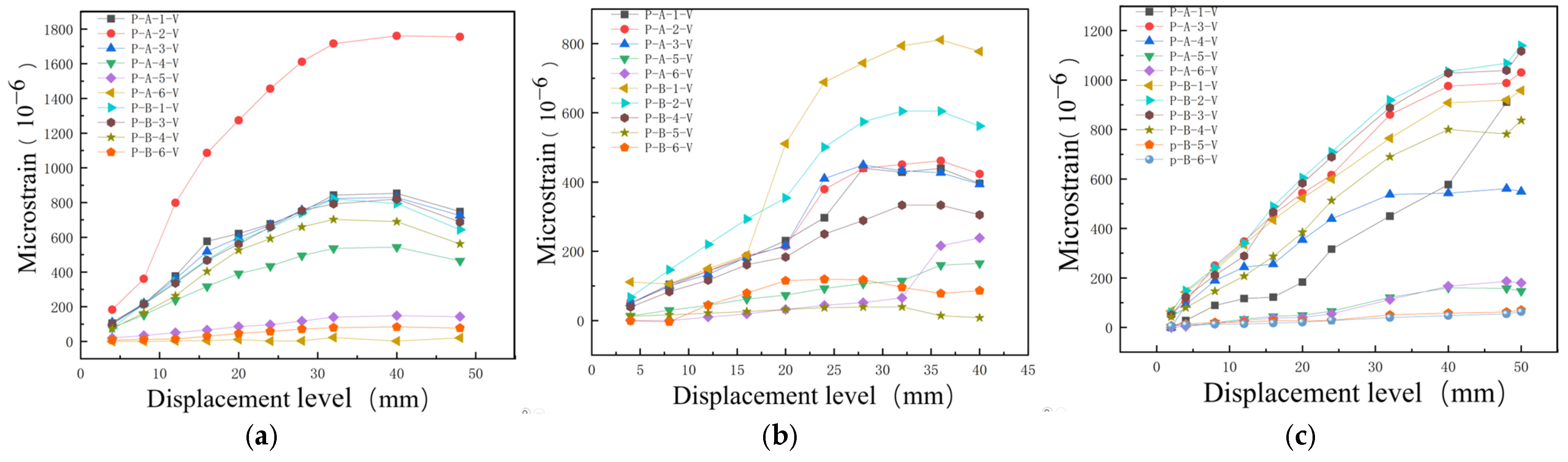

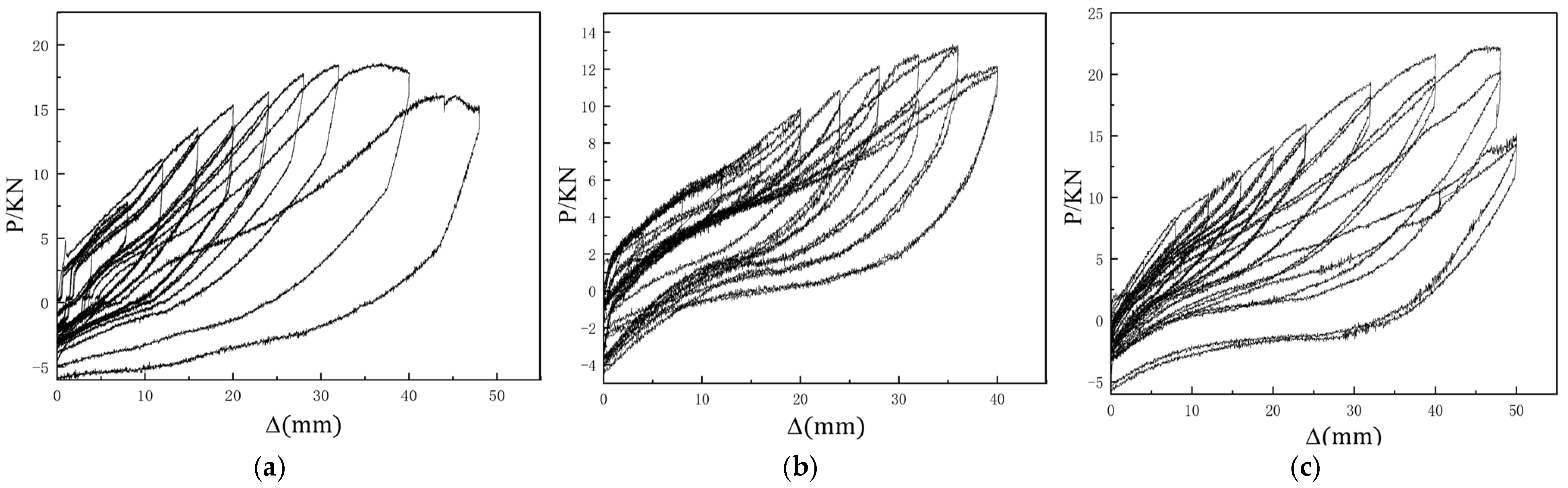

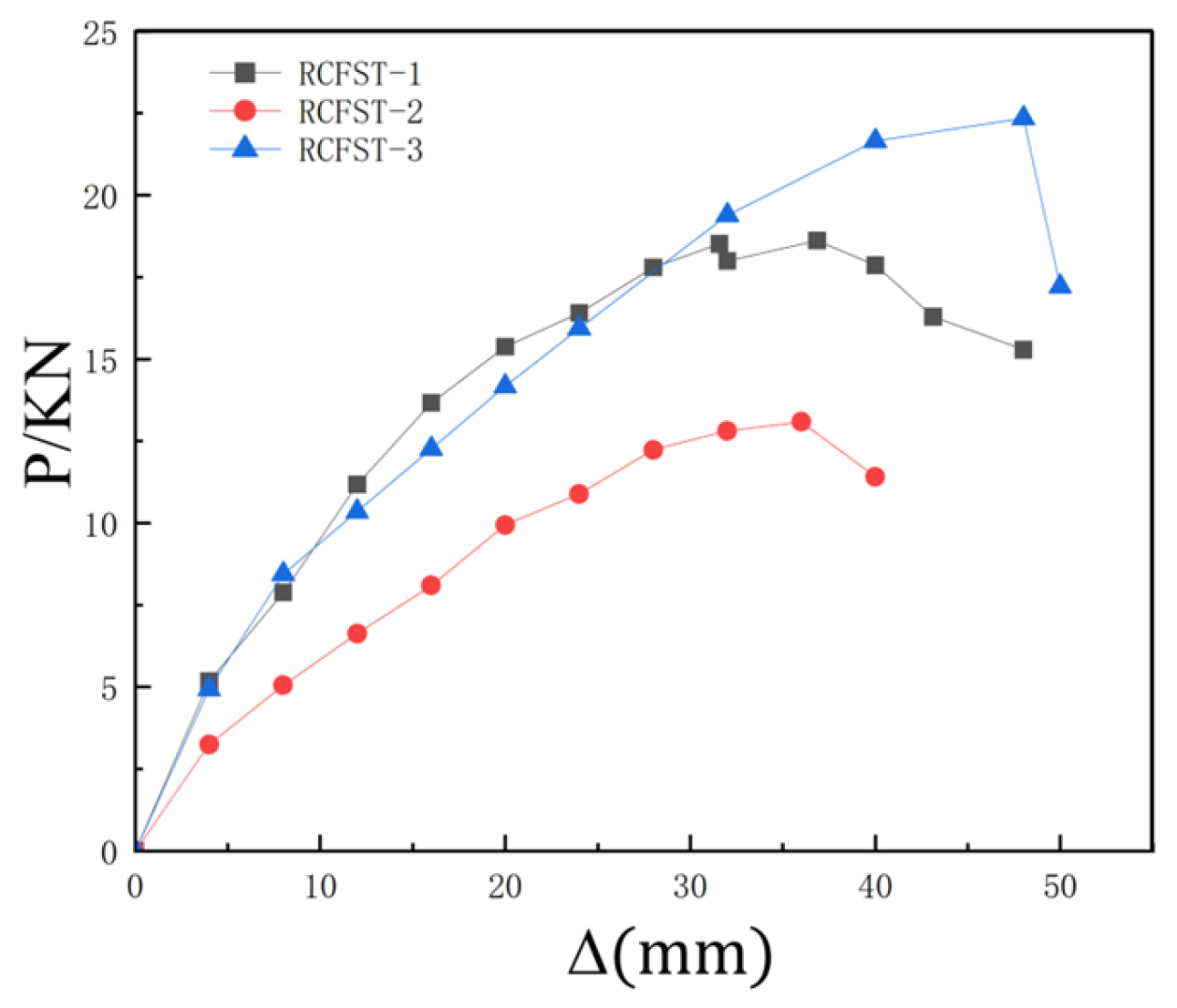

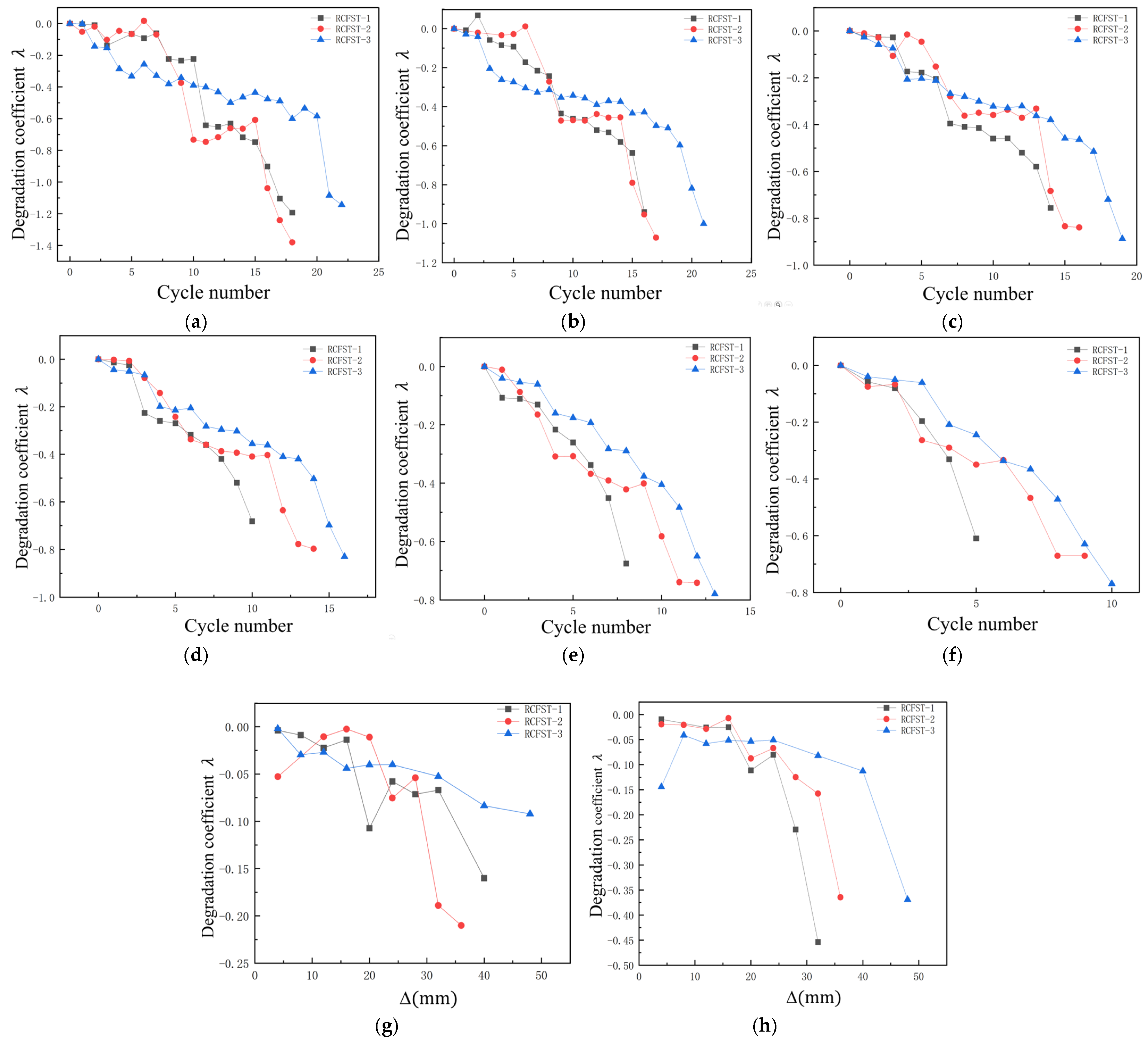

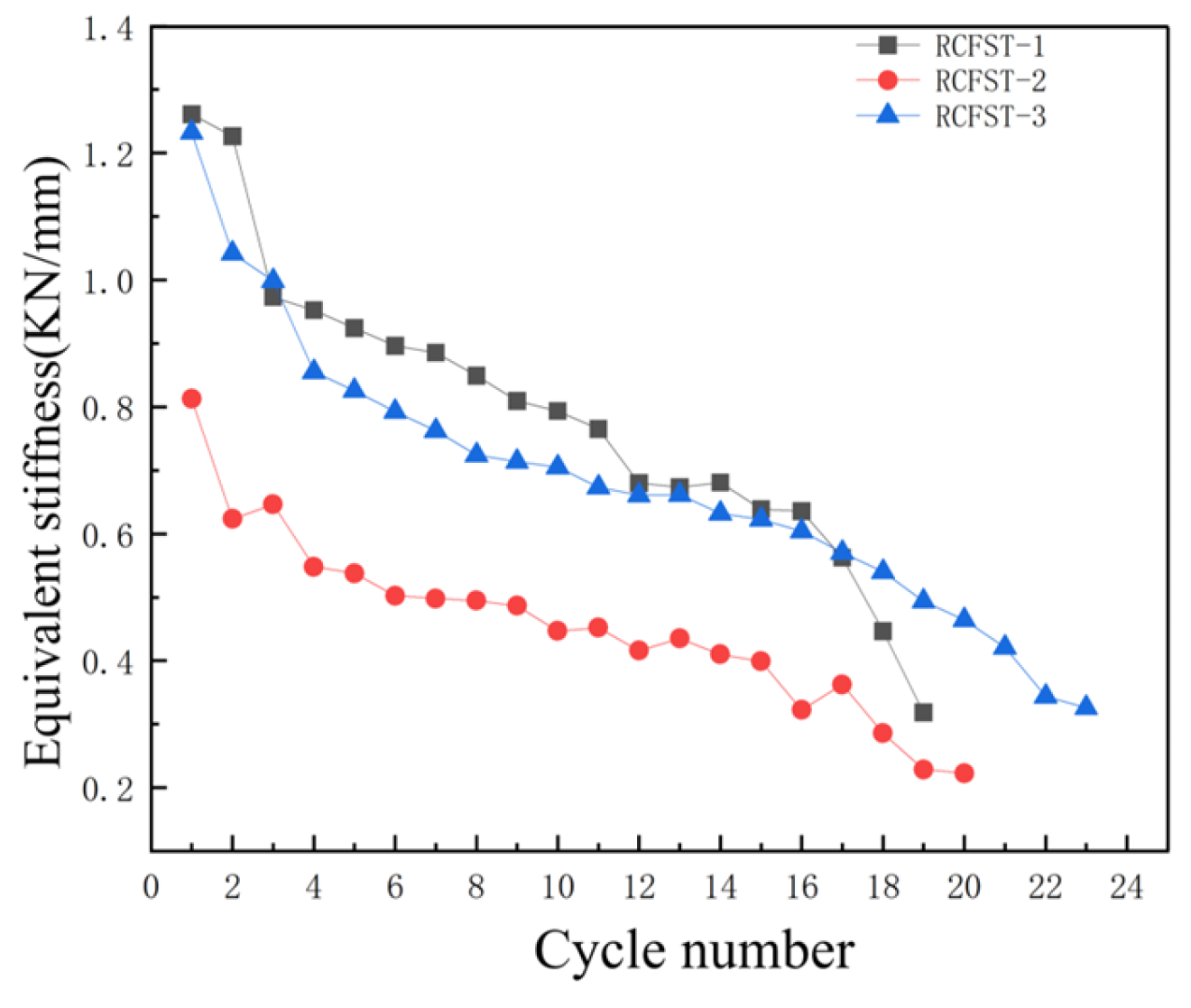

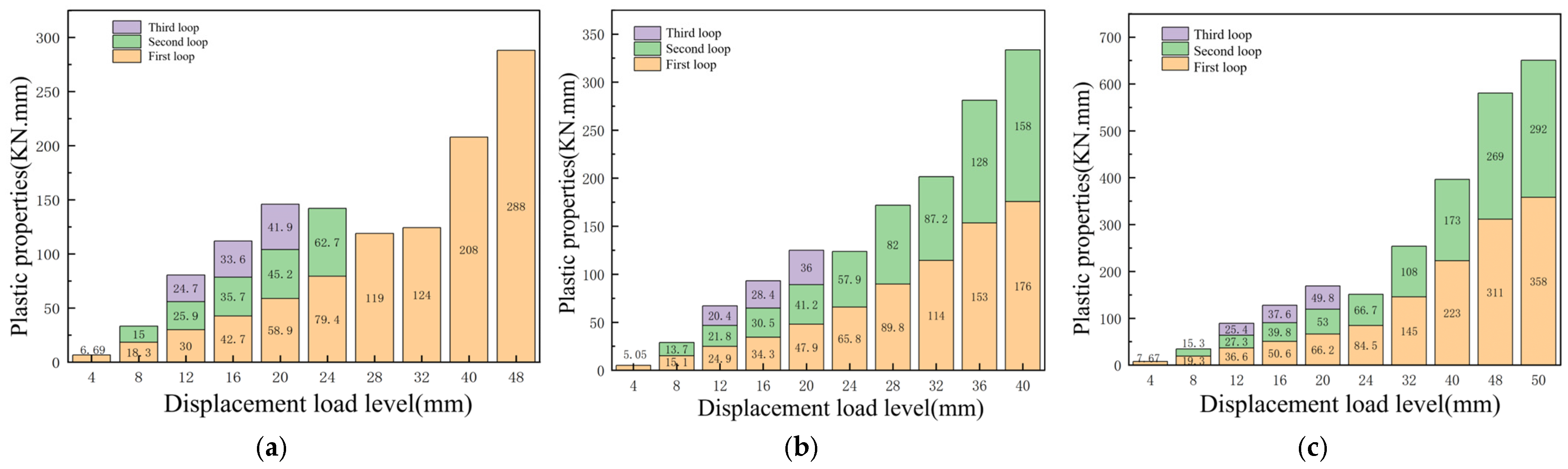

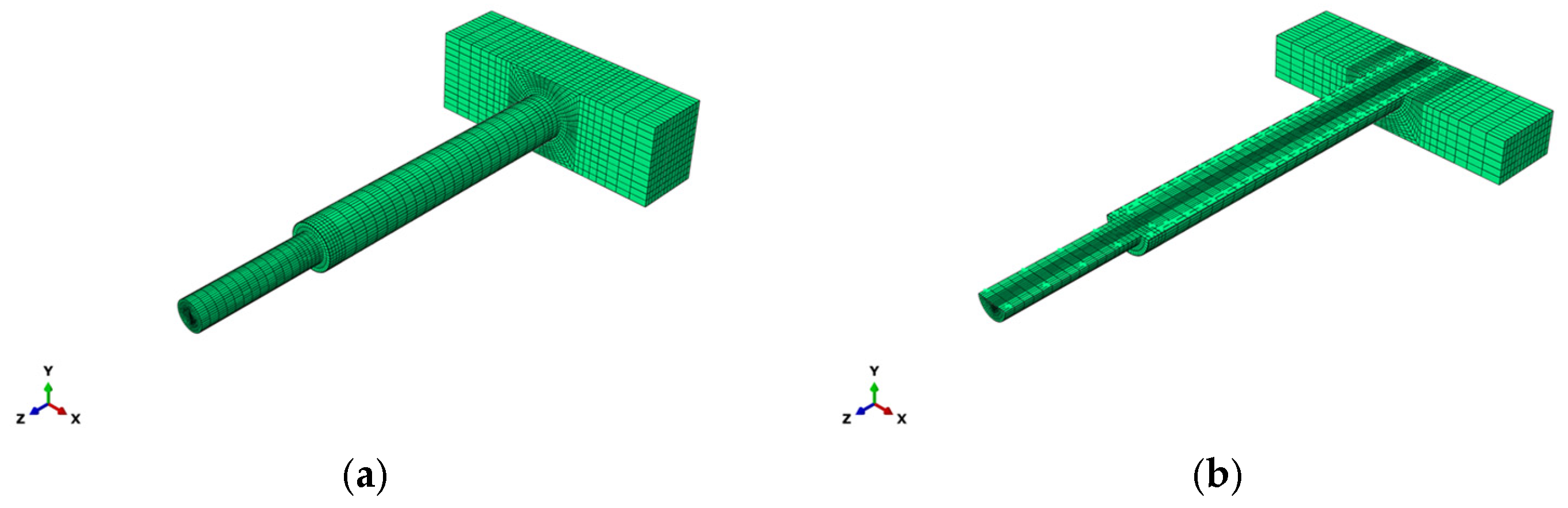

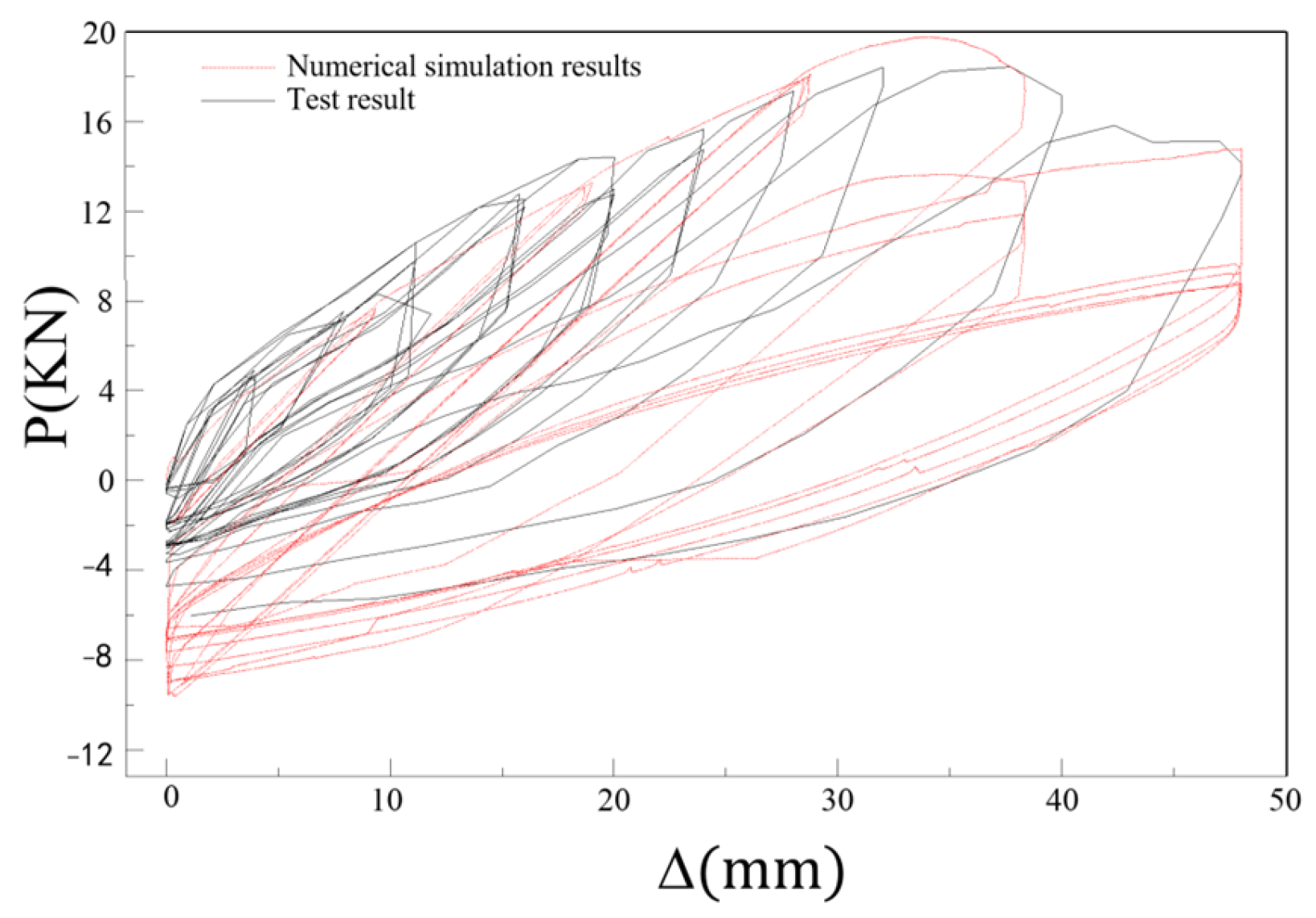

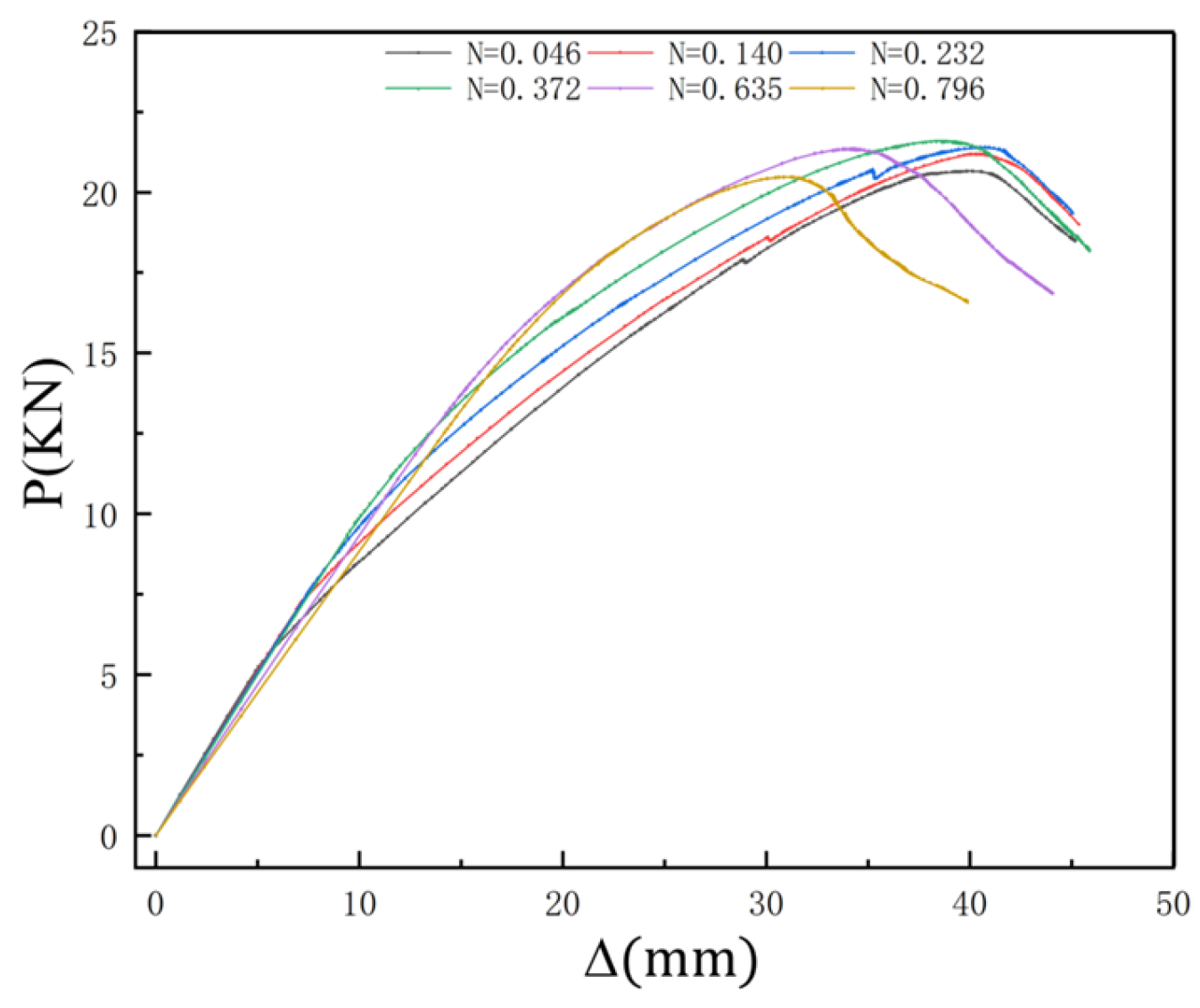

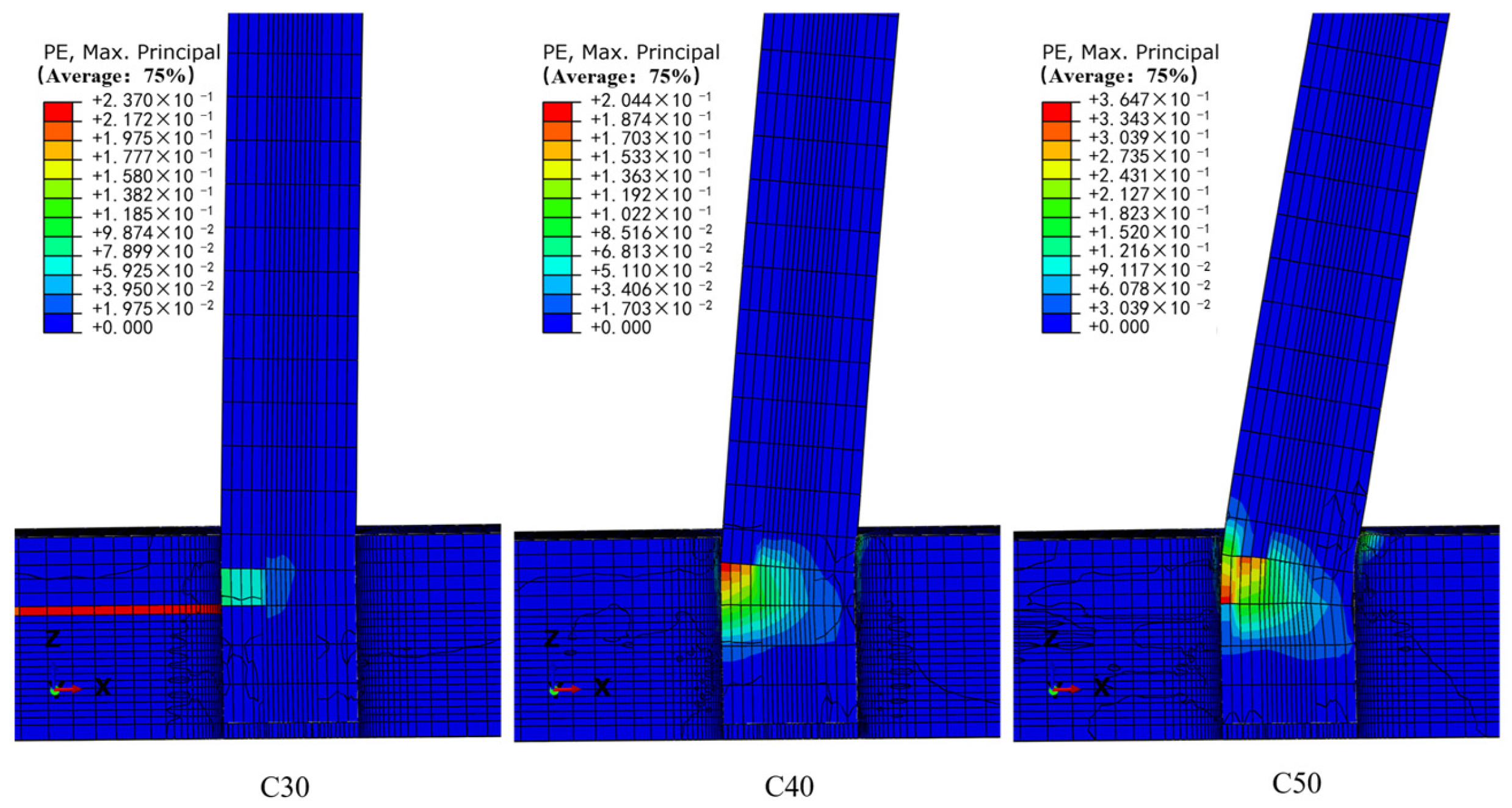

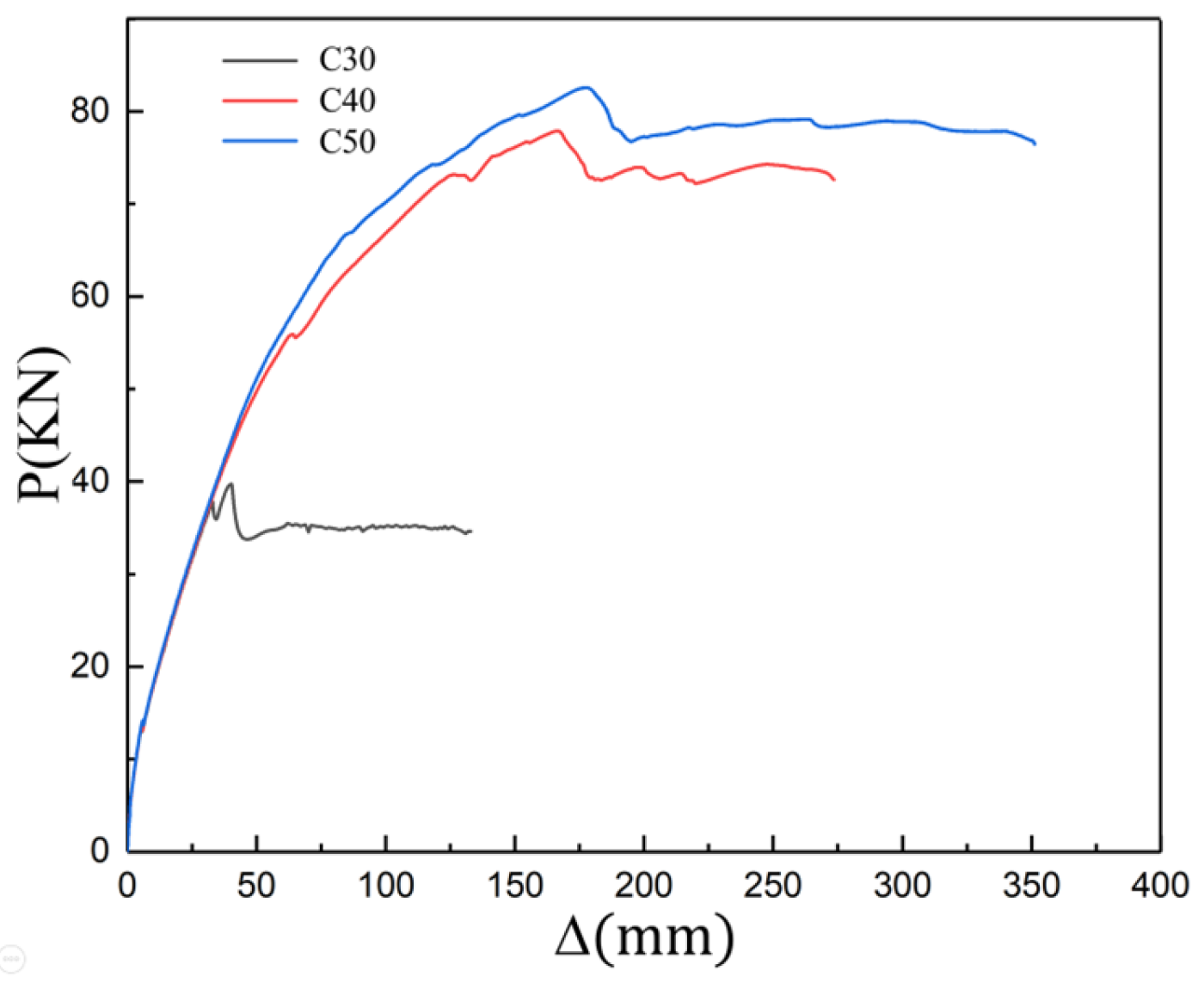

In this paper, three indoor physical model components, RCFST-1, RCFST-2, and RCFST-3, are designed according to similarity criteria based on the prototype structure of the Chongqing Orchard Port Project. And in the sample preparation process, this paper considers the impact of the reliability of physical modeling of sample preparation from the sub [

42]. The force development process and the final damage patterns of the combined structure, which is subjected to horizontal low cyclic loading, are influenced by varying the column diameters of the upper column members of the steel casing-reinforced concrete pile composite members. The differences in damage patterns under various variables and the damage patterns of this member are summarized. To investigate the lateral performance of the members under varying parameters, five groups of numerical models were established, each with different compressive axial force ratios, along with three groups representing different foundation strengths. This setup allows for an examination of the effects of each factor on the bearing capacity, ductility, and energy dissipation performance of the members. This paper further enriches the design theory and composite material theory of overhead vertical wharfs in inland rivers with large water level differences through the quasi-static loading test to study the lateral working properties of large-scale steel casing-reinforced concrete pile composite members, which is an important supplement to the research on large-scale steel casing-reinforced concrete pile composite members, with a view of providing a reference for the design of large-scale steel–concrete structures. Meanwhile, this study is of great significance for promoting the theoretical research on offshore hydraulic buildings and the structural design of harbor wharves in terms of both theoretical and practical applications.