Investigation of Power-Law Fluid Infiltration Grout Characteristics on the Basis of Fractal Theory

Abstract

1. Introduction

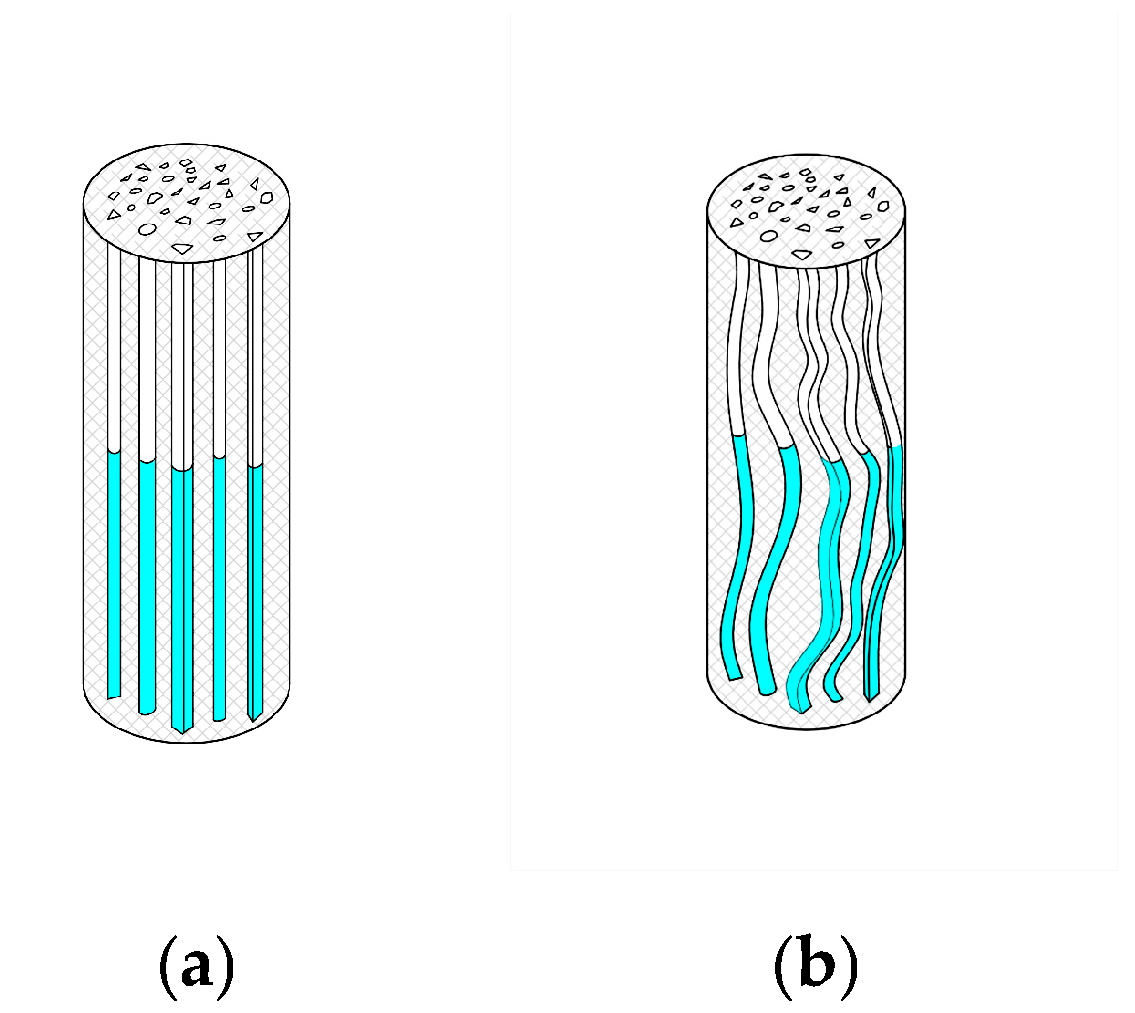

2. Modeling of Power-Law Fluid Diffusion Fractal Infiltration Grouting

2.1. Fractal Modeling of Porous Media

2.2. Fractal Dimension Power-Law Fluid Percolation Equation

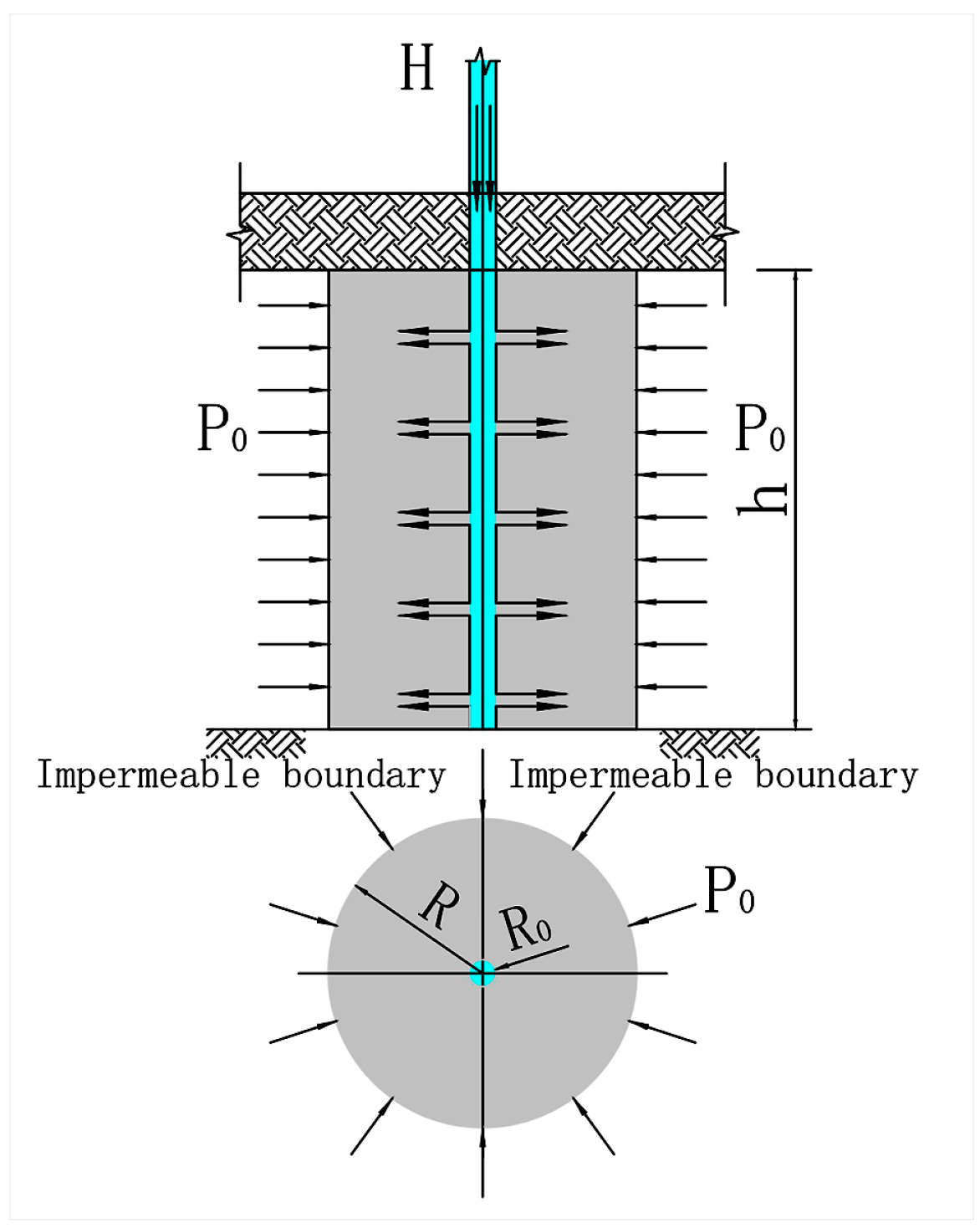

2.3. Power-Law Fluid Spherical Diffusion Fractal Infiltration Grouting Model

2.4. Power-Law Fluid Column Diffusion Fractal Infiltration Grouting Model

2.5. Scope of Application of the Formula and Discussion

2.5.1. Scope of Use of the Formula

- (1)

- The fluid movement within the formation is characterized by laminar flow, with a Reynolds number ;

- (2)

- The impact of the slurry’s self-weight is disregarded during the grouting process;

- (3)

- The injected porous medium consists of isotropic material, and the grouting process employs constant-pressure grouting;

- (4)

- In the context of a porous medium, the fractal dimension must adhere to specific constraints: and .

2.5.2. Solving for the Fractal Dimension

2.5.3. Discussion of the Diffusion Equation

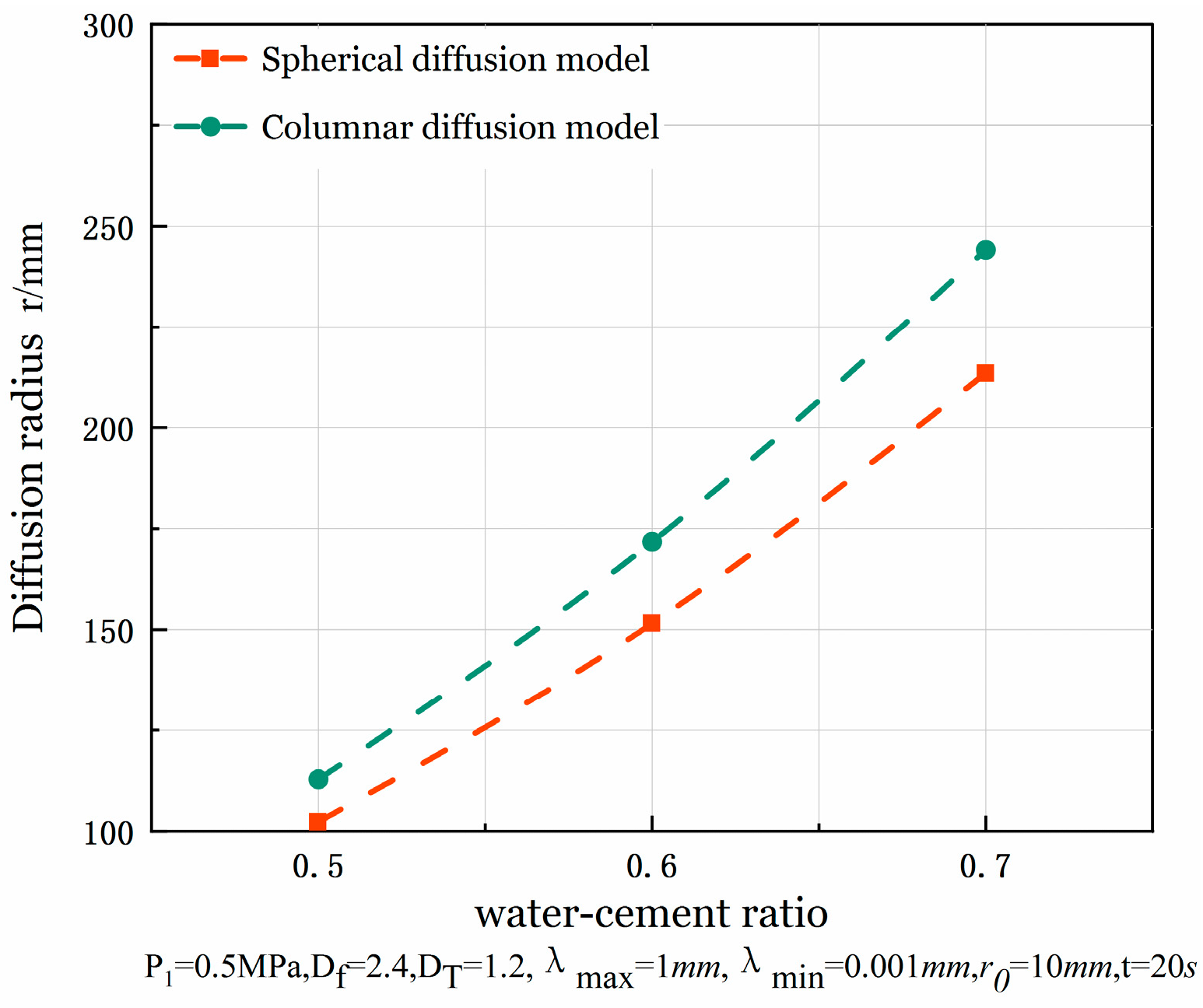

3. Study of the Laws of Diffusion

4. Indoor Grouting Experiment

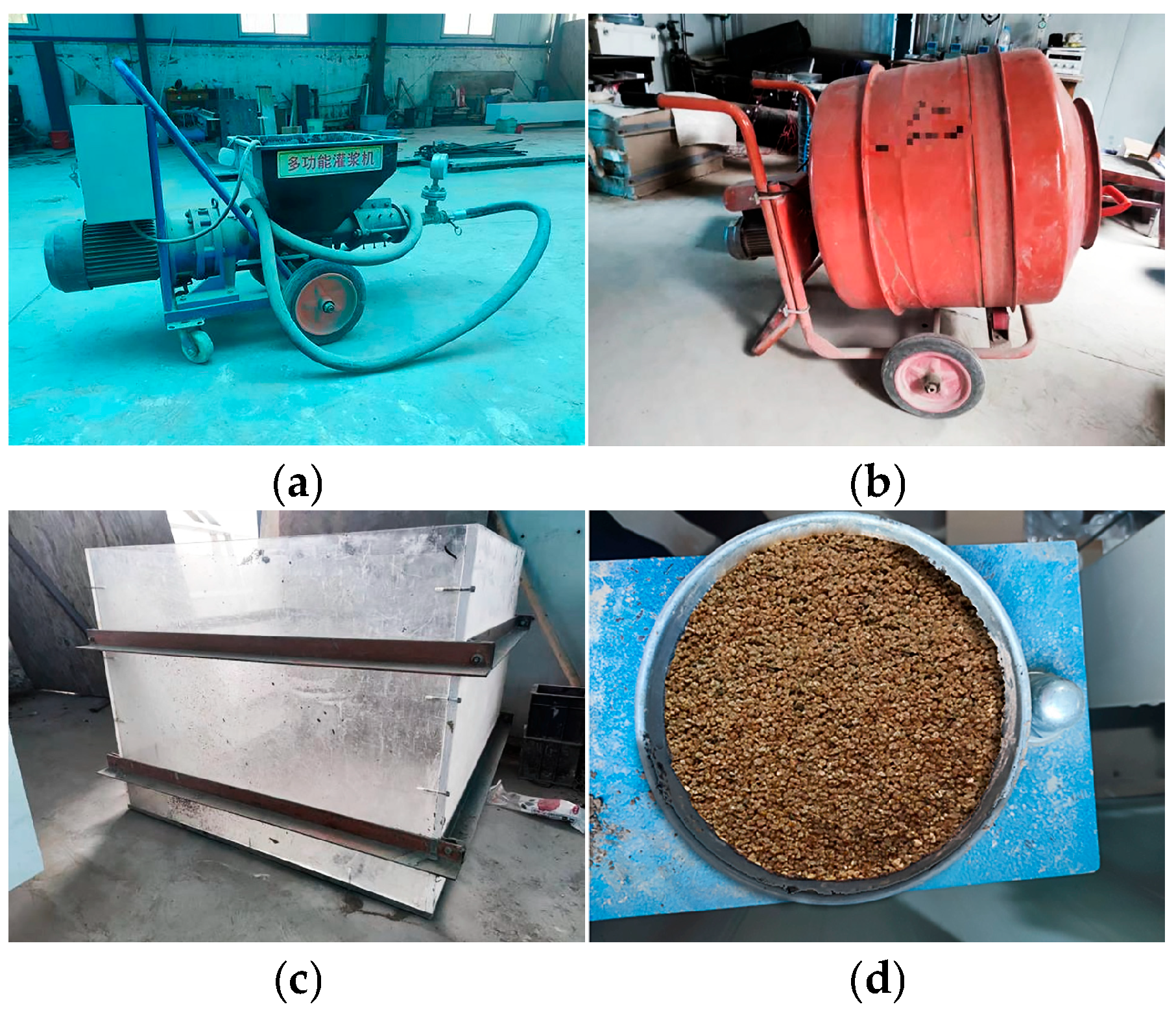

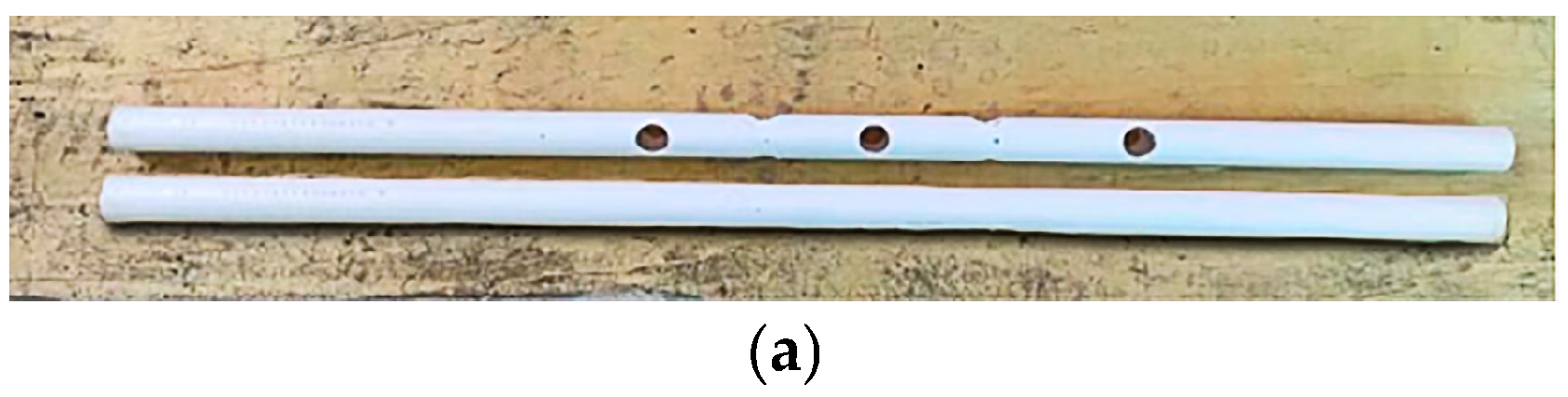

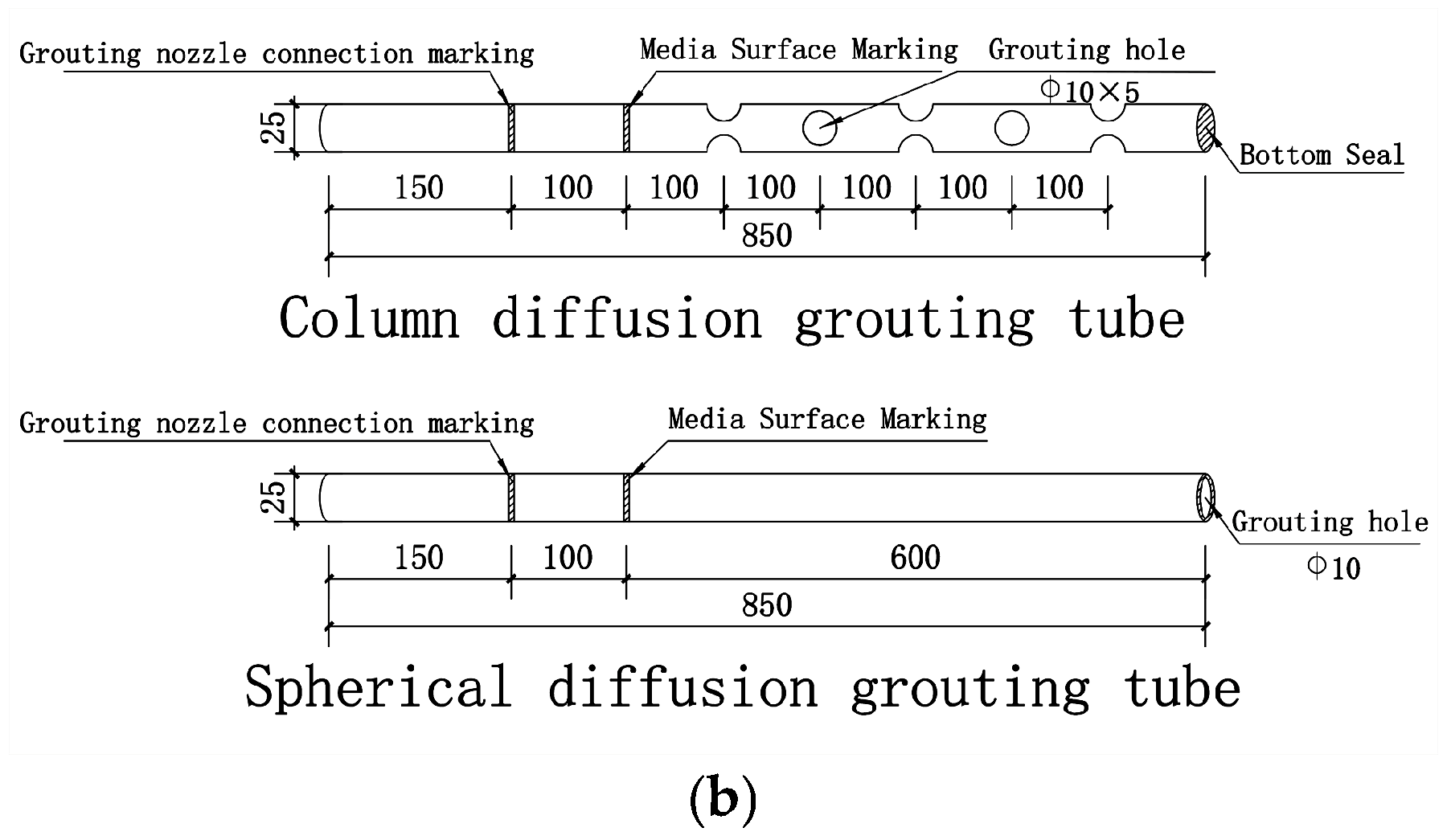

4.1. Experimental Setup and Grouting Materials

4.2. Determination of Fractal Parameters and Design of Grouting

- A high-resolution image of the injected medium is imported into the software and subsequently converted to a black-and-white format.

- The software’s color range feature is utilized to select the sample pores (Figure 9).

- The analysis tool is utilized to record measurements and identify the pixel area with the largest area in all the black ranges. The conversion results in . The minimum pore diameter differs from the maximum pore diameter by three orders of magnitude [48]. can be calculated using .

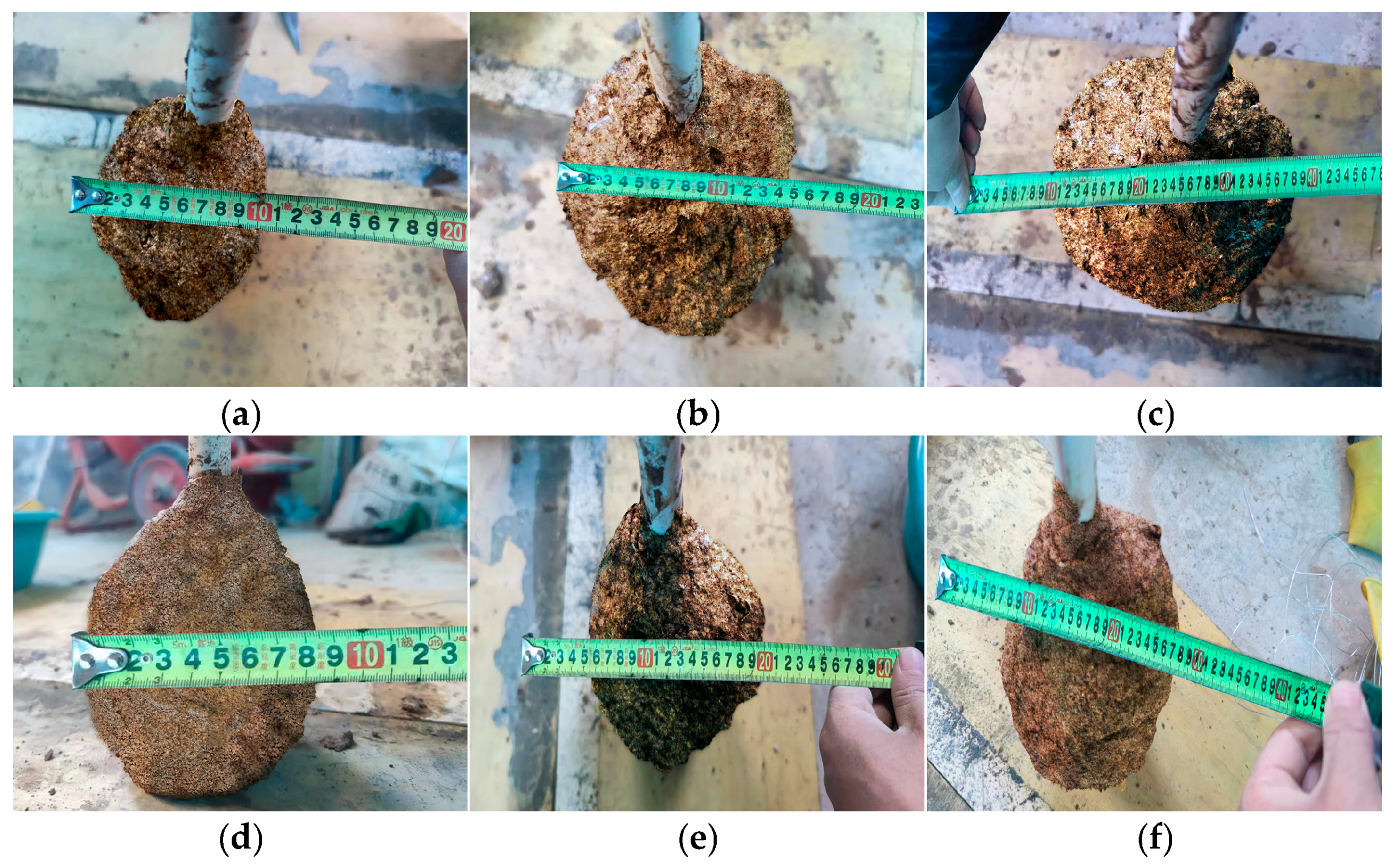

4.3. Experiments and Analysis of Results

- Neglect of the effect of the pressure-loading dynamic process

- 2.

- Geometric constraint and gravity coupling effect

- 3.

- Multi-scale uncertainty sources

5. Numerical Modeling Study

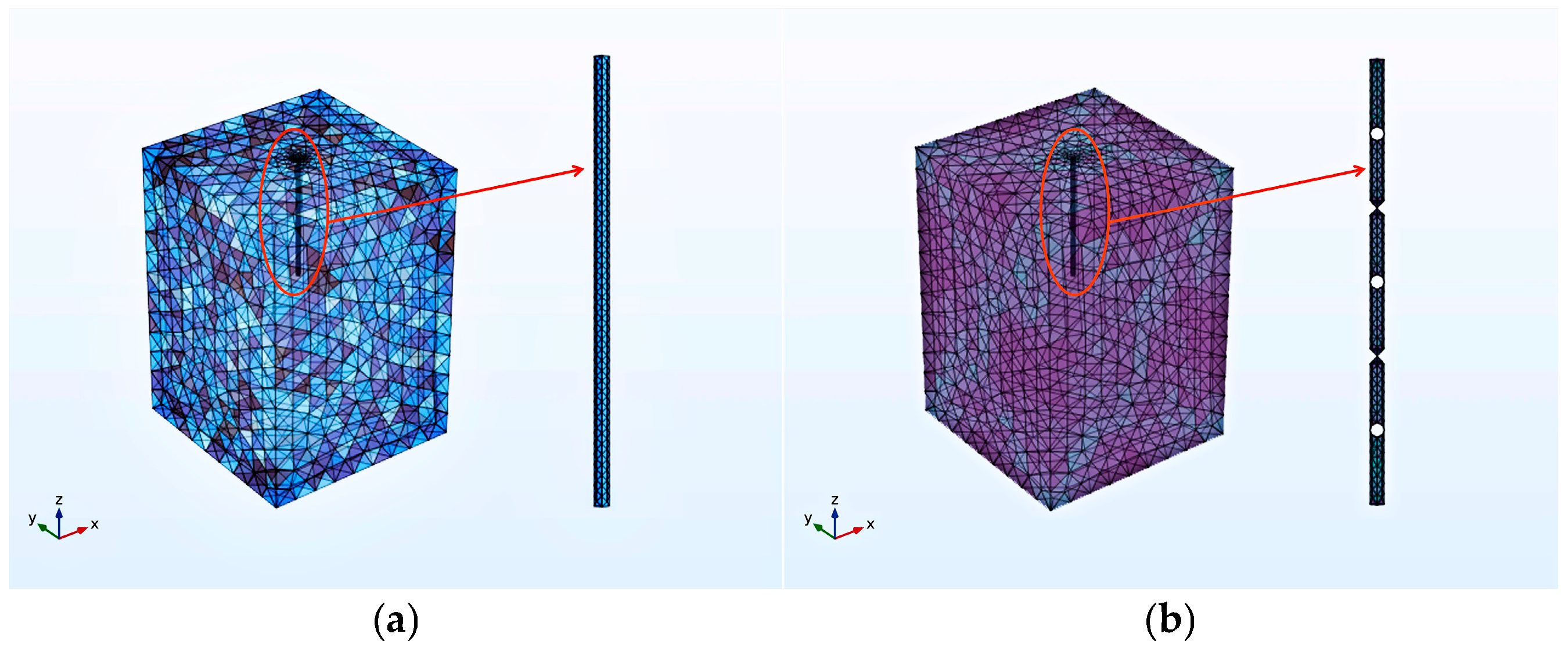

5.1. Creation of Models

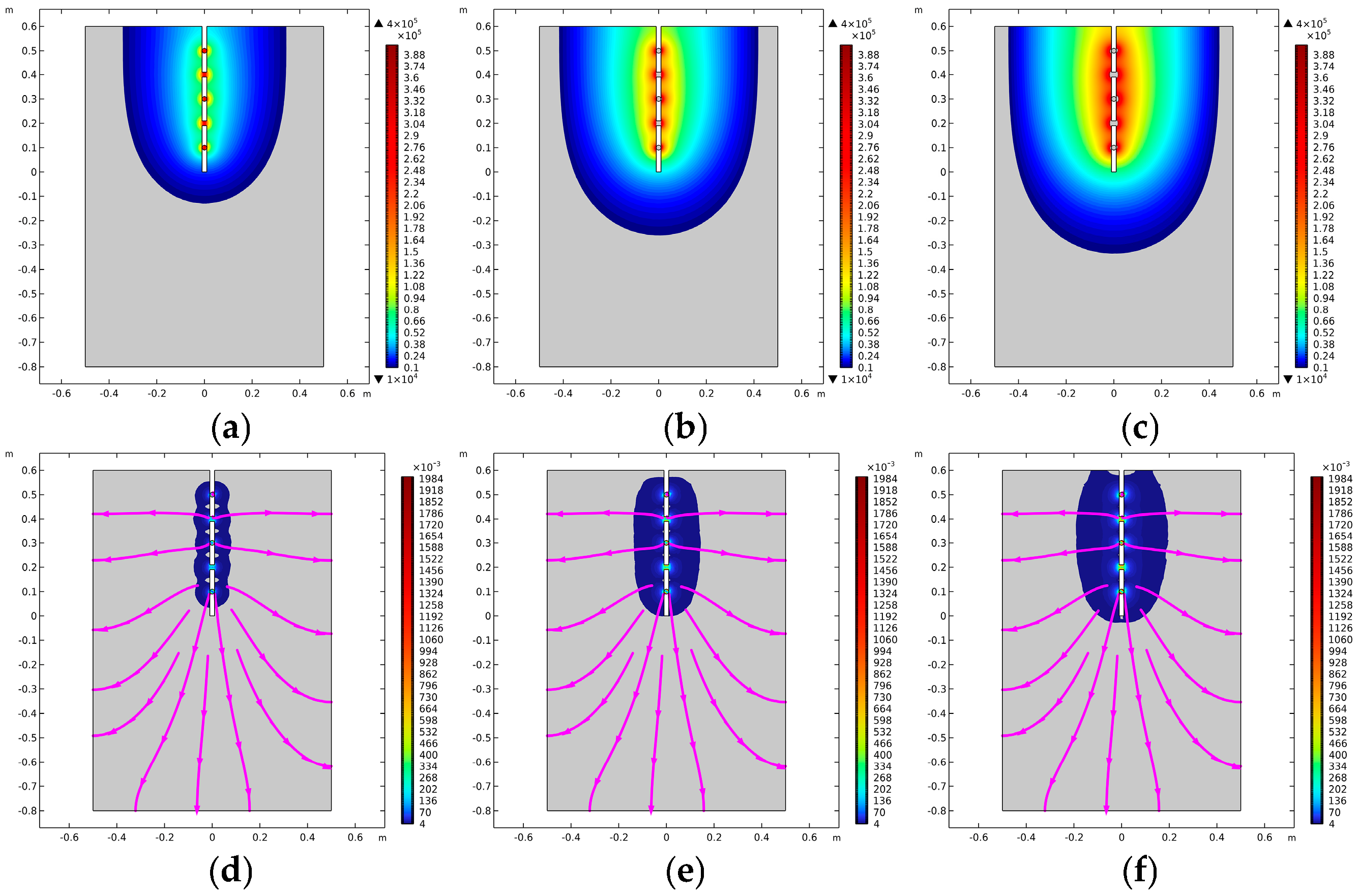

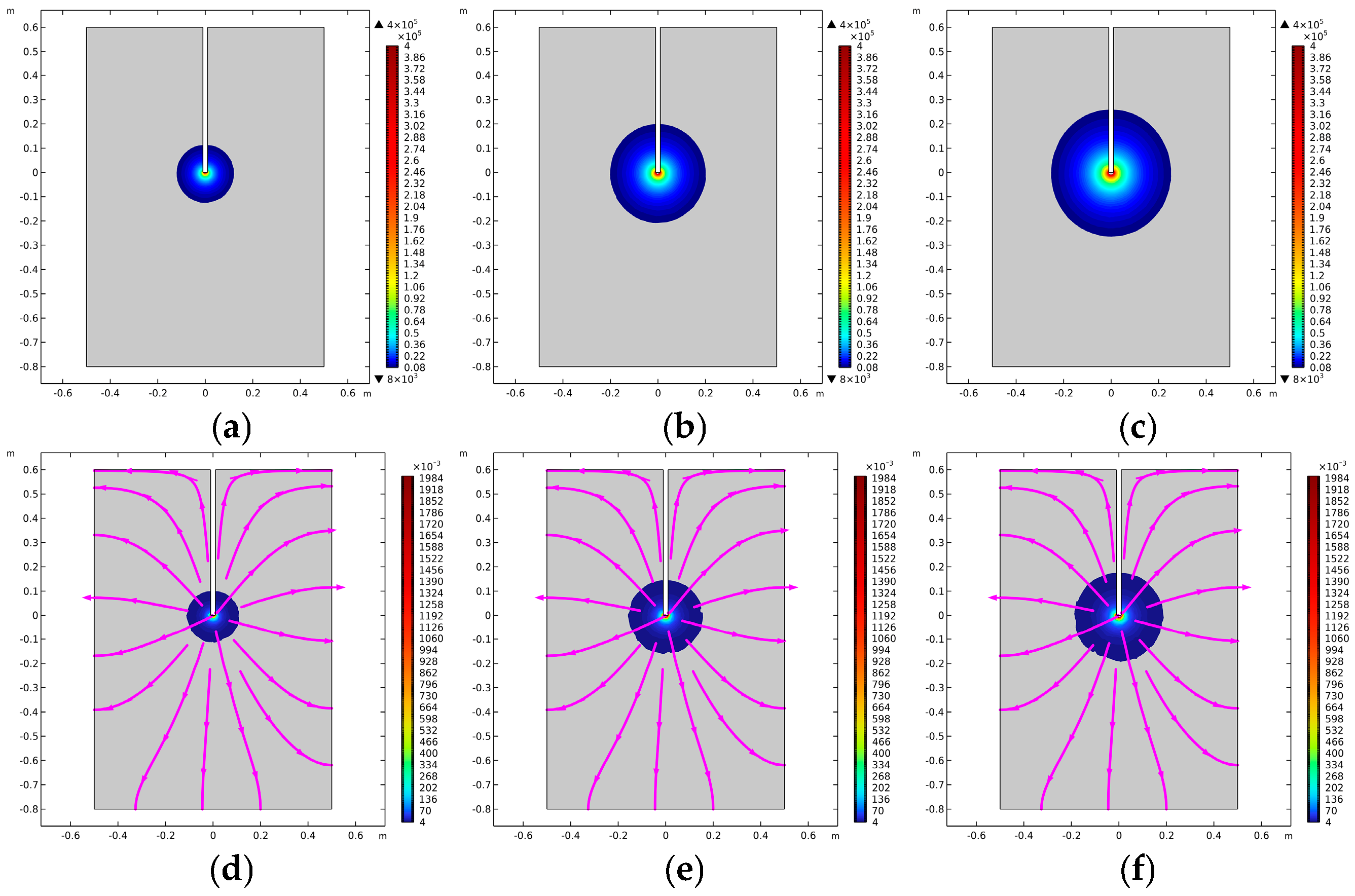

5.2. Simulation Results

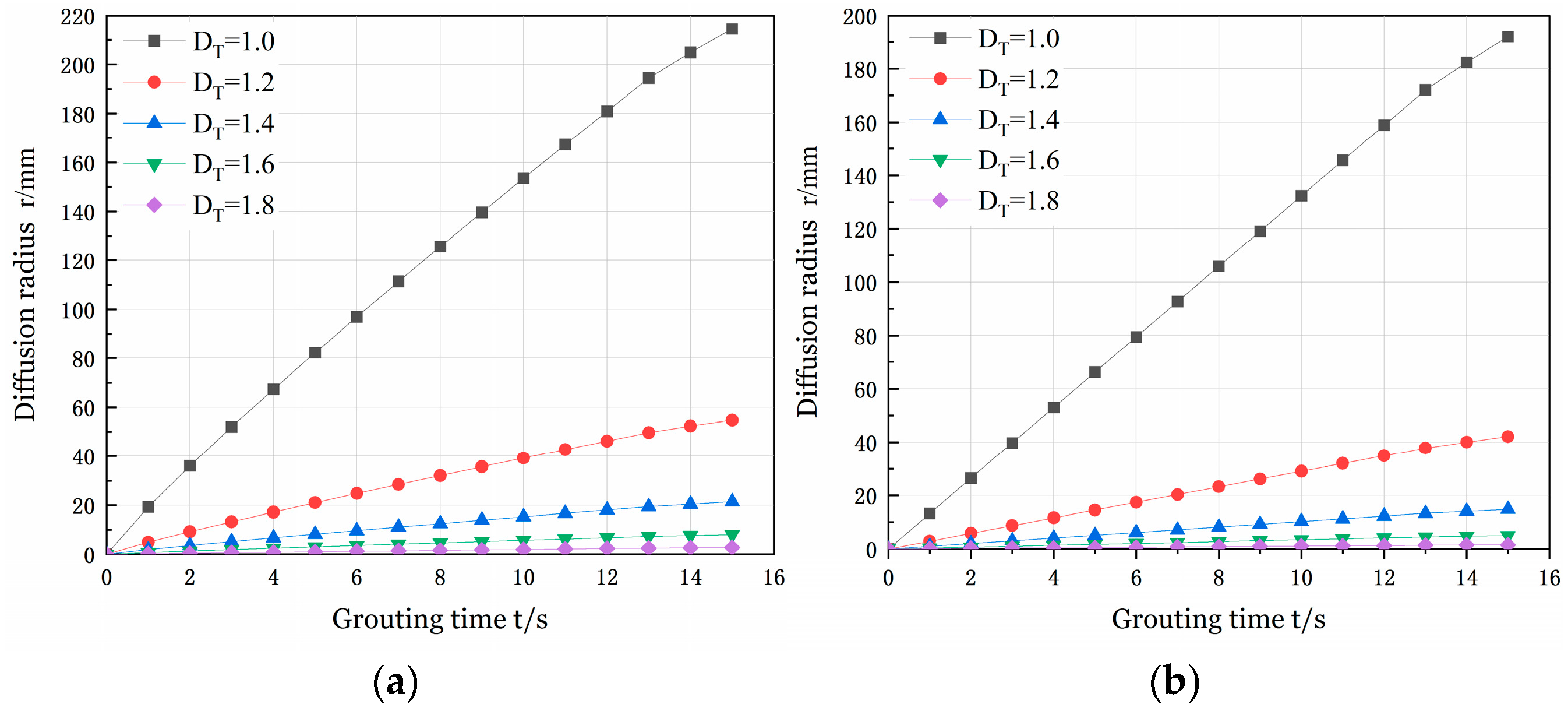

5.3. Numerical Simulation Results

6. Conclusions

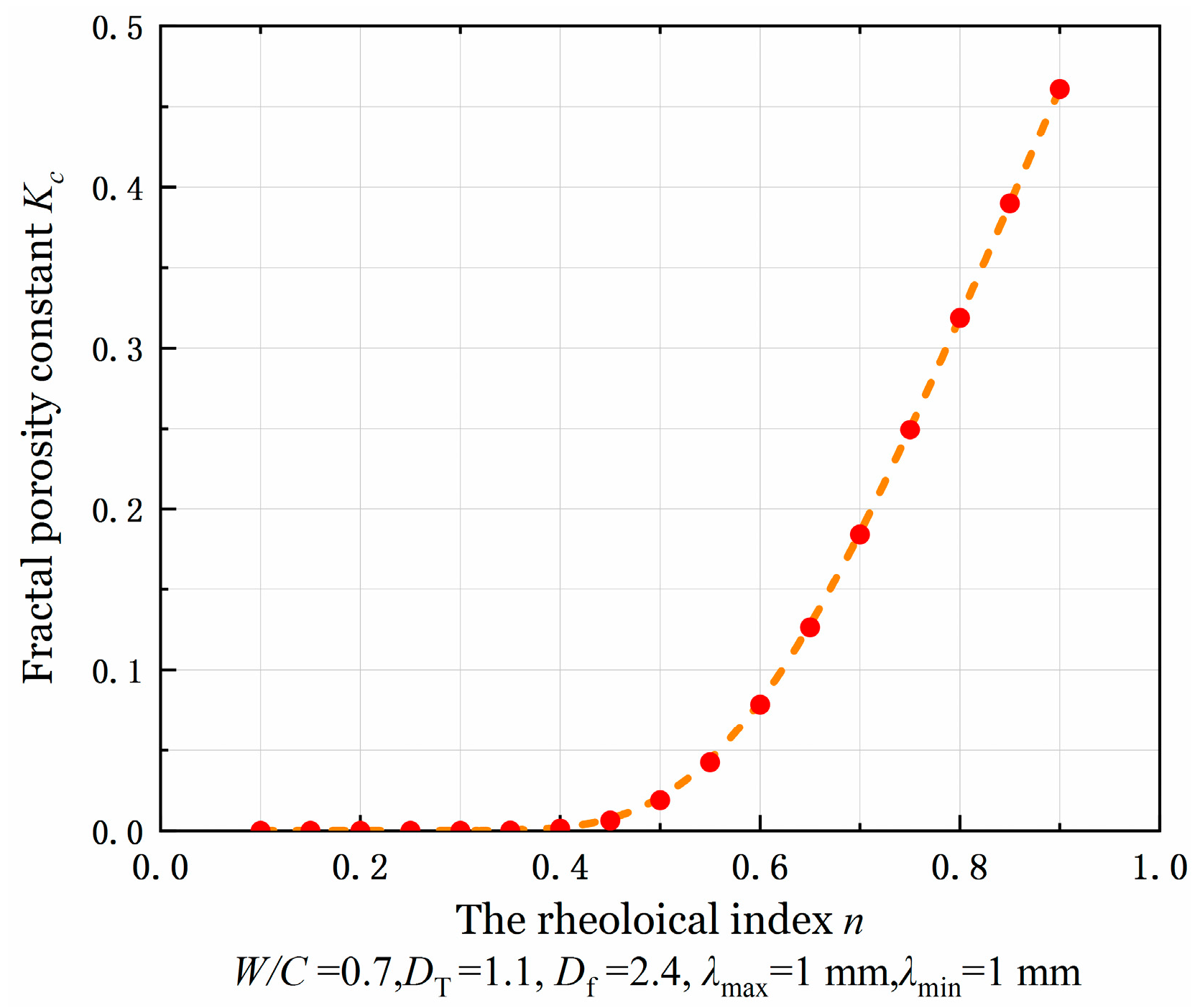

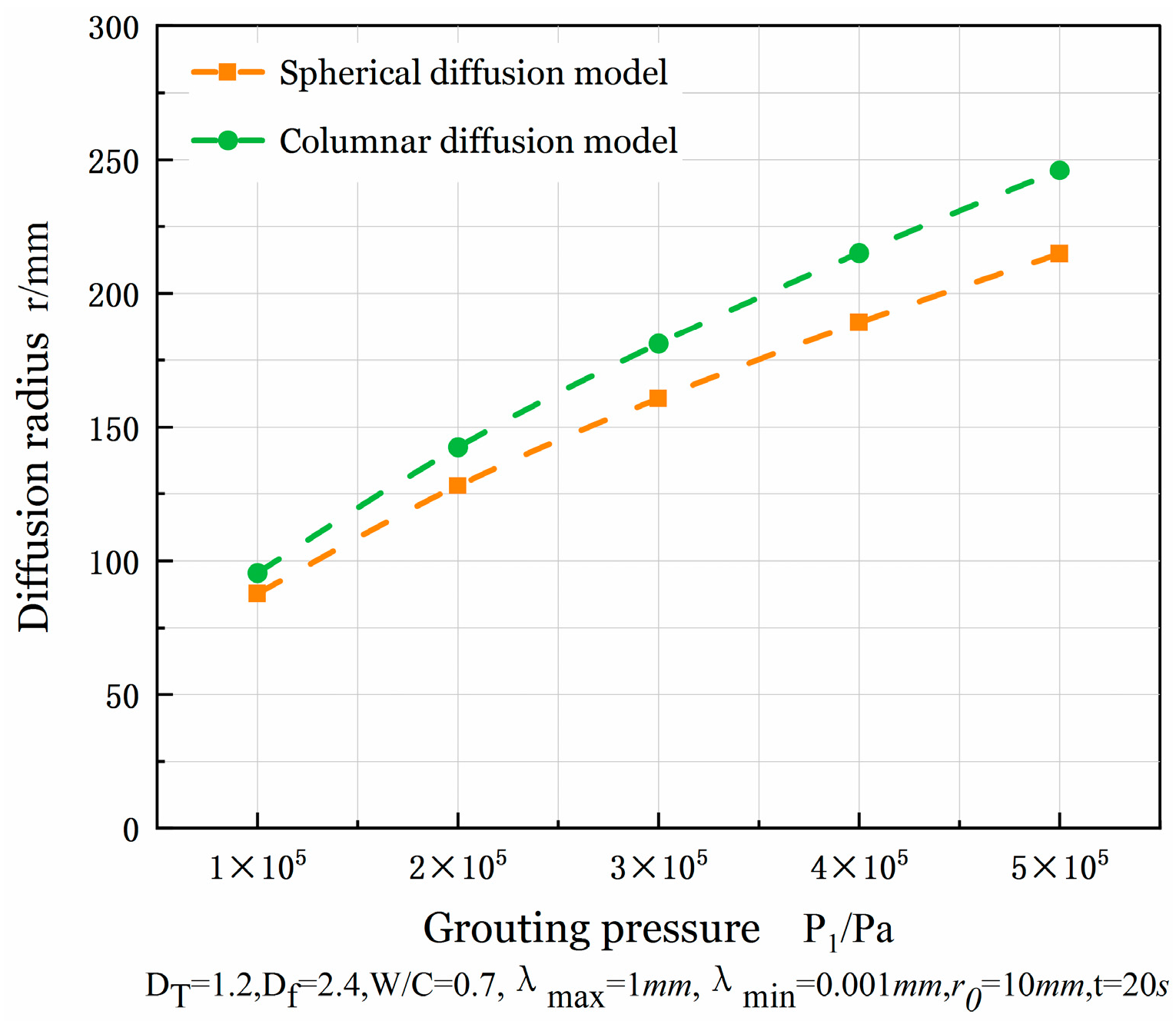

- The fractal permeability constant exhibits an exponential relationship with the rheological index, demonstrating a threshold effect on its sensitivity. When the rheological index, n, is below 0.4, the influence coefficient of the power index on the fractal permeability is minimal and the fractal permeability constant approaches 0. However, when n exceeds 0.4, the sensitivity increases significantly, with the fractal permeability constant reaching 0.48 at n = 0.9. In the diffusion model study, the pulp diffusion radius shows a non-linear proportional relationship to the slurry pressure and the water–cement ratio. At pressures below 0.1 MPa, the diffusion distance ratio between the spherical and columnar geometries is 1:0.96, indicating limited geometric constraint effects in low-energy grouting. At P = 0.5 MPa, the isotropic advantage of spherical diffusion becomes apparent, with the diffusion distance ratio expanding to 1:0.82. As the water–cement ratio increases from 0.5 to 0.7, the sensitivity of spherical grouting under high water–cement ratios significantly increases, enhancing the penetration efficiency advantage of spherical grouting. Mechanistically, the increase in the water–cement ratio leads to a synergistic decrease in slurry viscosity and yield stress, weakening the shear resistance at the slurry–soil interface and promoting seepage diffusion. This finding aligns closely with the use of high-water–cement ratio slurries for long-distance fissure sealing in engineering practice.

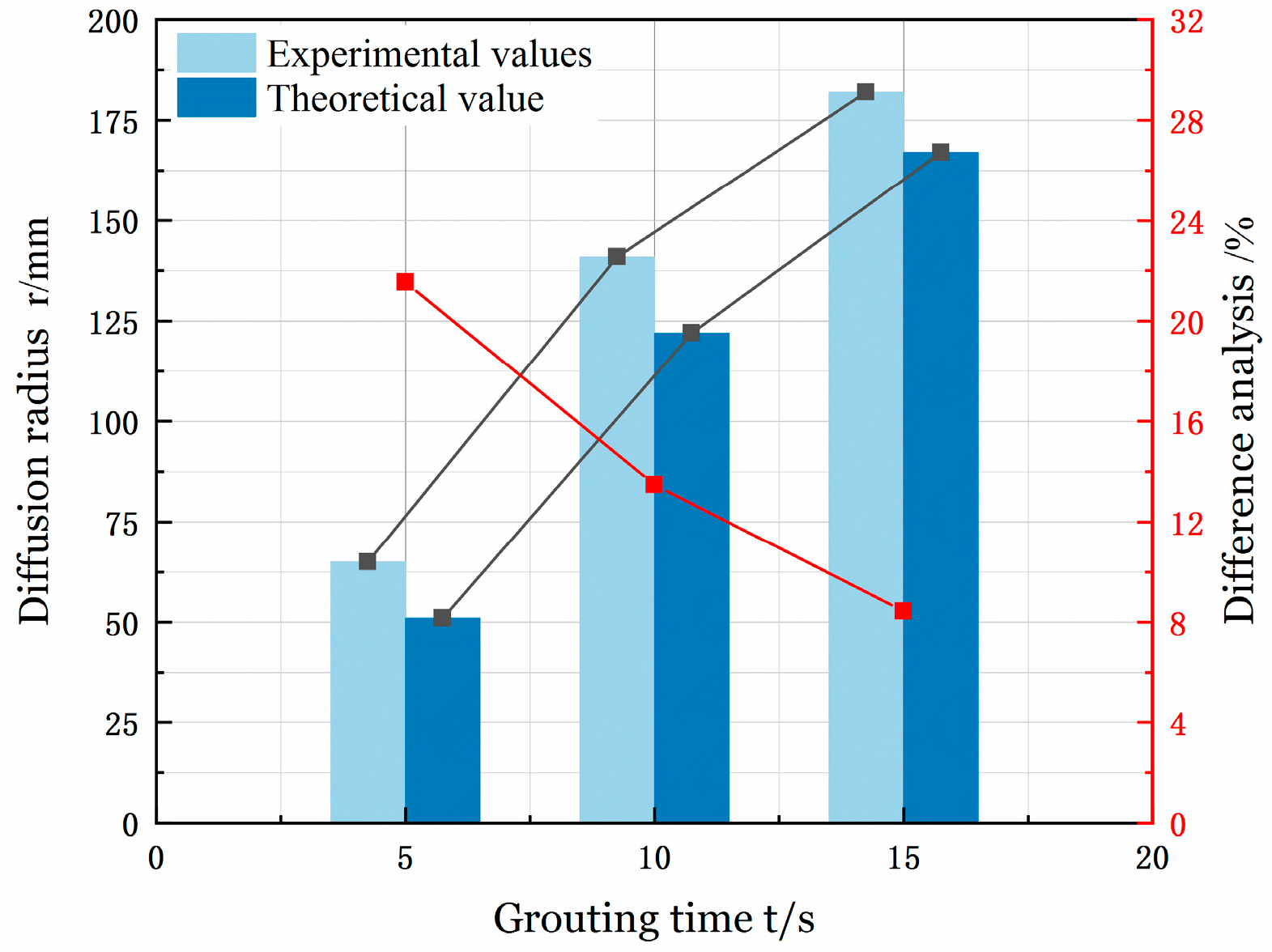

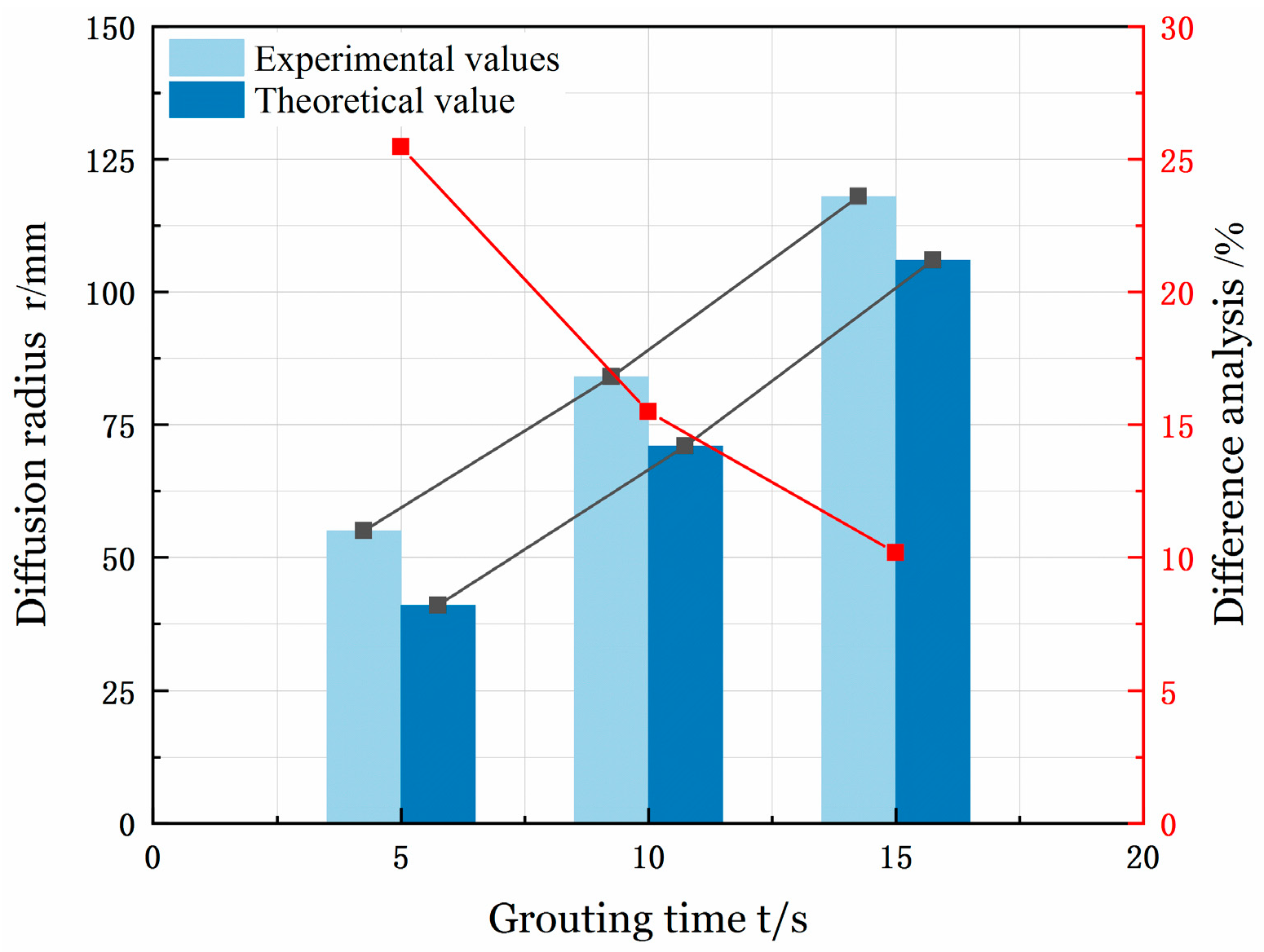

- In experimental and theoretical studies, the theoretical–experimental error of spherical grouting converged from the initial 21.54% (t = 5 s) to 8.43% (t = 15 s) by exponential decay, while the error of column grouting decreased non-linearly from 25.45% to 10.17%. Despite the above deviations, the errors were located within the engineering tolerance error band (−50%~100%), which proves the engineering applicability of the model. The errors were analyzed mainly from three aspects, neglecting the effect of the pressure-loading dynamic process, geometric constraint and gravity coupling effects, and multi-scale uncertainty sources.

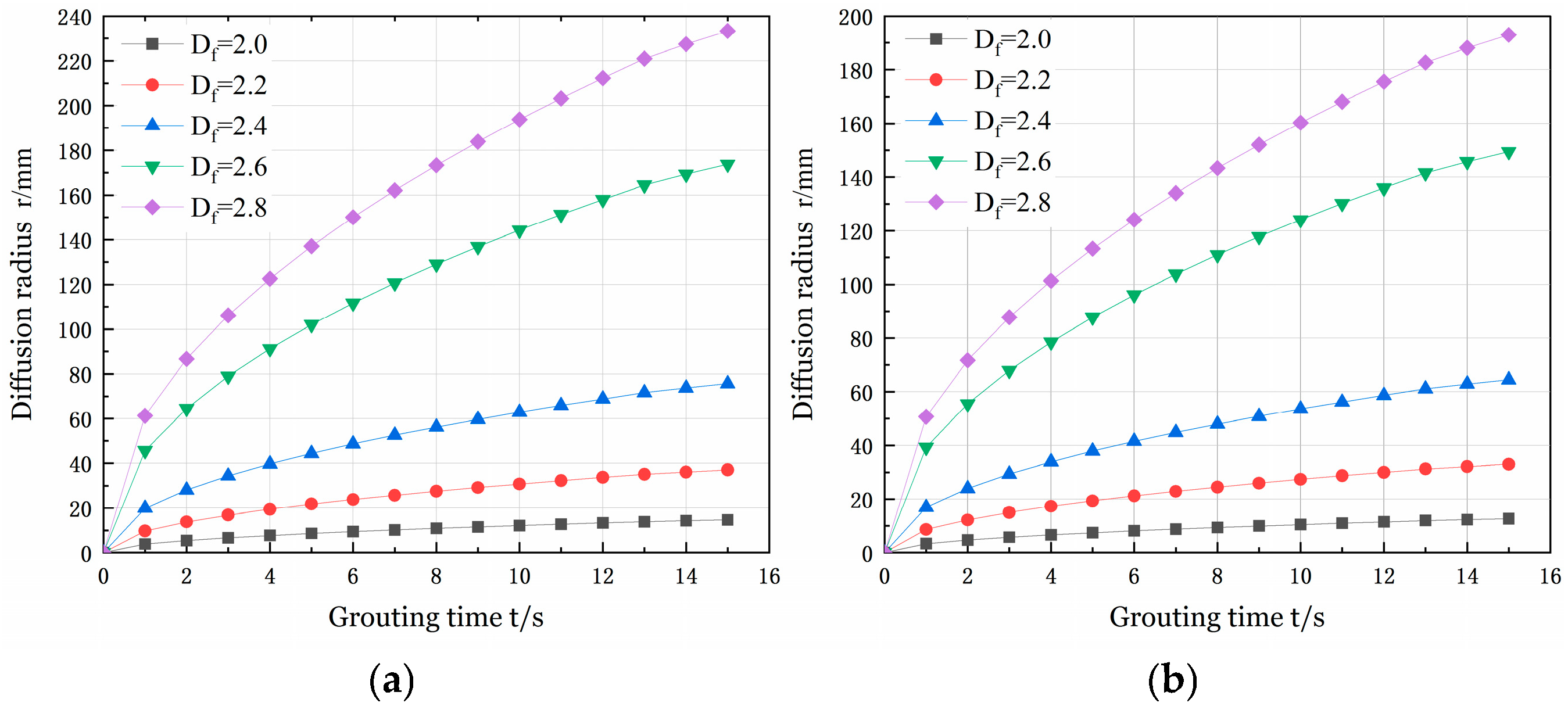

- Numerical simulation studies reveal that as grouting time increases, the pressure and slurry flow rate of power-law fluid columnar and spherical grouting continuously spread outward. The maximum grouting pressure reaches 0.4 MPa, while the maximum flow rate for both types is 2 m/s. Comparing the meander fractal dimension with the volume fractal dimension, it was observed that when the meander fractal dimension was 1.0, the columnar diffusion distance was 168 mm and the spherical diffusion distance was 216 mm. When the volume fractal dimension was 2.8, the columnar diffusion distance extended to 192 mm and the spherical diffusion distance reached 229 mm. The difference between these two scenarios (48 mm for the meander fractal dimension and 37 mm for the volume fractal dimension) indicates that the meander fractal dimension parameters are more sensitive. Furthermore, comparing spherical and columnar diffusion under the same fractal dimension demonstrates that spherical diffusion consistently exhibits a larger range than columnar diffusion.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Glossary

| Symbols | Definitions |

| Equivalent diameter | |

| Total cumulative number of pore areas | |

| Maximum pore diameter | |

| Volume fractal dimension | |

| Degree of tortuosity | |

| Effective length of pores | |

| Tortuous fractal dimension | |

| Pore length | |

| τ | Shear stress |

| Coefficient of consistency | |

| Rheological index | |

| Apparent viscosity | |

| Fluid flow | |

| Effective pore length | |

| Reference area | |

| Fractal permeability constant | |

| Effective volume of grouting | |

| Total volume of the sphere model | |

| Porosity | |

| Spherical modeling fluid flow | |

| Column modeled fluid flow | |

| Average flow rate of fluid in a pore | |

| Average fluid flow rate | |

| Ball model grouting area | |

| Area of column model grouting | |

| Grouting pipe radius | |

| Slurry diffusion radius | |

| Grouting pressure | |

| Water head pressure at grouting point | |

| d | Spatial geometric dimension |

| τav | Average tortuosity |

| λav | Average capillary diameter |

References

- Yang, Z.Q.; Hou, K.P.; Guo, T.T. Research on Time-Varying Behavior of Cement Grouts of Different Water-Cement Ratios. Appl. Mech. Mater. 2011, 71–78, 4398–4401. [Google Scholar] [CrossRef]

- AL-Shahrabalee, S.Q. Brief History and Fundamentals about the Grouting. J. Water Resour. Geosci. 2023, 2, 207–234. [Google Scholar]

- Niu, F.; Liu, Y.; Xue, F.; Sun, H.; Liu, T.; He, H.; Kong, X.; Chen, Y.; Liao, H. Ultra-high performance concrete: A review of its material properties and usage in shield tunnel segment. Case Stud. Constr. Mater. 2025, 22, e04194. [Google Scholar]

- Tang, K.; Qiu, J.; Lai, J.; Xue, F.; Wang, Z.; Li, X. Experimental investigation on deformation-failure mechanisms of a shallow-bias large-section loess tunnel induced by rainfall. Tunn. Undergr. Space Technol. 2025, 157, 106253. [Google Scholar]

- Zahra, Z.S.A. Review on Properties and Applications of Grouting Technique. J. Water Resour. Geosci. 2024, 3, 66–97. [Google Scholar]

- Zhou, Y.; Li, W.; Peng, Y.; Tang, S.; Wang, L.; Shi, Y.; Li, Y.; Wang, Y.; Geng, Z.; Wu, K. Hydration and fractal analysis on low-heat portland cement pastes using thermodynamics-based methods. Fractal Fract. 2023, 7, 606. [Google Scholar] [CrossRef]

- Guo, T.; Zhang, Z.; Yang, Z.; Zhu, Y.; Yang, Y.; Guo, Y.; Wang, R.; Zhang, B.; Fang, Y.; Yu, D. Penetration grouting mechanism of time-dependent power-law fluid for reinforcing loose gravel soil. Minerals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, X.; Lai, J.; Qin, Y. Steel fiber-reinforced recycled coarse aggregate shotcrete repair for tunnel lining corrosion: Experimental tests and calculation analysis. Tunn. Undergr. Space Technol. 2025, 157, 106236. [Google Scholar]

- Tang, G.; Shang, C.; Qin, Y.; Lai, J. Current Advances in Flame-Retardant Performance of Tunnel Intumescent Fireproof Coatings: A Review. Coatings 2025, 15, 99. [Google Scholar] [CrossRef]

- Zenit, R.; Koch, D.L.; Sangani, A.S. Measurements of the average properties of a suspension of bubbles rising in a vertical channel. J. Fluid Mech. 2001, 429, 307–342. [Google Scholar]

- Mandelbrot, B. How long is the coast of Britain? Statistical self-similarity and fractional dimension. Science 1967, 156, 636–638. [Google Scholar] [PubMed]

- Huang, Z.; Wu, Y.; Zhang, R.; Zhong, W.; Li, S.; Zhang, C.; Zhao, K. Experimental investigation on the grouting characteristics of fractured sandstones under different confining pressures. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 201. [Google Scholar] [CrossRef]

- Zhou, Z.; Du, X.; Wang, S.; Zang, H. Analysis and engineering application investigation of multiple-hole grouting injections into porous media considering filtration effects. Constr. Build. Mater. 2018, 186, 871–883. [Google Scholar]

- Hongyuan, F.; Chang, L.; Xueming, D.; Bin, L.; Kejie, Z.; Xiaohua, Z.; Mingrui, D.; Binghan, X.; Shanyong, W. Experimental study on the diffusion characteristics of nonaqueous reactive expansive polymers in sand and gravel media under dynamic water conditions. Tunn. Undergr. Space Technol. 2023, 142, 105433. [Google Scholar]

- Zhou, Z.; Cai, X.; Du, X.; Wang, S.; Ma, D.; Zang, H. Strength and filtration stability of cement grouts in porous media. Tunn. Undergr. Space Technol. 2019, 89, 1–9. [Google Scholar]

- Sun, X.; Wang, Y.; Liu, H.; Yang, Z.; Ma, H. Development of multivariate-coupled grouting diffusion model for RCC. Constr. Build. Mater. 2024, 435, 136748. [Google Scholar] [CrossRef]

- Du, J.; Zhou, A.; Shen, S.-L.; Bu, Y. Fractal-based model for maximum penetration distance of grout slurry flowing through soils with different dry densities. Comput. Geotech. 2022, 141, 104526. [Google Scholar] [CrossRef]

- Yao, M.; Liu, Z.; Yang, H.; Dong, S. Characteristics and factors influencing the nonlinear seepage of paste material injected into a fractal-like tree fracture bifurcation network around coal seam boreholes. Phys. Fluids 2025, 37, 013122. [Google Scholar] [CrossRef]

- Yang, Z.; Xiong, J.; Zhao, X.; Meng, X.; Wang, S.; Li, R.; Wang, Y.; Chen, M.; He, N.; Yang, Y. Column-hemispherical penetration grouting mechanism for Newtonian fluid considering the tortuosity of porous media. Processes 2023, 11, 1737. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, H.; Liu, R.; Li, S.; Zhang, L.; Zhu, G.; Zhang, L. Infiltration grouting mechanism of porous media considering diffusion paths of grout. Chin. J. Geotech. Eng. 2018, 40, 918–924. [Google Scholar]

- Wang, C.; Diao, Y.; Guo, C.; Li, P.; Du, X.; Pan, Y. Two-stage column–hemispherical penetration diffusion model considering porosity tortuosity and time-dependent viscosity behavior. Acta Geotech. 2023, 18, 2661–2680. [Google Scholar]

- Yang, X.; Liang, Y.; Chen, W. A fractal roughness model for the transport of fractional non-Newtonian fluid in microtubes. Chaos Solitons Fractals 2019, 126, 236–241. [Google Scholar]

- Xu, B.; Zhang, H.; Yin, J.; Xue, Y. Infiltration Grouting Mechanism of Bingham Fluids in Porous Media with Different Particle Size Distributions. Appl. Sci. 2023, 13, 11986. [Google Scholar] [CrossRef]

- Wang, H.; Dong, L.; Zhang, Q.; Li, Z.; Zhang, P. Permeation grouting mechanism of viscous time-varying fluid considering diffusion path. Front. Earth Sci. 2023, 10, 1100196. [Google Scholar]

- Wang, H.; Yu, Y.; Zhang, P.; Yang, C.; Wen, H.; Zhang, F.; Du, S. Study on the diffusion mechanism of infiltration grouting in fault fracture zone considering the time-varying characteristics of slurry viscosity under seawater environment. Int. J. Concr. Struct. Mater. 2024, 18, 65. [Google Scholar]

- Zhou, F.; Wei, F.; Yang, S. Based on the fractal seepage theory Bingham-type slurry column diffusion model. Tunn. Constr. 2024, 44, 1356–1364. (In Chinese) [Google Scholar]

- Wang, S.; Wu, T.; Su, Y. A Fractal Permeability Model for the Power-law Fluid Spherical Flow in Porous Media. J. Hubei Univ. Educ. 2021. (In Chinese) [Google Scholar]

- Wang, S.; Wu, T.; Zheng, Q. A Fractal Permeability Model for the Power Law Fluid Radial Flow in a Well in a Porous Medium. Chin. Q. Mech. 2016, 37, 7. (In Chinese) [Google Scholar]

- Zhang, B.; Yu, B.; Wang, H.; Yun, M. A fractal analysis of permeability for power-law fluids in porous media. Fractals 2006, 14, 171–177. [Google Scholar]

- Li, W.; Kou, L.; Sun, M.; Wang, Y.; Shi, X.; Liang, H. Fractal Analysis of Effective Permeability for Power-Law Fluid in Porous Media with Effective Pore Radius. Arab. J. Sci. Eng. 2024, 49, 9747–9756. [Google Scholar]

- Xiao, B.; Li, Y.; Long, G.; Yu, B. Fractal permeability model for power-law fluids in fractured porous media with rough surfaces. Fractals 2022, 30, 2250115. [Google Scholar]

- Yun, M. Seepage Characteristics Study on Power-Law Fluid in Fractal Porous Media. Math. Probl. Eng. 2014, 2014, 813561. [Google Scholar]

- Yang, Z.; Lu, J.; Wang, Y.; Zhang, Z.; Yang, Y.; Zhu, Y.; Zhang, J.; Guo, Y.; Chen, X. Column penetration grouting mechanism for power-law fluids considering tortuosity effect of porous media. Chin. J. Rock Mech. Eng. 2021, 40, 410–418. (In Chinese) [Google Scholar] [CrossRef]

- Wu, T.; Li, G. A fractal model of permeability for power-law fluids in porous-fracture dual media. J. Hua Zhong Norm. Univers 2021, 55, 376–381. [Google Scholar]

- Xu, P.; Yu, B. Developing a new form of permeability and Kozeny–Carman constant for homogeneous porous media by means of fractal geometry. Adv. Water Resour. 2008, 31, 74–81. [Google Scholar]

- Xu, P.; Yu, B.; Qiao, X.; Qiu, S.; Jiang, Z. Radial permeability of fractured porous media by Monte Carlo simulations. Int. J. Heat Mass Transf. 2013, 57, 369–374. [Google Scholar]

- Yang, S.; Liang, M.; Yu, B.; Zou, M. Permeability model for fractal porous media with rough surfaces. Microfluid. Nanofluidics 2015, 18, 1085–1093. [Google Scholar]

- Huang, J.; Li, W.; Huang, D.; Wang, L.; Chen, E.; Wu, C.; Wang, B.; Deng, H.; Tang, S.; Shi, Y. Fractal analysis on pore structure and hydration of magnesium oxysulfate cements by first principle, thermodynamic and microstructure-based methods. Fractal Fract. 2021, 5, 164. [Google Scholar] [CrossRef]

- Majumdar, A.; Bhushan, B. Role of fractal geometry in roughness characterization and contact mechanics of surfaces. J. Tribol. 1990, 112, 205–216. [Google Scholar]

- Wenjun, R. Research on diffusion of grouting and basic properties of grouts. Chin. J. Geotech. Eng. 2005, 27, 69–73. [Google Scholar]

- Yu, W.; Zhou, Y.; Zhao, Z.; Li, Y.; Long, Y.; Tang, S. Simulation of low-heat Portland cement permeability and thermal conductivity using thermodynamics. Proc. Inst. Civ. Eng. Transp. 2024, in press. [Google Scholar]

- Govier, G.W.; Aziz, K.; Schowalter, W. The flow of complex mixtures in pipes. J. Appl. Mech. 1973, 40, 404. [Google Scholar]

- Bo-Ming, Y. Fractal Character for Tortuous Streamtubes in Porous Media. Chin. Phys. Lett. 2005, 22, 3. [Google Scholar]

- Yu, B.; Li, J. Some fractal characters of porous media. Fractals 2001, 9, 365–372. [Google Scholar]

- Bo-Ming, Y.; Jian-Hua, L. A geometry model for tortuosity of flow path in porous media. Chin. Phys. Lett. 2004, 21, 1569. [Google Scholar]

- Wei, Y.; Kong, W.; Wang, Y.; Sha, A. Multifunctional application of nanoscratch technique to characterize cementitious materials. Cem. Concr. Res. 2021, 140, 106318. [Google Scholar]

- Kong Luzhi, D.J. Time dependent analysis of rheological parameters of cement slurry. In Proceedings of the 9th Slope Engineering Conference 2017, Ningbo, China, 24–27 October 2017; p. 4. (In Chinese). [Google Scholar]

- Wei, Y.; Liang, S.; Gao, X. Phase quantification in cementitious materials by dynamic modulus mapping. Mater. Charact. 2017, 127, 348–356. [Google Scholar]

| Rheological Characteristics | |||

|---|---|---|---|

| Coefficient of consistency | 6.475 | 3.246 | 1.569 |

| Rheological index | 0.324 | 0.330 | 0.308 |

| Apparent viscosity | 0.314 | 0.072 | 0.028 |

| Rheological equation |

| Parameter Category | Coarse Sand | |

|---|---|---|

| Experimental measurement index | Porosity, ϕ/ % | 41.80 |

| Maximum pore diameter, | 0.43 | |

| Derived calculated indicators | Average tortuosity, τav | 2.07 |

| Average capillary diameter, | 0.0072 | |

| Volume dimension, Df | 2.4596 | |

| Serial Number | Experimental Values | Theoretical Values | Difference Analysis % | |||

|---|---|---|---|---|---|---|

| Measured Grouting Pressure Value | Grouting Time | Experimental Diffusion Radius | Tortuous Fractal Dimension (Math.) | Calculated Diffusion Grouting | ||

| K1 | 0.418 | 5 | 65 | 1.1025 | 48 | 26.15 |

| K2 | 0.389 | 10 | 144 | 1.0995 | 128 | 11.11 |

| K3 | 0.394 | 15 | 182 | 1.0977 | 167 | 8.43 |

| S1 | 0.392 | 5 | 55 | 1.0700 | 41 | 25.45 |

| S2 | 0.408 | 10 | 84 | 1.0682 | 71 | 15.48 |

| S3 | 0.407 | 15 | 118 | 1.0670 | 106 | 10.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, F.; Lai, J.; Su, X. Investigation of Power-Law Fluid Infiltration Grout Characteristics on the Basis of Fractal Theory. Buildings 2025, 15, 987. https://doi.org/10.3390/buildings15060987

Wei F, Lai J, Su X. Investigation of Power-Law Fluid Infiltration Grout Characteristics on the Basis of Fractal Theory. Buildings. 2025; 15(6):987. https://doi.org/10.3390/buildings15060987

Chicago/Turabian StyleWei, Fucheng, Jinxing Lai, and Xulin Su. 2025. "Investigation of Power-Law Fluid Infiltration Grout Characteristics on the Basis of Fractal Theory" Buildings 15, no. 6: 987. https://doi.org/10.3390/buildings15060987

APA StyleWei, F., Lai, J., & Su, X. (2025). Investigation of Power-Law Fluid Infiltration Grout Characteristics on the Basis of Fractal Theory. Buildings, 15(6), 987. https://doi.org/10.3390/buildings15060987