Investigation of Fresh Properties of Self-Leveling Cement-Based Pastes with CFB Fly Ash as an SCM

Abstract

1. Introduction

2. Materials and Methods

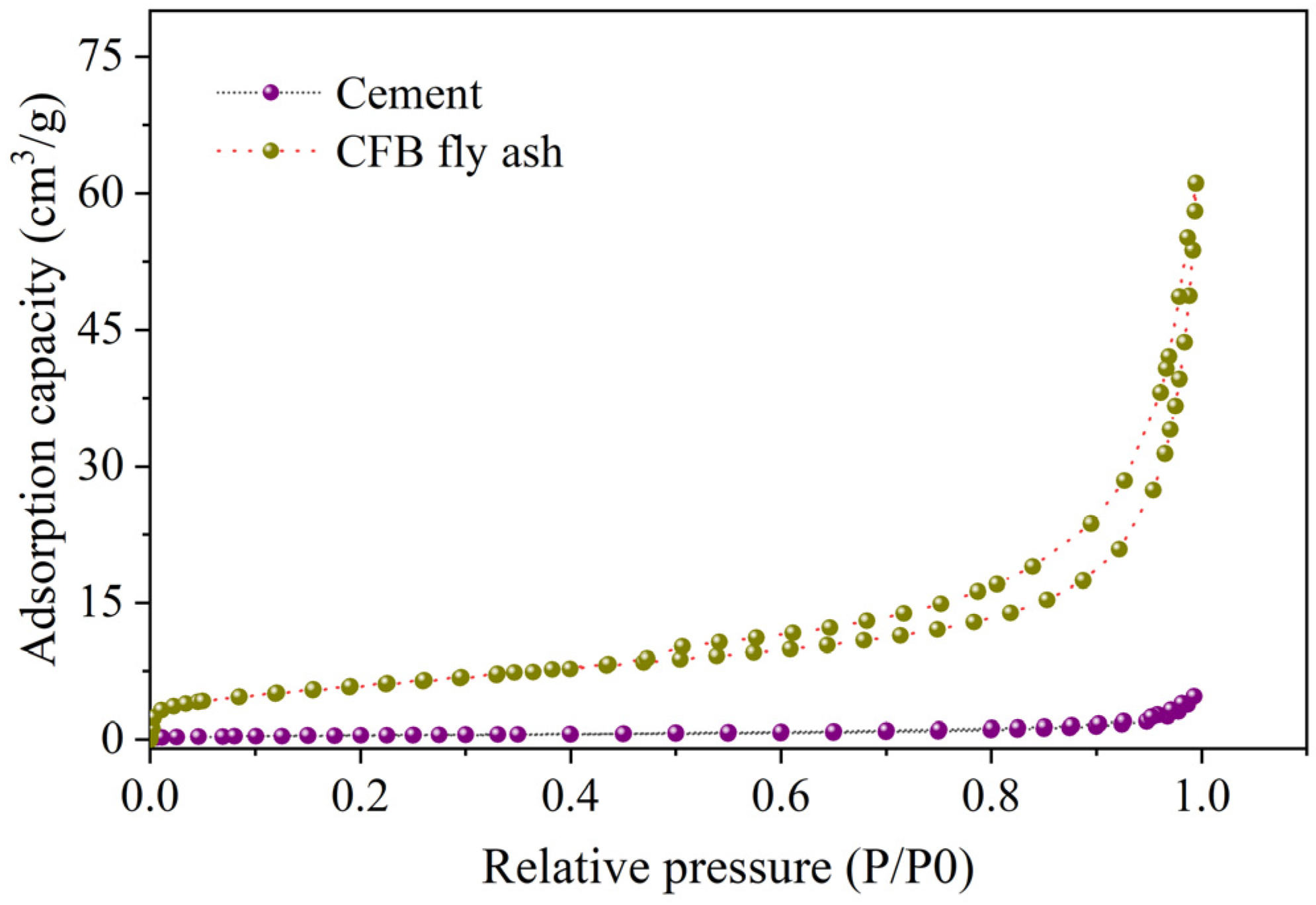

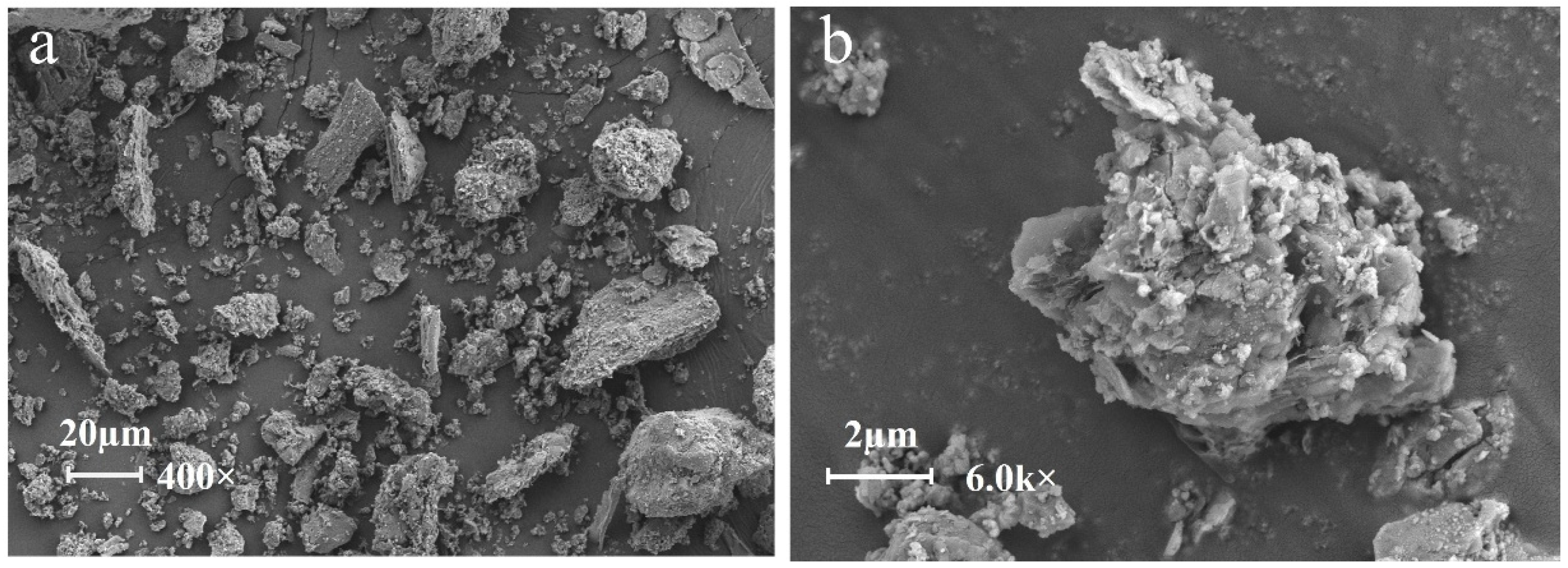

2.1. Materials

2.2. Methods

2.2.1. Preparation of Cement-Based Paste

2.2.2. Fluidity

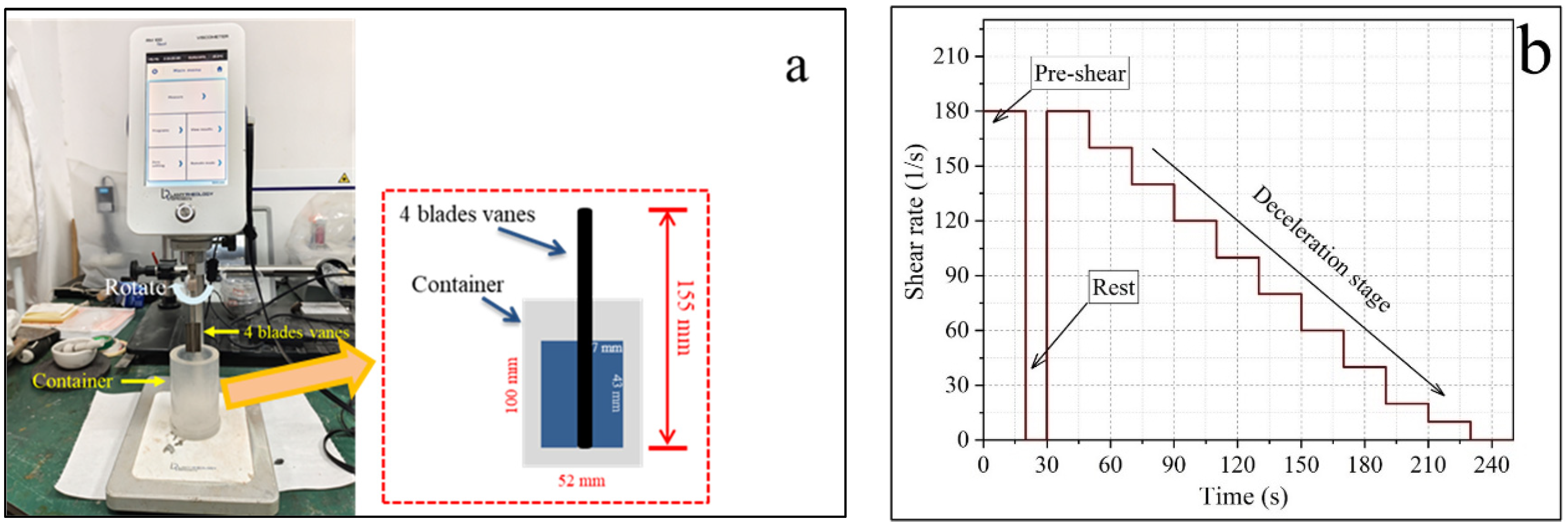

2.2.3. Rheological Properties

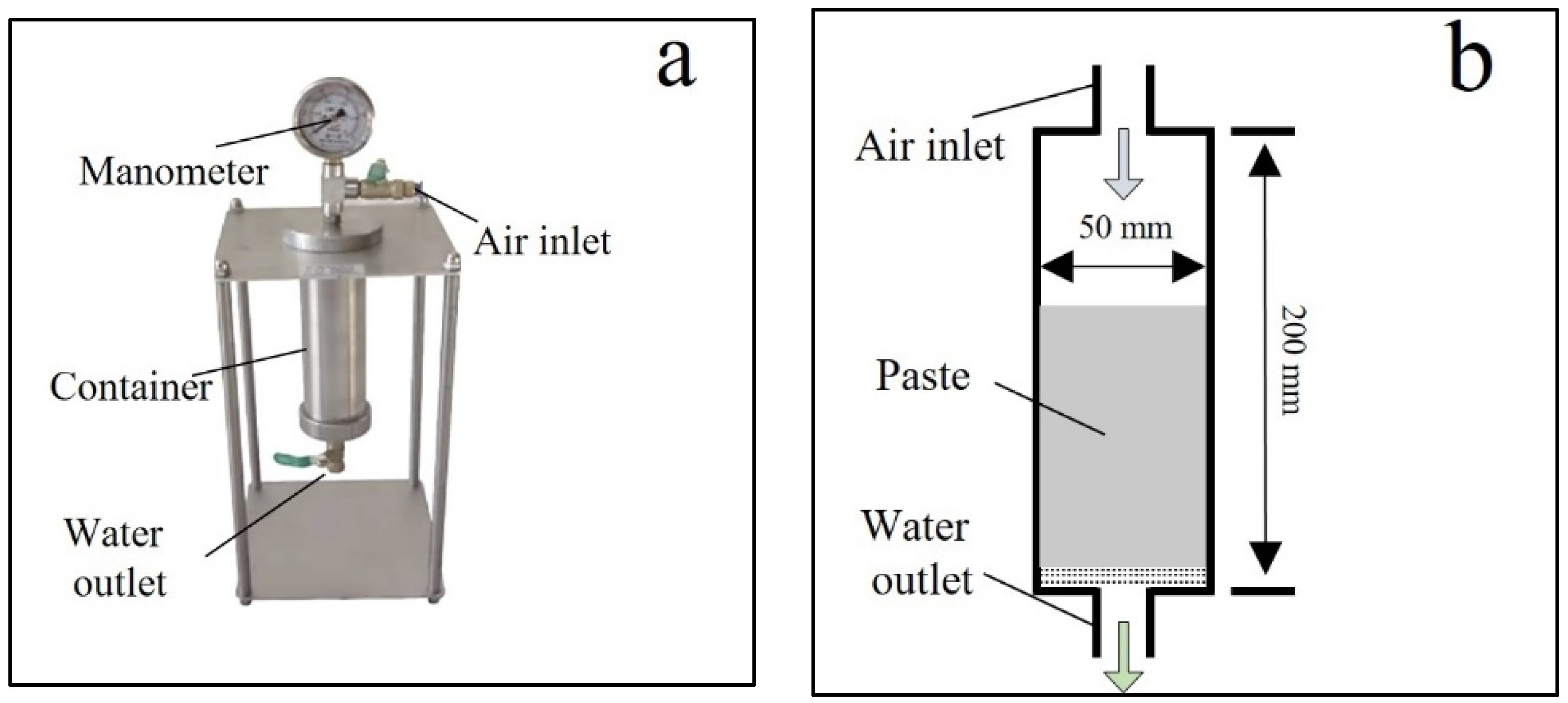

2.2.4. Bleeding Rate

2.2.5. Compatibility Between the CFB Fly Ash and PCE

3. Results and Discussion

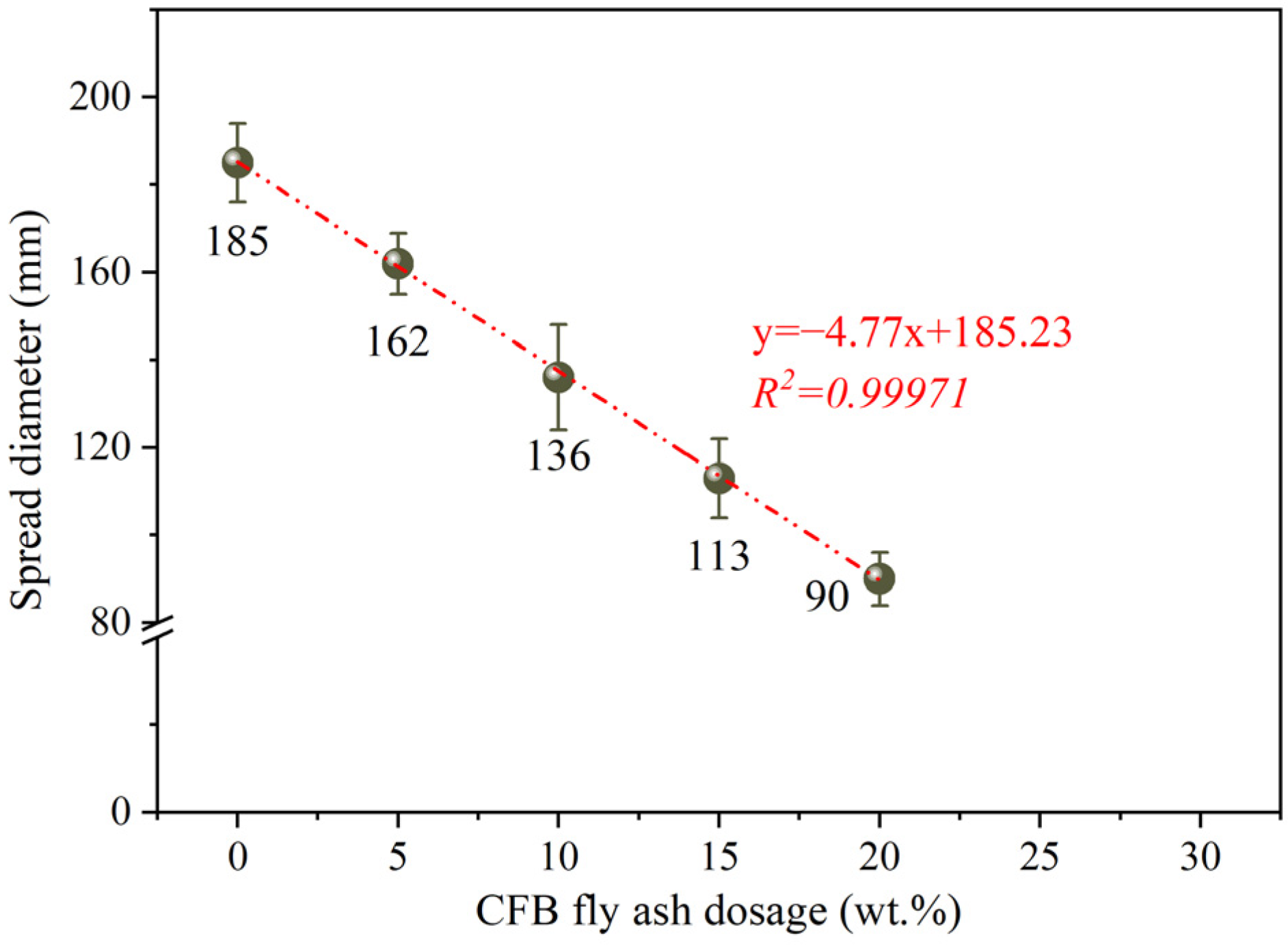

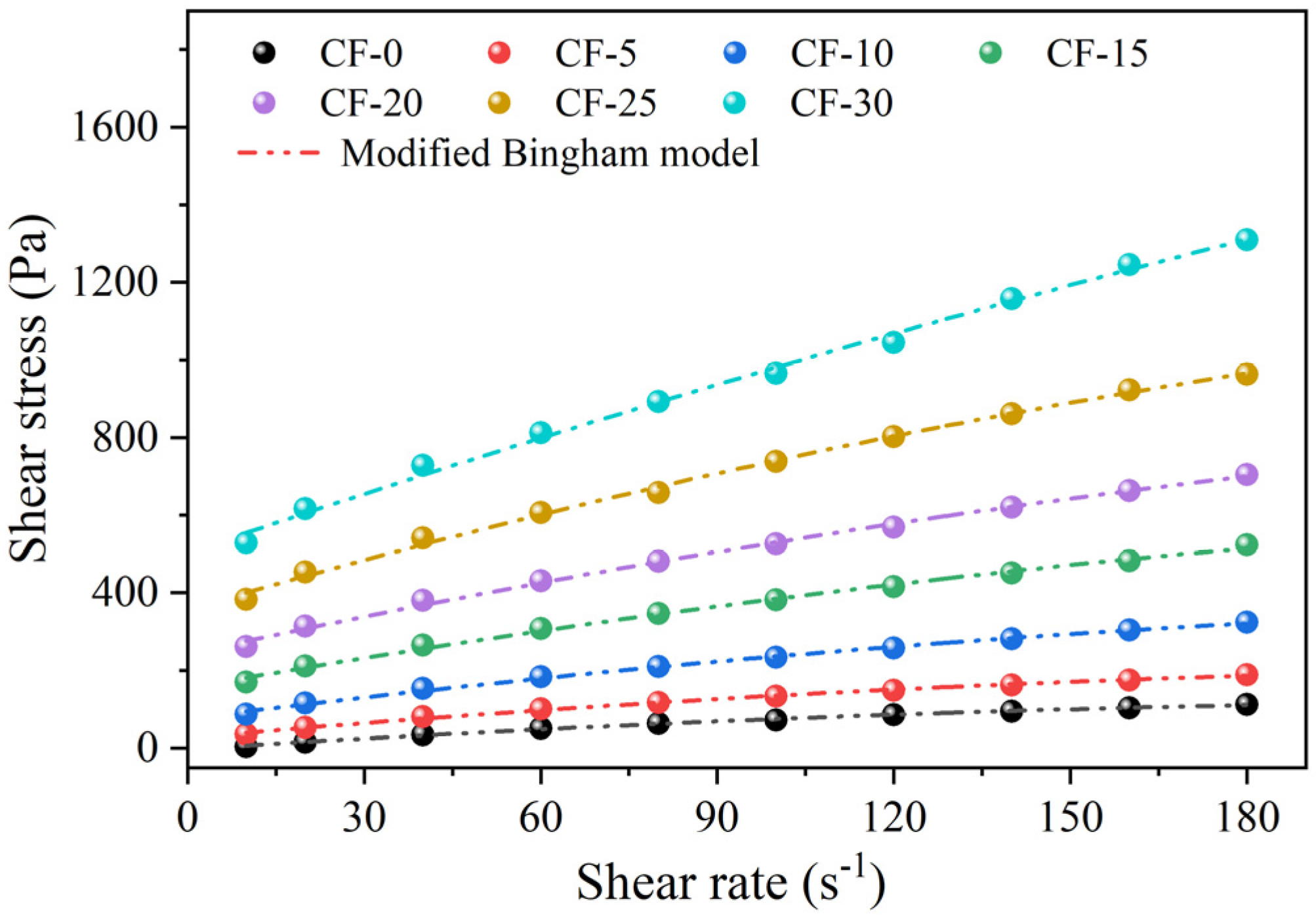

3.1. Fresh Properties (Series I)

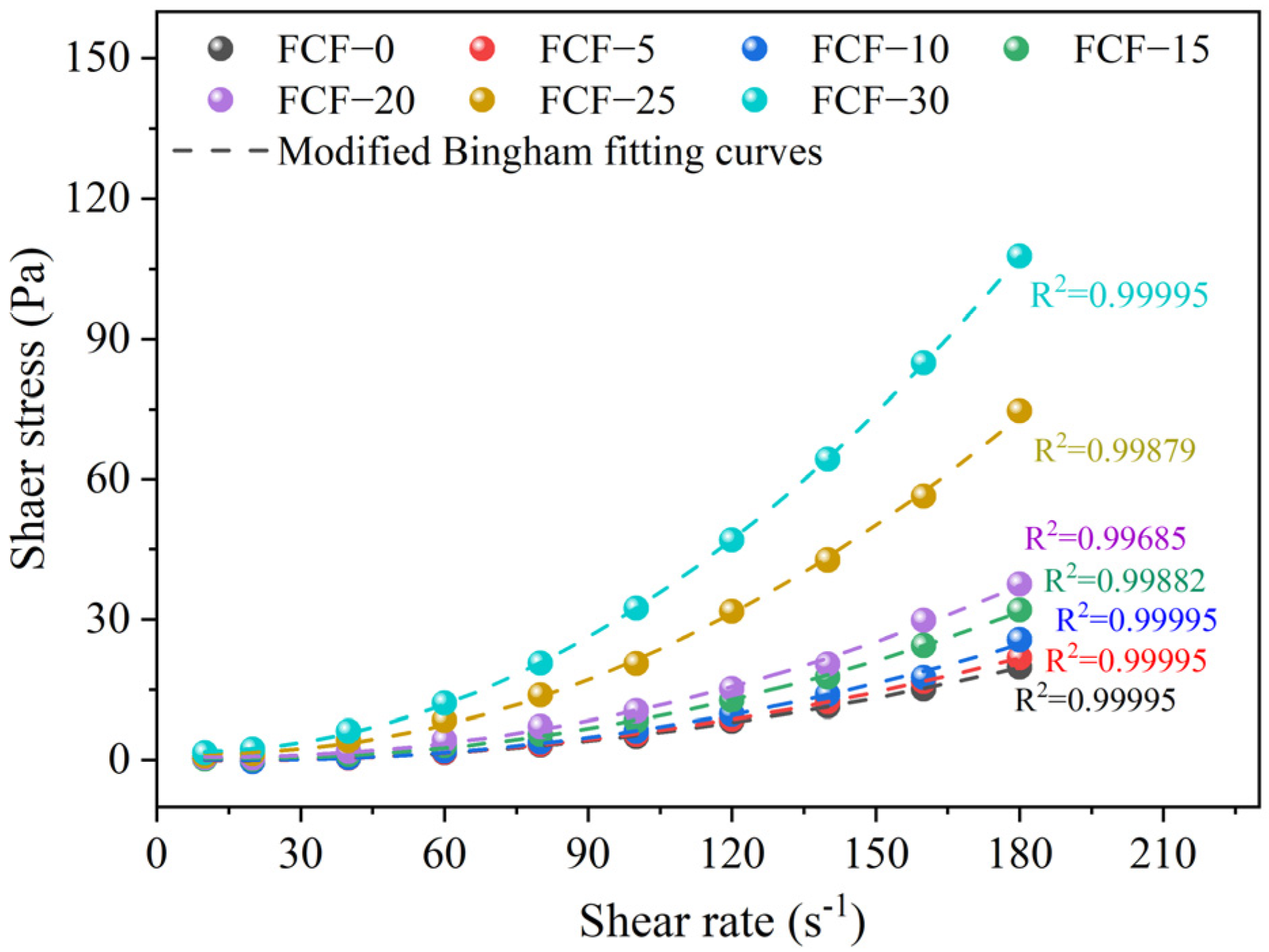

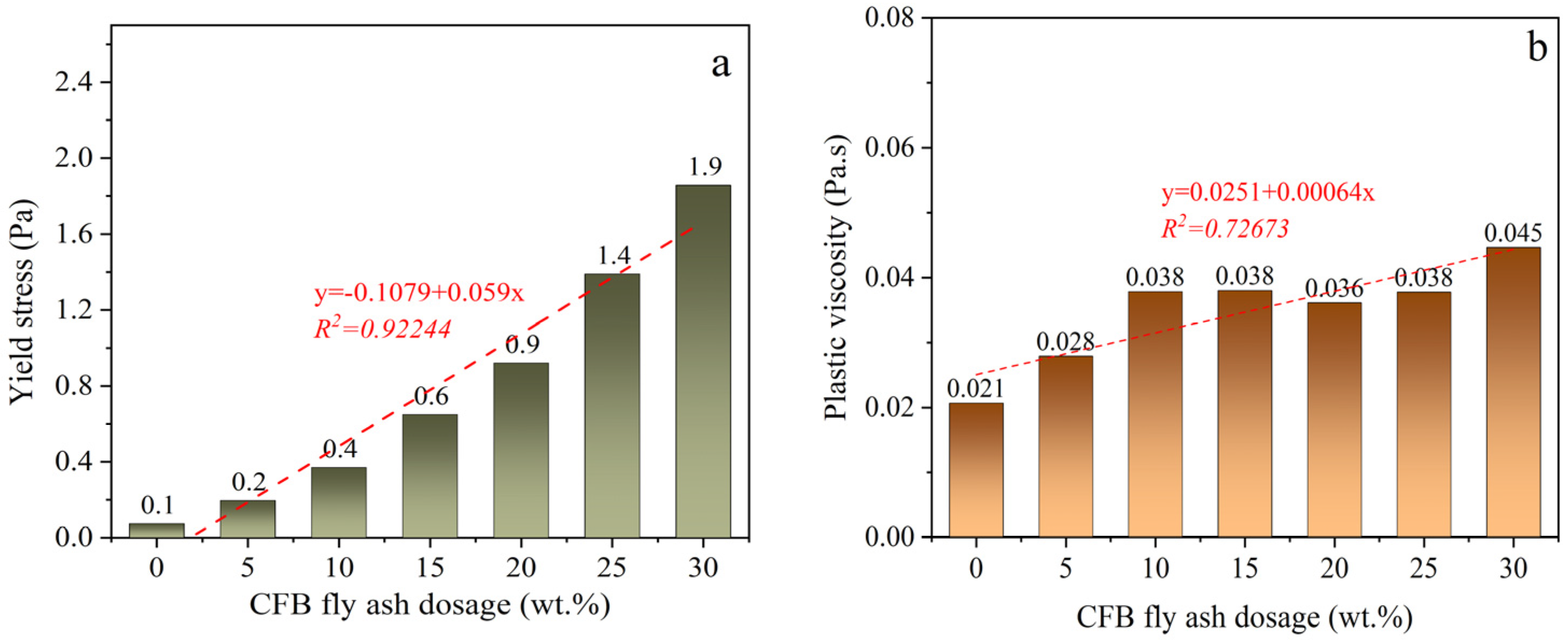

3.2. Fresh Properties (Series II)

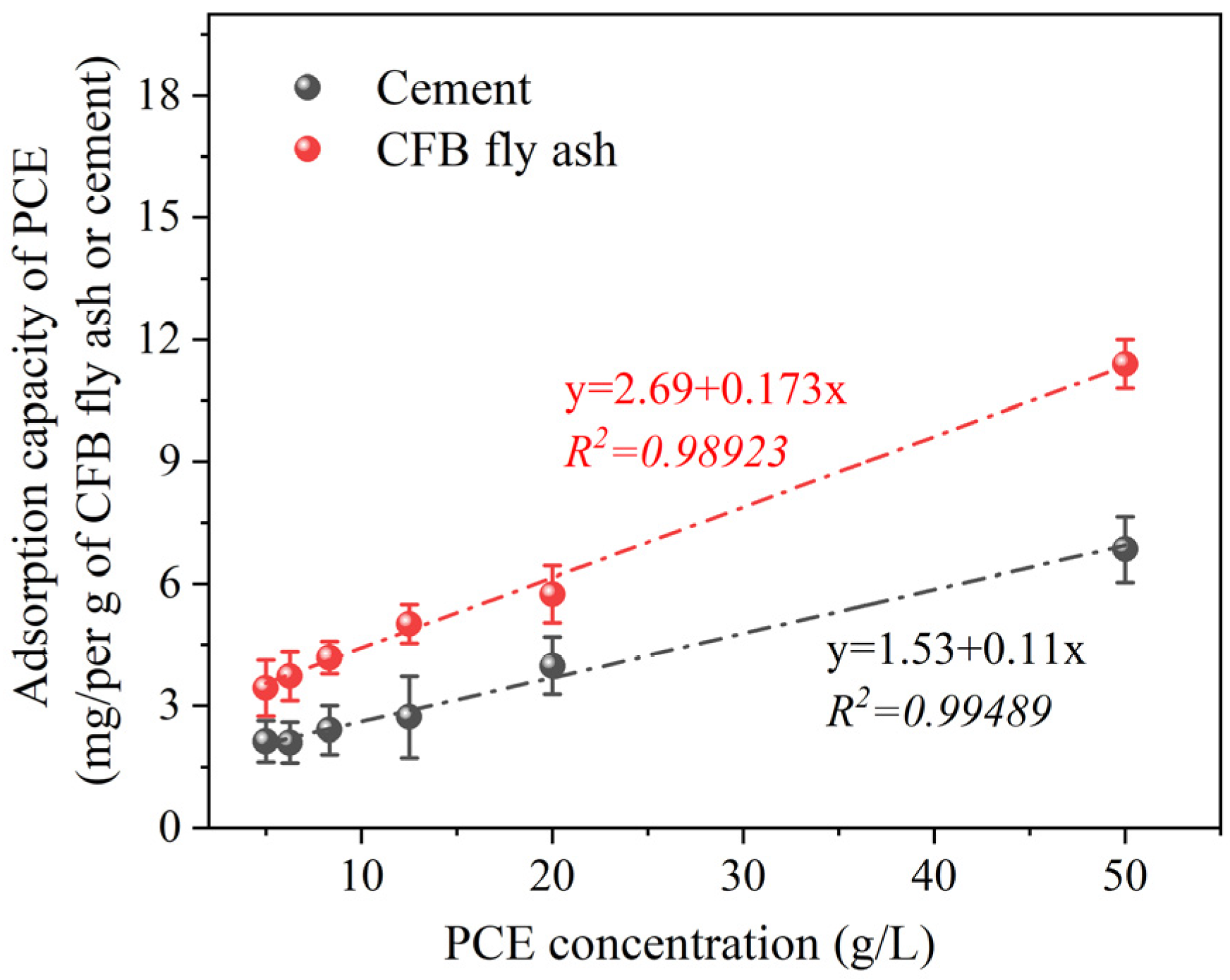

3.3. Compatibility Between the CFB Fly Ash and PCE

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Anjos, M.A.S.; Araújo, T.R.; Ferreira, R.L.S.; Farias, E.C.; Martinelli, A.E. Properties of self-leveling mortars incorporating a high-volume of sugar cane bagasse ash as partial Portland cement replacement. J. Build. Eng. 2020, 32, 101694. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, X.; Memon, S.A.; Dong, Z.; Li, D.; Cui, H. Effect of calcium sulfate type and dosage on properties of calcium aluminate cement-based self-leveling mortar. Constr. Build. Mater. 2018, 167, 253–262. [Google Scholar] [CrossRef]

- Terán-Cuadrado, G.; Tahir, F.; Nurdiawati, A.; Almarshoud, M.A.; Al-Ghamdi, S.G. Current and potential materials for the low-carbon cement production: Life cycle assessment perspective. J. Build. Eng. 2024, 96, 110528. [Google Scholar] [CrossRef]

- Benhelal, E.; Shamsaei, E.; Rashid, M.I. Challenges against CO2 abatement strategies in cement industry: A review. J. Environ. Sci. 2021, 104, 84–101. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A review of low-carbon technologies and projects for the global cement industry. J. Environ. Sci. 2024, 136, 682–697. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef] [PubMed]

- Reddy, P.-N.; Bode, V.-K. Durability performance of high strength concrete incorporating supplementary cementitious materials. Mater. Today Proc. 2020, 33, 66–72. [Google Scholar] [CrossRef]

- Lothenbach, B.; Scrivener, K.; Hooton, R.-D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Vargas, F.; Lopez, M.; Rigamonti, L. Environmental impacts evaluation of treated copper tailings as supplementary cementitious materials. Resources. Conserv. Recycl. 2020, 160, 104890. [Google Scholar] [CrossRef]

- Özkılıç, Y.; Althaqafi, E.; Bahrami, A.; Aksoylu, C.; Karalar, M.; Özdöner, N.; Shcherban, E.M.; Stel’makh, S.; Beskopylny, A.; Thomas, B.S. Influence of ceramic waste powder on shear performance of environmentally friendly reinforced concrete beams. Sci. Rep. 2024, 14, 10401. [Google Scholar] [CrossRef]

- Başaran, B.; Aksoylu, C.; Özkılıç, Y.O.; Karalar, M.; Hakamy, A. Shear behaviour of reinforced concrete beams utilizing waste marble powder. Structure 2023, 54, 1090–1100. [Google Scholar] [CrossRef]

- Jørgen, S.; Ruben, S. Reactivity of supplementary cementitious materials (SCMs) in cement blends. Cem. Concr. Res. 2019, 124, 105799. [Google Scholar]

- Targan, Ş.; Olgun, A.; Erdogan, Y.; Sevinc, V. Influence of natural pozzolan, colemanite ore waste, bottom ash, and fly ash on the properties of Portland cement. Cem. Concr. Res. 2003, 33, 1175–1182. [Google Scholar] [CrossRef]

- Elahi, A.; Basheer, P.A.M.; Nanukuttan, S.V.; Khan, Q.U.Z. Mechanical and durability properties of high performance concretes containing supplementary cementitious materials. Constr. Build. Mater. 2010, 24, 292–299. [Google Scholar] [CrossRef]

- Wu, C.; Zhan, B.; Hong, Z.; Cui, S.; Cui, P.; Kou, S. Hydration behavior of circulating fluidized bed fly ash (CFBFA) as a cementitious binder. Constr. Build. Mater. 2022, 314, 125625. [Google Scholar] [CrossRef]

- Li, D.L. Characteristics of Cement with Ultrafine Circulating Fluidized Bed Fly Ash. Ph. D. Thesis, China University of Mining and Technology, Beijing, China, 2018. [Google Scholar]

- GB/T 1596-2005; Fly Ash Used for Cement and Concrete. China National Standardization Management Committee: Beijing, China, 2005.

- He, P.; Zhang, X.; Chen, H.; Zhang, Y. Waste-to-resource strategies for the use of circulating fluidized bed fly ash in construction materials: A mini review. Powder Technol. 2021, 393, 773–785. [Google Scholar] [CrossRef]

- Li, D.; Wang, D.; Ren, C.; Rui, Y. Investigation of rheological properties of fresh cement paste containing ultrafine circulating fluidized bed fly ash. Constr. Build. Mater. 2018, 188, 1007–1013. [Google Scholar] [CrossRef]

- Guo, W.; Yao, W.; Liang, G.; Shi, C.; She, A.; Wei, Y. Mechanical properties, microstructure and life-cycle assessment of eco-friendly cementitious materials containing circulating fluidized bed fly ash and ground granulated blast furnace slag. J. Build. Eng. 2024, 95, 110293. [Google Scholar] [CrossRef]

- Chi, M.; Huang, R. Effect of circulating fluidized bed combustion ash on the properties of roller compacted concrete. Cem. Concr. Compos. 2014, 45, 148–156. [Google Scholar] [CrossRef]

- Zhou, M.; Chen, P.; Chen, X.; Ge, X.; Wang, Y. Study on hydration characteristics of circulating fluidized bed combustion fly ash (CFBCA). Constr. Build. Mater. 2020, 251, 118993. [Google Scholar] [CrossRef]

- Zahedi, M.; Jafari, K.; Rajabipour, F. Properties and durability of concrete containing fluidized bed combustion (FBC) fly ash. Constr. Build. Mater. 2020, 258, 119663. [Google Scholar] [CrossRef]

- Zheng, D.; Wang, D.; Cui, H.; Chen, X. Hydration characteristics of cement with high volume circulating fluidized bed fly ash. Constr. Build. Mater. 2023, 380, 131310. [Google Scholar] [CrossRef]

- Liu, W.; Liu, X.; Zhang, L.; Wan, Y.; Li, H.; Jiao, X. Rheology, mechanics, microstructure and durability of low-carbon cementitious materials based on circulating fluidized bed fly ash: A comprehensive review. Constr. Build. Mater. 2024, 411, 134688. [Google Scholar] [CrossRef]

- GB 175-2007; Common Portland Cement. China National Standardization Management Committee: Beijing, China, 2007.

- Li, J.; Chen, Z.; Li, L.; Qiao, Y.; Yuan, Z.; Zeng, L.; Li, Z. Study on pore and chemical structure characteristics of atmospheric circulating fluidized bed coal gasification fly ash. J. Clean. Prod. 2021, 308, 127395. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Basic, N.; Omran, A.F.; Tagnit-Hamou, A. Feasibility of using cellulose filaments as a viscosity modifying agent in self-consolidating concrete. Cem. Concr. Compos. 2018, 94, 327–340. [Google Scholar] [CrossRef]

- GB/T 8077-2012; Methods for Testing Uniformity of Concrete Admixture. China National Standardization Management Committee: Beijing, China, 2007.

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W.L. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Aiad, I. Influence of time addition of superplasticizers on the rheological properties of fresh cement pastes. Cem. Concr. Res. 2003, 33, 1229–1234. [Google Scholar] [CrossRef]

- Sonebi, M. Rheological properties of grouts with viscosity modifying agents as diutan gum and welan gum incorporating pulverised fly ash. Cem. Concr. Res. 2006, 36, 1609–1618. [Google Scholar] [CrossRef]

- Feys, D.; Roussel, N.; Verhoeven, R.; Schutter, G.D. Influence of air content on the steady state rheological properties of fresh self-compacting concrete, without air entraining agents. In 2nd International Symposium on Design, Performance and Use of Self-Consolidating Concrete (SCC2009); RILEM Publications: Bagneux, France, 2009. [Google Scholar]

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. The Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- Schmid, M.; Plank, J. Interaction of individual meta clays with polycarboxylate (PCE) superplasticizers in cement investigated via dispersion, zeta potential and sorption measurements. Appl. Clay Sci. 2021, 207, 106092. [Google Scholar] [CrossRef]

- Wu, C.; Tang, W.; Zhan, B.; Kou, S. Feasibility study on using red mud as a viscosity-modifying agent for self-compacting concrete. Constr. Build. Mater. 2024, 445, 137871. [Google Scholar] [CrossRef]

- Li, Y.; Mu, J.; Hao, J.; Liu, Y.; Jiang, X.; Luo, X. Research on the particle characteristics of manufactured sands affecting the flow ability of fresh mortar. Constr. Build. Mater. 2023, 382, 131287. [Google Scholar] [CrossRef]

- Feys, D. Ronny Verhoeven, and Geert De Schutter, Steady-State Rheological Properties of Fresh Self Compacting Concrete and Their Evolution in Time. In Proceedings of the Annual Transactions the Nordic Rheology Society-Nordic Rheology Conference, Stavanger, Norway, 13–15 June 2007; pp. 35–41. [Google Scholar]

- Ortiz-Álvarez, N.; Lizarazo-Marriaga, J.; Brandão, P.F.; Santos-Panqueva, Y.; Carrillo, J. Rheological properties of cement-based materials using a biopolymer viscosity modifying admixture (BVMA) under different dispersion conditions. Cem. Concr. Compos. 2021, 124, 104224. [Google Scholar] [CrossRef]

- Shen, W.; Yuan, Q.; Shi, C.; Ji, Y.; Zeng, R.; Li, W.; Wu, Y.; Lao, L.; Chen, Z.; Li, F. How do discharge rate and pipeline length influence the rheological properties of self-consolidating concrete after pumping? Cem. Concr. Compos. 2021, 124, 104231. [Google Scholar] [CrossRef]

- Feys, D.; Verhoeven, R.; De Schutter, G. Why is fresh self-compacting concrete shear thickening? Cem. Concr. Res. 2009, 39, 510–523. [Google Scholar] [CrossRef]

- Burgos-Montes, O.; Palacios, M.; Rivilla, P.; Puertas, F. Compatibility between superplasticizer admixtures and cements with mineral additions. Constr. Build. Mater. 2012, 31, 300–309. [Google Scholar] [CrossRef]

- He, D.; Liang, R.; Zhao, J.; Liu, Z.; Lu, Z.; Sun, G. Effect of ionic liquids in compatibility with PCE and cement paste containing clay. Constr. Build. Mater. 2020, 264, 120265. [Google Scholar] [CrossRef]

- Plank, J.; Sakai, E.; Miao, C.W.; Yu, C.; Hong, J.X. Chemical admixtures—Chemistry, applications and their impact on concrete microstructure and durability. Cem. Concr. Res. 2015, 79, 81–99. [Google Scholar] [CrossRef]

- Yamada, K. Basics of analytical methods used for the investigation of interaction mechanism between cements and superplasticizers. Cem. Concr. Res. 2011, 41, 793–798. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, H.; Gao, X.; Wu, W. Adsorption and desorption of polycarboxylate ether superplasticizer in fresh cementitious materials blended with mineral admixtures. J. Mater. Res. Technol. 2022, 17, 1740–1751. [Google Scholar] [CrossRef]

- Li, R.; Lei, L.; Sui, T.; Plank, J. Effectiveness of PCE superplasticizers in calcined clay blended cements. Cem. Concr. Res. 2021, 141, 106334. [Google Scholar] [CrossRef]

- Lei, L. A Comprehensive Study of Interactions Occurring Between Superplasticizers and Clays, and Superplasticizers and Cement, Chair for Construction Chemicals. Master’s Thesis, Technische Universität München, Munich, Germany, 2016; pp. 119–132. [Google Scholar]

- Chandara, C.; Sakai, E.; Azizli, K.A.M.; Ahmad, Z.A.; Hashim, S.F.S. The effect of unburned carbon in palm oil fuel ash on fluidity of cement pastes containing superplasticizer. Constr. Build. Mater. 2010, 24, 1590–1593. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | CaO | MgO | Fe2O3 | SO3 | Na2O | K2O | Others | LOI | |

|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 19.52 | 4.78 | 63.40 | 2.70 | 3.64 | 1.87 | 0.32 | 0.92 | 1.24 | 1.62 |

| CFB fly ash | 56.12 | 23.91 | 2.94 | 1.83 | 8.40 | 2.58 | 1.38 | 1.63 | 1.21 | 4.40 |

| Name | Cement (wt.%) | CFB Fly Ash (wt.%) | Water-to-Binder Ratio | PCE to the Binder (wt.%) | |

|---|---|---|---|---|---|

| Series I | CF-0 | 100 | 0 | 0.5 | - |

| CF-5 | 95 | 5 | |||

| CF-10 | 90 | 10 | |||

| CF-15 | 85 | 15 | |||

| CF-20 | 80 | 20 | |||

| CF-25 | 75 | 25 | |||

| CF-30 | 70 | 30 | |||

| Series II | FCF-0 | 100 | 0 | 0.5 | 0.15 |

| FCF-5 | 95 | 5 | 0.23 | ||

| FCF-10 | 90 | 10 | 0.44 | ||

| FCF-15 | 85 | 15 | 0.77 | ||

| FCF-20 | 80 | 20 | 1.21 | ||

| FCF-25 | 75 | 250 | 1.63 | ||

| FCF-30 | 70 | 30 | 2.19 |

| Name | Cement (wt.%) | CFB Fly Ash (wt.%) | Water-to-Binder Ratio | PCE-to-the-Binder (wt.%) | Fluidity (mm) |

|---|---|---|---|---|---|

| C-0 | 100 | 0 | 0.49 | 0 | 180 |

| E-0 | 0.23 | 0.2 | 176 | ||

| C-5 | 95 | 5 | 0.53 | 0 | 178 |

| E-5 | 0.29 | 0.2 | 181 | ||

| C-10 | 90 | 10 | 0.58 | 0 | 181 |

| E-10 | 0.36 | 0.2 | 178 | ||

| C-20 | 80 | 20 | 0.67 | 0 | 183 |

| E-20 | 0.46 | 0.2 | 179 | ||

| C-30 | 70 | 30 | 0.76 | 0 | 180 |

| E-30 | 0.55 | 0.2 | 182 |

| Number | Cement | CFB Fly Ash | PCE Diluent | PCE Diluent Type | Notes |

|---|---|---|---|---|---|

| 1 | 6 g | 0 | 30 mL | SP-20 | Experimental group for evaluating the adsorption capacity of PCE on cement particles |

| 2 | SP-50 | ||||

| 3 | SP-80 | ||||

| 4 | SP-120 | ||||

| 5 | SP-160 | ||||

| 6 | SP-200 | ||||

| 7 | 0 | 6 g | 30 mL | C-SP-20 | Experimental group for assessing the adsorption capacity of PCE on CFB fly ash particles |

| 8 | C-SP-50 | ||||

| 9 | C-SP-80 | ||||

| 10 | C-SP-120 | ||||

| 11 | C-SP-160 | ||||

| 12 | C-SP-200 | ||||

| C-1 | 6 g | 0 | 30 mL | Deionized water | Control group for evaluating the organic carbon content in the cement |

| C-2 | 0 | 6 g | Synthetic cement pore solution | Control group for evaluating the organic carbon content in the CFB fly ash | |

| C-3 | 0 | 0 | SP-50 | Control group for analyzing the organic carbon content in PCE | |

| C-4 | 0 | 0 | SP-160 |

| Parameters | CF-0 | CF-5 | CF-10 | CF-15 | CF-20 | CF-25 | CF-30 |

|---|---|---|---|---|---|---|---|

| Correlation coefficient (R2) | 0.99735 | 0.99622 | 0.99698 | 0.99524 | 0.99627 | 0.99627 | 0.99456 |

| Yield stress (Pa) | 3.3 | 26.2 | 75.2 | 154.8 | 243.5 | 356.5 | 503.9 |

| Plastic viscosity (Pa·s) | 1.0 | 1.3 | 1.9 | 2.7 | 3.3 | 4.4 | 5.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.-R.; Tang, W.; Huo, Y.-L.; Zhan, B.-J.; Kou, S.-C. Investigation of Fresh Properties of Self-Leveling Cement-Based Pastes with CFB Fly Ash as an SCM. Buildings 2025, 15, 966. https://doi.org/10.3390/buildings15060966

Wu C-R, Tang W, Huo Y-L, Zhan B-J, Kou S-C. Investigation of Fresh Properties of Self-Leveling Cement-Based Pastes with CFB Fly Ash as an SCM. Buildings. 2025; 15(6):966. https://doi.org/10.3390/buildings15060966

Chicago/Turabian StyleWu, Chun-Ran, Wei Tang, Yan-Lin Huo, Bao-Jian Zhan, and Shi-Cong Kou. 2025. "Investigation of Fresh Properties of Self-Leveling Cement-Based Pastes with CFB Fly Ash as an SCM" Buildings 15, no. 6: 966. https://doi.org/10.3390/buildings15060966

APA StyleWu, C.-R., Tang, W., Huo, Y.-L., Zhan, B.-J., & Kou, S.-C. (2025). Investigation of Fresh Properties of Self-Leveling Cement-Based Pastes with CFB Fly Ash as an SCM. Buildings, 15(6), 966. https://doi.org/10.3390/buildings15060966