The Impact of Manufacturing Technology on the Tube-Steel Concrete Columns Bearing Capacity Under Axial Load

Abstract

1. Introduction

- -

- the selection of the composition of vibrated, centrifuged and vibrocentrifuged concrete;

- -

- manufacturing, testing and evaluating the properties of experimental samples of V, C and VC concrete technology;

- -

- manufacturing laboratory prototypes of solid and hollow tube concrete columns from vibrated, centrifuged and vibrocentrifuged concrete;

- -

- preparation, implementation and analysis of experimental results;

- -

- the evaluation of the efficiency of hollow tube concrete columns manufactured using different technologies under load by comparing the ratios of the actual and calculated bearing capacity.

2. Materials and Methods

2.1. Materials

- -

- Portland cement CEM I 42.5H (PC) (Sebryakovcement, Mikhailovka, Russia).

- -

- Granite crushed stone (CrS) (Pavlovsk Nerud, Pavlovsk, Russia).

- -

- Quartz sand (QS) (Erofeevsky sand quarry, Erofeevka, Russia).

2.2. Methods

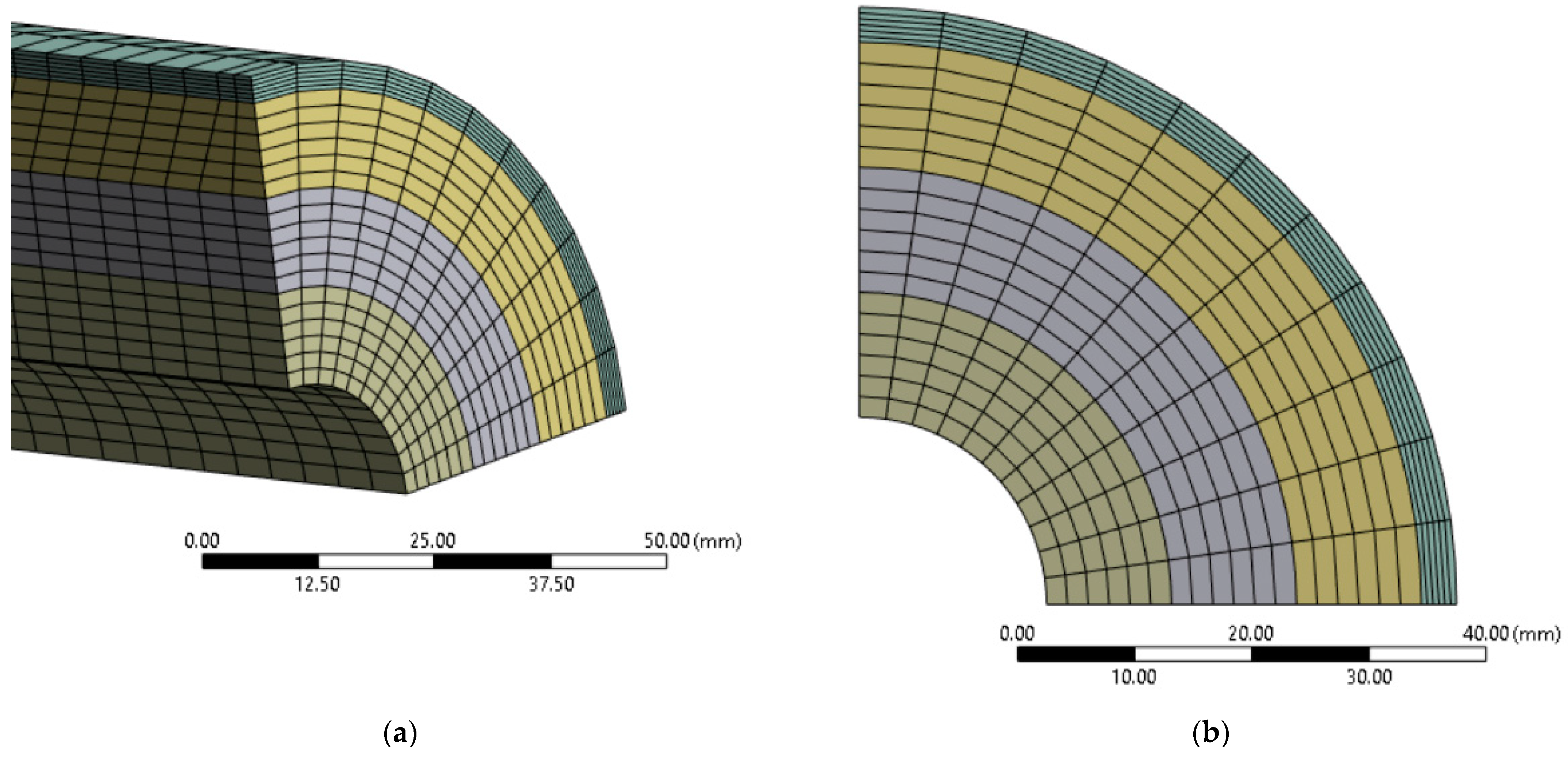

2.3. FEM Modeling

3. Results and Discussion

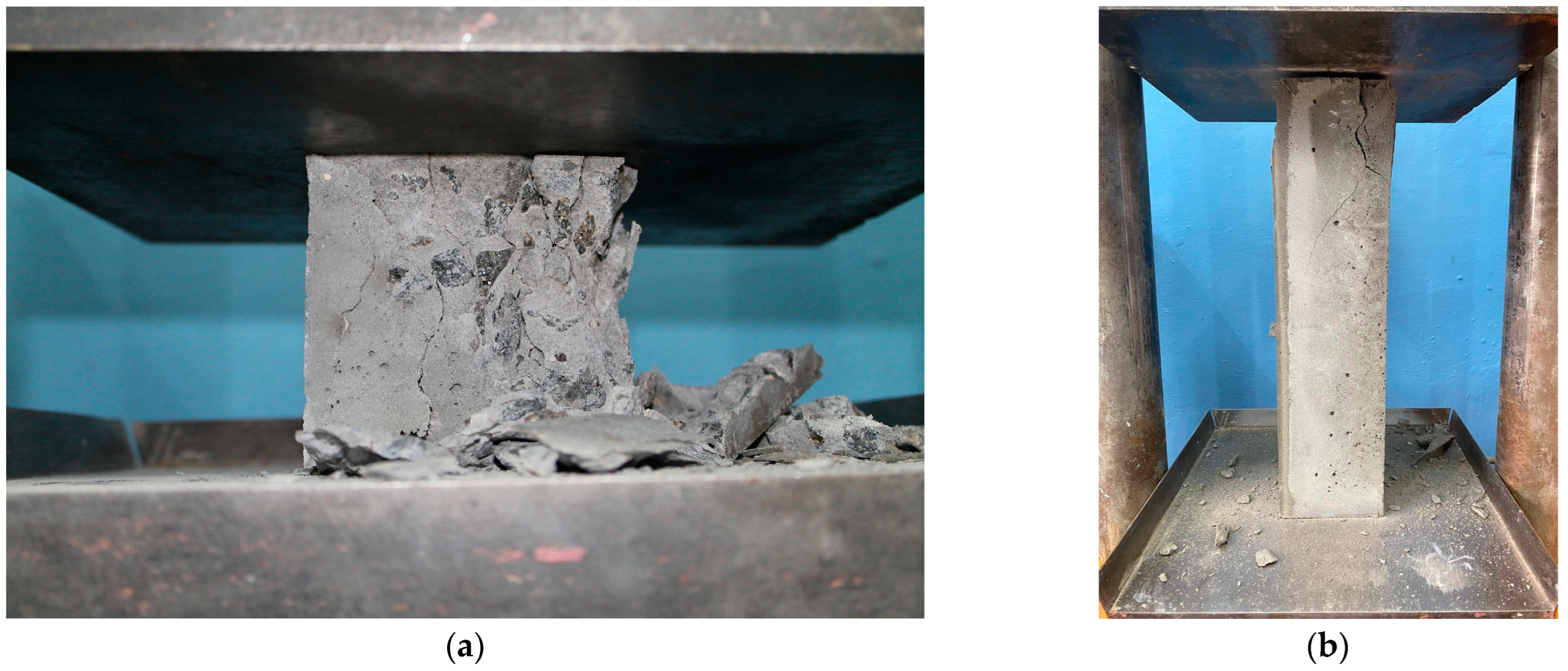

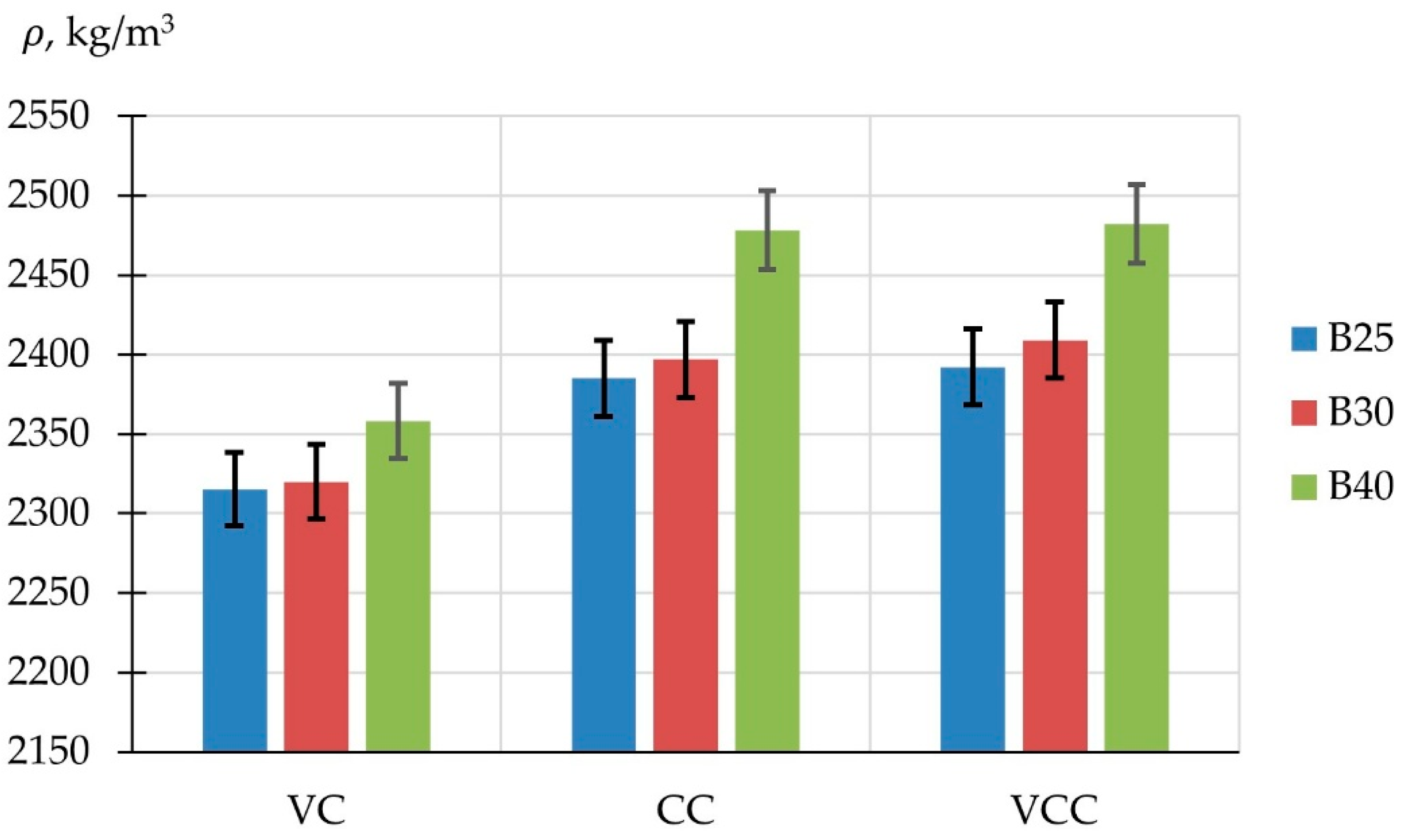

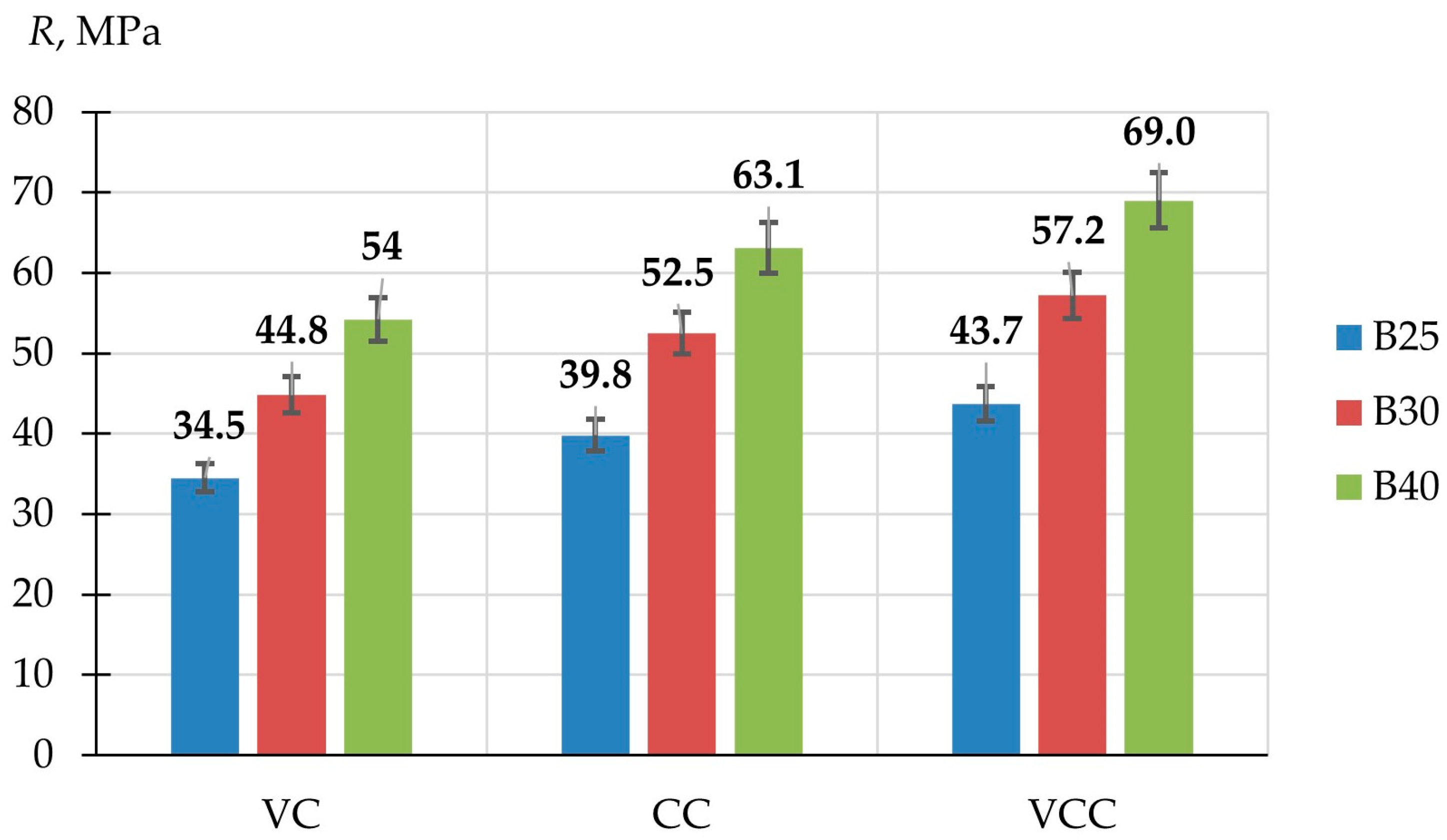

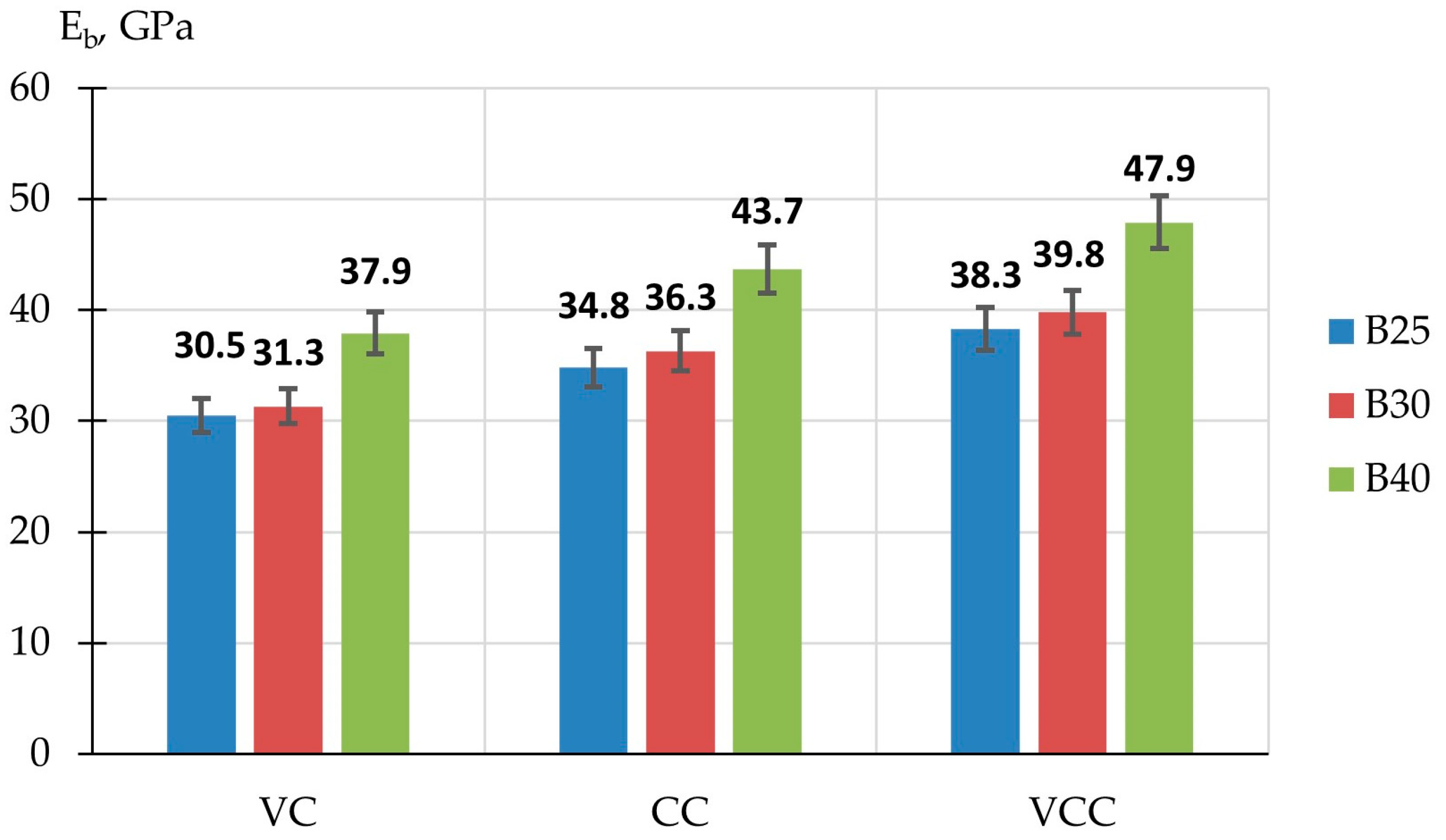

3.1. Results of Determining the Properties of Concretes Manufactured Using Different Technologies

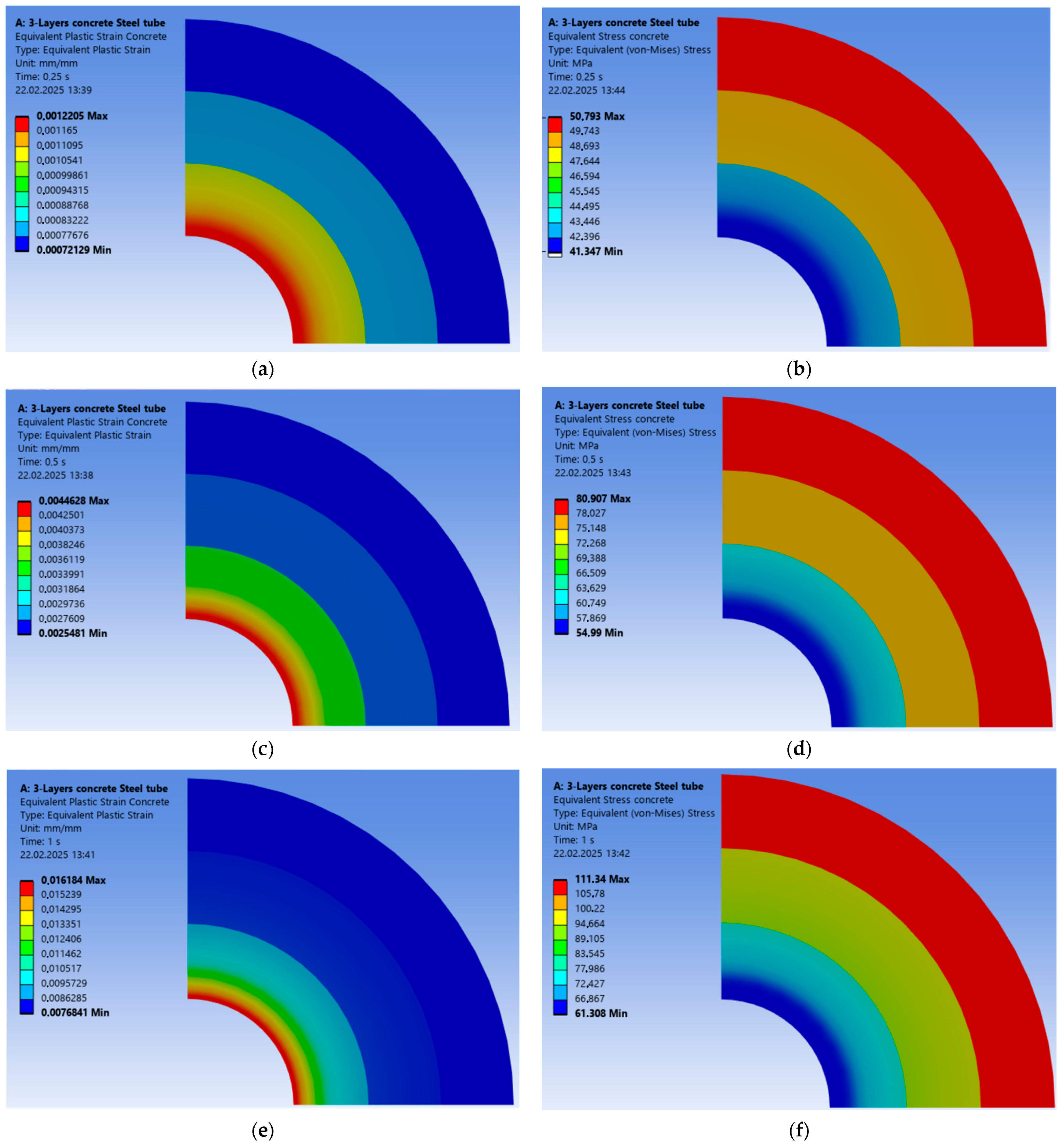

3.2. FEM Analysis

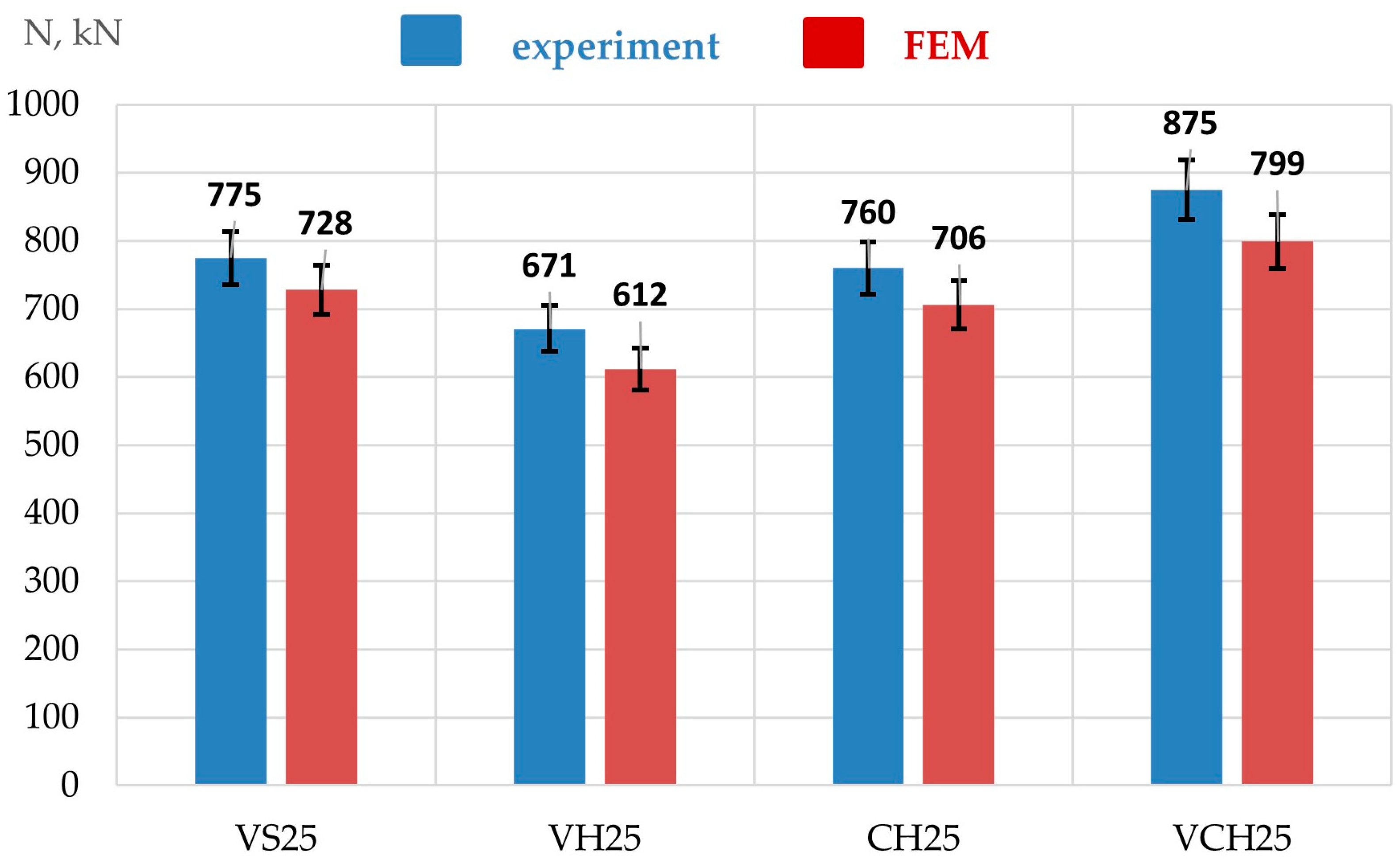

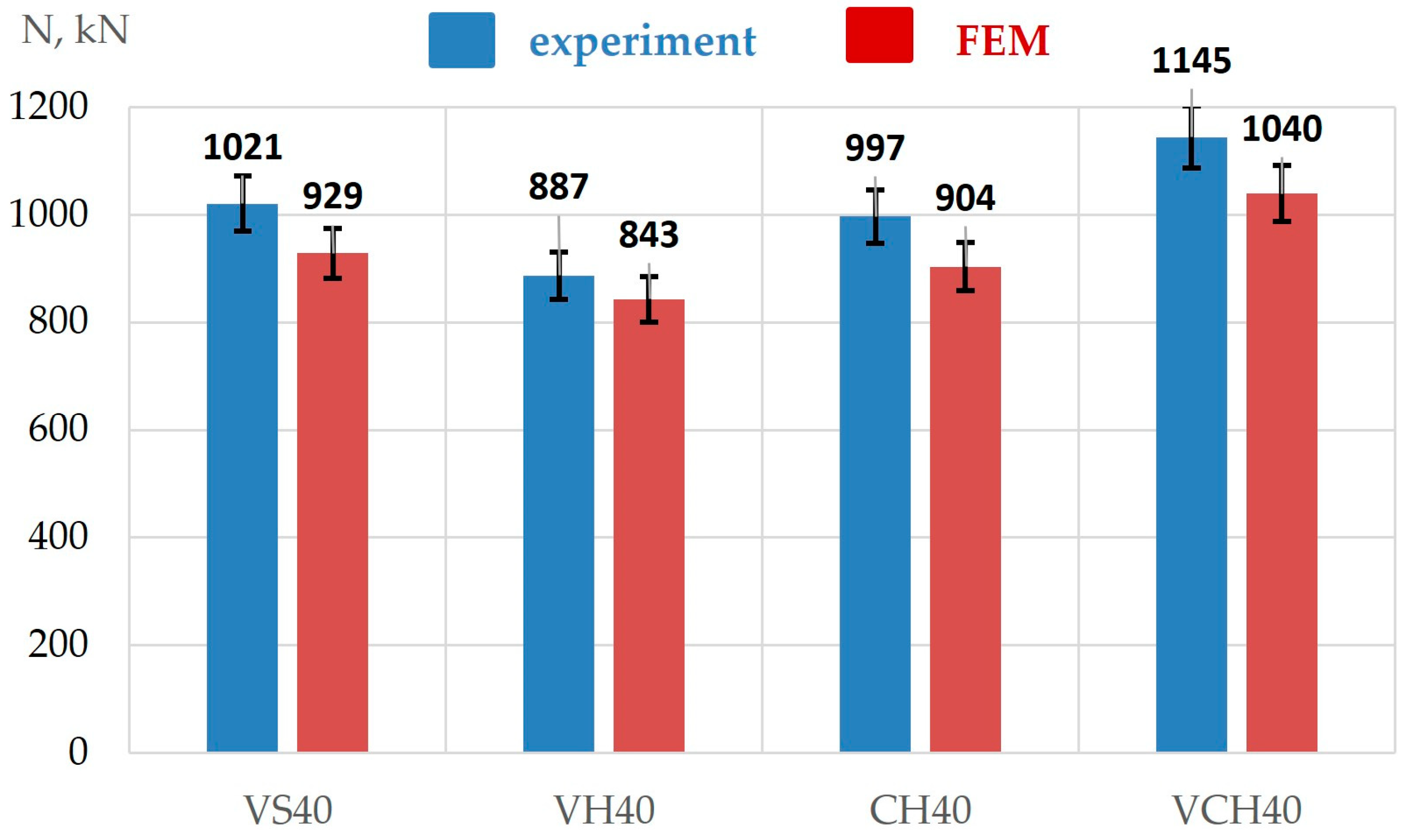

3.3. Bearing Capacity of Tube-Steel–Concrete Columns Manufactured Using Different Technologies

- -

- the bearing capacity of solid and hollow tube concrete columns manufactured using V technology for concrete grades B25, B30 and B40 was always lower in comparison with tube concrete columns manufactured using VC technology;

- -

- hollow centrifuged tube concrete columns had a higher bearing capacity in comparison with hollow vibrated columns, which were higher by up to 13.3%. In comparison with solid vibrated columns, their bearing capacity was lower by up to 2.4%, respectively;

- -

- hollow vibrocentrifuged tube concrete columns in comparison with samples of vibrated solid tube concrete columns had a bearing capacity value higher than 12.9%, and, in comparison with samples of hollow vibrated columns, higher than 30.4%.

4. Conclusions

- (1)

- Concrete of grades B25, B30 and B40, produced using the vibrocentrifugation technology, had the best strength properties. The compressive strength of centrifuged and vibrocentrifuged concrete of grades B25, B30 and B40 is on average 16.3% and 27.2% higher, respectively, than that of vibrated concrete. The axial compressive strength of centrifuged and vibrocentrifuged concrete is, on average, 15.7% and 26.4% higher, respectively, than that of vibrated concrete. The elastic modulus of centrifuged and vibrocentrifuged concrete is, on average, 15.1% and 26.4% higher, respectively, than that of vibrated concrete. Using centrifugal compaction technology ensures the formation of a pronounced heterogeneous structure in concrete samples of annular cross-section, where the outer layer is the densest and strongest because of the high content of coarse aggregate, the middle layer contains less coarse aggregate and a larger portion of cement-sand mortar, the inner layer is mainly represented by cement particles and water squeezed out of the outer layers, and is the least durable. This variatropic structure makes it possible to obtain composites with improved properties. When combining centrifugal compaction and vibration, the coarse aggregate is distributed most evenly between the middle and outer layers, due to which the effectiveness of the strength properties of concrete further increases.

- (2)

- A technology for manufacturing hollow tube concrete columns using the vibrocentrifugation method has been developed. Hollow vibrocentrifuged tube concrete columns have experimentally determined bearing capacity values of 875 kN for B25, which is 30.4% higher than the bearing capacity of a hollow vibrated tube concrete column, 1003 kN for B30 concrete, which is 28.9% higher, and 1145 kN for B40 concrete, which is 29.1% higher. The bearing capacity of centrifuged tube concrete columns is lower than that of solid vibrated columns by 1.9%, 2.1% and 2.4% for concrete grades B25, B30 and B40, respectively. The bearing capacity of vibrocentrifuged tube concrete columns is higher than that of solid vibrated tube concrete columns by 12.9%, 12.7% and 12.1% for concrete grades B25, B30 and B40, respectively.

- (3)

- All calculated values of the bearing capacity turned out to be less than the experimental values from 5.0% to 10.0%. There is a discrepancy between the experimental and calculated data, but in design calculation documents, such a discrepancy is acceptable and is controllable with the help of safety factors incorporated into the calculation methods.

- (4)

- The developed technology of vibrocentrifuging tube concrete products has several advantages. First, the weight of the structure is significantly reduced due to the production of a hollow concrete core. Second, the compression effect is achieved not by additional technological methods, but by the physical effect of centrifugal compaction.

- (5)

- The future direction of research is associated with the development of new types of vibrocentrifuged tube concrete columns with a hollow dispersion-reinforced concrete core and an expanded study of their deformation and strength properties.

- (6)

- The practical application of vibrocentrifuged tube concrete columns can be realized in the construction of civil and industrial buildings and structures, especially in areas with high seismic activity.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Ezzi, M.J.; Ayamsir, A.; Supian, A.B.M.; Beddu, S.; Al-Dala’ien, R.N. Flexural Behavior and Failure Modes of Pultruded GFRP Tube Concrete-Filled Composite Beams: A Review of Experimental and Numerical Studies. Buildings 2024, 14, 3966. [Google Scholar] [CrossRef]

- Kvocak, V.; Kanishchev, R.; Platko, P.; Hodovanets, E.; Al Ali, M. Stability of Steel Columns with Concrete-Filled Thin-Walled Rectangular Profiles. Sustainability 2023, 15, 16217. [Google Scholar] [CrossRef]

- Gershberg, O.A. Technology of Concrete and Reinforced Concrete Products; Stroiizdat: Moscow, Russia, 1971; p. 360. [Google Scholar]

- Zhang, Z.; Yang, Z.; Li, H.; Yang, W. Performance Analysis of the Structures Using Glass-Fiber-Reinforced-Polymer-Produced Hollow Internal Molds. Buildings 2024, 14, 1319. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, J.; Peng, K. The Potential of Multi-Task Learning in CFDST Design: Load-Bearing Capacity Design with Three MTL Models. Materials 2024, 17, 1994. [Google Scholar] [CrossRef] [PubMed]

- Gaidzhurov, P.P.; Volodin, V.A. Strength Calculation of the Coupling of the Floor Slab and the Monolithic Reinforced Concrete Frame Column by the Finite Element Method. Adv. Eng. Res. 2022, 22, 306–314. [Google Scholar] [CrossRef]

- Akhverdov, I.N. Reinforced Concrete Pressure Centrifuged Tubes; Stroyizdat: Moscow, Russia, 1967; p. 164. [Google Scholar]

- Krishan, A.L.; Astafeva, M.A.; Rimshin, V.I.; Shubin, I.L.; Stupak, A.A. Compressed Reinforced Concrete Elements Bearing Capacity of Various Flexibility. Lect. Notes Civ. Eng. 2022, 182, 283–291. [Google Scholar] [CrossRef]

- Krishan, A.; Troshkina, E.; Rimshin, V. Experimental Research of the Strength of Compressed Concrete Filled Steel Tube Elements. Adv. Intell. Syst. Comput. 2020, 1116, 560–566. [Google Scholar] [CrossRef]

- More, F.M.D.S.; Subramanian, S.S. Experimental Investigation on the Axial Compressive Behaviour of Cold-Formed Steel-Concrete Composite Columns Infilled with Various Types of Fibre-Reinforced Concrete. Buildings 2023, 13, 151. [Google Scholar] [CrossRef]

- Zhang, X.; Niu, J.; Qiao, S.; Luo, C.; Fan, Y.; Kuang, X.; Huang, Y. Study on Eccentric Compression Mechanical Characteristics of Basalt Fiber-Reinforced Recycled Aggregate Concrete-Filled Circular Steel Tubular Column. Coatings 2023, 13, 1923. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, C.; Wang, J.; Kuang, X.; Huang, Y. The Axial Compression Behavior of Basalt Fiber-Reinforced Recycled Aggregate Concrete-Filled Circular Steel-Tubular Column. Sustainability 2023, 15, 14351. [Google Scholar] [CrossRef]

- Xia, D.; Chang, W.; Li, B.; Gao, A.; Wu, F. Behaviour of steel-fibre-reinforced geopolymer concrete-filled square steel tubular stub column under axial compression. Structures 2024, 67, 107028. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, P.; Lu, Y.; Liu, Z. Hysteresis performance of steel fiber-reinforced high-strength concrete-filled steel tube columns. J. Constr. Steel Res. 2024, 219, 108755. [Google Scholar] [CrossRef]

- Mazhiev, K.N.; Mazhiev, K.K.; Panasenko, Y.V.; Mazhieva, A.K.; Mazhiev, A.K.; Mazhiev, A.K. Adhering to Regulatory Requirements in Calculation of Earthquake Resistance of the Structures of Life-Saving Buildings. Mod. Trends Constr. Urban Territ. Plan. 2024, 3, 17–29. [Google Scholar] [CrossRef]

- Bazhenov, Y.M.; Murtazaev, S.-A.; Bataev, D.-S.; Alaskhanov, A.H.; Murtazaeva, T.; Saydumov, M. High-strength concretes based on anthropogenic raw materials for earthquake resistant high-rise construction. Eng. Solid Mech. 2021, 9, 335–346. [Google Scholar] [CrossRef]

- Liu, B.; Zhang, L.; Feng, M.; Sun, H.; Chai, Y. Experimental Study of Rubber-Concrete-Filled CST Composite Column Under Axial Compression. Int. J. Steel Struct. 2022, 23, 247–262. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Zeng, W.; Ayough, P.; Ren, W.; Wang, W.; Loganathan, L.; Yap, S.P. Axial compression performance of rubberized concrete-filled steel tubular stub columns after fire exposure: Experimental investigation and calculation models. Constr. Build. Mater. 2024, 438, 137129. [Google Scholar] [CrossRef]

- Su, R.; Li, X.; Zhong, T.; Zhou, T. Axial behavior of novel CFDST columns with outer welded corrugated steel tubes. Structures 2021, 34, 2708–2720. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Y.; Elchalakani, M.; Fang, Y. Experimental behavior of concrete-filled corrugated steel tubular short columns under eccentric compression and non-uniform confinement. Eng. Struct. 2020, 220, 111009. [Google Scholar] [CrossRef]

- Šapalas, A.; Mudrov, A. Analysing the Confinement Effect in Hollow Core Steel-Concrete Composite Columns under Axial Compression. Materials 2021, 14, 6046. [Google Scholar] [CrossRef]

- Jing, C.; Zhao, L.; Wu, T.; Li, W. Experimental and Numerical Simulation of Reinforced Concrete-Filled Square GFRP Tubular Columns under Axial Compression. Materials 2024, 17, 2595. [Google Scholar] [CrossRef]

- Jiang, L.; Hong, Y.; Ji, J.; Liu, Y.; Zhang, Z.; Chu, X.; Ma, G. Bearing Behavior of Engineered Cementitious Composite and Ultra-High-Performance Concrete Filled-In Double Steel Tubular Composite Columns Subjected to Eccentrical Load. Buildings 2024, 14, 1487. [Google Scholar] [CrossRef]

- Liu, J.; Yu, W.; Fang, Y.; Pan, Z.; Cao, G. Finite Element Analysis on the Seismic Performance of Concrete-Filled Steel Tube Columns with a Multiple-Chamber Round-Ended Cross-Section. Buildings 2024, 14, 1154. [Google Scholar] [CrossRef]

- Wei, J.; Ying, H.; Yang, Y.; Zhang, W.; Bao, C. Experimental and numerical investigation of the seismic performance of concrete-filled steel tubular composite columns with UHPC plates. Structures 2023, 58, 10544. [Google Scholar] [CrossRef]

- Liao, J.; Asteris, P.G.; Cavaleri, L.; Mohammed, A.S.; Lemonis, M.E.; Tsoukalas, M.Z.; Skentou, A.D.; Maraveas, C.; Koopialipoor, M.; Armaghani, D.J. Novel Fuzzy-Based Optimization Approaches for the Prediction of Ultimate Axial Load of Circular Concrete-Filled Steel Tubes. Buildings 2021, 11, 629. [Google Scholar] [CrossRef]

- Chepurnenko, A.; Turina, V.; Akopyan, V. Artificial Neural Network Models for Determining the Load-Bearing Capacity of Eccentrically Compressed Short Concrete-Filled Steel Tubular Columns. CivilEng 2024, 5, 150–168. [Google Scholar] [CrossRef]

- Khan, K.; Biswas, R.; Gudainiyan, J.; Amin, M.N.; Qureshi, H.J.; Arab, A.M.A.; Iqbal, M. PCA-Based Hybrid Intelligence Models for Estimating the Ultimate Bearing Capacity of Axially Loaded Concrete-Filled Steel Tubes. Materials 2022, 15, 6477. [Google Scholar] [CrossRef]

- Le, T.T.; Chi Phan, H.; Duong, H.T.; Le, M.V. Optimal design of circular concrete-filled steel tubular columns based on a combination of artificial neural network, balancing composite motion algorithm and a large experimental database. Expert Syst. Appl. 2023, 223, 119940. [Google Scholar] [CrossRef]

- Faridmehr, I.; Nehdi, M.L.; Farokhi Nejad, A.; Sahraei, M.A.; Kamyab, H.R.; Kiyanets, A.V. An innovative multi-objective optimization approach for compact concrete-filled steel tubular (CFST) column design utilizing lightweight high-strength concrete. Int. J. Lightweight Mater. Manuf. 2024, 7, 405–425. [Google Scholar] [CrossRef]

- Hou, C.; Zhou, X.-G. Strength prediction of circular CFST columns through advanced machine learning methods. J. Build. Eng. 2022, 51, 104289. [Google Scholar] [CrossRef]

- Du, G.; Li, Z.; Song, G. A PVDF-Based Sensor for Internal Stress Monitoring of a Concrete-Filled Steel Tubular (CFST) Column Subject to Impact Loads. Sensors 2018, 18, 1682. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, H.; Zheng, X.; Gao, S. Axial Compressive Behaviours of Coal Gangue Concrete-Filled Circular Steel Tubular Stub Columns after Chloride Salt Corrosion. Materials 2024, 17, 2782. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hu, S. Experimental Investigation on the Response of Elliptical CFT Columns Subjected to Lateral Impact Loading. Buildings 2022, 12, 1847. [Google Scholar] [CrossRef]

- Tao, Z.; Hasan, M.M.; Han, D.; Qin, Q.; Abdul Ghafar, W. Study of the Axial Compressive Behaviour of Cross-Shaped CFST and ST Columns with Inner Changes. Buildings 2023, 13, 423. [Google Scholar] [CrossRef]

- Hasan, M.M.; Tao, Z.; Ghafar, W.A.; Huangfu, S.-E.; Zhang, Z. Investigating the axial compressive behavior of cruciform CFST columns: An experimental study. Structures 2024, 69, 107538. [Google Scholar] [CrossRef]

- Han, D.; Tao, Z.; Abdul Ghafar, W.; Hasan, M.M.; Xiao, W.; Wang, T.; Zhou, K.; Dai, H. Experimental Study on the Seismic Performance of L-Shaped CFST Columns in Different Combinations. Buildings 2023, 13, 2320. [Google Scholar] [CrossRef]

- Su, J.; Zhao, Q.; Cai, L.; Li, X.; Pu, H.; Dai, W.; Zhang, J.; Lu, D.; Liu, F. Feasibility of Recycled Aggregate Concrete in a Novel Anchoring Connection for Beam-to-Concrete-Filled Steel Tube Joints. Buildings 2024, 14, 1178. [Google Scholar] [CrossRef]

- Zheng, W.; Xu, B.; Xia, Z.; Wang, J.; Liu, J.; Yao, Y.; Wang, Y. A Concrete Core Void Imaging Approach and Parameter Analysis of Concrete-Filled Steel Tube Members Using Travel Time Tomography: Multi-Physics Simulations and Experimental Studies. Sensors 2024, 24, 2503. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Liu, Y.; Cheng, Q.; Sun, Z. Seismic Vulnerability Analysis of Concrete-Filled Steel Tube Structure under Main–Aftershock Earthquake Sequences. Buildings 2024, 14, 869. [Google Scholar] [CrossRef]

- Ovsyankin, V.I. Reinforced Concrete Tubes for Pressure Water Conduits; Stroyizdat: Moscow, Russia, 1971; p. 320. [Google Scholar]

- GOST 1577-2022; Rolled Sheets and Wide Strips of Structural Quality Steel. Specifications. Russian Institute of Standardization: Moscow, Russia, 2024. Available online: https://docs.cntd.ru/document/1300390693 (accessed on 10 February 2025).

- GOST R 70306-2022; Centrifugated Reinforced Concrete Posts of Annular Section for Industrial Buildings and Structures. Specifications. Russian Standardization Institute: Moscow, Russia, 2022. Available online: https://docs.cntd.ru/document/1200192844 (accessed on 14 March 2025).

- VSN 1-90; Fabrication Requirements for Centrifugal-Cast Support Pillars for Contact Lines, Communications Lines, and Lock-Out Systems. USSR Mintransstroy: Moscow, Russia, 1990. Available online: https://www.gostrf.com/normadata/1/4294851/4294851029.pdf (accessed on 3 February 2025).

- GOST 27006-2019; Concretes. Rules for Mix Proposing. Standartinform: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200165762 (accessed on 3 February 2025).

- Stel’makh, S.A.; Kholodnyak, M.G.; Shcherban’, E.M.; Nazhuev, M.P.; Chernil’nik, A.A. Device for the Manufacture of Products from Centrifuged Concrete. Russian Federation Patent RU 192 492 U1, 23 May 2019. Available online: https://yandex.ru/patents/doc/RU192492U1_20190918 (accessed on 16 March 2025).

- Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Smolyanichenko, A.S.; Chernil’nik, A.; Elshaeva, D.; Beskopylny, N. Influence of Polymer Fibers on the Structure and Properties of Modified Variatropic Vibrocentrifuged Concrete. Polymers 2024, 16, 642. [Google Scholar] [CrossRef]

- EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/811a0cf3-55e3-495a-b06e-5c302d5f2806/en-12390-7-2019 (accessed on 3 February 2025).

- GOST 10180-2012; Concretes. Methods for Strength Determination Using Reference Specimens. Standartinform: Moscow, Russia, 2018. Available online: https://docs.cntd.ru/document/1200100908 (accessed on 3 February 2025).

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements of Specimens and Moulds. iTeh Standards: Etobicoke, ON, Canada, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/d1c9ccee-2e5a-425e-a964-961da95d2f99/en-12390-1-2021 (accessed on 3 February 2025).

- EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/ae7e6a86-1cbc-455e-8b2a-8964be9087f9/en-12390-2-2019 (accessed on 3 February 2025).

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 3 February 2025).

- EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/10b1c613-819b-42d7-8f94-480cd37a666a/en-12390-4-2019 (accessed on 3 February 2025).

- GOST 24452-2023; Concretes. Methods for Determination of Prismatic Compressive Strength, Modulus of Elasticity and Poisson’s ratio. Standartinform: Moscow, Russia, 2024. Available online: https://docs.cntd.ru/document/1304463277 (accessed on 3 February 2025).

- Betz, P.; Curosu, V.; Loehnert, S.; Marx, S.; Curbach, M. Gradeification of Multiaxial Behaviour of Fine-Grained Concrete for the Calibration of a Microplane Plasticity Model. Buildings 2023, 13, 2704. [Google Scholar] [CrossRef]

- Nastri, E.; Todisco, P. Macromechanical Failure Criteria: Elasticity, Plasticity and Numerical Applications for the Non-Linear Masonry Modelling. Buildings 2022, 12, 1245. [Google Scholar] [CrossRef]

- Bilal, K.A.; Mahamid, M.; Hariri-Ardebili, M.A.; Tort, C.; Ford, T. Parameter Selection for Concrete Constitutive Models in Finite Element Analysis of Composite Columns. Buildings 2023, 13, 1759. [Google Scholar] [CrossRef]

- Luo, H.; Zhang, S.; Sun, M.; Gong, S.; Hu, C. Large-Deformation Modeling of Surface Instability and Ground Collapse during Tunnel Excavation by Material Point Method. Buildings 2024, 14, 2414. [Google Scholar] [CrossRef]

- Zhou, L.; Deng, Z.; Ren, J.; Zhu, Y. Structural Effects on Compressive Strength Enhancement of Cellular Concrete During the Split Hopkinson Pressure Bar Test. Materials 2025, 18, 552. [Google Scholar] [CrossRef]

- Peng, S.; Li, Z.; Cheng, H.; Xu, Y.; Zhang, T.; Cao, G. Mechanical Response Characteristics and Tangent Modulus Calculation Model of Expansive-Clay Unloading Stress Path. Buildings 2024, 14, 2497. [Google Scholar] [CrossRef]

- Telichko, V.; Slavcheva, G.; Levchenko, A. Finite elements procedure for modelling mechanichal behaviour of layered 3D printed concrete elements with experimental validation. J. Build. Rehabil. 2024, 9, 151. [Google Scholar] [CrossRef]

- Korolev, E.V.; Bazhenov, Y.M.; Smirnov, V.A. Building Materials of Variatropic Frame Structure; National Research Moscow State University of Civil Engineering: Moscow, Russia, 2011; p. 304. [Google Scholar]

- Kliukas, R.; Lukoševičienė, O.; Jaras, A.; Jonaitis, B. The Mechanical Properties of Centrifuged Concrete in Reinforced Concrete Structures. Appl. Sci. 2020, 10, 3570. [Google Scholar] [CrossRef]

- Kaufmann, J.; Hesselbarth, D. High performance composites in spun-cast elements. Cem. Concr. Compos. 2007, 29, 713–722. [Google Scholar] [CrossRef]

- Völgyi, I.; Farkas, G.; Nehme, S.G. Concrete strength tendency in the wall of cylindrical spun-cast concrete elements. Period. Polytech. Civ. Eng. 2010, 54, 23–30. [Google Scholar] [CrossRef]

- Kliukas, R.; Jaras, A.; Lukoševičienė, O. Reinforced Spun Concrete Poles—Case Study of Using Chemical Admixtures. Materials 2020, 13, 302. [Google Scholar] [CrossRef]

- Indriūnas, S.; Kliukas, R.; Juozapaitis, A. Behavioral Analysis of a Mast with a Combined Prestressed Stayed Columns System and Core of a Spun Concrete Circular Cross-Section. Buildings 2023, 13, 2175. [Google Scholar] [CrossRef]

- Kudzys, A.; Kliukas, R. Probability-based design of spun concrete beam-columns. J. Civ. Eng. Manag. 2010, 16, 451–461. [Google Scholar] [CrossRef]

- Feng, B.; Zhu, Y.-H.; Xie, F.; Chen, J.; Liu, C.-B. Experimental Investigation and Design of Hollow Section, Centrifugal Concrete-Filled GFRP Tube Columns. Buildings 2021, 11, 598. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Smolyanichenko, A.S.; Chernil’nik, A.A.; Elshaeva, D.M.; Beskopylny, N.A. Structure and Properties of Variatropic Concrete Combined Modified with Nano- and Micro-silica. Constr. Mater. Prod. 2024, 7, 3. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; El’shaeva, D. Influence of the Chemical Activation of Aggregates on the Properties of Lightweight Vibrocentrifuged Fiber-Reinforced Concrete. J. Compos. Sci. 2022, 6, 273. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Mailyan, A.L.; Shcherban’, N.; Chernil’nik, A.; Elshaeva, D. Composition and Properties of Lightweight Concrete of Variatropic Structure Based on Combined Aggregate and Microsilica. Buildings 2025, 15, 346. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Zherebtsov, Y.V.; Al-Tulaikhi, M.M. Researches of physicomechanical and design characteristics of vibrated, centrifuged and vibrocentrifuged concretes. Adv. Eng. Res. 2021, 21, 5–13. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Smolyanichenko, A.S.; Chernil’nik, A.; Elshaeva, D.; Beskopylny, N. Analytical Review of the Current State of Technology, Structure Formation, and Properties of Variatropic Centrifugally Compacted Concrete. Materials 2024, 17, 1889. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; El’shaeva, D.; Kotenko, M. The Investigation of Compacting Cement Systems for Studying the Fundamental Process of Cement Gel Formation. Gels 2022, 8, 530. [Google Scholar] [CrossRef]

- Wei, J.; Xie, Z.; Zhang, W.; Luo, X.; Yang, Y.; Chen, B. Experimental study on circular steel tube-confined reinforced UHPC columns under axial loading. Eng. Struct. 2021, 230, 111599. [Google Scholar] [CrossRef]

- Tokgoz, S. Tests on plain and steel fiber concrete-filled stainless steel tubular columns. J. Constr. Steel Res. 2015, 114, 129–135. [Google Scholar] [CrossRef]

- Zhao, B.; Xie, B.; Xu, Z.; Wang, F.; Gao, Y. Study on Fire Temperature Field in Small-Section Steel-Shell Concrete Immersed Tube Tunnel Structure Based on CFD-FEM Method. Materials 2025, 18, 187. [Google Scholar] [CrossRef] [PubMed]

- Kim, D.; Jeon, C.-H.; Park, K.-T. Cyclic Performance of Prefabricated Bridge Piers with Concrete-Filled Steel Tubes and Improved Bracing Connection Detail. Appl. Sci. 2024, 14, 11810. [Google Scholar] [CrossRef]

- Han, X.; Wei, D.; Wang, P.; Wang, M.; Du, Z.; Ling, Z. Microstructure characteristics and evolution of tube pile concrete under centrifugation and steam curing. Constr. Build. Mater. 2024, 450, 138554. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Veremeenko, A.; Shilov, A.V.; Ananova, O.; Karalar, M.; Aksoylu, C.; Onuralp Özkılıç, Y. Modeling and Calculation of Improved Centrifuged Reinforced Concrete Columns with Variatropic Structure. Buildings 2023, 13, 2005. [Google Scholar] [CrossRef]

| Raw Material | Indicator | Value |

|---|---|---|

| PC | Fineness of grinding (residue on the sieve No. 008) (%) | 3.9 |

| Uniformity of volume change (expansion) (mm) | 0 | |

| Setting times (min) - start - end | 115 220 | |

| Compressive strength at 2 (28) days (MPa) | 14.6 (50.1) | |

| CrS | Bulk density (kg/m3) | 1497 |

| Density (kg/m3) | 2700 | |

| Resistance to fragmentation (wt %) | 10.6 | |

| The content of lamellar and acicular grains (wt %) | 6.6 | |

| QS | Bulk density (kg/m3) | 1400 |

| Density (kg/m3) | 2600 | |

| Dust and clay particles (%) | 0.07 | |

| Clay in lumps (%) | 0 | |

| Organic and contaminant content (%) | No |

| Concrete Grade | Concrete Type | Concrete Mixture Proportion Per 1 m3 | Slump (cm) | Mixture Density (kg/m3) | |||

|---|---|---|---|---|---|---|---|

| PC (kg/m3) | W (L/m3) | CrS (kg/m3) | QS (kg/m3) | ||||

| B25 | VC | 325 | 195 | 1094 | 690 | 3.5 | 2304 |

| CC и VCC | 380 | 190 | 1139 | 689 | 3.0 | 2386 | |

| B30 | VC | 358 | 192 | 1083 | 673 | 3.0 | 2306 |

| CC и VCC | 392 | 190 | 1128 | 684 | 3.0 | 2399 | |

| B40 | VC | 439 | 200 | 1061 | 640 | 3.5 | 2340 |

| CC и VCC | 492 | 200 | 1109 | 673 | 3.0 | 2474 | |

| Sample Marking | Concrete Grade | Geometrical Characteristics | ||||

|---|---|---|---|---|---|---|

| Steel Shell | Concrete Core | |||||

| Outer Diameter (D), mm | Inner Diameter (d), mm | Wall Thickness (t), mm | Outer Diameter (D0), mm | Inner Diameter (d0), mm | ||

| VS25 | B25 | 102 | 96 | 3 | 96 | – |

| VH25 | 102 | 96 | 3 | 96 | 32 | |

| CH25 | 102 | 96 | 3 | 96 | 32 | |

| VCH25 | 102 | 96 | 3 | 96 | 32 | |

| VS30 | B30 | 102 | 96 | 3 | 96 | – |

| VH30 | 102 | 96 | 3 | 96 | 32 | |

| CH30 | 102 | 96 | 3 | 96 | 32 | |

| VCH30 | 102 | 96 | 3 | 96 | 32 | |

| VS40 | B40 | 102 | 96 | 3 | 96 | – |

| VH40 | 102 | 96 | 3 | 96 | 32 | |

| CH40 | 102 | 96 | 3 | 96 | 32 | |

| VCH40 | 102 | 96 | 3 | 96 | 32 | |

| ∆R (%) | B25 | B30 | B40 | ||||||

| CC > VC | VCC > VC | VCC > CC | CC > VC | VCC > VC | VCC > CC | CC > VC | VCC > VC | VCC > CC | |

| 15.4 | 26.7 | 9.8 | 17.2 | 27.7 | 9.0 | 16.4 | 27.3 | 9.4 | |

| ∆Rb (%) | B25 | B30 | B40 | ||||||

| CC > VC | VCC > VC | VCC > CC | CC > VC | VCC > VC | VCC > CC | CC > VC | VCC > VC | VCC > CC | |

| 15.1 | 25.1 | 8.7 | 15.5 | 26.3 | 9.3 | 16.3 | 27.8 | 9.9 | |

| ∆Eb (%) | B25 | B30 | B40 | ||||||

| CC > VC | VCC > VC | VCC > CC | CC > VC | VCC > VC | VCC > CC | CC > VC | VCC > VC | VCC > CC | |

| 14.1 | 25.6 | 10.1 | 16.0 | 27.2 | 9.6 | 15.3 | 26.4 | 9.6 | |

| ∆N (%) | B25 | B30 | B40 | |||||||||

| VS | VH | CH | VCH | VS | VH | CH | VCH | VS | VH | CH | VCH | |

| 6.1 | 8.8 | 7.1 | 8.7 | 10.0 | 9.5 | 8.0 | 9.1 | 9.0 | 5.0 | 9.3 | 9.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shcherban’, E.M.; Beskopylny, A.N.; Stel’makh, S.A.; Mailyan, L.R.; Panfilov, I.A.; Mailyan, A.L.; Shcherban’, N.; Vialikov, I.; Elshaeva, D.; Chernilnik, A. The Impact of Manufacturing Technology on the Tube-Steel Concrete Columns Bearing Capacity Under Axial Load. Buildings 2025, 15, 950. https://doi.org/10.3390/buildings15060950

Shcherban’ EM, Beskopylny AN, Stel’makh SA, Mailyan LR, Panfilov IA, Mailyan AL, Shcherban’ N, Vialikov I, Elshaeva D, Chernilnik A. The Impact of Manufacturing Technology on the Tube-Steel Concrete Columns Bearing Capacity Under Axial Load. Buildings. 2025; 15(6):950. https://doi.org/10.3390/buildings15060950

Chicago/Turabian StyleShcherban’, Evgenii M., Alexey N. Beskopylny, Sergei A. Stel’makh, Levon R. Mailyan, Ivan A. Panfilov, Alexander L. Mailyan, Natalya Shcherban’, Ivan Vialikov, Diana Elshaeva, and Andrei Chernilnik. 2025. "The Impact of Manufacturing Technology on the Tube-Steel Concrete Columns Bearing Capacity Under Axial Load" Buildings 15, no. 6: 950. https://doi.org/10.3390/buildings15060950

APA StyleShcherban’, E. M., Beskopylny, A. N., Stel’makh, S. A., Mailyan, L. R., Panfilov, I. A., Mailyan, A. L., Shcherban’, N., Vialikov, I., Elshaeva, D., & Chernilnik, A. (2025). The Impact of Manufacturing Technology on the Tube-Steel Concrete Columns Bearing Capacity Under Axial Load. Buildings, 15(6), 950. https://doi.org/10.3390/buildings15060950