Sustainable Earthen Construction: A Meta-Analytical Review of Environmental, Mechanical, and Thermal Performance

Abstract

1. Introduction

| Earth Construction Techniques | Description | Attributes | Performance | Refs. | |

|---|---|---|---|---|---|

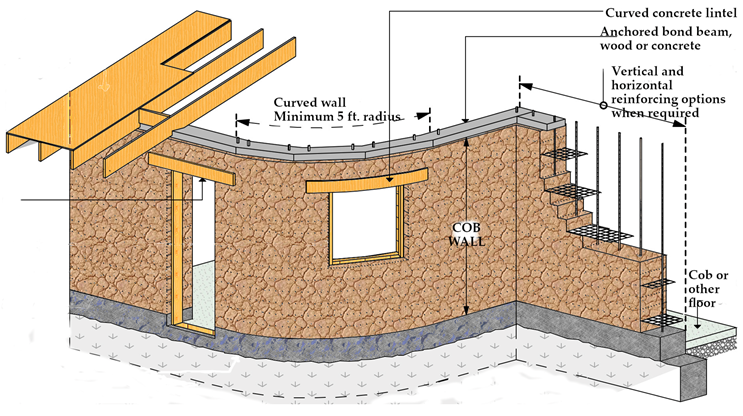

Adapted from: [28] | Cob | Technique of wet soil accumulation without formwork. The mixture of clay and straw is compacted in successive layers directly on the site, creating solid walls with high thermal mass. | Advantages: excellent thermal mass and energy efficiency. Disadvantages: time-consuming and labor-intensive. | Good compressive strength and high thermal mass but limited in tension without reinforcement. | [29,30] |

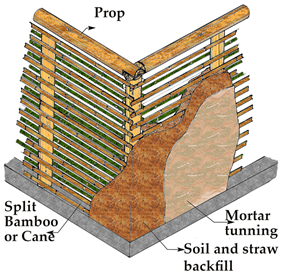

Adapted from: [31] | Daub and wattle | Traditional system that combines woven wood as a structure and mud as a filler, offering an economical construction that can be quickly implemented in rural areas. | Advantages: economical and easy to implement. Disadvantages: low durability without proper maintenance. | Good dynamic performance with medium compressive strength, but sufficient for light applications and non-load-bearing walls. | [32] |

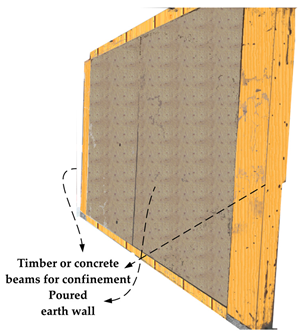

| Poured Earth | A recent technique that involves wet earth, with aggregates and gypsum, with a consistency like concrete, poured into molds, forming monolithic walls once dry. The technique is fast and versatile, although less used in modern construction. | Advantages: fast and adaptable to different shapes. Disadvantages: less availability of technical knowledge and specific materials. | Adequate strength for non-load-bearing structures. However, it depends on the soil mix, drying process, and additives. | [9,33] |

Adapted from: [34] | Adobe | Sun-dried clay blocks prepared from a mixture of clay, sand, and water. This method is ideal for dry climates and allows for an adaptable and environmental construction system. | Advantages: low cost and accessibility of materials. Disadvantages: limited resistance to moisture without treatment. | Low compressive strength in dry conditions, vulnerable to moisture without treatment. | [35,36] |

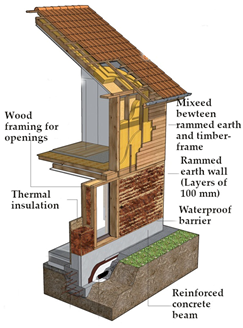

Adapted from: [37] | Rammed Earth Walls (REWs) | A construction method in which the soil is compacted in successive layers within formwork, generating robust, high-density structures that offer great strength and durability. | Advantages: great durability and resistance. Disadvantages: needs machinery for adequate compaction. | High compressive strength and durability, suitable for stable load-bearing structures. | [38,39] |

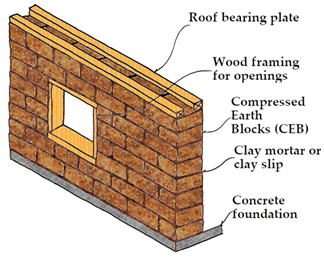

Adapted from: [40] | Compressed Earth Blocks (CEBs) | Compacted earth blocks in molds are used similarly to conventional bricks, combining earth and, sometimes, stabilizers to achieve a modular and energy-efficient structure. | Advantages: modular and easy to replicate. Disadvantages: less insulation than other techniques. | High compressive strength in individual blocks, usually used as a partition material, modularity allows fast construction. | [38,39] |

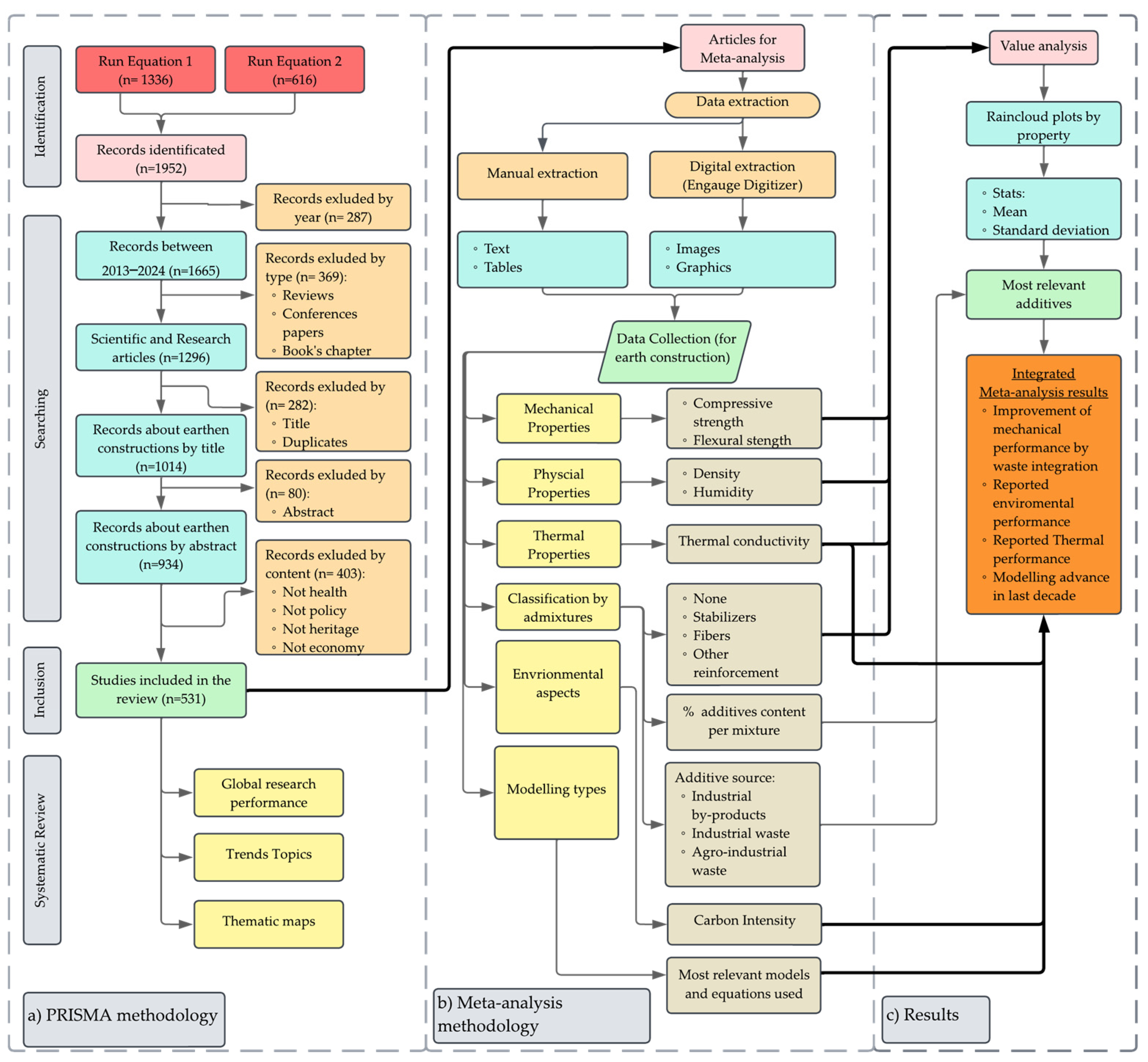

2. Materials and Methods

2.1. Search Query

| Adobe ID | Search Focus | Search Equation | Rationale and Keyword Justification |

| 1 | Mechanical and Structural Performance of Earthen Materials | (“rammed earth” OR adobe OR “mudbrick” OR “compressed earth blocks” OR CEB) AND (“compressive strength” OR “flexural strength” OR “shear strength” OR “tensile strength” OR “ductility” OR “elastic modulus” OR “stress-strain behavior” OR “load-bearing capacity” OR “seismic resistance” OR “dynamic response” OR “cyclic loading” OR “pseudostatic testing” OR “thermal performance” OR “hygrothermal properties” OR “push-over analysis” OR “pull-out strength” OR “fatigue behavior”) | This equation captures studies investigating the **mechanical, structural, and dynamic behavior** of earthen construction materials, including **compressive and flexural strength**, **seismic performance**, **thermal and hygrothermal properties**, and **experimental methodologies** such as **push-pull tests and pseudostatic testing**. |

| 2 | Sustainability and Environmental Impact of Earthen Construction | (“rammed earth” OR adobe OR “mudbrick” OR “compressed earth blocks” OR CEB) AND (“ecological industries” OR “life cycle assessment” OR “embodied carbon” OR “carbon footprint” OR “sustainable construction” OR “environmental performance” OR “energy efficiency” OR “resource efficiency” OR “circular economy” OR “low-impact materials” OR “green building materials”) | This equation is designed to retrieve research that evaluates the **sustainability aspects** of earthen construction, including **carbon footprint, life cycle analysis, energy efficiency, and circular economy principles** in the context of eco-friendly construction. |

2.2. Selection Criteria and Data Cleaning

2.3. Organization, Data Structure, and Data Analysis

2.4. Information Processing with Specialized Software

2.5. Meta-Analysis

3. Results and Discussion

3.1. Overview of Earth Construction

| Standard/Country/Year | Earth Technique | Additive Types and Content | Physical–Mechanical Requirements | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Type of Soil | Humidity | Density (kg/m3) | Water Absorption (%) | Compressive Strength (MPa) | Flexural Strength (MPa) | Ref. | |||

| NBR 8491 /Brazil/1986 | CEBs | 6–12% cement | 100% pass 4.75 mm, 10–50% pass 0.075 mm, IP ≤ 18%. | Optimum moisture proctor test | - | ≤20% | ≥2.0 | - | [54] |

| NBR 10833 /Brazil/1989 | CEBs | 6–10% cement | 100% pass 4.75 mm, 10–50% pass 0.075 mm, LL ≤ 45%; IP 18%. | - | ≤20% | ≥2.0 | - | [55] | |

| NBR 13553 /Brazil/1996 | REWs | 6–12% cement, 2–8% lime, 10–30% fly ash, 15–40% blast furnace slag, 5–20% silicates, 0.5–2% chlorides, 0.2–2% natural fibers | 100% pass 4.75 mm, 15–50% pass 0.075 mm, LL ≤ 45%; IP 18%. | - | ≤20% | ≥1.0 MPa | - | [76] | |

| NTC 5324 /Colombia/2004 | CEBs | No specified cement content | 75–50% pass 4.75 mm, 15–18% pass 0.075 mm, LL ≤ 45%; IP 18%. | 1800–2100 | 12–15% | 1.0–6.0 | - | [57] | |

| NMAC 14.7.4 /EEUU/2004 | Adobe, REWs and CEBs | 6% cement | No specified soil type, % soluble salts. | ≤10% | - | - | ≥2.0 | ≥0.345 | [58] |

| UNE E 41410 /Spain/2008 | CEBs | Max 6% cement, lime, or gypsum. | 0–15% retain 2 mm, 50–75% between 2 mm and 0.075 mm, 10–25% between 0.075 mm and 0.002 mm, and 10–20% pass 0.002 mm. | Optimum moisture proctor test | - | - | 1.0–5.0 | - | [77] |

| IS 2110 /India/1980 | REWs | 2.5–3.5% cement | ≥35% pass 4.75 mm, IP 5.3–10.5%, LL ≤ 27. | ≥1800 | - | 0.7–1.4 | - | [78] | |

| NTE E 0.80 /Peru/1979 | REWs and Adobe | 16% straw | 30–40% pass 4.75 mm, 20–30% pass 0.075 mm. | - | - | 0.6 | ≥0.14 | [79] | |

| NTP 331.202 /Peru/1979 | Adobe | 0.5–4% asphalt | - | - | ≤20% | ≥1.2 | ≥0.5 | [80] | |

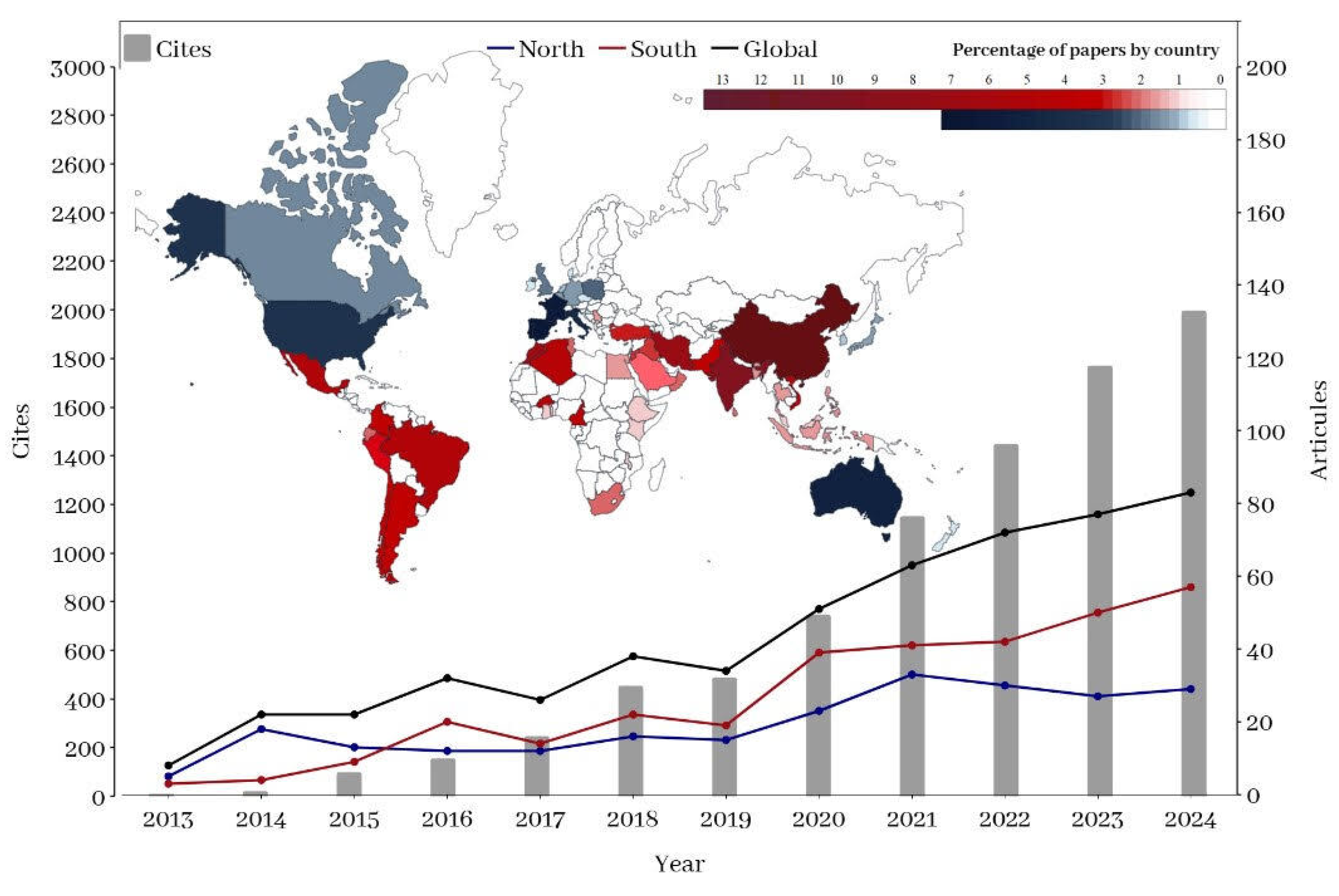

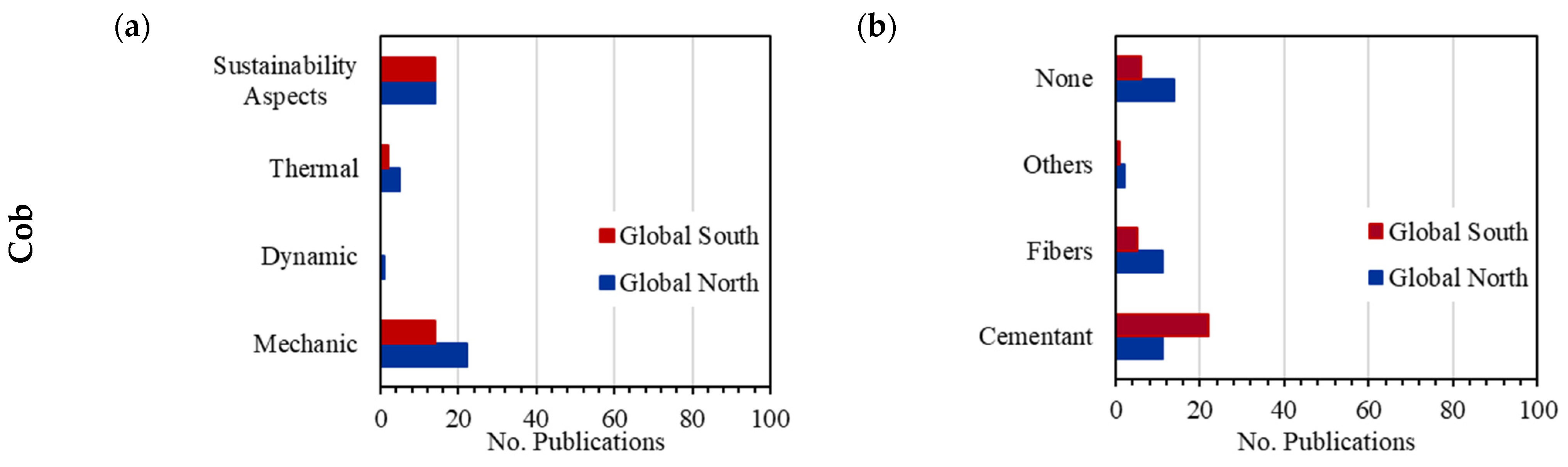

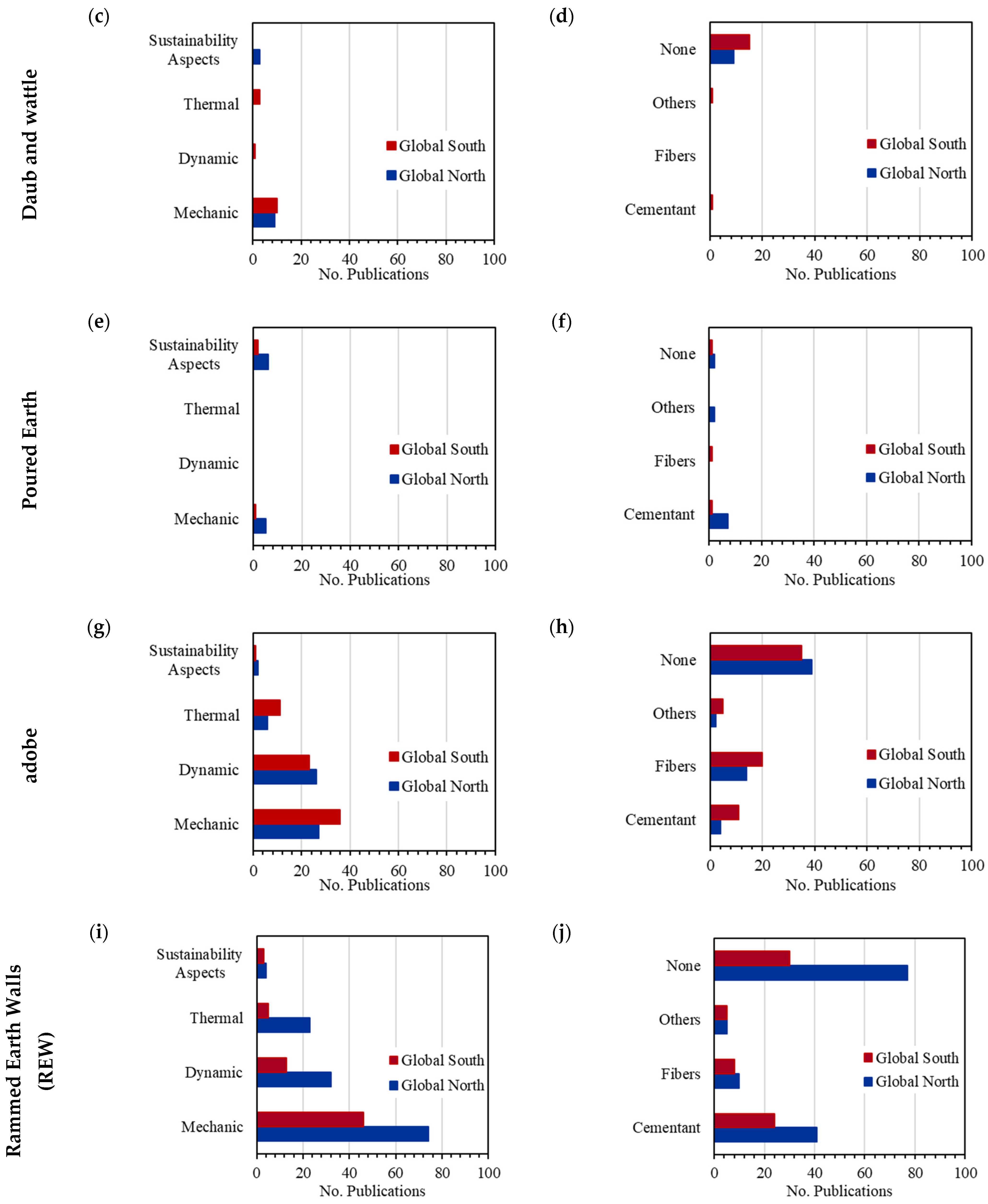

3.2. Global Intellectual Productivity Scenario: Global North (GN) and Global South (GS) Regions

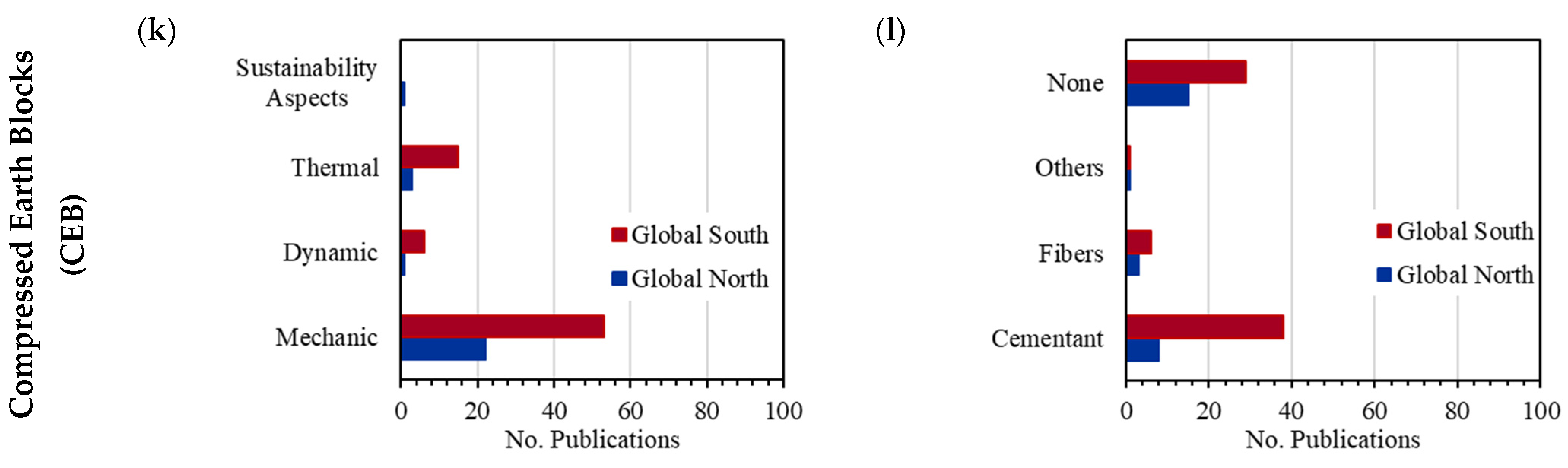

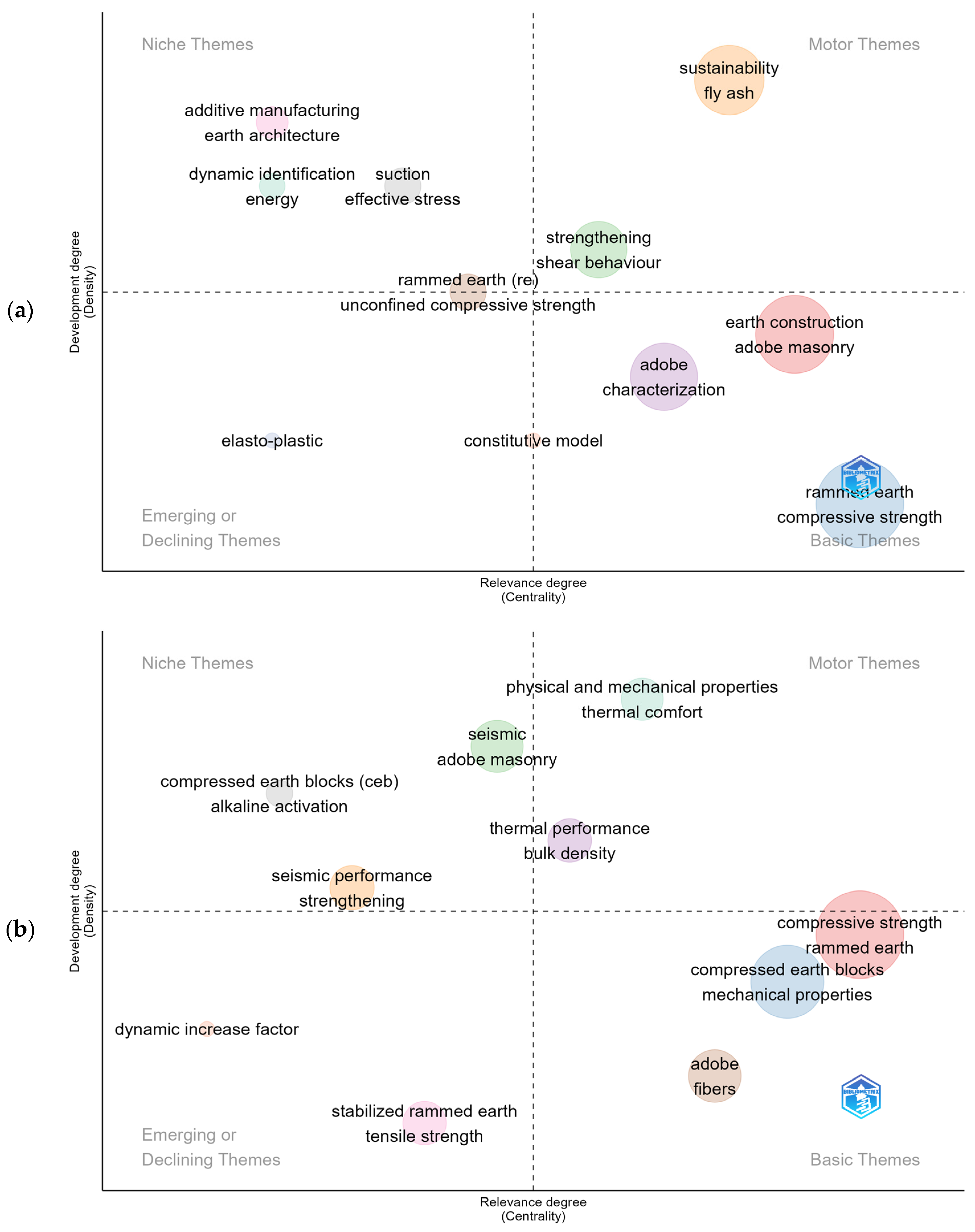

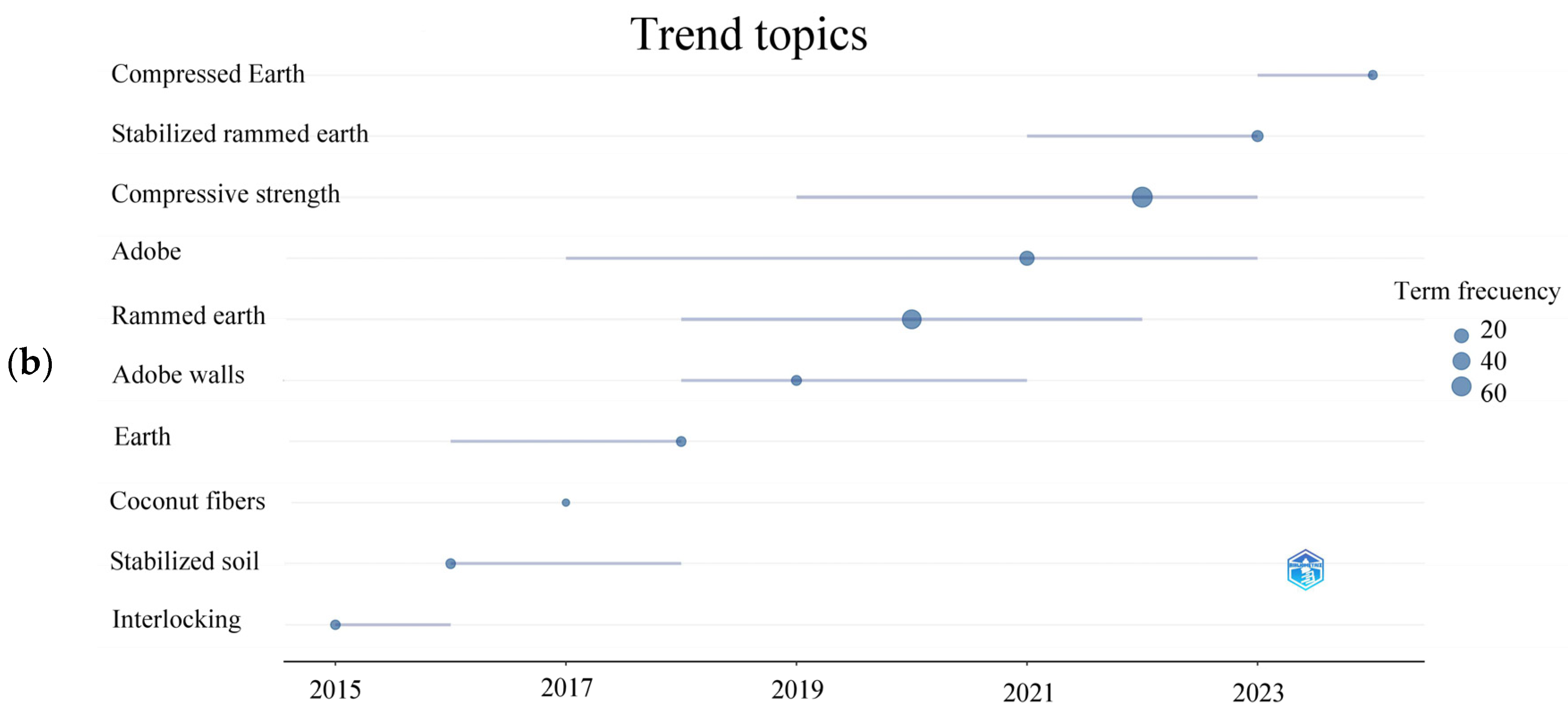

3.3. Research Trends on Earthen Constructions in the World

3.4. Environmental Performance of Earth as a Material

3.4.1. Environmental Performance of Earthen Constructions

| Earth Technique | Additive Content | Density (kg/m3) | Carbon Intensity (kg CO2/kg) | Carbon Intensity (kg CO2/m3) | Carbon Intensity (kg CO2/m2 of Floor Area, 20 cm Thickness) | Ref. |

|---|---|---|---|---|---|---|

| Cob | 0% | 1600–1800 | 0.022–0.025 | 40–44 | 8–9 | [153] |

| Daub and Wattle | 0% | 1200–1400 | 0.018–0.023 | 25–28 | 5–6 | [153] |

| Poured Earth | 0% | 1800–2000 | 0.095–0.011 | 19–20 | 4–5 | [153] |

| Adobe | 0% | 1600–1800 | 0.023–0.028 | 42–45 | 8–9 | [85,155] |

| Rammed Earth | 0% | 1900–2200 | 0.010–0.015 | 25–35 | 5–7 | [3] |

| Rammed Earth Stabilized (Cement) | 8–10% | 1900–2200 | 0.072–0.090 | 140–200 | 28–40 | [24] |

| Rammed Earth Stabilized (Fly Ash) | 8–10% | 1900–2200 | 0.02–0.045 | 75–95 | 15–19 | [24] |

| CEB | 0% | 1800–2000 | 0.014–0.017 | 28–30 | 5–6 | [3] |

| CEB Stabilized (Cement) | 10% | 1800–2000 | 0.082–0.095 | 165–172 | 33–34 | [3,156] |

| Cinder Block (Cement) | 10% | 1800–2000 | 0.085–0.097 | 170–175 | 34–35 | [153] |

3.4.2. Industrial and Agro-Industrial By-Products as the Key to the Future of Earthen Construction

| Type of Aggregate | Adobe | CEB | REW | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Additive | Industrial Waste | Ref. | Additive | Industrial Waste | Ref. | Additive | Industrial Waste | Ref. | |

| Fibers | Polypropylene | ⁂ | [94] | Polypropylene | ⁂ | [119] | Waste Tire Textile Fibers (WTTFs) | ✓ | [165] |

| Polytene | ⁂ 1 | [166] | - | - | - | Polypropylene | ⁂ | [167] | |

| Textile | ✓ | [95] | - | - | - | Wool | ⁂ | [130] | |

| Rubber | ✓ | [168] | - | - | - | Textile | ✓ | [169] | |

| GRPF | ⁂ | [20] | - | - | - | Glass Fiber | - | [170] | |

| Stabilizers | Fly Ash | ⁂ | [17] | Cement | ⁂ | [171] | Cement | ⁂ | [172] |

| Paper and Paper Plasters | ⁂ | [99] | Lime | ⁂ | [163] | Lime | ⁂ | [172] | |

| Cement | ⁂ | [173] | Fly Ash | ✓ | [174] | CDW | ✓ | [127] | |

| Bentonite | ⁂ | [98] | Granulated Blast Furnace Slag (GBFS) | ✓ | [114] | Magnesium Chloride | ⁂ | [175] | |

| Lime | ⁂ | [86] | CDW | ✓ | [115] | Mud | ✓ | [97] | |

| CDW | ✓ | [176] | Bentonite | ⁂ | [111] | Fly Ash, Sodium Hydroxide | ※ | [177] | |

| Mud | ✓ | [97] | - | - | - | - | - | - | |

| Stabilizers + Fibers | Polymer, Gypsum and Lime | ⁂ | [178] | Cement + Polypropylene Fibers | ⁂ | [119] | Cement, Steel Fibers | ⁂ | [132] |

| - | - | - | Lime + Polypropylene Fibers | ⁂ | [179] | - | - | - | |

| Others | Geogrid | ⁂ | [180] | Oil Shales | ✓ | [103] | Geogrid | ⁂ | [181] |

| Steel Mesh | ⁂ | [81] | - | - | - | - | - | ||

| Type of Aggregate | Adobe | CEB | REW | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Additive | Waste | Ref. | Additive | Waste | Ref. | Additive | Waste | Ref. | |

| Fibers | Straw | ⁂ 1 | [182] | Pig hair | ✓ | [118] | Bambu fibers | ✓ | [23] |

| Reed | ⁂ | [87] | Green mussel shells (GMS) + pig hair fibers | ✓ | [118] | Jute fibers | ✓ | [137] | |

| Saw dust | ✓ | [21] | Kenaf fibers | ✓ | [158] | Coconut fibers | ✓ | [183] | |

| Jute fibers | ✓ | [91] | Saw dust | ✓ | [69] | Barley fibers | ✓ | [164] | |

| Agave fibers | ✓ | [90] | Hemp | ✓ | [121] | Palm fibers | ✓ | [164] | |

| Stabilizers | Gypsum and straw | ※ | [184] | GOS | ✓ | [185] | Tannin | ✓ | [130] |

| Rice husk | ✓ | [159] | Sugar cane bagasse ash | ✓ | [157] | Lignin sulfonate | ⁂ | [186] | |

| Gypsum and sugarcane molasses | ※ | [187] | Rice husk ash | ✓ | [188] | - | - | - | |

| Natural biopolymer brown algae | ✓ | [189] | - | - | - | - | - | - | |

| Stabilizers + fibers | Cement + fiber Pinus Roxburghii | ※ | [173] | Date palm, cement and lime | - | [190] | Cement, coconut fibers | ※ | [191] |

| CaO3 + straw | ※ | [35] | Banana fibers and cement | ※ | [183] | - | - | - | |

| Lime + pineapple fiber | ※ | [86] | Sisal fibers, cement | ※ | [120] | - | - | - | |

| - | - | - | Bambu fibers, cement | ※ | [117] | - | - | - | |

| - | - | - | - | - | - | ||||

| Others | Wood | ⁂ | [36] | - | - | - | Bambu and steel frames | ※ | [192] |

| Rice starch | ✓ | [193] | - | - | - | Bambu, cement and steel frames | ※ | [194] | |

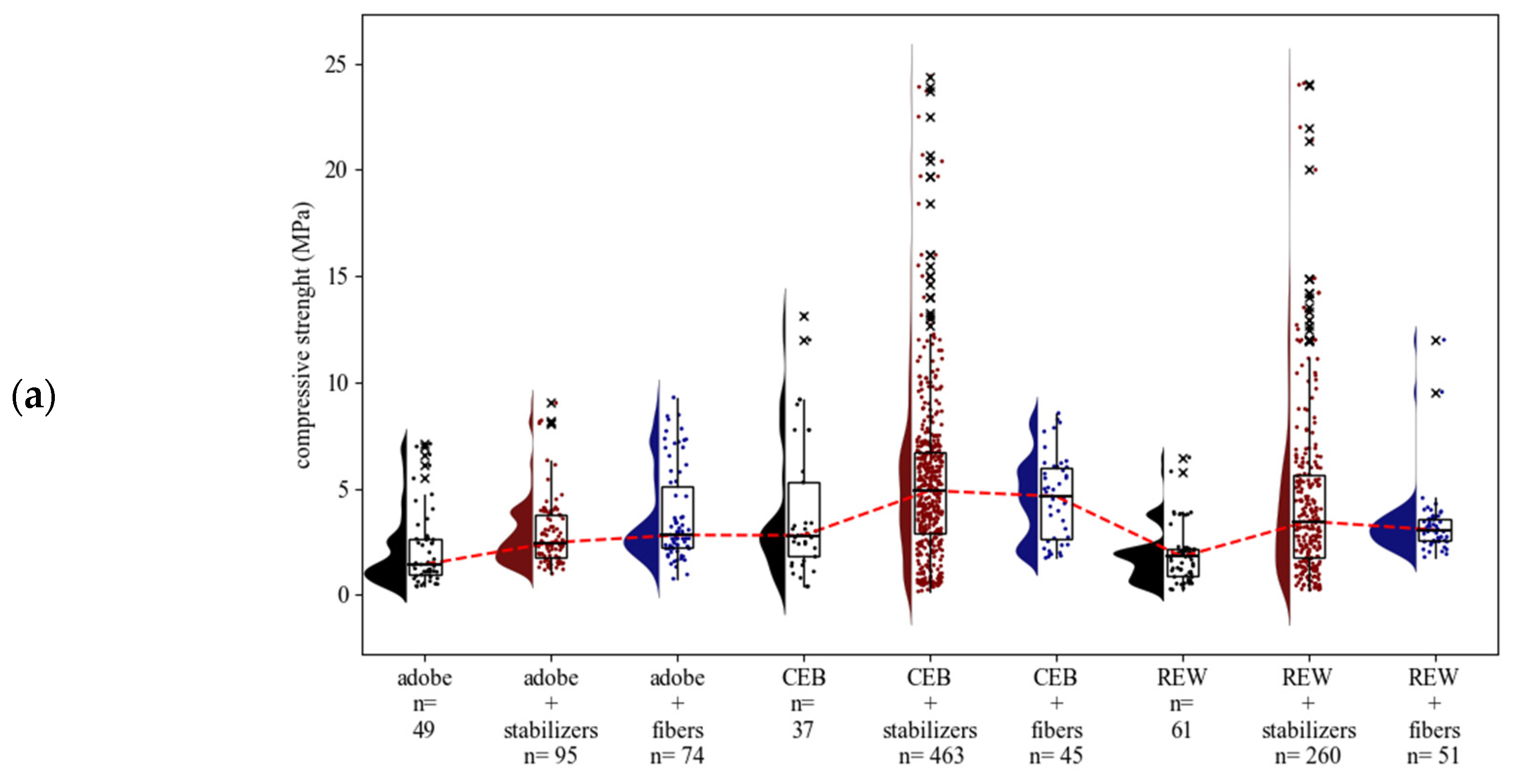

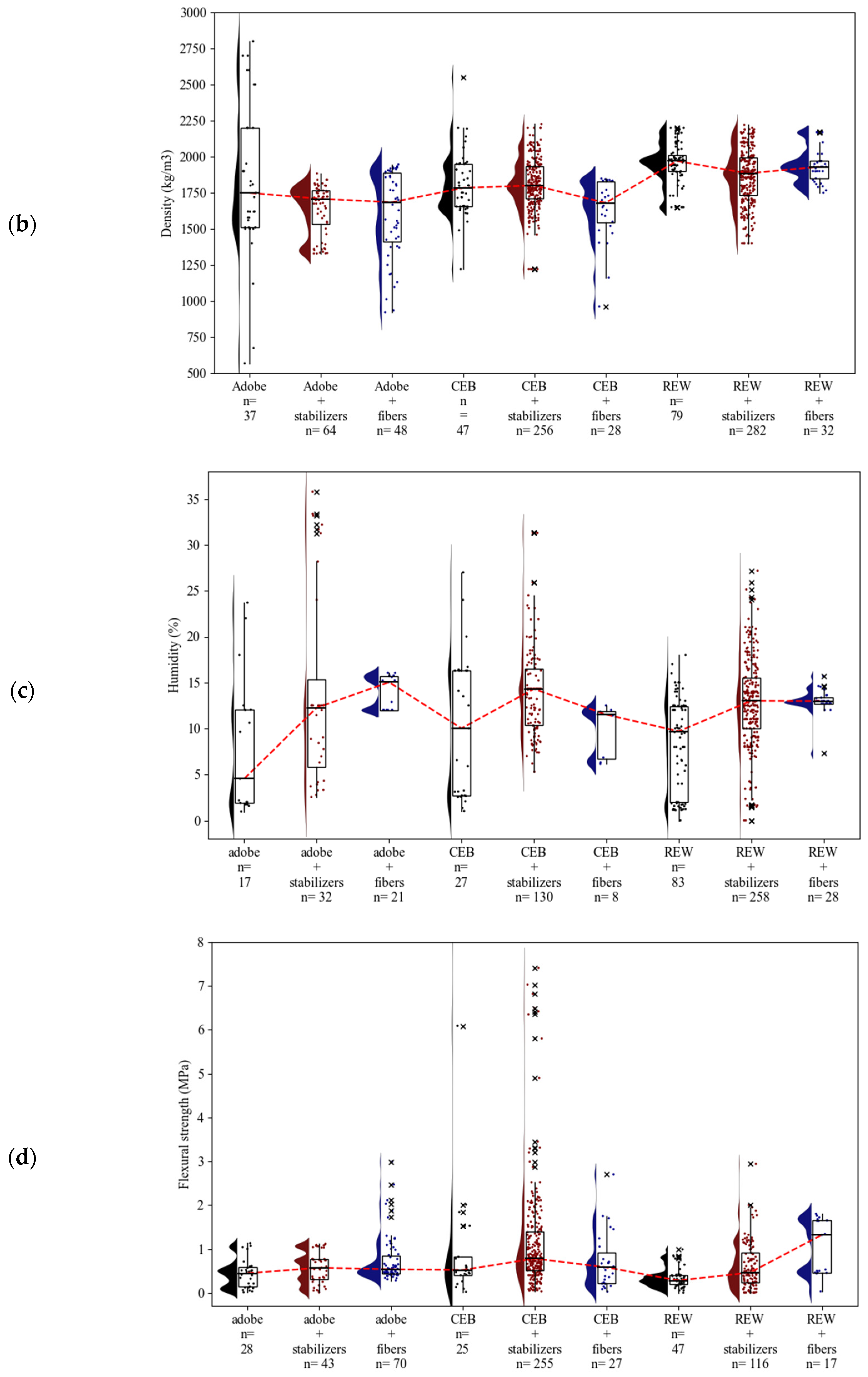

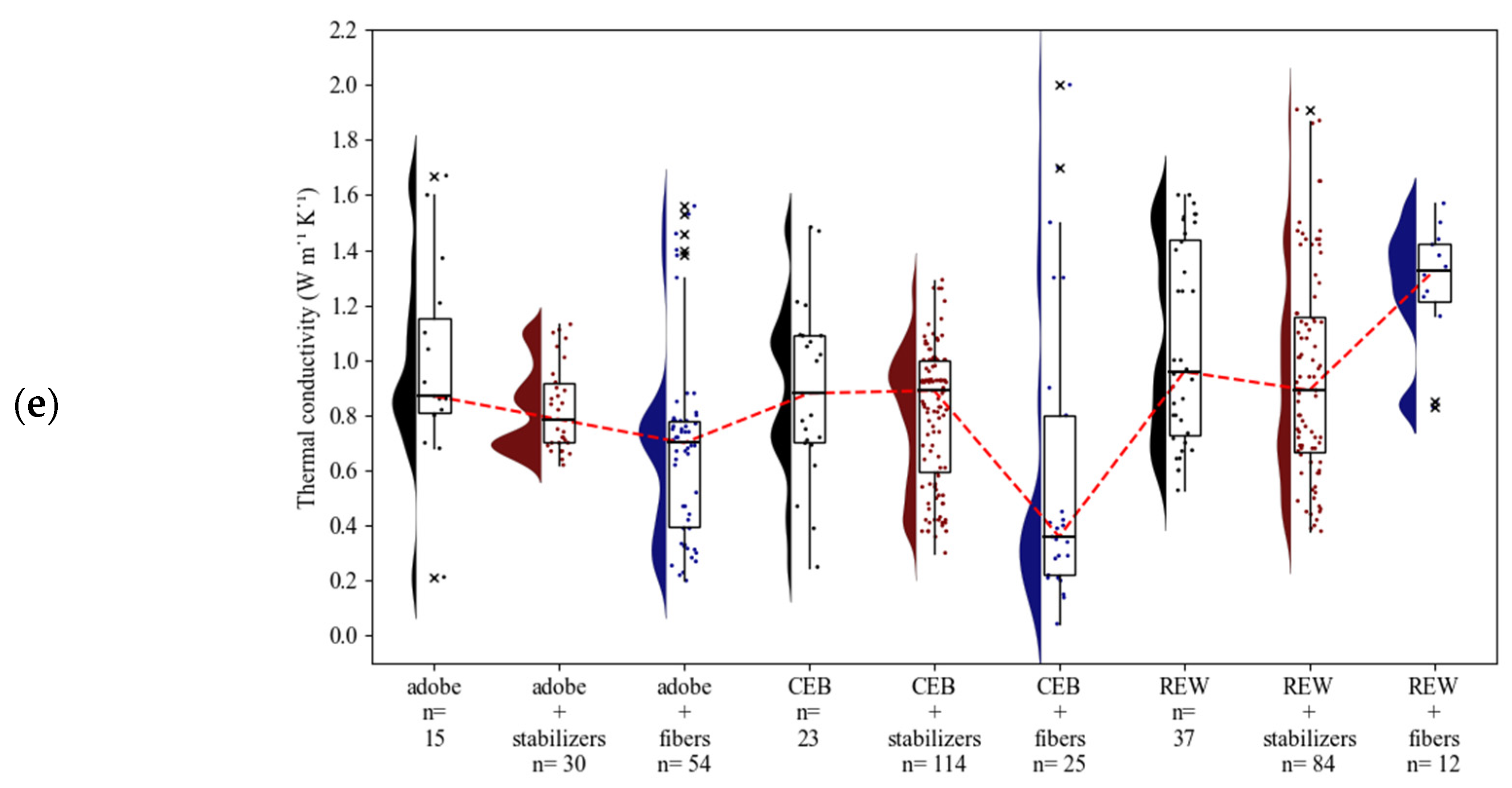

3.5. Meta-Analysis: Uses and Characteristics of Earthen Constructions

3.5.1. Compressive Strength Performance of Earthen Construction

| Earth Construction Technique | Type of Aggregate | Additive | Source | Reported Optimal Mixture Content | Max. Density (kg/m3) | Reported Humidity (%) | Element Size (mm) | Compressive Strength (MPa) | Meta-Analysis Compressive Strength Average (MPa) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Adobe | None | - | - | 0% | - | - | 200 × 200 × 45 | 4.43 | Adobe: 2.17 | [204] |

| Stabilizer | Fly ash and cement | IIW | 50% (fly ash), 8% (cement), 42% (sand) | 1746 | 3.71 | 230 × 108 × 70 | 9.03 | Stabilized adobe: 2.90 | [17] | |

| Fibers | Saw dust | AIW | 30% (Saw dust), 70% (clay) | 1505 | - | 450 × 300 × 50 | 7.32 | Adobe with fibers: 3.71 | [21] | |

| CEB | Stabilizer | Fly ash FA, sodium hydroxide NH, GBFS | IWP | Sand + 36% FA + 10% GBFS + 22.77% NA | - | - | 50 × 50 × 100 | 16 | CEB: 3.55 Stabilized CEB: 5.35 CEB with fibers: 4.58 | [174] |

| Stabilizer + fibers | Cement and date palm fibers | IPAW | CEBC8%F0.05% | - | - | 100 × 100 × 200 | 12.7 | [205] | ||

| Stabilizer | Lime and natural pozzolana | IP | CEB10%L30%PN | - | - | 100 × 100 × 200 | 16.00 | [163] | ||

| Stabilizer | Cement, and residual water from oil fields | IP | 15,38%C | 1786 | 23.08 | 300 × 150 × 100 | 14.63 | [199] | ||

| Stabilizer | Cement kiln powder with Adjika clay | IWP | AdjibaCKB25 | - | - | 40 × 200 × 160 | 22.72 | [206] | ||

| Stabilizer | Fly ash, waste glass and activator/precursor wt. ratio | IWP | 50%, 50% and 0.5% | - | - | - | 11.66 | [18] | ||

| Stabilizer | Cement and glass powder | IIW | S17-C + 4%CP + 3%GP | - | - | 100 × 200 × 60 | 12.26 | [109] | ||

| Stabilizer | Ceramic waste | IWP | 50% ceramic | 1765 | 18.15 | 100 × 50 × 40 | 19.7 | [207] | ||

| REW | Stabilizer + fiber | Cement, WTTF | IIP | 7% y 1% | 1700 | 18.5 | 70 × 142 | 6.24 | REW: 1.85 Stabilized REW: 4.59 REW with fibers: 3.35 | [165] |

| Stabilizer | Cement and lime | IP | 9% C, and 4% L | 2164 | 17 | 550 × 550 × 200 | 6.84 | [125] | ||

| Stabilizer + fiber | Cement, coconut fibers 25 mm | IPAW | C 1% CF 25 mm | 1740 | 11.32 | 100 × 100 × 100 | 7.63 | [186] | ||

| Stabilizer | Concrete masonry recycled, fly ash, GBFS, kaolin, silica fume and sodium hydroxide | IWP | 73.4%, 7.3%, 3.7%, 3.7%, 2.9% and 1.65% | 1950 | 7.35 | 200 × 200 | 24.07 | [127] | ||

| Stabilizer + fiber | Cement, steel | IP | C 8% S 10 mm | 1900 | 10.22 | 150 × 150 | 5.21 | [132] | ||

| Stabilizer | Cement | IP | 8% | 1919 | 9 | 104 × 200 | 14.9 | [208] | ||

| Cob | None | - | 0% | - | 1789 | 18–21 | 300 × 300 × 70 | 0.6–1.65 | - | [29,209] |

| Daub and wattle | None | - | - | 0% | 3% | 1500 × 2200 × 120 | 2.08 | - | [32] | |

| Poured Earth | None | - | - | 0% | 1850 | 20% | 40 × 40 × 160 | 3.2 | - | [8] |

| Stabilizer | Ceraplast 300–naphthalene-based superplasticizer | IWP | 3% | 2260 | 16% | 100 × 100 × 100 | 47.7 | - | [8,9,210] | |

| Fiber | Alginate | IPAW | 6%, 9% and 12% | 2200 | 300 × 500 | 2.1–2.8 | - | [33] |

3.5.2. Flexural Strength Performance of Earthen Construction

| Earth Construction Technique | Type of Aggregate | Additive | Source | Reported Optimal Mixture Content | Max. Density (kg/m3) | Reported Humidity (%) | Element Size (mm) | Flexural Strength (MPa) | Meta-Analysis Flexural Strength Average (MPa) | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| Adobe | Stabilizer + fibers | Lime and leaf pineapple fiber | IPAW | 0.9% and 0.5% | - | - | 400 × 200 × 200 | 0.77 | Adobe: 0.44 Stabilized adobe: 0.58 Adobe with fibers: 0.74 | [86] |

| CEB | Stabilizer | Geopolymer | IWP | CEB_20%G | 1760 | 22.3 | 140 × 140 × 94 | 1.68 | CEB: 0.51 Stabilized CEB: 1.14 CEB with fibers: 0.71 | [123] |

| Fibers | Kenaf fibers | AIW | 1.2% 20 mm | - | 12.5 | 40 × 40 × 160 | 2.70 | [158] | ||

| Stabilizer | Cement kiln powder with Adjika clay | IWP | 25% | - | - | 40 × 20 × 160 | 6.89 | [206] | ||

| Stabilizer + fibers | Cement and glass fiber | IP | 4% and 0.25% | - | - | 100 × 200 × 60 | 3.31 | [109] | ||

| Stabilizer | Cement | IP | 8% | 2080 | 12.06 | 40 × 40 × 160 | 3.29 | [213] | ||

| REW | Stabilizer | Concrete masonry recycled, fly ash, GBFS, kaolin, silica fume and sodium hydroxide | IWP | 73.4%, 7.3%, 3.7%, 3.7%, 2.9% and 1.65% | 1950 | 7.35 | 200 × 200 | 2.94 | REW: 0.34 Stabilized REW: 0.62 REW with fibers: 1.05 | [127] |

| Stabilizer + fibers | Cement and tire textile fibers | IIW | 8% and 4% | - | 4 | 600 × 600 × 150 | 1.32 | [129] | ||

| Stabilizer + fibers | Cement and coconut fibers | IPAW | 5%, 25 mm | 1600 | 17.77 | 100 × 100 × 100 | 1.20 | [186] | ||

| Cob | None | - | - | 0% | 1789 | 18–21 | 300 × 300 × 70 | 0.25 | [29,209] | |

| Daub and wattle | None | - | - | 0% | - | - | 40 × 160 | 2.47 | [214] | |

| Poured Earth | None | - | - | 0% | 1850 | 20 | 40 × 40 × 160 | 0.75 | [8] | |

| Stabilizer | NaHMP, citric acid, Na2CO3, oak tan | IWP | 0.5%, 2%, 3.5%, 5% | 1800–1950 | 20–30 | 40 × 40 × 160 | 0.75–1.5 | [8] |

3.6. Dynamic and Numerical Approach in Earthen Construction Field

| Equation | Description | Variables | Ref. | |

|---|---|---|---|---|

| Adobe | The yield criterion determines the limit at which a material begins to deform plastically. It is based on Von Mises‘ theory in adobe walls, analyzing principal stresses at different load states. | For the tensile test, the values for σ1, σ2 and σ1. σ3 in this equation are as follows: σ1 = σ0, σ2 = σ3 = 0, where σ0 is the yield stress of the tensile test. | [216] | |

| The Riedel–Hiermaier–Thomas (RHT) model is a concrete model used to simulate the behavior of materials such as adobe under impact or blast loads. The RHT model uses an equation of state (EOS) based on the form p-α, which is represented as follows for porous materials such as adobe. | Hereby, Γ is the Grüneisen parameter, ρ the current density, e the specific internal energy of the material, and ρ0 the initial density. A1, A2, A3: specific coefficients describing the stiffness of the material under compressive conditions. | [225] | ||

| CEBs | The Coulomb equation is used to determine the moment of failure of the CEB wall that occurs when the tangential stress (τ) on a surface exceeds the resistance value, which is related to the normal stress (σn) and the angle of internal friction (ϕ) of the material. | σn: normal stress on the sliding surface, N: compressive force applied, S: area of the surface on which the force acts, α: sliding angle between the contact surfaces. | [220] | |

| The plastic moment resistance of a wall refers to the maximum capacity of the wall to resist bending forces before undergoing permanent plastic deformations such as in the case of earthquakes. | Mp: maximum plastic moment, Cm: compressive strength of the block, c: depth of the neutral axis, a: depth of the equivalent tension block under compression, approximately 0.8c, Tsi: tensile strength in the reinforcing bars.di: distance from each reinforcing bar to the compressed edge of the wall, P: axial force applied at the top of the wall, L: total width of the wall. | [226] | ||

| REWs | The Mohr–Coulomb friction model is applied to the interfaces between compacted soil layers. In this model, the evaluated parameters E, v, fc, Gc, ft and G‘f are not a direct part of the equation but affect the elastic and fracture properties of the material and its interfaces in the finite element model (FEM). | τ: maximum shear stress, c: cohesion of material, represents the inherent resistance of the interfaces between layers. ϕ: internal friction angle, defines the resistance to sliding at the interfaces. The fc (compressive strength) and Gc (compressive fracture energy) values regulate how the material resists and fails under compression, while ft (tensile strength) and Gf′ (tensile fracture energy) determine when tensile fracture occurs. | [222] | |

| The equation predicts the horizontal force required to rotate a compacted earth wall as a rigid body. This prediction allows estimating the wall’s ability to resist overturning under horizontal loads, which is crucial for evaluating its out-of-plane behavior in the face of lateral forces, such as those produced by an earthquake. | Fht: horizontal force required to induce rotation.W: weight of the compacted soil section rotating as a rigid body.t: wall thickness.H: total height of the wall.θ: angle of rotation of the wall with respect to the pivot point.h: height from the point of rotation to the point of application of the force. | [223] | ||

3.7. Thermal Comfort Performance of Earth Construction Field

4. Recommendations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CDW | Construction and Demolition Waste |

| CEBs | Compressed Earth Blocks |

| DEM | Discrete Element Modeling |

| EE | Embodied Energy |

| EnCs | Earthen Constructions |

| EPDs | Environmental Product Declarations |

| EOS | Equation of the State |

| FEM | Finite Element Modeling |

| GBFS | Granulated Blast Furnace Slag |

| GMSs | Green Mussel Shells |

| GN | Global North |

| GOS | Grounded Olive Stone |

| GS | Global South |

| GRPFs | Glass Reinforcement Polymer Fibers |

| GWP | Global Warming Potential |

| ICE | British Inventory of Carbon and Energy |

| NSM | Near-Surface Mounted |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analysis |

| REW | Rammed Earth Walls |

| RHT | Riedel–Hiermaier–Thomas Model |

| SDGs | Sustainable Development Goals |

| WTTFs | Waste Tire Textile Fibers |

References

- Serrano, S.; Rincón, L.; González, B.; Navarro, A.; Bosch, M.; Cabeza, L.F. Rammed Earth Walls in Mediterranean Climate: Material Characterization and Thermal Behaviour. Int. J. Low-Carbon Technol. 2017, 12, 281–288. [Google Scholar] [CrossRef]

- Ouedraogo, A.L.S.-N.; Hema, C.; N’guiro, S.M.; Nshimiyimana, P.; Messan, A. Optimisation of Thermal Comfort of Building in a Hot and Dry Tropical Climate: A Comparative Approach between Compressed Earth/Concrete Block Envelopes. J. Miner. Mater. Charact. Eng. 2024, 12, 1–16. [Google Scholar] [CrossRef]

- Fernandes, J.; Peixoto, M.; Mateus, R.; Gervásio, H. Life Cycle Analysis of Environmental Impacts of Earthen Materials in the Portuguese Context: Rammed Earth and Compressed Earth Blocks. J. Clean. Prod. 2019, 241, 118286. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.; Ciancio, D.; Dotelli, G. Life Cycle Analysis of Environmental Impact vs. Durability of Stabilised Rammed Earth. Constr. Build. Mater. 2017, 142, 128–136. [Google Scholar] [CrossRef]

- Medvey, B.; Dobszay, G. Durability of Stabilized Earthen Constructions: A Review. Geotech. Geol. Eng. 2020, 38, 2403–2425. [Google Scholar] [CrossRef]

- Laborel-Préneron, A.; Aubert, J.E.; Magniont, C.; Tribout, C.; Bertron, A. Plant Aggregates and Fibers in Earth Construction Materials: A Review. Constr. Build. Mater. 2016, 111, 719–734. [Google Scholar] [CrossRef]

- Giuffrida, G.; Caponetto, R.; Nocera, F. Hygrothermal Properties of Raw Earth Materials: A Literature Review. Sustainability 2019, 11, 5342. [Google Scholar] [CrossRef]

- Brumaud, C.; Du, Y.; Ardant, D.; Habert, G. Earth, the New Liquid Stone: Development and Perspectives. Mater. Today Commun. 2024, 39, 108959. [Google Scholar] [CrossRef]

- Walter, L.; Estevez, Y.; Medjigbodo, G.; Aubert, J.E.; Linguet, L.; Nait-Rabah, O. Design of Poured Earth Construction Materials from the Elementary Characteristics of Tropical Soils. Case Stud. Constr. Mater. 2024, 20, e02709. [Google Scholar] [CrossRef]

- Bailly, G.C.; El Mendili, Y.; Konin, A.; Khoury, E. Advancing Earth-Based Construction: A Comprehensive Review of Stabilization and Reinforcement Techniques for Adobe and Compressed Earth Blocks. Eng 2024, 5, 750–783. [Google Scholar] [CrossRef]

- Pakand, M.; Toufigh, V. A Multi-Criteria Study on Rammed Earth for Low Carbon Buildings Using a Novel ANP-GA Approach. Energy Build. 2017, 150, 466–476. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Ciancio, D. Durability of Cement-Stabilised Rammed Earth: A Case Study in Western Australia. Aust. J. Civ. Eng. 2016, 14, 54–62. [Google Scholar] [CrossRef]

- Narani, S.S.; Zare, P.; Abbaspour, M.; Fahimifar, A.; Siddiqua, S.; Mir Mohammad Hosseini, S.M. Evaluation of Fiber-Reinforced and Cement-Stabilized Rammed-Earth Composite under Cyclic Loading. Constr. Build. Mater. 2021, 296, 123746. [Google Scholar] [CrossRef]

- Pavan, G.S.; Ullas, S.N.; Nanjunda Rao, K.S. Interfacial Behavior of Cement Stabilized Rammed Earth: Experimental and Numerical Study. Constr. Build. Mater. 2020, 257, 119327. [Google Scholar] [CrossRef]

- Ávila, F.; Puertas, E.; Gallego, R. Mechanical Characterization of Lime-Stabilized Rammed Earth: Lime Content and Strength Development. Constr. Build. Mater. 2022, 350, 128871. [Google Scholar] [CrossRef]

- Ammari, A.; Zerouaoui, J.; Cherraj, M. The Effect of Lime on Alumino-Silicate and Cement on the Behavior of Compressed Earth Blocks. J. Mater. Environ. Sci. 2015, 6, 3430–3435. [Google Scholar]

- Chokhani, A.; Divakar, B.S.; Jawalgi, A.S.; Renukadevi, M.V.; Jagadish, K.S. Properties of Fly Ash Blocks Made from Adobe Mould. J. Inst. Eng. Ser. A 2018, 99, 321–326. [Google Scholar] [CrossRef]

- Rivera, J.; Coelho, J.; Silva, R.; Miranda, T.; Castro, F.; Cristelo, N. Compressed Earth Blocks Stabilized with Glass Waste and Fly Ash Activated with a Recycled Alkaline Cleaning Solution. J. Clean. Prod. 2021, 284, 124783. [Google Scholar] [CrossRef]

- Brahim, M.; Ndiaye, K.; Aggoun, S.; Maherzi, W. Valorization of Dredged Sediments in Manufacturing Compressed Earth Blocks Stabilized by Alkali-Activated Fly Ash Binder. Buildings 2022, 12, 419. [Google Scholar] [CrossRef]

- Gandia, R.M.; Gomes, F.C.; Corrêa, A.A.R.; Rodrigues, M.C.; Mendes, R.F. Physical, Mechanical and Thermal Behavior of Adobe Stabilized with Glass Fiber Reinforced Polymer Waste. Constr. Build. Mater. 2019, 222, 168–182. [Google Scholar] [CrossRef]

- Costi de Castrillo, M.; Ioannou, I.; Philokyprou, M. Reproduction of Traditional Adobes Using Varying Percentage Contents of Straw and Sawdust. Constr. Build. Mater. 2021, 294, 123516. [Google Scholar] [CrossRef]

- Mostafa, M.; Uddin, N. Experimental Analysis of Compressed Earth Block (CEB) with Banana Fibers Resisting Flexural and Compression Forces. Case Stud. Constr. Mater. 2016, 5, 53–63. [Google Scholar] [CrossRef]

- Sen, B.; Saha, R. Experimental and Numerical Investigation of Mechanical Strength Characteristics of Natural Fiber Retrofitted Rammed Earth Walls. Geotext. Geomembr. 2022, 50, 970–993. [Google Scholar] [CrossRef]

- Meek, A.H.; Elchalakani, M.; Beckett, C.T.S.; Grant, T. Alternative Stabilised Rammed Earth Materials Incorporating Recycled Waste and Industrial By-Products: Life Cycle Assessment. Constr. Build. Mater. 2021, 267, 120997. [Google Scholar] [CrossRef]

- Turco, C.; Paula Junior, A.C.; Teixeira, E.R.; Mateus, R. Optimisation of Compressed Earth Blocks (CEBs) Using Natural Origin Materials: A Systematic Literature Review. Constr. Build. Mater. 2021, 309, 125140. [Google Scholar] [CrossRef]

- Valenzuela, M.; Ciudad, G.; Cárdenas, J.P.; Medina, C.; Salas, A.; Oñate, A.; Pincheira, G.; Attia, S.; Tuninetti, V. Towards the Development of Performance-Efficient Compressed Earth Blocks from Industrial and Agro-Industrial by-Products. Renew. Sustain. Energy Rev. 2024, 194, 114323. [Google Scholar] [CrossRef]

- Jiménez-Montoya, A.; Pascual-Francisco, J.B.; Sánchez-Cruz, G.; Ríos-Ledezma, M.G.; Novelo-Ramos, J.K.; Matías-Molina, A.L. Soil and Cement Bricks with Diverse Reinforcements: A Review. Rev. Politec. 2024, 53, 97–113. [Google Scholar]

- Dente, A.; Smith, M.G.; Burke, M. Essential Cob Construction: A Guide to Design, Engineering, and Building; New Society Publishers: Gabriola Island, BC, Canada, 2023; Volume 1, ISBN 0865719683. [Google Scholar]

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; DiPietro, G.; Hameen, E.C. Cradle to Site Life Cycle Assessment (LCA) of Natural vs Conventional Building Materials: A Case Study on Cob Earthen Material. Build. Env. 2019, 160, 106150. [Google Scholar] [CrossRef]

- Singh, S. Experimental Investigation of Corn Cob Ash on Silty Clay Stabilized with Calcium Carbide. Mater. Today: Proc. 2020, 37, 3658–3660. [Google Scholar] [CrossRef]

- Carazas Aedo, W.; Rivero Olmos, A. Bahareque: Guía de Construcción Parasísmica; Misereor: Aachen, Germany, 2002. [Google Scholar]

- Lara, M.L.; Bustamante, R. Characterization and Pathology of Earthen Building Walls in the Ecuadorian Andean Area. Rev. Politec. 2022, 49, 37–46. [Google Scholar] [CrossRef]

- Pinel, A.; Jorand, Y.; Olagnon, C.; Charlot, A.; Fleury, E. Towards Poured Earth Construction Mimicking Cement Solidification: Demonstration of Feasibility via a Biosourced Polymer. Mater. Struct./Mater. Constr. 2017, 50, 224. [Google Scholar] [CrossRef]

- Endeavour Centre Adobe—Endeavour Centre. Available online: https://endeavourcentre.org/resources-for-building-green/free-encyclopedia-of-sustainable-building-materials/walls/adobe/ (accessed on 19 December 2024).

- Aldawoodi, B.; Sabri, S.; Wis, A.A. Optimum Calcination Condition of Waste Stabilized Adobe for Alkali Activated High Volume Adobe-Slag Binder Cured at Room Temperature. J. Renew. Mater. 2022, 10, 1269–1285. [Google Scholar] [CrossRef]

- Wang, H.; Yuan, K.; Zhang, S.; Guo, J. Experimental Study on the Seismic Behavior of a Modified Adobe-Brick-Masonry Composite Wall with a Wooden-Construction Center Column. Sustainability 2023, 15, 8360. [Google Scholar] [CrossRef]

- Parc Naturel Régional Livradois-Forez 7—Lévolution Des Systèmes Constructifs—Parc Naturel Régional Livradois-Forez. Available online: https://www.parc-livradois-forez.org/preserver/architecture/le-pise/levolution-des-systemes-constructifs/ (accessed on 19 December 2024).

- Serrano-Chacón, Á.R.; Mascort-Albea, E.J.; Canivell, J.; Romero-Hernández, R.; Jaramillo-Morilla, A. Multi-Criteria Parametric Verifications for Stability Diagnosis of Rammed-Earth Historic Urban Ramparts Working as Retaining Walls. Appl. Sci. 2021, 11, 2744. [Google Scholar] [CrossRef]

- Mota-López, M.I.; Maderuelo-Sanz, R.; Pastor-Valle, J.D.; Meneses-Rodríguez, J.M.; Romero-Casado, A. Analytical Characterization of the Almohad Rammed-Earth Wall of Cáceres, Spain. Constr. Build. Mater. 2021, 273, 121676. [Google Scholar] [CrossRef]

- Endeavour Centre Compressed Earth Blocks (CEB)—Endeavour Centre. Available online: https://endeavourcentre.org/resources-for-building-green/free-encyclopedia-of-sustainable-building-materials/walls/compressed-earth-blocks-ceb/ (accessed on 19 December 2024).

- Soto-Paz, J.; Arroyo, O.; Torres-Guevara, L.E.; Parra-Orobio, B.A.; Casallas-Ojeda, M. The Circular Economy in the Construction and Demolition Waste Management: A Comparative Analysis in Emerging and Developed Countries. J. Build. Eng. 2023, 78, 107724. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Oviedo-Ocaña, R.; Torres-Lozada, P.; Marmolejo-Rebellón, L.F.; Manyoma-Velásquez, P.C. Compostaje de Biorresiduos: Tendencias de Investigación y Pertinencia En Países En Desarrollo. Dyna 2017, 84, 334–342. [Google Scholar] [CrossRef]

- Oviedo-Ocaña, E.R.; Soto-Paz, J.; Domínguez, I.; Sanchez-Torres, V.; Komilis, D. A Systematic Review on the Application of Bacterial Inoculants and Microbial Consortia During Green Waste Composting. Waste Biomass Valorization 2022, 13, 3423–3444. [Google Scholar] [CrossRef]

- Mitchell, M.; Muftakhidinov, B.; Winchen, T. Engauge Digitizer, version 12.1; Zenodo, 2019. Available online: https://zenodo.org/records/3558440 (accessed on 17 February 2025).

- Aria, M.; Cuccurullo, C. bibliometrix: Comprehensive Science Mapping Analysis, Version 4.3.0; CRAN, 2024. Available online: https://cran.r-project.org/package=bibliometrix (accessed on 17 February 2025).

- van Eck, N.J.; Waltman, L. VOSviewer, Version 1.6.18; Centre for Science and Technology Studies, Leiden University: Leiden, The Netherlands, 2022; Available online: https://www.vosviewer.com/download (accessed on 17 February 2025).

- Borrego, M.; Foster, M.J.; Froyd, J.E. Systematic Literature Reviews in Engineering Education and Other Developing Interdisciplinary Fields. J. Eng. Educ. 2014, 103, 45–76. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. An Approach for Detecting, Quantifying, and Visualizing the Evolution of a Research Field: A Practical Application to the Fuzzy Sets Theory Field. J. Inf. 2011, 5, 146–166. [Google Scholar] [CrossRef]

- Python Software Foundation. Python Language Reference, Version 3.3.4; Python Software Foundation: Wilmington, DE, USA, 2023. Available online: https://www.python.org/downloads/release/python-334/ (accessed on 17 February 2025).

- Barnaś, K. Earth-Based Construction: A Critical Review. Teka Kom. Urban. I Archit. Oddział PAN w Krakowie 2023, 50, 259–269. [Google Scholar] [CrossRef]

- Hernández Pocero, J. Construcción Con Tierra: Análisis, Conservación y Mejora. Un Caso Práctico En Senegal. Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2016. [Google Scholar]

- El-Nabouch, R.; Bui, Q.B.; Perrotin, P.; Plé, O. Shear Parameters of Rammed Earth Material: Results from Different Approaches. Adv. Mater. Sci. Eng. 2018, 2018, 8214604. [Google Scholar] [CrossRef]

- Piani, T.L.; Weerheijm, J.; Sluys, L.J. Critical Review on the Material Characterization of Adobe Elements. J. Green Build. 2022, 17, 203–226. [Google Scholar] [CrossRef]

- NBR 8491 EB1481; Tijolo Maciço de Solo-Cimento. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 1984.

- NBR 10833 NB1222; Fabricação de Tijolo Maciço e Bloco Vazado de Solo-Cimento Com. Utilização de Prensa Hidráulica. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 1989.

- NBR 10835; Bloco Vazado de Solo-Cimento Sem. Função Estrutural—Forma e Dimensões. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 1994.

- NTC 5324; Bloques de Suelo Cemento Para. Muros y Divisiones. Definiciones. Especificaciones. Métodos de Ensayo. Condiciones de Entrega. Instituto Colombiano de Normas Técnicas y Certificación (ICONTEC): Bogotá, Colombia, 2004.

- NMAC 14.7.4; Housing and Construction. Building Codes General. New Mexico Earthen Building Materials Code. Construction Industries Division (CID) of the Regulation and Licensing Department: Santa Fe, NM, USA, 2003.

- ARS 674:1996; Compressed Earth Blocks—Technical Specifications for Ordinary Compressed Earth Blocks. African Regional Organization for Standardization (ARSO): Nairobi, Kenya, 1996.

- ASTM E 2392-M10; Standard Guide for Design of Earthen Wall Building Systems. ASTM International: West Conshohocken, PA, USA, 2010; pp. 1–10.

- NZS 4298; Materials and Workmanship for Earth Buildings. New Zealand Technology Committee: Mairangi Bay, New Zealand, 1998; Volume 4298, p. 91.

- AIS 610-EP-17; Evaluación e Intervención de Edificaciones Patrimoniales de Uno y Dos. Pisos de Adobe y Tapia Pisada. Asociación Colombiana de Ingenieria Sismica: Bogotá, Colombia, 2017; pp. 1–68.

- RPS-2000; Morocco National Seismic Building Code. Ministry of Housing and Policy of the City: Morocco, 2000.

- BCOP–2007; Pakistan Building Code. Ministry of Housing and Works, Government of Pakistan: Islamabad, Pakistan, 2007.

- IS 13827:1993; Improving Earthquake Resistance of Earthen Buildings—Guidelines. Bureau of Indian Standards (BIS): Nueva Delhi, India, 1993.

- Cabrera, S.P.; Jiménez, Y.G.A.; Domínguez, E.J.S.; Rotondaro, R. Compressed Earth Blocks (CEB) Stabilized with Lime and Cement. Evaluation of Both Their Environmental Impact and Compressive Strength. Habitat Sustentable 2020, 10, 70–81. [Google Scholar] [CrossRef]

- Banakinao, S.; Drovou, S.; Attipou, K. Influence of Cement Dose on the Durability of Structures in Stabilized Compressed Earth Blocks. Int. J. Sustain. Constr. Eng. Technol. 2022, 13, 121–129. [Google Scholar] [CrossRef]

- Huamani, K.; Enciso, R.; Gonzales, M.; Zavaleta, D.; Aguilar, R. Experimental and Numerical Evaluation of a Stackable Compressed Earth Block Masonry System: Characterization at Cyclic Shear Loads. J. Build. Eng. 2022, 60, 105139. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Noureddine, O.; Erba, S.; Sahbi, H.; Khaldoun, A. Effect of Reinforced Recycled Sawdust-Fibers Additive on the Performance of Ecological Compressed Earth Bricks. J. Build. Eng. 2023, 68, 106140. [Google Scholar] [CrossRef]

- Taypondou Darman, J.; Keyangue Tchouata, J.H.; Ngôn Ngôn, G.F.; Ngapgue, F.; Lindou Ngakoupain, B.; Tchedele Langollo, Y. Evaluation of Lateritic Soils of Mbé for Use as Compressed Earth Bricks (CEB). Heliyon 2022, 8, e10147. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Quan, D.; Fang, K.; Wang, B.; Ma, Z. Properties of Sustainable Earth Construction Materials: A State-of-the-Art Review. Sustainability 2024, 16, 670. [Google Scholar] [CrossRef]

- Morel, J.C.; Charef, R.; Hamard, E.; Fabbri, A.; Beckett, C.; Bui, Q.B. Earth as Construction Material in the Circular Economy Context: Practitioner Perspectives on Barriers to Overcome. Philos. Trans. R. Soc. B Biol. Sci. 2021, 376, 20200182. [Google Scholar] [CrossRef]

- Montalbano, G.; Santi, G.; Kholoud, N. Rammed Earth Construction: A Circular Solution for Sustainable Building. Proc. Int. Struct. Eng. Constr. 2024, 11, 1–6. [Google Scholar] [CrossRef]

- Zami, M.S.; Lee, A. Economic Benefits of Contemporary Earth Construction in Low-Cost Urban Housing—State-of-the-Art Review. J. Build. Apprais. 2010, 5, 259–271. [Google Scholar] [CrossRef]

- Hall, M.; Morris, H.; North, G. Low Carbon Rules: An Interdisciplinary Approach to Writing Standards for Earth and Straw Construction in Aotearoa New Zealand. In Proceedings of the 54th International Conference of the Architectural Science Association (ANZAScA), Auckland, New Zealand, 26–28 November 2020. [Google Scholar]

- NBR 13553; Materiais Para. Emprego Em Parede Monolítica de Solo-Cimento Sem. Função Estrutural. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 1996.

- UNE 41410; Bloques de Tierra Comprimida Para. Muros y Tabiques: Definiciones, Especificaciones y Métodos de Ensayo. Asociación Española de Normalización (AENOR): Madrid, Spain, 2008.

- IS 2110:1980; Code of Practice for In-Situ Construction of Walls in Buildings with Soil-Cement. Bureau of Indian Standards (BIS): Nueva Delhi, India, 1980.

- NTE E 0.80; Diseño y Construcción Con Tierra Reforzada. Servicio Nacional de Capacitación para la Industria de la Construcción (SENCICO): Lima, Peru, 2000.

- NTP 331.202; Elementos de Suelos Sin Cocer: Adobe Estabilizado Con Asfalto Para Muros: Métodos de Ensayo. Instituto Nacional de Defensa de la Competencia y de la Protección de la Propiedad Intelectual (INDECOPI): Lima, Peru, 1978.

- Catalán-Quiroz, P.; Moreno-Martínez, J.Y.; Galván, A.; Arroyo-Matus, R. Shaking Table Tests on Strengthened Adobe Dwellings Typical of Mexico. Proc. Inst. Civ. Eng. Struct. Build. 2020, 173, 761–779. [Google Scholar] [CrossRef]

- Consoli, N.C.; Silvano, L.W.; Lotero, A.; Scheuermann Filho, H.C.; Moncaleano, C.J.; Cristelo, N. Key Parameters Establishing Alkali Activation Effects on Stabilized Rammed Earth. Constr. Build. Mater. 2022, 345, 128299. [Google Scholar] [CrossRef]

- Momin, S.; Lovon, H.; Silva, V.; Ferreira, T.M.; Vicente, R. Seismic Vulnerability Assessment of Portuguese Adobe Buildings. Buildings 2021, 11, 200. [Google Scholar] [CrossRef]

- Reyes, J.C.; Yamin, L.E.; Hassan, W.M.; Sandoval, J.D.; Gonzalez, C.D.; Galvis, F.A. Shear Behavior of Adobe and Rammed Earth Walls of Heritage Structures. Eng. Struct. 2018, 174, 526–537. [Google Scholar] [CrossRef]

- Christoforou, E.; Kylili, A.; Fokaides, P.A.; Ioannou, I. Cradle to Site Life Cycle Assessment (LCA) of Adobe Bricks. J. Clean. Prod. 2016, 112, 443–452. [Google Scholar] [CrossRef]

- Daniel, J.J.; Basoro, D.; Gebrie, M. An Engineered Alternative Brick Masonry Unit for the Poor Inhabitants at Hawassa Village, Ethiopia. Int. J. Adv. Technol. Eng. Explor. 2021, 8, 717–734. [Google Scholar] [CrossRef]

- Cedeño, G.M.Z.; Ullauri, M.d.C.A.; Cajamarca-Zúñiga, C.D.; Barbecho, J.G. Proposal for Seismic Reinforcement with Common Reed for Adobe Masonries in Heritage Buildings. Inf. Constr. 2023, 75, 569. [Google Scholar] [CrossRef]

- Mirjalili, A.; Eslami, A.; Morshed, R. Experimental Investigation into the Effect of Vertical Loading on In-Plane Cyclic Behavior of Adobe Walls. Constr. Build. Mater. 2020, 264, 120706. [Google Scholar] [CrossRef]

- Nshimiyimana, P.; Miraucourt, D.; Messan, A.; Courard, L. Calcium Carbide Residue and Rice Husk Ash for Improving the Compressive Strength of Compressed Earth Blocks. MRS Adv. 2018, 3, 2009–2014. [Google Scholar] [CrossRef]

- Caballero-Caballero, M.; Chinas-Castillo, F.; Montes Bernabé, J.L.; Alavéz-Ramirez, R.; Silva Rivera, M.E. Effect on Compressive and Flexural Strength of Agave Fiber Reinforced Adobes. J. Nat. Fibers 2018, 15, 575–585. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Antico, F.C.; Burbano-Garcia, C.; Concha-Riedel, J.; Norambuena-Contreras, J.; Concha, J.; Saavedra Flores, E.I. Experimental Evaluation of Adobe Mixtures Reinforced with Jute Fibers. Constr. Build. Mater. 2021, 276, 122127. [Google Scholar] [CrossRef]

- Olacia, E.; Pisello, A.L.; Chiodo, V.; Maisano, S.; Frazzica, A.; Cabeza, L.F. Sustainable Adobe Bricks with Seagrass Fibres. Mechanical and Thermal Properties Characterization. Constr. Build. Mater. 2020, 239, 117669. [Google Scholar] [CrossRef]

- Zaidi, A.; Izemmouren, O.; Taallah, B.; Guettala, A.; Zaidi, A.; Izemmouren, O.; Taallah, B.; Guettala, A. Mechanical and Durability Properties of Adobe Blocks Filled with Date Palm Wastes. WJEng 2022, 19, 532–545. [Google Scholar] [CrossRef]

- Burbano-Garcia, C.; Araya-Letelier, G.; Astroza, R.; Silva, Y.F. Adobe Mixtures Reinforced with Fibrillated Polypropylene Fibers: Physical/Mechanical/Fracture/Durability Performance and Its Limits Due to Fiber Clustering. Constr. Build. Mater. 2022, 343, 128102. [Google Scholar] [CrossRef]

- Sadeghi, N.H.; Oliveira, D.V.; Silva, R.A.; Mendes, N.; Correia, M.; Azizi-Bondarabadi, H. Experimental Characterization of Adobe Vaults Strengthened with a TRM-Based Compatible Composite. Constr. Build. Mater. 2021, 271, 121568. [Google Scholar] [CrossRef]

- Brito, M.R.; Marvila, M.T.; Linhares, J.A.T.; Azevedo, A.R.G. de Evaluation of the Properties of Adobe Blocks with Clay and Manure. Buildings 2023, 13, 657. [Google Scholar] [CrossRef]

- Minh Trang, N.T.; Dao Ho, N.A.; Babel, S. Reuse of Waste Sludge from Water Treatment Plants and Fly Ash for Manufacturing of Adobe Bricks. Chemosphere 2021, 284, 131367. [Google Scholar] [CrossRef]

- Andrejkovičová, S.; Alves, C.; Velosa, A.; Rocha, F. Bentonite as a Natural Additive for Lime and Lime-Metakaolin Mortars Used for Restoration of Adobe Buildings. Cem. Concr. Compos. 2015, 60, 99–110. [Google Scholar] [CrossRef]

- Muñoz, P.; Letelier, V.; Muñoz, L.; Bustamante, M.A. Adobe Bricks Reinforced with Paper & Pulp Wastes Improving Thermal and Mechanical Properties. Constr. Build. Mater. 2020, 254, 119314. [Google Scholar] [CrossRef]

- Zeng, M.; Huang, H.; Zhang, X. Experiment on the Performance of Recycled Powder of Construction Waste on Adobe Materials. Buildings 2023, 13, 1358. [Google Scholar] [CrossRef]

- Rojas-Valencia, M.N.; Bolaños, E.A. Sustainable Adobe Bricks with Construction Wastes. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2016, 169, 158–165. [Google Scholar] [CrossRef]

- Eslami, A.; Zahedi, A.; Mirabi Banadaki, H. In-Plane Seismic Behavior of NSM Strengthened Adobe Walls: Experimental Evaluation of Different Reinforcements. Eng. Struct. 2021, 246, 113016. [Google Scholar] [CrossRef]

- Al-Fhaid, H.; Edris, W.F.; Al-Tamimi, M. Potential Utilization of Oil Shale as a Stabilizing Material for Compressed Earth Block. Front. Built Environ. 2023, 9, 1199744. [Google Scholar] [CrossRef]

- Dime, T.; Sore, S.O.; Nshimiyimana, P.; Messan, A.; Courard, L. Comparative Study of the Reactivity of Clay Earth Materials for the Production of Compressed Earth Blocks in Ambient Conditions: Effect on Their Physico-Mechanical Performances. J. Miner. Mater. Charact. Eng. 2022, 10, 43–56. [Google Scholar] [CrossRef]

- Neya, I.; Yamegueu, D.; Messan, A.; Coulibaly, Y.; Ouedraogo, A.L.S.N.; Ayite, Y.M.X.D. Effect of Cement and Geopolymer Stabilization on the Thermal Comfort: Case Study of an Earthen Building in Burkina Faso. Int. J. Build. Pathol. Adapt. 2023. [Google Scholar] [CrossRef]

- Ganou Koungang, B.M.; Courard, L.; Tatchum Defo, U.; Ndapeu, D.; Njeugna, E.; Attia, S. Evaluating Thermal Performance and Environmental Impact of Compressed Earth Blocks with Cocos and Canarium Aggregates: A Study in Douala, Cameroon. Int. J. Eng. Res. Afr. 2023, 67, 49–66. [Google Scholar] [CrossRef]

- Cabrera, S.; Elert, K.; Guilarducci, A.; Margasin, A. The Effect of Local Pozzolans and Lime Additions on the Miner-Alogical, Physical and Mechanical Properties of Compressed Earth Blocks in Argentina. Rev. Constr. 2022, 21, 248–263. [Google Scholar] [CrossRef]

- Idriss, E.; Tome, S.; Rolande Aurelie, T.K.; Nana, A.; Nemaleu, J.G.D.; Judicaёl, C.; Spieß, A.; Fetzer, M.N.A.; Janiak, C.; Etoh, M.A. Engineering and Structural Properties of Compressed Earth Blocks (CEB) Stabilized with a Calcined Clay-Based Alkali-Activated Binder. Innov. Infrastruct. Solut. 2022, 7, 157. [Google Scholar] [CrossRef]

- Cherif, B.A.; Ali, F.; Tarek, M.; Massouh, F. Mechanical Behavior of the Extraction Mud Dam for Use in the Manufacture of CEB. Civ. Eng. J. 2021, 7, 1774–1786. [Google Scholar] [CrossRef]

- Oubaha, S.; Hakkou, R.; Taha, Y.; Mghazli, M.O.; Benzaazoua, M. Elaboration of Compressed Earth Blocks Based on Phosphogypsum and Phosphate Mining By-Products. J. Build. Eng. 2022, 62, 105423. [Google Scholar] [CrossRef]

- Lahbabi, S.; Bouferra, R.; Saadi, L.; Khalil, A. Evaluation of the Void Index Method on the Mechanical and Thermal Properties of Compressed Earth Blocks Stabilized with Bentonite Clay. Constr. Build. Mater. 2023, 393, 132114. [Google Scholar] [CrossRef]

- Dabakuyo, I.; Mutuku, R.N.N.; Onchiri, R.O. Mechanical Properties of Compressed Earth Block Stabilized with Sugarcane Molasses and Metakaolin-Based Geopolymer. Civ. Eng. J. 2022, 8, 780–795. [Google Scholar] [CrossRef]

- Nshimiyimana, P.; Messan, A.; Zhao, Z.; Courard, L. Chemico-Microstructural Changes in Earthen Building Materials Containing Calcium Carbide Residue and Rice Husk Ash. Constr. Build. Mater. 2019, 216, 622–631. [Google Scholar] [CrossRef]

- Hany, E.; Fouad, N.; Abdel-Wahab, M.; Sadek, E. Investigating the Mechanical and Thermal Properties of Compressed Earth Bricks Made by Eco-Friendly Stabilization Materials as Partial or Full Replacement of Cement. Constr. Build. Mater. 2021, 281, 122535. [Google Scholar] [CrossRef]

- Bogas, J.A.; Silva, M.; Glória Gomes, M. Unstabilized and Stabilized Compressed Earth Blocks with Partial Incorporation of Recycled Aggregates. Int. J. Archit. Herit. 2019, 13, 569–584. [Google Scholar] [CrossRef]

- Nshimiyimana, P.; Moussa, H.S.; Messan, A.; Courard, L. Effect of Production and Curing Conditions on the Performance of Stabilized Compressed Earth Blocks: Kaolinite vs Quartz-Rich Earthen Material. MRS Adv. 2020, 5, 1277–1283. [Google Scholar] [CrossRef]

- Abessolo, D.; Biwole, A.B.; Fokwa, D.; Ganou Koungang, B.M.; Baah, Y.B. Physical, Mechanical and Hygroscopic Behaviour of Compressed Earth Blocks Stabilized with Cement and Reinforced with Bamboo Fibres. Int. J. Eng. Res. Afr. 2022, 59, 29–41. [Google Scholar] [CrossRef]

- Lejano, B.A.; Gabaldon, R.J.; Go, P.J.; Juan, C.G.; Wong, M. Compressed Earth Blocks with Powdered Green Mussel Shell as Partial Binder and Pig Hair as Fiber Reinforcement. Int. J. Geomate 2019, 16, 137–143. [Google Scholar] [CrossRef]

- Donkor, P.; Obonyo, E.; Ferraro, C. Fiber Reinforced Compressed Earth Blocks: Evaluating Flexural Strength Characteristics Using Short Flexural Beams. Materials 2021, 14, 6906. [Google Scholar] [CrossRef] [PubMed]

- Thennarasan Latha, A.; Murugesan, B.; Skariah Thomas, B. Compressed Earth Block Reinforced with Sisal Fiber and Stabilized with Cement: Manual Compaction Procedure and Influence of Addition on Mechanical Properties. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Minguela, A.F. Bio-Composites to Tackle UK Built Environment Carbon Emissions: Comparative Analysis on Load-Bearing Capacity, Hygroscopic and Thermal Performance of Compressed Earth Blocks with Addition of Industrial Hemp Waste. Open Constr. Build. Technol. J. 2017, 11, 395–412. [Google Scholar] [CrossRef]

- Venkatarama Reddy, B.V.; Sri Bhanupratap Rathod, R. Influence of Interlayer Shear Studs on the Behaviour of Cement Stabilised Rammed Earth under Compression, Tension and Shear. J. Build. Eng. 2022, 49, 104096. [Google Scholar] [CrossRef]

- Omar Sore, S.; Messan, A.; Prud’homme, E.; Escadeillas, G.; Tsobnang, F. Stabilization of Compressed Earth Blocks (CEBs) by Geopolymer Binder Based on Local Materials from Burkina Faso. Constr. Build. Mater. 2018, 165, 333–345. [Google Scholar] [CrossRef]

- Zhou, T.; Zhang, Z.; Su, Z.; Tian, P. Seismic Performance Test of Rammed Earth Wall with Different Structural Columns. Adv. Struct. Eng. 2021, 24, 107–118. [Google Scholar] [CrossRef]

- Ramírez Eudave, R.; Silva, R.A.; Pereira, E.; Romanazzi, A. Early-Age Shrinkage and Bond of LC-TRM Strengthening in Rammed Earth. Constr. Build. Mater. 2022, 350, 128809. [Google Scholar] [CrossRef]

- Strazzeri, V.; Karrech, A. Energy and Thermal Performance of a Typical Rammed Earth Residential Building in Western Australia. Energy Build. 2022, 260, 111901. [Google Scholar] [CrossRef]

- Meek, A.H.; Elchalakani, M.; Beckett, C.T.S.; Dong, M. Alternative Stabilised Rammed Earth Materials Incorporating Recycled Waste and Industrial By-Products: A Study of Mechanical Properties, Flexure and Bond Strength. Constr. Build. Mater. 2021, 277, 122303. [Google Scholar] [CrossRef]

- Allahvirdizadeh, R.; Oliveira, D.V.; Silva, R.A. Numerical Modeling of the Seismic Out-of-Plane Response of a Plain and TRM-Strengthened Rammed Earth Subassembly. Eng. Struct. 2019, 193, 43–56. [Google Scholar] [CrossRef]

- Nouri, H.; Safehian, M.; Hosseini, S.M.M.M. Rammed Earth Structures Reinforced by Waste Tire Textile Fibers as an Attempt to Reduce the Environmental Impacts. Int. J. Environ. Sci. Technol. 2023, 20, 437–450. [Google Scholar] [CrossRef]

- Losini, A.E.; Grillet, A.C.; Vo, L.; Dotelli, G.; Woloszyn, M. Biopolymers Impact on Hygrothermal Properties of Rammed Earth: From Material to Building Scale. Build. Env. 2023, 233, 110087. [Google Scholar] [CrossRef]

- Correia Da Silva, J.J.; Pereira, J.P.B.; Sirgado, J. Improving Rammed Earth Wall Thermal Performance with Added Expanded Granulated Cork. Arch. Sci. Rev. 2015, 58, 314–323. [Google Scholar] [CrossRef]

- Lepakshi, R.; Venkatarama Reddy, B.V. Bond Strength of Rebars in Cement Stabilised Rammed Earth. Constr. Build. Mater. 2020, 255, 119405. [Google Scholar] [CrossRef]

- Hema, C.; Messan, A.; Lawane, A.; Soro, D.; Nshimiyimana, P.; van Moeseke, G. Improving the Thermal Comfort in Hot Region through the Design of Walls Made of Compressed Earth Blocks: An Experimental Investigation. J. Build. Eng. 2021, 38, 102148. [Google Scholar] [CrossRef]

- Khaksar, A.; Tabadkani, A.; Mofidi Shemirani, S.M.; Hajirasouli, A.; Banihashemi, S.; Attia, S. Thermal Comfort Analysis of Earth-Sheltered Buildings: The Case of Meymand Village, Iran. Front. Archit. Res. 2022, 11, 1214–1238. [Google Scholar] [CrossRef]

- Malbila, E.; Delvoie, S.; Toguyeni, D.; Courard, L.; Attia, S. Improving the Building Energy Efficiency and Thermal Comfort through the Design of Walls in Compressed Earth Blocks of Agricultural and Biopolymer Residues Masonry. Curr. J. Appl. Sci. Technol. 2021, 9, 7–22. [Google Scholar] [CrossRef]

- Thompson, D.; Augarde, C.; Osorio, J.P. A Review of Current Construction Guidelines to Inform the Design of Rammed Earth Houses in Seismically Active Zones. J. Build. Eng. 2022, 54, 104666. [Google Scholar] [CrossRef]

- Loccarini, F.; Ranocchiai, G.; Rotunno, T.; Fagone, M. Experimental and Numerical Analyses of Strengthened Rammed Earth Masonry Arches. Comput. Struct. 2020, 239, 106329. [Google Scholar] [CrossRef]

- Ramezanpour, M.; Eslami, A.; Ronagh, H. Seismic Performance of Stabilised/Unstabilised Rammed Earth Walls. Eng. Struct. 2021, 245, 112982. [Google Scholar] [CrossRef]

- Khtou, O.; Aalil, I.; Aboussaleh, M.; Wardi, F.Z. EL Mechanical Analysis of Fiber Reinforced Adobe. Civ. Eng. Archit. 2021, 9, 2160–2168. [Google Scholar] [CrossRef]

- Lakys, R.E.; Saad, A.; Ahmed, T.; Yassin, M.H. Investigating the Drivers and Acceptance of Sustainable Materials in Kuwait: A Case Study of CEB. Case Stud. Constr. Mater. 2022, 17, e01330. [Google Scholar] [CrossRef]

- Hafez, H.; El-Mahdy, D.; Marsh, A.T.M. Barriers and Enablers for Scaled-up Adoption of Compressed Earth Blocks in Egypt. Build. Res. Inf. 2023, 51, 783–797. [Google Scholar] [CrossRef]

- Fragnoli, P.; Cereda, S.; Liberotti, G. Earthen Stories. Cross-Craft Strategies in Raw Material Procurement and Production at the Tell Site of Arslantepe (Türkiye) during the 4th Millennium BCE. J. Archaeol. Sci. Rep. 2024, 54, 104447. [Google Scholar] [CrossRef]

- Ben Charif, H.; Belakehal, A.; Zerari, S. Earthen Architecture in Southern Algeria: An Assessment of Social Values and the Impact of Industrial Building Practices. Open Archaeol. 2023, 9, 20220324. [Google Scholar] [CrossRef]

- Genovese, L.; Varriale, R.; Luvidi, L.; Fratini, F. Italy and China Sharing Best Practices on the Sustainable Development of Small Underground Settlements. Heritage 2019, 2, 53. [Google Scholar] [CrossRef]

- Paul, S.; Islam, M.S.; Chakma, N. Effectiveness of Areca Fiber and Cement on the Engineering Characteristics of Compressed Stabilized Earth Blocks. Constr. Build. Mater. 2024, 427, 136290. [Google Scholar] [CrossRef]

- de Filippi, F.; Pennacchio, R.; Restuccia, L.; Torres, S. Towards a Sustainable and Context-Based Approach to Anti-Seismic Retrofitting Techniques for Vernacular Adobe Buildings in Colombia. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2020, 54, 1089–1096. [Google Scholar] [CrossRef]

- Angela, S.L.A.; Enrique, C.A.L.; Luz, C.A.E.; Torres, V.S.M. Lightened Blocks of Plant Fibers and Clay Applied in Construction Systems for Housing in High Andean Areas. In Proceedings of the 2024 9th International Conference on Sustainable and Renewable Energy Engineering (ICSREE 2024), Marseille, France, 9–11 May 2024; Volume 545. [Google Scholar]

- Chamasemani, N.F.; Kelishadi, M.; Mostafaei, H.; Najvani, M.A.D.; Mashayekhi, M. Environmental Impacts of Reinforced Concrete Buildings: Comparing Common and Sustainable Materials: A Case Study. Constr. Mater. 2023, 4, 1–15. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Ramli, M.Z. A Comparative Life Cycle Assessment (LCA) of Concrete and Steel-Prefabricated Prefinished Volumetric Construction Structures in Malaysia. Environ. Sci. Pollut. Res. 2020, 27, 43186–43201. [Google Scholar] [CrossRef]

- EN 15804+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Committee for Standardization (CEN): Brussels, Belgium, 2019.

- Association HQE. INIES Database: Environmental and Health Data for Construction Products and Equipment. Available online: https://www.inies.fr (accessed on 18 November 2024).

- Swiss Federal Office for the Environment (FOEN) Swiss Construction Material Database. Available online: https://www.bafu.admin.ch (accessed on 18 November 2024).

- Hammond, G.; Jones, C.; Lowrie, E.F.; Tse, P. Embodied Carbon: The Inventory of Carbon and Energy (ICE); BSRIA: Bracknell, UK, 2011; ISBN 9780860227038. [Google Scholar]

- Ecoinvent Association Ecoinvent Database Version 3.10. Available online: https://www.ecoinvent.org (accessed on 18 November 2024).

- Elena Roxana, F.; Smaranda Maria, B. Earth as an Alternative Indicator Regarding the Ecological Character of Building Materials. In Proceedings of the INTCESS 2020—7th International Conference on Education and Social Sciences, Dubai, United Arab Emirates, 20–22 January 2020; pp. 205–212. [Google Scholar]

- Mateus, R.; Fernandes, J.; Teixeira, E.R. Environmental Life Cycle Analysis of Earthen Building Materials. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; Volume 1–5, pp. 63–68. ISBN 9780128131961. [Google Scholar]

- Salim, R.W.; Ndambuki, J.M.; Adedokun, D.A. Improving the Bearing Strength of Sandy Loam Soil Compressed Earth Block Bricks Using Sugercane Bagasse Ash. Sustainability 2014, 6, 3686–3696. [Google Scholar] [CrossRef]

- Laibi, A.B.; Poullain, P.; Leklou, N.; Gomina, M.; Sohounhloué, D.K.C. Influence of the Kenaf Fiber Length on the Mechanical and Thermal Properties of Compressed Earth Blocks (CEB). KSCE J. Civ. Eng. 2018, 22, 785–793. [Google Scholar] [CrossRef]

- Ouedraogo, M.; Bamogo, H.; Sanou, I.; Dao, K.; Amed, K.; Ouedraogo, J.; Aubert, J.-E.; Millogo, Y. Microstructure, Physical and Mechanical Properties of Adobes Stabilized with Rice Husks. Int. J. Archit. Herit. 2023, 17, 1348–1363. [Google Scholar] [CrossRef]

- Sturm, T.; Ramos, L.F.; Lourenço, P.B. Characterization of Dry-Stack Interlocking Compressed Earth Blocks. Mater. Struct./Mater. Constr. 2015, 48, 3059–3074. [Google Scholar] [CrossRef]

- Qu, B.; Stirling, B.J.; Jansen, D.C.; Bland, D.W.; Laursen, P.T. Testing of Flexure-Dominated Interlocking Compressed Earth Block Walls. Constr. Build. Mater. 2015, 83, 34–43. [Google Scholar] [CrossRef]

- Ciancio, D.; Beckett, C.T.S.; Carraro, J.A.H. Optimum Lime Content Identification for Lime-Stabilised Rammed Earth. Constr. Build. Mater. 2014, 53, 59–65. [Google Scholar] [CrossRef]

- Izemmouren, O.; Guettala, A.; Guettala, S. Mechanical Properties and Durability of Lime and Natural Pozzolana Stabilized Steam-Cured Compressed Earth Block Bricks. Geotech. Geol. Eng. 2015, 33, 1321–1333. [Google Scholar] [CrossRef]

- Koutous, A.; Hilali, E. Reinforcing Rammed Earth with Plant Fibers: A Case Study. Case Stud. Constr. Mater. 2021, 14, e00514. [Google Scholar] [CrossRef]

- Zare, P.; Sheikhi Narani, S.; Abbaspour, M.; Fahimifar, A.; Mir Mohammad Hosseini, S.M.; Zare, P. Experimental Investigation of Non-Stabilized and Cement-Stabilized Rammed Earth Reinforcement by Waste Tire Textile Fibers (WTTFs). Constr. Build. Mater. 2020, 260, 120432. [Google Scholar] [CrossRef]

- Bertelsen, I.M.G.; Belmonte, L.J.; Fischer, G.; Ottosen, L.M. Influence of Synthetic Waste Fibres on Drying Shrinkage Cracking and Mechanical Properties of Adobe Materials. Constr. Build. Mater. 2021, 286, 122738. [Google Scholar] [CrossRef]

- Zhao, X.; Cai, H.; Zhou, T.; Liu, L.; Ding, Y. Research on the Factors Affecting the Development of Shrinkage Cracks of Rammed Earth Buildings. Earthq. Struct. 2021, 20, 365–375. [Google Scholar] [CrossRef]

- Khorasani, F.F.; Kabir, M.Z. Experimental Study on the Effectiveness of Short Fiber Reinforced Clay Mortars and Plasters on the Mechanical Behavior of Adobe Masonry Walls. Case Stud. Constr. Mater. 2022, 16, e00918. [Google Scholar] [CrossRef]

- Mercedes, L.; Bernat-maso, E.; Gil, L. In-Plane Cyclic Loading of Masonry Walls Strengthened by Vegetal-Fabric-Reinforced Cementitious Matrix (FRCM) Composites. Eng. Struct. 2020, 221, 111097. [Google Scholar] [CrossRef]

- Toufigh, V.; Kianfar, E. The Effects of Stabilizers on the Thermal and the Mechanical Properties of Rammed Earth at Various Humidities and Their Environmental Impacts. Constr. Build. Mater. 2019, 200, 616–629. [Google Scholar] [CrossRef]

- Goutsaya, J.; Ntamack, G.E.; D’Ouazzane, S.C. Damage Modelling of Compressed Earth Blocks Stabilised with Cement. Adv. Civ. Eng. 2022, 2022, 3342661. [Google Scholar] [CrossRef]

- Mustafa, Y.M.H.; Zami, M.S.; Al-Amoudi, O.S.B.; Al-Osta, M.A.; Wudil, Y.S. Analysis of Unconfined Compressive Strength of Rammed Earth Mixes Based on Artificial Neural Network and Statistical Analysis. Materials 2022, 15, 29. [Google Scholar] [CrossRef]

- Sharma, V.; Marwaha, B.M.; Vinayak, H.K. Enhancing Durability of Adobe by Natural Reinforcement for Propagating Sustainable Mud Housing. Int. J. Sustain. Built Environ. 2016, 5, 141–155. [Google Scholar] [CrossRef]

- Belayali, F.; Maherzi, W.; Benzerzour, M.; Abriak, N.E.; Senouci, A. Compressed Earth Blocks Using Sediments and Alkali-Activated Byproducts. Sustainability 2022, 14, 3158. [Google Scholar] [CrossRef]

- Araki, H.; Koseki, J.; Sato, T. Tensile Strength of Compacted Rammed Earth Materials. Soils Found. 2016, 56, 189–204. [Google Scholar] [CrossRef]

- Joshi, A.M.; Basutkar, S.M.; Ahmed, M.I.; Keshava, M.; Seshagiri Rao, R.; Kaup, S.J. Performance of Stabilized Adobe Blocks Prepared Using Construction and Demolition Waste. J. Build. Pathol. Rehabil. 2019, 4, 13. [Google Scholar] [CrossRef]

- Narayanaswamy, A.H.; Walker, P.; Venkatarama Reddy, B.V.; Heath, A.; Maskell, D. Mechanical and Thermal Properties, and Comparative Life-Cycle Impacts, of Stabilised Earth Building Products. Constr. Build. Mater. 2020, 243, 118096. [Google Scholar] [CrossRef]

- Pekrioglu Balkis, A. The Effects of Waste Marble Dust and Polypropylene Fiber Contents on Mechanical Properties of Gypsum Stabilized Earthen. Constr. Build. Mater. 2017, 134, 556–562. [Google Scholar] [CrossRef]

- Edris, W.F.; Jaradat, Y.; Al Azzam, A.O.; Al Naji, H.M.; Abuzmero, S.A. Effect of Volcanic Tuff on the Engineering Properties of Compressed Earth Block. Arch. Mater. Sci. Eng. 2020, 106, 5–16. [Google Scholar] [CrossRef]

- Bossio, S.; Blondet, M.; Rihal, S. Seismic Behavior and Shaking Direction Influence on Adobe Wall Structures Reinforced with Geogrid. Earthq. Spectra 2013, 29, 59–84. [Google Scholar] [CrossRef]

- Zhou, T.; Liu, B.; Zhao, X.; Mu, J. Experimental Testing of the In-Plane Behavior of Bearing Modern Rammed Earth Walls. Adv. Struct. Eng. 2018, 21, 2045–2055. [Google Scholar] [CrossRef]

- Giaretton, M.; Dizhur, D.; Morris, H. Material Characterisation of Heavy-Weight and Lightweight Adobe Brick Walls and in-Plane Strengthening Techniques. Constr. Build. Mater. 2021, 310, 125309. [Google Scholar] [CrossRef]

- Mostafa, M.; Uddin, N. Effect of Banana Fibers on the Compressive and Flexural Strength of Compressed Earth Blocks. Buildings 2015, 5, 282–296. [Google Scholar] [CrossRef]

- Escobar Copa, K.U.; Holguino Huarza, A. Thermal Comfort in an Adobe Room with Heat Storage System in the Andes of Peru. Rev. Investig. Altoandinas J. High. Andean Res. 2018, 20, 289–300. [Google Scholar] [CrossRef]

- Djadouf, S.; Chelouah, N.; Tahakourt, A. The Influence of the Addition of Ground Olive Stone on the Thermo-Mechanical Behavior of Compressed Earth Blocks. Mater. Tech. 2020, 108, 203. [Google Scholar] [CrossRef]

- Raavi, S.S.D.; Tripura, D.D. Predicting and Evaluating the Engineering Properties of Unstabilized and Cement Stabilized Fibre Reinforced Rammed Earth Blocks. Constr. Build. Mater. 2020, 262, 120845. [Google Scholar] [CrossRef]

- Rodriguez Cuervo, L.S. Adobe Bricks with Sugarcane Molasses and Gypsum to Enhance Compressive Strength in the City Cogua, Colombia. Rev. Constr. 2020, 19, 358–365. [Google Scholar] [CrossRef]

- Razafitrimo Rajaonarya, V.; Hamada Fakra, A.; Praene, J.-P.; Escadeillas, G.; Razafitrimo Rajaonary, V.; Fakra, D.; Praene, J.-P. Agricultural Waste Valorization in Construction Sector: Case of Rice Husk Ash in Madagascar. Int. J. Progress. Sci. Technol. 2021, 29, 512–533. [Google Scholar]

- Dove, C.A.; Bradley, F.F.; Patwardhan, S.V. Seaweed Biopolymers as Additives for Unfired Clay Bricks. Mater. Struct./Mater. Constr. 2016, 49, 4463–4482. [Google Scholar] [CrossRef]

- Taallah, B.; Guettala, A. The Mechanical and Physical Properties of Compressed Earth Block Stabilized with Lime and Filled with Untreated and Alkali-Treated Date Palm Fibers. Constr. Build. Mater. 2016, 104, 52–62. [Google Scholar] [CrossRef]

- Sri Bhanupratap Rathod, R.; Venkatarama Reddy, B.V. Strength and Stress–Strain Characteristics of Fibre Reinforced Cement Stabilised Rammed Earth. Mater. Struct./Mater. Constr. 2021, 54, 52. [Google Scholar] [CrossRef]

- Raavi, S.S.D.; Tripura, D.D. Predicting the Effect of Weathering and Corrosion on the Bond Properties of Bamboo- and Steel-Reinforced Cement-Stabilized Rammed Earth Blocks. Adv. Struct. Eng. 2021, 24, 3267–3280. [Google Scholar] [CrossRef]

- González-Sánchez, B.; Sandoval-Castro, K.; Navarro-Ezquerra, A.; Ramírez-Casas, J.; Sanchez-Calvillo, A.; Alonso-Guzmán, E.M.; Navarro-Mendoza, E.G. Development and Intervention Proposal with Earthen Refurbishments with Vegetal Origin Gel (VOG) for the Preservation of Traditional Adobe Buildings. Heritage 2023, 6, 3025–3042. [Google Scholar] [CrossRef]

- Tripura, D.D.; Singh, K.D. Axial Load-Capacity of Bamboo-Steel Reinforced Cement Stabilised Rammed Earth Columns. Struct. Eng. Int. 2019, 29, 133–143. [Google Scholar] [CrossRef]

- Ceballos-Medina, S.; González-Rincón, D.C.; Sánchez, J.D. Reciclaje de Residuos de Construcción y Demolición (RC&D) Generados En La Universidad Del Valle Sede Meléndez Para La Fabricación de Adoquines. Rev. Ion 2021, 34, 27–35. [Google Scholar] [CrossRef]

- Yadav, M.E.K.; Kishore, P.R.; Kumar, A.S.; Swetha Sri, A.S. Influence of Sisal Fibers on the Properties of Rammed Earth. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 663–667. [Google Scholar] [CrossRef]

- IS 1725; Soil Based Blocks Used in General Building Construction. Bureau of Indian Standards: Old Delhi, India, 1982.

- Elahi, T.E.; Shahriar, A.R.; Islam, M.S. Engineering Characteristics of Compressed Earth Blocks Stabilized with Cement and Fly Ash. Constr. Build. Mater. 2021, 277, 122367. [Google Scholar] [CrossRef]

- Al-Jabri, K.; Hago, A.W.; Al-Saadi, S.; Al-Harthy, I.; Amoatey, P. Physico-Thermal, Mechanical, and Toxicity Properties of Stabilised Interlocking Compressed Earth Blocks Made with Produced Water from Oilfields. J. Build. Eng. 2021, 42, 103029. [Google Scholar] [CrossRef]

- ASTM C90; Standard Specification for Loadbearing Concrete Masonry Units. ASTM International: West Conshohocken, PA, USA, 2016.

- NTC 4205; Construcción Sismo Resistente—Requisitos Generales. ICONTEC Norma Técnica Colombiana: Bogotá, Colombia, 2000.

- Nshimiyimana, P.; Messan, A.; Courard, L. Physico-Mechanical and Hygro-Thermal Properties of Compressed Earth Blocks Stabilized with Industrial and Agro by-Product Binders. Materials 2020, 13, 3769. [Google Scholar] [CrossRef]

- Siddiqua, S.; Barreto, P.N.M. Chemical Stabilization of Rammed Earth Using Calcium Carbide Residue and Fly Ash. Constr. Build. Mater. 2018, 169, 364–371. [Google Scholar] [CrossRef]

- Mirabi Banadaki, H.; Eslami, A.; Ronagh, H. Near-Surface-Mounted Retrofitting of Damaged/Undamaged Adobe Walls Using Steel Bars: Analytical Evaluation of Experimental Results. Structures 2020, 28, 2111–2121. [Google Scholar] [CrossRef]

- Taallah, B.; Guettala, A.; Guettala, S.; Kriker, A. Mechanical Properties and Hygroscopicity Behavior of Compressed Earth Block Filled by Date Palm Fibers. Constr. Build. Mater. 2014, 59, 161–168. [Google Scholar] [CrossRef]

- Mebarkia, R.; Bouzeroura, M.; Chelouah, N. Study of the Effect of Cement Kiln Dust on the Mechanical, Thermal and Durability Properties of Compressed Earth Blocks. Constr. Build. Mater. 2022, 349, 128707. [Google Scholar] [CrossRef]

- Ali, N.; Kharina, Y.; Yaacob, M.; Khairy Burhanudin, S.; Shahidan, S.; Radziah, A. Investigation of Compressed Earth Brick Containing Ceramic Waste. ARPN J. Eng. Appl. Sci. 2016, 11, 5459–5462. [Google Scholar]

- Romanazzi, A.; Oliveira, D.V.; Silva, R.A. An Analytical Bond Stress-Slip Model for a TRM Composite Compatible with Rammed Earth. Constr. Build. Mater. 2021, 310, 125228. [Google Scholar] [CrossRef]

- Azil, A.; Le Guern, M.; Touati, K.; Sebaibi, N.; Boutouil, M.; Streiff, F.; Goodhew, S.; Gomina, M. Earth Construction: Field Variabilities and Laboratory Reproducibility. Constr. Build. Mater. 2022, 314, 125591. [Google Scholar] [CrossRef]

- Vijay, A.; Sajeeb, R.; Ravi, A.; Ramaswamy, K.P. Effect of Dosage of Superplasticizer on Earth Concrete. Mater. Today Proc. 2023, 1–4. [Google Scholar] [CrossRef]

- Nshimiyimana, P.; Messan, A.; Courard, L. Hydric and Durability Performances of Compressed Earth Blocks Stabilized with Industrial and Agro By-Product Binders: Calcium Carbide Residue and Rice Husk Ash. J. Mater. Civ. Eng. 2021, 33, 04021121. [Google Scholar] [CrossRef]

- XP P 13-901; Blocs de Terre Comprimee Pour Murs et Cloisons: Definitions—Spécifications—Méthodes d’essais—Conditions de réception. Nomalistsation Francaise: Paris, France, 2001.

- Mansour, M.B.; Jelidi, A.; Cherif, A.S.; Jabrallah, S. Ben Optimizing Thermal and Mechanical Performance of Compressed Earth Blocks (CEB). Constr. Build. Mater. 2016, 104, 44–51. [Google Scholar] [CrossRef]

- Cristancho, K.; Otálvaro, I.F.; Ruiz, D.M.; Barrera, N.; Villalba-Morales, J.D.; Alvarado, Y.A.; Cundumí, O. Seismic Behavior of Bahareque Walls Under In-Plane Horizontal Loads. Buildings 2025, 15, 4. [Google Scholar] [CrossRef]

- Ruiz, G.; Zhang, X.; Edris, W.F.; Cañas, I.; Garijo, L. A Comprehensive Study of Mechanical Properties of Compressed Earth Blocks. Constr. Build. Mater. 2018, 176, 566–572. [Google Scholar] [CrossRef]

- Li, Z.; Noori, M.; Altabey, W.A. Experimental and Numerical Assessment on Seismic Performance of Earth Adobe Walls. SDHM Struct. Durab. Health Monit. 2021, 15, 103–123. [Google Scholar] [CrossRef]

- Greco, F.; Lourenço, P.B. Seismic Assessment of Large Historic Vernacular Adobe Buildings in the Andean Region of Peru. Learning from Casa Arones in Cusco. J. Build. Eng. 2021, 40, 102341. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, T.; Zhang, Z.; Tan, W.; Liang, Z. Near-Surface-Mounted Retrofitting of Adobe Walls Using Different Materials: Evaluation of Seismic Performance. Structures 2023, 54, 1149–1163. [Google Scholar] [CrossRef]

- Ahmadi, S.S.; Karanikoloudis, G.; Mendes, N.; Illambas, R.; Lourenço, P.B. Appraising the Seismic Response of a Retrofitted Adobe Historic Structure, the Role of Modal Updating and Advanced Computations. Buildings 2022, 12, 1795. [Google Scholar] [CrossRef]

- Samir, B.; Laidi, S.; Youssef, E.H. Failure Analysis of Compressed Earth Block Using Numerical Plastic Damage Model. Frat. Integrita Strutt. 2022, 16, 634–659. [Google Scholar] [CrossRef]

- Laursen, P.T.; Herskedal, N.A.; Jansen, D.C.; Qu, B. Out-of-Plane Structural Response of Interlocking Compressed Earth Block Walls. Mater. Struct./Mater. Constr. 2015, 48, 321–336. [Google Scholar] [CrossRef]

- Miccoli, L.; Drougkas, A.; Müller, U. In-Plane Behaviour of Rammed Earth under Cyclic Loading: Experimental Testing and Finite Element Modelling. Eng. Struct. 2016, 125, 144–152. [Google Scholar] [CrossRef]

- Wangmo, P.; Shrestha, K.C.; Miyamoto, M.; Aoki, T. Assessment of Out-of-Plane Behavior of Rammed Earth Walls by Pull-down Tests. Int. J. Archit. Herit. 2019, 13, 273–287. [Google Scholar] [CrossRef]

- Mora-Ruiz, V.; Mejía-Parada, C.; Nuñez, B.; Pineda, S.M.; Prado, N.I.; Vallejo-Borda, J.A.; Arrieta-Baldovino, J. Experimental Analysis of the Cyclic Behavior of Rammed Earth Walls Reinforced with Arundo Donax Natural Fiber. Heliyon 2024, 10, e37084. [Google Scholar] [CrossRef] [PubMed]

- Sauer, C.; Bagusat, F.; Heine, A.; Riedel, W. Shock Response of Lightweight Adobe Masonry. J. Dyn. Behav. Mater. 2018, 4, 231–243. [Google Scholar] [CrossRef]

- Qu, B.; Stirling, B.J.; Laursen, P.T.; Jansen, D.C. Analysis and Seismic Performance Evaluation of Flexure-Dominated Interlocking Compressed Earth Block Walls. Adv. Struct. Eng. 2015, 18, 2167–2179. [Google Scholar] [CrossRef]

- Mosquera, P.; Canas, I.; Cid-Falceto, J.; Marcos, F. Determination of the Thermal Conductivity in Adobe with Several Models. J. Heat. Transf. 2014, 136, 031303. [Google Scholar] [CrossRef]

- Bouchefra, I.; EL Bichri, F.Z.; Chehouani, H.; Benhamou, B. Mechanical and Thermophysical Properties of Compressed Earth Brick Rienforced by Raw and Treated Doum Fibers. Constr. Build. Mater. 2022, 318, 126031. [Google Scholar] [CrossRef]

- Hema, C.; Messan, A.; Lawane, A.; Van Moeseke, G. Impact of the Design of Walls Made of Compressed Earth Blocks on the Thermal Comfort of Housing in Hot Climate. Buildings 2020, 10, 157. [Google Scholar] [CrossRef]

- Jain, D.; Mukherjee, A.; Porter, H.; Blake, J. Enhanced Thermal Resistance of Rammed Earth Blocks with Recycled Industry By-Products. Int. J. Therm. Sci. 2019, 138, 447–458. [Google Scholar] [CrossRef]

- Jiang, B.; Wu, T.; Xia, W.; Liang, J. Hygrothermal Performance of Rammed Earth Wall in Tibetan Autonomous Prefecture in Sichuan Province of China. Build. Environ. 2020, 181, 107128. [Google Scholar] [CrossRef]

- Dong, X.; Soebarto, V.; Griffith, M. Achieving Thermal Comfort in Naturally Ventilated Rammed Earth Houses. Build. Environ. 2014, 82, 588–598. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mora-Ruiz, V.; Soto-Paz, J.; Attia, S.; Mejía-Parada, C. Sustainable Earthen Construction: A Meta-Analytical Review of Environmental, Mechanical, and Thermal Performance. Buildings 2025, 15, 918. https://doi.org/10.3390/buildings15060918

Mora-Ruiz V, Soto-Paz J, Attia S, Mejía-Parada C. Sustainable Earthen Construction: A Meta-Analytical Review of Environmental, Mechanical, and Thermal Performance. Buildings. 2025; 15(6):918. https://doi.org/10.3390/buildings15060918

Chicago/Turabian StyleMora-Ruiz, Viviana, Jonathan Soto-Paz, Shady Attia, and Cristian Mejía-Parada. 2025. "Sustainable Earthen Construction: A Meta-Analytical Review of Environmental, Mechanical, and Thermal Performance" Buildings 15, no. 6: 918. https://doi.org/10.3390/buildings15060918

APA StyleMora-Ruiz, V., Soto-Paz, J., Attia, S., & Mejía-Parada, C. (2025). Sustainable Earthen Construction: A Meta-Analytical Review of Environmental, Mechanical, and Thermal Performance. Buildings, 15(6), 918. https://doi.org/10.3390/buildings15060918