Solar Reflectance Index of Building Envelope Materials: A Comparative Review of North American and European Standards and Long-Term Performance

Abstract

1. Introduction

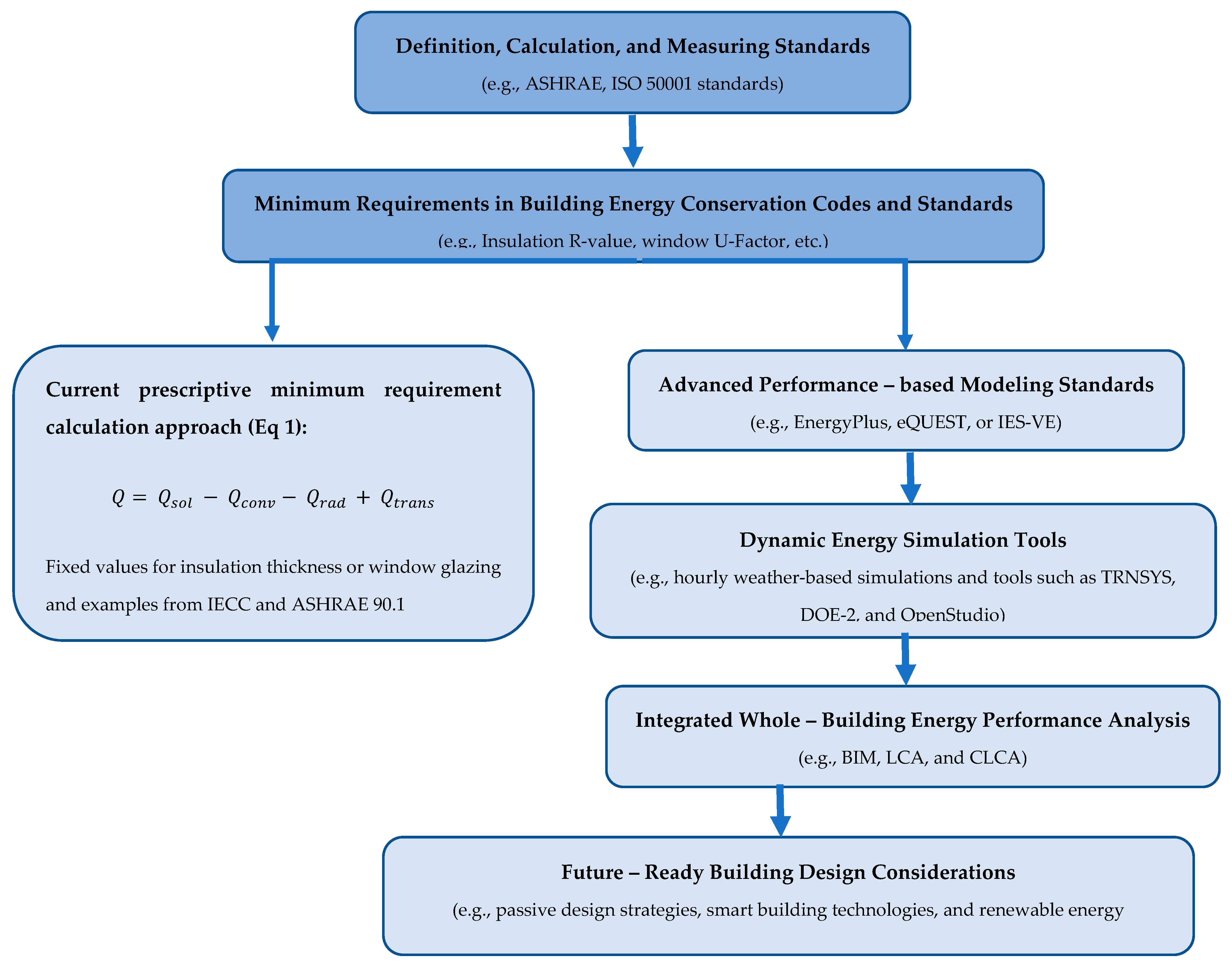

2. Overview of Solar Reflectance Index (SRI)

3. SRI Calculation and Measuring Standards

- (°C)

4. SRI Assessment Criteria

4.1. Energy Efficiency

4.2. Cost Estimation

5. SRI in Sustainable Building Design

5.1. Greenhouse Gas Emissions Reductions

- (1)

- Quantify cooling energy reduction

- (2)

- Determine reduction in energy-related GHG emissions

- (3)

- Incorporate ambient temperature reduction

- (4)

- Aggregate total GHG emissions reduction

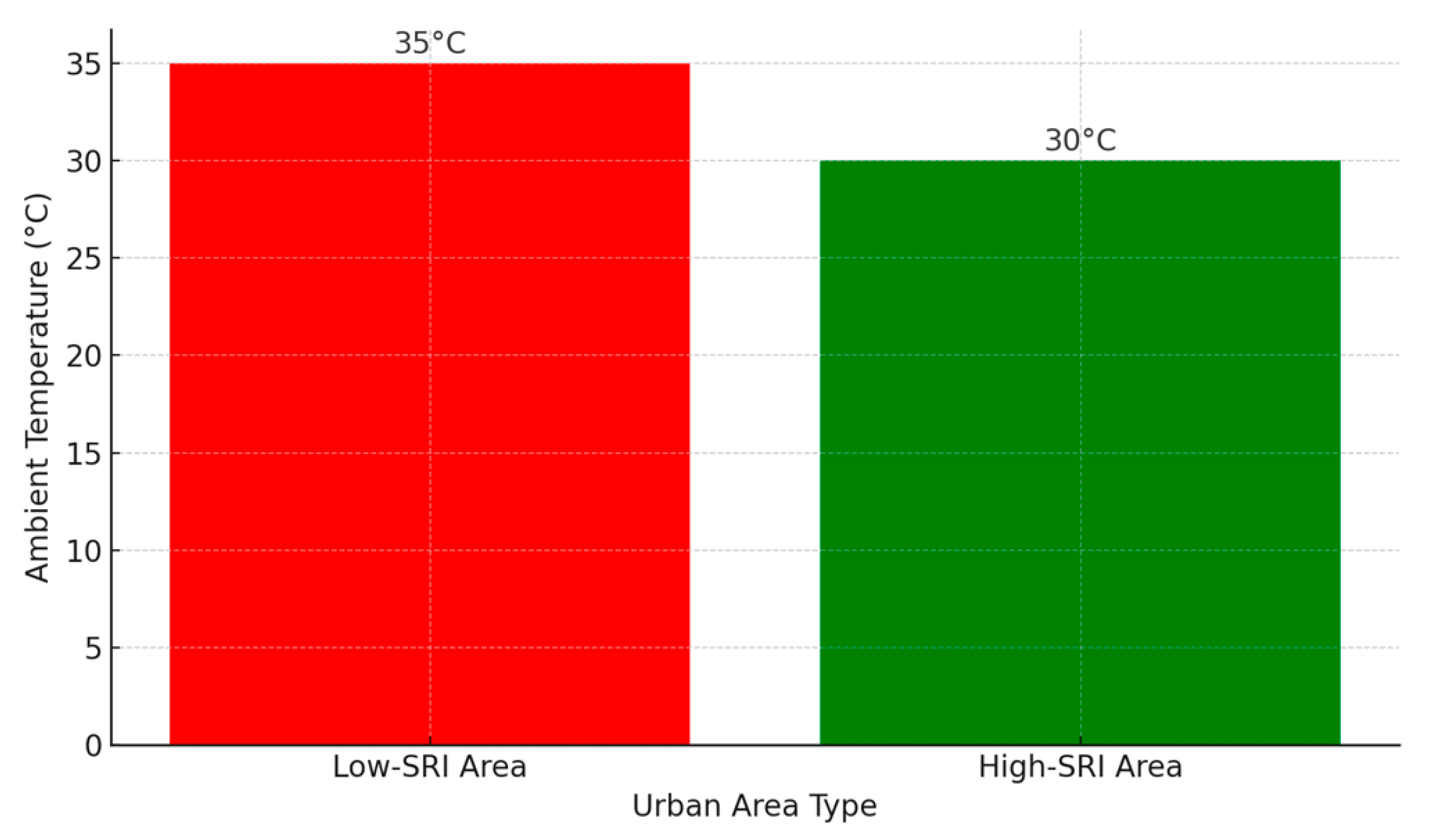

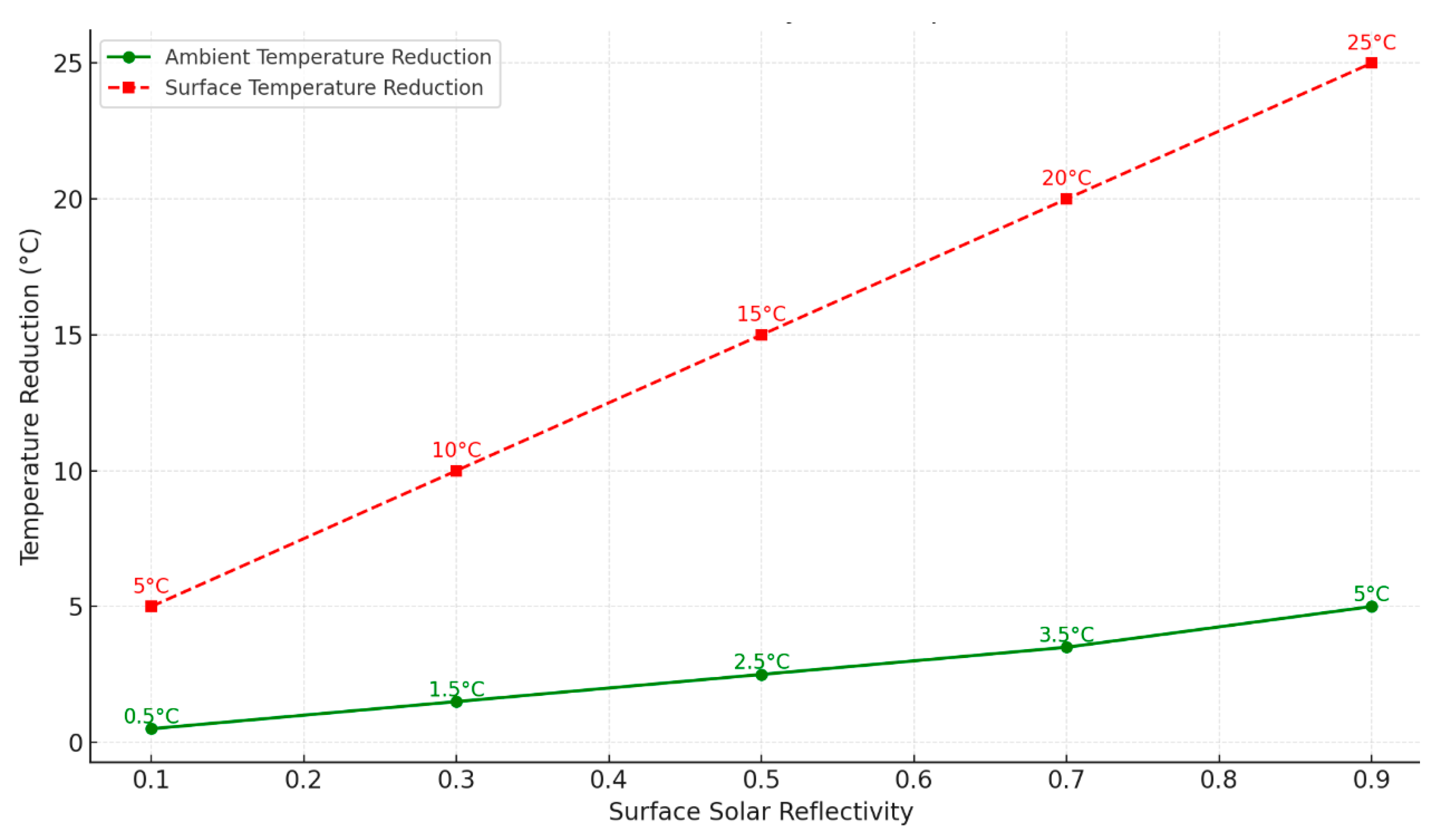

5.2. Urban Heat Islands Mitigation

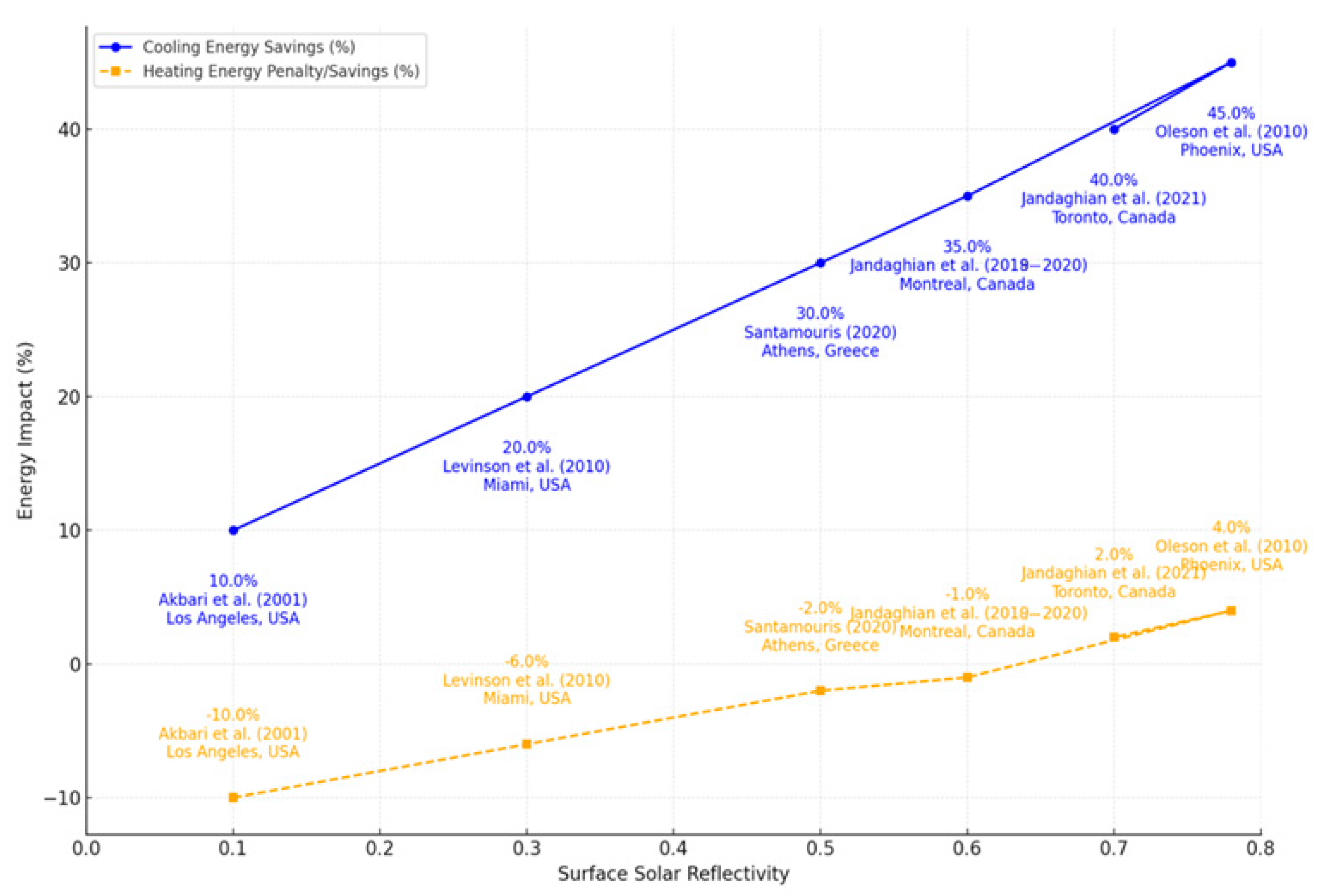

5.3. Economic Benefits and Energy Savings

6. Key Insights and Future Perspectives on SRI

- Current SRI measurement standards, such as those from ASTM and ASHRAE, predominantly address horizontal surfaces such as roofs, largely neglecting vertical surfaces such as building facades and walls. Vertical surfaces significantly impact building energy efficiency and thermal comfort, as their interaction with solar radiation varies based on orientation and time of the day. Developing comprehensive guidelines for measuring the SRI of vertical surfaces is a critical area for future investigation.

- There is limited research on integrating SRI optimization across the entire building envelope, including roofs, walls, windows, and pavements. A holistic approach is necessary to optimize thermal performance and ensure consistent energy savings across all building components. Research should focus on methodologies that evaluate the cumulative impact of both vertical and horizontal surfaces on energy efficiency and thermal comfort.

- Existing SRI criteria are primarily derived from energy conservation standards focused on cost–benefit analyses. These often overlook the broader benefits of SRI in mitigating UHI effects, enhancing public health, and improving urban sustainability. Future research should assess how high-SRI materials can reduce outdoor temperatures in densely populated areas, improve outdoor thermal comfort, and lower city-wide cooling energy demands.

- Current SRI standards emphasize reducing cooling demands during summer but may not be suitable for all climatic conditions. In colder climates, high-SRI materials can increase heating demands in winter, creating a heating penalty. Research is needed to develop climate-specific SRI criteria that balance cooling and heating needs. This could include a range of SRI standards with minimum values for cooling and maximum values for heating to optimize year-round energy performance.

- Changing weather patterns and global warming are likely to affect the performance of SRI materials. Rising temperatures, increased solar radiation, and extreme weather events may alter the effectiveness of these materials. Future studies should explore the performance of SRI under various climate scenarios, including long-term durability under conditions such as higher temperatures, intense UV exposure, and accelerated weathering.

- To address these gaps, the following areas of research are recommended:

- Develop SRI standards tailored to vertical surfaces, accounting for their orientation, solar exposure, and impact on energy efficiency. Research should explore how facade materials, surface textures, and coatings influence SRI and optimize these properties for specific climates.

- Create integrated energy models that incorporate SRI values across the entire building envelope, including walls and roofs. These models should simulate thermal performance under various weather conditions and climate scenarios, providing actionable insights for architects and urban planners.

- Expand the focus from individual buildings to the urban scale by assessing the effects of widespread high-SRI material adoption. This research could use geographic information systems (GIS) and remote sensing to map SRI distribution and model its cumulative impact on urban energy use, thermal comfort, and UHI mitigation.

- Investigate the development of materials with variable SRI properties that adapt to changing environmental conditions. Smart coatings, phase-change materials, and other innovative technologies could enable optimal thermal performance throughout the year.

- Study the long-term performance of high-SRI materials in real-world conditions, including their degradation due to weathering, UV exposure, and pollution. Research should also focus on maintenance strategies, such as self-cleaning surfaces or protective coatings, to preserve reflectance and emittance properties over the material’s lifecycle.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature List

| SRI | Solar Reflectance Index |

| UHI | Urban Heat Island |

| ASTM | American Society for Testing and Materials |

| EN | European Norm |

| CRRC | Cool Roof Rating Council |

| ECRC | European Cool Roof Council |

| Net heat gain or loss through the envelope (W/m2) | |

| Solar heat gain, influenced by the Solar Reflectance Index (SRI) and surface properties (W/m2) | |

| Convective heat loss (W/m2) | |

| Radiative heat exchange with the surroundings (W/m2) | |

| Heat transfer through conduction via the building envelope (W/m2) | |

| α | Solar absorptance |

| ε | Thermal emissivity |

| hc | Convective coefficient (W/m2·K) |

| Ts | Steady-state surface temperature (°C) |

| Tb | Black surface temperature (°C) |

| Tw | White surface temperature (°C) |

| CDD | Cooling Degree Days |

| HDD | Heating Degree Days |

| ISO | International Organization for Standardization |

| Cooling energy savings (kWh/m2/year) | |

| Baseline cooling energy demand (kWh/m2/year) | |

| Cooling energy reduction percentage due to reflectivity, derived from ambient and surface temperature reductions | |

| GHG emissions reduction (kg CO2/m2/year) | |

| Carbon emissions factor of electricity (kg CO2/kWh) | |

| Total area of reflective surfaces (e.g., roofs, walls, pavements) |

References

- Levinson, R.; Akbari, H.; Berdahl, P. Measuring solar reflectance—Part I: Defining a metric that accurately predicts solar heat gain. Sol. Energy 2010, 84, 1717–1744. [Google Scholar] [CrossRef]

- Akbari, H.; Konopacki, S. Calculating energy-saving potentials of heat-island reduction strategies. Energy Policy 2005, 33, 721–756. [Google Scholar] [CrossRef]

- Akbari, H.; Matthews, H.D. Global cooling: Policies to cool the world and offset global warming from CO2 using reflective roofs and pavements. Carbon Manag. 2012, 3, 201–206. [Google Scholar]

- Jandaghian, Z.; Berardi, U. Analysis of the cooling effects of higher albedo surfaces during heat waves coupling the Weather Research and Forecasting model with building energy models. Energy Build. 2020, 207, 109–627. [Google Scholar] [CrossRef]

- Akbari, H.; Menon, S.; Rosenfeld, A. Global cooling: Increasing world-wide urban albedos to offset CO2. Clim. Change 2001, 94, 275–286. [Google Scholar] [CrossRef]

- Jandaghian, Z.; Akbari, H. The Effect of Increasing Surface Albedo on Urban Climate and Air Quality: A Detailed Study for Sacramento, Houston, and Chicago. Climate 2018, 6, 19. [Google Scholar] [CrossRef]

- Santamouris, M. Regulating the damaged thermostat of the cities–Status, impacts and mitigation challenges. Energy Build. 2015, 91, 43–56. [Google Scholar] [CrossRef]

- Lu, H.; Gaur, A.; Krayenhoff, E.S.; Jandaghian, Z.; Lacasse, M.; Travis, M. Thermal effects of cool roofs and urban vegetation during extreme heat events in three Canadian regions. Build. Environ. 2023, 99, 104925. [Google Scholar] [CrossRef]

- Santamouris, M.; Kolokotsa, D. Passive cooling dissipation techniques for buildings and other structures: The state of the art. Energy Build. 2013, 57, 74–94. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, F. Influence of solar reflectance on urban heat islands: A study in tropical cities. Build. Environ. 2015, 93, 9–18. [Google Scholar]

- Dimoudi, A.; Zoras, S.; Kantzioura, A.; Stogiannou, X.; Kosmopoulos, P.; Pallas, C. Use of cool materials and other bioclimatic interventions in outdoor places in order o mitigate the urban heat island in a medium size city in Greece. Sustain. Cities Soc. 2024, 13, 89–96. [Google Scholar] [CrossRef]

- Kitsopoulou, A.; Bellos, B.; Tzivanidis, C. An Up-to-Date Review of Passive Building Envelope Technologies for Sustainable Design. Energies 2024, 17, 4039. [Google Scholar] [CrossRef]

- Santamouris, M.; Synnefa, A.; Karlessi, T. Using advanced cool materials in the urban built environment to mitigate heat islands and improve thermal comfort conditions. Sol. Energy 2020, 85, 3085–3102. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Z.-H.; Kaloush, K.E.; Shacat, J. Cool pavements for urban heat island mitigation: A synthetic review. Renew. Sustain. Energy Rev. 2021, 146, 111171. [Google Scholar] [CrossRef]

- El-Darwish, I.; Gomaa, M. Retrofitting strategy for building envelopes to achieve energy efficiency. Alex. Eng. J. 2017, 56, 579–589. [Google Scholar] [CrossRef]

- Jiao, K.; Lu, L.; Zhao, L.; Wang, G. Towards Passive Building Thermal Regulation: A State-of-the-Art Review on Recent Progress of PCM-Integrated Building Envelopes. Sustainability 2024, 16, 6482. [Google Scholar] [CrossRef]

- Jo, J.H.; Carlson, J.D.; Golden, J.S.; Bryan, H. An integrated empirical and modeling methodology for analyzing solar reflective roof technologies on commercial buildings. Build. Environ. 2010, 45, 453–460. [Google Scholar] [CrossRef]

- Haverstic, P. A Case Study on the Impact of Solar Reflectance Attenuation and Roof Cleaning on a Cool Roof Return on Investment. Master’s Thesis, Repository. Arizona State University, Tempe, AZ, USA, 2016. [Google Scholar]

- Hong, W.T.; Loo, S.C.; Ibrahim, K. Urging green retrofits of building facades in the tropics: A review and research agenda. Int. J. Sustain. Energy 2019, 10, 1140–1149. [Google Scholar] [CrossRef]

- Wei, L.J.; Islam, M.M.; Hasanuzzaman, M. Energy consumption, power generation, and performance analysis of solar photovoltaic module-based building roof. J. Build. Res. 2024, 90, 109361. [Google Scholar] [CrossRef]

- Emmanuel, R. Estimating the environmental suitability of wall materials: Preliminary results from Sri Lanka. Build. Environ. 2004, 39, 1181–1190. [Google Scholar] [CrossRef]

- Gago, E.J.; Roldan, J.; Pacheco-Torres, R.; Ordóñez, J. The city and urban heat islands: A review of strategies to mitigate adverse effects. Renew. Sustain. Energy Rev. 2013, 25, 749–758. [Google Scholar] [CrossRef]

- Synnefa, A.; Santamouris, M. Advances on technical, policy and market aspects of cool roof technology in Europe: The Cool Roofs project. Energy Build. 2012, 55, 35–41. [Google Scholar] [CrossRef]

- Synnefa, A.; Dandou, A.; Santamouris, M.; Tombrou, M.; Soulakellis, N. On the use of cool materials as a heat island mitigation strategy. J. Appl. Meteorol. Climatol. 2007, 47, 2846–2856. [Google Scholar] [CrossRef]

- Kolokotsa, D.; Santamouris, M.; Zerefos, S.C. Green and cool roofs’ urban heat island mitigation potential in European climates for office buildings under free floating conditions. Sol. Energy 2011, 95, 118–130. [Google Scholar] [CrossRef]

- Kolokotroni, M.; Gowreesunker, B.L.; Giridharan, R. Cool roof technology in London: An experimental and modelling study. Energy Build. 2012, 54, 181–189. [Google Scholar] [CrossRef]

- Levinson, R.; Berdahl, P.; Akbari, H. Solar spectral optical properties of pigments–Part II: Survey of common colorants. Sol. Energy Mater. Sol. Cells 2005, 89, 351–389. [Google Scholar] [CrossRef]

- Berdahl, P.; Bretz, S. Preliminary survey of the solar reflectance of cool roofing materials. Energy Build. 1997, 25, 149–158. [Google Scholar] [CrossRef]

- Rosenfeld, A.H.; Akbari, H.; Bretz, S.; Fishman, B.L.; Kurn, D.M.; Sailor, D.; Taha, H. Mitigation of urban heat islands: Materials, utility programs, updates. Energy Build. 1995, 22, 255–265. [Google Scholar] [CrossRef]

- Ziaeemehr, B.; Jandaghian, Z.; Ge, H.; Lacasse, M.; Moore, T. Increasing Solar Reflectivity of Building Envelope Materials to Mitigate Urban Heat Islands: State-of-the-Art Review. Buildings 2023, 13, 2868. [Google Scholar] [CrossRef]

- Levinson, R.; Akbari, H.; Miller, W. Climatic effects of cool roofs. Adv. Build. Energy Res. 2013, 7, 1–28. [Google Scholar]

- Georgescu, M.; Morefield, P.E.; Bierwagen, B.G.; Weaver, C.P. Urban adaptation can roll back warming of emerging megapolitan regions. Proc. Natl. Acad. Sci. USA 2014, 111, 2909–2914. [Google Scholar] [CrossRef] [PubMed]

- Berdahl, P.; Akbari, H. Evaluation of cool roof and cool pavement applications in Los Angeles. Energy Build. 2008, 40, 2600–2607. [Google Scholar]

- Levinson, R.; Berdahl, P.; Akbari, H. Aging of reflective roofs: Soot deposition. Appl. Opt. 2007, 46, 4592–4600. [Google Scholar]

- Li, D.; Bou-Zeid, E.; Oppenheimer, M. The effectiveness of cool and green roofs as urban heat island mitigation strategies. Environ. Res. Lett. 2014, 9, 055002. [Google Scholar] [CrossRef]

- McPherson, E.G.; Simpson, J.R.; Xiao, Q. The effects of green roofs on air pollution in urban environments: A review. J. Environ. Manag. 2016, 114, 1–8. [Google Scholar]

- Berdahl, P.; Akbari, H.; Levinson, R.; Miller, W.A. Weathering of roofing materials—An overview. Constr. Build. Mater. 2012, 22, 423–434. [Google Scholar] [CrossRef]

- Pisello, A.L.; Cotana, F. Experimental analysis of weathering effects on solar reflectance of roofing membranes and comparison with theoretical predictions. Energy Build. 2014, 68, 1–8. [Google Scholar]

- Hayes, A.T.; Jandaghian, Z.; Lacasse, M.A.; Gaur, A.; Lu, H.; Laouadi, A.; Wang, L. Nature-Based Solutions (NBSs) to Mitigate Urban Heat Island (UHI) Effects in Canadian Cities. Buildings 2022, 12, 925. [Google Scholar] [CrossRef]

- ASTM E903-20; Standard Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM E1980-11; Standard Practice for Calculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque Surfaces. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C1549-16; Standard Test Method for Determination of Solar Reflectance Near Ambient Temperature Using a Portable Solar Reflectometer. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C1371-15; Standard Test Method for Determination of Emittance of Materials Near Room Temperature Using Portable Emissometers. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM E1918-21; Standard Test Method for Measuring Solar Reflectance of Horizontal and Low-Sloped Surfaces in the Field. ASTM International: West Conshohocken, PA, USA, 2021.

- ANSI/CRRC S100; Standard Test Methods for Determining Radiative Properties of Materials. Cool Roof Rating Council: Portland, OR, USA, 2021.

- Cool Roofs in Europe. 2020. Available online: https://build-up.ec.europa.eu/sites/default/files/content/Cool%20Roofs_EN_1.pdf (accessed on 1 January 2025).

- Petrie, T.W.; Desjarlais, A.O.; Robertson, R.H.; Parker, D.S. Comparison of Techniques for In Situ Nondamaging Measurement of Solar Reflectances of Low-Slope Roof Membranes. Int. J. Thermophys. 2001, 22, 1613–1628. [Google Scholar] [CrossRef]

- Smith, G.B.; Gentle, A.R.; Arnold, M.D.; Gali, M.A.; Cortie, M.B. The importance of surface finish to energy performance. Renew. Energy Environ. Sustain. 2017, 2, 13. [Google Scholar] [CrossRef][Green Version]

- Brooks, A.; Zank, B.; Coakley, K.; Silverberg, S. 2022 Title 24, Part 6 Final CASE Document Information Category: Codes and Standards; ICC Digital Codes: Los Angeles, CA, USA, 2022. [Google Scholar]

- Bailey, J.; Edelson, J.; Ferguson, S.; Heizer, M.; Hickman, A.; Jonlin, D.; Makala, E. 2015 International Energy Conservation Code® and Commentary; International Code Council, Inc.: Washington, DC, USA, 2015. [Google Scholar]

- U.S. Environmental Protection Agency (EPA) and U.S. Department of Energy (DOE). Energy Star. Available online: https://www.energy.gov/eere/buildings/energy-starr (accessed on 15 January 2024).

- Alabama Energy Codes—Alabama Board of Heating, Air Conditioning & Refrigeration Contractors. Available online: https://hacr.alabama.gov/alabama-energy-codes/ (accessed on 1 January 2025).

- Los Angeles County. Title 31. Green Building Standards Code. 2016. Available online: https://library.municode.com/ca/los_angeles_county/codes/code_of_ordinances?nodeId=TIT31GRBUSTCO (accessed on 15 January 2024).

- City of Toronto Bylaw. Chapter 492. Available online: https://www.toronto.ca/legdocs/bylaws/2013/law1244.pdf (accessed on 1 January 2025).

- Denver’s Green Buildings Ordinance. Available online: https://www.denvergov.org/Government/Agencies-Departments-Offices/Agencies-Departments-Offices-Directory/Community-Planning-and-Development/Plan-Review-Permits-and-Inspections/Commercial-and-Multifamily-Projects/Green-Buildings-Ordinance (accessed on 1 January 2025).

- Urban Heat Island Ordinance. 2019. Available online: https://www.mbrisingabove.com/wp-content/uploads/2019-4252-Ordinance-Urban-Heat-Island-1.pdf (accessed on 1 January 2025).

- Georgia Department of Community Affairs Community Development Division. Georgia State Supplements and Amendments to the International Energy Conservation Code. 2015. Available online: www.dca.ga.gov (accessed on 1 January 2025).

- Hawaii State Energy Office. Energy Conservation Code. 2016. Available online: https://energy.hawaii.gov/ (accessed on 1 January 2025).

- Chicago Construction Code. 2019. Available online: https://www.chicago.gov/city/en/depts/bldgs/provdrs/bldg_code/svcs/chicago_buildingcodeonline.html (accessed on 1 January 2025).

- Energy Conservation Code. Chapter R4, Residential Energy Efficiency. In 2020 New York City Energy Conservation Code; ICC Digital Codes: Los Angeles, CA, USA, 2020. [Google Scholar]

- 2019 Chicago Building Code with May 2020 Supplement. Available online: https://codes.iccsafe.org/content/CHIBC2019P2 (accessed on 15 January 2025).

- Government of the District of Columbia. 2017 District of Columbia Energy Conservation Code; International Code Council, Inc.: Washington, DC, USA, 2017. [Google Scholar]

- Green Mark. Resilience Technical Guide. 2021. Available online: https://www1.bca.gov.sg/docs/default-source/docs-corp-buildsg/sustainability/20211028_-resilience-technical-guide_r1-1.pdf (accessed on 1 January 2025).

- 2017 DC Energy Code. Available online: https://dob.dc.gov/sites/default/files/dc/sites/dob/publication/attachments/2017%20DC%20Energy%20Code.pdf (accessed on 1 January 2025).

- Taleghani, M.; Sailor, D.J.; Ban-Weiss, G. The impact of reflective pavements on building energy use and the urban heat island effect. Urban Clim. 2014, 10, 114–134. [Google Scholar]

- Yang, J.; Zhang, G.; Wang, Z.H.; Bao, Z. Assessing the thermal performance of a high-reflectance roof in reducing building energy consumption and urban heat island effect. Sustain. Cities Soc. 2018, 43, 163–176. [Google Scholar]

- Jandaghian, Z.; Akbari, H. Heat Mitigation Strategy to Reduce Heat-related Mortality in Two Canadian Cities: Toronto and Montreal. Energy Build. 2021, 237, 110697. [Google Scholar] [CrossRef]

- Siu, C.Y.; O’Brien, W.; Touchie, M.; Armstrong, M.; Laouadi, A.; Gaur, A.; Jandaghian, Z.; Macdonald, I. Evaluating thermal resilience of building designs using building performance simulation—A review of existing practices. Build. Environ. 2023, 234, 110–124. [Google Scholar] [CrossRef]

- Yilmaz, M.; Erdogdu, S. Impact of high-SRI coatings on building energy performance in hot climates. Energy Build. 2021, 217, 112108. [Google Scholar]

- Wong, N.H.; Jusuf, S.K.; Tan, C.L. Computational evaluation of urban canyon temperature mitigation. Build. Simul. 2020, 13, 747–758. [Google Scholar]

- Oke, T.R.; Mills, G.; Christen, A.; Voogt, J.A. Urban Climates; Cambridge University Press: Cambridge, UK, 2017. [Google Scholar]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

- Rydin, Y.; Bleahu, A.; Davies, M. Shaping cities for health: Complexity and the planning of urban environments. Lancet 2012, 379, 2079–2108. [Google Scholar] [CrossRef]

- Oleson, K.W.; Bonan, G.B.; Feddema, J. Effects of white roofs on urban temperature in a global climate model. Geophys. Res. Lett. 2010, 37, L03701. [Google Scholar] [CrossRef]

- Jandaghian, Z.; Akbari, H. Effects of increasing surface reflectivity on aerosol, radiation, and cloud interactions in the urban atmosphere. Theor Appl. Climatol. 2020, 139, 873–892. [Google Scholar] [CrossRef]

- Jandaghian, Z.; Akbari, H. The effects of increasing surface reflectivity on heat-related mortality in Greater Montreal Area, Canada. Urban Clim. 2018, 25, 135–151. [Google Scholar] [CrossRef]

- Jandaghian, Z.; Berardi, U. Proper choice of urban canopy model for climate simulations. Build. Simul. 2019, 16, 3401–3405. [Google Scholar]

| Property | Cool Materials | Conventional Materials |

|---|---|---|

| Solar Reflectance | High (≥0.65) | Low (≤0.30) |

| Thermal Emittance | High (≥0.75) | Variable; often low |

| Surface Temperature | Reduces by 10–20 °C | Retains more heat |

| UHI Mitigation Potential | Significant | Limited |

| Degradation Rate | Lower due to UV-resistant coatings | Higher |

| Cost | Higher initial cost (10–50% more) | Lower initial cost |

| Energy Efficiency | Reduces cooling energy demand by 10–40% | High heat absorption increases cooling energy needs |

| Durability | Resistant to UV radiation and weathering (15–20 years) | Moderate lifespan (10–15 years), prone to heat degradation |

| Thermal Behavior | Reflects sunlight, emits absorbed heat efficiently | Absorbs and retains heat, contributing to urban warming |

| Payback Period | Typically 5–10 years due to energy savings | No significant payback benefits |

| Environmental Impact | Mitigates Urban Heat Island effect and reduces urban temperatures by up to 2 °C | Contributes to Urban Heat Island effect |

| Standard | Description | Ref. |

|---|---|---|

| ASTM E903 | This testing procedure involves the assessment of spectral absorptance, reflectance, and transmittance of materials using spectrophotometers equipped with integrating spheres. It is applicable to materials exhibiting both specular and diffuse optical properties. Measurements encompass the spectral near normal-hemispherical transmittance (or reflectance) over the range of 300 to 2500 nm with an integrating sphere spectrophotometer. The solar transmittance, reflectance, or absorptance is determined by computing a weighted average using a standard or selected solar spectral irradiance. | [40] |

| ASTM E1980 | The equilibrium surface temperature (Ts) in sunlight is closely linked to the solar reflectivity and thermal emissivity of the surface. This procedure outlines the computation of the SRI for horizontal and low-sloped opaque surfaces under standard conditions. The application of this method is designed for surfaces with emissivity exceeding 0.1. Solar reflectance and thermal emittance are pivotal factors influencing ambient air temperature near the surface and in its proximity. | [41] |

| ASTM C1549 | This testing procedure addresses the methodology for assessing the solar reflectance of flat opaque materials either in a laboratory setting or in the field, employing a commercial portable solar reflectometer. It is specifically designed for the measurement of solar reflectance in opaque materials. Opaque surfaces exposed to solar radiation typically attain temperatures higher than the surrounding air. This test method is applied to determine the solar reflectance of such flat opaque surfaces. | [42] |

| ASTM C1371 | In this testing procedure a method is given for determining the emittance of opaque and highly thermally conductive materials utilizing a portable differential thermopile emissometer. The objective is to offer a comparative means for quantifying material emittance near room temperature. It is important to note that this test method does not replace Test Method C835, an absolute method for determining total hemispherical emittance, or Test Method E408, which encompasses two comparative methods for determining total normal emittance. | [43] |

| ASTM E1918 | In this testing method, the measurement of solar reflectance for diverse horizontal and low-sloped surfaces and materials in outdoor settings is described, for which either an albedometer or pyranometer is prescribed. It is specifically designed for application when the angle of the sun to the normal from a surface is less than 45°. | [44] |

| ANSI/CRRC S100 USA | In this standard the preparation of test specimens is addressed and the methods for assessing the initial and aged radiative properties of roof products provided. This standard is cited by international building codes and rating programs to evaluate the initial and aged solar reflectance and thermal emittance of roofing products. | [45] |

| ECRC Europe | In this manual the preparation of test specimens is described, and methods are given for assessing the initial and aged radiative properties of roofing products. | [46] |

| ECRC | CRRC | |

|---|---|---|

| Solar reflectance | ASTM E903 | ASTM E903 |

| ASTM C1549 | ASTM C1549 | |

| CRRC-1 ANSI/CRRC S100 | CRRC-1 ANSI/CRRC S100 | |

| ASTM E1918 | ||

| ASTM C1864 | ||

| Emittance | ASTM C1371 | ASTM C1371 |

| EN 15976 | ||

| Devices and services technical notes | TN11-2, TN 04-01, and TN 10-2 | TN11-2. |

| SRI | ASTM E1980-11 [41] | ASTM E1980-11 |

| Specimen dimension | 10 cm × 15 cm | 10.3 cm × 15.2 cm |

| Field-applied coating thickness | ASTM D1005 | ASTM D1005 |

| ASTM D709 | ASTM D709 | |

| ISO 2178 | ASTM D1669 | |

| ENISO 2808 | ||

| Single ply thickness | ASTM D751 | ASTM D751 |

| EN 1849-1 | ||

| Climate for aging | Three years Koppen climate classification ISO 17025 | Three years CDD and HDD climate classification ASHRAE |

| Agency | SRI Requirement | Ref. |

|---|---|---|

| Alabama Energy and Residential Codes (AERC) Board, USA | Three-year-aged solar reflectance of 0.55 and three-year-aged thermal emittance of 0.75, three-year-aged solar reflectance index of 64. | [52] |

| Environmental Protection Agency, ENERGY STAR | An initial solar reflectance of 0.65 or higher and an aged solar reflectance of 0.50 or higher are required for low slope roofs. For steep sloped roofs, the criteria are 0.25 for initial solar reflectance and 0.15 for aged solar reflectance. | [53] |

| California Energy Commission, USA | The specific SRI values can vary based on regional climate considerations, building types, and local policies. For example, for non-residential building Steep-sloped roofs: In Climate Zones 1 and 3 shall have a minimum aged solar reflectance of 0.20 and a minimum thermal emittance of 0.75, or a minimum SRI of 16. In Climate Zones 2 and 4 through 16 shall have a minimum aged solar reflectance of 0.25 and a minimum thermal emittance of 0.80, or a minimum SRI of 23. Also, low-sloped roofs in climate zones 1 through 16 shall have: a minimum aged solar reflectance of 0.63 and a minimum thermal emittance of 0.75; or a minimum SRI of 75. California State has distinct criteria established for each of its 16 climate zones. | [54] |

| Los Angeles County, USA | For low-rise residential structures, with slopes ≤2:12, the minimum 3-year-aged solar reflectance must be 0.65, with a thermal emittance of 0.85, resulting in a Solar Reflectance Index (SRI) of 78. For slopes >2:12 in the same category, the requirements are a 0.25 minimum 3-year-aged solar reflectance, a thermal emittance of 0.85, and an SRI of 20. Additionally, for high-rise residential buildings, hotels, and motels, similar criteria apply, with the distinction of a slightly lower thermal emittance requirement of 0.75 for both slope categories, while maintaining the same solar reflectance and SRI specifications. | [55] |

| Toronto Municipality, Canada | Industrial building or a building addition to an industrial building, with a gross floor area of 2000 square meters or greater, should have a minimum SRI of 78. | [56] |

| Denver’s Green Buildings Ordinance (GBO), Colorado, USA | Must follow the LEED standards under certain requirements which requires roofing materials to have an SRI value of 29 or more for steep slope roofs and more than 78 on low sloping roofs. | [57] |

| City of Florida, USA | A reflective roofing with a high thermal emissivity rating (>0.8) will perform best and a solar reflectance value of 0.65 or greater. | [58] |

| City of Georgia, USA | All building and structural roofs shall be constructed of a heat-reflective material to achieve a minimum initial Solar SRI of 78 for a low-sloped roof (less than or equal to 2:12) and a minimum initial SRI of 29 for a steep-sloped roof (more than 2:12) except for those portions of roofing designated for vegetation. | [59] |

| Hawaii State Energy Office, USA | Cool roof with three-year-aged solar reflectance of 0.55 and 3-year-aged thermal emittance of 0.75 or 3-year-aged solar reflectance index of 64. | [60] |

| City of Chicago, USA | Roof coverings on low-sloped roofs shall have an initial reflectance value of 0.72 or a three-year-installed reflectance value of 0.5 or greater. | [61] |

| New York, USA | Roofs and walls are recommended to have a solar absorptance of 0.75 and an emittance of 0.90, aligning with the specifications outlined in the 2020 Energy Conservation Code. | [62] |

| City of Houston, Texas, USA | A minimum three-year-aged solar reflectance of 0.55 and a minimum three-year-aged thermal emittance of 0.75 or a minimum Solar Reflectance Index of 64. | [63] |

| Columbia Energy Conservation Code, USA | Roofs should have a minimum three-year-aged SRI of 64. | [64] |

| Italy | High solar reflectance materials for roofs (cool roof), with a minimum solar reflectance value of 0.65 for flat roofs; 0.30 for pitched roofs. | [23] |

| Green Mark, BCA, Singapore, internationally used for tropical climates | Roofing materials or coatings or cool paints with high Solar Reflectance Index (SRI) > 40. | [65] |

| France | Association Française de Normalisation (AFNOR) standards require minimum solar reflectance of 30% for façade coatings. | [66] |

| Greek, UK, Germany | Adopted initiatives to promote cool materials. | [67] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jandaghian, Z.; Lacasse, M.; Gaur, A. Solar Reflectance Index of Building Envelope Materials: A Comparative Review of North American and European Standards and Long-Term Performance. Buildings 2025, 15, 888. https://doi.org/10.3390/buildings15060888

Jandaghian Z, Lacasse M, Gaur A. Solar Reflectance Index of Building Envelope Materials: A Comparative Review of North American and European Standards and Long-Term Performance. Buildings. 2025; 15(6):888. https://doi.org/10.3390/buildings15060888

Chicago/Turabian StyleJandaghian, Zahra, Michael Lacasse, and Abhishek Gaur. 2025. "Solar Reflectance Index of Building Envelope Materials: A Comparative Review of North American and European Standards and Long-Term Performance" Buildings 15, no. 6: 888. https://doi.org/10.3390/buildings15060888

APA StyleJandaghian, Z., Lacasse, M., & Gaur, A. (2025). Solar Reflectance Index of Building Envelope Materials: A Comparative Review of North American and European Standards and Long-Term Performance. Buildings, 15(6), 888. https://doi.org/10.3390/buildings15060888