Influence of Test Configuration on the Bond–Slip Behavior of Hooked-End Steel Fibers in Concrete: Quantity, Inclination, and Spacing

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Properties

2.2. Composition and Preparation of the Mortar

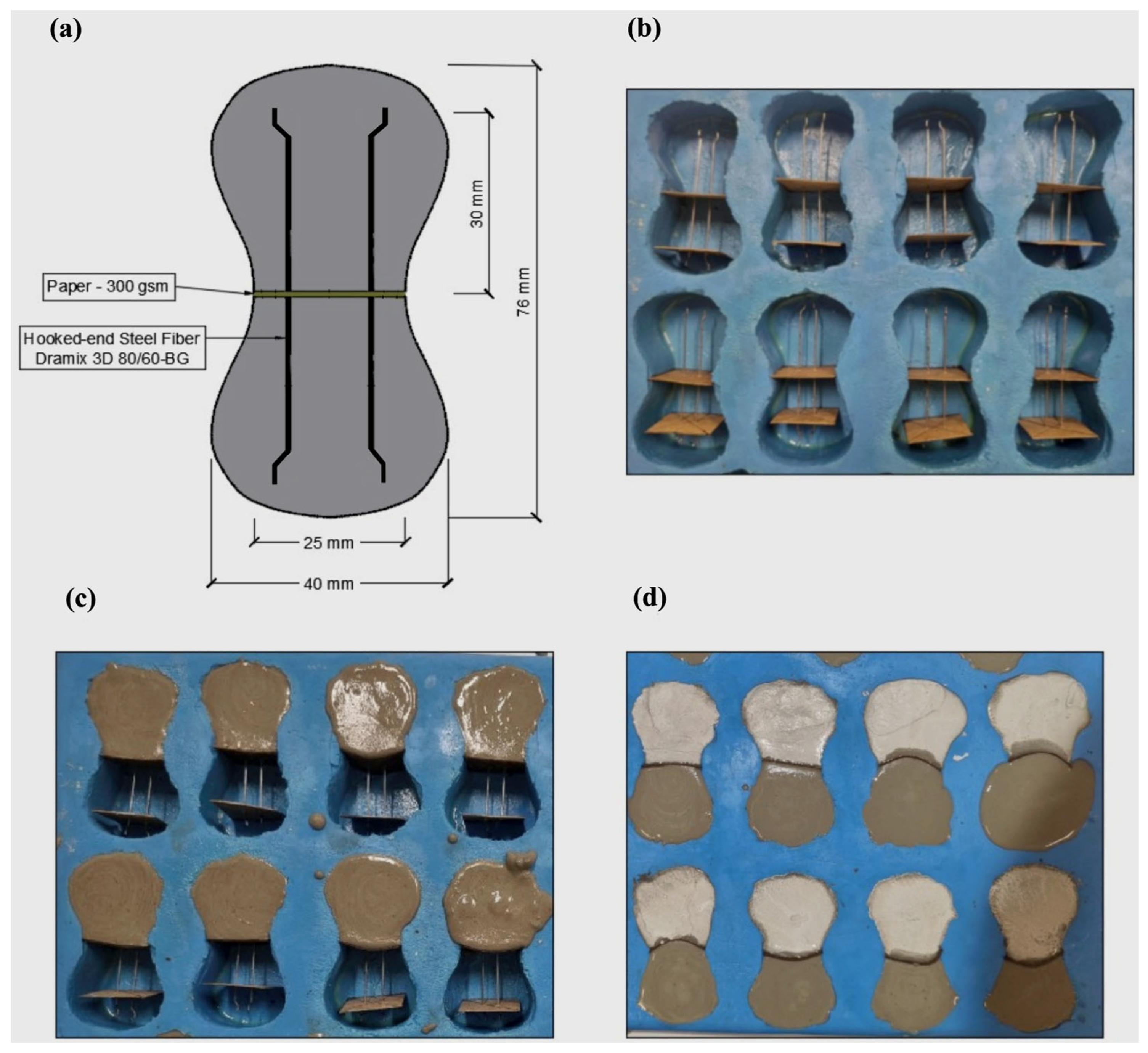

2.3. Casting of the Pullout Specimens

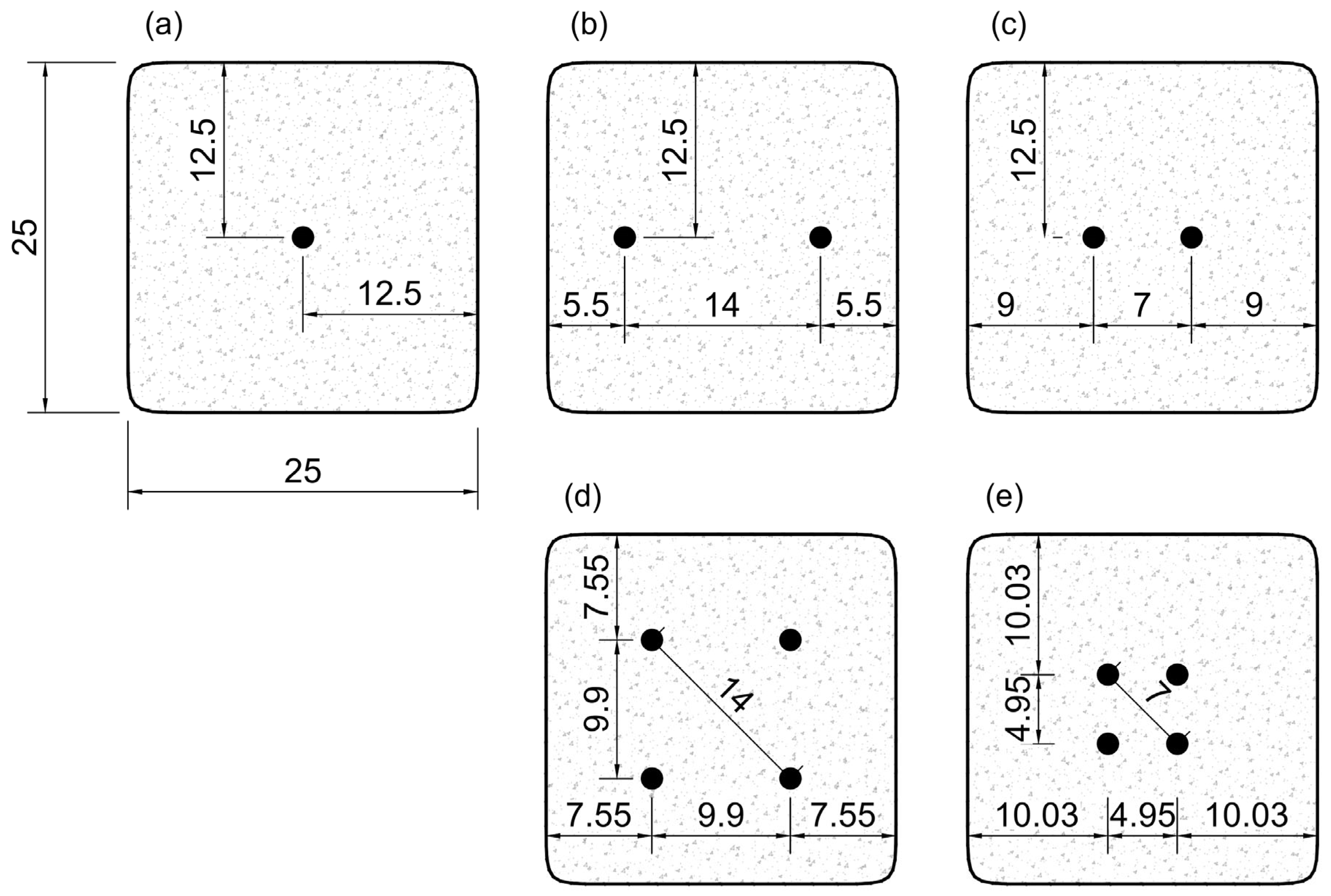

2.4. Testing of the Pullout Specimens

2.5. Statistical Analysis

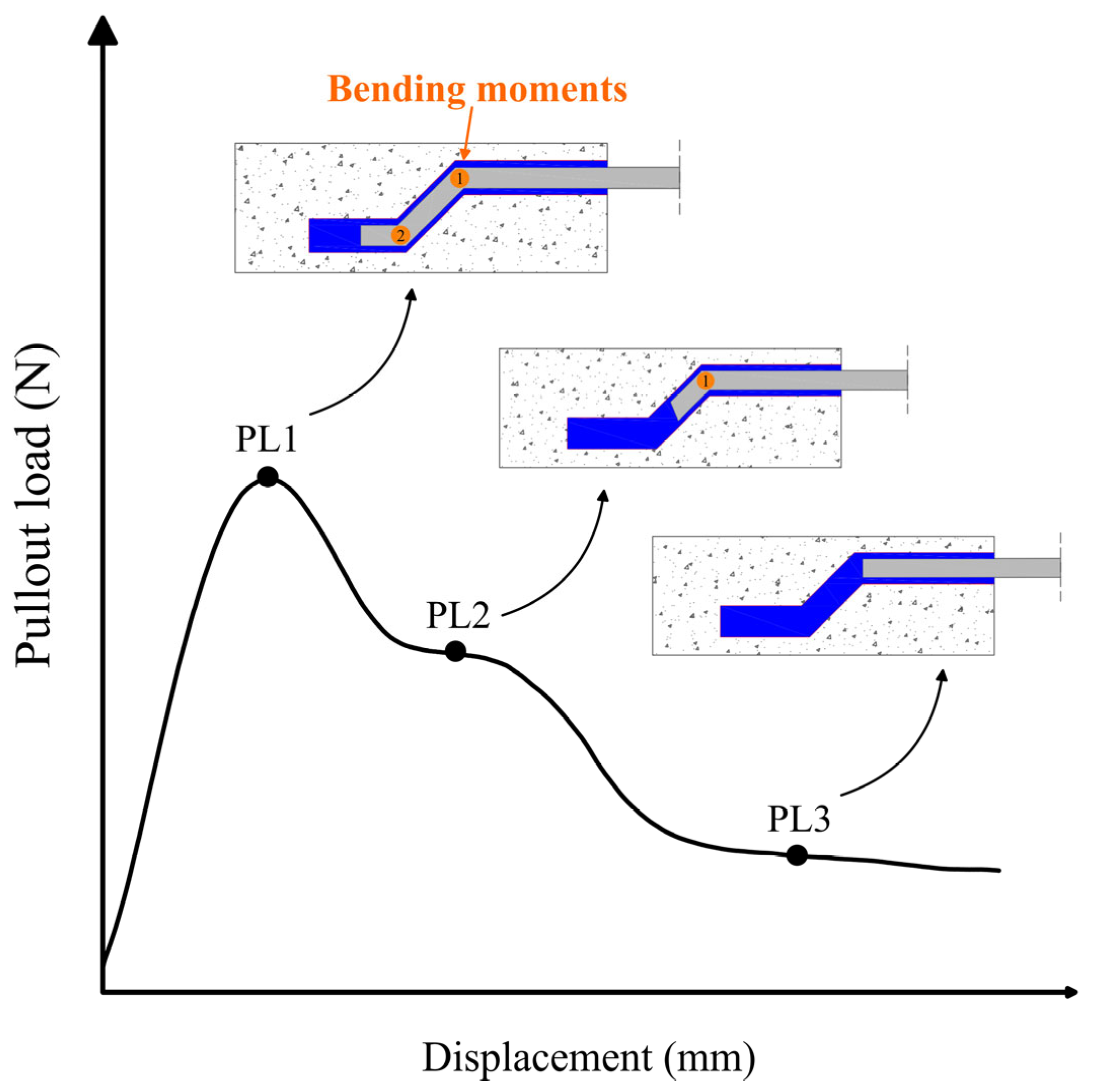

3. Experimental Results

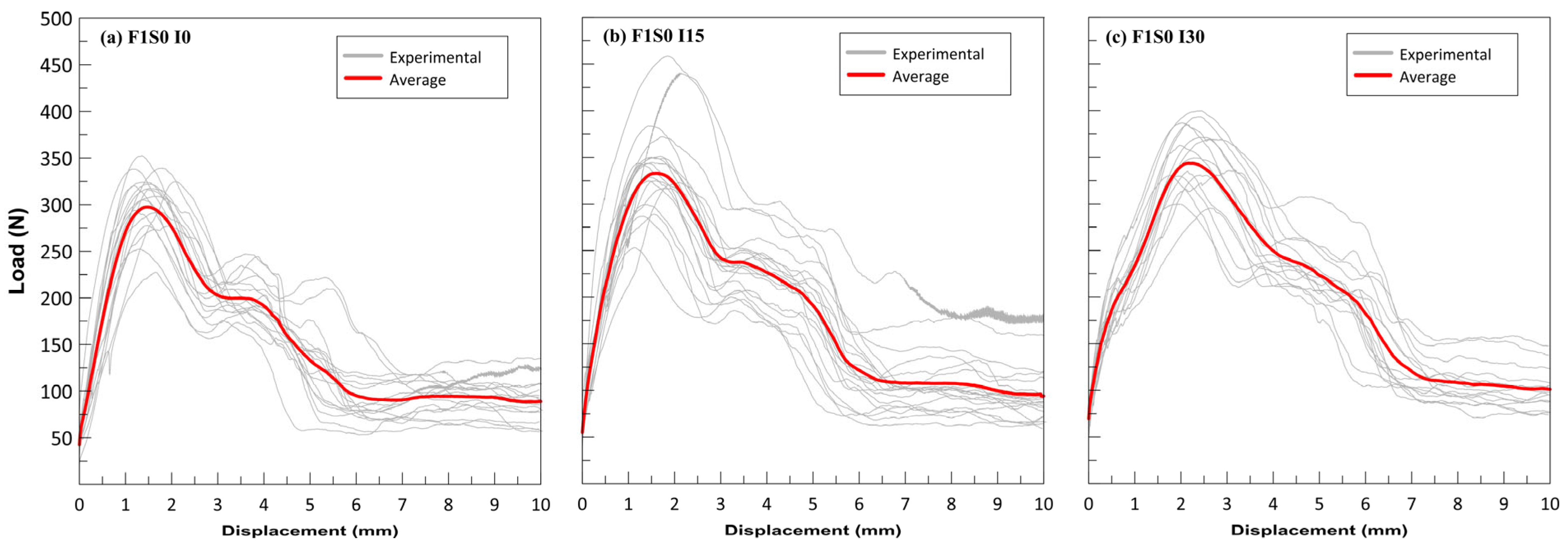

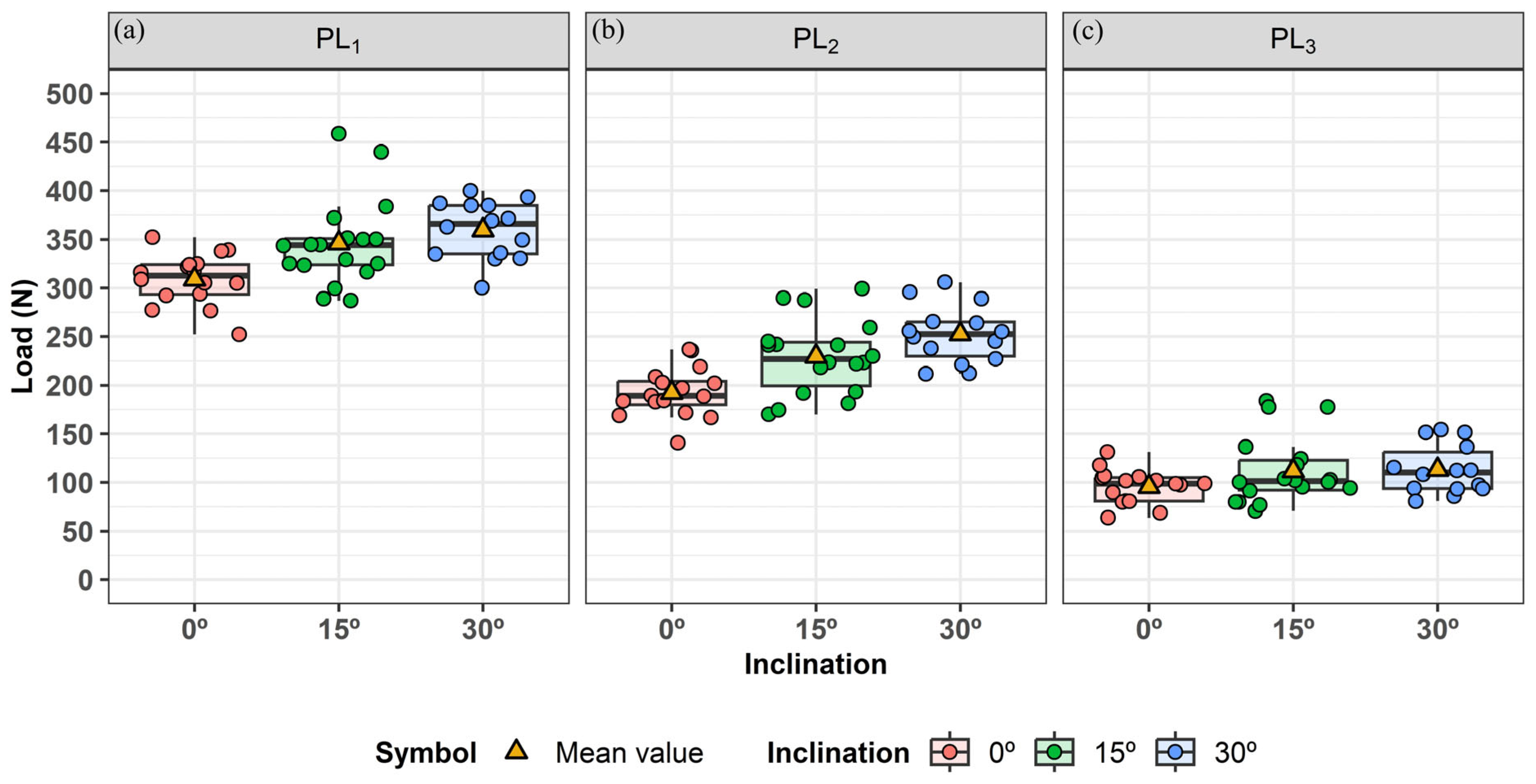

3.1. Influence of Fiber Inclination

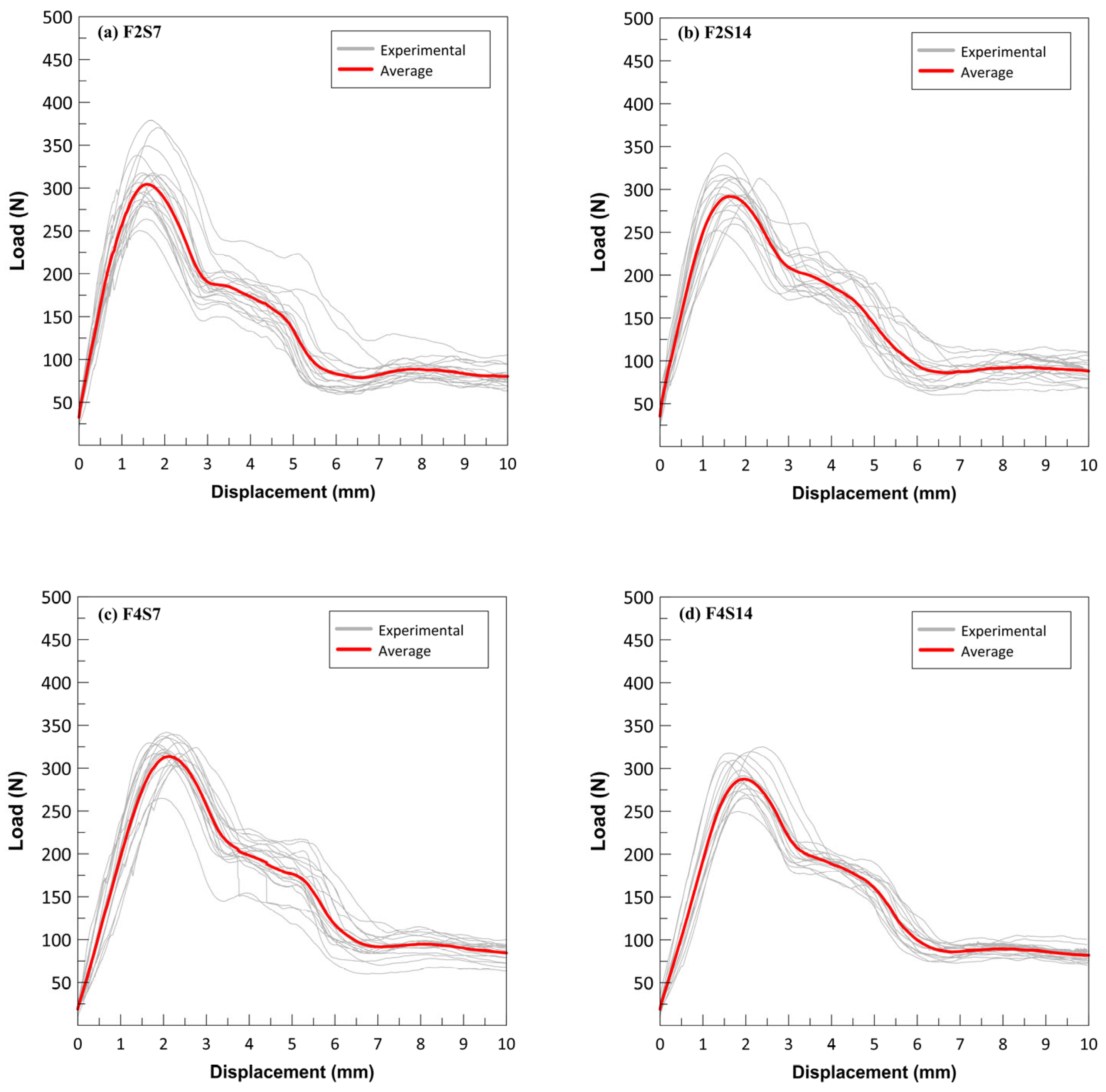

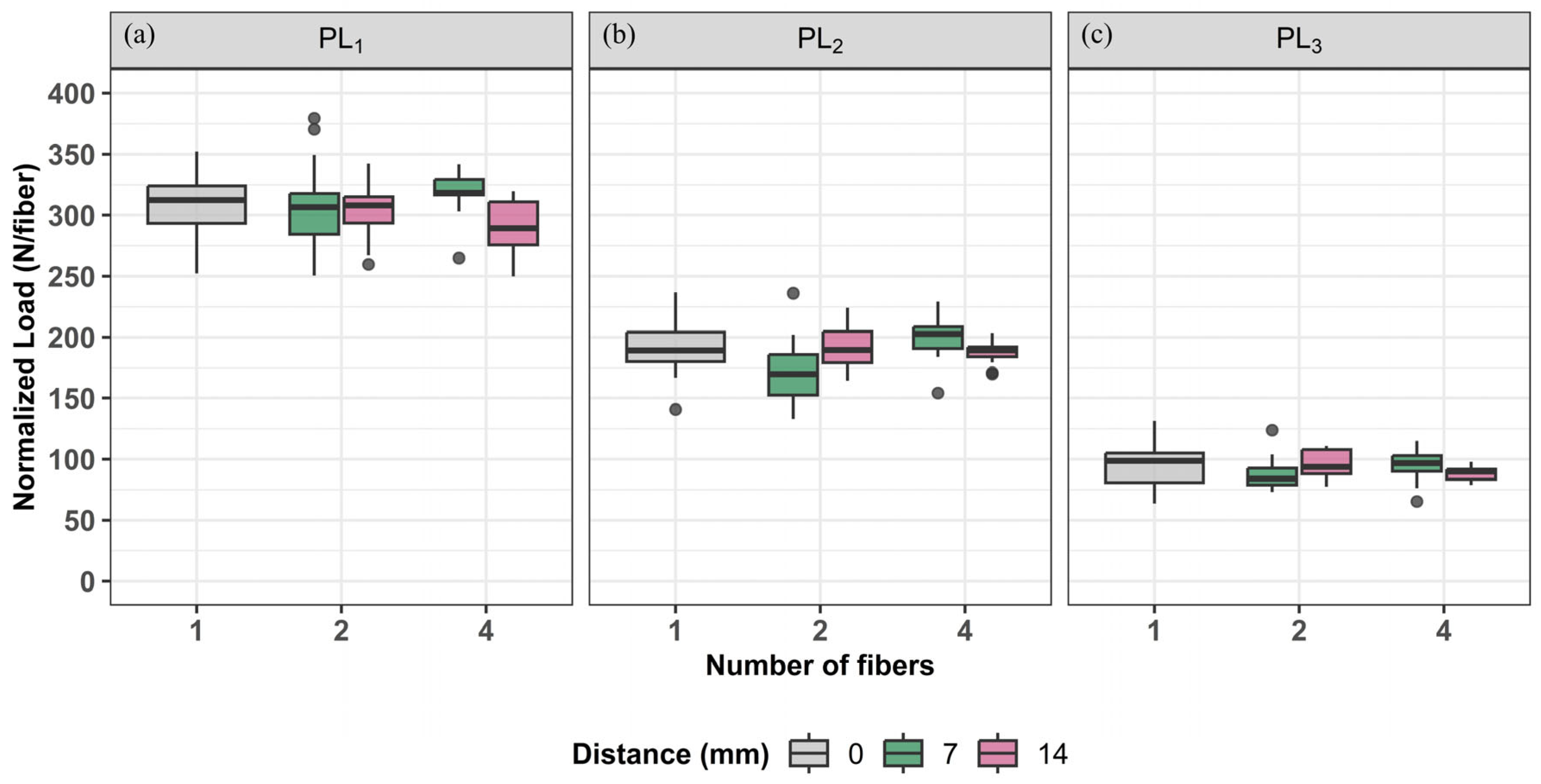

3.2. Influence of Fiber Spacing and Number of Fibers

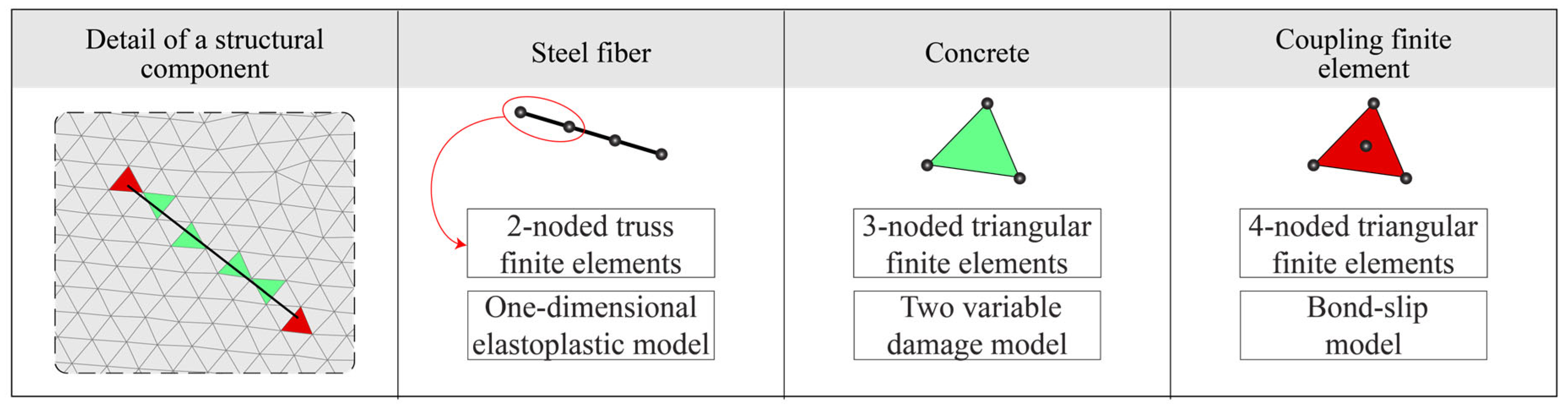

4. Numerical Analysis

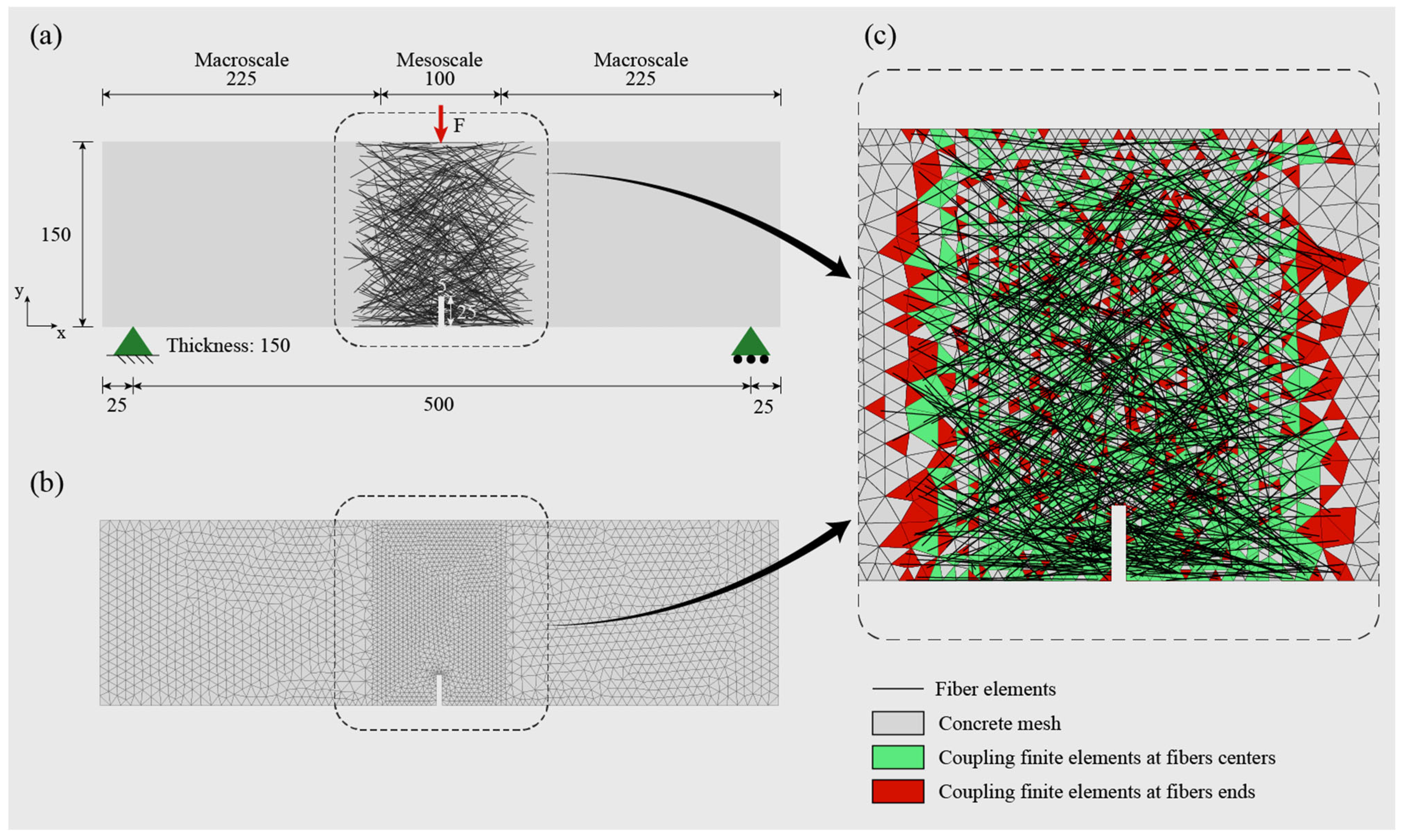

4.1. Three-Point Bending Test Simulations Setups

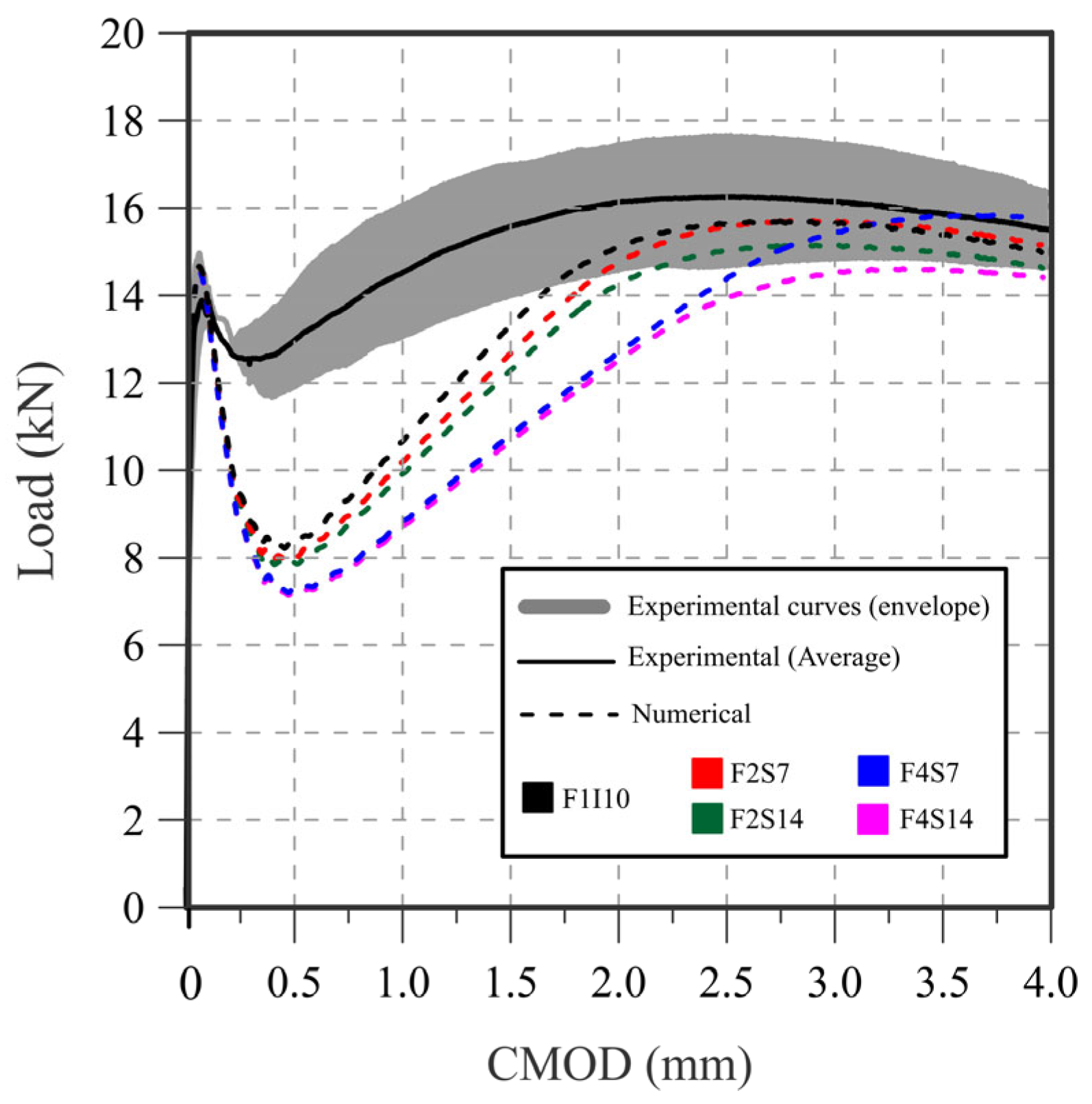

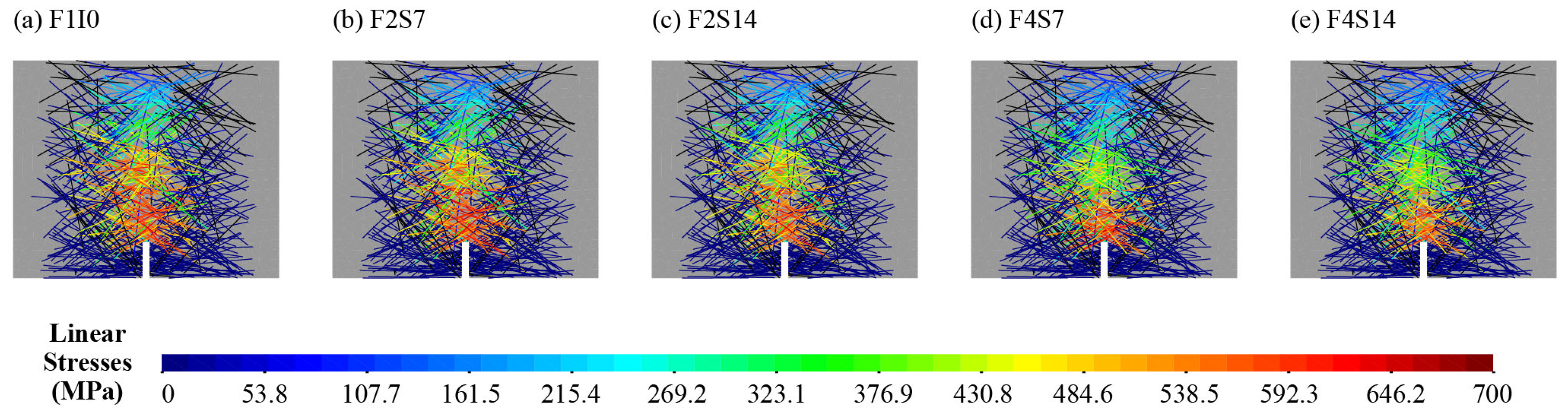

4.2. Mesoscale Simulation Analysis

5. Discussion

6. Conclusions

- The pullout loads for parameters PL1 and PL2 exhibited a clear and direct increase with fiber inclination, whereas the changes observed for PL3 were not statistically significant with varying fiber angles. This suggests that the influence of fiber inclination becomes less pronounced at higher stages of pullout, where kinetic friction predominates. At 30° inclination, approximately 21% of the test specimens experienced fiber rupture before the completion of pullout, suggesting that the stress generated during pullout exceeded the tensile strength of the fibers for higher inclinations.

- For setups with varying fiber numbers and spacings (F2S7, F2S14, F4S7, F4S14), no significant differences were observed in pullout loads for PL1, PL2, and PL3 compared to the single-fiber setup (F1S0), indicating that fiber count does not notably affect pullout behavior. However, higher fiber counts reduced the interquartile range (IQR), suggesting less variability. The F4S7 setup, with closer fiber spacing, showed higher pullout loads for PL1 and PL2 than F4S14 (p < 0.05), implying that closely spaced fibers may enhance load transfer by reinforcing the surrounding matrix during the pullout process.

- The pullout test results were used to calibrate a multiscale numerical model simulating fiber–matrix interactions in three-point bending tests (3-PBTs). The model effectively captured the anchorage effects of hooked-end fibers, with simulation results generally matching experimental data. The post-cracking load response was influenced by bond–slip law parameters from pullout tests. While the overall load–displacement behavior was consistent, discrepancies in the fR1 parameter highlighted the need for model refinement, particularly in capturing fiber slippage early in cracking. In terms of the fR3 parameter, the numerical results seemed consistent with the average experimental curves.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- di Prisco, M.; Plizzari, G.; Vandewalle, L. Fibre Reinforced Concrete: New Design Perspectives. Mater. Struct. 2009, 42, 1261–1281. [Google Scholar] [CrossRef]

- de la Fuente, A.; Blanco, A.; Armengou, J.; Aguado, A. Sustainability Based-Approach to Determine the Concrete Type and Reinforcement Configuration of TBM Tunnels Linings. Case Study: Extension Line to Barcelona Airport T1. Tunn. Undergr. Space Technol. 2017, 61, 179–188. [Google Scholar] [CrossRef]

- dos Anjos Coronel, S.; Serafini, R.; Rambo, D.A.S.; Salvador, R.P.; Bitencourt, L.A.G. Effect of DEWS Test Simplification on the Design Post-Crack Parameters of Steel Fiber Reinforced Concrete with Different Fiber Contents. Constr. Build. Mater. 2025, 470, 140584. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M.; Rees, D.W.A. Bonding Mechanisms and Strength of Steel Fiber–Reinforced Cementitious Composites: Overview. J. Mater. Civ. Eng. 2018, 30, 04018001. [Google Scholar] [CrossRef]

- Serafini, R.; Agra, R.R.; Bitencourt, L.A.G.; de la Fuente, A.; de Figueiredo, A.D. Bond-Slip Response of Steel Fibers after Exposure to Elevated Temperatures: Experimental Program and Design-Oriented Constitutive Equation. Compos. Struct. 2021, 255, 112916. [Google Scholar] [CrossRef]

- Naaman, A.E.; Najm, H. Bond-Slip Mechanisms of Steel Fibers in Concrete. ACI Mater. J. 1991, 88, 135–145. [Google Scholar]

- de Figueiredo, A.D.; Monte, R.; Bitencourt, L.A.G., Jr. Concreto Com Fibras. In Concreto: Ciência e Tecnologia; Tutikian, B., Pacheco, F., Isaía, G., Battagi, I., Eds.; Arte Interativa: São Paulo, Brazil, 2022; Volume II, pp. 1523–1560. [Google Scholar]

- Federation Internationale du Beton. Model Code for Concrete Structures 2010; Ernst & Sohn: Berlin, Germany, 2013; p. 434. ISBN 978-3-433-03061-5. [Google Scholar]

- ABNT NBR 16935; Projeto de Estruturas de Concreto Reforçado Com Fibras—Procedimento. Brazilian National Standards Organization: Rio de Janeiro, Brazil, 2021.

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites, 2nd ed.; Bentur, A., Mindess, S., Eds.; Taylor & Francis: New York, NY, USA, 2007. [Google Scholar]

- Wille, K.; Naaman, A.E. Pullout Behavior of High-Strength Steel Fibers Embedded in Ultra-High-Performance Concrete. ACI Mater. J. 2012, 109, 479–488. [Google Scholar] [CrossRef]

- Cunha, V.M.C.F.; Barros, J.A.O.; Sena-Cruz, J.M. Pullout Behavior of Steel Fibers in Self-Compacting Concrete. J. Mater. Civ. Eng. 2010, 22, 1–9. [Google Scholar] [CrossRef]

- Lee, Y.; Kang, S.T.; Kim, J.K. Pullout Behavior of Inclined Steel Fiber in an Ultra-High Strength Cementitious Matrix. Constr. Build. Mater. 2010, 24, 2030–2041. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M.; Cashell, K.A. Bond-Slip Behaviour of Steel Fibres in Concrete after Exposure to Elevated Temperatures. Constr. Build. Mater. 2017, 140, 542–551. [Google Scholar] [CrossRef]

- Naaman, A.E. Fiber Reinforced Concrete: Five Decades of Progress. In Proceedings of the 4th Brazilian Conference on Composite Materials, Rio de Janeiro, Brazil, 22–25 July 2018; pp. 35–56. [Google Scholar]

- Mineiro, M.L.R.; Monte, R.; Manzoli, O.L.; Bitencourt, L.A.G. An Integrated Experimental and Multiscale Numerical Methodology for Modeling Pullout of Hooked-End Steel Fiber from Cementitious Matrix. Constr. Build. Mater. 2022, 344, 128215. [Google Scholar] [CrossRef]

- Feng, H.; Sheikh, M.N.; Hadi, M.N.S.; Feng, L.; Gao, D.; Zhao, J. Pullout Behaviour of Different Types of Steel Fibres Embedded in Magnesium Phosphate Cementitious Matrix. Int. J. Concr. Struct. Mater. 2019, 13, 33. [Google Scholar] [CrossRef]

- Kim, J.-J.; Yoo, D.-Y. Effects of Fiber Shape and Distance on the Pullout Behavior of Steel Fibers Embedded in Ultra-High-Performance Concrete. Cem. Concr. Compos. 2019, 103, 213–223. [Google Scholar] [CrossRef]

- Bitencourt, L.A.G.; Manzoli, O.L.; Bittencourt, T.N.; Vecchio, F.J. Numerical Modeling of Steel Fiber Reinforced Concrete with a Discrete and Explicit Representation of Steel Fibers. Int. J. Solids Struct. 2019, 159, 171–190. [Google Scholar] [CrossRef]

- Serafini, R.; Santos, F.P.; Agra, R.R.; De la Fuente, A.; Figueiredo, A.D. de Effect of Specimen Shape on the Compressive Parameters of Steel Fiber Reinforced Concrete after Temperature Exposure. J. Urban Technol. Sustain. 2018, 1, 10–20. [Google Scholar] [CrossRef]

- Agra, R.R.; Serafini, R.; de Figueiredo, A.D. Effect of High Temperature on the Mechanical Properties of Concrete Reinforced with Different Fiber Contents. Constr. Build. Mater. 2021, 301, 124242. [Google Scholar] [CrossRef]

- Serafini, R.; de La Fuente, A.; de Figueiredo, A.D. Assessment of the Post-Fire Residual Bearing Capacity of FRC and Hybrid RC-FRC Tunnel Sections Considering Thermal Spalling. Mater. Struct. 2021, 54, 219. [Google Scholar] [CrossRef]

- Dantas, S.R.A.; Serafini, R.; de Oliveira Romano, R.C.; Vittorino, F.; Loh, K. Influence of Polypropylene Microfibers (PPMF) Dispersion Procedure on Fresh and Hardened Rendering Mortar Properties. Ambiente Construído 2020, 20, 7–23. [Google Scholar] [CrossRef]

- de la Fuente, A.; Pujadas, P.; Blanco, A.; Aguado, A. Experiences in Barcelona with the Use of Fibres in Segmental Linings. Tunn. Undergr. Space Technol. 2012, 27, 60–71. [Google Scholar] [CrossRef]

- Abdallah, S.M. Bonding Mechanisms and Strength of Hooked-End Steel Fibre Reinforced Cementitious Composites. Ph.D. Thesis, Brunel University London, London, UK, 2017. [Google Scholar]

- Bussab, W.; Morettin, P.A. Estatística Básica; Saraivauni, Ed.; Saraivauni: São Paulo, Brazil, 2017; ISBN 9788547220228. [Google Scholar]

- Kruskal, W.H.; Wallis, W.A. Use of Ranks in One-Criterion Variance Analysis. J. Am. Stat. Assoc. 1952, 47, 583–621. [Google Scholar] [CrossRef]

- Nemenyi, P. Distribution-Free Multiple Comparisons; Princeton University: Princeton, NJ, USA, 1963. [Google Scholar]

- Li, H.; Liu, F.; Li, Y.; Li, X.; Pan, Y.; Liu, C. Effects of Fiber Spacing and Inclination on the Pull-out Behaviors of Arc-Shaped Fibers in Brittle SIFCON Matrix. Constr. Build. Mater. 2024, 419, 135381. [Google Scholar] [CrossRef]

- Mineiro, M.L.R. Comportamento Ao Arrancamento de Fibras de Aço: Ensaios Experimentais, Previsões Analíticas e Modelagem Numérica. Master’s Thesis, Universidade de São Paulo, São Paulo, Brazil, 2022. [Google Scholar]

- EN 14651; Test Method for Metallic Fibred Concrete—Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual). British Standards Institution: London, UK, 2007; p. 19. [CrossRef]

- Etse, G.; Caggiano, A.; Vrech, S. Multiscale Failure Analysis of Fiber Reinforced Concrete Based on a Discrete Crack Model. Int. J. Fract. 2012, 178, 131–146. [Google Scholar] [CrossRef]

- Radtke, F.K.F.; Simone, A.; Sluys, L.J. A Partition of Unity Finite Element Method for Simulating Non-linear Debonding and Matrix Failure in Thin Fibre Composites. Int. J. Numer. Methods Eng. 2011, 86, 453–476. [Google Scholar] [CrossRef]

- Radtke, F.K.F.; Simone, A.; Sluys, L.J. A Computational Model for Failure Analysis of Fibre Reinforced Concrete with Discrete Treatment of Fibres. Eng. Fract. Mech. 2010, 77, 597–620. [Google Scholar] [CrossRef]

- Buttignol, T.E.T.; dos Santos, A.C.; Bitencourt, L.A.G. 3D DEWS Digital Parametric Modeling and Manufacturing for Obtaining the Post-Cracking Parameters of SFRC. Constr. Build. Mater. 2024, 428, 136326. [Google Scholar] [CrossRef]

- Cunha, V.M.C.F.; Barros, J.A.O.; Sena-Cruz, J.M. An Integrated Approach for Modelling the Tensile Behaviour of Steel Fibre Reinforced Self-Compacting Concrete. Cem. Concr. Res. 2011, 41, 64–76. [Google Scholar] [CrossRef]

- Cunha, V.M.C.F.; Barros, J.A.O.; Sena-Cruz, J.M. A Finite Element Model with Discrete Embedded Elements for Fibre Reinforced Composites. Comput. Struct. 2012, 94–95, 22–33. [Google Scholar] [CrossRef]

- Carvalho, M.R.; Barros, J.A.O.; Zhang, Y.; Dias-da-Costa, D. A Computational Model for Simulation of Steel Fibre Reinforced Concrete with Explicit Fibres and Cracks. Comput. Methods Appl. Mech. Eng. 2020, 363, 112879. [Google Scholar] [CrossRef]

- Trindade, Y.T.; Bitencourt, L.A.G., Jr.; Monte, R.; de Figueiredo, A.D.; Manzoli, O.L. Design of SFRC Members Aided by a Multiscale Model: Part I—Predicting the Post-Cracking Parameters. Compos. Struct. 2020, 241, 112078. [Google Scholar] [CrossRef]

- Trindade, Y.T.; Bitencourt, L.A.G., Jr.; Manzoli, O.L. Design of SFRC Members Aided by a Multiscale Model: Part II—Predicting the Behavior of RC-SFRC Beams. Compos. Struct. 2020, 241, 112079. [Google Scholar] [CrossRef]

- da Silva, A.P.; Bitencourt, L.A.G., Jr. An Algorithm for Distribution of Short Fibers in Multiscale Numerical Analysis. In Proceedings of the XLII Ibero-Latin American Congress on Computational Methods in Engineering (CILAMCE), Rio de Janeiro, Brazil, 9–12 November 2021. [Google Scholar]

- Cervera, M.; Oliver, J.; Manzoli, O. A Rate-Dependent Isotropic Damage Model for the Seismic Analysis of Concrete Dams. Earthq. Eng. Struct. Dyn. 1996, 25, 987–1010. [Google Scholar] [CrossRef]

- Prazeres, P.G.C.; Bitencourt, L.A.G.; Bittencourt, T.N.; Manzoli, O.L. A Modified Implicit–Explicit Integration Scheme: An Application to Elastoplasticity Problems. J. Braz. Soc. Mech. Sci. Eng. 2016, 38, 151–161. [Google Scholar] [CrossRef]

- Federation Internationale du Beton. Model Code for Concrete Structures 2020; Federation Internationale du Beton: Lausanne, Switzerland, 2024; p. 434. Available online: https://fib-international.org/publications/fib-bulletins/fib-model-code-2020-detail.html (accessed on 1 March 2025).

- Simo, J.; Hugles, T. Computational Inelasticity; Springer: New York, NY, USA, 1998; Volume 7, ISBN 0-387-97520-9. [Google Scholar]

- Cavalaro, S.H.P.; López, R.; Torrents, J.M.; Aguado, A. Improved Assessment of Fibre Content and Orientation with Inductive Method in SFRC. Mater. Struct. 2015, 48, 1859–1873. [Google Scholar] [CrossRef]

| Materials | d10 | d50 | d90 | FM |

|---|---|---|---|---|

| Cement CEM I 52.5R | 0.15 | 0.27 | 0.58 | − |

| Siliceous river sand | 0.07 | 0.80 | 3.70 | 1.39 |

| Artificial granite sand | 0.95 | 13.40 | 35.00 | 2.76 |

| Characteristic | d10 |

|---|---|

| Length (mm) | 60 |

| Diameter (mm) | 0.75 |

| Aspect ratio (l/d) | 80 |

| Specific weight (kg/m3) | 7850 |

| Tensile strength (MPa) | 1225 |

| Young’s modulus (GPa) | 210 |

| Materials | Dosage (kg/m3) |

|---|---|

| Cement CEM I 52.5R | 751 |

| Water | 289 |

| Siliceous river sand | 705 |

| Artificial granite sand | 471 |

| Superplasticizer | 5.25 |

| Identification | Number of Fibers | Spacing (mm) | Inclination (in °) |

|---|---|---|---|

| F1S0 I0 | 1 | N.A. * | 0 |

| F1S0 I15 | 1 | N.A. * | 15 |

| F1S0 I30 | 1 | N.A. * | 30 |

| F2S7 | 2 | 7 | 0 |

| F2S14 | 2 | 14 | 0 |

| F4S7 | 4 | 7 | 0 |

| F4S14 | 4 | 14 | 0 |

| Number of Load Steps | Truss Elements (Fibers) | 3-Noded Triangular Elements (Concrete) | 4-Noded Triangular Elements (CFEs) | Fibers Crossing the Fracture Section |

|---|---|---|---|---|

| 10,000 | 2565 | 4745 | 3074 | 168 |

| Compressive Strength (MPa) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Poisson’s Ratio (-) | Fracture Energy (N/mm) | Compressive Parameters |

|---|---|---|---|---|---|

| 46.50 | 2.39 | 29.25 | 0.20 | 0.146 | A = 1.00 B = 0.89 |

| Parameters | Central Region | FI10 | F2S7 | F2S14 | F4S7 | F4S17 |

|---|---|---|---|---|---|---|

| τmax (MPa) | 0.53 | 19.47 | 19.74 | 18.93 | 20.51 | 18.57 |

| τf (MPa) | 0.34 | 5.34 | 4.89 | 5.12 | 5.20 | 4.88 |

| s1 (mm) | 0.18 | 0.57 | 0.64 | 0.64 | 0.92 | 0.82 |

| s2 (mm) | 1.29 | 5.27 | 5.24 | 5.24 | 5.42 | 5.32 |

| Fiber Content (kg/m3) | Cx | Cy | Cz |

|---|---|---|---|

| 41.44 ± 3.27 | 0.515 ± 0.010 | 0.286 ± 0.008 | 0.199 ± 0.003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maia, J.S.; Serafini, R.; Mineiro, M.L.R.; Batista, A.M.; Agra, R.R. Influence of Test Configuration on the Bond–Slip Behavior of Hooked-End Steel Fibers in Concrete: Quantity, Inclination, and Spacing. Buildings 2025, 15, 868. https://doi.org/10.3390/buildings15060868

Maia JS, Serafini R, Mineiro MLR, Batista AM, Agra RR. Influence of Test Configuration on the Bond–Slip Behavior of Hooked-End Steel Fibers in Concrete: Quantity, Inclination, and Spacing. Buildings. 2025; 15(6):868. https://doi.org/10.3390/buildings15060868

Chicago/Turabian StyleMaia, Jonatas Santana, Ramoel Serafini, Maria Luísa Ribeiro Mineiro, Alicia Martinez Batista, and Ronney Rodrigues Agra. 2025. "Influence of Test Configuration on the Bond–Slip Behavior of Hooked-End Steel Fibers in Concrete: Quantity, Inclination, and Spacing" Buildings 15, no. 6: 868. https://doi.org/10.3390/buildings15060868

APA StyleMaia, J. S., Serafini, R., Mineiro, M. L. R., Batista, A. M., & Agra, R. R. (2025). Influence of Test Configuration on the Bond–Slip Behavior of Hooked-End Steel Fibers in Concrete: Quantity, Inclination, and Spacing. Buildings, 15(6), 868. https://doi.org/10.3390/buildings15060868