Mechanism of Strength Degradation of Fiber-Reinforced Soil Under Freeze–Thaw Conditions

Abstract

1. Introduction

2. Strength Behavior of Fiber-Reinforced Soil Under Freeze–Thaw Cycles

2.1. Experimental Materials

2.2. Experimental Procedures

3. Results and Discussion

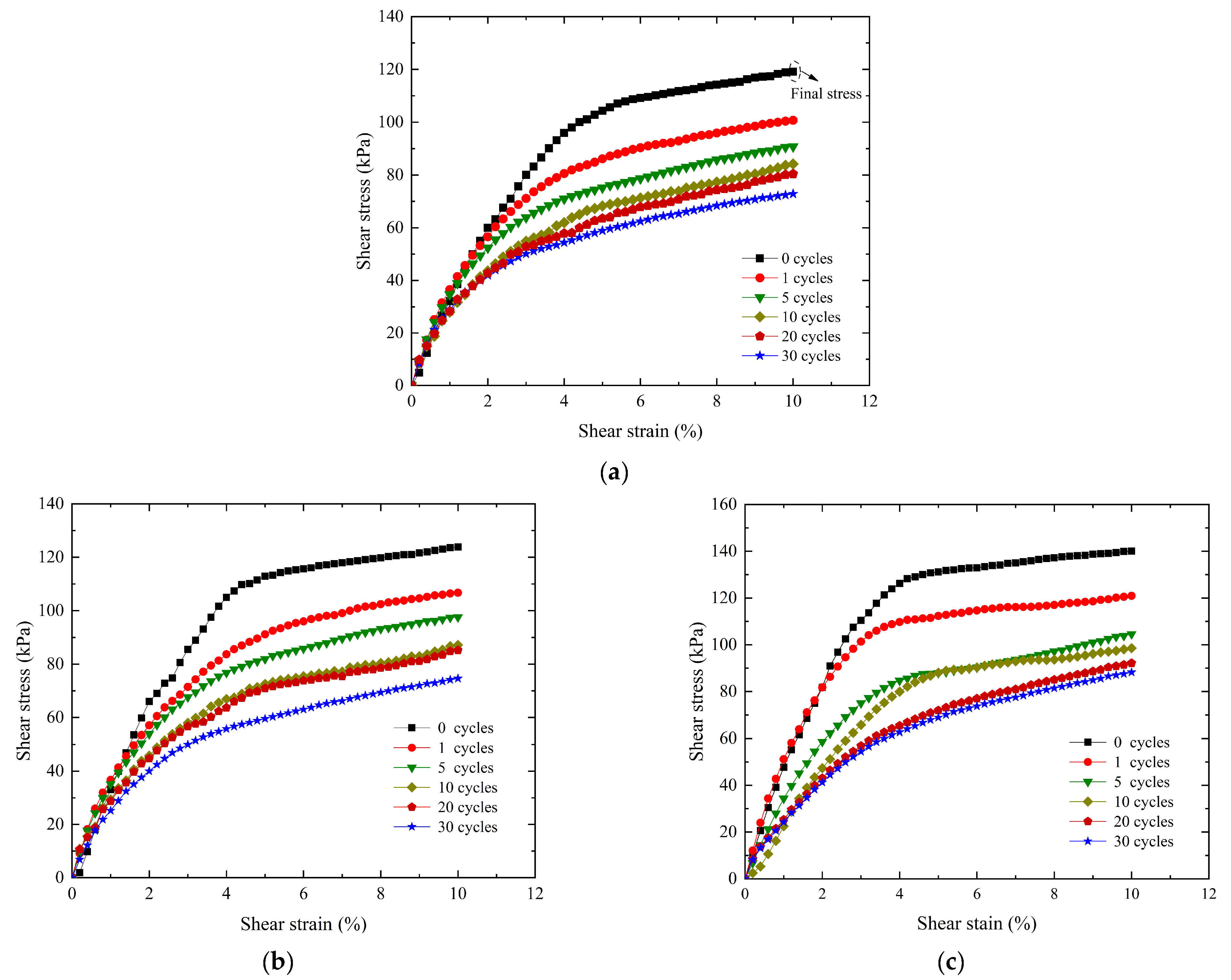

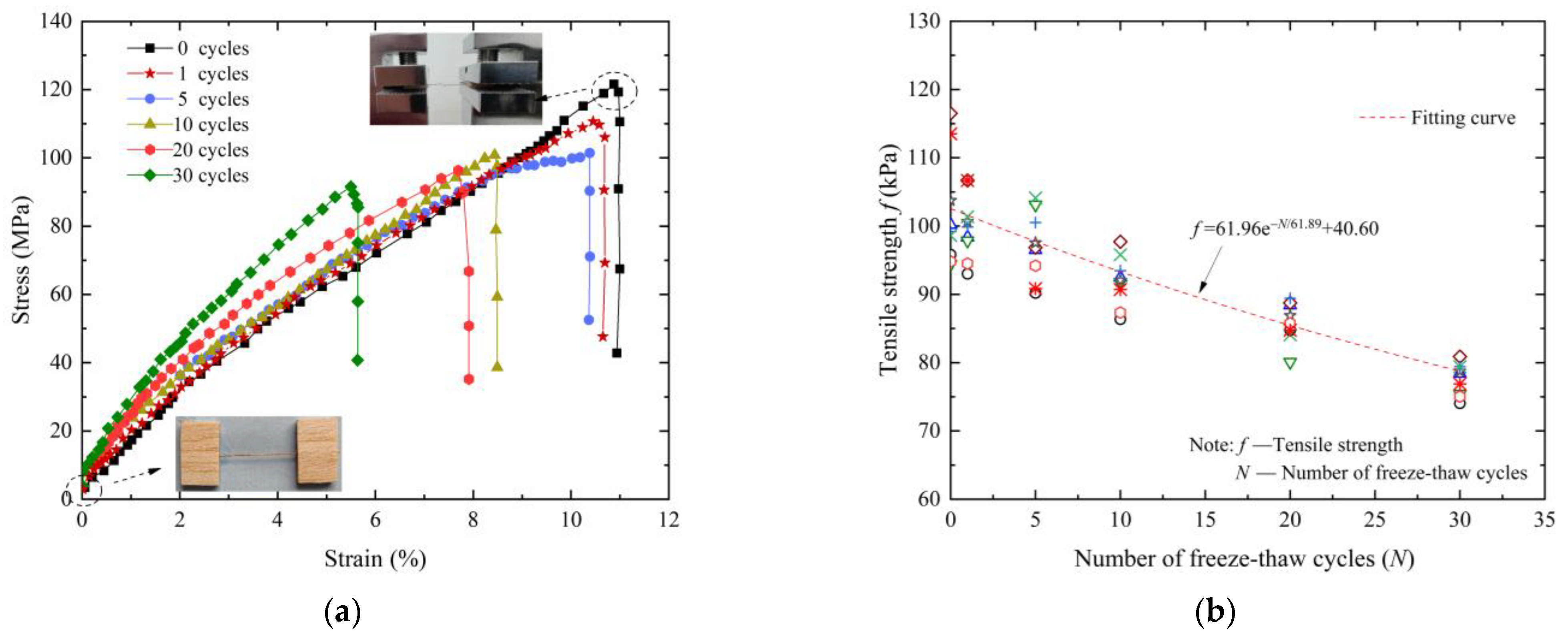

3.1. Stress–Strain Curves

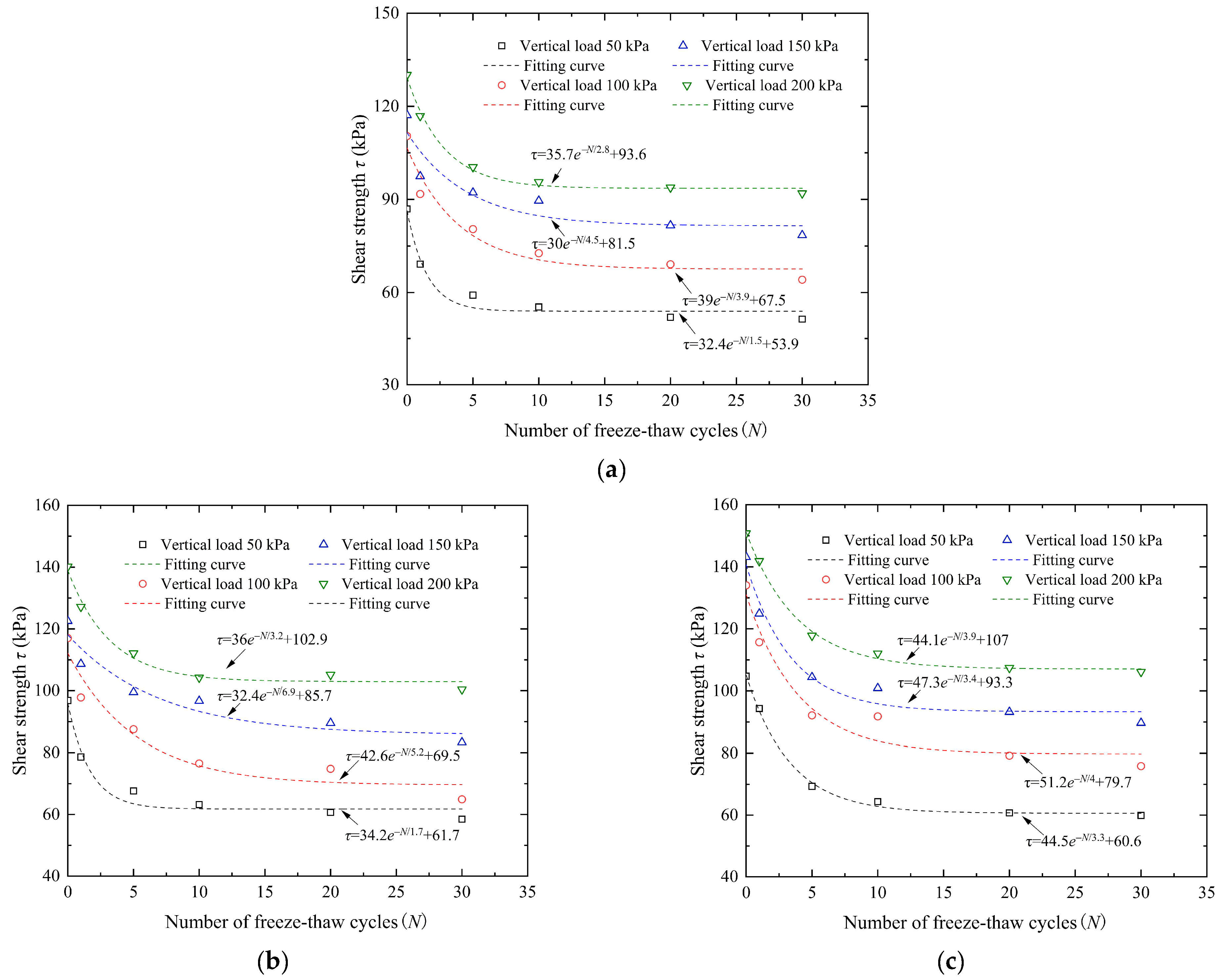

3.2. Shear Strength

4. Degradation Mechanism of Fiber-Reinforced Soil Strength Under Freeze–Thaw Conditions

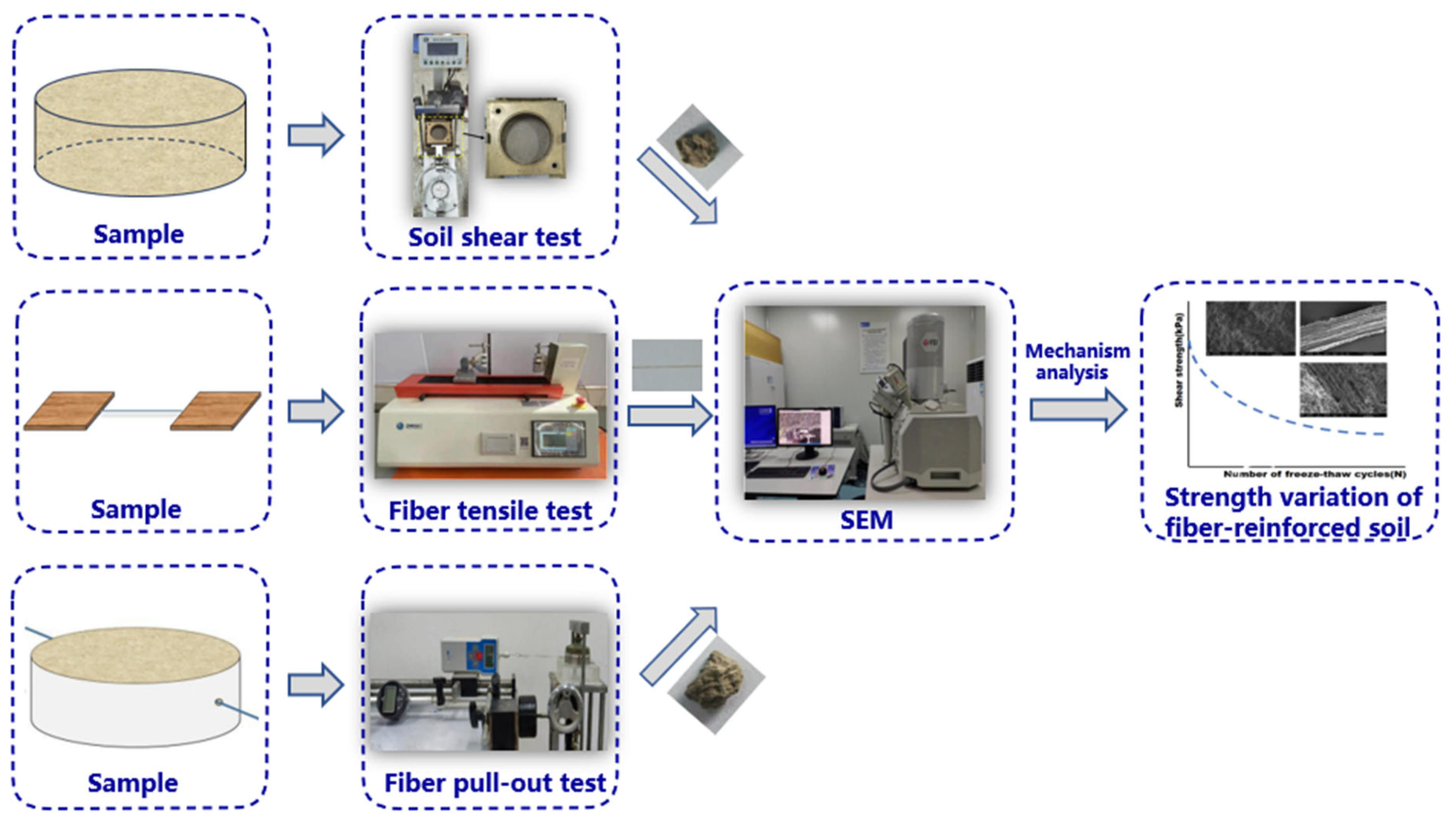

4.1. Experimental Methods

- (1)

- Soil shear tests

- (2)

- Fiber tensile tests

- (3)

- Fiber pull-out tests

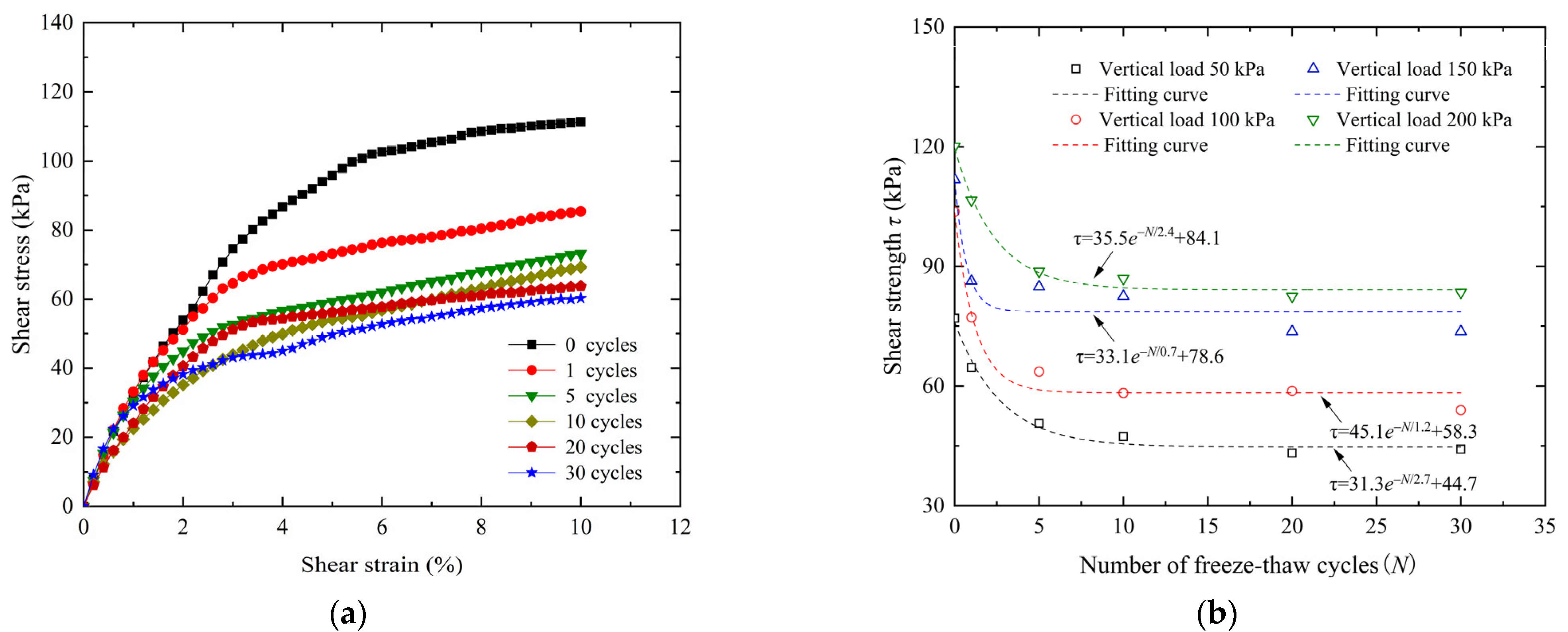

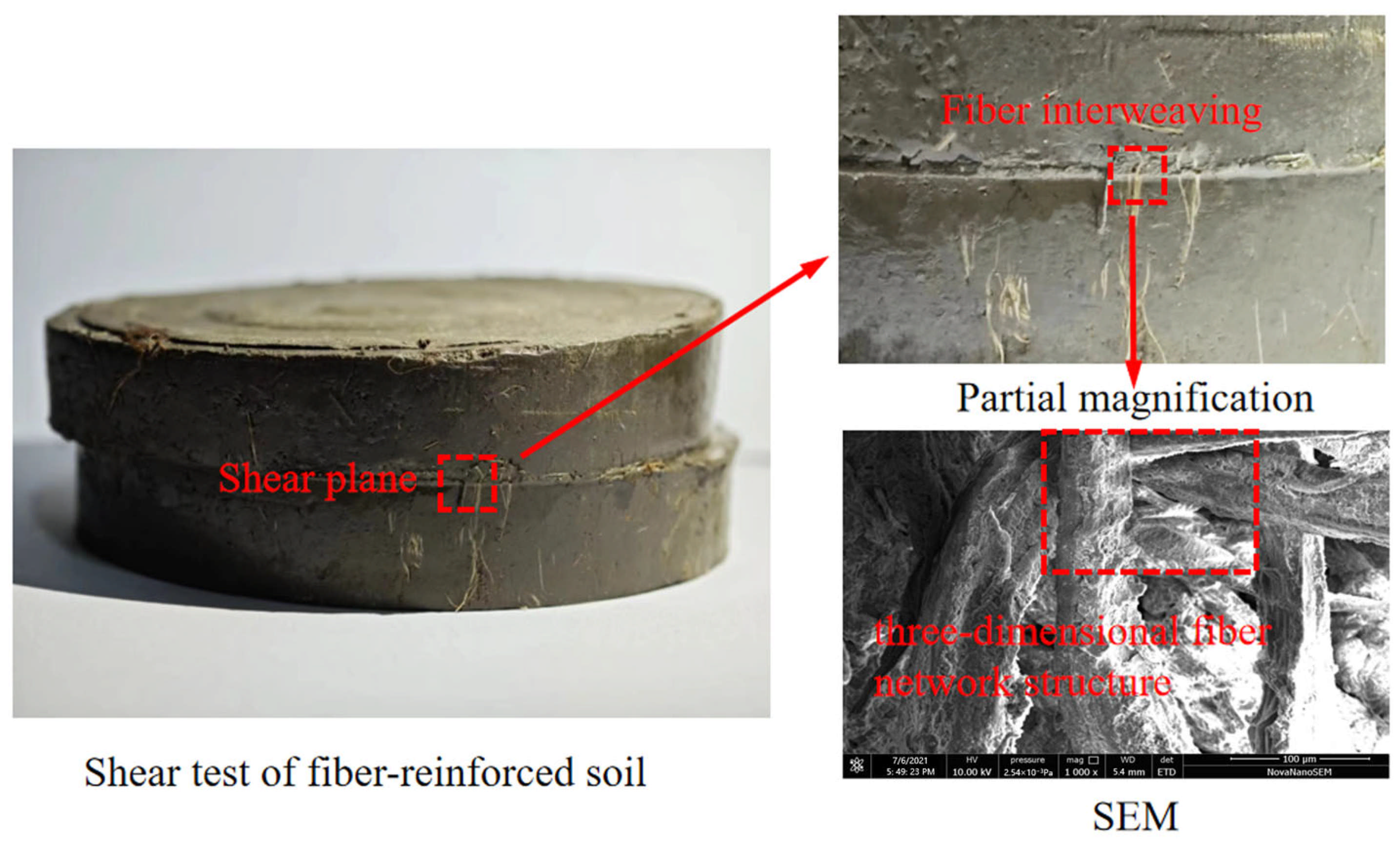

4.2. Shear Strength of Soil Subjected to Freeze–Thaw Cycles

4.3. Tensile Strength of Fiber Subjected to Freeze–Thaw Cycles

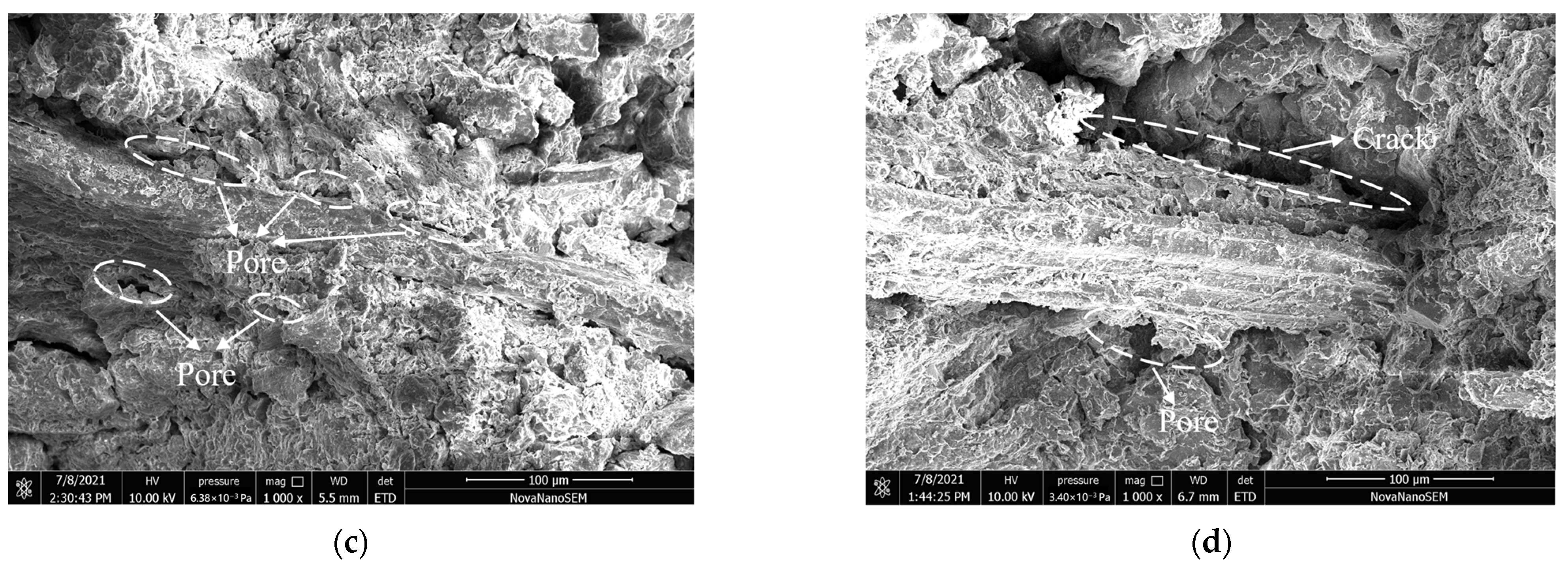

4.4. Interfacial Strength of Fiber–Soil Subjected to Freeze–Thaw Cycles

5. Discussion

6. Conclusions

- (1)

- The incorporation of 0.1–0.4% cotton straw fibers into freeze–thaw soil enhances its shear strength by 4.67% to 57.58%, with the degree of improvement positively correlated with the fiber content.

- (2)

- The shear strength of fiber-reinforced soil decreases exponentially with an increasing number of freeze–thaw cycles under constant load conditions, which can be described by a semiempirical equation developed to estimate the strength.

- (3)

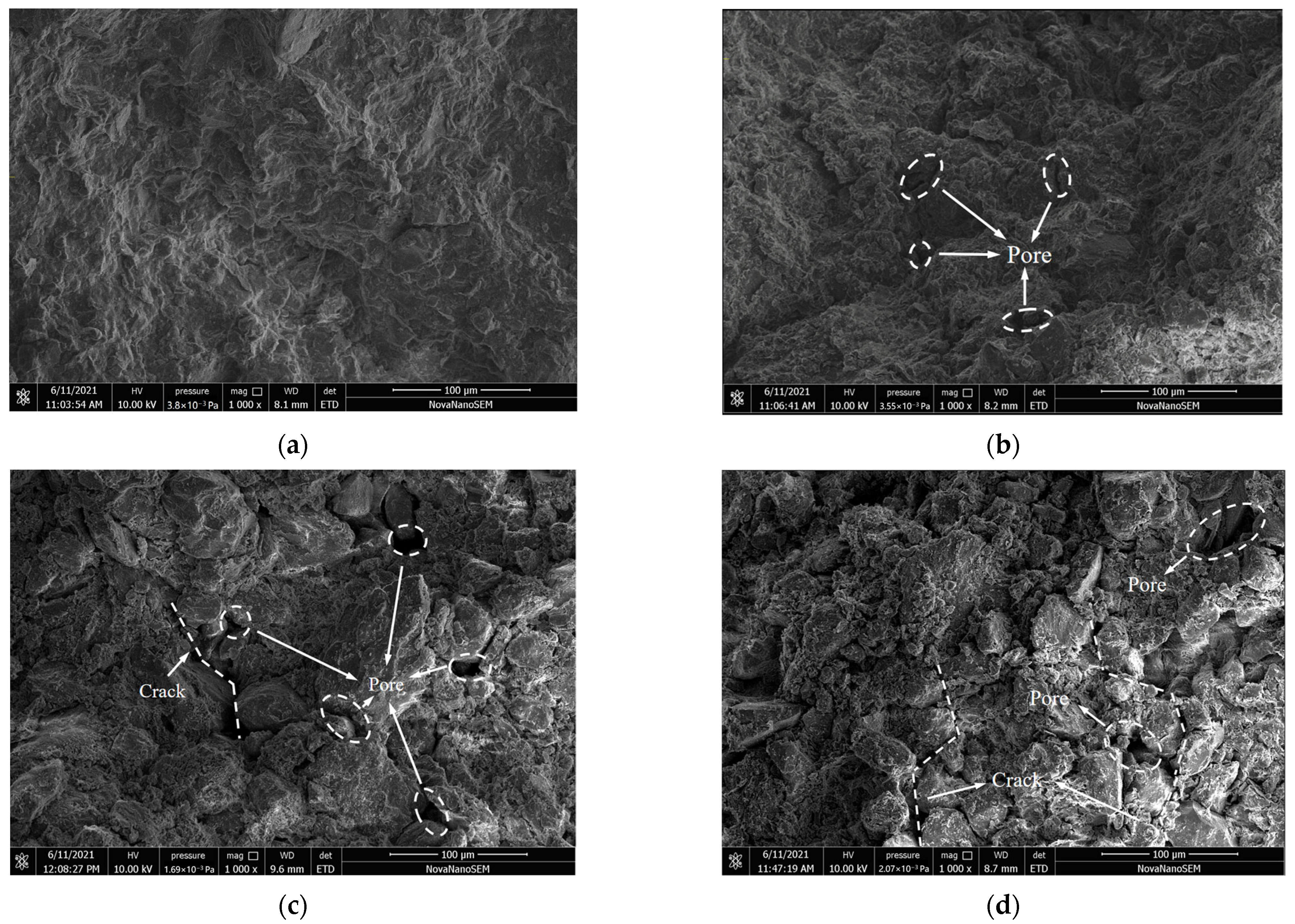

- SEM reveals that the formation of pores or cracks in the soil, fiber, and fiber–soil interface leads to strength degradation when subjected to freeze–thaw cycles. The strength of the soil, fiber, and fiber–soil interface decreases exponentially with the number of freeze–thaw cycles, significantly contributing to the exponential decrease in the shear strength of the fiber-reinforced soil.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hansson, K.; Lundin, L.-C. Equifinality and sensitivity in freezing and thawing simulations of laboratory and in situ data. Cold Reg. Sci. Technol. 2006, 44, 20–37. [Google Scholar] [CrossRef]

- Özgan, E.; Serin, S.; Ertürk, S.; Vural, I. Effects of freezing and thawing cycles on the engineering properties of soils. Soil Mech. Found. Eng. 2015, 52, 95–99. [Google Scholar] [CrossRef]

- Zhang, Y.; Bing, H.; Yang, C.S. Influences of freeze-thaw cycles on mechanical properties of silty clay based on SEM and MIP test. Chin. J. Rock Mech. Eng. 2015, 34 (Suppl. S1), 3597–3603. (In Chinese) [Google Scholar]

- Viklander, P. Permeability and volume changes in till due to cyclic freeze/thaw. Can. Geotech. J. 1998, 35, 471–477. [Google Scholar] [CrossRef]

- Xu, J.; Ren, J.; Wang, Z.; Wang, S.; Yuan, J. Strength behaviors and meso-structural characters of loess after freeze-thaw. Cold Reg. Sci. Technol. 2018, 148, 104–120. [Google Scholar] [CrossRef]

- Roustaei, M.; Eslami, A.; Ghazavi, M. Effects of freeze–thaw cycles on a fiber reinforced fine grained soil in relation to geotechnical parameters. Cold Reg. Sci. Technol. 2015, 120, 127–137. [Google Scholar] [CrossRef]

- Qi, J.; Vermeer, P.A.; Cheng, G. A review of the influence of freeze-thaw cycles on soil geotechnical properties. Permafr. Periglac. Process. 2006, 17, 245–252. [Google Scholar] [CrossRef]

- Lu, Z.; Xian, S.; Yao, H.; Fang, R.; She, J. Influence of freeze-thaw cycles in the presence of a supplementary water supply on mechanical properties of compacted soil. Cold Reg. Sci. Technol. 2019, 157, 42–52. [Google Scholar] [CrossRef]

- Liu, C.; Lv, Y.; Yu, X.; Wu, X. Effects of freeze-thaw cycles on the unconfined compressive strength of straw fiber-reinforced soil. Geotext. Geomembr. 2020, 48, 581–590. [Google Scholar] [CrossRef]

- Hohmann-Porebska, M. Microfabric effects in frozen clays in relation to geotechnical parameters. Appl. Clay Sci. 2002, 21, 77–87. [Google Scholar] [CrossRef]

- Xiang, B.; Liu, E.; Yang, L. Influences of freezing–thawing actions on mechanical properties of soils and stress and deformation of soil slope in cold regions. Sci. Rep. 2022, 12, 5387. [Google Scholar] [CrossRef]

- Yang, A.; Yang, S.; Zhong, X.; Zhang, X. Mechanical properties and structural evolution of sludge-cured lightweight soils subjected to freeze-thaw cycles. KSCE J. Civ. Eng. 2022, 26, 4478–4488. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, Z.; Li, H.; She, H.; Wang, X.; Han, X.; Yang, X. Mechanical Properties and Mesostructure Evolution of Fibre-Reinforced Loess under Freeze-Thaw Cycles. Adv. Civ. Eng. 2023, 2023, 3847003. [Google Scholar] [CrossRef]

- Yetimoglu, T.; Salbas, O. A study on shear strength of sands reinforced with randomly distributed discrete fibers. Geotext. Geomembr. 2003, 21, 103–110. [Google Scholar] [CrossRef]

- Hao, Y.; Cheng, L.; Hao, H.; Shahin, M.A. Enhancing fiber/matrix bonding in polypropylene fiber reinforced cementitious composites by microbially induced calcite precipitation pre-treatment. Cem. Concr. Compos. 2018, 88, 1–7. [Google Scholar] [CrossRef]

- Ma, Z.; Xing, Z.; Zhao, Y.; Hu, Y. Dynamic Strength Characteristics of Cement-Improved Silty Clay under the Effect of Freeze-Thaw Cycles. Sustainability 2023, 15, 3333. [Google Scholar] [CrossRef]

- Jia, Y.; Liu, Y.; Chen, J. Comparison of solidification characteristics between polymer-cured and bio-cured fly ash in the laboratory. Polymers 2023, 15, 1107. [Google Scholar] [CrossRef]

- Xu, G.; Han, Q.; Geng, W.; Yin, J.; Liu, L. Evaluation of fiber reinforcement on the strength behaviors of dredging slurry cemented at high water content. Soils Found. 2023, 63, 101264. [Google Scholar] [CrossRef]

- Shalchian, M.M.; Arabani, M. Application of plant-derived fibers in soil reinforcement on experimental, numerical, and case study scales: A review. Bull. Eng. Geol. Environ. 2023, 82, 19. [Google Scholar] [CrossRef]

- Wang, D.-L.; Tang, C.-S.; Pan, X.-H.; Liu, B.; Shi, B. Coupling effect of fiber reinforcement and MICP stabilization on the tensile behavior of calcareous sand. Eng. Geol. 2023, 317, 107090. [Google Scholar] [CrossRef]

- Su, X.; Yu, L.; Chen, J.; Li, H.; Liu, Q.; Zhang, H.; Liu, T. Mechanical properties and microstructure of SWGA-BF improved rock muck discharged from slurry shield tunnels. Constr. Build. Mater. 2023, 409, 133969. [Google Scholar] [CrossRef]

- Salimi, M.; Payan, M.; Hosseinpour, I.; Arabani, M.; Ranjbar, P.Z. Effect of glass fiber (GF) on the mechanical properties and freeze-thaw (F-T) durability of lime-nanoclay (NC)-stabilized marl clayey soil. Constr. Build. Mater. 2024, 416, 135227. [Google Scholar] [CrossRef]

- Güllü, H.; Khudir, A. Effect of freeze–thaw cycles on unconfined compressive strength of fine-grained soil treated with jute fiber, steel fiber and lime. Cold Reg. Sci. Technol. 2014, 106, 55–65. [Google Scholar] [CrossRef]

- Dang, L.C.; Fatahi, B.; Khabbaz, H. Behaviour of expansive soils stabilized with hydrated lime and bagasse fibres. Procedia Eng. 2016, 143, 658–665. [Google Scholar] [CrossRef]

- Zaimoğlu, A.Ş.; Akbulut, R.K.; Arasan, S. Effect of freeze-thaw cycles on strength behavior of compacted chicken quill-clay composite in undrained loading. J. Nat. Fibers 2016, 13, 299–308. [Google Scholar] [CrossRef]

- Yarbaşi, N. Effect of freezing-thawing on clayey soils reinforced with human hair fibers. J. Nat. Fibers 2020, 17, 921–931. [Google Scholar] [CrossRef]

- Orakoglu, M.E.; Liu, J. Effect of freeze-thaw cycles on triaxial strength properties of fiber-reinforced clayey soil. KSCE J. Civ. Eng. 2017, 21, 2128–2140. [Google Scholar] [CrossRef]

- Tang, Q.; Shi, P.; Zhang, Y.; Liu, W.; Chen, L. Strength and Deformation Properties of Fiber and Cement Reinforced Heavy Metal-Contaminated Synthetic Soils. Adv. Mater. Sci. Eng. 2019, 2019, 5746315. [Google Scholar] [CrossRef]

- Jiang, D.; An, P.; Cui, S.; Sun, S.; Zhang, J.; Tuo, T. Effect of modification methods of wheat straw fibers on water absorbency and mechanical properties of wheat straw fiber cement-based composites. Adv. Mater. Sci. Eng. 2020, 2020, 5031025. [Google Scholar] [CrossRef]

- Yang, Y.; Shi, J.; Qian, X. Effect of temperature on internal shear strength mechanism of needle-punched GCL. Sustainability 2021, 13, 4585. [Google Scholar] [CrossRef]

- GB/T 50123-1999; Standard for Soil Test Method. Ministry of Construction: Beijing, China, 1999.

- Kravchenko, E.; Liu, J.; Niu, W.; Zhang, S. Performance of clay soil reinforced with fibers subjected to freeze-thaw cycles. Cold Reg. Sci. Technol. 2018, 153, 18–24. [Google Scholar] [CrossRef]

- Chen, C.; Guo, W.; Ren, Y.X. Properties and microscopic analysis of lignin fiber-reinforced soils under freeze-thaw cycles. Chin. J. Geotech. Eng. 2020, 42 (Suppl. S2), 135–140. (In Chinese) [Google Scholar]

- Gao, Z.; Zhong, X.; Ma, H.; Liu, F.; Ma, J.; Wang, Q. Effect of freeze-thaw cycles on shear strength properties of loess reinforced with lignin fiber. Geofluids 2022, 2022, 8685553. [Google Scholar] [CrossRef]

- ASTM D3822-07; Standard Test Method for Tensile Properties of Single Textile Fibers. ASTM International: West Conshohocken, PA, USA, 2007.

- Sun, M.R. Study on Mechanical Property of Straw Fiber Reforced Soil in Different Environment. Master’s Thesis, AnHui University of Science and Technology, Huainan, China, 2022. (In Chinese). [Google Scholar]

- Yzombard, A.; Gordon, S.G.; Miao, M. Morphology and tensile properties of bast fibers extracted from cotton stalks. Text. Res. J. 2014, 84, 303–311. [Google Scholar] [CrossRef]

- Lin, T. The Study on Properties of Cotton Stalk Fibre and Composites. Ph.D. Thesis, Chinese Academy of Forestry, Beijing, China, 2012. (In Chinese). [Google Scholar]

- Tang, C.S.; Shi, B.; Zhao, L.Z. Interfacial shear strength of fiber reinforced soil. Geotext. Geomembr. 2010, 28, 54–62. [Google Scholar] [CrossRef]

- Zhu, H.H.; Zhang, C.C.; Tang, C.S.; Shi, B.; Wang, B.J. Modeling the pullout behavior of short fiber in reinforced soil. Geotext. Geomembr. 2014, 42, 329–338. [Google Scholar] [CrossRef]

- Liu, B.S.; Tang, C.S.; Li, J.; Wang, D.Y.; Zhu, K.; Tang, W. Research progress on engineering properties of fiber-reinforced soils. J. Eng. Geol. 2013, 21, 540–547. (In Chinese) [Google Scholar]

| Natural Water Content | Liquid Limit | Plastic Limit | Specific Gravity | Optimum Water Content | Maximum Dry Density | Organic Matter Content |

|---|---|---|---|---|---|---|

| % | % | % | % | g/cm3 | % | |

| 38.00 | 57.75 | 22.90 | 2.72 | 23.04 | 1.57 | 2.93 |

| Length | Diameter | Tensile Strength | Density | Elongation | Modulus of Elasticity |

|---|---|---|---|---|---|

| mm | mm | MPa | g/cm3 | % | MPa |

| 12.00 | 0.10 | 103.39 | 1.50 | 7.00–8.00 | 5500.00 |

| Author | Soil | Fiber Type | Freeze–Thaw Cycles | Fiber Content | Vertical Load | a | b | c | R2 |

|---|---|---|---|---|---|---|---|---|---|

| Roustaei et al. [6] | Fine grained soil | Polypropylene fiber | 9 | 1.5% | 30 | 447.2 | −4.9 | 728.9 | 0.998 |

| 90 | 389.8 | −3.4 | 990.0 | 0.939 | |||||

| Chen et al. [33] | Soft clay | Lignin fiber | 9 | 0.7% | 300 | 75.2 | −0.8 | 503.9 | 0.910 |

| Gao et al. [34] | Loess | Lignin Fiber | 10 | 1.5% | 80 | 20.0 | −0.4 | 438.2 | 0.977 |

| 3.0% | 80 | 41.9 | −0.1 | 455.2 | 0.955 | ||||

| Orakoglu and Liu [27] | Clay | Glass fiber | 10 | 0.5% | 100 | 836.8 | −5.5 | 375.7 | 0.920 |

| Basalt fiber | 10 | 0.5% | 100 | 975.8 | −6.1 | 270.4 | 0.991 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, X.; Wu, X.; Zhu, P.; Liu, C.; Qiu, C.; Cai, Z. Mechanism of Strength Degradation of Fiber-Reinforced Soil Under Freeze–Thaw Conditions. Buildings 2025, 15, 842. https://doi.org/10.3390/buildings15060842

Yu X, Wu X, Zhu P, Liu C, Qiu C, Cai Z. Mechanism of Strength Degradation of Fiber-Reinforced Soil Under Freeze–Thaw Conditions. Buildings. 2025; 15(6):842. https://doi.org/10.3390/buildings15060842

Chicago/Turabian StyleYu, Xiaojuan, Xingyu Wu, Peng Zhu, Chao Liu, Chengchun Qiu, and Zhongbing Cai. 2025. "Mechanism of Strength Degradation of Fiber-Reinforced Soil Under Freeze–Thaw Conditions" Buildings 15, no. 6: 842. https://doi.org/10.3390/buildings15060842

APA StyleYu, X., Wu, X., Zhu, P., Liu, C., Qiu, C., & Cai, Z. (2025). Mechanism of Strength Degradation of Fiber-Reinforced Soil Under Freeze–Thaw Conditions. Buildings, 15(6), 842. https://doi.org/10.3390/buildings15060842