New Insights into Traditional Construction Behind Sibe Dwellings with Swastika Kang for Space Heating in North China

Abstract

1. Introduction

- Validating and analyzing traditional construction wisdom using modern technologies.

- Conducting an in-depth analysis of the “Swastika kang”, a traditional heating system (For a detailed explanation, please refer to Nomenclature).

- Exploring optimization strategies by integrating passive insulation with active heating systems.

2. Literature Review

2.1. Indoor Thermal Comfort

2.2. Kang

2.3. Research Status

3. Methods

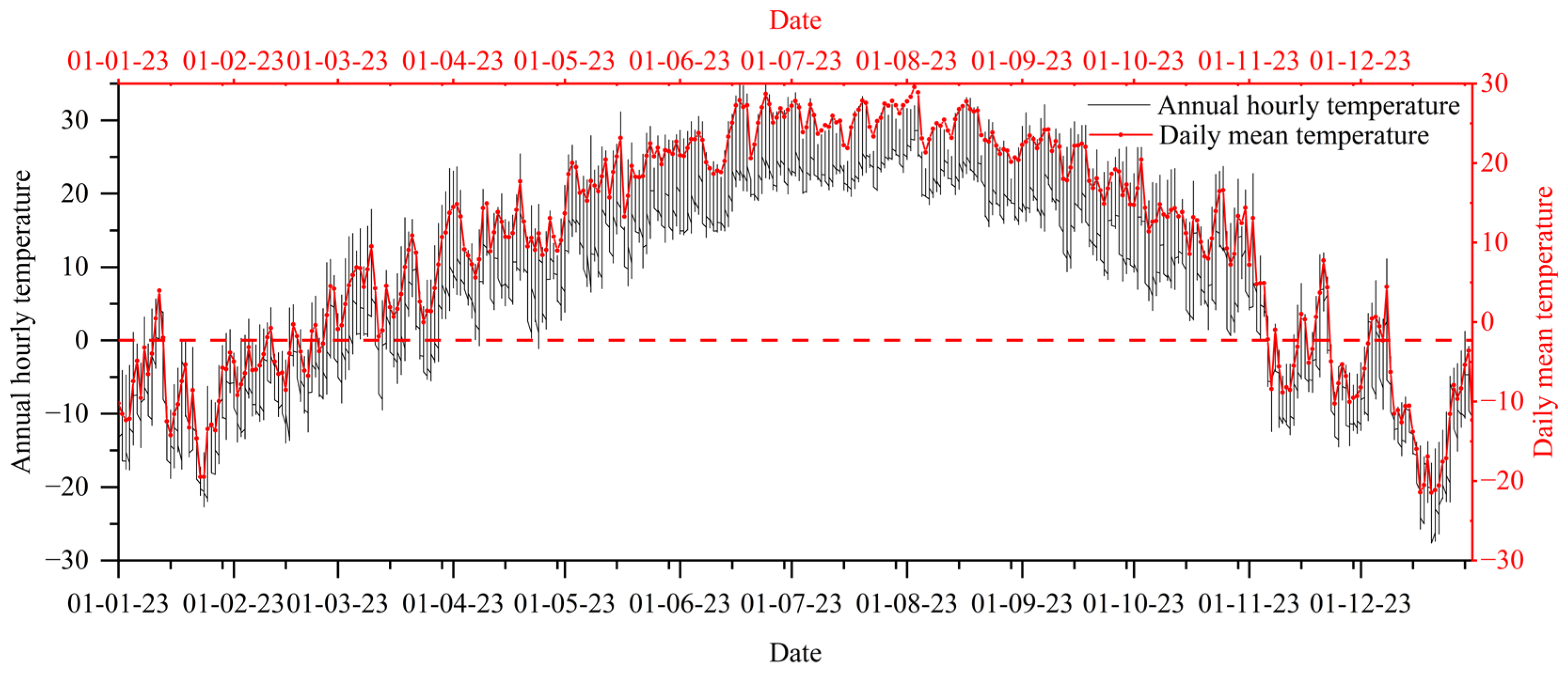

3.1. Geographic and Climatic Information

3.2. Building Thermal Model

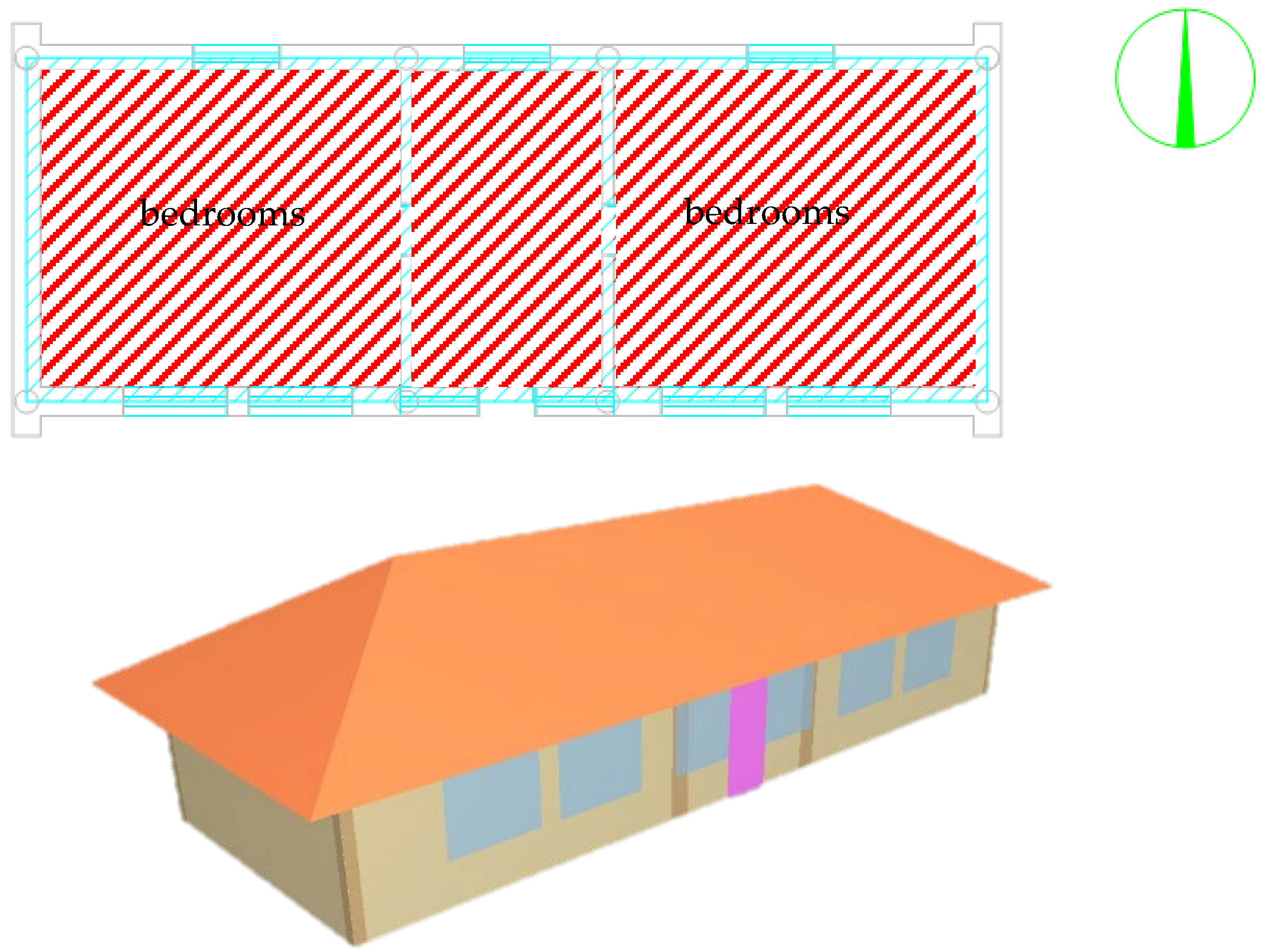

3.3. Folk Houses and Kang

| Number | Equation | Define | |

|---|---|---|---|

| (1) | Material Layer Thermal Resistance | R: Material Layer Thermal Resistance (m2·K/W). δ: Material layer thickness (m). λ: Material thermal conductivity [W/(m·k)]. | |

| (2) | Heat transfer resistance of the envelope | R0: Enclosure heat transfer resistance (m2·K/W). Ri: Internal surface heat transfer resistance (m2·K/W). R: Enclosure flat wall thermal resistance (m2·K/W). Re: External surface heat transfer resistance (m2·K/W). | |

| (3) | Heat transfer coefficient | K: Heat transfer coefficient of the enclosure [W/(m2·K)]. | |

| (4) | Heat storage capacity | S: Heat storage capacity [W/(m2·K)]. c: Specific heat capacity [KJ/(kg·K)]. ρ: Densities (kg/m3). T: Temperature fluctuation period (h), generally T = 24 h. π: The circular ratio, π = 3.14. | |

| (5) | Thermal inertness index | D: Thermal inertness index. |

| Material | Thic Thickness (mm) | Thermal Conductivity (λ) W/(m·K) | Heat Storage Coefficient (S) W/(m2·K) | Correction Factor α | Resistance (R) (m2·K/W) | Thermal Inertia D = R × S | Heat Transfer Coefficient K = 1/(0.15 + ∑R) W/(m2·K) |

|---|---|---|---|---|---|---|---|

| Concrete Tile | 20 | 0.93 | 10.583 | 1 | 0.022 | 0.228 | 1.58 |

| lime mortar | 40 | 0.81 | 10.07 | 1 | 0.049 | 0.497 | |

| Sagebrush clay | 40 | 0.58 | 7.723 | 1 | 0.069 | 0.533 | |

| Planks | 20 | 0.058 | 1.627 | 1 | 0.345 | 0.561 | |

| Brickyard | 450 | 0.265 | 10 | 1 | 1.698 | 16.981 | 0.54 |

| Wood-plastic windows | 2.5 |

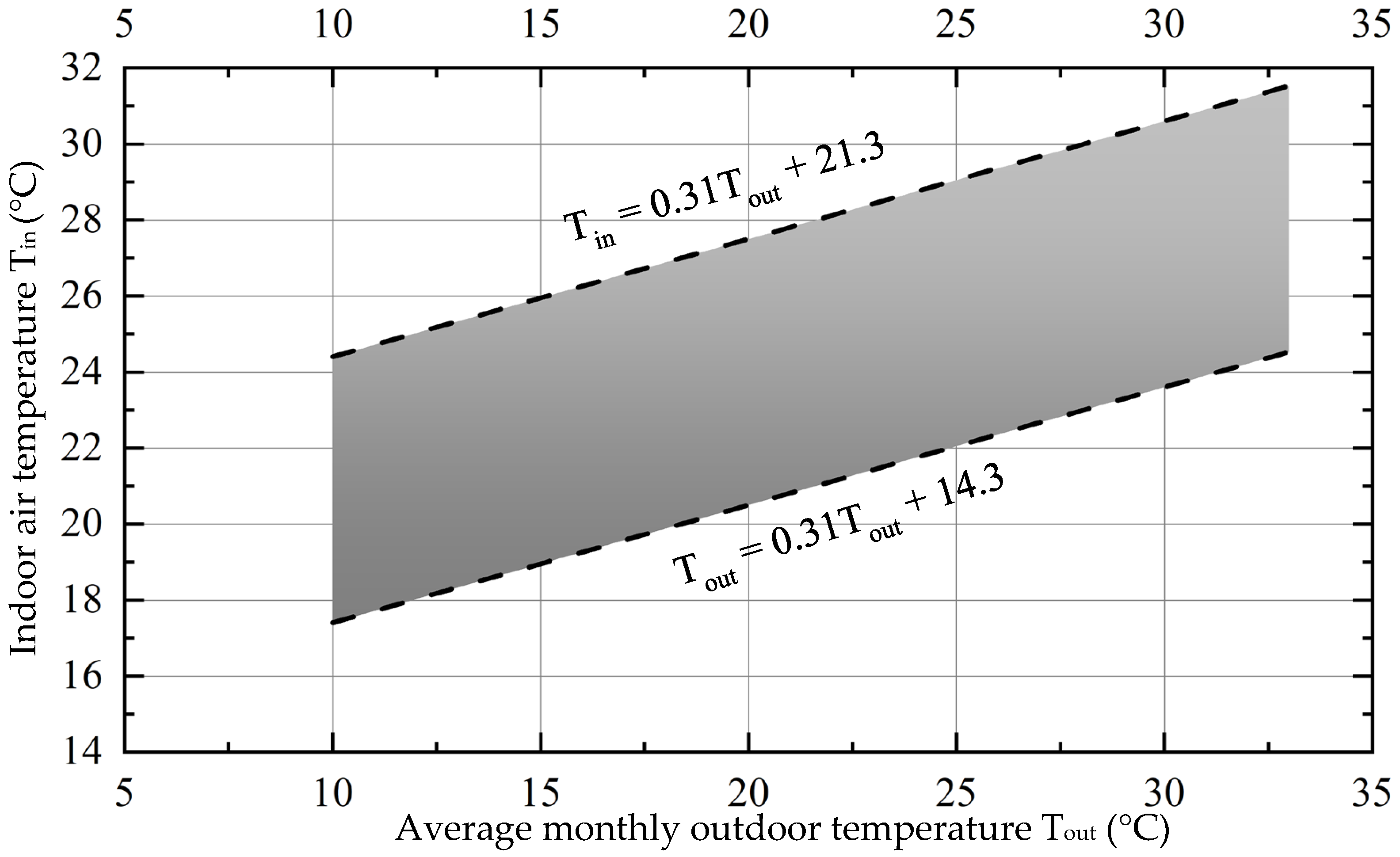

3.4. Indoor Thermal Comfort Evaluation

- APMV: Expected adaptive mean thermal sensory index

- λ: Adaptive coefficient

- PMV: Projected average thermal sensory indicators

3.5. Building Simulation

- External Walls: Two sets of experiments were performed:

- 2.

- Roof: Three sets of experiments were conducted:

- 3.

- Windows: three sets of experiments were carried out using different modern window constructions to study their effects on the indoor thermal environment.

4. Results

4.1. External Wall Impact

- The wall thickness was increased and decreased by 50 mm to 500 mm and 400 mm, respectively. The overall heat transfer coefficients were 0.49 and 0.60, while the thermal inertia index was 18.868 and 15.094, respectively. Simulation results indicated that whether increasing or decreasing wall thickness, the proportion of time meeting the criteria for thermal comfort remained at 24.03%, similar to the baseline case.

- Maintaining a constant wall thickness, adding 20 mm extruded polystyrene foam insulation for both interior and exterior walls resulted in overall heat transfer coefficients of 0.41 and 0.42, with thermal inertia indices of 16.453 and 15.944, respectively. At this point, the proportion of time meeting the criteria for thermal comfort remained at 24.03%.

- Maintaining a constant wall thickness, adding 20 mm extruded polystyrene foam and 20 mm lime mortar for external wall insulation led to a heat transfer coefficient of 0.42 and a thermal inertia index of 15.944. The results showed that the proportion of time meeting the criteria for thermal comfort remained at 24.03%.

- By maintaining consistent insulation materials and thickness while increasing the total wall thickness, constructing interior and exterior walls with 450 mm bricks and 20 mm extruded polystyrene foam for the simulation, the overall heat transfer coefficients and thermal inertia indices reached 17.208. Under these conditions, the proportion of time meeting the criteria for thermal comfort remained at 24.03%.

- Adjusting wall thickness and increasing the insulation material thickness, with walls composed of 450 mm bricks and 50 mm extruded polystyrene foam, yielded a heat transfer coefficient of 0.29 and a thermal inertia index of 17.548. The results showed that the proportion of time meeting the criteria for thermal comfort remained at 24.03%.

4.2. Roof Impact

- With the total roof thickness unchanged and other roof materials held constant, the 20 mm lime mortar was replaced with the same thickness of aerated concrete and foam concrete (ρ = 700), resulting in a heat transfer coefficient of 1.51 and a thermal inertia index of 1.399. In this scenario, the proportion of time within the thermal comfort zone increased to 24.14%, an increment of 0.11% compared to the baseline roof structure.

- Maintaining the total roof structure thickness and other roof materials unchanged, the 20 mm mixed clay was replaced with 20 mm rigid polyurethane foam board PUR (ρ ≥ 35), resulting in a heat transfer coefficient of 0.93 and a thermal inertia index of 4.612. Under these conditions, the proportion of time within the thermal comfort zone remained at 24.03%, consistent with the baseline roof structure.

4.3. External Window Impact

- Replacing the window structure with 6 mm + LE35AMARL film glass, with a heat transfer coefficient of 4.60, resulted in a thermal comfort time ratio of 22.83%, representing a decrease of 1.2% compared to the baseline structure.

- Substituting the window structure with plastic + 6Low-E + 12A + 6 mm transparent hollow glass, with a heat transfer coefficient of 1.90, yielded a thermal comfort time ratio of 23.31%, exhibiting a decrease of 0.72% compared to the baseline structure.

- Changing the window structure to [5 mm + 9A (air) + 5 mm] nanometer-coated glass (HJ-N-series) + 9A (air) + 5 mm white glass (warm edge seal), with a heat transfer coefficient of 1.56, resulted in a thermal comfort time ratio of 24.09%, indicating an increase of 0.06% compared to the baseline structure.

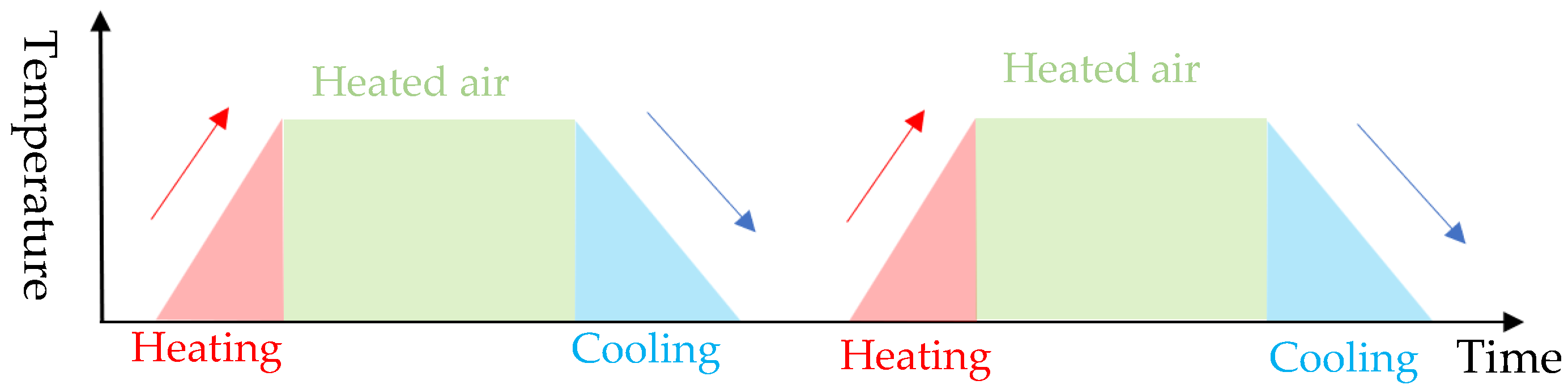

5. Discussion: Swastika Kang Heating Effect

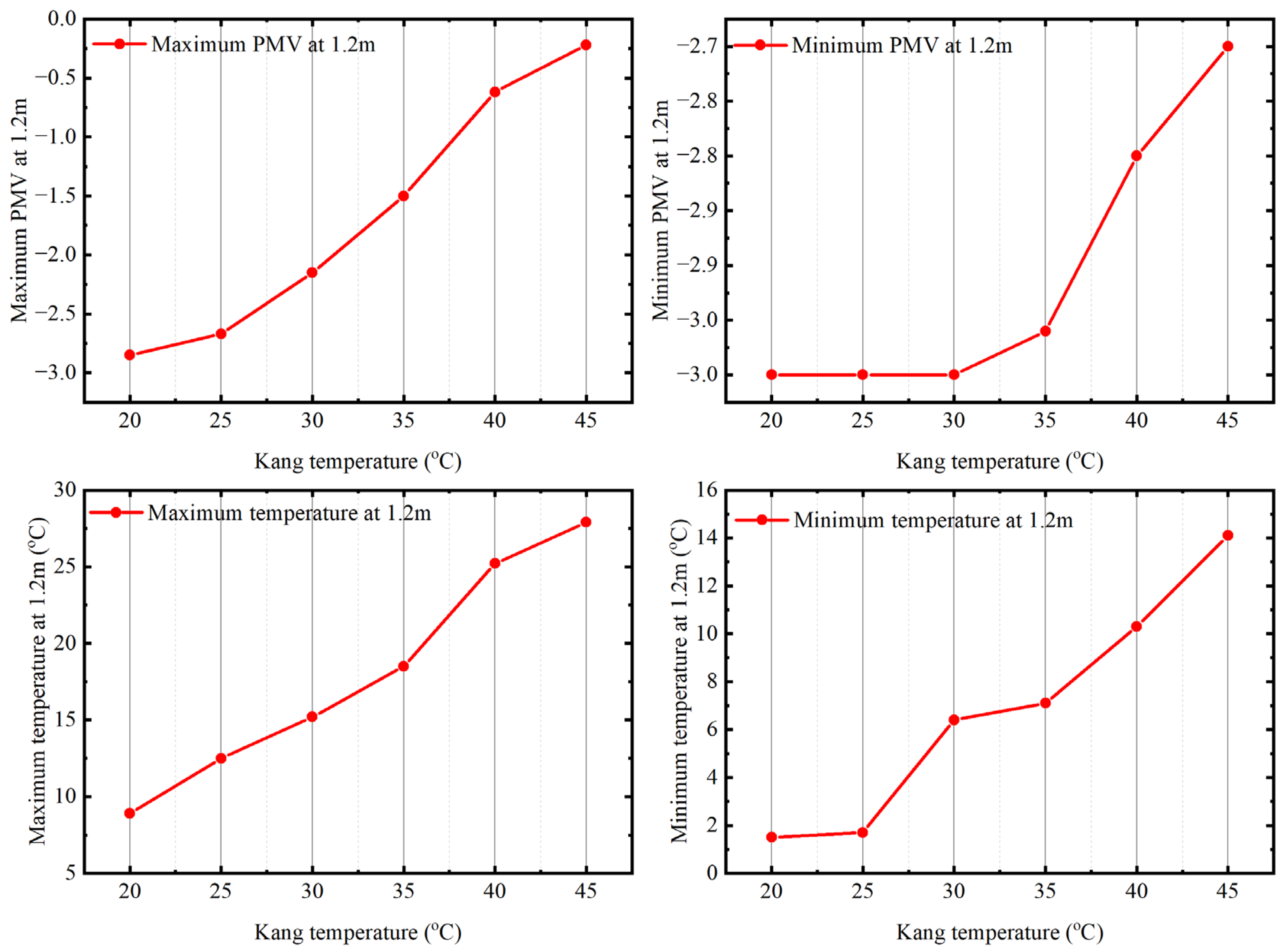

5.1. Surface Temperature Impact

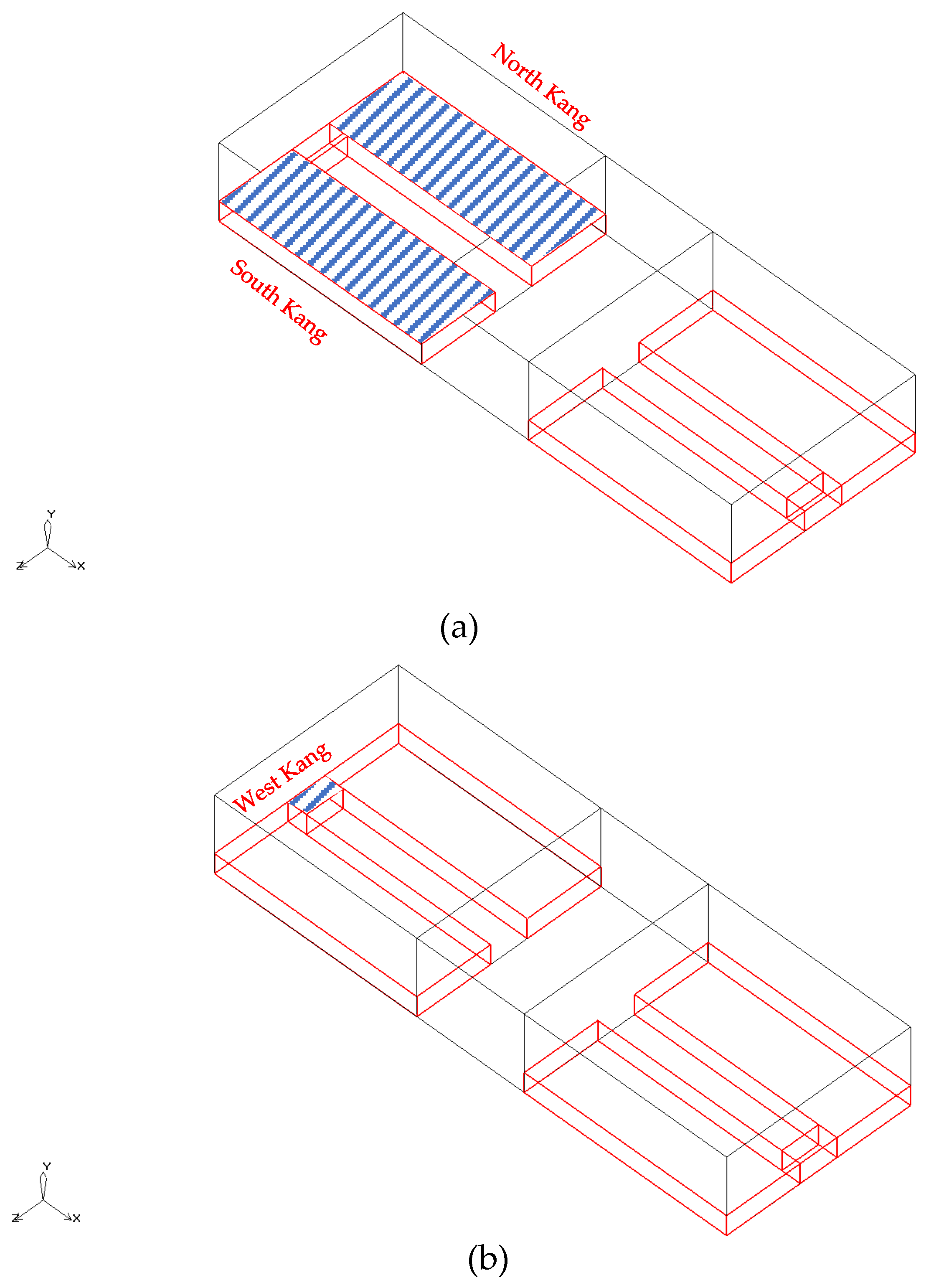

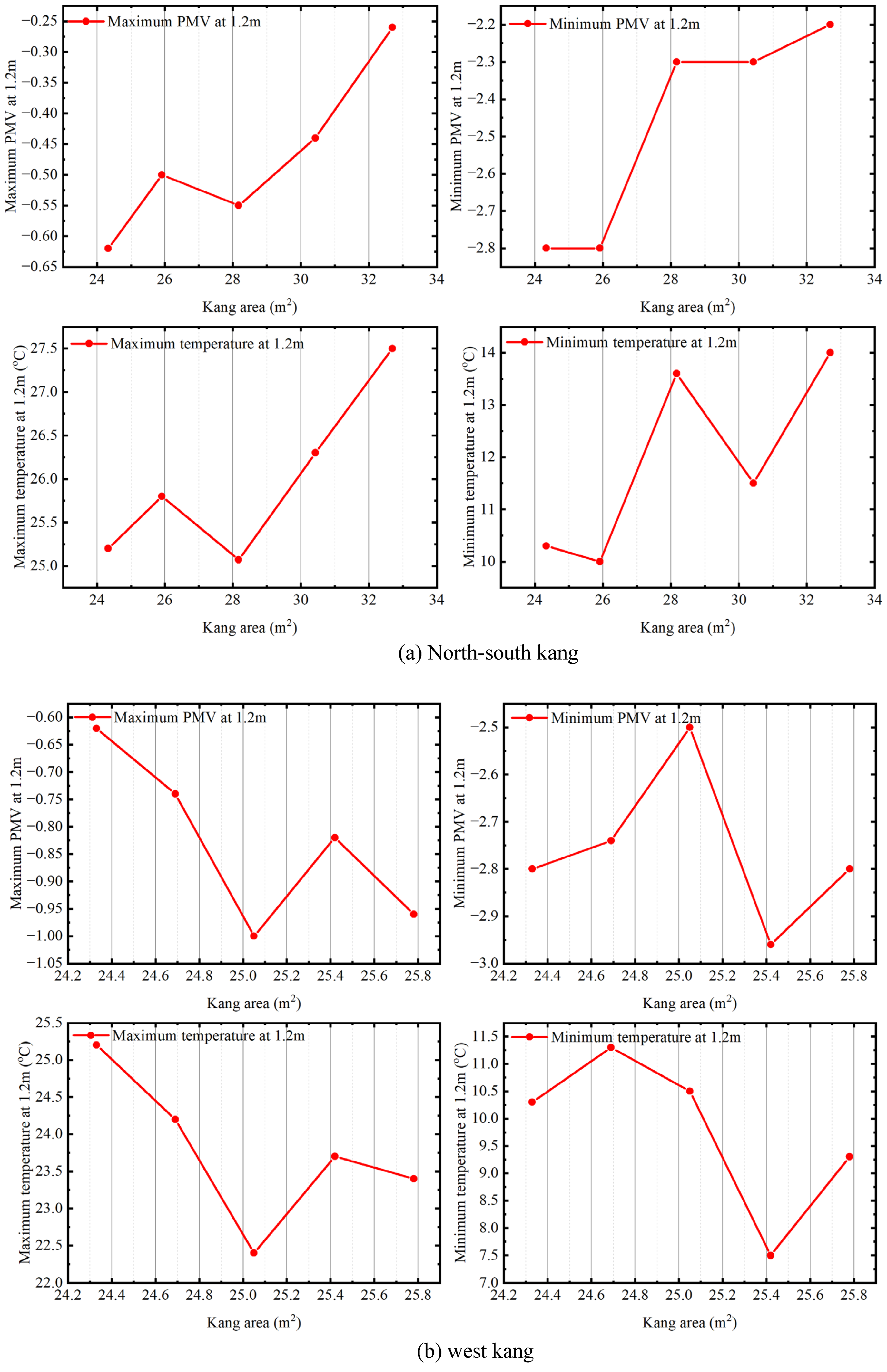

5.2. Heating Area Impact

6. Conclusions

- Simulations of residential structural enclosures revealed that enhancing roof insulation had the most pronounced effect on indoor thermal comfort compared to improving wall or window insulation. However, simulations also indicated that despite continuous enhancements, the effectiveness of passive strategy methods on indoor thermal comfort within structural enclosures is limited and less applicable to Sibe dwellings.

- The configuration of the traditional “kang” combined with the architectural layout of the Sibe residence is better suited for space heating

- Regarding the simulation research on the active heating device—”kang”—it was found that raising “kang” temperature significantly improves indoor thermal comfort, while increasing the “kang” area has a comparatively small effect. Therefore, future improvement measures could emphasize temperature-related factors.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Nomenclature | Definition |

| Heat storage coefficient (S) W/(m2·K) | The ability of a material to store heat is defined as its thermal capacity. The greater this value, the better the thermal stability of the material. |

| Heat transfer coefficient W/(m2·K) | Under steady-state heat transfer conditions, it refers to the amount of heat transferred per unit time through a unit area of a building envelope when there is a temperature difference of 1 degree (K or °C) between the air on either side. |

| Kang | In northern China, a kang is a sleeping platform constructed from bricks or adobe, featuring hollow spaces underneath that are connected to a chimney. It can be heated by burning fuel, providing warmth for sleeping and living areas. |

| Resistance (R) (m2·K/W) | When heat is transferred through an object, the ratio between the temperature difference across the object and the power of the heat source is defined as the thermal resistance. |

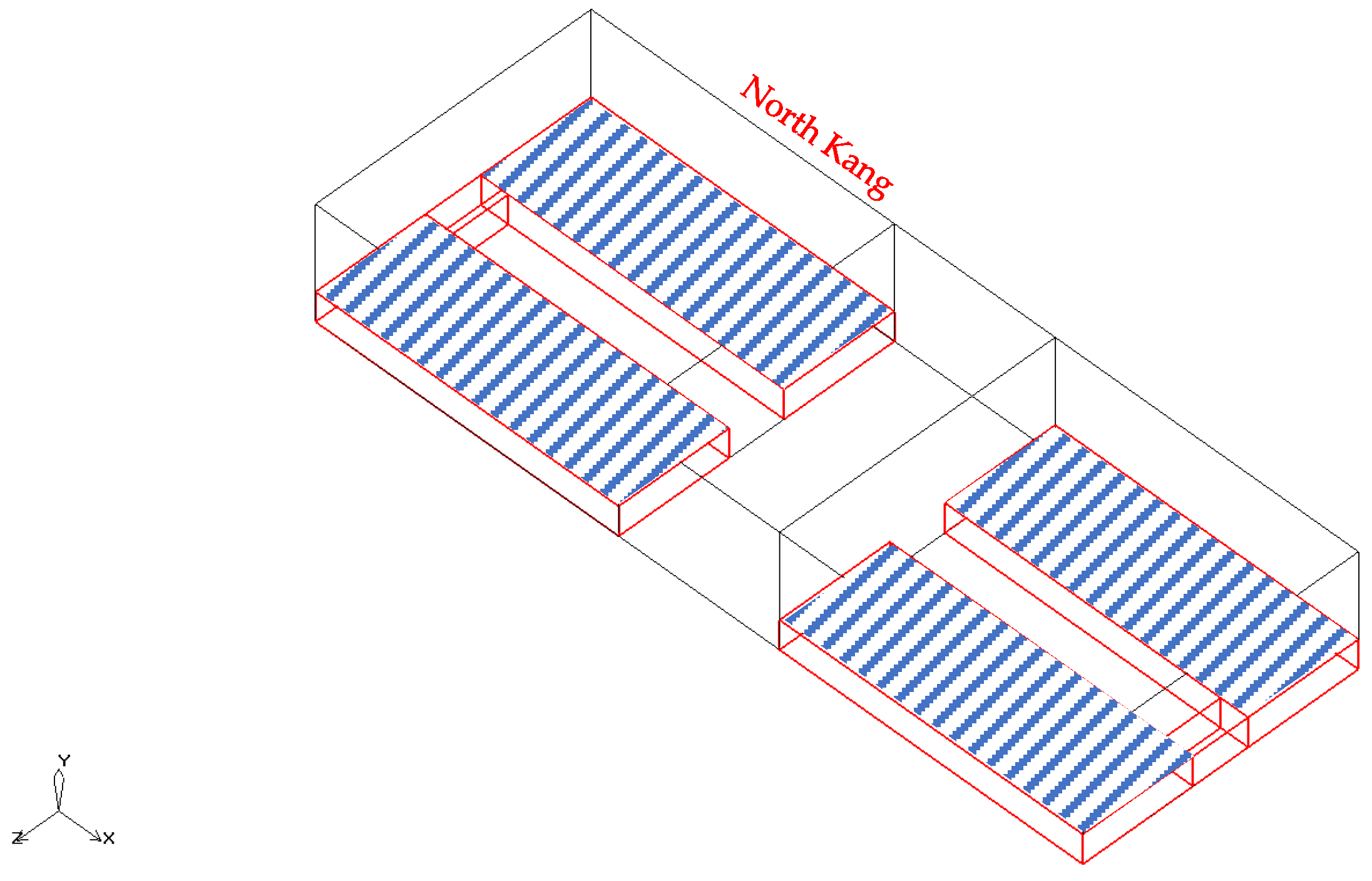

| “Swastika kang” | In the bedroom, a continuous kang is built along the north and south walls, with a narrower kang constructed on the west side. In some cases, the west kang is of the same width as the south and north kangs, connecting with them to form a “π”-shaped structure. The chimney extends through the wall to the outside. |

| Thermal conductivity (λ) W/(m·K) | The measure of a material’s ability to conduct heat. |

| Thermal inertia | The thermal inertia index is a measure of how quickly temperature fluctuations on one side of an object’s surface attenuate within the object when subjected to periodic thermal effects. |

References

- Zhao, H.; Jiang, Y. Research on Strategies for Improving Rural Human Settlements in the Context of Rural Revitalization—A Case Study of Zhejiang Province. Small Town Constr. 2019, 37, 9–14+93. (In Chinese) [Google Scholar]

- Ma, B. Research on Energy-Saving Design Solutions for Rural Houses in Northern China from the Perspective of Rural Revitalization. Master’s Thesis, North China University of Science and Technology, Tangshan, China, 2021. (In Chinese). [Google Scholar]

- Bao, C.; Zhang, C.; Bi, L. Research on Optimization Strategies for Indoor Thermal Comfort in Rural Houses in Severe Cold Regions. Archit. Cult. 2023, 26–27. (In Chinese) [Google Scholar] [CrossRef]

- Hou, J. Research on Optimization of Indoor Thermal Environment in Traditional Tibetan Dwellings on the Northwest Sichuan Plateau during Winter. Master’s Thesis, Sichuan Agricultural University, Ya’an, China, 2019. (In Chinese). [Google Scholar]

- Kaynakli, O.; Kilic, M. Investigation of Indoor Thermal Comfort under Transient Conditions. Build. Environ. 2005, 40, 165–174. [Google Scholar] [CrossRef]

- Cheng, C.; Deng, X.; Zhao, X.; Xiong, Y.; Zhang, Y. Multi-Occupant Dynamic Thermal Comfort Monitoring Robot System. Build. Environ. 2023, 234, 110137. [Google Scholar] [CrossRef]

- Ma, K.; Yu, Y.; Yang, B.; Yang, J. Demand-Side Energy Management Considering Price Oscillations for Residential Building Heating and Ventilation Systems. IEEE Trans. Ind. Inform. 2019, 15, 4742–4752. [Google Scholar] [CrossRef]

- Deng, X.; Zhang, Y.; Zhang, Y.; Qi, H. Toward Smart Multizone HVAC Control by Combining Context-Aware System and Deep Reinforcement Learning. IEEE Internet Things J. 2022, 9, 21010–21024. [Google Scholar] [CrossRef]

- Wang, X.; Mai, X.; Lei, B.; Bi, H.; Zhao, B.; Mao, G. Collaborative Optimization between Passive Design Measures and Active Heating Systems for Building Heating in Qinghai-Tibet Plateau of China. Renew. Energy 2020, 147, 683–694. [Google Scholar] [CrossRef]

- Li, X.; Shen, C.; Yu, C.W.F. Building Energy Efficiency: Passive Technology or Active Technology? Indoor Built Environ. 2017, 26, 729–732. [Google Scholar] [CrossRef]

- Imbabi, M.S.-E. A Passive–Active Dynamic Insulation System for All Climates. Int. J. Sustain. Built Environ. 2012, 1, 247–258. [Google Scholar] [CrossRef]

- Liu, J. Research on Optimization Strategies for Traditional Dwellings in Jia County Based on Thermal Comfort Improvement. Master’s Thesis, Zhengzhou University, Zhengzhou, China, 2022. (In Chinese). [Google Scholar]

- Wei, D.; Zhao, G.; Liu, S.; Yang, L. Indoor Thermal Comfort in a Rural Dwelling in Southwest China. Front. Public Health 2022, 10, 1029390. [Google Scholar] [CrossRef]

- Wang, Y.; Dong, Q.; Guo, H.; Yin, L.; Gao, W.; Yao, W.; Sun, L. Indoor Thermal Comfort Evaluation of Traditional Dwellings in Cold Region of China: A Case Study in Guangfu Ancient City. Energy Build. 2023, 288, 113028. [Google Scholar] [CrossRef]

- He, Q.; Liu, D.; Zhu, X.; Yang, L.; Liu, J. Field Study on Indoor Thermal Environment of Tibetan Dwellings in the Western Sichuan Plateau. J. Xi’an Univ. Archit. Technol. Nat. Sci. Ed. 2015, 47, 402–406. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, C.; Pomianowski, M.; Heiselberg, P.K.; Yu, T. A Review of Integrated Radiant Heating/Cooling with Ventilation Systems- Thermal Comfort and Indoor Air Quality. Energy Build. 2020, 223, 110094. [Google Scholar] [CrossRef]

- Minglu, Q.; Liang, X.; Deng, S.; Yiqiang, J. Improved Indoor Thermal Comfort during Defrost with a Novel Reverse-Cycle Defrosting Method for Air Source Heat Pumps. Build. Environ. 2010, 45, 2354–2361. [Google Scholar] [CrossRef]

- Myhren, J.A.; Holmberg, S. Flow Patterns and Thermal Comfort in a Room with Panel, Floor and Wall Heating. Energy Build. 2008, 40, 524–536. [Google Scholar] [CrossRef]

- Zhuang, Z.; Li, Y.; Chen, B.; Guo, J. Chinese Kang as a Domestic Heating System in Rural Northern China—A Review. Energy Build. 2009, 41, 111–119. [Google Scholar] [CrossRef]

- Yu, K.; Tan, Y.; Zhang, T.; Zhang, J.; Wang, X. The Traditional Chinese Kang and Its Improvement: A Review. Energy Build. 2020, 218, 110051. [Google Scholar] [CrossRef]

- Wei, L. Research on the Cultural Value of the Manchu “Swastika Kang”. Master’s Thesis, Jilin University of Arts, Changchun, China, 2022. (In Chinese). [Google Scholar]

- Zhang, Q. Simulation Analysis of Flow and Heat Transfer of Flue Gas in Traditional Kang of Northeast China. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2017. (In Chinese). [Google Scholar]

- Liu, Y.; Gu, Y.; Li, Y. Comparative Analysis of Energy-Saving Design between Ground Kang and Elevated Kang in Rural Houses in Northeast China. J. Anhui Agric. Sci. 2014, 42, 4326–4328. (In Chinese) [Google Scholar] [CrossRef]

- GB 50352-2019; Uniform Standard for Design of Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019. (In Chinese)

- Xiao, H.; Jiang, N. Investigation and Conservation Strategies for the Living Environment of Traditional Xibo Ethnic Villages—A Case Study of Shifosi Village, Shenbei New District, Shenyang, Liaoning Province. Urban Hous. 2020, 27, 98–102. (In Chinese) [Google Scholar]

- Lin, H.; Wang, J.-B.; Zhang, X.; Hu, F.; Liu, J.; Hong, X.-C. Historical Sensing: The Spatial Pattern of Soundscape Occurrences Recorded in Poems between the Tang and the Qing Dynasties amid Urbanization. Humanit. Soc. Sci. Commun. 2024, 11, 730. [Google Scholar] [CrossRef]

- GB 50176-2016; Code for Thermal Design of Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2016. (In Chinese)

- Wang, Y.; Zhang, X.; Zhang, H. Thermal Comfort Analysis of Loader Cab Based on PMV-PPD. J. Taiyuan Univ. Sci. Technol. 2024, 45, 38–43. (In Chinese) [Google Scholar]

- GB/T 50785-2012; Evaluation Standard for Indoor Thermal Environment in Civil Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2012. (In Chinese)

- Yao, R.; Li, B.; Liu, J. A Theoretical Adaptive Model of Thermal Comfort—Adaptive Predicted Mean Vote (aPMV). Build. Environ. 2009, 44, 2089–2096. [Google Scholar] [CrossRef]

- Shi, J. Research on the Interpretation of the Character "Kang" and the Development Process and Origin of Kang. Pop. Art Lit. 2016, 266. (In Chinese) [Google Scholar]

| Number | Indoor Thermal Comfort | Passive | Active | |

|---|---|---|---|---|

| Modern Technologies | Traditional Wisdom | |||

| [4] | ✓ | ✓ | ✓ | |

| [11] | ✓ | ✓ | ✓ | |

| [16] | ✓ | ✓ | ||

| [17] | ✓ | ✓ | ||

| [18] | ✓ | ✓ | ||

| [19] | ✓ | ✓ | ||

| [20] | ✓ | ✓ | ||

| [21] | ✓ | ✓ | ||

| [22] | ✓ | ✓ | ||

| Number | Types | Structure | Indoor Thermal Environment | Cultural | ||

|---|---|---|---|---|---|---|

| “Swastika Kang” | Other | Review | ||||

| [14] | ✓ | ✓ | ||||

| [15] | ✓ | ✓ | ||||

| [23] | ✓ | ✓ | ||||

| [24] | ✓ | ✓ | ||||

| [25] | ✓ | ✓ | ||||

| Months | Average Monthly Outdoor Temperature (°C) | Indoor Thermal Comfort Temperature Range (°C) |

|---|---|---|

| 1 | −11.5 | 17.4–24.4 |

| 2 | −6.5 | 17.4–24.4 |

| 3 | 1.7 | 17.4–24.4 |

| 4 | 10 | 17.4–24.4 |

| 5 | 16.7 | 19.5–26.5 |

| 6 | 21.5 | 21.0–28.0 |

| 7 | 25.7 | 22.3–29.3 |

| 8 | 23.2 | 21.5–28.5 |

| 9 | 17.2 | 19.6–26.6 |

| 10 | 10.3 | 17.5–24.5 |

| 11 | 1.1 | 17.4–24.4 |

| 12 | −7.5 | 17.4–24.4 |

| Analogue Serial Number | Materials (From Outside to Inside) | Thicknesses (mm) | Heat Transfer Coefficient (k) K = 1/(0.15 + ∑R) (W/m2·k) | Thermal Inertia D = R × S | Thermal Comfort Time Percentage | |

|---|---|---|---|---|---|---|

| External wall | Standard | Brickyard | 450 | 0.54 | 16.981 | 24.03% |

| 1 | Brickyard | 400 | 0.6 | 15.094 | 24.03% | |

| Brickyard | 500 | 0.49 | 18.868 | 24.13% | ||

| Total thickness of the wall remains the same, changing the wall construction | ||||||

| 1 | Brickyard (430 mm) Extruded polystyrene foam (with skin) (20 mm) | 450 | 0.41 | 16.453 | 24.03% | |

| Extruded polystyrene foam (with skin) (20 mm), Brickyard (430 mm) | 450 | 0.41 | 16.453 | 24.03% | ||

| 2 | Brickyard (410 mm), Extruded polystyrene foam (with skin) (20 mm), lime mortar (20 mm) | 450 | 0.42 | 15.944 | 24.03% | |

| Changing the total thickness of the wall | ||||||

| 1 | Brickyard (450 mm), Extruded polystyrene foam (with skin) (20 mm) | 470 | 0.40 | 17.208 | 24.03% | |

| 2 | Brickyard (450 mm), Extruded polystyrene foam (with skin) (50 mm) | 500 | 0.29 | 17.548 | 24.03% | |

| Analogue Serial Number | Materials (From Outside to Inside) | Thicknesses (mm) | Heat Transfer Coefficient (k) K = 1/(0.15 + ∑R) (W/m2·k) | Thermal Inertia D = R × S | Thermal Comfort Time Percentage | |

|---|---|---|---|---|---|---|

| Roof | Standard | Concrete tiles (20 mm), Lime mortar (1) (20 mm), Grass-filled clay (ρ = 1400) (20 mm), Wooden boards (20 mm) | 80 | 1.74 | 1.301 | 24.03% |

| 1 | Concrete tiles (30 mm), Lime mortar (1) (30 mm), Grass-filled clay (ρ = 1400) (30 mm), Wooden boards (30 mm) | 120 | 1.27 | 1.951 | 24.03% | |

| Changing the roof structure while keeping the total thickness of the roof structure unchanged | ||||||

| 1 | Concrete tiles (20 mm), Aerated concrete, foam concrete (ρ = 700) (20 mm), Grass-filled clay (ρ = 1400) (20 mm), Wooden boards(20 mm) | 80 | 1.51 | 1.399 | 24.14% | |

| 2 | Concrete tiles (20 mm), Lime mortar (1) (20 mm), Rigid-foam polyurethane sheet PUR (ρ ≥ 35) (20 mm), Wooden boards (20 mm) | 80 | 0.73 | 4.612 | 24.03% | |

| Changing the total thickness of the roof and the thickness of the insulation | ||||||

| 1 | Concrete tiles (20 mm), Lime mortar (20 mm), Rigid-foam polyurethane sheet PUR (ρ ≥ 35) (1) (60 mm), Wooden boards (20 mm) | 120 | 0.33 | 11.770 | 24.35% | |

| Analogue Serial Number | Materials (From Outside to Inside) | Thicknesses (mm) | Heat Transfer Coefficient (k) K = 1/(0.15 + ∑R) (W/m2·k) | Thermal Inertia D = R × S | Thermal Comfort Time Percentage | |

|---|---|---|---|---|---|---|

| External wall | standard | Wooden, plastic-double-glazed windows (double-glazed spacing (100–140) | 2.50 | 24.03% | ||

| 1 | 6 mm + LE35AMARL film glass | 4.60 | 22.83% | |||

| 2 | Plastic +6Low-E + 12A + 6 mm white transparent insulating glass | 1.90 | 23.31% | |||

| 3 | [5 mm + 9A (air) + 5 mm] nano-coated (HJ-N-series) + 9A (air) + 5 mm white glass (warm edge sealing) | 1.56 | 24.09% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Shang, Z.; Luo, K.; Xie, K. New Insights into Traditional Construction Behind Sibe Dwellings with Swastika Kang for Space Heating in North China. Buildings 2025, 15, 795. https://doi.org/10.3390/buildings15050795

Zhang M, Shang Z, Luo K, Xie K. New Insights into Traditional Construction Behind Sibe Dwellings with Swastika Kang for Space Heating in North China. Buildings. 2025; 15(5):795. https://doi.org/10.3390/buildings15050795

Chicago/Turabian StyleZhang, Menglong, Zhiyuan Shang, Keqian Luo, and Kai Xie. 2025. "New Insights into Traditional Construction Behind Sibe Dwellings with Swastika Kang for Space Heating in North China" Buildings 15, no. 5: 795. https://doi.org/10.3390/buildings15050795

APA StyleZhang, M., Shang, Z., Luo, K., & Xie, K. (2025). New Insights into Traditional Construction Behind Sibe Dwellings with Swastika Kang for Space Heating in North China. Buildings, 15(5), 795. https://doi.org/10.3390/buildings15050795