An Investigation of the Effect of Fissure Inclination on Specimen Deformation and the Damage Mechanism Based on the DIC Method

Abstract

1. Introduction

2. Materials and Methods

2.1. Principles of Specimen Preparation

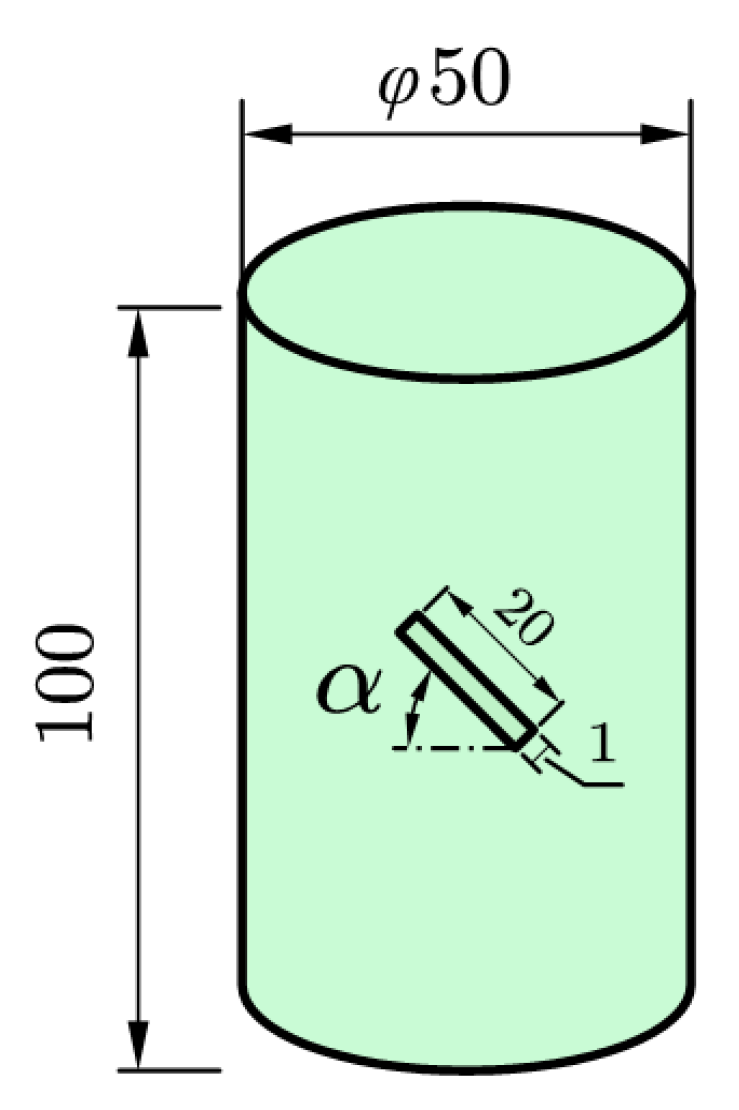

2.2. Specimen Preparation

2.3. Experiment Design

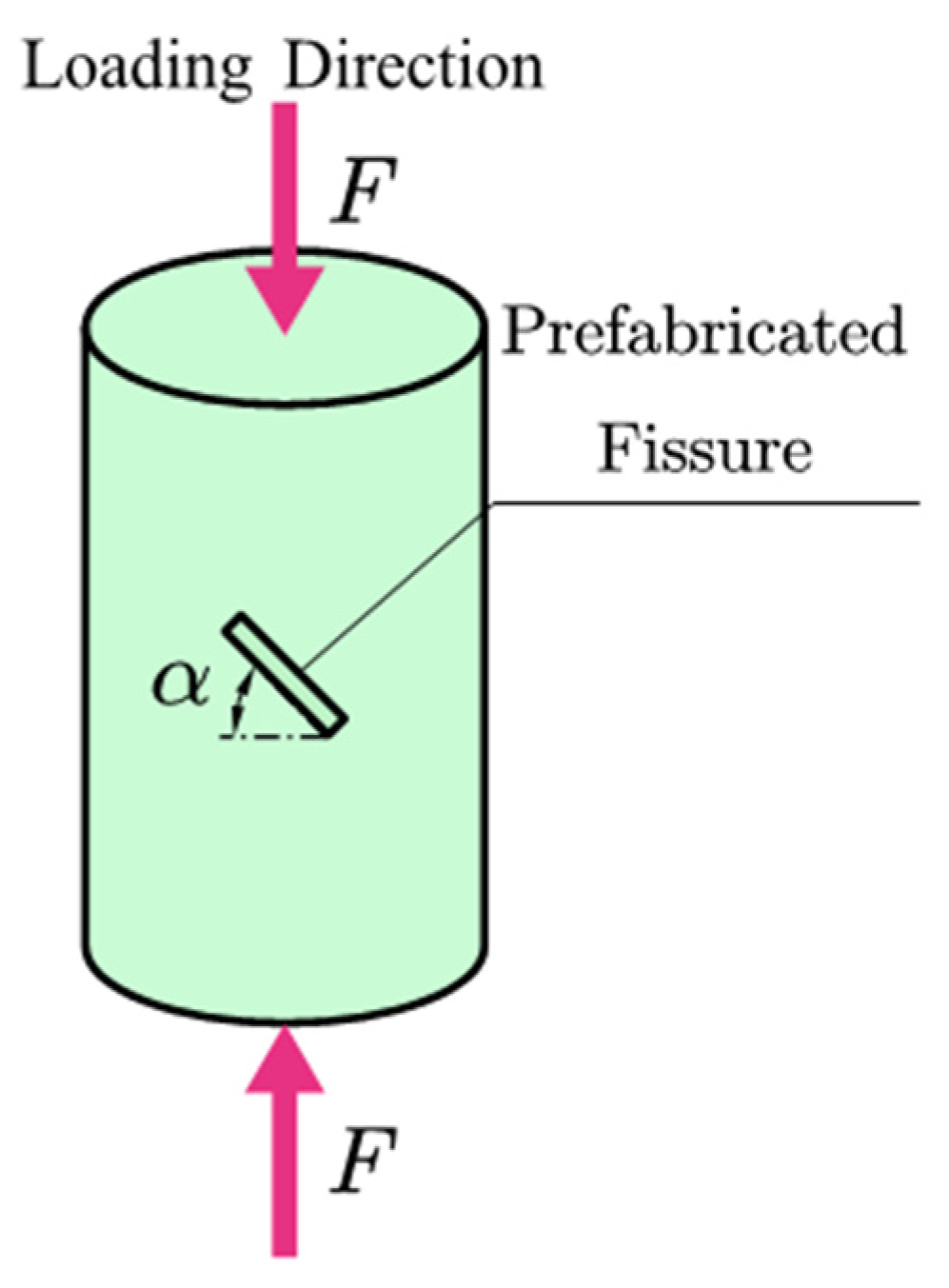

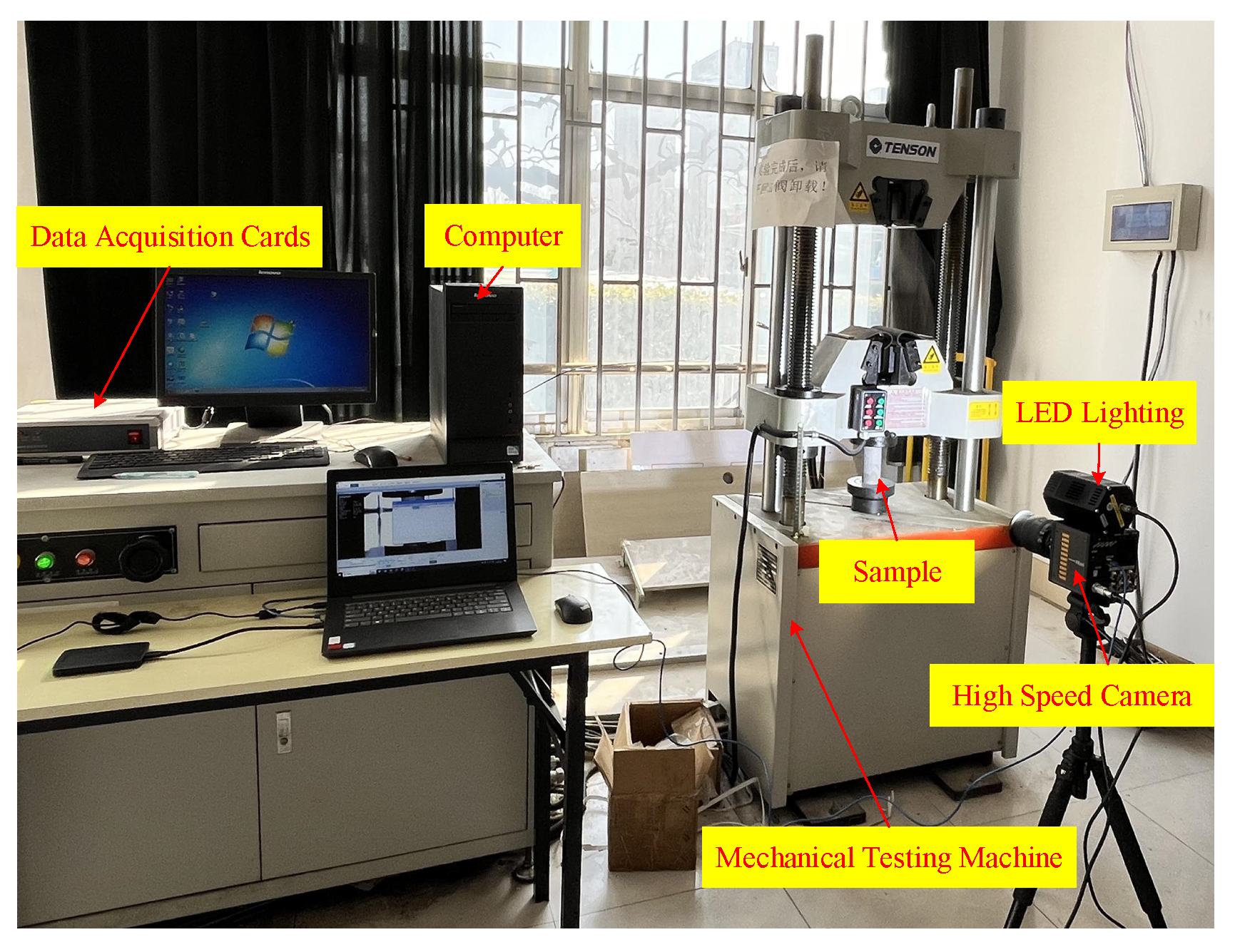

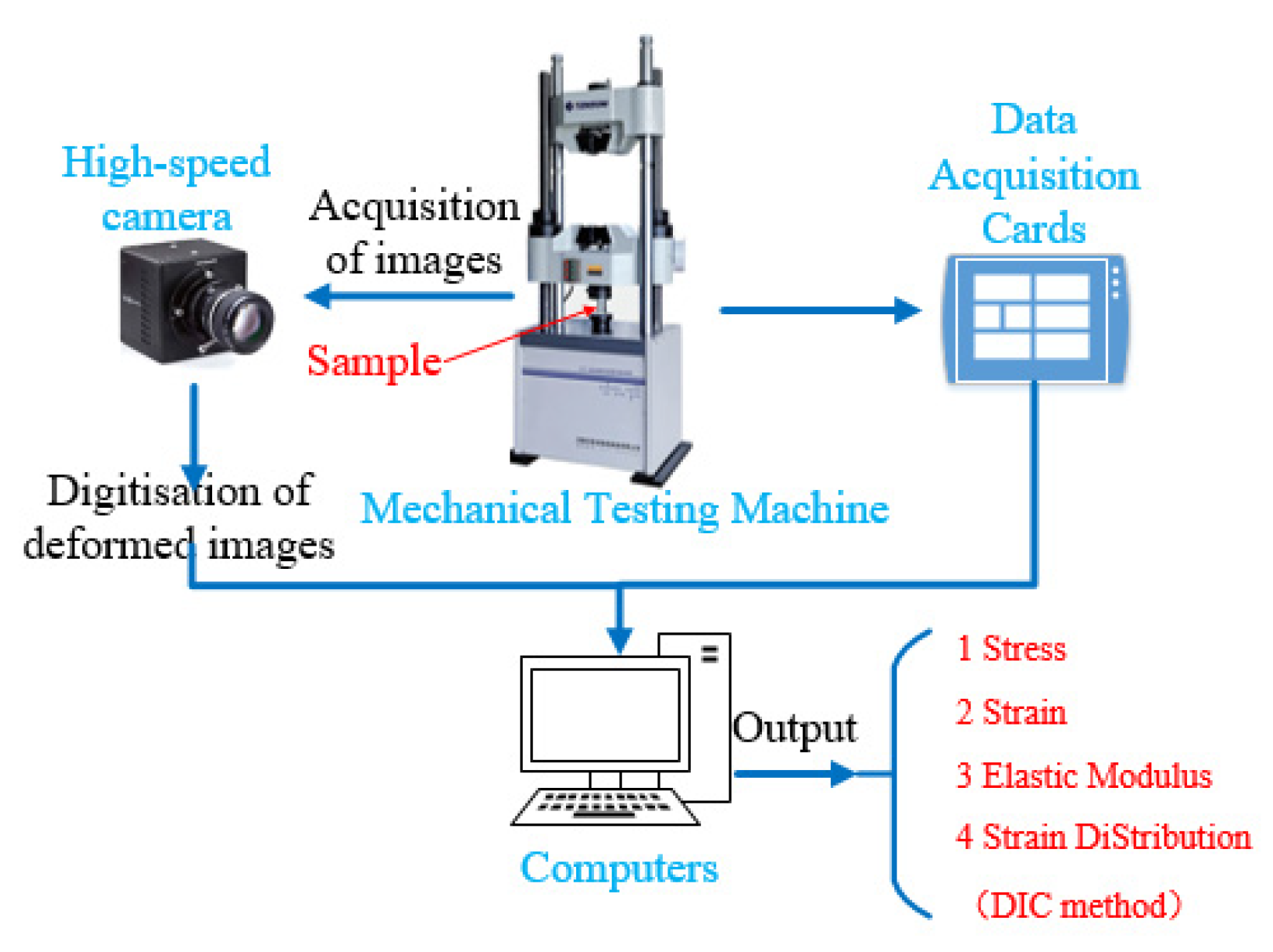

2.4. Experimental Process

- Loading process. The loading process entailed uniaxial compression tests on intact specimens and specimens with prefabricated fissures, respectively. The loading was halted immediately upon the specimen’s loss of bearing capacity and the emergence of discernible cracks on its surface.

- Image acquisition. The deformation images of the specimen surface were captured with a high-speed camera. In order to obtain a clear image of the specimen, an LED flash was employed to illuminate the specimen.

- Strain calculation. A comparison and analysis of the images of the deformed and undeformed specimens was conducted using the DIC method in order to calculate the strain distribution on the specimen surface.

3. Results and Discussion

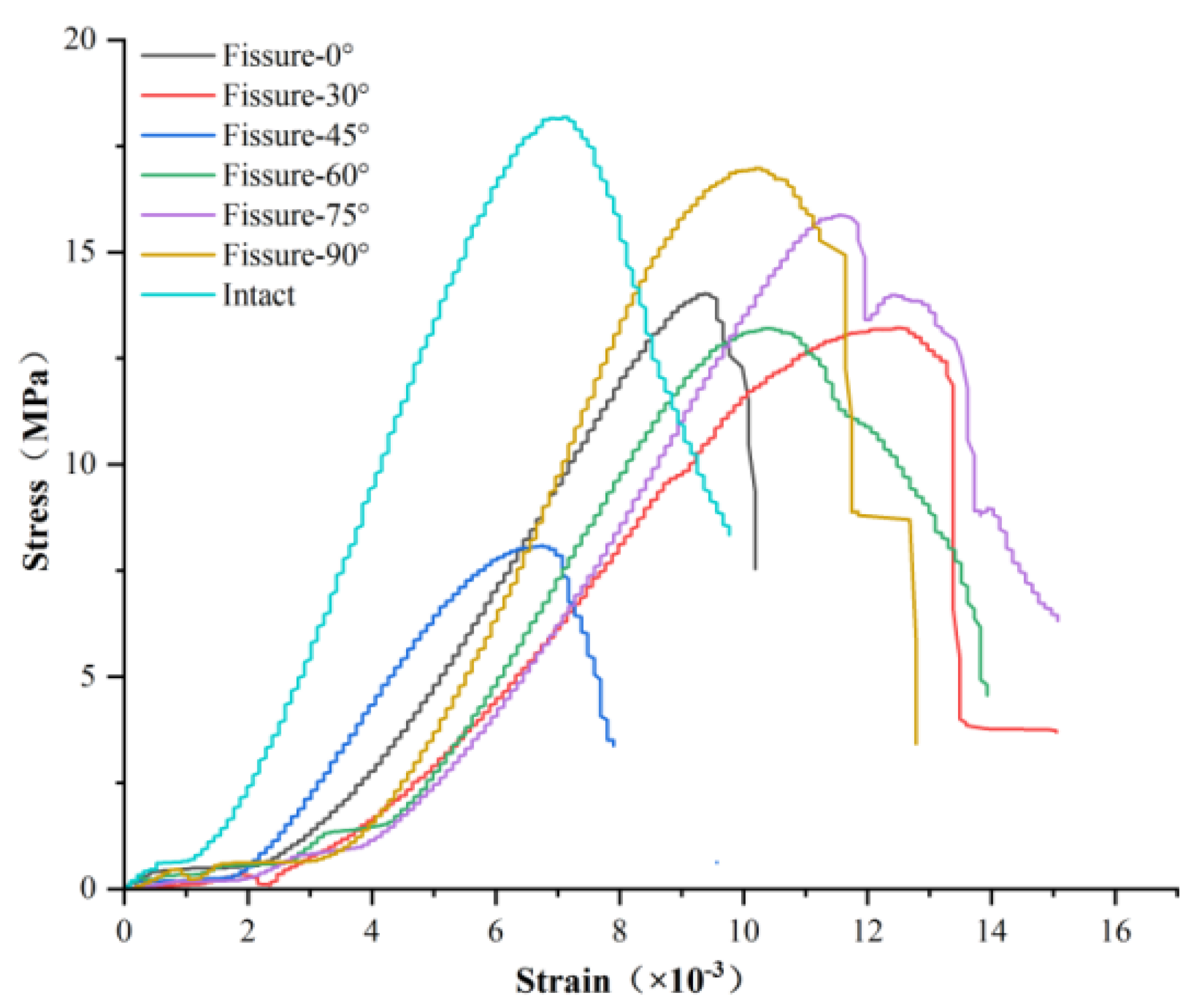

3.1. Stress–Strain Curves and Mechanical Parameters

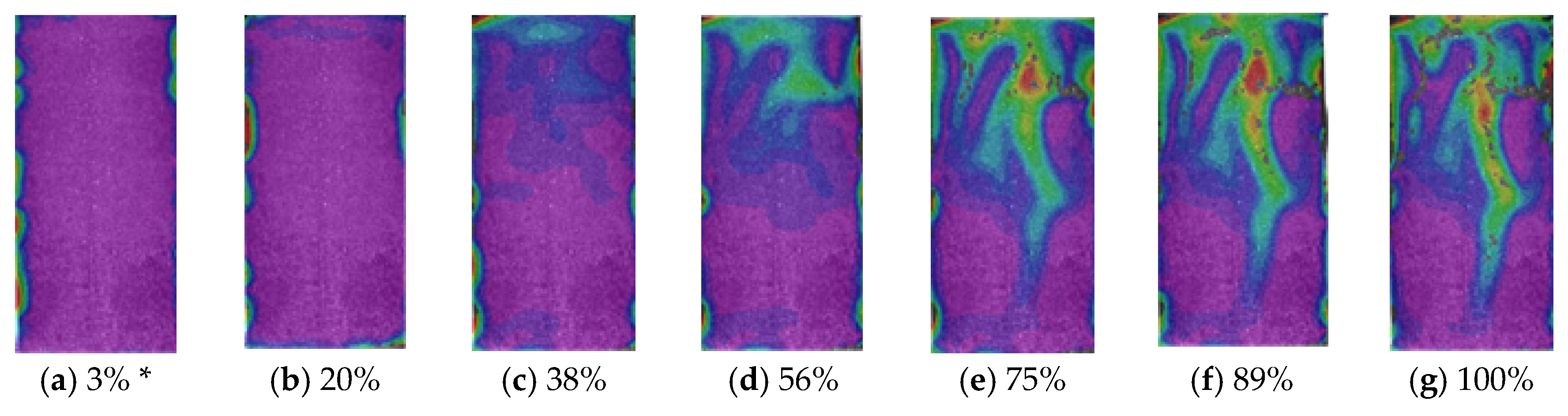

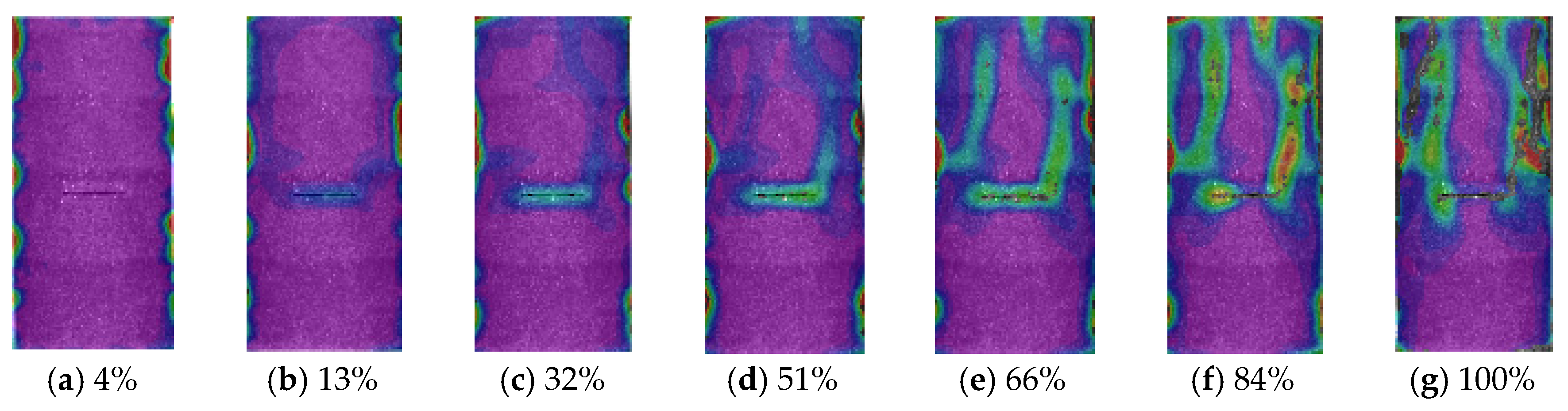

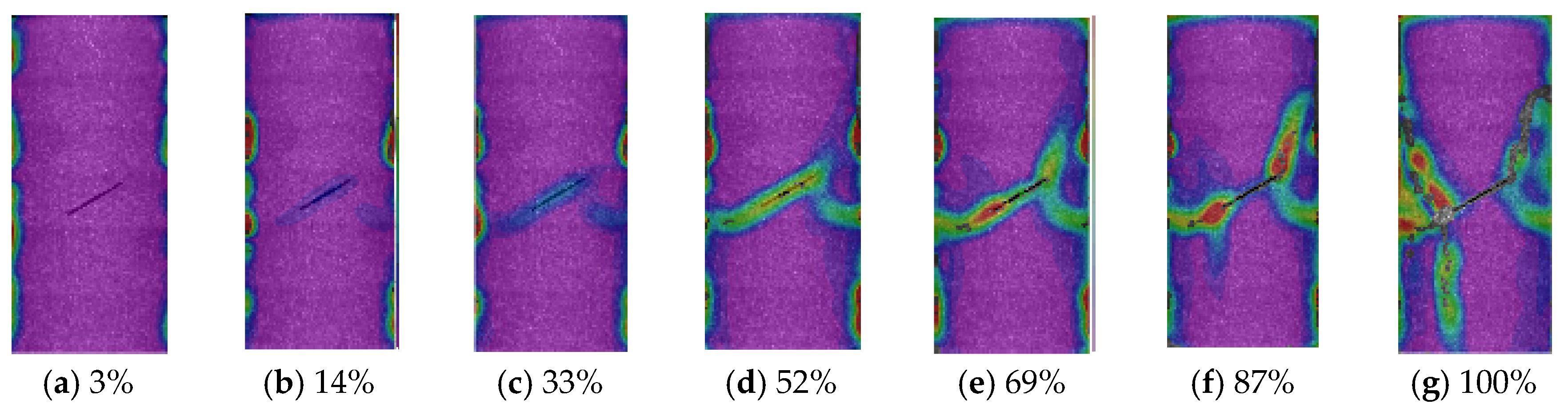

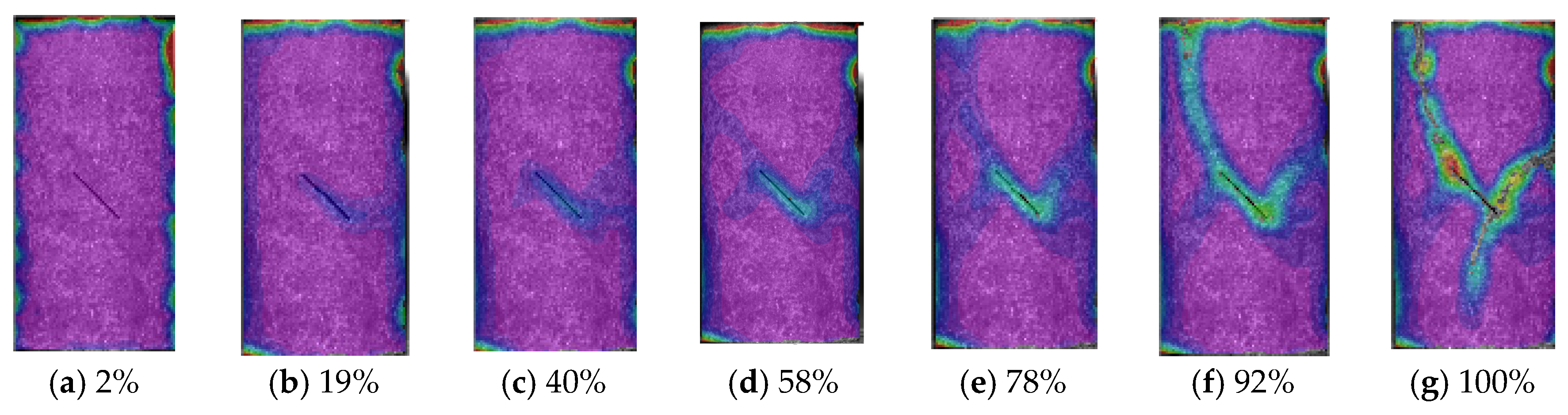

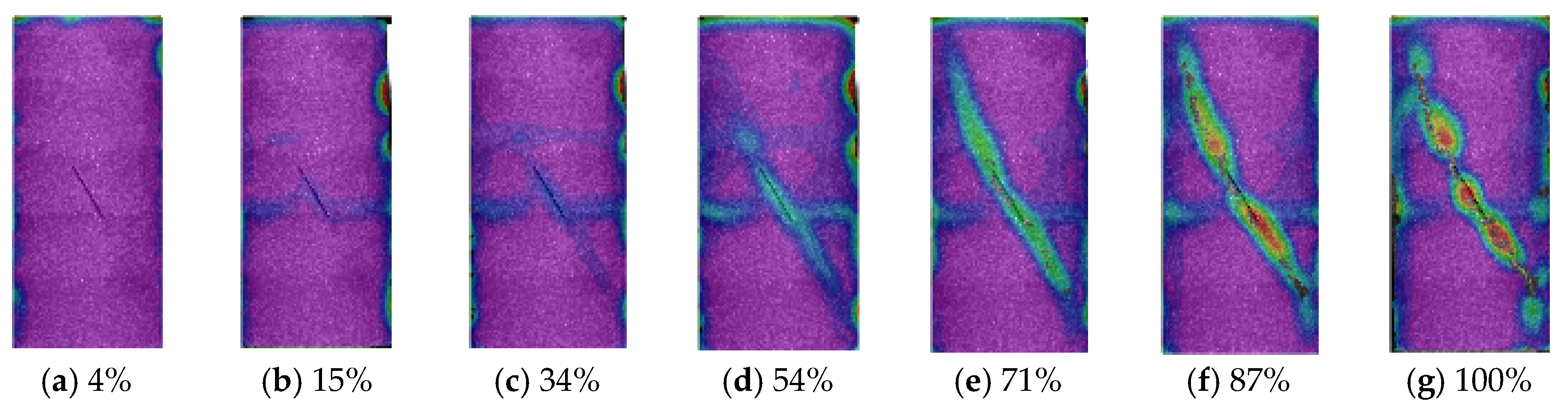

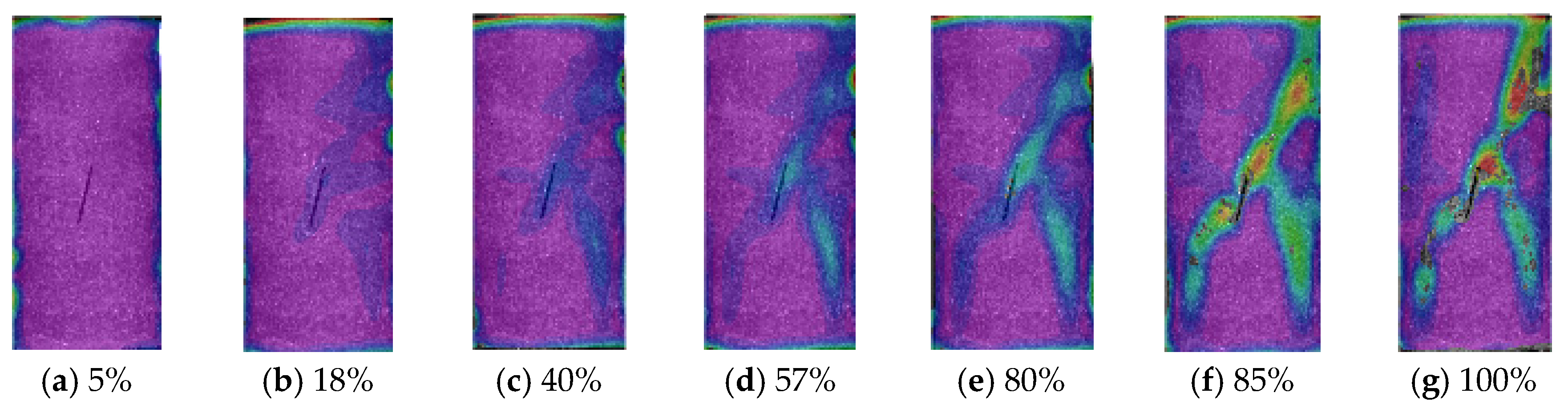

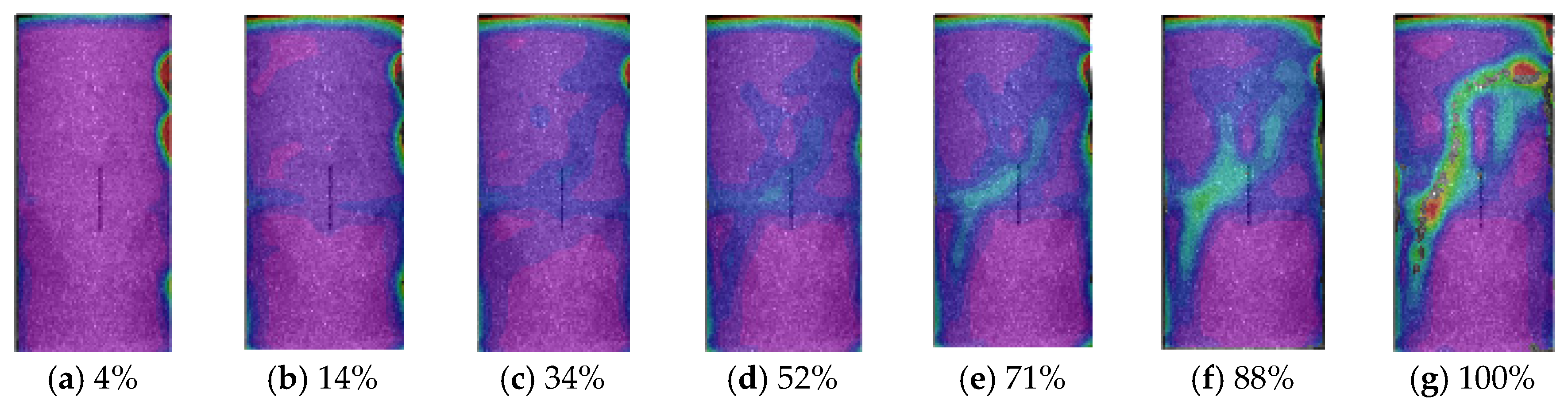

3.2. Analysis of Crack Evolution Based on the DIC Method

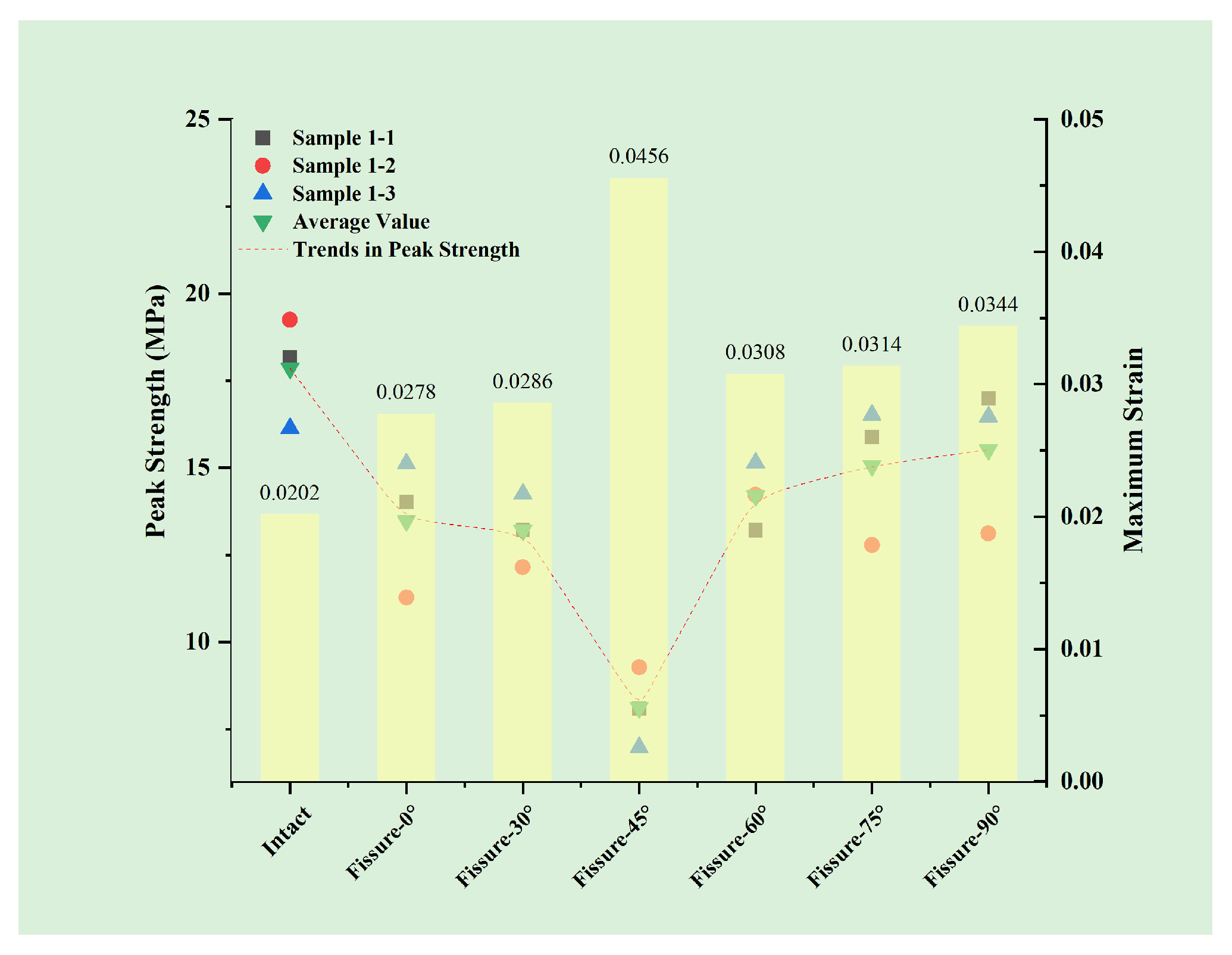

3.3. Effect of Fissure Inclination on Peak Strength and Maximum Strain

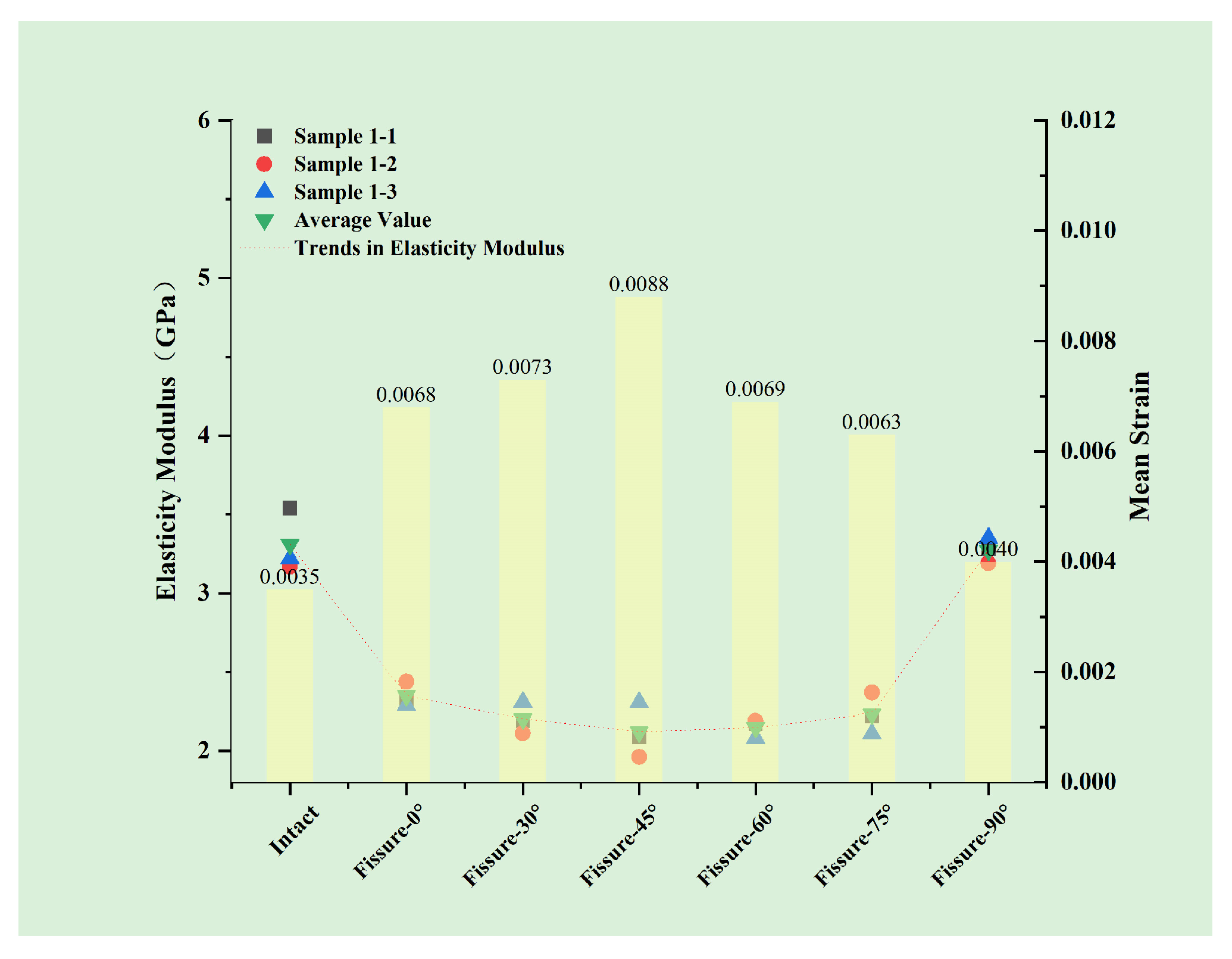

3.4. Effect of Fissure Inclination on the Elastic Modulus

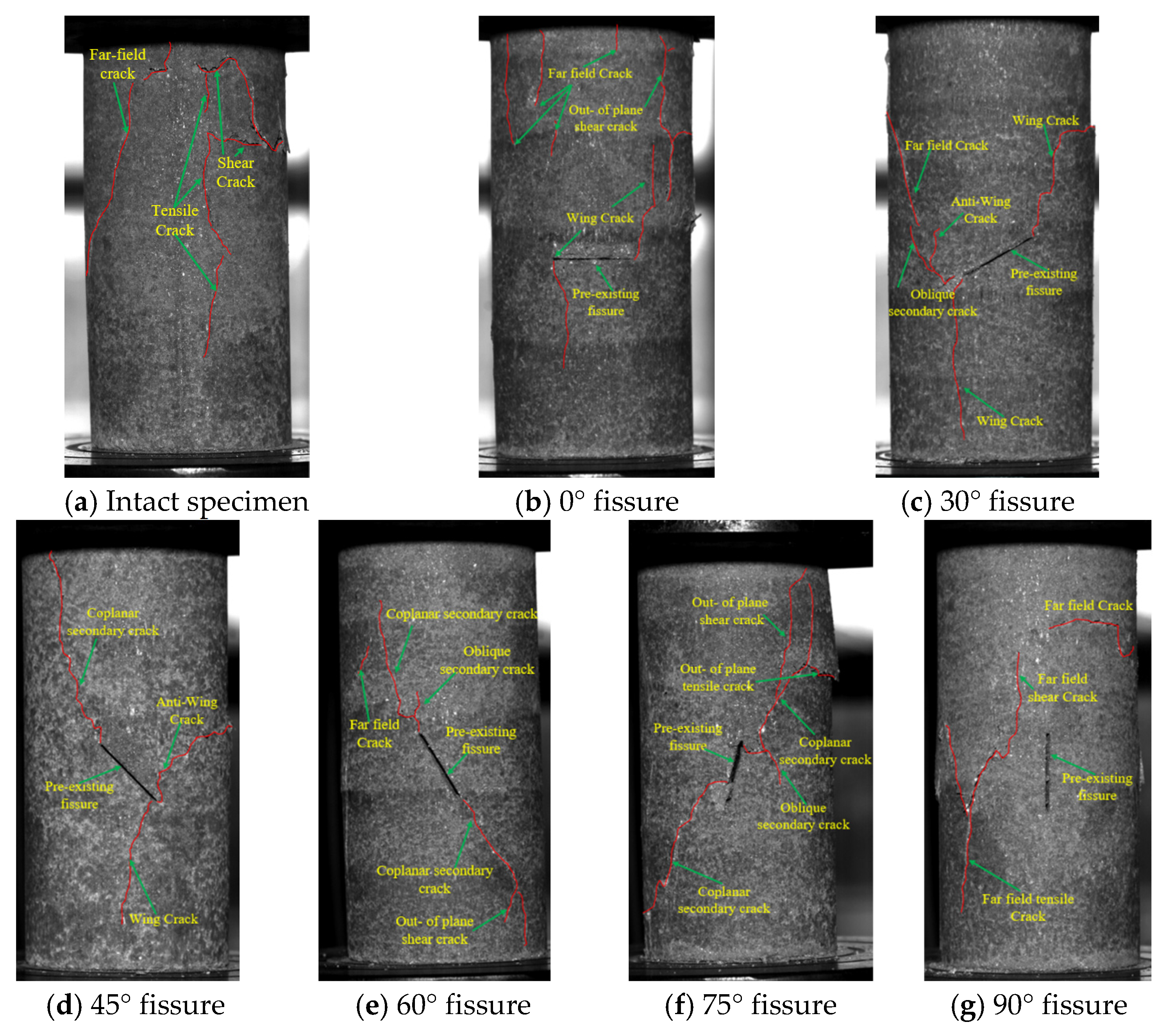

3.5. Crack Pattern of the Damaged Specimen

4. Conclusions

- The DIC method revealed that the maximum strain of the fissured specimen was predominantly concentrated at the fissured tips. The intact specimen was found to generate new cracks at approximately 75% of the peak strength, while the fissured specimen exhibited new crack formation at 50–60% of the peak strength. It was determined that as the fissure inclination approaches 45°, the strain on the specimen’s surface increases. Conversely, as the fissure inclination approaches 90°, the strain on the specimen’s surface approaches that of the intact specimen.

- The presence of the fissure reduced the strength and elastic modulus while increasing the strain. The magnitude of these changes is related to the fissure inclination. The fissure inclination of 45° exhibited the most significant changes compared to the intact specimen. The peak strength and elastic modulus decreased by 54.52% and 35.95%, respectively, and the strain increased by 151.42%. The fissure inclination of 90° exhibited the least significant change compared to the intact specimen, with the peak strength and elastic modulus reduced by only 13.02% and 1.11%, respectively, and the strain increased by 14.29%.

- The intact specimen and specimen with 90° inclination are mainly distributed with the shear crack, tensile crack, and far-field crack, which are mainly tensile–tension damage; specimens with 0~75° inclination are mainly distributed with the wing crack, anti-wing crack, oblique secondary crack, and coplanar secondary crack, which are mainly shear slip damage.

- The new cracks mainly originate from the tip of the fissure and propagate at an angle to the direction of the principal stress. For specimens with 0° inclination, the new cracks mainly propagate in the direction perpendicular to the fissure; for specimens with 30° and 45° inclinations, the new cracks mainly propagate in the direction parallel and perpendicular to the fissure; for specimens with 60° and 75° inclinations, the new cracks propagate in the direction parallel to the fissure; and for specimens with 90° inclination, the new cracks propagate in the direction parallel to the fissure.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kang, H.P. Seventy years development and prospects of strata control technologies for coal mine roadways in China. Chin. J. Rock Mech. Eng. 2021, 40, 1–30. [Google Scholar] [CrossRef]

- Yang, J.; Min, T.J.; Liu, B.H.; Chen, K.K.; Yang, L. Research progress on disasters and prevention in deeping mining. Sci. Technol. Eng. 2020, 20, 14767–14776. [Google Scholar]

- Zhao, Y.M.; Feng, X.T.; Jiang, Q.; Han, Y.; Zhou, Y.Y.; Guo, H.G.; Kou, Y.Y.; Shi, Y.E. Large Deformation Control of Deep Roadways in Fractured Hard Rock Based on Cracking-Restraint Method. Rock Mech. Rock Eng. 2021, 54, 2559–2580. [Google Scholar] [CrossRef]

- Alneasan, M.; Behnia, M. An experimental investigation on tensile fracturing of brittle rocks by considering the effect of grain size and mineralogical composition. Int. J. Rock Mech. Min. 2021, 137, 104570. [Google Scholar] [CrossRef]

- Alneasan, M.; Alzo’ubi, A.K. Comprehensive investigation of rock fracture behaviour in clay-rich rocks under the effect of temperature: Experimental study under three loading modes (I, I/II, II). Eng. Fract. Mech. 2022, 276, 108933. [Google Scholar] [CrossRef]

- Zengin, E.; Erguler, Z.A. Experimental investigation of pore-fracture relationship on failure behaviour of porous rock materials. Bull. Eng. Geol. Environ. 2022, 81, 351. [Google Scholar] [CrossRef]

- Zare, S.; Karimi-Nasab, S.; Jalalifar, H. Analysis and determination of the behavioral mechanism of rock bridges using experimental and numerical modeling of non-persistent rock joints. Int. J. Rock Mech. Min. 2021, 141, 104714. [Google Scholar] [CrossRef]

- Moura, D.D.; Bobet, A. Crack Interaction with a Frictional Interface in a Rock-Model Material: An Experimental Investigation. Rock Mech. Rock Eng. 2022, 55, 6187–6207. [Google Scholar] [CrossRef]

- Klammer, A.; Peintner, C.; Gottsbacher, L.; Biermann, J.; Bluemel, M.; Schubert, W.; Marcher, T. Investigation of the Influence of Grain-Scale Heterogeneity on Strainburst Proneness Using Rock-Like Material. Rock Mech. Rock Eng. 2023, 56, 407–425. [Google Scholar] [CrossRef]

- Asadizadeh, M.; Khosravi, S.; Abharian, S.; Imani, M.; Shakeri, J.; Hedayat, A.; Babanouri, N.; Sherizadeh, T. Tensile behavior of layered rock disks under diametral loading: Experimental and numerical investigations. Granul. Matter 2023, 25, 21. [Google Scholar] [CrossRef]

- Gögüs, Ö.; Avsar, E. Stress levels of precursory strain localization subsequent to the crack damage threshold in brittle rock. PLoS ONE 2022, 17, e0276214. [Google Scholar] [CrossRef]

- Sisodiya, M.; Zhang, Y.D. A Time-Dependent Directional Damage Theory for Brittle Rocks Considering the Kinetics of Microcrack Growth. Rock Mech. Rock Eng. 2022, 55, 2693–2710. [Google Scholar] [CrossRef]

- Öge, I.F.; Erkayaoglu, M. Pre- and post-failure characterisation of low-strength rocks by generalised crack initiation and crack damage. Bull. Eng. Geol. Environ. 2024, 83, 91. [Google Scholar] [CrossRef]

- Lee, J.; Ha, Y.D.; Hong, J.W. Crack coalescence morphology in rock-like material under compression. Int. J. Fract. 2017, 203, 211–236. [Google Scholar] [CrossRef]

- Hedan, S.; Valle, V.; Giot, R.; Cosenza, P. Behavior in mixed-mode of desiccation cracks on a clayey rock front gallery. Int. J. Rock Mech. Min. 2022, 154, 105104. [Google Scholar] [CrossRef]

- Bahrani, N.; Kaiser, P.K. Estimation of Confined Peak Strength of Crack-Damaged Rocks. Rock Mech. Rock Eng. 2017, 50, 309–326. [Google Scholar] [CrossRef]

- Cui, C.; Gratchev, I. Effects of pre-existing cracks and infillings on strength of natural rocks—Cases of sandstone, argillite and basalt. J. Rock Mech. Geotech. Eng. 2020, 12, 1333–1338. [Google Scholar] [CrossRef]

- Hu, G.J.; Ma, G. Size effect of parallel-joint spacing on uniaxial compressive strength of rock. PLoS ONE 2021, 16, e0257245. [Google Scholar] [CrossRef]

- Liu, L.W.; Li, H.B.; Li, X.F. A state-of-the-art review of mechanical characteristics and cracking processes of pre-cracked rocks under quasi-static compression. J. Rock Mech. Geotech. Eng. 2022, 14, 2034–2057. [Google Scholar] [CrossRef]

- Del Zoppo, M.; Menna, C.; Di Ludovico, M.; Asprone, D.; Prota, A. Opportunities of light jacketing with Fibre Reinforced Cementitious Composites for seismic retro fi tting of existing RC columns. Compos. Struct. 2021, 263, 113717. [Google Scholar] [CrossRef]

- Wu, X.H.; Wu, X.; Zhang, S.K.; Zhu, Y. Macro/Microfracture evolution and instability behaviors of high-temperature granite under water-cooling subjected to Brazilian splitting test using the DIC technique. PLoS ONE 2023, 18, e0294258. [Google Scholar] [CrossRef]

- Sharafisafa, M.; Aliabadian, Z.; Tahmasebinia, F.; Shen, L.M. A comparative study on the crack development in rock-like specimens containing unfilled and filled flaws. Eng. Fract. Mech. 2021, 241, 107405. [Google Scholar] [CrossRef]

- San Miguel, C.R.; Petropoulos, N.; Yi, C.P.; Johansson, D. Experimental Investigation of Blast-Induced Crack Propagation Based on Digital Image Correlation Analysis. Shock Vib. 2024, 2024, 4149322. [Google Scholar] [CrossRef]

- Chen, Y.W.; Feng, J.L.; Li, H.; Meng, Z.F. Effect of coarse aggregate volume fraction on mode II fracture toughness of concrete. Eng. Fract. Mech. 2021, 242, 107472. [Google Scholar] [CrossRef]

- GB/T 50266-2013; Standard for Test Methods of Engineering Rock Masses. China Planning Press: Beijing, China, 2013.

- Zhou, X.P.; Li, L.H.; Berto, F. Cracking Behaviors of Rock-Like Specimens Containing Two Sets of Preexisting Cross Flaws under Uniaxial Compression. J. Test. Eval. 2019, 47, 838–867. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, Y.M.; Zhao, C.F.; Bao, C. Cracking Processes and Coalescence Modes in Rock-Like Specimens with Two Parallel Pre-existing Cracks. Rock Mech. Rock Eng. 2018, 51, 3377–3393. [Google Scholar] [CrossRef]

- Liu, J.W.; Wu, N.; Si, G.Y.; Zhao, M.X. Experimental study on mechanical properties and failure behaviour of the pre-cracked coal-rock combination. Bull. Eng. Geol. Environ. 2021, 80, 2307–2321. [Google Scholar] [CrossRef]

- Yang, S.Q.; Huang, Y.H.; Tian, W.L.; Zhu, J.B. An experimental investigation on strength, deformation and crack evolution behavior of sandstone containing two oval flaws under uniaxial compression. Eng. Geol. 2017, 2017, 326–327. [Google Scholar] [CrossRef]

- Aboayanah, K.R.; Abdelaziz, A.; Haile, B.F.; Zhao, Q.; Grasselli, G. Evaluation of Damage Stress Thresholds and Mechanical Properties of Granite: New Insights from Digital Image Correlation and GB-FDEM. Rock Mech. Rock Eng. 2024, 57, 4679–4706. [Google Scholar] [CrossRef]

- Shen, P.W.; Tang, H.M.; Zhang, B.C.; Ning, Y.B.; Su, X.X.; Sun, S.X. Weakening Investigation of Reservoir Rock by Coupled Uniaxial Compression, Computed Tomography and Digital Image Correlation Methods: A Case Study. Sensors 2021, 21, 344. [Google Scholar] [CrossRef] [PubMed]

- Xiu, Z.G.; Wang, S.H.; Ji, Y.C.; Wang, F.L.; Ren, F.Y.; Nguyen, V.T. Loading rate effect on the uniaxial compressive strength (UCS) behavior of cemented paste backfill (CPB). Constr. Build. Mater. 2021, 271, 121526. [Google Scholar] [CrossRef]

- Yin, Q.; Jing, H.W.; Zhu, T.T. Mechanical behavior and failure analysis of granite specimens containing two orthogonal fissures under uniaxial compression. Arab. J. Geosci. 2016, 9, 31. [Google Scholar] [CrossRef]

- Liu, H.F.; Zhu, C.Q.; Zheng, K.; Ma, C.H.; Yi, M.X. Crack Initiation and Damage Evolution of Micritized Framework Reef Limestone in the South China Sea. Rock Mech. Rock Eng. 2021, 54, 5591–5601. [Google Scholar] [CrossRef]

- Yang, S.Q.; Huang, Y.H. Failure behaviour of rock-like materials containing two pre-existing unparallel flaws: An insight from particle flow modeling. Eur. J. Environ. Civ. Eng. 2018, 22, s57–s78. [Google Scholar] [CrossRef]

- Zou, C.J.; Wong, L.N.Y.; Loo, J.J.; Gan, B.S. Different mechanical and cracking behaviors of single-flawed brittle gypsum specimens under dynamic and quasi-static loadings. Eng. Geol. 2016, 201, 71–84. [Google Scholar] [CrossRef]

- Yang, S.Q.; Xu, T.; He, L.; Jing, H.W.; Wen, S.; Yu, Q.L. Numerical study on failure behavior of brittle rock specimen containing pre-existing combined flaws under different confining pressure. Arch. Civ. Mech. Eng. 2015, 15, 1085–1097. [Google Scholar] [CrossRef]

- Duriez, J.; Scholtès, L.; Donzé, F.V. Micromechanics of wing crack propagation for different flaw properties. Eng. Fract. Mech. 2016, 153, 378–398. [Google Scholar] [CrossRef]

- Tian, W.; Han, N.V. Mechanical properties of rock specimens containing pre-existing flaws with 3D printed materials. Strain 2017, 53, e12240. [Google Scholar] [CrossRef]

- Cheng, H.; Zhou, X.P.; Zhu, J.; Qian, Q.H. The Effects of Crack Openings on Crack Initiation, Propagation and Coalescence Behavior in Rock-Like Materials Under Uniaxial Compression. Rock Mech. Rock Eng. 2016, 49, 3481–3494. [Google Scholar] [CrossRef]

| Index | Density (g/cm3) | Compressive Strength (MPa) | Elastic Modulus (GPa) | Poisson’s Ratio | Internal Friction Angle (°) |

|---|---|---|---|---|---|

| Sandstone | 1.2~2.75 | 4.5~51 | 0.6~2.2 | 0.25~0.30 | 27~45 |

| Sandstone-like Materials | 1.6~1.8 | 6.5~22.3 | 0.96~3.54 | 0.21~0.32 | 23~51 |

| Number | High (mm) | Diameter (mm) | Density (g/cm3) | Peak Stress (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| Intact-1 | 100.32 | 50.12 | 2.12 | 18.17 | 3.54 |

| Intact-2 | 99.68 | 49.72 | 2.16 | 19.25 | 3.17 |

| Intact-3 | 99.82 | 49.74 | 2.19 | 20.13 | 3.22 |

| Fissure 0°-1 | 100.12 | 49.92 | 2.12 | 14.02 | 2.32 |

| Fissure 0°-2 | 100.16 | 50.26 | 2.10 | 13.28 | 2.44 |

| Fissure 0°-3 | 100.28 | 49.90 | 2.05 | 15.12 | 2.29 |

| Fissure 30°-1 | 100.20 | 50.28 | 2.04 | 13.22 | 2.19 |

| Fissure 30°-2 | 100.30 | 50.26 | 2.07 | 12.15 | 2.11 |

| Fissure 30°-3 | 99.88 | 50.02 | 2.05 | 14.25 | 2.31 |

| Fissure 45°-1 | 99.76 | 49.94 | 2.11 | 8.10 | 2.09 |

| Fissure 45°-2 | 99.64 | 50.16 | 2.14 | 9.28 | 1.96 |

| Fissure 45°-3 | 100.22 | 50.18 | 2.09 | 7.98 | 2.31 |

| Fissure 60°-1 | 99.58 | 50.06 | 2.12 | 13.21 | 2.17 |

| Fissure 60°-2 | 99.92 | 49.80 | 2.07 | 14.23 | 2.19 |

| Fissure 60°-3 | 99.84 | 50.22 | 2.16 | 13.15 | 2.08 |

| Fissure 75°-1 | 99.58 | 50.12 | 2.16 | 15.88 | 2.22 |

| Fissure 75°-2 | 99.70 | 50.14 | 2.11 | 14.78 | 2.37 |

| Fissure 75°-3 | 100.20 | 50.18 | 2.08 | 16.52 | 2.11 |

| Fissure 90°-1 | 100.14 | 50.22 | 2.10 | 16.99 | 3.28 |

| Fissure 90°-2 | 100.10 | 49.78 | 2.09 | 15.12 | 3.19 |

| Fissure 90°-3 | 99.90 | 50.22 | 2.13 | 16.47 | 3.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Xie, F.; Fu, X.; Wang, Y.; Yin, Z. An Investigation of the Effect of Fissure Inclination on Specimen Deformation and the Damage Mechanism Based on the DIC Method. Buildings 2025, 15, 713. https://doi.org/10.3390/buildings15050713

Wang H, Xie F, Fu X, Wang Y, Yin Z. An Investigation of the Effect of Fissure Inclination on Specimen Deformation and the Damage Mechanism Based on the DIC Method. Buildings. 2025; 15(5):713. https://doi.org/10.3390/buildings15050713

Chicago/Turabian StyleWang, Hongwei, Fuxiang Xie, Xi Fu, Yongyan Wang, and Zhaoming Yin. 2025. "An Investigation of the Effect of Fissure Inclination on Specimen Deformation and the Damage Mechanism Based on the DIC Method" Buildings 15, no. 5: 713. https://doi.org/10.3390/buildings15050713

APA StyleWang, H., Xie, F., Fu, X., Wang, Y., & Yin, Z. (2025). An Investigation of the Effect of Fissure Inclination on Specimen Deformation and the Damage Mechanism Based on the DIC Method. Buildings, 15(5), 713. https://doi.org/10.3390/buildings15050713