Current Insight on Eco-Friendly Concrete: A Review

Abstract

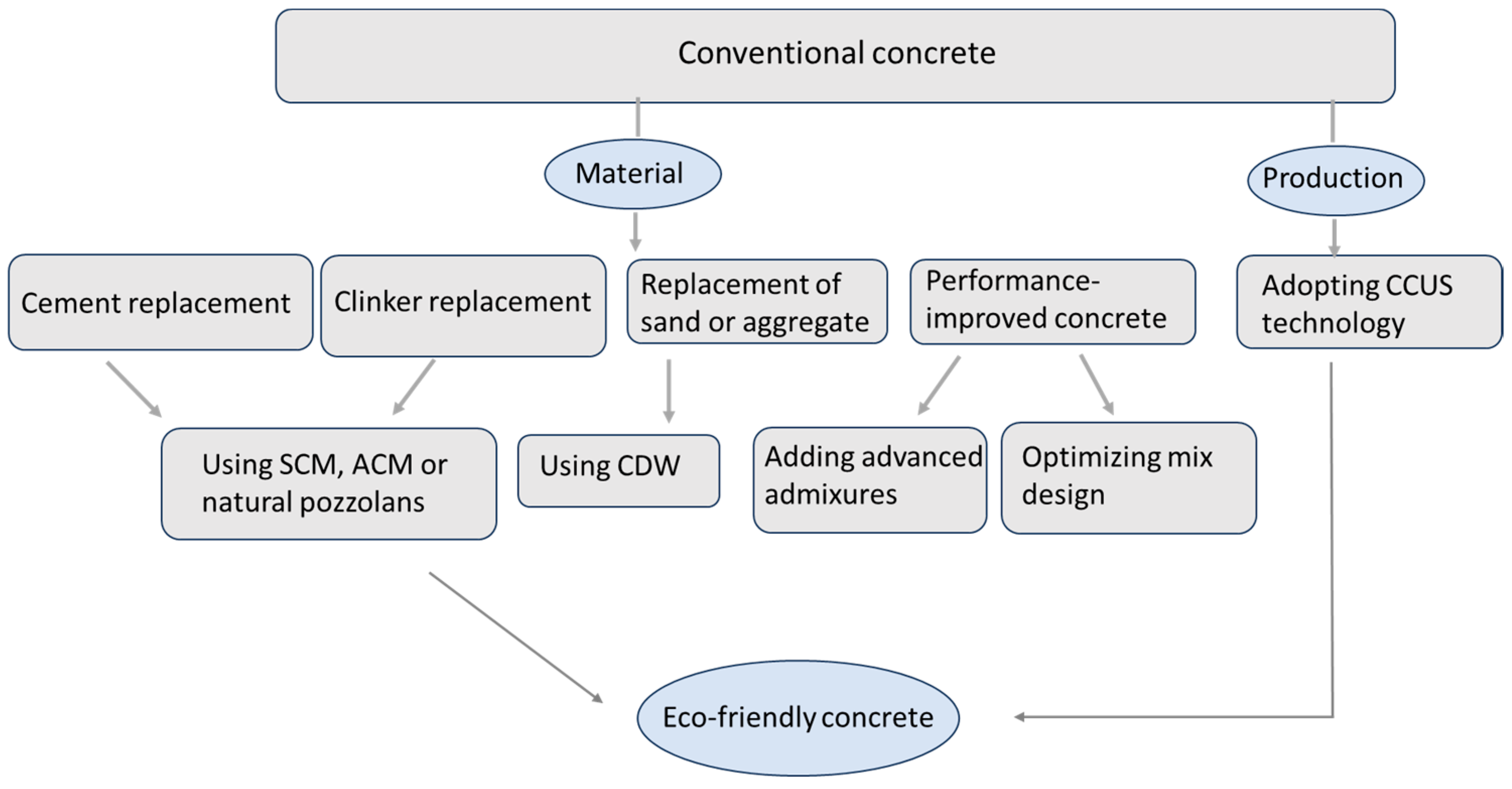

1. Introduction and Background

Scopes and Limitations of This Study

2. Method

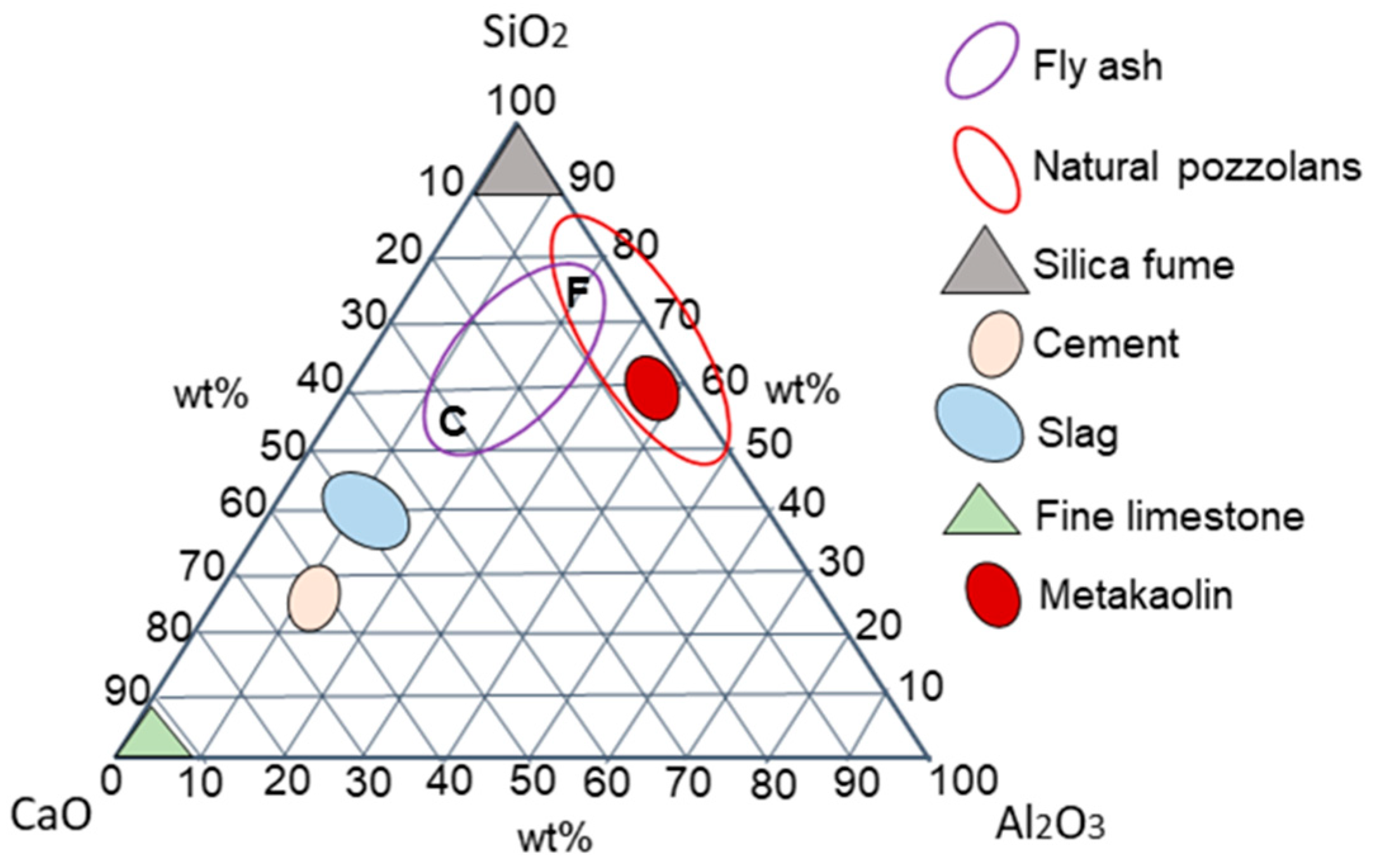

3. Supplementary Cementitious Materials

3.1. Fly Ash

3.2. Ground Granulated Blast Furnace Slag

3.3. Silica Fume

3.4. Calcined Clay

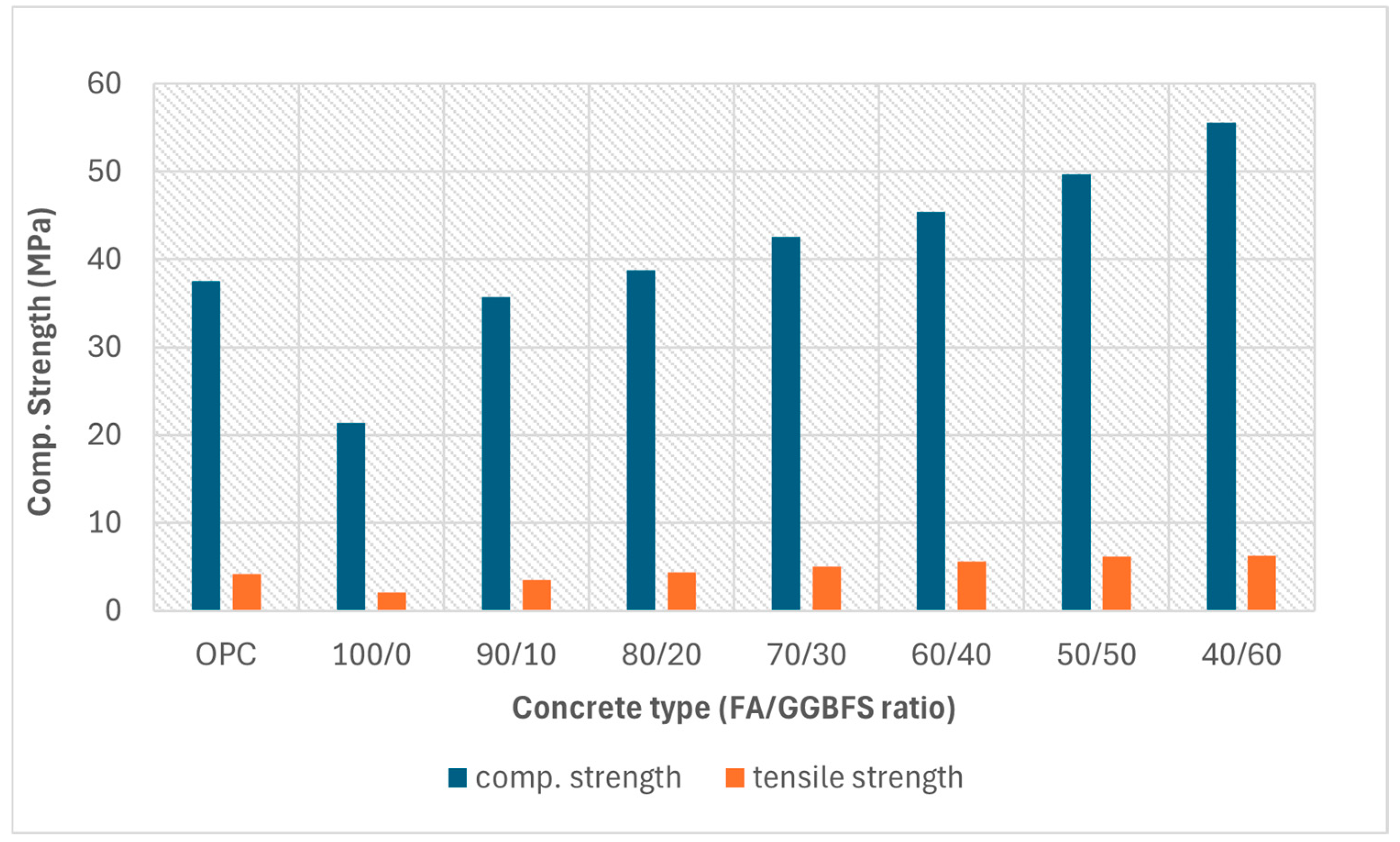

3.5. Geopolymer

3.6. Rice Husk Ash

3.7. Wood Ash

3.8. Municipal Solid Waste Incineration Bottom Ash (MSWI-BA)

3.9. Mine Waste Tailings

| Concrete/Mortar | Description of Study | Reference | Outcome |

|---|---|---|---|

| Coal fly ash-incorporated concrete (w/c ratio 0.4) High-volume (>45%) fly ash-contained mortar, concrete for different w/c ratios | Reviewed a large number of studies for mechanical properties and the durability of concrete and mortar | Golewski [27] Rashad [34] | Eco-friendly concrete with FA is possible by maintaining structural performance and qualities, like compressive strength and fracture toughness. Maximum comp. strength of 48.96 MPa was found for 20% FA-contained concrete compared to 47.51 MPa for Ref. concrete. Reported a decreased compressive and flexural strength along with E-modulus and abrasion resistance for all high-volume FA-contained concrete and mortar with increasing setting time. Suggested using additives or high pozzolanic materials for hardening properties and increasing strength. Addition of 10–20% SF or slag can modify comp. strength and abrasion resistance significantly. |

| GGBFS concrete (w/c ratio 0.4 and 0.5) GGBFS mortar (w/c ratio 0.4) | Comp. strength, hardening properties (up to 91 days) and influence of temperature on GGBFS concrete for 0–50% cement replacement were investigated Evolution of comp. strength with time for 20 to 80% cement replacement Initial and final setting time | Hedlund et al. [42] Cahyani & Rusdianto [41] | A higher percentage of GGBFS in concrete resulted in higher comp. strength. The resulting 56-day comp. strength of 30% GGBFS containing concrete and Ref. concrete were 71 MPa and 65 MPa, respectively. Extra measures are suggested to prevent temperature cracks during winter. Early-age comp. strength is inversely corelated with GGBFS percentage. After 28 days of curing, a higher comp. Strength were noticed for 20–60% GGBFS mortar compared to Ref. concrete, where the optimal replacement level was 40–50%. Delayed setting time was noticed in comparison to Ref. |

| UHPC containing SF Concrete and mortar with silica fume (w/c ratios vary) | Influence of SF on mechanical prop. of concrete for 5–25% cement replacement Reviewed results of comp. strength, and tensile strength of silica fume-incorporated concrete or mortar (0% to 30% by weight of cement content) | Amin et al. [48] Hamada et al. [44] | Max. comp strength was observed for 20% SF replacement, with an increase of about 20% with respect to Ref. concrete; after that, a decrease in strength was noticed. An increase in comp. strength was noticed for increasing SF content up to a certain level (about 10–20%); after that, a decreasing trend was noticed. A similar trend was noticed for tensile strength. |

| Concrete with fly ash and blended concrete with calcined clay (varied w/c ratio of 0.35 to 0.5) Metakaolin mortar | Mechanical properties, autogenous drying shrinkage and durability of fly ash concrete (30%) were compared with Ref. and blended concrete composed of clinker, limestone, calcined clay and gypsum Pozzolanic reactivity of mortar for 5–25% cement replacement | Dhandapani et al. [50] Abdelli et al. [51] | Higher comp. strength at later ages (from 28 days to 365 days) in the fly ash and limestone concrete were found as opposed to the conventional concrete. Better chloride resistance was noticed for calcined clay containing concrete due to a compact and dense microstructure. Similar shrinkage properties were found for all three types of concrete. Metakaolin contributes to higher early-age strength development. Max. strength (about 28% increase) was found for 10% metakaolin mortar in comparison to Ref. mortar. A higher strength (3, 28 and 90 days) was observed up to 15% cement replacement, compared to Ref. mortar. |

| Geopolymer concrete with FA and GGBFS (w/c ratio 0.4) | Mechanical properties and durability for different FA/GGBFS mix ratios | Bellum et al. [59] | Increased strength for increasing GGBFS contents for comp., tensile and flexural strength. Dense microstructure and better chloride resistance were observed. |

| RHA-contained concrete (w/c ratio 0.53) | RHA varying from 0 to 30% are used as SCMs in concrete to assess mechanical properties, long-term (365 days) strength development, and durability of concrete in compared to Ref. concrete | Madandoust et al. [70] | Concrete with RHA showed slow early strength development. At 20% RHA content, it achieved 65% of the 28-day comp. strength compared to Ref. concrete, reaching 98% at 180 days and slightly surpassing it at 365 days. Tensile strength followed a similar trend. Increasing RHA decreases strength, where 20% replacement seemed reasonable. RHA concrete showed better performance in chloride resistance. |

| WA mortar (w/c ratio 0.5) | Influence of sieving and washing WA on physicochemical characteristics, mechanical response and phase development of WA-contained concrete were investigated. For mortar’s strength and phase development, Ref., 10% and 20% cement replacement were considered | Sigvardsen M. [24] | The strength development of WA mortar at 1 and 3 days was similar to the Ref. mortar. However, from 7 to 90 days, the Ref. mortar outperformed the WA mortar. At 365 days, the average comp. strength of mortar with untreated WA was 86% and 87% of the Ref. mortar for the 10% and 20% cement replacement, respectively. For washed WA mortar, the values were 91% and 84% of the Ref. mortar for 10% and 20% cement replacement respectively. |

| Cement paste containing MSWI-BA (w/c ratio 0.5) | Comp. strength development (1–28 days) of 0–12.5% MSWI-BA-contained cement paste was investigated | Klieb et al. [78] | The hydration process was slower compared to the Ref. cement paste. The 28-day comp. strength of the cement paste with 12.5% MSWI-BA was 45.6 MPa, compared to 49 MPa for the Ref. paste. |

| Mortar with mine tailings | Comp. strength (1–28 days) with two types of mine tailings mortar with 0, 5 and 10% replacement studied | Sigvardsen et al. [90] | A slower initial hardening rate was observed. The 28-day compressive strength of mortar with 10% mine tailing content was 45–46 MPa compared to 54 MPa for the reference concrete. |

4. Recycled Aggregate

5. Innovative Technologies and Practices

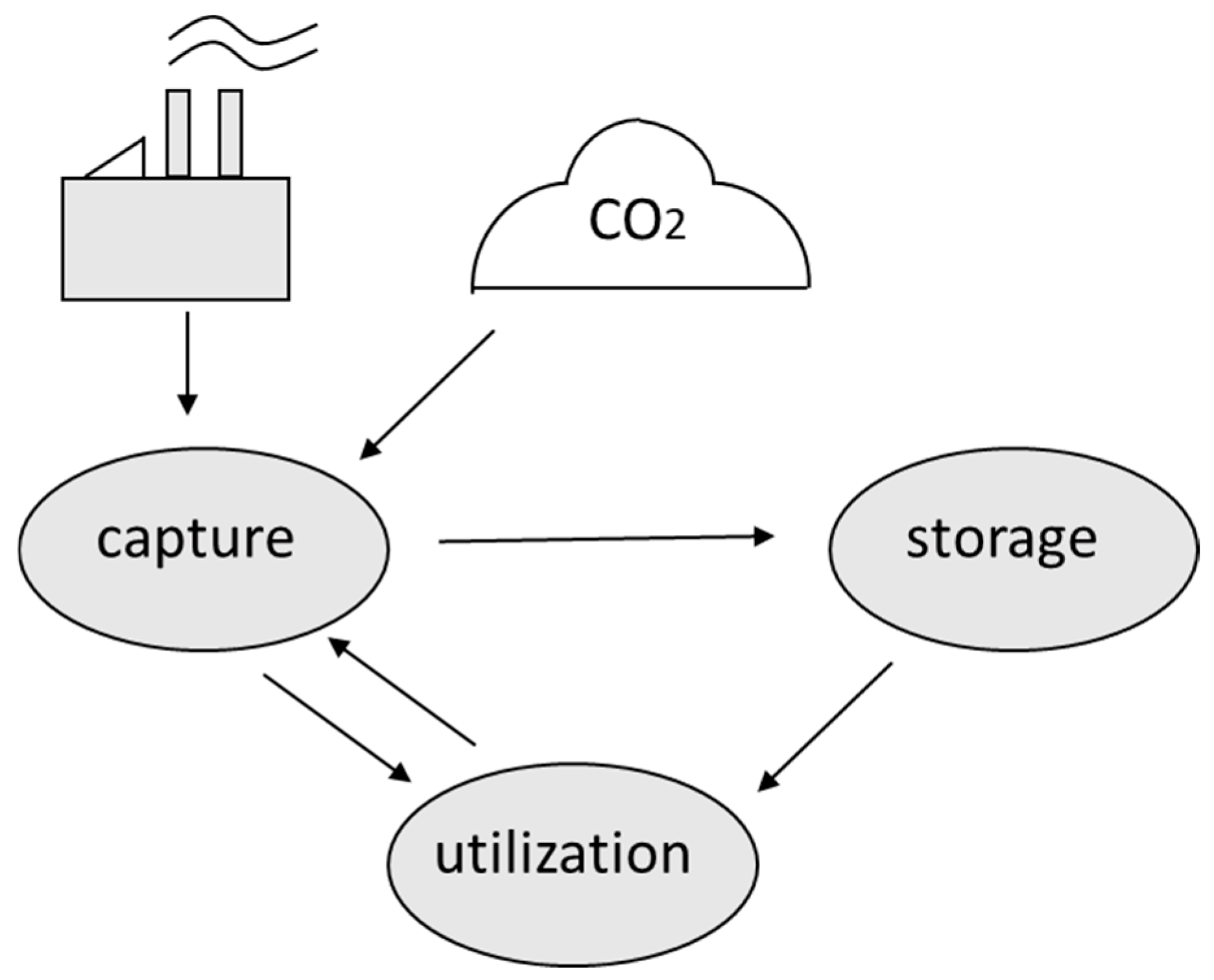

5.1. Carbon Capture Utilization and Storage

5.1.1. Amine Scrubbing

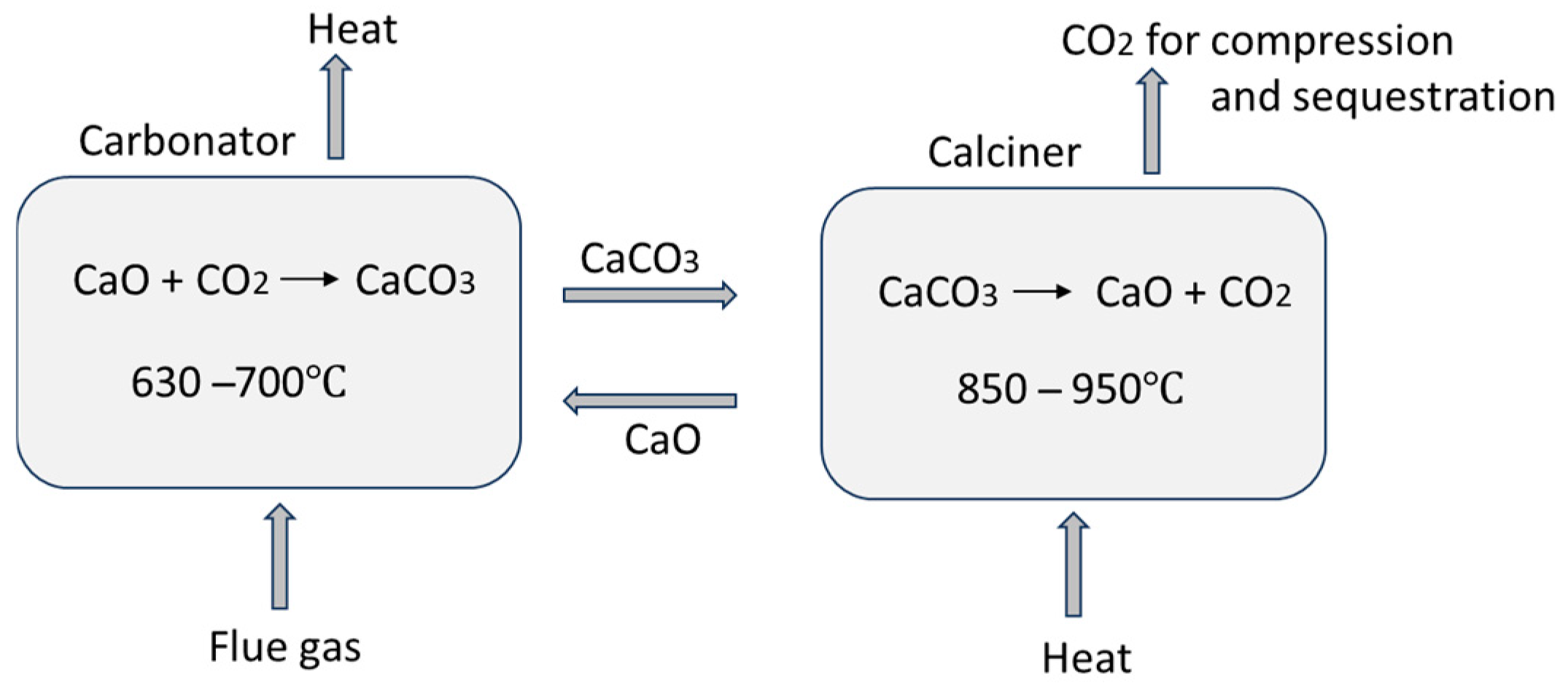

5.1.2. Calcium Looping

5.1.3. Direct Separation

5.1.4. Oxy Combustion

5.2. Performance-Improved Concrete

5.2.1. Permeable Concrete

5.2.2. Ultra High-Performance Concrete

5.2.3. Self-Healing Concrete

6. Challenges and Potential Strategies

6.1. Challenges

6.2. Potential Approaches in Overcoming the Challanges

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- UNEP. Global Status Report for Buildings and Construction: Towards a Zero-Emissions, Efficient and Resilient Buildings and Construction Sector. 2022. Available online: https://www.unep.org/resources/publication/2022-global-status-report-buildings-and-construction (accessed on 14 February 2024).

- UNEP. Building Materials and the Climate: Constructing A New Future. 2023. Available online: https://www.unep.org/resources/report/building-materials-and-climate-constructing-new-future (accessed on 14 February 2024).

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Lehne, J.; Preston, F. Making Concrete Change: Innovation in Low-Carbon Cement and Concrete. Chatham House, The Royal Institute of International Affairs, United Kingdom. 2018. Available online: https://www.chathamhouse.org/sites/default/files/publications/research/2018-06-13-making-concrete-change-cement-lehne-preston.pdf (accessed on 13 August 2024).

- Bahrami, A.; Lindqvist, M.; Lindqvist, L.B.; Eriksson, B. Important Criteria for Swedish Construction Companies to Choose Environmentally Friendly Concrete. Civ. Eng. J. 2023, 9, 197–207. [Google Scholar] [CrossRef]

- Fossil Free Sweden. Roadmap for Climate Neutral Competitiveness: Concrete Industry. 2018. Available online: https://fossilfrittsverige.se/en/roadmap/the-concrete-industry/ (accessed on 13 February 2024). (In Swedish).

- Energimyndigheten. Sweden’s Energy and Climate Goals. 2019. Available online: https://www.energimyndigheten.se/klimat--miljo/sveriges-energi--och-klimatmal/ (accessed on 14 February 2024). (In Swedish).

- IPCC. Mitigation of Climate Change, Working Group III Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change. 2022. Available online: www.ipcc.ch (accessed on 14 February 2024).

- Nilimaa, J. Smart materials and technologies for sustainable concrete construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Thomas, M. Supplementary Cementing Materials in Concrete; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar] [CrossRef]

- Panesar, D.K. Supplementary cementing material. In Developments in the Formulation and Reinforcement of Concrete, 2nd ed.; Woodhead Publishing Series in Civil and Structural Engineering: Cambridge, UK, 2019; pp. 55–85. [Google Scholar] [CrossRef]

- International Energy Agency. Technology Roadmap: Low-Carbon Transition in the Cement Industry. Available online: https://www.iea.org/reports/technology-roadmap-low-carbon-transition-in-the-cement-industry (accessed on 13 August 2024).

- Charitha, V.; Athira, V.S.; Jittin, V.; Bahurudeen, A.; Nanthagopalan, P. Use of different agro-waste ashes in concrete for effective upcycling of locally available resources. Constr. Build. Mater. 2021, 285, 122851. [Google Scholar] [CrossRef]

- Lockrey, S.; Nguyen, H.; Crossin, E.; Verghese, K. Recycling the construction and demolition waste in Vietnam: Opportunities and challenges in practice. J. Clean. Prod. 2016, 133, 757–766. [Google Scholar] [CrossRef]

- Zakka, W.P.; Lim, N.; Khun, M. A scientometric review of geopolymer concrete. J. Clean. Prod. 2021, 280, 1274353. [Google Scholar] [CrossRef]

- Hanifa, M.; Agarwal, R.; Sharma, U.; Thapliyal, P.C.; Singh, L.P. A review on CO2 capture and sequestration in the construction industry: Emerging approaches and commercialised technologies. J. CO2 Util. 2023, 67, 102292. [Google Scholar] [CrossRef]

- Althoey, F.; Wajahat Sammer Ansari, W.S.; Sufian, M.; Deifalla, A.F. Advancements in low-carbon concrete as a construction material for the sustainable built environment. Dev. Built Environ. 2023, 16, 100284. [Google Scholar] [CrossRef]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 339. [Google Scholar] [CrossRef]

- Chen, B.; Zuo, Y.; Zhang, S.; de Lima Junior, L.M.; Liang, X.; Chen, Y.; Zijl, M.; Ye, G. Reactivity and leaching potential of municipal solid waste incineration (MSWI) bottom ash as supplementary cementitious material and precursor for alkali-activated materials. Constr. Build. Mater. 2023, 409, 133890. [Google Scholar] [CrossRef]

- Heede, P.; Belie, N. Environmental impact and life cycle assessment (LCA) of traditional and ‘green’ concretes: Literature review and theoretical calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete Microstructure, Properties and Materials; McGraw Hill: London, UK, 2006. [Google Scholar]

- Lothenbach, B.; Karen Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Nascimento, L.C.; Junior, G.B.; de Xavier, G.C.; Monteiro, S.N.; Vieira, C.F.; Azevedo, A.R.G.; Alexandre, J. Use of wood bottom ash in cementitious materials: A review. J. Mater. Res. Technol. 2023, 23, 4226–4243. [Google Scholar] [CrossRef]

- Sigvardsen, N.M. Utilization of Wood Ash in Cement-Based Materials. Ph.D. Thesis, Technical University of Denmark, Copenhagen, Denmark, 2020. [Google Scholar]

- EN 450-1; Fly Ash for Concrete—Part 1: Definitions, Specifications and Conformity Criteria. The European Committee for Standardization (CEN): Brussels, Belgium, 2012.

- C311-C311M; Standard Test Methods for Sampling and Testing Fly Ash or Natural Pozzolans for Use in Portland-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2007; pp. 204–212.

- ASTM C618-23e1; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use. ASTM International: West Conshohocken, PA, USA, 2010. [CrossRef]

- SS-EN 206:2013; Concrete—Specification, Performance, Production and Conformity. Swedish Institute for Standards: Stockholm, Sweden, 2013.

- SS 137003:2015; Concrete—Application of EN 206 in Sweden. Swedish Institute for Standards: Stockholm, Sweden, 2019.

- Bhatt, B.; Priyadarshini, S.; Mohanakrishnan, A.A.; Abri, A.; Sattler, M.; Techapaphawit, S. Physical, chemical, and geotechnical properties of coal fly ash: A global review. Case Stud. Constr. Mater. 2019, 11, e00263. [Google Scholar] [CrossRef]

- Svensk Betong, Vägledning Klimatförbättrad Betong, Utgåva 2 (Guidance for Climate Improved Concrete, Second Edition). 2022. Available online: https://www.svenskbetong.se/hallbarhet/klimatforbattrad-betong (accessed on 16 August 2024).

- Malhotra, V.M. Making Concrete Greener with Fly Ash. Concr. Int. 1999, 21, 61–66. [Google Scholar]

- Golewski, G.L. Green concrete composite incorporating fly ash with high strength and fracture toughness. J. Clean. Prod. 2018, 172, 218–226. [Google Scholar] [CrossRef]

- Rashad, A.M. A brief on high-Class F fly ash as cement replacement—A guide for Civil Engineer. Int. J. Sustain. Built Environ. 2015, 4, 278–306. [Google Scholar] [CrossRef]

- Martins, N.P.; Srivastava, S.; Simão, F.V.; Niu, H.; Perumal, P.; Snellings, R.; Illikainen, M.; Chambart, H.; Habert, G. Exploring the Potential for Utilization of Medium and Highly Sulfidic Mine Tailings in Construction Materials: A Review. Sustainability 2021, 13, 12150. [Google Scholar] [CrossRef]

- Mueller, U.; Plusquellec, G.; Malaga, K. Potential for Use of Activated Clays in Concrete in Sweden—Roadmap; Technical Report 2021:110; Research Institutes of Sweden: Gothenburg, Sweden, 2021. [Google Scholar] [CrossRef]

- Attia, D.; Kiryakos, S. Climate-Improved Concrete Structures: Possibilities in Design and Construction. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2023. [Google Scholar]

- Couvidat, C.; Diliberto, C.; Meux, M.; Cotelle, S.; Bojic, C.; Izoret, L.; Lecomte, A. Greening effect of slag cement-based concrete: Environmental and ecotoxicological impact. Environ. Technol. Innov. 2021, 22, 101467. [Google Scholar] [CrossRef]

- Liu, Y.; Su, Y.; Xu, G.; Chen, Y.; You, G. Research Progress on Controlled Low-Strength Materials: Metallurgical Waste Slag as Cementitious Materials. J. Mater. 2022, 15, 727. [Google Scholar] [CrossRef]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Cahyani, R.A.T.; Rusdianto, Y. An Overview of Behavior of Concrete with Granulated Blast Furnace Slag as Partial Cement Replacement. In Proceedings of the 6th International Conference on Sustainable Built Environment (ICSBE), Yogyakarta, Indonesia, 19–20 October 2021. [Google Scholar] [CrossRef]

- Hedlund, H.; Wiberg, H.; Nilsson, M.; Persson, M. Grönare anläggningsbetong—Data för Temperatur-Och Härdningsstyrning, Projektrapport, SBUF 2023. (Greener Construction Concrete—Data for Temperature and Curing Control). Available online: https://www.sbuf.se/projektresultat/projekt?id=476ebce2-68f6-4eb3-adc2-77ca1e924103 (accessed on 11 January 2024).

- Zhang, S.; Niu, D.; Wang, Y.; Tian, W.; Luo, D.; Zhang, L. Insight into mechanical properties and microstructure of concrete containing steel slag and ground-granulated blast-furnace slag. J. Sustain. Cem. Based Mater. 2023, 12, 1259–1280. [Google Scholar] [CrossRef]

- Hamada, H.M.; Abed, A.; Katman, H.; Humada, A.M.; Jawahery, M.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Effect of silica fume on the properties of sustainable cement concrete. J. Mater. Res. Technol. 2023, 24, 8887–8908. [Google Scholar] [CrossRef]

- ACI PRC-234-06; Guide for the Use of Silica Fume in Concrete (Reapproved 2012). ACI Committee, American Concrete Institute: Detroit, MI, USA, 2012.

- Kim, S.S.; Qudoos, A.; Jakhrani, S.H.; Lee, J.B.; Gi, H. Influence of Coarse Aggregates and Silica Fume on the Mechanical Properties, Durability, and Microstructure of Concrete. Materials 2019, 12, 3324. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Predicting the compressive strength of silica fume concrete using hybrid artificial neural network with multi-objective grey wolves. J. Clean. Prod. 2018, 202, 54–64. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of ferrosilicon and silica fume on mechanical, durability, and microstructure characteristics of ultra high-performance concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Roman Jaskulski, R.; Jóźwiak-Niedźwiedzka, D.; Yakymechko, Y. Calcined Clay as Supplementary Cementitious Material. Materials 2020, 13, 4734. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G. Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 136–151. [Google Scholar] [CrossRef]

- Abdelli, K.; Tahlaiti, M.; Belarbi, R.; Oudjit, M.N. Influence of the pozzolanic reactivity of the Blast Furnace Slag (BFS) and Metakaolin on mortars. Energy Procedia 2017, 139, 224–229. [Google Scholar] [CrossRef]

- SS-EN 197-5:2021; Cement—Part 5: Portland-Composite Cement CEM II/C-M and Composite Cement CEM VI. Swedish Institute for standards: Stockholm, Sweden, 2021.

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Ma, C.K.; Awang, A.Z.; Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Singh, K. Experimental study on metakolin and baggashe ash based geopolymer concrete. Mater. Today Proc. 2021, 37, 3289–3295. [Google Scholar] [CrossRef]

- Xing, J.; Zhao, Y.; Qiu, J.; Sun, X. Microstructural and Mechanical Properties of Alkali Activated Materials from Two Types of Blast Furnace Slags. Materials 2019, 12, 2089. [Google Scholar] [CrossRef] [PubMed]

- Prasad, B.V.; Anand, N.; Kiran, T.; Jayakumar, G.; Sohliya, A.; Ebenezer, S. Influence of fibers on fresh properties and compressive strength of geo-polymer concrete. Mater. Today Proc. 2022, 57, 2255–2263. [Google Scholar] [CrossRef]

- Verma, M.; Dev, N.; Rahman, I.; Nigam, M.; Ahmed, M.; Mallick, J. Geopolymer Concrete: A Material for Sustainable Development in Indian Construction Industries. Crystals 2022, 12, 514. [Google Scholar] [CrossRef]

- Bellum, R.R.; Muniraj, K.; Madduru, S.R. Exploration of mechanical and durability characteristics of fy ash-GGBFS based green geopolymer concrete. SN Appl. Sci. 2020, 2, 919. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 2016, 62, 32–39. [Google Scholar] [CrossRef]

- Habeeb, G.A.; Mahmud, H.B. Studies on properties of rice husk ash and its use as cement replacement material. Mater. Res. 2010, 13, 185–190. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Alaskar, A. Recycling of rice husk waste for a sustainable concrete: A critical review. J. Clean. Prod. 2021, 312, 127734. [Google Scholar] [CrossRef]

- Umasabor, R.I.; Okovido, J.O. Fire resistance evaluation of rice husk ash concrete. Heliyon 2018, 4, e01035. [Google Scholar] [CrossRef]

- Das, S.K.; Mishra, J.; Singh, S.K.; Mustakim, S.M.; Patel, A.; Das, S.K.; Behera, U. Characterization and utilization of rice husk ash (RHA) in fly ash—Blast furnace slag based geopolymer concrete for sustainable future. Mater. Today Proc. 2022, 33, 5162–5167. [Google Scholar] [CrossRef]

- Vieira, A.P.; Toledo Filho, R.D.; Tavares, L.M.; Cordeiro, G.C. Effect of particle size, porous structure and content of rice husk ash on the hydration process and compressive strength evolution of concrete. Constr. Build. Mater. 2020, 236, 117553. [Google Scholar] [CrossRef]

- Ali, T.; Saand, A.; Bangwar, D.K.; Buller, A.S.; Ahmed, Z. Mechanical and Durability Properties of Aerated Concrete Incorporating Rice Husk Ash (RHA) as Partial Replacement of Cement. Crystals 2021, 11, 604. [Google Scholar] [CrossRef]

- Bui, D.; Hu, J.; Stoeven, P. Particle size effect on the strength of rice husk ash blended gap-graded Portland cement concrete. Cem. Concr. Compos. 2005, 27, 357–366. [Google Scholar] [CrossRef]

- Singh, B. Rice husk ash. In Waste and Supplementary Cementitious Materials in Concrete: Characterization, Properties and Applications; Woodhead Publishing Series in Civil and Structural Engineering: Cambridge, UK, 2018; pp. 417–460. [Google Scholar] [CrossRef]

- Rumman, R.; Manzur, B.; Kamal, M.R.; Noor, M. A durable concrete mix design approach using combined aggregate gradation bands and rice husk ash based blended cement. J. Build. Eng. 2020, 30, 101303. [Google Scholar] [CrossRef]

- Madandoust, R.; Ranjbar, M.; Moghadam, H.A.; Mousavi, S.Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Thomas, B.S. Green concrete partially comprised of rice husk ash as a supplementary cementitious material–A comprehensive review. Renew. Sustain. Energ. Rev. 2018, 82, 3913–3923. [Google Scholar] [CrossRef]

- Gill, A.S.; Siddique, R. Strength and micro-structural properties of self-compacting concrete containing metakaolin and rice husk ash. Constr. Build. Mater. 2017, 157, 51–64. [Google Scholar] [CrossRef]

- Tuan, N.V.; Ye, G.; Breugel, K.V.; Copuroglu, O. Hydration and microstructure of ultra high performance concrete incorporating rice husk ash. Cem. Concr. Res. 2011, 41, 1104–1111. [Google Scholar] [CrossRef]

- Ercan, E.; Andreas, L.; Cwirzen, A.; Habermehl-Cwirzen, K. Wood Ash as Sustainable Alternative Raw Material for the Production of Concrete—A Review. J. Mater. 2023, 16, 2557. [Google Scholar] [CrossRef]

- Zhuge, Y.; Duan, W.; Liu, Y. Utilization of wood waste ash in green concrete production. In Sustainable Concrete Made with Ashes and Dust from Different Sources: Materials, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2022; pp. 419–450. [Google Scholar] [CrossRef]

- Carević, I.; Serdar, M.; Štirmer, N.; Ukrainczyk, N. Preliminary Screening of Wood Biomass Ashes for Partial Resources Replacements in Cementitious Materials. J. Clean. Prod. 2019, 229, 1045–1064. [Google Scholar] [CrossRef]

- Clavier, K.A.; Paris, J.M.; Ferraro, C.C.; Townsend, T.G. Opportunities and challenges associated with using municipal waste incineration ash as a raw ingredient in cement production—A review. Resourc. Conserv. Recycl. 2020, 160, 104888. [Google Scholar] [CrossRef]

- Kleib, J.; Aouad, G.; Abriak, N.; Benzerzour, M. Production of Portland cement clinker from French Municipal Solid Waste Incineration Bottom Ash. Case Stud. Constr. Mater. 2021, 15, e00629. [Google Scholar] [CrossRef]

- Loginova, E.; Volkov, D.S.; Wouw, P.M.F.; Florea, M.V.A.; Brouwers, H.J.H. Detailed characterization of particle size fractions of municipal solid waste incineration bottom ash. J. Clean. Prod. 2019, 207, 866–874. [Google Scholar] [CrossRef]

- Tang, L.; Zhang, E.; Ahamadi, A.; Löfgren, I.H.; Fedje, K.K. Bottom Ashes for Green Aggregate, Energyforsk. 2021. Available online: https://energiforsk.se/program/askprogrammet/rapporter/bottom-ashes-for-green-aggregate-2021-795/ (accessed on 4 March 2024).

- Phua, Z.; Giannis, A.; Dong, Z.L.; Lisak, G.; Ng, W.J. Characteristics of incineration ash for sustainable treatment and reutilization. Environ. Sci. Pollut. Res. 2019, 26, 16974–16997. [Google Scholar] [CrossRef]

- Blasenbauer, D.; Huber, F.; Lederer, J.; Quina, M.J.; Blanc-Biscarat, D.; Bogush, A.; Bontempi, E.; Blondeau, J.; Chimenos, J.M.; Dahlbo, H.; et al. Legal situation and current practice of waste incineration bottom ash utilisation in Europe. J. Waste Manag. 2020, 102, 868–883. [Google Scholar] [CrossRef]

- Tiberg, C.; Sjöstedt, C.; Fedje, K.K. Speciation of Cu and Zn in bottom ash from solid waste incineration studied by XAS, XRD, and geochemical modelling. Waste Manag. 2021, 119, 389–398. [Google Scholar] [CrossRef]

- Müller, U.; Rübner, K. The microstructure of concrete made with municipal waste incinerator bottom ash as an aggregate component. Cem. Concr. Res. 2006, 36, 1434–1443. [Google Scholar] [CrossRef]

- Lu, J.; Yang, X.; Lai, Y.; Wan, X.; Gao, J.; Wang, Y.; Tan, L.; Deng, F. Utilization of municipal solid waste incinerator bottom ash (MSWIBA) in concrete as partial replacement of fine aggregate. Constr. Build. Mater. 2024, 414, 134918. [Google Scholar] [CrossRef]

- Matos, M.A.; Sousa-Coutinho, J. Municipal solid waste incineration bottom ash recycling in concrete: Preliminary approach with Oporto wastes. Constr. Build. Mater. 2022, 323, 126548. [Google Scholar] [CrossRef]

- Jones, H.; Boger, D.V. Sustainability and Waste Management in the Resource Industries. Ind. Eng. Chem. Res. 2012, 51, 10057–10065. [Google Scholar] [CrossRef]

- Ikotun, J.; Adeyeye, R.; Otieno, M. Application of mine tailings sand as construction material—A review. In Proceedings of the MATEC Web of Conferences, International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR), Cape Town, South Africa, 3–5 October 2022; Volume 364, p. 05008. [Google Scholar] [CrossRef]

- Adiguzel, D.; Tuylu, S.; Eker, H. Utilization of tailings in concrete products: A review. Constr. Build. Mater. 2022, 360, 129574. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Nielsen, M.R.; Potier, C.; Ottosen, L.M.; Jensen, P.E. Utilization of Mine Tailings As Partial Cement Replacement. Mod. Environ. Sci. Eng. 2018, 4, 365–374. [Google Scholar]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- SGU. Statistics of the Swedish Mining Industry 2021 (Report), Geological Survey of Sweden. 2022. Available online: https://resource.sgu.se/dokument/publikation/pp/pp202202rapport/pp2022-2-rapport.pdf (accessed on 22 August 2024).

- Gou, M.; Zhou, L.; Then, N.W.Y. Utilization of tailings in cement and concrete: A review. Sci. Eng. Compos. Mater. Gruyter 2019, 26, 449–464. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Rocha, J.; Filho, R. The utilization of recycled concrete powder as supplementary cementitious material in cement-based materials: A systematic literature review. J. Build. Eng. 2023, 76, 107319. [Google Scholar] [CrossRef]

- Pacheco, J.; Brit, J. Recycled Aggregates Produced from Construction and Demolition Waste for Structural Concrete: Constituents, Properties and Production. Materials 2021, 14, 5748. [Google Scholar] [CrossRef]

- Cassiani, J.; Martinez-Arguelles, G.; Penabaena-Niebles, R.; Keßler, S.; Dugarte, M. Sustainable concrete formulations to mitigate Alkali-Silica reaction in recycled concrete aggregates (RCA) for concrete infrastructure. Constr. Build. Mater. 2021, 307, 124919. [Google Scholar] [CrossRef]

- Driver, J.G.; Hills, T.; Hodgson, P.; Sceats, M.; Fennell, P.S. Simulation of direct separation technology for carbon capture and storage in the cement industry. J. Chem. Eng. 2022, 76, 137721. [Google Scholar] [CrossRef]

- Romano, M.C.; Spinelli, M.; Campanari, S.; Consonni, S.; Cinti, G.; Marchi, M.; Borgarello, E. The Calcium looping process for low CO2 emission cement and power. Energy Procedia 2013, 37, 7091–7099. [Google Scholar] [CrossRef]

- Lena, E.; Spinelli, M.; Romano, M.C. CO2 capture in cement plants by “Tail-End” Calcium Looping process. Energy Procedia 2018, 148, 186–193. [Google Scholar] [CrossRef]

- Hodgson, P.; Vincent, A.; Rennie, D.; Fennell, P.; Hills, T.; Sceats, M. Direct Separation Calcination Technology for Carbon Capture: Demonstrating a Low Cost Solution for the Lime and Cement Industries in the LEILAC Project. In Proceedings of the 14th International Conference on Greenhouse Gas Control Technologies, GHGT-14, Melbourne, Australia, 21–26 October 2018; Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3365844 (accessed on 5 November 2024).

- Monteiro, J.; Roussanaly, S. CCUS scenarios for the cement industry: Is CO2 utilization feasible? J. CO2 Util. 2022, 61, 102015. [Google Scholar] [CrossRef]

- Leilac. Heidelberg Materials & the CO2 Neutrality Target 2050. Available online: https://www.leilac.com/conference/heidelberg-materials-the-co2-neutrality-target-2050/ (accessed on 16 October 2024).

- Doctor, R.D.; Molburg, J.C.; Mendelsonh, M.H.; Brockmeier, N.F. CO2 Capture for PC-Boilers Using Oxy-fuels—A Transition Strategy. In Proceedings of the 7th International Conference on Greenhouse Gas Control Technologies, Vancouver, BC, Canada, 5 September 2004; Volume II—Part 1. pp. 1205–1210. [Google Scholar]

- Gerbelová, H.; Van Der Spek, M.; Schakel, W. Feasibility assessment of CO2 capture retrofitted to an existing cement plant: Post-combustion vs. oxy-fuel combustion technology. Energy Procedia 2017, 114, 6141–6149. [Google Scholar] [CrossRef]

- World Cement. An Overview of Oxy-Combustion. 27 October 2023. Available online: https://www.worldcement.com/special-reports/27102023/an-overview-of-oxy-combustion/ (accessed on 24 April 2024).

- Akhnoukh, A.K.; Buckhalter, C. Ultra-high-performance concrete: Constituents, mechanical properties, applications and current challenges. Case Stud. Constr. Mater. 2021, 15, e00559. [Google Scholar] [CrossRef]

- Xue, C.; Yu, M.; Xu, H.; Xu, L.; Saafi, M.; Ye, J. Experimental study on thermal performance of ultra-high performance concrete with coarse aggregates at high temperature. Constr. Build. Mater. 2022, 314, 125585. [Google Scholar] [CrossRef]

- Islam, M.M.; Zhang, Q.; Jin, Q. A review of existing codes and standards on design factors for UHPC placement and fiber orientation. Constr. Build. Mater. 2022, 345, 128308. [Google Scholar] [CrossRef]

- Han, B.; Yu, X.; Ou, J. Self- Sensing Concrete in Smart Structures; Butterworth Heinemann: Oxford, UK, 2014. [Google Scholar] [CrossRef]

- Brabandere, L.D.; Mullem, T.V.; Lee, J.H.; Suh, J.; Lee, K.; Belie, N. Comparative analysis of three different types of self-healing concrete via permeability testing and a quasi-steady-state chloride migration test. Constr. Build. Mater. 2024, 411, 134288. [Google Scholar] [CrossRef]

- Hossain, M.U.; Ng, S.T.; Antwi-Afari, P.; Amor, B. Circular economy and the construction industry: Existing trends, challenges and prospective framework for sustainable construction. Renew. Sustain. Energy Rev. 2020, 130, 109948. [Google Scholar] [CrossRef]

- Opoku, D.G.J.; Ayarkwa, J.; Agyekum, K. Barriers to environmental sustainability of construction projects. Smart Sust. Built Environ. 2019, 8, 292–306. [Google Scholar] [CrossRef]

- Ayarkwa, J.; Opoku, D.G.J.; Afari, P.; Li, R. Sustainable building processes’ challenges and strategies: The relative important index approach. Clean. Eng. Technol. 2022, 7, 100455. [Google Scholar] [CrossRef]

- Pham, H.; Kim, S.Y.; Luu, T.V. Managerial perceptions on barriers to sustainable construction in developing countries: Vietnam case. Environ. Dev. Sustain. 2020, 22, 2979–3003. [Google Scholar] [CrossRef]

- Liew, K.M.; Sojobi, A.O.; Zhang, L.W. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

| Properties | Limit Set by EN 450-1 | Impact |

|---|---|---|

| Sum of oxides | >70 | Higher value having a positive impact on reactivity |

| LOI | <9 | Negative impact on setting time and/or effectiveness of chemical admixtures |

| Finer particle size D50 < 45 µm | positive impact on reactivity | |

| Total alkaline content Na2O | <5 | Negative impact on durability |

| Sulfate content | <3 | Negative impact on durability |

| Phosphate content | <5 | Negative impact on setting time |

| Magnesium oxide | <4 | Negative impact on volume instability |

| Calcium oxide content | <1.5 | Negative impact on volume instability |

| Heavy metal content | Negative impact on health | |

| SO3 content | <3 | High value has negative impact on steel corrosion |

| Material | Properties | Impact on Concrete | Remarks |

|---|---|---|---|

| Fly ash | - Fine particle size of 1 µm to 150 µm and - Mostly amorphous in nature | - Improve workability, durability, and resistance to chemical attacks and long-term strength | - Availability in scarce due to shift in policy to renewable energy |

| Silica fume | - Ultra-fine particles of 0.1–0.3 µm comprising about 75% SiO2 -Amorphous in nature | - Contribute to high early-age strength - Reduce permeability, - Increase durability, i.e., resistance against corrosion, and sulfate attack - Reduce workability | - High price - Limited availability |

| Ground granulated blast furnace slags | - Granular particle size <5 mm - Sub-angular or sub-spherical in shape - Glassy phase - Contains high oxide | - Enhance concrete durability, workability - Reduce permeability - Slow early-age strength development - Can achieve higher long-term compressive - Increase corrosion, and sulfate attack resistance | - Limited availability |

| Calcined clay | - Spherical particle size with diameter < 2 μm - Primarily amorphous in nature | - Increase durability, corrosion and sulfate attack resistance - Reduce workability | - The legal permission of extract clays, activation at large scale, and missing standards and guidelines for utilizing it in concrete are challenging |

| RHA | - Angular and coarser particles - Particle size smaller than 7.3 μm - Rich in silica - Amorphous in nature | - Low early-age and long-term strength - Reduce workability - Improve sodium sulfate attack resistance - Suitable for light-weight concrete - Due to high pozzolanic nature, it can be used in UHPC as mineral admixture | - Incineration temp and process are crucial for properties of RHA - Missing standards for using as mineral additive and guidelines for using |

| WA | -Larger particle size of irregular shape of size varies 86 and 176 µm -High LOI | - Reduce workability, - Comparatively lower compressive and flexural strength | - Can be used as partial cement replacement -More research needed |

| MSWIBA | -Larger particle size of 0.05 to 16 mm - Possess pozzolanic characteristic | - Slow hydration rate - Lower early strength - Increase steel corrosion | - Large variations in particle size and chemical and mineral contents are challenging - High metal content and their impact on concrete and recyclability are major concerns - Missing standards and guidelines for utilization |

| Mine tailings | - Highly rough and irregular surface particles - Particle size less than 1 mm | - Reduce workability - Lower strength | - Can be used as cement or fine aggregate - Metal toxicity is a concern, which can be increased during grinding - More research is essential - Missing permission, standards, and guidelines for utilization |

| CO2 Capture Technology | Advantages | Drawbacks | Cost |

|---|---|---|---|

| Amine scrubbing | - High capture efficiency - Well-known and widely used technology - Recovery rate is high, about 95% - Thermally stable - Can be retrofitted to existing plants | - Loss of capacity after multiple cycles - High-energy consumption - Degradation and equipment corrosion - Negative environmental impact for solvent emissions | - High operational cost due to high energy consumption. - MEA-based scrubbing costs approx. USD 80/t CO2 capture |

| Calcium looping | - High capture capacity - Well-known technology - No thermal formation of NOx - Exhaust gas stream is not harmful - Potential for low cost | - Energy-intensive - Requires large reactors | - Potential for low cost. - Approx. cost for integrated and tail-end tech. are USD 61/t and USD 55/t CO2 capture, respectively. |

| Oxy-combustion | - High-purity CO2 (60%) - CO2 separation is easier with N2 - NOX free emission - Involves smaller plant size | - CO2 recycle required to control combustion - Requires oxygen production Energy intensive - Possibility of corrosion problems - Complex technology | - High capital cost |

| Direct separation | - High CO2 removal capacity - Can achieve net zero even net negative emissions - High-purity CO2 - Can be integrated with industrial processes | - Low-concentration of CO2 in air - Energy-intensive | - Require high initial investment. - The estimated cost is USD 94–USD 232/t CO2 capture |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akter, S.T.; Hawas, A. Current Insight on Eco-Friendly Concrete: A Review. Buildings 2025, 15, 682. https://doi.org/10.3390/buildings15050682

Akter ST, Hawas A. Current Insight on Eco-Friendly Concrete: A Review. Buildings. 2025; 15(5):682. https://doi.org/10.3390/buildings15050682

Chicago/Turabian StyleAkter, Shaheda T., and Allan Hawas. 2025. "Current Insight on Eco-Friendly Concrete: A Review" Buildings 15, no. 5: 682. https://doi.org/10.3390/buildings15050682

APA StyleAkter, S. T., & Hawas, A. (2025). Current Insight on Eco-Friendly Concrete: A Review. Buildings, 15(5), 682. https://doi.org/10.3390/buildings15050682