Abstract

Concrete is known for its high structural performance and workability, but its environmental impact is significant in terms of the utilization of virgin resources and greenhouse gas emissions. To mitigate the negative climate effects of concrete, it is essential to continuously develop and adopt eco-friendly practices in the construction sector. This paper provides an overview of current practices, opportunities, and challenges for developing and adopting eco-friendly concrete. Promising paths for eco-friendly concrete construction include using supplementary cementitious materials (SCMs) instead of energy-intensive traditional cement, incorporating locally available, waste-based materials rather than virgin resources, adopting recycling and reusing techniques, employing advanced technologies, such as performance-enhanced concrete and carbon capture and utilization techniques, etc. Among the studied materials, some waste materials such as rice husk ash, mine tailings, and municipal solid waste ash have found potential and demand further research. The adoption of new materials in concrete and attributing them in practices faces significant social, economic, and regulatory challenges. Addressing these obstacles requires interdisciplinary research and development, the establishment of clear standards and incentives, and educating skilled professionals and efforts to raise social awareness.

1. Introduction and Background

The increasing world population and rapid urbanization demand new infrastructures, which are adding CO2 in the atmosphere and causing global warming. The building and construction sectors account for about 39% of energy and process-related carbon dioxide (CO2) emissions in the atmosphere [1]. Despite many countries giving emphasis to the construction sector in their national agendas to meet the climate target set in the Paris Agreement, the global status report for Buildings and Constructions reveals a record high CO2 emission of about 10 gigatons in 2021 [2]. Concrete is one of the greatest CO2 emitters in nature because of its mass production and worldwide utilization. Each year, over 10 billion tons of concrete are produced in the world [3]. The high emission of concrete is directly connected with ordinary Portland cement, as the production of cement involves the generation of high temperature, i.e., 1500 °C to 2000 °C, for the calcination process of limestone, often by fossil fuel combustion. Studies indicate that cement itself accounts for roughly 8% of global emissions [4,5]. In addition to the CO2 emission, the depletion of natural resources for concrete production, such as limestone, and aggregate extraction pose a significant threat to ecological balance and the well-being of future generations.

To achieve the targeted goal by the Paris Agreement and the global sustainable goals (SDSs) by the United Nations, Sweden’s national target is to obtain net-zero emissions by 2045 and a 60% reduction in greenhouse gas emissions from the construction sector by 2030 compared to the levels of 2015 [6,7]. Consequently, researchers, policy makers, cement producers and the construction industry are actively seeking sustainable solutions to reduce the carbon footprint and lessen reliance on finite natural resources from the construction sector. Among others, the development and utilization of eco-friendly concrete and some emerging technologies to reduce carbon footprint from the construction sector have received much attention in recent years. However, to reach the targeted climate goal, various alternative solutions for developing eco-friendly concrete and its wide application is obvious, which necessitates further research on the topic.

The terms eco-friendly concrete or, alternatively, climate-improved concrete, sustainable concrete, or green concrete [4,5,6,7,8,9] are used to describe the concrete that has less environmental effects and better functionality in terms of sustainability compared to traditional concrete. Eco-friendly concrete can be developed with a partial replacement of an ingredient in conventional concrete by an environmentally friendly material. The replacement can be for cementitious material or inert materials in concrete. Generally, the term supplementary cementitious material (SCM) [10,11] is used to refer to the materials used in concrete as a partial replacement of cement, to reduce the adverse environmental effects directly related to cement. Ground granulated blast furnace slag (GGBFS), fly ash, and silica fume are commonly used SCMs. Additionally, alternative cementitious materials, like industrial, agricultural, and other waste-based materials [12,13], and natural pozzolans [10] can be used in concrete instead of energy-intensive cement. Natural pozzolans can be used directly but often require processing, like drying, grinding, calcining, etc. Various calcined clays, cherts, and shales and volcanic ashes are examples of natural pozzolans. Replacing a part of inert material, i.e., course or fine aggregates in concrete with eco-friendly materials contributes to preserving natural resources, re-circulates the material flow, and offers environmental benefits [14]. Thus, recycled aggregates from construction demolition, glass, and plastic industries have received attention as well [4]. Besides this, the use of local waste materials in concrete production is another sustainable approach to reduce environmental impact by reducing transportation-related emissions and energy consumption [7]. Moreover, local materials often have less variabilities in compositions, which have a positive effect on the workability of the final production. The use of alternative binder systems in concrete production is significant for developing sustainable concrete. Geopolymers [15], which utilize alkali-activated materials instead of cement, are one such example. Geopolymer binders in concrete can have an 80–90% lower carbon footprint than conventional concrete [4]. Additionally, implementing innovative technologies such as carbon capture, utilization [16], and storage techniques [12] and developing new products and methods like permeable concrete, high-performance insulating concrete, and self-healing concrete [9], along with optimizing mix designs and water–cement ratios [4], offer various advantages in reducing the environmental impact of concrete structures. The viable options for eco-friendly concrete are depicted in Figure 1.

Figure 1.

Different alternatives of achieving eco-friendly concrete [17].

This paper aims to offer an overview of current scientific knowledge regarding available opportunities and practices, scopes, and limitations in the development and implementation of eco-friendly concrete. This study specifically focuses on the scopes of integrating SCMs, different waste-based alternative cementitious and inert materials, and advanced technologies for developing sustainable concrete from a structural perspective. It highlights future research needs and identifies the obstacles impeding their practical implementation and suggests strategies to overcome the hindrances.

Scopes and Limitations of This Study

This review paper discusses the use of various SCMs, alternative binders, and construction and demolition waste in concrete. It examines how the material properties of these alternative materials affect the mechanical properties and durability of concrete. It also addresses emerging technologies and methods, such as carbon capture, utilization, and storage (CCUS), and performance-enhancing materials for low-carbon concrete. Additionally, this review discusses the barriers in applications of eco-friendly concrete in practice and potential strategies to overcome the challenges, the role of regulations and policies, incentives, and research, and development work to advance sustainability in concrete construction.

However, this proposed study has certain limitations. Although the paper focuses on using different SCMs and alternative waste-based materials in concrete, not all SCMs and feasible alternative binders or aggregates are covered herein. Similarly, not all studied concrete mix ratio results are discussed due to the broadness of the topic and this paper’s length. This paper does not critically discuss the microstructure’s role in the strength and durability of eco-friendly concrete except for a few occasions.

2. Method

The method used herein is a semi-systemic or narrative review, addressed in Snyder, 2019 [18]. It is suitable for this study, where the inclusion of all publications on the topic was not possible due to the broadness of the topic. For the literature search, Web of Science and Google Scholar search engines were used primarily with keywords, i.e., green concrete, cementitious materials, mechanical properties, low carbon, cement industry, carbon capture, challenges and strategies, etc., in different combinations. A preliminary screening was performed by reading the title and abstract, focusing on publications that dealt with integrating alternative materials or innovative technologies in concrete. The inclusion and exclusion of publications have been based on following preferences and on the relevance to this study. At the first stage, for exclusion, all others, except open access publications and English language, were defined. Priority was given to peer-reviewed articles, doctoral dissertations, and recent publications for acceptance of the results and updated research knowledge. The final selection of publications was made after reading the contents, which focused on the material properties, i.e., physical, chemical, and mineralogical analyses of the integrable materials, the mechanical properties and durability of concrete, and the potentiality of reducing CO2 emissions, etc. The final number of the publications aimed to be over 100, with 7–10 items per material or topic, since the method does not have any specific restrictions. In addition, scientific publications, standards, and guidelines including some local authorities’ scientific reports were included, considering their importance.

The selected publications were then categorized in different topic areas such as climate-improved policy-related reports, standards and regulations, materials and innovative technologies, and related challenge categories. The former two categories were used for background descriptions, and findings from materials and innovative technologies were compared and analyzed to understand the influences of the selected materials on durability and performances of eco-friendly concrete. This identifies the challenges involved and the needs for further research.

3. Supplementary Cementitious Materials

The cement industry has a significant role in reducing climate impact from the construction sector. Each ton of cement production generates about 0.5–0.6 tons of CO2 in the atmosphere. Moreover, the increasing rate of using concrete and, thus, cement for the construction of new infrastructure increases the CO2 emission from construction sector. Approximately 1.4 billion tons of CO2 were emitted from the world’s cement industries in the year 2002, which increased more than two times in 19 years, and amounted to about 2.9 billion tons in the year 2021 [12,16]. According to the IPCC [8], there is a significant potential to reduce the climate impact of concrete structures if the amount of cement used in concrete can be reduced by replacing it with an eco-friendly cementitious material. Previous life cycle analysis revealed that 40% to 80% of CO2 emissions from concrete can be reduced by replacing Portland cement with a supplementary cementitious material [19,20].

According to ASTM International, SCM is an inorganic material that enhances the properties of a cement mixture through hydraulic or pozzolanic activity, or both [10]. Hydraulic activity is commonly associated with the material’s ability to set and harden through a chemical reaction with water. This reaction forms calcium silicate hydrate (CSH), which provides strength, and calcium hydroxide (CH), which contributes little strength and can lead to material-related distress mechanisms [21]. In general, a SCM with hydraulic properties is classified as latent hydraulic, which means that they need an activator. A known SCM with latent hydraulic properties is granular blast furnace slag from iron production.

Pozzolanic reactivity, on the other hand, requires both water and portlandite (CH) as reactants to harden. The pozzolanicity of a material is one of the important characteristics of SCMs, contributing to gaining strength and increasing the durability of cementitious matrices. This pozzolanicity depends on the chemical composition and the presence of glassy (amorphous) phases of the material [21,22]. Pozzolanic SCM is defined as siliceous (S) or siliceous and aluminous (AS) material, which possess little or no cementitious value, but can be formed through chemical reactions [23,24]. A high specific surface area and a low level of crystallinity increase the pozzolanicity of materials.

Another important criterion of an SCM is the loss of ignition (LOI), which indicates the percentage of unburned carbonaceous material. Materials with high LOI values can increase the water demand for a given consistency and, consequently, affect the resistance of cementitious matrices adversely. High values of the LOI tend to decrease the performance of concrete, requiring prior processing [23].

There are some regulations set by The European committee for standardization, EN 450-1 [25], American Society for Testing and Materials, US standard ASTM C311 [26], ASTM C 618 [27], and in Sweden by Swedish standard SS-EN 206 [28] and SS 137003 [29] for using SCMs or alternative cementitious materials (ACMs) in concrete. In Table 1, criteria set by European committee for standardization, EN 450-1 for SCMs, are presented.

Table 1.

Properties of SCM with their recommended values set by the EN 450-1 and their impact on the durability of concrete, based on Nascimento et al. [23].

In the following, different SCMs are discussed, along with their limitations and scopes for utilizing in concrete.

3.1. Fly Ash

Fly ash is a recognized alternative cementitious material utilized in the production of environmentally sustainable concrete. It is a byproduct of heat and power production plants generated through the burning of coal and bio-based fuels. It consists of fine, powdery particles, generally spherical in shape, either solid or hollow with a wide variation in particle sizes varying <1 µm to 150 µm, and mostly amorphous in nature [10,30]. The quality and chemical composition of fly ash varies depending on the source. However, an extensive review investigation conducted by Bhatt et al. [24] on physical, chemical, and geotechnical properties of fly ash mentioned that all fly ash includes substantial amounts of silicon dioxide (SiO2), aluminum oxide (Al2O3), iron oxide (Fe2O3), and calcium oxide (CaO). FA is classified in C- and F-classes based on the total amount of silica, iron oxide, and aluminum oxide percentages, see Figure 2. For C-class FA, the total percentage of these oxides should be at least 50%, while, for F-class, the total oxides should be at least 70%. The utilization of fly ash in different sectors is an increasing trend, with about 44% utilization in cement and concrete industries. It is one of the established and well-proven cementitious materials used in concrete around the world, including Sweden for numerous benefits, including cost effectiveness [31].

Figure 2.

Ternary diagram of cement, SCMs, and natural pozzolans adapted from Lothenbach et al. [22], with permission from Elsevier Ltd., London, UK, 2010.

Using fly ash as cementitious material enhances the workability, durability, chemical resistance, and long-term strength of concrete. The incorporation of fly ash in concrete can lead to a more workable texture compared to cement due to the spherical shape of its particles, reducing friction. Unburned carbon in fly ash acts as binding substances, facilitating the incorporation of air into the concrete and resisting chemical damage and sulfate attacks. Fly ash-included concrete generates lower heat than conventional Portland cement concrete, thus reducing the likelihood of cracking in concrete subjected to elevated temperatures. A concrete mixture with a high proportion of cement replacement, up to 60%, was investigated by Malhotra [32]. The relatively slow early-age strength development of fly ash-incorporated concrete was noticed by Golewski [33], who investigated the development of compressive and fracture toughness strength of 20 and 30% fly ash-contained concrete for a curing time of 365 days. The results showed that fly ash-based concrete could even have higher compressive strength and fracture toughness than conventional concrete. However, in the beginning, up to 3 days of curing, the strength was found to be much lower than ordinary concrete. The difference in strength decreases with increasing curing time. The same conclusion was drawn by Rashad [34], who performed an extensive review study for the high percentage (≥45%) replacement of cement with FA. He reported a reduction in compressive strength of 40.47%, 33.6%, 23.8%, and 18.29% at ages 7, 28, 91, and 365 days, respectively, for 45% FA-contained concrete in comparison to Ref. concrete, which clearly shows that the difference in strength compared to the Ref. mix reduced with an increasing number of days. The relatively slow rate of strength development of fly ash concrete is a disadvantage in applications where high early strength is required. However, accelerators can be used to speed up the hardening and strength development, if necessary. Often, 90-day strengths are specified for fly ash concrete instead of 28-day strengths.

The availability of fly ash is already scarce because coal-based thermal power plants are being closed worldwide [35,36], which emphasizes the necessity of including new SCMs in concrete.

3.2. Ground Granulated Blast Furnace Slag

Ground granulated blast furnace slag (GGBS) is one of the most widely investigated and established alternative cementitious material used in numerous countries including Sweden [37]. Granulated blast furnace slag is a byproduct of the iron and steel industries. They constitute a vitreous granular substance formed when molten blast furnace slag is rapidly solidified by high-pressure water quenching [38]. The particle shape varies from a sub-angle to a sub-circle, with a typical dimension of ≤5 mm [39]. Granulated slags are ground down to use as a cementitious material in concrete [40]. GGBS is mainly composed of CaO, SiO2, Al2O3, MgO, and smaller amounts of other oxides. The hydration rate of slag is lower than that of cement, which reduces the water consumption in early hydration when GGBS is used as a cementitious material. GGBS can be used as high as 70 to 80% as a cement replacement, whereas about 50% replacement is often mentioned as an optimal level [3]. It offers several benefits like fly ash-incorporated concrete. GGBS-integrated concrete can enhance concrete’s durability, workability, and reduced porosity with improved pore refinement, higher long-term compressive and flexural strengths than traditional concrete and enhanced corrosion, and sulfate attack resistance [39,41].

With the aim of using GGBS containing climate-improved concrete in the Hamnbanan (Eriksberg—Pölsebo) in Gothenburg, in collaboration with the Swedish Transport Administration, Skanska Sverige AB carried out a solid testing program, which included concrete development, tests, and trial castings to investigate the temperature and hardening properties of eco-friendly concrete for different mix ratios containing 10 to 50% GGBS [42]. The main conclusion from the results was that concrete consisting of less than 25% slag can often be designed in a similar way and at a similar extent as conventional concrete regardless of casting seasons. Concrete with 25% to 50% slag needs extra measures to take care of temperature cracking during the winter period; however, during summer, no extra measure is necessary compared to conventional concrete. However, a comparatively longer demolding time may require concrete with a high percentage of slag, i.e., greater than 50%, and extra insulation covering is required to prevent the cooling/freezing of concrete and thermal cracking.

Regarding the compressive stiffness and strength of GGBS-incorporated concrete, a comparatively lower early-age strength is mentioned in the literature [40,43]. However, after 90 days, a higher compressive strength than traditional concrete is achievable depending on the cement replacement ratio.

The dependence of strength development of the GGBS concrete on curing temperature is mentioned by Cahyani and Rusdianto [41]. Elevated curing temperature increases the hydration of cementitious material, which contributes to increasing early-age strength. The increase in strength is found to be more prominent for a higher percentage of GGBS-contained concrete. However, conversely, a decreased long-term strength was noticed by them for specimens with an elevated curing temperature than a normal temperature cured specimens. The availability of GGBS is a challenge, as the annual production of 100 Ktons of GGBS against the cement production of 2.8 Mtons in Sweden is much lower, and similar situations prevail in other countries, which emphasizes the need of developing other alternative SCMs [36].

3.3. Silica Fume

Silica fume forms in electric arc furnaces during the manufacturing process of silicon or silicon-containing alloys. At temperatures around 2000 °C, the purity of quartz diminishes, leading to the production of silicon dioxide vapor. When this vapor cools at lower temperatures, it condenses to form silica fume. Silica fume can be used in concrete as a filler and supplementary cementitious material because of its highly reactive pozzolan characteristics [3,11]. It is amorphous, having ultra-fine particles (0.1–0.3 µm), comprising about 75% SiO2 [44]. In some cases, individual particles can fuse together to form small agglomerates that may range from 1 to 100 μm in size [45].

When silica fume is used in concrete, it enhances the microstructure interfacial transition zone [46,47] increasing density and reducing permeability [44]. Concrete including silica fume is recognized for its superior strength, durability, and resistance to corrosion and chemical attacks. Unlike fly ash and GGBS, silica fumes contribute to developing high early-age compressive strength. Because of this advantage, silica fume is utilized in ultrahigh performance concrete (UHPC) and ultra-high strength concrete for skyscrapers, highways, bridges, and marine projects. Amin et al. [48] observed a 6%, 10%, 15%, 20%, and 12% increase in the compressive strength of UHPC for 5%, 10%, 15%, 20%, and 25% SF content, respectively. A reduced flowability was observed in the slump test with increased SF content due to the higher surface area and fineness of SF, which increases water absorption.

Because of limited availability and the relatively higher price than ordinary Portland cement and other pozzolans, silica fume is being currently used as a property-enhancing material other than as an SCM in concrete. The fine particle size of the silica fume makes it challenging to handle, from a practical perspective. The use of silica fume in concrete typically elevates water demand, hence diminishing the workability of the mixture. To preserve the similar apparent workability like conventional concrete, it is required to add a water-reducing admixture and a higher slump of silica fume-incorporated concrete [45].

3.4. Calcined Clay

Due to the policy shift from fossil fuels to renewable energy, the availability of coal fly ash and GGBFS is expected to become limited, emphasizing the need for alternative SCMs. Calcined clay can be an alternative sustainable solution for use in cement clinkers, as a SCM, and as a mineral addition in concrete [36,49]. Clay, as a geotechnical term, refers to all loose geomaterials, like rock and soil, with a diameter smaller than <2 μm. Activated or calcined clay can be obtained by two ways; activating clays with Portland cement, forming composite cement, or by alkali-containing chemicals, creating geopolymer binders (for details, see Section 3.5) to be used in environmentally friendly construction materials. The reactivity of clay depends on mineral composition. In Sweden, two types of clay are present, Kaolinitic clays and illitic or chloritic clays [36].

Kaolinitic and montmorillonitic clays can be activated by heating between 600 °C and 800 °C, forming metakaolin, a highly reactive material. However, illitic or chloritic clays are harder to activate due to their higher dihydroxylation temperature, which can exceed temperatures where stable ceramic phases form. Activated clays can be utilized alongside Portland cement (binary binder) or with Portland cement and a filler-like limestone (ternary binder). The use of limestone increases the substitution rate of cement and enhances the density of the cement paste, thereby improving durability by reducing porosity. In ternary binders, gypsum addition is essential to facilitate the proper hydration of the cementitious material. Alternatively, biomass ash, GGBS, or other rock fillers can replace limestone in the mix.

Clays with at least 40% kaolinite can replace up to 30% of cement in a binary binder, while, in a ternary binder, it can substitute up to 50% of cement, comprising 30% activated clay, 15% limestone, and 5% gypsum, to preserve comparable mechanical properties to mortar made with conventional cement [50]. Recently, a plethora of studies and development endeavors have focused on the utilization of calcined clays in cement clinkers.

Mueller et al. [36] mentioned that incorporating calcined clay binders can replace up to 45 to 50% of clinkers in cement production while maintaining properties such as strength, durability, and shrinkage in a favorable range. The use of calcined clays in cement production offers several advantages, including calcination at a lower temperature and the possible use of existing rotary kilns. Denmark’s Aalborg Portland has already implemented cement production with calcined clays. Abdelli et al. [51] compared the pozzolanic reactivity of metakaolin and GGBFS in cement mortar for a cement replacement ratio of 5%, 10%, 15%, 20%, and 25%. Maximum comp strength (90 days) was observed for 15% metakaolin mortar, which was 85 MPa in compared to 75 MPa for Ref. mortar. A total of 5–15% metakaolin-contained mortar yielded higher strength at all ages (3, 28, and 90 days), while GGBFS mortar resulted in much lower early-age strength than the reference mortar. A high pozzolanic effect and the specific surface area of metakaolin contributes to early-age strength development.

The water demand of cementitious material containing activated clay is higher, meaning a loss of workability for the same water–cement ratio compared to pure OPC. In ternary binders, porosity reduces; thus, durability enhances by decreasing chloride penetration, which lowers the risk of corrosion in steel-reinforced concrete. Mueller et al. [36] also exhibit higher sulfate resistance and mitigate the risk of alkali silica reaction. The presence of limestone with calcined clay can improve concrete’s microstructure and pore structure at an early stage in ternary binders. Dhandapani et al. [50] studied the mechanical strength and durability performance of concretes with calcined clay limestone as a cementitious material. Results showed that, when compared with OPC, calcined clay with limestone concrete possesses comparable mechanical strength development, better chloride resistance, lower gas permeability and capillary water absorption, and the early enhancement of durability parameters. Furthermore, it is likely to be a good cementitious material to immobilize contaminants because of its low permeability.

According to the Swedish Standard, SS-EN 197-5:2021 [52], activated clays can be considered in cement production by replacing the cement clinker up to a higher percentage of 50%; however, the permission of using activated clay as a mineral addition in concrete is missing. The legal permission of extract clays, activation at large scale, missing permission for using calcined clay as a mineral addition, and missing standards and guidelines to use calcined clay in concrete are the main challenges [36].

3.5. Geopolymer

The development of geopolymer binder-based construction materials is still ongoing. The geopolymer concept, introduced by Davidovits in the 1970s, involves activating high alumina silica-rich materials with an alkaline solution, typically consisting of sodium or potassium silicate and hydroxide [53]. Any source of silica and alumina that can dissolve in alkaline solution can act as a geopolymer precursor. Various industrial and agricultural waste-based materials such as fly ash, granulated blast furnace slag, metakaolin, rice hush ash, bagasse ash, etc., are utilized for the production of geopolymers [54].

Several factors including composition, the type of alkali metals, the ratio of activator to binding materials, the ratio of silicate and alumina, the amount of calcium content in binding materials, and the curing temperature and time influence the strength and quality of geopolymer concrete [55,56]. Alkali metals significantly influence the reaction rate and the resulting products. A geopolymer is an inorganic polymer characterized by its amorphous structure at elevated temperatures. Heat curing occurs between 30 °C and 90 °C, but predominantly up to 60 °C accelerates the geopolymerization rate relative to ambient-temperature curing [57], hence facilitating the formation of early-age high-strength concrete through enhanced temperature curing.

A reduction in the activator to binder share from 0.40 to 0.35 results in diminished workability of the fresh mix; however, the addition of more water improves workability, albeit at the expense of compressive strength [58]. An activator containing sodium demonstrates heat stability up to 500 °C in geopolymer materials, surpassing that of a regular concrete mix. Thermal shrinkage in geopolymers is largely influenced by the Si/Al ratio and the type of alkali in the activator. A lower Si/Al ratio enhances thermal stability compared to higher ratios and leads to densification at higher temperatures. Moreover, the content of the alkali activator significantly impacts the compressive strength of geopolymer concrete [56,57]. Increased alkali content enhances compressive strength by promoting the solubility of alumino-silicate with rising Na2O concentration. A 10% alkali content was found optimal by Verma et al. [58], as further increments do not contribute to significant strength increase.

The increasing molar concentration of activator solution increases the comp. strength of geopolymer concrete as well. Prashad et al. [57] reported 28 days of compressive strength for different combinations of FA/GGBFS geopolymer concrete with 8 M and 12 M concentrations of NaOH. For all combinations, a higher molar concentration of NaOH resulted in higher comp. strength. Increasing GGBFS contents increase the compressive and tensile strength of geopolymer concrete [59,60]. Bellum et al. [59] investigated mechanical properties and the durability of GGBFS and FA-based geopolymer concrete in ambient air curing conditions. The reported 28 days of compressive strength was 55.6 MPa compared to 37.5 MPa for the Ref. mix. for a w/c ratio of 0.4 (see Figure 3). A similar trend was noticed for tensile and flexural strengths. Higher contents of GGBFS contribute to the formation of C-S-H and C-A-S-H gel, leading to a dense microstructure and enhanced strength; this was noticed in microscopic image analysis.

Figure 3.

Comp. and tensile strength of FA and GGBFS-based geopolymer concrete for different mix ratio, data from Bellum et al. [59].

Curing temperature has a strong effect on the hardening properties of geopolymer concrete. Verma et al. [58] observed that geopolymer concrete, when subjected to elevated curing temperatures, can attain compressive strength comparable to the 28-day strength of concrete cured at standard temperatures within a single day. Nonetheless, the extended curing duration at elevated temperatures results in the formation of microcavities within the microstructure, which induces cracks in the sample due to moisture evaporation from the matrix.

While preliminary findings indicate strengths in geopolymer mortar and concrete, there is a noticeable decline in strength over time, as observed by Mueller et al. [36]. Therefore, they noted that further comprehensive research is essential to understand the long-term performance and durability of geopolymer binder-based construction materials. Regarding standard and implementation geopolymer binders for using in concrete or construction materials is not covered by the European standard or Swedish standard currently, which is a great challenge.

3.6. Rice Husk Ash

Rice husk ash (RHA) is a viable cementitious material from agro-industrial byproducts. Annually, around 120 million tons (Mt) of rice husk are generated globally, where approximately 200 kg of ash is produced from each ton of rice [61]. RHA contains high silica, which contributes to cementitious property. Tayeh et al. [62] reviewed 25 case studies of RHA and found that the mean SiO2 content in RHA is about 90%, primarily in an amorphous state. The combined content of iron oxide, silicon dioxide, and aluminum oxide, totaling 89.6%, indicates the pozzolanic nature of RHA [63].

The low loss on the ignition rate (around 3.5%) suggests the effective removal of carbon-rich compounds during calcination. RHA particles are typically angular and coarser than ordinary Portland cement, and about 80% of RHA passes through a 75 µm sieve [62,63,64]. It has a lower density than ordinary Portland cement, making it advantageous for lightweight concrete [65]. Several studies [66,67] have investigated the mechanical properties of RHA concrete, typically with a 5–30% replacement. The recommended suggestion is replacing 5 to 15% of cement with RHA to maintain the mechanical properties of concrete without compromising in strength [68,69].

By adjusting the water–cement ratio, a higher compressive strength of RHA incorporated concrete can be achieved. Remarkably, concrete with 30% RHA content has shown higher compressive strength than ordinary concrete, when the water–cement ratio is increased, and chemical activators are used [69]. Bui et al. [70] and Madandoust et al. [70] noted lower early-age strength in RHA concrete compared to ordinary concrete when substituting 20% of cement with RHA. At 3 days, RHA concrete strength was found to be 65% of reference concrete, but, by 90 days, it reached 96% of ordinary concrete’s strength. Low early-age strength could be related to coarser grains and less reactive hydration materials of RHA than ordinary Portland cement.

RHA enhances concrete’s resistance to sodium sulfate attack, attributed to its lower Al2O3 content compared to cement. This suggests that increasing RHA volume significantly improves concrete’s protection against sulfate attacks [71]. RHA concrete also offers higher resistance to corrosion and chemical attacks, with a smaller diffusion coefficient due to finer pore formation, leading to reduced chloride ion diffusivity. Furthermore, the minimal calcium hydroxide content in RHA concrete makes it less vulnerable to acid attack.

Because of high active pozzolanic characteristics, and high specific surface area [72,73], RHA can be used for producing UHPC. The comparison investigation conducted by Tuan et al. [73] of using SF and RHA in UHPC showed that 91 days comp. strength of RHA contained concrete resulted in even higher than SF contained concrete for 20% cement replacement.

However, the addition of RHA as a mineral additive is missing permission in the European standard. More in-depth research and analysis of the effects of RHA in concrete mixture should be conducted including mechanical and physical properties, workability, durability, long-term behavior, and environmental and economic aspects.

3.7. Wood Ash

Wood ash (WA) can be another alternative option of SCMs in concrete considering the scarcity of well-renowned fly ash and GGBS [23]. It is a waste product of combusting wood and wood products, consisting of both organic and inorganic wastes. About 6–10% of the mass of combusted wood is converted into ash. Approximately 4600 million tons worldwide of woody biomass are produced annually, with 60% used for energy, 20% for industrial purposes, and 20% lost to decomposition [74]. The disposal of WA in landfills raises concerns about land occupation and potential groundwater contamination and health risks associated with airborne particles of wood ash. Using wood ash in concrete not only provides a sustainable disposal method but also offers an eco-friendly alternative for construction materials.

The quality control of wood ash is challenging due to variations in organic and inorganic content influenced by factors such as tree species, combustion technology, and storage conditions. Unlike coal fly ash, which is widely used in concrete production, the usage of WA in concrete is not recommended in standards like EN 450-1 and ASTM C618 [25,27]. However, several studies investigated the potential of WA for utilization in concrete [23,24,74,75,76]. WA particles have a porous structure. Generally, they have larger and more irregular particles and larger specific surface areas compared to Portland cement. Particle sizes vary from 86 and 176 µm [74]. The density of WA is significantly lower than ordinary Portland cement and varies from 2.35 g/cm3 and 2.76 g/cm3. Nascimento et al. [23] demonstrated in their review paper that the main oxides present in wood bottom ashes are calcium, silicon, aluminum and iron, with the highest amounts of calcium oxide. However, in some cases, a higher percentage of silicon oxide was observed. It is also noted that the LOI values are greater than 9% and may reach about 60%. This indicates that there is still carbonaceous material in the ash. The high LOI increases the water demand to maintain the desired consistency and consequently affects the resistance of cement matrices. Thus, material with a high LOI requires pre-processing.

Generally, lower workability, a higher water demand ratio, and lower compressive and flexural strength are found in wood ash-based mortar/concrete than a reference mix [23,74]. A larger specific surface area and porous particle microstructure of WA can cause reduced workability.

Carević et al. [76] evaluated the workability of concrete samples incorporating WA with 5%, 10%, and 15% cement substitution, where the findings indicated that an increase in WA % diminishes workability. Pre-treatment methods such as water washing and the incorporation of superplasticizer can enhance workability. Generally, a decreasing trend in compressive strength with increasing WA content was noticed. An optimal cement replacement ratio can vary between 10 and 20%. Sigvardsen [24] mentioned that the combustion technique has a great influence on physical and chemical properties of wood ashes. In Table 2, the influence of physical and chemical properties of selected SCMs on concrete’s durability and strengths is shown. Sigvardsen investigated two wood ashes, one possessing hydraulic properties and one possessing pozzolanic properties, to investigate the SCM properties of WA. Surprisingly, both wood ash mixes showed hydraulic properties but no pozzolanic properties with differences in strength development, attributed to variations in aluminum content and formation of ettringite. There is a consensus of delaying setting with the incorporation of WA in concrete. Setting time increases with increasing the WA percentage in concrete. Carević et al. [76] reported that high alkali and magnesium oxide contents and the LOI can contribute delay in the setting time of WA concrete. Further investigations, as well as inclusion in standards, are needed to utilize WA in construction materials.

Table 2.

Summary of different alternative cementitious materials, physical and chemical properties, and their impacts on concrete.

3.8. Municipal Solid Waste Incineration Bottom Ash (MSWI-BA)

Utilizing waste-based byproducts in innovative building materials has received much attention during the last decades concerning the global climate issue and the environmental impact from construction industries.

In many countries, municipal solid wastes are incinerated to produce electricity or heat in waste-to-energy plants. As a result, a large quantity of incineration residue is produced including bottom ash (BA) and fly ash. BA is heavier and coarser, settles in the bottom of the combustion chamber, and accounts for about 80% of total residues. In general, they are used for landfills. However, the main chemical components of BA are silica, aluminum, and iron oxides, making it a potential candidate for using as an SCM, while the construction sector is facing a great challenge to reduce its carbon footprint [77,78,79]. Only in Sweden, over 1 million tons of municipal solid waste incineration (MSWI) ash is produced in waste-to-energy plants [80]. Incorporating MSWI-BA into concrete not only helps reduce its carbon footprint but also promotes waste valorization by transforming substantial waste streams into valuable construction products. This process can significantly divert waste from landfills and potentially lower the energy consumption associated with transportation [81].

BA consists of non-combustible materials like stone, glass, and sand, along with metallic materials like aluminum, which are considered hazardous. Through pre-treatment and stabilization processes, such as washing, sorting out metals and weathering, the leaching effects of metals can be reduced, allowing the stabilized bottom ash (known as MIBA, the Mineral Fraction of Incinerator Bottom Ash), to be used in construction materials [82,83]. The wide range of particle sizes (0.05 to 16 mm) makes it suitable for using as aggregates in addition to SCMs [80].

Several studies have investigated the material characterization, leaching effects, and pre-treatment requirements for using MSWI-BA in construction materials, such as in the cement clinker, mortar, and concrete as SCMs and aggregates [78,79,80,81,82,83,84,85,86]. Klieb et al. [78] utilized 0–2 mm fractions of MSWI-BA from France in cement mortar after grinding and sieving through 100 µm. The 28-day compressive strength was reasonable, slightly lower than the controlled mix, for 5 to 12.5% cement replacement. A summary of selected investigations on alternative materials incorporated concrete are presented in Table 3.

Tang et al. [80], Müller and Rübner [84], and Lu et al. [85] studied the potential application of a coarser fraction (>3–4 mm) of MSWI-BA in concrete as an alternative to natural aggregate. Concrete incorporating MSWI-BA as a partial replacement of natural aggregate has been observed to suffer from surface damage due to expansive reactions associated with metallic aluminum or aluminum compounds [78,80,84,86]. Comparatively, lower stiffness and strength were reported in utilizing the finer fraction (<3 mm) of MSWI-BA in concrete. The lower stiffness and strength are associated with high porosity, low density, and increased water requirements of MSWI-BA-incorporated mortar or concrete [85].

Loginova et al. [79] highlighted several challenges in using MSWI-BA as a cementitious material in concrete due to its wide particle size distributions, chloride content, and alkaline properties. These factors contribute to slow hydration, steel corrosion, and leaching effects, with finer particles exhibiting a leaching rate 5–10 times higher than that of coarser particles. Furthermore, grinding MSWI-BA into a powder to improve its use as a binding material significantly increases metal leaching [19].

Additional complications with MSWI-BA-incorporated concrete include the presence of metals like aluminum, which can cause hydrogen formation and lead to cracking. The material also suffers from low compressive and flexural strength, likely due to its low density and high porosity, underscoring the need for further investigation before MSWI-BA can be widely implemented in concrete production. Concerns also remain regarding long-term leaching and recyclability, though some studies suggest that weathering can reduce leaching over time. To ensure the safe use of MSWI-BA in construction, further studies are required, alongside legislation to establish acceptable levels of metallic content from both environmental and social perspectives.

3.9. Mine Waste Tailings

The mining industry is the world’s largest waste producer, producing about 65 billion tons each year, primarily in the form of solid rock waste and fine particle tailings [87]. Disposal methods for these materials include storage in cross-valley or hillside dams, raised embankments, impoundments, dry stacking on land, and backfilling into abandoned open-pit or underground mines. However, these disposal practices present numerous challenges, such as extensive land use, ecological risks, and environmental contamination, necessitating rigorous maintenance and monitoring efforts [88,89,90]. Reusing fine particle tailings as SCM is one of the key strategies proposed by Edraki et al. [91], to enhance environmental, social, and economic outcomes.

Table 3.

Mechanical properties and strength of eco-friendly concrete from selected studies.

Table 3.

Mechanical properties and strength of eco-friendly concrete from selected studies.

| Concrete/Mortar | Description of Study | Reference | Outcome |

|---|---|---|---|

| Coal fly ash-incorporated concrete (w/c ratio 0.4) High-volume (>45%) fly ash-contained mortar, concrete for different w/c ratios | Reviewed a large number of studies for mechanical properties and the durability of concrete and mortar | Golewski [27] Rashad [34] | Eco-friendly concrete with FA is possible by maintaining structural performance and qualities, like compressive strength and fracture toughness. Maximum comp. strength of 48.96 MPa was found for 20% FA-contained concrete compared to 47.51 MPa for Ref. concrete. Reported a decreased compressive and flexural strength along with E-modulus and abrasion resistance for all high-volume FA-contained concrete and mortar with increasing setting time. Suggested using additives or high pozzolanic materials for hardening properties and increasing strength. Addition of 10–20% SF or slag can modify comp. strength and abrasion resistance significantly. |

| GGBFS concrete (w/c ratio 0.4 and 0.5) GGBFS mortar (w/c ratio 0.4) | Comp. strength, hardening properties (up to 91 days) and influence of temperature on GGBFS concrete for 0–50% cement replacement were investigated Evolution of comp. strength with time for 20 to 80% cement replacement Initial and final setting time | Hedlund et al. [42] Cahyani & Rusdianto [41] | A higher percentage of GGBFS in concrete resulted in higher comp. strength. The resulting 56-day comp. strength of 30% GGBFS containing concrete and Ref. concrete were 71 MPa and 65 MPa, respectively. Extra measures are suggested to prevent temperature cracks during winter. Early-age comp. strength is inversely corelated with GGBFS percentage. After 28 days of curing, a higher comp. Strength were noticed for 20–60% GGBFS mortar compared to Ref. concrete, where the optimal replacement level was 40–50%. Delayed setting time was noticed in comparison to Ref. |

| UHPC containing SF Concrete and mortar with silica fume (w/c ratios vary) | Influence of SF on mechanical prop. of concrete for 5–25% cement replacement Reviewed results of comp. strength, and tensile strength of silica fume-incorporated concrete or mortar (0% to 30% by weight of cement content) | Amin et al. [48] Hamada et al. [44] | Max. comp strength was observed for 20% SF replacement, with an increase of about 20% with respect to Ref. concrete; after that, a decrease in strength was noticed. An increase in comp. strength was noticed for increasing SF content up to a certain level (about 10–20%); after that, a decreasing trend was noticed. A similar trend was noticed for tensile strength. |

| Concrete with fly ash and blended concrete with calcined clay (varied w/c ratio of 0.35 to 0.5) Metakaolin mortar | Mechanical properties, autogenous drying shrinkage and durability of fly ash concrete (30%) were compared with Ref. and blended concrete composed of clinker, limestone, calcined clay and gypsum Pozzolanic reactivity of mortar for 5–25% cement replacement | Dhandapani et al. [50] Abdelli et al. [51] | Higher comp. strength at later ages (from 28 days to 365 days) in the fly ash and limestone concrete were found as opposed to the conventional concrete. Better chloride resistance was noticed for calcined clay containing concrete due to a compact and dense microstructure. Similar shrinkage properties were found for all three types of concrete. Metakaolin contributes to higher early-age strength development. Max. strength (about 28% increase) was found for 10% metakaolin mortar in comparison to Ref. mortar. A higher strength (3, 28 and 90 days) was observed up to 15% cement replacement, compared to Ref. mortar. |

| Geopolymer concrete with FA and GGBFS (w/c ratio 0.4) | Mechanical properties and durability for different FA/GGBFS mix ratios | Bellum et al. [59] | Increased strength for increasing GGBFS contents for comp., tensile and flexural strength. Dense microstructure and better chloride resistance were observed. |

| RHA-contained concrete (w/c ratio 0.53) | RHA varying from 0 to 30% are used as SCMs in concrete to assess mechanical properties, long-term (365 days) strength development, and durability of concrete in compared to Ref. concrete | Madandoust et al. [70] | Concrete with RHA showed slow early strength development. At 20% RHA content, it achieved 65% of the 28-day comp. strength compared to Ref. concrete, reaching 98% at 180 days and slightly surpassing it at 365 days. Tensile strength followed a similar trend. Increasing RHA decreases strength, where 20% replacement seemed reasonable. RHA concrete showed better performance in chloride resistance. |

| WA mortar (w/c ratio 0.5) | Influence of sieving and washing WA on physicochemical characteristics, mechanical response and phase development of WA-contained concrete were investigated. For mortar’s strength and phase development, Ref., 10% and 20% cement replacement were considered | Sigvardsen M. [24] | The strength development of WA mortar at 1 and 3 days was similar to the Ref. mortar. However, from 7 to 90 days, the Ref. mortar outperformed the WA mortar. At 365 days, the average comp. strength of mortar with untreated WA was 86% and 87% of the Ref. mortar for the 10% and 20% cement replacement, respectively. For washed WA mortar, the values were 91% and 84% of the Ref. mortar for 10% and 20% cement replacement respectively. |

| Cement paste containing MSWI-BA (w/c ratio 0.5) | Comp. strength development (1–28 days) of 0–12.5% MSWI-BA-contained cement paste was investigated | Klieb et al. [78] | The hydration process was slower compared to the Ref. cement paste. The 28-day comp. strength of the cement paste with 12.5% MSWI-BA was 45.6 MPa, compared to 49 MPa for the Ref. paste. |

| Mortar with mine tailings | Comp. strength (1–28 days) with two types of mine tailings mortar with 0, 5 and 10% replacement studied | Sigvardsen et al. [90] | A slower initial hardening rate was observed. The 28-day compressive strength of mortar with 10% mine tailing content was 45–46 MPa compared to 54 MPa for the reference concrete. |

According to the Geological Survey of Sweden (SGU), about 58 million tons of mine tailings are generated in 2021 in Sweden [92]. They are mostly deposited in tailing storage facilities. Fine particle tailings from the mining industry possess the criteria to be utilized as cementitious material in concrete [35,91,93]. The use of mine tailings in concrete contributes to sustainability mainly in two significant ways; providing an efficient utilization of mine wastes and reducing greenhouse gas emissions from the construction sector.

In general, mine tailings have a highly rough and irregular surface and a fine-grained particle with a size less than 1 mm [93]. Their chemical composition varies based on the source of the mine and the specific enrichment processes used [35]. Despite their potential, the application of tailings in construction materials remains underexplored in the existing literature. Sigvardsen et al. [90] studied the effects of mine tailings from Sweden and Greenland as partial cement replacements in mortar. They observed the development of compressive strength in mortar samples with replacement ratios of up to 10% over 28 days of curing. Both types of mine tailings demonstrated pozzolanic reactivity, though with slightly lower compressive strength compared to a reference mix. The incorporation of tailings increased water demand, affecting consistency; however, no significant leaching effects were detected.

In a comprehensive review, Gou et al. [93] summarized findings on the use of mine tailings as fine aggregate or cementitious material in the cement clinker, mortar, or concrete. Reduced workability and compressive strength were commonly observed in tailing-incorporated products. To fully harness the potential of mine tailings in concrete construction, further investigation into the mechanical properties of tailing-incorporated concrete, along with the suggestions for guidelines and standards, are essential.

4. Recycled Aggregate

Approximately 10 billion tons of construction and demolition (C&D) waste is generated globally each year. Recycling and reusing this waste in concrete production can significantly mitigate environmental impacts by reducing the need for natural aggregate extraction, minimizing landfill contributions, and lowering carbon emissions from transportation and waste management. C&D waste recycling is well established in many countries, with recovery rates reaching nearly 100% in nations like Japan and the Netherlands, while, in some low-income countries, recycling rates remain close to zero [94].

C&D waste includes demolished structures and rejected concrete products. Various factors, including taxes, regulations, and recycling schemes, influence the application of recycled aggregate. In Europe, countries like Sweden, Denmark, and the UK have implemented aggregate taxes that promote higher recycling rates by incentivizing material substitution. In Japan and the Netherlands, recycling rates for concrete waste reach 98%, demonstrating the effectiveness of robust recycling frameworks.

The process of converting C&D waste to recycled concrete aggregate (RCA) involves mechanical crushing, ferrous metal removal, and the separation of wood, glass, plastic and other materials and screening. According to Tang et al. [80], over 50% of recycled aggregate particles exceed 4 mm in size, allowing them to replace coarse aggregates in concrete without compromising quality. Particles between 2 and 4 mm, comprising about 10% of the total volume, can also be reused, while the fine RCA fraction (<2 mm) poses challenges due to its potential negative impact on concrete’s mechanical properties and durability. However, by enhancing the properties of fine RCA through carbonation or mixing with other materials, they can be utilized as a partial replacement of sand in concrete.

During the crushing of C&D waste, a very fine fraction (less than 150 μm) representing about 3% of the total waste is named as recycled concrete powder (RCP). Rocha and Filho [95] mentioned that RCP contains various compounds, such as CaCO3, SiO2 highlighting its potential to be utilized in concrete as an SCM. Furthermore, thermal activation and carbonation can enhance the reactivity of RCP, making it more suitable for use in concrete production.

In general, the lower density of RCA compared to natural aggregate, because of attached cement mortar with aggregate, leads to lower strength than ordinary concrete [3]. The same reason also causes extra water demand for RCA-incorporated concrete. Moreover, the presence of other contaminants from demolished structures such as asphalt, rubber, bitumen, gypsum, and plastic can degrade the mechanical properties and durability of concrete [3,96]. Cassiani et al. [97] mentioned the durability problem caused by the alkali–silica reaction in RCA-integrated concrete. This happens as a result of a chemical reaction between the alkalis from cement and silica from aggregates, which produces an expansive gel causing cracks in concrete structures.

5. Innovative Technologies and Practices

5.1. Carbon Capture Utilization and Storage

The carbon capture utilization and storage (CCUS) technique is one of the emerging techniques to mitigate climate impact from construction industry [98]. It involves capturing carbon dioxide (CO2) emissions generated during the production of building materials and construction activities and storing them to prevent their release into the atmosphere. The stored CO2 can also be utilized in the production of e-fuels, crop growths, feedstock of chemical, food and beverage industries, and even re-using in construction industry. The CCUS concept is shown in Figure 4.

Figure 4.

Carbon capture utilization and storage concept.

The cement industry is one of the largest sources to CO2 emissions, releasing approximately 0.5–0.6 tons of CO2 per ton of cement production. Several carbon capture technologies are available, including pre-combustion, post-combustion, such as chemical absorption with amines, direct separation, calcium looping, and oxy-fuel techniques [16]. However, pre-combustion methods are not suitable for the cement industry, as they cannot capture the CO2 generated during the calcination process [9,16]. The major carbon capture technologies suitable for cement industry are discussed in the following sections.

5.1.1. Amine Scrubbing

The cement industry has utilized amine scrubbing technology since the 1930s to capture CO2 emissions from flue gases before they are released into the atmosphere. This process involves using an amine solvent, like monoethanolamine (MEA) and diethanolamine (DEA), in an absorber column to remove CO2, followed by regeneration in a stripper column to recover CO2 [16]. The first global CO2 capture technology based on amine scrubbing that reached a milestone in the cement industry is Norway’s Longship. Additionally, Heidelberg Cement Group is planning to build its first full-scale CCUS facility at the NORCEM cement plant in Brevik, Norway, and in Slite, Gotland Island, Sweden, aiming to capture about 400,000 and 1.8 million tons of CO2 annually, respectively. The main drawback of amine scrubbing is its high energy requirement for regeneration, which accounts for 50–80% of the total cost of CO2 capture. Furthermore, flue gas contaminants such as SO2 and NO2 can react with absorption solvents to form toxic byproducts, reducing the scrubber’s efficiency. There are also environmental risks linked to the release of amine solutions, as they can produce harmful substances, including isocyanic acids and nitrosamines.

5.1.2. Calcium Looping

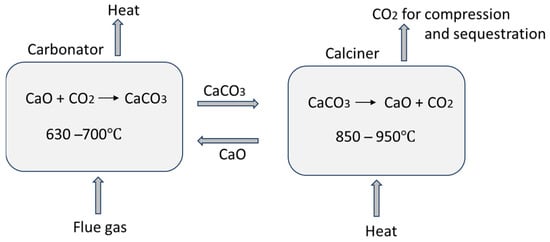

Calcium looping (CaL) technology, also referred to as the regenerative carbon cycle, was first proposed by Shimizu in 1999. The process eliminates CO2 from the flue gases of cement plants and industrial facilities, by utilizing a calcium oxide (CaO) sorbent [99,100]. This process is based on two reversible chemical reactions, carbonation and calcination. During the process, CaO-based energy effectively releases CO2 from combustion through carbonation–calcination reaction cycles. In the carbonator, CO2 reacts with CaO at high temperatures (600–700 °C) to form solid CaCO3, while, in the calciner, CaCO3 is heated to about 950° C to obtain CO2 gas and CaO (see Figure 5). The process removes impurities such as NO2 and SO2 from the flue gas. However, repeated calcination and carbonation processes can lead to sorbent deactivation due to sintering and irreversible sulphation. To mitigate this, it is important to keep calcination temperatures as low as possible.

Figure 5.

Calcium looping concept.

The cement industry mainly uses two configurations in CaL techniques, such as integrated and tail-end. In integrated configuration, a cement kiln with an integrated calciner performs calcination, whereas the tail-end configuration captures CO2 from the clinker process using a carbonator at the end of the pipe. The tail-end configuration is more suitable for large-scale implementation and is more mature than the integrated configuration. Despite its potential, calcium looping faces challenges such as high calcination temperatures and declining CO2 capture efficiency over time.

5.1.3. Direct Separation

Direct separation is also known as indirect calcination, representing a group of technologies that revolutionizes how limestone is heated in cement manufacturing [101]. Traditional cement manufacturing heats limestone directly in the calciner, producing CO2 emissions from both fuel combustion and limestone decomposition. Contradictorily, in direct separation, limestone heats indirectly, keeping process emissions separate. Process emissions mainly consist of CO2 and steam, making CO2 capture straightforward without additional treatment. This captured CO2 can then be compressed for geological storage or other uses. Direct separation enables the capture of process emissions, which constitute about two-thirds of CO2 emissions from cement production, without significant energy or capital costs. It can also be easily integrated into existing processes. The technology developed by Calix, an Australian technology company, is being implemented in a project called low-emission intensity lime and cement (LEILAC) to capture about 25,000 t CO2 per year [101,102,103]. After the completion of LELAC 1 (first phase), LEILAC 2, which has almost four times larger capacity than LEILAC 1, is going to be built at the Heidelberg cement plant in Hanover, Germany [16,103]. Despite advantages such as applicability anywhere and the potential for zero net emissions, the extensive high cost (USD 94–USD 232 per ton CO2 capture) for this technique remains a challenge.

5.1.4. Oxy Combustion

Oxy-combustion technology offers a promising solution for CO2 separation in the cement industry, involving CO2 enrichment via oxygen injection and/or by using H2 as a fuel [104,105]. This technology has received research attention in recent years. Two different approaches are under investigation: partial oxy combustion and full oxy combustion. In partial oxy-combustion, a CO2 enrichment of about 55–75% can be achieved with minimal modifications to cement plants, making it a cost-effective CO2 capture method. In contrast, full oxy-combustion achieves higher capture rates of 90–99% but requires extensive adaptation of the cement production line (GGCA). Implementing oxy-fuel technology involves setting up an air separation unit to supply the necessary oxygen for creating oxy-fuel conditions. Additionally, to maintain similar kiln and calciner temperatures, CO2 recirculation is necessary when replacing nitrogen from combustion or cooling air with oxygen during oxy-combustion. This requires some clinker cooler modifications or the installation of a heat recovery system to recirculate flue gases, reducing the need for extra firing and preventing uncontrolled CO2 emissions. This integration increases the electricity demand per ton of clinker by over twofold, leading to a 40% to 50% rise in production costs. Despite the increased cost, in comparison to other CO2 separation technologies, oxy-combustion is an attractive and economical option for the cement industry.

Since 2007, the European Cement Research Academy (ECRA) has been leading a long-term research project on CO2 capture. In 2018, industrial-scale oxy-combustion CO2 capture was successfully demonstrated at two European cement plants—Lafarge Holcim in Retznei, Austria, and Heidelberg Cement in Colleferro, Italy—providing valuable insights into the industrial performance of the technology [11]. This project, with an estimated cost of USD 84.1 million, aims to assess the technical feasibility of oxy-combustion technology on a large scale, with no observed negative effects on clinker quality, refractory life, though higher CO2 concentrations inhibited calcination efficiency [106]. Additionally, a new EU-funded initiative in Eastern Europe is exploring the complete capture and transport of CO2 via pipeline to offshore storage under the Black Sea, with operations potentially starting by 2028.

In summary, direct separation technology offers a promising approach to carbon capture and utilization in the cement industry, providing an alternative to traditional methods that rely on capturing CO2 from flue gases. However, further research and development are needed to overcome cost and efficiency challenges for widespread adoption. In Table 4, the advantages and drawbacks of different carbon capture techniques are summarized.

Table 4.

Advantages and drawbacks of different carbon capture techniques [16,98,101].

5.2. Performance-Improved Concrete

Performance-improved concrete refers to concrete that has been engineered to provide superior properties compared to conventional concrete. These enhancements can include increased strength, durability, and workability, as well as improved resistance to environmental factors such as freeze–thaw cycles, chemical attacks, and abrasion. High-performance concrete can be achieved through the careful selection and proportioning of ingredients, including high-quality aggregates, advanced admixtures, and SCMs, depending on the desired applications [73]. Below, a few performance-improved concrete types are discussed.

5.2.1. Permeable Concrete

Permeable concrete, also known as pervious or porous concrete, is a special type of concrete with high porosity that allows water to pass through it. It is structured to facilitate the infiltration of rainwater through the surface into the ground below, rather than pooling on the surface or running off into storm drains, especially suitable for use in pavement, roads, sideways, parking areas, etc. It typically contains a lower percentage of fine material, such as sand and a higher percentage of coarse aggregate, i.e., gravel, stone compared to traditional concrete, allowing for larger void spaces within the concrete structure. These voids create pathways for water to flow through. There are several benefits to using permeable concrete including stormwater management, flood prevention, and pollution reduction for underground water as it filters out the pollutant materials like heavy metals, oils, and sediments. Unlike traditional concrete, which absorbs heat and contributes to the urban heat island effect, it is not suitable for heavy-load applications or roads with high traffic volumes. Over time, the voids in permeable concrete can become clogged with debris and sediments, leading to diminished infiltration capacity. Consequently, routine maintenance, including vacuum sweeping and pressure cleaning, is crucial for sustaining long-term performance. Furthermore, in areas experiencing freeze–thaw cycles, the efficacy of permeable concrete may be compromised by the expansion and contraction of water within the linked voids [9]. This may result in diminished strength, durability, and overall performance. Nonetheless, formulating an appropriate mix ratio and including air-entraining admixtures enhance freeze–thaw resistance and prolong the lifespan of permeable concrete buildings.

5.2.2. Ultra High-Performance Concrete

Ultra high-performance concrete (UHPC) is generally characterized by its outstanding mechanical properties, remarkable strength, and impressive durability [107,108]. This is generally accomplished through the utilization of high-strength fibers, along with supplementary cementitious materials (fly ash, silica fume), adding super-plasticizers or other additives in concrete mix and by using a very low water–cement ratio (less than 0.2). UPHC is alternatively known as reactive powder concrete. Fiber types often used in UHPC include carbon, high-carbon steel, glass, PVA, or a mix thereof. The application of SCM and a low water–cement percentage provides a compact and dense structure with a smooth surface valued for its esthetics. The high strength and mechanical properties of UHPC makes it a desirable material for different construction applications, where improved structural performance and sustainability are required. The material’s low permeability offers high resistance against chloride penetration and carbonation, which yields superior durability characteristics.

UHPC can significantly reduce the climate impact of concrete construction in several ways. Its high strength allows for reduced material usage, which in turn reduces the carbon footprint linked to production, transportation, and installation. Moreover, its remarkable durability prolongs the lifespan of concrete structures, minimizing the necessity for maintenance, repair, and eventual replacement, hence significantly mitigating environmental effects in the long term. The low permeability and dense composition of UHPC efficiently insulate structures and diminish heat transmission, leading to decreased energy consumption for heating and cooling [108].

Despite its many benefits, several challenges and barriers must be overcome to fully realize the potential of UHPC as a sustainable construction material. One significant barrier is the high cost of UHPC, especially compared to traditional concrete. This cost is primarily driven by its complex composition, which includes specialized fibers, admixtures, and fine aggregates [9]. Another major obstacle is the lack of specifications and code provisions for accurately estimating the structural capacity of UHPC sections under various types of loading. Although guidelines and specifications have been developed in countries like France, Japan, and Australia, the United States lacks global standardization, authoritative documents describing UHPC constituents, fiber orientations, mixing, batching, and quality control procedures, as well as design codes for calculating member performance [107,109].

5.2.3. Self-Healing Concrete

Self-healing concrete is a cutting-edge technique designed to enhance the resilience, performance, and sustainability of concrete structures. It allows concrete to self-repair fissures and damage [4], hence prolonging the lifespan of structures and diminishing the necessity for maintenance and repairs. This technology provides multiple advantages, such as mitigating corrosion and deterioration risks, decreasing the necessity for manual inspections and interventions, and yielding substantial cost savings throughout a structure’s lifespan. Furthermore, prolonging the lifespan of concrete structures can lead to a decrease in resource utilization, waste production, and total ecological footprint.

The novel technique entails integrating specialized materials like fibers or capsules containing healing agents into the concrete mix. When cracks occur, these materials break, releasing the agents to heal the cracks. Various self-healing methods have been proposed recently, including capsule-based, vascular, autogenous, electrodeposition, and microbial methods [110,111].

Nevertheless, challenges persist, including scalability, long-term performance, reliability of the self-healing mechanism, and high initial costs. Further research and development are essential for surmounting these hurdles and actualizing the complete potential of self-healing concrete within the construction sector.

In addition to the efforts of electrification of construction machinery and vehicles, the use of renewable energy sources plays a crucial role in reducing GHG emissions in the construction industry. By replacing traditional fossil fuel-powered machinery with electric alternatives, the carbon footprint associated with construction activities can significantly be lowered. Electric equipment not only reduces direct emissions but also operates more quietly, improving the working environment and reducing noise pollution. Additionally, integrating renewable energy sources, such as solar or wind power, or waste-based fuels into construction processes further minimizes reliance on fossil fuels, leading to a more sustainable and eco-friendly practices in the industry, paving the way for a greener future in construction.

6. Challenges and Potential Strategies

6.1. Challenges

Implementing eco-friendly concrete and sustainable practices in the construction industry includes technical, economic, and social challenges [107]. The integration of new materials in concrete, such as SCMs, performance-improving materials and technologies, and using recycled materials in innovative concrete introduces performances characteristics that differ from the conventional concrete. The divergence necessitates extensive research and development to fully understand the newly developed eco-friendly concrete’s material properties, durability, and environmental benefits [112,113,114,115,116]. Moreover, construction processes may need to be adjusted to ensure that these materials meet the required standards of performance and durability. The complexity of integration of these materials lies in optimizing their benefits while mitigating any potential drawbacks [31,42].

The adoption of innovative material technologies, such as high-performance concrete, self-healing concrete, and carbon capture and storage methods are crucial for advancing sustainability in the concrete industry. However, these technologies are still in the developmental phase and require comprehensive testing to confirm their long-term reliability, efficiency, and effectiveness [9]. For instance, self-healing concrete needs to be assessed for its ability to autonomously repair cracks over extended periods, while carbon capture and utilization techniques must be evaluated for their practicality and scalability in various construction scenarios.

Economic challenges include high initial costs and market acceptance. These can be a barrier to the adoption of eco-friendly concrete, especially in smaller projects with constrained budgets. The building sector is generally conservative and sluggish in embracing new materials and methodologies. Persuading stakeholders of the enduring advantages of sustainable concrete construction is difficult, especially when confronted with elevated initial costs and relatively inferior mechanical qualities compared to conventional concrete [97].

Social issues are regarded as one of the significant obstacles in adopting climate improved solutions in concrete construction. The lack of acceptance, awareness, and understanding of the long-term environmental benefits of eco-friendly concrete among industry professionals and the general public, workforce skills, and regulatory barriers are the main factors to mention [107,108,109,110,111,112,113,114,115,116]. The adoption of sustainable concrete construction practices necessitates proficient professionals who are well versed in innovative materials, technologies, and methodologies. The industry may encounter a deficiency of skilled labor, thus hindering the extensive implementation of sustainable practices. Current building codes, regulations, and standards may inadequately accommodate eco-friendly concrete and construction processes and necessitate revision. This may pose challenges and impediments to the implementation of novel materials and technologies, as they could encounter regulatory hurdles or delays.

6.2. Potential Approaches in Overcoming the Challanges

Implementing sustainable practices, i.e., eco-friendly concrete and smart technologies in construction, requires a multifaceted approach. Here are some potential strategies:

Collaborative research and development: Investment in research and development is crucial to enhance the performance, durability, reliability, and cost-efficiency of sustainable concrete and smart technologies to address associated difficulties. Collaboration among industrial stakeholders and interdisciplinary scholars will facilitate the resolution of technical issues and improve comprehension of the advantages of sustainable concrete and technology [112,113]. This fosters networking among researchers, industry experts, and policymakers, enhancing the sharing of ideas and knowledge, raising social awareness, and thereby facilitating the wider adoption of eco-friendly solutions within the building industry.

Education and training: Education and training are fundamental in equipping industry professionals, stakeholders, and upcoming generations of engineers with the skills and knowledge needed to adopt sustainable practices effectively. The incorporation of sustainable materials and technologies in university education and providing training and educational opportunities for the industry professionals and stakeholders can help address knowledge and skill gaps and promote the adoption of new practices [9,115,116].

Regulatory and policy reform: Governments and regulatory agencies can significantly advance sustainable concrete construction by revising building codes and standards, establishing regulations and requirements for essential materials and product characteristics, standardizing testing methodologies, offering guidelines for low-carbon concrete design and its integration with traditional concrete, facilitating research and development initiatives, providing incentives for the implementation of sustainable practices, and advocating for more stringent environmental regulations [9,113,114,115,116].

7. Conclusions

This paper has presented a current insight on eco-friendly concrete, highlighting various innovative alternatives for cementitious material, smart practices, and advanced technologies that enhance the sustainability of concrete construction. Key findings underscore the potential of eco-friendly concrete, the use of SCM, the incorporation of local waste-based materials and recycled materials in concrete, along with performance-enhancing additives. Additionally, innovative concrete solutions—such as high-performance concrete, self-healing concrete, and CCUS technologies—are discussed.