Enhancement of Mechanical Properties, Wettability, Roughness, and Thermal Insulation of Epoxy–Cement Composites for Building Construction

Abstract

1. Introduction

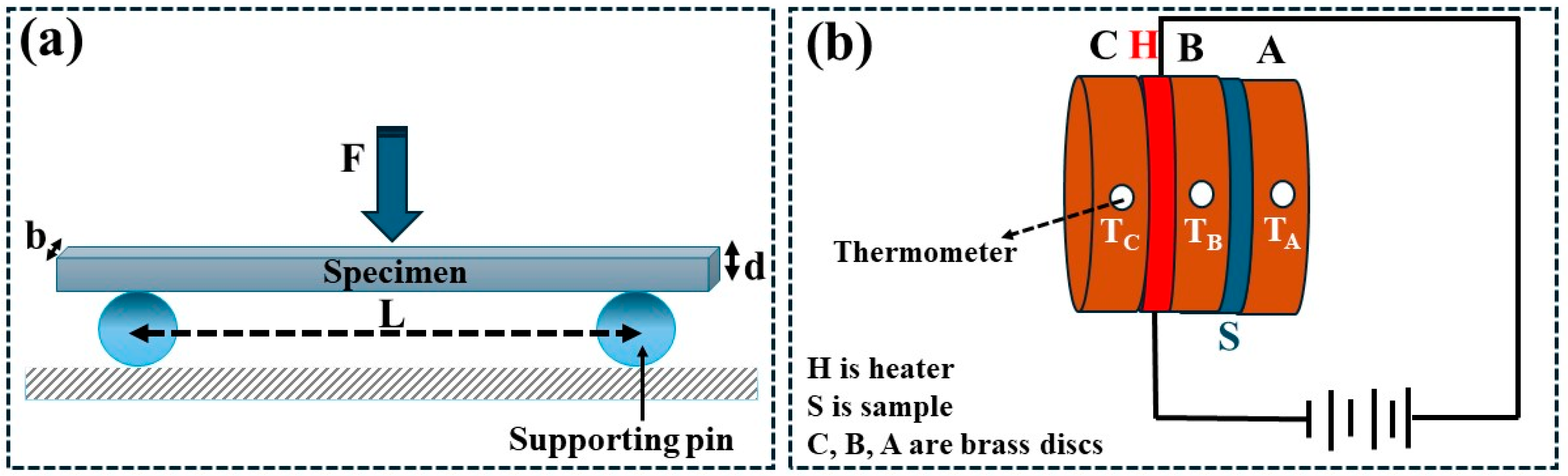

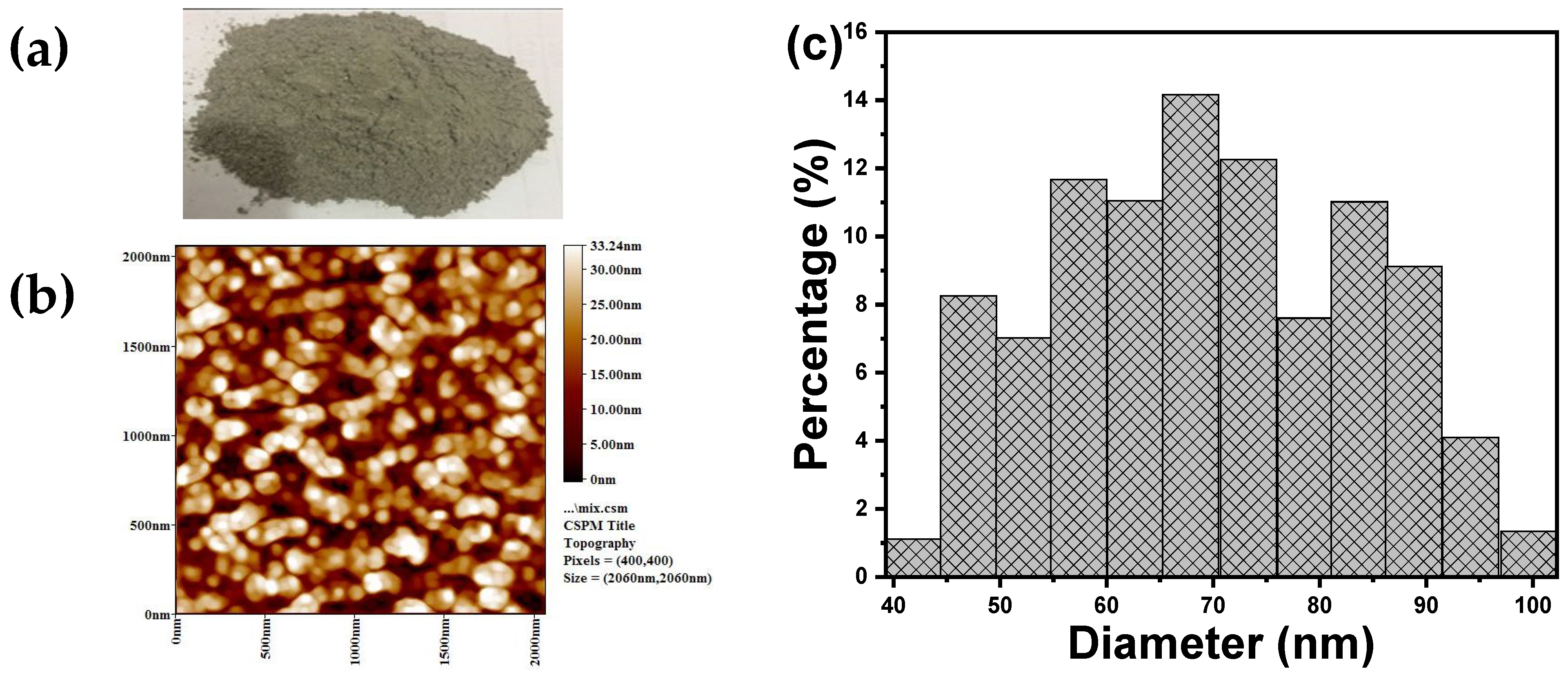

2. Materials and Methods

3. Results and Discussion

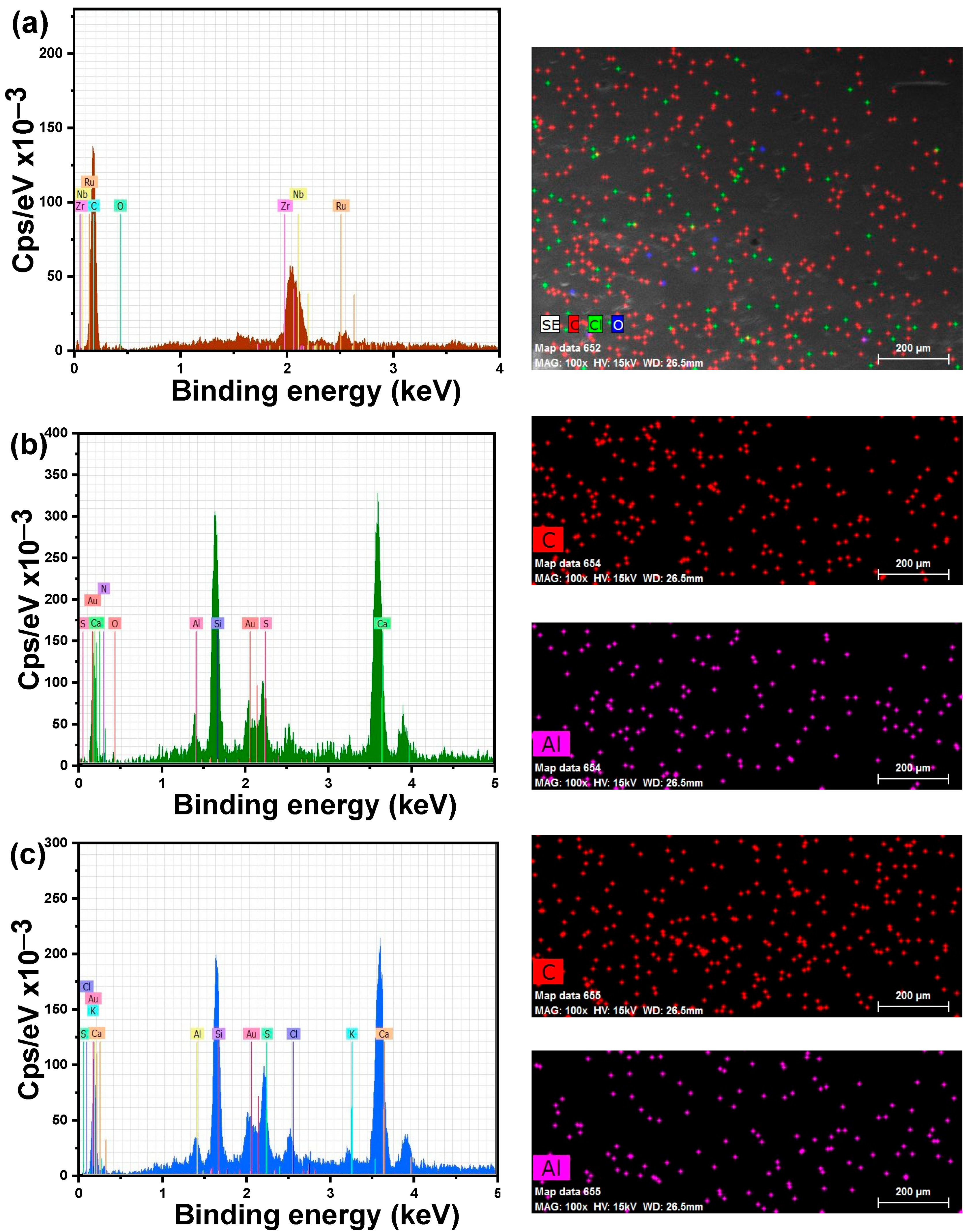

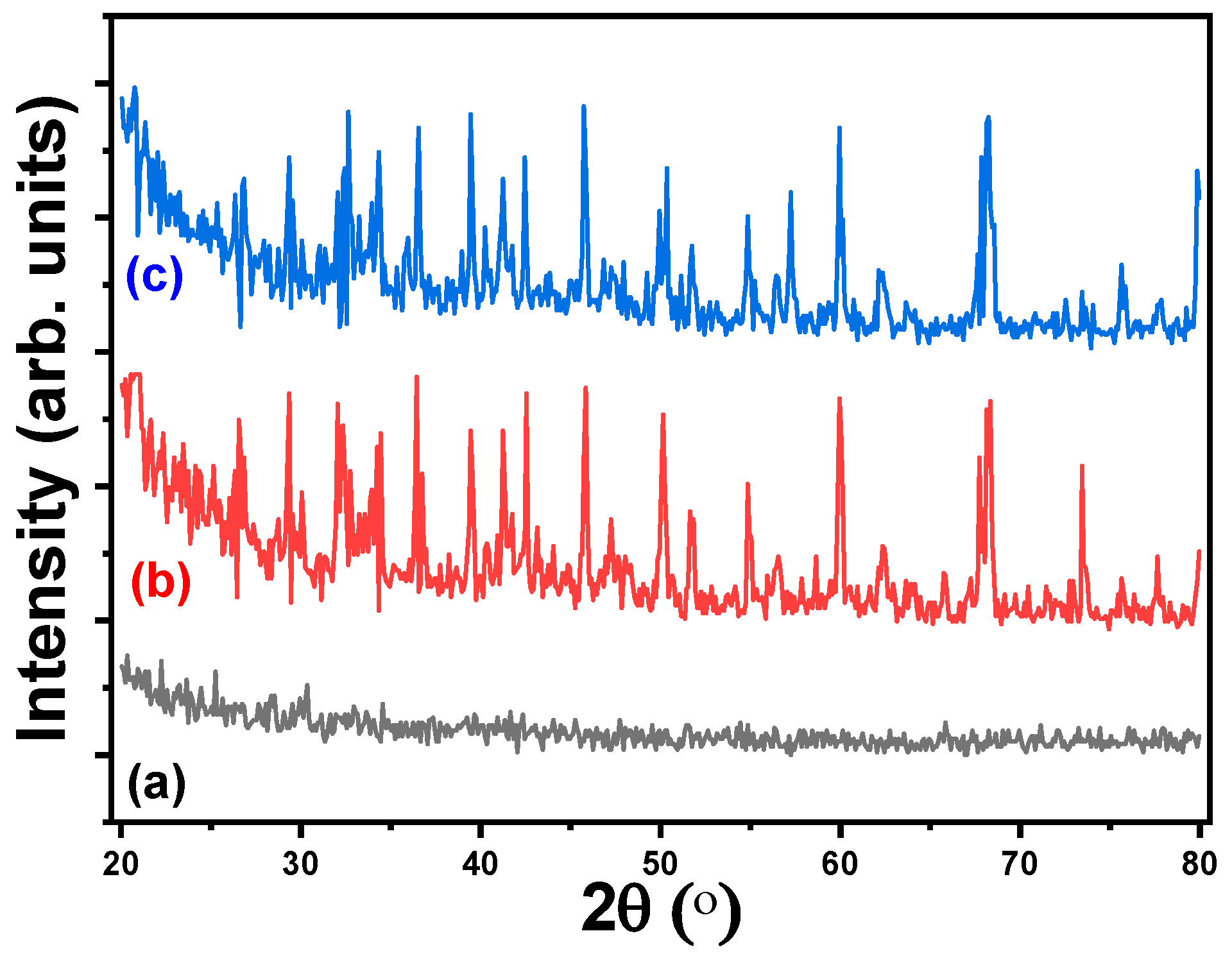

3.1. Structural Properties

3.2. Mechanical Properties

3.3. Thermal Conductivity

4. Conclusions

- The structure transitioned from amorphous (pure epoxy) to crystalline (epoxy–cement composites). Cement addition hindered crack propagation, with distinct interfaces between the cement and epoxy matrix visible.

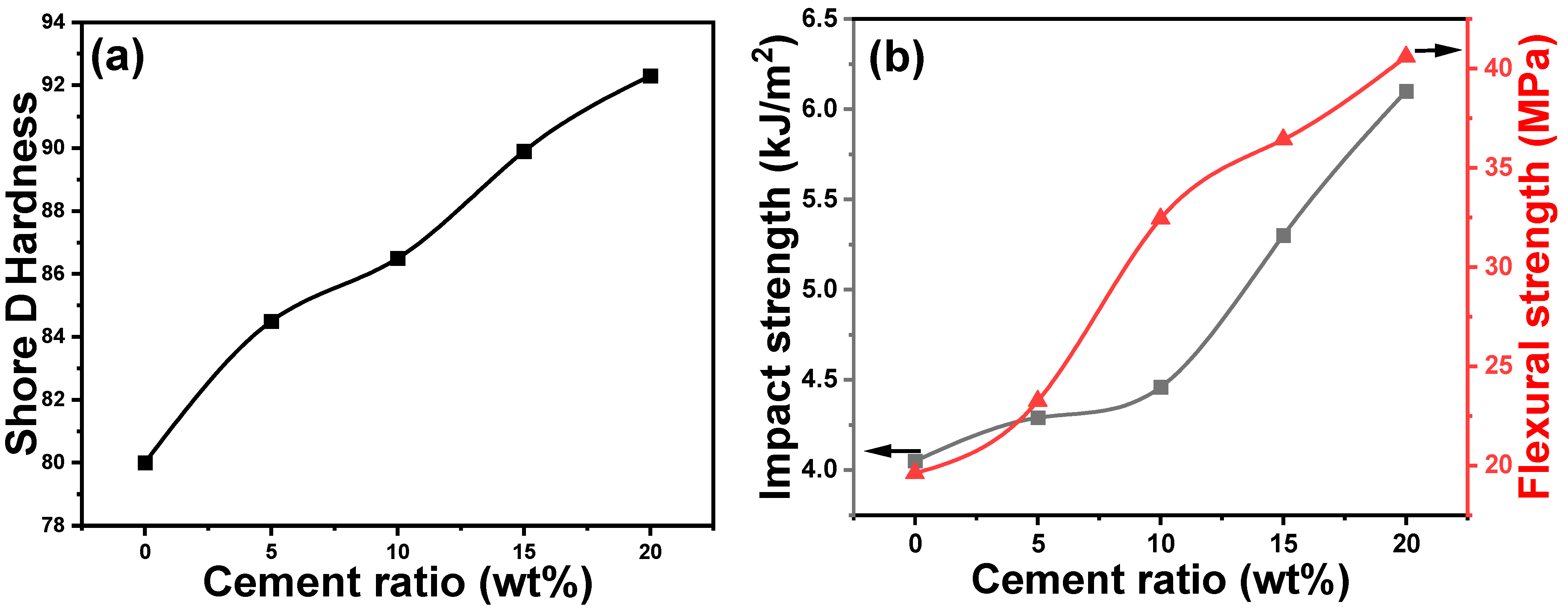

- Increasing the cement ratio up to 20 wt% led to gradual improvements in Shore D hardness, impact strength, flexural strength, and thermal insulation. The addition of fine cement fillers (up to 20 wt%) enhanced molecular compaction, improving mechanical resistance and thermal insulation by approximately four-fold compared to Portland cement concrete.

- The epoxy–cement blend exhibited excellent mechanical and thermal insulation properties, making it highly suitable for building construction applications. The incorporation of cement nanoparticles significantly improved the Shore D hardness, impact strength, and flexural strength of epoxy composites. These improvements make epoxy–cement composites suitable for structural applications in building construction, such as beams, columns, and coatings, where high mechanical performance is critical.

- The thermal conductivity of epoxy–cement composites decreased with increasing cement content, indicating enhanced thermal insulation. This property is beneficial for energy-efficient building materials, reducing heat transfer and improving energy savings.

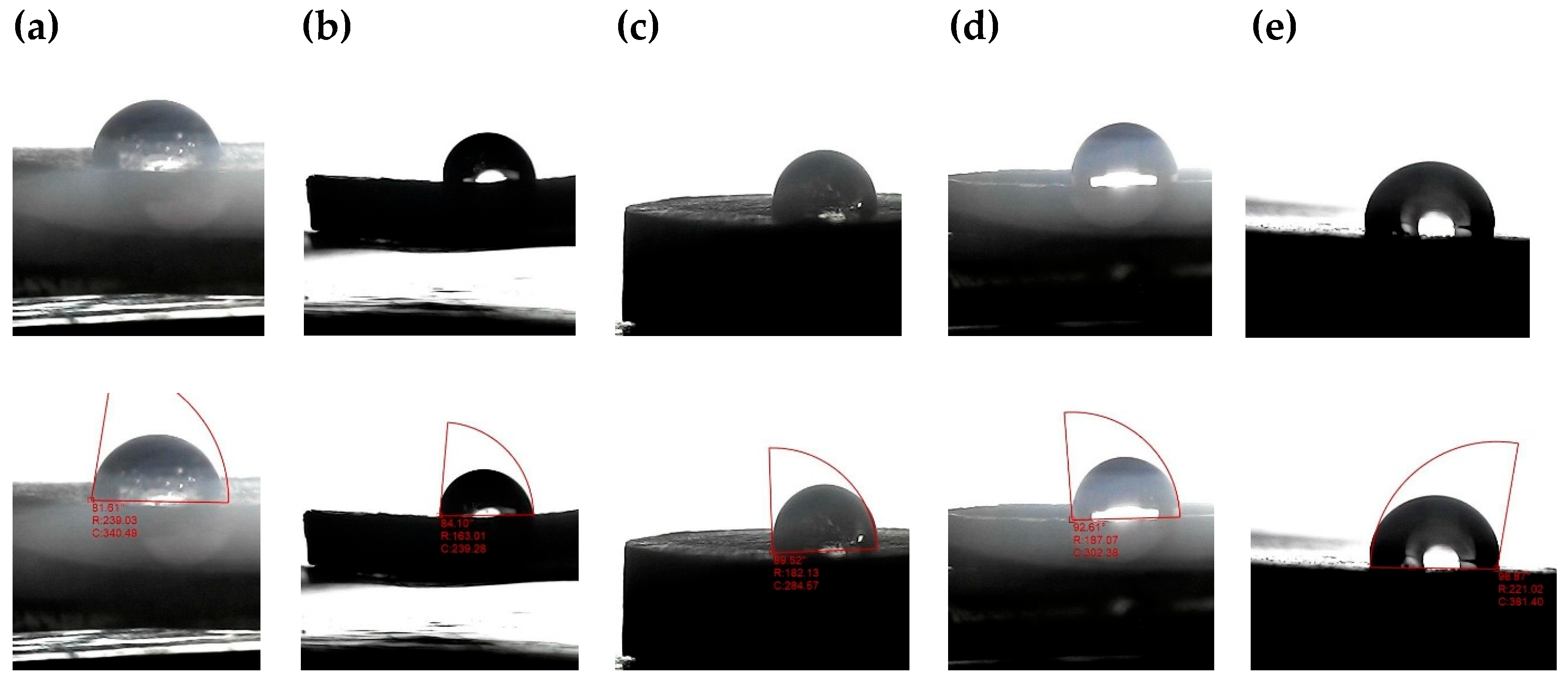

- The WCA increased with cement content, demonstrating improved hydrophobicity. The hydrophobic nature of the composites makes them ideal for water-resistant coatings, self-cleaning surfaces, and anti-corrosion applications in construction.

- SEM and EDS analysis confirmed the uniform dispersion of cement nanoparticles and strong interfacial adhesion with the epoxy matrix. This ensures the structural integrity and durability of the composites, making them reliable for long-term use in harsh environments.

- XRD analysis revealed a low-crystalline nature for epoxy–cement composites, with the formation of calcium silicate (Ca₃SiO₅) and hydration products. This microstructure contributes to the material’s mechanical and thermal properties, enhancing its overall performance.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rashad, M.; Abd-Elnaiem, A.M.; Hanafy, T.A.; Shaalan, N.M.; Shamekh, A.M.A. Optical properties of functional Al2O3 nano-filler in eco-friendly PVA polymer for flexible optoelectronic devices. Opt. Mater. 2023, 141, 113990. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, H.; Jia, Z.; Cao, R.; Xiong, Y.; Chen, C.; Zhang, Y. Thermal properties of amino-functionalized multi-walled carbon nanotubes reinforced epoxy-based transducers embedded in concrete. Cem. Concr. Compos. 2022, 127, 104411. [Google Scholar] [CrossRef]

- Lokuge, W.; Aravinthan, T. Effect of fly ash on the behaviour of polymer concrete with different types of resin. Mater. Des. 2013, 51, 175–181. [Google Scholar] [CrossRef]

- Prabakaran, E.; Kumar, D.V.; Jaganathan, A.; Kumar, P.A.; Veeerapathran, M. Analysis on Fiber Reinforced Epoxy Concrete Composite for Industrial Flooring–A Review. J. Phys. Conf. Ser. 2022, 2272, 012026. [Google Scholar] [CrossRef]

- Mercante, I.; Alejandrino, C.; Ojeda, J.P.; Chini, J.; Maroto, C.; Fajardo, N. Mortar and concrete composites with recycled plastic: A review. Sci. Technol. Mater. 2018, 30, 69–79. [Google Scholar] [CrossRef]

- Mohammed, T.; Rahmah, N.; Jawad, L. Thermal properties of nano-composites: A comparative study between epoxy/graphene and epoxy/CaCO3. J. Eng. Sci. Technol. 2023, 18, 424–436. [Google Scholar]

- Mohammed Ali, A.N.; Ali, N.A.; Hussein, S.I.; Hakamy, A.; Raffah, B.; Alofi, A.S.; Abd-Elnaiem, A.M. Nanoarchitectonics of silver/poly (methyl methacrylate) films: Structure, optical characteristics, antibacterial activity, and wettability. J. Inorg. Organomet. Polym. Mater. 2023, 33, 694–706. [Google Scholar] [CrossRef]

- Abd-Elnaiem, A.M.; Hussein, S.I.; Assaedi, H.S.; Mebed, A.M. Fabrication and evaluation of structural, thermal, mechanical and optical behavior of epoxy–TEOS/MWCNTs composites for solar cell covering. Polym. Bull. 2021, 78, 3995–4017. [Google Scholar] [CrossRef]

- Hassani Niaki, M.; Fereidoon, A.; Ghorbanzadeh Ahangari, M. Mechanical properties of epoxy/basalt polymer concrete: Experimental and analytical study. Struct. Concr. 2018, 19, 366–373. [Google Scholar] [CrossRef]

- Zeng, X.; Zhang, Z.; Pan, Y.; Zhang, Y.; Hou, L. Epoxy-based composites with enhanced thermal properties through collective effect of different particle size fillers. Polym. Polym. Compos. 2022, 30, 09673911221106686. [Google Scholar] [CrossRef]

- Benega, M.A.G.; Silva, T.F.; Santos, S.F. Improvements in thermal and mechanical properties of composites based on epoxy-carbon nanomaterials: A brief landscape. Polym. Test. 2021, 98, 107180. [Google Scholar] [CrossRef]

- Zhou, H.; Brooks, A.L. Thermal and mechanical properties of structural lightweight concrete containing lightweight aggregates and fly-ash cenospheres. Constr. Build. Mater. 2019, 198, 512–526. [Google Scholar] [CrossRef]

- Dagdag, O.; Benhiba, F.; Guenbour, A.; Bellaouchou, A.; Hajjaji, N.; Jama, C.; Zarrouk, A. Study on thermal conductivity and mechanical properties of cyclotriphosphazene resin-forced epoxy resin composites. Crystals 2023, 13, 478. [Google Scholar] [CrossRef]

- Ghazi, I.F.; Jaddan, R.I. Thermal conductivity characterization of epoxy-based composites reinforced with date palm waste particles. J. Phys. Conf. Ser. 2021, 1973, 012144. [Google Scholar] [CrossRef]

- Janjaroen, T.; Panitchanit, C.; Kaewthai, N.; Boonserm, K.; Sanawung, A.; Pakawanit, P. The mechanical and thermal properties of cement CAST mortar/graphene oxide composites materials. Int. J. Concr. Struct. Mater. 2022, 16, 34. [Google Scholar] [CrossRef]

- Colangelo, F.; Roviello, G.; Ricciotti, L.; Ferrandiz-Mas, V.; Messina, F.; Ferone, C.; Tarallo, O.; Cioffi, R.; Cheeseman, C.R. Mechanical and thermal properties of lightweight geopolymer composites. Cem. Concr. Compos. 2018, 86, 266–272. [Google Scholar] [CrossRef]

- Golestaneh, M.; Amini, G.; Najafpour, G.D.; Beygi, M.A. Evaluation of mechanical strength of epoxy polymer concrete with silica powder as filler. World Appl. Sci. J. 2010, 9, 216–220. [Google Scholar]

- Mao, L.; Barnett, S.J.; Tyas, A.; Warren, J.; Schleyer, G.K.; Zaini, S.S. Response of small-scale ultra-high performance fibre reinforced concrete slabs to blast loading. Constr. Build. Mater. 2015, 93, 822–830. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high-performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Wang, W.; Shen, A.; Lyu, Z.; He, Z.; Nguyen, K.T.Q. Fresh and rheological characteristics of fiber reinforced concrete—A review. Constr. Build. Mater. 2021, 296, 123734. [Google Scholar] [CrossRef]

- Shi, J.; Chen, D.; Yu, Z. Novel epoxy resin-bonded sand system: Mechanical strength, deterioration resistance, and failure mechanism. Eng. Fail. Anal. 2024, 158, 108020. [Google Scholar] [CrossRef]

- Hussein, S.I.; Abd-Elnaiem, A.M.; Asafa, T.B.; Jaafar, H.I. Effect of incorporation of conductive fillers on mechanical properties and thermal conductivity of epoxy resin composite. Appl. Phys. A 2018, 124, 475. [Google Scholar] [CrossRef]

- Elalaoui, O.; Ghorbel, E.; Mignot, V.; Ben Ouezdou, M. Mechanical and physical properties of epoxy polymer concrete after exposure to temperatures up to 250 °C. Constr. Build. Mater. 2012, 27, 415–424. [Google Scholar] [CrossRef]

- Abd-Elnaiem, A.M.; El-Aziz, M.A.; Hassan, A.I.; Shalaby, T.A.; Al-Kahtani, A.M. Ameliorating the mechanical parameters, thermal stability, and wettability of acrylic polymer by cement filling for high-efficiency waterproofing. Polymers 2022, 14, 4671. [Google Scholar] [CrossRef] [PubMed]

- Abd-Elnaiem, A.M.; El-Aziz, M.A.; Hassan, A.I.; Shalaby, T.A.; Al-Kahtani, A.M. Mechanical characteristics and thermal stability of hybrid epoxy and acrylic polymer coating/nanoclay of various thicknesses. J. Inorg. Organomet. Polym. Mater. 2022, 32, 2094–2102. [Google Scholar] [CrossRef]

- Sivasankar, S.; Dhal, L.; Gopalakrishnan, R.; Velrajkumar, G.; Jose, A. Strength and ductility of reinforced concrete using basalt fibre-reinforced polymers. Polym. Bull. 2024, 81, 6473–6493. [Google Scholar] [CrossRef]

- Wang, R.; Shi, X.X.; Wang, P.M. Recent research on polymer-modified cement mortar in China. Adv. Mater. Res. 2013, 687, 57–67. [Google Scholar] [CrossRef]

- Łukowski, P. Studies on the microstructure of epoxy-cement composites. Arch. Civ. Eng. 2016, 62, 101–113. [Google Scholar] [CrossRef]

- Song, Y.; Chunmei, Z.; Xiaowei, C.; Xiaoyang, G. Modification of toughness of oil well cement by plasma modified rock asphalt. Bull. Chin. Ceram. Soc. 2016, 35, 4082–4087. [Google Scholar] [CrossRef]

- Papanicolaou, G.C.; Anastasiou, D.E. Development of environmentally friendly epoxy and composite adhesives and applications in single and mixed-modulus joints. J. Adhes. Sci. Technol. 2021, 35, 1138–1153. [Google Scholar] [CrossRef]

- Ferrari, F.; Lotti, N.; Celli, A.; Bonetti, F.; D’Urso, L.; Malucelli, G. Fully recyclable bio-based epoxy formulations using epoxidized precursors from waste flour: Thermal and mechanical characterization. Polymers 2021, 13, 2768. [Google Scholar] [CrossRef] [PubMed]

- Ming, L.I.; Zhang, J.; Wang, H.; Liu, Y.; Xie, S. Mechanical properties of oil well cement stone reinforced with hybrid fiber of calcium carbonate whisker and carbon fiber. Petrol. Explor. Dev. 2015, 42, 104–111. [Google Scholar] [CrossRef]

- Chen, X.; Chen, S.; Xu, Z.; Zhang, J.; Miao, M.; Zhang, D. Degradable and recyclable bio-based thermoset epoxy resins. Green Chem. 2020, 22, 4187–4198. [Google Scholar] [CrossRef]

- Li, J.; Xie, J.; Liu, F.; Lu, Z. A Critical Review and Assessment for FRP-Concrete Bond Systems with Epoxy Resin Exposed to Chloride Environments. Compos. Struct. 2019, 229, 111372. [Google Scholar] [CrossRef]

- Chung, S.-L.; Lin, J.-S. Thermal conductivity of epoxy resin composites filled with combustion synthesized h-BN particles. Molecules 2016, 21, 670. [Google Scholar] [CrossRef]

- Jaafar, H.I. Effect of SiC particles and water absorption on thermal conductivity of epoxy reinforcement by (bi-directional) glass fiber. Iraqi J. Phys. 2011, 9, 13–17. [Google Scholar]

- Shen, D.; Zhan, Z.; Liu, Z.; Cao, Y.; Zhou, L.; Liu, Y.; Dai, W.; Zhang, Y. Enhanced thermal conductivity of epoxy composites filled with silicon carbide nanowires. Sci. Rep. 2017, 7, 2606. [Google Scholar] [CrossRef]

- Matlk, B.M.; Fahad, B.M.; Ghalib, L. Effect of epoxy addition on thermal conductivity, expansion, and permeability of cement mortar. J. Eng. Sustain. Dev. 2020, 24, 388–394. [Google Scholar] [CrossRef]

- Ali, N.A.; Aljohani, N.R.; Alshahrani, S.M.; Zaki, F.H.; Khan, A. Thermal and mechanical properties of epoxy resin functionalized copper and graphene hybrids using in-situ polymerization method. Curr. Nanosci. 2021, 17, 494–502. [Google Scholar] [CrossRef]

- Jiang, J.; Lu, Z.; Niu, Y.; Li, J. Investigation of the properties of high-porosity cement foams containing epoxy resin. Constr. Build. Mater. 2017, 154, 115–122. [Google Scholar] [CrossRef]

- Viapiana, R.; Smaniotto, A.; Martins, L.M.; Monteiro, M.G.; Parizotto, N.A.; Oliveira, P.T.; Petzhold, C.L. Chemical characterization and bioactivity of epoxy resin and Portland cement-based sealers with niobium and zirconium oxide radiopacifiers. Dent. Mater. 2014, 30, 1005–1020. [Google Scholar] [CrossRef] [PubMed]

- Sarathi, R.; Sahu, R.K.; Rajeshkumar, P. Understanding the thermal, mechanical and electrical properties of epoxy nanocomposites. Mater. Sci. Eng. A 2007, 445, 567–578. [Google Scholar] [CrossRef]

- Ranella, A.; Barberoglou, M.; Bakogianni, S.; Fotakis, C.; Stratakis, E. Tuning cell adhesion by controlling the roughness and wettability of 3D micro/nano silicon structures. Acta Biomater. 2010, 6, 2711–2720. [Google Scholar] [CrossRef] [PubMed]

- Conradi, M.; Kocijan, A. Fine-tuning of surface properties of dual-size TiO2 nanoparticle coatings. Surf. Coat. Technol. 2016, 304, 486–491. [Google Scholar] [CrossRef]

- Wassmann, T.; Seitz, M.; Müller, P.; Winter, M.; Dvorak, J.; Moser, J.; Hellwig, E. The influence of surface texture and wettability on initial bacterial adhesion on titanium and zirconium oxide dental implants. Int. J. Implant Dent. 2017, 3, 32. [Google Scholar] [CrossRef] [PubMed]

- Dowling, D.P.; Miller, I.S.; Ardhaoui, M.; Gallagher, W.M. Effect of surface wettability and topography on the adhesion of osteosarcoma cells on plasma-modified polystyrene. J. Biomater. Appl. 2011, 26, 327–334. [Google Scholar] [CrossRef]

- Sarathi, R.; Sahu, R.K.; Tanaka, T. Understanding the hydrophobic characteristics of epoxy nanocomposites using wavelets and fractal technique. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 178–186. [Google Scholar] [CrossRef]

- Zavrl, E.; El Mankibi, M.; Dovjak, M.; Stritih, U. Enhancing performance of building elements with phase change materials for cooling with air-based systems. J. Energy Storage 2022, 51, 104461. [Google Scholar] [CrossRef]

- Daghash, S.M.; Soliman, E.M.; Kandil, U.F.; Taha, M.M.R. Improving impact resistance of polymer concrete using CNTs. Int. J. Concr. Struct. Mater. 2016, 10, 539–553. [Google Scholar] [CrossRef]

- Ary Subagia, I.D.G.; Kim, Y. A study on flexural properties of carbon-basalt/epoxy hybrid composites. J. Mech. Sci. Technol. 2013, 27, 987–992. [Google Scholar] [CrossRef]

- Raju, G.U.; Gaitonde, V.N.; Kumarappa, S. Experimental study on optimization of thermal properties of groundnut shell particle reinforced polymer composites. Int. J. Emerg. Sci. 2012, 2, 433–454. [Google Scholar] [CrossRef]

- ElSafty, A.; Abdel-Mohti, A. Investigation of likelihood of cracking in reinforced concrete bridge decks. Int. J. Concr. Struct. Mater. 2013, 7, 79–93. [Google Scholar] [CrossRef]

- Greco, A.; Esposito Corcione, C.; Maffezzoli, A. Effect of multi-scale diffusion on the permeability behavior of intercalated nanocomposites. J. Membr. Sci. 2016, 505, 92–99. [Google Scholar] [CrossRef]

- Jo, Y.K.; Do, J. Hardening properties of epoxy-modified cement composites without hardener. Polymers Polymer Compos. 2016, 24, 195–204. [Google Scholar] [CrossRef]

- Doumeng, M.; Makhlouf, L.; Berthet, F.; Marsan, O.; Delbé, K.; Denape, J.; Chabert, F. A comparative study of the crystallinity of polyetheretherketone by using density, DSC, XRD, and Raman spectroscopy techniques. Polym. Test. 2021, 93, 106878. [Google Scholar] [CrossRef]

- Seo, Y.; Kim, S.-M. Longitudinal cracking at transverse joints caused by dowel bars in Jointed Concrete Pavements. KSCE J. Civ. Eng. 2013, 17, 395–402. [Google Scholar] [CrossRef]

- Li, Y.; Guo, Y.; Lyu, Z.; Wei, X. Investigation of the effect of waterborne epoxy resins on the hydration kinetics and performance of cement blends. Constr. Build. Mater. 2021, 301, 124045. [Google Scholar] [CrossRef]

- Reis, J.M.L. Fracture and flexural assessment of red mud in epoxy polymer mortars. Mater. Struct. 2015, 48, 3929–3936. [Google Scholar] [CrossRef]

- Shen, F.; Huang, S.; Sun, Z.; Ding, Q. Research on Hardening Mechanism of Cement-Emulsified Asphalt-Epoxy Resin. Adv. Mater. Res. 2012, 430–432, 434–437. [Google Scholar] [CrossRef]

- Sasaki, I.; Nishizaki, I. Study on the durability of surface coating materials for concrete structures. City 2008, 305, 8516. [Google Scholar]

- Zhong, W.; Wu, Y. Influence of damage degree on self-healing of concrete. Constr. Build. Mater. 2008, 22, 1137–1142. [Google Scholar] [CrossRef]

- Peiyu, Y.; Lei, Y.; Dan, D.; Yuwei, L. Effect of epoxy resin on the hydration and mechanical property of oil well cement stone. Bull. Chin. Ceram. Soc. 2016, 35, 2019–2023. [Google Scholar] [CrossRef]

- Rajab, M.A.; Kader, E.I.; Hammod, A.A.; Hameed, A.H.I. Mechanical properties (Tensile, Hardness, and Shock resistance) for the phenol formaldehyde resin with epoxy resin. Diyala J. Eng. Sci. 2019, 15, 35–43. [Google Scholar] [CrossRef]

- Girimurugan, R.; Pugazhenthi, R.; Maheskumar, P.; Suresh, T.; Vairavel, M. Impact and hardness behaviour of epoxy resin matrix composites reinforced with banana fiber/camellia sinensis particles. Mater. Today Proc. 2021, 39, 373–377. [Google Scholar] [CrossRef]

- Siva, R.; Kesavaram, B.; Martin, J.J.; Mathiselvan, G.; Navas, K.B.; Sangeetha, M. Mechanical behavior of sisal and banana fiber reinforced hybrid epoxy composites. Mater. Today Proc. 2021, 44, 3692–3696. [Google Scholar] [CrossRef]

- Smirnov, S.; Konovalov, D.; Veretennikova, I.; Pestov, A.; Smirnova, E. Effect of modifying dopes on the mechanical properties of epoxy coatings affected by thermocycling. Procedia Struct. Integr. 2020, 25, 209–213. [Google Scholar] [CrossRef]

- Oleiwi, J.K.; Abass, B.A. Thermal Properties of Polymeric Composites Reinforced by Nanoceramic Materials. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 517–524. [Google Scholar] [CrossRef]

- Edaan, G.E. Measurement of Thermal Conductivity of Epoxy Resin Reinforced With Different Weight Ratios of Glass and Carbon Powders. Al-Bahir J. Eng. Pure Sci. 2023, 3, 5. [Google Scholar] [CrossRef]

- Suarsana, K.; Putra Negara, D.N.K.; Suryawan, I. Properties of Thermal Conductivity Hybrid Epoxy Resin Composite Reinforced Natural Fiber as Alternative Insulator Material. Teknik 2023, 43, 264–271. [Google Scholar] [CrossRef]

- Pi, Z.; Xiao, H.; Du, J.; Liu, M.; Li, H. Interfacial microstructure and bond strength of nano-SiO2-coated steel fibers in cement matrix. Cem. Concr. Compos. 2019, 103, 1–10. [Google Scholar] [CrossRef]

- Dos Santos, V.; Tonoli, G.H.D.; Marmol, G.; Savastano, H., Jr. Fiber-cement composites hydrated with carbonated water: Effect on physical-mechanical properties. Cem. Concr. Res. 2019, 124, 105812. [Google Scholar] [CrossRef]

- Kocijan, A.; Conradi, M.; Hočevar, M. The Influence of Surface Wettability and Topography on the Bioactivity of TiO2/Epoxy Coatings on AISI 316L Stainless Steel. Materials 2019, 12, 1877. [Google Scholar] [CrossRef]

- Petrik, P.; Biró, L.P.; Fried, M.; Lohner, T.; Berger, R.; Schneider, C.; Gyulai, J.; Ryssel, H. Comparative Study of Surface Roughness Measured on Polysilicon Using Spectroscopic Ellipsometry and Atomic Force Microscopy. Thin Solid Film. 1998, 315, 186–191. [Google Scholar] [CrossRef]

- Al-Shomar, S.M.; Barakat, M.A.Y.; Abdallah, A.W. Ellipsometric and ultrasonic studies of nano titanium dioxide specimens doped with Erbium. Mater. Res. Express 2020, 7, 106413. [Google Scholar] [CrossRef]

- Khalil, N.Z.; Johanne, M.F.; Ishak, M. Influence of Al2O3 nanoreinforcement on the adhesion and thermomechanical properties for epoxy adhesive. Compos. Part B Eng. 2019, 172, 9–15. [Google Scholar] [CrossRef]

- Hill, D.; Barron, A.R.; Alexander, S. Comparison of hydrophobicity and durability of functionalized aluminum oxide nanoparticle coatings with magnetite nanoparticles–links between morphology and wettability. J. Colloid Interface Sci. 2019, 555, 323–330. [Google Scholar] [CrossRef]

- Jadhav, A.; Pawar, A.; Hwang, T.R.; Lee, J.W.; Choi, M.W.; Kim, B.K.; Kang, Y.S. Wavelength conversion using rare earth doped oxides in polyolefin based nanocomposite films. Polym. Int. 2012, 61, 943–950. [Google Scholar] [CrossRef]

- Kennedy, S.B.; Washburn, N.R.; Simon, C.G., Jr.; Amis, E.J. Combinatorial screen of the effect of surface energy on fibronectin-mediated osteoblast adhesion, spreading and proliferation. Biomaterials 2006, 27, 3817–3824. [Google Scholar] [CrossRef]

- Ashley, K.M.; Raghavan, D.; Douglas, J.F.; Karim, A. Wetting−Dewetting Transition Line in Thin Polymer Films. Langmuir 2005, 21, 10297–10305. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, E.J.; Kim, D.H.; Jeong, M.-G.; Kim, Y.D. Superhydrophobic surfaces with photo-catalytic activity under UV and visible light irradiation. Catal. Today 2016, 260, 32–38. [Google Scholar] [CrossRef]

- Mohsin, M.M.; Ali, F.H. Enhancement of pigments hydrophobicity by mixing with Cr doped SiO2 nanoparticles. Chem. Methodol. 2023, 7, 335–347. [Google Scholar] [CrossRef]

- Syakur, A.; Sutanto, H. Determination of hydrophobic contact angle of epoxy resin compound silicon rubber and silica. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; Volume 190, p. 012025. [Google Scholar] [CrossRef]

- Lafuma, A.; Quéré, D. Superhydrophobic states. Nat. Mater. 2003, 2, 457–460. [Google Scholar] [CrossRef] [PubMed]

- Pinto, D.; Amaro, A.M.; Bernardo, L. Experimental study on the surface properties of nanoalumina-filled epoxy resin nanocomposites. Appl. Sci. 2020, 10, 733. [Google Scholar] [CrossRef]

- Daniel, A.; Islam, M.R.; Sumdani, M.G.; Firouzi, A. Influence of Hydration on the Mechanical, Structural, Thermal, and Morphological Properties of Cement-Filled Epoxy Composites. J. Vinyl Addit. Technol. 2020, 26, 527–538. [Google Scholar] [CrossRef]

| Element | Pure Epoxy | Epoxy-5 wt% Cement | Epoxy-20 wt% Cement | |||

|---|---|---|---|---|---|---|

| wt% | at.% | wt% | at.% | wt% | at.% | |

| C | 68.56 | 93.25 | 14.87 | 50.51 | 12.97 | 47.93 |

| Zr | 14.46 | 2.59 | - | - | - | - |

| Nb | 12.30 | 2.16 | - | - | - | - |

| Ru | 3.23 | 0.52 | - | - | 4.47 | 1.96 |

| O | 1.45 | 1.48 | - | - | - | - |

| Sb | - | - | 31.93 | 10.70 | 24.82 | 9.04 |

| Rb | - | - | 25.65 | 12.24 | 18.88 | 9.80 |

| Ca | - | - | 10.88 | 11.07 | 9.04 | 10.01 |

| Mo | - | - | 8.59 | 3.65 | 12.19 | 5.64 |

| Si | - | - | 6.18 | 8.98 | 5.74 | 9.07 |

| Al | - | - | 1.89 | 2.85 | 1.95 | 3.21 |

| Pt | - | - | - | - | 8.76 | 1.99 |

| K | - | - | - | - | 1.18 | 1.34 |

| Samples | Roughness (μm) | WCA (°) | γ (Dyne/cm) |

|---|---|---|---|

| Epoxy | 2.71 | 81.61 | 32.09 |

| Epoxy + 5 wt% cement | 3.54 | 84.10 | 30.41 |

| Epoxy + 10 wt% cement | 5.10 | 89.52 | 26.69 |

| Epoxy + 15 wt% cement | 5.84 | 92.61 | 25.67 |

| Epoxy + 20 wt% cement | 6.21 | 98.87 | 20.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasim, S.M.; Ali, N.A.; Hussein, S.I.; Al Bahir, A.; Abd EL-Gawaad, N.S.; Sedky, A.; Mebed, A.M.; Abd-Elnaiem, A.M. Enhancement of Mechanical Properties, Wettability, Roughness, and Thermal Insulation of Epoxy–Cement Composites for Building Construction. Buildings 2025, 15, 643. https://doi.org/10.3390/buildings15040643

Jasim SM, Ali NA, Hussein SI, Al Bahir A, Abd EL-Gawaad NS, Sedky A, Mebed AM, Abd-Elnaiem AM. Enhancement of Mechanical Properties, Wettability, Roughness, and Thermal Insulation of Epoxy–Cement Composites for Building Construction. Buildings. 2025; 15(4):643. https://doi.org/10.3390/buildings15040643

Chicago/Turabian StyleJasim, Saif M., Nadia A. Ali, Seenaa I. Hussein, Areej Al Bahir, Nashaat S. Abd EL-Gawaad, Ahmed Sedky, Abdelazim M. Mebed, and Alaa M. Abd-Elnaiem. 2025. "Enhancement of Mechanical Properties, Wettability, Roughness, and Thermal Insulation of Epoxy–Cement Composites for Building Construction" Buildings 15, no. 4: 643. https://doi.org/10.3390/buildings15040643

APA StyleJasim, S. M., Ali, N. A., Hussein, S. I., Al Bahir, A., Abd EL-Gawaad, N. S., Sedky, A., Mebed, A. M., & Abd-Elnaiem, A. M. (2025). Enhancement of Mechanical Properties, Wettability, Roughness, and Thermal Insulation of Epoxy–Cement Composites for Building Construction. Buildings, 15(4), 643. https://doi.org/10.3390/buildings15040643