Evaluating the Impact of Insulation Materials on Energy Efficiency Using BIM-Based Simulation for Existing Building Retrofits: Case Study of an Apartment Building in Kanazawa, Japan

Abstract

1. Introduction

2. Literature Review

2.1. Utilization of Building Information Modeling to Enhance Building Energy Efficiency

2.2. Building Insulation Material for Energy Efficiency

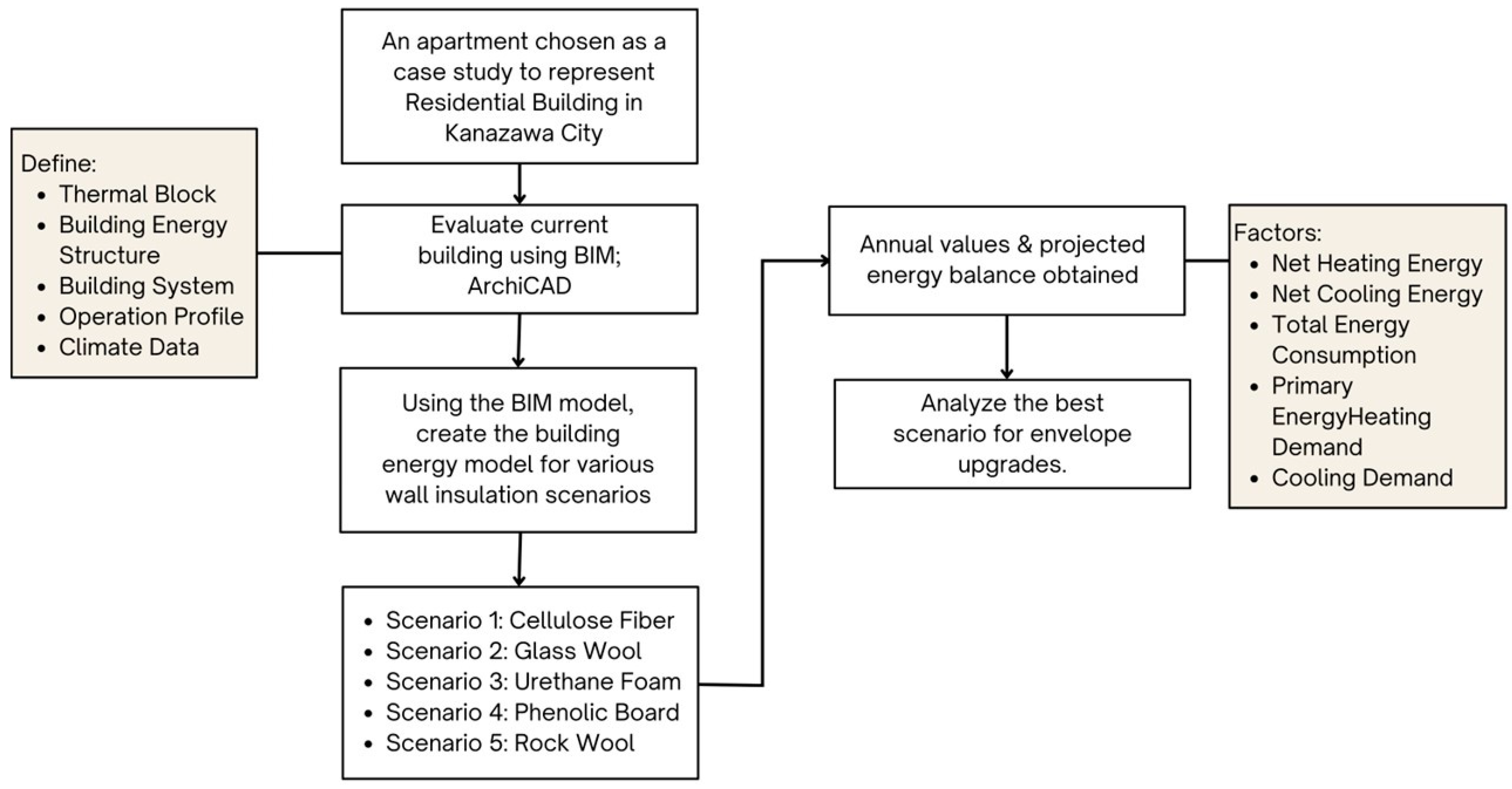

3. Methodology

4. Case Study in Japan

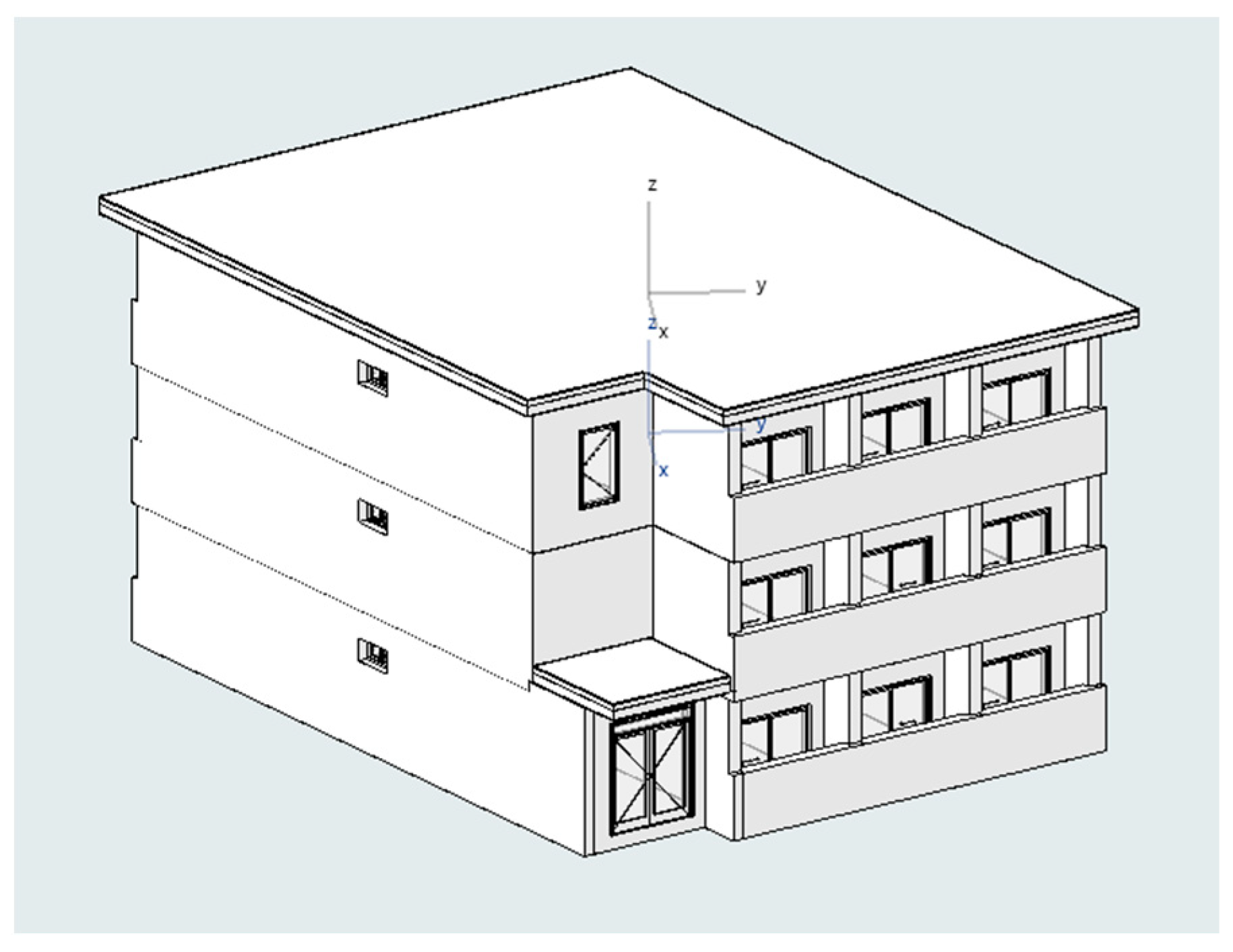

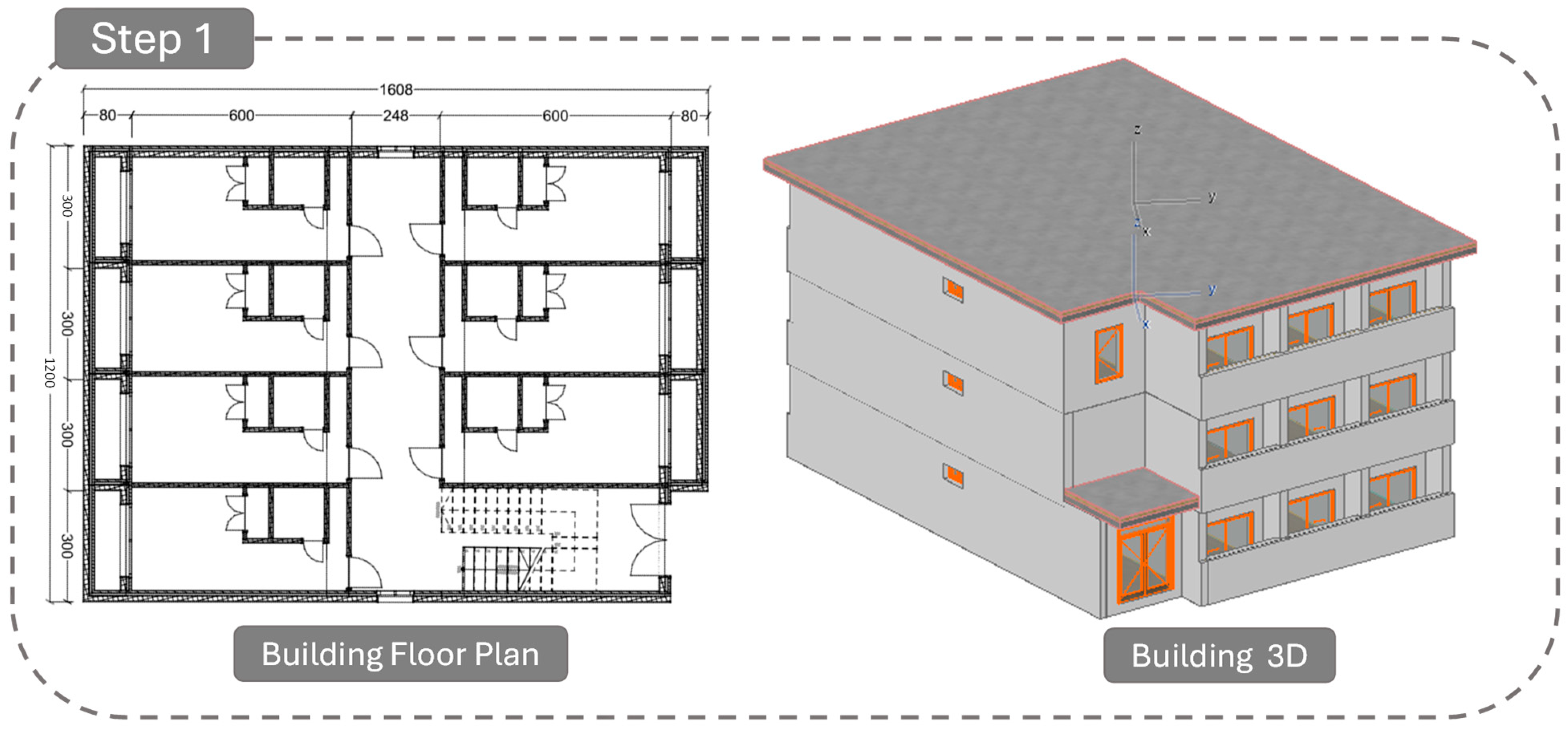

4.1. Overview of the Case Study Building

4.2. Scenario Setting for Simulation

5. BIM Energy Simulation

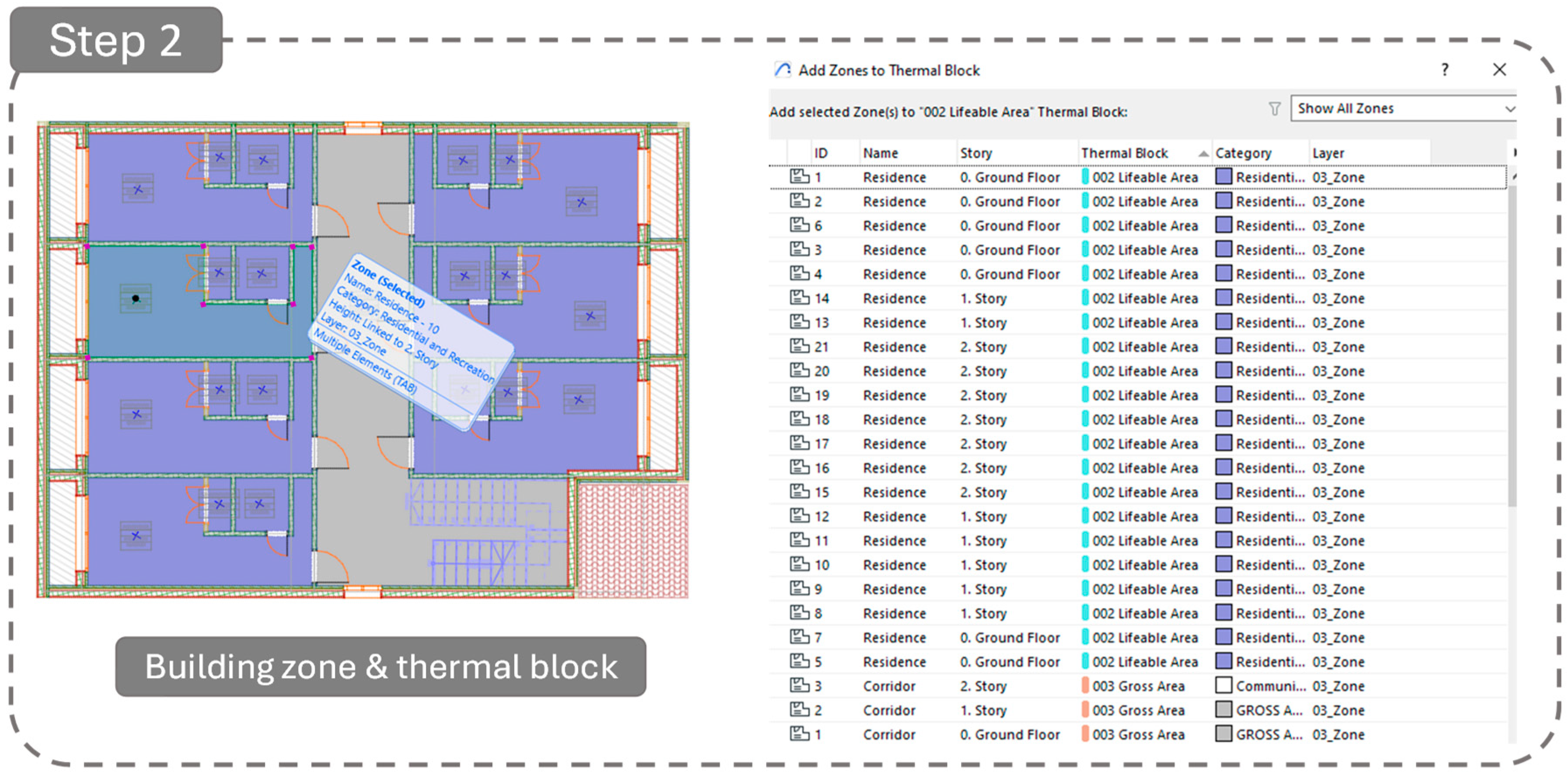

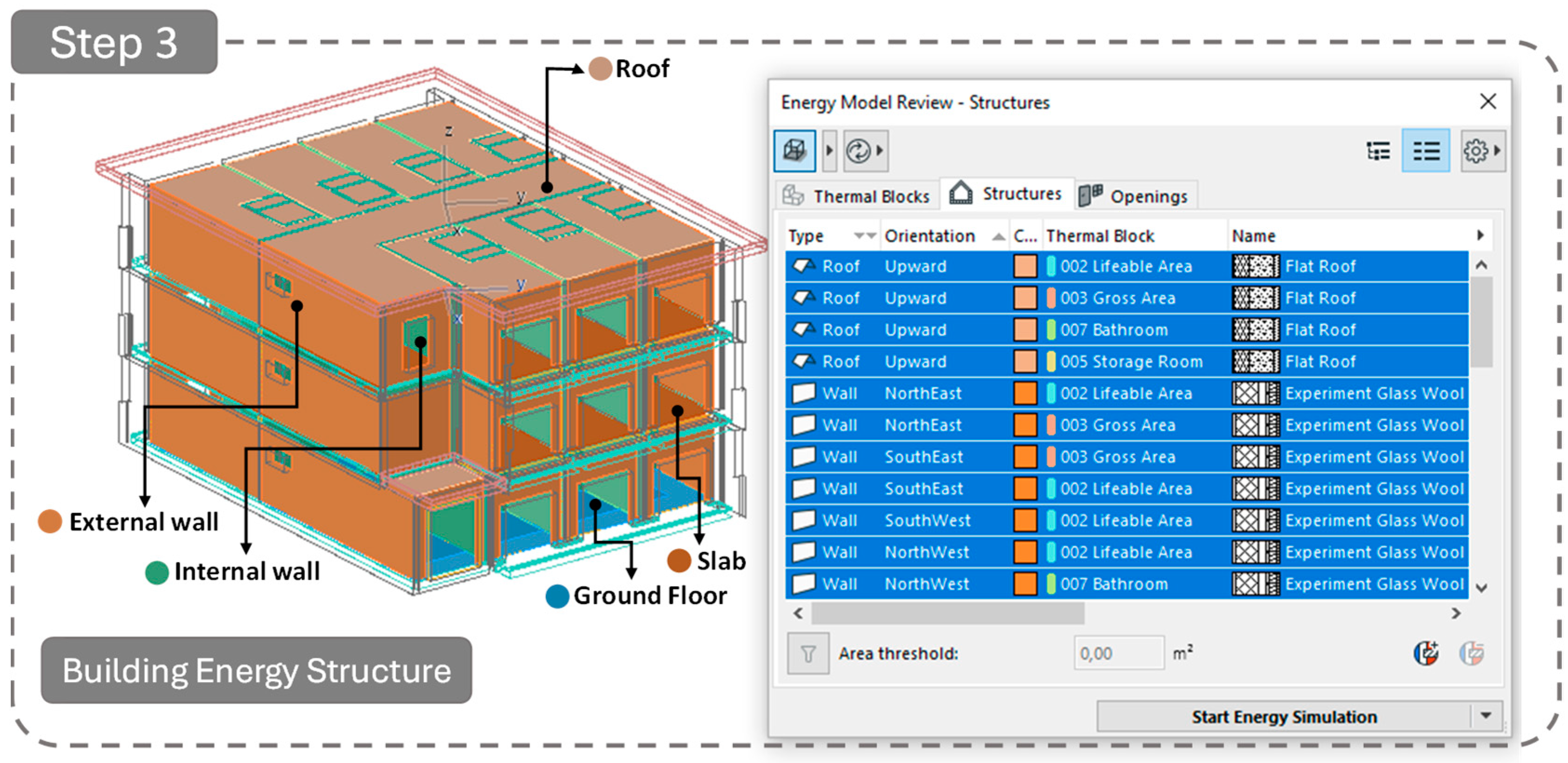

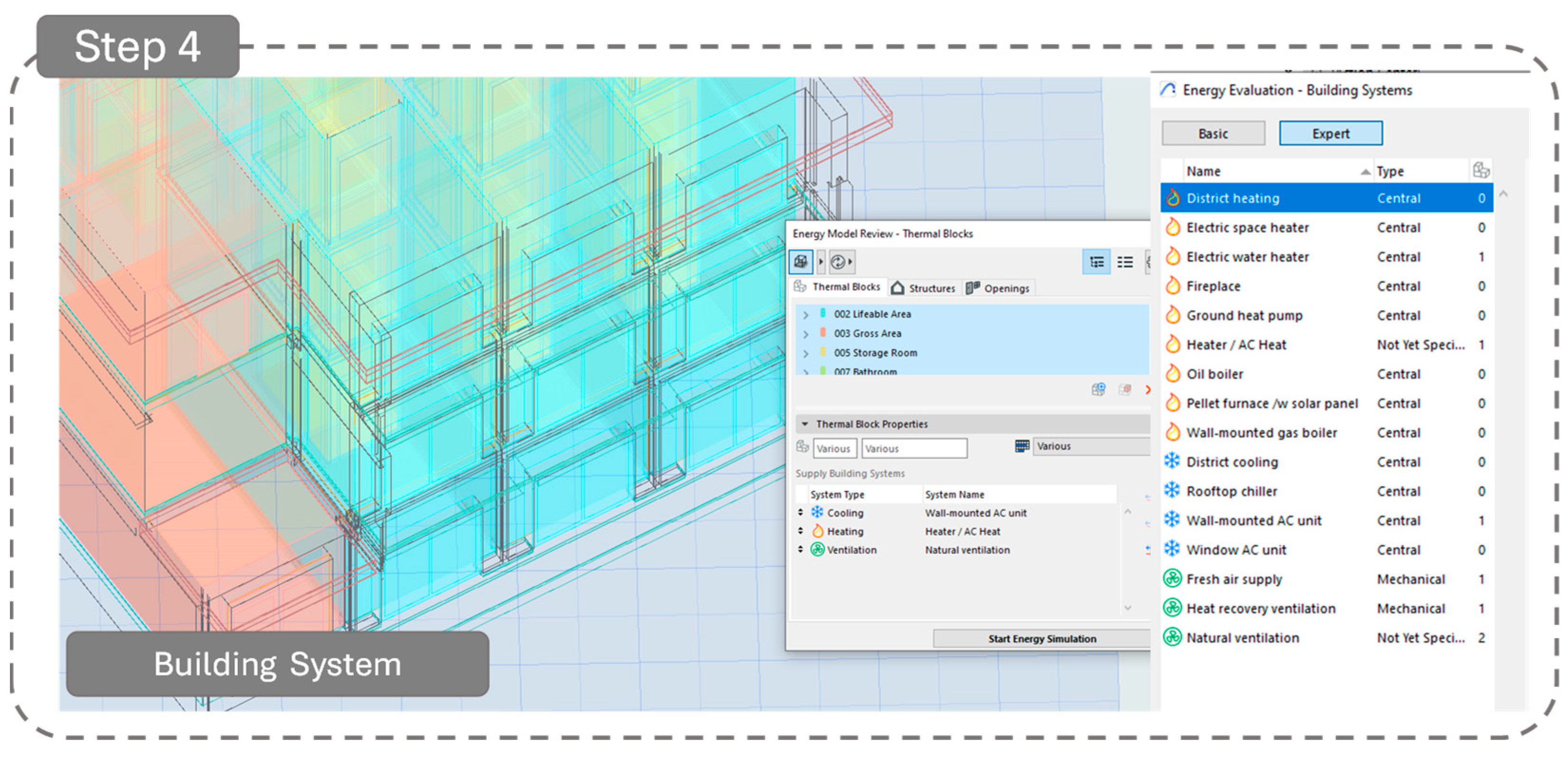

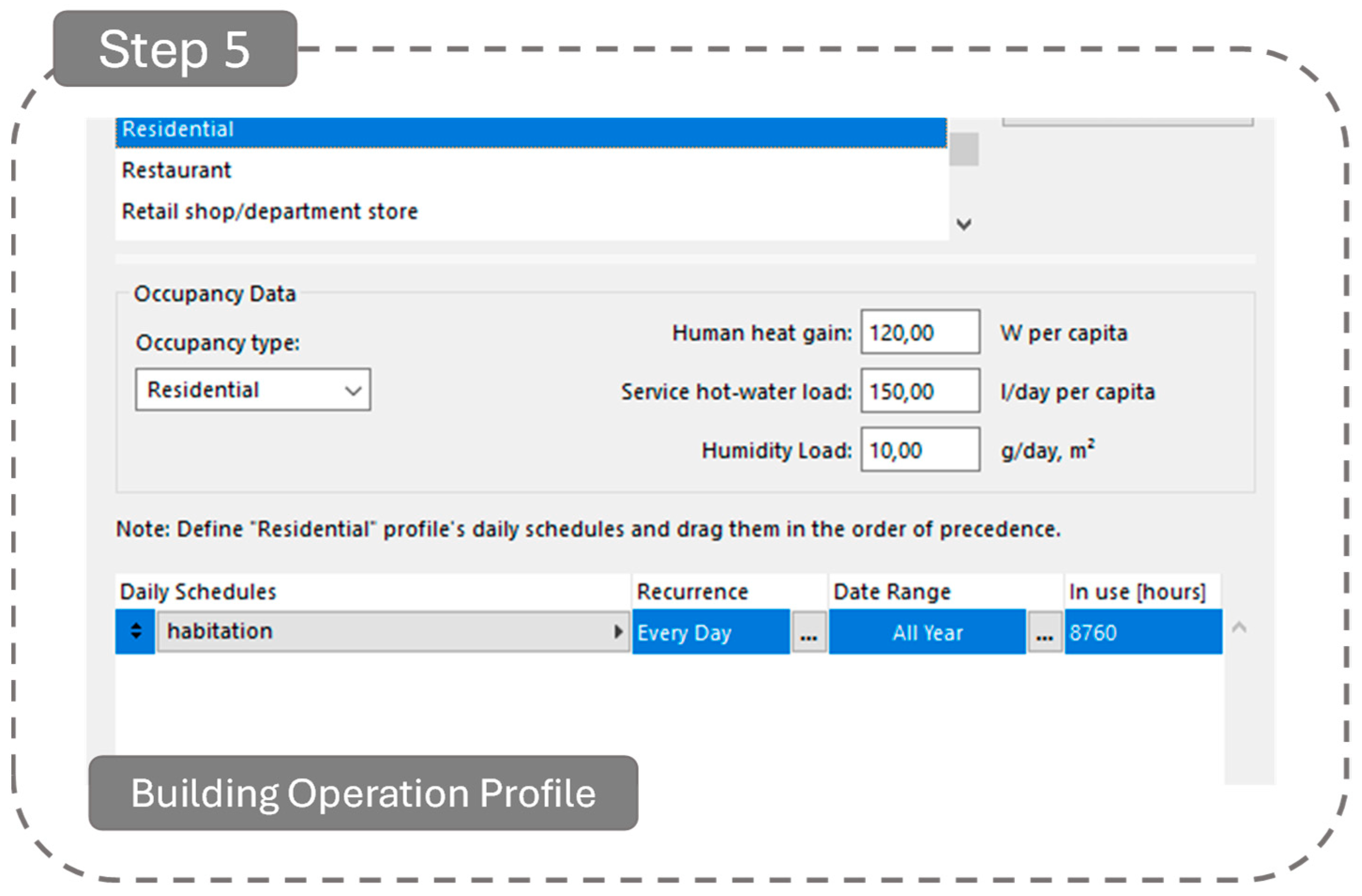

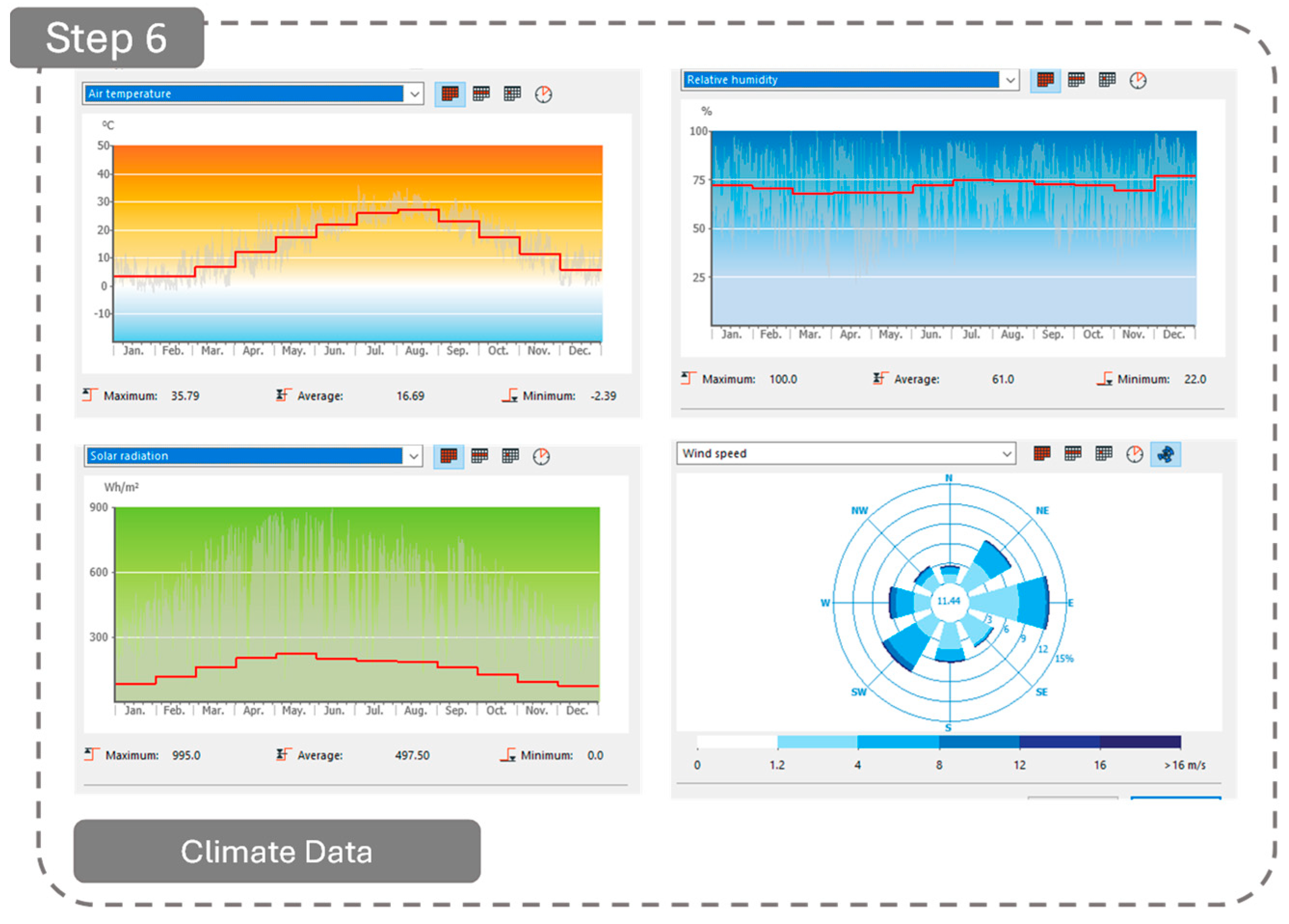

5.1. BIM-Based Building Energy Simulation Steps

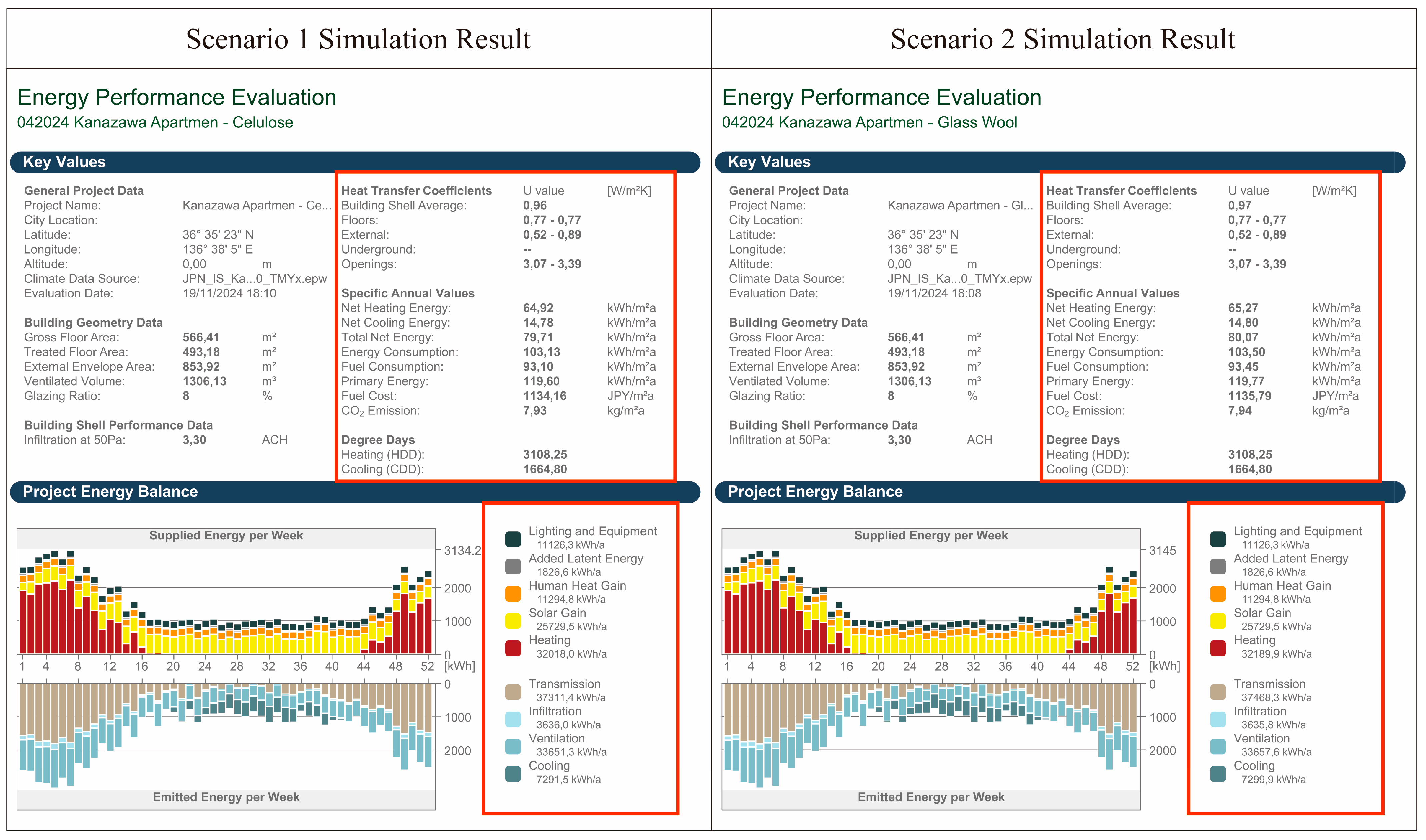

5.2. Energy Performance Evaluation and Simulation Results

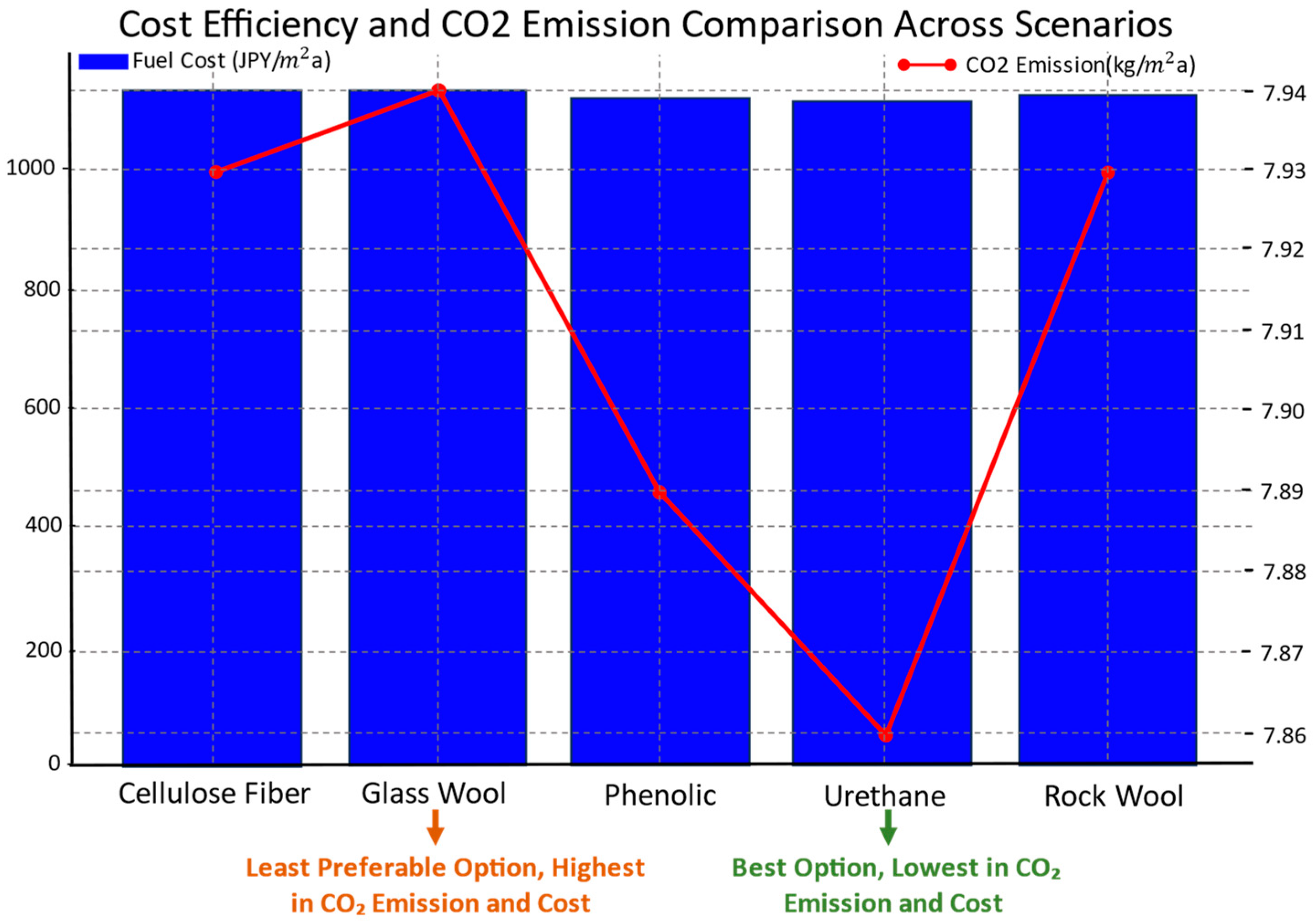

6. Comparative Analysis of Insulation Materials: Energy Efficiency, Cost, and Carbon Emissions

6.1. Simulation Results and Performance Overview

6.2. Energy Efficiency Factor

6.3. Cost Efficiency Consideration

6.4. Carbon Emission Factor

6.5. Material Selection Considering Energy Efficiency, Cost, and CO2 Emission

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akram, M.W.; Zublie, M.F.M.; Hasanuzzaman, M.; Rahim, N.A. Global Prospects, Advance Technologies and Policies of Energy-Saving and Sustainable Building Systems: A Review. Sustainability 2022, 14, 1316. [Google Scholar] [CrossRef]

- Kuwahara, R.; Kim, H.; Sato, H. Evaluation of Zero-Energy Building and Use of Renewable Energy in Renovated Buildings: A Case Study in Japan. Buildings 2022, 12, 561. [Google Scholar] [CrossRef]

- Rauschen, M.; Ikaga, T.; Thomas, S.; Hoshi, H.; Karwatzki, J.; Winterseel, B. Energy Efficiency in Buildings, Particularly for Heating and Cooling; Wuppertal Institute for Climate, Environment and Energy: Wuppertal, Germany, 2020. [Google Scholar]

- Sharma, S.K.; Mohapatra, S.; Sharma, R.C.; Alturjman, S.; Altrjman, C.; Mostarda, L.; Stephan, T. Retrofitting Existing Buildings to Improve Energy Performance. Sustainability 2022, 14, 666. [Google Scholar] [CrossRef]

- Gardezi, S.S.S.; Haris Ali, S.H.; Fayaz, R.; Shah, H.H. Energy Performance Analysis of a Multi-Story Building Using Building Information Modeling (BIM). J. Sustain. Perspect. 2022, 2, 16–23. [Google Scholar] [CrossRef]

- Del Ama Gonzalo, F.; Moreno Santamaría, B.; Montero Burgos, M.J. Assessment of Building Energy Simulation Tools to Predict Heating and Cooling Energy Consumption at Early Design Stages. Sustainability 2023, 15, 1920. [Google Scholar] [CrossRef]

- Teng, X.; Shen, Z.; Xixi, W.; Tri, N. Pre-evaluation and visual simulation of energy consumption influencing factors of smart and healthy architecture in the design stage. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: London, UK, 2023. [Google Scholar]

- Teng, X.; Shen, Z. Design of a smart visiting service management system for personal information collection in order to integrate tourism management into an isolated island. Appl. Sci. 2020, 10, 6442. [Google Scholar] [CrossRef]

- Truong, N.S.; Luong, D.L.; Nguyen, Q.T. BIM to BEM Transition for Optimizing Envelope Design Selection to Enhance Building Energy Efficiency and Cost-Effectiveness. Energies 2023, 16, 3976. [Google Scholar] [CrossRef]

- Chen, Z.S.; Yang, L.P.; Rodríguez, R.M.; Zhu, Z.; Pedrycz, W.; Skibniewski, M.J. BIM-aided large-scale group decision support: Optimization of the retrofit strategy for existing buildings. Appl. Soft Comput. 2022, 131, 109790. [Google Scholar] [CrossRef]

- Yildirim, M.; Polat, H. Building Information Modeling Applications in Energy-Efficient Refurbishment of Existing Building Stock: A Case Study. Sustainability 2023, 15, 13600. [Google Scholar] [CrossRef]

- Dauletbek, A.; Zhou, P. BIM-based LCA as a comprehensive method for the refurbishment of existing dwellings considering environmental compatibility, energy efficiency, and profitability: A case study in China. J. Build. Eng. 2022, 46, 103852. [Google Scholar] [CrossRef]

- Khan, A.M.; Tariq, M.A.; Alam, Z.; Alaloul, W.S.; Waqar, A. Optimizing energy efficiency through building orientation and building information modelling (BIM) in diverse terrains: A case study in Pakistan. Energy 2024, 311, 133307. [Google Scholar] [CrossRef]

- González, J.; Figueiredo, K.; Hammad, A.W.A.; Tam, V.W.Y.; Haddad, A.N.; Illankoon, C. Heritage BIM (HBIM) applied in emergency scenarios: A case study of the National Museum in Brazil. Int. J. Constr. Manag. 2024, 1–15. [Google Scholar] [CrossRef]

- Hmidah, N.A.; Bin Haron, N.A.; Hizami, A.A.; Law, T.H.; Altohami, A.B.A. Energy Consumption of Retrofitting Existing Public Buildings in Malaysia under BIM Approach: Pilot Study. Sustainability 2023, 15, 10293. [Google Scholar] [CrossRef]

- Dolzhencko, A.V.; Grebenik, A.V.; Sedashova, M.A.; Rudenskyi, D.S. Expanding the capabilities of the ARCHICAD software package for effective solution of construction design tasks. In Journal of Physics: Conference Series; IOP Publishing Ltd.: Bristol, UK, 2021. [Google Scholar]

- Ali, S.B.M.; Mehdipoor, A.; Samsina Johari, N.; Hasanuzzaman, M.; Rahim, N.A. Modeling and Performance Analysis for High-Rise Building Using ArchiCAD: Initiatives towards Energy-Efficient Building. Sustainability 2022, 14, 9780. [Google Scholar] [CrossRef]

- Fitriaty, P.; Shen, Z. Predicting energy generation from residential building attached Photovoltaic Cells in a tropical area using 3D modeling analysis. J. Clean. Prod. 2018, 195, 1422–1436. [Google Scholar] [CrossRef]

- Rashid, F.L.; Dulaimi, A.; Hatem, W.A.; Al-Obaidi, M.A.; Ameen, A.; Eleiwi, M.A.; Jawad, S.A.; Bernardo, L.F.A.; Hu, J.W. Recent Advances and Developments in Phase Change Materials in High-Temperature Building Envelopes: A Review of Solutions and Challenges. Buildings 2024, 14, 1582. [Google Scholar] [CrossRef]

- Riantini, L.S.; Machfudiyanto, R.A.; Rachmawati, T.S.N.; Rachman, M.D.A.; Fachrizal, R.; Shadram, F. Energy Efficiency Analysis of Building Envelope Renovation and Photovoltaic System in a High-Rise Hotel Building in Indonesia. Buildings 2024, 14, 1646. [Google Scholar] [CrossRef]

- Nasrollahzadeh, N. Comprehensive building envelope optimization: Improving energy, daylight, and thermal comfort performance of the dwelling unit. J. Build. Eng. 2021, 44, 103418. [Google Scholar] [CrossRef]

- Rijal, H.B.; Yoshida, K.; Humphreys, M.A.; Nicol, J.F. Development of an adaptive thermal comfort model for energy-saving building design in Japan. Archit. Sci. Rev. 2021, 64, 109–122. [Google Scholar] [CrossRef]

- Lakatos, Á. Novel Thermal Insulation Materials for Buildings. Energies 2022, 15, 6713. [Google Scholar] [CrossRef]

- Kumar, D.; Alam, M.; Zou, P.X.W.; Sanjayan, J.G.; Memon, R.A. Comparative analysis of building insulation material properties and performance. Renew. Sustain. Energy Rev. 2020, 131, 110038. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Hwang, J.; Kim, Y.; Park, J.; Rie, D. A Study on the Evaluation of Thermal Insulation Performance of Cellulose-Based Silica Aerogel Composite Building Materials. Polymers 2024, 16, 1848. [Google Scholar] [CrossRef] [PubMed]

- Dai, H.; Gao, H.; Yang, P.; Mo, J.; Zhang, H.; Lei, S.; Wang, L. Thermal insulation performance of rock wool reinforced kaolinite-based porous geopolymer. Appl. Clay Sci. 2023, 246, 107176. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Song, Z.; Lei, Y.; Ran, W.; Yuan, M.; Shang, S.; Cui, S. Structural properties and barrier performance of low-cost aerogel composites for building insulation. J. Build. Eng. 2024, 90, 109485. [Google Scholar] [CrossRef]

- ANSI/ASHRAE Standard 140-2007; Standard Method of Test for the Evaluation of Building Energy Analysis Computer Programs (Addendum C). ASHRAE: Atlanta, GA, USA, 2011.

- Kanazawa City Open Data Portal: Housing Construction Methods [Proportion] National Census. Available online: https://portal-data.city.kanazawa.ishikawa.jp/ (accessed on 8 January 2025).

- Shimoda, Y.; Sugiyama, M.; Nishimoto, R.; Momonoki, T. Evaluating decarbonization scenarios and energy management requirement for the residential sector in Japan through bottom-up simulations of energy end-use demand in 2050. Appl. Energy 2021, 303, 117510. [Google Scholar] [CrossRef]

- Huyen Nguyen, T.; Take, K.; Take, K. Reviewing of the net-zero energy buildings and housings in Japan. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: London, UK, 2024. [Google Scholar]

- General Incorporated Association for the Promotion of Wood Utilization in Architecture: FY 2023 (Reiwa 5) Ministry of Land, Infrastructure, Transport and Tourism (MLIT) Subsidy Project: Energy-Saving Design and Construction for Housing [Regions 4-7 Edition] [Revised] Compliance with the 2016 Energy Efficiency Standards. 2024. Available online: https://www.mlit.go.jp/jutakukentiku/house/04.html (accessed on 21 November 2024).

- Ministry of Land, Infrastructure, Transport and Tourism. Insulation Renovation of Openings, Criteria for Applicable Construction Works. Available online: https://kosodate-ecohome.mlit.go.jp/material/ (accessed on 17 October 2024).

- ANSI/ASHRAE Standard 140-2017; Standard Method of Test for the Evaluation of Building Energy Analysis Computer Programs. ANSI: Washington, DC, USA, 2017.

- Vycital, M.; Jarský, C. N automated nD model creation on BIM models. Organ. Technol. Manag. Constr. 2020, 12, 2218–2231. [Google Scholar] [CrossRef]

- Muhaxheri, K.; Muhaxheri, B.B. Impact of U-Values in Evaluation of Implemented Energy Efficiency Measures and Energy Savings in Public Buildings in Context of Kosovo Legislation. WSEAS Trans. Environ. Dev. 2023, 19, 11–24. [Google Scholar] [CrossRef]

- Bass, B.; Ezell, E.; New, J. Using Measured Building Energy Data to Infer Building Characteristics for Urban Building Energy Modeling. In Proceedings of the 2022 Building Performance Analysis Conference and SimBuild, Chicago, IL, USA, 14–16 September 2022. [Google Scholar]

- Otsuka, A. Industrial electricity consumption efficiency and energy policy in Japan. Util. Policy 2023, 81, 101519. [Google Scholar] [CrossRef]

- Sustainable Open Innovation Initiative: ZEH Information ZEH (Detached House) Case Study Search Tool Fiscal Year 2024. Available online: https://zehweb.jp/zehinfo/example/ (accessed on 20 January 2025).

- Institute for Built Environment and Carbon Neutral for SDGs: LCCM Housing Certification. Available online: https://www.ibecs.or.jp/rating/lccm.html (accessed on 20 January 2025).

- Khan, S.A.; Alam, T.; Khan, M.S.; Blecich, P.; Kamal, M.A.; Gupta, N.K.; Yadav, A.S. Life Cycle Assessment of Embodied Carbon in Buildings: Background, Approaches and Advancements. Buildings 2022, 12, 1944. [Google Scholar] [CrossRef]

- Meng, Q.; Hu, L.; Li, M.; Qi, X. Assessing the environmental impact of building life cycle: A carbon reduction strategy through innovative design, intelligent construction, and secondary utilization. Dev. Built Environ. 2023, 16, 100230. [Google Scholar] [CrossRef]

- Seo, M.S.; Kim, T.; Hong, G.; Kim, H. On-Site measurements of CO2 emissions during the construction phase of a building complex. Energies 2016, 9, 599. [Google Scholar] [CrossRef]

- Zhan, Z.; Xia, P.; Xia, D. Study on Carbon Emission Measurement and Influencing Factors for Prefabricated Buildings at the Materialization Stage Based on LCA. Sustainability 2023, 15, 13648. [Google Scholar] [CrossRef]

- Hertwich, E.G. Increased carbon footprint of materials production driven by rise in investments. Nat. Geosci. 2021, 14, 151–155. [Google Scholar] [CrossRef]

| Category | Details | Materials |

|---|---|---|

| By Material |

| Glass Wool, Rock Wool |

| Rigid Urethane Foam, extruded polystyrene foam | |

| By Form and Application |

|

|

|

| |

|

| |

| By Permeability |

|

|

|

| |

| Rigid Urethane Foam under JIS A 9526 |

| Scenario | Material | Properties | ||||

|---|---|---|---|---|---|---|

| Thermal Conductivity (W/mK) | Density (kg/m3) | Heat Capacity (J/kgK) | Embodied Energy (MJ/kg) | Embodied Carbon (kgCO2/kg) | ||

| Scenario 1 | Cellulose Fiber | 0.04 | 50,000 | 2500 | 14.7 | 1.12 |

| Scenario 2 | Glass Wool | 0.045 | 13,000 | 1500 | 40.1 | 1.6 |

| Scenario 3 | Urethane Foam | 0.021 | 32,000 | 1450 | 102.1 | 4.84 |

| Scenario 4 | Phenolic Board | 0.028 | 24,000 | 1450 | 102.1 | 4.84 |

| Scenario 5 | Rock Wool | 0.04 | 60,000 | 840 | 16.8 | 0.84 |

| Scenario | Net Heating Energy (kWh/m2a) | Net Cooling Energy (kWh/m2a) | Total Energy Consumption (kWh/m2a) | Primary Energy (kWh/m2a) | Fuel Cost (JPY/m2a) | CO2 Emissions (kg/m2a) |

|---|---|---|---|---|---|---|

| Cellulose Fiber | 64.92 | 14.78 | 103.13 | 119.6 | 1134.16 | 7.93 |

| Glass Wool | 65.27 | 14.8 | 103.5 | 119.77 | 1135.79 | 7.94 |

| Urethane Foam | 62.8 | 14.68 | 100.9 | 118.58 | 1124.19 | 7.86 |

| Phenolic Board | 63.78 | 14.73 | 101.94 | 119.06 | 1128.81 | 7.89 |

| Rock Wool | 64.92 | 14.78 | 103.13 | 119.6 | 1134.16 | 7.93 |

| Web Data | Building Type | Insulation Type | Primary Energy Reduction Rate | Simulation Result Performance Ranking |

|---|---|---|---|---|

| Case Study 1 | 2-story building | Glass Wool | 21% | 4 |

| Case Study 2 | 2-story building | Glass Wool | 26% | 4 |

| Case Study 3 | 2-story building | Phenolic foam | 27% | 2 |

| Case Study 4 | 2-story building | Phenolic foam | 32% | 2 |

| Case Study 5 | 2-story building | Phenolic foam | 38% | 2 |

| Case Study 6 | 2-story building | Rockwool | 26% | 3 |

| Case Study 7 | 2-story building | Sprayed Rigid Urethane foam | 26% | 1 |

| Case Study 8 | 2-story building | Sprayed Rigid Urethane foam | 37% | 1 |

| Case Study 9 | 2-story building | Sprayed Rigid Urethane foam | 40% | 1 |

| Type | Material | Feature |

|---|---|---|

| Low Cost | Glass Wool, Rock Wool, Cellulose Fiber | Basic performance, affordable initial cost, requires maintenance for moisture control for installment, and considered as a shorter lifespan. |

| Moderate Cost | Combination of Fiber-based material and Foam Based material | Moderate performance and cost: the use of mixed materials should incorporate the existing building conditions to determine which materials are best suited for specific parts of the building. |

| High Cost | Urethane foam and Phenolic board | High performance with high initial cost, ideal for prioritizing long-term efficiency with high durability and seamless installation. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teng, X.; Shen, Z.; Tutuko, D.C.S. Evaluating the Impact of Insulation Materials on Energy Efficiency Using BIM-Based Simulation for Existing Building Retrofits: Case Study of an Apartment Building in Kanazawa, Japan. Buildings 2025, 15, 570. https://doi.org/10.3390/buildings15040570

Teng X, Shen Z, Tutuko DCS. Evaluating the Impact of Insulation Materials on Energy Efficiency Using BIM-Based Simulation for Existing Building Retrofits: Case Study of an Apartment Building in Kanazawa, Japan. Buildings. 2025; 15(4):570. https://doi.org/10.3390/buildings15040570

Chicago/Turabian StyleTeng, Xiao, Zhenjiang Shen, and Dara Citra Saraswati Tutuko. 2025. "Evaluating the Impact of Insulation Materials on Energy Efficiency Using BIM-Based Simulation for Existing Building Retrofits: Case Study of an Apartment Building in Kanazawa, Japan" Buildings 15, no. 4: 570. https://doi.org/10.3390/buildings15040570

APA StyleTeng, X., Shen, Z., & Tutuko, D. C. S. (2025). Evaluating the Impact of Insulation Materials on Energy Efficiency Using BIM-Based Simulation for Existing Building Retrofits: Case Study of an Apartment Building in Kanazawa, Japan. Buildings, 15(4), 570. https://doi.org/10.3390/buildings15040570