1. Introduction

The rapid development of the global construction industry presents significant challenges to traditional building methods. Many conventional designs often neglect energy efficiency and sustainability, failing to consider the effective utilization of resources [

1,

2]. Consequently, this oversight results in excessive energy consumption and substantial carbon emissions during the lifespan of these buildings, placing an additional burden on the environment. Furthermore, traditional construction typically employs non-environmentally friendly materials and outdated techniques, which exacerbate high energy consumption and contribute to considerable carbon footprints on construction sites. Additionally, traditional design models tend to be relatively inflexible, lacking the adaptability and innovation necessary to address the rapidly evolving demands of contemporary society and technological advancements [

3,

4]. In response to these challenges, prefabricated construction has emerged as a promising alternative, garnering increasing attention. This method employs factory-produced components that facilitate rapid assembly on-site, significantly reducing construction timelines while enhancing component quality control in the manufacturing phase [

5,

6]. Consequently, prefabricated buildings improve construction quality and efficiency, positioning themselves as a viable solution to the array of challenges posed by traditional building practices.

The composite slab is a crucial building component that plays an essential role in prefabricated construction. It exhibits high strength, excellent integrity, and a significant degree of prefabrication [

7,

8,

9], making it extensively utilized in various construction projects, particularly in scenarios requiring substantial lateral load resistance. As a horizontal element, the composite slab not only enhances the structural stability of buildings but also accelerates construction processes and improves economic efficiency. The fundamental components of the composite slab consist of a prefabricated base slab, a concrete topping layer, and an embedded steel reinforcement framework. The incorporation of a prefabricated base slab effectively reduces construction time while enhancing quality; the concrete topping layer further bolsters the integrity and load-bearing capacity of the component; and the embedded steel reinforcement framework significantly increases the tensile strength of the composite slab, thereby enhancing its overall structural performance.

Despite the advancements in composite slab technology, several shortcomings persist. In terms of flexural performance, particularly in the design of large-span structures, the flexural capacity of composite slabs often fails to meet the requisite engineering standards. Due to their structural form and material characteristics, composite slabs struggle to withstand increased bending stresses as span lengths increase, resulting in excessive deflection. This limitation curtails their applicability in projects requiring significant spans. In comparison to ideal floor structures, composite slabs demonstrate relatively inadequate flexural stiffness. When subjected to loads, they are often unable to effectively resist bending deformation, which compromises the overall stability of the structure. From an economic perspective, the design and construction of reinforced truss composite slabs entail substantial steel consumption. The extensive use of steel not only inflates material costs, which constitute a significant portion of building project expenditures but also diminishes the project’s competitiveness. Increased steel consumption corresponds to greater component weight, introducing numerous practical challenges during construction. These challenges include the need for larger equipment and additional manpower for handling and lifting, thereby increasing construction complexity and duration, and placing higher load-bearing demands on structural elements, such as foundations. This ultimately contributes to elevated foundational infrastructure costs. Regarding stability and safety, reinforced truss composite slabs exhibit considerable instability risks during load transfer. Due to their structural characteristics and force mechanisms, localized or global instability can easily manifest when loads reach critical levels or are unevenly distributed, potentially initiating a chain reaction within the structure that poses significant threats to the safety of the entire construction project. Furthermore, the tensile strength of composite slabs is relatively low, rendering them susceptible to cracking under typical or extreme loads. Such cracks not only detract from the aesthetic quality of the structure but, more critically, impair its durability and waterproofing. Harmful agents, such as moisture, can infiltrate through these fissures, leading to the corrosion of materials like reinforcing steel, thereby accelerating structural degradation and severely compromising safety and longevity. Consequently, this paper aims to address the limitations of existing methods by harnessing the advantages of material combinations and innovative designs for the reinforcing framework, thereby ensuring the effective application of composite slabs in future construction projects. Researchers must delve into the design, material selection, and construction processes of composite slabs to confront current challenges and enhance their overall performance.

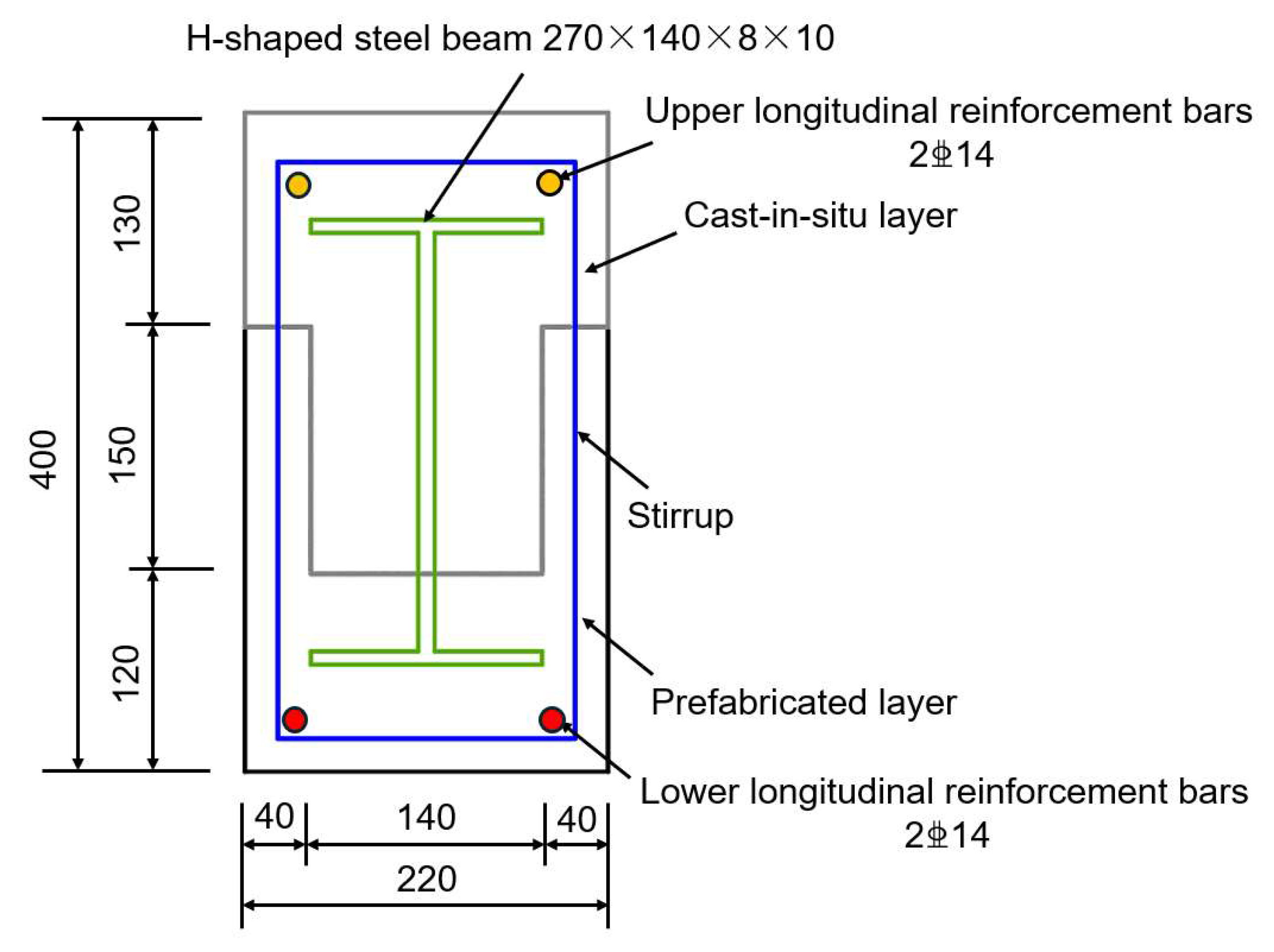

In the contemporary construction industry, the selection of materials and structural design significantly influences both the safety and economic viability of projects. Accordingly, this paper presents an innovative methodology that employs ultra-high-performance concrete (UHPC) for the casting of precast slabs, while utilizing Normal Concrete (NC) for the on-site casting layer. This approach aims to enhance the overall performance of the structure by rationally combining different materials to maximize their respective advantages.

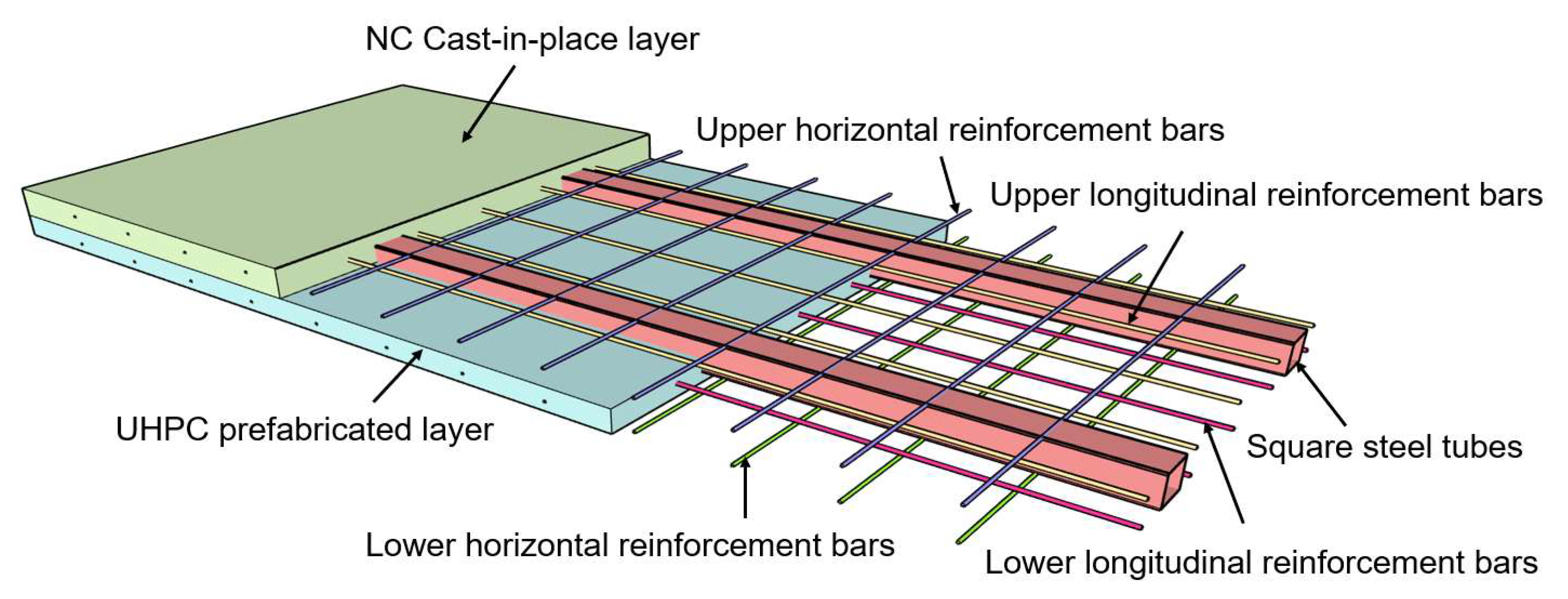

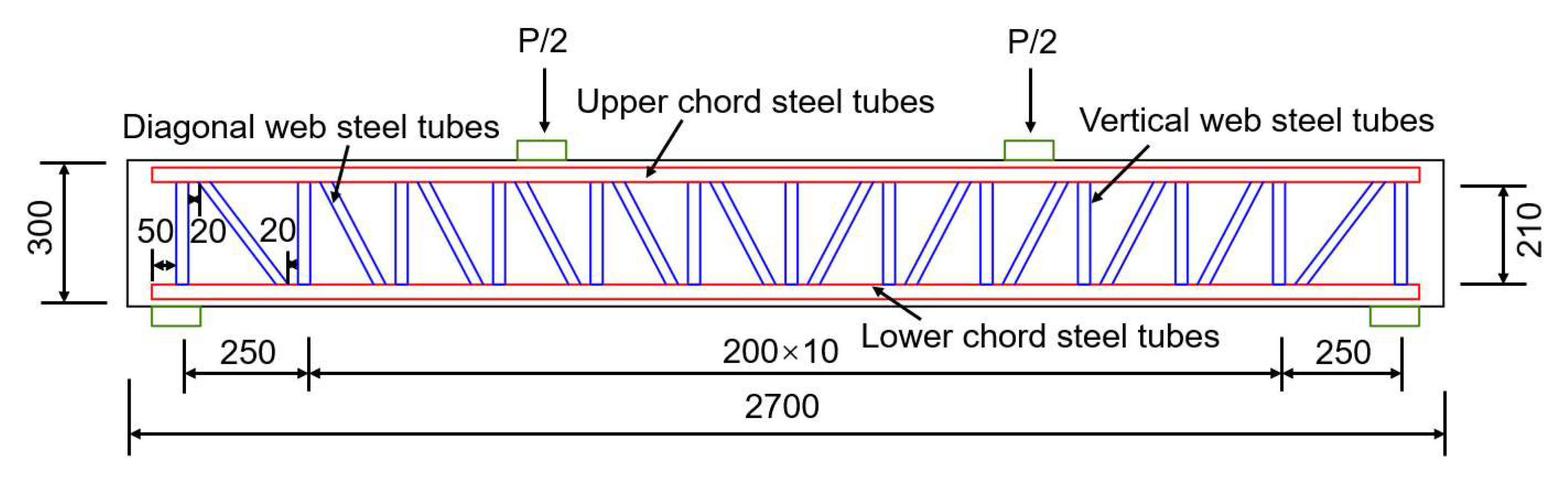

Initially, a steel reinforcement framework consisting of square steel tubes, longitudinal rebars, and transverse rebars was constructed. The welding of the steel pipes and rebars resulted in a monolithic structure that enhanced the firmness of the connection points and overall stability. The use of welding simplifies on-site connections and increases construction efficiency. As welding can be performed indoors, only minimal assembly is required on-site, significantly reducing construction time. Compared to mechanical connections, welded connections exhibit superior tensile and shear capacities, effectively resisting external loads. Furthermore, the compact nature of the welded connection structure facilitates inspection and repair during subsequent maintenance, thereby ensuring long-term safety. This reinforcement framework, coupled with UHPC and NC, creates a prefabricated hollow composite slab, as illustrated in

Figure 1. UHPC, characterized by its exceptionally high tensile strength, contributes outstanding toughness and stability to the composite slab, effectively mitigating the risk of cracking during transportation and construction. This enhancement not only preserves the integrity of the structure but also significantly prolongs its expected service life.

In the context of material selection, square steel pipes represent a primary alternative to traditional reinforcement bars. This approach not only reduces overall steel consumption but also effectively mitigates the instability issues associated with upper chord reinforcement during the construction process. Such innovative design strategies simplify and enhance construction efficiency while also decreasing project costs. Furthermore, the newly developed prefabricated hollow composite slabs exhibit superior bending performance compared to conventional materials, making them a more reliable solution for large-span structures. This performance advantage is particularly significant in modern architecture, especially in the design and construction of high-rise buildings and expansive public facilities. The amalgamation of UHPC and square steel pipes not only substantially improves the structural integrity of the composite slabs but also enhances construction efficiency. This novel design framework provides effective solutions to various challenges currently confronting the construction industry, aligning seamlessly with the modern demands of large-span structures and underscoring the substantial potential for future architectural advancements.

In recent years, researchers have investigated the utilization of steel tubes in concrete structures, focusing on the synergistic effects of steel tubes and concrete in enhancing component performance. Nie et al. [

10] explored a method for filling steel tubes with concrete. The collaboration between these two materials significantly increases their efficiency, rendering them particularly suitable for concrete slab applications. Jia et al. [

11] found that embedding steel plates within concrete slabs can greatly improve their shear performance, especially in shear walls of high-rise buildings. Furthermore, Wang et al. [

12] examined a dual-layer pipe component composed of carbon steel, concrete, and stainless steel, designed for submarine pipelines. This configuration allows the steel tube to function synergistically with the concrete, thereby enhancing overall performance. Nakahara et al. [

13] tested concrete-filled steel tube (CFST) structures. The load–deformation relationship obtained from the tests was well tracked through three-dimensional finite element analysis.

UHPC, recognized for its exceptional durability and significantly enhanced compressive and tensile strengths compared to conventional concrete, has received considerable attention and application in construction engineering. Its potential is especially prominent in the design and manufacturing of precast components. Researchers have increasingly acknowledged that leveraging the high tensile performance of UHPC can substantially improve the structural performance of composite slabs, thus elevating their overall tensile capacity. A study by Qasim et al. [

14] demonstrates that implementing a UHPC layer on the surface of reinforced concrete components can markedly enhance their flexural strength. Zhu et al. [

15] proposed a coating technique for applying a UHPC layer to the surfaces of damaged reinforced concrete slabs, effectively increasing their flexural load-bearing capacity. Xue et al. [

16] utilized UHPC in load-bearing components, joints, and composite layers of bridge surfaces in bridge engineering, revealing that UHPC can significantly lower the construction costs of steel–concrete composite bridges. Additionally, Abo El-Khier et al. [

17] introduced a methodology for connecting precast concrete slabs to steel beams using UHPC, achieving full composite action. Wang et al. [

18] examined the bonding characteristics between UHPC and ordinary concrete, which is crucial for the effective application of UHPC–ordinary concrete composite slabs. The study conducted by Momeni et al. [

19] indicates that the utilization of UHPC can substantially enhance the performance of panels, modify their failure modes, and thus improve their overall structural integrity when subjected to high strain conditions.

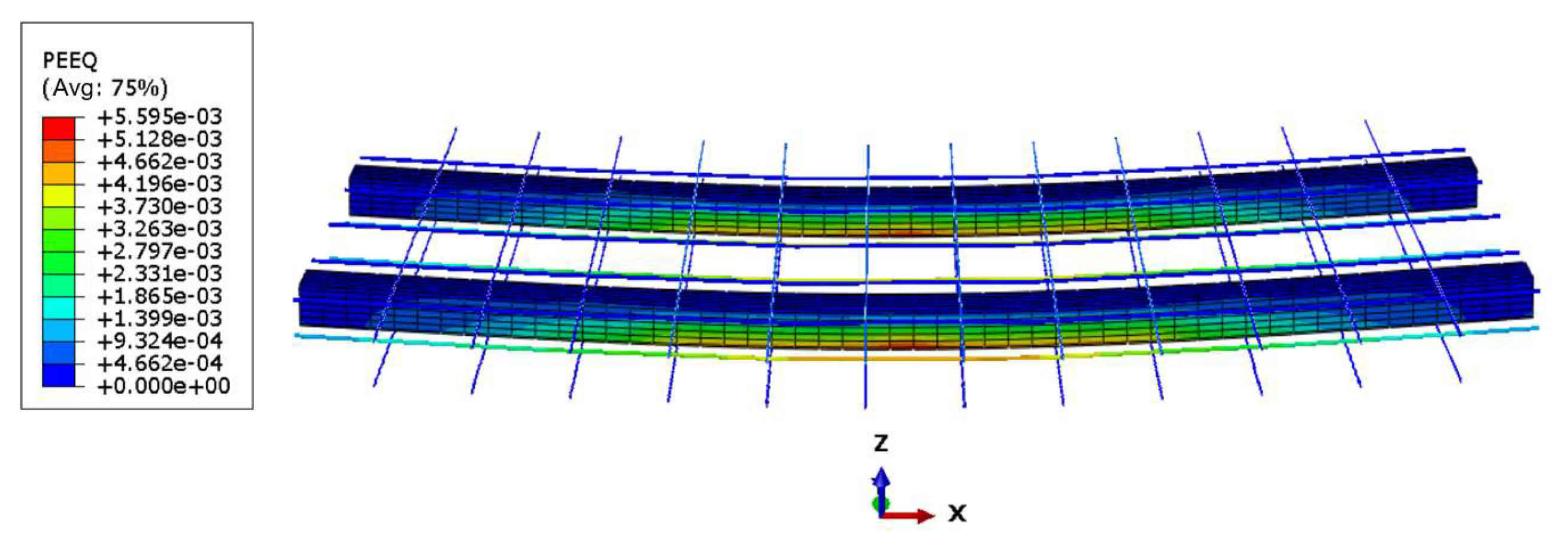

In recent years, the application of UHPC in construction materials has garnered significant attention within the field of building materials research. Although extensive studies have been conducted on the properties and applications of UHPC in various concrete components, research on composite structures incorporating steel tubes and UHPC remains relatively scarce. This area demands further exploration to fully harness the exceptional performance of UHPC. Currently, a systematic and comprehensive investigation into the factors influencing the mechanical properties of composite slabs with integrated steel tube frameworks is lacking. This deficiency has resulted in incomplete design references and calculation formulas. To address this gap, this paper establishes a finite element numerical model for prefabricated hollow composite slabs made of UHPC and NC. Following the development of the model, experimental validation confirmed its accuracy, thereby enhancing the reliability and applicability of the research findings.

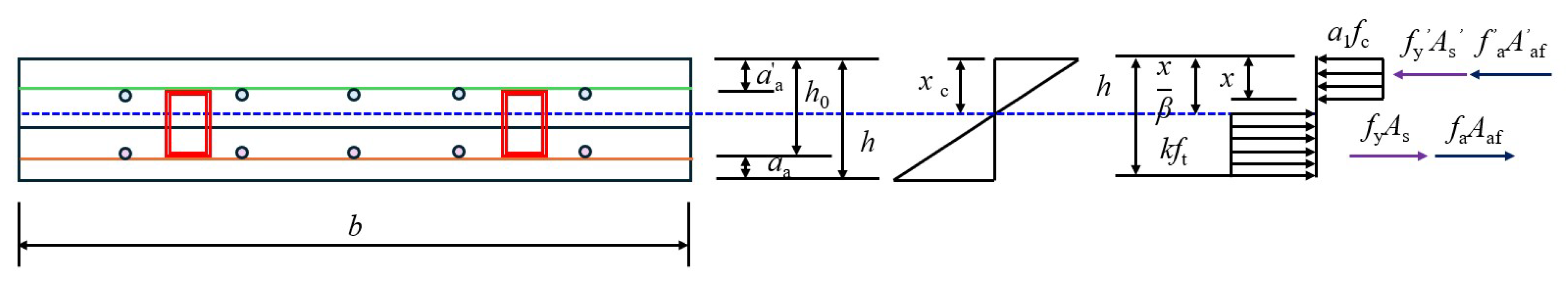

This study specifically examines the influence of several key factors on the bending performance of composite slabs. These factors include the wall thickness of square steel tubes, the diameter of transverse reinforcement bars, the thickness of prefabricated bottom plates, and the strength class of concrete, among others. An in-depth analysis of these factors enhances the understanding of their actual effects on the performance of composite slabs, thereby providing a scientific basis for future design and applications. Furthermore, a set of applicable formulas for calculating the positive section bending load capacity of UHPC-NC prefabricated hollow composite slabs has been proposed. These formulas not only offer theoretical support for the design of composite slabs but also facilitate structural analysis and optimization in practical applications.

This research comprehensively examines the limitations of conventional composite slab designs and introduces an innovative design scheme that integrates UHPC with steel tubes for prefabricated hollow composite slabs. This integration maximizes the exceptional properties of UHPC, significantly improving the bending stiffness and overall structural safety of the composite slabs, thus fulfilling contemporary architectural requirements for high-strength and large-span structures. Additionally, this paper not only presents novel design concepts derived from systematic investigations of various material combinations but also offers practical calculation formulas and foundational principles for engineering applications. This innovation addresses prevailing challenges in the construction industry, including energy consumption, cost efficiency, and safety, while paving the way for new avenues in architectural design and material applications, thereby possessing both substantial theoretical and practical significance. Consequently, the primary innovation of this study is the enhancement of performance and practicality in prefabricated buildings through material innovation and structural optimization, providing viable solutions for the sustainable evolution of the construction industry.

3. Finite Element Model Validation

To validate the rationality of the established model, this paper conducts a finite element analysis of structures closely related to the UHPC-NC prefabricated hollow-core slabs. These structures include the flexural performance study of concrete beams with built-in grouting in square steel pipe trusses, prefabricated steel–concrete composite beams, and ultra-high-performance concrete beams with high-strength steel. Firstly, these cases represent common and typical structural types in current engineering applications, effectively reflecting the performance of the design model in practical applications. Secondly, the selected cases encompass different types of steel and concrete combinations, ensuring the breadth and applicability of the model parameter validation. Finally, ample experimental data exists for these structures, providing a solid foundation for the accuracy of the finite element analysis. Therefore, these specific test cases are chosen to verify the accuracy of the model parameters, ensuring the scientific and practical nature of the design. Through comparative analysis with the corresponding experimental results, a solid theoretical basis and validity verification are provided for the numerical model of the UHPC-NC prefabricated hollow-core slab constructed in this study.

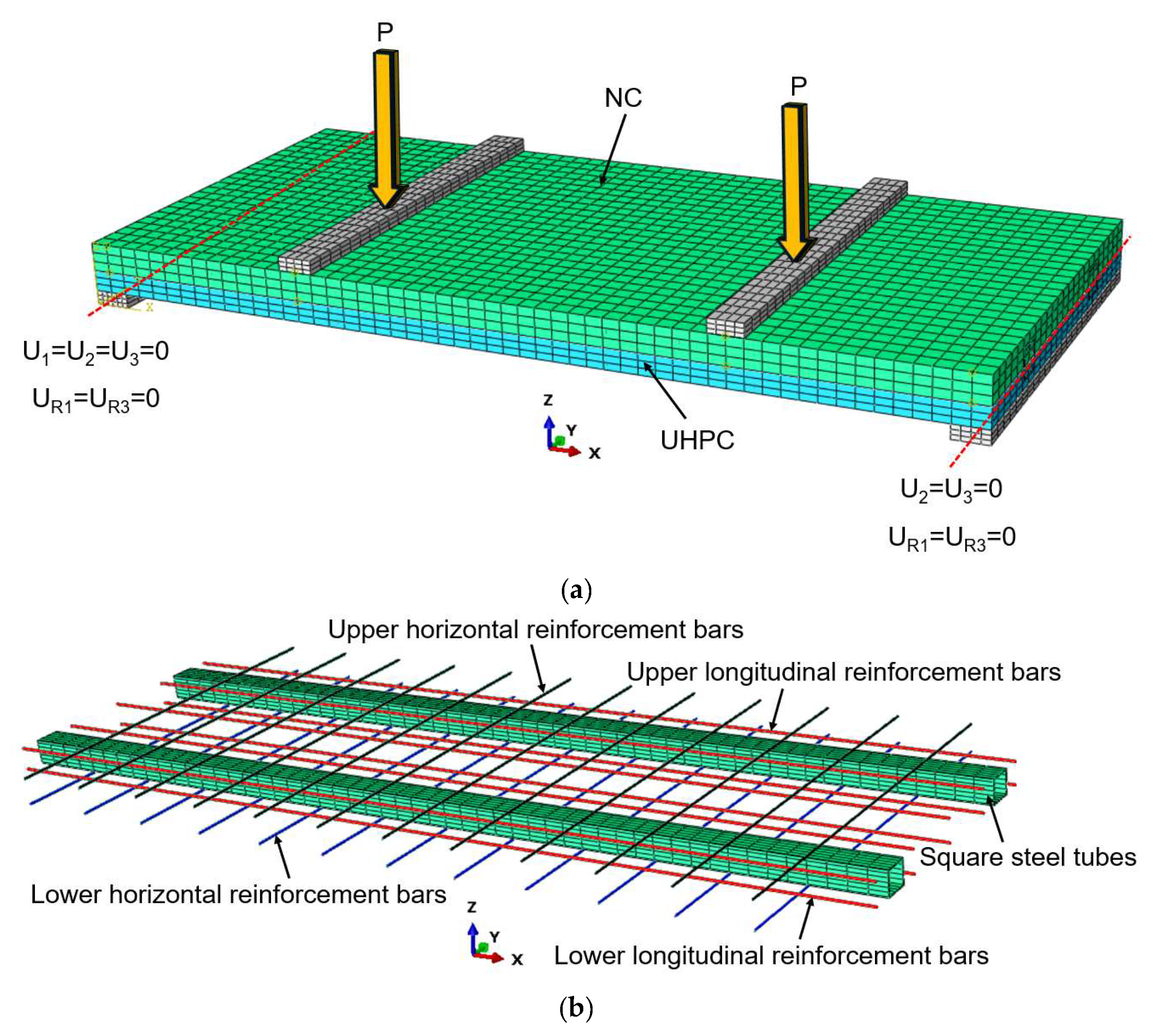

3.1. Concrete Beam with Embedded Grouted Square Steel Tube Truss

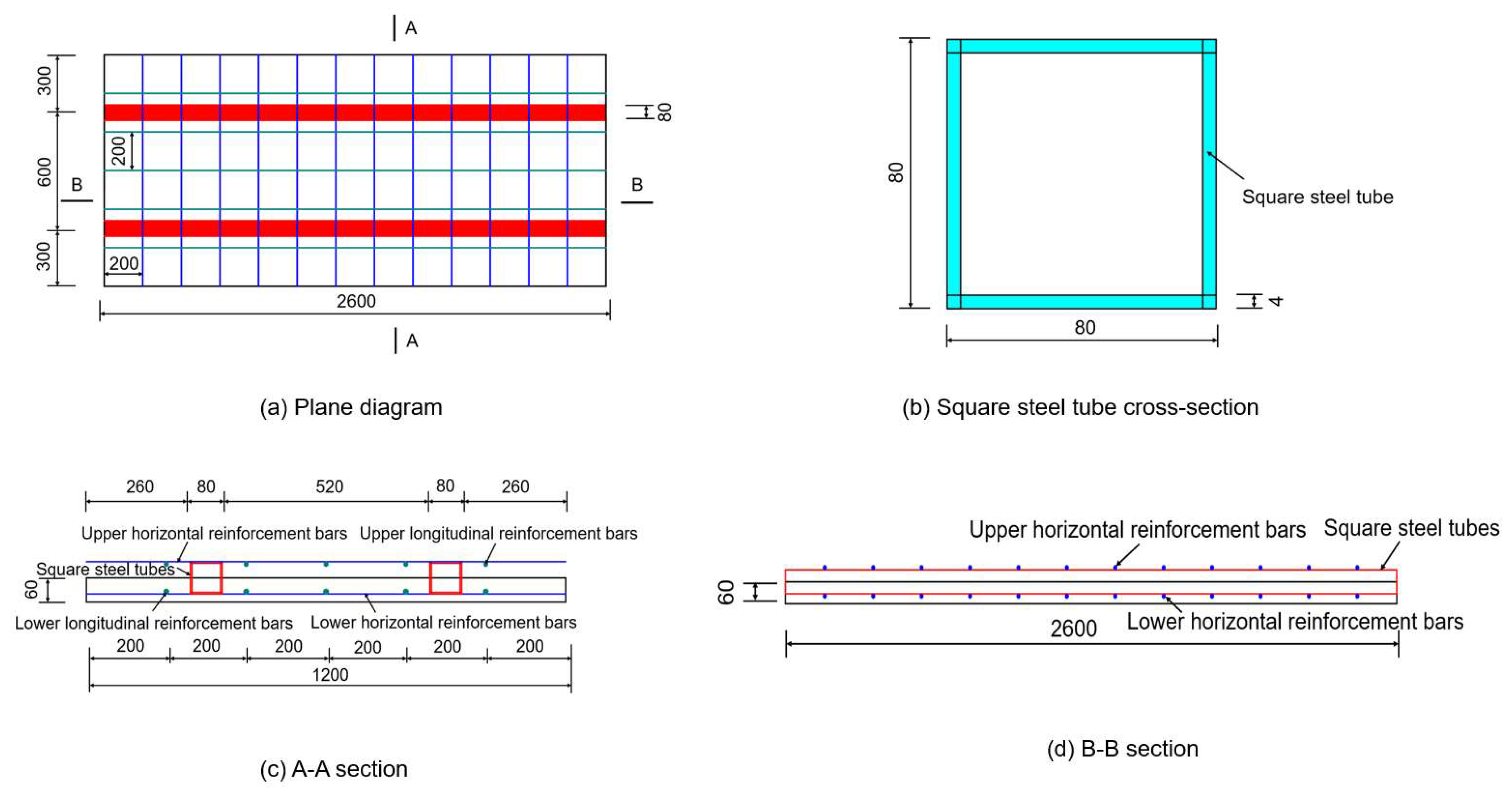

The study referenced in ref. [

30] conducted experimental research on built-in grouted square tube truss concrete beams. Specimen B-5 was selected as the subject for finite element analysis. The three-dimensional structural diagram of specimen B-5 is depicted in

Figure 4, while its specific geometric dimensions and reinforcement details are provided in

Figure 5. The total length of the specimen is 2700 mm, the width is 200 mm, and the effective span is 2500 mm, with a three-point loading method applied. The center point of the bottom support block is positioned 100 mm from the lateral edge of the bottom of the beam. The thickness of the concrete protective layer surrounding the outermost square tube is 15 mm, and the overall thickness of specimen B-5 is 300 mm.

The test specimen’s material composition comprises two primary components: the upper and lower chords, both constructed from square steel tubes. The upper chord is specified as 30 mm × 30 mm with a wall thickness of 2 mm, while the lower chord also measures 30 mm × 30 mm but features a greater wall thickness of 3 mm. The web member specifications are 25 mm × 25 mm with a wall thickness of 2 mm, as are those of the connection member. This material selection ensures that the test specimen maintains substantial load-bearing capacity and stability. All square steel tubes are fabricated from Q235 grade steel, which is known for its advantageous plasticity and strength characteristics. The longitudinal square steel tubes are oriented transversely across the beam, with two located on the top and two on the bottom. The spacing between the transverse square steel tubes is 130 mm, and they are interconnected using coupling rods arranged in the transverse direction. The grout material is composed of ordinary Portland cement P.O42.5, a UEA expansion agent, an FDN high-efficiency water-reducing agent, and tap water mixed together. The water-to-cement ratio is 0.4, with the expansion agent UEA (accounting for the weight of the cement) being 7% and the water-reducing agent FDN (also accounting for the weight of the cement) being 0.7%. The cubic compressive strength is 36.3 MPa.

In this study, C40 concrete has been selected, exhibiting a measured cubic compressive strength

fcu of 44.8 MPa and an elastic modulus

Es of approximately 3.36 × 10

4 MPa. Regarding the strength of the steel tubes, the measured yield strength

fy of the upper chord member is 297 MPa, whereas the yield strength

fy of the lower chord member is 345 MPa. The measured yield strength of the web and connecting members reaches 360 MPa, which is significantly higher. It is noteworthy that the constitutive relationship between ordinary concrete and square steel tubes discussed in this article adheres to the principles outlined in

Section 2.1.

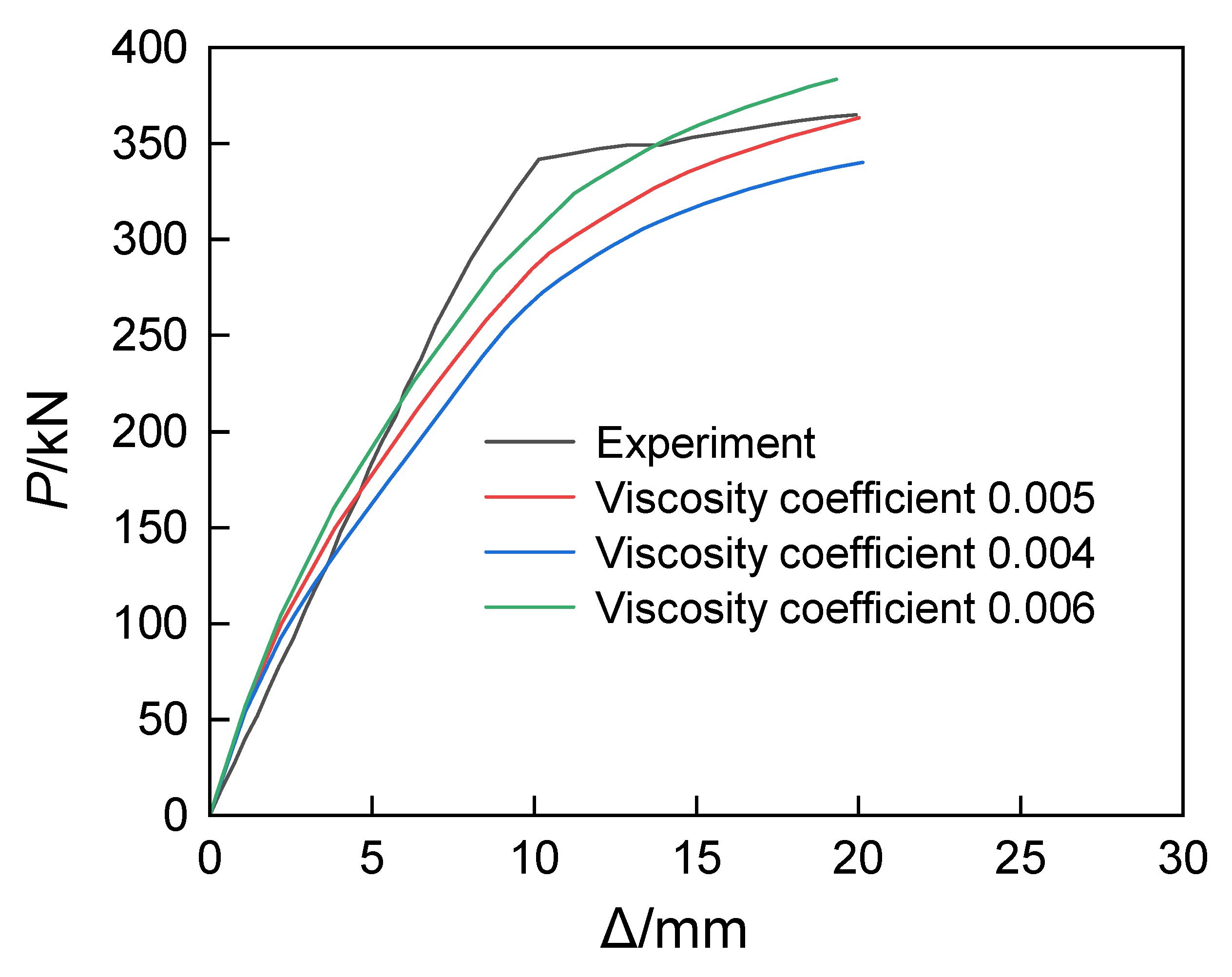

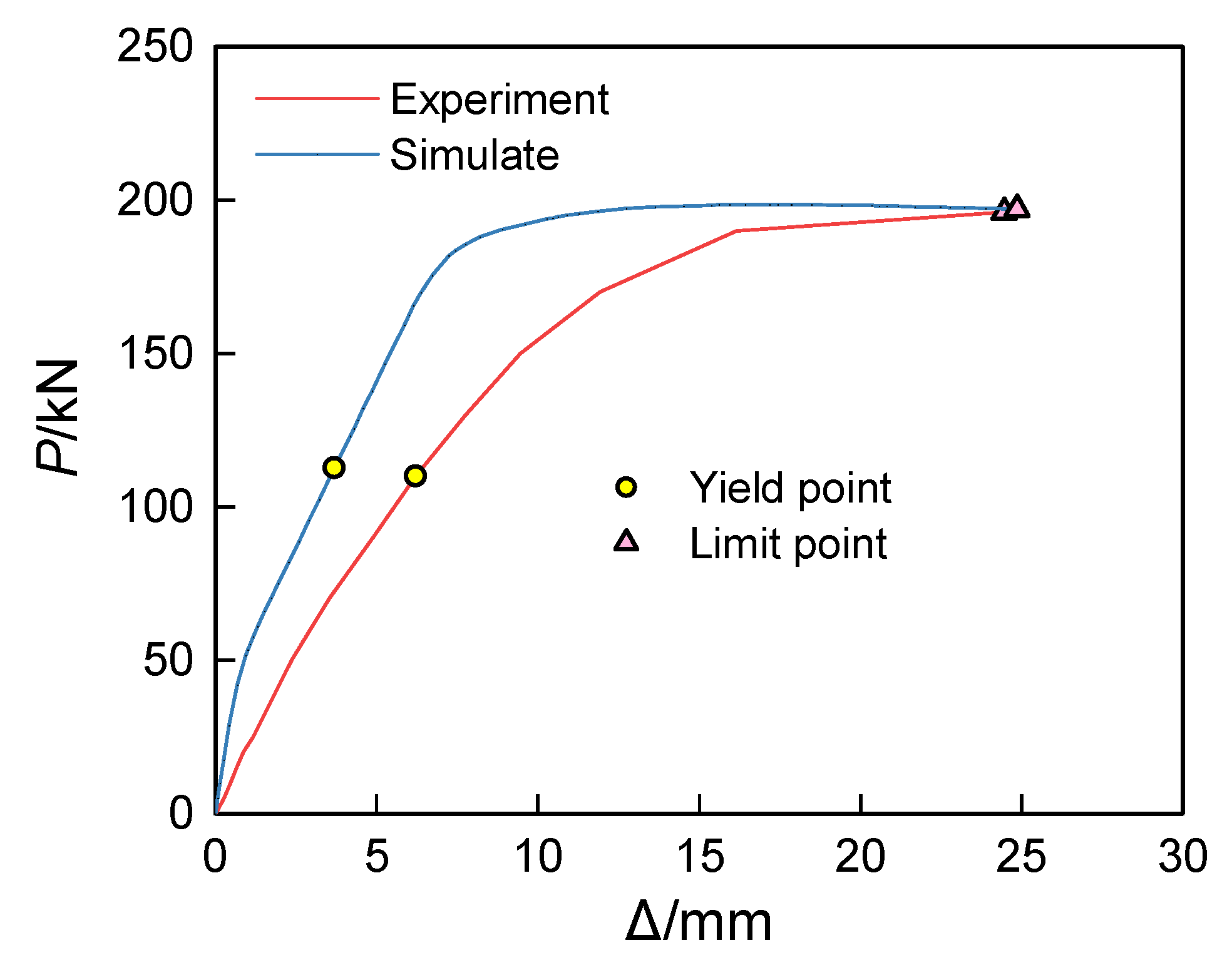

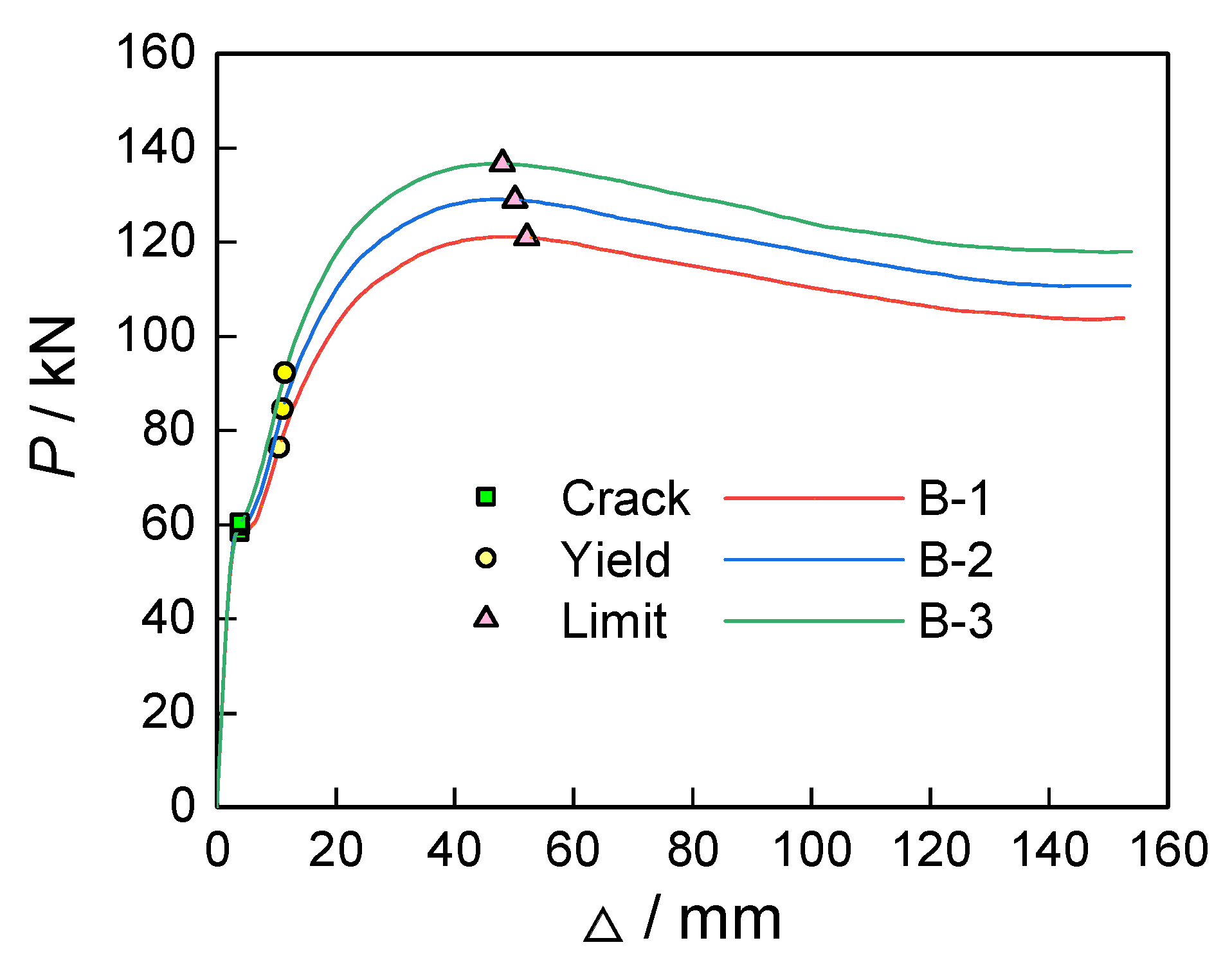

In this study, we conducted a detailed comparison between finite element simulations and experimental data, with a particular focus on the performance of the mid-span deflection–load (

P − Δ) curves.

Figure 6 clearly displays the results of this comparison, allowing for an intuitive analysis of the differences and similarities between the simulation and experimental results. Through experimental measurements, a yield load

Pyt of 110.00 kN and a failure load

Put of 196.00 kN were obtained. Meanwhile, in the finite element simulation, the yield load

PyFE was 112.65 kN and the ultimate load

PuFE was 197.10 kN. Further analysis shows that in the comparison of yield points between the experimental and simulation results, the ratio of experimental value to simulated value is approximately 0.98, with a deviation percentage of 2.41%; at the ultimate state, the ratio approaches 0.99, with a deviation percentage of 0.56%, indicating a strong convergence between the two. This suggests that the (

P − Δ) curve obtained via the finite element method can accurately reflect the response characteristics of real components, successfully validating the accuracy and reliability of the constructed finite element model. The analysis confirms that the concrete beam of the square steel tube truss with grouted chord tubes mainly experiences the following four stages during vertical loading: (1) Elastic stage: Before the concrete cracks, the mid-span deflection shows a nearly linear change with the vertical load. (2) Cracked working stage: After cracks occur in the lower part of the concrete at the mid-span of the test beam, the (

P − Δ) curve of the test beam gradually deviates from the linear line. Due to the influence of the embedded square steel tube truss, the loading stiffness of the test beam slightly decreases after cracking. (3) Steel tube yield stage: When the lower edge of the lower chord steel tube of the test beam shows tensile yielding, the (

P − Δ) curve begins to deviate significantly from the linear line, exhibiting a certain degree of inflection, and the loading stiffness further decreases. (4) Failure stage: When the lower chord steel tube of the test beam fully yields under tension, further loading results in a significant deflection of the (

P − Δ) curve. As the vertical load increases, the stiffness of the composite beam decreases markedly, and the mid-span deformation increases sharply.

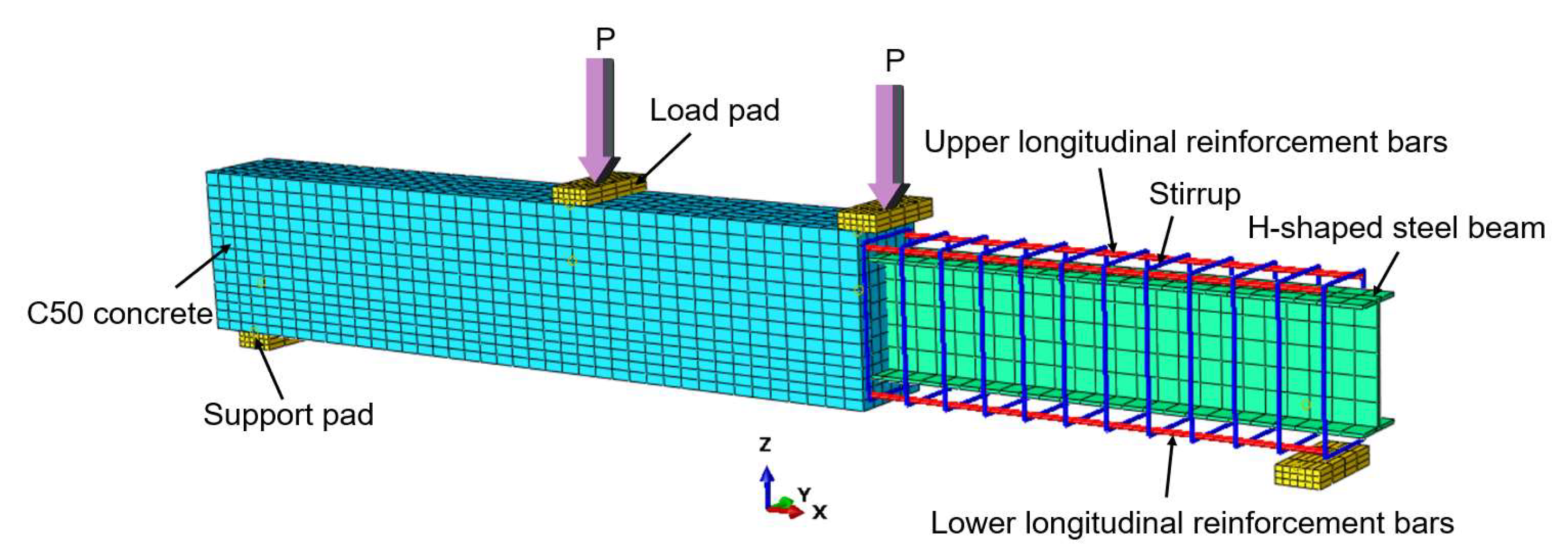

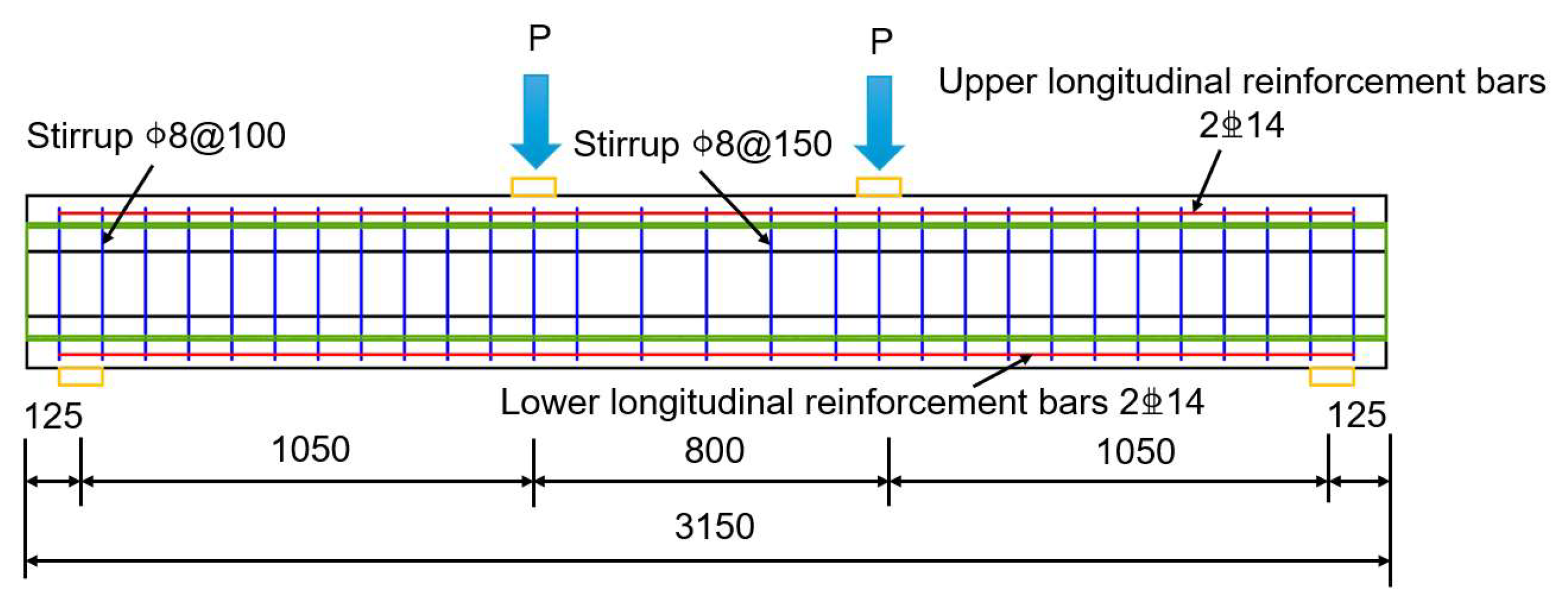

3.2. Prefabricated Steel-Concrete Beam

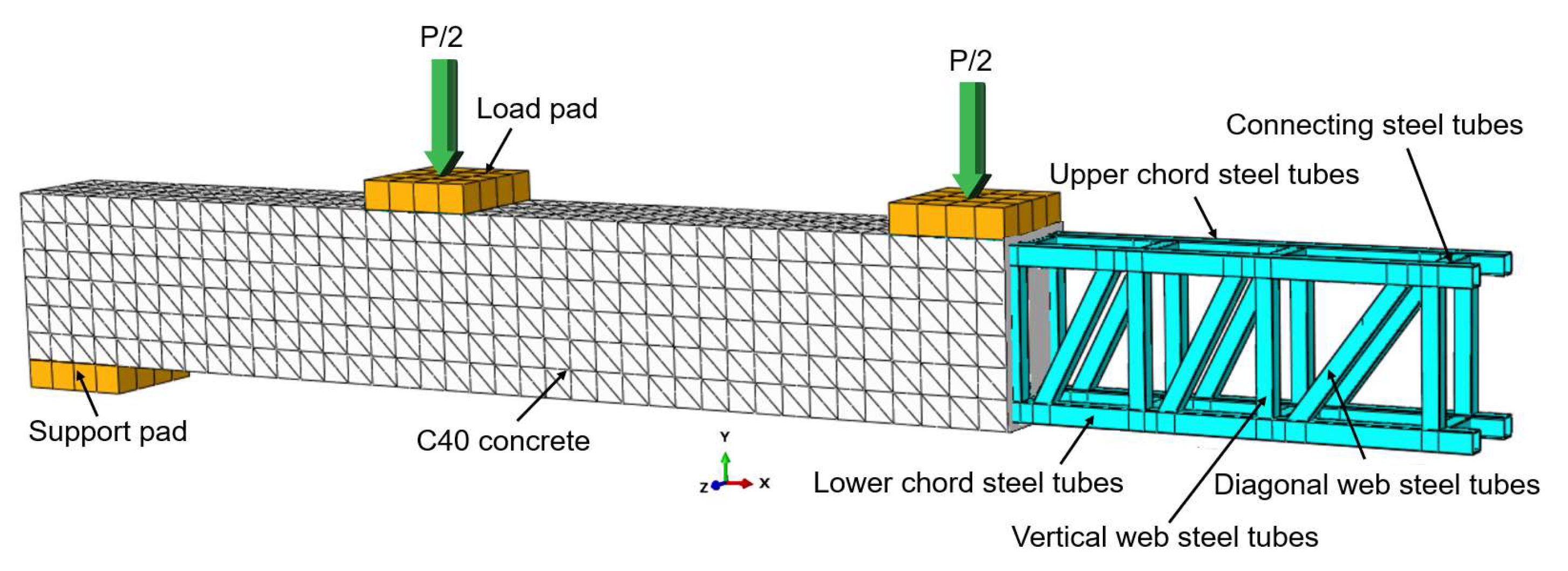

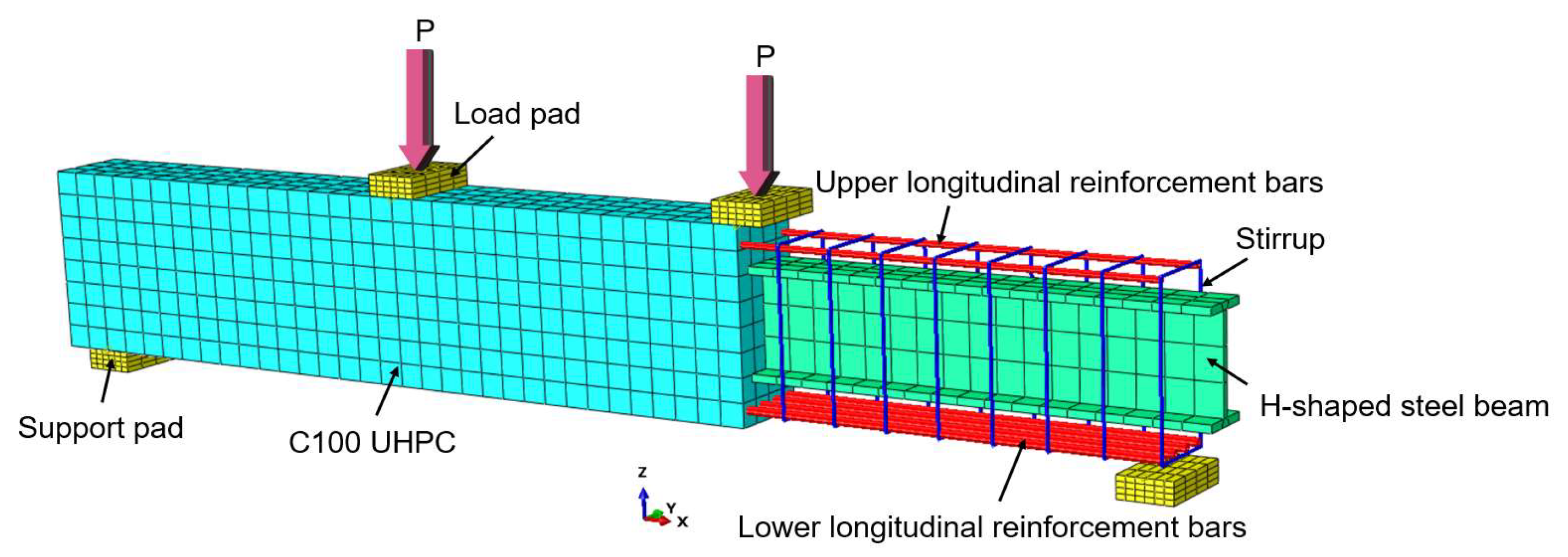

The literature [

31] presents experimental research on prefabricated steel–concrete beams, with specimen RSPB-1-1 selected as the validation object for finite element analysis. The three-dimensional structural schematic of this specimen is illustrated in

Figure 7, while detailed information regarding the elevation view and cross-sectional dimensions is provided in

Figure 8 and

Figure 9. The specific dimensions of the specimen include a total length of 3150 mm, a width of 220 mm, a total thickness of 400 mm, and a calculated span of 2900 mm, where a three-point loading method is employed. Additionally, the center distance from the supporting block of the base to the lateral edge of the specimen measures 125 mm.

Regarding the construction details, the stirrups of the specimen are fabricated from an A8 diameter rebar, with the outer stirrups positioned 75 mm from the edge of the beam. In order to improve the shear capacity of the beam, the stirrup spacing on both sides is set at 100 mm with 12 stirrups, while the stirrups in the middle are arranged at 150 mm with 4 stirrups.

This study utilized C50 concrete with a measured cube compressive strength fcu of 55.2 MPa. Additionally, the strength of the reinforcing steel is a critical focus of the research. The yield strength fy of the HRB400 rebar was found to be 497 MPa, while the flange of the H-shaped steel, made from Q235 steel, exhibited a yield strength fy of 364 MPa. The yield strength fy of the web of the H-shaped steel was measured at 406 MPa.

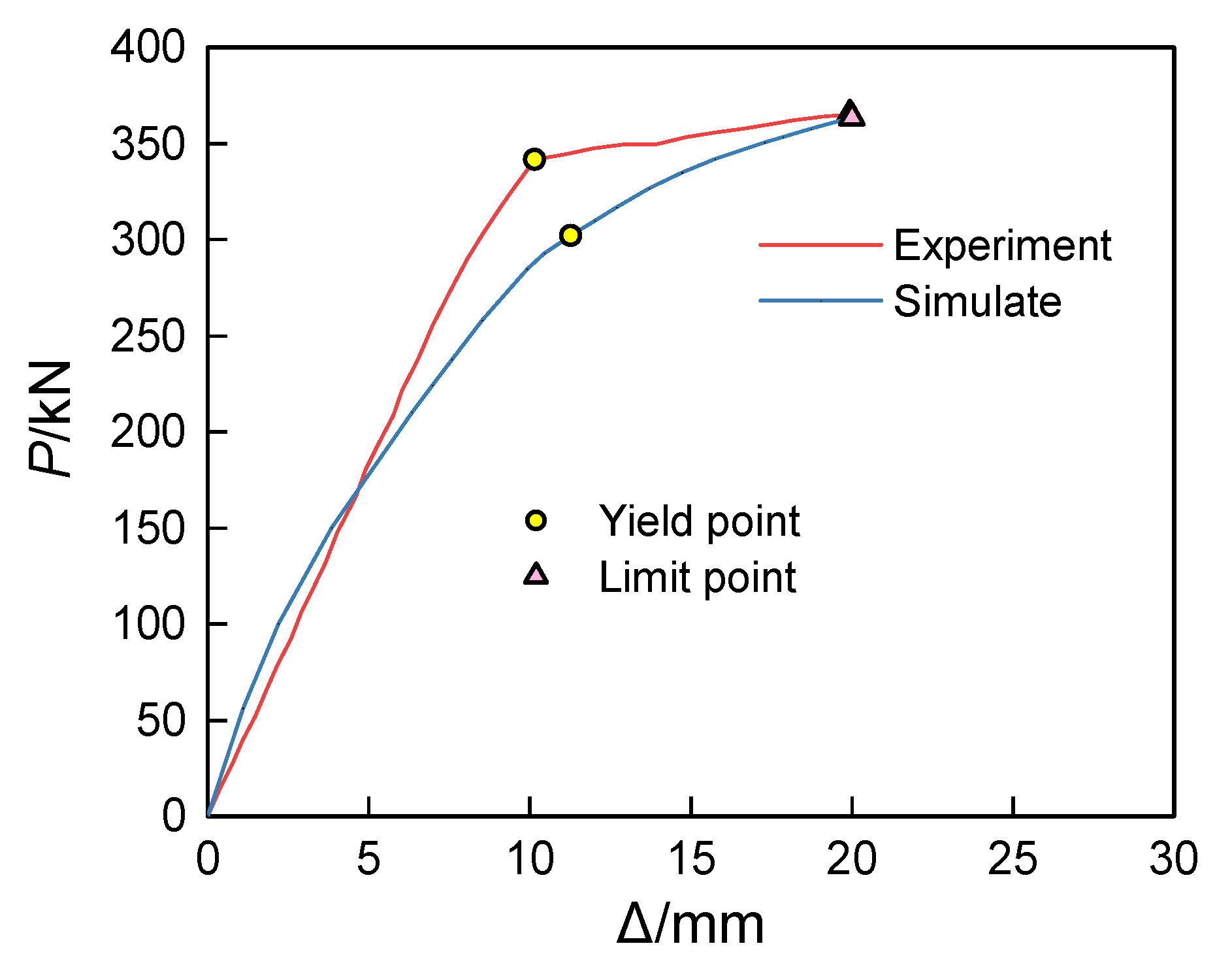

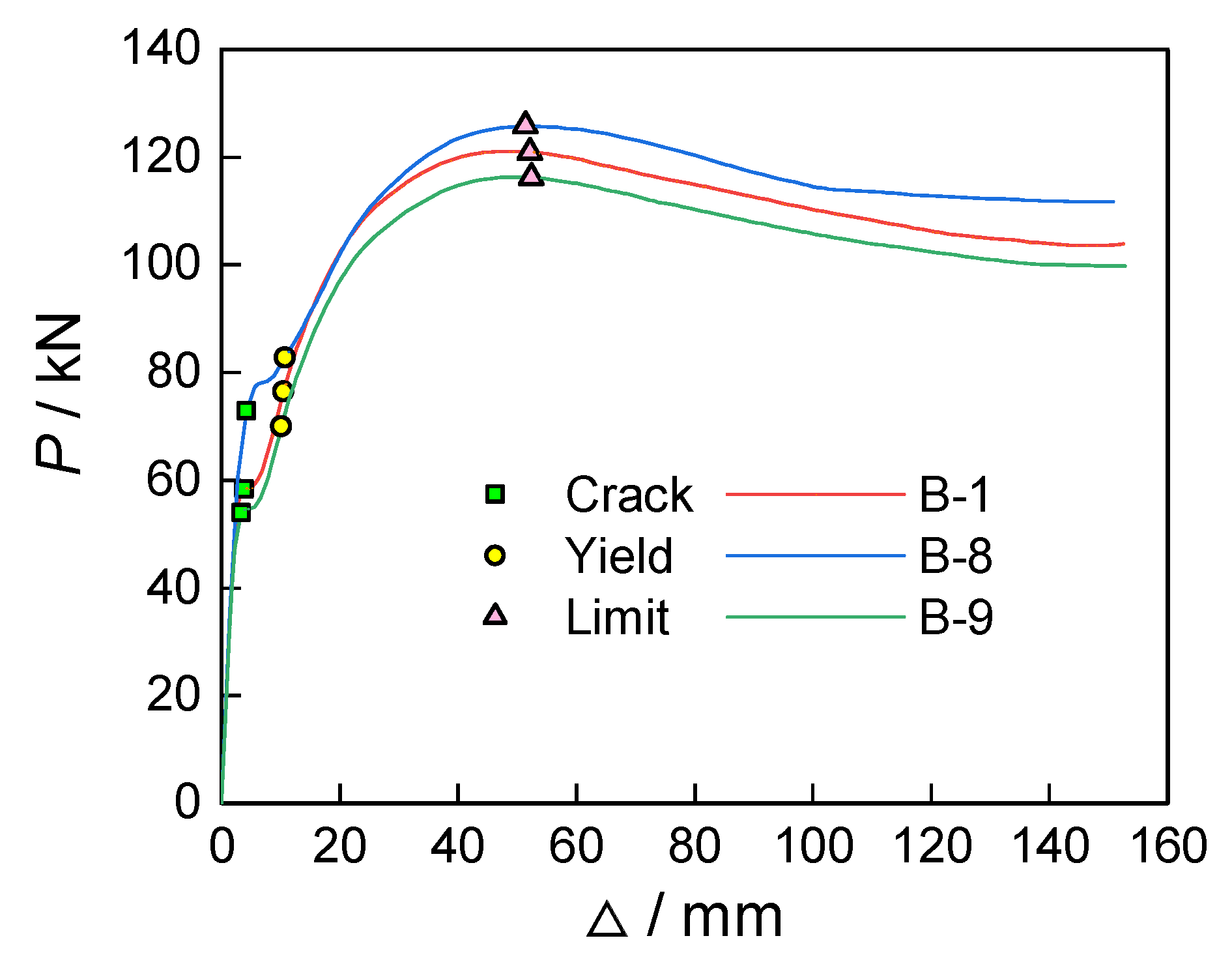

In

Figure 10, the load–deflection (

P − Δ) curves of the finite element simulation results are compared with the actual test data. By comparing these two curves, it can be observed that the yield load obtained from the experiment

Pyt is 341.68 kN, while the ultimate load

Put reaches 365.02 kN. Meanwhile, the yield load from the finite element simulation

PyFE is 339.84 kN, and the ultimate load

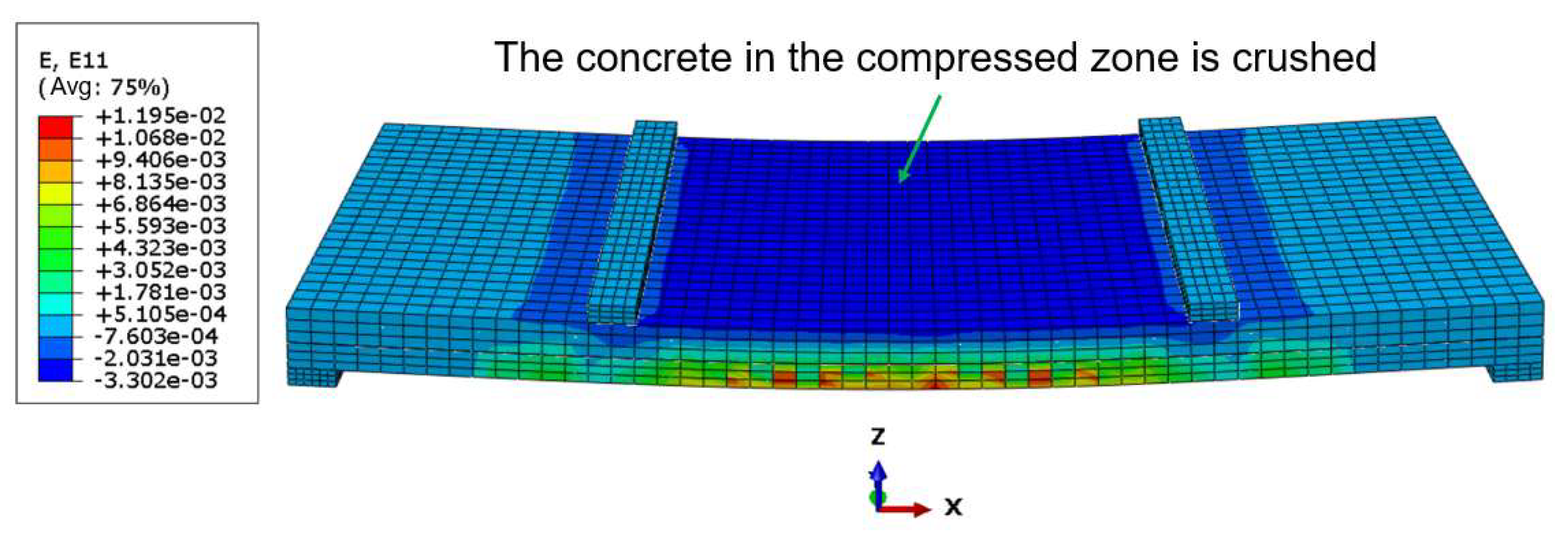

PuFE is 362.28 kN. Comparing these two sets of data, the ratio of the experimental yield point to the simulated value is approximately 1.01, with a deviation percentage of −0.54%. Although the predicted simulated yield load is slightly lower than the experimental value, the difference between the two is very small, indicating that the finite element simulation can accurately capture the yielding behavior of the material. At the ultimate state, the ratio approaches 1.01, with a deviation percentage of −0.75%, suggesting that the finite element simulation is also relatively accurate in predicting the ultimate load and is generally consistent with the experimental results. The finite element simulation results show a good agreement with the test data, further validating the reliability of the simulation method. From the overall development trend, the curve can be divided into three parts: the crack working stage, the yield strengthening stage, and the failure stage. In the initial loading phase, the deflection increases uniformly, and the slope of the curve remains basically unchanged, with minimal variation in the overall stiffness of the specimen; when the load reaches the yield load, the curve exhibits a turning point, and the slope decreases rapidly, leading to a reduction in the stiffness of the specimen, with the width of the concrete cracks continuously increasing and deflection persistently rising; when the ultimate load is reached, the concrete in the compressed region is crushed.

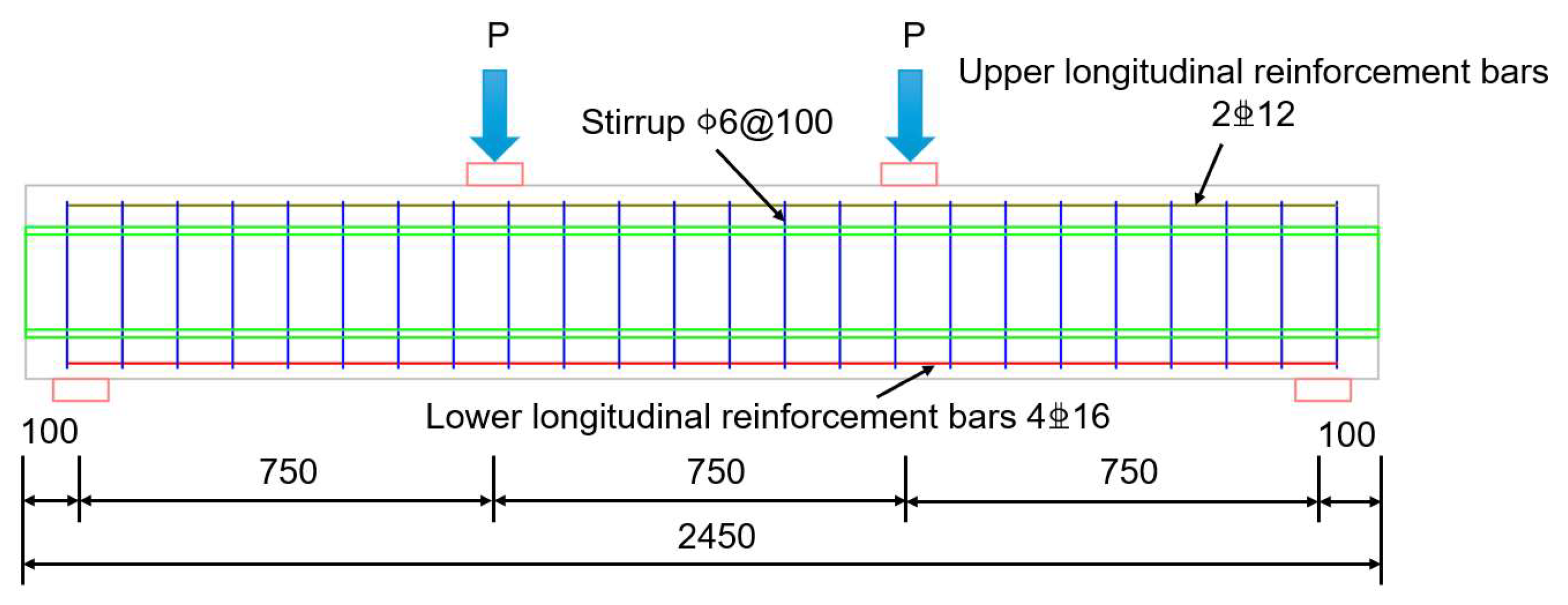

3.3. High-Strength Steel Ultra-High-Performance Concrete Beam

The literature [

32] examines UHPC beams reinforced with high-strength steel, with a particular focus on specimen B-1. The three-dimensional structural schematic of this specimen is presented in

Figure 11, while detailed elevation views and cross-sectional dimensions are provided in

Figure 12 and

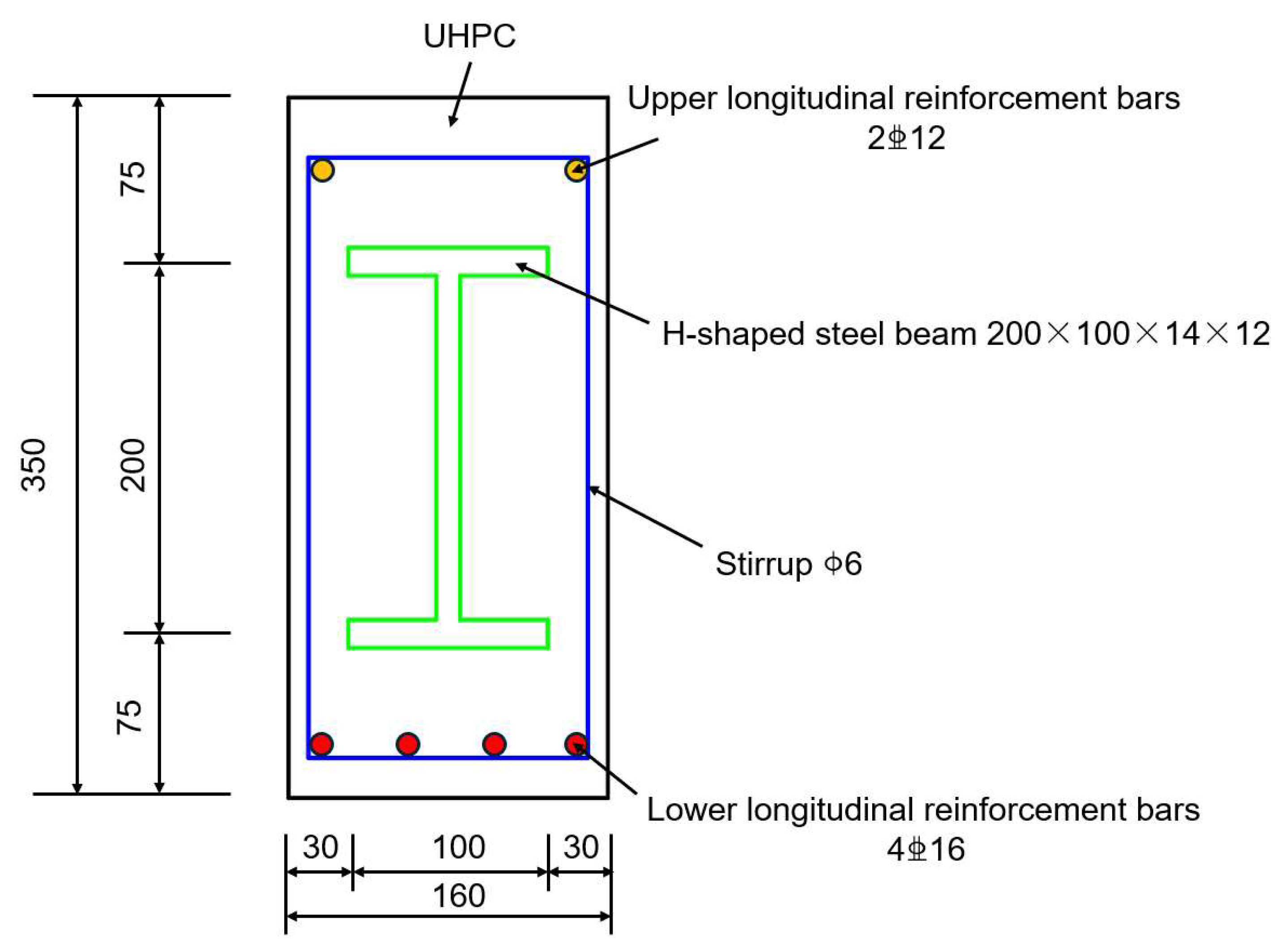

Figure 13. The specifications for the specimen include a total length of 2450 mm, a width of 160 mm, and a thickness of 350 mm, alongside an effective span of 2250 mm, which can be accurately determined. The tests were performed using a three-point loading method.

In relation to support and reinforcement, the distance between the specimen’s support block and the edge is established at 100 mm. Furthermore, the stirrup reinforcement is arranged at intervals of 100 mm, with a diameter of A6, and the outermost stirrup is located 75 mm from the edge of the concrete beam.

In terms of material performance, the UHPC utilized in the specimen is classified as C100, demonstrating a measured cube compressive strength fcu of 101.0 MPa. The reinforcement selection includes a C12 rebar, which has a measured yield strength fy of 414 MPa, and a C16 rebar, with a yield strength fy of 441 MPa, slightly exceeding that of the C12 rebar. Additionally, the H-beam in the specimen displays high strength characteristics, exhibiting a measured yield strength fy of 573 MPa in the flange section and 553 MPa in the web section.

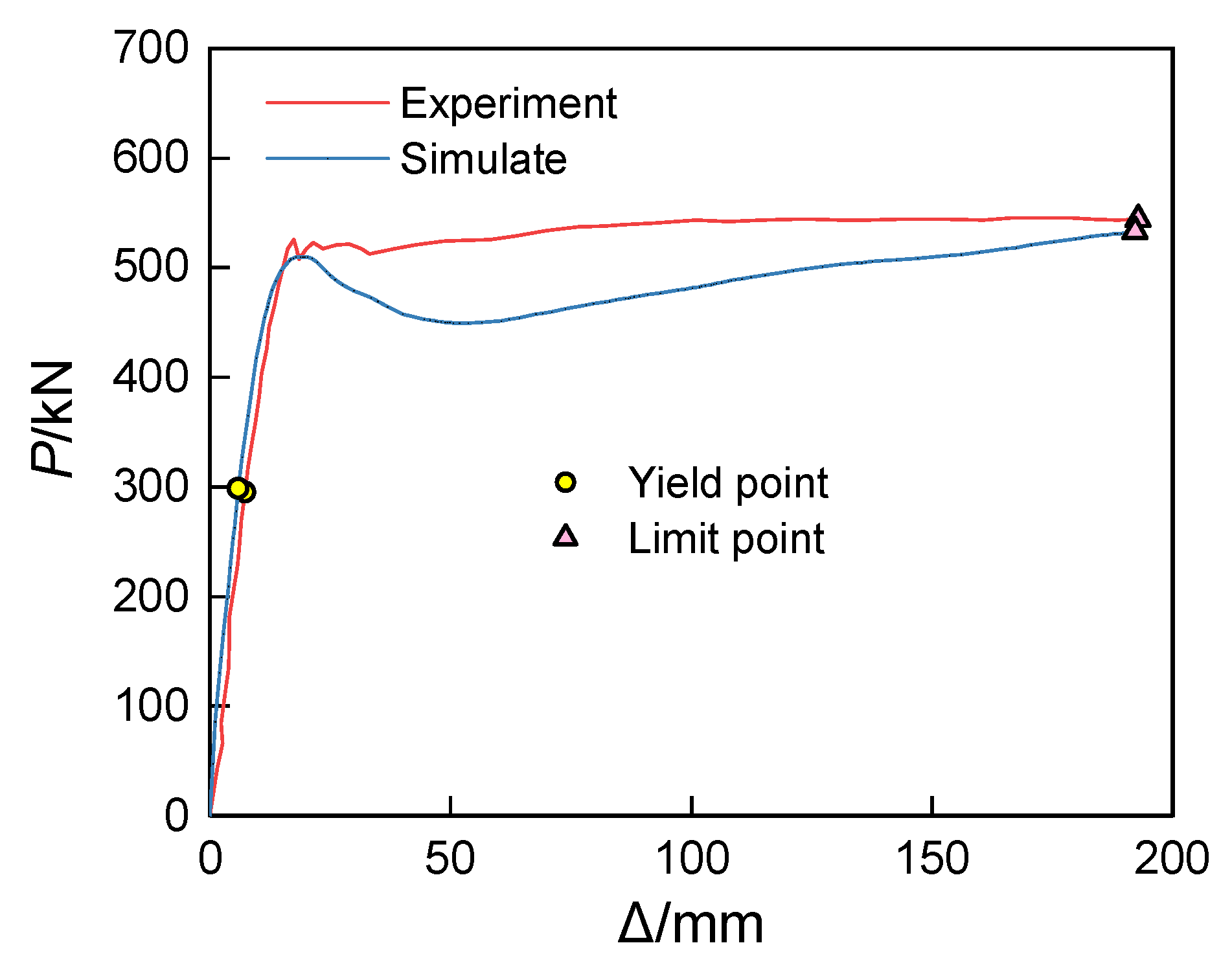

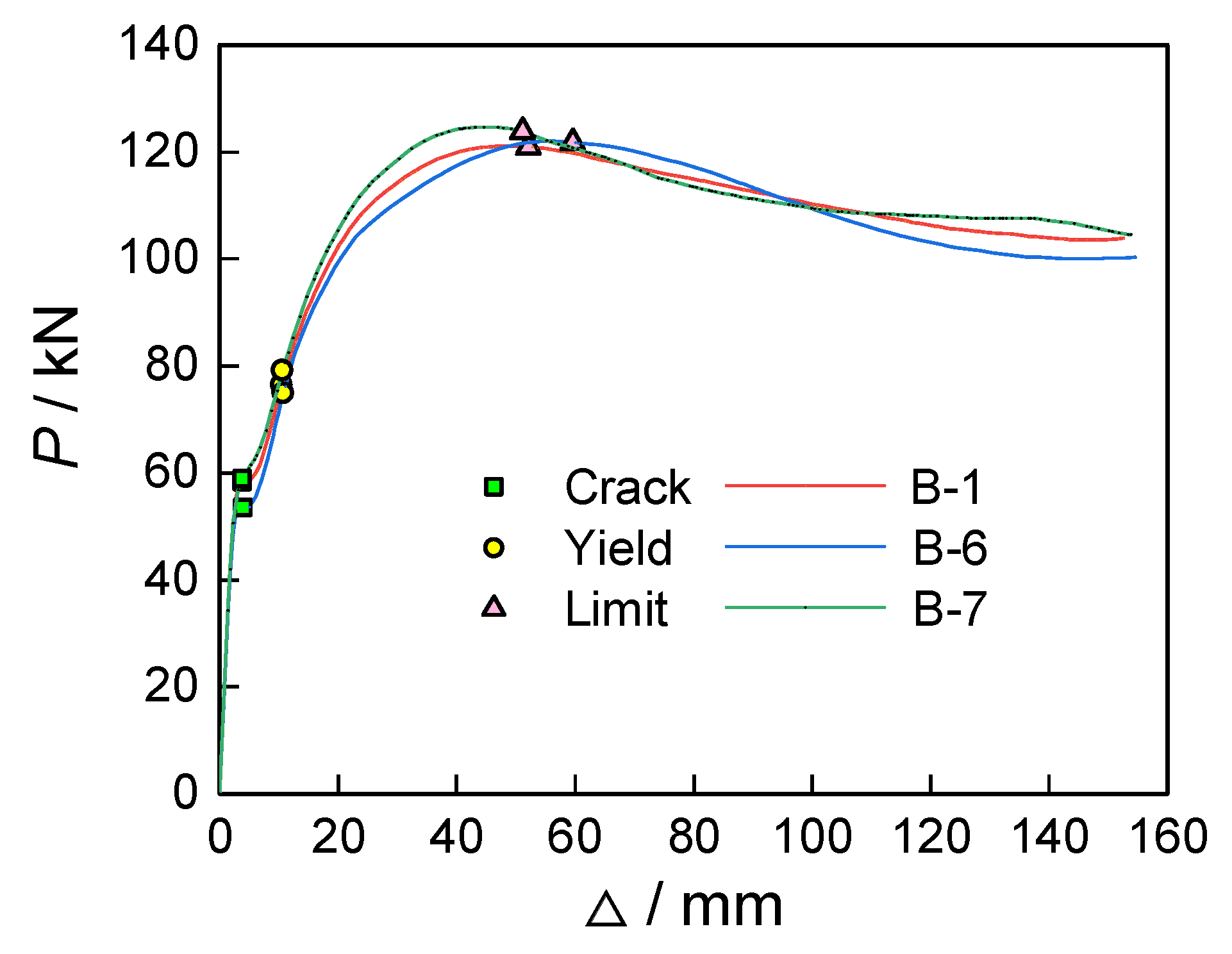

Figure 14 shows the comparison between the finite element simulation results and the actual test-derived mid-span deflection–load curve (

P − Δ). This figure visually reflects the deformation characteristics of both under load, providing an important basis for subsequent result analysis. Through experimentation, the actual yield load

Pyt measured was 295.19 kN, and the ultimate load

Put was 544.48 kN. From finite element analysis, the yield load

PyFE was 298.79 kN, and the ultimate load

PuFE was 533.26 kN. The comparison reveals that the ratio of the experimentally obtained yield load to the simulated value is approximately 0.99, with a deviation percentage of 1.22%; meanwhile, the ratio for the ultimate load is close to 1.02, with a deviation percentage of −2.06%. This indicates that the error between the two is very small, demonstrating a high consistency between the finite element model and the experimental results. Overall, the (

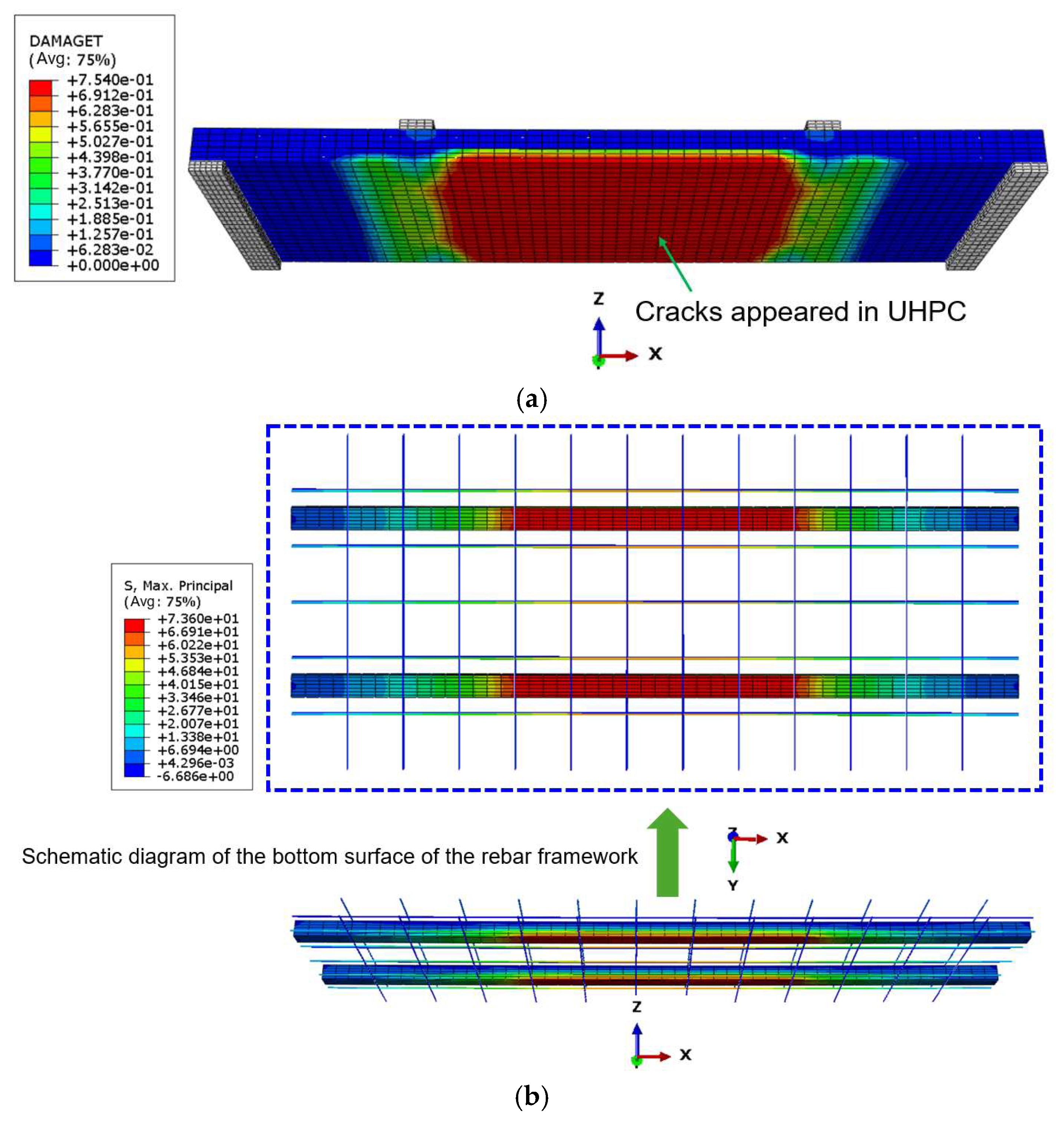

P − Δ) relationship curve predicted by the finite element model aligns closely with the experimental observation data, confirming the model’s effectiveness and reliability in describing structural responses. Based on the analysis of the load process of ultra-high-performance concrete beams reinforced with high-strength steel, the process can be roughly divided into three stages. The first stage (uncracked stage): In the early loading phase, the load–displacement curve increases proportionally, displaying no inflection point. The stress and strain in the beam cross-section are small, and the entire cross-section participates in the load-bearing, with the ultra-high-performance concrete, steel shapes, and longitudinal reinforcements all in an elastic working state. The second stage (cracked stage): After cracking of the beam, although the cross-section’s stiffness decreases, the substantial stiffness of the steel shape significantly constrains the core concrete, such that the load-mid-span degree curve shows no noticeable inflection point; the slope slightly decreases, but the curve remains approximately linear. The third stage (failure stage): Although the compressive strength of ultra-high-performance concrete is very high and steel fibers have been added, it still exhibits considerable brittleness, causing the beam’s bearing capacity to rapidly drop from its peak, leading to fluctuations in the curve. However, due to the presence of steel shapes in the cross-section, the beam does not fail, continues to carry loads, and its bearing capacity rises again after undergoing significant deformation while the curve maintains a stable change. At this point, the ultimate load is reached, and the compression zone of the concrete experiences crushing phenomena.

Table 3 compares the experimental yield load

Pyt and ultimate load

Put data with the finite element simulation results (

PyFE and

PuFE). The average ratio of experimental values to simulated values is 1.000, with a standard deviation of 0.0141 and a coefficient of variation of 0.0141. These statistics indicate that the finite element simulation results closely align with the experimental data, demonstrating a high degree of consistency. The constitutive model of materials under different loads may not fully account for all nonlinear factors. There is a discrepancy between the actual loading conditions of the structure and the idealized conditions assumed in the model. The setting of boundary conditions in the finite element model, whether it accurately reflects the real situation, may affect the analysis results. Overall, there is a high degree of consistency between the results of finite element analysis and experimental measurements. However, it is noteworthy that, despite the small deviations, continuous validation and calibration of the finite element model are needed to enhance the accuracy of predictions and the reliability of the model. Future work could consider gathering more experimental data and conducting comprehensive analyses under various conditions to further improve the model’s accuracy.