Prediction of Strength Properties of Reinforced and Stabilized Sandy Soil as a Building Foundation Material

Abstract

1. Introduction

| Soil Classification (USCS) | Objective | Fiber Type | Chemical Additive | Testing Program | Results | Ref. |

|---|---|---|---|---|---|---|

| SC-SM (Clayey Sand–Silty Sand) | Improved long-term dynamic behavior of a sandy subgrade reinforced by waste tire textile fibers. | Recycled tire fiber | - | Compaction and repeated load triaxial (RLT) test. |

| [7] |

| CL | Clay reinforcement using recycled tire fibers and glass fibers. | Recycled tire fiber and glass fiber | - | Compaction, UCS, and direct shear test. |

| [14] |

| CL | Improved mechanical properties of fiber-reinforced and geopolymer-stabilized clay soil. | Basalt fiber | Metakaolin, quicklime, sodium silicate | UCS, direct shear, and indirect tensile test. Diffraction analysis, and microstructural analysis. |

| [30] |

| CL | Improved mechanical and microstructural properties of waste tire improved cemented clay. | Tire rubber fiber | Cement | UCS, SEM, and ultrasonic pulse velocity test. |

| [31] |

2. Scope and Limitations

2.1. Scope

2.2. Limitations

3. Materials and Methods

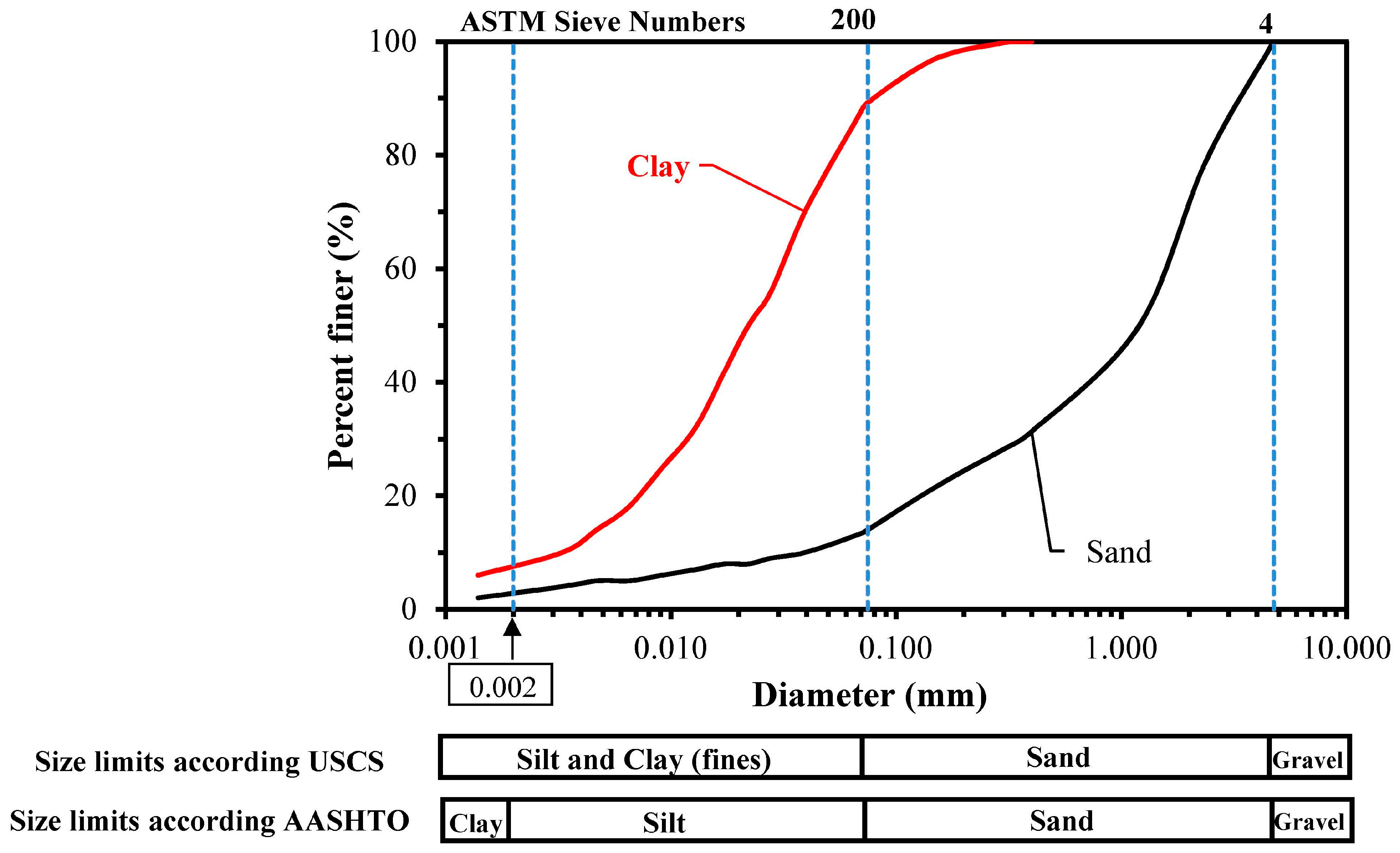

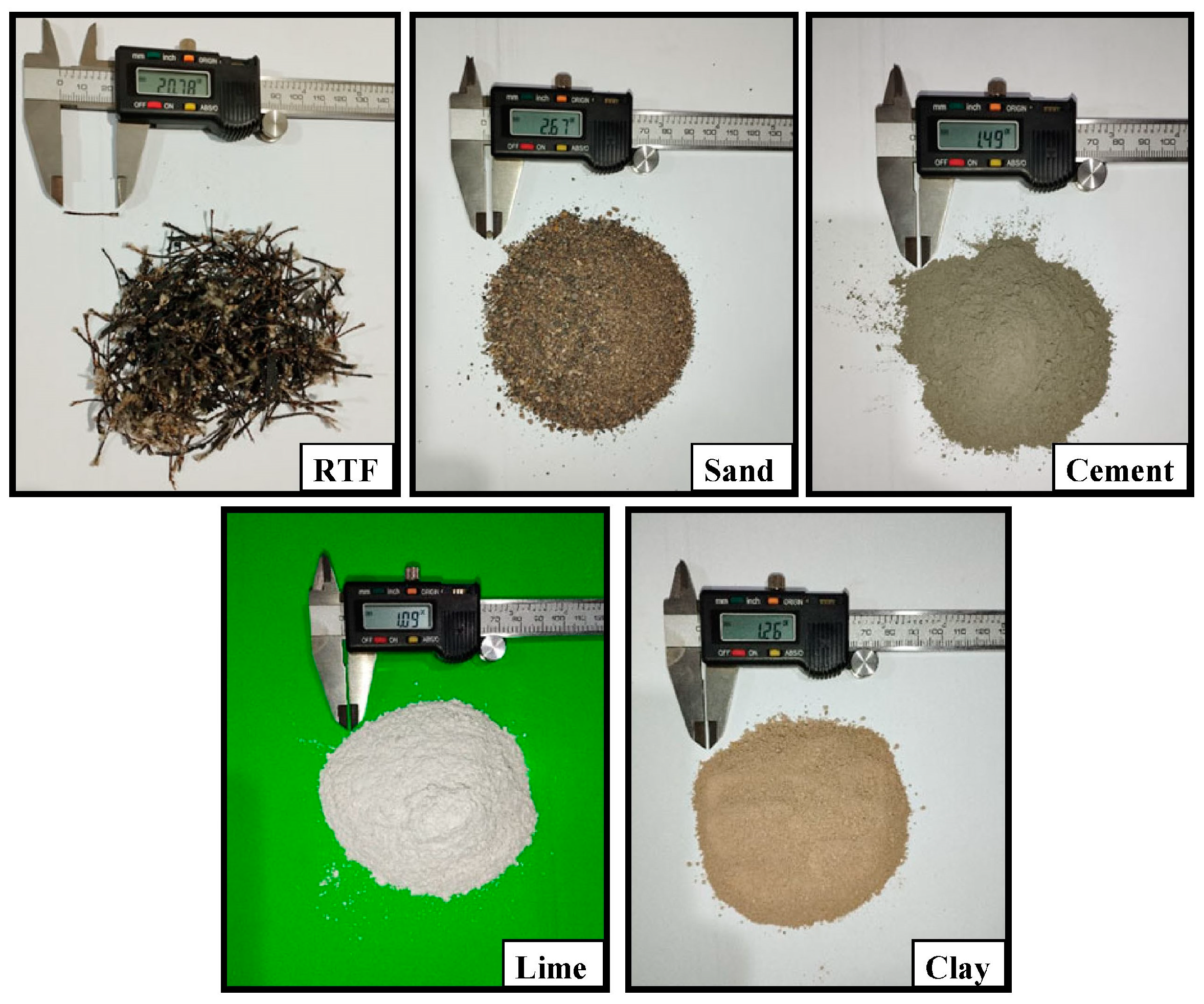

3.1. Natural Soils and Stabilizers

3.2. Recycled Tire Fibers

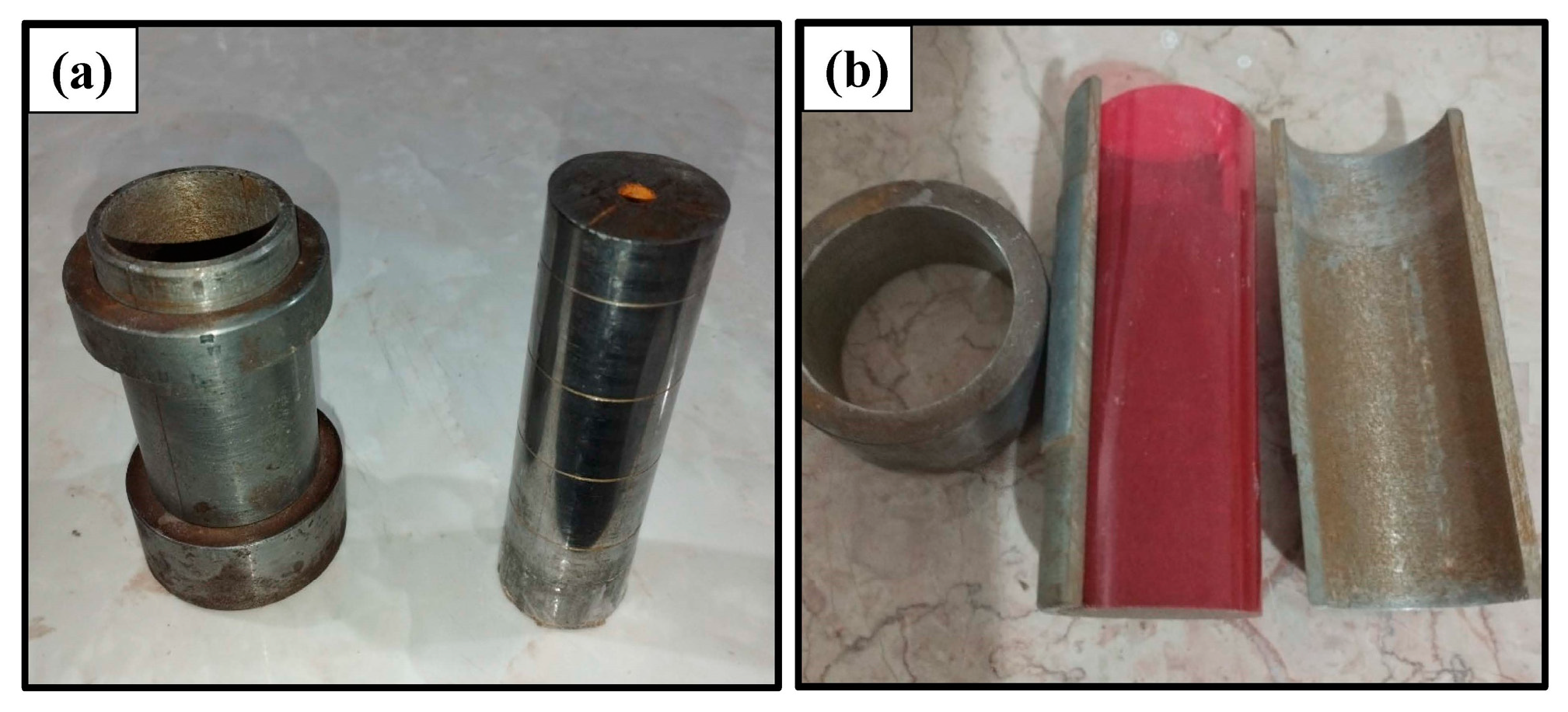

3.3. Mixtures, Sample Preparation, and UCS Testing

3.4. Determination of Strength Properties

3.5. Scanning Electron Microscopy (SEM)

4. Results and Discussion

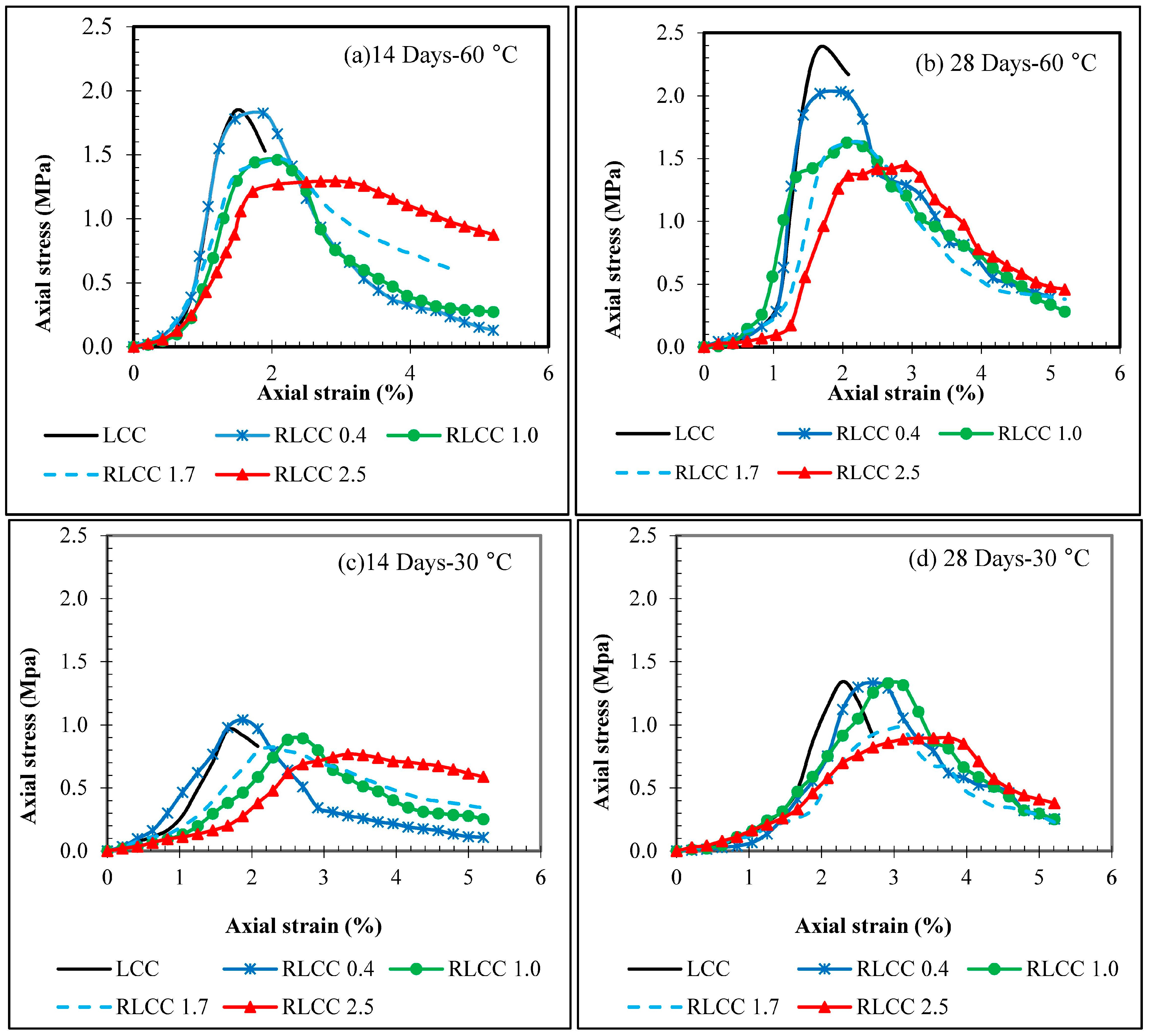

4.1. Uniaxial Compressive Strength

- Initial Compression Region (AB): This region represents the initial compression of the stress–strain curve, where uneven surfaces in contact with the loading jaw are leveled and voids are compressed. In this region, the strain increases rapidly but the stress grows at a slower rate.

- Linear Region (BC): In this region, the stress–strain curve exhibits a linear increase, indicating the stable development of cracks in the sample. Compared to the AB region, the strain increases at a slower rate, and the stress–strain curve has a steeper slope. As shown in Figure 5, increasing the cement content in the mix leads to a steeper slope in this region.

- Nonlinear Region (CD): This region corresponds to the accelerated expansion of cracks, where the stress–strain curve becomes nonlinear. Strain increases at a faster rate compared to the BC region. The stress reaches its maximum value at the end of this region, referred to as the unconfined compressive strength (UCS), and the corresponding strain is called the failure strain.

- Failure Region (DE): Beyond the failure strain, the stress–strain curve descends as the strain increases, indicating a reduction in the sample’s load-bearing capacity.

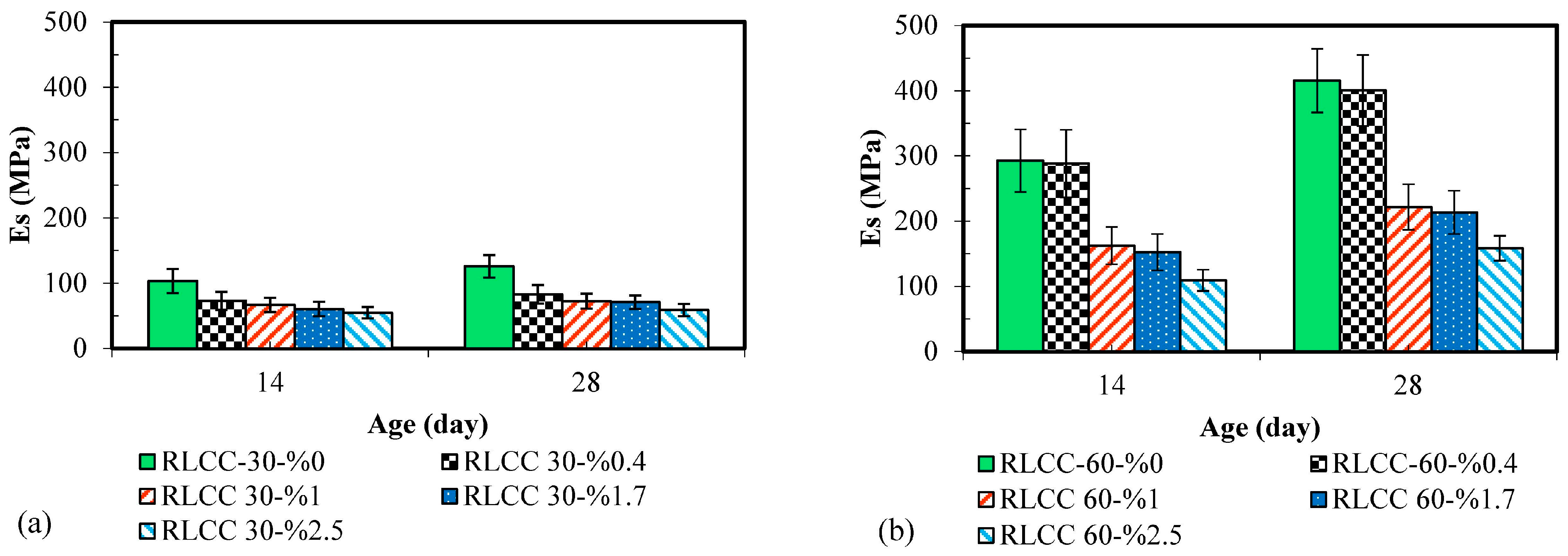

4.2. Modulus of Elasticity

4.3. Scanning Electron Microscope Images

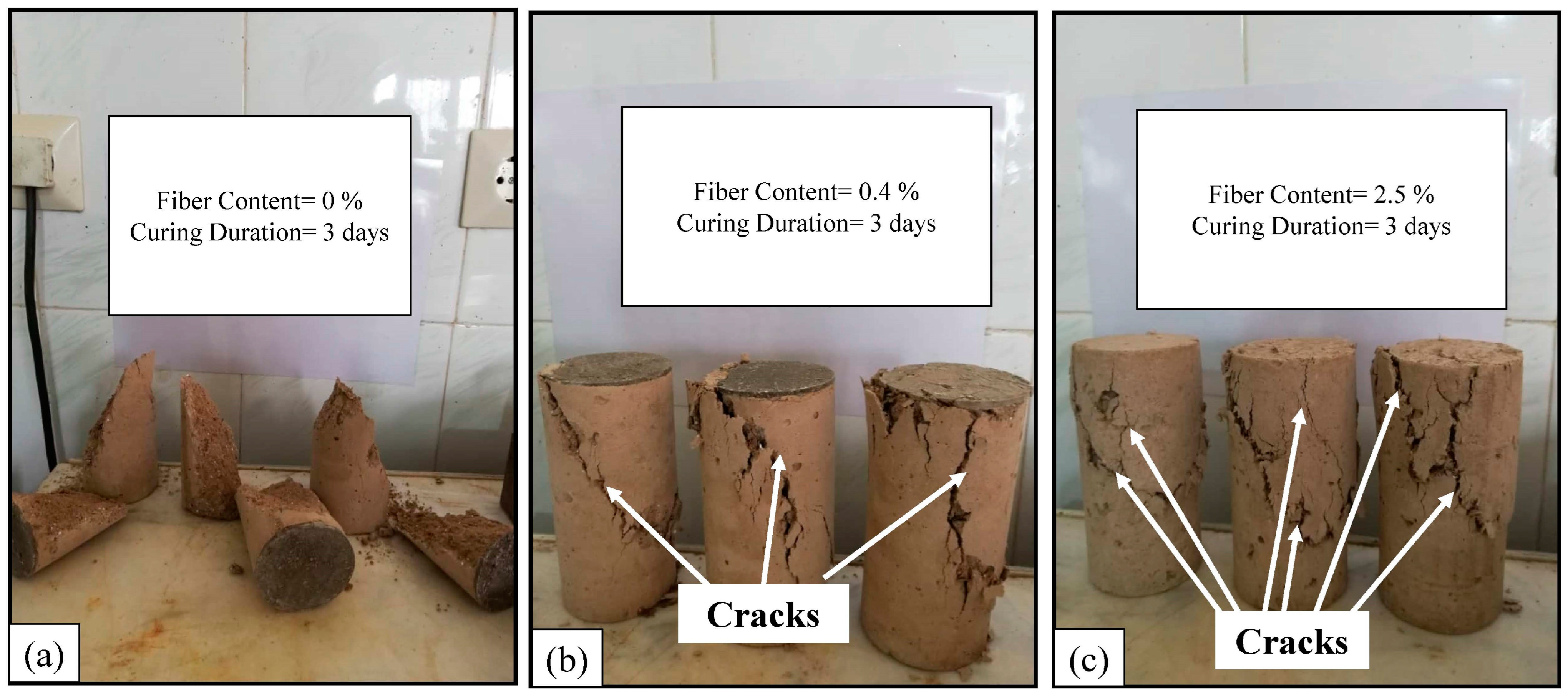

4.4. Effect of Fibers on the Failure Pattern of Samples

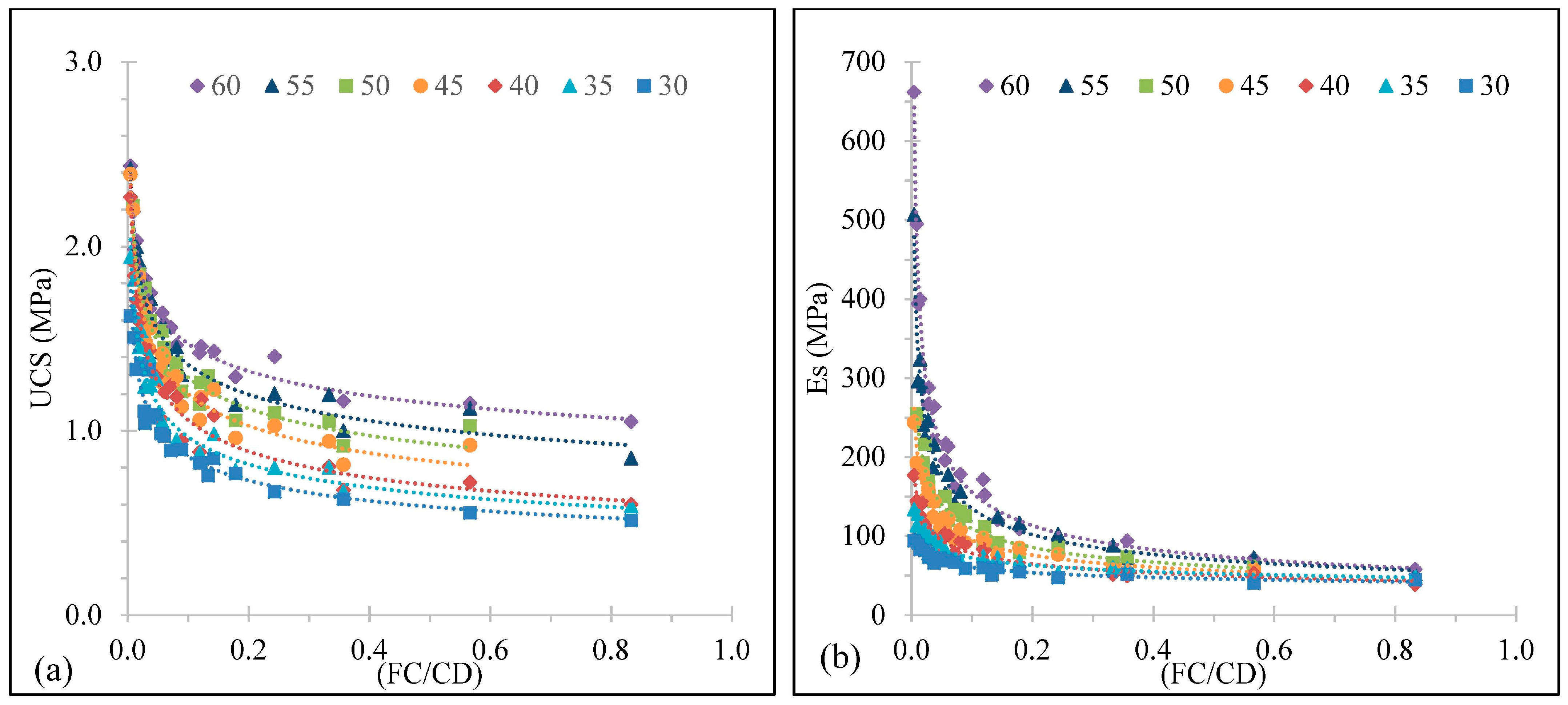

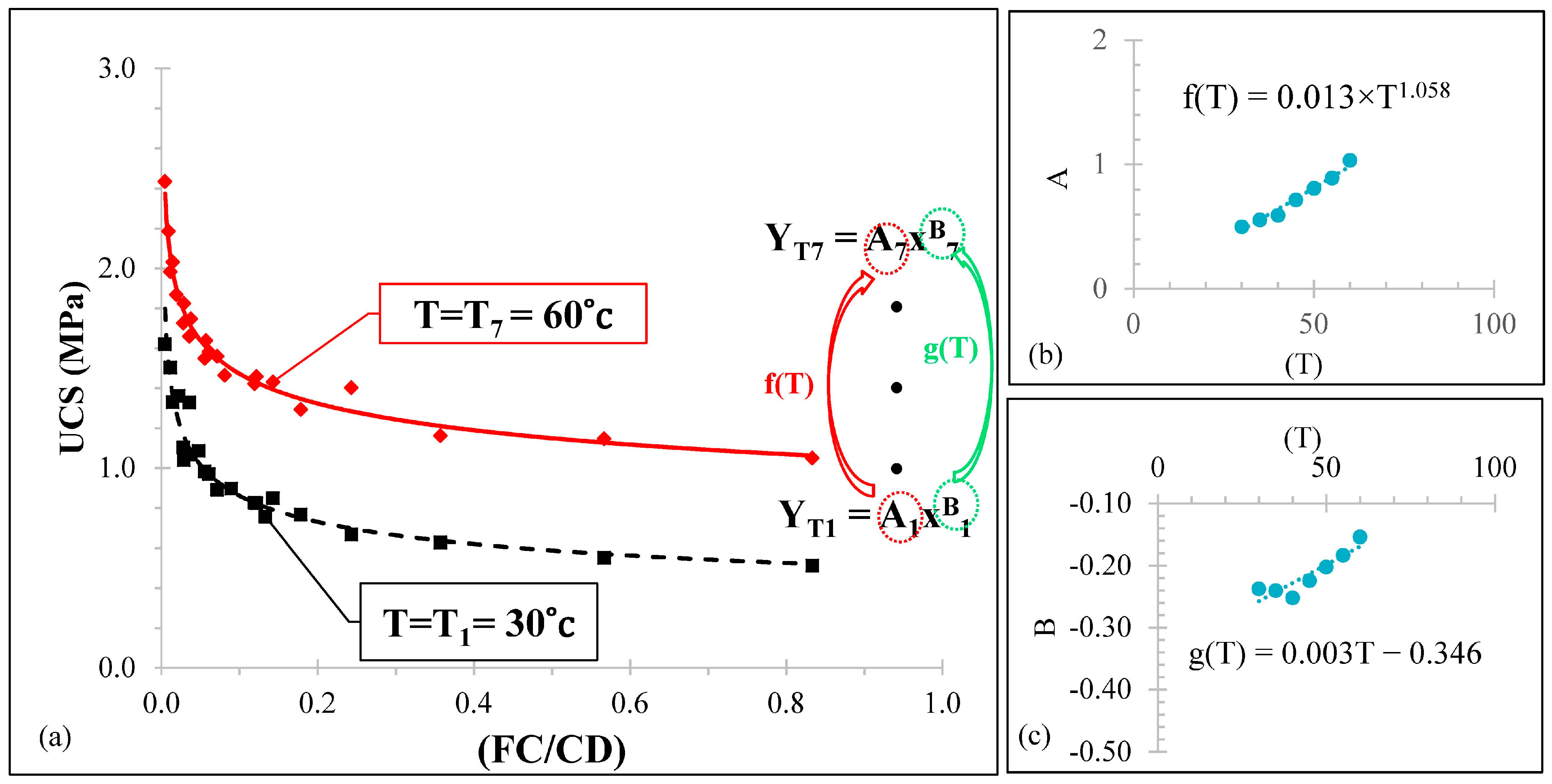

4.5. Mathematical Model for Predicting Strength Properties

4.6. Discussion on the Scale Effect

5. Conclusions

- The curing age was one of the most important factors in governing the behavior of mixtures. As an example, the UCS of the 28-day Lime Cement Concrete (LCC) samples cured at 30 °C was 40% higher than the corresponding 14-day samples. Also, the modulus of elasticity (Es) of the 28-day LCC samples cured at 30 °C was 1.22 times greater than that of the 14-day samples.

- The curing temperature was another factor that significantly influenced the behavior of materials. As an example, the UCS of LCC samples that were cured for 14 and 28 days at 60 °C was 1.92 and 1.78 times the corresponding samples that were cured for 14 and 28 days at 30 °C, respectively. Also, the modulus of elasticity of the LCC samples cured at 60 °C was 183.7% and 230.5% greater than that of the 14- and 28-day samples cured at 30 °C.

- The addition of fibers increased the ductility of samples; however, it also decreased their strength. Thus, an important positive role of fibers was controlling the width of cracks and preventing their expansion. This resulted in changing the behavior of mixtures from a brittle to a ductile building material, which prevents a sudden and catastrophic failure due to loading. For example, the failure strain in 14-day samples cured at 60 °C without fibers was 1.466%. By introducing 0.4%, 1%, 1.7%, and 2.5% of fiber content, the failure strain increased to reach 1.874%, 2.082%, 2.199%, and 2.915%, respectively. The issue of ductility is important when constructing retaining walls and building foundations, as it allows the structure to withstand a greater level of deformation before causing structural failure.

- Microstructural studies supported the strength testing outcomes. Based on scanning electron microscopy (SEM) results, the addition of clay, cement, and lime to the soil greatly reduced the pores in the soil, resulting in the improvement of various properties of the stabilized soil. SEM images also revealed that the bonds formed from pozzolanic reactions did not effectively penetrate the fibers to establish a strong bond. Consequently, the addition of fibers to the mixture did not effectively increase the strength properties, although it did enhance the ductility.

- The role of fibers in controlling the width of cracks and preventing their expansion is an effective factor in changing the behavior of materials from brittle to ductile and from strain-softening to strain-hardening.

- The developed predictive mathematical model is capable of predicting the UCS and Es of stabilized and reinforced sandy soil. The proposed equations are able to provide building designers with an initial estimation of the strength properties of stabilized and reinforced sandy soil in applications such as foundation stabilization, the guarding of retaining walls, or in soil reinforcement projects, using commonly available laboratory tests.

- Using fiber for soil stabilization is a method that has the advantages of both reinforcement and stabilization, and this method can be used in construction projects that require soil improvement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Notations and Abbreviations

| γdmax | Maximum dry density |

| ωopt | Optimum moisture content |

| Cc | Coefficient of curvature |

| Cu | Coefficient of uniformity |

| D10 | Effective particle size |

| Es | Modulus of elasticity (MPa) |

| Gs | Specific gravity |

| LL | Liquid limit |

| PI | Plasticity Index |

| T | Temperature (°C) |

| BSE | Backscattered electrons |

| CA | Curing age (day) |

| CC | Cement concrete |

| CL | Clay with low plasticity |

| CT | Curing temperature (°C) |

| FC | Fiber content (% of total dry weight of materials) |

| LC | Lime Concrete |

| LCC | Lime–Cement Concrete |

| LOI | Loss on ignition |

| NOS | Number of samples |

| OPC | Ordinary Portland cement |

| RLCC | Reinforced Lime–Cement Concrete |

| RTF | Recycled tire fiber |

| SEM | Scanning electron microscopy |

| SM | Silty sand |

| UCS | Unconfined compressive strength |

| USCS | Unified soil classification system |

| % DWM | % of dry weight of materials |

References

- Jafari, M.M.; Bagheripour, M.H.; Lakzadeh, M. Experimental Study of the Effect of Polypropylene Fiber on Mechanical Properties of Lime and Cement Stabilized Soil. Karafan J. 2021, 19, 59–81. [Google Scholar]

- Yaghoubi, E.; Azadegan, O.; Li, J. Effect of surface layer thickness on the performance of lime and cement treated aggregate surfaced roads. Electron. J. Geotech. Eng. 2013, 18, 1081–1094. [Google Scholar]

- Jahandari, S.; Saberian, M.; Zivari, F.; Li, J.; Ghasemi, M.; Vali, R. Experimental study of the effects of curing time on geotechnical properties of stabilized clay with lime and geogrid. Int. J. Geotech. Eng. 2019, 13, 172–183. [Google Scholar] [CrossRef]

- Jahandari, S.; Saberian, M.; Tao, Z.; Mojtahedi, S.F.; Li, J.; Ghasemi, M.; Rezvani, S.S.; Li, W. Effects of saturation degrees, freezing-thawing, and curing on geotechnical properties of lime and lime-cement concretes. Cold Reg. Sci. Technol. 2019, 160, 242–251. [Google Scholar] [CrossRef]

- Jafari, M.M.; Bagheripour, M.H. Laboratory study of the effect of age, temperature and fiber content on the behavior of environmentally friendly Reinforced Lime-Cement Concrete (RLCC). J. Civ. Environ. Eng. 2022, 53, 61–75. [Google Scholar]

- Baadiga, R.; Balunaini, U. Evaluation of pavement design input parameters of biaxial and triaxial geogrid stabilized flexible pavements overlying soft subgrades. Clean. Mater. 2023, 9, 100192. [Google Scholar] [CrossRef]

- Narani, S.; Abbaspour, M.; Hosseini, S.M.M.; Nejad, F.M. Long-term dynamic behavior of a sandy subgrade reinforced by Waste Tire Textile Fibers (WTTFs). Transp. Geotech. 2020, 24, 100375. [Google Scholar] [CrossRef]

- Mirzababaei, M.; Miraftab, M.; Mohamed, M.; McMahon, P. Unconfined Compression Strength of Reinforced Clays with Carpet Waste Fibers. J. Geotech. Geoenv. Eng. 2013, 139, 483–493. [Google Scholar] [CrossRef]

- Bilondi, M.P.; Toufigh, M.M.; Toufigh, V. Using calcium carbide residue as an alkaline activator for glass powder–clay geopolymer. Constr. Build. Mater. 2018, 183, 417–428. [Google Scholar] [CrossRef]

- Koley, S. Arsenic calamity in India’s West Bengal: A critical review of mitigation scenarios. Proc. Inst. Civ. Eng.-Eng. Sustain. 2023, 176, 198–213. [Google Scholar] [CrossRef]

- Silva, S.S.; Mendes, B.C.; da Silva, T.O.; Lopes, E.C.; Ferreira, F.A.; Pedroti, L.G. Use of Red Mud in Soil Stabilization for Pavement Through Alkali Activation. In TMS Annual Meeting & Exhibition; Springer: Cham, Switzerland, 2024; pp. 693–700. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Mohammadinia, A.; Disfani, M.M.; Narsilio, G.A.; Aye, L. Mechanical behaviour and load bearing mechanism of high porosity permeable pavements utilizing recycled tire aggregates. Constr. Build. Mater. 2018, 168, 794–804. [Google Scholar] [CrossRef]

- Valipour, M.; Shourijeh, P.T.; Mohammadinia, A. Application of recycled tire polymer fibers and glass fibers for clay reinforcement. Transp. Geotech. 2021, 27, 100474. [Google Scholar] [CrossRef]

- Saberian, M.; Khotbehsara, M.M.; Jahandari, S.; Vali, R.; Li, J. Experimental and phenomenological study of the effects of adding shredded tire chips on geotechnical properties of peat. Int. J. Geotech. Eng. 2018, 12, 347–356. [Google Scholar] [CrossRef]

- Hataf, N.; Rahimi, M.M. Experimental investigation of bearing capacity of sand reinforced with randomly distributed tire shreds. Constr. Build. Mater. 2006, 20, 910–916. [Google Scholar] [CrossRef]

- Arulrajah, A.; Mohammadinia, A.; Maghool, F.; Horpibulsuk, S. Tire derived aggregates as a supplementary material with recycled demolition concrete for pavement applications. J. Clean. Prod. 2019, 230, 129–136. [Google Scholar] [CrossRef]

- Kalkan, E. Preparation of scrap tire rubber fiber-silica fume mixtures for modification of clayey soils. Appl. Clay Sci. 2013, 80–81, 117–125. [Google Scholar] [CrossRef]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A state-of-the-art review of polymers used in soil stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Abdeldjouad, L.; Asadi, A.; Nahazanan, H.; Huat, B.B.K.; Dheyab, W.; Elkhebu, A.G. Effect of Clay Content on Soil Stabilization with Alkaline Activation. Int. J. Geosynth. Ground Eng. 2019, 5, 4. [Google Scholar] [CrossRef]

- Kastiukas, G.; Zhou, X. Effects of waste glass on alkali-activated tungsten mining waste: Composition and mechanical properties. Mater. Struct. 2017, 50, 194. [Google Scholar] [CrossRef]

- Adeyanju, E.A.; Okeke, C.A. Clay soil stabilization using cement kiln dust. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012080. [Google Scholar] [CrossRef]

- Kermanipour, M.J.; Bagheripour, M.H.; Yaghoubi, E. Mechanical and Microstructural Characterization of a Nano-stabilized Sandy Soil. Geotech. Geol. Eng. 2024, 42, 6131–6146. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Zhang, M.; Jiang, X.; Zhang, Y.; Huang, B.; Hu, W. Evaluation of Glass Powder-Based Geopolymer Stabilized Road Bases Containing Recycled Waste Glass Aggregate. Transp. Res. Rec. 2020, 2674, 22–32. [Google Scholar] [CrossRef]

- Abed, M.H.; Abed, F.H.; Zareei, S.A.; Abbas, I.S.; Canakci, H.; Kurdi, N.H.; Emami, A. Experimental feasibility study of using eco- and user-friendly mechanochemically activated slag/fly ash geopolymer for soil stabilization. Clean. Mater. 2024, 11, 100226. [Google Scholar] [CrossRef]

- Cong, M.; Longzhu, C.; Bing, C. Analysis of strength development in soft clay stabilized with cement-based stabilizer. Constr. Build. Mater. 2014, 71, 354–362. [Google Scholar] [CrossRef]

- Yonekura, R.; Kaga, M. Current Chemical Grout Engineering in Japan. In Grouting, Soil Improvement and Geosynthetics; American Society of Civil Engineers: Reston, VA, USA, 1992. [Google Scholar]

- Horpibulsuk, S.; Rachan, R.; Suddeepong, A. Assessment of strength development in blended cement admixed Bangkok clay. Constr. Build. Mater. 2011, 25, 1521–1531. [Google Scholar] [CrossRef]

- Jahandari, S.; Mojtahedi, S.F.; Zivari, F.; Jafari, M.; Mahmoudi, M.R.; Shokrgozar, A.; Kharazmi, S.; Hosseini, B.V.; Rezvani, S.; Jalalifar, H. The impact of long-term curing period on the mechanical features of lime-geogrid treated soils. Géoméch. Geoengin. 2022, 17, 269–281. [Google Scholar] [CrossRef]

- Wang, S.; Xue, Q.; Ma, W.; Zhao, K.; Wu, Z. Experimental study on mechanical properties of fiber-reinforced and geopolymer-stabilized clay soil. Constr. Build. Mater. 2021, 272, 121914. [Google Scholar] [CrossRef]

- Al-Subari, L.; Ekinci, A. Evaluation of Mechanical and Microstructural Properties of Waste Tire Improved Cemented Clay. J. Nat. Fibers 2024, 21, 2349750. [Google Scholar] [CrossRef]

- Habibi, A.A.; Tafti, M.F.; Narani, S.; Abbaspour, M. Effects of waste tire textile fibres on geotechnical properties of compacted lime-stabilized low plastic clays. Int. J. Geotech. Eng. 2021, 15, 1118–1134. [Google Scholar] [CrossRef]

- ASTM D422-63; Standard Method for Particle-Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM D2487-11; Standard Practice for Classification of Soils for Engineering Purposes. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D423-66; Standard Test Method of Test for Liquid Limit of Soil. ASTM International: West Conshohocken, PA, USA, 1972.

- Das, B.M. Advanced Soil Mechanics; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar] [CrossRef]

- ASTM D 854-10; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2010.

- AASHTO T 99; Standard Method of Test for Moisture-Density Relations of Soils Using a 2.5-kg (5.5-lb) Rammer and a 305-mm (12-in.) Drop. American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2022.

- ASTM C977-18; Standard Specification for Quicklime and Hydrated Lime for Soil Stabilization. ASTM International: West Conshohocken, PA, USA, 2018.

- Abbaspour, M.; Narani, S.S.; Aflaki, E.; Nejad, F.M. Dynamic characteristics of a sandy subgrade reinforced by waste tire textile fibres. Int. J. Pavement Eng. 2022, 23, 2293–2308. [Google Scholar] [CrossRef]

- Abbaspour, M.; Narani, S.S.; Aflaki, E.; Nejad, F.M.; Hosseini, S.M.M.M. Strength and swelling properties of a waste tire textile fiber-reinforced expansive soil. Geosynth. Int. 2020, 27, 476–489. [Google Scholar] [CrossRef]

- ASTM D885 -02(2017); Standard Test Methods for Tire Cords, Tire Cord Fabrics, and Industrial Filament Yarns Made from Manufactured Organic-Base Fibers. ASTM International: West Conshohocken, PA, USA, 2017.

- Jahandari, S.; Toufigh, M.M.; Li, J.; Saberian, M. Laboratory Study of the Effect of Degrees of Saturation on Lime Concrete Resistance Due to the Groundwater Level Increment. Geotech. Geol. Eng. 2018, 36, 413–424. [Google Scholar] [CrossRef]

- Abbaspour, M.; Narani, S.S.; Aflaki, E.; Nejad, F.M. Behavior of a Subgrade Soil Reinforced by Waste Tire Textile Fibers under Static and Cyclic Loading. J. Mater. Civ. Eng. 2020, 32, 04020208. [Google Scholar] [CrossRef]

- Morin, M.A.; Ficarazzo, F. Monte Carlo simulation as a tool to predict blasting fragmentation based on the Kuz–Ram model. Comput. Geosci. 2006, 32, 352–359. [Google Scholar] [CrossRef]

- Liu, J.; Feng, Q.; Wang, Y.; Zhang, D.; Wei, J.; Kanungo, D.P. Experimental Study on Unconfined Compressive Strength of Organic Polymer Reinforced Sand. Int. J. Polym. Sci. 2018, 2018, 3503415. [Google Scholar] [CrossRef]

- Saberian, M.; Jahandari, S.; Li, J.; Zivari, F. Effect of curing, capillary action, and groundwater level increment on geotechnical properties of lime concrete: Experimental and prediction studies. J. Rock Mech. Geotech. Eng. 2017, 9, 638–647. [Google Scholar] [CrossRef]

- Mohammadifar, L.; Miraki, H.; Rahmani, A.; Jahandari, S.; Mehdizadeh, B.; Rasekh, H.; Samadi, P.; Samali, B. Properties of Lime-Cement Concrete Containing Various Amounts of Waste Tire Powder under Different Ground Moisture Conditions. Polymers 2022, 14, 482. [Google Scholar] [CrossRef]

- Tang, L.; Cong, S.; Geng, L.; Ling, X.; Gan, F. The effect of freeze-thaw cycling on the mechanical properties of expansive soils. Cold Reg. Sci. Technol. 2018, 145, 197–207. [Google Scholar] [CrossRef]

- Park, S.-S. Effect of fiber reinforcement and distribution on unconfined compressive strength of fiber-reinforced cemented sand. Geotext. Geomembr. 2009, 27, 162–166. [Google Scholar] [CrossRef]

- Guleria, S.; Dutta, R. Effect of addition of tire chips on the unconfined compressive strength of fly ash-lime-gypsum mixture. Int. J. Geotech. Eng. 2012, 6, 1–13. [Google Scholar] [CrossRef]

- Singh, S.P.; Roy, N.; Sangita, S. Strength and hydraulic conductivity of sedimented ash deposits treated with lime column. Int. J. Geotech. Eng. 2017, 11, 217–224. [Google Scholar] [CrossRef]

- Yi, Y.; Gu, L.; Liu, S. Microstructural and mechanical properties of marine soft clay stabilized by lime-activated ground granulated blastfurnace slag. Appl. Clay Sci. 2015, 103, 71–76. [Google Scholar] [CrossRef]

- Bekhiti, M.; Trouzine, H.; Rabehi, M. Influence of Waste Tire Rubber Fibers on Swelling Behavior, Unconfined Compressive Strength and Ductility of Cement Stabilized Bentonite Clay Soil. Constr. Build. Mater. 2019, 208, 304–313. [Google Scholar] [CrossRef]

- Consoli, N.C.; Prietto, P.D.M.; Ulbrich, L.A. Influence of Fiber and Cement Addition on Behavior of Sandy Soil. J. Geotech. Geoenv. Eng. 1998, 124, 1211–1214. [Google Scholar] [CrossRef]

- Hejazi, S.M.; Sheikhzadeh, M.; Abtahi, S.M.; Zadhoush, A. A simple review of soil reinforcement by using natural and synthetic fibers. Constr. Build. Mater. 2012, 30, 100–116. [Google Scholar] [CrossRef]

- Duan, X.L.; Zhang, J.S. Mechanical Properties, Failure Mode, and Microstructure of Soil-Cement Modified with Fly Ash and Polypropylene Fiber. Adv. Mater. Sci. Eng. 2019, 2019, 9561794. [Google Scholar] [CrossRef]

- Tang, C.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Bearce, R.G.; Mooney, M.A. Seismic Modulus Maturity Function for Lime and Lime–Cement Stabilized Clay. J. Mater. Civ. Eng. 2016, 28, 4015150. [Google Scholar] [CrossRef]

- Consoli, N.C.; Samaniego, R.A.Q.; Villalba, N.M.K. Durability, Strength, and Stiffness of Dispersive Clay–Lime Blends. J. Mater. Civ. Eng. 2016, 28, 4016124. [Google Scholar] [CrossRef]

- Saldanha, R.B.; Consoli, N.C. Accelerated Mix Design of Lime Stabilized Materials. J. Mater. Civ. Eng. 2016, 28, 6015012. [Google Scholar] [CrossRef]

- Jahandari, S.; Li, J.; Saberian, M.; Shahsavarigoughari, M. Experimental study of the effects of geogrids on elasticity modulus, brittleness, strength, and stress-strain behavior of lime stabilized kaolinitic clay. GeoResJ 2017, 13, 49–58. [Google Scholar] [CrossRef]

- Ren, Q.; Ding, L.; Dai, X.; Jiang, Z.; De Schutter, G. Prediction of Compressive Strength of Concrete with Manufactured Sand by Ensemble Classification and Regression Tree Method. J. Mater. Civ. Eng. 2021, 33, 4021135. [Google Scholar] [CrossRef]

- Ghorbani, B.; Yaghoubi, E.; Arulrajah, A. Thermal and mechanical characteristics of recycled concrete aggregates mixed with plastic wastes: Experimental investigation and mathematical modeling. Acta Geotech. 2022, 17, 3017–3032. [Google Scholar] [CrossRef]

- Buckingham, E. On Physically Similar Systems; Illustrations of the Use of Dimensional Equations. Phys. Rev. B 1914, 4, 345–376. [Google Scholar] [CrossRef]

- Langhaar, H.L. Dimensional Analysis and Theory of Models; Wiley: New York, NY, USA, 1951. [Google Scholar]

- Love, J.P. Model Testing of Geogrids in Unpaved Roads. Ph.D. Thesis, University Oxford, Oxford, UK, 1984; p. 219. [Google Scholar]

- Fakher, A.; Jones, C. A New Unit-Cell to Study the Deformation Mechanism of Super Soft Clay Overlaid by Geogrid and Sand. Geosynth. Int. 1996, 3, 349–367. [Google Scholar] [CrossRef]

- Fakher, A. Laboratory and Analytical Investigation into Construction over Super Soft Clays. Ph.D. Thesis, University of Newcastle upon Tyne, Newcastle upon Tyne, UK, 1997. [Google Scholar]

- El-Emam, M.M.; Bathurst, R.J. Influence of reinforcement parameters on the seismic response of reduced-scale reinforced soil retaining walls. Geotext. Geomembr. 2007, 25, 33–49. [Google Scholar] [CrossRef]

- Tafreshi, M.S.N.; Mehrjardi, G.T.; Ahmadi, M. Experimental and numerical investigation on circular footing subjected to incremental cyclic loads. Int. J. Civ. Eng. 2011, 9, 265–274. [Google Scholar]

- Di Filippo, G.; Casablanca, O.; Biondi, G.; Cascone, E. Calibration of a large shaking table equipment for testing geotechnical physical models under plane strain conditions. Soil Dyn. Earthq. Eng. 2023, 166, 107726. [Google Scholar] [CrossRef]

- Ma, W.; Yang, Y.; Yang, W.; Lv, C.; Yang, J.; Song, W.; Sun, H.; Zhang, L.; Zhang, K.; Yao, J. Digital Rock Mechanical Properties by Simulation of True Triaxial Test: Impact of Microscale Factors. Geotechnics 2023, 3, 3–20. [Google Scholar] [CrossRef]

- Ye, H.; Zhu, S.; Pan, J.; Zhong, C.; Han, C.; Jia, Y. Study on scale effect and particle crushing characteristics of continuously graded coarse-grained soil. Eur. J. Environ. Civ. Eng. 2024, 28, 2475–2506. [Google Scholar] [CrossRef]

| Properties | Clay | Sand | Reference |

|---|---|---|---|

| % finer than 4.75 mm | 100% | 100% | [33] |

| % finer than 75 μm | 89.2% | 14% | [33] |

| Classification (USCS) | CL | SM | [34] |

| Effective Particle Size (D10) | 0.0033 mm | 0.0395 mm | [33] |

| Average Particle Size (D50) | 0.022 mm | 1.190 mm | [33] |

| Coefficient of Uniformity (Cu) | - | 41.1 | [33] |

| Coefficient of Curvature (Cc) | - | 2.0 | [33] |

| Liquid Limit (LL) | 33% | - | [35] |

| Plasticity Index (PI) | 12% | - | [36] |

| Specific Gravity (Gs) | 2.727 | 2.673 | [37] |

| γdmax − ωopt | 18.38 kN/m3—15.9% | 16.04 kN/m3—12.9% | [38] |

| Available Oxides | Clay (%) | Sand (%) | Cement (%) | Lime (%) |

|---|---|---|---|---|

| CaO | 63.41 | 9.7 | 19.05 | 62.96 |

| SiO2 | 21.66 | 56.9 | 41.75 | 4.78 |

| Al2O3 | 4.21 | 13.2 | 14.47 | 3.90 |

| Fe2O3 | 3.10 | 4.7 | 7.08 | 1.21 |

| MgO | 2.82 | 1.7 | 1.40 | 3.97 |

| SO3 | 2.61 | 0.1 | 0.03 | 0.016 |

| Mn | - | 0.07 | - | 0.006 |

| LOI * | 0.81 | 8.48 | 13.48 | 23.15 |

| Characteristic | Values | Unit | Reference | |

|---|---|---|---|---|

| The Most Frequent | Typical Range | |||

| Diameter | 0.75 | 0.03–1.50 | mm | [42] |

| Length | 20–30 | 0–60 | mm | [42] |

| Elongation at break | 13 | 11–17 | % | [42] |

| Elastic modulus | 4.6 | 4.3–4.8 | GPa | [42] |

| Water absorption | 9 | 4–14 | % | [42] |

| Melting point | 255 | 250–260 | °C | [42] |

| Group | Abb. | CT | FC | CA | NOS | Cement (% DWM) | Lime (% DWM) |

|---|---|---|---|---|---|---|---|

| 1 | SM | 30 | 0 | 14 | 3 | 0 | 0 |

| 2 | LC | 30 | 0 | 14 | 3 | 0 | 3 |

| 3 | CC | 30 | 0 | 14 | 3 | 4 | 0 |

| 4 | LCC | 30 | 0 | 14 | 3 | 4 | 3 |

| 5 | RLCC-30 | 30 | 0-0.4-1-1.7-2.5 | 3-7-14-21-28-45-90 | 105 | 4 | 3 |

| 6 | RLCC-35 | 35 | 0-0.4-1-1.7-2.5 | 3-7-14-21-28-45-90 | 105 | 4 | 3 |

| 7 | RLCC-40 | 40 | 0-0.4-1-1.7-2.5 | 3-7-14-21-28-45-90 | 105 | 4 | 3 |

| 8 | RLCC-45 | 45 | 0-0.4-1-1.7-2.5 | 3-7-14-21-28-45-90 | 105 | 4 | 3 |

| 9 | RLCC-50 | 50 | 0-0.4-1-1.7-2.5 | 3-7-14-21-28-45-90 | 105 | 4 | 3 |

| 10 | RLCC-55 | 55 | 0-0.4-1-1.7-2.5 | 3-7-14-21-28-45-90 | 105 | 4 | 3 |

| 11 | RLCC-60 | 60 | 0-0.4-1-1.7-2.5 | 3-7-14-21-28-45-90 | 105 | 4 | 3 |

| Fiber Cont. (%) | Curing Age (Day) | UCS (MPa) | Es (MPa) | ||

|---|---|---|---|---|---|

| 30 °C | 60 °C | 30 °C | 60 °C | ||

| 0 | 14 | 0.96 | 1.84 | 103.2 | 292.8 |

| 0.4 | 14 | 1.04 | 1.83 | 73.0 | 288.2 |

| 1.0 | 14 | 0.89 | 1.56 | 66.7 | 162.5 |

| 1.7 | 14 | 0.83 | 1.46 | 60.2 | 152.4 |

| 2.5 | 14 | 0.77 | 1.29 | 54.6 | 109.1 |

| 0 | 28 | 1.34 | 2.39 | 125.7 | 415.5 |

| 0.4 | 28 | 1.33 | 2.03 | 83.0 | 400.3 |

| 1.0 | 28 | 1.33 | 1.66 | 72.4 | 221.5 |

| 1.7 | 28 | 0.97 | 1.58 | 70.8 | 213.5 |

| 2.5 | 28 | 0.90 | 1.44 | 58.9 | 158.5 |

| Predictive Mathematical Model | T °C | R2 |

|---|---|---|

| UCS = 0.499 × (FC/CD)−0.237 | 30 | 0.955 |

| UCS = 0.556 × (FC/CD)−0.240 | 35 | 0.950 |

| UCS = 0.592 × (FC/CD)−0.252 | 40 | 0.950 |

| UCS = 0.716 × (FC/CD)−0.224 | 45 | 0.942 |

| UCS = 0.810 × (FC/CD)−0.202 | 50 | 0.925 |

| UCS = 0.891 × (FC/CD)−0.183 | 55 | 0.949 |

| UCS = 1.033 × (FC/CD)−0.154 | 60 | 0.975 |

| Predictive Mathematical Model | T °C | R2 |

|---|---|---|

| Es = 40.802 × (FC/CD)−0.170 | 30 | 0.926 |

| Es = 45.779 × (FC/CD)−0.199 | 35 | 0.910 |

| Es = 41.602 × (FC/CD)−0.274 | 40 | 0.945 |

| Es = 44.900 × (FC/CD)−0.325 | 45 | 0.949 |

| Es = 48.444 × (FC/CD)−0.353 | 50 | 0.955 |

| Es = 52.818 × (FC/CD)−0.407 | 55 | 0.973 |

| Es = 54.471 × (FC/CD)−0.456 | 60 | 0.981 |

| Property | Predictive Mathematical Model | R2 |

|---|---|---|

| UCS | UCS (MPa) = (0.01 × T1.058) × (FC/CD)(0.003T − 0.35) | 0.95 |

| Modulus of Elasticity | Es (MPa) = (10.51 × T0.395) × (FC/CD)(−0.0098T + 0.1275) | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jafari, M.M.; Bagheripour, M.H.; Yaghoubi, E. Prediction of Strength Properties of Reinforced and Stabilized Sandy Soil as a Building Foundation Material. Buildings 2025, 15, 382. https://doi.org/10.3390/buildings15030382

Jafari MM, Bagheripour MH, Yaghoubi E. Prediction of Strength Properties of Reinforced and Stabilized Sandy Soil as a Building Foundation Material. Buildings. 2025; 15(3):382. https://doi.org/10.3390/buildings15030382

Chicago/Turabian StyleJafari, Mohammad Mostafa, Mohammad Hossein Bagheripour, and Ehsan Yaghoubi. 2025. "Prediction of Strength Properties of Reinforced and Stabilized Sandy Soil as a Building Foundation Material" Buildings 15, no. 3: 382. https://doi.org/10.3390/buildings15030382

APA StyleJafari, M. M., Bagheripour, M. H., & Yaghoubi, E. (2025). Prediction of Strength Properties of Reinforced and Stabilized Sandy Soil as a Building Foundation Material. Buildings, 15(3), 382. https://doi.org/10.3390/buildings15030382