Barriers, Bottlenecks, and Challenges in Implementing Safety I- and Safety II-Enabled Safe Systems of Working in Construction Projects: A Scoping Review

Abstract

1. Introduction

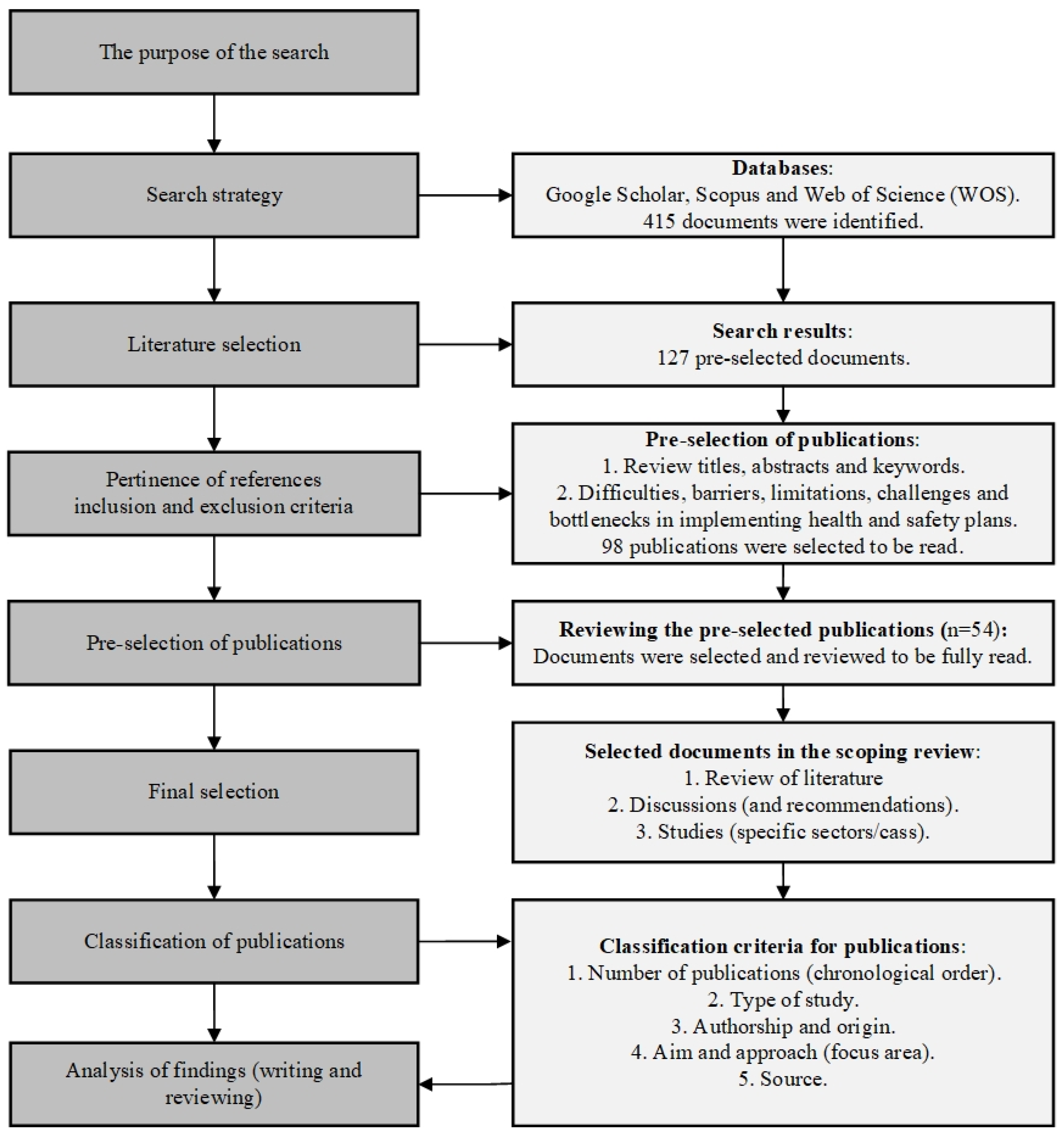

2. Research Methodology

2.1. Study Design

2.2. Literature Search

2.3. Literature Selection

3. Findings

3.1. Safety I: Traditional Safety Approaches in Construction

3.2. Safety II: The New Paradigm in Construction Safety

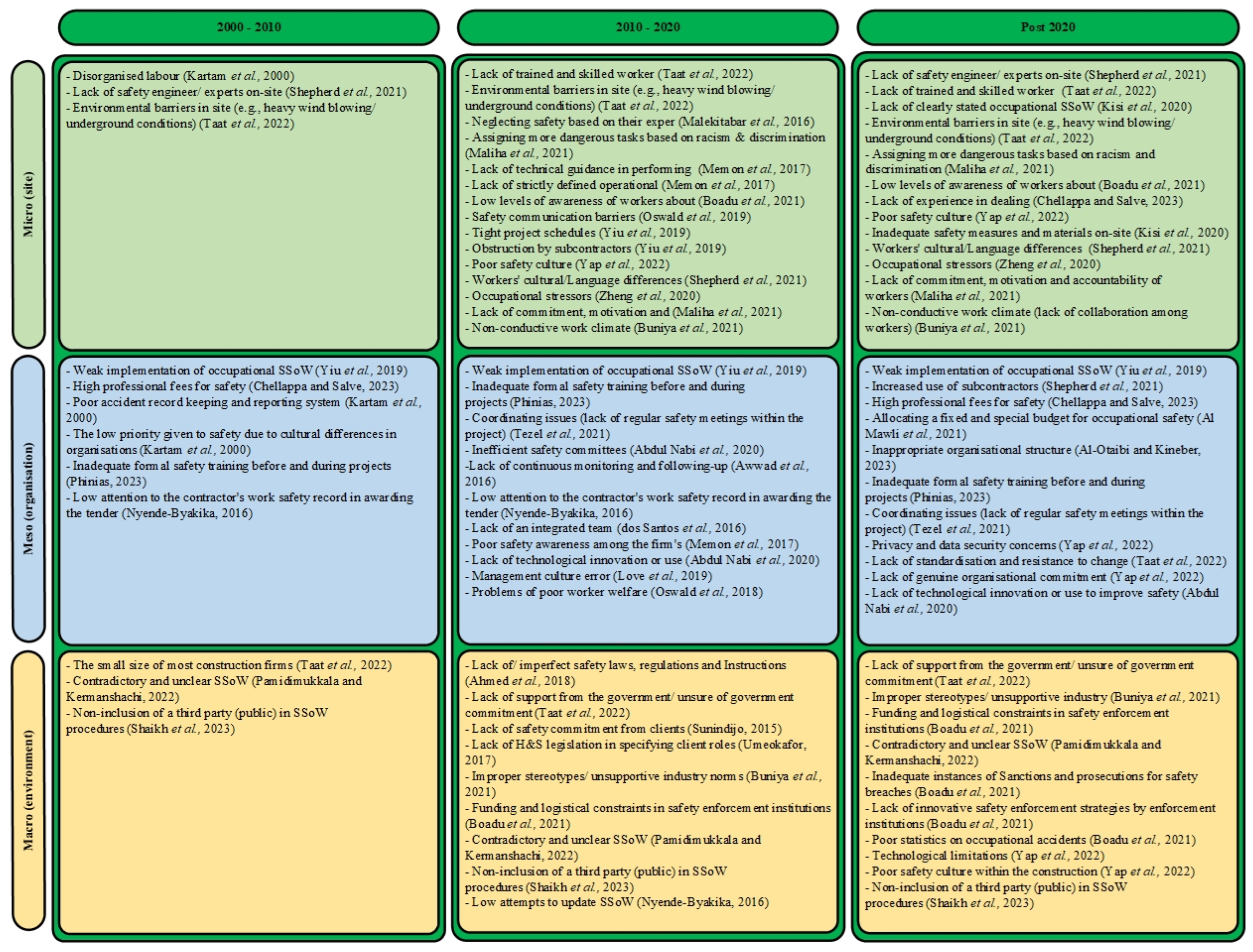

3.3. Barriers, Bottlenecks and Challenges of Implementation of Safety I- and II-Enabled SSoWs

3.4. Chronological Discussion

3.4.1. The New Millennium (2000s)

3.4.2. 2010–2020

3.4.3. Post 2020

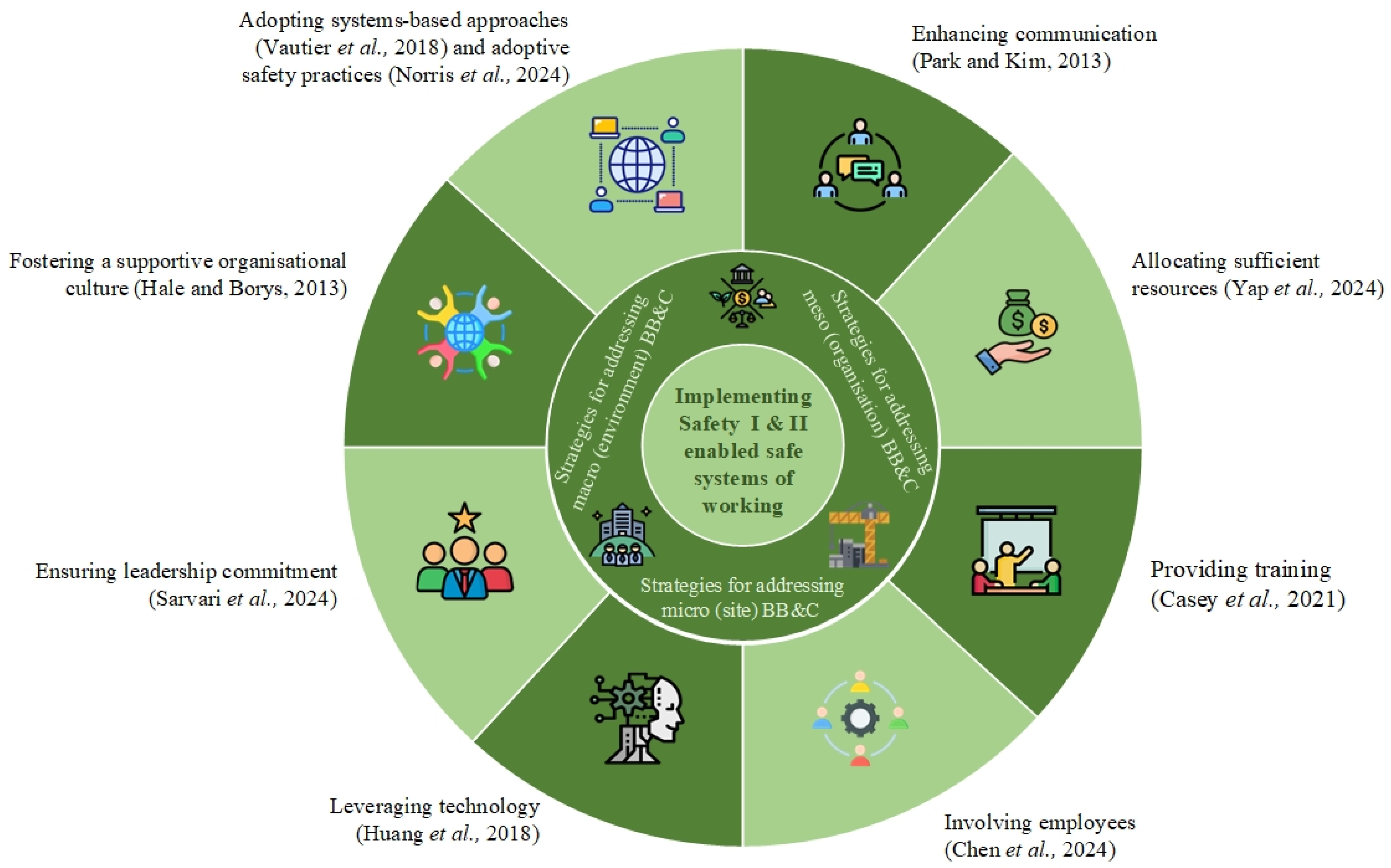

4. Discussion and Implications

4.1. Strategies for Facilitating the Implementation of Safety I- and II-Enabled SSoWs

4.2. Research Limitations

4.3. Future Work

- Increasing risk awareness: future research should prioritise and develop techniques aimed at augmenting risk awareness and rectifying misperceptions through specialised training and educational initiatives tailored to construction professionals [29];

- Developing industry standards: To tackle the issues of tight project schedules, insufficient dedication to safety and the absence of safety regulations and policies, future research should investigate strategies to enhance industry standards and cultivate a culture that prioritises safety. This may entail the creation of frameworks to enhance safety governance and policy formation that can be adjusted to suit the requirements of nations [176];

- Upgrading governance and policy frameworks: An additional crucial element in implementing Safety I- and II-enabled SSoWs is establishing a governance structure to enhance safety performance. Subsequent investigations should focus on developing and executing appropriate governance frameworks customised to various regions’ distinct regulatory and cultural environments [113];

- Incorporating safety into design processes: Further investigation should also examine the advancement of alternative project delivery systems, such as Design–Build, which could more efficiently incorporate safety issues starting from the design stage [192];

- Utilising technology to address organisational and systemic obstacles: Future studies should explore methods to address obstacles related to organisational, infrastructure, expenses, and system integration. One such approach is to create a framework that combines IoT and other upcoming technologies with current safety management approaches [26];

- Developing risk and safety management models: future studies must prioritise the creation of models capable of accurately delineating the interconnections between the BB&Cs and provide guidance for the formulation of culturally and geographically suitable risk management methods [191];

- Developing flexible safety protocols: insufficient safety protocols and excessive psychological stress in the workplace on construction sites are additional significant BB&Cs in the execution of Safety I and II initiatives. Given the circumstances, future research must focus on creating strong and flexible safety protocols that can be quickly updated in response to changing conditions, such as those encountered during a pandemic [5].

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Roberts, C.; Edwards, D.J. Post-occupancy evaluation: Identifying and mitigating implementation barriers to reduce environmental impact. J. Clean. Prod. 2022, 374, 133957. [Google Scholar] [CrossRef]

- Owusu-Manu, D.; Edwards, D.J.; Ghansah, F.A.; Asiedu, O.A.; Tagoe, D.S.N.; Birch, T. Assessing the Policy Provisions and Institutional Behavioural Factors Influencing Rail Infrastructure Financing in Developing Countries. ASCE J. Infrastruct. Syst. 2020, 27, 05021004. [Google Scholar] [CrossRef]

- Hinze, J.W.; Teizer, J. Visibility-related fatalities related to construction equipment. Saf. Sci. 2011, 49, 709–718. [Google Scholar] [CrossRef]

- Warburton, N. Construction Tops Fatal Workplace Injuries List But Agriculture Remains Deadliest Industry, Latest Stats Reveal. IOSH Magazine. 2023. Available online: https://www.ioshmagazine.com/2023/07/10/construction-tops-fatal-workplace-injuries-list-agriculture-remains-deadliest-industry (accessed on 19 January 2024).

- Enshassi, A.; Choudhry, R.M.; Mayer, P.E.; Shoman, Y. Safety performance of subcontractors in the Palestinian construction industry. J. Constr. Dev. Ctries. 2008, 13, 51–62. [Google Scholar]

- Golzad, H.; Teimoory, T.; Mousavi JBayramova, A.; Edwards, D.J. Mental Health Causation in the Construction Industry: A Systematic Review Employing Psychological Safety Climate Model. Buildings 2023, 13, 2442. [Google Scholar] [CrossRef]

- Bayramova, A.; Edwards, D.J.; Roberts, C.; Rillie, I. Enhanced safety in complex socio-technical systems via safety-in-cohesion. Saf. Sci. 2023, 164, 106176. [Google Scholar] [CrossRef]

- Aven, T. A risk science perspective on the discussion concerning Safety I, Safety II and Safety III. Reliab. Eng. Syst. Saf. 2022, 217, 108077. [Google Scholar] [CrossRef]

- Martinetti, A.; Chatzimichailidou, M.M.; Maida, L.; van Dongen, L. Safety I–II, resilience and antifragility engineering: A debate explained through an accident occurring on a mobile elevating work platform. Int. J. Occup. Saf. Ergon. 2019, 25, 66–75. [Google Scholar] [CrossRef]

- Elliott, J. Safety I and II: The past and future of safety management. Ergonomics 2016, 59, 859–860. [Google Scholar] [CrossRef]

- Martins, J.B.; Carim, G., Jr.; Saurin, T.A.; Costella, M.F. Integrating Safety I and II: Learning from failure and success in construction sites. Saf. Sci. 2022, 148, 105672. [Google Scholar] [CrossRef]

- Hollnagel, E. Safety-II in Practice: Developing the Resilience Potentials; Routledge: London, UK, 2018. [Google Scholar]

- Hollnagel, E.; Wears, R.L.; Braithwaite, J. From Safety-I to Safety-II: A WhitePaper. In The Resilient Health Care Net; University of Southern Denmark: Odense, Denmark; University of Florida: Florida, FL, USA; Macquarie University: Macquarie Park, Australia, 2015. [Google Scholar]

- Bayramova, A.; Edwards, D.J.; Roberts, C.; Rillie, I. Unravelling the Gordian knot of leading indicators. Saf. Sci. 2024, 177, 106603. [Google Scholar] [CrossRef]

- Sarvari, H.; Edwards, D.J.; Rillie, I.; Posillico, J.J. Building a safer future: Analysis of studies on safety I and safety II in the construction industry. Saf. Sci. 2024, 178, 106621. [Google Scholar] [CrossRef]

- Homann, F.; Limbert, C.; Bell, N.; Sykes, P. Safety through engaged workers: The link between Safety II and work engagement. Saf. Sci. 2022, 146, 105521. [Google Scholar] [CrossRef]

- Osei-Kyei, R.; Narbaev, T.; Ampratwum, G. A Scientometric analysis of studies on risk management in construction projects. Buildings 2022, 12, 1342. [Google Scholar] [CrossRef]

- Karimi, H.; Sarvari, H.; Edwards, D.J.; Chan, D.W.; Olawumi, T.O. Deploying Bottleneck Management Strategies for Ameliorating Critical Delays in Building Construction Projects: A Case for Developing Country of Iran. Systems 2024, 12, 195. [Google Scholar] [CrossRef]

- Karakhan, A.A.; Gambatese, J.A. Safety innovation and integration in high-performance designs: Benefits, motivations, and obstacles. Pract. Period. Struct. Des. Constr. 2017, 22, 04017018. [Google Scholar] [CrossRef]

- Tavassolirizi, M.; Sarvari, H.; Chan, D.W.; Olawumi, T.O. Factors affecting delays in rail transportation projects using Analytic Network Process: The case of Iran. Int. J. Constr. Manag. 2022, 22, 2712–2723. [Google Scholar] [CrossRef]

- Pillay, P.; Mafini, C. Supply chain bottlenecks in the South African construction industry: Qualitative insights. J. Transp. Supply Chain. Manag. 2017, 11, 1–12. Available online: https://hdl.handle.net/10520/EJC-8dcd99fe0 (accessed on 15 August 2024). [CrossRef]

- Vaghefi-Rezaee, H.A.; Khademi-Adel, S.; Sarvari, H.; Edwards, D.J.; Rashidi, A. A hybrid risk-based maintenance approach for evaluating the maintenance risks of urban tunnel lighting systems. J. Qual. Maint. Eng. 2025. ahead-of-print. [Google Scholar] [CrossRef]

- Sadeghi, J.; Sarvari, H.; Zangeneh, S.; Fatemi, A.; Edwards, D.J. An analysis of intuitionistic fuzzy sets in risk-based inspection: A case study of hydrogen crack damage in steel tanks under gas pressure. Clean. Eng. Technol. 2024, 23, 100855. [Google Scholar] [CrossRef]

- Awwad, R.; El Souki, O.; Jabbour, M. Construction safety practices and challenges in a Middle Eastern developing country. Saf. Sci. 2016, 83, 1–11. [Google Scholar] [CrossRef]

- Hussain, R.; Sabir, A.; Lee, D.Y.; Zaidi, S.F.A.; Pedro, A.; Abbas, M.S.; Park, C. Conversational AI-based VR system to improve construction safety training of migrant workers. Autom. Constr. 2024, 160, 105315. [Google Scholar] [CrossRef]

- Akindele, N.; Taiwo, R.; Sarvari, H.; Oluleye, B.; Awodele, I.A.; Olaniran, T.O. A State-of-the-art Analysis of Virtual Reality Applications in Construction Health and Safety. Results Eng. 2024, 23, 102382. [Google Scholar] [CrossRef]

- Chan, D.W.M.; Cristofaro, M.; Nassereddine, H.; Yiu, N.S.N.; Sarvari, H. Perceptions of Safety Climate in Construction Projects between Workers and Managers/Supervisors in the Developing Country of Iran. Sustainability 2021, 13, 10398. [Google Scholar] [CrossRef]

- Park, C.S.; Kim, H.J. A framework for construction safety management and visualization system. Autom. Constr. 2013, 33, 95–103. [Google Scholar] [CrossRef]

- Casey, T.; Turner, N.; Hu, X.; Bancroft, K. Making safety training stickier: A richer model of safety training engagement and transfer. J. Saf. Res. 2021, 78, 303–313. [Google Scholar] [CrossRef]

- Baccarini, D. The concept of project complexity—A review. Int. J. Proj. Manag. 1996, 14, 201–204. [Google Scholar] [CrossRef]

- Dekker, S.; Cilliers, P.; Hofmeyr, J.H. The complexity of failure: Implications of complexity theory for safety investigations. Saf. Sci. 2011, 49, 939–945. [Google Scholar] [CrossRef]

- Newman, C.; Edwards, D.J.; Martek, I.; Lai, J.; Thwala, W.D. Industry 4.0 Deployment in the Construction Industry: A Bibliometric Literature Review and UK-based Case Study. Smart Sustain. Built Environ. 2021, 10, 557–580. [Google Scholar] [CrossRef]

- Posillico, J.J.; Edwards, D.J.; Roberts, C.; Shelbourn, M. A conceptual construction management curriculum model grounded in scientometric analysis. Eng. Constr. Archit. Manag. 2023, 30, 4143–4170. [Google Scholar] [CrossRef]

- Arksey, H.; O’malley, L. Scoping studies: Towards a methodological framework. Int. J. Soc. Res. Methodol. 2005, 8, 19–32. [Google Scholar] [CrossRef]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper; Sage Publications: Thousand Oaks, CA, USA, 2019. [Google Scholar]

- Tricco, A.C.; Lillie, E.; Zarin, W.; O’Brien, K.K.; Colquhoun, H.; Levac, D.; Moher, D.; Peters, M.D.; Horsley, T.; Weeks, L.; et al. PRISMA extension for scoping reviews (PRISMA-ScR): Checklist and explanation. Ann. Intern. Med. 2018, 169, 467–473. [Google Scholar] [CrossRef]

- Jayasanka, T.A.D.K.; Darko, A.; Edwards, D.J.; Chan, A.P.C.; Jalaei, F. Automating building environmental assessment: A systematic review and future research directions. Environ. Impact Assess. Rev. 2024, 106, 107465. [Google Scholar] [CrossRef]

- Peters, M.D.; Marnie, C.; Tricco, A.C.; Pollock, D.; Munn, Z.; Alexander, L.; McInerney, P.; Godfrey, C.M.; Khalil, H. Updated methodological guidance for the conduct of scoping reviews. JBI Evid. Synth. 2020, 18, 2119–2126. [Google Scholar] [CrossRef]

- Siame, S.; Bygvraa, D.A.; Jensen, O.C. Facilitators and barriers to implementing occupational safety interventions in the fishing industry: A scoping review. Saf. Sci. 2022, 145, 105512. [Google Scholar] [CrossRef]

- Safarpour, H.; Khorasani-Zavareh, D.; Mohammadi, R. The common road safety approaches: A scoping review and thematic analysis. Chin. J. Traumatol. 2020, 23, 113–121. [Google Scholar] [CrossRef]

- Hayashi, H.; Li, Y.; Sussman, D.D.; Okuzono, S.; Viswanath, K.; Kawachi, I. A Scoping Review of Interventions to Improve Occupational Safety and Health of Construction Workers. Am. J. Health Promot. 2023, 37, 1162–1170. [Google Scholar] [CrossRef]

- Booth, A.; Sutton, A.; Clowes, M.; Martyn-St James, M. Systematic Approaches to a Successful Literature Review; SAGE Publications Ltd.: Thousand Oaks, CA, USA, 2021. [Google Scholar]

- Zhou, Z.; Goh, Y.M.; Li, Q. Overview and analysis of safety management studies in the construction industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Salguero-Caparrós, F.; Pardo-Ferreira, M.D.C.; Martínez-Rojas, M.; Rubio-Romero, J.C. Management of legal compliance in occupational health and safety. A literature review. Saf. Sci. 2020, 121, 111–118. [Google Scholar] [CrossRef]

- Adams, J. Information and misinformation in bibliometric time-trend analysis. J. Informetr. 2018, 12, 1063–1071. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, Q.; Zheng, F.; Long, C.; Lu, Z.; Duan, Z. Comparing keywords plus of WOS and author keywords: A case study of patient adherence research. J. Assoc. Inf. Sci. Technol. 2016, 67, 967–972. [Google Scholar] [CrossRef]

- van Wee, B.; Banister, D. Literature review papers: The search and selection process. J. Decis. Syst. 2024, 33, 559–565. [Google Scholar] [CrossRef]

- Dambiski Gomes de Carvalho, G.; Resende, L.M.M.D.; Pontes, J.; Gomes de Carvalho, H.; Mendes Betim, L. Innovation and management in MSMEs: A literature review of highly cited papers. SAGE Open 2021, 11, 21582440211052555. [Google Scholar] [CrossRef]

- Gavgani, V.Z.; Vahed, N. 184: Key word validity ratio (KWVR); a tool for validity of keywords for building an accurate literature search strategy. BMJ Open 2017, 7 (Suppl. S1), bmjopen-2016. [Google Scholar] [CrossRef][Green Version]

- Greenhalgh, T.; Peacock, R. Effectiveness and efficiency of search methods in systematic reviews of complex evidence: Audit of primary sources. BMJ 2005, 331, 1064–1065. [Google Scholar] [CrossRef]

- Cagno, E.; Micheli, G.J.; Masi, D.; Jacinto, C. Economic evaluation of OSH and its way to SMEs: A constructive review. Saf. Sci. 2013, 53, 134–152. [Google Scholar] [CrossRef]

- Martínez-Airesa, M.; López-Alonsob, M.; Martínez-Rojasc, M. Building information modeling and safety management: A systematic review. Saf. Sci. 2018, 101, 11–18. [Google Scholar] [CrossRef]

- Buniya, M.K.; Othman, I.; Sunindijo, R.Y.; Kineber, A.F.; Mussi, E.; Ahmad, H. Barriers to safety program implementation in the construction industry. Ain Shams Eng. J. 2021, 12, 65–72. [Google Scholar] [CrossRef]

- Antonsen, S. Safety Culture: Theory, Method and Improvement; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Ouyang, M. Review on modeling and simulation of interdependent critical infrastructure systems. Reliab. Eng. Syst. Saf. 2014, 121, 43–60. [Google Scholar] [CrossRef]

- Patterson, M.; Deutsch, E.S. Safety I, Safety II and resilience engineering. Curr. Probl. Pediatr. Adolesc. Health Care 2015, 45, 382–389. [Google Scholar] [CrossRef]

- Provan, D.J.; Woods, D.D.; Dekker, S.W.; Rae, A.J. Safety II professionals: How resilience engineering can transform safety practice. Reliab. Eng. Syst. Saf. 2020, 195, 106740. [Google Scholar] [CrossRef]

- Burnard, K.; Bhamra, R. Organisational resilience: Development of a conceptual framework for organisational responses. Int. J. Prod. Res. 2011, 49, 5581–5599. [Google Scholar] [CrossRef]

- Vinodkumar, M.N.; Bhasi, M. Safety management practices and safety behaviour: Assessing the mediating role of safety knowledge and motivation. Accid. Anal. Prev. 2010, 42, 2082–2093. [Google Scholar] [CrossRef] [PubMed]

- Rafieyan, A.; Sarvari, H.; Chan, D.W. Identifying and evaluating the essential factors affecting the incidence of site accidents caused by human errors in industrial parks construction projects. Int. J. Environ. Res. Public Health 2022, 19, 10209. [Google Scholar] [CrossRef]

- Rafieyan, A.; Sarvari, H.; Beer, M.; Chan, D.W. Determining the effective factors leading to incidence of human error accidents in industrial parks construction projects: Results of a fuzzy Delphi survey. Int. J. Constr. Manag. 2024, 24, 748–760. [Google Scholar] [CrossRef]

- Dillon, R.L.; Tinsley, C.H.; Burns, W.J. Near-misses and future disaster preparedness. Risk Anal. 2014, 34, 1907–1922. [Google Scholar] [CrossRef]

- Delikhoon, M.; Zarei, E.; Banda, O.V.; Faridan, M.; Habibi, E. Systems thinking accident analysis models: A systematic review for sustainable safety management. Sustainability 2022, 14, 5869. [Google Scholar] [CrossRef]

- Hale, A.; Borys, D. Working to rule or working safely? Part 2: The management of safety rules and procedures. Saf. Sci. 2013, 55, 222–231. [Google Scholar] [CrossRef]

- Bluff, E. How SMEs respond to legal requirements to provide information, training, instruction and supervision to workers about work health and safety matters. Saf. Sci. 2019, 116, 45–57. [Google Scholar] [CrossRef]

- Park, J.; Kim, J.T.; Lee, S.; Kim, J. Modeling Safety II based on unexpected reactor trips. Ann. Nucl. Energy 2018, 115, 280–293. [Google Scholar] [CrossRef]

- Weaver, S.; Edrees, H.H. Organizational safety culture. In Leading Reliable Healthcare; Taylor and Francis: Abingdon, UK, 2017; pp. 1–24. [Google Scholar]

- Kim, J.T.; Park, J.; Kim, J.; Seong, P.H. Development of a quantitative resilience model for nuclear power plants. Ann. Nucl. Energy 2018, 122, 175–184. [Google Scholar] [CrossRef]

- Bagian, J.P.; Lee, C.; Gosbee, J.; DeRosier, J.; Stalhandske, E.; Eldridge, N.; Williams, R.; Burkhardt, M. Developing and deploying a patient safety program in a large health care delivery system: You can’t fix what you don’t know about. Jt. Comm. J. Qual. Improv. 2001, 27, 522–532. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Hou, L.; Li, M.; Zheng, R. A novel fire risk assessment approach for large-scale commercial and high-rise buildings based on fuzzy analytic hierarchy process (Fahp) and coupling revision. Int. J. Environ. Res. Public Health 2021, 18, 7187. [Google Scholar] [CrossRef]

- Waqar, A.; Othman, I.; González-Lezcano, R.A. Challenges to the implementation of BIM for the risk management of oil and gas construction projects: Structural equation modeling approach. Sustainability 2023, 15, 8019. [Google Scholar] [CrossRef]

- Enshassi, A.; Saleh, N.; Mohamed, S. Barriers to the application of lean construction techniques concerning safety improvement in construction projects. Int. J. Constr. Manag. 2021, 21, 1044–1060. [Google Scholar] [CrossRef]

- Maliha, M.N.; Abu Aisheh, Y.I.; Tayeh, B.A.; Almalki, A. Safety barriers identification, classification, and ways to improve safety performance in the architecture, engineering, and construction (AEC) industry: Review study. Sustainability 2021, 13, 3316. [Google Scholar] [CrossRef]

- Famakin, I.O.; Aigbavboa, C.; Molusiwa, R. Exploring challenges to implementing health and safety regulations in a developing economy. Int. J. Constr. Manag. 2023, 23, 89–97. [Google Scholar] [CrossRef]

- Hallowell, M.R. Safety-knowledge management in American construction organizations. J. Manag. Eng. 2012, 28, 203–211. [Google Scholar] [CrossRef]

- Nnaji, C.; Karakhan, A.A. Technologies for safety and health management in construction: Current use, implementation benefits and limitations, and adoption barriers. J. Build. Eng. 2020, 29, 101212. [Google Scholar] [CrossRef]

- Marefat, A.; Toosi, H.; Hasankhanlo, R.M. A BIM approach for construction safety: Applications, barriers and solutions. Engineering. Constr. Archit. Manag. 2018, 26, 1855–1877. [Google Scholar] [CrossRef]

- Kartam, N.A.; Flood, I.; Koushki, P. Construction safety in Kuwait: Issues, procedures, problems, and recommendations. Saf. Sci. 2000, 36, 163–184. [Google Scholar] [CrossRef]

- Toole, T.M. Increasing engineers’ role in construction safety: Opportunities and barriers. J. Prof. Issues Eng. Educ. Pract. 2005, 131, 199–207. [Google Scholar] [CrossRef]

- Shepherd, R.; Lorente, L.; Vignoli, M.; Nielsen, K.; Peiró, J.M. Challenges influencing the safety of migrant workers in the construction industry: A qualitative study in Italy, Spain, and the UK. Saf. Sci. 2021, 142, 105388. [Google Scholar] [CrossRef]

- Taat, N.H.M.; Abas, N.H.; Hasmori, M.F. The barriers of Building Information Modelling (BIM) for construction safety. In Proceedings of the 3rd International Conference on Green Environmental Engineering and Technology: IConGEET 2021, Penang, Malaysia, 8–9 September 2021; Springer Nature: Singapore, 2022; pp. 121–130. [Google Scholar] [CrossRef]

- Sunindijo, R.Y. Improving safety among small organisations in the construction industry: Key barriers and improvement strategies. Procedia Eng. 2015, 125, 109–116. [Google Scholar] [CrossRef]

- Oswald, D.; Sherratt, F.; Smith, S.D.; Hallowell, M.R. Exploring safety management challenges for multi-national construction workforces: A UK case study. Constr. Manag. Econ. 2018, 36, 291–301. [Google Scholar] [CrossRef]

- Kisi, K.P.; Shrestha, K.J.; Kayastha, R. Labor shortage and safety issues in postearthquake building construction: Case study. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2020, 12, 05020011. [Google Scholar] [CrossRef]

- Ibrahim, K.; Simpeh, F.; Adebowale, O. Benefits and challenges of wearable safety devices in the construction sector. Smart Sustain. Built Environ. 2025, 14, 50–71. [Google Scholar] [CrossRef]

- Ngowi, A.B.; Mselle, P.C. Barriers to using environmental, safety and health (ESH) record as a competitive advantage in the construction industry. In Proceedings of the Second International Conference of CIB Working Commission W99 on Implementation of Safety and Health on Construction Sites, Honolulu, HI, USA, 24–27 March 1999; AA Balkema: Honolulu, HI, USA, 1999; pp. 79–85. [Google Scholar]

- Sun, H.S.; Yang, D.; Wei, S.J.; Wen, Q.M. Problems and Strategy of Construction Safety Management. In Proceedings of the 2014 International Conference on Management Science and Management Innovation (MSMI 2014), Changsha, China, 14–15 June 2014; Atlantis Press: Dordrecht, The Netherlands, 2014; pp. 654–657. [Google Scholar]

- Malekitabar, H.; Ardeshir, A.; Sebt, M.H.; Stouffs, R. Construction safety risk drivers: A BIM approach. Saf. Sci. 2016, 82, 445–455. [Google Scholar] [CrossRef]

- Hallowell, M.R.; Yugar-Arias, I.F. Exploring fundamental causes of safety challenges faced by Hispanic construction workers in the US using photovoice. Saf. Sci. 2016, 82, 199–211. [Google Scholar] [CrossRef]

- Memon, A.H.; Soomro, M.A.; Memon, N.M.; Abassi, M.N. Factors causing health and safety hazards in construction projects in Pakistan. Mehran Univ. Res. J. Eng. Technol. 2017, 36, 559–568. [Google Scholar] [CrossRef]

- Kozlovská, M.; Struková, Z. Overview of safety risk perception in construction. J. Civ. Eng. Archit. 2012, 6, 211. [Google Scholar] [CrossRef][Green Version]

- Umeokafor, N. An appraisal of the barriers to client involvement in health and safety in Nigeria’s construction industry. J. Eng. Des. Technol. 2017, 15, 471–487. [Google Scholar] [CrossRef]

- Ahmed, I.; Shaukat, M.Z.; Usman, A.; Nawaz, M.M.; Nazir, M.S. Occupational health and safety issues in the informal economic segment of Pakistan: A survey of construction sites. Int. J. Occup. Saf. Ergon. 2018, 24, 240–250. [Google Scholar] [CrossRef]

- Boadu, E.F.; Wang, C.C.; Sunindijo, R.Y. Challenges for occupational health and safety enforcement in the construction industry in Ghana. Constr. Econ. Build. 2021, 21, 1–21. [Google Scholar] [CrossRef]

- Chan, A.P.; Wong, F.K.; Hon, C.K.; Ali Javed, A.; Lyu, S. Construction safety and health problems of ethnic minority workers in Hong Kong. Eng. Constr. Archit. Manag. 2017, 24, 901–919. [Google Scholar] [CrossRef]

- Oswald, D.; Wade, F.; Sherratt, F.; Smith, S.D. Communicating health and safety on a multinational cct: Challenges and strategies. J. Constr. Eng. Manag. 2019, 145, 04019017. [Google Scholar] [CrossRef]

- Yiu, N.S.; Chan, D.W.; Shan, M.; Sze, N.N. Implementation of safety management system in managing construction projects: Benefits and obstacles. Saf. Sci. 2019, 117, 23–32. [Google Scholar] [CrossRef]

- Lingard, H.; Holmes, N. Understandings of occupational health and safety risk control in small business construction firms: Barriers to implementing technological controls. Constr. Manag. Econ. 2001, 19, 217–226. [Google Scholar] [CrossRef]

- Kidd, P.; Parshall, M.; Wojcik, S.; Struttmann, T. Overcoming recruitment challenges in construction safety intervention research. Am. J. Ind. Med. 2004, 45, 297–304. [Google Scholar] [CrossRef]

- Wadick, P. Challenges for OHS Implementation in Building and Construction. In Vocational Learning: Transitions, Interrelationships, Partnerships and Sustainable Futures: Proceedings of the 13th Annual International Conference on Post-Compulsory Education and Training, Gold Coast, Australia, 5–7 December 2005; Australian Academic Press: Brisbane, Australia, 2005; pp. 516–520. [Google Scholar]

- Chellappa, V.; Salve, U.R. Exploring barriers to effective safety risk assessment in Indian construction projects. Proc. Inst. Civ. Eng. Manag. Procure. Law 2023, 176, 122–130. [Google Scholar] [CrossRef]

- Belayutham, S.; Ibrahim, C.K.I.C. Barriers and strategies for better safety practices: The case of construction SMEs in Malaysia. Constr. Econ. Build. 2019, 19, 6331. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Lam, C.G.Y.; Skitmore, M.; Talebian, N. Barriers to the adoption of new safety technologies in construction: A developing country context. J. Civ. Eng. Manag. 2022, 28, 120–133. [Google Scholar] [CrossRef]

- Wu, C.; Luo, X.; Wang, T.; Wang, Y.; Sapkota, B. Safety challenges and improvement strategies of ethnic minority construction workers: A case study in Hong Kong. Int. J. Occup. Saf. Ergon. 2018, 26, 80–90. [Google Scholar] [CrossRef]

- Zheng, J.; Gou, X.; Li, H.; Xue, H.; Xie, H. Linking challenge–hindrance stressors to safety outcomes and performance: A dual mediation model for construction workers. Int. J. Environ. Res. Public Health 2020, 17, 7867. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Kazaz, A.; Er, B. Health and safety perception of workers in Turkey: A survey of construction sites. Int. J. Occup. Saf. Ergon. 2014, 20, 323–338. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Guo, H.Y.; Huo, X.Y. Critical antecedents for construction organizational learning concerning safety knowledge from success and accidents. In Proceedings of the 2015 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 6–9 December 2015; IEEE: New York, NY, USA, 2015; pp. 333–337. [Google Scholar]

- Marsh, R.J.; Brent, A.C.; De Kock, I.H. Understanding the barriers and drivers of sustainable construction adoption and implementation in South Africa: A quantitative study using the Theoretical Domains Framework and COM-B model. J. South Afr. Inst. Civ. Eng. 2021, 63, 11–23. [Google Scholar] [CrossRef]

- Ahmed, S.M.; Tang, S.L.; Poon, T.K. Problems of implementing safety programmes on construction sites and some possible solutions. In Proceedings of the 2nd International Conference of International Council for Research and Innovation in Building and Construction (CIB) Working Commission W99, Honolulu, HI, USA, 24–27 March 1999; pp. 525–529. [Google Scholar]

- Venkatesh, P.; Ergan, S. Classification of Challenges in Achieving BIM-Based Safety-Requirement Checking in Vertical Construction Projects. J. Constr. Eng. Manag. 2023, 149, 04023131. [Google Scholar] [CrossRef]

- Al Mawli, B.; Al Alawi, M.; Elazouni, A.; Al-Mamun, A. Construction SMEs safety challenges in water sector in Oman. Saf. Sci. 2021, 136, 105156. [Google Scholar] [CrossRef]

- Pittokopiti, M.; Grammenos, R. Infrastructureless UWB based collision avoidance system for the safety of construction workers. In Proceedings of the 2019 26th International Conference on Telecommunications (ICT), Hanoi, Vietnam, 8–10 April 2019; IEEE: New York, NY, USA, 2019; pp. 490–495. [Google Scholar] [CrossRef]

- Al-Otaibi, A.; Kineber, A.F. Identifying and Assessing Health and Safety Program Implementation Barriers in the Construction Industry: A Case of Saudi Arabia. Appl. Sci. 2023, 13, 2630. [Google Scholar] [CrossRef]

- Zhang, J.G.; Zhang, G.Y.; Yuan, Z.L.; Fang, X.J. Discussion on the Issue of Safety Training of Construction Industry Peasant Laborer. In Proceedings of the 2010 Chinese Seminar on the Principles of Safety Science and Technology, Beijing, China; Science Press: Beijing, China, 2010; pp. 607–611. [Google Scholar]

- Alsharef, A.; Albert, A.; Jaselskis, E.; Bhandari, S. Construction safety training: Barriers, challenges, and opportunities. In Proceedings of the Construction Research Congress 2020, Tempe, AZ, USA, 8–10 March 2020; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 547–555. [Google Scholar]

- Choi, S.D.; Carlson, K. Occupational safety issues in residential construction surveyed in Wisconsin, United States. Ind. Health 2014, 52, 541–547. [Google Scholar] [CrossRef]

- Phinias, R.N. Benefits and challenges relating to the implementation of health and safety leading indicators in the construction industry: A systematic review. Saf. Sci. 2023, 163, 106131. [Google Scholar] [CrossRef]

- Antonio, R.S.; Isabel, O.M.; Gabriel, P.S.J.; Angel, U.C. A proposal for improving safety in construction projects by strengthening coordinators’ competencies in health and safety issues. Saf. Sci. 2013, 54, 92–103. [Google Scholar] [CrossRef]

- Enshassi, A. Construction safety issues in Gaza Strip. Build. Res. Inf. 1997, 25, 370–373. [Google Scholar] [CrossRef]

- Nyende-Byakika, S. Occupational safety and health issues on road construction sites in sub-Saharan Africa: A case study from Uganda. Afr. J. Sci. Technol. Innov. Dev. 2016, 8, 256–263. [Google Scholar] [CrossRef]

- Tezel, A.; Dobrucali, E.; Demirkesen, S.; Kiral, I.A. Critical success factors for safety training in the construction industry. Buildings 2021, 11, 139. [Google Scholar] [CrossRef]

- Abdul Nabi, M.; El-adaway, I.H.; Fayek, S.; Howell, C.; Gambatese, J. Contractual guidelines for construction safety–related issues under design–build standard forms of contract. J. Constr. Eng. Manag. 2020, 146, 04020074. [Google Scholar] [CrossRef]

- Chileshe, N.; Dzisi, E. Benefits and barriers of construction health and safety management (HSM) perceptions of practitioners within design organisations. J. Eng. Des. Technol. 2012, 10, 276–298. [Google Scholar] [CrossRef]

- Dos Santos, R.A.; de Aquino, G.C.; Matias, B.S.; Braga FA, V.; da Silva, C.S.; da Silva, H.G. Waste of Civil Construction: A Issue Health and Safety at Construction Site, Sho2016: Proceedings of the 12th International Symposium on Occupational Safety and Hygiene; Instituto Federal De Educãçao, Ciência E Tecnologia Paraíba: Joao Pessoa, Brazil, 2016; pp. 305–307. [Google Scholar]

- Love, P.E.; Smith, J.; Ackermann, F.; Irani, Z.; Fang, W.; Luo, H.; Ding, L. Houston, we have a problem! Understanding the tensions between quality and safety in construction. Prod. Plan. Control. 2019, 30, 1354–1365. [Google Scholar] [CrossRef]

- Guo, M.L.; Huang, S.P. Safety problems and control measures in the construction of the building project. In Green Building, Environment, Energy and Civil Engineering; CRC Press: Boca Raton, FL, USA, 2016; pp. 17–20. [Google Scholar]

- Zaid Alkilani, S.; Jupp, J.; Sawhney, A. Issues of construction health and safety in developing countries: A case of Jordan. Australas. J. Constr. Econ. Build. 2013, 13, 141–156. [Google Scholar] [CrossRef]

- Othman, A.A.E. A study of the causes and effects of con’ractors’ non-compliance with the health and safety regulations in the South African construction industry. Archit. Eng. Des. Manag. 2012, 8, 180–191. [Google Scholar] [CrossRef]

- Binhomaid, O.; Hegazy, T. Agent-based simulation of workers’ behaviors, productivity, and safety around construction obstacles. Can. J. Civ. Eng. 2021, 48, 969–978. [Google Scholar] [CrossRef]

- Pamidimukkala, A.; Kermanshachi, S. Occupational health and safety challenges in construction industry: A gender-based analysis. In Proceedings of the Construction Research Congress 2022, Arlington, VT, USA, 9–12 March 2022; pp. 491–500. [Google Scholar]

- Shaikh, A.Y.; Osei-Kyei, R.; Hardie, M.; Stevens, M. Review of drivers of teamwork for construction health and safety. Int. J. Build. Pathol. Adapt. 2023. [CrossRef]

- Pinder, A. Safety on construction sites. In Safety At Work; Butterworth-Heinemann: Oxford, UK, 1990; pp. 650–678. [Google Scholar] [CrossRef]

- Melagoda, D.G.; Rowlinson, S. The institutional framework of construction safety management: A case study of Sri Lanka. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1101, p. 042038. [Google Scholar]

- Vakillinezhad, M.; Dias, P.; Ergan, S. Achieving model-based safety at construction sites: BIM and safety requirements representation. In Proceedings of the 33rd CIB W78 Conference, Brisbane, Australia, 31 October–2 November 2016; University of Auckland: Auckland, New Zealand, 2016. [Google Scholar]

- Lombardi, M.; Fargnoli, M.; Parise, G. Risk profiling from the European statistics on accidents at work (ESAW) accidents′ databases: A case study in construction sites. Int. J. Environ. Res. Public Health 2019, 16, 4748. [Google Scholar] [CrossRef] [PubMed]

- Sawacha, E.; Naoum, S.; Fong, D. Factors affecting safety performance on construction sites. Int. J. Proj. Manag. 1999, 17, 309–315. [Google Scholar] [CrossRef]

- Hogan, J. Implementing a Construction Safety Program for Seaport Facilities. In Proceedings of the Ports 2004: Port Development in the Changing World, Houston, TX, USA, 23–26 May 2004; pp. 1–6. [Google Scholar] [CrossRef]

- Cheng, E.W.; Li, H.; Fang, D.P.; Xie, F. Construction safety management: An exploratory study from China. Constr. Innov. 2004, 4, 229–241. [Google Scholar] [CrossRef]

- Aksorn, T.; Hadikusumo, B.H.W. Gap analysis approach for construction safety program improvement. J. Constr. Dev. Ctries. 2007, 12, 77–97. [Google Scholar]

- Mahalingam, A.; Levitt, R.E. Safety issues on global projects. J. Constr. Eng. Manag. 2007, 133, 506–516. [Google Scholar] [CrossRef]

- MacCollum, D.V.; Davis, R. Engineering Principles For Safer Design. In Proceedings of the ASSE Professional Development Conference and Exposition, Las Vegas, NV, USA, 9–12 June 2008; ASSE: Las Vegas, NV, USA, 2008; p. ASSE-08. [Google Scholar]

- Choudhry, R.M.; Fang, D.; Rowlinson, S. Challenging and enforcing safety management in developing countries: A strategy. Int. J. Constr. Manag. 2008, 8, 87–101. [Google Scholar] [CrossRef]

- Sherratt, F.S. Constructing Safety on Sites: An Exploration of the Social Construction of Safety on Large UK Construction Sites. Ph.D. Thesis, University of Bolton, Bolton, UK, 2012. [Google Scholar]

- Aswile, A. Challenges of Implementing Strategic Plans in Organizations: A Case of Deloitte Company. Ph.D. Thesis, Mzumbe University, Mzumbe, Tanzania, 2013. [Google Scholar]

- Ogwueleka, A.C. A review of safety and quality issues in the construction industry. J. Constr. Eng. Proj. Manag. 2013, 3, 42–48. [Google Scholar] [CrossRef]

- Sunindijo, R.Y.; Zou, P.X. Aligning safety policy development, learning and implementation: From boardroom to site. In Proceedings of the 19th CIB World Building Congress, Brisbane, Australia, 5–9 May 2013; Kajewski, S., Manley, K., Hampson, K., Eds.; pp. 5–9. [Google Scholar]

- Swuste, P. Safety in Construction? Taylor & Francis Group/CRC Press: London, UK, 2014; pp. 1585–1593. [Google Scholar]

- Debnath, A.K.; Banks, T.; Blackman, R.; Dovan, N.; Haworth, N.; Biggs, H. Beyond the barriers: Road construction safety issues from the office and the roadside. Adv. Saf. Manag. Hum. Factors 2014, 10, 185. [Google Scholar]

- Vitharana, V.H.P.; De Silva, G.H.M.J.; De Silva, S. Health hazards, risk and safety practices in construction sites–a review study. Eng. J. Inst. Eng. Sri Lanka 2015, 48, 35–44. [Google Scholar] [CrossRef]

- Wong, J.Y.Y.; Gray, J.; Sadiqi, Z. Barriers to good occupational health and safety (OHS) practices by small construction firms. NICMAR J. Constr. Manag. 2015, 30, 55–66. [Google Scholar]

- Hubner, M. Constructing Safety Training: Foundations of Attitudes and Perceptions of the Construction Site Supervisor. Ph.D. Thesis, Victoria University, Sydney, Australia, 2016. [Google Scholar]

- Zoufa, T.; Ochieng, E.G. Revitalising Safety Practices in Construction Projects: The Case of Nigeria and United Kingdom (September 6, 2016). Available online: https://ssrn.com/abstract=3105987 (accessed on 10 January 2025).

- Umar, T.; Wamuziri, S.C. A review of construction safety, challenges and opportunities-Oman perspective. In Proceedings of the The 5th World Construction Symposium 2016: Greening Environment, Eco Innovations & Entrepreneurship, Colombo, Sri Lanka, 29–31 July 2016. [Google Scholar]

- Nnedinma, U. Barriers to construction health and safety self-regulation: A scoping case of Nigeria. Civ. Eng. Dimens. 2017, 19, 44–53. [Google Scholar] [CrossRef]

- McCabe, B.Y.; Alderman, E.; Chen, Y.; Hyatt, D.E.; Shahi, A. Safety performance in the construction industry: Quasi-longitudinal study. J. Constr. Eng. Manag. 2017, 143, 04016113. [Google Scholar] [CrossRef]

- Ogundipe, K.E.; Ogunde, A.O.; Olaniran, H.F.; Ajao, A.M.; Ogunbayo, B.F.; Ogundipe, J.A. Missing gaps in safety education and practices: Academia perspectives. Int. J. Civ. Eng. Technol. (IJCIET) 2018, 9, 273–289. [Google Scholar]

- Maund, K.; Gajendran, T.; Brewer, G. Key issues for implementation of environmental planning policy: Construction management practice. Sustainability 2018, 10, 2156. [Google Scholar] [CrossRef]

- Liu, Y. Safety barriers: Research advances and new thoughts on theory, engineering and management. J. Loss Prev. Process Ind. 2020, 67, 104260. [Google Scholar] [CrossRef]

- Sarvari, H.; Chen, Z.; Chan, D.W.; Lester, E.A.; Yahaya, N.; Nassereddine, H.; Lotfata, A. A global survey of infection control and mitigation measures for combating the transmission of COVID-19 pandemic in buildings under facilities management services. Front. Built Environ. 2022, 7, 644104. [Google Scholar] [CrossRef]

- Bou Hatoum, M.; Faisal, A.; Nassereddine, H.; Sarvari, H. Analysis of COVID-19 concerns raised by the construction workforce and development of mitigation practices. Front. Built Environ. 2021, 7, 66. [Google Scholar] [CrossRef]

- Amoah, C.; Simpeh, F. Implementation challenges of COVID-19 safety measures at construction sites in South Africa. J. Facil. Manag. 2021, 19, 111–128. [Google Scholar] [CrossRef]

- Andersen, L.P.S.; Grytnes, R. Different ways of perceiving risk and safety on construction sites and implications for safety cooperation. Constr. Manag. Econ. 2021, 39, 419–431. [Google Scholar] [CrossRef]

- Vigneshkumar, C.; Saravanamuthu, K. Barriers to promote occupational health and safety (OHS) among different construction types in India. In Ergonomics for Improved Productivity: Proceedings of HWWE 2017, Aligarh, India, 8–10 December 2017; Springer: Singapore, 2021; pp. 655–661. [Google Scholar] [CrossRef]

- Sierra, F. COVID-19: Main challenges during construction stage. Eng. Constr. Archit. Manag. 2022, 29, 1817–1834. [Google Scholar] [CrossRef]

- Khelwade, V.; Ghadge, A.; Parihar, A.; Khobragde, R.; Rathod, N. Barriers to Safety Practices Adoption in Construction Projects. Int. J. Sci. Technol. Eng. 2022, 10, 1856–1859. [Google Scholar] [CrossRef]

- Tabrizikahou, A.; Nowotarski, P. Analysis of problems and barriers in construction sites processes. Mater. Bud. 2022, 12, 141192. [Google Scholar] [CrossRef]

- Chan, D.W.; Aghimien, D.O. Bolstering measures for combating the challenges of safe working cycle implementation in Hong Kong’s construction industry. Sustainability 2022, 14, 3772. [Google Scholar] [CrossRef]

- Tabatabaee, S.; Mohandes, S.R.; Ahmed, R.R.; Mahdiyar, A.; Arashpour, M.; Zayed, T.; Ismail, S. Investigating the barriers to applying the internet-of-things-based technologies to construction site safety management. Int. J. Environ. Res. Public Health 2022, 19, 868. [Google Scholar] [CrossRef]

- Rey-Merchán, M.D.C.; Delgado-Fernández, V.J.; López-Arquillos, A. Barriers to the Integration of IoT Safety Devices in Construction Environments. In The International Conference on Industrial Engineering and Industrial Management; Springer International Publishing: Cham, Switzerlands, 2022; pp. 191–196. [Google Scholar] [CrossRef]

- Ndekugri, I.; Ankrah, N.A.; Adaku, E. Performance Barriers for Coordination of Health and Safety during the Preconstruction Phase of Construction Projects. J. Constr. Eng. Manag. 2023, 149, 04023045. [Google Scholar] [CrossRef]

- Melo RR, S.; Costa, D.B. Safety-I and Safety-II: Constributions of UAS safety monitoring on construction sites. In Proceedings of the 31st Annual Conference of the International Group for Lean Construction (IGLC31), Lille, France, 26 June–2 July 2023; pp. 377–386. [Google Scholar] [CrossRef]

- El-Gafy, M.; Korkmaz, K.; Dubey, N. Assessing Good Practices in Construction Safety and Phasing Plans. Curr. Trends Eng. Sci. 2023, 3, 1024. [Google Scholar] [CrossRef]

- Baracho, R.O.; Scalize, P.S. Challenges and Facilitating Factors to Implement Water Safety Plans: A Systematic Review. Rev. Gestão Soc. Ambient. 2023, 17, e03206. [Google Scholar] [CrossRef]

- Kheni, N.A.; Afatsawu, P.K. A study of challenges faced by regulatory authorities for implementing health and safety compliance in the Ghana construction industry context. Int. J. Manag. Entrep. Res. 2022, 4, 315–333. [Google Scholar] [CrossRef]

- Flin, R.; Yule, S. Leadership for safety: Industrial experience. BMJ Qual. Saf. 2004, 13 (Suppl. S2), ii45–ii51. [Google Scholar] [CrossRef]

- Naevestad, T.O.; Hesjevoll, I.S.; Ranestad, K.; Antonsen, S. Strategies regulatory authorities can use to influence safety culture in organizations: Lessons based on experiences from three sectors. Saf. Sci. 2019, 118, 409–423. [Google Scholar] [CrossRef]

- Chen, F.; Wei, Y.; Ji, H.; Xu, G. A multiplex network based analytical framework for safety management standardization in construction engineering. Adv. Eng. Inform. 2024, 59, 102278. [Google Scholar] [CrossRef]

- Vautier, J.F.; Dechy, N.; Coye de Brunélis, T.; Hernandez, G.; Launay, R.; Moreno Alarcon, D.P. Benefits of systems thinking for a human and organizational factors approach to safety management. Environ. Syst. Decis. 2018, 38, 353–366. [Google Scholar] [CrossRef]

- Bal, O.; Tverdomed, V.; Kovalchuk, O. Innovative approaches to developing national railway safety policy and training safety leaders. Transp. Syst. Technol. 2024, 43, 121–135. [Google Scholar] [CrossRef]

- Dekker, S.W.; Breakey, H. ‘Just culture:’Improving safety by achieving substantive, procedural and restorative justice. Saf. Sci. 2016, 85, 187–193. [Google Scholar] [CrossRef]

- Yap, J.B.H.; Skitmore, M.; Lam, C.G.Y.; Lee, W.P.; Lew, Y.L. Advanced technologies for enhanced construction safety management: Investigating Malaysian perspectives. Int. J. Constr. Manag. 2024, 24, 633–642. [Google Scholar] [CrossRef]

- Ganiyev, K.; Alizada, S.; Asgarov, A.; Gasimli, M.; Gasimzade, N. Safety management in the construction industry: Bibliometric analysis. Probl. Perspect. Manag. 2024, 22, 198. [Google Scholar] [CrossRef]

- Bortey, L.; Edwards, D.J.; Roberts, C.; Rillie, I. A Review of Safety Risk Theories and Models and the Development of a Digital Highway Construction Safety Risk Model. Digital 2022, 2, 206–223. [Google Scholar] [CrossRef]

- Huang, L.; Wu, C.; Wang, B.; Ouyang, Q. Big-data-driven safety decision-making: A conceptual framework and its influencing factors. Saf. Sci. 2018, 109, 46–56. [Google Scholar] [CrossRef]

- Tao, J.; Yang, F.; Qiu, D.; Reniers, G. Analysis of safety leadership using a science mapping approach. Process Saf. Environ. Prot. 2020, 140, 244–257. [Google Scholar] [CrossRef]

- Lyubykh, Z.; Gulseren, D.; Turner, N.; Barling, J.; Seifert, M. Shared transformational leadership and safety behaviours of employees, leaders, and teams: A multilevel investigation. J. Occup. Organ. Psychol. 2022, 95, 431–458. [Google Scholar] [CrossRef]

- Bhosale, T.; Biradar, A.; Bhat, K.; Barhate, S.; Kotwal, J. Applied Deep Learning for Safety in Construction Industry. In Data Intelligence and Cognitive Informatics: Proceedings of ICDICI 2022; Springer Nature: Singapore, 2022; pp. 167–181. [Google Scholar] [CrossRef]

- Wirth, O.; Sigurdsson, S.O. When workplace safety depends on behavior change: Topics for behavioral safety research. J. Saf. Res. 2008, 39, 589–598. [Google Scholar] [CrossRef] [PubMed]

- Norris, D.; Foote, J.; Greatbanks, R. Mode 2 critical systems practice for complex safety decisions: Reflections from New Zealand’s dairy industry. Syst. Res. Behav. Sci. 2024, 1–17. [Google Scholar] [CrossRef]

- Lakshmi, H.; Ajay, S. Learning Loops and the Process of Continuous. In Unleashing Absorptive Capacity and Unlearning for Organizational Excellence; IGI Global: Hershey, PA, USA, 2024; p. 113. [Google Scholar]

- Valipour, A.; Yahaya, N.; Md Noor, N.; Kildienė, S.; Sarvari, H.; Mardani, A. A fuzzy analytic network process method for risk prioritization in freeway PPP projects: An Iranian case study. J. Civ. Eng. Manag. 2015, 21, 933–947. [Google Scholar] [CrossRef]

- Aslam, M.; Gao, Z.; Smith, G. Integrated implementation of Virtual Design and Construction (VDC) and lean project delivery system (LPDS). J. Build. Eng. 2021, 39, 102252. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Alsaud, M.; Al-Dossary, S.; Sherif, M.; Abotaleb, I.S.; Mohamed, A.G. Evaluation of insurance policies in the Saudi Arabian construction contracts. Heliyon 2024, 10, e31841. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, Z. Identification of Key Risk Nodes and Invulnerability Analysis of Construction Supply Chain Networks. Buildings 2024, 14, 1997. [Google Scholar] [CrossRef]

- Sivan, S.; Anuar, R.; Krishnasamy, T.; Bahrin, A.S.; Narayanan, N.S.P.; Sundram, V.P.K. Integrating Safety Practices into the Supply Chain for Sustainable Development in Malaysia’s Building Construction Sites. Inf. Manag. Bus. Rev. 2024, 16, 24–32. [Google Scholar] [CrossRef]

| Group | Barriers, Bottlenecks, and Challenges | References | 2000–2010 | 2010–2020 | Post 2020 |

|---|---|---|---|---|---|

| Micro (site) | Disorganised labour | [78] | ✓ | ||

| Lack of safety engineer/experts on site | [79,80] | ✓ | ✓ | ||

| Lack of trained and skilled workers | [81,82,83] | ✓ | ✓ | ||

| Lack of clearly stated occupational SSoWs by contractor | [84] | ✓ | |||

| Environmental barriers on site (e.g., heavy wind blowing/underground conditions/limited space) | [81,85,86,87] | ✓ | ✓ | ✓ | |

| Neglecting safety based on their experiences | [88,89] | ✓ | |||

| Assigning more dangerous tasks based on racism and discrimination | [24,73,82,89] | ✓ | ✓ | ||

| Lack of technical guidance in performing construction operations | [90] | ✓ | |||

| Lack of strictly defined operational procedures | [90] | ✓ | |||

| Low levels of awareness of workers about safety laws/standards | [80,81,83,91,92,93,94] | ✓ | ✓ | ✓ | |

| Safety communication barriers | [95,96] | ✓ | |||

| Tight project schedules | [97] | ✓ | |||

| Obstruction by subcontractors | [97,98,99,100] | ✓ | |||

| Lack of experience in dealing with emergencies | [73,101] | ✓ | |||

| Poor safety culture | [97,102,103] | ✓ | ✓ | ||

| Inadequate safety measures and materials on site | [84] | ✓ | |||

| Cultural/language differences among workers | [80,83,104] | ✓ | ✓ | ||

| Occupational stressors | [77,105] | ✓ | ✓ | ||

| Lack of commitment, motivation, and accountability of workers to implement occupational SSoWs | [24,73,82,106,107,108] | ✓ | ✓ | ||

| Non-conductive work climate (lack of collaboration among workers) | [53,81,102] | ✓ | ✓ | ||

| Meso (organisation) | Weak implementation of occupational SSoWs | [53,71,97,109,110,111,112] | ✓ | ✓ | ✓ |

| Increased use of subcontractors | [80] | ✓ | |||

| High professional fees for safety | [79,81,101] | ✓ | ✓ | ||

| Poor accident record keeping and reporting system | [78] | ✓ | |||

| Allocating a fixed and special budget for occupational safety | [111] | ✓ | |||

| The low priority given to safety due to cultural differences in organisations | [78] | ✓ | |||

| Inappropriate organisational structure | [53,113] | ✓ | |||

| Inadequate formal safety training before and during projects | [73,80,81,95,114,115,116,117,118,119,120] | ✓ | ✓ | ✓ | |

| Coordinating issues (lack of regular safety meetings within the project) | [118,121] | ✓ | ✓ | ||

| Inefficient safety regulatory committees | [120,122] | ✓ | ✓ | ||

| Lack of continuous monitoring and follow-up | [24] | ✓ | |||

| Low attention to the contractor’s work safety record in awarding the tender | [78,82,120,123] | ✓ | ✓ | ||

| Lack of an integrated team | [124] | ✓ | |||

| Poor safety awareness among the firm’s leadership | [90] | ✓ | |||

| Lack of technological innovation or use to improve safety | [90,122] | ✓ | ✓ | ||

| Management culture error | [96,122,125] | ✓ | ✓ | ||

| Privacy and data security concerns | [103] | ✓ | |||

| Lack of standardisation and resistance to change | [81] | ✓ | |||

| Lack of genuine organisational commitment | [103] | ✓ | |||

| Problems of poor worker welfare | [83] | ✓ | |||

| Macro (environment) | Lack of/imperfect safety laws, regulations, and instructions | [93,126] | ✓ | ||

| The small size of most construction firms | [78] | ✓ | |||

| Lack of support from the government/unsure of government commitment | [81,82,102,127] | ✓ | ✓ | ||

| Lack of safety commitment from clients | [82] | ✓ | |||

| Lack of H&S legislation in specifying client roles | [92] | ✓ | |||

| Improper stereotypes/unsupportive industry norms | [53,104] | ✓ | ✓ | ||

| Funding and logistical constraints in safety enforcement institutions | [94,102] | ✓ | ✓ | ||

| Contradictory and unclear SSoWs | [78,92,128,129,130] | ✓ | ✓ | ✓ | |

| Inadequate instances of sanctions and prosecutions for safety breaches | [94] | ✓ | |||

| Lack of innovative safety enforcement strategies by enforcement institutions | [94] | ✓ | |||

| Poor statistics on occupational accidents and diseases | [94] | ✓ | |||

| Technological limitations | [103] | ✓ | |||

| Poor safety culture within the construction industry | [103,113] | ✓ | |||

| Non-inclusion of a third party (public) in SSoW procedures | [78,90,119,131] | ✓ | ✓ | ✓ | |

| Low attempts to update SSoWs | [120] | ✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarvari, H.; Edwards, D.J.; Rillie, I.; Roberts, C. Barriers, Bottlenecks, and Challenges in Implementing Safety I- and Safety II-Enabled Safe Systems of Working in Construction Projects: A Scoping Review. Buildings 2025, 15, 347. https://doi.org/10.3390/buildings15030347

Sarvari H, Edwards DJ, Rillie I, Roberts C. Barriers, Bottlenecks, and Challenges in Implementing Safety I- and Safety II-Enabled Safe Systems of Working in Construction Projects: A Scoping Review. Buildings. 2025; 15(3):347. https://doi.org/10.3390/buildings15030347

Chicago/Turabian StyleSarvari, Hadi, David J. Edwards, Iain Rillie, and Chris Roberts. 2025. "Barriers, Bottlenecks, and Challenges in Implementing Safety I- and Safety II-Enabled Safe Systems of Working in Construction Projects: A Scoping Review" Buildings 15, no. 3: 347. https://doi.org/10.3390/buildings15030347

APA StyleSarvari, H., Edwards, D. J., Rillie, I., & Roberts, C. (2025). Barriers, Bottlenecks, and Challenges in Implementing Safety I- and Safety II-Enabled Safe Systems of Working in Construction Projects: A Scoping Review. Buildings, 15(3), 347. https://doi.org/10.3390/buildings15030347