The Application and Optimization of a New Tunnel Ventilation Method for the Control Room of Electric Submersible Pump Systems on Jack-Up Offshore Platforms

Abstract

1. Introduction

2. Methods

2.1. Numerical Research

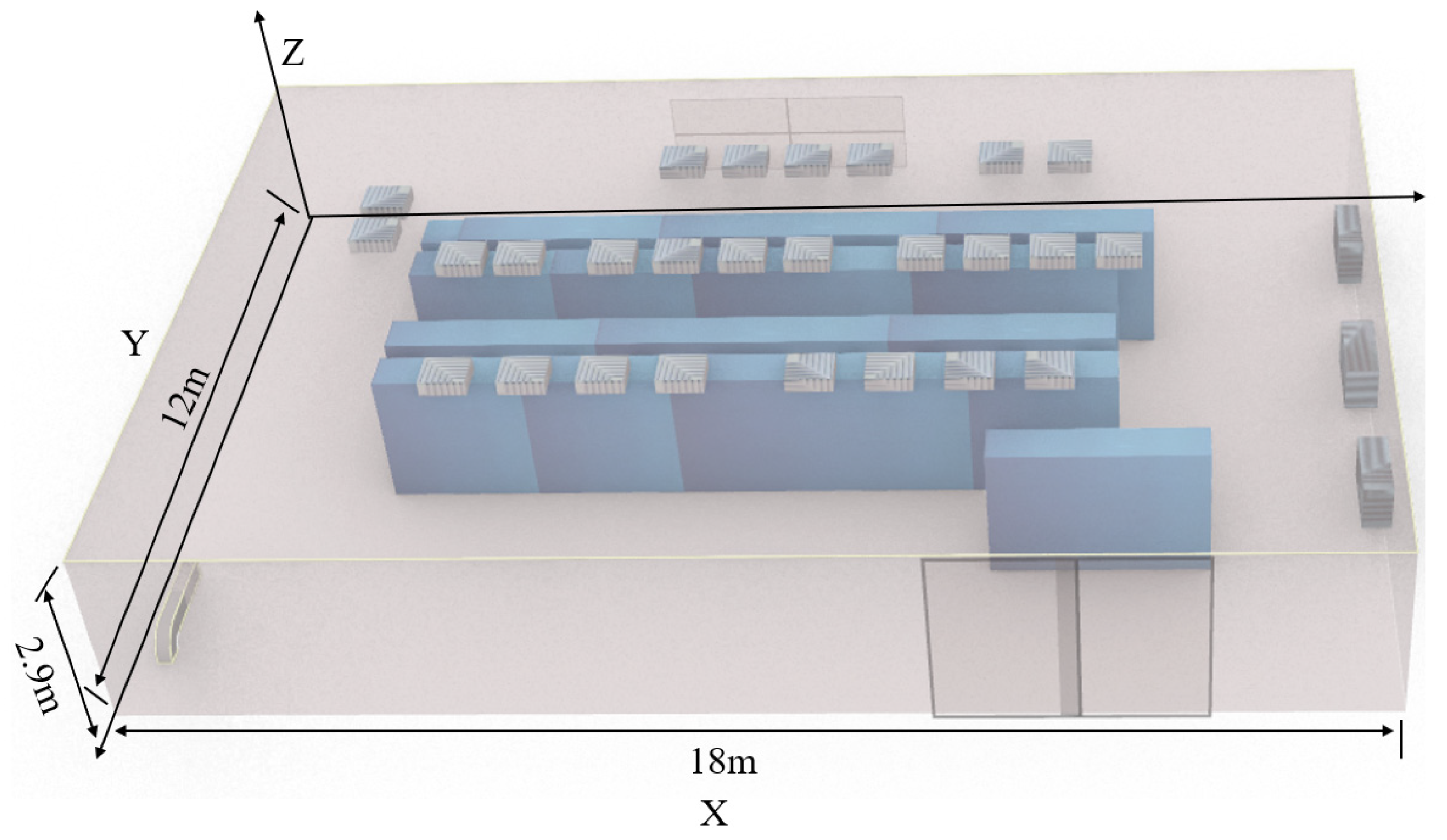

2.1.1. Geometry

2.1.2. Turbulence Model

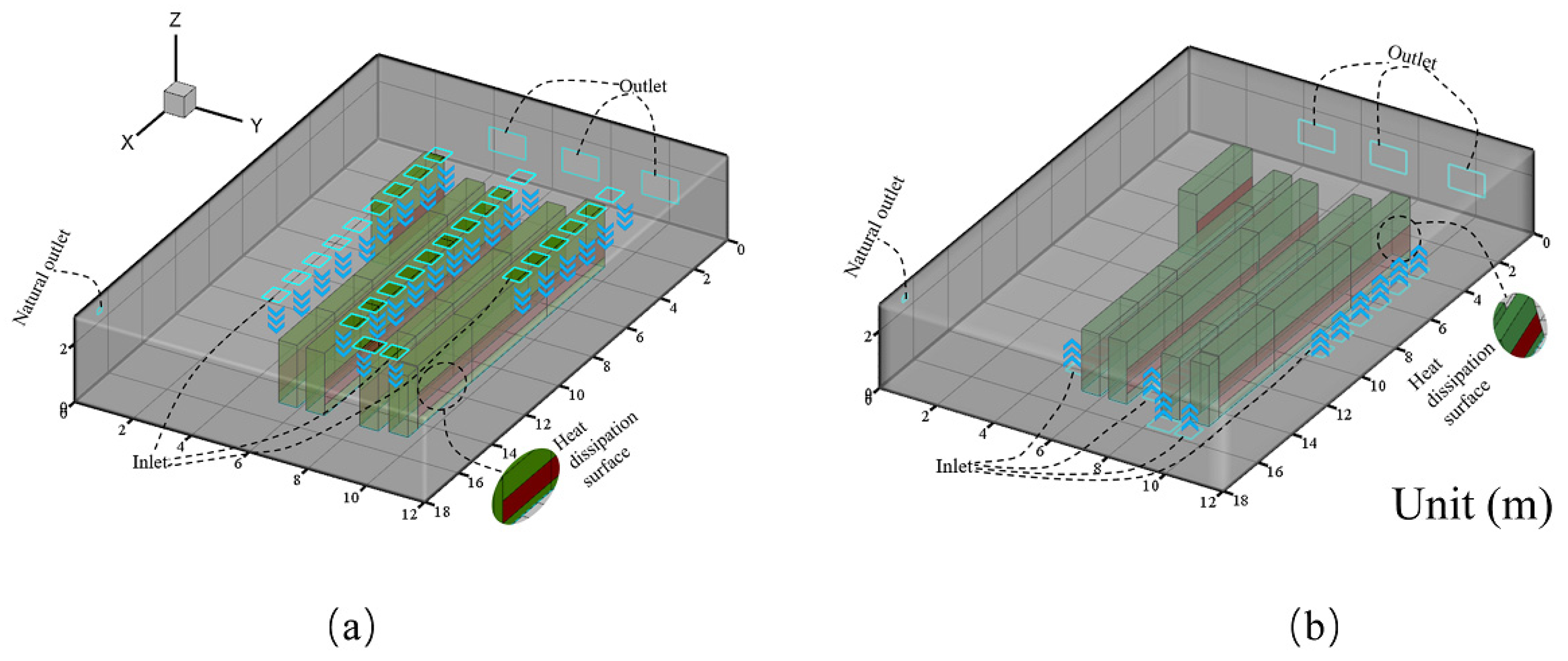

2.2. Boundary Condition Settings

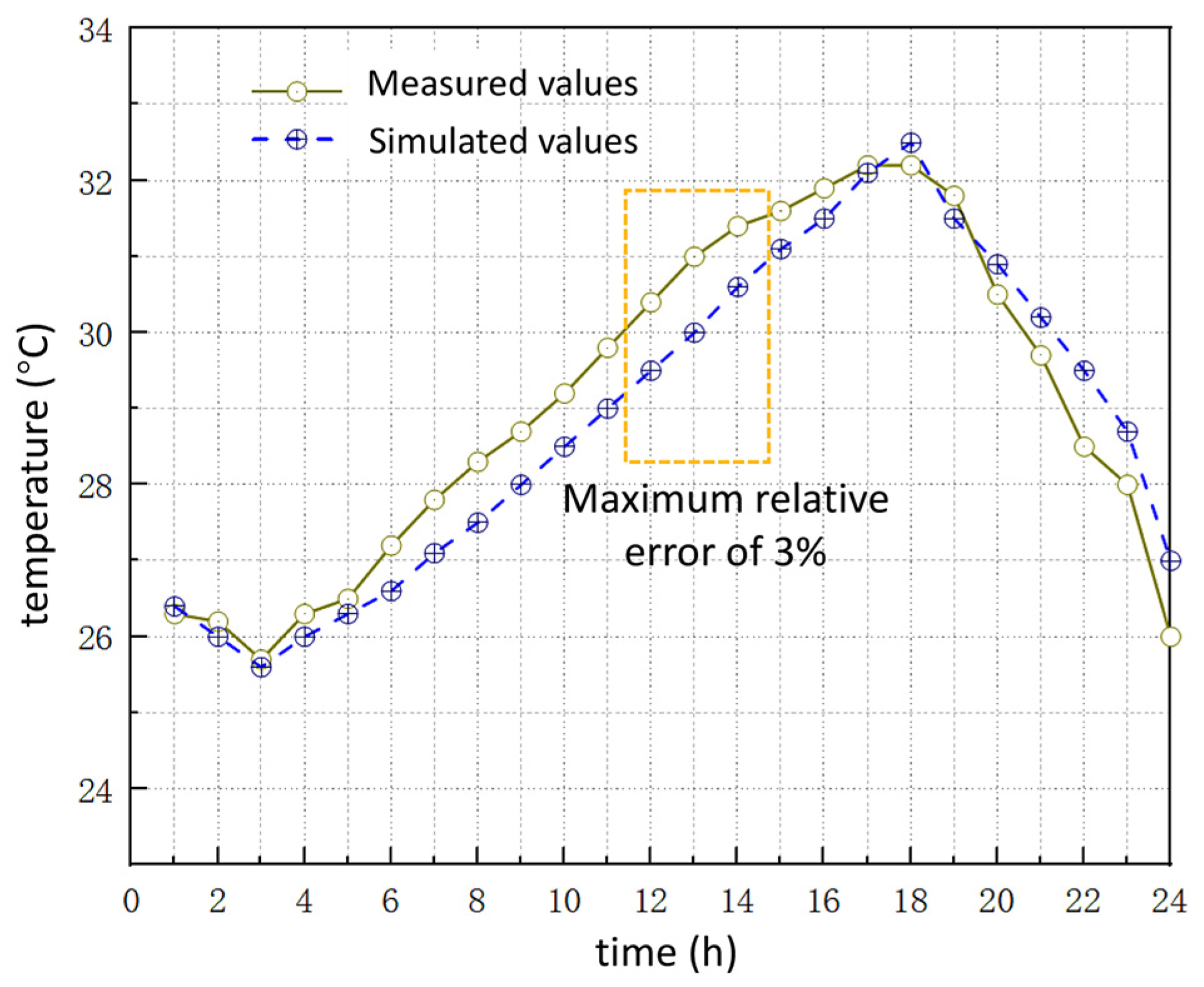

2.3. Field Measurements and Model Validation

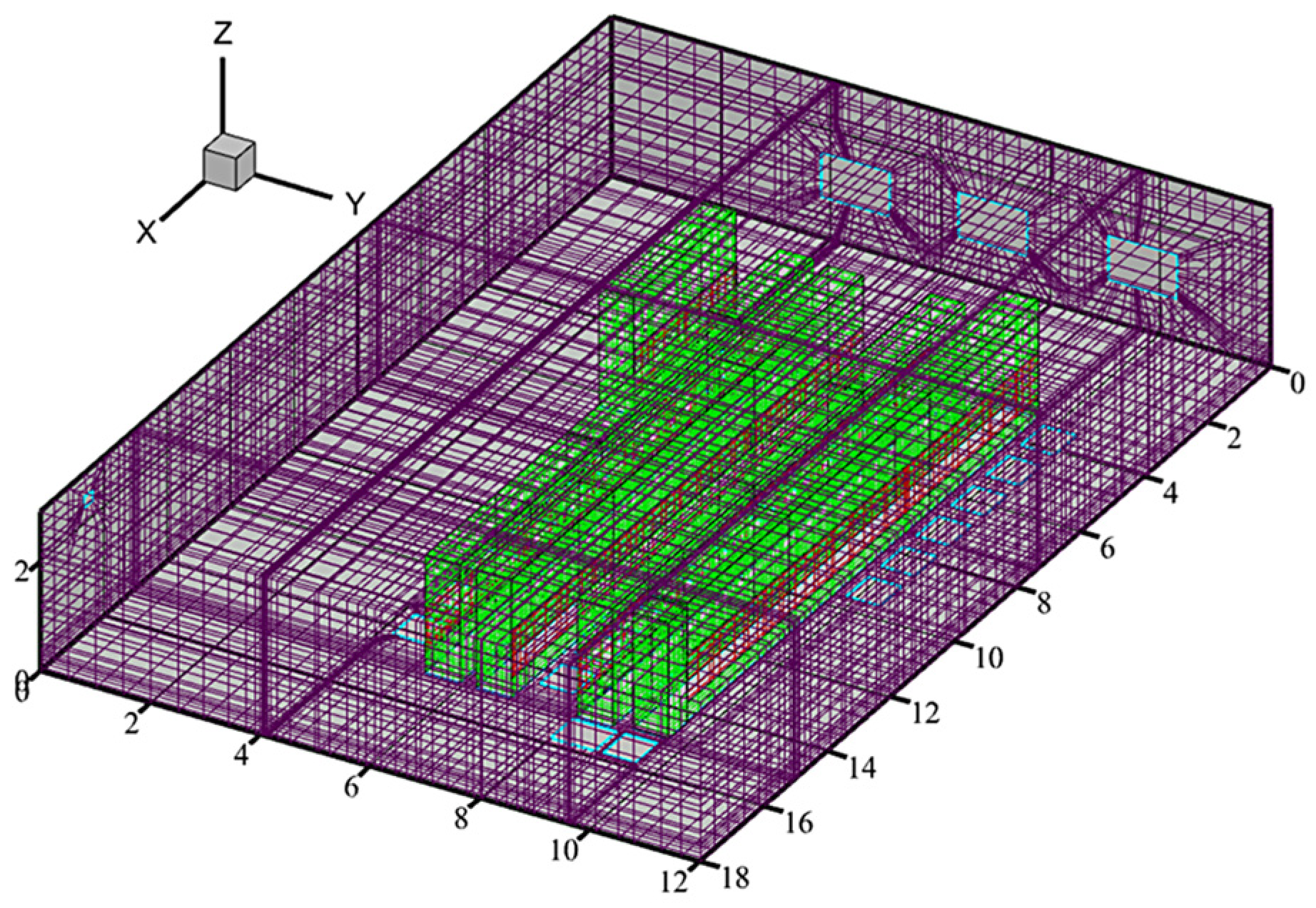

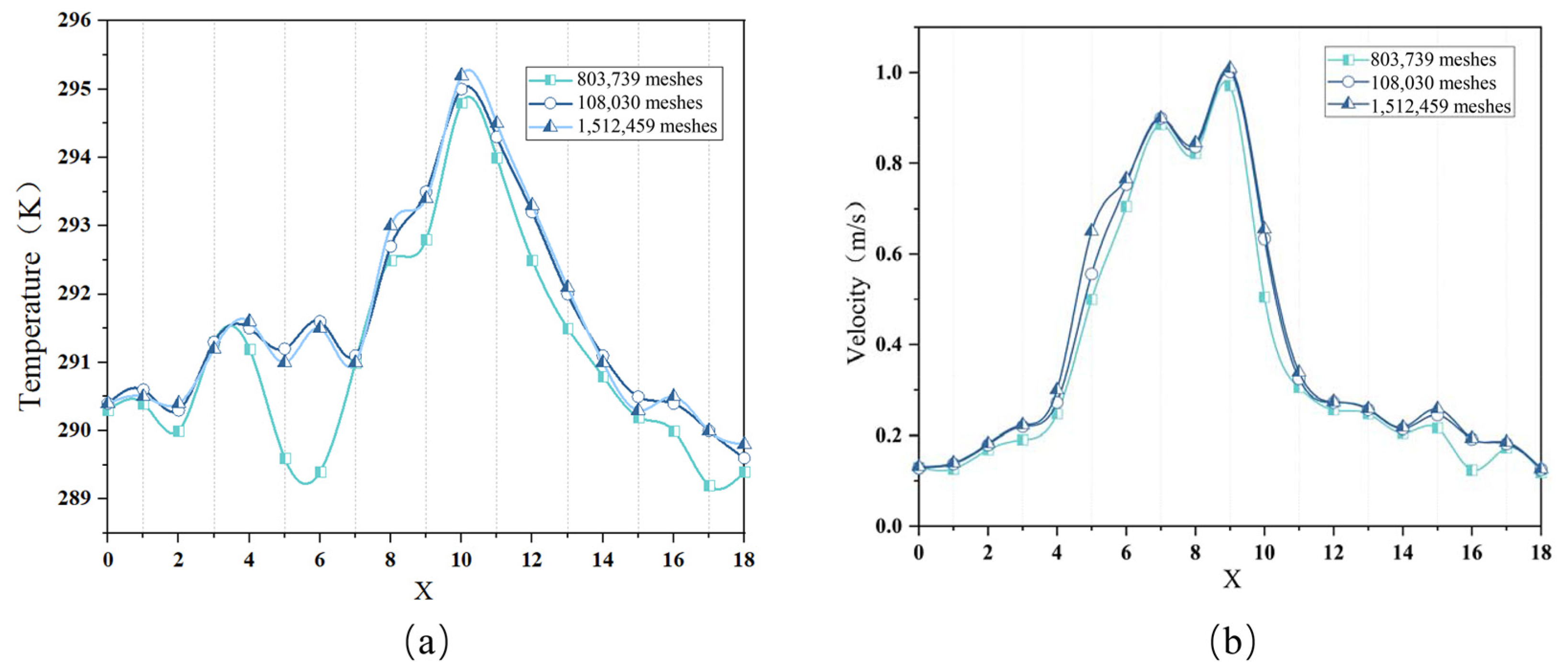

2.4. Mesh Generation and Independence Verification

3. Results and Analysis

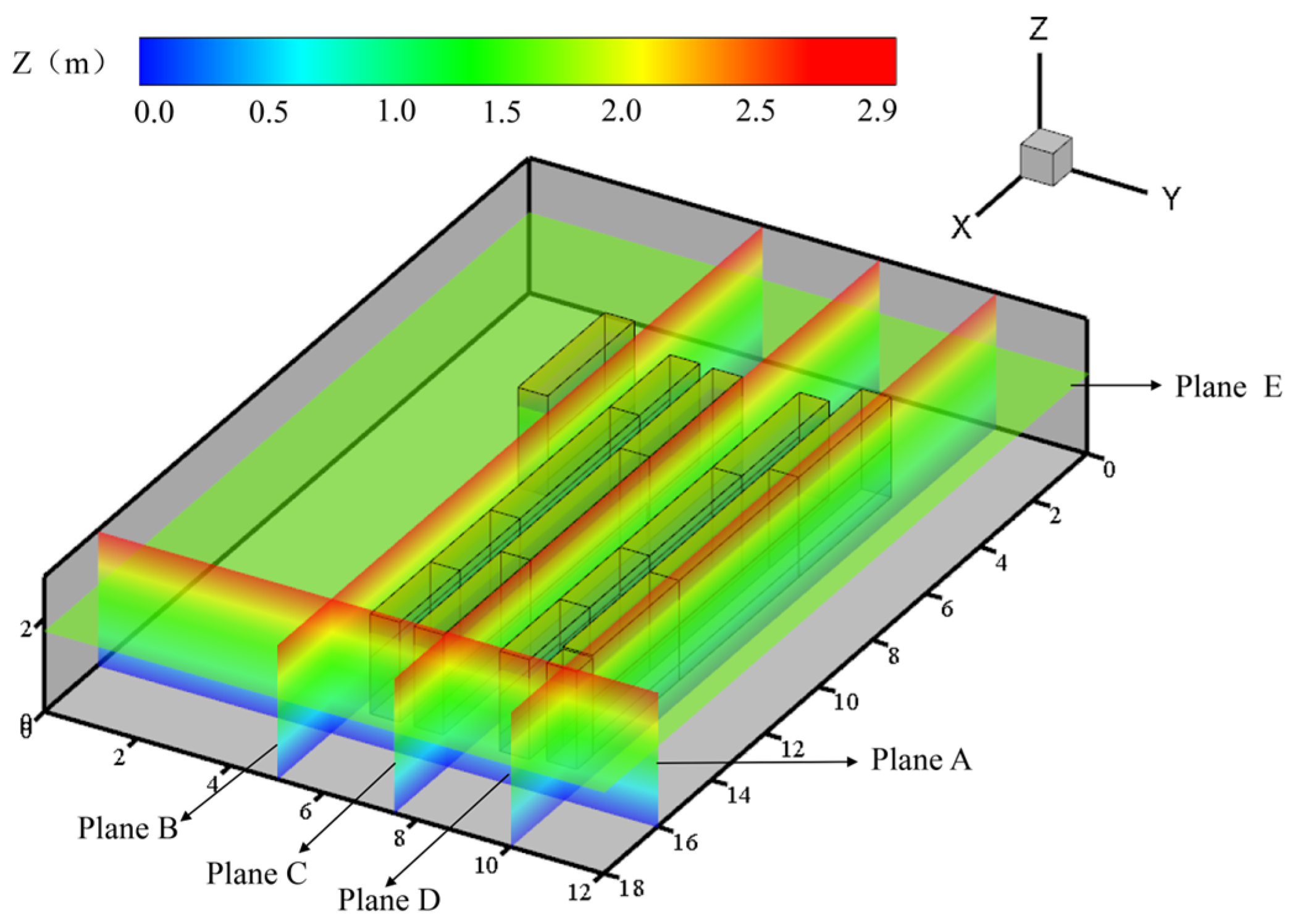

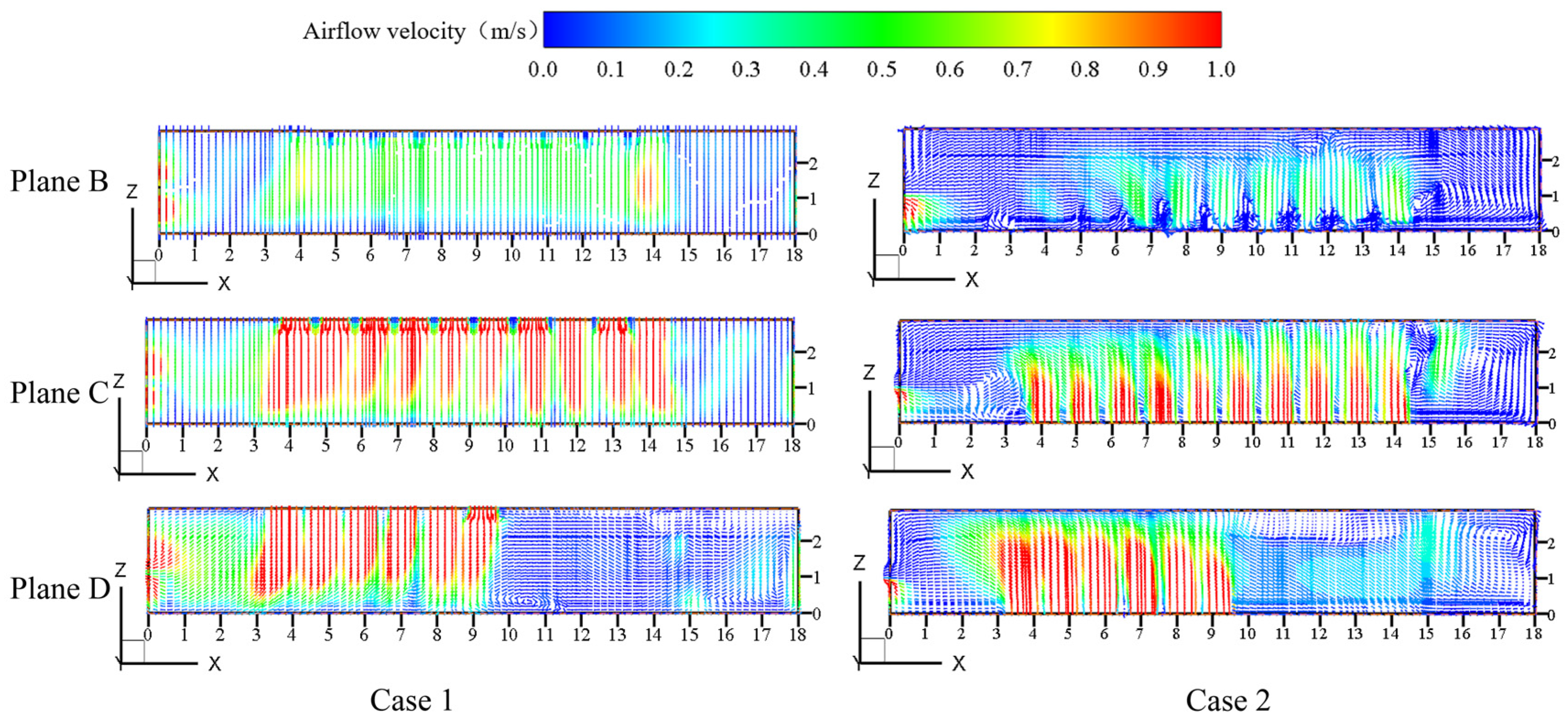

3.1. The Comparative Analysis of the Simulated Results of Case 1 and Case 2

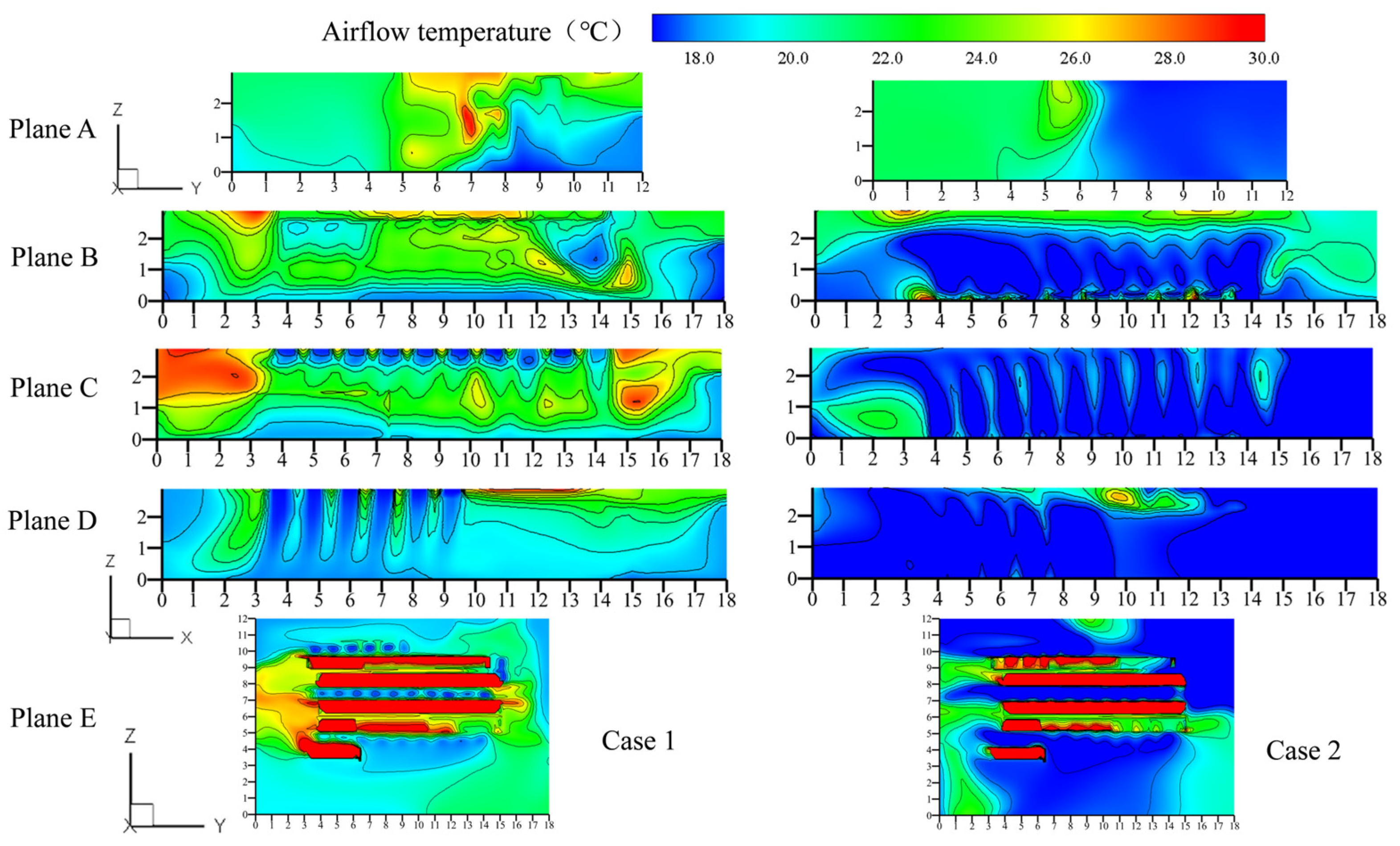

3.1.1. The Comparative Analysis of the Distributions of the Air Temperatures

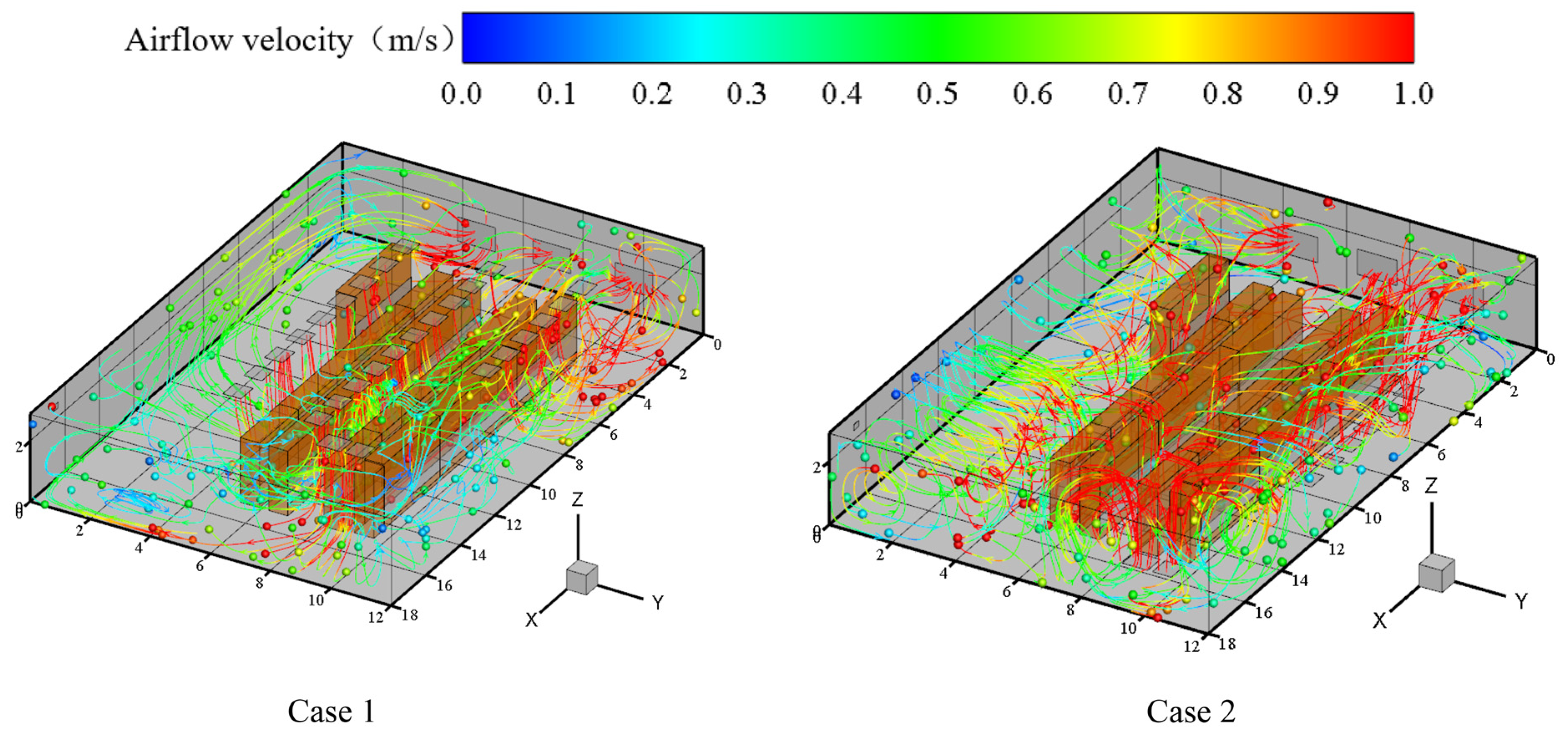

3.1.2. The Comparative Analysis of the Distributions of the Air Velocities

3.1.3. The Comparative Analysis of the Thermal Comfort

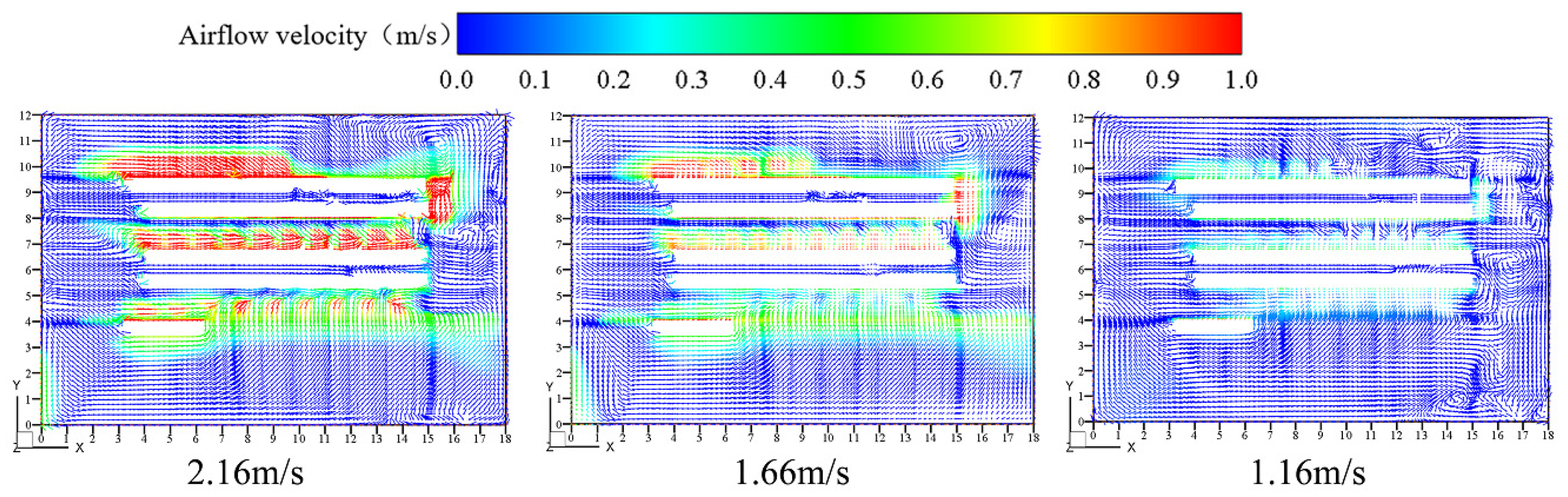

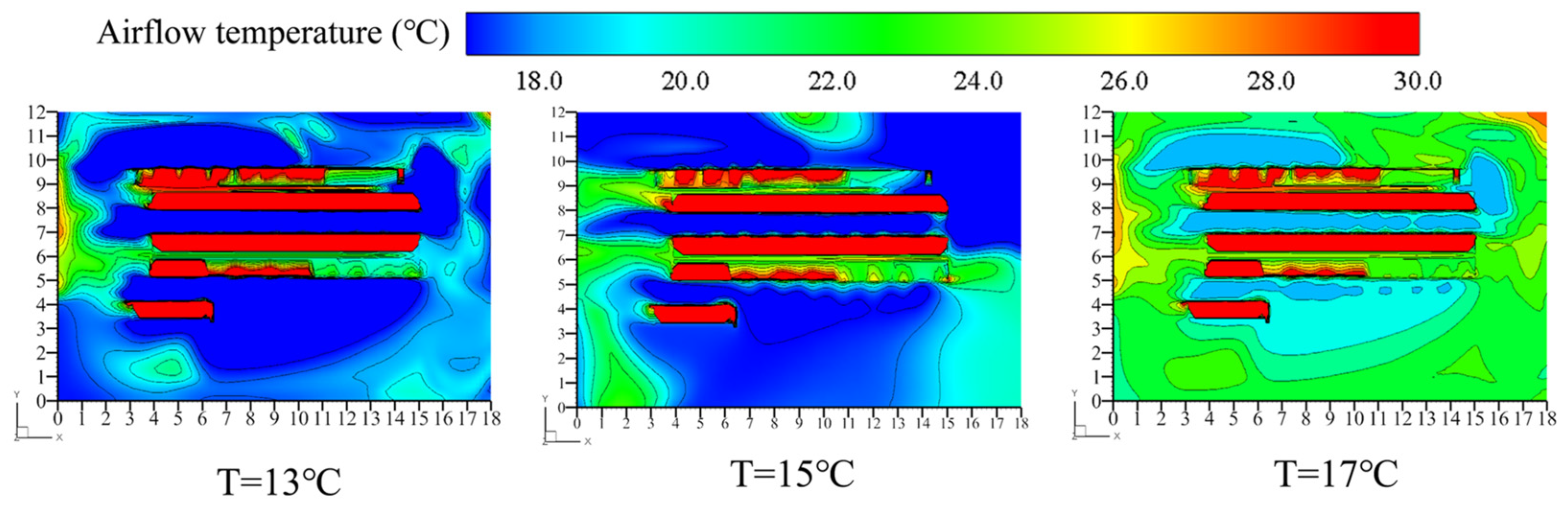

3.2. The Optimization of the Air Supply Conditions of the Control Room

3.2.1. The Optimization of the Air Supply Velocity

3.2.2. Optimization of the Air Supply Temperature

4. Limitations and Research Prospects

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| v | velocity vector of the airflow, m/s | k | Turbulent kinetic energy, m2/s2 |

| ρ | Airflow density, kg/m3 | αk | Turbulent Prandtl number for k |

| μ | Dynamic viscosity of the airflow, kg/(m·s) | μeff | Effective viscosity, kg/(m·s) |

| p | Static pressure, N/kg | μt | Turbulent viscosity of the airflow, kg/(m·s) |

| τ | Stress tensor, N/kg | Gk | Generation of turbulent kinetic energy due to the mean velocity gradients, Pa/s |

| g | Gravitational acceleration, m/s2 | Gb | Turbulent kinetic energy generated by buoyancy, Pa/s |

| F | Pressure, contact force and surface tension in the domain, N/kg | αε | Inverse effective turbulent Prandtl number for ϵ |

| u | Viscosity of the airflow, m/s | C1ε | Model constant |

| E | Total energy, W/m3 | C2ε | Model constant |

| Cμ | Model constant | C3ε | Model constant |

| T | Airflow temperature, K or °C | Sh | Heat source in the solid body, W/m3 |

| PMV | Predicted mean vote | PPD | Predicted percentage dissatisfied |

References

- Yang, L.; Li, M.; Li, X.; Tu, J. The effects of diffuser type on thermal flow and contaminant transport in high-speed train (HST)cabins–a numerical study. Int. J. Vent. 2018, 17, 48–62. [Google Scholar] [CrossRef]

- Xu, X.; Xiao, Z.; Wang, M.; Zhu, N.; Qiang, F.; Xiao, N. Prediction Model of Exhaust Smoke Density of Non-road Mobile Machinery Based on Self—Paced Ensemble Learning. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2023, 42, 100–109. [Google Scholar]

- Lubosz, A.; Smoliło, J.; Chmiela, M.; Chmiela, A.; Gajdzik, M.; Smoliński, A. Assessment of the Benefits of Cooling Vests on Working Conditions of Mine Operators in Hard Climatic Conditions: A Case Study. J. Ind. Saf. 2024, 1, 100001. [Google Scholar] [CrossRef]

- Liu, C.; Feng, Q.; Tan, X.; Wang, Y.; Chen, Z. Design optimization of ventilation system for the main machinery room of offshore platforms. Pet. Chem. Equip. 2021, 24, 62–65. [Google Scholar]

- Yu, X.; Yu, H. Automated design of ventilation system for main transformer room of offshore oil platform. Pet. Chem. Equip. 2017, 20, 12–14. [Google Scholar]

- Ma, Z.; Xiong, Z.; Li, T.; Zhang, W. Numerical simulation of ventilation and heat dissipation of offshore platform generator set. Chem. Mach. 2020, 47, 503–507+537. [Google Scholar]

- Sun, D.; Zheng, X.; Tian, W.; Mao, L. HVAC optimization design of electrical room of offshore platform based on high heat dissipation. Ocean Eng. Equip. Technol. 2022, 9, 23–26. [Google Scholar]

- Yang, S.; Ren, R.; Wang, Y.-Q. Study on Air Cabin Ventilation System by Local Structural Optimization During Tunnel Construction. Buildings 2022, 12, 2235. [Google Scholar] [CrossRef]

- Wu, C.; Ahmed, N.A. A Novel Mode of Air Supply for Aircraft Cabin Ventilation. Build. Environ. 2012, 56, 47–56. [Google Scholar] [CrossRef]

- Xie, Y.; Zheng, Z.; Wang, H.; Xu, Z.; Liu, G.; Li, Z. Analysis of a Main Cabin Ventilation System in a Jack-Up Offshore Platform Part I: Numerical Modelling. Appl. Sci. 2019, 9, 3185. [Google Scholar] [CrossRef]

- Xie, Y.; Qin, J.; Zhu, J.; Liu, G.; Zheng, Z.; Yuan, H. Experimental Research on Ventilation Characteristics of a Main Engine Room in a Jack-up Offshore Platform. Appl. Ocean Res. 2021, 117, 102897. [Google Scholar] [CrossRef]

- Li, X. Research on Large-Scale Pig Floor Tunnel Precision Ventilation System. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2022. [Google Scholar]

- Wang, C.; Ni, X.; Wei, M.; Li, Q.; Wang, S.; Cao, X. Research on the cooling effect of plastic greenhouses with different ventilation methods based on CFD. Trans. CSAM 2023, 54, 351–356+439. [Google Scholar]

- Liu, T.; He, S.; Zang, J. Effect of bottom tuyere on ventilation characteristics of equipment compartment of high-speed train. Refrigeration 2018, 37, 48–54. [Google Scholar]

- Yin, H.; Xie, B.; Huang, B. Assessment of thermocline, temperature front and mesoscale eddy of the South China Sea climate based on numerical products of thermohaline currents in the South China Sea. Ocean Forecast. 2023, 40, 34–46. [Google Scholar]

- Ren, Z.; Luo, Y. GB 50019-2015 Code for Design of Heating, Ventilation and Air Conditioning in Industrial Buildings has been submitted for approval in English. HVAC 2019, 49, 59. [Google Scholar]

- GB 50019-2015; Design Code for Heating Ventilation and Air Conditioning of Industrial Buildings. China Nonferrous Metals Industry Association; Ministry of Housing and Urban Rural Development of the People’s Republic of China; China Planning Press: Beijing, China, 2015. Available online: https://openstd.samr.gov.cn/bzgk/gb/ (accessed on 20 January 2025).

- He, G. Improvement of Typical Compartment Ventilation System of Jack-Up Drilling Platform. Master’s Thesis, Harbin Engineering University, Harbin, China, 2019. [Google Scholar]

- Liu, Y.; Liu, C.; Wang, L.; Ai, W.; Zhao, Y.; Han, C. Research on deck plate recognition technology for offshore platform construction. Ship Sci. Technol. 2024, 46, 159–163. [Google Scholar]

- Pang, D.; Wen, J.; Wu, Y.; Du, B.; Ma, Y. Application of Django framework in the construction management of offshore platform decks. Tianjin Sci. Technol. 2023, 50, 56–58+62. [Google Scholar] [CrossRef]

- Xue, Y.; He, S.; Xue, P.; Xiang, L.; Hu, K.; Wu, W. Selection of turbulence model in numerical simulation of coalescence separation of alcohols. Sci. Technol. Eng. 2023, 23, 5995–6002. [Google Scholar]

- Chen, J.; Zhang, C.; Wu, X.; Zhao, W. Uncertainty quantification introduced by turbulence model selection considering numerical discrete error. Acta Aeronaut. Sin. 2021, 42, 234–245. [Google Scholar]

- Xiang, C. Applicability Analysis of Turbulence Models for Several Typical Flows. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2021. [Google Scholar]

- Hussain, S.; Oosthuizen, P.; Kalendar, A. Evaluation of various turbulence models for the prediction of the airflow and temperature distributions in atria. Energy Build. 2012, 48, 18–28. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.; Jiang, J. Numerical Simulation of Heat Transfer of Supercritical Fluids in Circular Tubes Using Different Turbulence Models. J. Nucl. Sci. Technol. 2011, 48, 366–373. [Google Scholar] [CrossRef]

- Park, I.H.; Cho, Y.J.; Lee, J.S. Analysis of Empirical Constant of Eddy Viscosity by K-ε and RNG k-ε Turbulence Model in Wake Simulation. J. Korean Soc. Mar. Environ. Saf. 2019, 25, 344–353. [Google Scholar] [CrossRef]

- Lateb, M.; Masson, C.; Stathopoulos, T.; Bédard, C. Comparison of Various Types of k–ε Models for Pollutant Emissions Around a Two-Building Configuration. J. Wind. Eng. Ind. Aerodyn. 2013, 115, 9–21. [Google Scholar] [CrossRef]

- Küçüktopcu, E.; Cemek, B. Evaluating the Influence of Turbulence Models Used in Computational Fluid Dynamics for the Prediction of Airflows inside Poultry Houses. Biosyst. Eng. 2019, 183, 1–12. [Google Scholar] [CrossRef]

- Zhu, Z.; Qin, B.; Li, S.; Liu, Y.; Li, X.; Cui, P.; Wang, Y.; Gao, J. Multi-Dimensional Analysis of Turbulence Models for Immiscible Liquid-Liquid Mixing in Stirred Tank Based on Numerical Simulation. Sep. Sci. Technol. 2021, 56, 411–424. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, L.; Zhao, J.; Zhang, Y.; Zhao, S.; Li, W.; Zou, X.; Jiang, Y.; Shi, S.; Hong, J.; et al. Main characteristics and main weather and climate events in China in 2021. Meteorology 2022, 48, 470–478. [Google Scholar]

- Liang, Z.; Huang, L.; Huang, J.; Liu, X.; Su, J. Analysis of climate change characteristics of summer monsoon water vapor transport in northern South China Sea. Brand Res. 2018, 212–215. [Google Scholar] [CrossRef]

- Wang, L.; Wang, D.; Qiu, C.; Zhang, G.; Zou, Z.; Hu, Z.; Dai, X.; Yang, T.; Xi, Z.; He, Y.; et al. Review of marine meteorological research hotspots in 2023. Sci. Technol. Rev. 2024, 42, 124–135. [Google Scholar]

- Xu, J.; Li, J.; Pan, S.; Yao, Y.; Chen, L.; Wu, Z. Assessment of Wind and Wave Energy in China Seas Under Climate Change Based on CMIP6 Climate Model. Energy 2024, 310, 133207. [Google Scholar] [CrossRef]

- Xie, X.; Zheng, H.-B.; Qiao, P.-J. Millennial Climate Changes since MIS 3 Revealed by Element Records in Deep-Sea Sediments from Northern South China Sea. Chin. Sci. Bull. 2014, 59, 776–784. [Google Scholar] [CrossRef]

- Hendrix, C.S.; Glaser, S.M.; Lambert, J.E.; Roberts, P.M. Global Climate, El Niño, and Militarized Fisheries Disputes in the East and South China Seas. Mar. Policy 2022, 143, 105137. [Google Scholar] [CrossRef]

- Huang, R.X.; Du, Y. Scientific Questions About South China Sea Ocean Dynamics. Acta Oceanol. Sin. 2015, 34, 1–5. [Google Scholar] [CrossRef]

- Luo, Y.; Shi, H.; Wang, W. Response of Extreme Significant Wave Height to Climate Change in the South China Sea and Northern Indian Ocean. Aquat. Ecosyst. Health Manag. 2021, 24, 103–110. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Yang, P.; Liu, Y.; Zhu, C.; Wang, L.; Zhong, H. Optimizing Air Inlet Designs for Enhanced Natural Ventilation in Indoor Substations: A Numerical Modelling and CFD Simulation Study. Case Stud. Therm. Eng. 2024, 59, 104408. [Google Scholar] [CrossRef]

- Hu, J.; Kang, Y.; Lu, Y.; Yu, J.; Zhong, K. Simplified Models for Predicting Thermal Stratification in Impinging Jet Ventilation Rooms Using Multiple Regression Analysis. Build. Environ. 2021, 206, 108311. [Google Scholar] [CrossRef]

- Zhang, T.; Zhou, X.; Zhang, Z.; Qu, F. Research on the Influence Mechanism of Outdoor Wind Environment on Indoor Smoke Exhaust Efficiency in the Super-High-Rise Tower Crown Based on Airpak Simulation. Atmosphere 2023, 14, 1048. [Google Scholar] [CrossRef]

- Xu, X.; Li, H.; Lin, Y. Mesh–Order Independence in CFD Simulation. IEEE Access 2019, 7, 119069–119081. [Google Scholar] [CrossRef]

- Lee, M.; Park, G.; Park, C.; Kim, C. Improvement of Grid Independence Test for Computational Fluid Dynamics Model of Building Based on Grid Resolution. Adv. Civ. Eng. 2020, 2020, 8827936. [Google Scholar] [CrossRef]

- Cheung, T.; Schiavon, S.; Parkinson, T.; Li, P.; Brager, G. Analysis of the Accuracy on PMV–PPD Model Using the ASHRAE Global Thermal Comfort Database II. Build. Environ. 2019, 153, 205–217. [Google Scholar] [CrossRef]

- Vera, S.; Fazio, P.; Rao, J. Interzonal Air and Moisture Transport Through Large Horizontal Openings in a Full-Scale Two-Story Test-Hut: Part 2—CFD Study. Build. Environ. 2010, 45, 622–631. [Google Scholar] [CrossRef]

- GB 50736-2012; Design Code for Heating Ventilation and Air Conditioning of Civil Buildings. Ministry of Housing and Urban Rural Development of the People’s Republic of China; China Architecture & Building Press: Beijing, China, 2012. Available online: https://openstd.samr.gov.cn/bzgk/gb/ (accessed on 20 January 2025).

- ISO 7730-2005; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comport Criteria. International Organization for Standardization: Geneva, Switzerland, 2005. Available online: https://www.iso.org (accessed on 20 January 2025).

- Yu, W.; Zhang, J.; Li, H. Numerical Simulation and Analysis of Thermal Environment in Air-Conditioning Office Building. IOP Conf. Ser. Earth Environ. Sci. 2018, 199, 032068. [Google Scholar] [CrossRef]

- Kashi, E.; Mirzaei, F.; Mirzaei, F. Analysis of Gas Dispersion and Ventilation Within a Comprehensive CAD Model of an Offshore Platform via Computational Fluid Dynamics. J. Loss Prev. Process Ind. 2015, 36, 125–133. [Google Scholar] [CrossRef]

- Zhang, D.; Qu, B.; Liu, P.; An, Z. Comprehensive Evaluation and Optimization of Rural Space Heating Modes in Cold Areas Based on PMV-PPD. Energy Build. 2021, 246, 111120. [Google Scholar]

- Chirico, F.; Magnavita, N. New and Old Indices for Evaluating Heat Stress in an Indoor Environment: Some Considerations. Comment on Kownacki, L.; Gao, C.; Kuklane, K.; Wierzbicka, A. Heat Stress in Indoor Environments of Scandinavian Urban Areas: A Literature Review. Int. J. Environ. Res. Public Health 2019, 16, 560. [Google Scholar] [CrossRef]

- Wang, Y.J.; Chen, S.; Zhang, H.; Zhang, W. Research on the selection of electrical equipment for offshore platforms. China Pet. Chem. Ind. Stand. Qual. 2023, 43, 32–34. [Google Scholar]

- Gu, J.; Xie, Y.; Zhao, Y.; Li, W.; Tao, Y.; Huang, X. Study on Vortex-Induced Motions of A New Type of Deep Draft Multi-Columns FDPSO. China Ocean Eng. 2018, 32, 1–13. [Google Scholar] [CrossRef]

- Ma, P.F. Numerical simulation of air intake filter for cabin ventilation system of offshore platform. Sci. Technol. Innov. 2024, 23, 77–80. [Google Scholar]

| Research Interests | The Literature | The Current State of Research in the Relevant Field | The Novelty of This Study | The Research Objectives of This Paper |

|---|---|---|---|---|

| Application of CFD numerical simulation | [4,5,6,7,8,9,10,11] | Most conventional CFD software has two significant limitations: first, it uses default settings without optimizing the parameters based on the complex internal structure; second, in terms of the study of thermal comfort for personnel, it can only provide qualitative descriptions and cannot quantitatively assess comfort using metrics such as the PMV-PPD, as performed in this study. This makes it difficult to provide effective feedback on personnel comfort for ventilation optimization. | By utilizing Airpak 3.0, this study investigated key indicators such as the PMV and PPD to quantify personnel comfort under different ventilation systems. | This research fills the gap in the practical application of tunnel ventilation in marine compartments. Using Airpak 3.0, a comparison was made between the new tunnel ventilation system and traditional ventilation in the electric submersible pump control room on an offshore platform. The unique PMV-PPD indicators were employed to quantify human thermal comfort, and multi-scenario, multi-parameter simulations were conducted to optimize the new tunnel ventilation system. |

| Optimization research on cabin ventilation solutions | Traditional studies often focus on isolated improvements to a single ventilation method, such as simply increasing the size of ceiling ventilation vents, without considering the overall heat load distribution within the compartment and its impact on the airflow organization. This results in an uneven temperature distribution, with frequent cold or hot spots and ventilation dead zones. | Based on the specific distribution of thermal loads within the electric submersible pump control room, the ventilation method was precisely adjusted to achieve optimal alignment with the thermal load characteristics, ensuring the efficient operation of the ventilation system. | ||

| Application of tunnel ventilation | [12,13,14] | Regarding tunnel ventilation, it has been applied in various contexts, such as large-scale pig farms, greenhouse cooling, and high-speed train cabins, but has not yet been explored in marine platform compartments. | This study was the first to apply innovative tunnel ventilation in the electric submersible pump control rooms on offshore platforms, utilizing simulation techniques to conduct multi-parameter optimization. |

| Equipment | Size (W × D × H mm) | Heat Dissipation Power (kw) |

|---|---|---|

| DPP-VSD-A1 | 3430 × 636 × 2145 | 25.8 |

| DPP-VSD-A2 | 3430 × 636 × 2145 | 23.65 |

| DPP-VSD-A3H | 2230 × 636 × 2145 | 13.07 |

| DPP-VSD-A4H | 2230 × 636 × 2145 | 15.27 |

| DPP-VSD-A5H | 2230 × 636 × 2145 | 18.74 |

| DPP-VSD-A6H | 2230 × 636 × 2145 | 17 |

| DPP-VSD-A7H | 2230 × 636 × 2145 | 17.51 |

| DPP-VSD-A8H | 3220 × 636 × 2145 | 22.5 |

| DPP-VSD-A9H | 3220 × 636 × 2145 | 21.66 |

| DPP-VSD-A10H | 3220 × 636 × 2145 | 17 |

| DPP-VSD-A11H | 3220 × 636 × 2145 | 20.05 |

| DPP-VSD-PY191A1H | 3430 × 636 × 2145 | 24.15 |

| DPP-VSD-PY191A2H | 4430 × 636 × 2145 | 27.71 |

| DPP-VSD-PY191A3H | 4430 × 636 × 2145 | 25.97 |

| DPP-VSD-PY191A4H | 4430 × 636 × 2145 | 27.5 |

| DPP-CCP-001 | 600 × 650 × 2100 | 20.05 |

| Cold | Cool | Slightly Cool | Neutral | Slightly Warm | Warm | Hot |

|---|---|---|---|---|---|---|

| −3 | −2 | −1 | 0 | +1 | +2 | +3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, T.; Li, M.; Zhang, S.; Wu, Y.; Zhang, Y.; Wang, X.; Zeng, X.; Huang, S.; Yang, W. The Application and Optimization of a New Tunnel Ventilation Method for the Control Room of Electric Submersible Pump Systems on Jack-Up Offshore Platforms. Buildings 2025, 15, 325. https://doi.org/10.3390/buildings15030325

Gao T, Li M, Zhang S, Wu Y, Zhang Y, Wang X, Zeng X, Huang S, Yang W. The Application and Optimization of a New Tunnel Ventilation Method for the Control Room of Electric Submersible Pump Systems on Jack-Up Offshore Platforms. Buildings. 2025; 15(3):325. https://doi.org/10.3390/buildings15030325

Chicago/Turabian StyleGao, Tenghua, Menglin Li, Shunxin Zhang, Yuwei Wu, Yu Zhang, Xiaoyu Wang, Xiangfeng Zeng, Shengxiang Huang, and Wenyu Yang. 2025. "The Application and Optimization of a New Tunnel Ventilation Method for the Control Room of Electric Submersible Pump Systems on Jack-Up Offshore Platforms" Buildings 15, no. 3: 325. https://doi.org/10.3390/buildings15030325

APA StyleGao, T., Li, M., Zhang, S., Wu, Y., Zhang, Y., Wang, X., Zeng, X., Huang, S., & Yang, W. (2025). The Application and Optimization of a New Tunnel Ventilation Method for the Control Room of Electric Submersible Pump Systems on Jack-Up Offshore Platforms. Buildings, 15(3), 325. https://doi.org/10.3390/buildings15030325