Effect of Steel Slag Coarse Aggregate Particle Size and Replacement Ratio on Concrete Mechanical Properties and Mesoscale Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Test Details

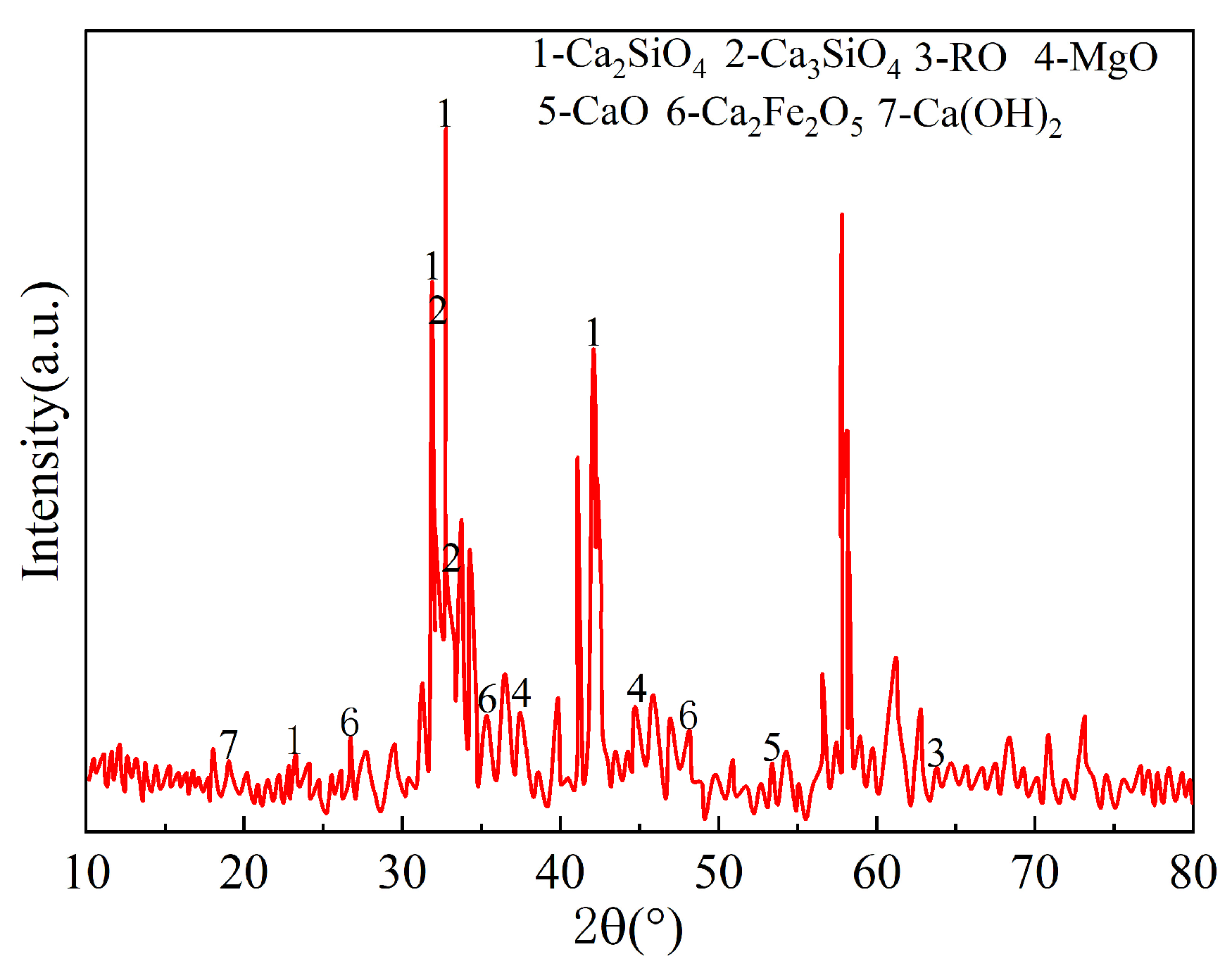

2.1.1. Materials

2.1.2. Mix Proportion Design and Specimen Preparation

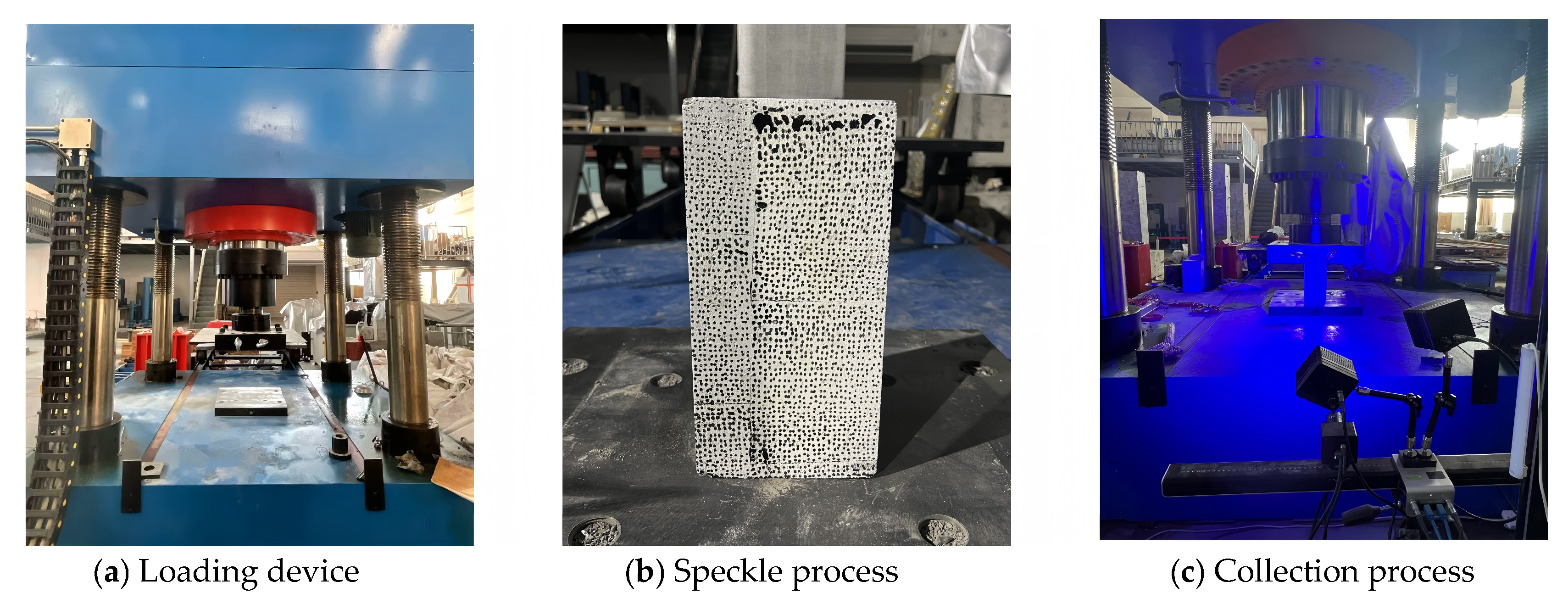

2.1.3. Experimental Setup

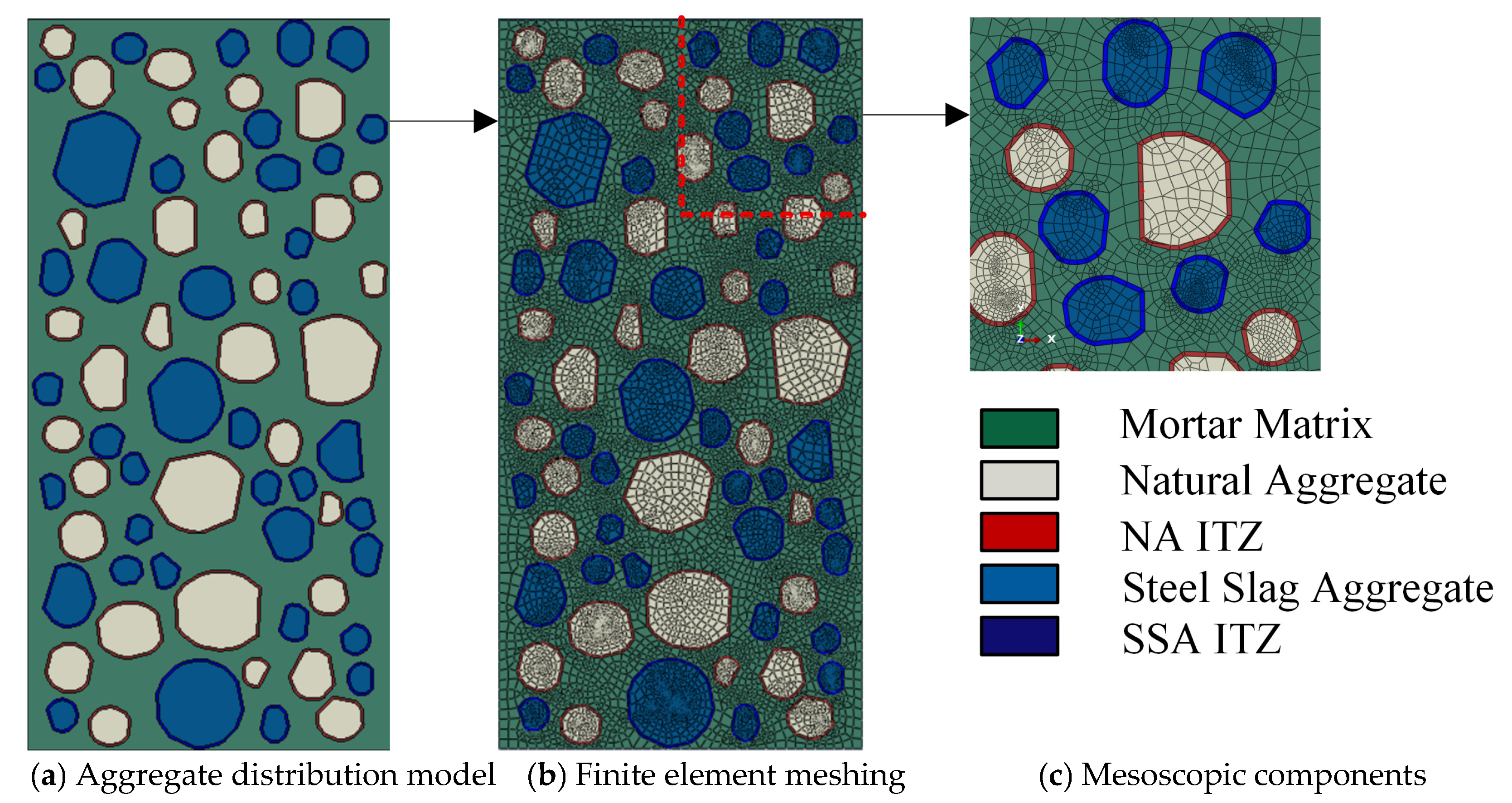

2.2. Mesoscopic Model of Steel Slag Coarse Aggregate Concrete and Its Constitutive Relationship

2.2.1. Mesoscopic Model Establishment

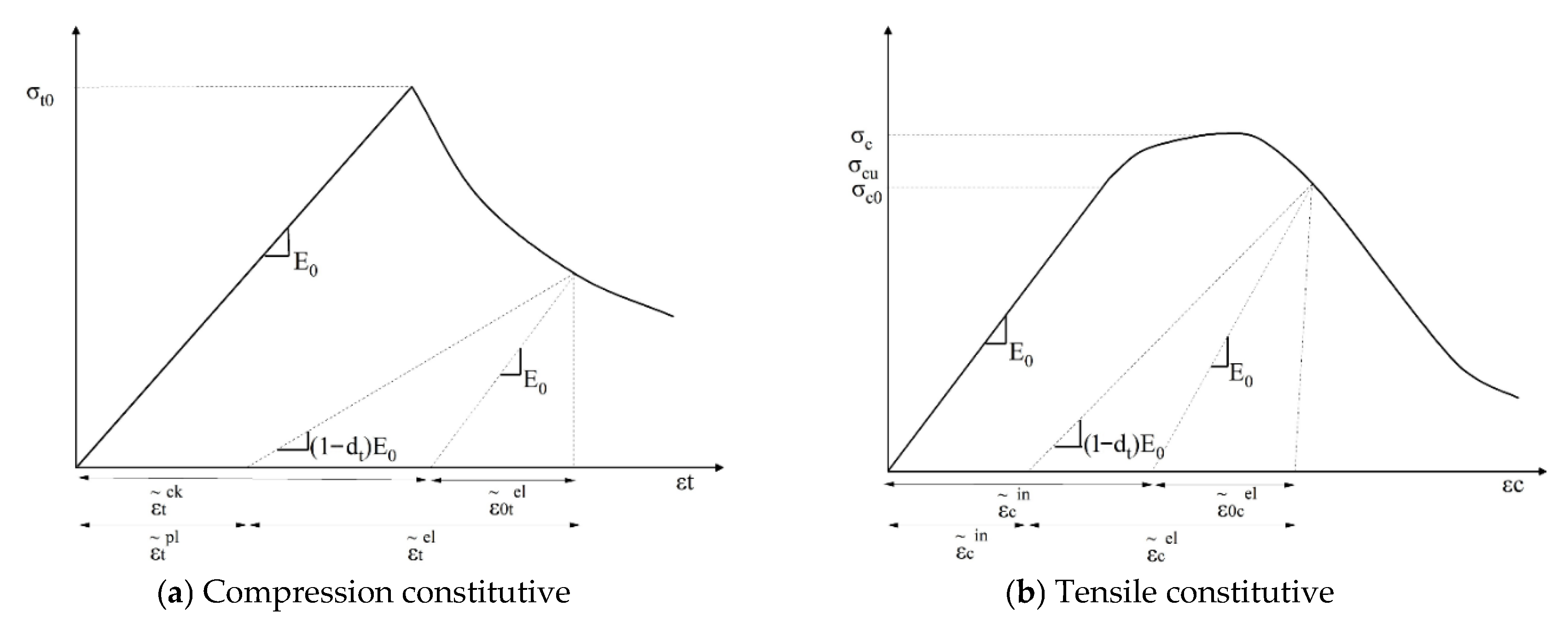

2.2.2. Constitutive Model of Steel Slag Coarse Aggregate Concrete

3. Results and Discussion

3.1. Experimental Results

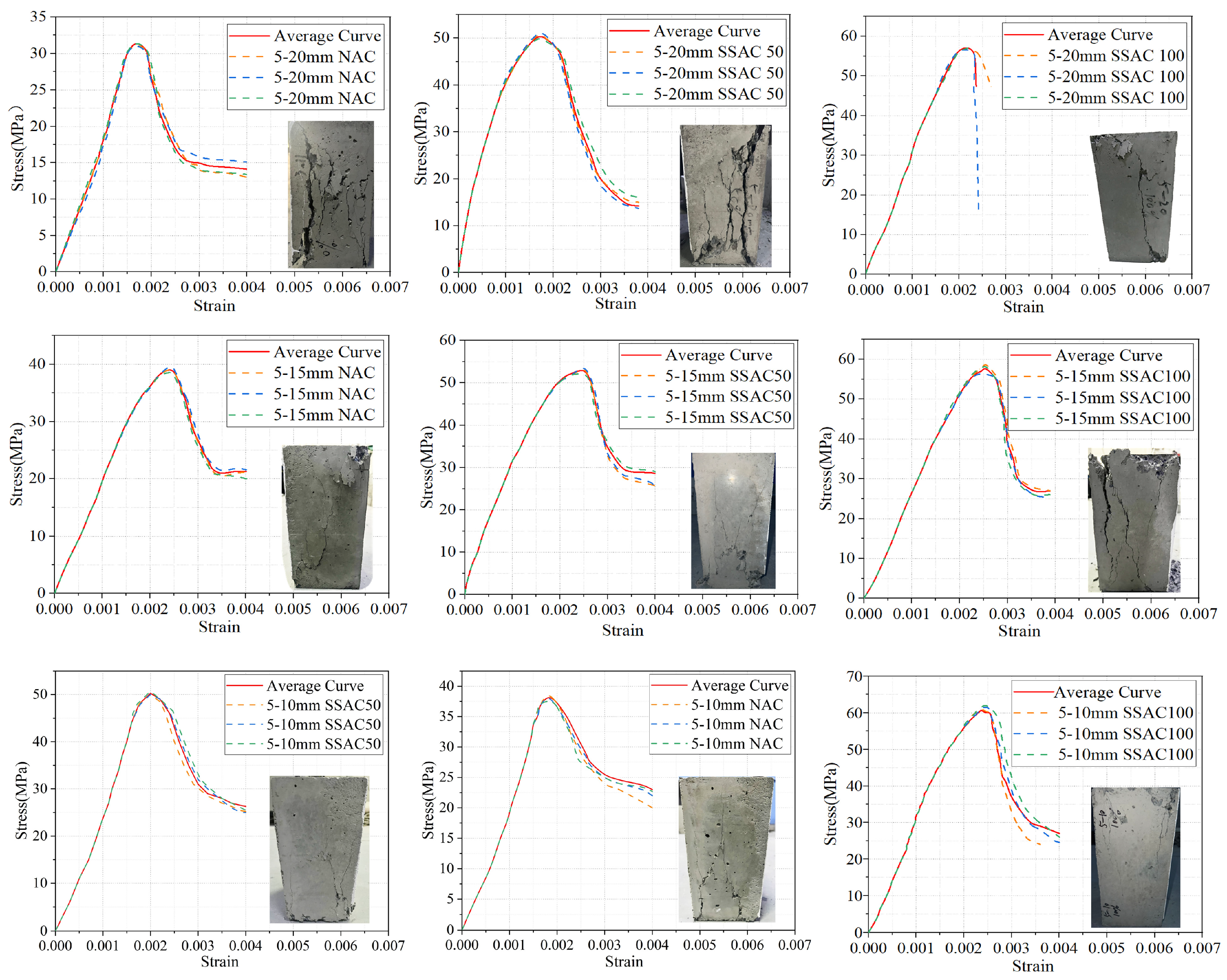

3.1.1. Failure Modes of Steel Slag Coarse Aggregate Concrete

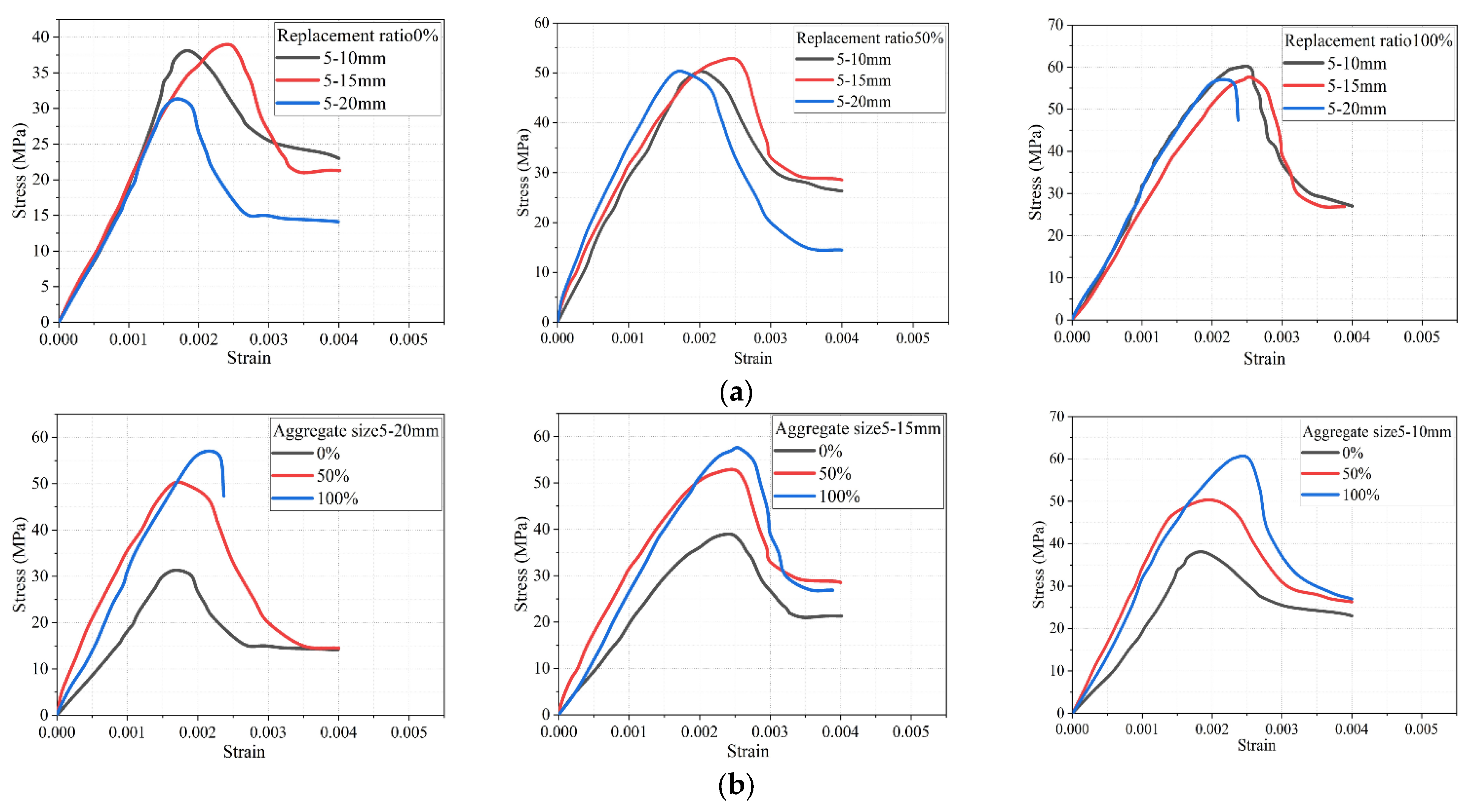

3.1.2. Comparative Analysis of Stress–Strain Curves Under Different Aggregate Size Ranges and Replacement Ratios

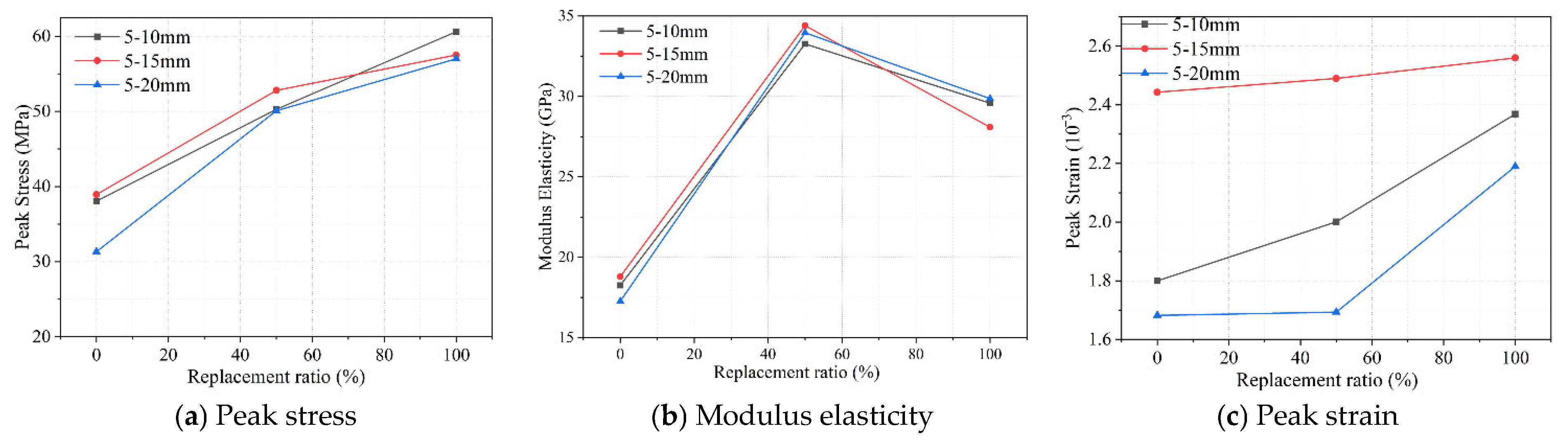

3.1.3. Characteristic Parameters of Steel Slag Coarse Aggregate Concrete

3.2. Mesoscale Model Simulation Results of Steel Slag Coarse Aggregate Concrete

3.2.1. Validation of the Mesoscale Model

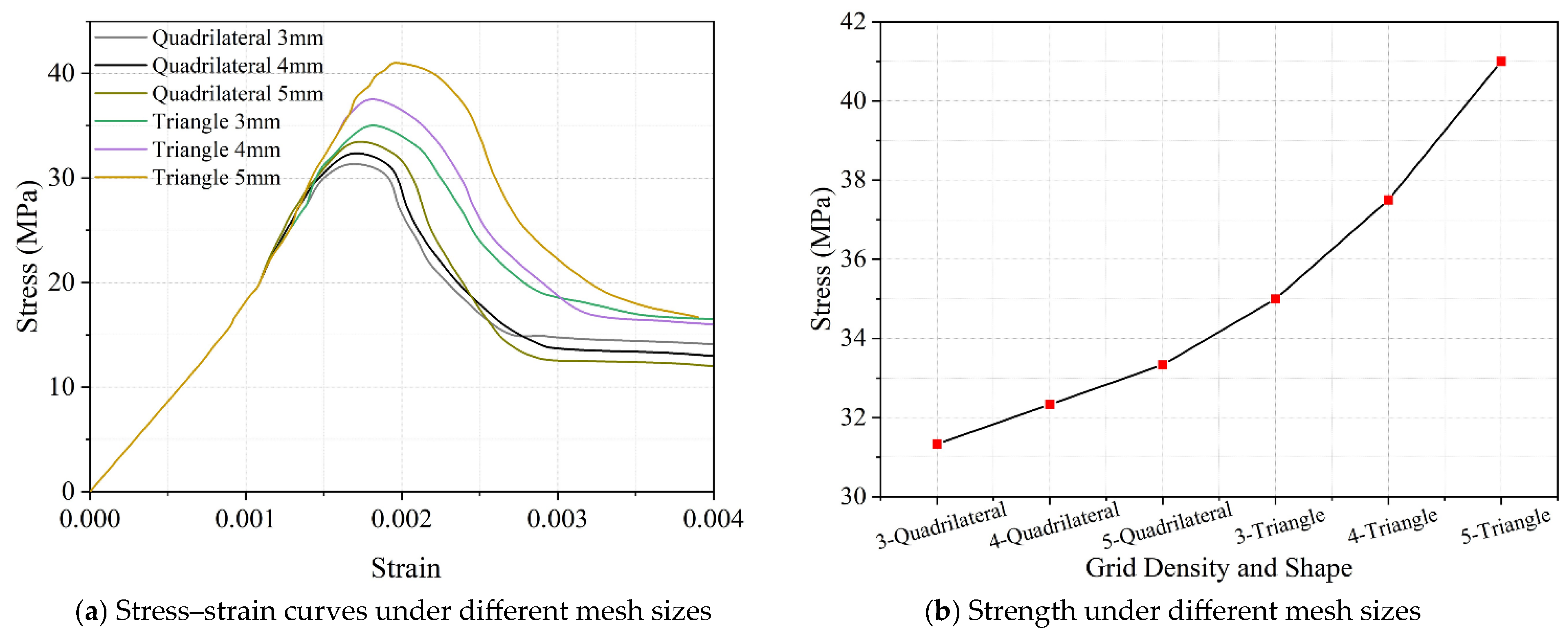

Mesh Sensitivity Analysis

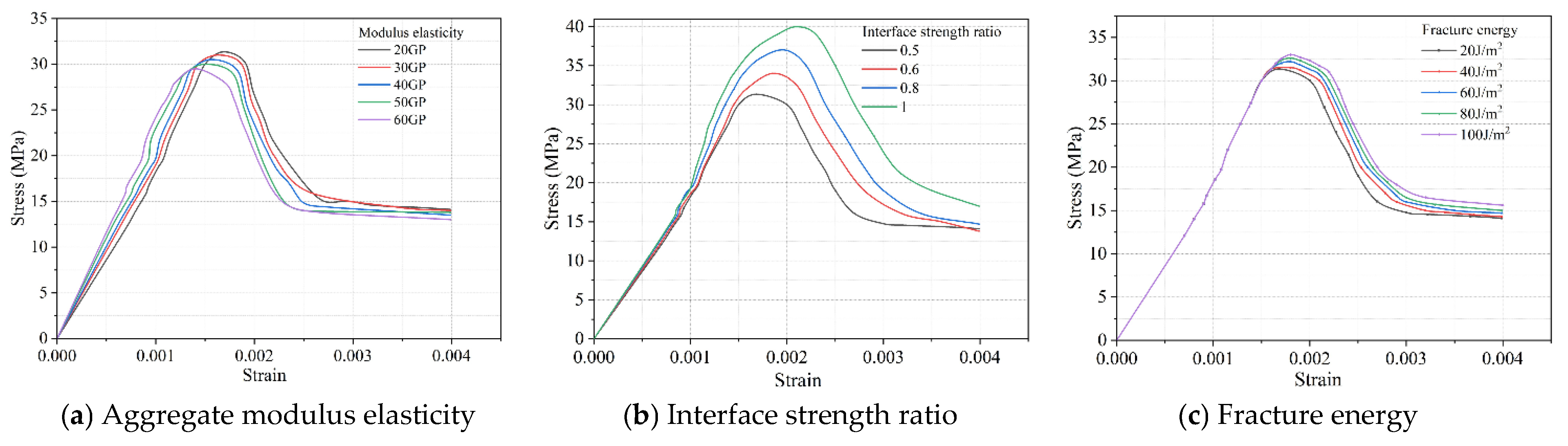

Mesoscale Parameters of Steel Slag Coarse Aggregate

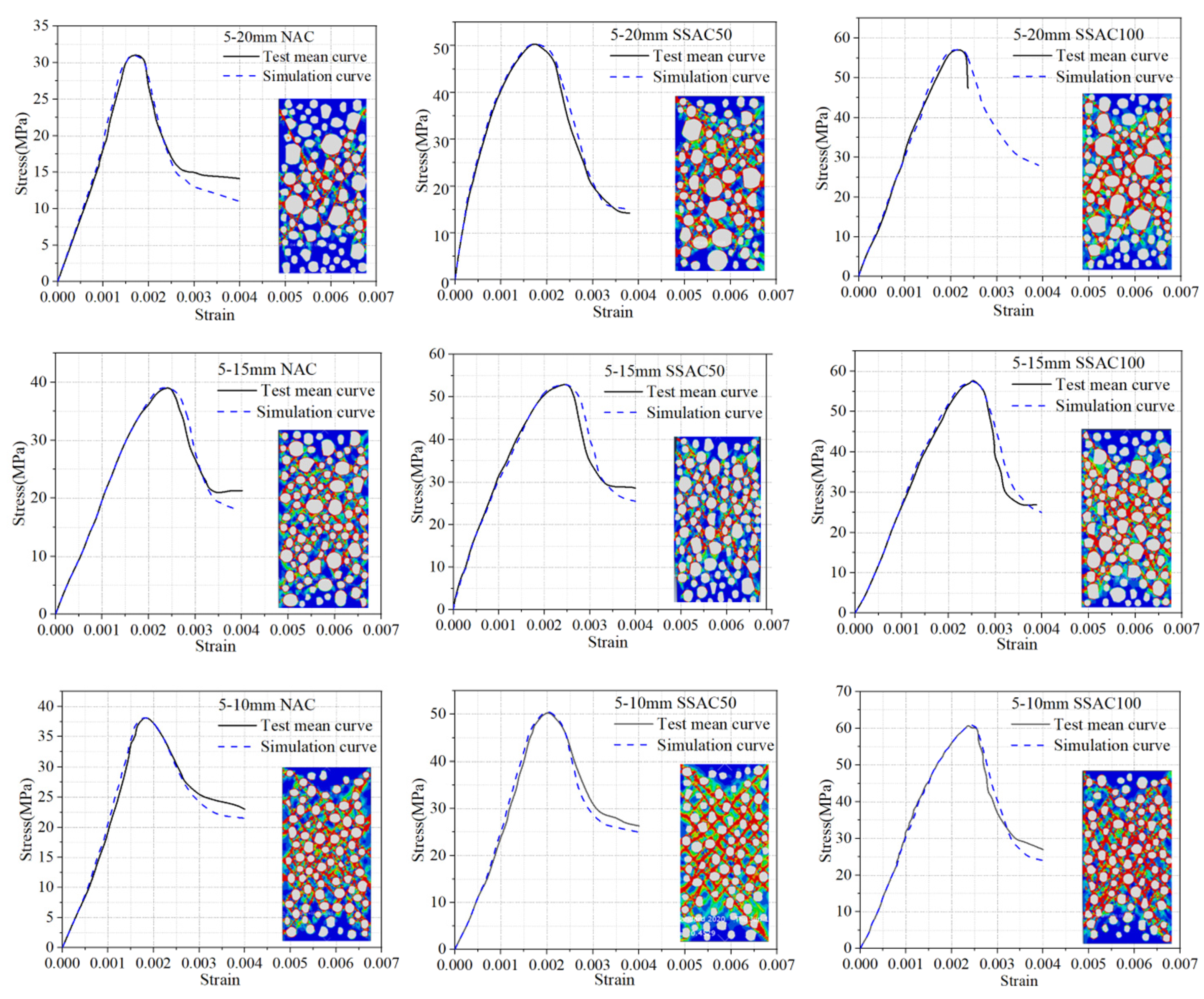

Validation of Simulation Results

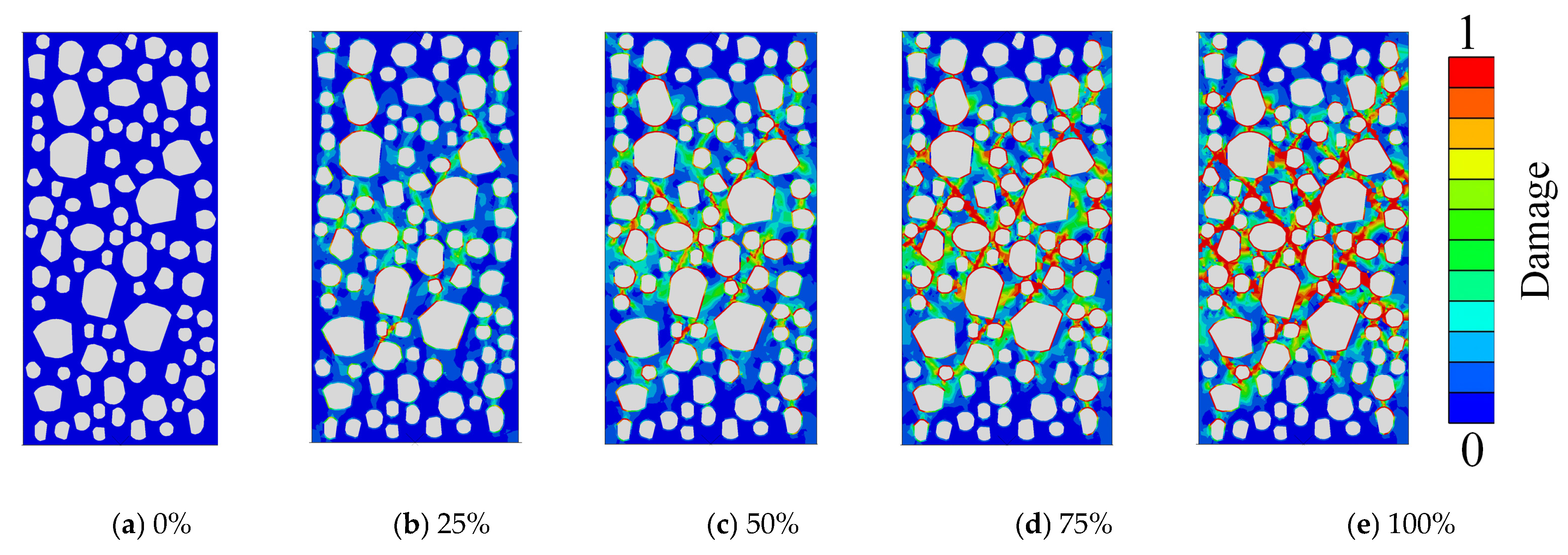

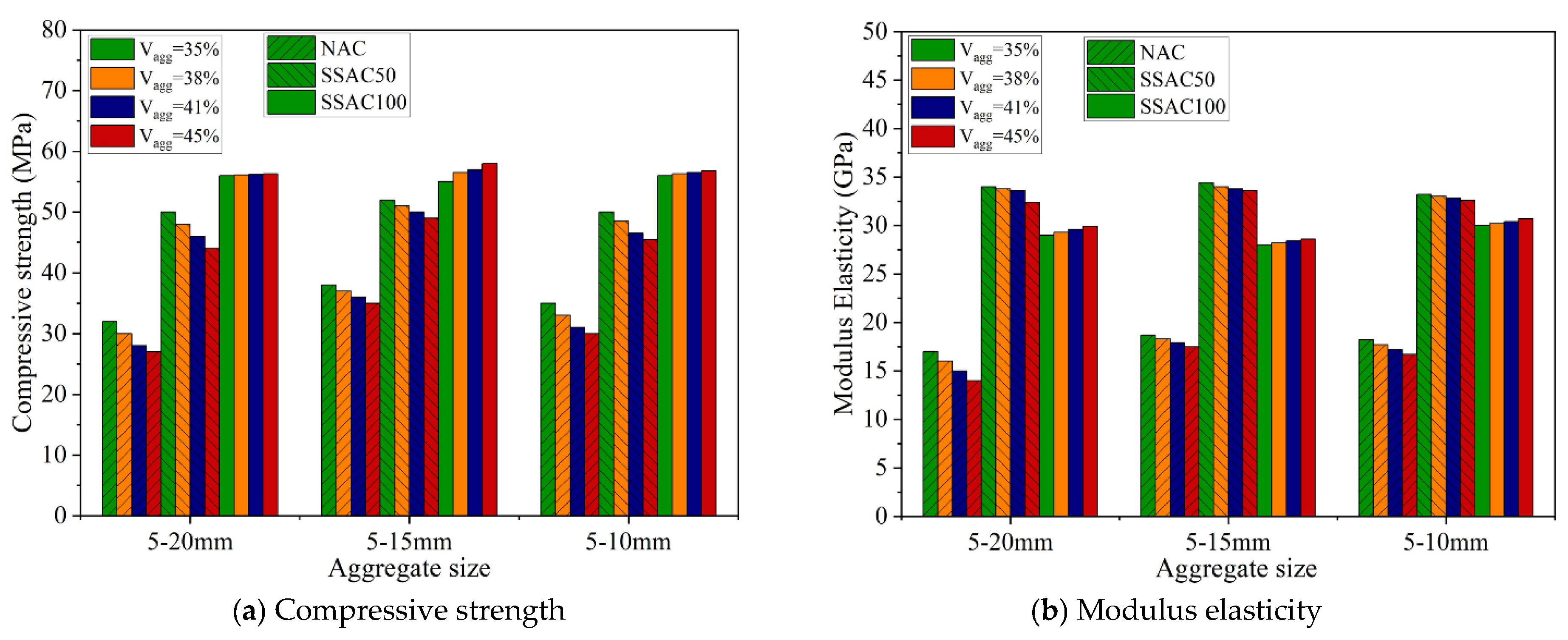

3.2.2. Effect of Coarse Aggregate Volume Fraction on the Strengthening Effect of SSA

3.3. Research Limitations and Reliability

4. Conclusions

- 1.

- The failure modes of SSAC and NAC are fundamentally similar, with both evolving from the propagation of internal microcracks to the formation of macroscopic diagonal cracks. However, compared with NAC, SSAC with a 5–20 mm aggregate size exhibits faster macroscopic crack development and more pronounced acoustic effects during failure. In terms of mechanical response, the stress–strain curve of SSAC is steeper with a more abrupt descending branch; as the aggregate size range decreases, the descending branch becomes gentler, whereas a rise in the SSA replacement ratio results in a steeper descending branch.

- 2.

- The incorporation of SSA can effectively enhance the peak stress, peak strain, and elastic modulus of concrete. The peak stress increases continuously with the SSA replacement ratio; for a given aggregate size range, the elastic modulus first increases and then decreases with increasing replacement, reaching an optimum at a 50% replacement ratio. At this replacement level, the peak stress of concrete with 5–10 mm, 5–15 mm, and 5–20 mm aggregate ranges increased by 32.26%, 35.73%, and 45.74%, respectively, while the elastic modulus increased by 66.7%, 71.4%, and 70.1%, respectively. In addition, the variation in peak strain with replacement ratio differs with aggregate size, showing linear growth, gradual growth, and a trend from gradual to rapid increase, respectively.

- 3.

- Mesoscale numerical simulation results indicate that as the cohesive strength of the ITZ around SSA is increased relative to NA by 75% (5–20 mm), 106% (5–15 mm), and 92% (5–10 mm), the simulated stress–strain curves are in good agreement with the experimental results. The validated model and parameters can serve as a reference for structural simulations of SSAC under different service conditions.

- 4.

- Increasing the coarse aggregate volume fraction from 35% to 45% has an adverse impact on the mechanical properties of NAC, but exhibits a beneficial strengthening effect on SSAC100 (full replacement), with the enhancement becoming more pronounced at higher coarse aggregate contents.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baalamurugan, J.; Kumar, V.G.; Padmapriya, R.; Raja, V.B. Recent applications of steel slag in construction industry. Environ. Dev. Sustain. 2024, 26, 2865–2896. [Google Scholar] [CrossRef]

- Ye, G.; Yuen, K.-V.; Jin, Q.; Zhou, M.; Yin, C.; Jiang, Q.; Zhao, S.; Su, W. Evaluation Method for Uniformity of Steel Slag Concrete Aggregate Based on Improved YOLOv8. J. Build. Eng. 2024, 98, 111046. [Google Scholar] [CrossRef]

- Ma, H.-C.; Geng, Y.; Wang, Q.-H.; Lai, L.-H.; Li, G.-D.; Wang, Y.-Y. Autogenous Shrinkage M-odel for Concrete with Weathered Steel Slag Coarse Aggregate. Structures 2025, 75, 108862. [Google Scholar] [CrossRef]

- Meddah, M.S.; Zitouni, S.; Belâabes, S. Effect of Content and Particle Size Distribution of Coarse Aggregate on the Compressive Strength of Concrete. Constr. Build. Mater. 2010, 24, 505–512. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E.K. Pre-Peak and Post-Peak Rock Strain Characteristics During Uniaxial Compression by 3D Digital Image Correlation. Rock Mech. Rock Eng. 2016, 49, 2541–2554. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology; Longman Scientific & Technical: Harlow, UK, 1987. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Ltd.: Harlow, UK, 2011. [Google Scholar]

- Liu, M.; Wang, F. Numerical Simulation of Influence of Coarse Aggregate Crushing on Mechanical Properties of Concrete under Uniaxial Compression. Constr. Build. Mater. 2022, 342, 128081. [Google Scholar] [CrossRef]

- Jia, J.; Cao, Q.; Luan, L.; Wang, Z.; Zhang, L. Mechanical Properties of Large Slump Concrete Made by Post-Filling Coarse Aggregate Mixing Procedure. Materials 2020, 13, 2761. [Google Scholar] [CrossRef]

- Uddin, M.T.; Mahmood, A.H.; Kamal, M.R.I.; Yashin, S.M.; Zihan, Z.U.A. Effects of Maximum Size of Brick Aggregate on Properties of Concrete. Constr. Build. Mater. 2017, 134, 713–726. [Google Scholar] [CrossRef]

- Aïtcin, P.C. High Performance Concrete; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Vu, X.H.; Daudeville, L.; Malecot, Y. Effect of Coarse Aggregate Size and Cement Paste Volume on Concrete Behavior under High Triaxial Compression Loading. Constr. Build. Mater. 2011, 25, 3941–3949. [Google Scholar] [CrossRef]

- Ghorbani, S.; Sharifi, S.; Ghorbani, S.; Tam, V.W.; de Brito, J.; Kurda, R. Effect of Crushed Concrete Waste’s Maximum Size as Partial Replacement of Natural Coarse Aggregate on the Mechanical and Durability Properties of Concrete. Resour. Conserv. Recycl. 2019, 149, 664–673. [Google Scholar] [CrossRef]

- Vishalakshi, K.P.; Revathi, V.; Reddy, S.S. Effect of Type of Coarse Aggregate on the Strength Properties and Fracture Energy of Normal and High Strength Concrete. Eng. Fract. Mech. 2018, 194, 52–60. [Google Scholar] [CrossRef]

- Tozsin, G.; Yonar, F.; Yucel, O.; Dikbas, A. Utilization Possibilities of Steel Slag as Backfill Material in Coastal Structures. Sci. Rep. 2023, 13, 4318. [Google Scholar] [CrossRef]

- Roslan, N.H.; Ismail, M.; Abdul-Majid, Z.; Ghoreishiamiri, S.; Muhammad, B. Performance of Steel Slag and Steel Sludge in Concrete. Constr. Build. Mater. 2016, 104, 16–24. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, G.; Wang, B.; Wu, M. Mechanical Strengths and Durability Properties of Pervious Concretes with Blended Steel Slag and Natural Aggregate. J. Clean. Prod. 2020, 271, 122590. [Google Scholar] [CrossRef]

- Cheng, X.; Tian, W.; Gao, J.; Gao, Y. Performance Evaluation and Lifetime Prediction of Steel Slag Coarse Aggregate Concrete under Sulfate Attack. Constr. Build. Mater. 2022, 344, 128203. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, L.; Kong, D.; Zhou, T.; Ren, C.; Yang, R.; Yuan, Q. Effect Evaluation and Mechanism Analysis of Steel Slag Fine Aggregate on the Strengths of Recycled Aggregate Concretes. Eur. J. Environ. Civ. Eng. 2025, 29, 1178–1195. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, W.; Wang, J.; Huang, R.; Lou, G.; Luo, S. Effects of Coarse Aggregate Size on Thickness and Micro-Properties of ITZ and the Mechanical Properties of Concrete. Cem. Concr. Compos. 2024, 154, 105777. [Google Scholar] [CrossRef]

- Padmanabhan, K.A. Mechanical Properties of Nanostructured Materials. Mater. Sci. Eng. A 2001, 304–306, 200–205. [Google Scholar] [CrossRef]

- Cascardi, A.; Verre, S.; Ombres, L.; Aiello, M.A. Carbon Fabric Reinforced Cementitious Mortar Confinement of Concrete Cylinders: The Matrix Effect for Multi-Ply Wrapping. Compos. Struct. 2024, 332, 117919. [Google Scholar] [CrossRef]

- Deng, K.K.; Wu, K.; Wu, Y.W.; Nie, K.B.; Zheng, M.Y. Effect of Submicron Size SiC Particula-tes on Microstructure and Mechanical Properties of AZ91 Magnesium Matrix Composites. J. Alloys Compd. 2010, 504, 542–547. [Google Scholar] [CrossRef]

- Lin, J.; Zhao, Q.; Chen, H.; Li, M.; Yuan, L. A Numerical Framework for the ITZ Percolation, Effective Fraction and Diffusivity of Concrete Systems Considering the Nonuniform ITZ. J. Build. Eng. 2023, 77, 107429. [Google Scholar] [CrossRef]

- Zhou, Z.; Jin, Q.; Hu, D.; Zhu, L.; Li, Z.; Su, W. Long-Term Volume Stability of Steel Slag Sand Mortar and Concrete. Case Stud. Constr. Mater. 2025, 22, e04179. [Google Scholar] [CrossRef]

- Mitwally, M.E.; Elnemr, A.; Shash, A.; Babiker, A. Utilization of Steel Slag as Partial Replacement for Coarse Aggregate in Concrete. Innov. Infrastruct. Solut. 2024, 9, 175. [Google Scholar] [CrossRef]

- Gao, M.; Wang, J.; Sha, W.; Guo, Y. Physico-Mechanical Properties and Synergistic Hydration Mechanism of Steel Slag-GBFS Based Alkali-Activated Composites Incorporated with Silica Fume. J. Mater. Res. Technol. 2025, 36, 3327–3341. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Z.; Wang, D.; Yan, P.; Luo, L.; Zhang, H.; Zhang, H.; Gu, X. Hydration Superposition Effect and Mechanism of Steel Slag Powder and Granulated Blast Furnace Slag Powder. Constr. Build. Mater. 2023, 366, 130101. [Google Scholar] [CrossRef]

- Bian, Z.; Fang, Y.; Yu, F.; Wang, X.; Xiang, G. Numerical Simulation of Basic Properties of Fu-ll-Steel Slag Aggregate Concrete. Adv. Civ. Eng. 2021, 2021, 8845329. [Google Scholar] [CrossRef]

- Ren, Z.; Li, D. Uniaxial Compressive Behavior Study of Normal-Strength Concrete Using Waste Steel Slag Aggregate through Laboratory Tests and Numerical Simulation. J. Build. Eng. 2024, 85, 108720. [Google Scholar] [CrossRef]

- Ukpata, J.O.; Ewa, D.E.; Success, N.G.; Alaneme, G.U.; Otu, O.N.; Olaiya, B.C. Effects of Aggregate Sizes on the Performance of Laterized Concrete. Sci. Rep. 2024, 14, 448. [Google Scholar] [CrossRef]

- Zeng, M.-H.; Wu, Z.-M.; Wang, Y.-J. A Stochastic Model Considering Heterogeneity and Crack Propagation in Concrete. Constr. Build. Mater. 2020, 254, 119289. [Google Scholar] [CrossRef]

- Hillerborg, A. Results of Three Comparative Test Series for Determining the Fracture energyG F of Concrete. Mater. Struct. 1985, 18, 407–413. [Google Scholar] [CrossRef]

- Rao, G.A.; Prasad, B.K.R. Fracture Energy and Softening Behavior of High-Strength Concrete. Cem. Concr. Res. 2002, 32, 247–252. [Google Scholar] [CrossRef]

- Zhuo, J.; Zhang, Y.; Ma, M.; Zhang, Y.; Zheng, Y. Uniaxial Compression Failure and Size Effect of Recycled Aggregate Concrete Based on Meso-Simulation Analysis. Materials 2022, 15, 5710. [Google Scholar] [CrossRef]

- Schlangen, E.; Garboczi, E.J. Fracture Simulations of Concrete Using Lattice Models: Computational Aspects. Eng. Fract. Mech. 1997, 57, 319–332. [Google Scholar] [CrossRef]

- Zhang, X.; Ding, J.; Zhang, Y. A Rate-Dependent Peridynamic Model of Reinforced Concrete S-ubjected to Explosive Loading. Eng. Fract. Mech. 2023, 292, 109666. [Google Scholar] [CrossRef]

- Kim, K.; Lim, Y.M. Simulation of Rate Dependent Fracture in Concrete Using an Irregular Lattice Model. Cem. Concr. Compos. 2011, 33, 949–955. [Google Scholar] [CrossRef]

- Mohamed, A.R.; Hansen, W. Micromechanical Modeling of Crack-Aggregate Interaction in Concrete Materials. Cem. Concr. Compos. 1999, 21, 349–359. [Google Scholar] [CrossRef]

- Peng, Y.; Chen, X.; Ying, L.; Kamel, M.M.A. Research on Softening Curve of Recycled Concrete Using Base Force Element Method in Meso-Level. Eng. Comput. 2019, 36, 2414–2429. [Google Scholar] [CrossRef]

- Zhou, M.; Ye, G.; Yuen, K.-V.; Yu, W.; Jin, Q. A Graph Attention Reasoning Model for Prefabricated Component Detection. Comput. Civ. Infrastruct. Eng. 2025, 40, 1606–1626. [Google Scholar] [CrossRef]

- GB175-2023; General Portland Cement Released. China’s State Administration for Market Regulation (SAMR): Beijing, China, 2024.

- GB/T 1346-2024; Test Methods for Water Requirement of Standard Consistency, Setting Time and Soundness of the Portland Cement. China Standards Press: Beijing, China, 2025.

- GB/T14685-2011; Specification of Pebble and Crushedstone for Building. China Standards Press: Beijing, China, 2011.

- YB/T 4328-2012; Method for the Determination of Content of Free Calcium Oxide in Steel Slag. Metallurgical Industry Press: Beijing, China, 2012.

- JGJ/T 70-2009; Standard for Test Method of Performance on Building Mortar. Industry Standard of the People’s Republic of China. China Architecture & Building Press: Beijing, China, 2009.

- ISO 7500-1:2004; Metallic Materials—Verification of Staticuniaxial Testing Machines—Part 1: Tension/Compression Testing Machines—Verification and Calibration of the Force-Measuring System, IDT. International Organization for Standardization: Geneva, Switzerland, 2004.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture Building Press: Beijing, China, 2019.

- Shaik, A.R.; Pandey, A.V.; Karthik, V.; Kolhatkar, A.; Abhishek, G.; Divakar, R. Application of Digital Image Correlation to Small Punch Test for Determination of Stress–Strain Properties. Trans. Indian. Inst. Met. 2024, 77, 3879–3892. [Google Scholar] [CrossRef]

- Peng, Y.; Wang, Q.; Ying, L.; Kamel, M.M.A.; Peng, H. Numerical Simulation of Dynamic Mechanical Properties of Concrete under Uniaxial Compression. Materials 2019, 12, 643. [Google Scholar] [CrossRef]

- Wu, K.; Kang, W.; Xu, L.; Sun, D.; Wang, F.; Schutter, G.D. Damage Evolution of Blended Cement Concrete under Sodium Sulfate Attack in Relation to ITZ Volume Content. Constr. Build. Mater. 2018, 190, 452–465. [Google Scholar] [CrossRef]

- Wu, K.; Shi, H.; Xu, L.; Ye, G.; Schutter, G.D. Microstructural Characterization of ITZ in Blended Cement Concretes and Its Relation to Transport Properties. Cem. Concr. Res. 2016, 79, 243–256. [Google Scholar] [CrossRef]

- Xu, F.; Tian, B.; Xu, G. Influence of the ITZ Thickness on the Damage Performance of Recycled Concrete. Adv. Mater. Sci. Eng. 2021, 2021, 6643956. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Fu, Q.; Xue, G.; Xu, S.; Li, J.; Dong, W. Mechanical Performance, Microstructure, and Damage Model of Concrete Containing Steel Slag Aggregate. Struct. Concr. 2022, 24, 2189–2207. [Google Scholar] [CrossRef]

- Xue, G.; Zhao, Y.; Zhou, H.; Sun, L. Experimental Study on Uniaxial Compressive Stress-Strain Relationship of Steel Slag Coarse Aggregate Concrete. Eng. Mech. 2022, 39, 86–95. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, X.; Wang, S.; Liu, Z.; Liu, L.; Xu, B. Evaluating Cement Treated Aggregate Base Containing Steel Slag: Mechanical Properties, Volume Stability and Environmental Impacts. Materials 2022, 15, 8277. [Google Scholar] [CrossRef]

- Wang, C.; Ye, G.; Jin, Q.; Zhou, Z.; Hu, D.; Wei, Y. The Uniaxial Compressive Stress-Strain Relations of Steel Slag Fine Aggregate Concrete under Steam Curing. Constr. Build. Mater. 2025, 459, 139820. [Google Scholar] [CrossRef]

- Nguyen, T.-T.-H.; Mai, H.-H.; Phan, D.-H.; Nguyen, D.-L. Responses of Concrete Using Steel Slag as Coarse Aggregate Replacement under Splitting and Flexure. Sustainability 2020, 12, 4913. [Google Scholar] [CrossRef]

- Shang, J.; Xing, L. Study on the Interface Transition Zone of Steel Slag Coarse Aggregate Concrete. J. Build. Mater. 2013, 16, 217–220. [Google Scholar] [CrossRef]

- Li, L.; Chen, T.; Gao, X.; Yang, W. New Insights into the Effects of Different CO2 Mineralization Conditions on Steel Slag as Supplemental Cementitious Material. J. Build. Eng. 2024, 84, 108566. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Interfacial Transition Zone of Cement Composites with Steel Furnace Slag Aggregates. Cem. Concr. Compos. 2018, 86, 117–129. [Google Scholar] [CrossRef]

- Wang, S.; Wang, M.; Liu, F.; Song, Q.; Deng, Y.; Ye, W.; Ni, J.; Si, X.; Wang, C. A Review on the Carbonation of Steel Slag: Properties, Mechanism, and Application. Materials 2024, 17, 2066. [Google Scholar] [CrossRef]

- Peng, Z.; Liu, Q. Effects of aggregate size on the mechanical behaviors of interfacial transition zone and concrete: A DEM study. J. Southeast Univ. (Nat. Sci. Ed.) 2025, 55, 1600–1607. [Google Scholar]

- Jin, L.; Wang, Z.; Jiao, P.; Zhou, P.; Wu, T. Mesoscale-Based Failure Mechanism of Recycled Aggregate Concrete under Axial Compression Considering End Restraint Effect. Mater. Today Commun. 2024, 40, 109549. [Google Scholar] [CrossRef]

- Jin, L.; Yu, W.; Li, D.; Du, X. Numerical and Theoretical Investigation on the Size Effect of Concrete Compressive Strength Considering the Maximum Aggregate Size. Int. J. Mech. Sci. 2021, 192, 106130. [Google Scholar] [CrossRef]

- Chen, H.; Xu, B.; Mo, Y.L.; Zhou, T. Behavior of Meso-Scale Heterogeneous Concrete under Uniaxial Tensile and Compressive Loadings. Constr. Build. Mater. 2018, 178, 418–431. [Google Scholar] [CrossRef]

- Wang, G.; Chen, X.; Dong, Q.; Yuan, J.; Hong, Q. Mechanical Performance Study of Pervious Concrete Using Steel Slag Aggregate through Laboratory Tests and Numerical Simulation. J. Clean. Prod. 2020, 262, 121208. [Google Scholar] [CrossRef]

| Coarse Aggregate | Particle Size (mm) | Apparent Density (kg/m3) | Bulk Density (kg/m3) | Crushing Index (%) | Water Absorption (%) |

|---|---|---|---|---|---|

| Steel Slag Stone | 5–10 | 3256 | 1981 | 6.8 | 1.9 |

| 5–15 | 3120 | 1843 | 6.3 | 2.2 | |

| 5–20 | 3063 | 1689 | 6.6 | 2.8 | |

| Natural Stone | 5–20 | 2656 | 1434 | 13.8 | 0.65 |

| Component | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | f-CaO | Others |

|---|---|---|---|---|---|---|---|

| Content % | 32.63 | 22.13 | 8.1 | 15.61 | 8.88 | 0.91 | 11.74 |

| Mineral Phase | Ca2Fe2O5 (C2F) | Ca2SiO4 (C2S) | Ca3SiO5 (C3S) | Ca(OH)2 | MgO | RO | CaO |

|---|---|---|---|---|---|---|---|

| Mass fraction (%) | 25.4 | 2.4 | 35.1 | 1.3 | 12.3 | 11 | 0.74 |

| Label | Water (Kg/m3) | Cement (Kg/m3) | River Sand (Kg/m3) | NA (Kg/m3) | SSA (Kg/m3) | Water Reducer (%) |

|---|---|---|---|---|---|---|

| 5–20 mm NAC | 169 | 375 | 852 | 1017 | 0 | 3.75 |

| 5–20 mm SSAC50 | 169 | 375 | 852 | 508.3 | 684.2 | 4.05 |

| 5–20 mm SSAC100 | 169 | 375 | 852 | 0 | 1368.5 | 4.36 |

| 5–15 mm NAC | 169 | 375 | 852 | 1017 | 0 | 3.82 |

| 5–15 mmSSAC50 | 169 | 375 | 852 | 508.3 | 684.2 | 4.23 |

| 5–15 mm SSAC100 | 169 | 375 | 852 | 0 | 1368.5 | 4.41 |

| 5–10 mm NAC | 169 | 375 | 852 | 1017 | 0 | 3.80 |

| 5–10 mm SSAC50 | 169 | 375 | 852 | 508.3 | 684.2 | 4.18 |

| 5–10 mm SSAC100 | 169 | 375 | 852 | 1017 | 0 | 4.38 |

| Item | Compressive Strength (MPa) | u | CV (%) | |

|---|---|---|---|---|

| Test Value | Average Value | |||

| Mortar | 53 | 54.1 | 1.05 | 1.94% |

| 54.2 | ||||

| 55.1 | ||||

| Aggregate Size | Material Parameters | Mortar | NA | ITZ-NA | SSA | ITZ-SSA |

|---|---|---|---|---|---|---|

| 5–20 mm | Compressive strength (MPa) | 54.1 * | / | 32.5 | / | 56 |

| Tensile strength (MPa) | 5.4 | 3.2 | / | 5.6 | ||

| Elastic modulus (GPa) | 25.2 * | 60 | 15.1 | 90 | 22.7 | |

| Poisson’s ratio (%) | 0.2 | 0.22 | 0.2 | 0.22 | 0.2 | |

| Fracture energy (J/m2) | / | / | 50 | / | 87.5 | |

| 5–15 mm | Compressive strength (MPa) | 54.1 * | / | 40.5 | / | 82.4 |

| Tensile strength (MPa) | 5.4 | / | 4 | / | 8.24 | |

| Elastic modulus (GPa) | 25.2 * | 60 | 27.11 | 90 | 32.9 | |

| Poisson’s ratio (%) | 0.2 | 0.22 | 0.2 | 0.22 | 0.2 | |

| Fracture energy (J/m2) | / | / | 80 | / | 165 | |

| 5–10 mm | Compressive strength (MPa) | 54.1 * | / | 36 | / | 69.1 |

| Tensile strength (MPa) | 5.4 | / | 3.6 | / | 6.91 | |

| Elastic modulus (GPa) | 25.2 * | 60 | 26.8 | 90 | 31.6 | |

| Poisson’s ratio (%) | 0.2 | 0.22 | 0.2 | 0.2 | 0.2 | |

| Fracture energy (J/m2) | / | / | 65 | / | 125 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Zhou, Z.; Gong, J.; Jin, Q. Effect of Steel Slag Coarse Aggregate Particle Size and Replacement Ratio on Concrete Mechanical Properties and Mesoscale Structure. Buildings 2025, 15, 4493. https://doi.org/10.3390/buildings15244493

Liu X, Zhou Z, Gong J, Jin Q. Effect of Steel Slag Coarse Aggregate Particle Size and Replacement Ratio on Concrete Mechanical Properties and Mesoscale Structure. Buildings. 2025; 15(24):4493. https://doi.org/10.3390/buildings15244493

Chicago/Turabian StyleLiu, Xuanxuan, Zhenhao Zhou, Jingwei Gong, and Qiang Jin. 2025. "Effect of Steel Slag Coarse Aggregate Particle Size and Replacement Ratio on Concrete Mechanical Properties and Mesoscale Structure" Buildings 15, no. 24: 4493. https://doi.org/10.3390/buildings15244493

APA StyleLiu, X., Zhou, Z., Gong, J., & Jin, Q. (2025). Effect of Steel Slag Coarse Aggregate Particle Size and Replacement Ratio on Concrete Mechanical Properties and Mesoscale Structure. Buildings, 15(24), 4493. https://doi.org/10.3390/buildings15244493