Mechanical Characteristics Based on the Microstructure Analysis of Cementitious Composites Incorporating Polypropylene Powder

Abstract

1. Introduction

2. Experimental Programs

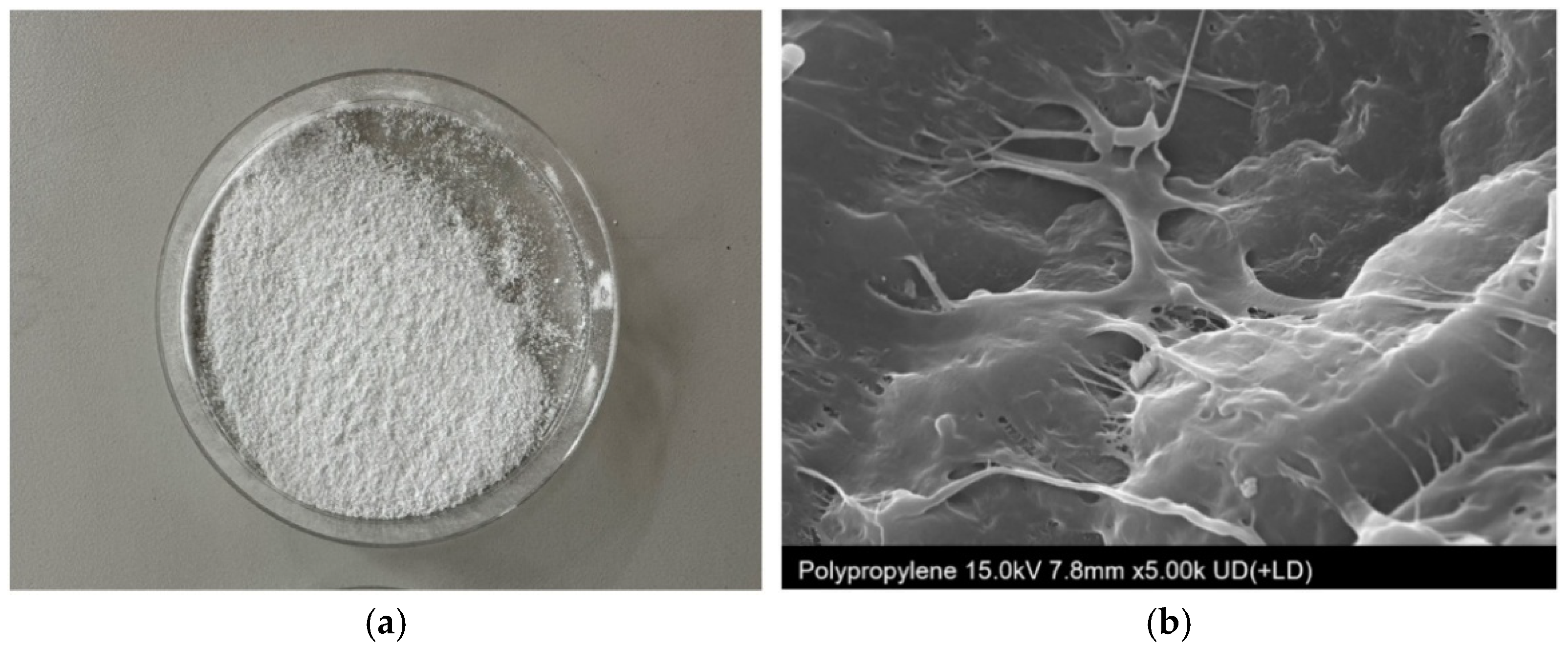

2.1. Fabrication of Specimens

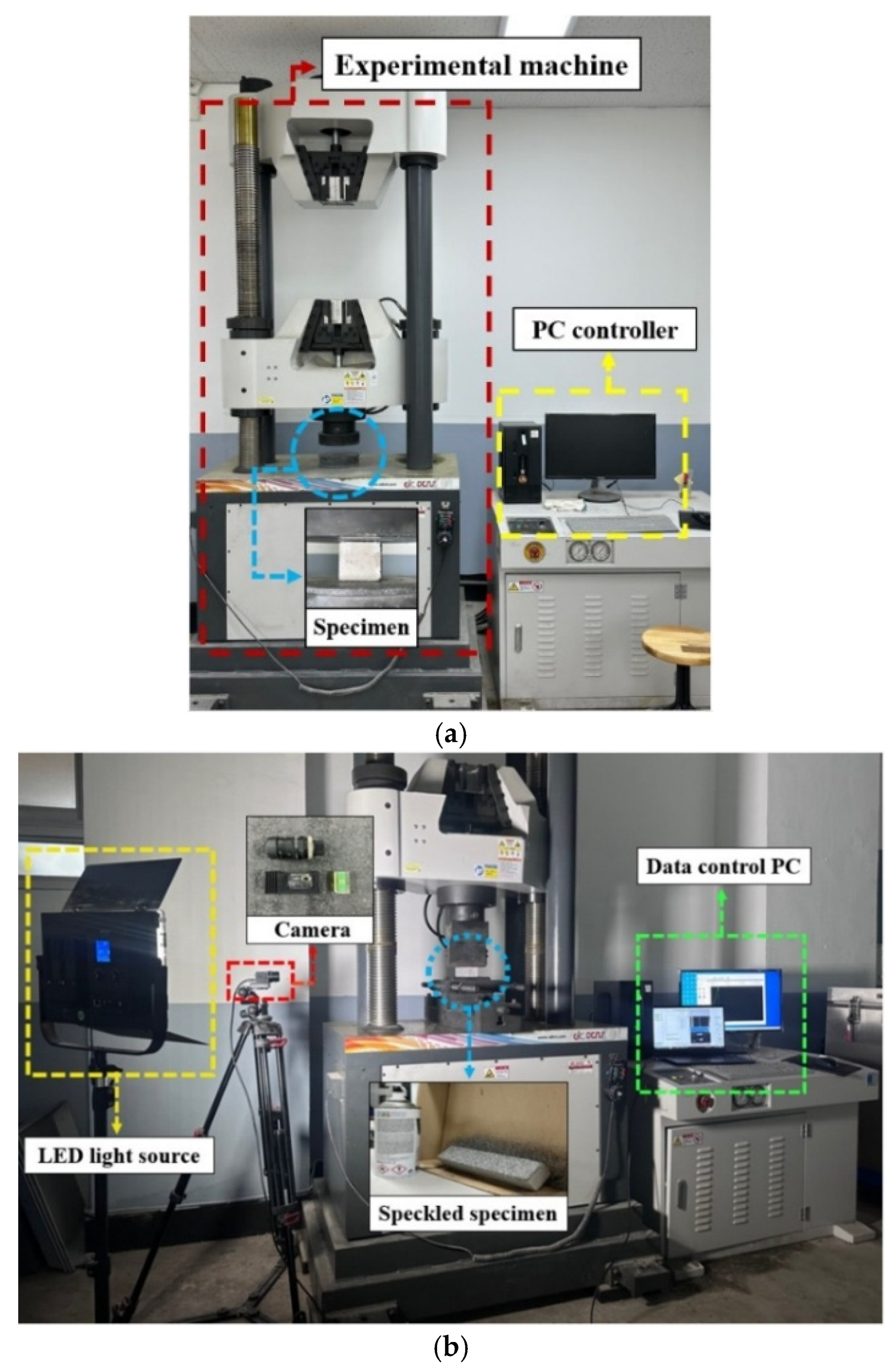

2.2. Mechanical Characteristics of the Specimens

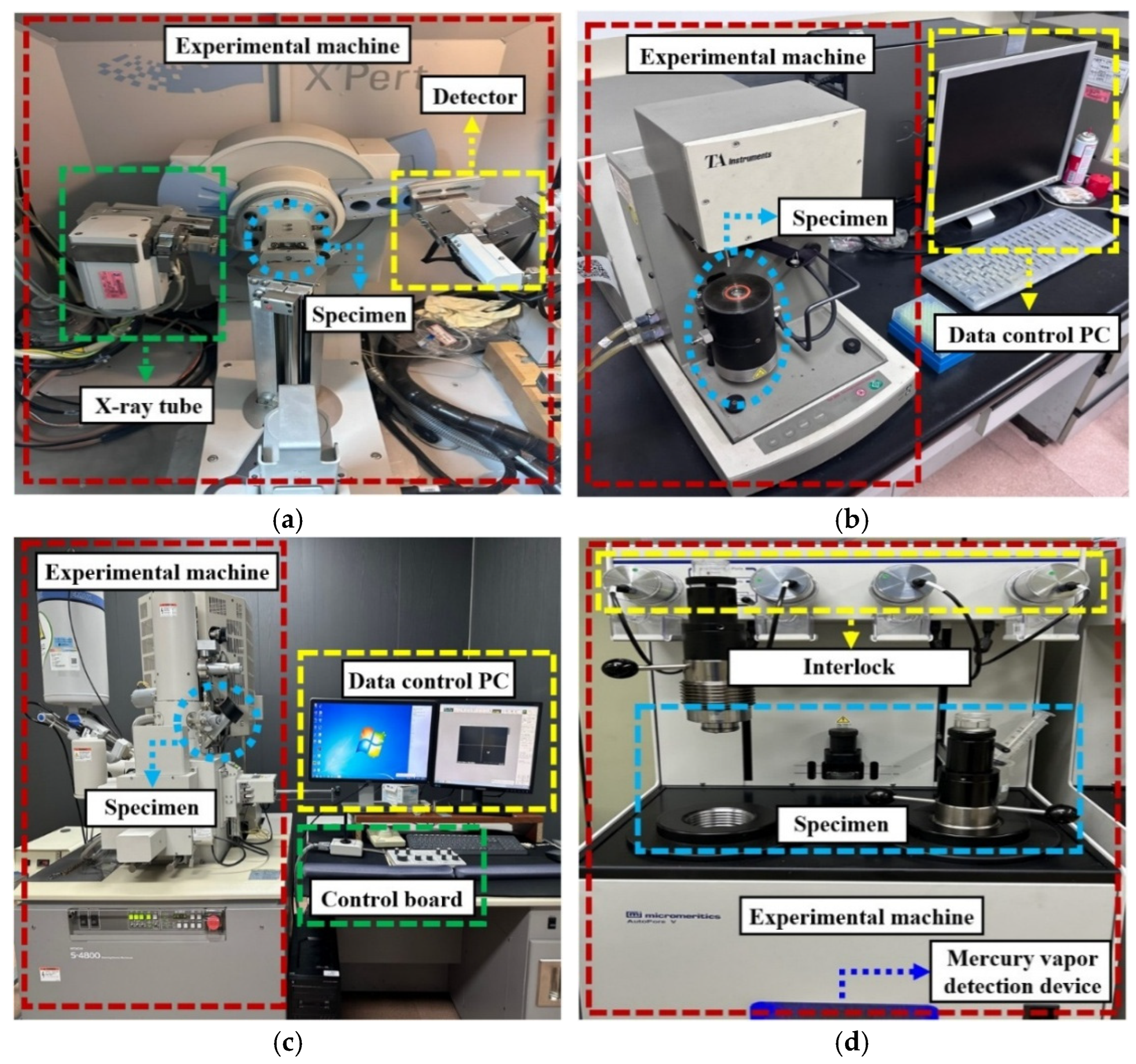

2.3. Internal Structure Analysis Methods

2.3.1. FE-SEM Test Method

2.3.2. MIP Test Method

2.3.3. XRD Test Method

2.3.4. TGA Test Method

2.4. Pearson Correlation Analysis

3. Experimental Results and Discussion

3.1. Mechanical Characteristics of PP Cementitious Composites

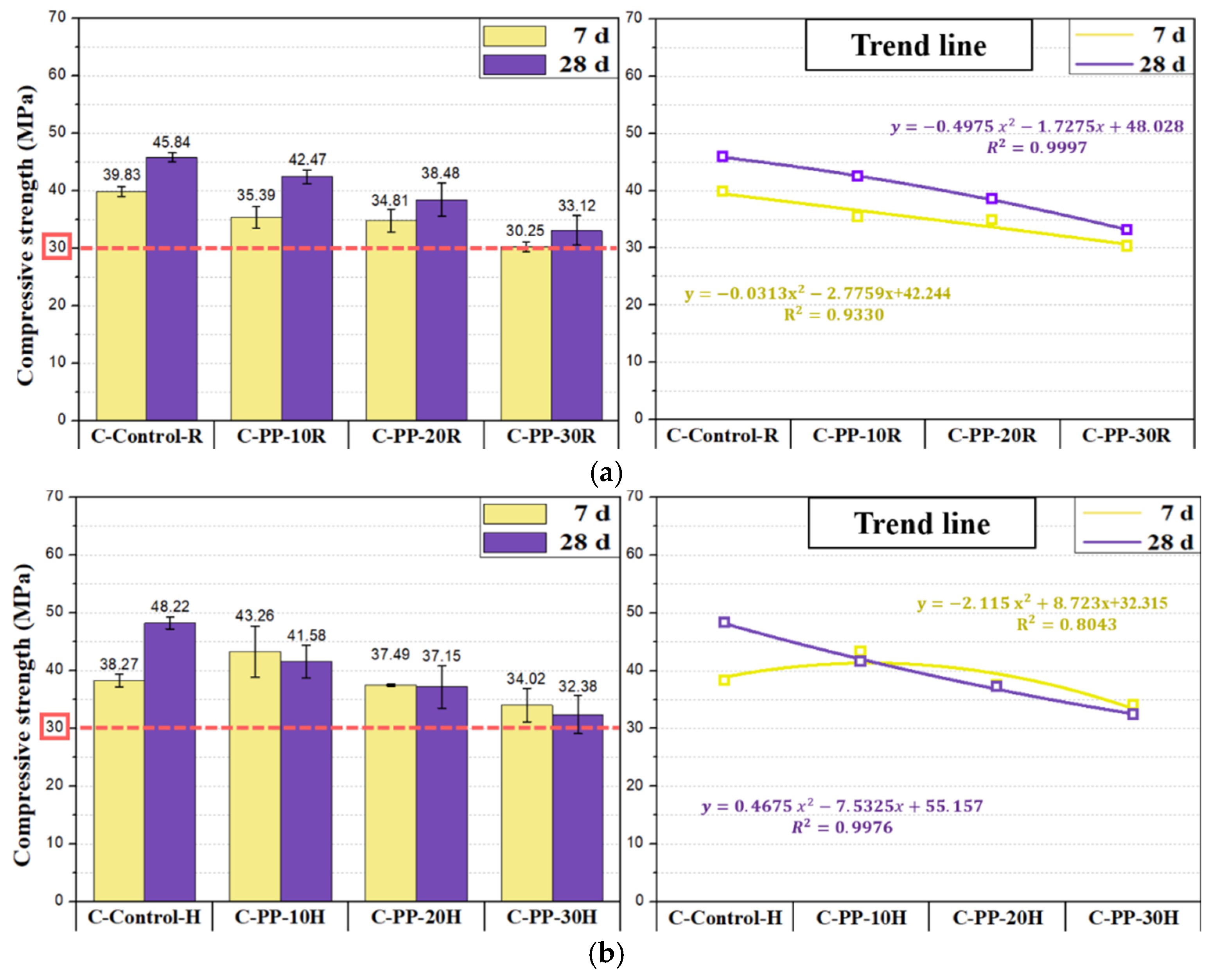

3.1.1. Compressive Strength and Trend Analysis

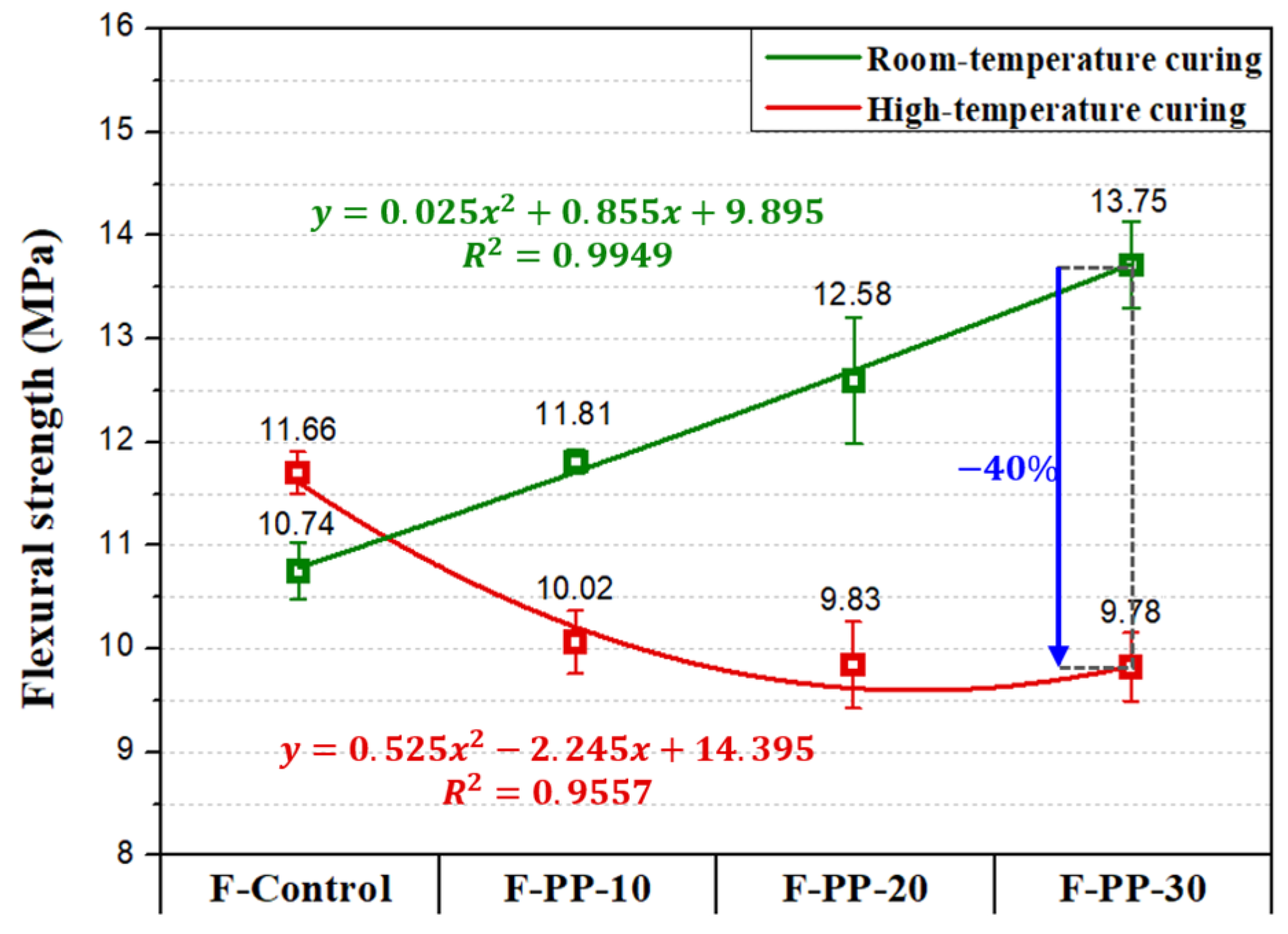

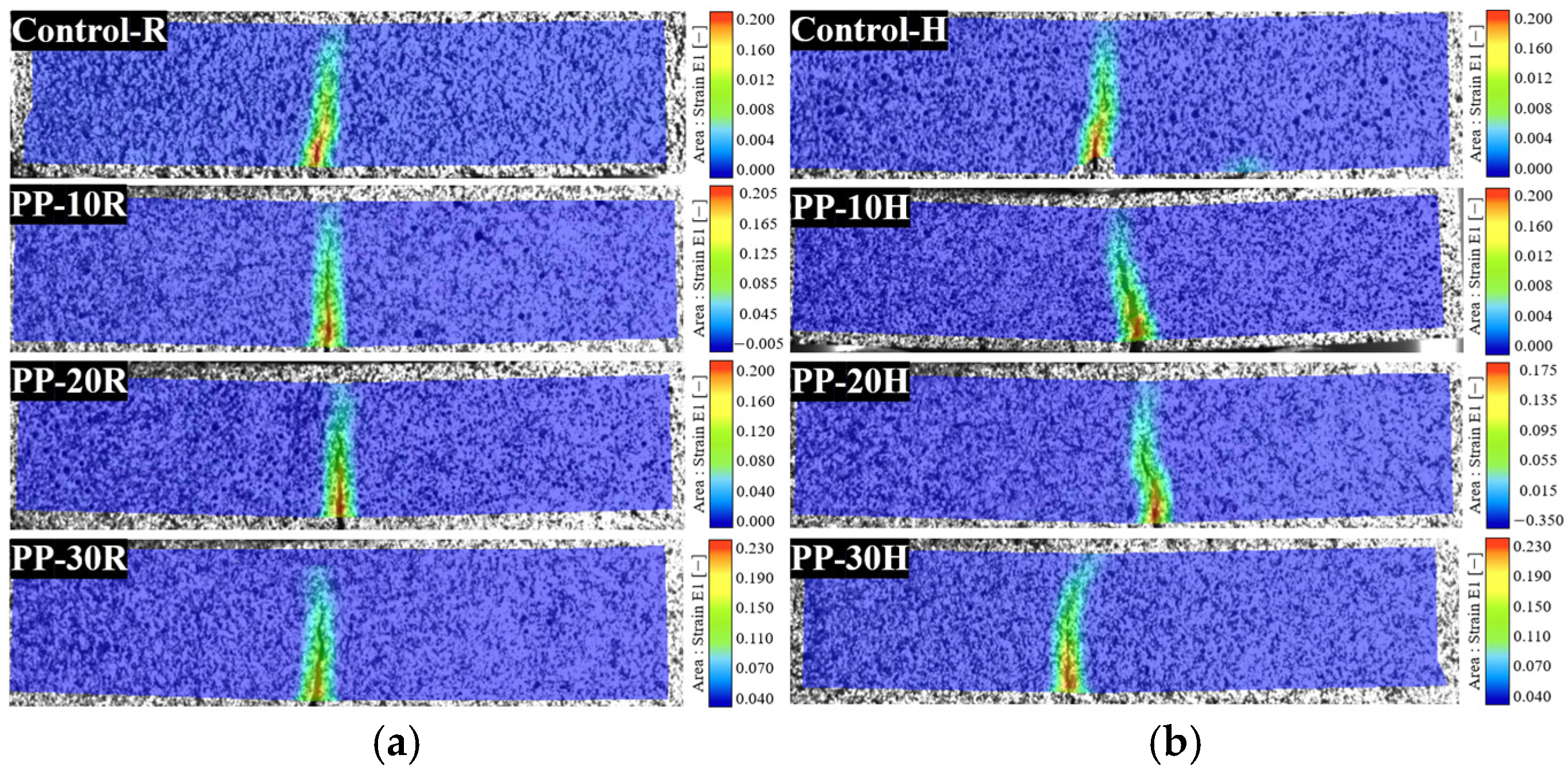

3.1.2. Flexural Strength and DIC Analysis

3.2. Internal Structure Analysis

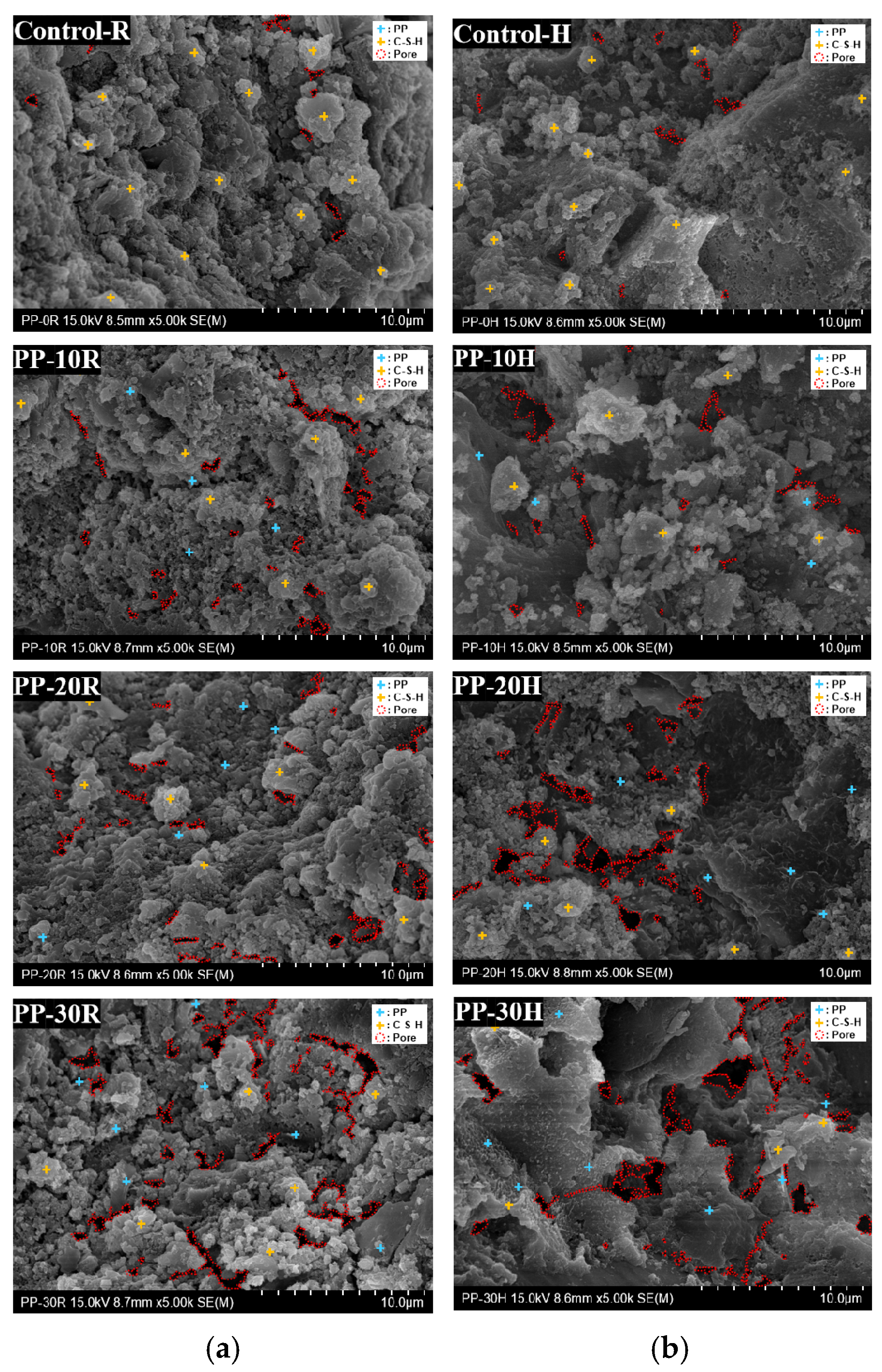

3.2.1. FE-SEM

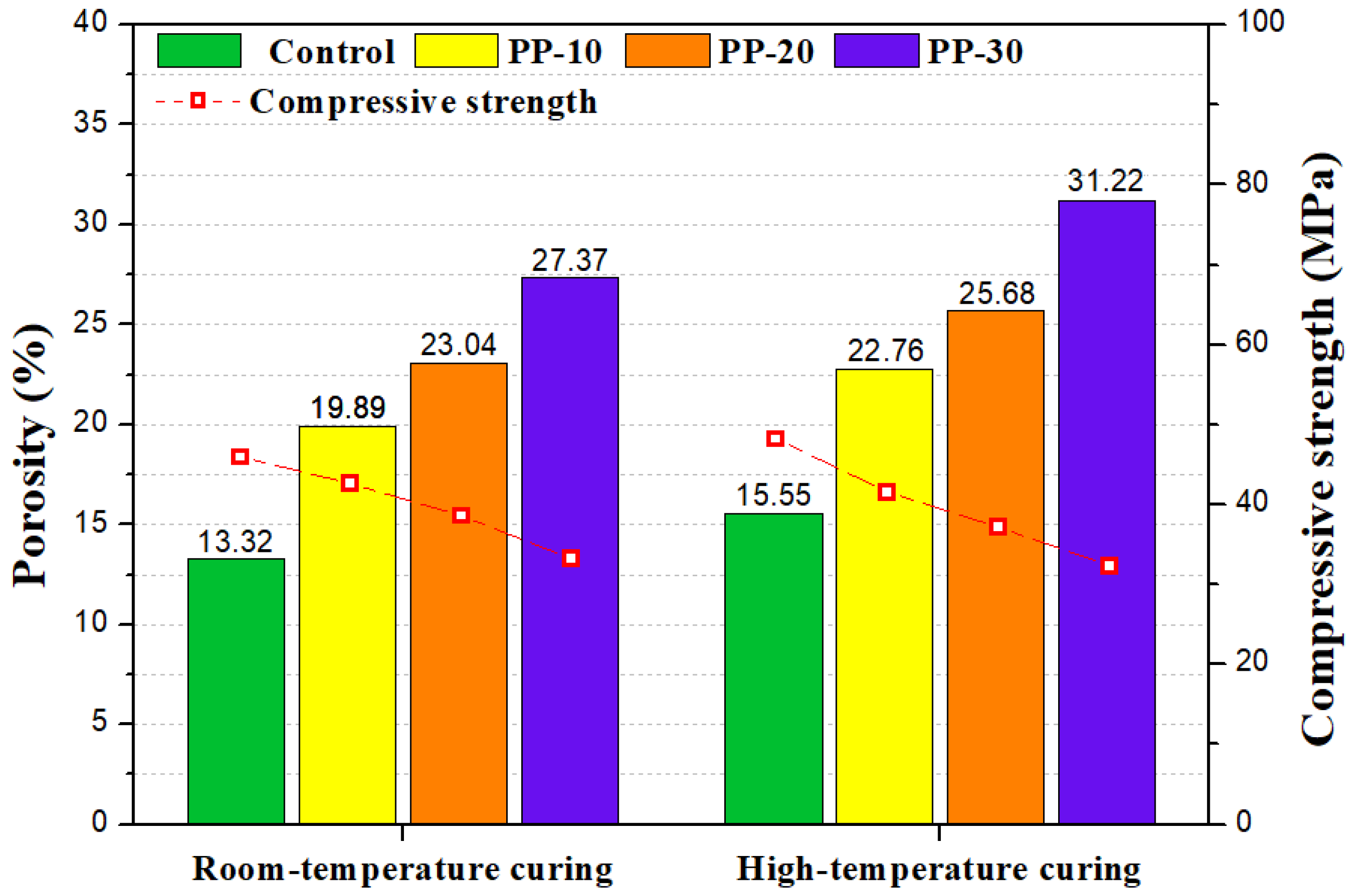

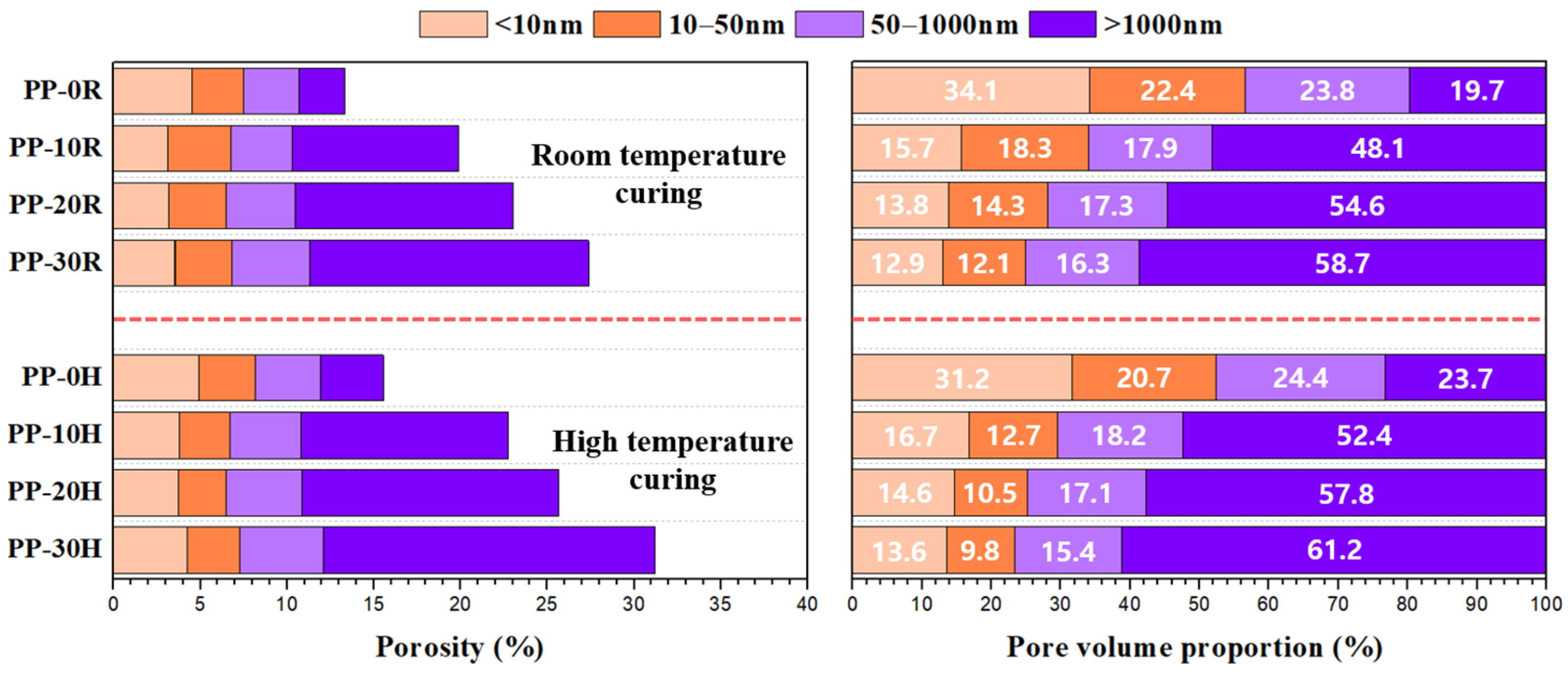

3.2.2. MIP

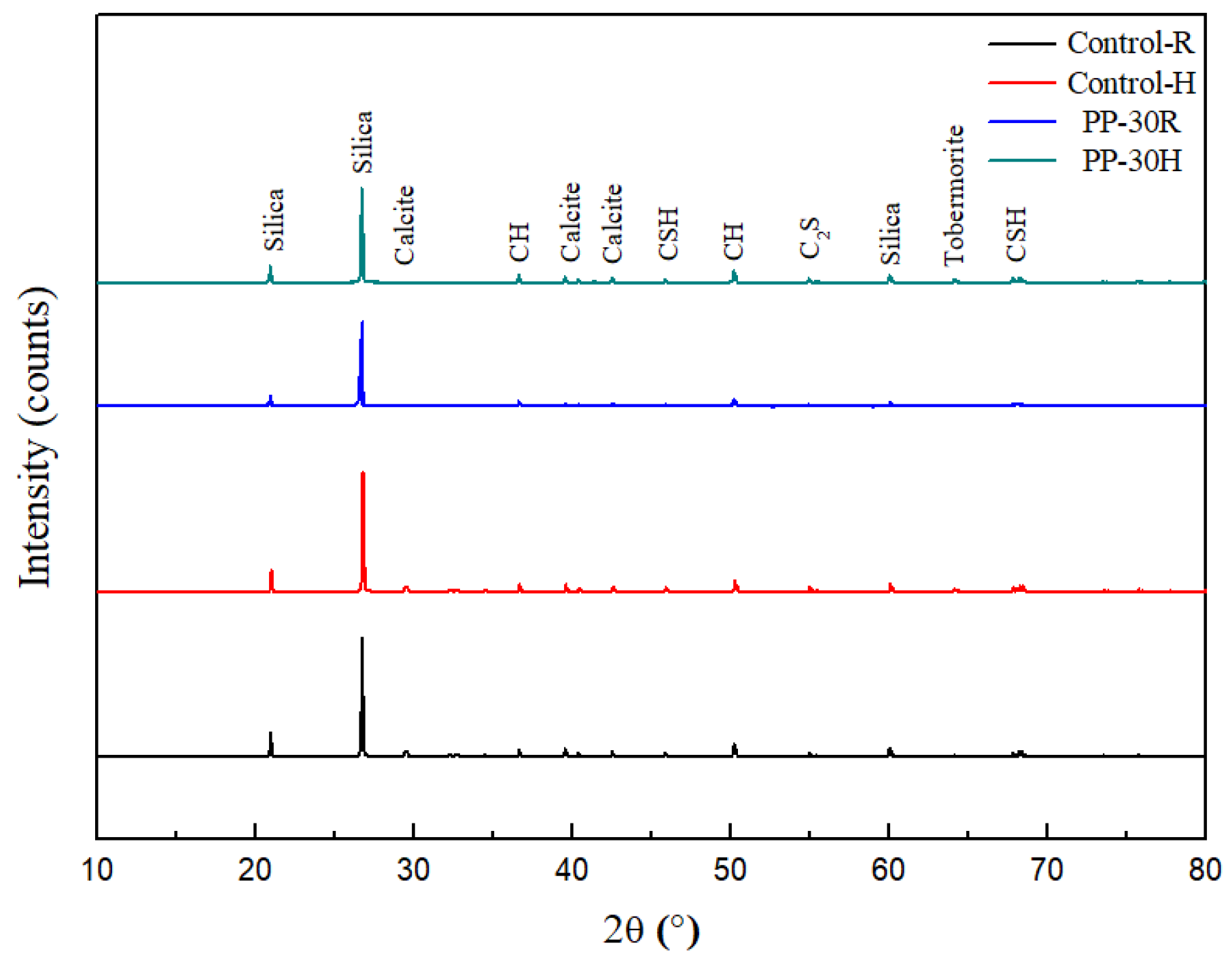

3.2.3. XRD Analysis

3.2.4. TGA

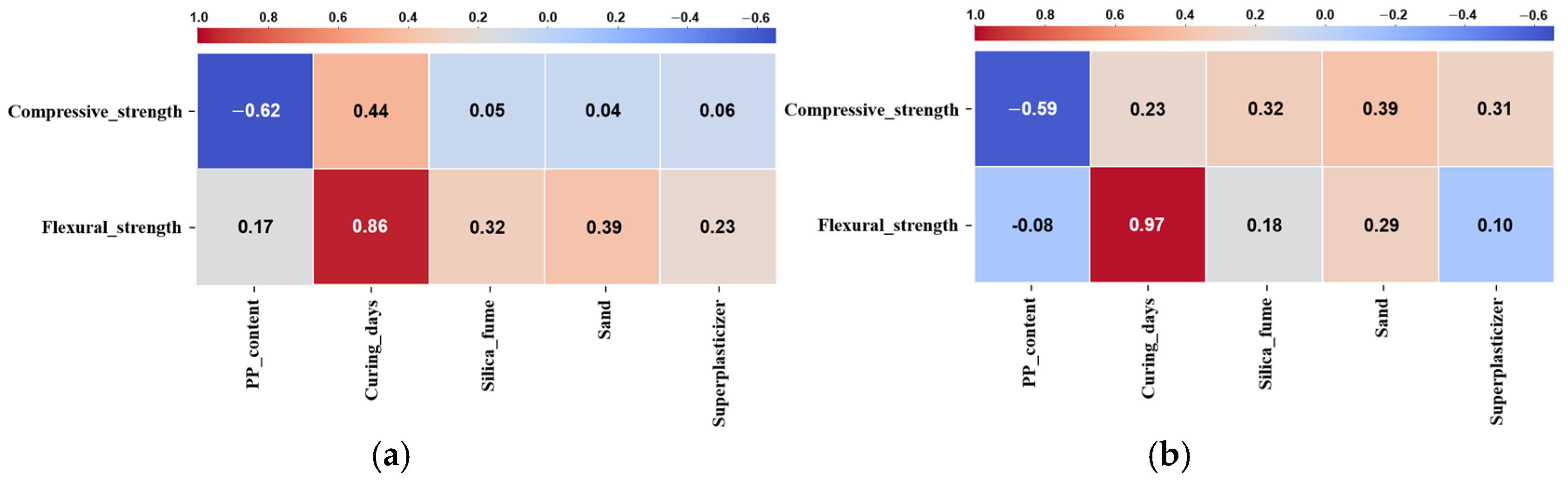

3.3. Pearson Correlation Analysis of the PP Cementitious Composites

4. Conclusions

- Increased PP content reduced compressive strength under all curing conditions owing to poor bonding and interruption of hydration. HT curing accelerated early strength but decreased long-term strength because of microcracks and porosity.

- At RT curing, PP enhanced the flexural strength of a cementitious composite by up to 28%. Under HT curing, degradation of the PP and cement matrix reduced flexural strength by up to 40%. DIC analysis revealed irregular cracks resulting from uneven pore distribution and thermal deformation.

- FE-SEM and MIP confirmed increased porosity and altered pore structure with PP addition. HT curing resulted in the formation of multi-scale pores and defects due to PP shrinkage and expansion, lowering structural integrity. As a result, the compressive strength of the PP cementitious composite decreased by up to 30%.

- XRD results indicated that PP did not chemically react with the components of the cementitious composite and interfered with hydrate formation. The HT promoted hydration, but the resulting products did not improve mechanical strength owing to microstructural defects in the cementitious composite. TGA revealed greater weight loss with higher PP content owing to thermal decomposition and reduced hydration.

- Pearson correlation analysis was conducted to investigate the overall effect of parameters on cementitious composites. Curing temperature significantly affected hydration, pore structure, and overall strength development. Ensuring the desired performance of cementitious composites in specific structural or environmental applications requires careful selection of the curing method.

- With the use of suitable admixtures, the compressive strength of PP cementitious composites exceeded 30 MPa across all tested parameters. These findings highlight the importance of optimizing the mix design to balance mechanical performance and sustainability, ensuring that the incorporation of PP provides environmental benefits while minimizing impact on structural integrity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Organization for Economic Co-Operation and Development. Global Plastics Outlook: Policy Scenarios to 2060; OECD Publishing: Paris, France, 2022. [Google Scholar] [CrossRef]

- MacLeod, M.; Arp, H.P.H.; Tekman, M.B.; Jahnke, A. The global threat from plastic pollution. Science 2021, 373, 61–65. [Google Scholar] [CrossRef]

- Ivar do Sul, J.A.I.I.; Costa, M.F. The present and future of microplastic pollution in the marine environment. Environ. Pollut. 2014, 185, 352–364. [Google Scholar] [CrossRef] [PubMed]

- Thushari, G.G.N.; Senevirathna, J.D.M. Plastic pollution in the marine environment. Heliyon 2020, 6, e04709. [Google Scholar] [CrossRef] [PubMed]

- Shen, M.; Huang, W.; Chen, M.; Song, B.; Zeng, G.; Zhang, Y. plastic crisis: Unignorable contribution to global greenhouse gas emissions and climate change. J. Clean. Prod. 2020, 254, 120138. [Google Scholar] [CrossRef]

- Stegmann, P.; Daioglou, V.; Londo, M.; van Vuuren, D.P.; Junginger, M. Plastic futures and their CO2 emissions. Nature 2022, 612, 272–276. [Google Scholar] [CrossRef]

- Schlegel, I.; Gibson, C. The Making of an Echo Chamber: How the Plastic Industry Exploited Anxiety About COVID-19 to Attack Reusable Bags. 2020. Available online: https://trashhero.org/wp-content/uploads/2019/11/The-Making-of-an-Echo-Chamber_-How-the-plastic-industry-exploited-anxiety-about-COVID-19-to-attack-reusable-bags-1.pdf (accessed on 26 March 2020).

- Prata, J.C.; Silva, A.L.P.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. COVID-19 pandemic repercussions on the use and management of plastics. Environ. Sci. Technol. 2020, 54, 7760–7765. [Google Scholar] [CrossRef]

- Shams, M.; Alam, I.; Mahbub, M.S. Plastic pollution during COVID-19: Plastic waste directives and its long-term impact on the environment. Environ. Adv. 2021, 5, 100119. [Google Scholar] [CrossRef]

- Patrício Silva, A.L.P.P.; Prata, J.C.; Walker, T.R.; Duarte, A.C.; Ouyang, W.; Barcelò, D.; Rocha-Santos, T. Increased plastic pollution due to COVID-19 pandemic: Challenges and recommendations. Chem. Eng. J. 2021, 405, 126683. [Google Scholar] [CrossRef]

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef]

- Yaqub, W.; Aslani, F. Mechanical properties and fire resistance of 3D-printed cementitious composites with plastic waste. Int. J. Concr. Struct. Mater. 2024, 18, 84. [Google Scholar] [CrossRef]

- Da Costa, J.P.; Mouneyrac, C.; Costa, M.; Duarte, A.C.; Rocha-Santos, T. The role of legislation, regulatory initiatives and guidelines on the control of plastic pollution. Front. Environ. Sci. 2020, 8, 104. [Google Scholar] [CrossRef]

- Adam, I.; Walker, T.R.; Bezerra, J.C.; Clayton, A. Policies to reduce single-use plastic marine pollution in West Africa. Mar. Policy 2020, 116, 103928. [Google Scholar] [CrossRef]

- Thiounn, T.; Smith, R.C. Advances and approaches for chemical recycling of plastic waste. J. Pol. Sci. 2020, 58, 1347–1364. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Norval, C.; Kolawole, J.T.; Chandra Paul, S.C.; Ibrahim, K.A. 3D-printed limestone calcined clay cement concrete incorporating recycled plastic waste (RESIN8). Results Eng. 2024, 22, 102112. [Google Scholar] [CrossRef]

- Bharadwaaj, S.K.; Jaudan, M.; Kushwaha, P.; Saxena, A.; Saha, B. Exploring cutting-edge approaches in plastic recycling for a greener future. Results Eng. 2024, 23, 102704. [Google Scholar] [CrossRef]

- Duan, Z.; Deng, Q.; Liang, C.; Ma, Z.; Wu, H. Upcycling of recycled plastic fiber for sustainable cementitious composites: A critical review and new perspective. Cem. Concr. Compos. 2023, 142, 105192. [Google Scholar] [CrossRef]

- Li, L.; Yan, C.; Zhang, N.; Farooqi, M.U.; Xu, S.; Deifalla, A.F. Flexural fracture parameters of polypropylene fiber reinforced geopolymer. J. Mater. Res. Technol. 2023, 24, 1839–1855. [Google Scholar] [CrossRef]

- Ramos, F.J.H.T.V.; Reis, R.H.M.; Grafova, I.; Grafov, A.; Monteiro, S.N. Eco-friendly recycled polypropylene matrix composites incorporated with geopolymer concrete waste particles. J. Mater. Res. Technol. 2020, 9, 3084–3090. [Google Scholar] [CrossRef]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-friendly concrete containing recycled plastic as partial replacement for sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Adesina, A. Recent advances in the concrete industry to reduce its carbon dioxide emissions. Environ. Chall. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Zulkernain, N.H.; Gani, P.; Chuck Chuan, N.C.C.; Uvarajan, T. Utilisation of plastic waste as aggregate in construction materials: A review. Constr. Build. Mater. 2021, 296, 123669. [Google Scholar] [CrossRef]

- Vijayan, V.; Manthos, E.; Mantalovas, K.; Di Mino, G. Multi-recyclability of asphalt mixtures modified with recycled plastic: Towards a circular economy. Results Eng. 2024, 23, 102523. [Google Scholar] [CrossRef]

- Wetchakornborirak, K.; Prommanee, P.; Supakata, N. Characteristics of aerogel-incorporated concrete with polyethylene terephthalate fiber. Results Eng. 2025, 27, 107135. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Al-Tayeb, M.M.; Aisheh, Y.I.A.; Qaidi, S.M.A.; Tayeh, B.A. Experimental and simulation study on the impact resistance of concrete to replace high amounts of fine aggregate with plastic waste. Case Stud. Constr. Mater. 2022, 17, e01324. [Google Scholar] [CrossRef]

- Ahdal, A.Q.; Amrani, M.A.; Ghaleb, A.A.A.; Abadel, A.A.; Alghamdi, H.; Alamri, M.; Wasim, M.; Shameeri, M. Mechanical performance and feasibility analysis of green concrete prepared with local natural zeolite and waste PET plastic fibers as cement replacements. Case Stud. Constr. Mater. 2022, 17, e01256. [Google Scholar] [CrossRef]

- Agyeman, S.; Obeng-Ahenkora, N.K.; Assiamah, S.; Twumasi, G. Exploiting recycled plastic waste as an alternative binder for paving blocks production. Case Stud. Constr. Mater. 2019, 11, e00246. [Google Scholar] [CrossRef]

- Blazy, J.; Blazy, R. Polypropylene fiber reinforced concrete and its application in creating architectural forms of public spaces. Case Stud. Constr. Mater. 2021, 14, e00549. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Mustafa, M.A.T.; Hanafi, I.; Mahmoud, R.; Tayeh, B.A. Effect of partial replacement of sand by plastic waste on impact resistance of concrete: Experiment and simulation. Structures 2019, 20, 519–526. [Google Scholar] [CrossRef]

- Ochi, T.; Okubo, S.; Fukui, K. Development of recycled PET fiber and its application as concrete-reinforcing fiber. Cem. Concr. Compos. 2007, 29, 448–455. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Saikia, N. Influence of curing conditions on the durability-related performance of concrete made with selected plastic waste aggregates. Cem. Concr. Compos. 2013, 35, 23–31. [Google Scholar] [CrossRef]

- Feng, H.; Shao, Q.; Yao, X.; Li, L.; Yuan, C. Investigating the Hybrid Effect of Micro-steel Fibres and Polypropylene Fibre-Reinforced Magnesium Phosphate Cement Mortar. Int. J. Concr. Struct. Mater. 2022, 16, 35. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, E.; Wong, Y.C.; Horpibulsuk, S. Recycled plastic granules and demolition wastes as construction materials: Resilient moduli and strength characteristics. Constr. Build. Mater. 2017, 147, 639–647. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.M.; Queneudec, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- Aneke, F.I.; Shabangu, C. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 2021, 14, e00515. [Google Scholar] [CrossRef]

- Kangavar, M.E.; Lokuge, W.; Manalo, A.; Karunasena, W.; Frigione, M. Investigation on the properties of concrete with recycled polyethylene terephthalate (PET) granules as fine aggregate replacement. Case Stud. Constr. Mater. 2022, 16, e00934. [Google Scholar] [CrossRef]

- Akhmetov, D.; Akhazhanov, S.; Jetpisbayeva, A.; Pukharenko, Y.; Root, Y.; Utepov, Y.; Akhmetov, A. Effect of low-modulus polypropylene fiber on physical and mechanical properties of self-compacting concrete. Case Stud. Constr. Mater. 2022, 16, e00814. [Google Scholar] [CrossRef]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.H.J.; Song, Y.C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Huynh, T.-P.; Ho Minh Le, T.; Vo Chau Ngan, N. An experimental evaluation of the performance of concrete reinforced with recycled fibers made from waste plastic bottles. Results Eng. 2023, 18, 101205. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R.J. Performance of structural concrete with recycled plastic waste as a partial replacement for sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

- Saikia, N.; De Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Juki, M.I.; Awang, M.; Annas, M.M.K.; Boon, K.H.; Othman, N.; Kadir, A.A.; Roslan, M.A.; Khalid, F.S. Relationship between compressive, splitting tensile and flexural strength of concrete containing granulated waste polyethylene terephthalate (PET) bottles as fine aggregate. Adv. Mater. Res. 2013, 795, 356–359. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Mohammed, I.I.; Mohammed, S.A. Some properties of concrete with plastic aggregate derived from shredded PVC sheets. Constr. Build. Mater. 2019, 201, 232–245. [Google Scholar] [CrossRef]

- Saxena, R.; Siddique, S.; Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance and energy absorption capacity of concrete containing plastic waste. Constr. Build. Mater. 2018, 176, 415–421. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Hansu, O.; Etli, S.; Alhassan, M. Mechanical and fracture characteristics of self-compacting concretes containing different percentage of plastic waste powder. Constr. Build. Mater. 2017, 140, 562–569. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Balgourinejad, N.; Haghighifar, M.; Madandoust, R.; Charkhtab, S. Experimental study on mechanical properties, microstructural of lightweight concrete incorporating polypropylene fibers and metakaolin at high temperatures. J. Mater. Res. Technol. 2022, 18, 5238–5256. [Google Scholar] [CrossRef]

- Orouji, M.; Zahrai, S.M.; Najaf, E. Effect of glass powder & polypropylene fibers on compressive and flexural strengths, toughness and ductility of concrete: An environmental approach. Structures 2021, 33, 4616–4628. [Google Scholar] [CrossRef]

- Fraternali, F.; Ciancia, V.; Chechile, R.; Rizzano, G.; Feo, L.; Incarnato, L. Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Comput. Struct. 2011, 93, 2368–2374. [Google Scholar] [CrossRef]

- Ghernouti, Y.; Rabehi, B.; Bouziani, T.; Ghezraoui, H.; Makhloufi, A. Fresh and hardened properties of self-compacting concrete containing plastic bag waste fibers (WFSCC). Constr. Build. Mater. 2015, 82, 89–100. [Google Scholar] [CrossRef]

- Al-Kerttani, O.M.G.; Hilal, N.; Hama, S.M.; Sor, N.H.; Banyhussan, Q.S.; Tawfik, T.A. Durability and hardened characteristics of cement mortar incorporating waste plastic and polypropylene exposed to MgSO4 attack. Results Eng. 2024, 24, 103310. [Google Scholar] [CrossRef]

- Rhee, I.; Lee, J.S.; Kim, Y.A.; Kim, J.M. Mechanical properties of cement mortar with gamma-irradiated recycled plastic powder, pellet, and fiber. Results Eng. 2023, 20, 101614. [Google Scholar] [CrossRef]

- Ali, K.; Qureshi, M.I.; Saleem, S.; Khan, S.U. Effect of waste electronic plastic and silica fume on mechanical properties and thermal performance of concrete. Constr. Build. Mater. 2021, 285, 122952. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutiérrez, A. Influence of content and particle size of waste PET bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef] [PubMed]

- Naik, T.R.; Singh, S.S.; Huber, C.O.; Brodersen, B.S. Use of post-consumer waste plastics in cement-based composites. Cem. Concr. Res. 1996, 26, 1489–1492. [Google Scholar] [CrossRef]

- Abbas, S.N.; Qureshi, M.I.; Abid, M.M.; Tariq, M.A.U.R.; Ng, A.W.M. An investigation of mechanical properties of concrete by applying sand coating on recycled high-density polyethylene (HDPE) and electronic-wastes (E-Wastes) used as a partial replacement of natural coarse aggregates. Sustainability 2022, 14, 4087. [Google Scholar] [CrossRef]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- Zhao, Y.B.; Lv, X.D.; Ni, H.G. Solvent-based separation and recycling of waste plastics: A review. Chemosphere 2018, 209, 707–720. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Yang, G.; Bi, J.; Dong, Z.; Li, Y.; Liu, Y. Experimental study on dynamic tensile properties of macro-polypropylene fiber reinforced cementitious composites. Int. J. Concr. Struct. Mater. 2022, 16, 66. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Luo, Y.; Shao, H.; Zhou, X.; Bai, S. Early-age autogenous shrinkage, tensile creep, and restrained cracking behavior of ultra-high-performance concrete incorporating polypropylene fibers. Cem. Concr. Compos. 2023, 138, 104948. [Google Scholar] [CrossRef]

- Hassan, S.A.; Hanoon, A.N.; Abdulhameed, A.A. Push-out test of eco-friendly steel-concrete–steel composite sections enhanced by polypropylene fibers: An experimental study and statistical analysis. Results Eng. 2024, 23, 102393. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Mandegari, M.; Sanginabadi, K.; Mostofinejad, D.; Abtahi, S.M. The effect of concrete alkalinity on behavior of reinforcing polyester and polypropylene fibers with similar properties. Cem. Concr. Compos. 2019, 97, 118–124. [Google Scholar] [CrossRef]

- Kang, S.; Pyo, S.; Lee, H. Thermal, electrical, and mechanical performances of ultrahigh-performance cementitious composites with multiwalled carbon nanotubes. Case Stud. Constr. Mater. 2024, 21, e03691. [Google Scholar] [CrossRef]

- ASTM C1240-20; Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2003; Volume 15, pp. 1–6. [CrossRef]

- ASTM C494/C494M-19e1; Standard Specification for Chemical Admixtures for Concrete, Annual Book of ASTM Standards. American Society for Testing and Materials: West Conshohocken, PA, USA, 1999. [CrossRef]

- López-Buendía, A.M.; Romero-Sánchez, M.D.; Climent, V.; Guillem, C. Surface treated polypropylene (PP) fibres for reinforced concrete. Cem. Concr. Res. 2013, 54, 29–35. [Google Scholar] [CrossRef]

- ASTM D1238-10; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2005.

- Astm Committee D-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 1991.

- ASTM D638-03; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D790-15e2; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D256-10; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D648; Standard Test Method for Deflection Temperature of Plastics Under Flexural Load in the Edgewise Position. Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in, or [50-mm] cube specimens). Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C 348-08; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2008.

- Choi, E.; Ostadrahimi, A.; Kim, W.J. Enhancement of compressive strength and strain ductility of SMA fiber reinforced concrete considering fiber’s aspect ratios. Constr. Build. Mater. 2022, 345, 128346. [Google Scholar] [CrossRef]

- ISO 19749:2021; Nanotechnologies—Measurements of Particle Size and Shape Distributions by Scanning Electron Microscopy. International Organization for Standardization: Geneva, Switzerland, 2021.

- Washburn, E.W. Note on a method of determining the distribution of pore sizes in a porous material. Proc. Natl. Acad. Sci. USA 1921, 7, 115–116. [Google Scholar] [CrossRef]

- Lee, H.; Jeong, S.; Cho, S.; Chung, W. Enhanced bonding behavior of multi-walled carbon nanotube cement composites and reinforcing bars. Comput. Struct. 2020, 243, 112201. [Google Scholar] [CrossRef]

- ASTM E915–96; Test Method for Verifying the Alignment of X-Ray Diffraction Instrumentation for Residual Stress Measurement. ASTM International: West Conshohocken, PA, USA, 2002.

- ASTM C1872; Standard Test Method for Thermogravimetric Analysis of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2018.

- Ma, Q.; Guo, R.; Zhao, Z.; Lin, Z.; He, K. Mechanical properties of concrete at high temperature—A review. Constr. Build. Mater. 2015, 93, 371–383. [Google Scholar] [CrossRef]

- Köksal, F.; Altun, F.; Yiğit, İ.; Şahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Lee, J.H.; Cho, B.; Choi, E. Flexural capacity of fiber reinforced concrete with a consideration of concrete strength and fiber content. Constr. Build. Mater. 2017, 138, 222–231. [Google Scholar] [CrossRef]

- Abbass, W.; Khan, M.I.; Mourad, S. Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Constr. Build. Mater. 2018, 168, 556–569. [Google Scholar] [CrossRef]

- Xu, B.W.; Shi, H.S. Correlations among mechanical properties of steel fiber reinforced concrete. Constr. Build. Mater. 2009, 23, 3468–3474. [Google Scholar] [CrossRef]

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Pekmezci, B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Abu-Saleem, M.; Zhuge, Y.; Hassanli, R.; Ellis, M.; Rahman, M.M.; Levett, P. Microwave radiation treatment to improve the strength of recycled plastic aggregate concrete. Case Stud. Constr. Mater. 2021, 15, e00728. [Google Scholar] [CrossRef]

- Sáez del Bosque, I.F.; Zhu, W.; Howind, T.; Matías, A.; Sánchez de Rojas, M.I.; Medina, C. Properties of interfacial transition zones (ITZs) in concrete containing recycled mixed aggregate. Cem. Concr. Compos. 2017, 81, 25–34. [Google Scholar] [CrossRef]

- Chan, Y.N.; Luo, X.; Sun, W. Compressive strength and pore structure of high-performance concrete after exposure to high temperature up to 800 °C. Cem. Concr. Res. 2000, 30, 247–251. [Google Scholar] [CrossRef]

- Jin, S.; Zhou, J.; Zhao, X.; Sun, L. Quantitative relationship between pore size distribution and compressive strength of cementitious materials. Constr. Build. Mater. 2021, 273, 121727. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006. [Google Scholar]

- Silva, D.A.; John, V.M.; Ribeiro, J.L.D.; Roman, H.R. Pore size distribution of hydrated cement pastes modified with polymers. Cem. Concr. Res. 2001, 31, 1177–1184. [Google Scholar] [CrossRef]

- Zhang, M.H.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar] [CrossRef]

- Seleem, H.E.H.; Rashad, A.M.; Elsokary, T. Effect of elevated temperature on physico-mechanical properties of blended cement concrete. Constr. Build. Mater. 2011, 25, 1009–1017. [Google Scholar] [CrossRef]

| W/C | Cement | Sand | Silica Fume | Superplasticizer |

|---|---|---|---|---|

| 0.4 | 1.0 | 2.0 | 0.125 | 0.005 |

| Chemical Composition (%) | |||||

|---|---|---|---|---|---|

| CaO | MgO | ||||

| Silica fume | 90.0 | 3.0 | 2.0 | 1.5 | 0.3 |

| Category | Property | Test Method | Units | Value |

|---|---|---|---|---|

| Physical properties | Melt index (230 °C, 2.16 kg) | ASTM D1238 [72] | g/10 min | 27 |

| Density | ASTM D792 [73] | 900 | ||

| Mechanical properties | Yield stress | ASTM D638 [74] | MPa | 22.6 |

| Elongation | ASTM D638 [74] | % | <100 | |

| Flexural modulus | ASTM D790 [75] | MPa | 1226 | |

| Impact properties | IZOD impact strength (23 °C) | ASTM D256 [76] | J/m | 98 |

| IZOD impact strength (−10 °C) | ASTM D256 [76] | J/m | 49 | |

| Thermal properties | Heat deflection temperature | ASTM D648 [77] | °C | 105 |

| Specimen Name | Test Type | PP Content (%) | Curing Method | Curing Period |

|---|---|---|---|---|

| C-Control-R | Compressive strength test | 0 | Room-temperature curing (23 ± 2 °C) | 7, 28 |

| C-PP-10R | 10 | |||

| C-PP-20R | 20 | |||

| C-PP-30R | 30 | |||

| C-Control-H | 0 | High-temperature curing (200 °C) | ||

| C-PP-10H | 10 | |||

| C-PP-20H | 20 | |||

| C-PP-30H | 30 | |||

| F-Control-R | Flexural strength test | 0 | Room-temperature curing (23 ± 2 °C) | 28 |

| F-PP-10R | 10 | |||

| F-PP-20R | 20 | |||

| F-PP-30R | 30 | |||

| F-Control-H | 0 | High-temperature curing (200 °C) | ||

| F-PP-10H | 10 | |||

| F-PP-20H | 20 | |||

| F-PP-30H | 30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mun, J.; Kim, D.; Kang, S.; Lee, H. Mechanical Characteristics Based on the Microstructure Analysis of Cementitious Composites Incorporating Polypropylene Powder. Buildings 2025, 15, 4257. https://doi.org/10.3390/buildings15234257

Mun J, Kim D, Kang S, Lee H. Mechanical Characteristics Based on the Microstructure Analysis of Cementitious Composites Incorporating Polypropylene Powder. Buildings. 2025; 15(23):4257. https://doi.org/10.3390/buildings15234257

Chicago/Turabian StyleMun, Jeonguk, Dongwook Kim, Sunho Kang, and Heeyoung Lee. 2025. "Mechanical Characteristics Based on the Microstructure Analysis of Cementitious Composites Incorporating Polypropylene Powder" Buildings 15, no. 23: 4257. https://doi.org/10.3390/buildings15234257

APA StyleMun, J., Kim, D., Kang, S., & Lee, H. (2025). Mechanical Characteristics Based on the Microstructure Analysis of Cementitious Composites Incorporating Polypropylene Powder. Buildings, 15(23), 4257. https://doi.org/10.3390/buildings15234257