Demonstration of 3D-Printed Concrete Containing Fine Recycled Concrete Aggregates (fCAs) and Recycled Concrete Powder (RCP): Rheology, Early-Age, Shrinkage, Mechanical, and Durability Performance

Abstract

1. Introduction

1.1. General Remarks

1.2. Significance

- Investigates the influence of fRA and recycled concrete powder (RCP) on the printability of 3DPC.

- Analyses the influence of fRA and RCP on several key fresh and hardened state properties of 3DPC.

- Presents a comparative life cycle assessment in which the economic and environmental impacts of the production of 3DPC with and without fRA and RCP are compared.

2. Materials and Methods

2.1. Raw Materials and 3DPC Mix Design

2.2. Rheological Tests

2.2.1. Static Yield Stress Test

2.2.2. Dynamic Yield Stress Test

2.2.3. Three-Interval Thixotropy Test

2.3. Adiabatic and Isothermal Calorimetry Tests

2.3.1. Adiabiatic Calorimetry Tests

2.3.2. Isothermal Calorimetry Tests

2.4. Flow Table

2.5. Green Strength

2.6. Early-Age Shrinkage

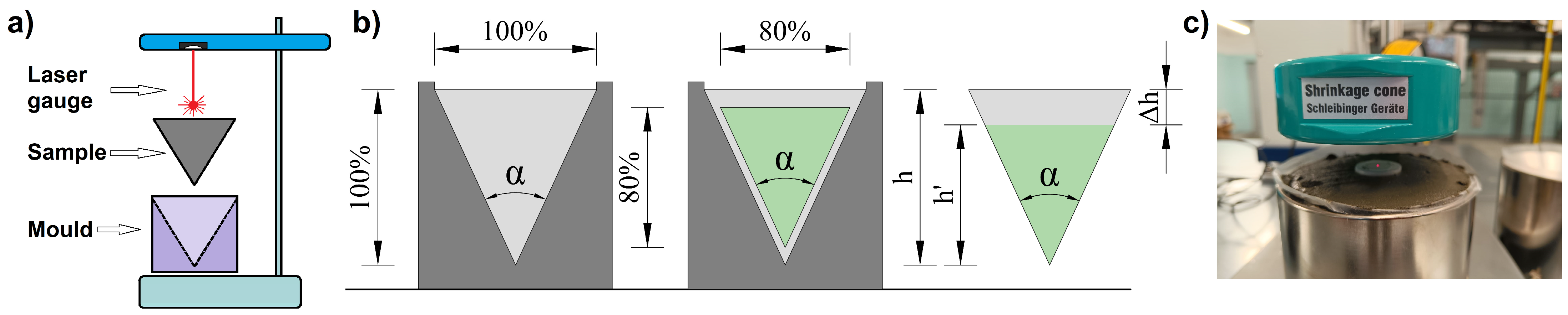

2.7. Hardened Properties

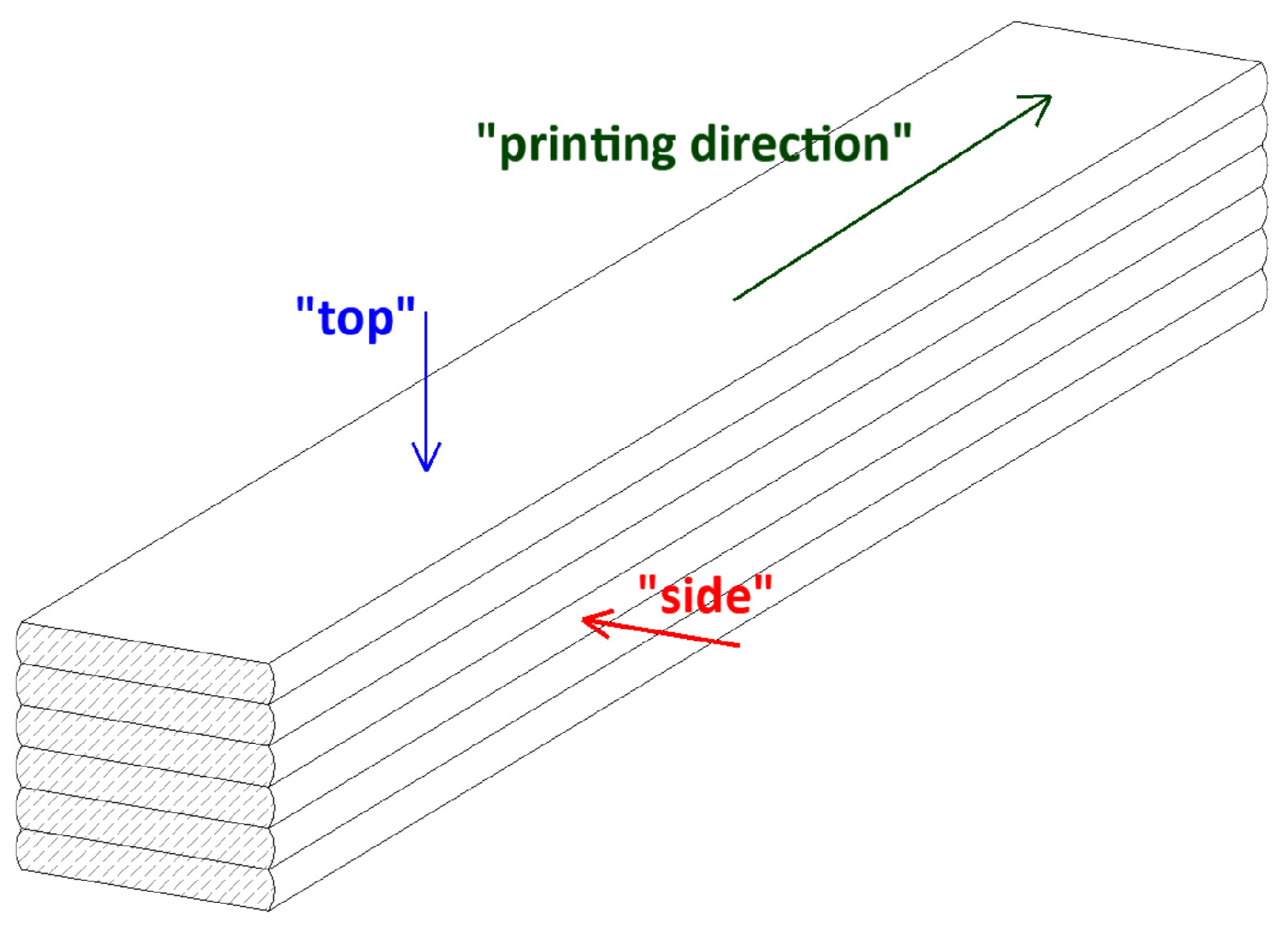

2.7.1. Strength Development (Cast vs. Printed Samples)

2.7.2. Elastic Modulus

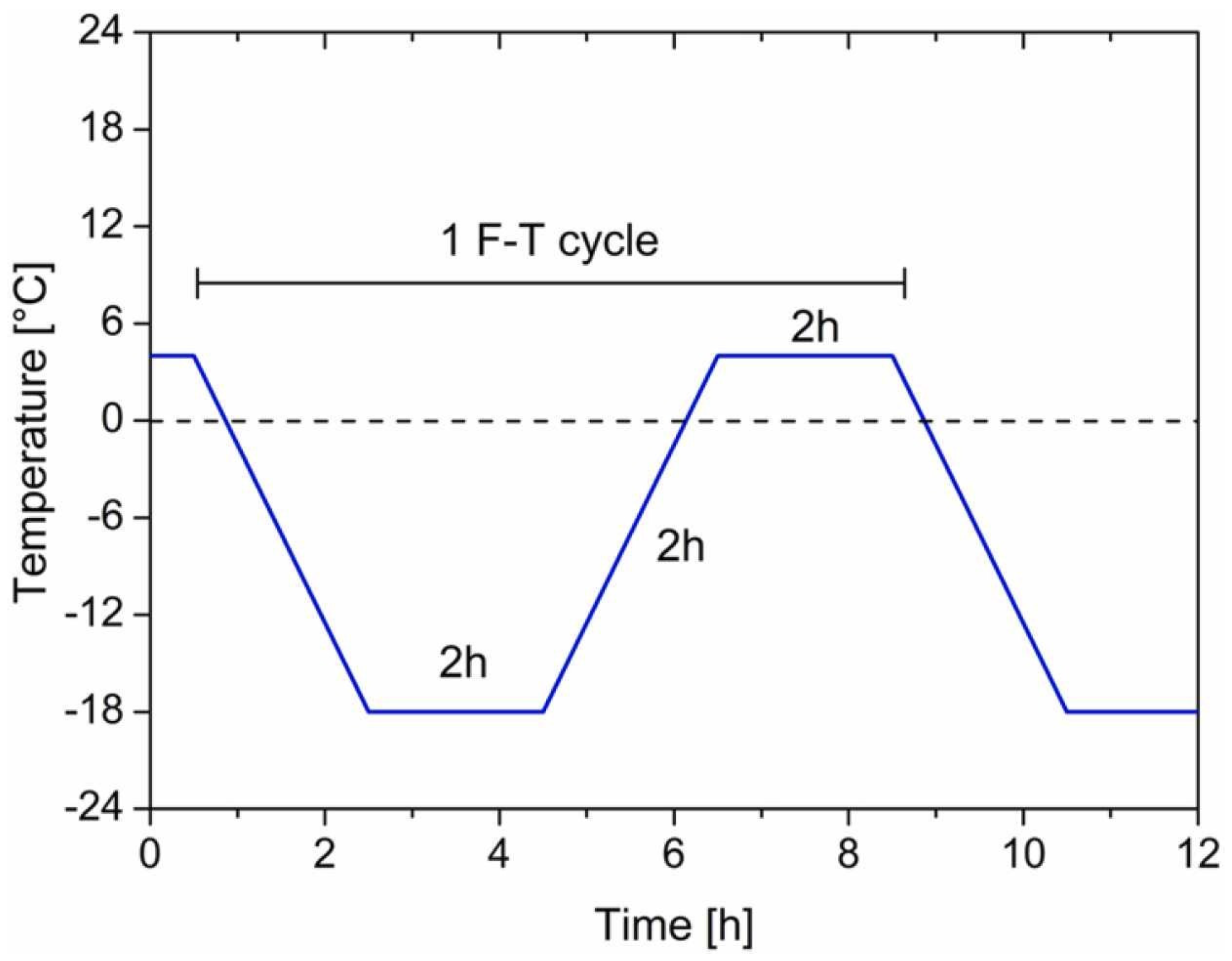

2.8. Freeze–Thaw Resistance

2.9. Interlayer Adhesion

2.10. Buildability

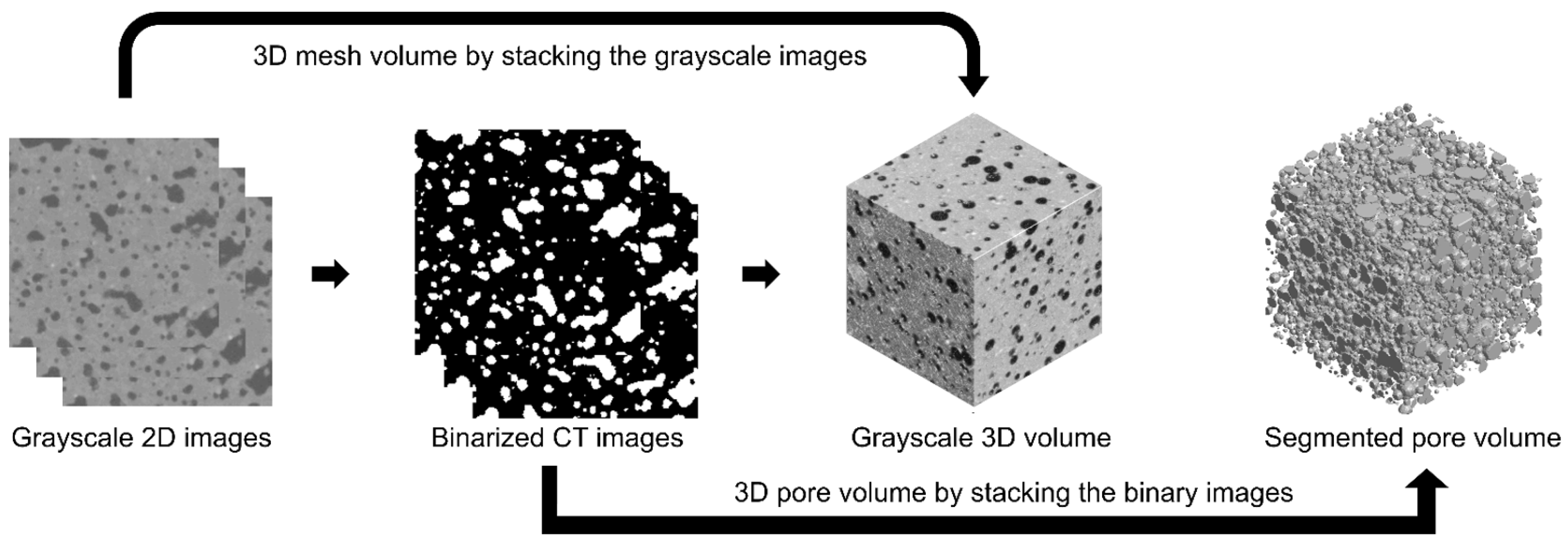

2.11. X-Ray Micro-Computed Tomography (Micro-CT)

2.12. Environmental and Economic Impact

- The environmental and economic impacts of the production of cementitious materials lie primarily on the production and transport of raw materials, with little impact due to information module 3—the GWP and cost of several concrete mixes presented in scientific publications was determined in [56] and the impacts of concrete production are well below 5% of the impact of raw material production and transport.

- The scope of this LCA is to assess the economic and environmental consequences of replacing sand with fRA, and this has no consequence on the impacts of the production of the 3DPC (e.g., fRA use has no relevant consequences on the mixing and ancillary operations carried out at the 3DPC factory).

- Three-dimensional printing is an innovative technology, and it is not yet clear which of the following is the most representative production process: on-site 3DPC production and printing of the structure, pre-cast 3DPC production and printing and on-site assembly, dry-3DPC production, or on-site or at-factory mixing. The impacts related to mixing will differ depending on these conditions, with scarce data available to determine the impacts of each of these hypotheses. The methodology used in this paper ensures a fair comparison of impacts but avoids speculative assessments regarding mixing and printing.

3. Results

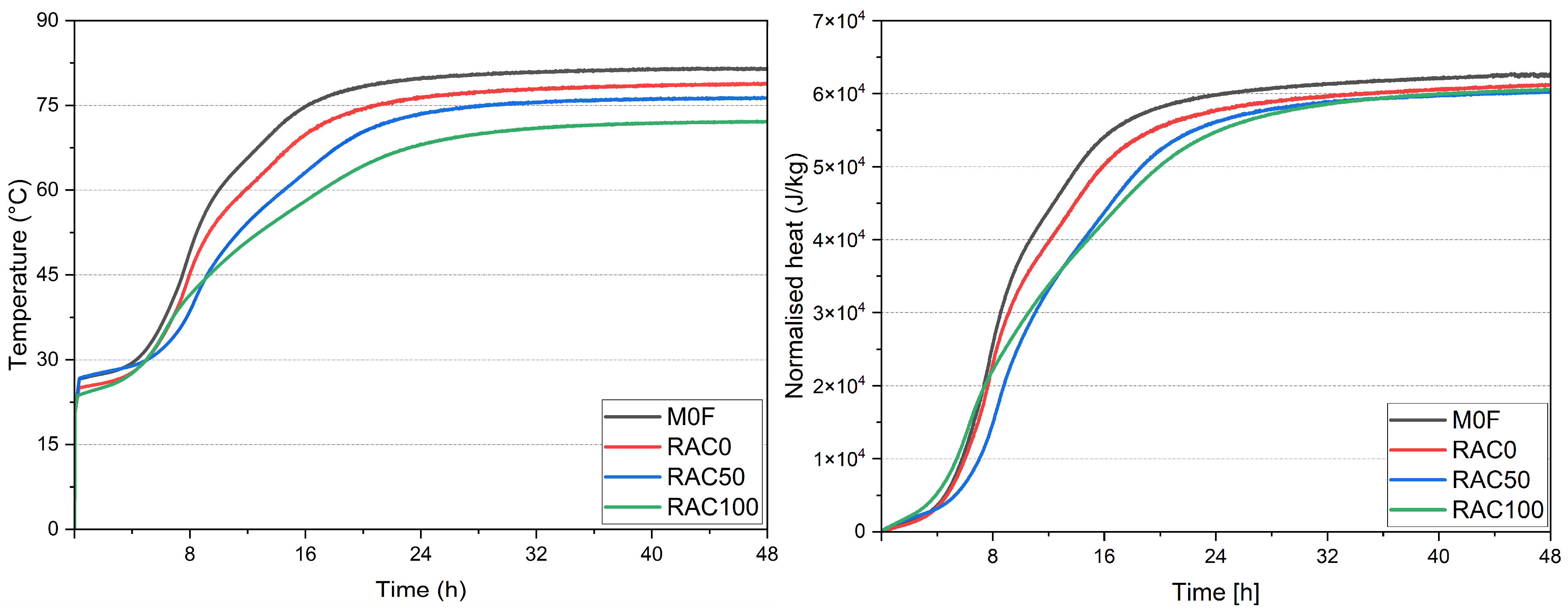

3.1. Adiabatic and Isothermal Calorimetry

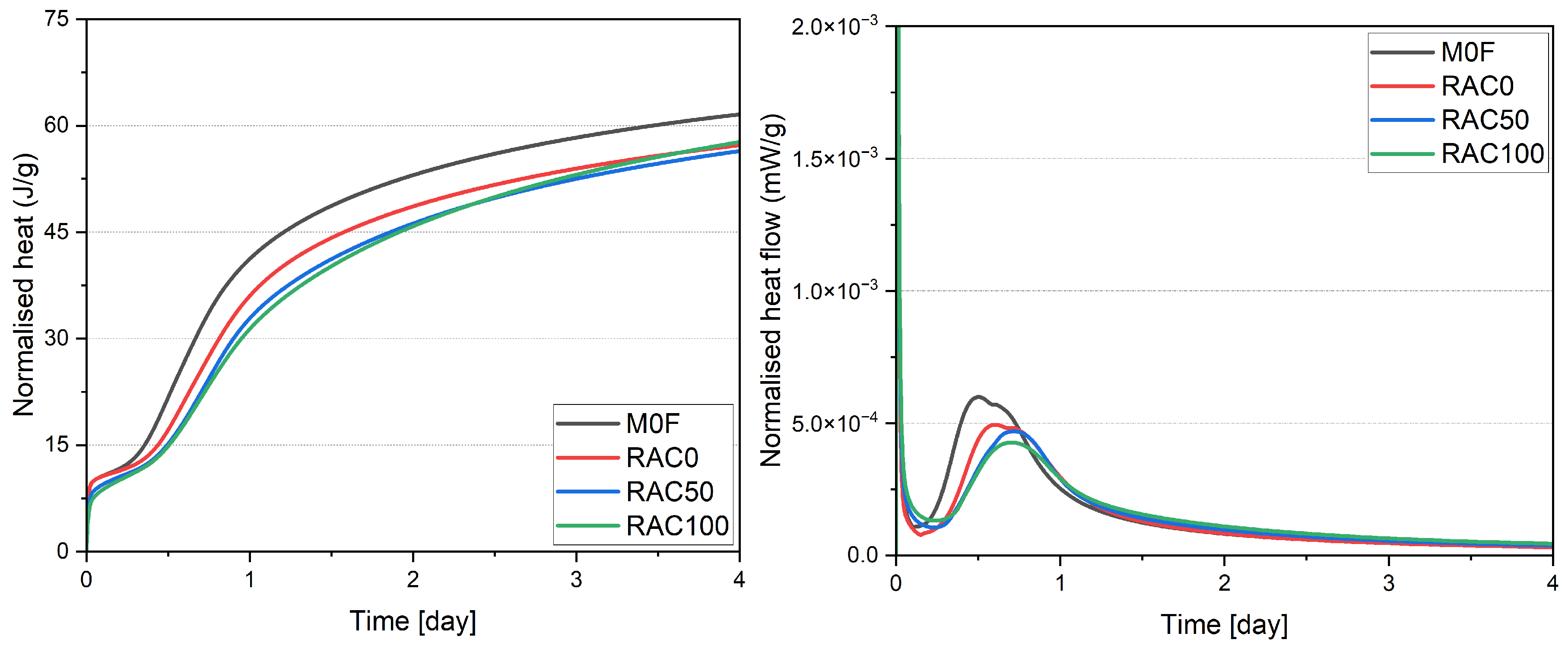

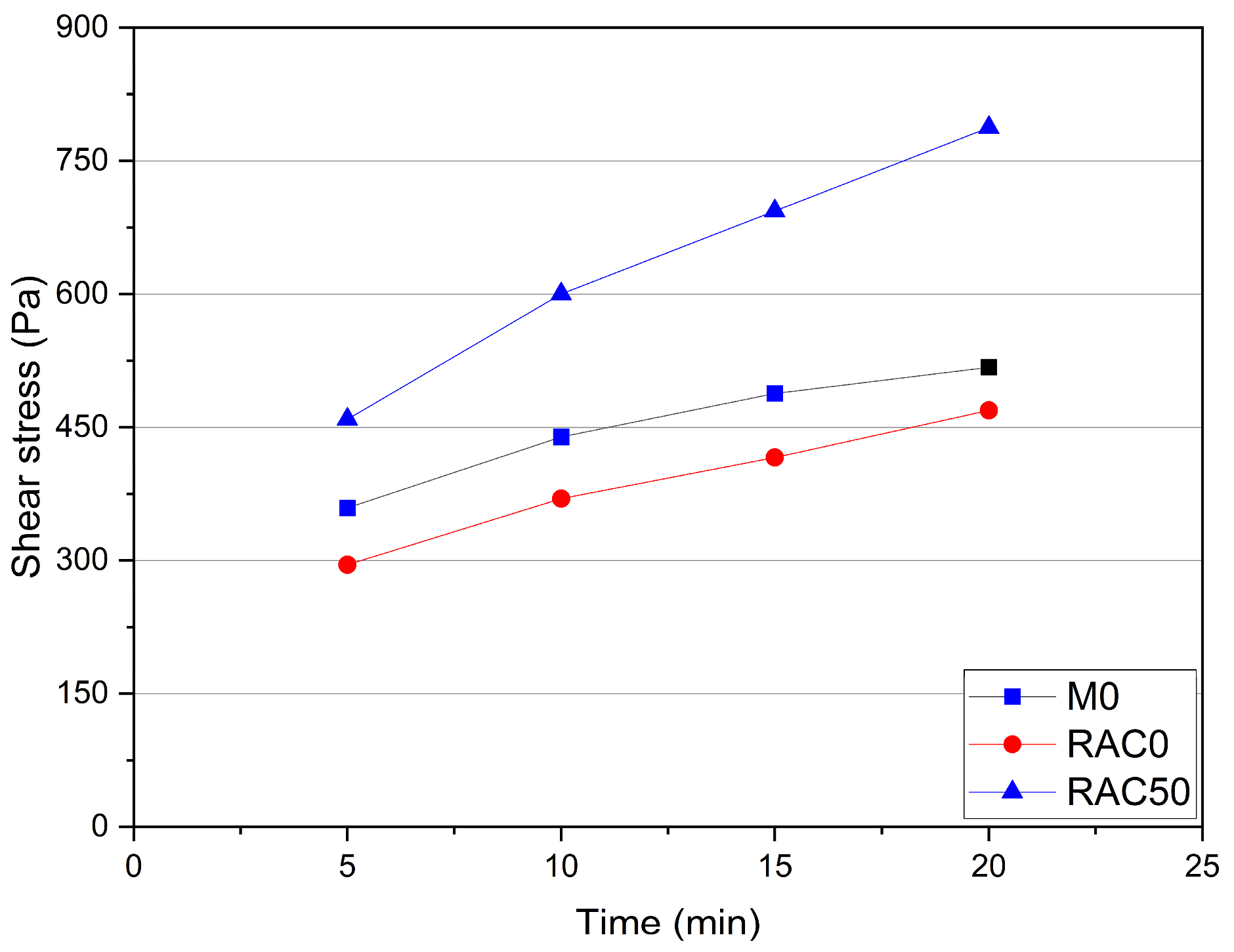

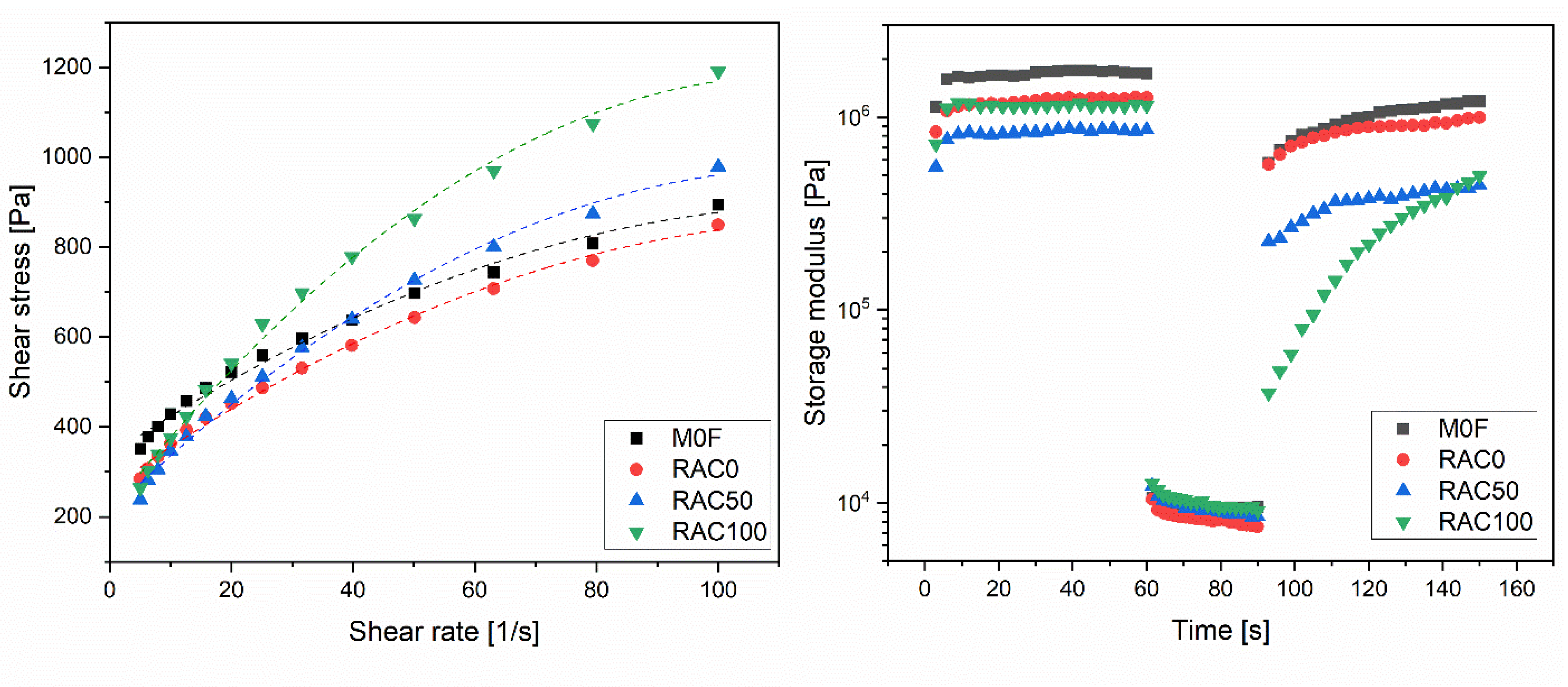

3.2. Rheological Properties

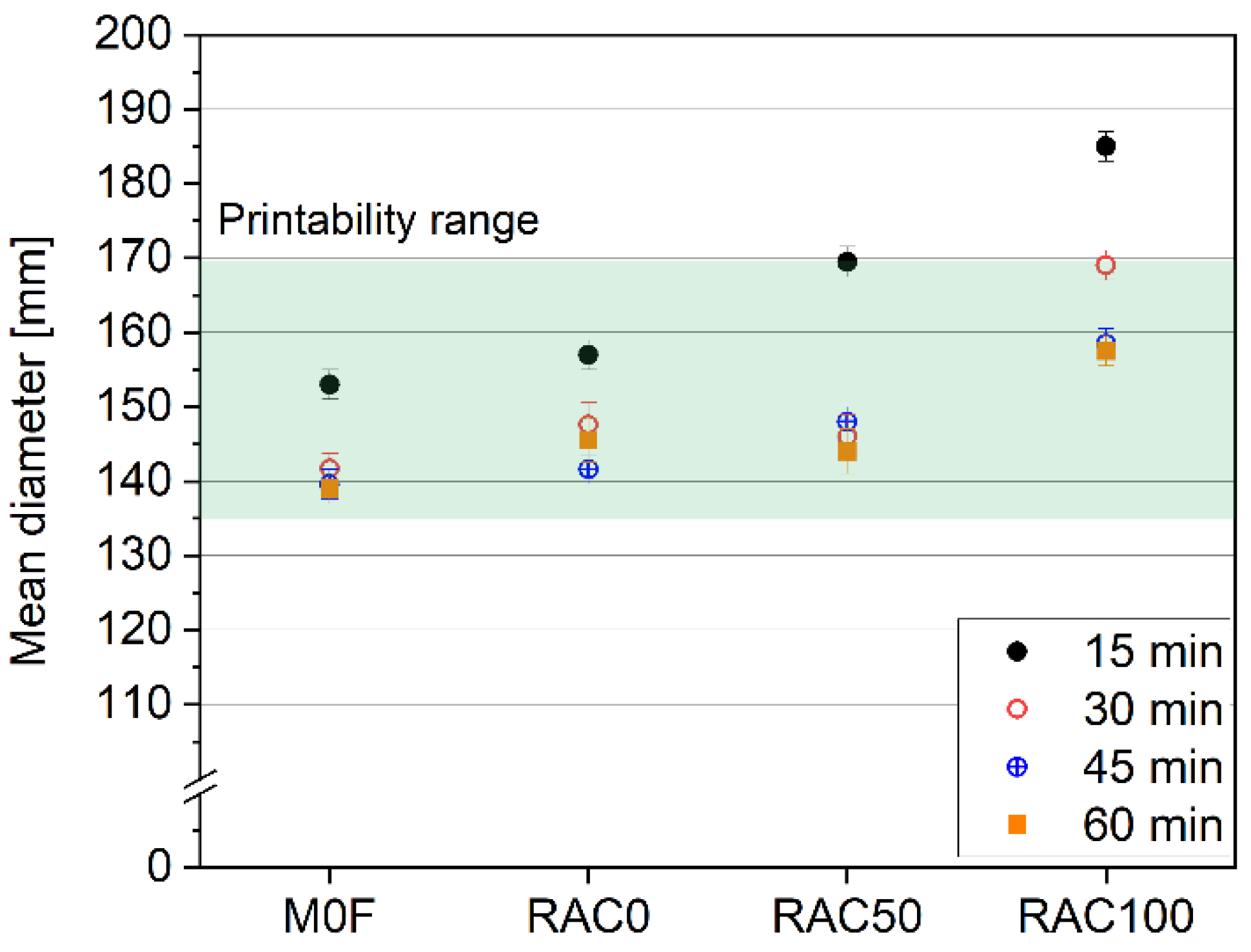

3.3. Flow Table

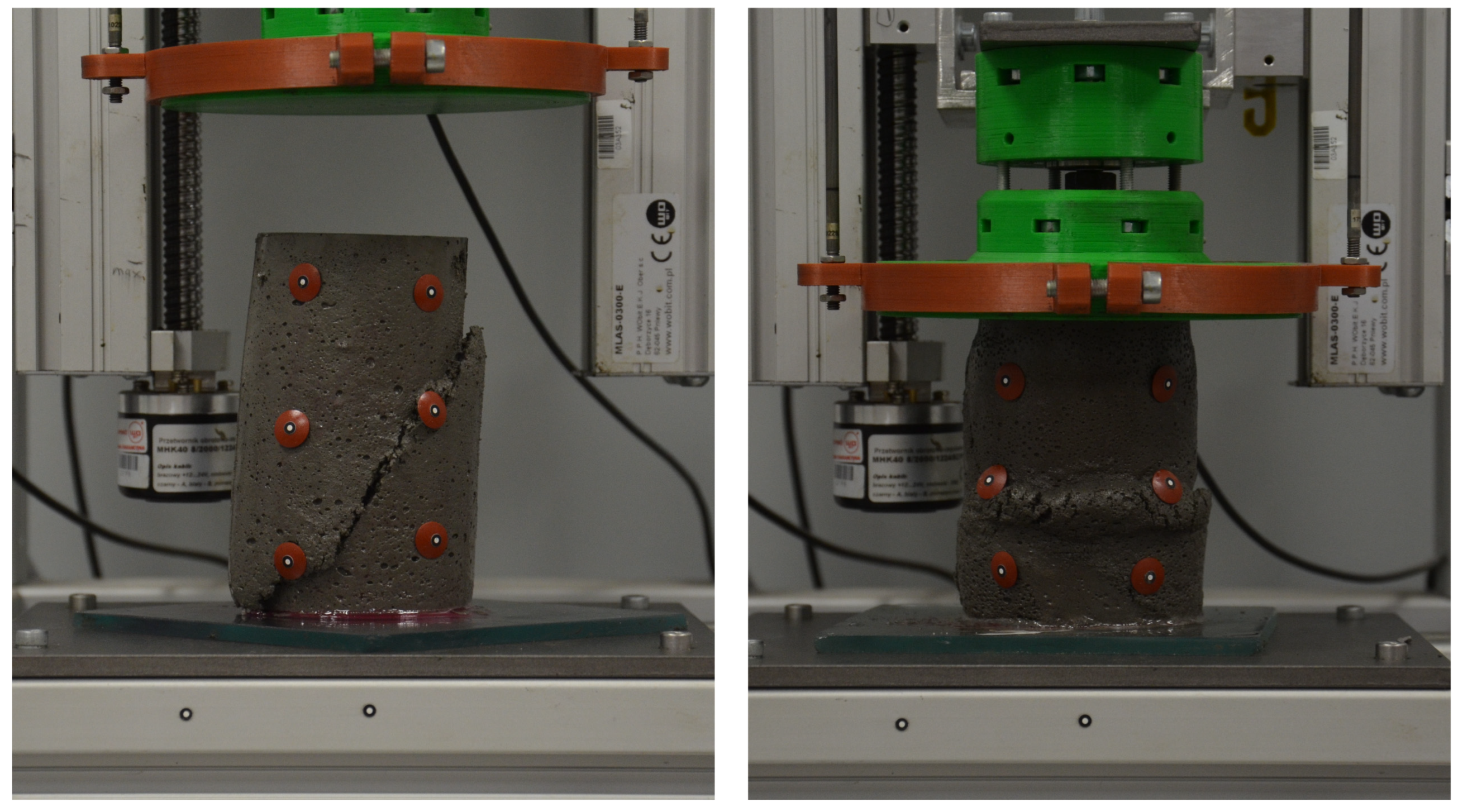

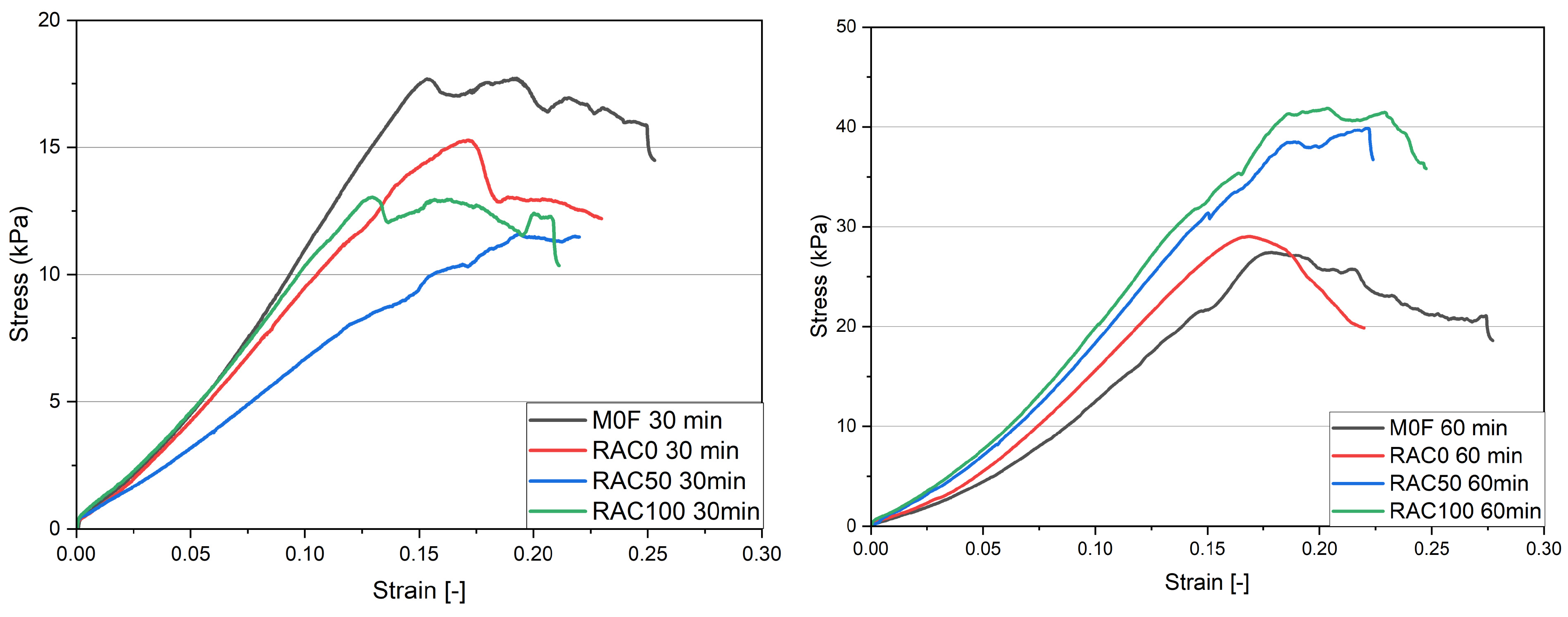

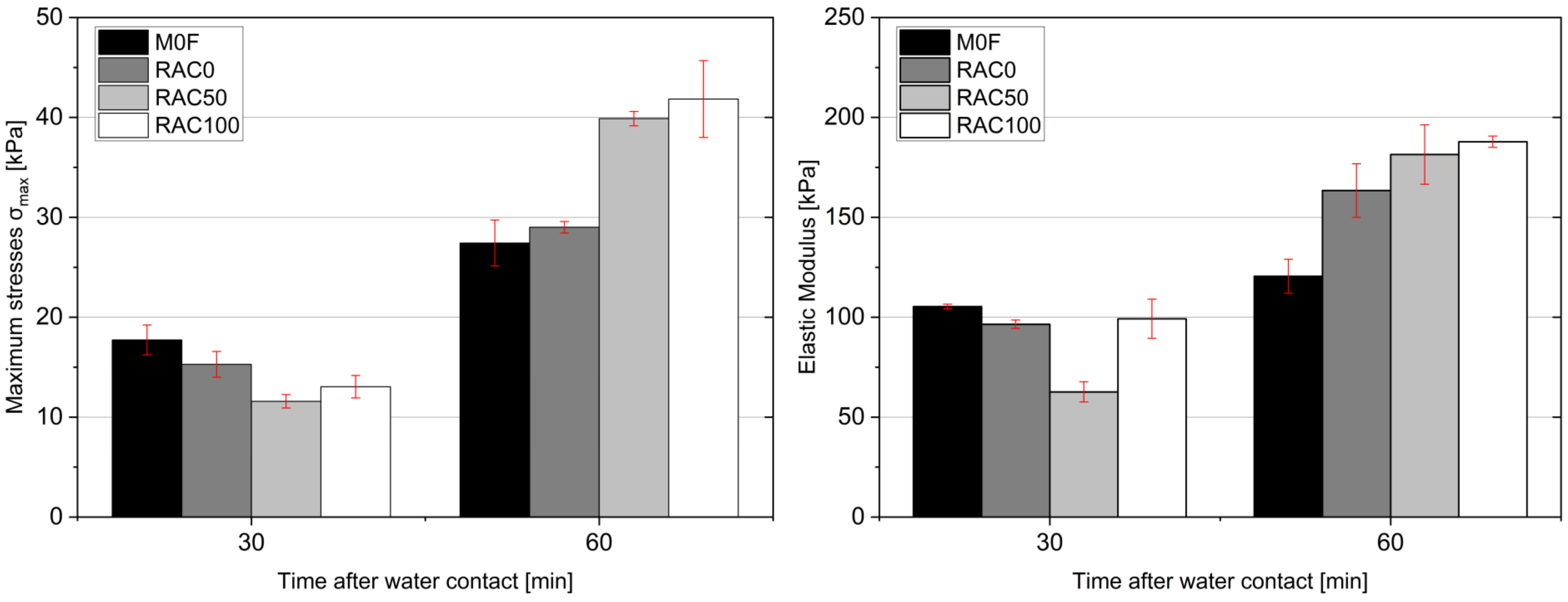

3.4. Green Strength

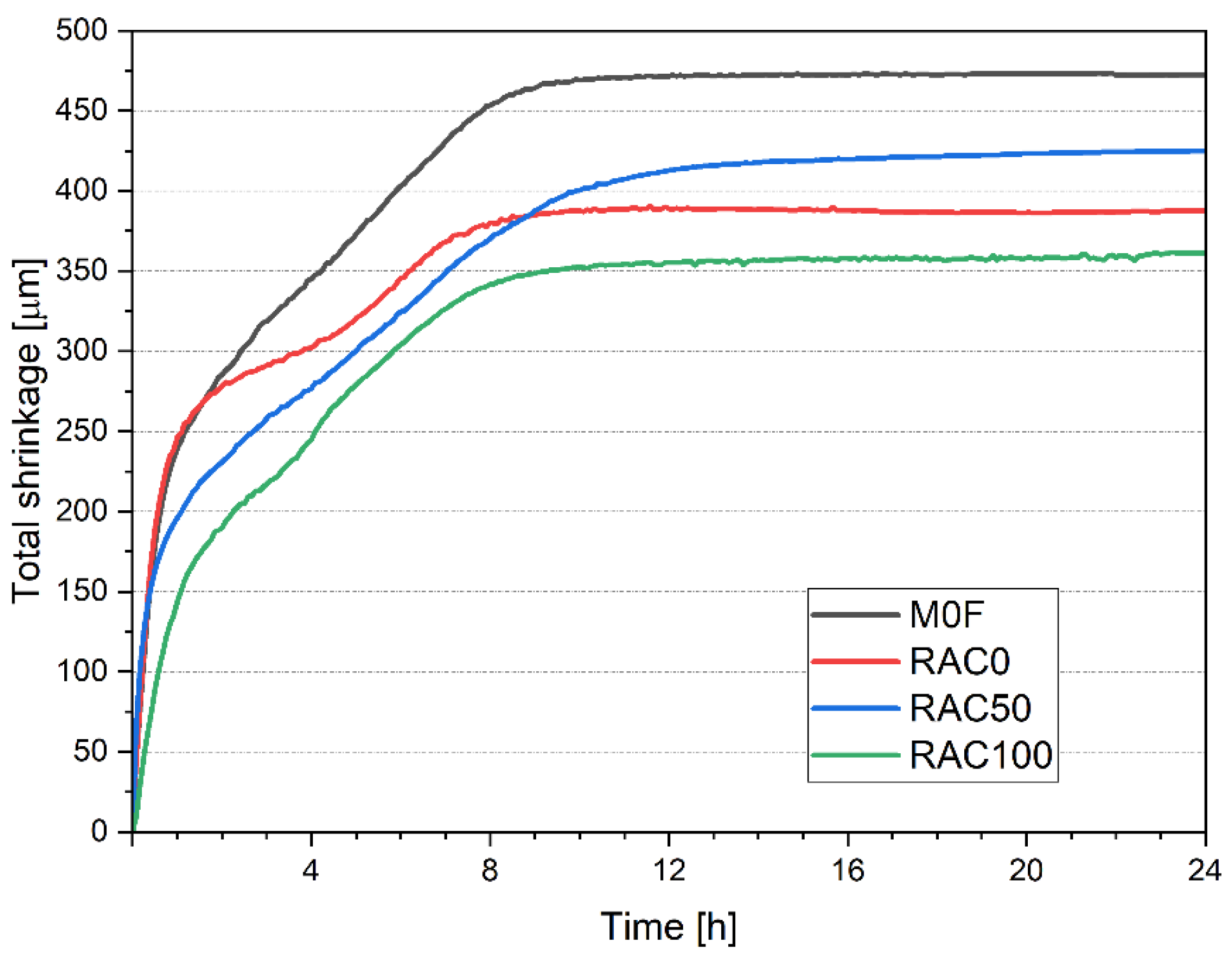

3.5. Early-Age Shrinkage

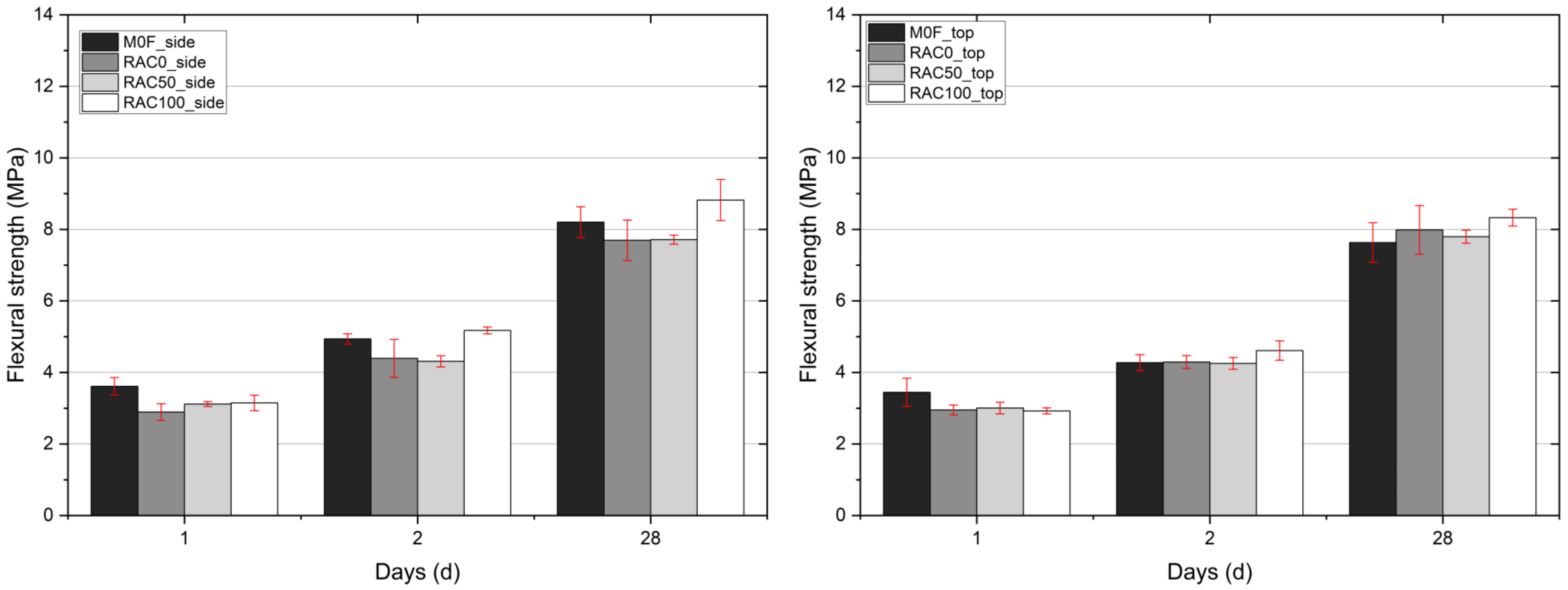

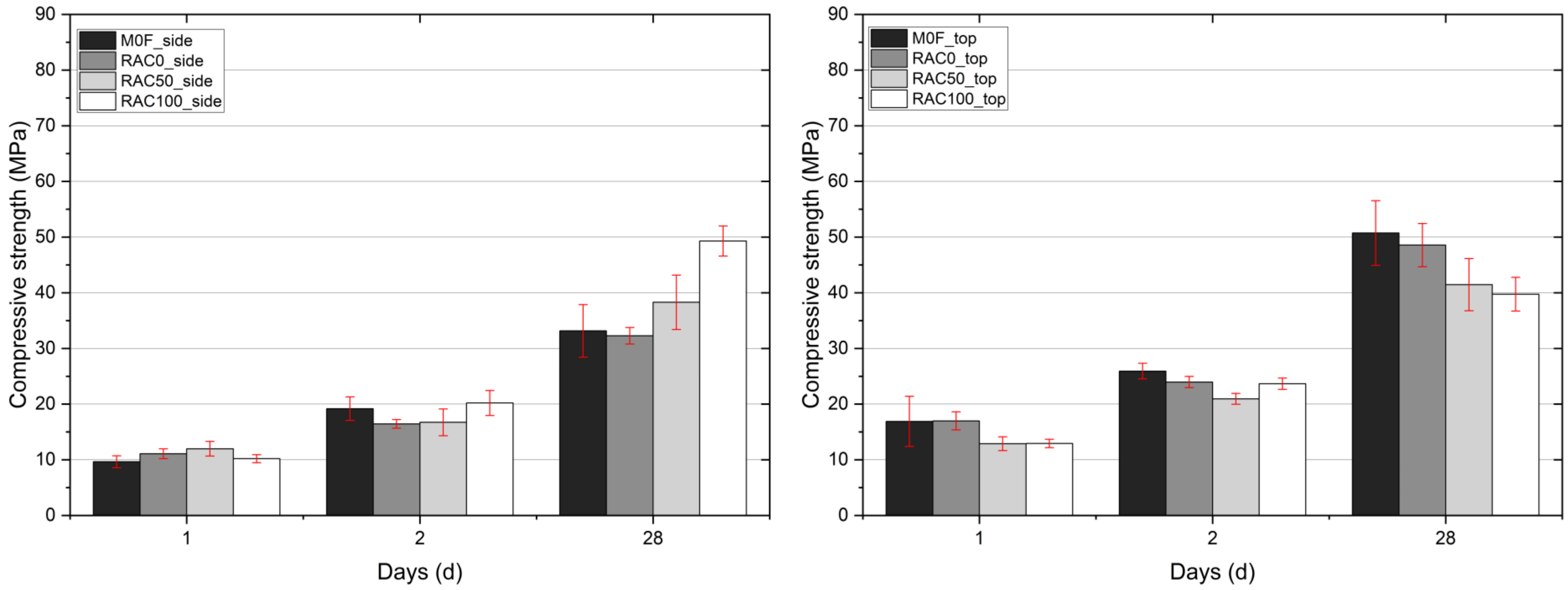

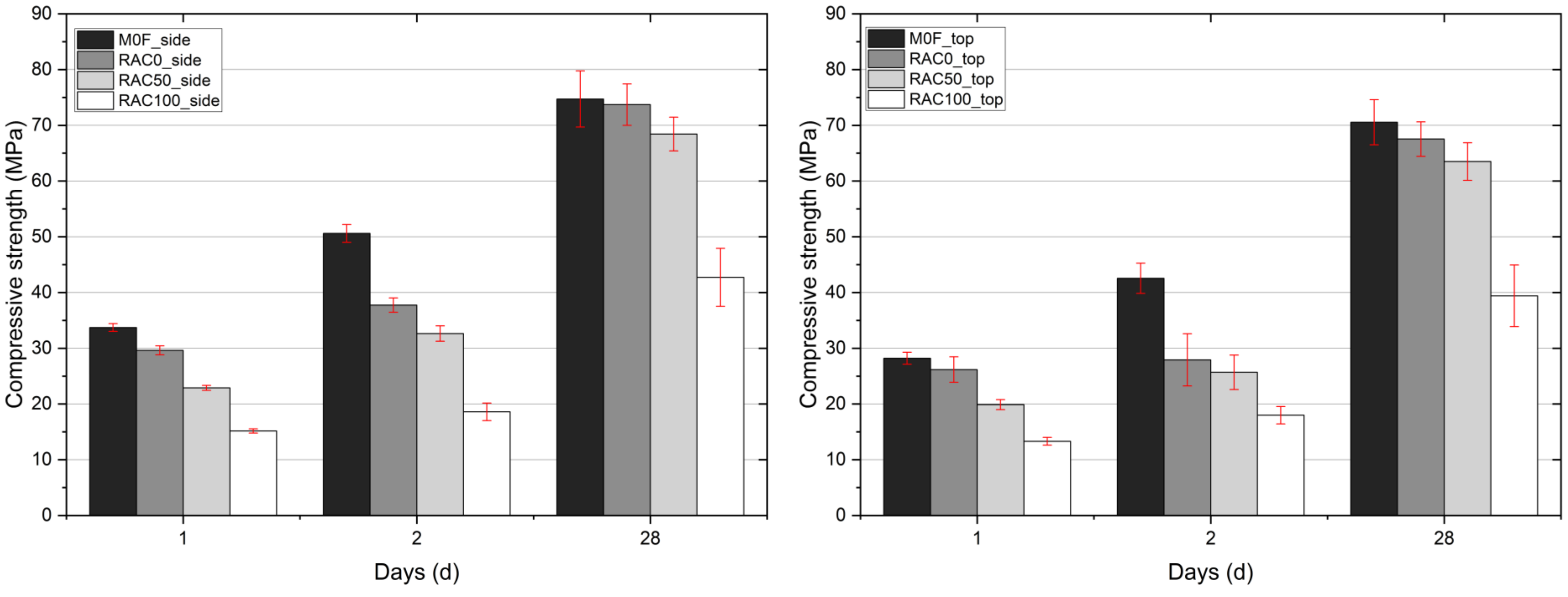

3.6. Strength Development (Cast vs. Printed Samples)

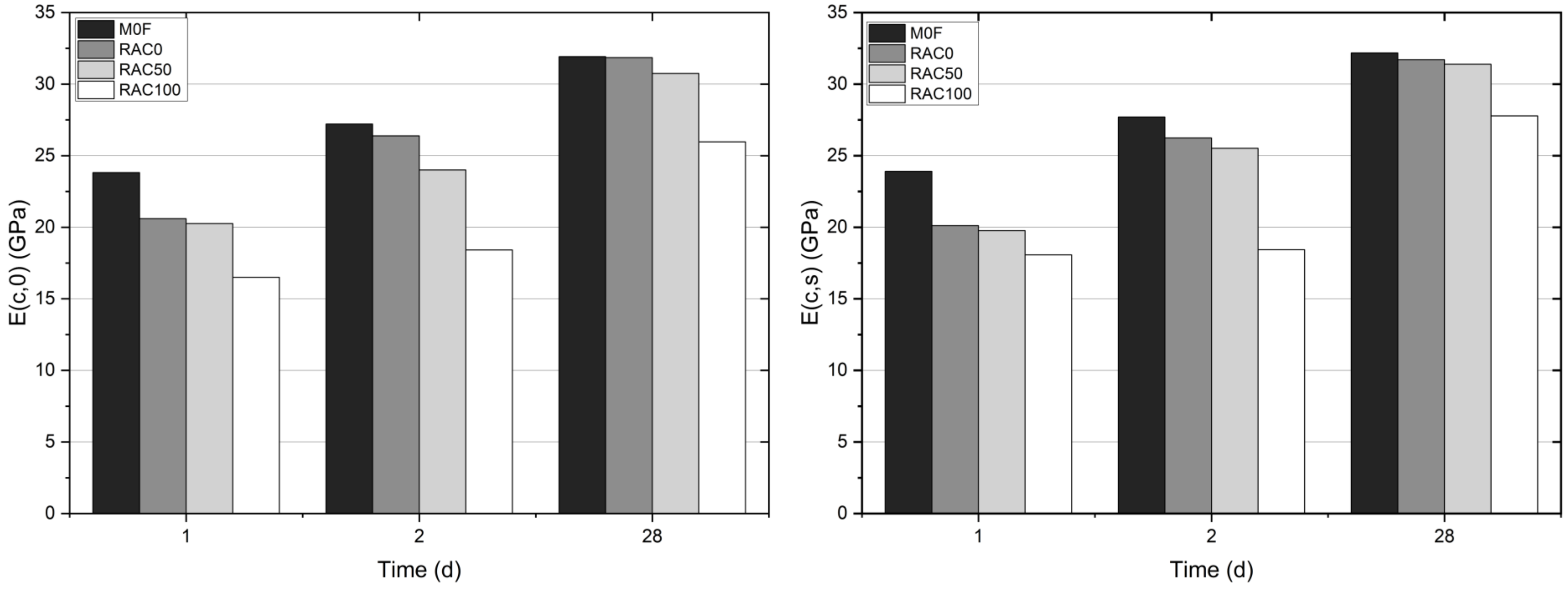

3.7. Elastic Modulus

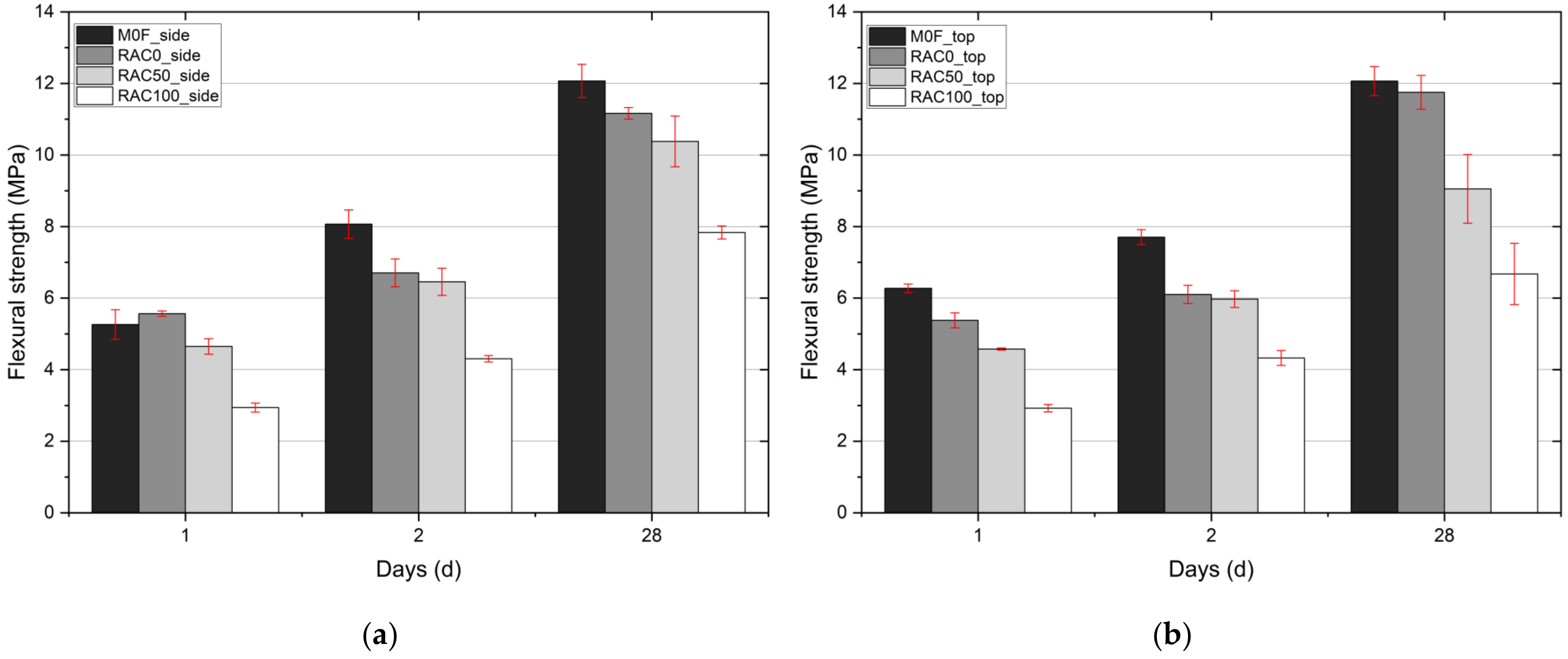

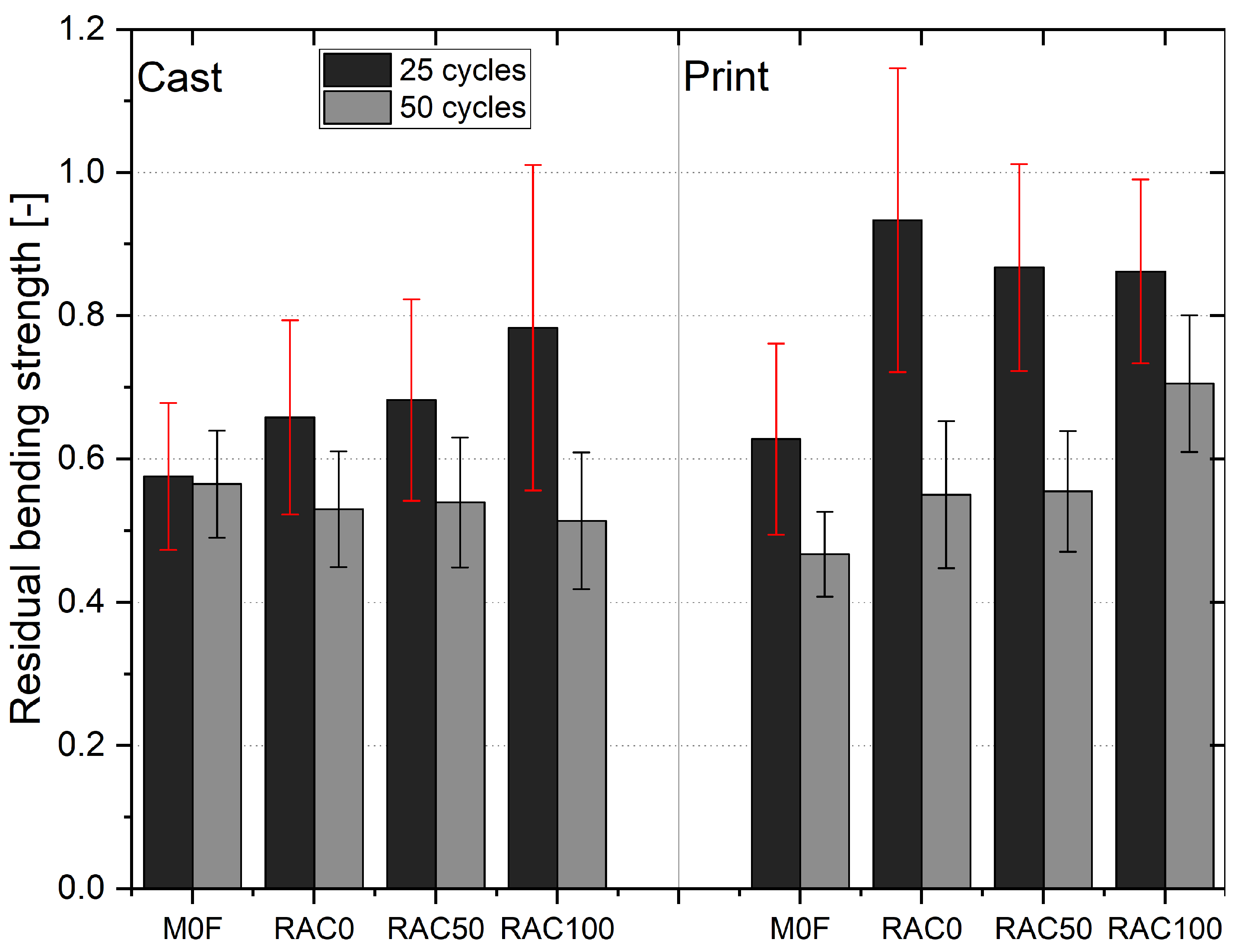

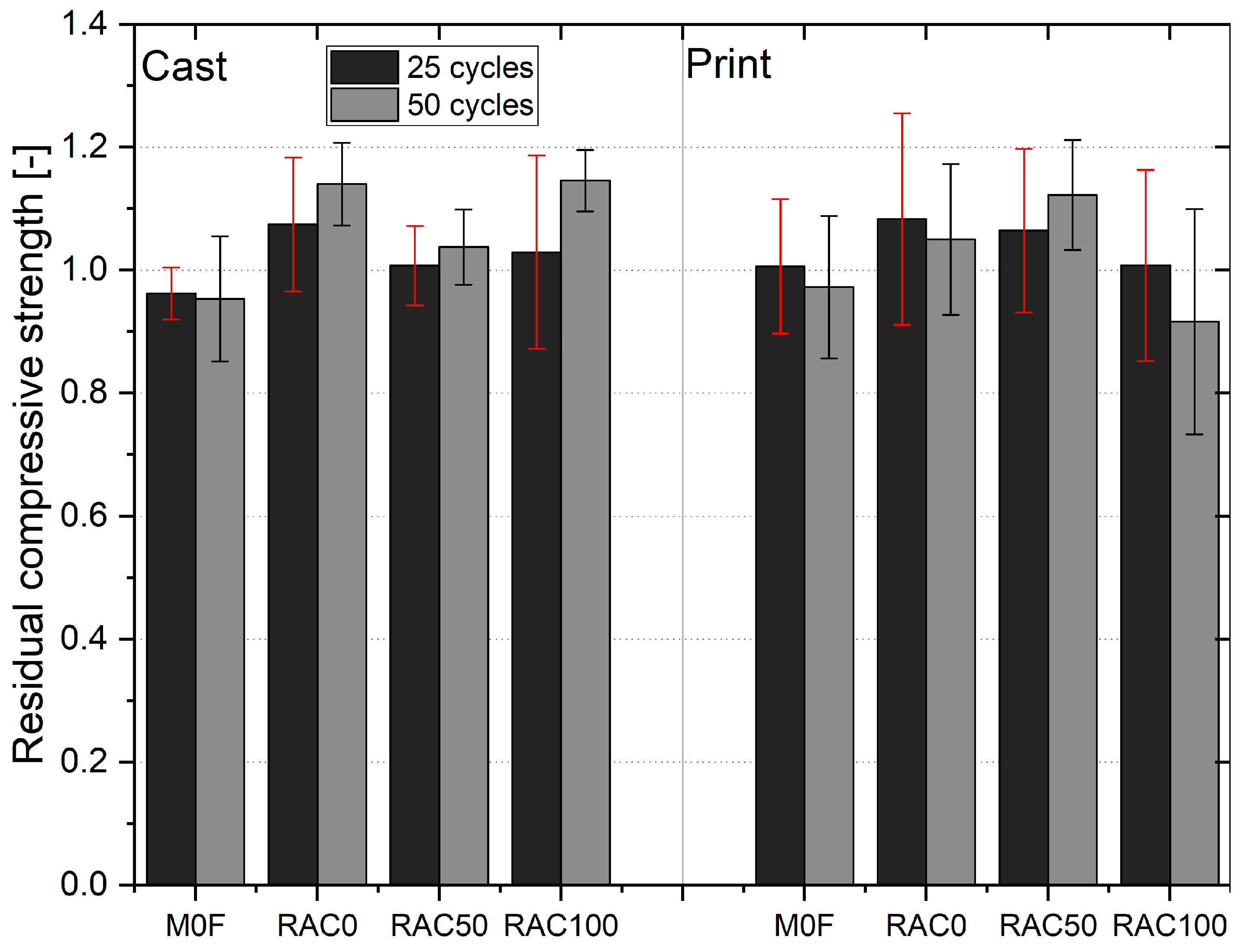

3.8. Freeze–Thaw Resistance

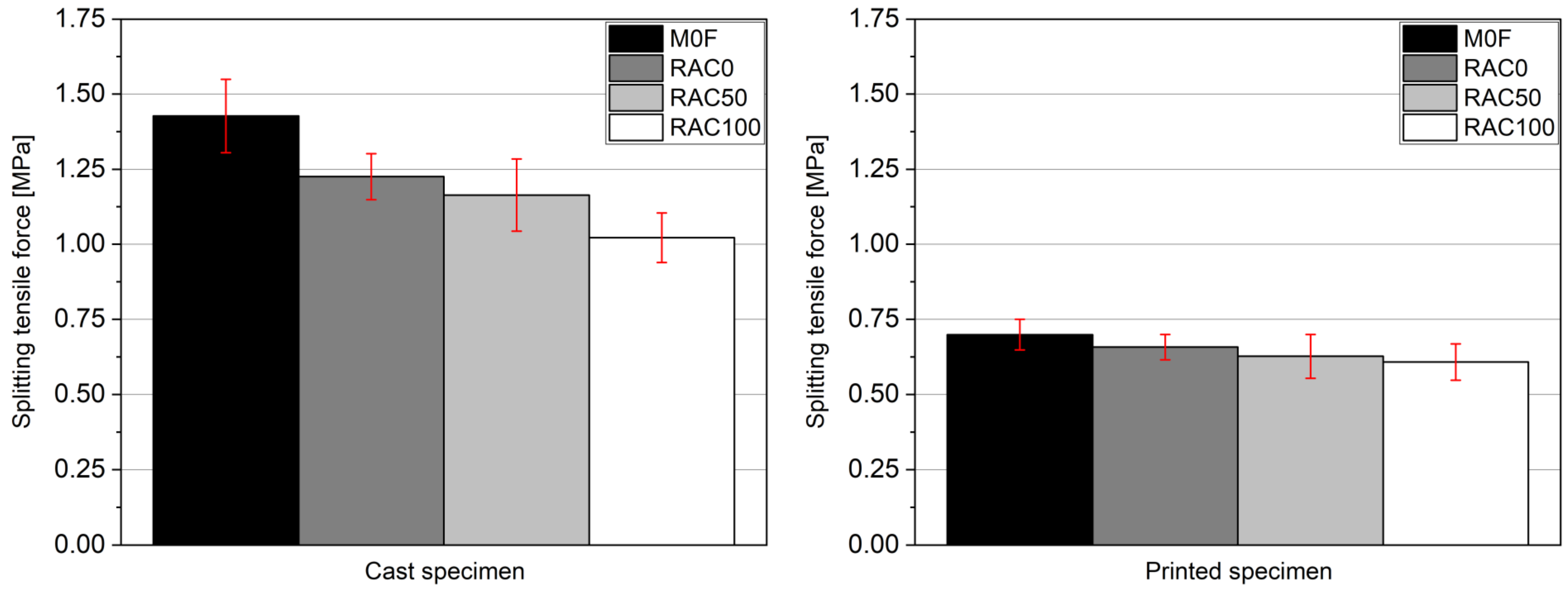

3.9. Interlayer Adhesion

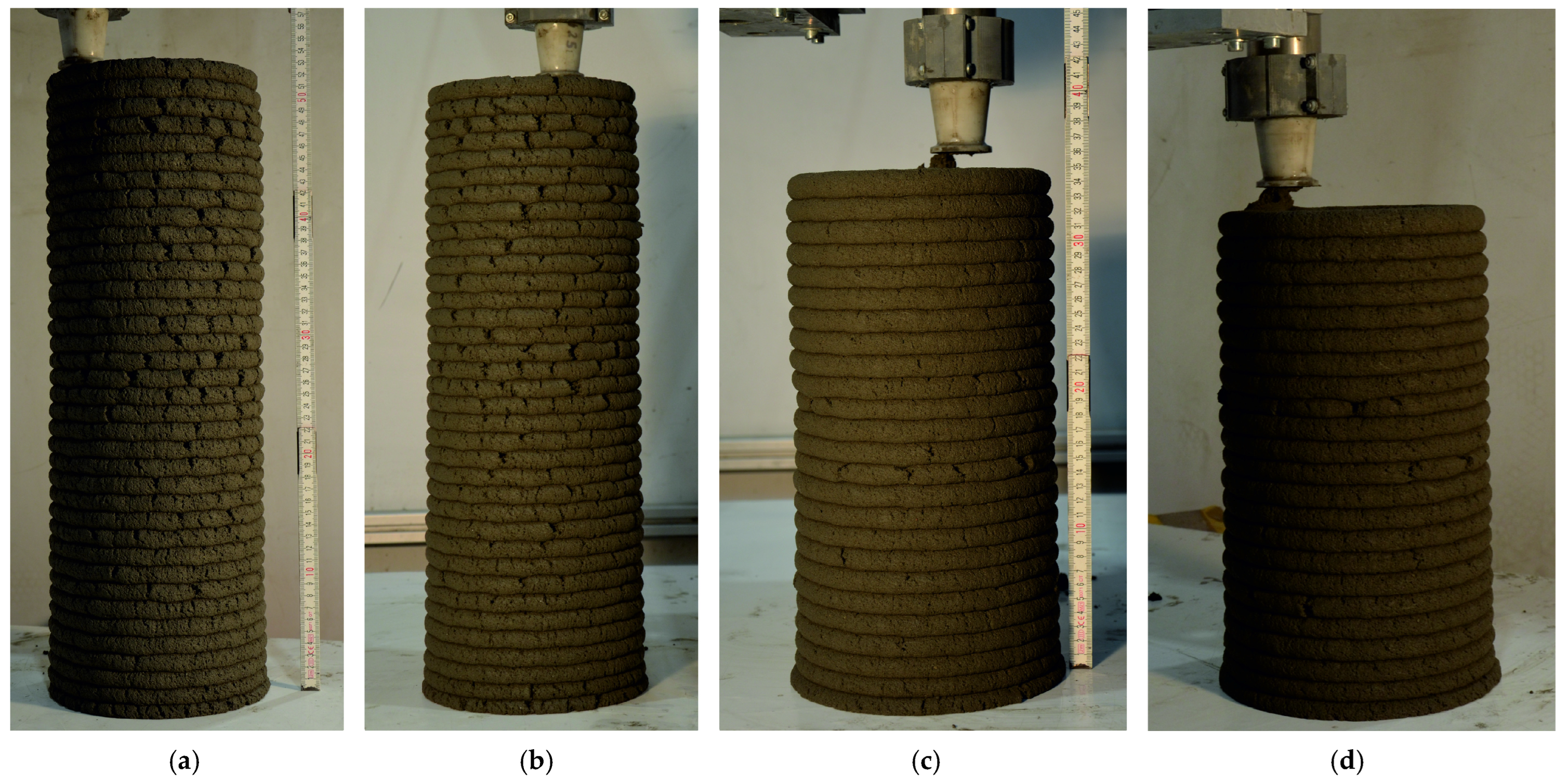

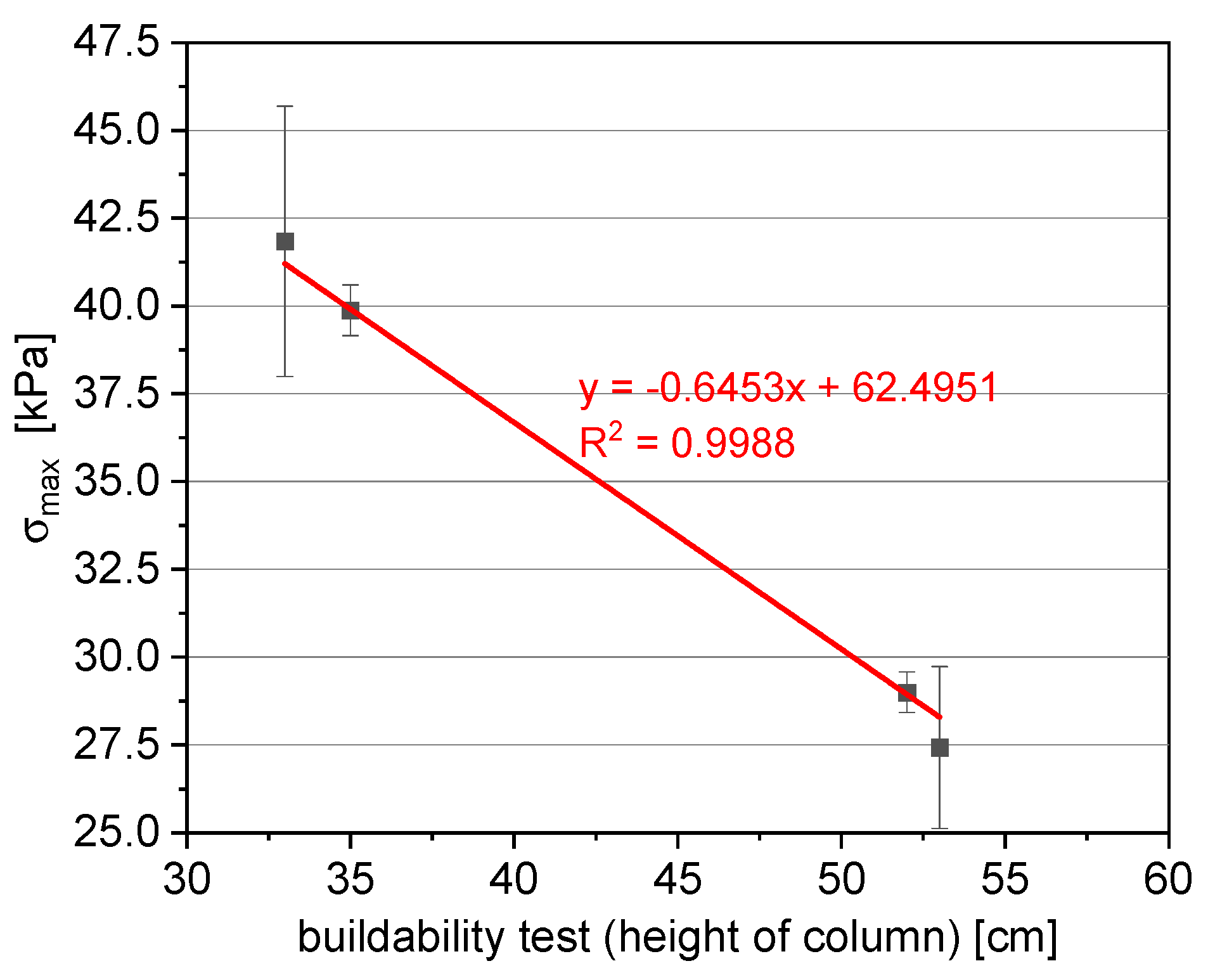

3.10. Buildability

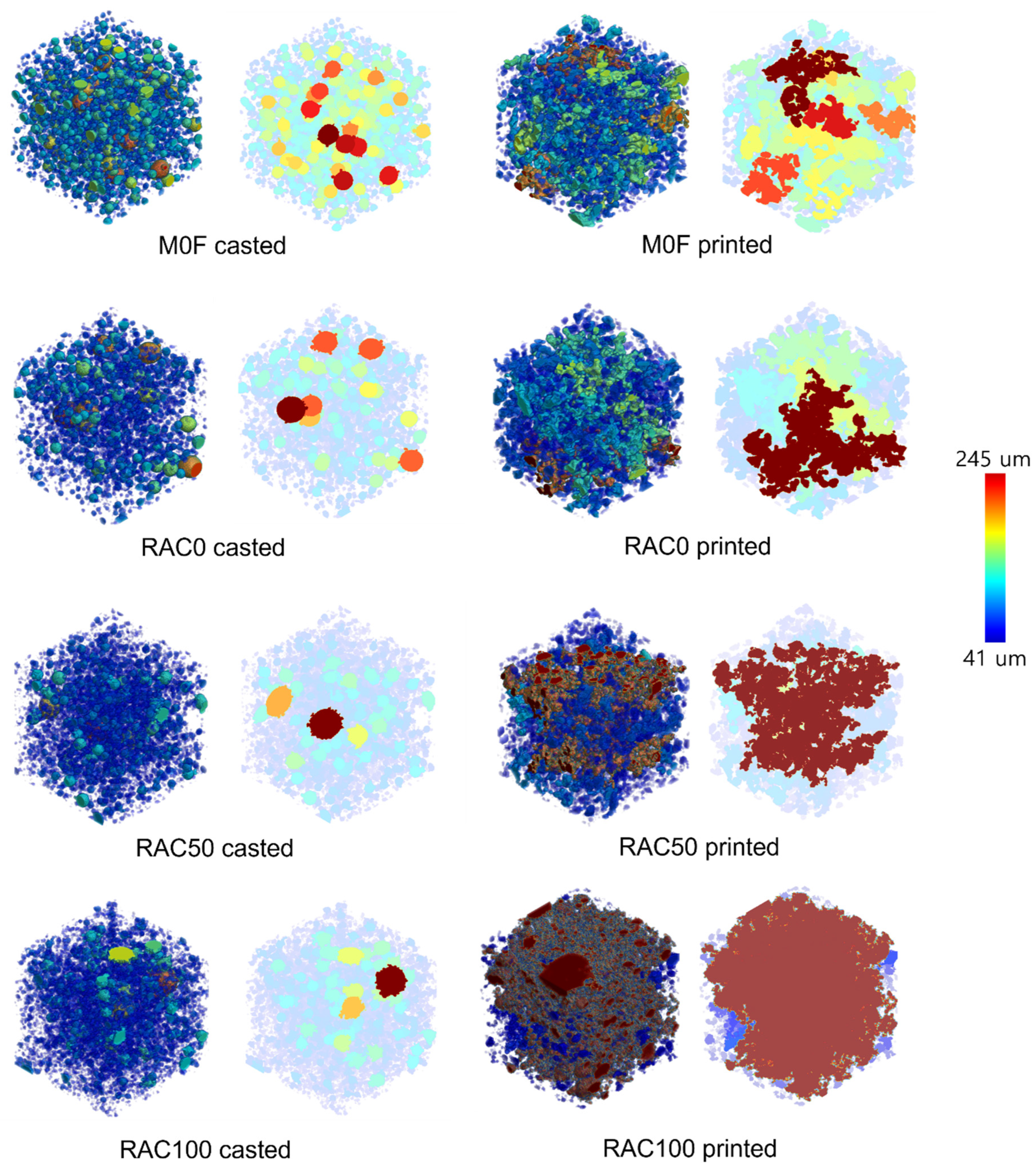

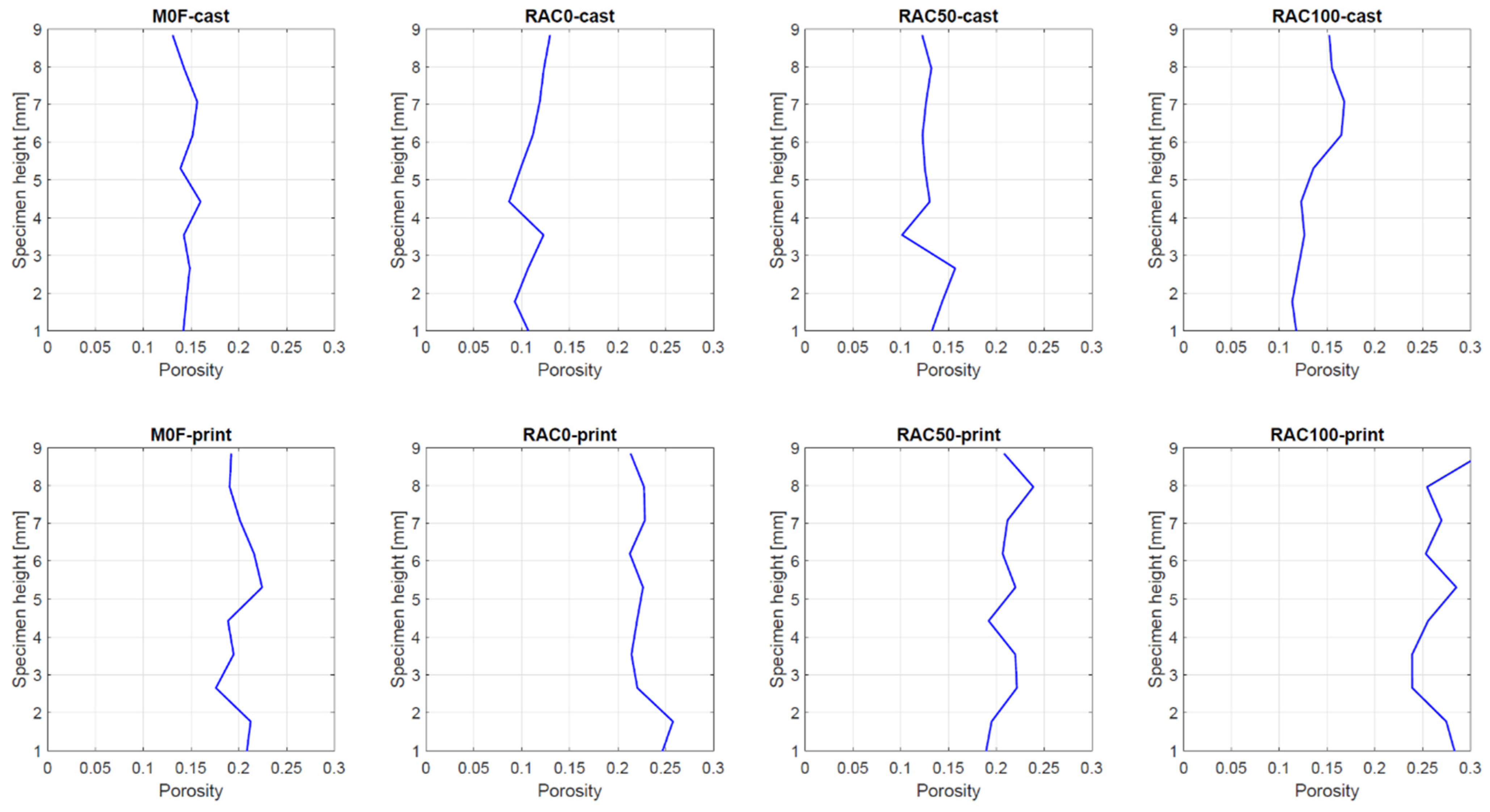

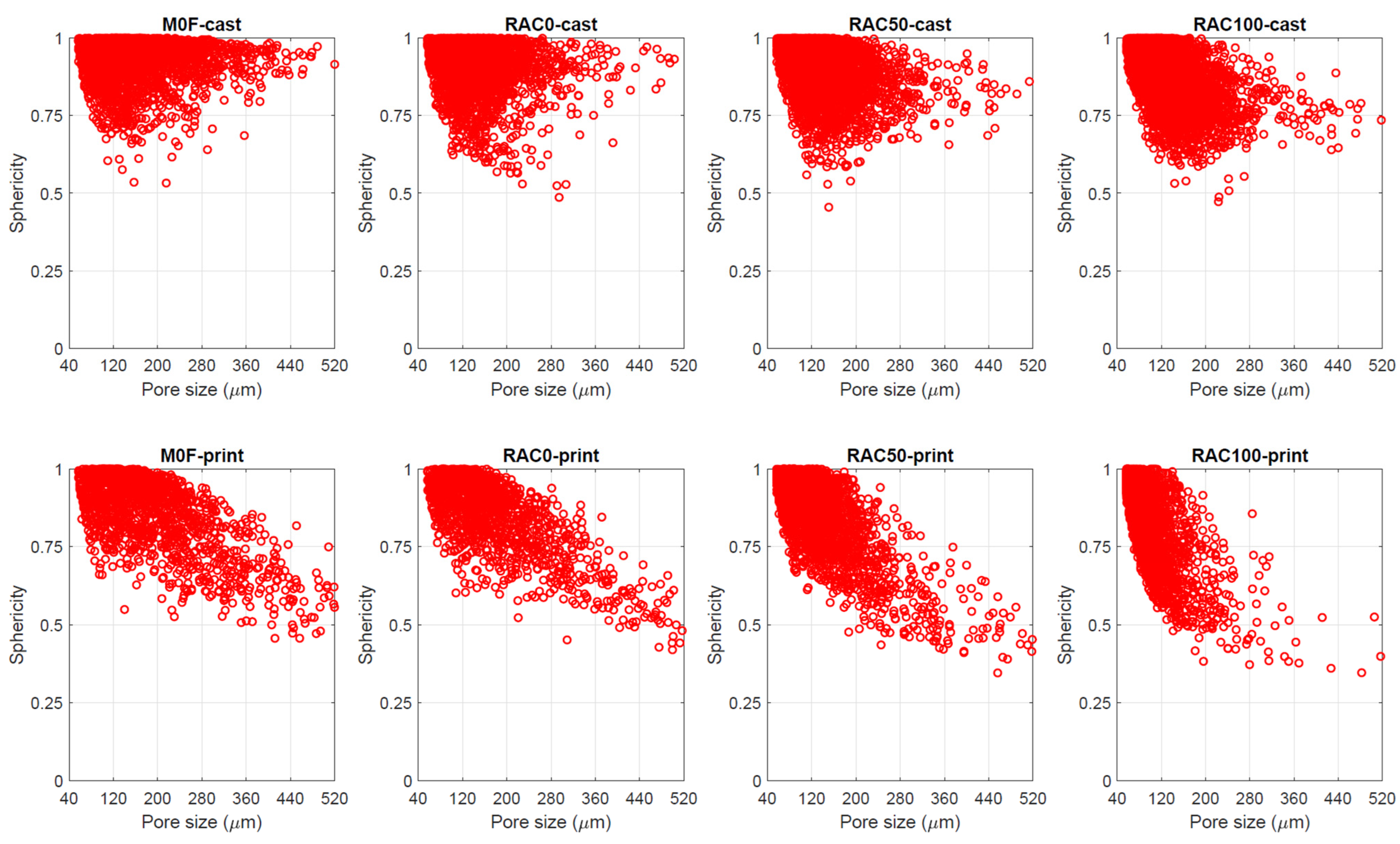

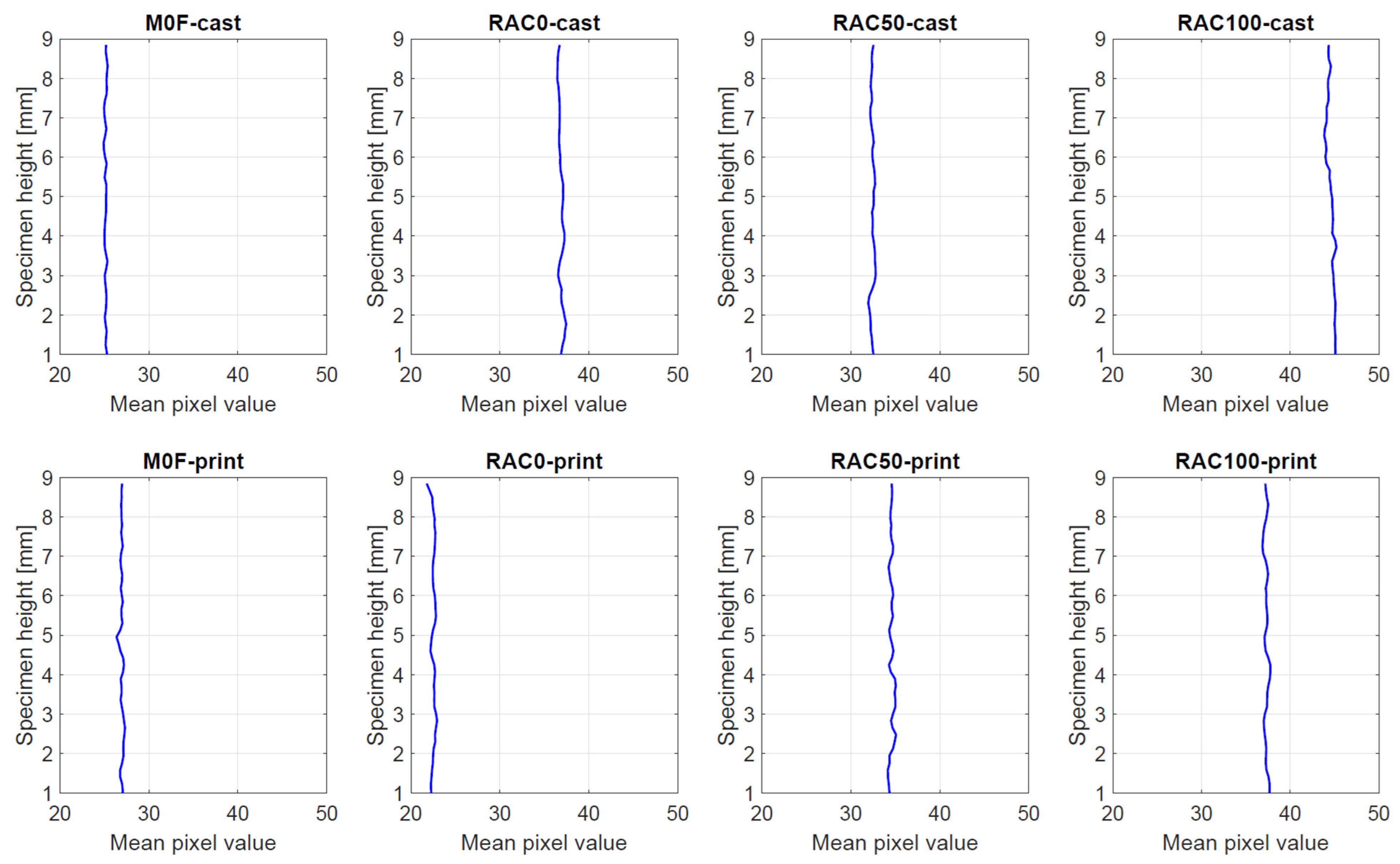

3.11. X-Ray Micro-Computed Tomography (Micro-CT)

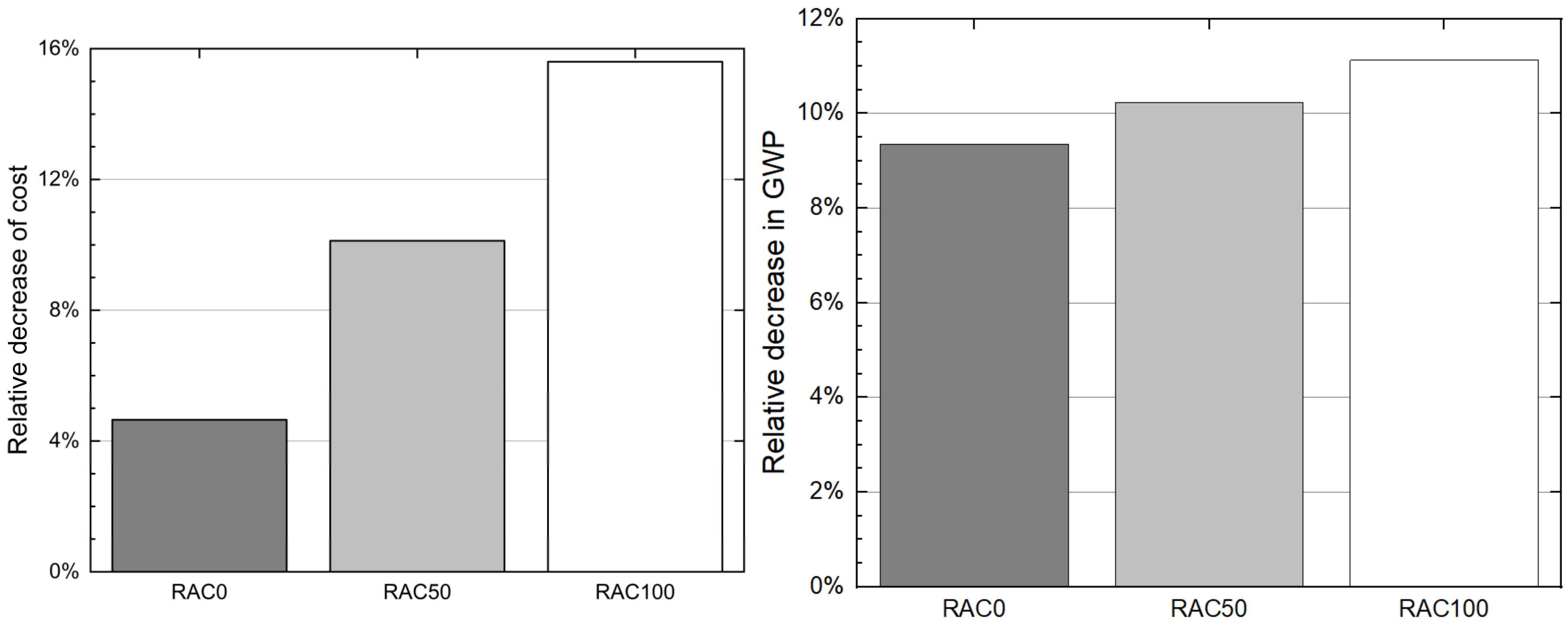

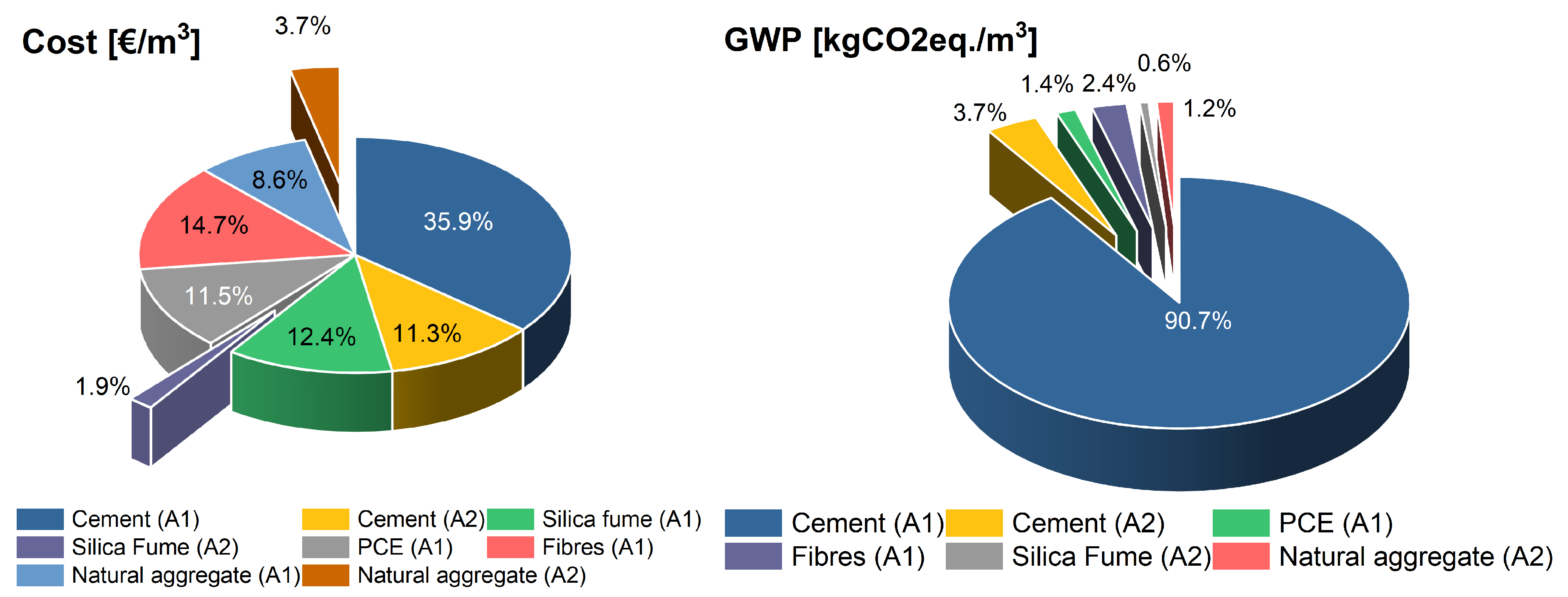

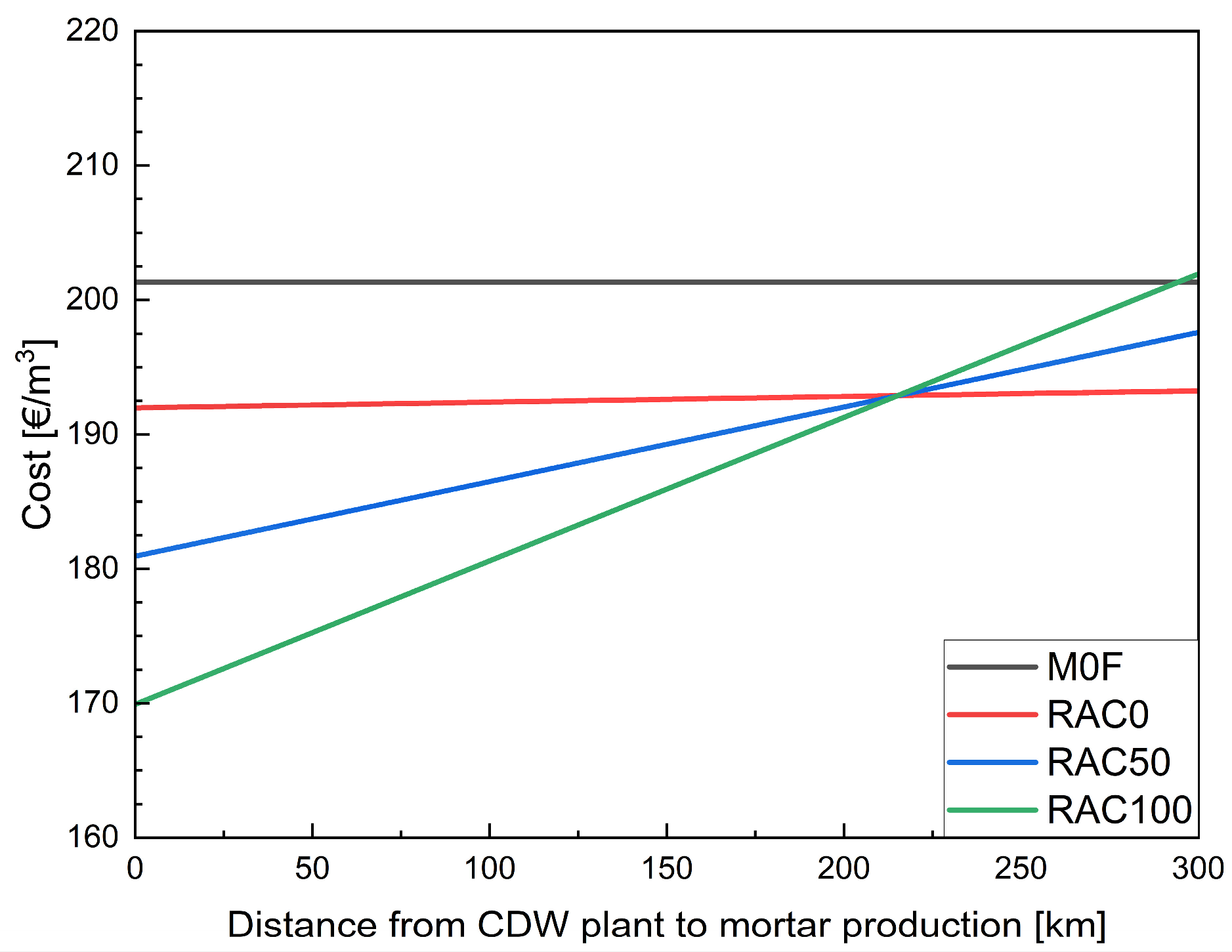

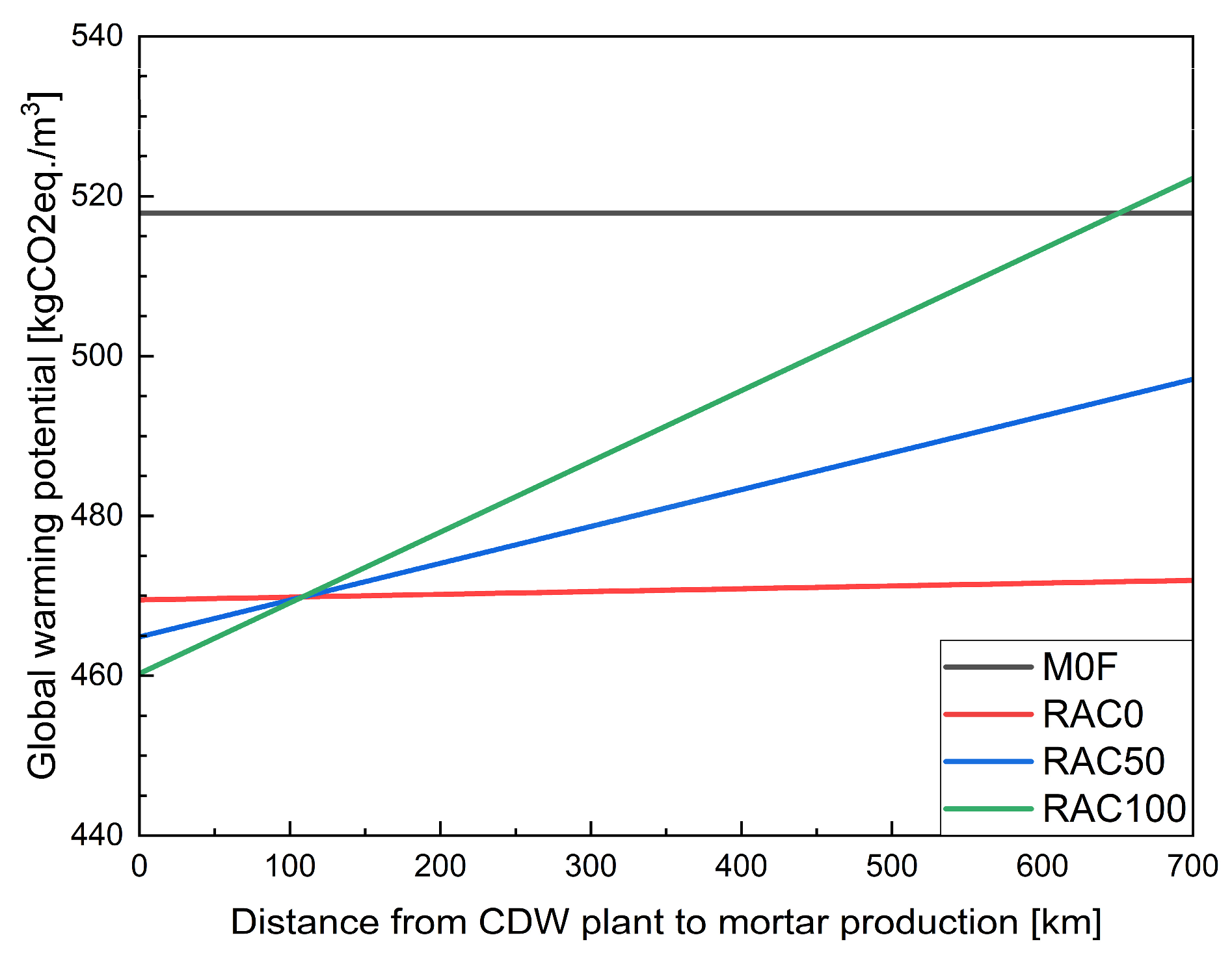

3.12. Environmental and Economic Impact

4. Conclusions

- 1.

- It is feasible to print composites containing up to 100% fRA as a replacement for natural river sand. Notably, an increase in fRA content enhances the buildability of the mix, as confirmed by green strength tests. The results indicate that, due to the high water absorption capacity of fRA, the green strength of the RAC100 and RAC50 mixes significantly increased after 60 min. However, for samples tested within 30 min after water contact, the highest green strength was observed in the mix with a higher cement content (M0F) and in the RAC0 mix (with natural aggregate and reduced cement content). To summarise, the timing after water contact plays a crucial role in green strength development.

- 2.

- The findings show that substituting Portland cement (PC) with recycled powder (RCP), as in the RAC0 mix, led to a slight increase in plastic viscosity, while yield shear stress decreased by 22% compared to the M0F mix. The replacement of natural sand with fRA had a more pronounced effect on rheological behaviour. Replacing 50% and 100% of natural sand with fRA reduced yield shear stress by 20% and 19%, respectively, compared to RAC0. However, RAC100 showed a slight increase in yield shear stress compared to RAC50, likely due to limited lubrication resulting from the higher water absorption of fRA. Thixotropic recovery also declined significantly, from 79% in RAC0 to 51.5% in RAC50 and 43% in RAC100, indicating a reduced ability of the mix to rebuild its internal structure after shear. These results underline the impact of fRA content on both the flowability and structural recovery of the mixes.

- 3.

- The addition of fRA led to a decrease in total shrinkage. This reduction is attributed to the lower binder content in the mixes and the internal curing effect provided by the fRA.

- 4.

- The addition of fRA influences the mechanical properties of the mixes. In terms of compressive strength for printed specimens loaded from the side, the addition of fRA resulted in a slight increase in strength. Conversely, for specimens loaded from the top, as well as for cast specimens, a significant reduction in compressive strength was observed—up to 55% for RAC100. This decline is primarily associated with increased porosity, as confirmed by microstructural analysis.

- 5.

- Anisotropy in 3D-printed samples was found to be minimal in flexural strength, with differences generally below 16% and negligible after 28 days. In compressive strength, the reference mix showed strong directional dependence (>40%), while mixes with fRA and fibres significantly reduced these differences to within experimental variability. Overall, the inclusion of fRA and fibres improves interlayer bonding and limits anisotropy, resulting in more uniform mechanical performance.

- 6.

- In line with the aforementioned findings, microstructural analysis revealed that porosity increases with the addition of fRA, progressing from RAC0 to RAC100. Interestingly, in cast specimens, the M0F mix (without fRA) exhibited the highest porosity. For printed specimens, the M0F mix also showed slightly higher porosity than RAC0 and RAC50.

- 7.

- The durability properties of mixes modified with fRA show that there is a statistically significant reduction in flexural strength after 25 and 50 freeze–thaw cycles. In terms of compressive strength, cast specimens did not exhibit any notable reduction in durability. For printed specimens, a reduction in compressive strength was observed only after 50 cycles, and only in the RAC100 and M0F mixes. However, this reduction is minimal and falls within the coefficient of variation of the results.

- 8.

- The replacement of cement by RCP makes a significant contribution to reducing GWP, whereas replacing sand with fRA leads to a greater cost decrease for short transport distances (e.g., up to 50 km). As the transport distance of the fRA and RCP increases, the increase in the cost of the 3DPC with fRA is more relevant than the increase in their GWP.

- 9.

- To sum up, the research proves that the addition of fRA as a replacement for natural aggregate can be beneficial for 3D printing, particularly when the printing process is carried out approximately 45 min after water contact.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Omrane, M.; Rabehi, M. Effect of Natural Pozzolan and Recycled Concrete Aggregates on Thermal and Physico-Mechanical Characteristics of Self-Compacting Concrete. Constr. Build. Mater. 2020, 247, 118576. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status Quo and Future Directions of Construction and Demolition Waste Research: A Critical Review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Pacheco, J.; De, B.J.; Lamperti, T.M. Use of Recycled Aggregates in Concrete: Opportunities for Upscaling in Europe. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC131294 (accessed on 20 August 2025).

- Ajayi, S.O.; Oyedele, L.O.; Akinade, O.O.; Bilal, M.; Owolabi, H.A.; Alaka, H.A.; Kadiri, K.O. Reducing Waste to Landfill: A Need for Cultural Change in the UK Construction Industry. J. Build. Eng. 2016, 5, 185–193. [Google Scholar] [CrossRef]

- European Commission. A New Circular Economy Action Plan. For a Cleaner and More Competitive Europe 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52020DC0098 (accessed on 5 June 2025).

- Skibicki, S.; Federowicz, K.; Hoffmann, M.; Chougan, M.; Sibera, D.; Cendrowski, K.; Techman, M.; Pacheco, J.N.; Liard, M.; Sikora, P. Potential of Reusing 3D Printed Concrete (3DPC) Fine Recycled Aggregates as a Strategy towards Decreasing Cement Content in 3DPC. Materials 2024, 17, 2580. [Google Scholar] [CrossRef] [PubMed]

- Bernardo, M.; Gomes, M.C.; de Brito, J. Demolition Waste Generation for Development of a Regional Management Chain Model. Waste Manag. 2016, 49, 156–169. [Google Scholar] [CrossRef]

- Singh, A.; Miao, X.; Zhou, X.; Deng, Q.; Li, J.; Zou, S.; Duan, Z. Use of Recycled Fine Aggregates and Recycled Powders in Sustainable Recycled Concrete. J. Build. Eng. 2023, 77, 107370. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of Concrete Incorporating Fine Recycled Aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical Behaviour of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability Performance of Concrete Made with Fine Recycled Concrete Aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D Concrete Printing for Sustainable and Economical Construction: A Comparative Study. Autom. Constr. 2022, 134, 104087. [Google Scholar] [CrossRef]

- Venugopal Reddy, P.; Nakkeeran, G.; Roy, D.; Alaneme, G.U. Evaluating the Use of Recycled Fine Aggregates in 3D Printing: A Systematic Review. Discov. Appl. Sci. 2024, 6, 630. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A Critical Review of the Use of 3-D Printing in the Construction Industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Aquino Rocha, J.H.; Toledo Filho, R.D. The Utilization of Recycled Concrete Powder as Supplementary Cementitious Material in Cement-Based Materials: A Systematic Literature Review. J. Build. Eng. 2023, 76, 107319. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Wang, Y. Hardened Properties of Layered 3D Printed Concrete with Recycled Sand. Cem. Concr. Compos. 2020, 113, 103724. [Google Scholar] [CrossRef]

- Xiao, J.; Zou, S.; Yu, Y.; Wang, Y.; Ding, T.; Zhu, Y.; Yu, J.; Li, S.; Duan, Z.; Wu, Y.; et al. 3D Recycled Mortar Printing: System Development, Process Design, Material Properties and on-Site Printing. J. Build. Eng. 2020, 32, 101779. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, C.; Liu, H.; Zhang, Z.; He, C.; Liu, S.; Zhang, R.; Wang, Y.; Bai, G. Study on the Rheology and Buildability of 3D Printed Concrete with Recycled Coarse Aggregates. J. Build. Eng. 2021, 42, 103030. [Google Scholar] [CrossRef]

- Rahul, A.V.; Mohan, M.K.; De Schutter, G.; Van Tittelboom, K. 3D Printable Concrete with Natural and Recycled Coarse Aggregates: Rheological, Mechanical and Shrinkage Behaviour. Cem. Concr. Compos. 2022, 125, 104311. [Google Scholar] [CrossRef]

- Duan, Z.; Hou, S.; Xiao, J.; Singh, A. Rheological Properties of Mortar Containing Recycled Powders from Construction and Demolition Wastes. Constr. Build. Mater. 2020, 237, 117622. [Google Scholar] [CrossRef]

- Hou, S.; Xiao, J.; Duan, Z.; Ma, G. Fresh Properties of 3D Printed Mortar with Recycled Powder. Constr. Build. Mater. 2021, 309, 125186. [Google Scholar] [CrossRef]

- Zhang, H.; Xiao, J.; Duan, Z.; Zou, S.; Xia, B. Effects of Printing Paths and Recycled Fines on Drying Shrinkage of 3D Printed Mortar. Constr. Build. Mater. 2022, 342, 128007. [Google Scholar] [CrossRef]

- Cavalcante, T.C.; Filho, R.D.T.; Reales, O.A.M. Rheological and Environmental Implications of Recycled Concrete Powder as Filler in Concrete 3D Printing. Buildings 2025, 15, 1280. [Google Scholar] [CrossRef]

- Qian, H.; Hua, S.; Yue, H.; Feng, G.; Qian, L.; Jiang, W.; Zhang, L. Utilization of Recycled Construction Powder in 3D Concrete Printable Materials through Particle Packing Optimization. J. Build. Eng. 2022, 61, 105236. [Google Scholar] [CrossRef]

- Robayo–Salazar, R.; Vargas, A.; Martínez, F.; Mejía de Gutiérrez, R. Utilization of Powders and Fine Aggregates from the Recycling of Construction and Demolition Waste in the 3D Printing of Portland-Based Cementitious Materials. Clean. Mater. 2024, 11, 100234. [Google Scholar] [CrossRef]

- Xiao, J.; Zou, S.; Ding, T.; Duan, Z.; Liu, Q. Fiber-Reinforced Mortar with 100% Recycled Fine Aggregates: A Cleaner Perspective on 3D Printing. J. Clean. Prod. 2021, 319, 128720. [Google Scholar] [CrossRef]

- EN 197-1:2011; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. iTeh, Inc.: Newark, DE, USA, 2011.

- Marmash, B.; Elliott, K. The Properties of Recycled Precast Concrete Hollow Core Slabs for Use as Replacement Aggregate in Concrete. In Waste Management Series; Woolley, G.R., Goumans, J.J.J.M., Wainwright, P.J., Eds.; Waste Materials in Construction Wascon 2000; Elsevier: Amsterdam, The Netherlands, 2000; Volume 1, pp. 769–781. [Google Scholar]

- Pacheco, J.; de Brito, J. Recycled Aggregates Produced from Construction and Demolition Waste for Structural Concrete: Constituents, Properties and Production. Materials 2021, 14, 5748. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of Fine Recycled Concrete Aggregates in Concrete: A Critical Review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Chougan, M.; Marotta, E.; Lamastra, F.R.; Vivio, F.; Montesperelli, G.; Ianniruberto, U.; Bianco, A. A Systematic Study on EN-998-2 Premixed Mortars Modified with Graphene-Based Materials. Constr. Build. Mater. 2019, 227, 116701. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Advances in Rheological Measurement and Characterization of Fresh Cement Pastes. Powder Technol. 2023, 429, 118903. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Evaluation of Rheo-Viscoelasticity of Magnesium-Silicate-Hydrate Mixes Incorporating Different Superplasticizers. Dev. Built Environ. 2024, 20, 100544. [Google Scholar] [CrossRef]

- EN 12390-15:2019; Testing Hardened Concrete—Part 15: Adiabatic Method for the Determination of Heat Released by Concrete During Its Hardening Process. iTeh, Inc.: Newark, DE, USA, 2019.

- EN 12390-14:2018; Testing Hardened Concrete—Part 14: Semi-Adiabatic Method for the Determination of Heat Released by Concrete During Its Hardening Process. iTeh, Inc.: Newark, DE, USA, 2018.

- EN 196-11:2018; Methods of Testing Cement—Part 11: Heat of Hydration—Isothermal Conduction Calorimetry Method. iTeh, Inc.: Newark, DE, USA, 2018.

- EN 1015-3:1999/A2:2006; Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). iTeh, Inc.: Newark, DE, USA, 2006.

- Perrot, A.; Rangeard, D.; Pierre, A. Structural Built-up of Cement-Based Materials Used for 3D-Printing Extrusion Techniques. Mater. Struct. 2016, 49, 1213–1220. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Hardened Properties of 3D Printed Concrete: The Influence of Process Parameters on Interlayer Adhesion. Cem. Concr. Res. 2019, 119, 132–140. [Google Scholar] [CrossRef]

- Federowicz, K.; Cendrowski, K.; Sikora, P. Low-Carbon Cementitious Composite Incorporated with Biochar and Recycled Fines Suitable for 3D Printing Applications: Hydration, Shrinkage and Early-Age Performance. Frat. Integrita. Strutr. 2025, 19, 91–107. [Google Scholar] [CrossRef]

- EN 1015-11:1999/A1:2006; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. iTeh, Inc.: Newark, DE, USA, 2006.

- EN 12390-13:2013; Testing Hardened Concrete—Part 13: Determination of Secant Modulus of Elasticity in Compression. iTeh, Inc.: Newark, DE, USA, 2013.

- ASTM C666-97; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM International: West Conshohocken, PA, USA, 2017.

- Sikora, P.; Techman, M.; Federowicz, K.; El-Khayatt, A.M.; Saudi, H.A.; Abd Elrahman, M.; Hoffmann, M.; Stephan, D.; Chung, S.-Y. Insight into the Microstructural and Durability Characteristics of 3D Printed Concrete: Cast versus Printed Specimens. Case Stud. Constr. Mater. 2022, 17, e01320. [Google Scholar] [CrossRef]

- EN 12390-6:2009; Testing Hardened Concrete—Part 6: Tensile Splitting Strength of Test Specimens. iTeh, Inc.: Newark, DE, USA, 2009.

- ISO/ASTM 52939:2023; Additive Manufacturing for Construction—Qualification Principles—Structural and Infrastructure Elements. ISO: London, UK, 2023.

- Chougan, M.; Skibicki, S.; Al-Noaimat, Y.A.; Federowicz, K.; Hoffmann, M.; Sibera, D.; Cendrowski, K.; Techman, M.; Nuno Pacheco, J.; Ghaffar, S.H.; et al. Comparative Analysis of Ternary Blended Cement with Clay and Engineering Brick Aggregate for High-Performance 3D Printing. Dev. Built Environ. 2024, 20, 100529. [Google Scholar] [CrossRef]

- Chotard, T.J.; Boncoeur-Martel, M.P.; Smith, A.; Dupuy, J.P.; Gault, C. Application of X-Ray Computed Tomography to Characterise the Early Hydration of Calcium Aluminate Cement. Cem. Concr. Compos. 2003, 25, 145–152. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef]

- European Commission. The European Green Deal 2019. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 5 June 2025).

- Cembureau. The European Cement Association Cementing the European Green Deal, Reaching Climate Neutrality Along the Cement and Concrete Value Chain by 2050. 2020. Available online: https://cembureau.eu/media/kuxd32gi/cembureau-2050-roadmap_final-version_web.pdf (accessed on 5 June 2025).

- GCCA. Concrete Future: The GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete. Global Cement and Concrete Association. Available online: https://gccassociation.org/concretefuture/ (accessed on 5 June 2025).

- Dias, A.B.; Pacheco, J.N.; Silvestre, J.D.; Martins, I.M.; de Brito, J. Environmental and Economic Life Cycle Assessment of Recycled Coarse Aggregates: A Portuguese Case Study. Materials 2021, 14, 5452. [Google Scholar] [CrossRef]

- Ioannidou, D.; Meylan, G.; Sonnemann, G.; Habert, G. Is Gravel Becoming Scarce? Evaluating the Local Criticality of Construction Aggregates. Resour. Conserv. Recycl. 2017, 126, 25–33. [Google Scholar] [CrossRef]

- EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. iTeh, Inc.: Newark, DE, USA, 2009.

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared Environmental and Economic Impact from Cradle to Gate of Concrete with Natural and Recycled Coarse Aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Bistyp. Informative Price List of Building Materials. Estimated Labor and Equipment Rental Rates. 3rd Quarter of the Year 2023; Bistyp: Warsaw, Poland, 2023. [Google Scholar]

- Swiss Centre for Life Cycle Inventories. Ecoinvent LCA Database v3.8; Swiss Centre for Life Cycle Inventories: Zurich, Switzerland, 2023. [Google Scholar]

- CEMBUREAU. Environmental Product Declaration (EPD) According to EN 15804 and ISO 14025: Portland Cement (CEM I) Produced in Europe; CEMBUREAU: Brussels, Belgium, 2020. [Google Scholar]

- Teixeira, E.R.; Mateus, R.; Camões, A.F.; Bragança, L.; Branco, F.G. Comparative Environmental Life-Cycle Analysis of Concretes Using Biomass and Coal Fly Ashes as Partial Cement Replacement Material. J. Clean. Prod. 2016, 112, 2221–2230. [Google Scholar] [CrossRef]

- Hájek, P.; Fiala, C.; Kynčlová, M. Life Cycle Assessments of Concrete Structures—A Step towards Environmental Savings. Struct. Concr. 2011, 12, 13–22. [Google Scholar] [CrossRef]

- Semtrio Sustainability Consulting. Environmental Product Declaration in Accordance with ISO 14025 & EN 15804:2012 + A2:2019, S-P-04127: Polymacro from Polyfibres; EPDTurkey: İstanbul, Türkiye, 2022. [Google Scholar]

- Kurda, R.M.S. Sustainable Development of Cement-Based Materials: Application to Recycled Aggregates Concrete. Ph.D. Thesis, Instituto Superior Técnico, Lisbon, Portugal, 2017. Available online: https://scholar.tecnico.ulisboa.pt/records/4Lg24hlX61779gwlzXYsGF0GI01lA5utvCQw (accessed on 5 June 2025).

- EPDItaly. Environmental Product Declaration in Accordance with ISO 14025 and EN 15804:2012+ A2:2019 for Aggregato Riciclato—CIAT, S.P.A.; EPDItaly: Milano, Italy, 2023. [Google Scholar]

- EPDIAustralasia. Environmental Product Declaration in Accordance with ISO 14025 and EN 15804:2012+ A2:2019 for Recycled Crushed Concrete Aggregates from Green Vision Recycling; EPDIAustralasia: Sydney, Australia, 2022. [Google Scholar]

- GlobalEPD. Declaración Ambiental de Producto: ISO 14025:2010 and EN 15804:2012+ A2:2020 for Áridos Reciclados for Federación de Áridos; GlobalEPD: Madrid, Spain, 2022. [Google Scholar]

- EPD International AB. Environmental Product Declaration in Accordance with ISO 14025 and EN 15804:2012+ A2:2019 for Recycled Aggregate Products from Argent Materials Inc.; EPD International AB: Stockholm, Sweden, 2021. [Google Scholar]

- EPD Ireland. Environmental Product Declaration as per ISO 14025 and EN 15804 + A1: Recycled Aggregates from Greenstone Recycling. IMS Site Services Ltd; EPD Ireland: Dublin, Ireland, 2020. [Google Scholar]

- SÜGB. Environmental Product Declaration According to ISO 14025 and EN 15804: Average EPD for Aggregates. Owner of the Declaration: Association of the Swiss Aggregate and Concrete Industry (ASAC); SÜGB: Bern, Switzerland, 2018. [Google Scholar]

- Della. Della—Truck Transport 2024. Available online: https://della.eu/ (accessed on 5 June 2025).

- Deng, X.; Li, J.; Lu, Z.; Zhang, J.; Luo, K.; Niu, Y.; Hu, J.; He, K. Rheological and Early Hydration of Cementitious Material Containing Recycled Concrete Powders Collected from Recycled Aggregates. Constr. Build. Mater. 2023, 393, 132108. [Google Scholar] [CrossRef]

- Zou, S.; Xiao, J.; Duan, Z.; Ding, T.; Hou, S. On Rheology of Mortar with Recycled Fine Aggregate for 3D Printing. Constr. Build. Mater. 2021, 311, 125312. [Google Scholar] [CrossRef]

- Li, Z.; Bian, Y.; Zhao, J.; Wang, Y.; Yuan, Z. Recycled Concrete Fine Powder (RFP) as Cement Partial Replacement: Influences on the Physical Properties, Hydration Characteristics, and Microstructure of Blended Cement. J. Build. Eng. 2022, 62, 105326. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability Region for 3D Concrete Printing Using Slump and Slump Flow Test. Compos. Part B: Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Qin, F.; Duan, Z. Mechanical Behavior of 3D Printed Mortar with Recycled Sand at Early Ages. Constr. Build. Mater. 2020, 248, 118654. [Google Scholar] [CrossRef]

- Skibicki, S.; Jakubowska, P.; Kaszyńska, M.; Sibera, D.; Cendrowski, K.; Hoffmann, M. Early-Age Mechanical Properties of 3D-Printed Mortar with Spent Garnet. Materials 2022, 15, 100. [Google Scholar] [CrossRef]

- Federowicz, K.; Kaszyńska, M.; Zieliński, A.; Hoffmann, M. Effect of Curing Methods on Shrinkage Development in 3D-Printed Concrete. Materials 2020, 13, 2590. [Google Scholar] [CrossRef] [PubMed]

- Shakor, P.; Nejadi, S.; Sutjipto, S.; Paul, G.; Gowripalan, N. Effects of Deposition Velocity in the Presence/Absence of E6-Glass Fibre on Extrusion-Based 3D Printed Mortar. Addit. Manuf. 2020, 32, 101069. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.F.; Thorpe, T. Hardened Properties of High-Performance Printing Concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Paul, S.C.; Tay, Y.W.D.; Panda, B.; Tan, M.J. Fresh and Hardened Properties of 3D Printable Cementitious Materials for Building and Construction. Arch. Civ. Mech. Eng. 2018, 18, 311–319. [Google Scholar] [CrossRef]

- Nerella, V.N.; Mechtcherine, V. Chapter 16—Studying the Printability of Fresh Concrete for Formwork-Free Concrete Onsite 3D Printing Technology (CONPrint3D). In 3D Concrete Printing Technology; Sanjayan, J.G., Nazari, A., Nematollahi, B., Eds.; Butterworth-Heinemann: Oxford, UK, 2019; pp. 333–347. ISBN 978-0-12-815481-6. [Google Scholar]

- Zhang, Y.; Zhang, Y.; Yang, L.; Liu, G.; Chen, Y.; Yu, S.; Du, H. Hardened Properties and Durability of Large-Scale 3D Printed Cement-Based Materials. Mater. Struct. 2021, 54, 45. [Google Scholar] [CrossRef]

- Bradshaw, J.; Si, W.; Khan, M.; McNally, C. Emerging Insights into the Durability of 3D-Printed Concrete: Recent Advances in Mix Design Parameters and Testing. Designs 2025, 9, 85. [Google Scholar] [CrossRef]

- Oh, S.-E.; Kim, J.-S.; Maeng, S.K.; Oh, S.; Chung, S.-Y. Influence of Bacterial Biomineralization Conditions on the Microstructural Characteristics of Cement Mortar. J. Build. Eng. 2024, 91, 109455. [Google Scholar] [CrossRef]

- Kleijer, A.L.; Lasvaux, S.; Citherlet, S.; Viviani, M. Product-Specific Life Cycle Assessment of Ready Mix Concrete: Comparison between a Recycled and an Ordinary Concrete. Resour. Conserv. Recycl. 2017, 122, 210–218. [Google Scholar] [CrossRef]

| Material | M0F | RAC0 | RAC-50 | RAC-100 |

|---|---|---|---|---|

| kg/m3 | ||||

| Cement CEM I 42.5R | 580 | 522 | 522 | 522 |

| Fly ash | 166 | 166 | 166 | 166 |

| Silica fume | 83 | 83 | 83 | 83 |

| fNA (river sand) | 1300 | 1300 | 650 | - |

| RCP | - | 48.2 | 48.2 | 48.2 |

| fRA | - | - | 644 | 1289 |

| Superplasticizer | 2.70 | 2.70 | 2.70 | 2.70 |

| Glass fibres 6 mm | 3.86 | 3.86 | 3.86 | 3.86 |

| Effective water | 200 | 200 | 200 | 200 |

| Compensation water | - | - | 46.75 | 93.51 |

| Property | fNA | fRA |

|---|---|---|

| —Apparent particle density (kg/m3) | 2650 | 2682 |

| —Oven-dried particle density (kg/m3) | 2620 | 2246 |

| —Saturated and surface-dried particle density (kg/m3) | 2630 | 2408 |

| WA24—Water absorption 24 h | 0.40% | 7.25% |

| Raw Material | Cement | Fly Ash | Silica Fume | PCE | Water | Fibres | Sand | fRA | RCP |

|---|---|---|---|---|---|---|---|---|---|

| GWP (kg.CO2eq./ton) | 803 [59] | 0.01 [60] | 1.22 [61] | 2732 [58] | 0.246 [58] | 3240 [62] | 2.44 [58] | 1.14 See below | 1.14 See below |

| Cost (€/ton) | 124 [57] | 0.22 [57] | 299 [57] | 8817 [57] | 0.31 [57] | 7621 [57] | 13.2 [57] | 2.0 [63] | 2.0 [63] |

| Value | M0F | RAC0 | RAC50 | RAC100 |

|---|---|---|---|---|

| C (J/kg·K) | 1093.4 | 1094.1 | 1144.9 | 1191.9 |

| Δt (C) | 55.6 | 53.9 | 50.1 | 48.6 |

| Q(t) J/kg | 60,794.5 | 58,972 | 57,360.1 | 57,928 |

| Mix | Dynamic Yield Stress (τ0) [Pa] | Plastic Viscosity (ηp) [Pa.s] | Correlation Coefficient (R2) | Thixotropic Recovery [%] |

|---|---|---|---|---|

| M0F | 336.1 | 9.1 | 0.9896 | 71.91 |

| RAC0 | 262.8 | 9.6 | 0.99447 | 78.75 |

| RAC50 | 209.8 | 13.1 | 0.9942 | 51.49 |

| RAC100 | 212.7 | 17.2 | 0.99481 | 43.09 |

| Mix | RAC100 | RAC50 | RAC0 | M0F |

|---|---|---|---|---|

| height [cm] | 52 | 53 | 35 | 33 |

| height [no. of layers] | 36 | 37 | 25 | 23 |

| mean value of layer thickness [cm] | 1.44 | 1.43 | 1.40 | 1.43 |

| M0F | RAC0 | RAC50 | RAC100 | |

|---|---|---|---|---|

| Cast | 14.58% | 10.98% | 12.91% | 13.77% |

| Printed | 22.63% | 20.34% | 21.12% | 26.69% |

| Raw Material | Cement | Fly Ash | Silica Fume | PCE | Water | Fibres | Sand | fRA | RCP |

|---|---|---|---|---|---|---|---|---|---|

| Location | Chorula | Dolna Odra | Warsaw | Stuttgart | Szczecin | Gdańsk | Bielinek | Szczecin | Szczecin |

| Distance (km) | 480 | 55 | 570 | 791 | 0 | 369 | 70 | 0 | 0 |

| 3DPC | Content of RCP (kg/kg) | Content of fRA (kg/kg) | Content of fRA + RCP (kg/kg) |

|---|---|---|---|

| M0F | 0% | 0% | 0% |

| RAC0 | 2% | 0% | 2% |

| RAC50 | 2% | 27% | 29% |

| RAC100 | 2% | 53% | 55% |

| Mix | Cost (EUR/m3) | GWP (kgCO2eq./m3) | ||||

|---|---|---|---|---|---|---|

| A1 | A2 | Total | A1 | A2 | Total | |

| M0F | 166.3 | 35.0 | 201.3 | 488.7 | 29.2 | 517.9 |

| RAC0 | 159.2 | 32.7 | 192.0 | 442.2 | 27.3 | 469.5 |

| RAC50 | 151.9 | 29.0 | 181.0 | 440.7 | 24.2 | 464.9 |

| RAC100 | 144.6 | 25.3 | 169.9 | 439.2 | 21.1 | 460.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikora, P.; Federowicz, K.; Skibicki, S.; Techman, M.; Hoffmann, M.; Pacheco, J.N.; Chougan, M.; Grochała, D.; Cendrowski, K.; Sibera, D.; et al. Demonstration of 3D-Printed Concrete Containing Fine Recycled Concrete Aggregates (fCAs) and Recycled Concrete Powder (RCP): Rheology, Early-Age, Shrinkage, Mechanical, and Durability Performance. Buildings 2025, 15, 4255. https://doi.org/10.3390/buildings15234255

Sikora P, Federowicz K, Skibicki S, Techman M, Hoffmann M, Pacheco JN, Chougan M, Grochała D, Cendrowski K, Sibera D, et al. Demonstration of 3D-Printed Concrete Containing Fine Recycled Concrete Aggregates (fCAs) and Recycled Concrete Powder (RCP): Rheology, Early-Age, Shrinkage, Mechanical, and Durability Performance. Buildings. 2025; 15(23):4255. https://doi.org/10.3390/buildings15234255

Chicago/Turabian StyleSikora, Pawel, Karol Federowicz, Szymon Skibicki, Mateusz Techman, Marcin Hoffmann, Joao Nuno Pacheco, Mehdi Chougan, Daniel Grochała, Krzysztof Cendrowski, Daniel Sibera, and et al. 2025. "Demonstration of 3D-Printed Concrete Containing Fine Recycled Concrete Aggregates (fCAs) and Recycled Concrete Powder (RCP): Rheology, Early-Age, Shrinkage, Mechanical, and Durability Performance" Buildings 15, no. 23: 4255. https://doi.org/10.3390/buildings15234255

APA StyleSikora, P., Federowicz, K., Skibicki, S., Techman, M., Hoffmann, M., Pacheco, J. N., Chougan, M., Grochała, D., Cendrowski, K., Sibera, D., Błyszko, J., Budziński, B., Lin, G., & Ludwiczak-Sarzała, A. (2025). Demonstration of 3D-Printed Concrete Containing Fine Recycled Concrete Aggregates (fCAs) and Recycled Concrete Powder (RCP): Rheology, Early-Age, Shrinkage, Mechanical, and Durability Performance. Buildings, 15(23), 4255. https://doi.org/10.3390/buildings15234255