Enabling Real-Time Mechanical Analysis in Digital Twin Systems: A Study on Multi-Source Heterogeneous Data Fusion via Midas Civil Integration

Abstract

1. Introduction

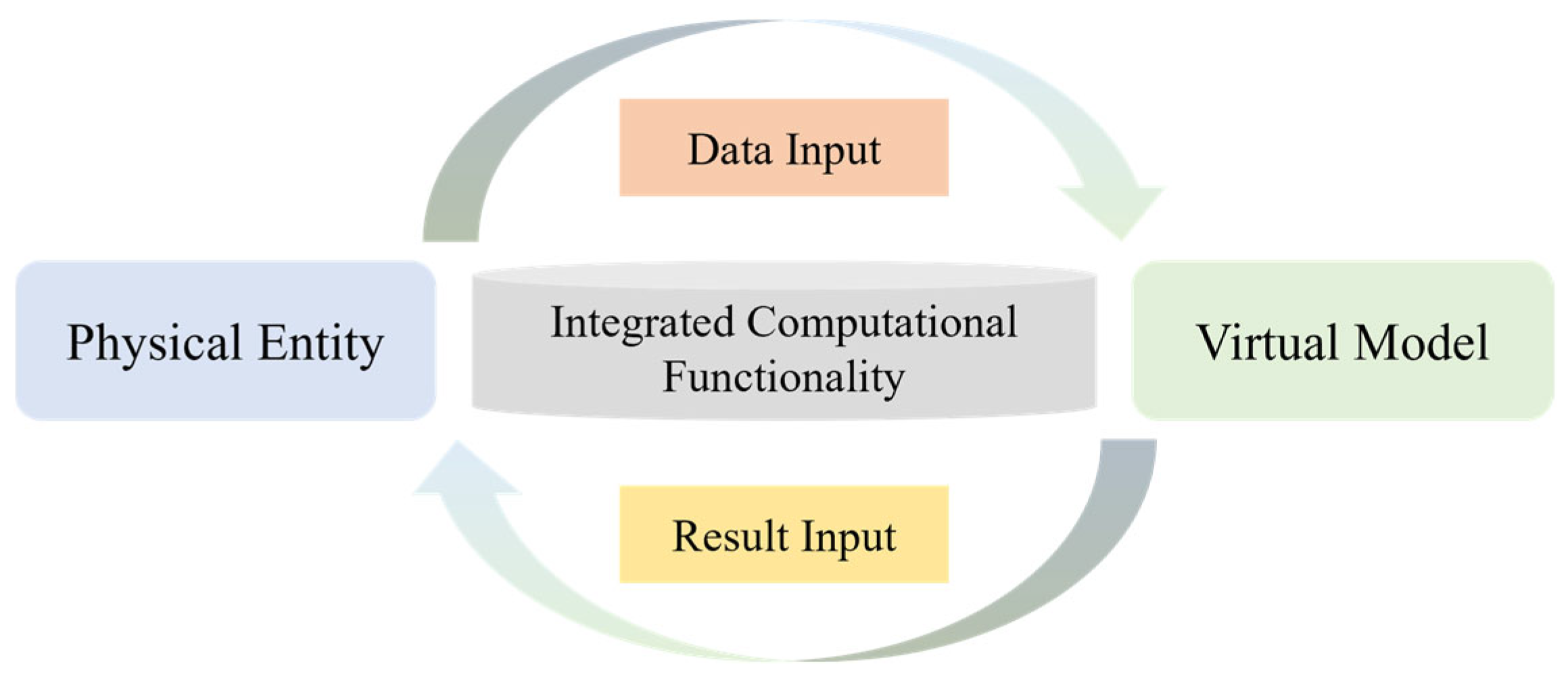

2. Digital Twin System

2.1. Experimental Study

2.2. Data Structure Development for Digital Twin Systems

3. Integration of Mechanical Calculation Functions in Digital Twin Systems

3.1. System Architecture

3.2. Key Technologies in Digital Twins and Methods for Integrating Mechanical Analysis Functions

4. Case Studies

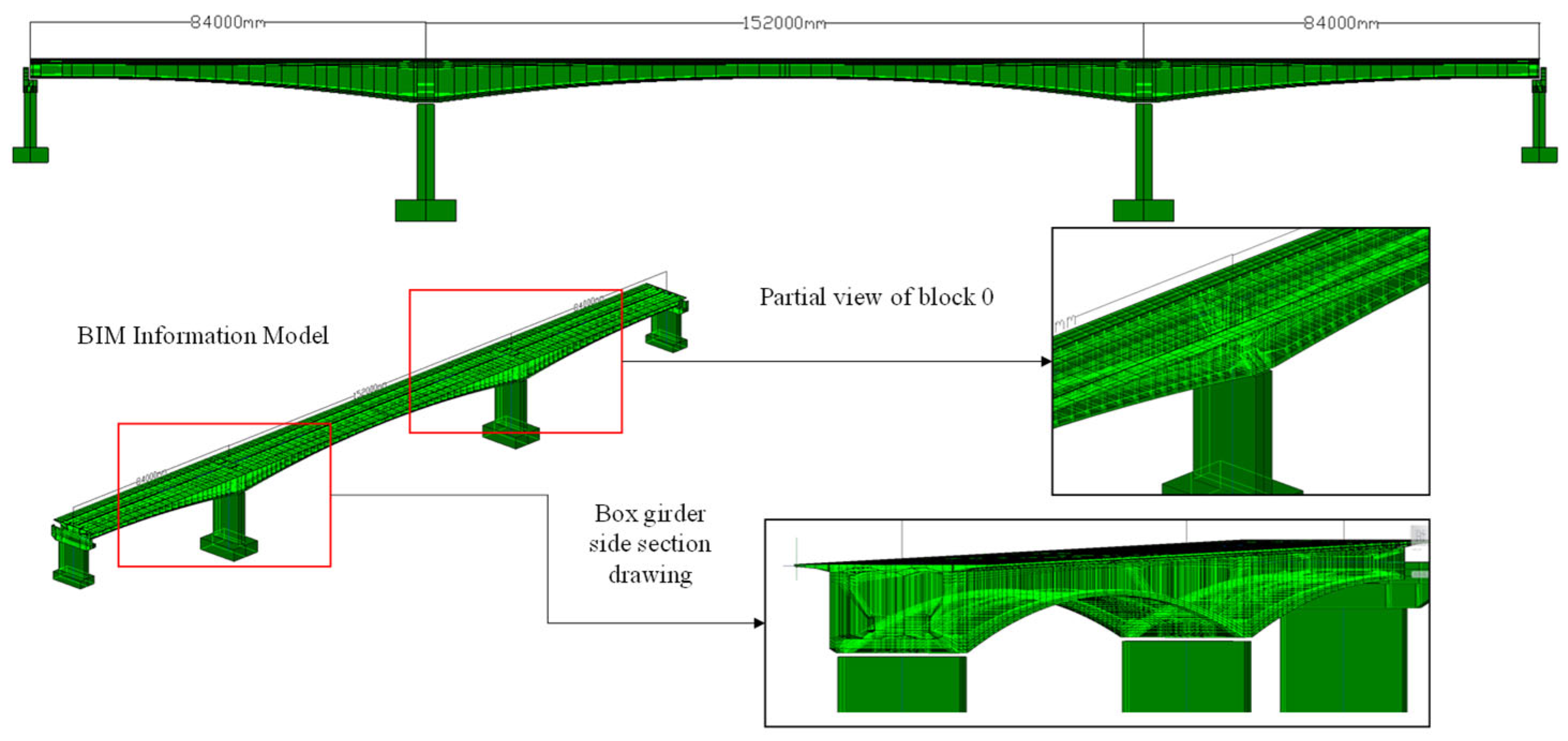

4.1. Continuous Beam Bridge Digital Twin Modeling

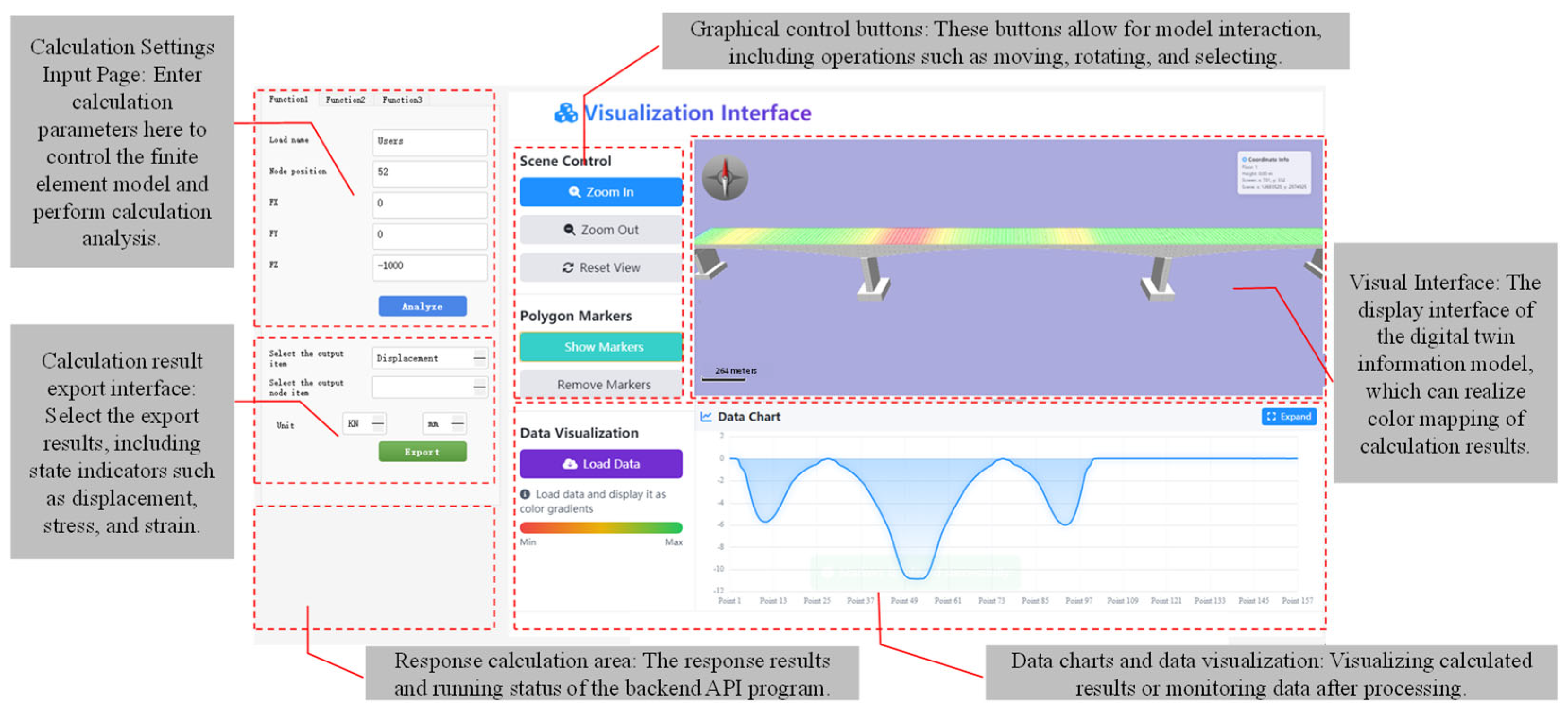

4.2. Dynamic Data Interaction and Real-Time Mechanical Analysis Calculation

5. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, Y.; Taib, N. Cloud-based Building Information Modelling (Cloud-BIM): Systematic literature review and Bibliometric-qualitative Analysis. Autom. Constr. 2022, 142, 104468. [Google Scholar] [CrossRef]

- Grieves, M. Origins of the Digital Twin Concept; Florida Institute of Technology/NASA: Melbourne, FL, USA, 2016. [Google Scholar]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, characterization and implementation. Decis. Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Li, L.; Aslam, S.; Wileman, A.; Perinpanayagam, S. Digital Twin in Aerospace Industry: A Gentle Introduction. IEEE Access 2022, 10, 9543–9562. [Google Scholar] [CrossRef]

- Sun, T.; He, X.; Li, Z. Digital twin in healthcare: Recent updates and challenges. Digit. Health 2023, 9, 20552076221149651. [Google Scholar] [CrossRef] [PubMed]

- Pesantez, J.E.; Alghamdi, F.; Sabu, S.; Mahinthakumar, G.; Berglund, E.Z. Using a digital twin to explore water infrastructure impacts during the COVID-19 pandemic. Sustain. Cities Soc. 2022, 77, 103520. [Google Scholar] [CrossRef] [PubMed]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Madubuike, O.C.; Anumba, C.J.; Khallaf, R. A review of digital twin applications in construction. J. Inf. Technol. Constr. 2022, 27, 145–172. [Google Scholar] [CrossRef]

- Hadjidemetriou, L.; Stylianidis, N.; Englezos, D.; Papadopoulos, P.; Eliades, D.; Timotheou, S.; Polycarpou, M.M.; Panayiotou, C. A digital twin architecture for real-time and offline high granularity analysis in smart buildings. Sustain. Cities Soc. 2023, 98, 104795. [Google Scholar] [CrossRef]

- Weil, C.; Bibri, S.E.; Longchamp, R.; Golay, F.; Alahi, A. Urban Digital Twin Challenges: A Systematic Review and Perspectives for Sustainable Smart Cities. Sustain. Cities Soc. 2023, 99, 104862. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, G.; Tian, W.; Mei, X.; Nee, A.Y.C.; Ong, S.K. Microservice-based digital twin system towards smart manufacturing. Robot. Comput.-Integr. Manuf. 2025, 91, 102858. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, Y.; Zhu, H.; Sumarac, D.; Cao, M. Digital Twin-Driven Intelligent Construction: Features and Trends. Struct. Durab. Health Monit. 2021, 15, 183–206. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Hui, F.K.P.; Shirowzhan, S.; Foroozanfar, M.; Yang, L.; Aye, L. Lean Practices Using Building Information Modeling (BIM) and Digital Twinning for Sustainable Construction. Sustainability 2020, 13, 161. [Google Scholar] [CrossRef]

- Liu, Z.; Li, A.; Sun, Z.; Shi, G.; Meng, X. Digital Twin-Based Risk Control during Prefabricated Building Hoisting Operations. Sensors 2022, 22, 2522. [Google Scholar] [CrossRef] [PubMed]

- Reja, V.K.; Varghese, K.; Ha, Q.P. Computer vision-based construction progress monitoring. Autom. Constr. 2022, 138, 104245. [Google Scholar] [CrossRef]

- Zhao, Y.; Cao, C.; Liu, Z. A Framework for Prefabricated Component Hoisting Management Systems Based on Digital Twin Technology. Buildings 2022, 12, 276. [Google Scholar] [CrossRef]

- Wang, W.-C.; Weng, S.-W.; Wang, S.-H.; Chen, C.-Y. Integrating building information models with construction process simulations for project scheduling support. Autom. Constr. 2014, 37, 68–80. [Google Scholar] [CrossRef]

- González-Böhme, L.F.; Valenzuela-Astudillo, E. Mixed Reality for Safe and Reliable Human-Robot Collaboration in Timber Frame Construction. Buildings 2023, 13, 1965. [Google Scholar] [CrossRef]

- Wang, X.; Liu, C.; Song, X.; Cui, X. Development of an Internet-of-Things-Based Technology System for Construction Safety Hazard Prevention. J. Manag. Eng. 2022, 38, 04022009. [Google Scholar] [CrossRef]

- Kamari, M.; Ham, Y. AI-based risk assessment for construction site disaster preparedness through deep learning-based digital twinning. Autom. Constr. 2022, 134, 104091. [Google Scholar] [CrossRef]

- Liu, J.; Duan, L.; Lin, S.; Miao, J.; Zhao, J. Concept, Creation, Services and Future Directions of Digital Twins in the Construction Industry: A Systematic Literature Review. Arch. Comput. Methods Eng. 2024, 32, 319–342. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, S.; Yoon, K. Class Abstraction and Upcasting for Self-evolving Digital Twin System. In Proceedings of the 2023 International Conference on Electronics, Information, and Communication (ICEIC), Singapore, 5–8 February 2023; pp. 1–3. [Google Scholar]

- Zhang, J.; Chen, C.; Zhang, Y.; Cui, Y.; Han, P.; Meng, N.; Xu, Y. The Framework and Practices of Digital Twin City. In Proceedings of the 2022 IEEE 12th International Conference on Electronics Information and Emergency Communication (ICEIEC), Beijing, China, 15–17 July 2022; pp. 111–116. [Google Scholar]

- Obi, T.; Iwasaki, N. Smart Government using Digital Twin in Japan. In Proceedings of the 2021 International Conference on ICT for Smart Society (ICISS), Bandung, Indonesia, 2–4 August 2021; pp. 1–4. [Google Scholar]

- Hetherington, J.; West, M.; Makri, C.; Hajj, P.B.E. The Pathway Towards an Information Management Framework; Centre for Digital Built Britain: Cambridge, UK, 2020. [Google Scholar]

- Lu, Q.; Parlikad, A.K.; Woodall, P.; Don Ranasinghe, G.; Xie, X.; Liang, Z.; Konstantinou, E.; Heaton, J.; Schooling, J. Developing a Digital Twin at Building and City Levels: Case Study of West Cambridge Campus. J. Manag. Eng. 2020, 36, 05020004. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, F.; Cai, J.; Wang, Y.; Guo, H.; Zheng, J. Digital twin and its applications: A survey. Int. J. Adv. Manuf. Technol. 2022, 123, 4123–4136. [Google Scholar] [CrossRef]

- Li, L.; Chen, T.; Kong, Q. The Study on Problems and Solutions of Digital Twin Technology Application under River Chief System. In Proceedings of the 2022 8th International Conference on Hydraulic and Civil Engineering: Deep Space Intelligent Development and Utilization Forum (ICHCE), Xi’an, China, 25–27 November 2022; pp. 647–650. [Google Scholar]

- Wang, B.; Zhang, C.; Zhang, M.; Liu, C.; Xie, Z.; Zhang, H. Digital Twin Analysis for Driving Risks Based on Virtual Physical Simulation Technology. IEEE J. Radio Freq. Identif. 2022, 6, 938–942. [Google Scholar] [CrossRef]

- Newrzella, S.R.; Franklin, D.W.; Haider, S. Methodology for Digital Twin Use Cases: Definition, Prioritization, and Implementation. IEEE Access 2022, 10, 75444–75457. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, A.-S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J.d.J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1335. [Google Scholar] [CrossRef]

- Orukele, O.; Polette, A.; Gonzalez Lorenzo, A.; Mari, J.L.; Pernot, J.P. A Data Structure for Developing Data-Driven Digital Twins. In Proceedings of the IFIP International Conference on Product Lifecycle Management, Bangkok, Thailand, 7–10 July 2024. [Google Scholar]

- Liu, S.; Lu, Y.; Zheng, P.; Shen, H.; Bao, J. Adaptive reconstruction of digital twins for machining systems: A transfer learning approach. Robot. Comput.-Integr. Manuf. 2022, 78, 102390. [Google Scholar] [CrossRef]

- Gattulli, V.; Franchi, F.; Graziosi, F.; Marotta, A.; Rinaldi, C.; Potenza, F.; Sabatino, U.D. Design and evaluation of 5G-based architecture supporting data-driven digital twins updating and matching in seismic monitoring. Bull. Earthq. Eng. 2022, 20, 4345–4365. [Google Scholar] [CrossRef]

- Van Den Brand, M.; Cleophas, L.; Gunasekaran, R.; Haverkort, B.; Negrin, D.A.M.; Muctadir, H.M. Models Meet Data: Challenges to Create Virtual Entities for Digital Twins. In Proceedings of the 2021 ACM/IEEE International Conference on Model Driven Engineering Languages and Systems Companion (MODELS-C), Fukuoka, Japan, 10–15 October 2021; pp. 225–228. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Hu, P.; Chen, M.; Liu, Z.; Song, G.; Hong, D. Enabling Real-Time Mechanical Analysis in Digital Twin Systems: A Study on Multi-Source Heterogeneous Data Fusion via Midas Civil Integration. Buildings 2025, 15, 4228. https://doi.org/10.3390/buildings15234228

Cao L, Hu P, Chen M, Liu Z, Song G, Hong D. Enabling Real-Time Mechanical Analysis in Digital Twin Systems: A Study on Multi-Source Heterogeneous Data Fusion via Midas Civil Integration. Buildings. 2025; 15(23):4228. https://doi.org/10.3390/buildings15234228

Chicago/Turabian StyleCao, Linhui, Peng Hu, Maomao Chen, Zhanghong Liu, Guquan Song, and Daosen Hong. 2025. "Enabling Real-Time Mechanical Analysis in Digital Twin Systems: A Study on Multi-Source Heterogeneous Data Fusion via Midas Civil Integration" Buildings 15, no. 23: 4228. https://doi.org/10.3390/buildings15234228

APA StyleCao, L., Hu, P., Chen, M., Liu, Z., Song, G., & Hong, D. (2025). Enabling Real-Time Mechanical Analysis in Digital Twin Systems: A Study on Multi-Source Heterogeneous Data Fusion via Midas Civil Integration. Buildings, 15(23), 4228. https://doi.org/10.3390/buildings15234228