Optimisation of Sunflower Husk Ash-Activated Slag Binder

Abstract

1. Introduction

2. Experimental Programme

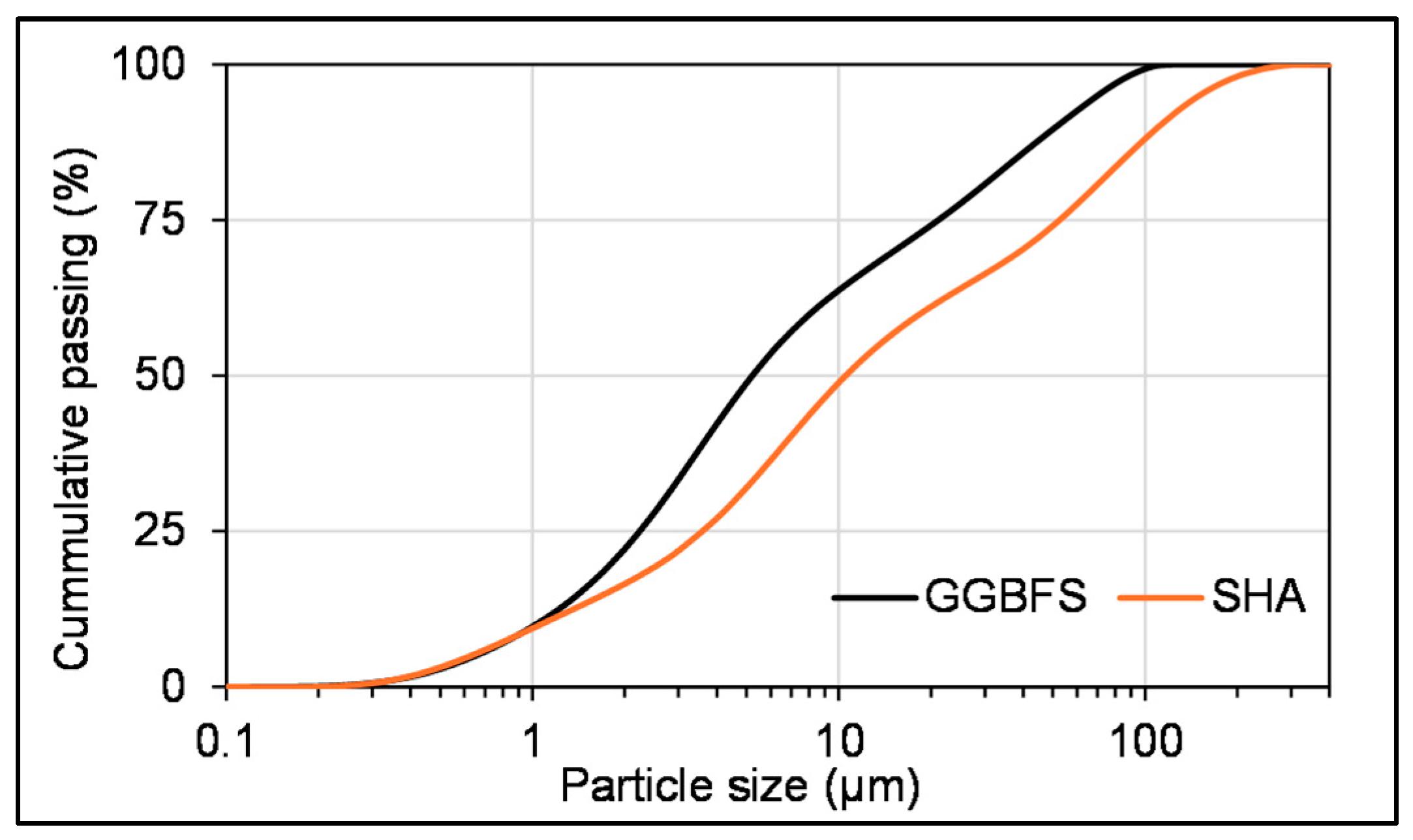

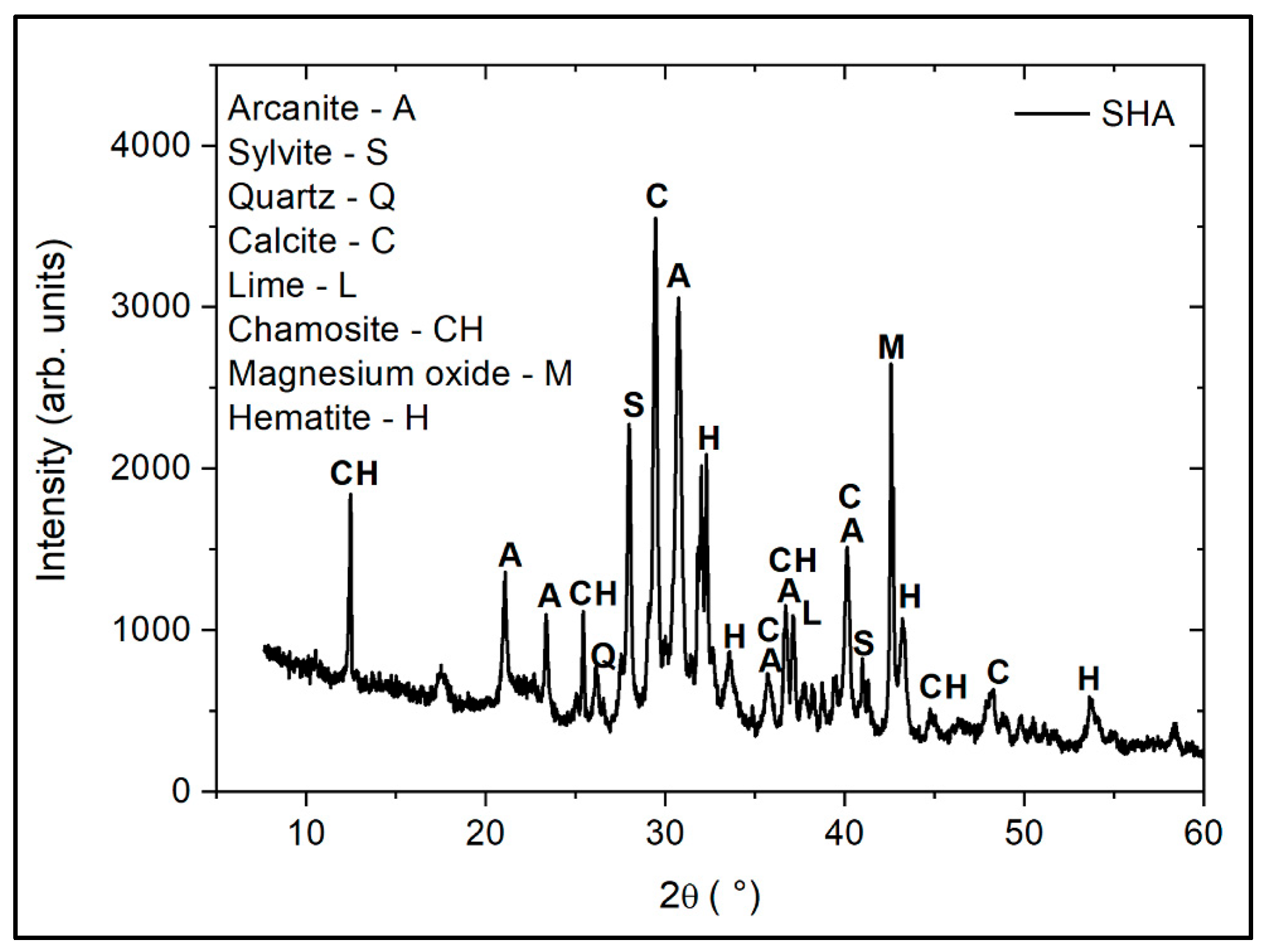

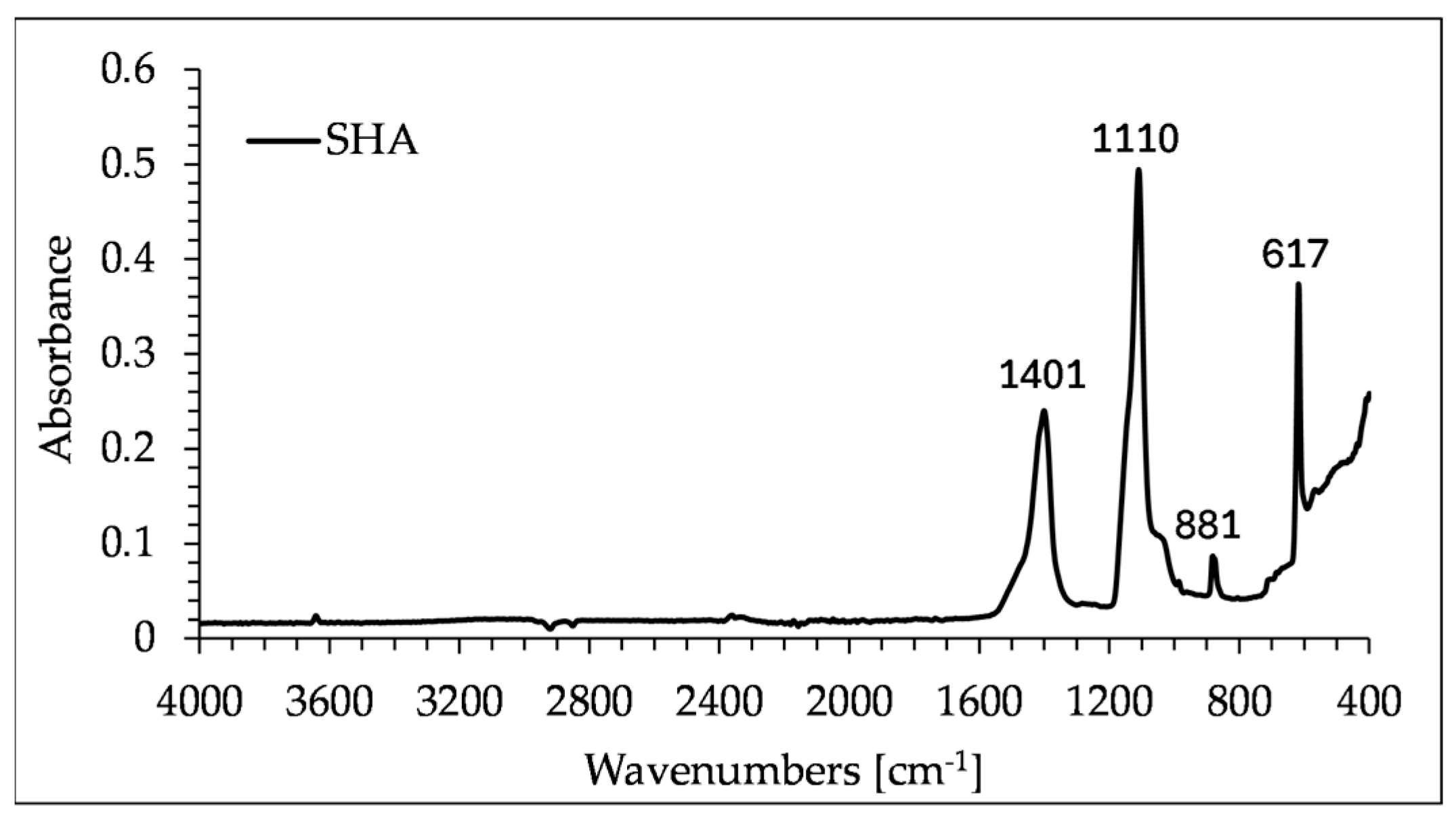

2.1. Materials

2.2. Mix Design

2.3. Methods

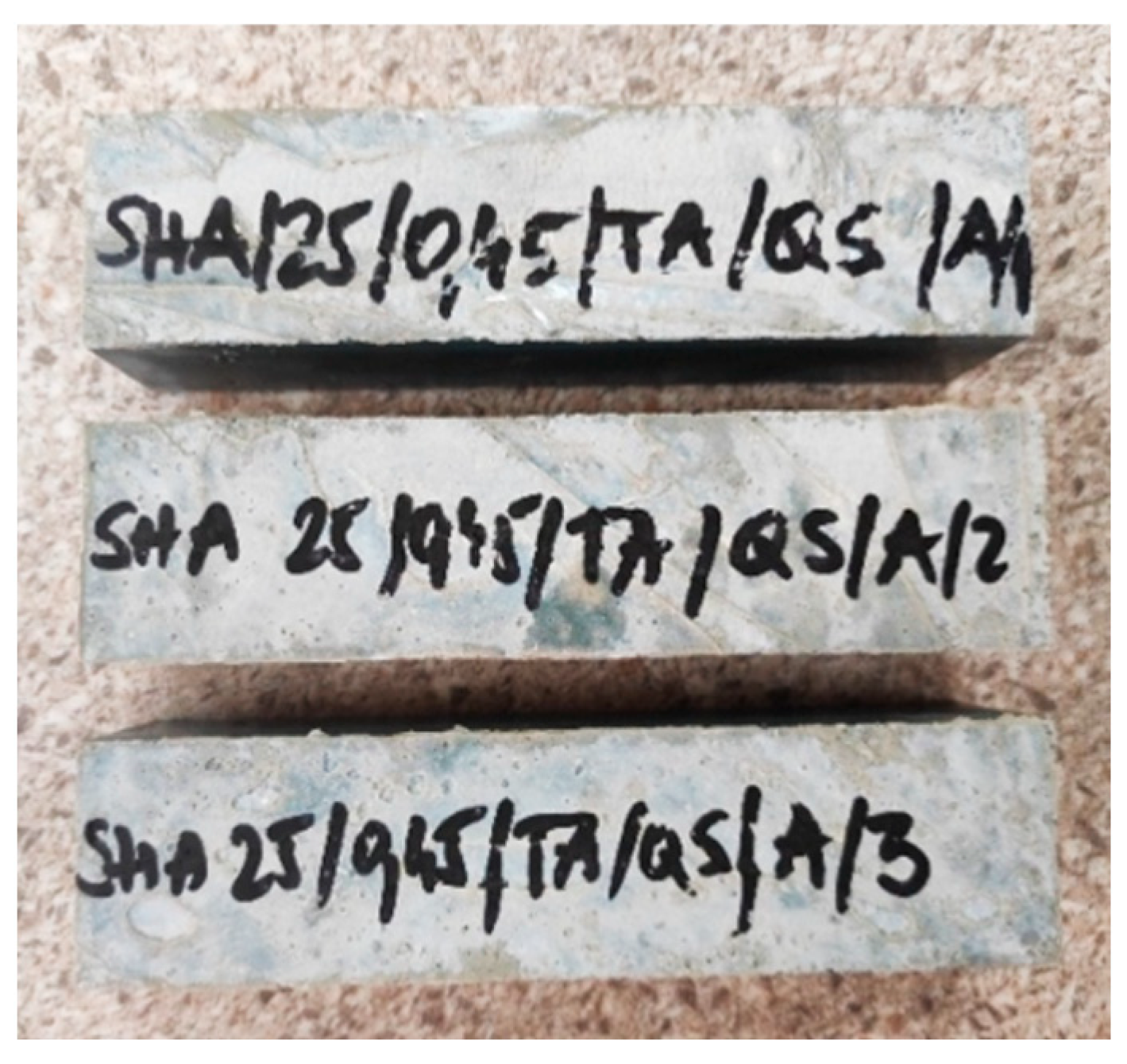

2.3.1. Mixing, Sample Casting and Curing

2.3.2. Testing Procedures

Phase Composition and Reaction Products

Workability and Compressive Strength

The Influence of Immersion Time on SHA Dissolution

3. Results and Discussion

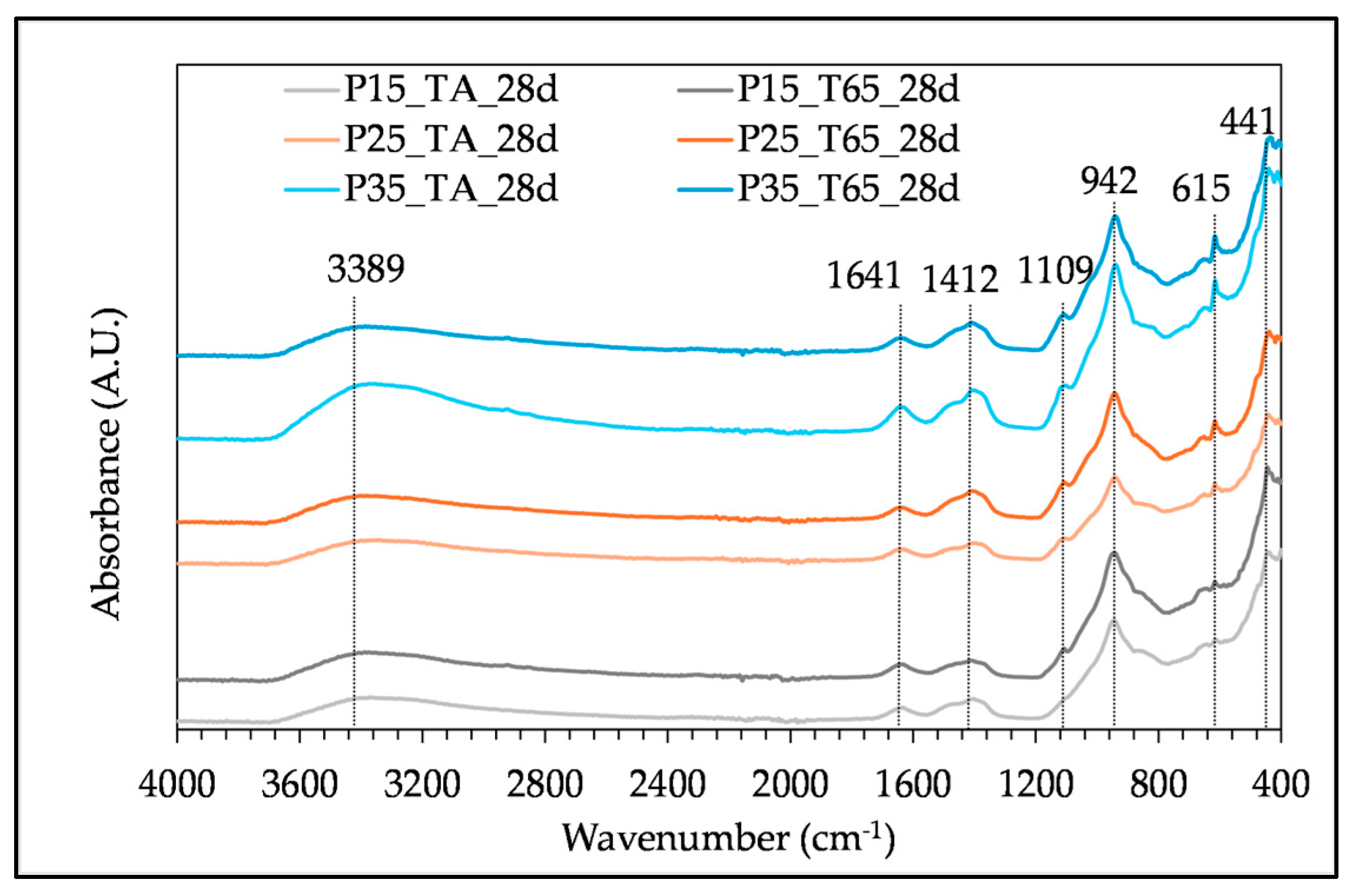

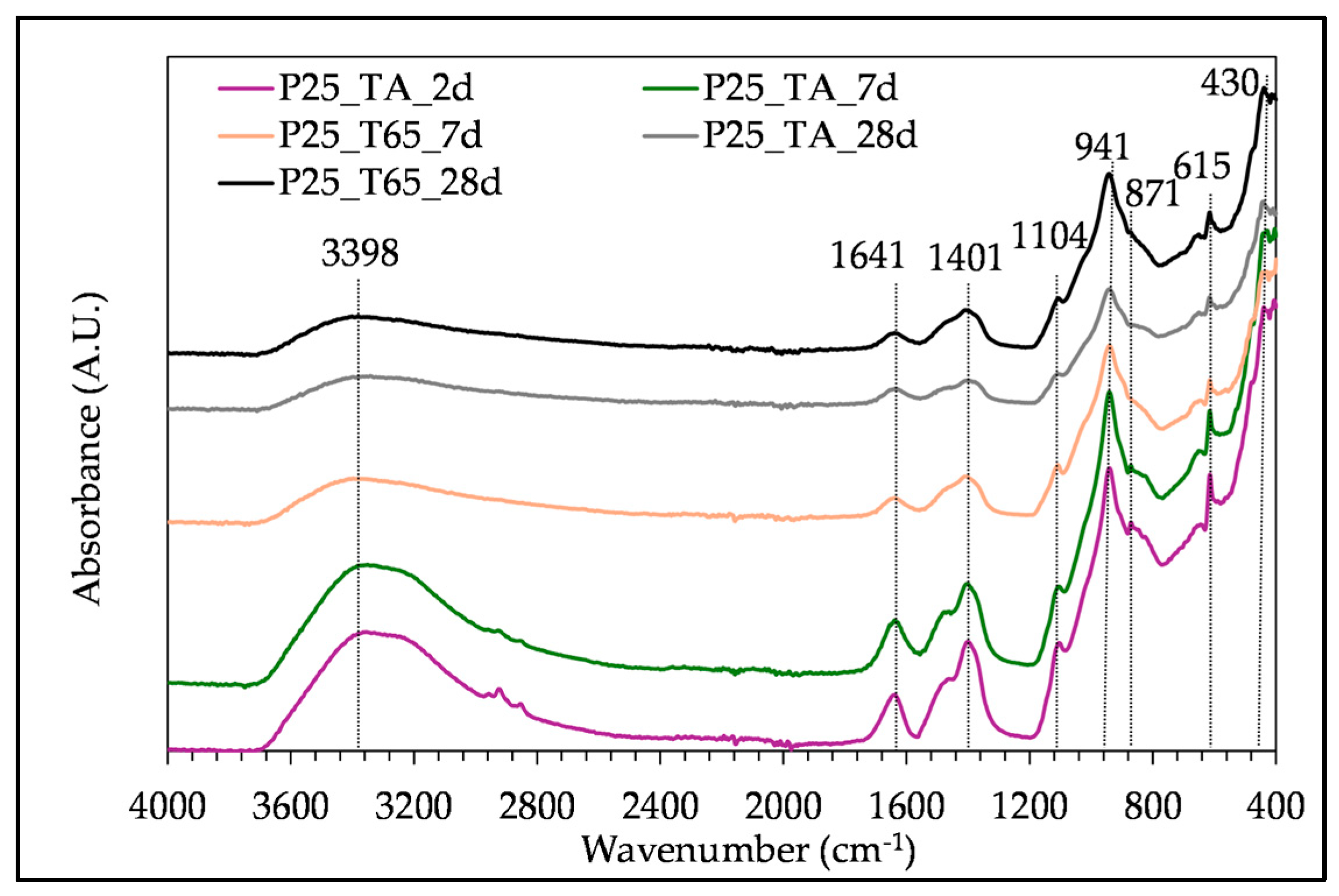

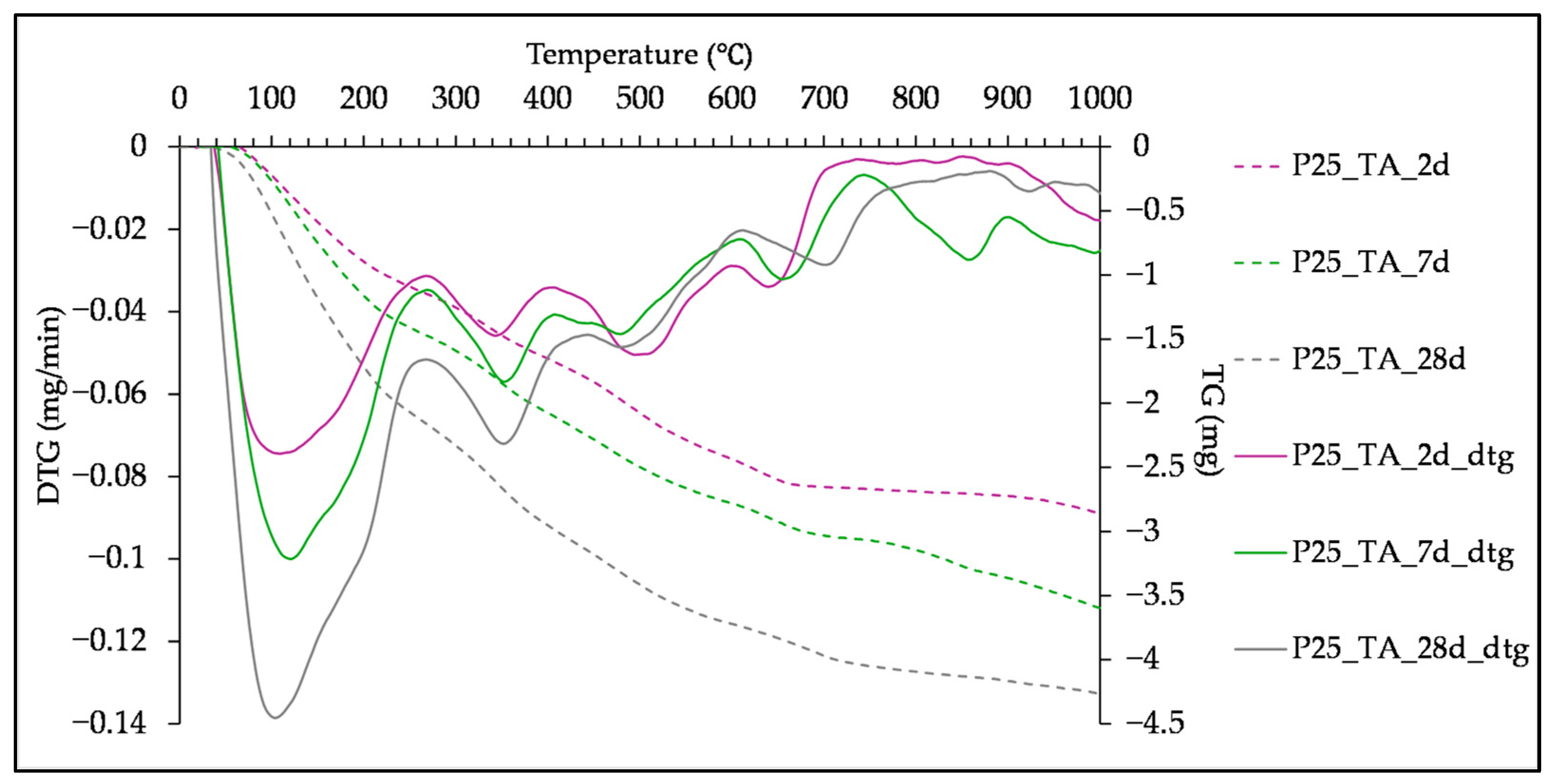

3.1. Phase Composition and Reaction Products

3.2. Workability

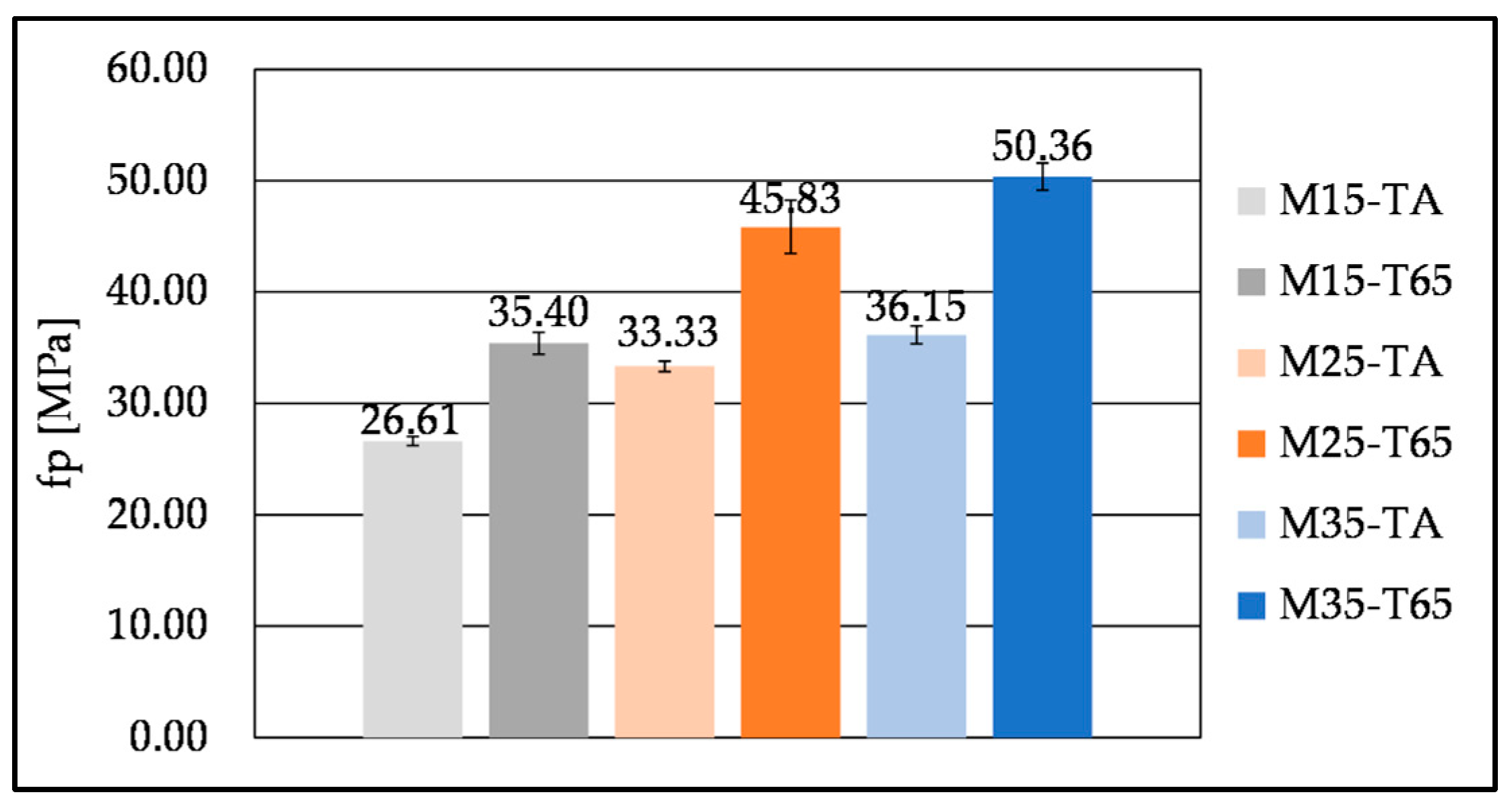

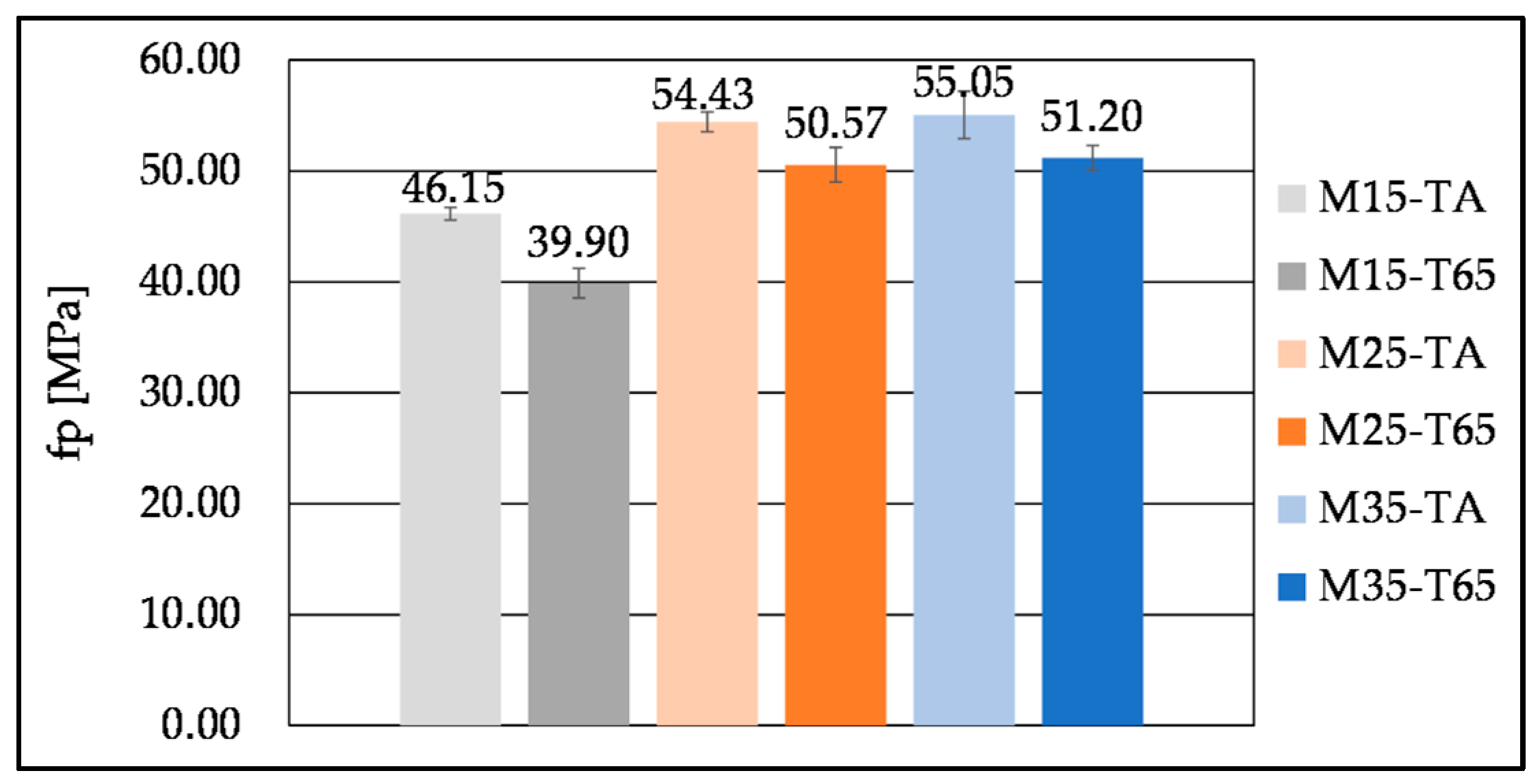

3.3. Compressive Strength—Influence of Curing Regime and SHA Content

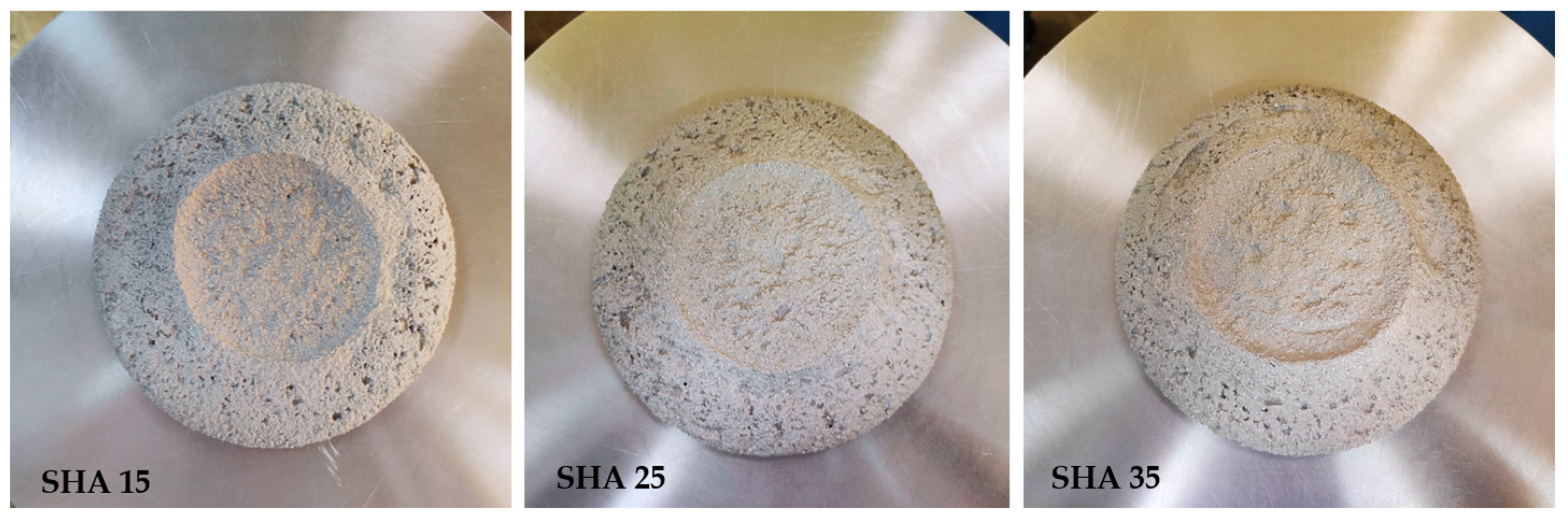

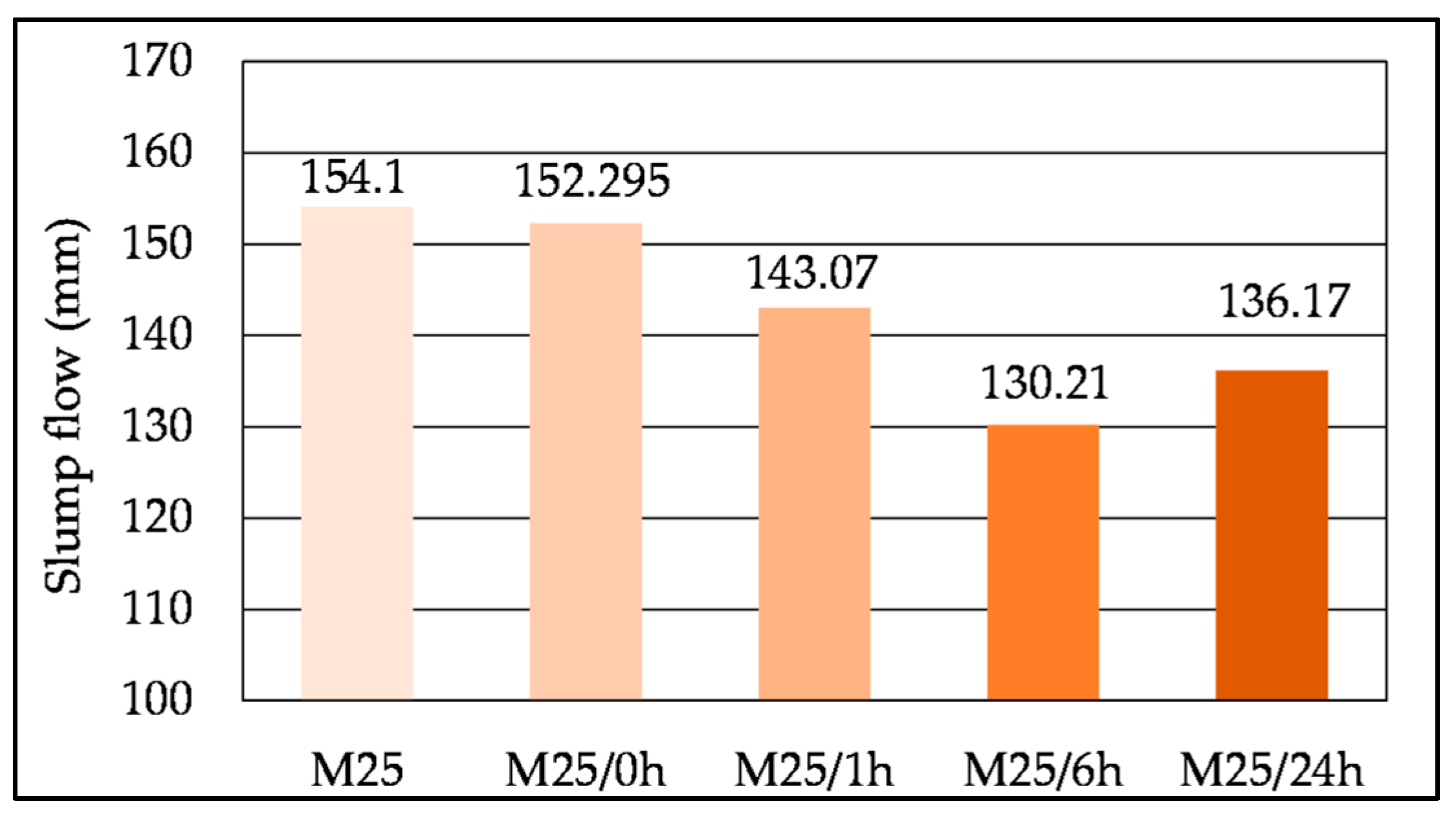

3.4. Influence of Mixing Procedure on Workability and Compressive Strength of the Mix M25

4. Conclusions

- FTIR and TGA analyses confirmed that the reaction between SHA and GGBFS results in the formation of C-S-H and C-A-S-H gels, characteristic of alkali-activation of slag.

- Increasing the SHA content leads to a minor reduction in workability and alters gel formation, consequently increasing compressive strength.

- Curing at 65 °C promotes early strength development (attaining 89–98% of 28-day compressive strength) but results in lower 28-day compressive strength compared to ambient curing.

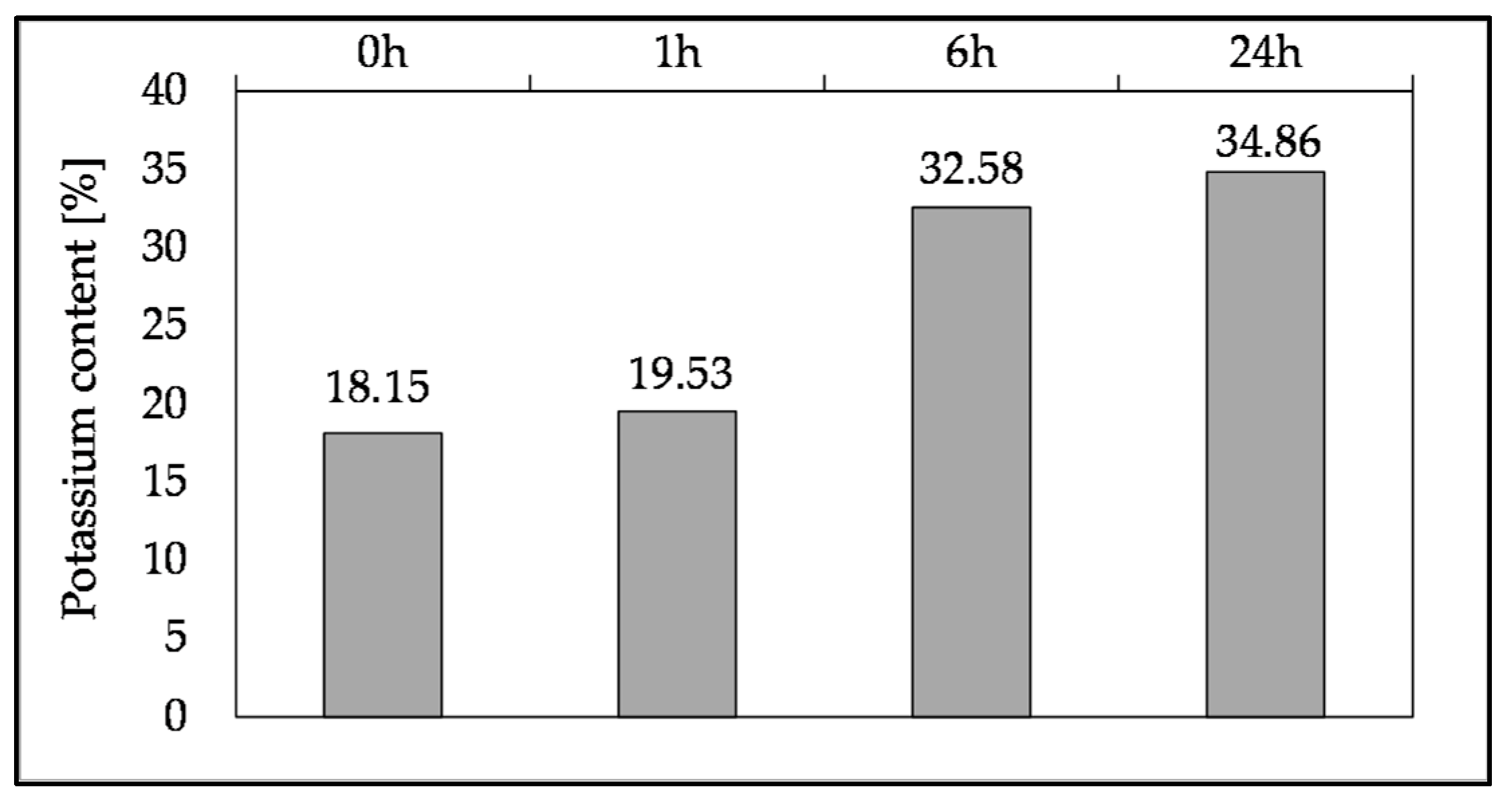

- Immersion of SHA in water before mixing enhances the dissolution of potassium ions and results in higher compressive strength up to 14.7%, depending on the immersion duration; however, it negatively impacts workability.

- The highest 28-day compressive strength of 55 MPa (25% SHA) is attained with minimal technological requirements, without SHA pretreatment and dissolution in water before mixing, cured at ambient temperature. This is 15 MPa higher than reported in the literature, highlighting the novelty for mortar mixes with similar component materials, mix designs, and curing conditions.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Marsh, A.; Dillon, T.; Bernal, S. Cement and Concrete Decarbonisation Roadmaps—A Meta-Analysis within the Context of the United Kingdom. RILEM Tech. Lett. 2023, 8, 94–105. [Google Scholar] [CrossRef]

- United Nations Environment Programme. Building Materials and the Climate: Constructing a New Future; United Nations Environment Programme: Paris, France, 2023; ISBN 978-92-807-4064-6.

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental Impacts and Decarbonization Strategies in the Cement and Concrete Industries. Nat. Rev. Earth Env. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-Activated Materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Ramagiri, K.K.; Kar, A. Environmental Impact Assessment of Alkali-Activated Mortar with Waste Precursors and Activators. J. Build. Eng. 2021, 44, 103391. [Google Scholar] [CrossRef]

- Provis, J.L.; Van Deventer, J.S.J. Geopolymers and Other Alkali-Activated Materials. In Lea’s Chemistry of Cement and Concrete; Butterworth-Heinemann: Oxford, UK, 2019; pp. 779–805. ISBN 978-0-08-100773-0. [Google Scholar]

- Provis, J.L. Green Concrete or Red Herring?–Future of Alkali-Activated Materials. Adv. Appl. Ceram. 2014, 113, 472–477. [Google Scholar] [CrossRef]

- Komkova, A.; Habert, G. Environmental Impact Assessment of Alkali-Activated Materials: Examining Impacts of Variability in Constituent Production Processes and Transportation. Constr. Build. Mater. 2023, 363, 129032. [Google Scholar] [CrossRef]

- Pol Segura, I.; Ranjbar, N.; Juul Damø, A.; Skaarup Jensen, L.; Canut, M.; Arendt Jensen, P. A Review: Alkali-Activated Cement and Concrete Production Technologies Available in the Industry. Heliyon 2023, 9, e15718. [Google Scholar] [CrossRef] [PubMed]

- Segura, I.P.; Luukkonen, T.; Yliniemi, J.; Sreenivasan, H.; Damø, A.J.; Jensen, L.S.; Canut, M.; Kantola, A.M.; Telkki, V.-V.; Jensen, P.A. Comparison of One-Part and Two-Part Alkali-Activated Metakaolin and Blast Furnace Slag. J. Sustain. Metall. 2022, 8, 1816–1830. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-Part Alkali-Activated Materials: A Review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Kim, T.; Hajimohammadi, A. Waste-Derived Activators for Alkali-Activated Materials: A Review. Cem. Concr. Compos. 2021, 118, 103980. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F.; Marvila, M.; Azevedo, A.R.G.; Franco De Carvalho, J.M.; Ribeiro, J.C.L. Application of Eco-Friendly Alternative Activators in Alkali-Activated Materials: A Review. J. Build. Eng. 2021, 35, 102010. [Google Scholar] [CrossRef]

- Mohapatra, S.S.; Mishra, J.; Nanda, B.; Patro, S.K. A Review on Waste-Derived Alkali Activators for Preparation of Geopolymer Composite. Mater. Today Proc. 2022, 56, 440–446. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Composition and Application of Biomass Ash. Part 1. Phase–Mineral and Chemical Composition and Classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Munawar, M.A.; Khoja, A.H.; Naqvi, S.R.; Mehran, M.T.; Hassan, M.; Liaquat, R.; Dawood, U.F. Challenges and Opportunities in Biomass Ash Management and Its Utilization in Novel Applications. Renew. Sustain. Energy Rev. 2021, 150, 111451. [Google Scholar] [CrossRef]

- Odzijewicz, J.I.; Wołejko, E.; Wydro, U.; Wasil, M.; Jabłońska-Trypuć, A. Utilization of Ashes from Biomass Combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- Marathe, S.; Sadowski, Ł. Developments in Biochar Incorporated Geopolymers and Alkali Activated Materials: A Systematic Literature Review. J. Clean. Prod. 2024, 469, 143136. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; Kirchheim, A.P.; Provis, J.L. Management and Valorisation of Wastes through Use in Producing Alkali-activated Cement Materials. J. Chem. Technol. Biotechnol. 2016, 91, 2365–2388. [Google Scholar] [CrossRef]

- Ahmad, Z.; Qureshi, M.I.; Ahmad, F.; El Ouni, M.H.; Asghar, M.Z.; Ghazouani, N. Effect of Macro Synthetic Fiber (MSF) on the Behavior of Conventional Concrete and the Concrete Containing e-Waste Aggregates. Mater. Struct. 2025, 58, 234. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; de Gutiérrez, R.M.; Provis, J.L. Performance at High Temperature of Alkali-Activated Slag Pastes Produced with Silica Fume and Rice Husk Ash Based Activators. Mater. Construcción 2015, 65, e049. [Google Scholar] [CrossRef]

- Mejía, J.M.; de Gutiérrez, R.M.; Montes, C. Rice Husk Ash and Spent Diatomaceous Earth as a Source of Silica to Fabricate a Geopolymeric Binary Binder. J. Clean. Prod. 2016, 118, 133–139. [Google Scholar] [CrossRef]

- Moraes, J.C.B.; Font, A.; Soriano, L.; Akasaki, J.L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. New Use of Sugar Cane Straw Ash in Alkali-Activated Materials: A Silica Source for the Preparation of the Alkaline Activator. Constr. Build. Mater. 2018, 171, 611–621. [Google Scholar] [CrossRef]

- Gomonsirisuk, K.; Thavorniti, P. Use of Water Glass from Rice Husk and Bagasse Ashes in the Preparation of Fly Ash Based Geopolymer. KEM 2019, 798, 364–369. [Google Scholar] [CrossRef]

- Villaquirán-Caicedo, M.A. Studying Different Silica Sources for Preparation of Alternative Waterglass Used in Preparation of Binary Geopolymer Binders from Metakaolin/Boiler Slag. Constr. Build. Mater. 2019, 227, 116621. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Ranjbar, N. Synthesis of Sodium Waterglass from White Rice Husk Ash as an Activator to Produce Metakaolin-Based Geopolymer Cements. J. Build. Eng. 2016, 6, 252–261. [Google Scholar] [CrossRef]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Kamseu, E.; Leonelli, C. Geopolymer Binders from Metakaolin Using Sodium Waterglass from Waste Glass and Rice Husk Ash as Alternative Activators: A Comparative Study. Constr. Build. Mater. 2016, 114, 276–289. [Google Scholar] [CrossRef]

- Bernal, S.A.; Rodríguez, E.D.; Mejia De Gutiérrez, R.; Provis, J.L.; Delvasto, S. Activation of Metakaolin/Slag Blends Using Alkaline Solutions Based on Chemically Modified Silica Fume and Rice Husk Ash. Waste Biomass Valor. 2012, 3, 99–108. [Google Scholar] [CrossRef]

- Tong, K.T.; Vinai, R.; Soutsos, M.N. Use of Vietnamese Rice Husk Ash for the Production of Sodium Silicate as the Activator for Alkali-Activated Binders. J. Clean. Prod. 2018, 201, 272–286. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; de Moraes Pinheiro, S.M.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Design and Properties of 100% Waste-Based Ternary Alkali-Activated Mortars: Blast Furnace Slag, Olive-Stone Biomass Ash and Rice Husk Ash. J. Clean. Prod. 2020, 243, 118568. [Google Scholar] [CrossRef]

- Font, A.; Soriano, L.; Moraes, J.C.B.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. A 100% Waste-Based Alkali-Activated Material by Using Olive-Stone Biomass Ash (OBA) and Blast Furnace Slag (BFS). Mater. Lett. 2017, 203, 46–49. [Google Scholar] [CrossRef]

- de Moraes Pinheiro, S.M.; Font, A.; Soriano, L.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. Olive-Stone Biomass Ash (OBA): An Alternative Alkaline Source for the Blast Furnace Slag Activation. Constr. Build. Mater. 2018, 178, 327–338. [Google Scholar] [CrossRef]

- Alonso, M.M.; Gascó, C.; Morales, M.M.; Suárez-Navarro, J.A.; Zamorano, M.; Puertas, F. Olive Biomass Ash as an Alternative Activator in Geopolymer Formation: A Study of Strength, Radiology and Leaching Behaviour. Cem. Concr. Compos. 2019, 104, 103384. [Google Scholar] [CrossRef]

- Soriano, L.; Font, A.; Borrachero, M.V.; Monzó, J.M.; Payá, J.; Tashima, M.M. Biomass Ashes to Produce an Alternative Alkaline Activator for Alkali-Activated Cements. Mater. Lett. 2022, 308, 131198. [Google Scholar] [CrossRef]

- Peys, A.; Rahier, H.; Pontikes, Y. Potassium-Rich Biomass Ashes as Activators in Metakaolin-Based Inorganic Polymers. Appl. Clay Sci. 2016, 119, 401–409. [Google Scholar] [CrossRef]

- Balo, A.M.; Rahier, H.; Mobili, A.; Katsiki, A.; Fagel, N.; Chinje, U.M.; Njopwouo, D. Metakaolin-Based Inorganic Polymer Synthesis Using Cotton Shell Ash as Sole Alkaline Activator. Constr. Build. Mater. 2018, 191, 1011–1022. [Google Scholar] [CrossRef]

- Adesanya, E.; Perumal, P.; Luukkonen, T.; Yliniemi, J.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Opportunities to Improve Sustainability of Alkali-Activated Materials: A Review of Side-Stream Based Activators. J. Clean. Prod. 2021, 286, 125558. [Google Scholar] [CrossRef]

- Cheah, C.B.; Part, W.K.; Ramli, M. The Hybridizations of Coal Fly Ash and Wood Ash for the Fabrication of Low Alkalinity Geopolymer Load Bearing Block Cured at Ambient Temperature. Constr. Build. Mater. 2015, 88, 41–55. [Google Scholar] [CrossRef]

- Soriano, L.; Font, A.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Payá, J. One-Part Blast Furnace Slag Mortars Activated with Almond-Shell Biomass Ash: A New 100% Waste-Based Material. Mater. Lett. 2020, 272, 127882. [Google Scholar] [CrossRef]

- Soriano, L.; Font, A.; Tashima, M.M.; Monzó, J.; Borrachero, M.V.; Bonifácio, T.; Payá, J. Almond-Shell Biomass Ash (ABA): A Greener Alternative to the Use of Commercial Alkaline Reagents in Alkali-Activated Cement. Constr. Build. Mater. 2021, 290, 123251. [Google Scholar] [CrossRef]

- Omur, T.; Kanat, D.; Kabay, N. Innovative Use of Hazelnut Shell Ash as an Alkali Activator: A Comparative Analysis with Commercial Activators. J. Build. Eng. 2024, 90, 109466. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, X.; Liu, R.; Wang, Z.; Zhang, H.; Zhao, D.; Bai, J.; Chen, M.; Li, W. Workability and Environmental Evaluation of Using Sunflower Stalk Ash as an Alkali Activator with Blast Furnace Slag and Black Rice Hull Ash to Prepare Geopolymer Grouts. Waste Biomass Valor. 2025, 16, 1609–1626. [Google Scholar] [CrossRef]

- Zhu, Z.; Xu, X.; Liu, R.; Liu, P.; Tang, H.; Gong, Y.; Zhang, C.; Li, X.; Liu, Y.; Bai, J.; et al. Feasibility Study of Highly Alkaline Biomass Ash to Activate Alkali-Activated Grouts. Constr. Build. Mater. 2023, 393, 132067. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, C.; Liu, R.; Li, S.; Wang, M. Sunflower Straw Ash as an Alternative Activator in Alkali-Activated Grouts: A New 100% Waste-Based Material. Ceram. Int. 2023, 49, 32308–32312. [Google Scholar] [CrossRef]

- Lima, F.S.; Gomes, T.C.F.; Moraes, J.C.B. Effect of Coffee Husk Ash as Alkaline Activator in One-Part Alkali-Activated Binder. Constr. Build. Mater. 2023, 362, 129799. [Google Scholar] [CrossRef]

- Bedov, O.; Andabaka, A.; Draganić, S. Turning Agricultural Biomass Ash into a Valuable Resource in the Construction Industry—Exploring the Potential of Industrial Symbiosis. Buildings 2025, 15, 273. [Google Scholar] [CrossRef]

- Nikolov, A.; Kostov, V.; Petrova, N.; Tsvetanova, L.; Vassilev, S.V.; Titorenkova, R. Sunflower Shells Biomass Fly Ash as Alternative Alkali Activator for One-Part Cement Based on Ladle Slag. Ceramics 2025, 8, 79. [Google Scholar] [CrossRef]

- World Steel Association. Steel Statistical Yearbook 2022; World Steel Association: Brussels, Belgium, 2022. [Google Scholar]

- Shen, H.; Forssberg, E. An Overview of Recovery of Metals from Slags. Waste Manag. 2003, 23, 933–949. [Google Scholar] [CrossRef] [PubMed]

- Draganić, S.; Šupić, S.; Laban, M.; Malešev, M.; Bulatović, V.; Lukić, I.; Bukvić, O. Agricultural Biomass Ash as a Circular Building Material: Connecting Agriculture and Construction Industry. In Creating a Roadmap Towards Circularity in the Built Environment; Springer: Cham, Switzerland, 2023; pp. 225–236. ISBN 978-3-031-45979-5. [Google Scholar]

- Statistical Office of the Republic of Serbia. Industrial Production by Products; Statistical Office of the Republic of Serbia: Belgrade, Serbia, 2024.

- SRPS EN 1015-3:2008; Methods of Test for Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Flow Table). Institute for Standardization of Serbia: Belgrade, Serbia, 2008.

- SRPS EN 196-1: 2017; Methods of Testing Cement-Part 1: Determination of Strength. Institute for Standardization of Serbia: Belgrade, Serbia, 2017.

- Ghorbani, S.; Stefanini, L.; Sun, Y.; Walkley, B.; Provis, J.L.; De Schutter, G.; Matthys, S. Characterisation of Alkali-Activated Stainless Steel Slag and Blast-Furnace Slag Cements. Cem. Concr. Compos. 2023, 143, 105230. [Google Scholar] [CrossRef]

- Lecomte, I.; Henrist, C.; Liégeois, M.; Maseri, F.; Rulmont, A.; Cloots, R. (Micro)-Structural Comparison between Geopolymers, Alkali-Activated Slag Cement and Portland Cement. J. Eur. Ceram. Soc. 2006, 26, 3789–3797. [Google Scholar] [CrossRef]

- Sun, Y.; De Lima, L.M.; Rossi, L.; Jiao, D.; Li, Z.; Ye, G.; De Schutter, G. Interpretation of the Early Stiffening Process in Alkali-Activated Slag Pastes. Cem. Concr. Res. 2023, 167, 107118. [Google Scholar] [CrossRef]

- Ismail, I.; Bernal, S.A.; Provis, J.L.; San Nicolas, R.; Hamdan, S.; van Deventer, J.S.J. Modification of Phase Evolution in Alkali-Activated Blast Furnace Slag by the Incorporation of Fly Ash. Cem. Concr. Compos. 2014, 45, 125–135. [Google Scholar] [CrossRef]

- Li, B.; Sun, Q.; Chen, X.; Xu, Z.; Yang, L. Preparation and Microstructure Analysis of Alkali-Activated Ground Granulated Blast Furnace Slag-Steel Slag Grouting Materials. Case Stud. Constr. Mater. 2024, 20, e03235. [Google Scholar] [CrossRef]

- Shi, Z.; Shi, C.; Wan, S.; Li, N.; Zhang, Z. Effect of Alkali Dosage and Silicate Modulus on Carbonation of Alkali-Activated Slag Mortars. Cem. Concr. Res. 2018, 113, 55–64. [Google Scholar] [CrossRef]

- Bílek, V.; Švec, J.; Másilko, J.; Sedlačík, M.; Materak, K.; Wieczorek, A.; Koniorczyk, M.; Hajzler, J.; Kucharczyková, B. Comparison of Thermogravimetry Response of Alkali-Activated Slag and Portland Cement Pastes after Stopping Their Hydration Using Solvent Exchange Method. J. Therm. Anal. Calorim. 2025, 150, 1013–1037. [Google Scholar] [CrossRef]

- Ben Haha, M.; Le Saout, G.; Winnefeld, F.; Lothenbach, B. Influence of Activator Type on Hydration Kinetics, Hydrate Assemblage and Microstructural Development of Alkali Activated Blast-Furnace Slags. Cem. Concr. Res. 2011, 41, 301–310. [Google Scholar] [CrossRef]

- Sona, S.; Sangeetha, S.P. Eco-Friendly Alternative Activators Derived from Industrial Wastes for the Sustainable Production of Two-Part Geopolymer Concrete at Low Cost. Constr. Build. Mater. 2025, 467, 140374. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y.-B. Effect of Elevated Temperature Curing on Properties of Alkali-Activated Slag Concrete. Cem. Concr. Res. 1999, 29, 1619–1625. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Emam, M.A. Factors Affecting the Mechanical Properties of Alkali Activated Ground Granulated Blast Furnace Slag Concrete. Constr. Build. Mater. 2019, 197, 339–355. [Google Scholar] [CrossRef]

- Collins, F.; Sanjayan, J.G. Microcracking and Strength Development of Alkali Activated Slag Concrete. Cem. Concr. Compos. 2001, 23, 345–352. [Google Scholar] [CrossRef]

| Material | Oxide (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | Al2O3 | Fe2O3 | MgO | SO3 | K2O | Na2O | LOI | |

| GGBFS | 38.69 | 37.19 | 9.51 | 0.47 | 10.52 | 2.17 | 0.83 | 0.41 | 0.90 |

| SHA | 1.75 | 14.29 | 0.59 | 0.21 | 10.46 | 13.53 | 38.00 | 0.07 | 10.45 |

| Mix | GGBFS (g) | SHA (g) | SHA′ (g) | SHA″ (g) | Water (g) | Quartz Sand Fraction (mm) | |||

|---|---|---|---|---|---|---|---|---|---|

| 0.008–0.16 (g) | 0.16–0.5 (g) | 0.5–1.0 (g) | 1.0–2.0 (g) | ||||||

| Pastes | |||||||||

| P15 | 400 | 60 | 27 | 33 | 192 | - | - | - | - |

| P25 | 400 | 100 | 45 | 55 | 200 | - | - | - | - |

| P35 | 400 | 140 | 63 | 77 | 208 | - | - | - | - |

| Mortars | |||||||||

| M15 | 400 | 60 | 27 | 33 | 192 | 277 | 139 | 416 | 416 |

| M25 | 400 | 100 | 45 | 55 | 200 | 285 | 142 | 427 | 427 |

| M35 | 400 | 140 | 63 | 77 | 208 | 292 | 146 | 438 | 438 |

| Procedure | Step 1: Immersion | Step 2: Dry-Mixing, Manual | Step 3: Mixing, Manual | Step 4: Mixer |

|---|---|---|---|---|

| Mx,0 h | SHA immersed just before binder mixing | GGBFS + aggregate | GGBFS + aggregate + SHA suspension | GGBFS + aggregate + SHA suspension |

| Mx,1 h | SHA was immersed in water for 1 h | GGBFS + aggregate | GGBFS + aggregate + SHA suspension | GGBFS + aggregate + SHA suspension |

| Mx,6 h | SHA was immersed in water for 6 h | |||

| Mx,24 h | SHA was immersed in water for 24 h |

| Day of Testing | Curing Regime | First 24 h | 5 Days | Until the Day of Testing |

|---|---|---|---|---|

| 2, 7, 28 | TA | sealed, ambient temperature | ||

| 7, 28 | T65 | sealed, ambient temperature | sealed, 65 °C | sealed, ambient temperature |

| Sample | Absolute Peak Intensity * (a.u.) | Integrated Peak Area * (a.u.) |

|---|---|---|

| P15_T65 | 0.164 | 25.541 |

| P25_T65 | 0.175 | 24.826 |

| P35_T65 | 0.179 | 25.764 |

| Mass Loss (%) | ||||||

|---|---|---|---|---|---|---|

| Sample | P15 | P25 | P35 | |||

| Curing regime | TA | T65 | TA | T65 | TA | T65 |

| Peak 1 (30–240 °C) | 4.777 | 3.386 | 6.790 | 5.458 | 6.145 | 5.942 |

| Peak 2 (300–400 °C) | 1.472 | 0.963 | 2.055 | 1.767 | 1.563 | 1.851 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bedov, O.; Draganić, S.; Vučetić, S.; Serdar, M. Optimisation of Sunflower Husk Ash-Activated Slag Binder. Buildings 2025, 15, 4210. https://doi.org/10.3390/buildings15234210

Bedov O, Draganić S, Vučetić S, Serdar M. Optimisation of Sunflower Husk Ash-Activated Slag Binder. Buildings. 2025; 15(23):4210. https://doi.org/10.3390/buildings15234210

Chicago/Turabian StyleBedov, Olivera, Suzana Draganić, Snežana Vučetić, and Marijana Serdar. 2025. "Optimisation of Sunflower Husk Ash-Activated Slag Binder" Buildings 15, no. 23: 4210. https://doi.org/10.3390/buildings15234210

APA StyleBedov, O., Draganić, S., Vučetić, S., & Serdar, M. (2025). Optimisation of Sunflower Husk Ash-Activated Slag Binder. Buildings, 15(23), 4210. https://doi.org/10.3390/buildings15234210