Life Cycle Assessment of Engineered Wood Products in the Building Sector: A Review

Abstract

1. Introduction

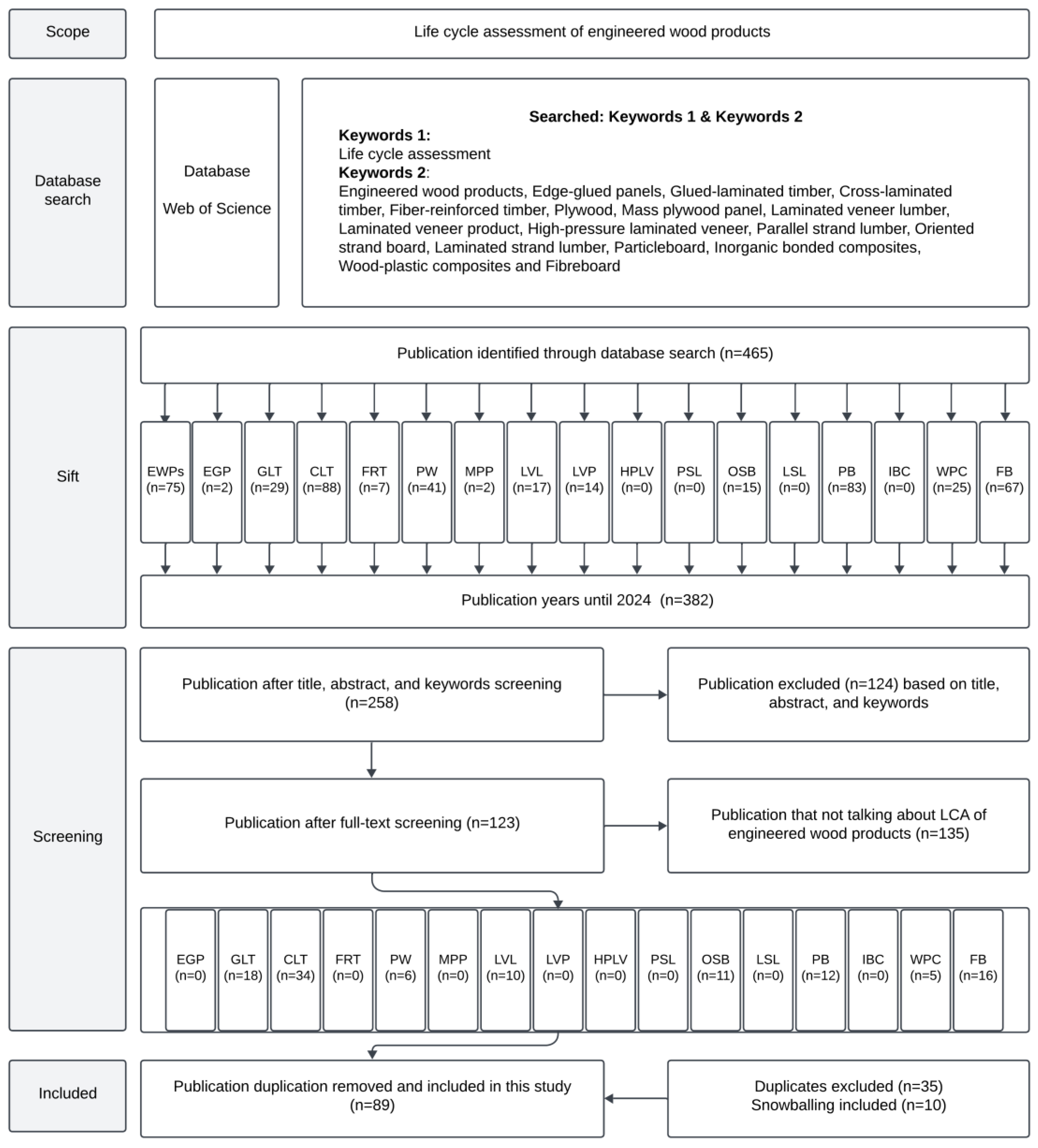

2. Materials and Methods

2.1. Literature Searching

2.2. Research Screening

2.3. Data Synthesis and Analysis

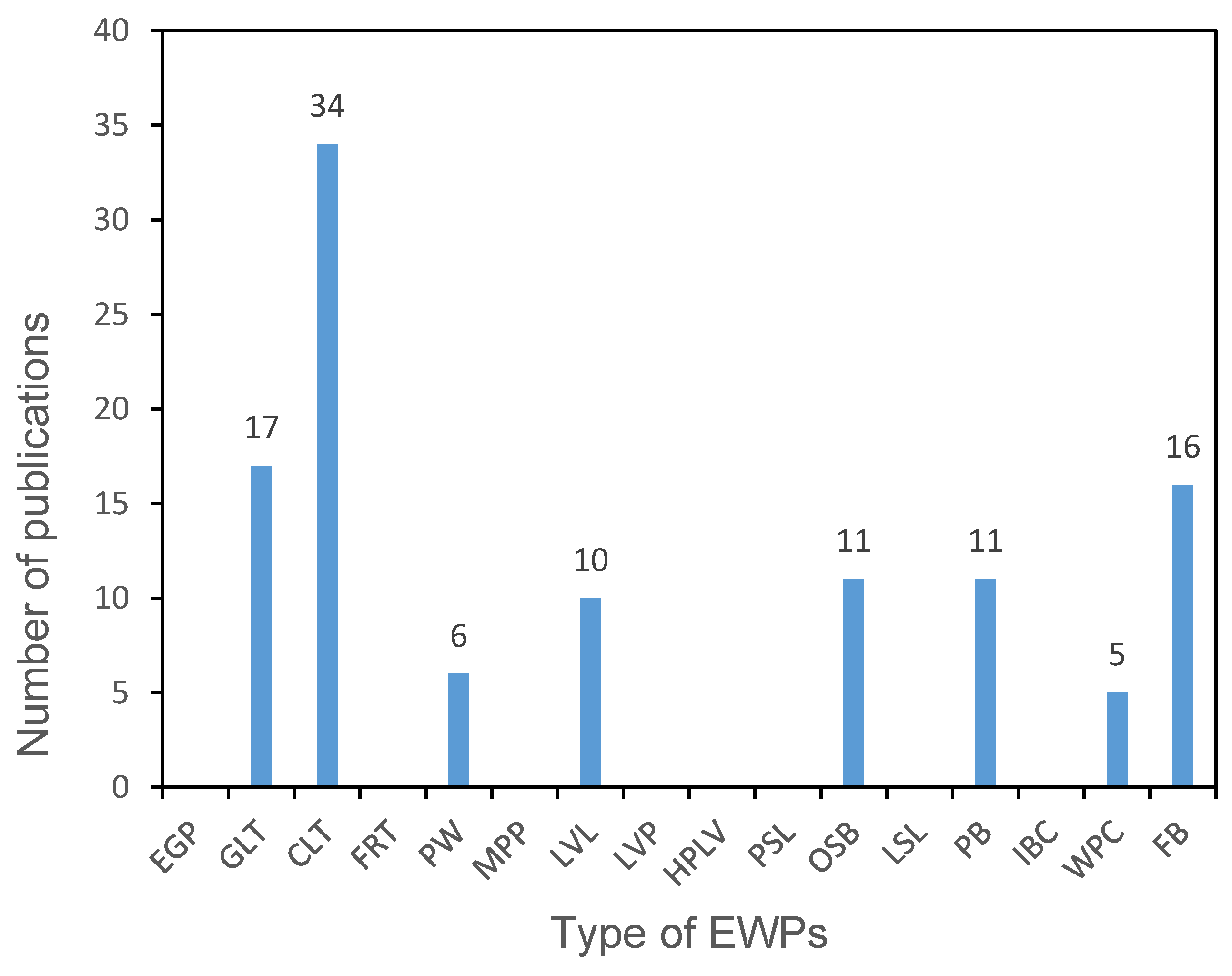

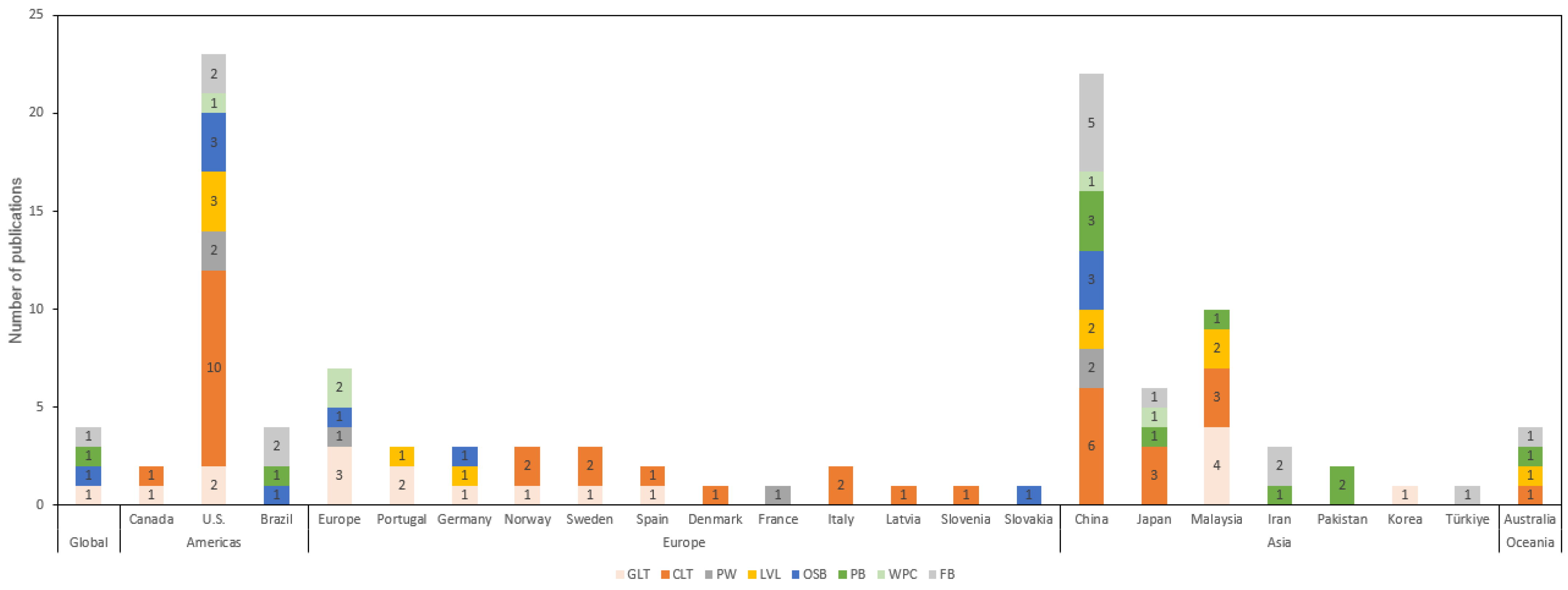

3. Overview of the Selected Papers

4. Detailed Review Results

4.1. Goal and Scope Definition

4.1.1. Scope of the Study

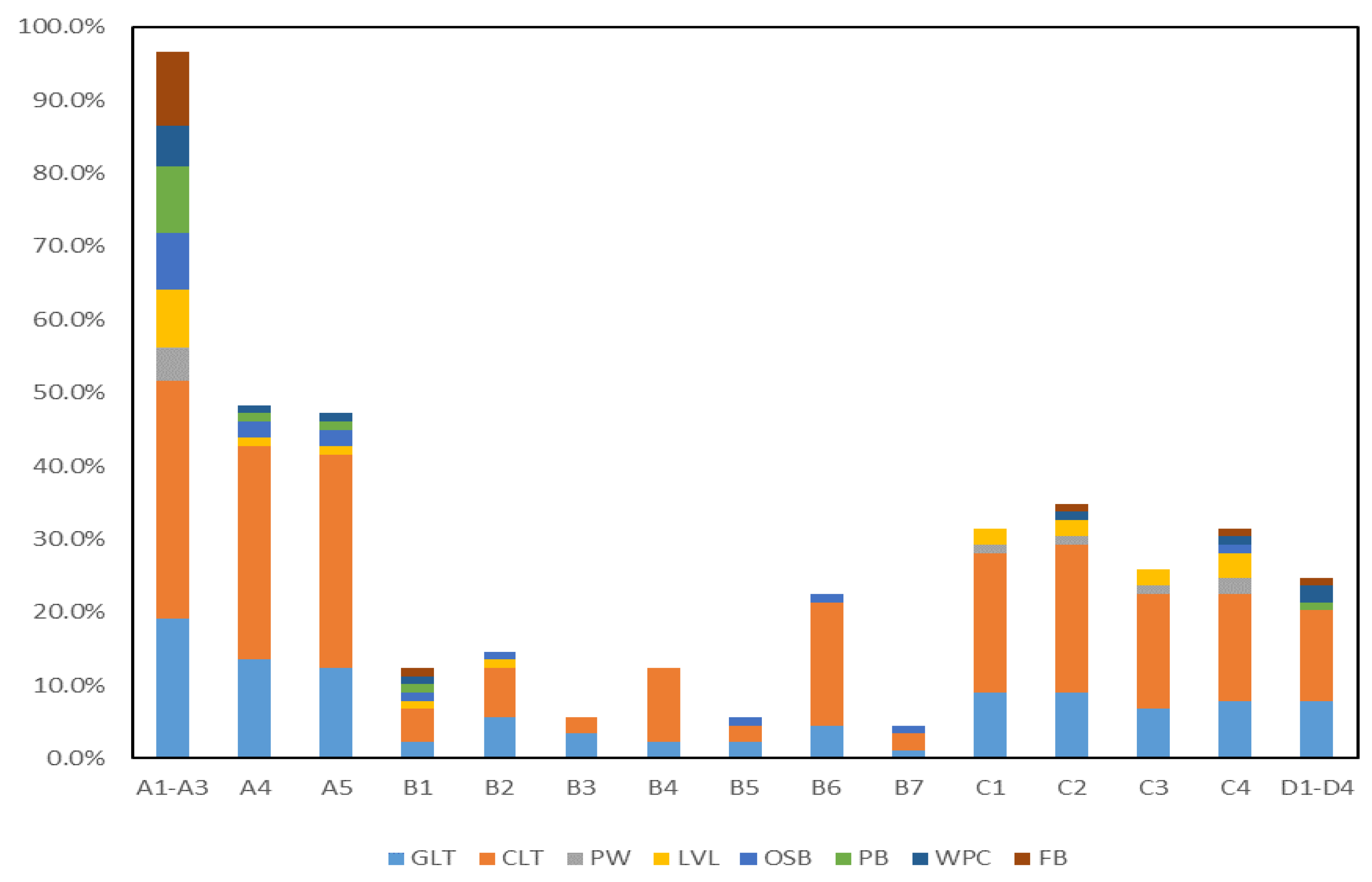

4.1.2. System Boundary

4.1.3. Functional Unit

4.2. Life Cycle Inventory Analysis

4.3. Life Cycle Impact Assessment and Interpretation

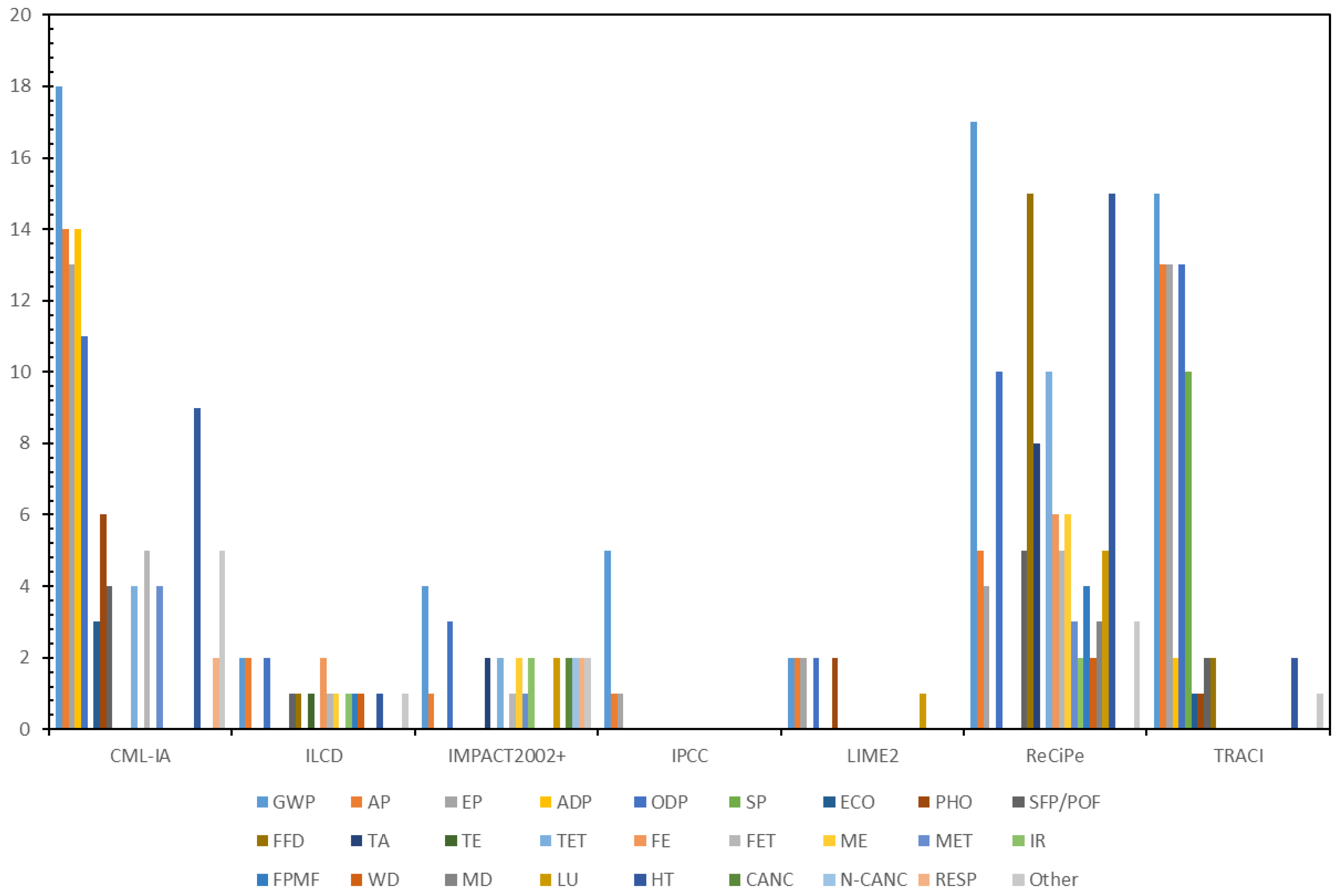

4.3.1. Life Cycle Impact Assessment Method

4.3.2. Life Cycle Impact Assessment Categories

4.3.3. Life Cycle Impact Assessment Comparison

5. Comparative Results and Discussions

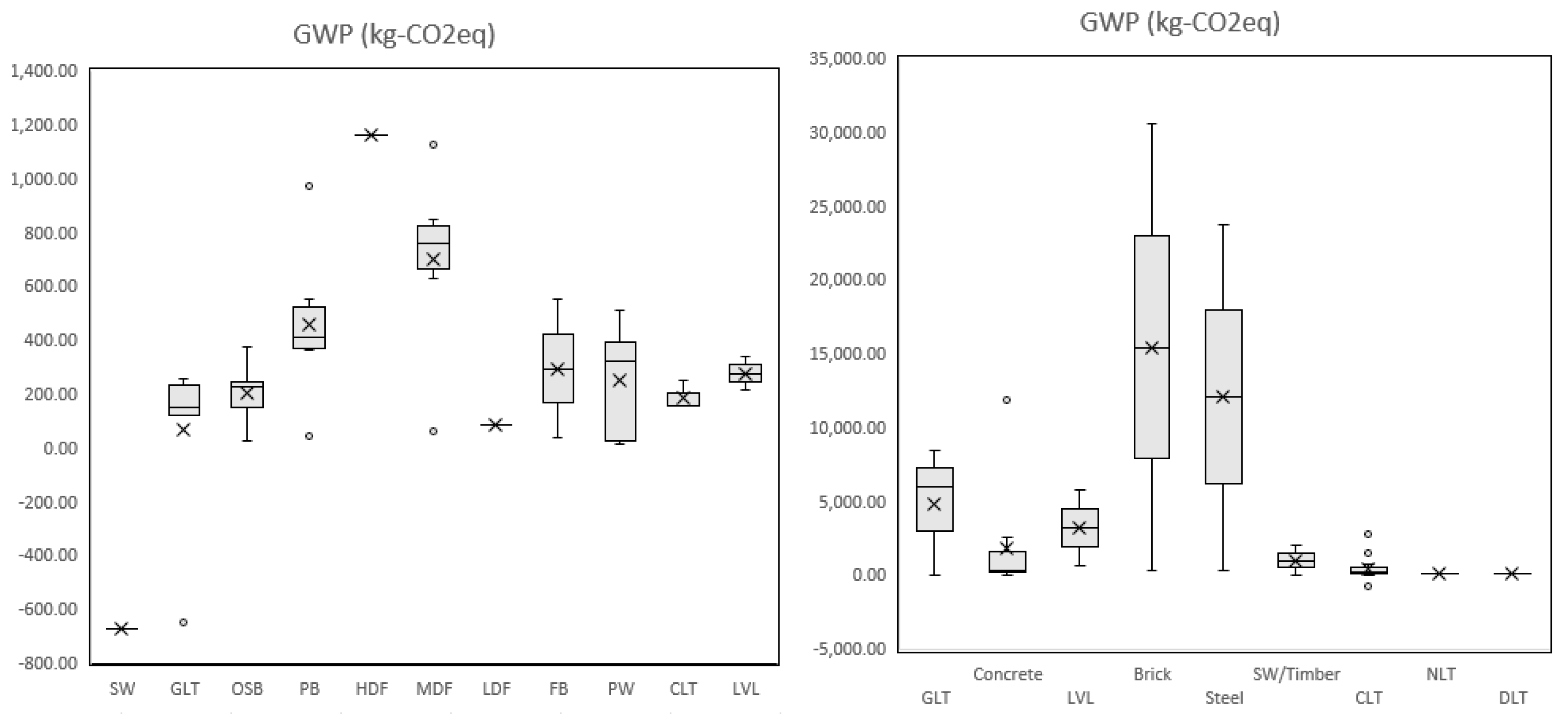

5.1. Greenhouse Gas Emission Comparison

5.2. Impacts Comparison Across Different Life Cycle Stages

5.3. Influence of Key Parameters on LCA Outcomes

- (1)

- Lifespan

- (2)

- Material source

- (3)

- Wood species

- (4)

- Building height

- (5)

- Other factors

5.4. Recommendation for Future Studies

5.4.1. Expanding the Scope of LCA Studies

5.4.2. Broadening System Boundaries

5.4.3. Standardizing Functional Units

5.4.4. Developing Region-Specific LCI Databases

5.4.5. Adopting Standardized LCIA Frameworks

5.4.6. Exploring Emerging and Understudied EWPs

5.4.7. Investigating the Potential of Bio-Based and Nanotechnology-Enhanced Materials

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, S.; Feng, H. Construction and Demolition Waste Circulation and Its Sustainability Performance in the Building Sector: Current Trend and Future Directions. Eng. Constr. Archit. Manag. 2025. [Google Scholar] [CrossRef]

- Forster, E.J.; Styles, D.; Healey, J.R. Temperate Forests Can Deliver Future Wood Demand and Climate-Change Mitigation Dependent on Afforestation and Circularity. Nat. Commun. 2025, 16, 3872. [Google Scholar] [CrossRef]

- Walley, S.M.; Rogers, S.J. Is Wood a Material? Taking the Size Effect Seriously. Materials 2022, 15, 5403. [Google Scholar] [CrossRef]

- Klarić, S.; Obučina, M. New Trends in Engineering Wood Technologies. In New Technologies, Development and Application II; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 712–727. [Google Scholar]

- Blanchet, P.; Perez, C.; Cabral, M.R. Wood Building Construction: Trends and Opportunities in Structural and Envelope Systems. Curr. Rep. 2023, 10, 21–38. [Google Scholar] [CrossRef]

- Kitek Kuzman, M.; Zbašnik-Senegačnik, M.; Kosanović, S.; Miloshevska Janakieska, M.; Novaković, N.; Rajković, I.; Grošelj, P. Architectural Perspectives on Wood Reuse within Circular Construction: A South–Central European Study. Buildings 2024, 14, 560. [Google Scholar] [CrossRef]

- Kuzman, M.K.; Sandberg, D. Engineered Wood Products in Contemporary Architectural Use—A Concise Overview. Wood Mater. Sci. Eng. 2023, 18, 2112–2115. [Google Scholar] [CrossRef]

- Sandberg, D. Additives in Wood Products—Today and Future Development. In Environmental Footprints and Eco-Design of Products and Processes; Springer: Singapore, 2016; pp. 105–172. [Google Scholar]

- Yang, M.; Rosentrater, K.A. Life Cycle Assessment of Urea-Formaldehyde Adhesive and Phenol-Formaldehyde Adhesives. Environ. Process. 2020, 7, 553–561. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Farjana, S.H.; Ashraf, M. Developing the Conceptual Framework for the Key Performance Indicators for Sustainable Wood Waste Supply Chain. Environ. Dev. Sustain. 2023, 27, 6921–6944. [Google Scholar] [CrossRef]

- Jia, L.; Chu, J.; Ma, L.; Qi, X.; Kumar, A. Life Cycle Assessment of Plywood Manufacturing Process in China. Int. J. Environ. Res. Public Health 2019, 16, 2037. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W. Comparative Sustainability Evaluation of Two Engineered Wood-Based Construction Materials: Life Cycle Analysis of CLT versus GLT. Build. Environ. 2021, 204, 108112. [Google Scholar] [CrossRef]

- Costa, D.; Serra, J.; Quinteiro, P.; Dias, A.C. Life Cycle Assessment of Wood-Based Panels: A Review. J. Clean. Prod. 2024, 444, 140955. [Google Scholar] [CrossRef]

- Duan, Z.; Huang, Q.; Zhang, Q. Life Cycle Assessment of Mass Timber Construction: A Review. Build. Environ. 2022, 221, 109320. [Google Scholar] [CrossRef]

- Sahoo, K.; Bergman, R.; Alanya-Rosenbaum, S.; Gu, H.; Liang, S. Life Cycle Assessment of Forest-Based Products: A Review. Sustainability 2019, 11, 4722. [Google Scholar] [CrossRef]

- Snyder, H. Literature Review as a Research Methodology: An Overview and Guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Zeng, R.; Chini, A. A Review of Research on the Embodied Energy of Buildings Using Bibliometric Analysis. Energy Build. 2017, 155, 172–184. [Google Scholar] [CrossRef]

- Ilgın, H.E.; Karjalainen, M.; Mikkola, P. Views of Cross-Laminated Timber (CLT) Manufacturer Representatives around the World on CLT Practices and Its Future Outlook. Buildings 2023, 13, 2912. [Google Scholar] [CrossRef]

- Miyamoto, B.T.; Sinha, A.; Morrell, I. Connection Performance of Mass Plywood Panels. Prod. J. 2020, 70, 88–99. [Google Scholar] [CrossRef]

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Lolli, N.; Fufa, S.M.; Wiik, M.K. An Assessment of Greenhouse Gas Emissions from CLT and Glulam in Two Residential Nearly Zero Energy Buildings. Wood Mater. Sci. Eng. 2019, 14, 342–354. [Google Scholar] [CrossRef]

- Puettmann, M.; Sinha, A.; Ganguly, I. Life Cycle Energy and Environmental Impacts of Cross Laminated Timber Made with Coastal Douglas-Fir. J. Green. Build. 2019, 14, 17–33. [Google Scholar] [CrossRef]

- Vidal, R.; Sánchez-Pantoja, N.; Martínez, G. Análisis del ciclo de vida de un edificio con estructura de madera contralaminada en Granada-España. Inf. Constr. 2019, 71, 289. [Google Scholar] [CrossRef]

- Vamza, I.; Diaz, F.; Resnais, P.; Radziņa, A.; Blumberga, D. Life Cycle Assessment of Reprocessed Cross Laminated Timber in Latvia. Environ. Clim. Technol. 2021, 25, 58–70. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W. Economic and Environmental Life Cycle Assessment of Alternative Mass Timber Walls to Evaluate Circular Economy in Building: MCDM Method. Environ. Dev. Sustain. 2022, 26, 239–268. [Google Scholar] [CrossRef]

- Zeug, W.; Bezama, A.; Thrän, D. Application of Holistic and Integrated LCSA: Case Study on Laminated Veneer Lumber Production in Central Germany. Int. J. Life Cycle Assess. 2022, 27, 1352–1375. [Google Scholar] [CrossRef]

- Vaňová, R. Influence of Carbon Accounting on Assessment of Wood-Based Products. Acta Fac. Xylologiae Zvolen. 2021, 63, 143–152. [Google Scholar]

- Vilčeková, S.; Harčárová, K.; Moňoková, A.; Burdová, E.K. Life Cycle Assessment and Indoor Environmental Quality of Wooden Family Houses. Sustainability 2020, 12, 10557. [Google Scholar] [CrossRef]

- Nakano, K.; Ando, K.; Takigawa, M.; Hattori, N. Life Cycle Assessment of Wood-Based Boards Produced in Japan and Impact of Formaldehyde Emissions during the Use Stage. Int. J. Life Cycle Assess. 2017, 23, 957–969. [Google Scholar] [CrossRef]

- Taylor, A.M.; Bergman, R.D.; Puettmann, M.E.; Alanya-Rosenbaum, S. Impacts of the Allocation Assumption in Life-Cycle Assessments of Wood-Based Panels. Prod. J. 2017, 67, 390–396. [Google Scholar] [CrossRef]

- Liikanen, M.; Grönman, K.; Deviatkin, I.; Havukainen, J.; Hyvärinen, M.; Kärki, T.; Varis, J.; Soukka, R.; Horttanainen, M. Construction and Demolition Waste as a Raw Material for Wood Polymer Composites—Assessment of Environmental Impacts. J. Clean. Prod. 2019, 225, 716–727. [Google Scholar] [CrossRef]

- Qiang, T.; Chou, Y.; Gao, H. Environmental Impacts of Styrene-Butadiene-Styrene Toughened Wood Fiber/Polylactide Composites: A Cradle-to-Gate Life Cycle Assessment. Int. J. Environ. Res. Public Health 2019, 16, 3402. [Google Scholar] [CrossRef]

- BS EN 15978:2011; Sustainability of Construction Works. Assessment of Environmental Performance of Buildings. Calculation Method. European Standards: Brussels, Belgium, 2011.

- Silva, D.A.L.; Firmino, A.S.; Ferro, F.S.; Christoforo, A.L.; Leite, F.R.; Lahr, F.A.R.; Kellens, K. Life Cycle Assessment of a Hot-Pressing Machine to Manufacture Particleboards: Hotspots, Environmental Indicators, and Solutions. Int. J. Life Cycle Assess. 2020, 25, 1059–1077. [Google Scholar] [CrossRef]

- Fuchigami, Y.; Kojiro, K.; Furuta, Y. Quantification of Greenhouse Gas Emissions from Wood-Plastic Recycled Composite (WPRC) and Verification of the Effect of Reducing Emissions through Multiple Recycling. Sustainability 2020, 12, 2449. [Google Scholar] [CrossRef]

- Sommerhuber, P.F.; Wenker, J.L.; Rüter, S.; Krause, A. Life Cycle Assessment of Wood-Plastic Composites: Analysing Alternative Materials and Identifying an Environmental Sound End-of-Life Option. Resour. Conserv. Recycl. 2017, 117, 235–248. [Google Scholar] [CrossRef]

- Risse, M.; Weber-Blaschke, G.; Richter, K. Eco-Efficiency Analysis of Recycling Recovered Solid Wood from Construction into Laminated Timber Products. Sci. Total Environ. 2019, 661, 107–119. [Google Scholar] [CrossRef]

- Lan, K.; Kelley, S.S.; Nepal, P.; Yao, Y. Dynamic Life Cycle Carbon and Energy Analysis for Cross-Laminated Timber in the Southeastern United States. Environ. Res. Lett. 2020, 15, 124036. [Google Scholar] [CrossRef]

- Allan, K.; Phillips, A.R. Comparative Cradle-to-Grave Life Cycle Assessment of Low and Mid-Rise Mass Timber Buildings with Equivalent Structural Steel Alternatives. Sustainability 2021, 13, 3401. [Google Scholar] [CrossRef]

- Taskhiri, M.S.; Jeswani, H.; Geldermann, J.; Azapagic, A. Optimising Cascaded Utilisation of Wood Resources Considering Economic and Environmental Aspects. Comput. Chem. Eng. 2019, 124, 302–316. [Google Scholar] [CrossRef]

- Lao, W.; Li, W. Comparative Carbon Footprint Estimation of Three Types of Wooden Door: A Case Study from China. J. Clean. Prod. 2023, 433, 139745. [Google Scholar] [CrossRef]

- Wang, X.; Yang, G.; Tan, F.; Lin, Y.; Zhai, B. The Performance of Construction Waste Backfilling Subway Depot—A Case Study in Zhengzhou. Case Stud. Constr. Mater. 2023, 18, e01900. [Google Scholar] [CrossRef]

- Dias, A.M.A.; Dias, A.M.P.G.; Silvestre, J.D.; Brito, J. Comparison of Environmental Impacts of Structurally Equivalent Wood-Based Floors. Eur. J. Wood Prod. 2021, 79, 1607–1622. [Google Scholar] [CrossRef]

- Freire, A.L.F.; Araújo Júnior, C.P.; Freitas Rosa, M.; Almeida Neto, J.A.; Figueirêdo, M.C.B. Environmental Assessment of Bioproducts in Development Stage: The Case of Fiberboards Made from Coconut Residues. J. Clean. Prod. 2017, 153, 230–241. [Google Scholar] [CrossRef]

- Tokede, O.O.; Rodgers, G.; Waschl, B.; Salter, J.; Ashraf, M. Harmonising Life Cycle Sustainability Thinking in Material Substitution for Buildings. Resour. Conserv. Recycl. 2022, 185, 106468. [Google Scholar] [CrossRef]

- Kouchaki-Penchah, H.; Sharifi, M.; Mousazadeh, H.; Zarea-Hosseinabadi, H. Life Cycle Assessment of Medium-Density Fiberboard Manufacturing Process in Islamic Republic of Iran. J. Clean. Prod. 2016, 112, 351–358. [Google Scholar] [CrossRef]

- Iwase, T.; Sasaki, T.; Araki, S.; Huzita, T.; Kayo, C. Environmental and Economic Evaluation of Small-Scale Bridge Repair Using Cross-Laminated Timber Floor Slabs. Sustainability 2020, 12, 3424. [Google Scholar] [CrossRef]

- Leskovar, V.Ž.; Žigart, M.; Premrov, M.; Lukman, R.K. Comparative Assessment of Shape Related Cross-Laminated Timber Building Typologies Focusing on Environmental Performance. J. Clean. Prod. 2019, 216, 482–494. [Google Scholar] [CrossRef]

- Atnoorkar, S.; Ghatpande, O.A.; Haile, S.L.; Goetsch, H.E.; Harris, C.B. Carbon Intensity of Mass Timber Materials: Impacts of Sourcing and Transportation. Front. Built Environ. 2024, 9, 1321340. [Google Scholar] [CrossRef]

- Bergman, R.D.; Alanya-Rosenbaum, S. Cradle-to-Gate Life-Cycle Assessment of Composite I-Joist Production in the United States. Prod. J. 2017, 67, 355–367. [Google Scholar] [CrossRef]

- Greene, J.M.; Hosanna, H.R.; Willson, B.; Quinn, J.C. Whole Life Embodied Emissions and Net-Zero Emissions Potential for a Mid-Rise Office Building Constructed with Mass Timber. Sustain. Mater. Technol. 2023, 35, 00528. [Google Scholar] [CrossRef]

- Laurin, L.; Dhaliwal, H. Life Cycle Environmental Impact Assessment. In Elsevier eBooks; Elsevier: Amsterdam, The Netherlands, 2017; pp. 225–232. [Google Scholar]

- Liu, Y.; Guo, H.; Sun, C.; Chang, W.S. Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China—A Life-Cycle Assessment Approach. Sustainability 2016, 8, 1047. [Google Scholar] [CrossRef]

- Lao, W.; Chang, L. Greenhouse Gas Footprint Assessment of Wood-Based Panel Production in China. J. Clean. Prod. 2023, 389, 136064. [Google Scholar] [CrossRef]

- Bergeron, F.C. Energy and Climate Impact Assessment of Waste Wood Recovery in Switzerland. Biomass Bioenergy 2016, 94, 245–257. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Marsono, A.K.B. Strategies for Reducing Greenhouse Gas Emissions from Residential Sector by Proposing New Building Structures in Hot and Humid Climatic Conditions. Build. Environ. 2017, 124, 357–368. [Google Scholar] [CrossRef]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental Benefits of Using Hybrid CLT Structure in Midrise Non-Residential Construction: An LCA Based Comparative Case Study in the U.S. Pac. Northwest. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Salcido, J.C.; Raheem, A.A.; Ravi, S. Comparison of Embodied Energy and Environmental Impact of Alternative Materials Used in Reticulated Dome Construction. Build. Environ. 2016, 96, 22–34. [Google Scholar] [CrossRef]

- Lu, H.R.; Hanandeh, A.E.; Gilbert, B.P. A Comparative Life Cycle Study of Alternative Materials for Australian Multi-Storey Apartment Building Frame Constructions: Environmental and Economic Perspective. J. Clean. Prod. 2017, 166, 458–473. [Google Scholar] [CrossRef]

- Al-Majali, Y.A.; Chirume, C.T.; Marcum, E.P.; Daramola, D.A.; Kappagantula, K.S.; Trembly, J.P. Coal-Filler-Based Thermoplastic Composites as Construction Materials: A New Sustainable End-Use Application. ACS Sustain. Chem. Eng. 2019, 7, 16870–16878. [Google Scholar] [CrossRef]

- Bowers, T.; Puettmann, M.E.; Ganguly, I.; Eastin, I. Cradle-to-Gate Life-Cycle Impact Analysis of Glued-Laminated (Glulam) Timber: Environmental Impacts from Glulam Produced in the US Pacific Northwest and Southeast. Prod. J. 2017, 67, 368–380. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life Cycle Assessment (LCA) of Cross-Laminated Timber (CLT) Produced in Western Washington: The Role of Logistics and Wood Species Mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef]

- Ferro, F.S.; Silva, D.A.L.; Lahr, F.A.R.; Argenton, M.; González-García, S. Environmental Aspects of Oriented Strand Boards Production. A Brazilian Case Study. J. Clean. Prod. 2018, 183, 710–719. [Google Scholar] [CrossRef]

- Lao, W.; Chang, L. Comparative Life Cycle Assessment of Medium Density Fiberboard and Particleboard: A Case Study in China. Ind. Crops Prod. 2023, 205, 117443. [Google Scholar] [CrossRef]

- Zhu, S.; Feng, H. End-of-Life Scenario-Based Assessment of Building Wood Waste Circulation through Deconstruction: A Case Study in Canada. Build. Environ. 2025, 287, 113835. [Google Scholar] [CrossRef]

- Larivière-Lajoie, R.; Blanchet, P.; Amor, B. Evaluating the Importance of the Embodied Impacts of Wall Assemblies in the Context of a Low Environmental Impact Energy Mix. Build. Environ. 2022, 207, 108534. [Google Scholar] [CrossRef]

- Pommier, R.; Grimaud, G.; Prinçaud, M.; Perry, N.; Sonnemann, G. LCA (Life Cycle Assessment) of EVP—Engineering Veneer Product: Plywood Glued Using a Vacuum Moulding Technology from Green Veneers. J. Clean. Prod. 2016, 124, 383–394. [Google Scholar] [CrossRef]

- Guo, H.; Liu, Y.; Meng, Y.; Huang, H.; Sun, C.; Shao, Y. A Comparison of the Energy Saving and Carbon Reduction Performance between Reinforced Concrete and Cross-Laminated Timber Structures in Residential Buildings in the Severe Cold Region of China. Sustainability 2017, 9, 1426. [Google Scholar] [CrossRef]

- Vaňová, R.; Štefko, J. Assessment of Selected Types of the Structural Engineered Wood Production from the Environmental Point of View. Acta Fac. Xylologiae Zvolen. Res. Publica Slovaca 2021, 63, 117–130. [Google Scholar] [CrossRef]

- Mashrah, W.A.H.; Boufendassa, R.; Fu, X.; Al-Mansour, A.; Yu, Y.; Amer, M.; Mo, S. Comprehensive Review of Engineered Bamboo in Structural Engineering: Comparative Insights into Laminated Bamboo and Bamboo Scrimber. Structures 2025, 76, 108896. [Google Scholar] [CrossRef]

- Xiong, W.; Xu, J.; Li, Z.; Xiao, Y. Use of Glued Laminated Bamboo (Glubam), and Cross-Laminated Bamboo and Timber (CLBT) in the Environmentally-Friendly Construction: A Study from the Perspective of Fatigue Propertiess. Eng. Struct. 2025, 342, 120979. [Google Scholar] [CrossRef]

- Mao, Y.; Hu, L.; Ren, Z.J. Engineered Wood for a Sustainable Future. Matter 2022, 5, 1326–1329. [Google Scholar] [CrossRef]

| EWP Type | Main Applications | Common Comparisons | Life Cycle Phases Covered | Notable Study Focus |

|---|---|---|---|---|

| GLT | Floor slabs, wall panels, beams, columns | Concrete, solid timber, CLT | Production, Use, End-of-Life | Hybrid structural systems |

| CLT | Walls, floors, roofs | Reinforced Concrete, NLT, DLT | Production, Use | High-rise buildings, recycling potential |

| LVL | Walls, framing, doors | GLT, OSB, Steel | Production, Use | Joinery and structural comparison |

| PW | Structural and non-structural panels | OSB, MDF | Mainly Production | New manufacturing techniques |

| OSB | Exterior walls, indoor panels | PW, FB | Production, some Use | Structural vs. indoor use |

| PB/FB | Indoor panels, furniture | OSB, PW, GLT | Mainly Production | Density-dependent performance |

| WPC | Specialized panels, decking | - | Production | Waste reuse, polymer modification |

| EWP Type | Common Functional Unit | Alternative Functional Units | Number of Studies Using Functional Unit | Study Focus |

|---|---|---|---|---|

| GLT | 1 m2 of floor or heated area | 1 ton of recovered wood [38] | 24 (floor area), 11 (entire system) | Structural applications, building systems |

| CLT | 1 m2 of floor or heated area | 1 hectare of forest land [39], 0.1316 m3 of CLT walls (5-story), 0.1064 m3 of CLT walls (12-story) [40] | 24 (floor area), 11 (entire system) | Mass timber buildings, high-rise |

| PW | 1 m3 of product | None | Majority of studies | Material-focused, production phase |

| OSB | 1 m3 of product | 455,500 m3 annual production volume (Lower Saxony) [41] | Majority of studies | Material-focused, production phase |

| PB/FB | 1 m3 of product | Full-scale wardrobe system [35] | Few studies | Indoor applications, furniture |

| LVL | 1 m3 of product or mass-based units (kg) [27,42] | Specific structural elements [43] | Few studies | Framing, structural applications |

| WPC | 1 ton or 1 kg [33,37] | None | Majority of studies | Product-focused, polymer modification |

| Country | Database | Reference | Country | Database | Reference |

|---|---|---|---|---|---|

| Australia | Literature review Forest and Wood Products Association Australia (FWPA) EPDs AusLCI version 36 EcoInvent version 3.71 | Tokede et al., 2022 Farjana et al., 2023 | Iran | Industry data literature review Ecoinvent database ETH-ESU 96 | Kouchaki-Penchah et al., 2016 Kouchaki-Penchah, Sharifi, Mousazadeh, & Zarea-Hosseinabadi, 2016 Hafezi et al., 2021 |

| Brazil | Industry data Literature review GaBi 6.5 LCI database Ecoinvent database | Freire et al., 2017 Piekarski et al., 2017 Ferro et al., 2018 D. a. L. Silva et al., 2020 | Japan | Industry data IDEA database Literature review | Nakano et al., 2017 Nakano, Koike, et al., 2020 Iwase et al., 2020 Nakano et al., 2020 |

| Canada | Ecoinvent database EPDs On-site measurement Literature review | Larivière-Lajoie et al., 2022 Shin et al., 2023 | Korea | EPDs One Click LCA database. | Amoruso & Schuetze, 2022 |

| China | On-site measurement Surveys/onsite interviews Literature review CLCD Ecoinvent Athena Sustainable Materials Institute USEI 2.2 ELCD Wood waste recycler ILCD IPCC NDRC | Liu et al., 2016 Guo et al., 2017 Hossain et al., 2018 S. Wang et al., 2018 Jia et al., 2019 Qiang et al., 2019 Liang et al., 2020 Zhang et al., 2020 C. X. Chen et al., 2021 Duan, Huang, Sun, et al., 2022 Duan, 2023 Wang et al., 2023 Lao & Li, 2023 Lao & Chang, 2023 | Malaysia | Literature review Ecoinvent database Simapro database MY-LCID | Balasbaneh & Marsono, 2017 Azman et al., 2021 Balasbaneh & Sher, 2021 Balasbaneh, Sher, Yeoh, & Koushfar, 2022 Balasbaneh & Sher, 2022 Balasbaneh, Sher, & Yeoh, 2022 Balasbaneh, Sher, Yeoh, & Yasin, 2022 |

| Denmark | EPDs Literature review | Felicioni et al., 2023 | Latvia | Literature review | Vamza et al., 2021 |

| Europe | Literature review Ecoinvent database EPDs GaBi professional database | Sommerhuber et al., 2017 Dias et al., 2020 Morris et al., 2021 Vaňová & Štefko, 2021 Sugahara et al., 2023 | Norway | Databased provided by the building owners and from architectural drawings Ecoinvent v3.5 | Lolli et al., 2019 Andersen et al., 2022 |

| France | Ecoinvent | Pommier et al., 2016 | Pakistan | Particleboard mill surveys Literature review | Hussain et al., 2017 |

| Finland | Literature review GaBi LCI data | Liikanen et al., 2019 | Portugal | Ecoinvent database | Silva et al., 2022 |

| Germany | Literature review Ecoinvent database SoCa V.1 | Risse et al., 2019 Taskhiri et al., 2019 Zeug et al., 2022 | Slovakia | Industry data | Vilčeková et al., 2020 |

| Italy | Ecoinvent databse Literature review | Corradini et al., 2018 Pittau et al., 2019 | Slovenia | IBO life cycle inventory databases | Leskovar et al., 2019 |

| South Korea | Literature review EPDs | Shin, Wi, et al., 2023 | USA | Literature review EcoInvent database Industry data EPDs NREL Life Cycle Inventory Database U.S. LCI Database Athena LCI database DATASMART Athena Impact Estimator (AIE) ELCD GaBi database CORRIM reports | Salcido et al., 2016 Bowers et al., 2017 R. D. Bergman & Alanya-Rosenbaum, 2017 Chen et al., 2019 Al-Majali et al., 2019 Puettmann et al., 2019 Pierobon et al., 2019 Lan et al., 2020 Z. Chen et al., 2020 Allan & Phillips, 2021 Liang et al., 2021 Greene et al., 2023 Greene et al., 2023 Atnoorkar et al., 2024 |

| Spain | Literature review Ecoinvent 3.0 EPDs | Vidal et al., 2019 Garnica et al., 2023 | |||

| Sweden | EPDs | Al-Najjar & Dodoo, 2022 | |||

| Türkiye | Industry data Literature review Ecoinvent database | Yılmaz, 2024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, C.; Zhu, S.; Feng, H. Life Cycle Assessment of Engineered Wood Products in the Building Sector: A Review. Buildings 2025, 15, 4193. https://doi.org/10.3390/buildings15224193

Jin C, Zhu S, Feng H. Life Cycle Assessment of Engineered Wood Products in the Building Sector: A Review. Buildings. 2025; 15(22):4193. https://doi.org/10.3390/buildings15224193

Chicago/Turabian StyleJin, Ciyuan, Shiyao Zhu, and Haibo Feng. 2025. "Life Cycle Assessment of Engineered Wood Products in the Building Sector: A Review" Buildings 15, no. 22: 4193. https://doi.org/10.3390/buildings15224193

APA StyleJin, C., Zhu, S., & Feng, H. (2025). Life Cycle Assessment of Engineered Wood Products in the Building Sector: A Review. Buildings, 15(22), 4193. https://doi.org/10.3390/buildings15224193