Research on Causes of Unsafe Behaviors Among Special Operations Personnel in Building Construction Based on DEMATEL-ISM-BN

Abstract

1. Introduction

2. Identification of Causal Factors for Unsafe Behaviors Among Special Operation Personnel from the AMO Theory Perspective

2.1. Definition and Operational Characteristics of Special-Operation Personnel in Building Construction

- (1)

- Technical Complexity and Professional Barriers

- (2)

- High-Risk Nature of Operations and Severity of Accident Consequences

- (3)

- Strong Coupling within the Human-Machine-Environment System and High Demands for Coordination

- (4)

- Mandatory Safety Management Requirements and Public Safety Attributes

2.2. Ability-Motivation-Opportunity Theoretical Framework

2.3. Determination of Causal Factors for Unsafe Behaviors

3. Research Methods

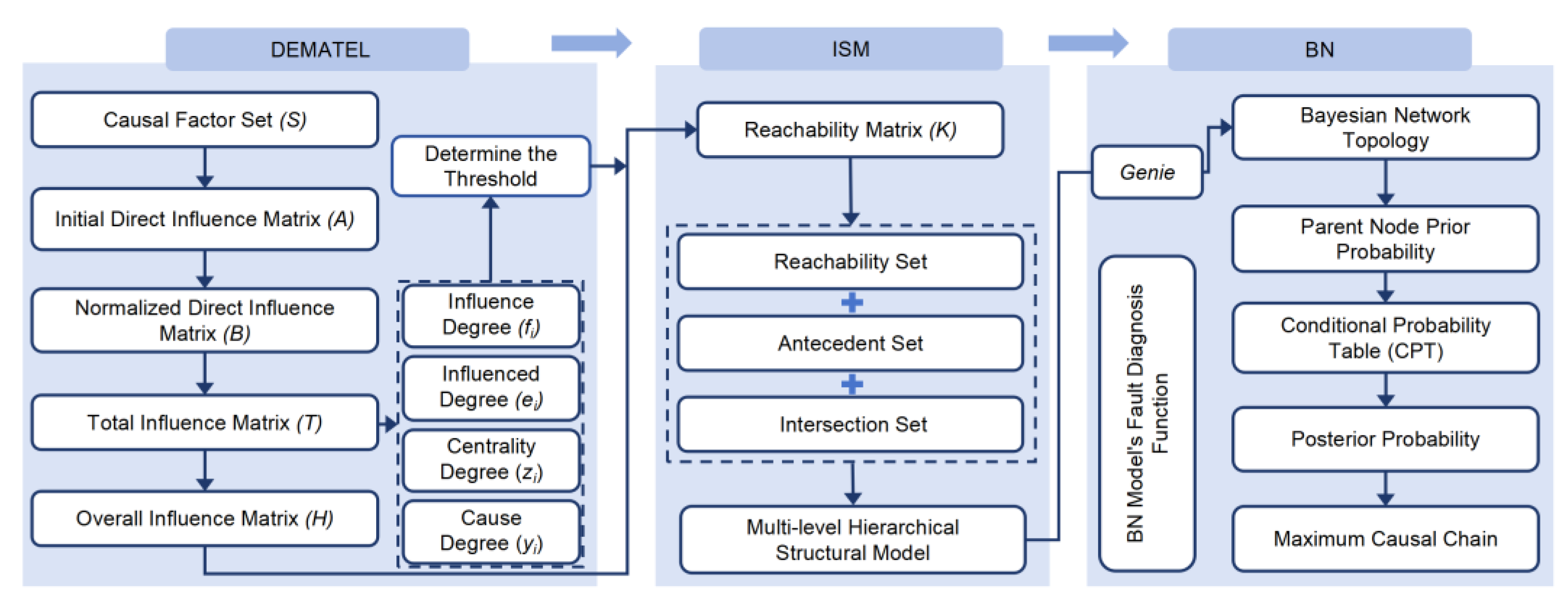

3.1. DEMATEL-ISM-BN Methodological Analysis

3.2. Procedural Steps of the DEMATEL-ISM-BN Method

4. Case Study

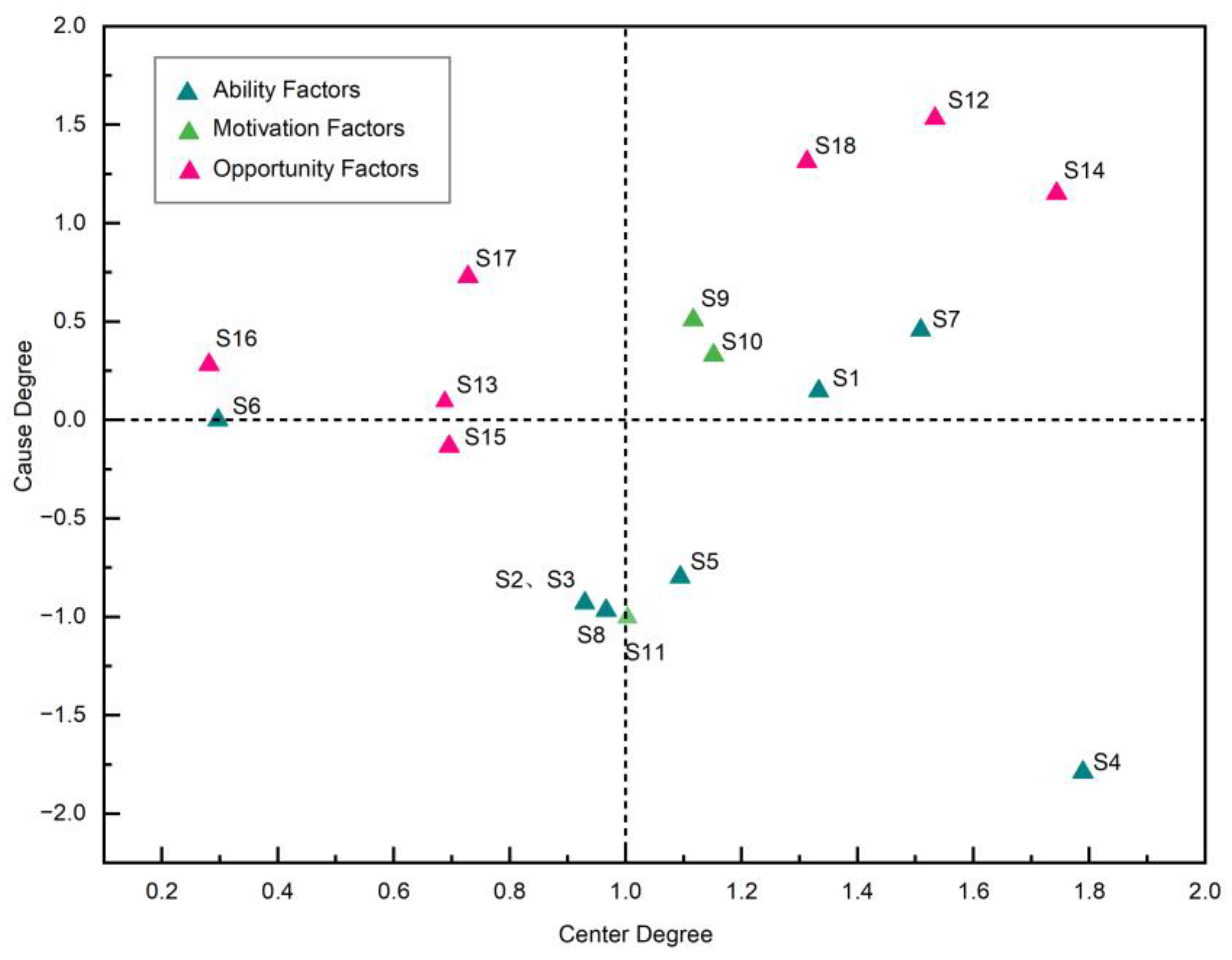

4.1. Causal Interdependence Analysis Based on DEMATEL

- (1)

- Center Degree Analysis

- (2)

- Cause Degree Analysis

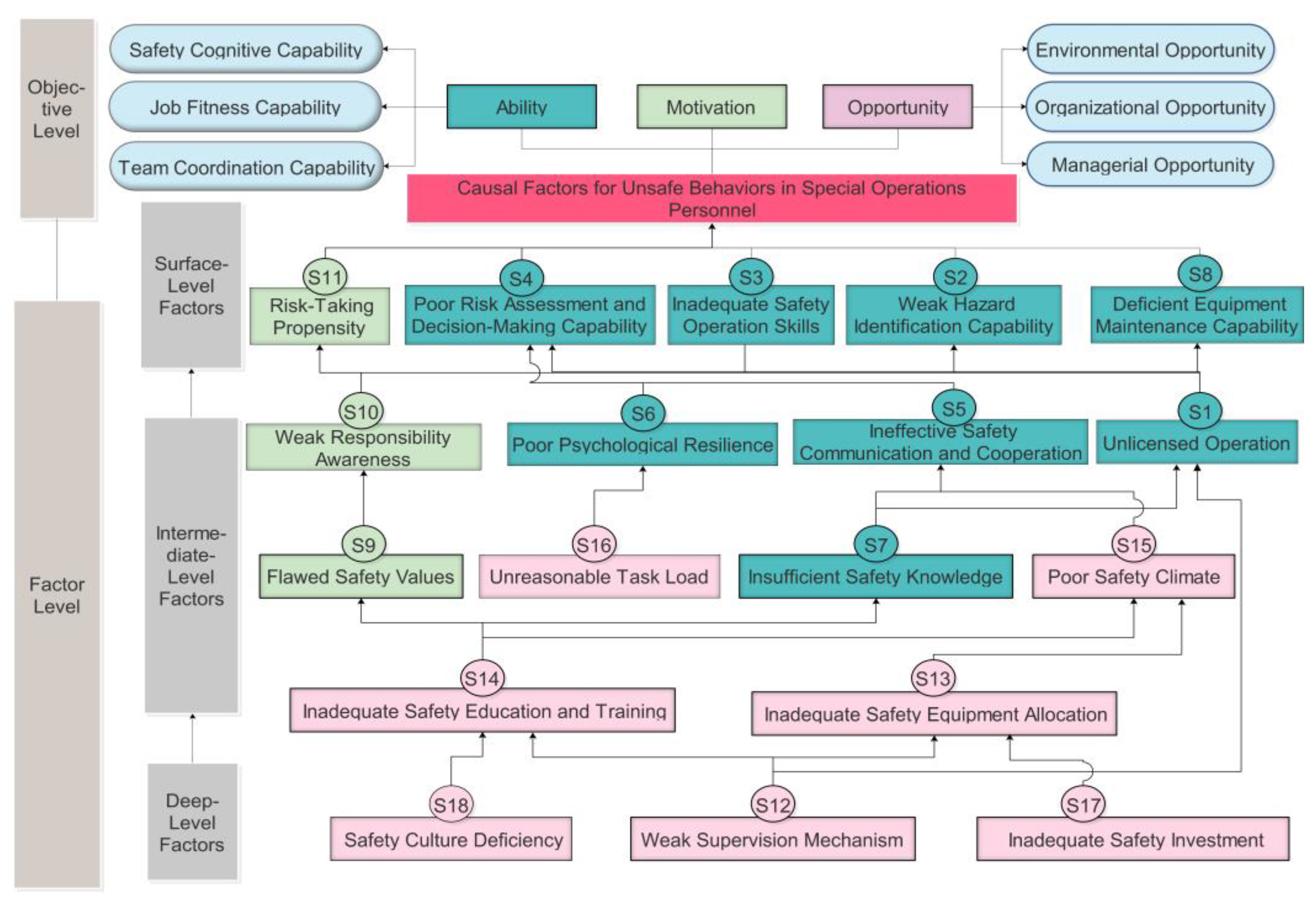

4.2. Hierarchical Causation Analysis Based on ISM

- (1)

- Deep-Level Factors

- (2)

- Intermediate-Level Factors

- (3)

- Surface-Level Factors

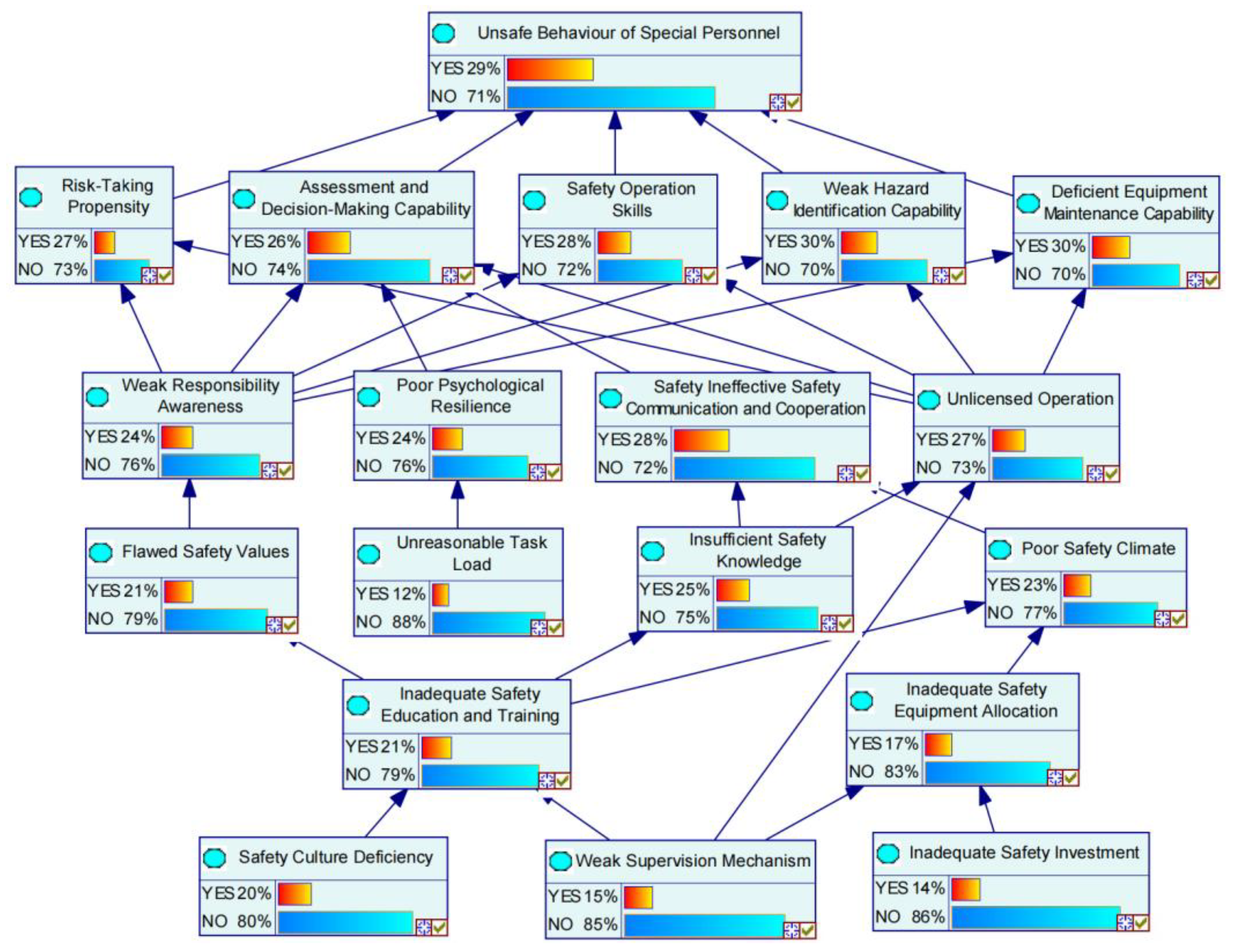

4.3. Bayesian Network-Based Causal Path Analysis

5. Results Analysis and Discussion

5.1. Analysis of Results Based on the Ability, Motivation, Opportunity Three-Dimensional Framework

- (1)

- Ability Dimension

- (2)

- Motivation Dimension

- (3)

- Opportunity Dimension

5.2. Management Implications and Practical Recommendations

6. Conclusions

- (1)

- Using the DEMATEL method to analyze the causal characteristics of each factor, the study found that within the motivation dimension, weak responsibility awareness and flawed safety values exhibit high centrality and causality, serving as prerequisites for developing risk-taking propensity. Within the opportunity dimension, weak supervision mechanisms, inadequate safety education and training, and safety culture deficiency occupy core positions in the causal network, constituting systemic drivers of unsafe behavior. Within the ability dimension, poor risk assessment and decision-making abilities, insufficient safety knowledge reserves, and unlicensed operation are key manifestations of ability deficiencies.

- (2)

- A multi-level hierarchical structure model was developed using the ISM method, which revealed a five-tier causal relationship behind unsafe behaviors. Causative factors in the opportunity dimension predominantly reside at the lowest level, while factors in the motivation and ability dimensions occupy the middle and upper levels. Among these, safety culture deficiency and inadequate safety investment within unsafe opportunities represent the fundamental causes of unsafe behaviors by personnel, warranting particular attention. Weak supervision mechanisms, and inadequate safety investment within unsafe opportunities are the root causes of unsafe behaviors among special operations personnel and warrant particular attention.

- (3)

- Through the BN model, the primary chain of unsafe behaviors among special operations personnel was identified as: safety culture deficiency (S18) → Inadequate safety education and training (S14) → Insufficient safety knowledge (S7) → Unlicensed operation (S1) → Risk-taking propensity (S11). Identifying these chain factors enables construction managers to implement targeted, sequential behavioral controls for special operations personnel and develop scientifically grounded plans, thereby reducing the blind implementation of measures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xia, N.P.; Yang, G.S. Identification of Safety Impact Factors of Special Operations in Construction. J. Civ. Eng. Manag. 2016, 33, 125–129. [Google Scholar]

- Cheng, L.H.; Ren, H.N.; Guo, H.M.; Cao, D.Q. Research on the evaluation method for safety cognitive ability of workers in high-risk construction positions. Eng. Constr. Archit. Manag. 2024. [Google Scholar] [CrossRef]

- Sun, K.C.; Li, Q.; Xu, X.F.; Sun, Z.W. Risk analysis on human factors in operation of high risk construction based on dynamic Bayesian network. J. Hydroelectr. Eng. 2017, 36, 28–35. [Google Scholar]

- Gu, B.T.; Cao, S.H.; Wang, Y.; Huang, Y.C.; Fang, D.P. Types and characteristics of unsafe behaviors in construction teamwork. J. Tsinghua Univ. (Sci. Technol.) 2023, 63, 160–168. [Google Scholar]

- Ni, G.D.; Li, H.K.; Cao, M.X.; Wang, K.D. Inducing Factors of and Intervention Countermeasures against Unsafe Behavior of New Generation of Construction Workers. Saf. Environ. Eng. 2022, 29, 8–16. [Google Scholar]

- Zhu, L.; Xiong, K. Identification of key factors influencing unsafe behavior of decoration workers. Int. J. Occup. Saf. Ergon. 2024, 30, 936–945. [Google Scholar] [CrossRef]

- Raviv, G.; Shapira, A.; Fishbain, B. AHP-based analysis of the risk potential of safety incidents: Case study of cranes in the construction industry. Saf. Sci. 2017, 91, 298–309. [Google Scholar] [CrossRef]

- Li, Q.M.; Ji, C.; Yuan, J.; Han, R.R. Developing dimensions and key indicators for the safety climate within China’s construction teams: A questionnaire survey on construction sites in Nanjing. Saf. Sci. 2017, 93, 266–276. [Google Scholar] [CrossRef]

- Yue, H.Z.; Ye, G.; Cao, H.Y.; Liu, Q.J.; Xiang, Q.T.; Luo, Y.L. Exploring the Internal Influence Mechanism of Group Safety Behavior of Construction Workers: Qualitative Method Approach. J. Constr. Eng. Manag. 2024, 150, 04024163. [Google Scholar] [CrossRef]

- Malakoutikhah, M.; Jahangiri, M.; Alimohammadlou, M.; Faghihi, S.A.; Kamalinia, M. The Factors Affecting Unsafe Behaviors of Iranian Workers: A Qualitative Study Based on Grounded Theory. Saf. Health Work 2021, 12, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Malakoutikhah, M.; Jahangiri, M.; Alimohammadlou, M.; Jahangiri, M.; Rabiei, H.; Faghihi, S.A.; Kamalinia, M. Modeling the factors affecting unsafe behaviors using the fuzzy best-worst method and fuzzy cognitive map. Appl. Soft Comput. 2022, 114, 108119. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, B.Y.; Wang, Q.Y.; Huang, Q.Q.; You, M.Y. Study on the formation mechanism of unsafe behavior of construction workers from the perspective of TPB. J. Saf. Environ. 2024, 24, 2701–2711. [Google Scholar]

- Gou, Y.L.; Zhang, Y.Z. Influence effect of safety cognitive bias on unsafe behavior of construction workers in different generations. J. Saf. Sci. Technol. 2024, 20, 216–222. [Google Scholar]

- Zhang, Z.T.; Li, H.; Guo, H.L.; Wu, Y.; Luo, Z.B. Causal inference of construction safety management measures towards workers’ safety behaviors: A multidimensional perspective. Saf. Sci. 2024, 172, 106432. [Google Scholar] [CrossRef]

- Huang, Y.C.; Li, B.N.; Yu, X.X.; Wang, Y.; Fang, D.P. Path analysis of attachment in the safety interactions of construction team members. J. Tsinghua Univ. (Sci. Technol.) 2023, 63, 169–178. [Google Scholar]

- Duan, P.S.; Zhou, J.L. Cascading vulnerability analysis of unsafe behaviors of construction workers from the perspective of network modeling. Eng. Constr. Archit. Manag. 2021, 30, 1037–1060. [Google Scholar] [CrossRef]

- Guo, S.Y.; Tang, B.; Liang, K.Z.; Zhou, X.Y.; Li, J.C. Comparative Analysis of the Patterns of Unsafe Behaviors in Accidents between Building Construction and Urban Railway Construction. J. Constr. Eng. Manag. 2021, 147, 5. [Google Scholar] [CrossRef]

- Guo, S.Y.; Zhou, X.Y.; Tang, B.; Gong, P.S. Exploring the behavioral risk chains of accidents using complex network theory in the construction industry. Phys. A-Stat. Mech. Appl. 2020, 560, 125012. [Google Scholar] [CrossRef]

- Yao, F.Y.; Shi, C.F.; Wang, X.W.; Ji, Y.B.; Liu, Y.; Li, H.X. Exploring the intentional unsafe behavior of workers in prefabricated construction based on structural equation modeling. Environ. Sci. Pollut. Res. 2024, 31, 1621–1636. [Google Scholar] [CrossRef]

- Blumberg, M.; Pringle, C.D. The missing opportunity in organizational research: Some implications for a theory of work performance. Acad. Manag. Rev. 1982, 7, 560–569. [Google Scholar] [CrossRef]

- Yu, X.Z.; Mou, R.F. Research on factors influencing railway accidents based on DEMATEL and ISM integrated method. J. Saf. Environ. 2022, 22, 2334–2341. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Circular on Issuing the “Administrative Regulations for Special-Type Operation Personnel in Construction”: Jian Zhi [2008] No. 75. [EB/OL]. 2008.04.18. Available online: https://www.scsfjt.com/uploads/20230824/7c35f18a4b94b6b6a48d7f9433f780b2.pdf (accessed on 20 October 2025).

- Enno, S.; Aleda, V.; Sridhar, B. How Motivation, Opportunity, and Ability Drive Knowledge Sharing: The Constraining-factor Model. J. Oper. Manag. 2008, 26, 426–445. [Google Scholar]

- Yang, S.; Yao, W.B.; Wang, T.; Cheng, B.Q.; Zhu, S.Y. Research on influence of safety motivation on construction workers safety behavior based on AMO-SDT. China Saf. Sci. J. 2025, 35, 19–27. [Google Scholar]

- Ye, G.; Yang, L.J.; Wang, Y.H.; Wei, Y.; Fu, Y. Review on the influence paths of unsafe behavior of construction workers. J. Chongqing Univ. 2020, 43, 111–120. [Google Scholar]

- Liu, W.Y.; Meng, Q.F.; Li, Z.; Chong, H.Y.; Li, K.Y.; Tang, H. Linking organizational safety support and construction workers’ safety behavior: The roles of safety motivation, emotional exhaustion and psychosocial safety climate. Eng. Constr. Archit. Manag. 2024, 22–30. [Google Scholar] [CrossRef]

- Törner, M.; Pousette, A. Coping with Paradoxical Demands Through an Organizational Climate of Perceived Organizational Support: An Empirical Study Among Workers in Construction and Mining Industry. J. Appl. Behav. Sci. 2017, 53, 117–141. [Google Scholar] [CrossRef]

- Ni, G.D.; Zhang, Q.; Fang, Y.Q.; Zhang, Z.Y.; Qian, Y.N.; Wang, W.S.; Deng, Y.L. How resilient safety culture correct unsafe behavior of new generation of construction workers: The mediating effects of job crafting and perceived work meaningfulness. Eng. Constr. Archit. Manag. 2022, 30, 4821–4845. [Google Scholar] [CrossRef]

- Wu, F.; Xu, H.Y.; SUN, K.S.; Hsu, W.L. Analysis of Behavioral Strategies of Construction Safety Subjects Based on the Evolutionary Game Theory. Buildings 2022, 12, 313. [Google Scholar] [CrossRef]

- Liang, Q.; Zhou, Z.Y.; Ye, G.; SHEN, L.Y. Unveiling the mechanism of construction workers’ unsafe behaviors from an occupational stress perspective: A qualitative and quantitative examination of a stress-cognition-safety model. Saf. Sci. 2022, 145, 105486. [Google Scholar] [CrossRef]

- Yu, J.Y.; Wang, J.Q.; Shi, Q.Y.; Xu, J.; Wang, J.F. Exploring job competency related to intelligent construction in China using a text mining method. Eng. Constr. Archit. Manag. 2024. [Google Scholar] [CrossRef]

- Acheampong, A.; Adjei, E.K.; Adade-Boateng, A.; Acheamfour, V.K.; Afful, A.E.; Boateng, E. Impact of construction workers informal safety communication (CWISC) on safety performance on construction sites. Eng. Constr. Archit. Manag. 2025, 32, 4338–4356. [Google Scholar] [CrossRef]

- Li, G.L.; Zhang, M.; Li, Y.L. Meta-analysis of the Relationship between Safety Climate and Safety Behavior of Construction Workers. Saf. Environ. Eng. 2023, 30, 13-20+44. [Google Scholar]

- Cheng, L.H.; Zhao, X.D.; Hao, J. Research on influencing factors of construction workers’ safety competency integrating ISM and G1 method. China Saf. Sci. J. 2023, 33, 61–68. [Google Scholar]

- Cheng, L.H.; Zhao, X.D.; Hao, J.; Cao, D.Q.; Jiang, B.L. Influence of construction workers’ safety ability on safety behavior Dual perspectives of information cognition and AMO theory. J. Xi’an Univ. Sci. Technol. 2023, 43, 449–456. [Google Scholar]

- Hashiguchi, N.; Sengoku, S.; Kubota, Y.; Kitahara, S.; Lim, Y.; Kodama, K. Age-Dependent Influence of Intrinsic and Extrinsic Motivations on Construction Worker Performance. Int. J. Environ. Res. Public Health 2021, 18, 111. [Google Scholar] [CrossRef] [PubMed]

- Idrees, M.D.; Hafeez, M.; Kim, J.Y. Workers’ Age and the Impact of Psychological Factors on the Perception of Safety at Construction Sites. Sustainability 2017, 9, 745. [Google Scholar] [CrossRef]

- Man, S.S.; Xie, Y.H.; Chen, Y.W.; Chan, A.H.S.; Liu, L. Role of safety supervision, coworker support and safety training in shaping the safety behavior of construction workers. Saf. Sci. 2025, 192, 106998. [Google Scholar] [CrossRef]

- Shi, X.B.; Liu, Y.; Ma, K.K.; Gu, Z.X.; Ojum, C.; Opoku, A.; Liu, Y. Evaluation of risk factors affecting the safety of coal mine construction projects using an integrated DEMATEL-ISM approach. Eng. Constr. Archit. Manag. 2025, 32, 3432–3452. [Google Scholar] [CrossRef]

- Hon, C.K.H.; Sun, C.J.Y.; Xia, B.; Jimmieson, N.L.; Way, K.A.; Wu, P.P.Y. Applications of Bayesian approaches in construction management research: A systematic review. Eng. Constr. Archit. Manag. 2022, 29, 2153–2182. [Google Scholar] [CrossRef]

- Xue, X.J.; Xin, C.C.; Xu, T.P.; Liu, T.S. Cause analysis of falling accidents in construction engineering based on improved ISM-MICMAC. J. Saf. Environ. 2023, 23, 2802–2809. [Google Scholar]

- Xue, Y.; Luo, X.; Li, H.J.; Liu, J. Shield construction safety risks and their interrelations analysis of subway tunnel undercrossing a river based on Grey-DEMATEL-ISM. Front. Public Health 2025, 13, 1536706. [Google Scholar] [CrossRef]

- Li, G.Y.; Wu, X.F.; Han, J.C.; Li, B.; Huang, Y.F.; Wang, Y.Q. Flood risk assessment by using an interpretative structural modeling based Bayesian network approach (ISM-BN): An urban-level analysis of Shenzhen, China. J. Environ. Manag. 2023, 329, 117040. [Google Scholar] [CrossRef]

- Wang, J.W.; Guo, F.; Song, Y.H.; Liu, Y.P.; Hu, X.; Yuan, C.B. Safety Risk Assessment of Prefabricated Buildings Hoisting Construction: Based on IHFACS-ISAM-BN. Buildings 2022, 12, 811. [Google Scholar] [CrossRef]

- Wang, Z.F.; He, C.R.; Deng, S.Y.; Xie, K.Y.; Liu, W. Analysis of Urban Gas Pipeline Network Safety Operation Influencing Factors Integrating Fuzzy DEMATEL-ISM-BN. Saf. Environ. Eng. 2025, 1–12. [Google Scholar] [CrossRef]

- Rahman, F.A.; Arifin, K.; Abas, A.; Mahfudz, M.; Cyio, M.B.; Khairil, M.; Ali, M.N.; Lampe, I.; Samad, M.A. Sustainable Safety Management: A Safety Competencies Systematic Literature Review. Sustainability 2022, 14, 6885. [Google Scholar] [CrossRef]

- Nykänen, M.; Puro, V.; Tiikkaja, M.; Kannisto, H.; Lantto, E.; Simpura, F.; Uusitalo, J.; Lukander, K.; Räsänen, T.; Teperi, A.M. Evaluation of the efficacy of a virtual reality-based safety training and human factors training method: Study protocol for a randomised-controlled trial. Inj. Prev. 2020, 26, 360–369. [Google Scholar] [CrossRef] [PubMed]

- Ghoddousi, P.; Zamani, A. The effect of emotional intelligence, motivation and job burnout on safety behaviors of construction workers: A case study. Eng. Constr. Archit. Manag. 2023, 32, 1211–1228. [Google Scholar] [CrossRef]

| Dimension | Causal Factors | Meaning | |

|---|---|---|---|

| Ability | S1 | Unlicensed Operation | Operating without a special operations qualification certificate (e.g., unlicensed personnel operating construction elevators, causing a fall accident due to unfamiliarity with the emergency stop procedure). |

| S2 | Weak Hazard Identification Capability | Unable to identify or assess on-site hazards (e.g., scaffolders fail to notice cracks in the scaffolding foundation due to subsidence and continue to raise the scaffolding). | |

| S3 | Inadequate Safety Operation Skills | Technical inexperience or failure to master standard operating procedures (e.g., a newly hired signalman who has not mastered the blind spot control techniques for “no entry within the swing radius of the load” and failed to clear the area when directing the hoisting of steel bars, resulting in the load swinging and colliding with workers below). | |

| S4 | Poor Risk Assessment and Decision-Making Capability | Misjudgment in response to sudden situations (e.g., a tower crane operator insisting on lifting heavy objects in windy weather, resulting in loss of control and a fall). | |

| S5 | Ineffective Safety Ineffective Safety Communication and Cooperation | Poor teamwork leads to miscommunication (e.g., crane operators and signalmen misunderstanding each other’s hand signals, causing the load to hit workers below). | |

| S6 | Poor Psychological Resilience | Emotional fluctuations or tension can affect operational safety (e.g., an elevator operator distracted by a family dispute fails to pay attention to the floor where the elevator stops, causing someone to fall). | |

| S7 | Insufficient Safety Knowledge | Lack of necessary safety regulations and professional technical knowledge (e.g., welders working in confined spaces without testing harmful gas concentrations, resulting in poisoning). | |

| S8 | Deficient Equipment Maintenance Capability | Unfamiliarity with equipment maintenance or fault handling procedures (e.g., excavator operators failing to replace worn hydraulic hoses in a timely manner, resulting in burst pipes and loss of control during construction). | |

| Motivation | S9 | Flawed Safety Values | Insufficient awareness of the importance of safety, prioritizing efficiency and progress over safety (e.g., tower crane operators overloading the crane to speed up construction progress). |

| S10 | Weak Responsibility Awareness | Lack of responsibility for the safety consequences of one’s own actions (e.g., scaffolding erectors failing to check the tightness of fasteners, leading to a risk of collapse). | |

| S11 | Risk-Taking Propensity | Habitually engaging in high-risk behavior and taking chances (such as workers at heights not wearing safety harnesses or climbing steel structures with bare hands). | |

| Opportunity | S12 | Weak Supervision Mechanism | Safety supervision is lacking or merely perfunctory (e.g., safety officers do not regularly check the operating certificates of special operations personnel and tacitly allow uncertified personnel to operate welding machines). |

| S13 | Inadequate Safety Equipment Allocation | Lack of necessary protective equipment or equipment failure (e.g., electricians not equipped with insulated gloves, or lift limiters not repaired when faulty). | |

| S14 | Inadequate Safety Education and Training | Training content is vague, infrequent, or lacks specificity (e.g., newly hired crane signal operators only receive theoretical training and do not participate in on-site command practical exercises). | |

| S15 | Poor Safety Climate | Construction sites generally disregard safety rules, creating a negative atmosphere (e.g., workers mock welders who wear protective masks as required for being “afraid of death,” and there is collective rejection of safety measures). | |

| S16 | Unreasonable Task Load | Overworking leads to fatigue or psychological stress (e.g., crane operators working under excessive pressure misjudge the distance of the load due to fatigue, causing a collision). | |

| S17 | Inadequate Safety Investment | Companies cut safety resources to save costs (e.g., construction companies purchase substandard safety ropes or refuse to install fall protection systems on aerial work platforms). | |

| S18 | Safety Culture Deficiency | Companies lack long-term safety values and institutional support (e.g., management never holds safety meetings, and only fines are imposed after accidents without any corrective measures). | |

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 | S13 | S14 | S15 | S16 | S17 | S18 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 0 | 4 | 4 | 4 | 0 | 0 | 0 | 4 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S5 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S6 | 0 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S7 | 4 | 3 | 3 | 3 | 4 | 0 | 0 | 3 | 0 | 0 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S9 | 0 | 3 | 3 | 3 | 0 | 0 | 0 | 3 | 0 | 4 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S10 | 0 | 4 | 4 | 4 | 0 | 0 | 0 | 4 | 0 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S12 | 4 | 1 | 1 | 1 | 2 | 0 | 3 | 1 | 0 | 0 | 3 | 0 | 4 | 4 | 3 | 0 | 0 | 0 |

| S13 | 0 | 0 | 0 | 2 | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 4 | 0 | 0 | 0 |

| S14 | 3 | 2 | 2 | 2 | 3 | 0 | 4 | 2 | 4 | 3 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S15 | 0 | 0 | 0 | 3 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S16 | 0 | 0 | 0 | 3 | 0 | 4 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S17 | 0 | 0 | 0 | 1 | 2 | 0 | 3 | 1 | 0 | 0 | 0 | 0 | 4 | 0 | 3 | 0 | 0 | 0 |

| S18 | 2 | 1 | 1 | 1 | 2 | 0 | 3 | 1 | 3 | 2 | 1 | 0 | 0 | 4 | 0 | 0 | 0 | 0 |

| Factors | Impact Degree | Affected Degree | Center Degree | Cause Degree | Weight | Ranking | Factor Type |

|---|---|---|---|---|---|---|---|

| S1 | 0.74074 | 0.59224 | 1.33298 | 0.1485 | 0.06979 | 5 | Cause Factor |

| S2 | 0.0000 | 0.92933 | 0.92933 | −0.92933 | 0.04866 | 12 | Effect Factor |

| S3 | 0.0000 | 0.92933 | 0.92933 | −0.92933 | 0.04866 | 12 | Effect Factor |

| S4 | 0.0000 | 1.789 | 1.789 | −1.789 | 0.09366 | 1 | Effect Factor |

| S5 | 0.14815 | 0.94579 | 1.09394 | −0.79764 | 0.05727 | 9 | Effect Factor |

| S6 | 0.14815 | 0.14815 | 0.2963 | 0.0000 | 0.01551 | 17 | Cause Factor |

| S7 | 0.98354 | 0.52538 | 1.50892 | 0.45816 | 0.079 | 4 | Cause Factor |

| S8 | 0.0000 | 0.96636 | 0.96636 | −0.96636 | 0.05059 | 11 | Effect Factor |

| S9 | 0.81344 | 0.30316 | 1.1166 | 0.51028 | 0.05846 | 8 | Cause Factor |

| S10 | 0.74074 | 0.41117 | 1.15191 | 0.32957 | 0.06031 | 7 | Cause Factor |

| S11 | 0.0000 | 1.0034 | 1.0034 | −1.0034 | 0.05253 | 10 | Effect Factor |

| S12 | 1.53365 | 0.0000 | 1.53365 | 1.53365 | 0.08029 | 3 | Cause Factor |

| S13 | 0.39145 | 0.2963 | 0.68775 | 0.09515 | 0.03601 | 16 | Cause Factor |

| S14 | 1.44729 | 0.2963 | 1.74359 | 1.15099 | 0.09129 | 2 | Cause Factor |

| S15 | 0.28121 | 0.41427 | 0.69548 | −0.13306 | 0.03641 | 15 | Effect Factor |

| S16 | 0.28121 | 0.0000 | 0.28121 | 0.28121 | 0.01472 | 18 | Cause Factor |

| S17 | 0.72801 | 0.0000 | 0.72801 | 0.72801 | 0.03812 | 14 | Cause Factor |

| S18 | 1.31257 | 0.0000 | 1.31257 | 1.31257 | 0.06872 | 6 | Cause Factor |

| S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 | S11 | S12 | S13 | S14 | S15 | S16 | S17 | S18 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S2 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S3 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S4 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S5 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S6 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S7 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S8 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S9 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S10 | 0 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S11 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| S12 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 0 |

| S13 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 |

| S14 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 |

| S15 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 |

| S16 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 |

| S17 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 0 | 1 | 0 |

| S18 | 1 | 1 | 1 | 1 | 1 | 0 | 1 | 1 | 1 | 1 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, L.; Miao, Y.; Guo, H.; Ren, H.; Zhu, W. Research on Causes of Unsafe Behaviors Among Special Operations Personnel in Building Construction Based on DEMATEL-ISM-BN. Buildings 2025, 15, 4184. https://doi.org/10.3390/buildings15224184

Cheng L, Miao Y, Guo H, Ren H, Zhu W. Research on Causes of Unsafe Behaviors Among Special Operations Personnel in Building Construction Based on DEMATEL-ISM-BN. Buildings. 2025; 15(22):4184. https://doi.org/10.3390/buildings15224184

Chicago/Turabian StyleCheng, Lianhua, Yuxin Miao, Huimin Guo, Huina Ren, and Wenyu Zhu. 2025. "Research on Causes of Unsafe Behaviors Among Special Operations Personnel in Building Construction Based on DEMATEL-ISM-BN" Buildings 15, no. 22: 4184. https://doi.org/10.3390/buildings15224184

APA StyleCheng, L., Miao, Y., Guo, H., Ren, H., & Zhu, W. (2025). Research on Causes of Unsafe Behaviors Among Special Operations Personnel in Building Construction Based on DEMATEL-ISM-BN. Buildings, 15(22), 4184. https://doi.org/10.3390/buildings15224184