The Deformation Characteristics and Patterns of Adjacent Existing Metro Structures Caused by Foundation Pit Excavation Under Different Support Forms

Abstract

1. Introduction

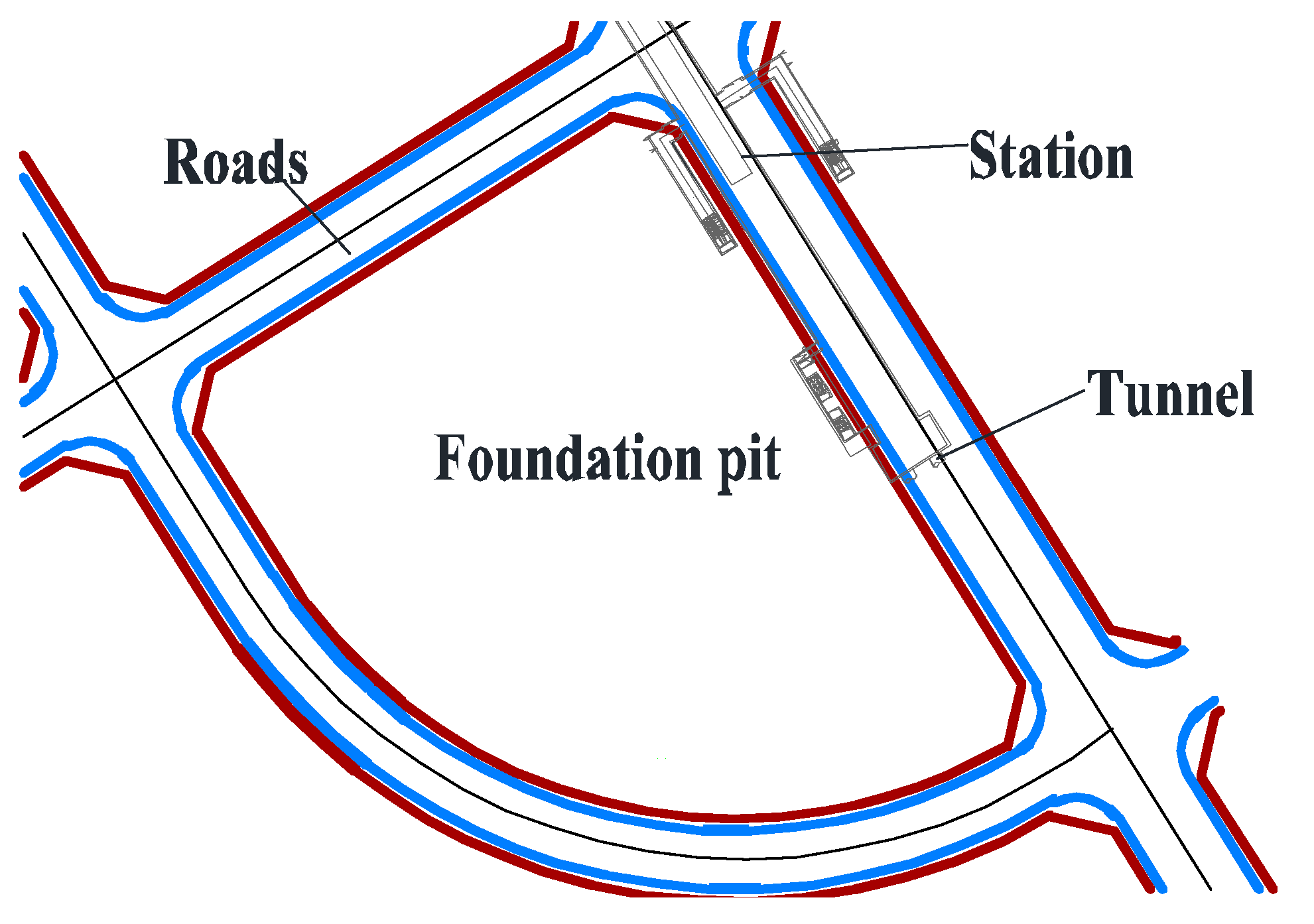

2. Engineering Situation

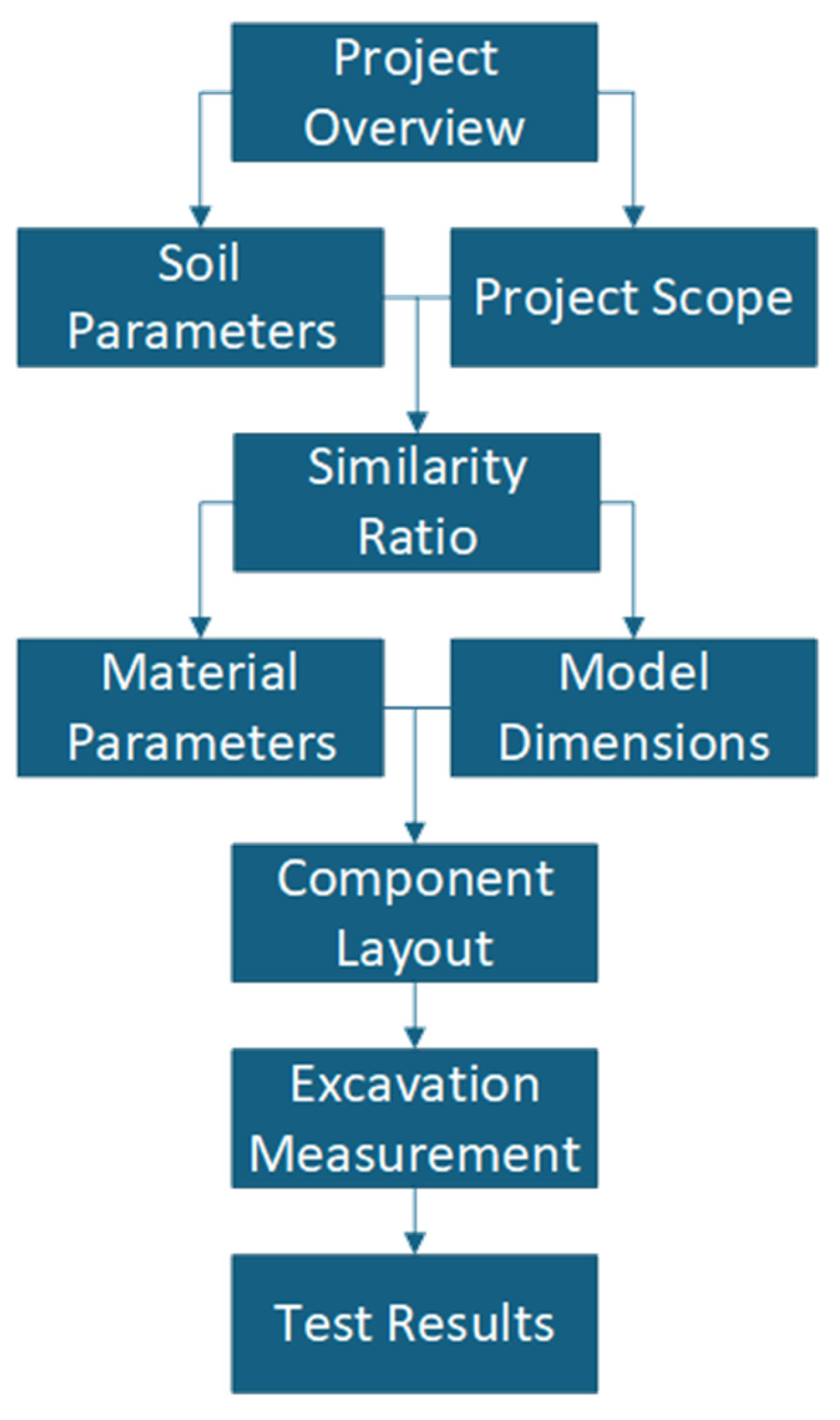

3. Test Design

3.1. Similar Design

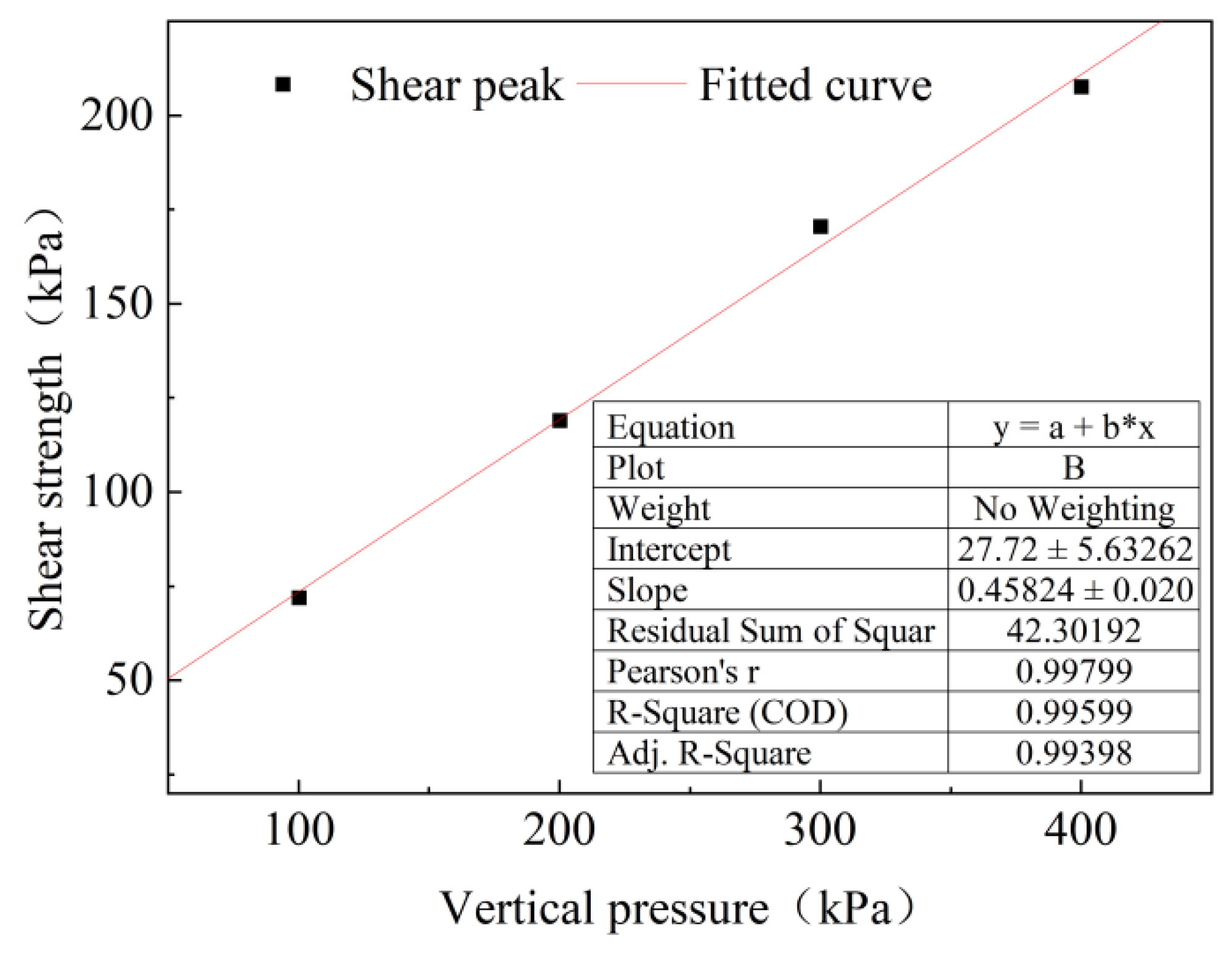

3.2. Selection of Similar Materials

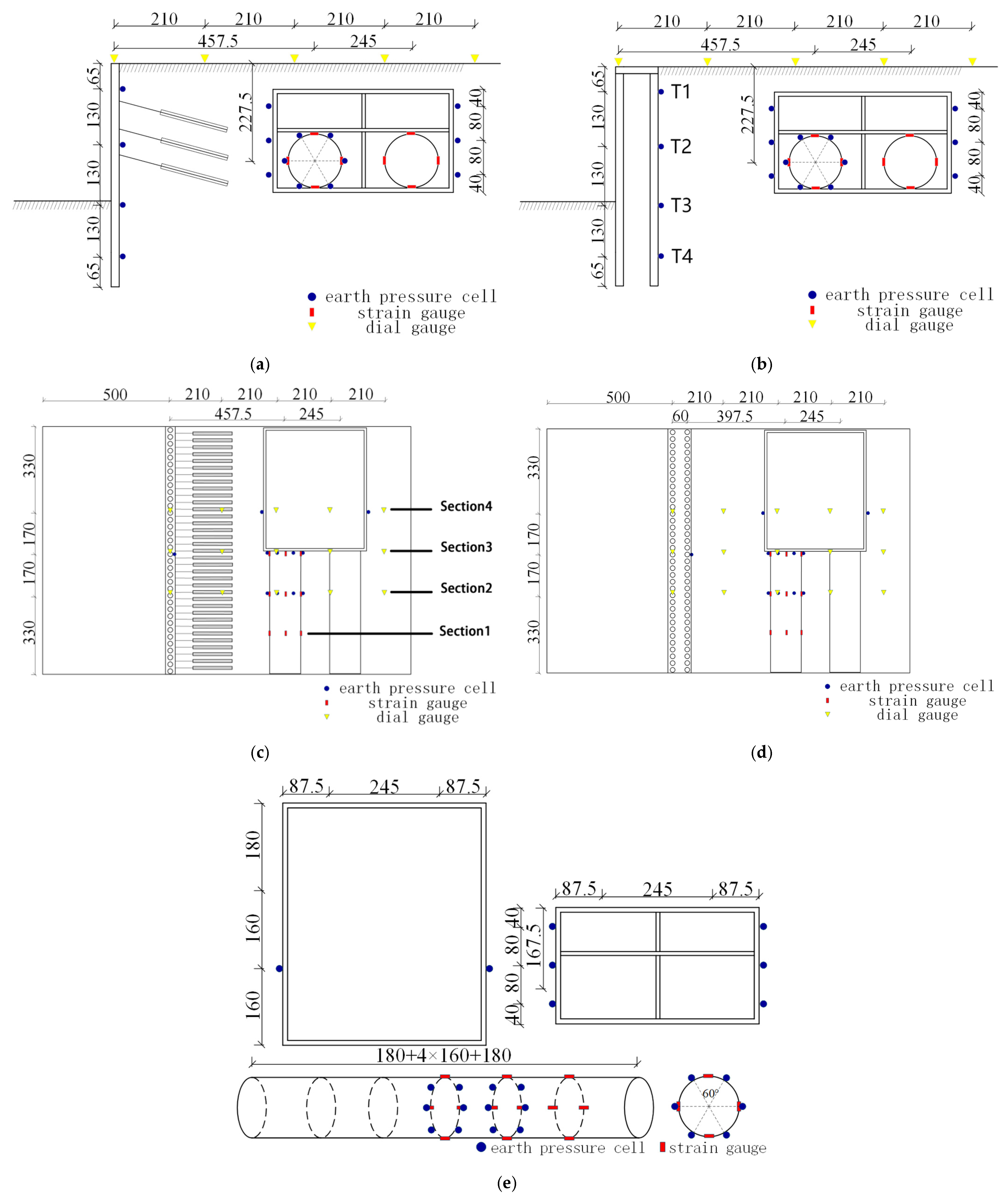

3.3. Model Structure Design

3.4. Test Conditions and Steps

3.4.1. Filling Soil and Placing Components

3.4.2. Excavation Process

3.4.3. Test Working Condition Setting

4. Result Analysis

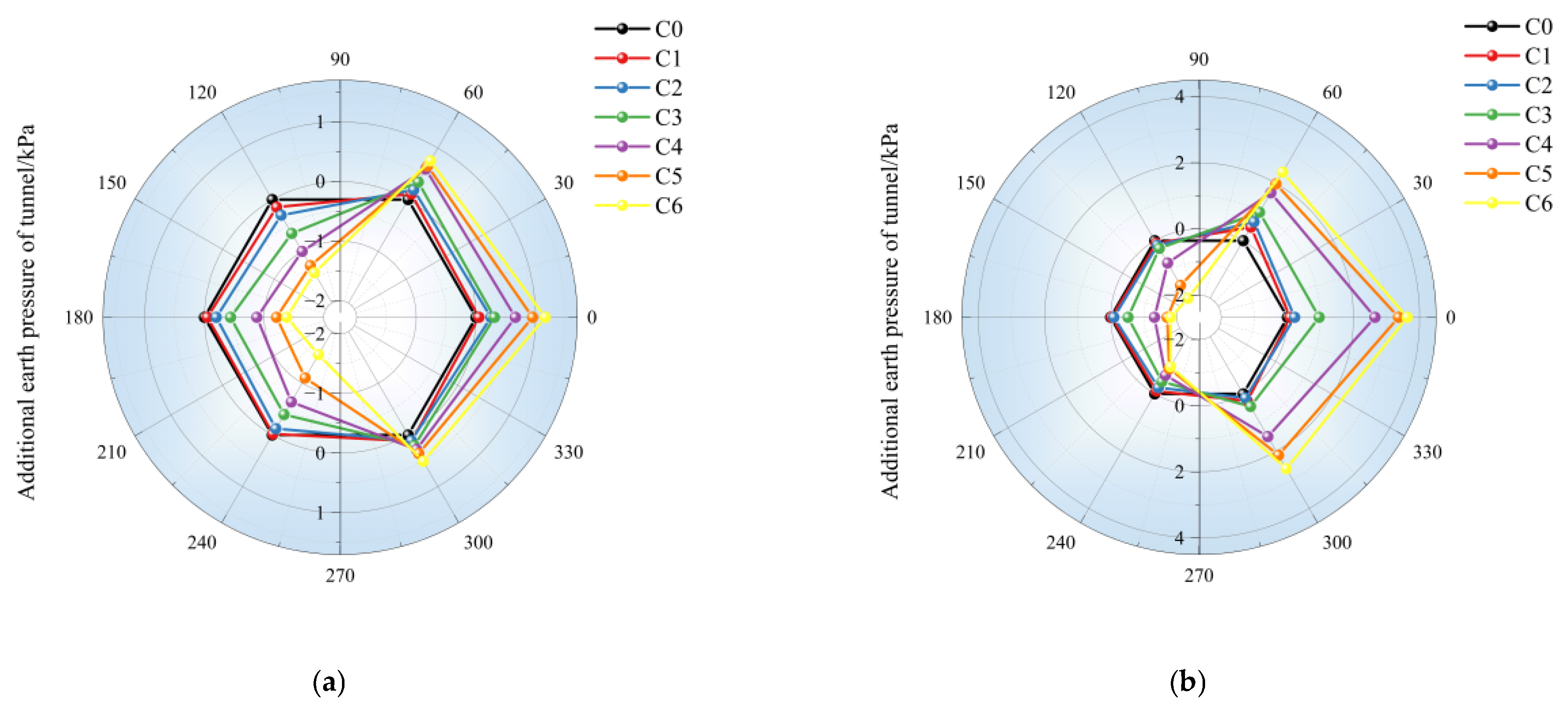

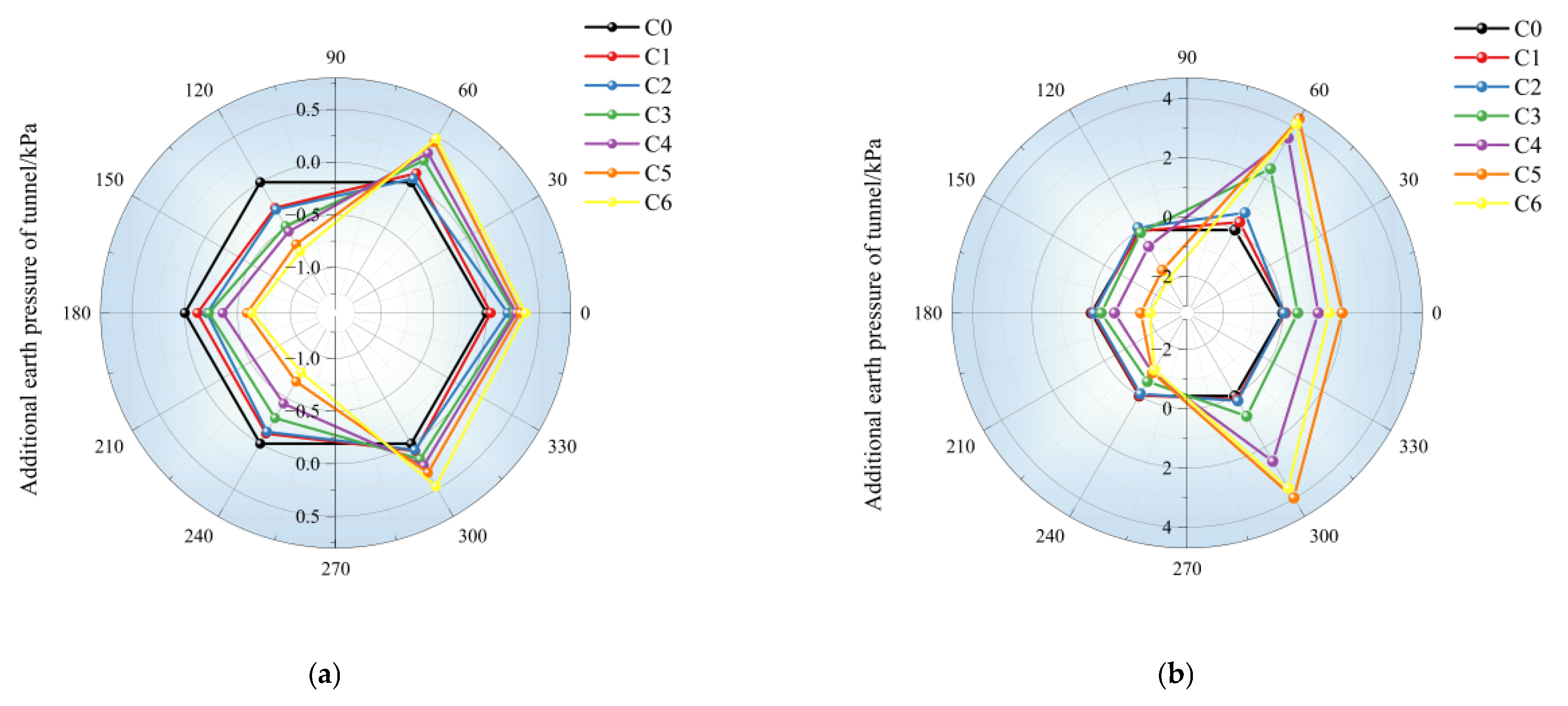

4.1. Earth Pressure Around the Tunnel

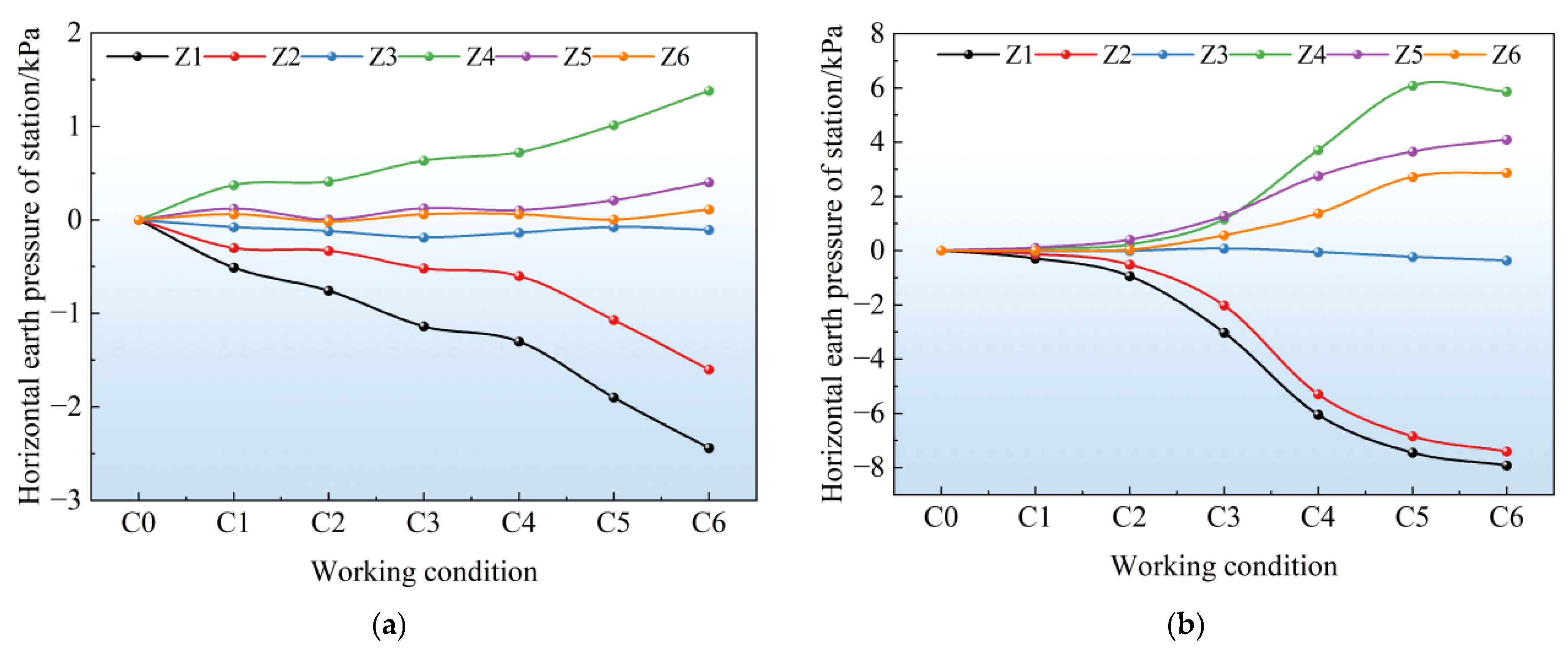

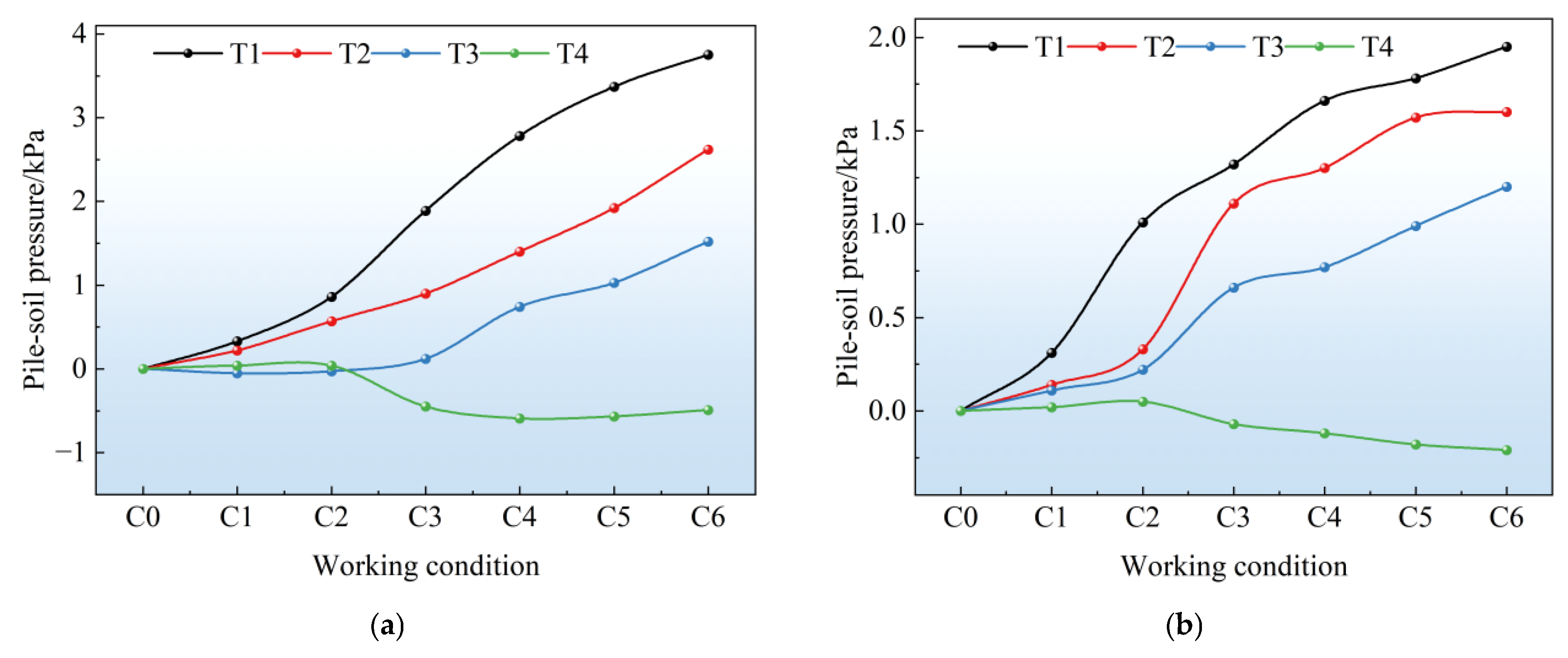

4.2. Earth Pressure on the Side Wall of the Station and Pile-Soil Pressure

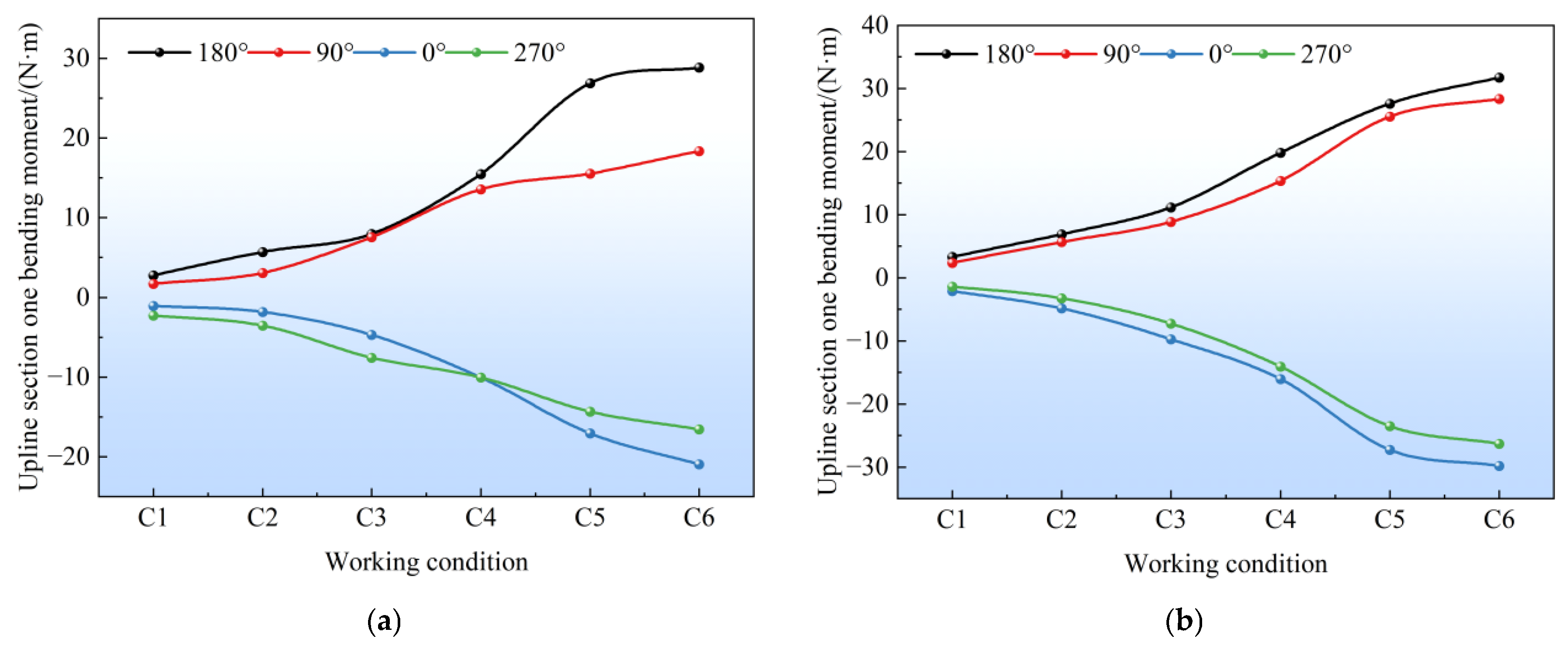

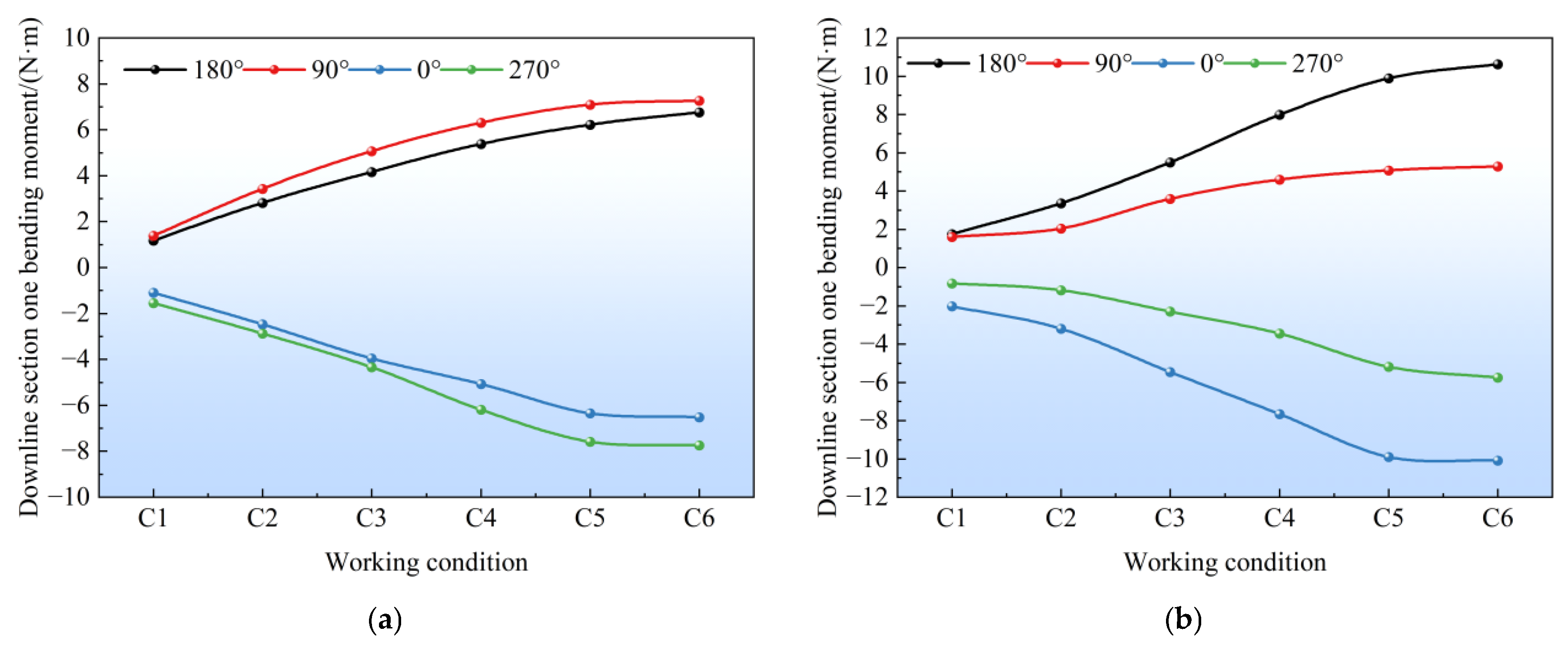

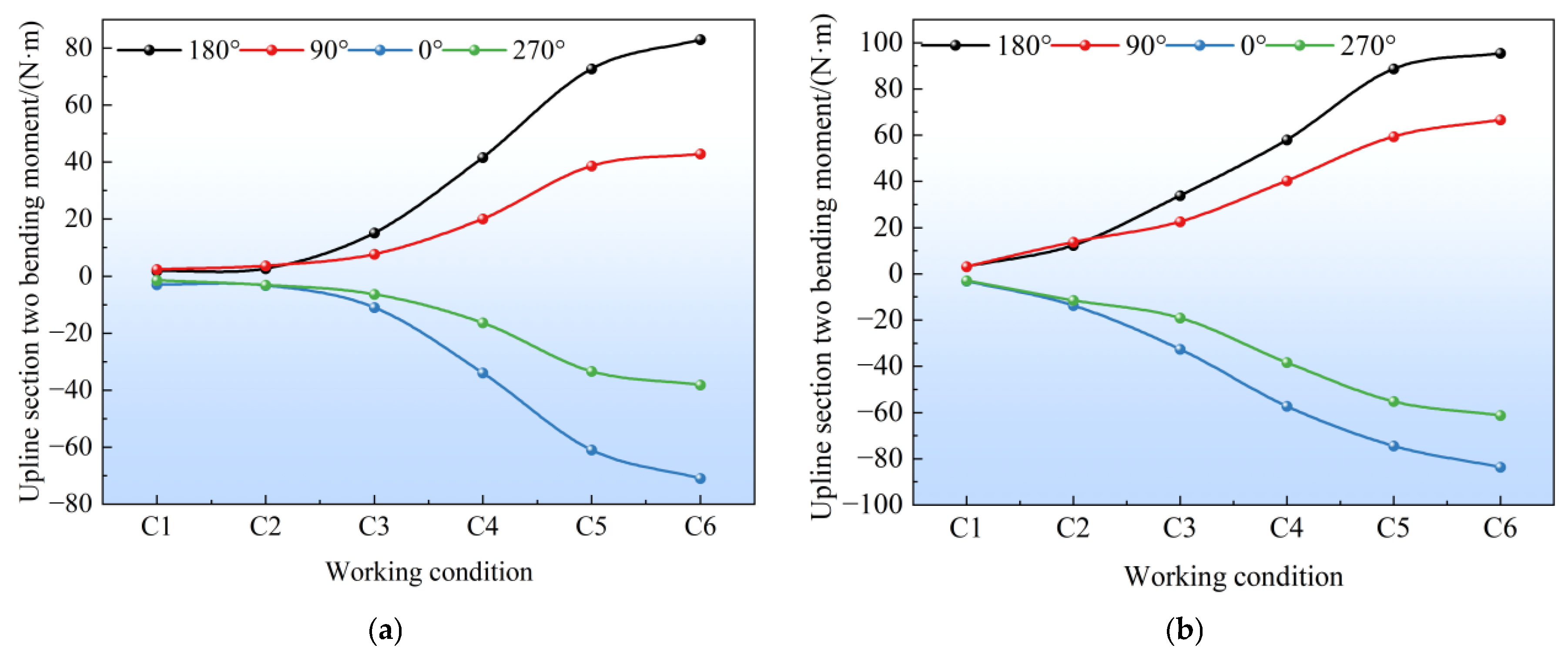

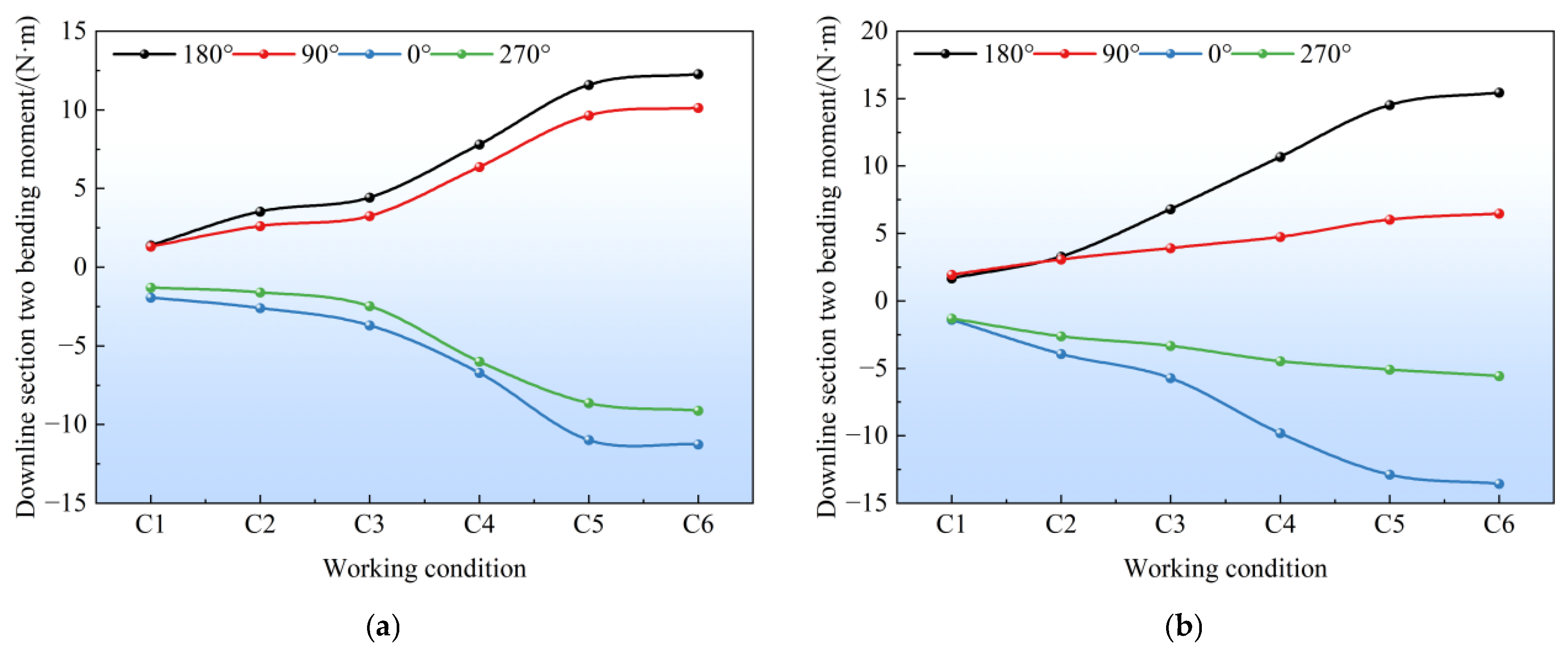

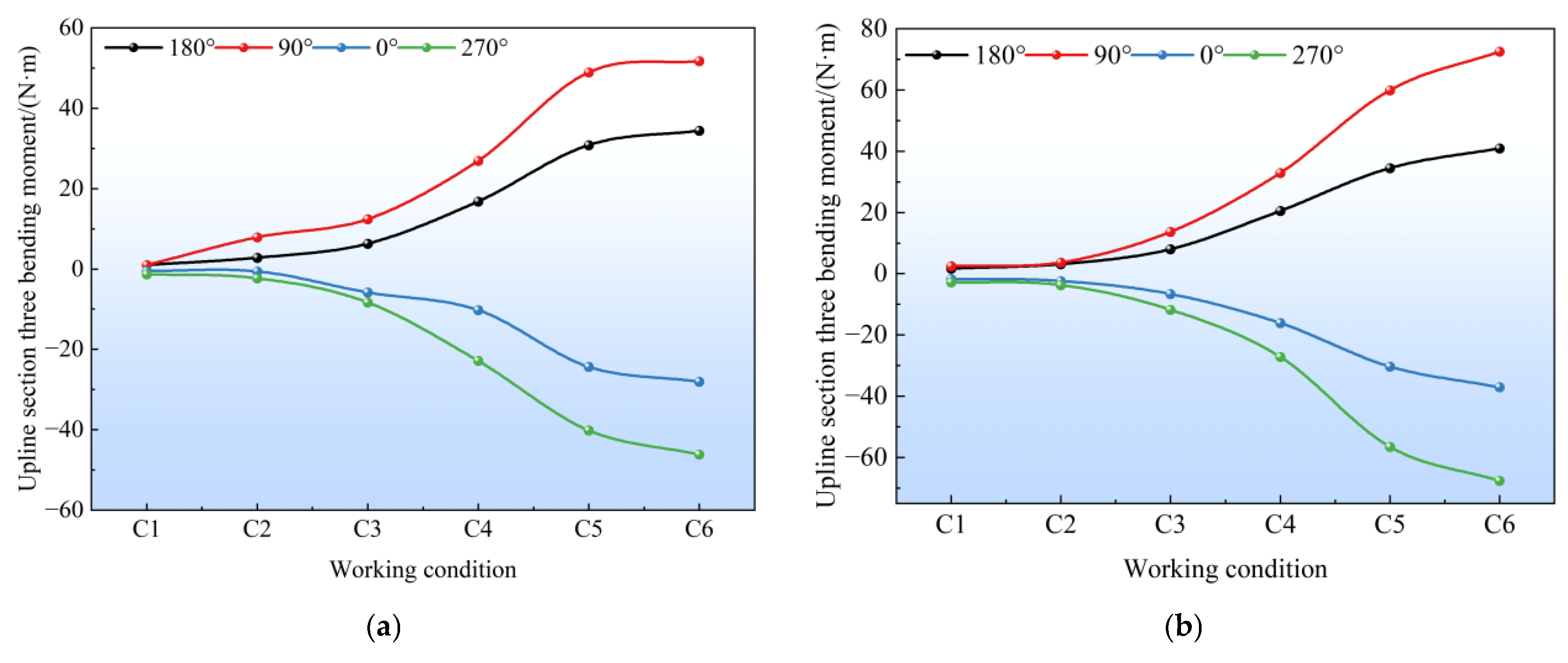

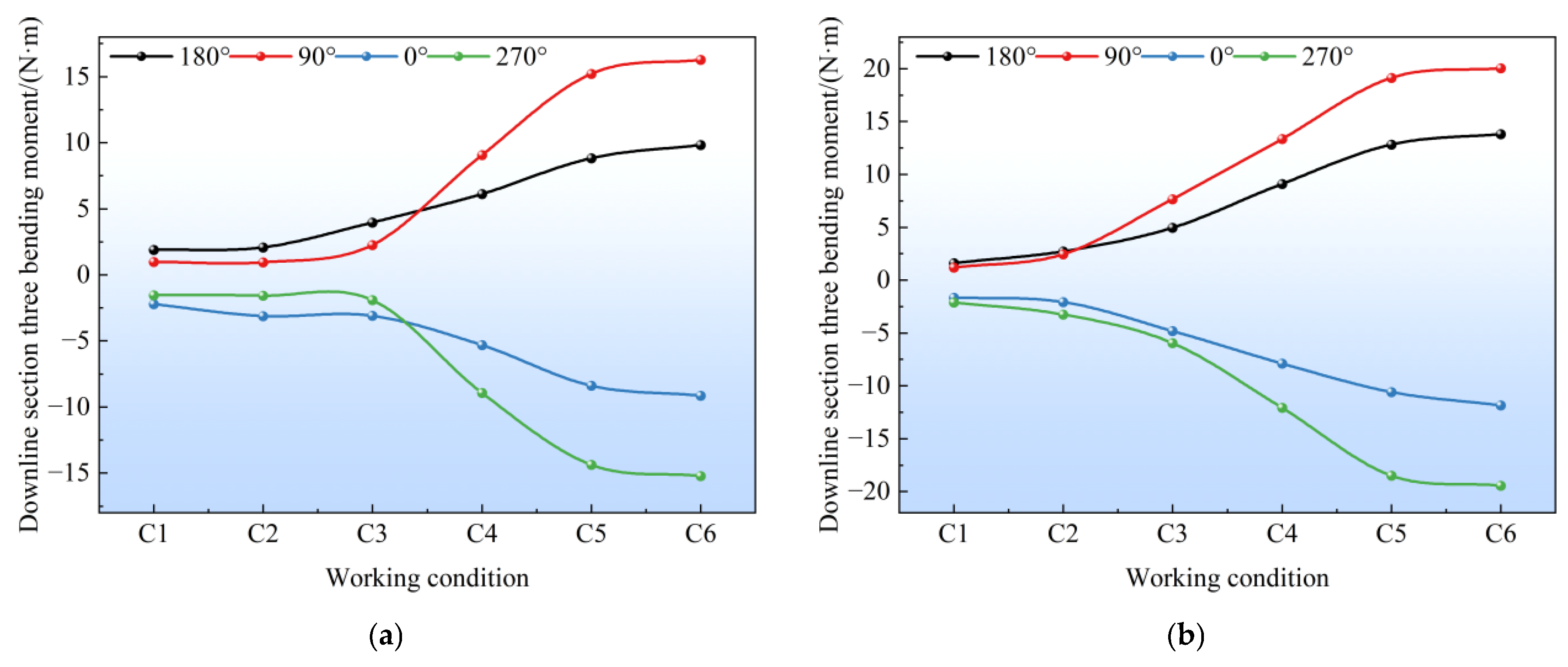

4.3. Longitudinal Bending Moment of the Tunnel

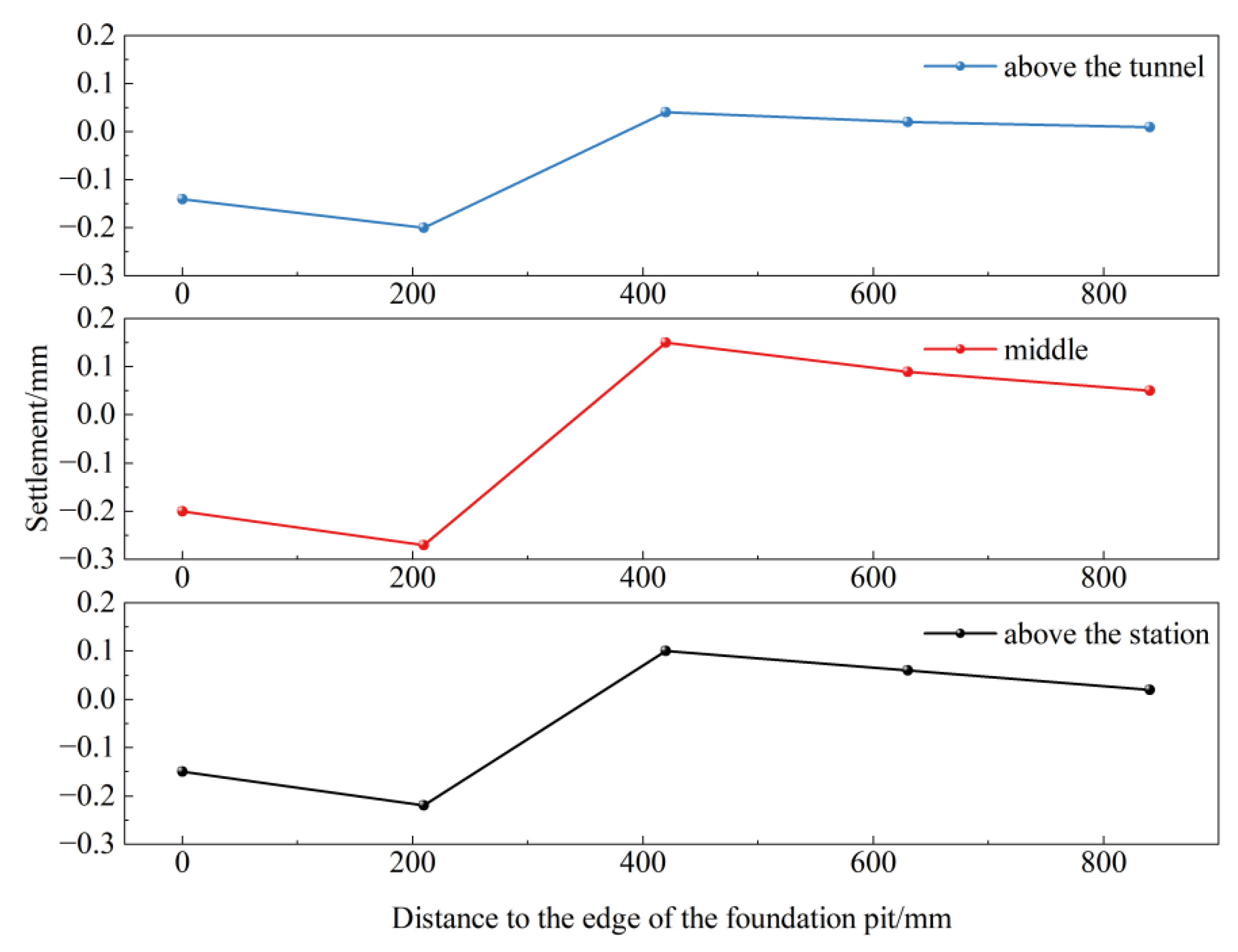

4.4. Ground Surface Settlement Above

4.5. Comprehensive Comparison

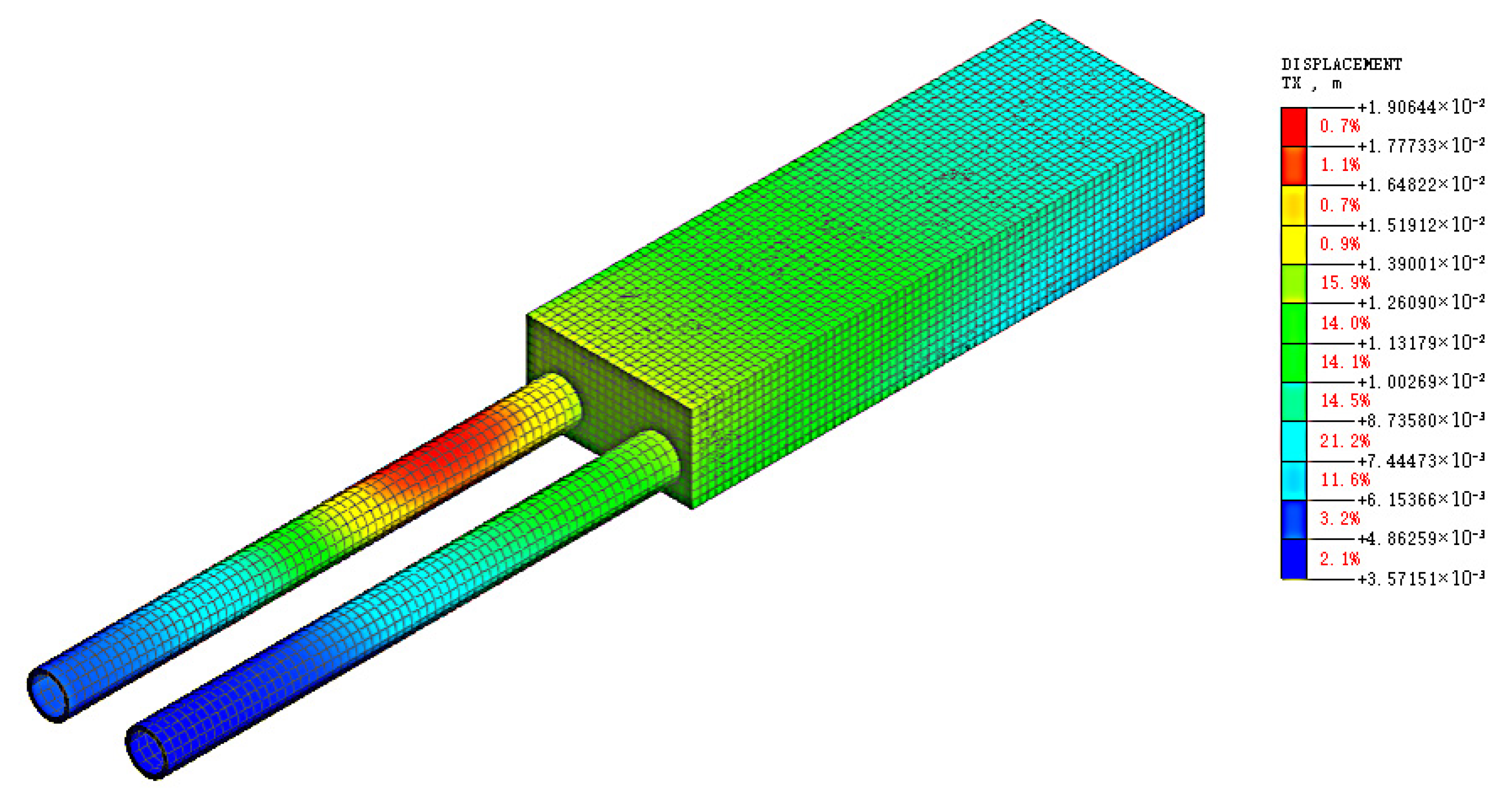

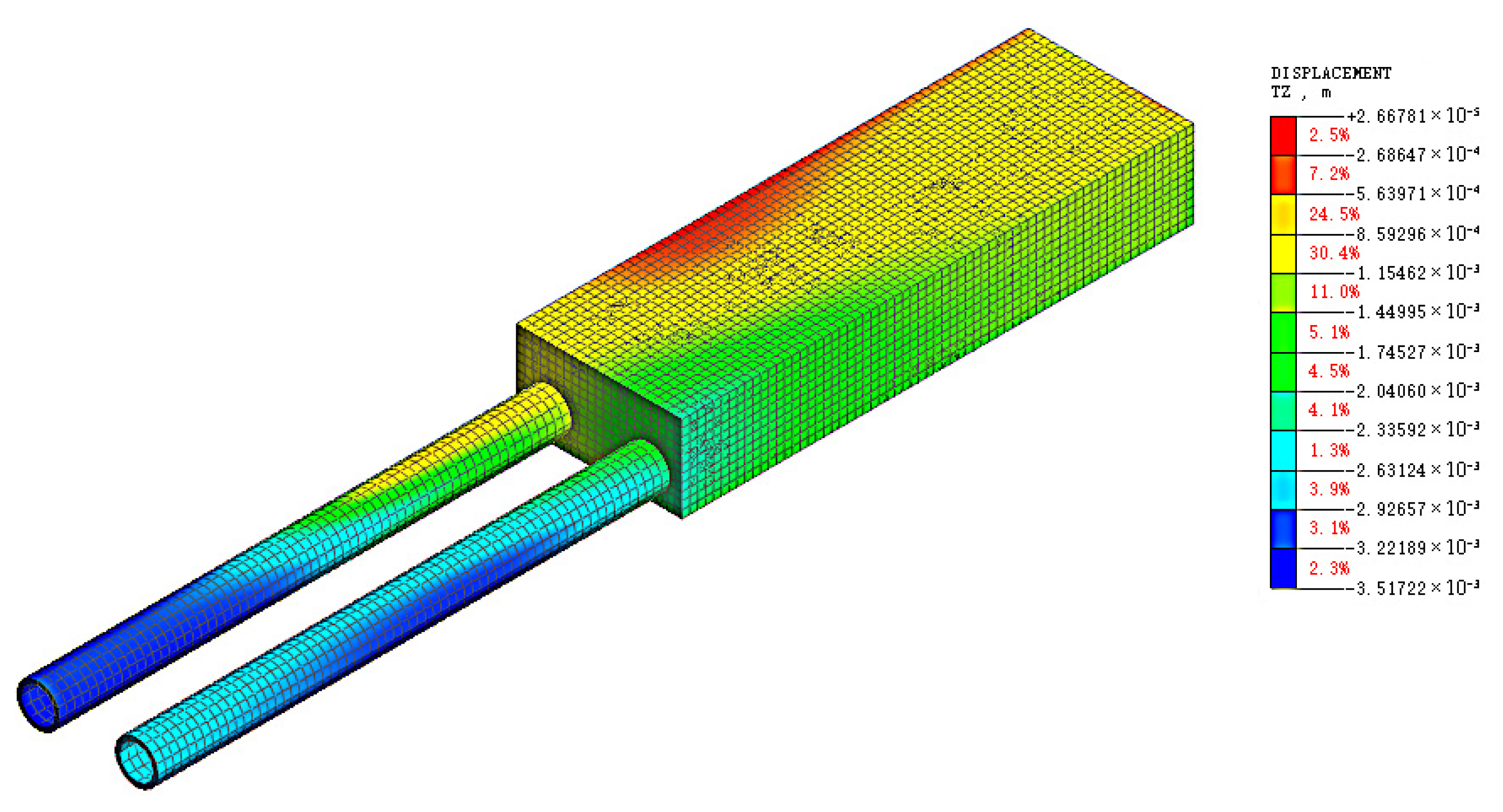

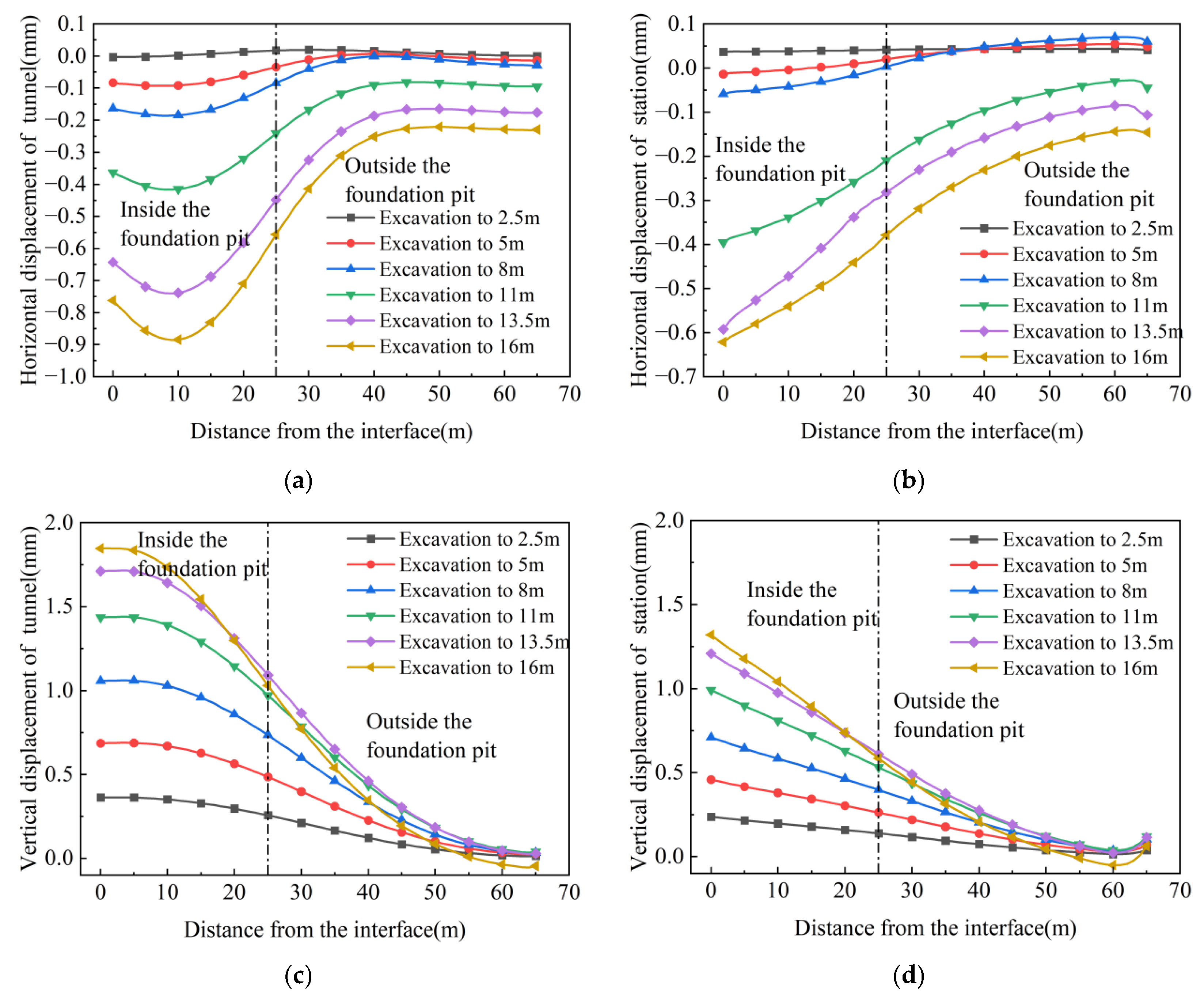

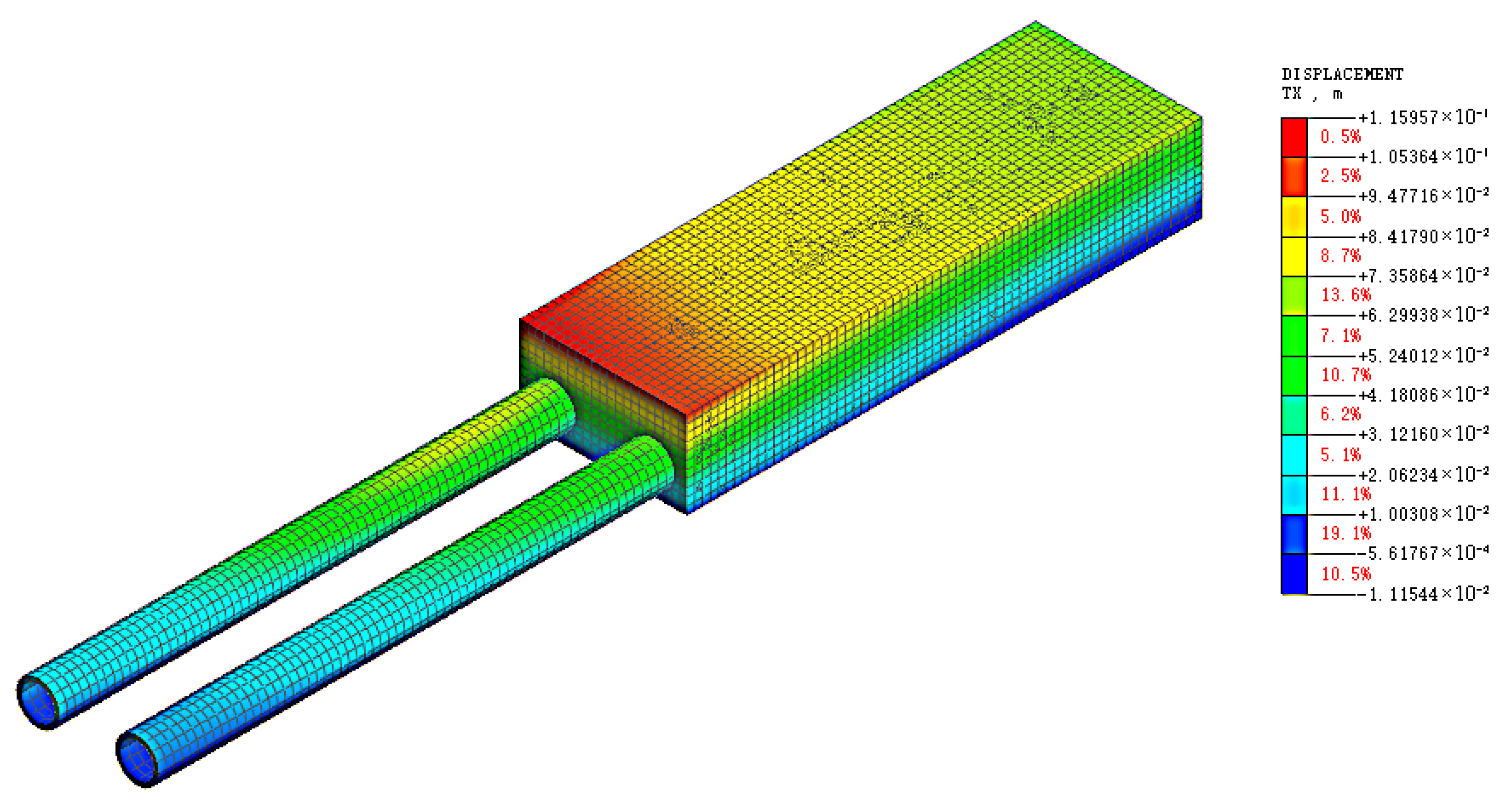

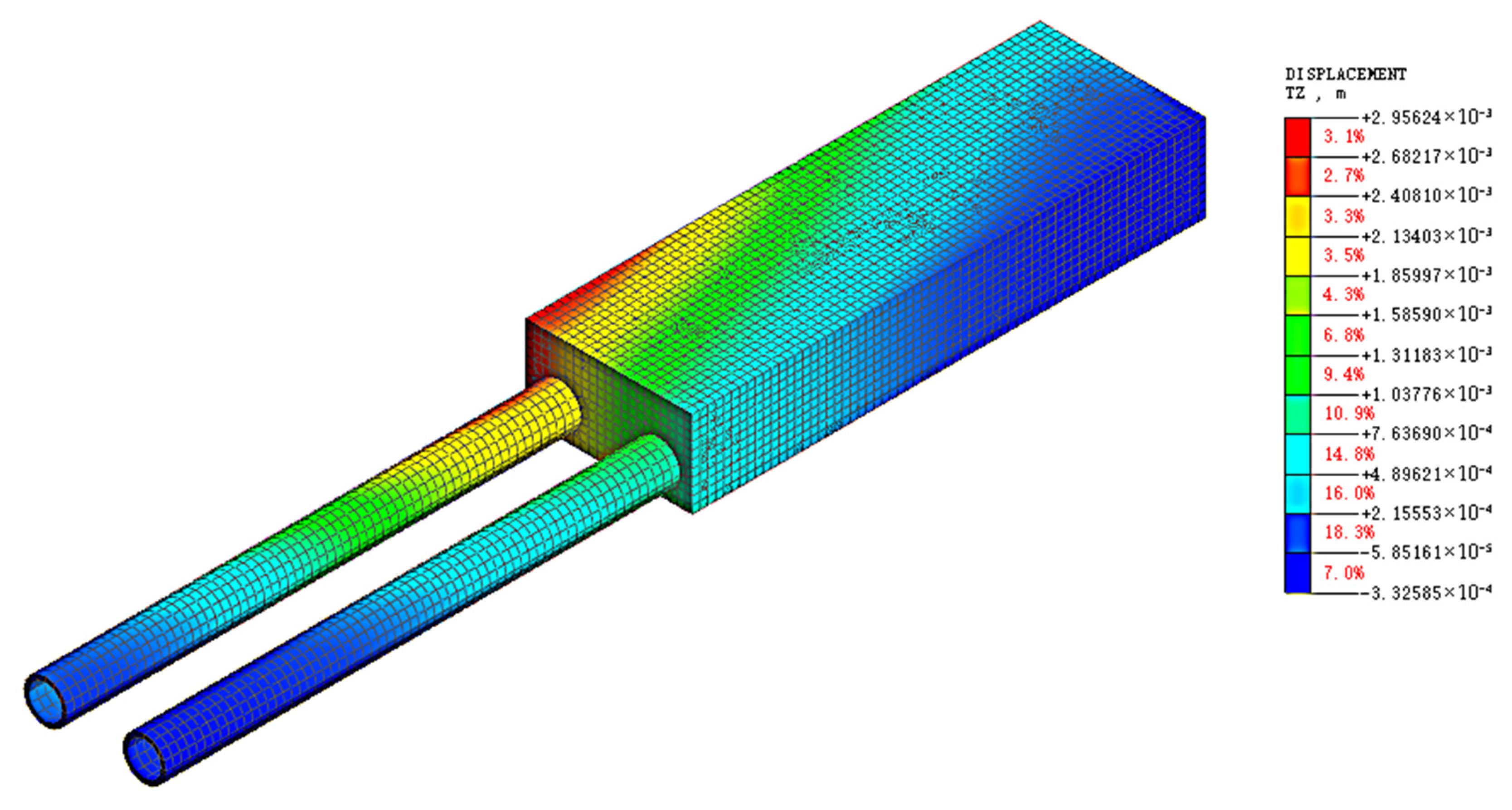

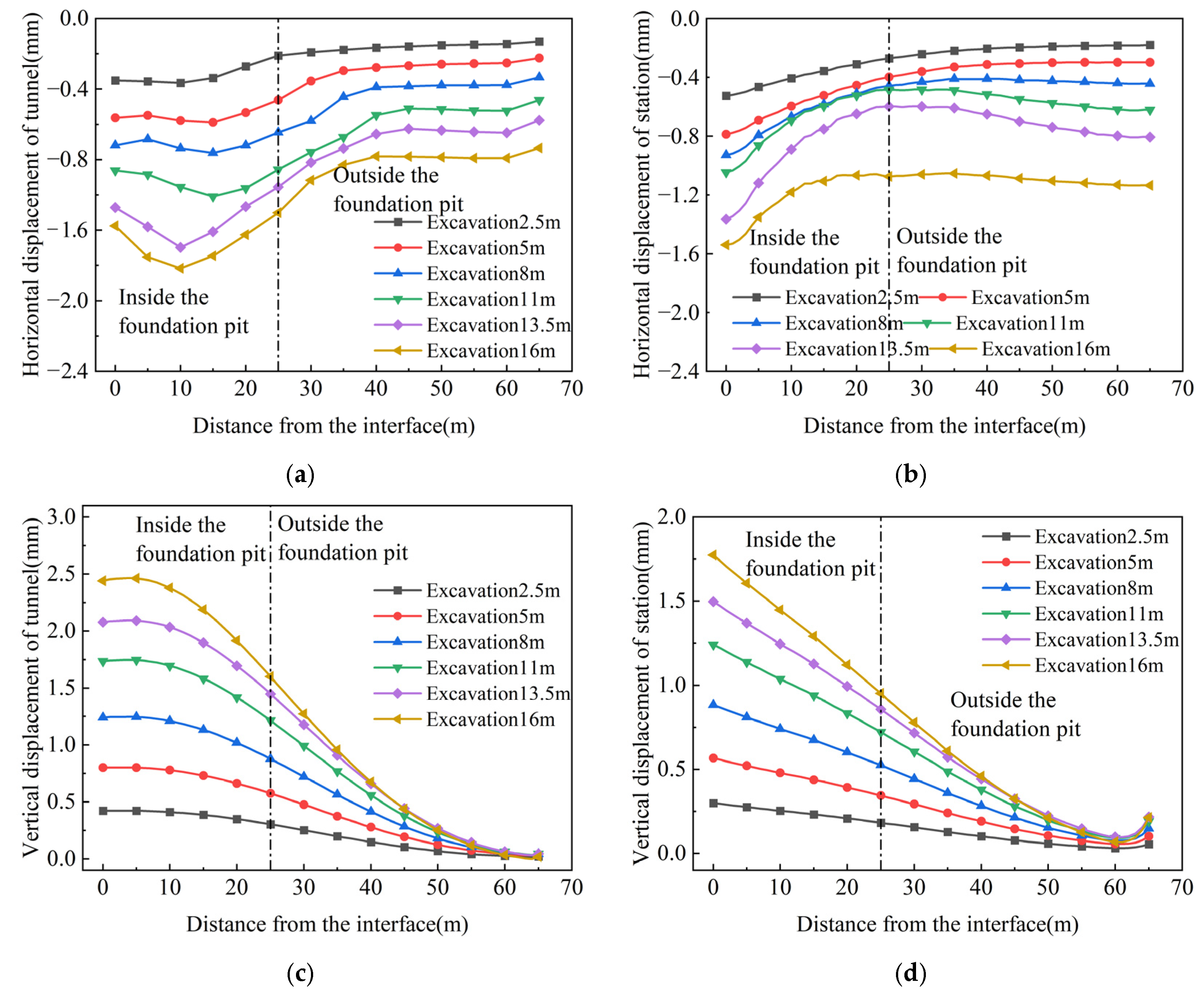

5. Comparative Verification of Numerical Simulation

6. Conclusions

- 1.

- Under different support structures, there were differences in the influence of foundation pit excavation on the earth pressure of adjacent subway tunnels and stations: For tunnels, the variation range of earth pressure under the double-row pile support structure was significantly larger than that under the pile-anchor support structure. Both sections showed a trend of decreased earth pressure on the left side and increased earth pressure on the right side, with the earth pressure on the excavation side decreasing significantly. For stations, the variation in earth pressure under the pile-anchor support structure was smoother, resulting in less disturbance to the station. In contrast, the variation in earth pressure on the station under the double-row pile support was mainly concentrated in the excavation process corresponding to the buried depth of the station, indicating that excavation to the buried depth of the underground structure caused the greatest disturbance to it.

- 2.

- The pile-anchor support structure withstood greater earth pressure than the double-row pile support structure. Withstanding relatively high earth pressure within a reasonable range could effectively reduce the adverse effects caused by soil displacement, exhibiting better control over the deformation of surrounding soil and less disturbance to adjacent existing subway structures. In contrast, the maximum positive and negative bending moments of the tunnel under the double-row pile support structure were both greater than those under the pile-anchor support structure. In terms of tunnel longitudinal deformation control, the pile-anchor support structure was superior, and the deformation of the left tunnel was greater than that of the right tunnel. The tunnel as a whole exhibited horizontal deformation toward the foundation pit excavation side and upward heave deformation.

- 3.

- The bending moment increment of the tunnel’s middle section was significant. The closer to the center of the foundation pit, the more obvious the excavation unloading effect was, resulting in a greater impact on adjacent existing subway structures—with horizontal deformation as the main form. Although the tunnel-station junction was located at the foundation pit center, its horizontal deformation was smaller than that of the tunnel’s middle section due to the influence of the station’s stiffness. Moreover, the deformation at the vault was greater than that at the arch waist, which was related to the fact that the station’s heave deformation was greater than its horizontal deformation, thereby driving the tunnel to heave and inhibiting its horizontal deformation. Overall, the tunnel’s heave deformation gradually increased from the edge to the center of the foundation pit, while its horizontal deformation first increased and then decreased—with the maximum value occurring near the center rather than at the exact center.

- 4.

- Foundation pit excavation induced settlement of the surrounding ground surface. The heave of the subway structure caused a slight heave of the soil above the tunnel and station; in contrast, the soil between the subway structure and support structure underwent slight settlement, which was due to soil relaxation caused by the unloading effect of foundation pit excavation.

- 5.

- It can be concluded from this study that the pile-anchor support had better protective capacity for subway structures than the double-row pile support when excavating foundation pits adjacent to subway structures. Therefore, when construction conditions permit, priority should be given to selecting the pile-anchor support. Additionally, the subway operation company can be contacted to focus on strengthening and protecting the position corresponding to Section 2 in this study.

- 6.

- While scaled model tests offer excellent economic efficiency and convenience, their test results had certain errors compared with field tests and full-scale model tests. Specifically, the measured values of stress and other parameters could not accurately reflect actual levels. However, the trends they revealed were correct and reasonable. Additionally, due to objective factors, this study had not yet considered other support forms for analysis, thus having certain limitations. The material parameters in this study are all based on natural loess, and the mutual comparison and consistency between the numerical simulation and model test results have verified the accuracy of the research. However, since this test did not consider the collapsibility of loess, it may not be well applicable to engineering projects in non-arid loess regions. In non-arid regions, attention should be paid to preventing disasters caused by loess collapsibility and high water content.

- 7.

- Given the limitations of this study, future research can further explore the impact of foundation pit excavation in high water content loess and collapsible loess regions on adjacent existing subway stations and tunnels. This research direction has strong prospects.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, G.; Zhu, H.H.; Liu, X.R.; Yang, G.H. Control of safety of deep excavations and underground engineering and its impact on surrounding environment. China Civ. Eng. J. 2016, 49, 1–24. [Google Scholar]

- Chang, C.T.; Sun, C.W.; Duann, S.W.; Hwang, R.N. Response of a Taipei Rapid Transit System (TRTS) tunnel to adjacent excavation. Tunn. Undergr. Space Technol. 2001, 16, 151–158. [Google Scholar] [CrossRef]

- Hu, Z.F.; Yue, Z.Q.; Zhou, J.; Tham, L.G. Design and construction of a deep excavation in soft soils adjacent to the Shanghai Metro tunnels. Can. Geotech. J. 2003, 40, 933–948. [Google Scholar] [CrossRef]

- Sharma, J.S.; Hefny, A.M.; Zhao, J.; Chan, C.W. Effect of large excavation on deformation of adjacent MRT tunnels. Tunn. Undergr. Space Technol. 2001, 16, 93–98. [Google Scholar] [CrossRef]

- Li, Y.; Yang, W. Analysis on influence of deep pit construction on neighboring metro tunnel. Chin. J. Undergr. Space Eng. 2013, 9, 358–364. [Google Scholar]

- Wang, W.D.; Shen, J.; Weng, Q.P.; Wu, J.B. Analysis and countermeasures of influence of excavation on adjacent tunnels. Chin. J. Geotech. Eng. 2006, 28, 1340–1345. [Google Scholar]

- Zou, W.B.; Zhang, D.M.; Cai, X.W. Numerical simulation and real time monitoring of foundation pit excavation on deformation of adjacent MRT tunnel. Chin. J. Undergr. Space Eng. 2012, 8, 1728–1731. [Google Scholar]

- Zheng, G.; Wei, S.W. Numerical analyses of influence of overlying pit excavation on existing tunnels. J. Cent. South Univ. Technol. 2008, 15 (Suppl. S2), 69–75. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H. Analysis on the Displacement of Metro Tunnel and Metro Station around the Excavation. Rock Soil Mech. 2011, 11, 5854–5857. [Google Scholar]

- Qi, Q.; Fang, Y. Study on influence of deep excavation and cover load on the underlying subway tunnel structure. Build. Struct. 2012, 42, 107–111. [Google Scholar]

- Zhang, Z.G.; Zhang, M.X.; Wang, W.D. Two-stage method for analyzing effects on adjacent metro tunnels due to foundation pit excavation. Rock Soil Mech. 2011, 32, 2085–2092. [Google Scholar]

- Zhou, S.H.; He, C.; Xiao, J.H. Energy method for calculating deformation of adjacent shield tunnels due to foundation pit excavation considering step between rings. China Railw. Sci. 2016, 37, 53–60. [Google Scholar]

- Huang, X.; Schweiger, H.F.; Huang, H. Influence of deep excavations on nearby existing tunnels. Int. J. Geomech. 2013, 13, 170–180. [Google Scholar] [CrossRef]

- Liang, F.Y.; Chu, F.; Song, Z.; Li, Y.S. Centrifugal model test research on deformation behaviors of deep foundation pit adjacent to metro stations. Rock Soil Mech. 2012, 33, 657–664. [Google Scholar]

- Hu, X. Influence of foundation pit excavation under different conditions simulating by model test on existing tunnel. Subgr. Eng. 2015, 6, 151–155. [Google Scholar]

- Hisatake, M.; Ohno, S.; Katayama, T.; Ohmae, Y. Effects of the ring-cut excavation method on ground displacements and stability of a tunnel face. J. Tunn. Eng. 2007, 17, 547–554. [Google Scholar]

- Huang, X.; Huang, H.; Zhang, D. Centrifuge modelling of deep excavation over existing tunnels. Proc. Inst. Civ. Eng.-Geotech. Eng. 2014, 167, 3–18. [Google Scholar] [CrossRef]

- Kim, S.H.; Burd, H.J.; Milligan, G.W.E. Model testing of closely spaced tunnels in clay. Geotechnique 1998, 48, 375–388. [Google Scholar] [CrossRef]

- Xu, S.; Zhang, Q.; Zhang, W.; Zhang, Y.; Wang, Z. Influences of construction of foundation pits on deformation of adjacent operating tunnels in whole process based on monitoring data. Chin. J. Geotech. Eng. 2021, 43, 804–812. [Google Scholar]

- Zhang, X.; Su, H.; Jiang, B. Influence of Foundation Pit Excavation on Adjacent Subway Tunnel. Shanghai Geol. 2008, 2, 27–29+34. [Google Scholar]

- Guang, L.; Xu, C.; Ke, W.; Di, H.; Zhang, G.; Yang, W. Analysis of horizontal pipeline deformation caused by shield tunnelling. J. Civ. Environ. Eng. 2020, 42, 54–62. [Google Scholar]

- Lo, K.Y.; Ramsay, J.A. The effect of construction on existing subway tunnels—A case study from Toronto. Tunn. Undergr. Space Technol. 1991, 6, 287–297. [Google Scholar] [CrossRef]

- Yu, J.-X.; Ye, J.-N.; Kuang, Z.-R.; Zhang, W.-B.; Cheng, H.-Z. Measurement analysis of deformation in metro tunnels adjacent to large-scale foundation pit excavation in soft soil. J. Railw. Sci. Eng. 2025, 1–11. [Google Scholar] [CrossRef]

- Zhang, Z.G.; Chen, Y.J.; Wei, G. Time-dependent analysis on deformation of adjacent tunnel with small curvature radius induced by excavation in soft soil. Chin. J. Geotech. Eng. 2025, 47, 1793–1803. [Google Scholar]

- Klar, A.; Vorster, T.E.B.; Soga, K.; Mair, R.J. Soil—Pipe interaction due to tunnelling: Comparison between Winkler and elastic continuum solutions. Géotechnique 2005, 55, 461–466. [Google Scholar] [CrossRef]

- Attewell, P.B.; Woodman, J.P. Predicting the dynamics of ground settlement and its derivitives caused by tunnelling in soil. Ground Eng. 1982, 15, 13. [Google Scholar]

- Vorster, T.E.; Klar, A.; Soga, K.; Mair, R.J. Estimating the effects of tunneling on existing pipelines. J. Geotech. Geoenviron. Eng. 2005, 131, 1399–1410. [Google Scholar] [CrossRef]

- Zhen-Ke, H. Research on the Construction Design of Overlying Foundation Pit of Shield Tunnel. J. Railw. Eng. Soc. 2024, 41, 109–113+118. [Google Scholar]

- Rui, J.; Ji, Y.; Zhang, G.; Li, H. Analysis of Influence of Foundation Pit Excavation on Adjacent Tunnel in Structured Clays Under Different Degrees of Previous Construction Disturbance. J. Tianjin Univ. (Sci. Technol.) 2024, 58, 801–809. [Google Scholar]

- Cai, R.; Li, M.; Ma, F.; Li, Z.; Wang, H.; Cai, H. Circumferential forces and deformations of shield tunnels due to lateral excavation. Chin. J. Geotech. Eng. 2023, 45, 24–32. [Google Scholar]

- Huang, M.H.; Zhong, Y.X.; Lu, J.B. Deformation analysis of underlying shield tunnel induced by foundation pit excavation based on discontinuous foundation beam model. Rock Soil Mech. 2025, 46, 492–504. [Google Scholar]

- Feng, G.H.; Xu, C.J.; Zheng, M.W.; Xue, W.J.; Yang, K.F.; Guan, L.X. Study of longitudinal deformation of existing underlying tunnel due to above excavation considering shear deformation of tunnel. J. China Railw. Soc. 2022, 44, 132–141. [Google Scholar]

- Wei, G.; Mu, Z.Y.; Qi, Y.J.; Guo, B.L.; Xiang, P.F. Deformation protection of shield tunnels next to foundation pits by isolation piles considering formation loss. Chin. J. Geotech. Eng. 2024, 46, 480–489. [Google Scholar]

- Zhang, Z.W.; Liang, Q.Z.; Gao, K.; Li, Z.C.; Xiao, M.Z.; Guo, Y.; Sheng, W.; Wu, W.B. Analysis of longitudinal displacement of existing shield tunnel due to construction of above-crossing new tunnel considering the weakening of circumferential joint. Chinese Chin. J. Rock Mech. Eng. 2022, 41, 2955–2970. [Google Scholar]

- Xu, S.F.; Yu, J.H.; Wang, Z. A computational method for the lateral displacement of tunnels caused by foundation pit excavation based on non-limit earth pressure. J. Zhejiang Univ. Technol. 2024, 52, 312–318. [Google Scholar]

- Ying, H.W.; Cheng, K.; Yu, J.L.; Xu, R.Q.; Qiu, Z.J.; Zhang, X.B.; Qin, J.S.; Lou, C.H. Prediction of shield tunnel displacement due to adjacent basement excavation considering continuous deformation of ground. J. Zhejiang Univ. (Eng. Sci.) 2021, 55, 318–329. [Google Scholar]

- Zhou, Z.; Chen, S.; Tu, P.; Zhang, H. Coupling method for analyzing the influence on existing tunnel due to adjacent foundations pit excavation. Rock Soil Mech. 2018, 39, 1440–1449. [Google Scholar]

- Guan, L.X.; Xu, C.J.; Luo, Q.; Ding, H.B.; Ke, W.H. Underlying tunnel deformation caused by excavation and dewatering of foundation pit based on kerr foundation model. Eng. Mech. 2023, 42, 145–153. [Google Scholar]

- Liang, R.Z.; Zhang, Z.W.; Li, Z.C. Simplified solutions for longitudinal deformation of shield tunnels considering influences of circumferential joints. Chin. J. Geotech. Eng. 2024, 46, 254–263. [Google Scholar]

- Xu, C.; Hu, X.L.; He, C.C.; Xu, Y.; Zhou, C. Development and application of similar material for reservoir landslide model test. Rock Soil Mech. 2018, 39, 4287–4293. [Google Scholar]

| Serial Number | Physical Quantity | Similarity Relation | Model |

|---|---|---|---|

| 1 | Strain ) | 1 | |

| 2 | Length ) | 1/50 | |

| 3 | Area () | 1/2500 | |

| 4 | Stiffness (E) | 1/50 | |

| 5 | Flexural rigidity | 1/312,500,000 | |

| 6 | Density () | 1 | |

| 7 | Mass ) | 1/125,000 | |

| 8 | Poisson’s ratio () | 1 | |

| 9 | Compressive stiffness | 1/125,000 | |

| 10 | Prestress | 1/125,000 | |

| 11 | Cohesion ( | 1/50 | |

| 12 | Displacement (u) | 1/50 |

| Number | Object | Material | Elastic Modulus of Prototype Material | Elastic Modulus |

|---|---|---|---|---|

| 1 | Pile | PE | 30 GPa | 500 MPa |

| 2 | Anchor Cable | iron wire | 200 GPa | 180 GPa |

| 3 | Tunnel | PVC | 30 GPa | 2.0 GPa |

| Construction Conditions | NO. | Construction Scope | Excavation Depth (cm) |

|---|---|---|---|

| 1 | C0 | Initial state | 0 |

| 2 | C1 | First excavation | 5 |

| 3 | C2 | Second excavation | 5 |

| 4 | C3 | Third excavation, lock the second layer of anchor cables | 6 |

| 5 | C4 | Fourth excavation, lock the second layer of anchor cables | 6 |

| 6 | C5 | Fifth excavation | 5 |

| 7 | C6 | Sixth excavation, lock the second layer of anchor cables | 5 |

| Number | Support Structure | Excavation Depth/cm | Foundation Pit Width/cm |

|---|---|---|---|

| 1 | Pile-Anchor Support | 32 | 50 |

| 2 | Double-row pile support | 32 | 50 |

| Support Structure | Pile-Anchor Support | Double-Row Pile Support |

|---|---|---|

| Maximum Value of Tunnel Earth Pressure Change | 0.53 kPa | 4.18 kPa |

| Maximum Value of Station Earth Pressure Change | 2.44 kPa | 7.92 kPa |

| Maximum Value of Pile Earth Pressure Change | 3.75 kPa | 1.95 kPa |

| Maximum Value of Tunnel Bending Moment Change | 83.02 N·m | 95.40 N·m |

| Maximum Value of Station Bending Moment Change | 53.65 N·m | 78.48 N·m |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, Z.; Ding, T.; Hu, F.; Ye, S.; Ding, L.; Shu, R.; Zhang, X.; Song, M. The Deformation Characteristics and Patterns of Adjacent Existing Metro Structures Caused by Foundation Pit Excavation Under Different Support Forms. Buildings 2025, 15, 4178. https://doi.org/10.3390/buildings15224178

Mao Z, Ding T, Hu F, Ye S, Ding L, Shu R, Zhang X, Song M. The Deformation Characteristics and Patterns of Adjacent Existing Metro Structures Caused by Foundation Pit Excavation Under Different Support Forms. Buildings. 2025; 15(22):4178. https://doi.org/10.3390/buildings15224178

Chicago/Turabian StyleMao, Zhitong, Tian Ding, Fengchao Hu, Shuaihua Ye, Linzhao Ding, Rong Shu, Xiaoning Zhang, and Minghua Song. 2025. "The Deformation Characteristics and Patterns of Adjacent Existing Metro Structures Caused by Foundation Pit Excavation Under Different Support Forms" Buildings 15, no. 22: 4178. https://doi.org/10.3390/buildings15224178

APA StyleMao, Z., Ding, T., Hu, F., Ye, S., Ding, L., Shu, R., Zhang, X., & Song, M. (2025). The Deformation Characteristics and Patterns of Adjacent Existing Metro Structures Caused by Foundation Pit Excavation Under Different Support Forms. Buildings, 15(22), 4178. https://doi.org/10.3390/buildings15224178