On-Site Welding Research for High-Strength S690 Steel

Abstract

1. Introduction

- (1)

- Preheating temperature.

- (2)

- Heat input energy and inter-pass temperature.

- (3)

- Post-weld heat treatment (PWHT).

2. Research Focuses

- (1)

- As stated above, the heat input energy is one of the key welding parameters. To gain the practicable range of heat input energy and expand the welder’s operating flexibility, 4 heat input energy values were studied.

- (2)

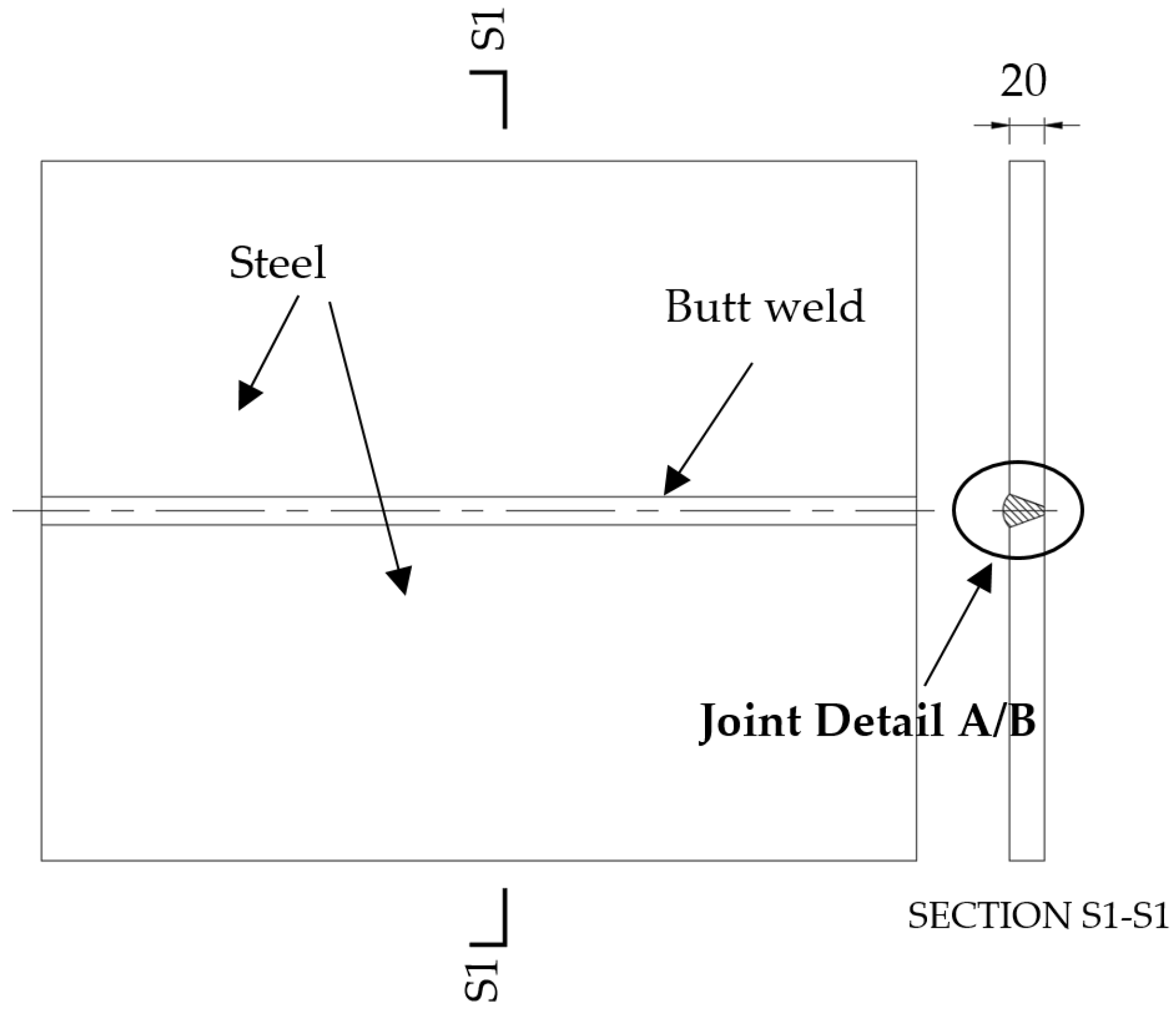

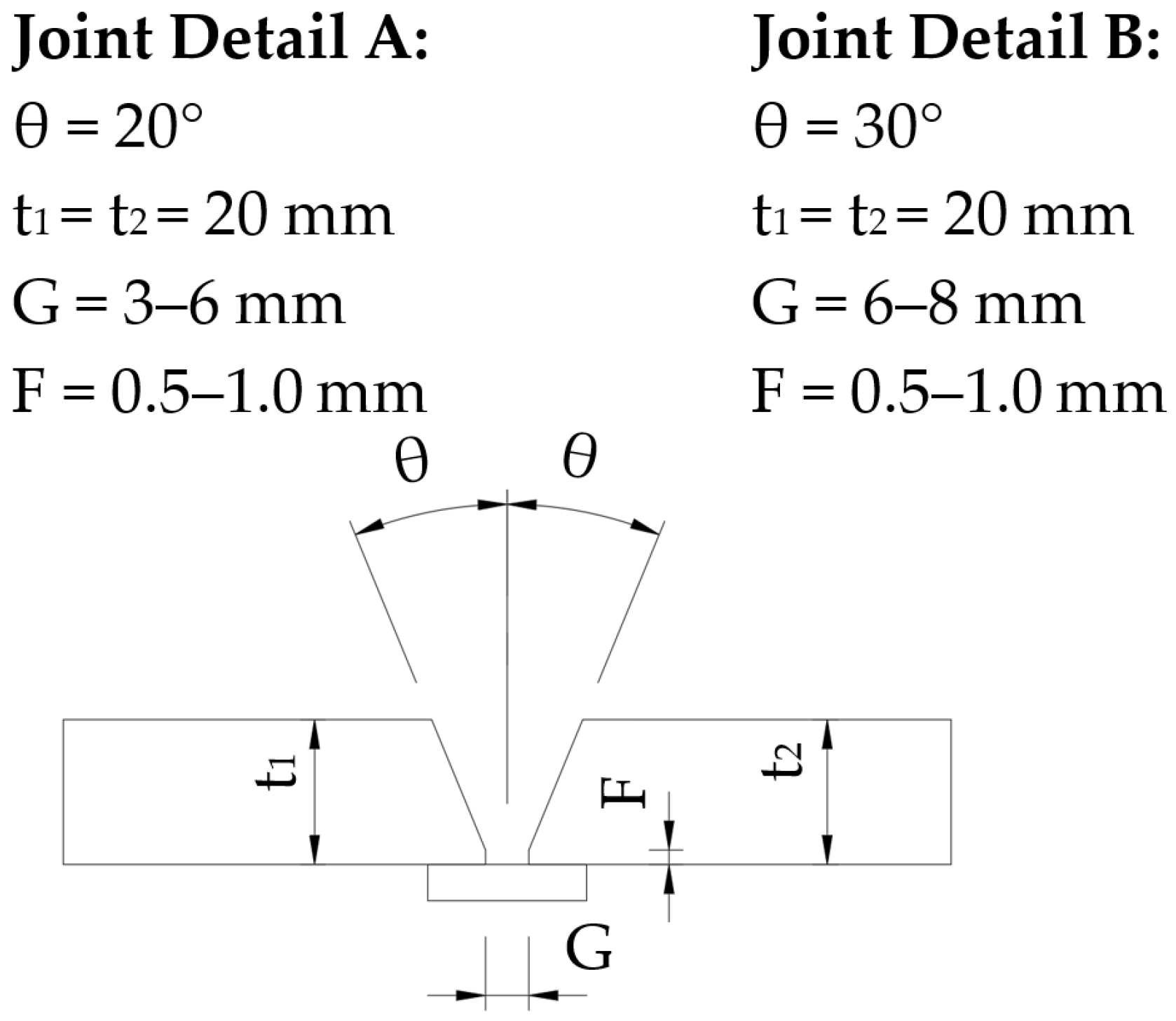

- Additionally, two joint details were employed to investigate their effects on welding quality and efficiency, aiming to identify the optimal joint detail.

- (3)

- Traditionally, it is recommended to perform PWHT to accelerate hydrogen release for the welding of high-strength steel [17,18,19]. Various PWHT processes for diffusing hydrogen, which were recommended or adopted, are listed in Table 2. PWHT for shop welding was typically performed with temperature-controlled heaters through thermal radiation or conduction, making on-site operation challenging.

- (4)

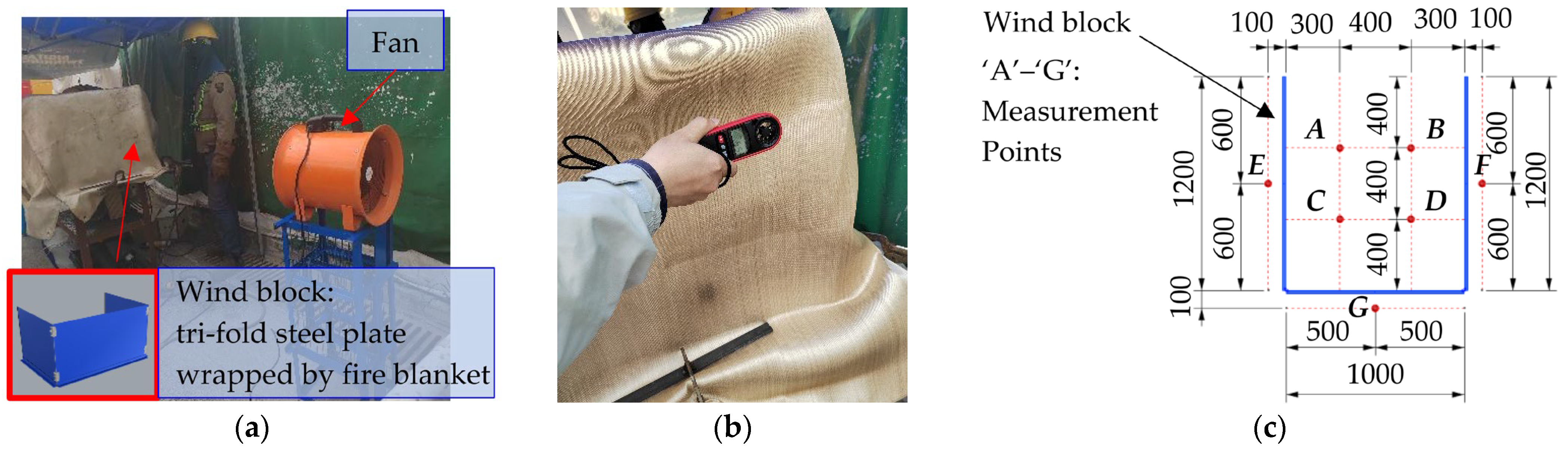

- Differing from the in-shop welding, on-site welding could be impacted significantly by wind. An effective wind block must be implemented when the wind velocity is high [21,22]. In this study, an easily installable and removable wind block was proposed, and the effectiveness of blocking wind was studied.

3. On-Site Welding Test Methodology

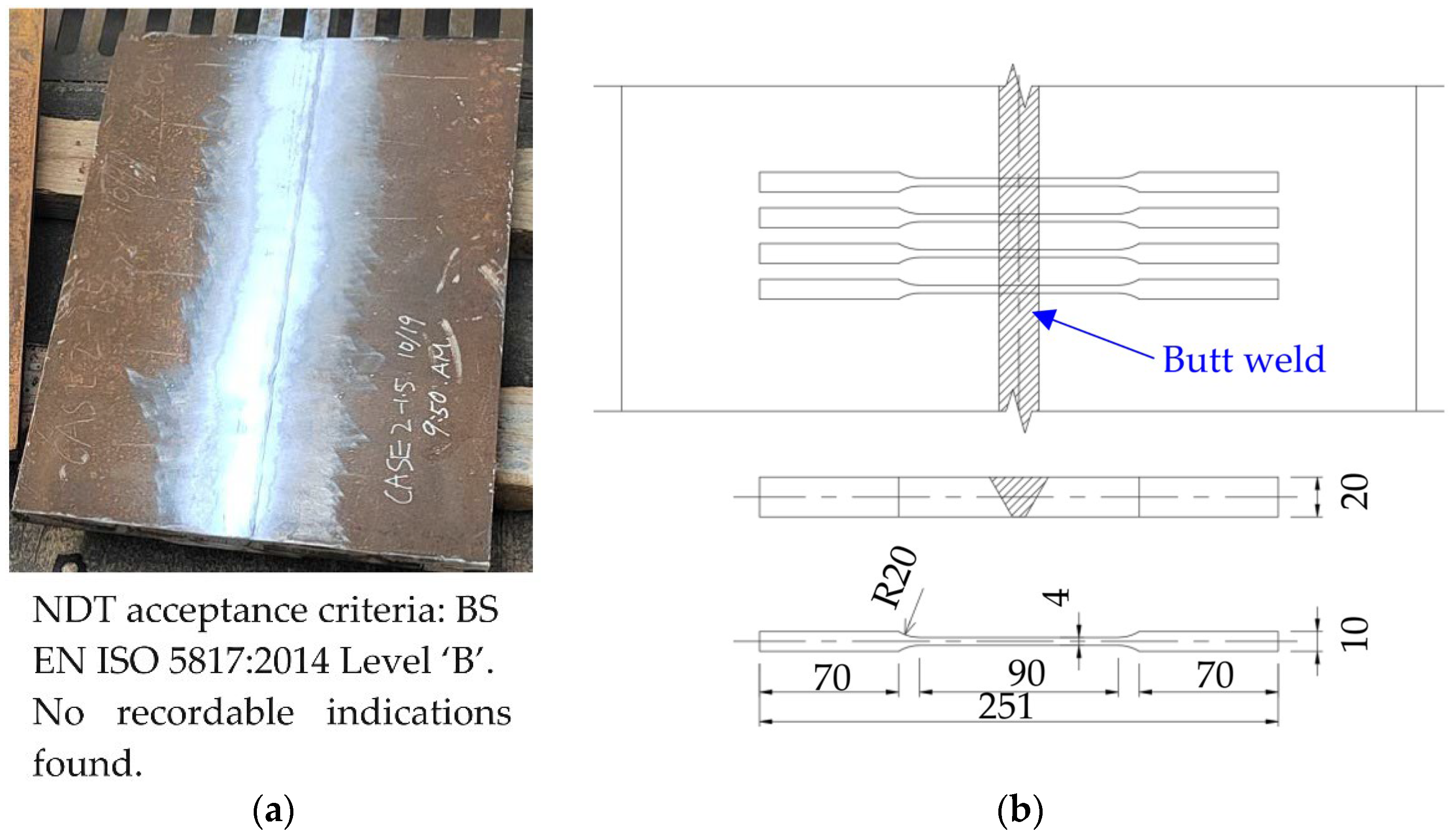

3.1. Test Methodology for Tensile Resistances

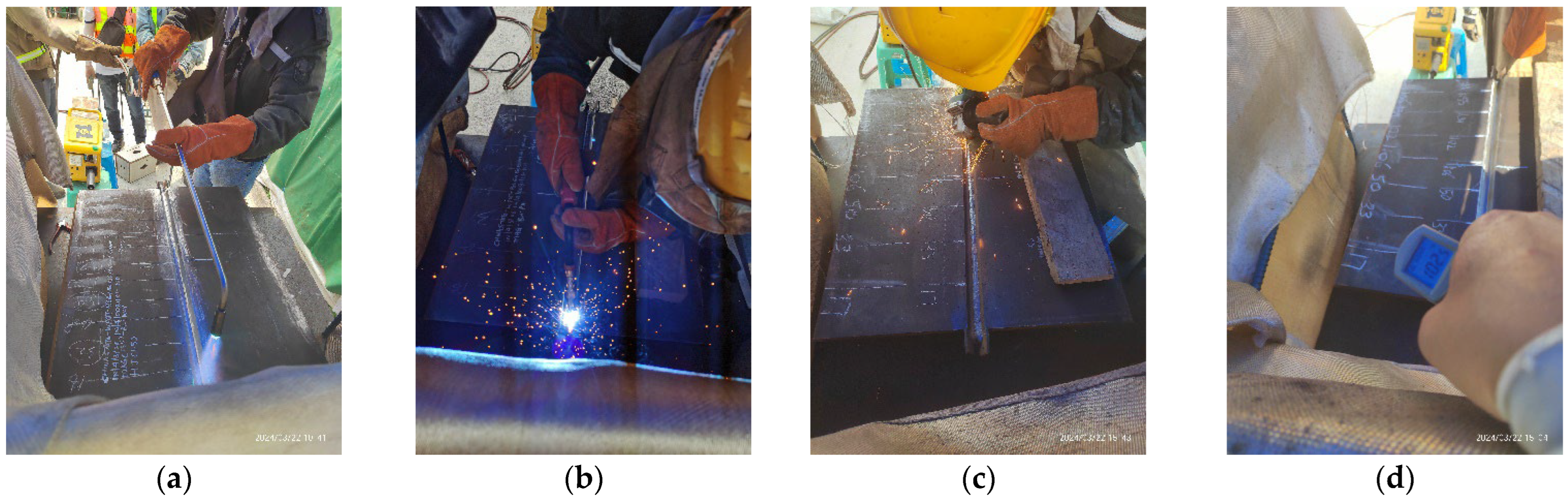

- (1)

- Preheating

- (2)

- Welding

- (3)

- Weld bead cleaning

- (4)

- Temperature measurement in the weld zone

- (5)

- Repeating steps (2) to (4) until the welding passes are completed

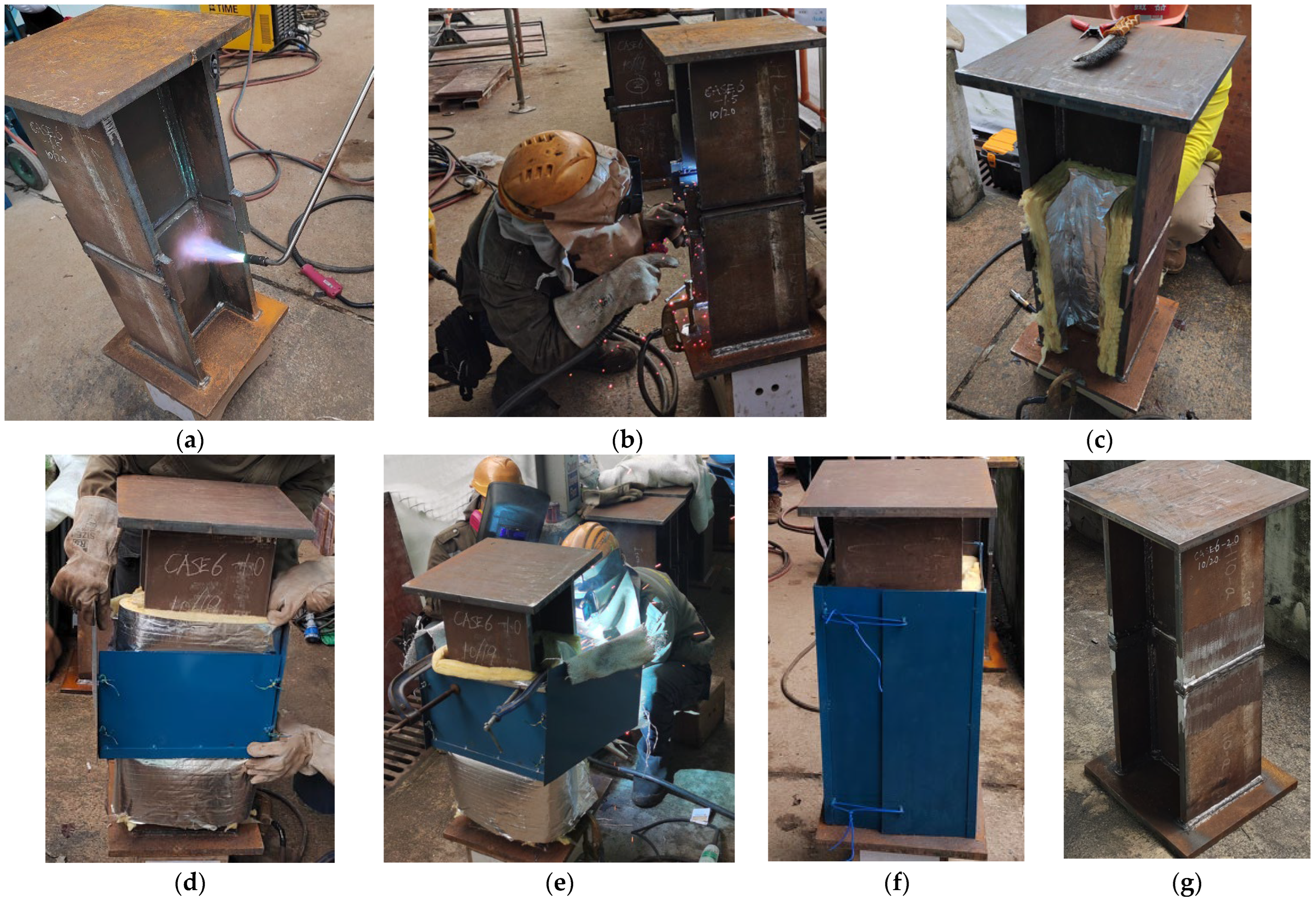

3.2. Test Methodology for Compressive Resistances

- (1)

- Stage 1, the fabrication of H-sections;

- (2)

- Stage 2, the temporary connecting;

- (3)

- Stage 3, the on-site splicing of two H-sections.

- (1)

- Pre-heating;

- (2)

- Multi-pass welding of the web plate;

- (3)

- Wrapping insulation material around the web plate;

- (4)

- Installation of windshield;

- (5)

- Multi-pass welding of the first flange plate;

- (6)

- Wrapping insulation material around the first flange plate;

- (7)

- Relocation of the windshield;

- (8)

- Multi-pass welding of the second flange plate;

- (9)

- Wrapping insulation material around the second flange plate.

4. On-Site Welding Test Result

4.1. Test Results of Tensile Resistances

- (1)

- The use of fire blankets or insulated materials for slow cooling is a viable alternative to post-weld heat treatment (PWHT) in different scenarios;

- (2)

- Heat input energy range of 0.7 kJ/mm–1.5 kJ/mm is practicable;

- (3)

- Both welding joint details A and joint details B are suitable;

- (4)

- The wind block device employed can effectively function to ensure that GMAW welding can be performed in the shielded area, even with an ambient wind speed of 5.5 m/s;

- (5)

- Based on the test results of Series III, the ultimate strength of tensile coupons decreases with increasing heat input energy, which is consistent with the former research [10].

4.2. Test Results of Compressive Resistances

- (1)

- Using insulated materials for slow cooling is a feasible alternative to PWHT;

- (2)

- Heat input energy range of 1.0 kJ/mm–2.0 kJ/mm is practicable for the splicing of compressive members tested, as the splicing welding showed minor influence on the compressive strength;

- (3)

- The wind block device used was easy to operate and convenient for on-site welding.

5. Conclusions

- (1)

- Compliance with strength requirements:

- (2)

- Impact on compressive strength:

- (3)

- Optimal heat input energy range:

- (4)

- Effectiveness of joint details:

- (5)

- Feasibility of eliminating PWHT:

- (6)

- Wind block efficiency:

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rasmussen, K.J.; Hancock, G.J. Plate slenderness limits for high strength steel sections. J. Constr. Steel Res. 1992, 23, 73–96. [Google Scholar] [CrossRef]

- Rasmussen, K.J.; Hancock, G.J. Tests of high strength steel columns. J. Constr. Steel Res. 1995, 34, 27–52. [Google Scholar] [CrossRef]

- Coelho, A.M.G.; Bijlaard, F.S.K. Experimental behaviour of high strength steel end-plate connections. J. Constr. Steel Res. 2007, 63, 1228–1240. [Google Scholar] [CrossRef]

- Coelho, A.M.G.; Bijlaard, F. High strength steel in buildings and civil engineering structures: Design of connections. Adv. Struct. Eng. 2010, 13, 413–429. [Google Scholar] [CrossRef]

- Shi, G.; Ban, H.Y.; Bijlaard, F.S.K. Tests and numerical study of ultra-high strength steel columns with end restraints. J. Constr. Steel Res. 2012, 70, 236–247. [Google Scholar] [CrossRef]

- Xia, J. Flexural behavior of high-strength steel and ultra-high-performance fiber-reinforced concrete composite beams. Buildings 2024, 14, 131. [Google Scholar] [CrossRef]

- Li, Y.H.; Lee, C.C.; Cai, Y.C. Recent research advances in high-performance steel tubular members: Material Properties, Stub Columns, and Beams. Buildings 2023, 13, 2713. [Google Scholar] [CrossRef]

- Chung, K.F. Effective use of high strength S690 to S960 steel in construction. Hong Kong Eng. 2022, 50, 8–18. [Google Scholar]

- Liu, X.; Chung, K.F.; Ho, H.C.; Xiao, M.; Hou, Z.X.; Nethercot, D.A. Mechanical behavior of high strength S690-QT steel welded sections with various heat input energy. Eng. Struct. 2018, 175, 245–256. [Google Scholar] [CrossRef]

- Chung, K.F.; Ho, H.C.; Hu, Y.F.; Wang, K.; Liu, X.; Xiao, M.; Nethercot, D.A. Experimental evidence on structural adequacy of high strength S690 steel welded joints with different heat input energy. Eng. Struct. 2020, 204, 110051. [Google Scholar] [CrossRef]

- Sun, F.F.; Ran, M.M.; Li, G.Q.; Kanvinde, A.; Wang, Y.B.; Xiao, R.Y. Strength model for mismatched butt welded joints of high strength steel. J. Constr. Steel Res. 2018, 150, 514–527. [Google Scholar] [CrossRef]

- Zeng, Z.; Li, G.; Liu, S.W.; Huang, D.H.; Liu, Y.P.; Chan, S.L. Low-cycle fatigue of laser-arc hybrid welded S960 high-strength steel joints. J. Constr. Steel Res. 2026, 236, 110040. [Google Scholar] [CrossRef]

- Buildings Department of Hong Kong SAR Government. Code of Practice for the Structural Use of Steel 2011, 2023 ed.; Buildings Department of Hong Kong SAR Government: Hong Kong, China, 2023.

- Development Bureau; Chinese National Engineering Research Centre for Steel Construction (Hong Kong Branch) of The Hong Kong Polytechnic University; Department of Civil Environmental Engineering of Imperial College London, U.K. Design and construction in Hong Kong using high strength S690 steel. Hong Kong Eng. 2023, 51, 8–16. [Google Scholar]

- Schröter, F. Trends of using high-strength steel for heavy steel structures. In Progress in Steel, Composite and Aluminium Structures; Giejowski, M.A., Kozowski, A., lczka, L., Zióko, J., Eds.; Taylor & Francis: London, UK, 2006; pp. 292–293. [Google Scholar]

- Samuelsson, A.; Schröter, F. High performance steels in Europe-production processes, mechanical and chemical properties, fabrication properties. In Use and Application of High-Performance Steels (HPS) for Steel Structures; IABSE: Zurich, Switzerland, 2005. [Google Scholar]

- BS EN 1011-2:2001; Welding—Recommendations for Welding of Metallic Materials—Part 2: Arc Welding of Ferritic Steels. British Standards Institution: London, UK, 2001.

- Arsić, D.; Lazic, V.; Nikolic, R.; Aleksandrovic, S.; Marinkovic, P.; Djordjevic, M.; Rajko, Č. Application of the S690QL class steels in responsible welded structures. Mater. Eng.-Mater. Inžinierstvo 2013, 20, 174–183. [Google Scholar]

- Baddoo, N.; Chen, A. High Strength Steel Design and Execution Guide; Steel Construction Institute: Bracknell, UK, 2020. [Google Scholar]

- Nevasmaa, P. Prevention of weld metal hydrogen cracking in high-strength multipass welds. Weld. World 2004, 48, 2–18. [Google Scholar] [CrossRef]

- BS EN 1011-1:2009; Welding—Recommendations for Welding of Metallic Materials—Part 1: General Guidance for Arc Welding. British Standards Institution: London, UK, 2009.

- AWS D1.1/D1.1M:2020; Structural Welding Code-Steel. American Welding Society: Miami, FL, USA, 2020.

- EN 10025-6; Hot Rolled Products of Structural Steels—Part 6: Technical Delivery Conditions for Flat Products of High Yield Strength Structural Steels in the Quenched and Tempered Condition. European Committee for Standardization: Brussels, Belgium, 2019.

- EN ISO 16834; Welding Consumables—Wire Electrodes, Wires, Rods and Deposits for Gas Shielded Arc Welding of High Strength Steels—Classification. International Organization for Standardization: Geneva, Switzerland, 2012.

- BS EN ISO 17637; Non-Destructive Testing of Welds—Visual Testing of Fusion-Welded Joints. British Standards Institution: London, UK, 2016.

- BS EN ISO 17638; Non-Destructive Testing of Welds—Magnetic Particle Testing. British Standards Institution: London, UK, 2016.

- BS EN ISO 17640; Non-Destructive Testing of Welds—Ultrasonic Testing—Techniques, Testing levels, and Assessment. British Standards Institution: London, UK, 2018.

- BS EN ISO 5817; Welding—Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded)—Quality Levels for Imperfections. British Standards Institution: London, UK, 2014.

| Material | Welding Process | Heat Input Energy (kJ/mm) | Pre-Heat Temperature (°C) | Inter-Pass Temperature (°C) | Post-Weld Heating |

|---|---|---|---|---|---|

| S690 | Metal Active Gas Welding (MAGW) | 1.0–1.5 | 120–130 | 120–180 | 230 °C hold for 1 h |

| S355 | Flux Cored Arc Welding (FCAW) | 1.3–2.2 | Not required | ≤300 | Not required |

| No. | PWHT Process | References |

|---|---|---|

| (1) | 150 °C, lasting for 1 h for each 10 mm of thickness | [18] |

| (2) | 200 °C to 300 °C, lasting for at least 2 h | [17] |

| (3) | Around 200 °C, lasting time not mentioned | [19] |

| (4) | 230 °C, lasting for 1 h | WPS for welding S690 in an actual project |

| Material | C | Si | Mn | P | S | Cr | Ni | Cu | Mo |

|---|---|---|---|---|---|---|---|---|---|

| S690 steel plate | 0.13 | 0.29 | 1.36 | 0.01 | 0.0014 | 0.42 | 0.03 | 0.04 | 0.038 |

| Welding material | 0.071 | 0.58 | 1.70 | 0.009 | 0.004 | 0.19 | 1.32 | 0.10 | 0.35 |

| Material | Yield Strength, fy (MPa) | Tensile Strength, fu (MPa) | Elongation at Fracture (%) | Diffusible Hydrogen (mL/100 g) |

|---|---|---|---|---|

| S690 steel plate | 878 | 898 | 14.5 | --- |

| Welding material | 736 | 825 | 22 | 2.8 (using the mercury method) |

| Series | Welded Sections | Pre-heat Temperature | Inter-Pass Temperature (°C) | q0* (kJ/mm) | Voltage U (V) | Current I (A) | Welding Speed v (mm/s) | q* (kJ/mm) | Joint Detail |

|---|---|---|---|---|---|---|---|---|---|

| Series I | BW10A | 100–130 | 100–250 | 1.0 | 24.0 | 210 | 4.3 | 0.99 | Joint Detail A |

| Series II | BW10B | 100–130 | 100–165 | 1.0 | 26.2 | 260 | 5.2 | 1.11 | Joint Detail B |

| Series III | BW07C | 100–130 | 100–165 | 0.7 | 23.7 | 255 | 7.1 | 0.72 | Joint Detail B |

| BW10C | 1.0 | 26.2 | 260 | 5.2 | 1.11 | ||||

| BW15C | 1.5 | 26.2 | 245 | 3.5 | 1.56 |

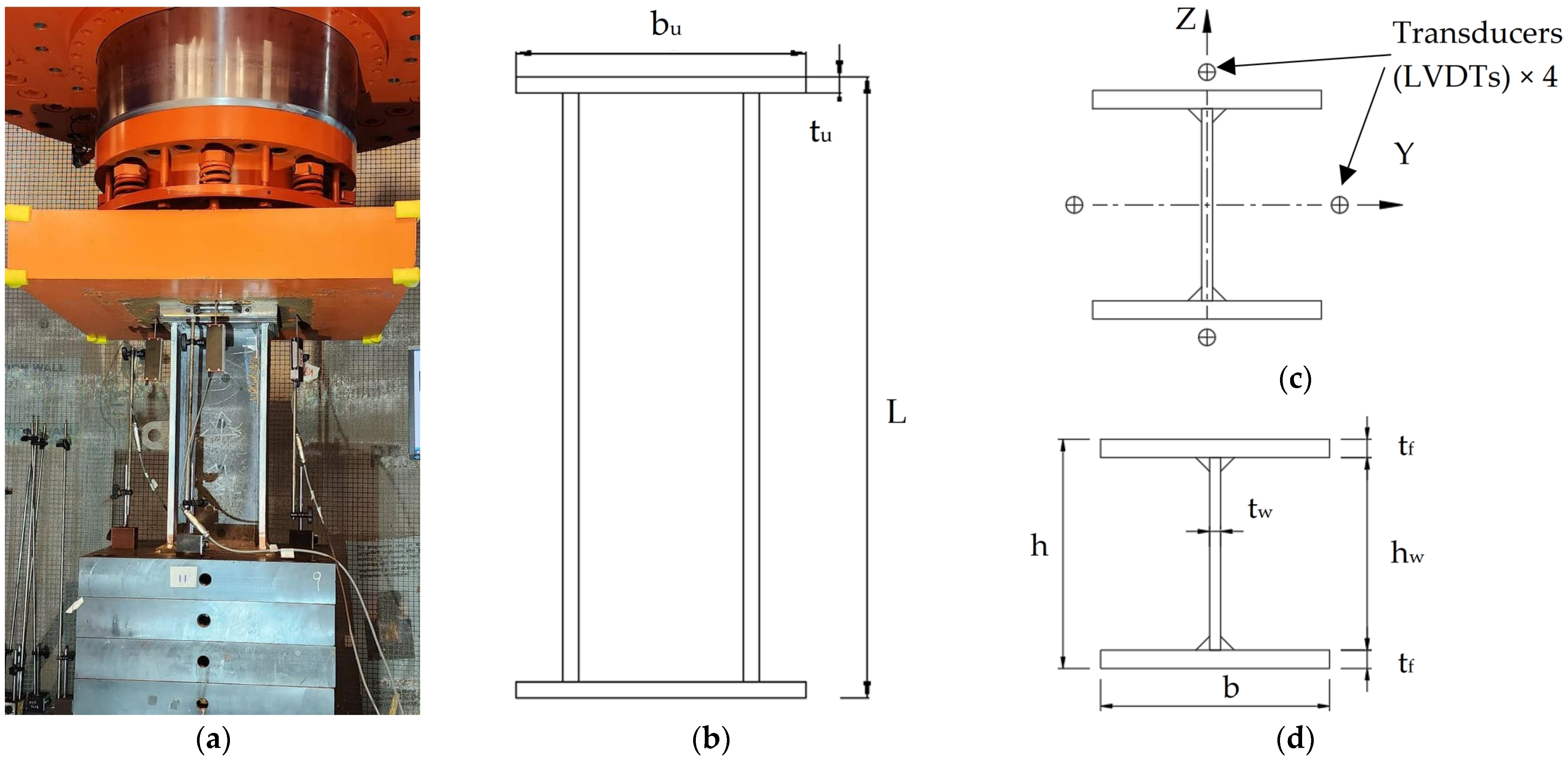

| Description | Column Length, L | Endplate Thickness, tu | Endplate Width, bu | Section Height, h | Slenderness (x Axis) |

|---|---|---|---|---|---|

| Size | 750 mm | 20 mm | 370 mm | 250 mm | 6.96 |

| Description | Section width, b | Web thickness, tw | flange thickness, tf | Web height, hw | Endplate flatness tolerance |

| Size | 250 mm | 20 mm | 20 mm | 210 mm | 0.3 mm |

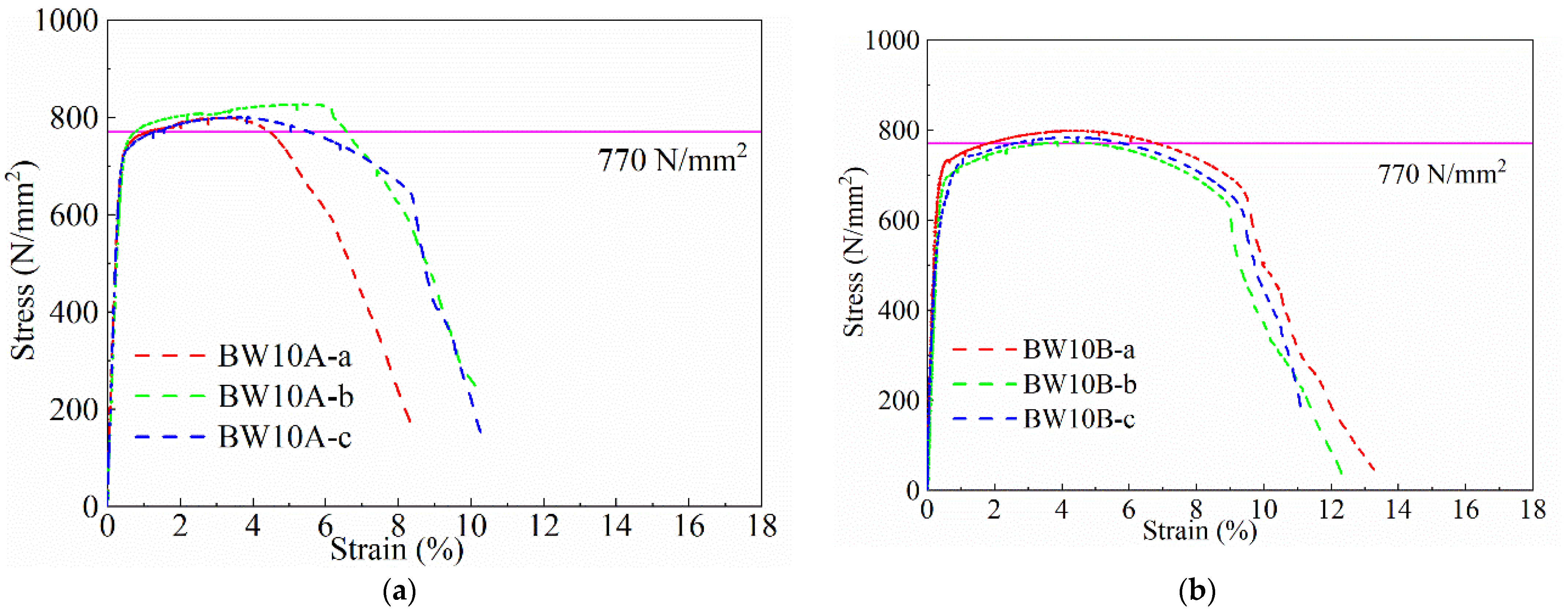

| Welded Section | Tensile Specimen | Heat Input Energy, q (kJ/mm) | Tensile Strength, fu (N/mm2) | Elongation at Fracture, εf (%) | Fracture Position |

|---|---|---|---|---|---|

| BW10A | BW10A-a | 0.99 | 798 | 7.60 | WM |

| BW10A-b | 827 | 9.37 | WM | ||

| BW10A-c | 799 | 9.27 | HAZ | ||

| Average | 808 | 8.75 | - |

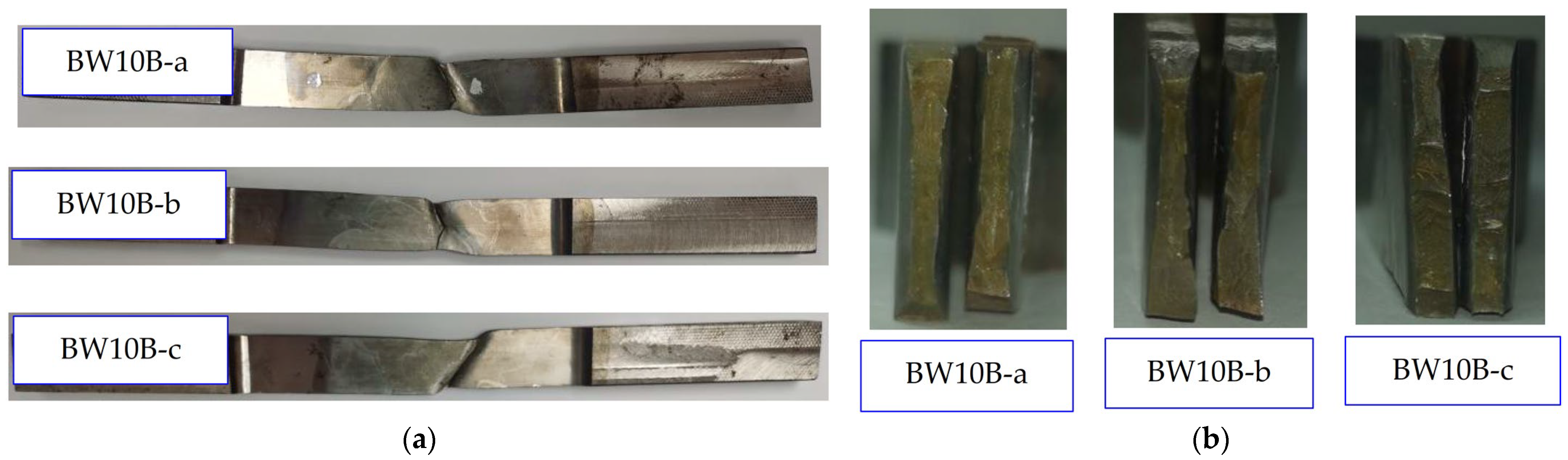

| Welded Section | Tensile Specimen | Heat Input Energy, q (kJ/mm) | Tensile Strength, fu (N/mm2) | Elongation at Fracture, εf (%) | Fracture Position |

|---|---|---|---|---|---|

| BW10B | BW10B-a | 1.11 | 798 | 9.07 | HAZ |

| BW10B-b | 773 | 10.16 | HAZ | ||

| BW10B-c | 783 | 9.63 | HAZ | ||

| Average | 785 | 9.62 | - |

| Welded Section | Heat Input Energy, q (kJ/mm) | Tensile Strength, fu (N/mm2) | Charpy Impact Energy at −40 °C, (J) | Hardness Test (Vickers HV10) | Bend Test | |||

|---|---|---|---|---|---|---|---|---|

| HAZ | WM | BP | HAZ | WM | ||||

| BW07C | 0.72 | 829, 839 | 237, 182, 214 | 92, 69, 90 | 263–290 | 239–299 | 247–332 | No rejectable defect |

| Average | 834 | 211 > 30 | 83 > 30 | <450 | ||||

| BW10C | 1.11 | 812, 818 | 207, 69, 114 | 93, 63, 86 | 259–322 | 230–286 | 250–264 | No rejectable defect |

| Average | 815 | 130 > 30 | 81 > 30 | <450 | ||||

| BW15C | 1.56 | 791, 788 | 50, 39, 151 | 66, 94, 80 | 235–282 | 226–264 | 235–256 | No rejectable defect |

| Average | 789.5 | 80 > 30 | 80 > 30 | <450 | ||||

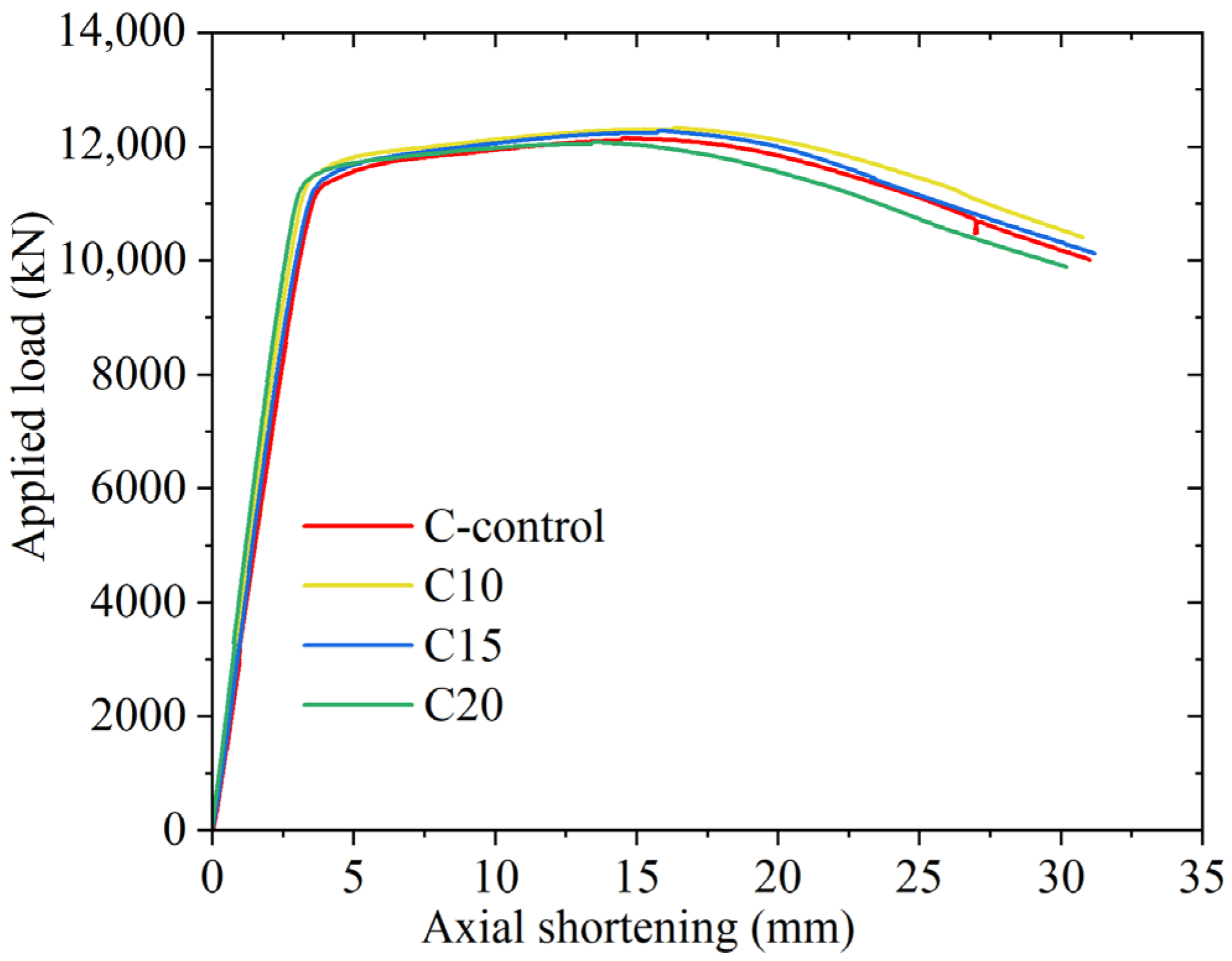

| Specimen | Measured Area, A0 (mm2) | Measured Resistance | Design Resistance, Nc,Rd (kN) | Estimated Yield Strength, fy,e (N/mm2) | Nc,Rt/Nc,Rd | Ratio of fy,e | |

|---|---|---|---|---|---|---|---|

| Nc,Rty (kN) | Nc,Rt (kN) | ||||||

| C-control | 14,550 | 11,564 | 12,154 | 10,040 | 794.8 | 1.21 | 1.000 |

| C10 | 14,659 | 11,490 | 12,335 | 10,115 | 783.8 | 1.22 | 0.986 |

| C15 | 14,703 | 11,303 | 12,281 | 10,145 | 768.8 | 1.21 | 0.967 |

| C20 | 14,580 | 11,482 | 12,087 | 10,060 | 787.6 | 1.20 | 0.991 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, X.; Zhang, Y.; Huang, J.; Shi, J.; Zhao, Z.; Lu, W.; Qiang, W.; Yang, M.; He, Z.; Feng, J. On-Site Welding Research for High-Strength S690 Steel. Buildings 2025, 15, 4102. https://doi.org/10.3390/buildings15224102

Zou X, Zhang Y, Huang J, Shi J, Zhao Z, Lu W, Qiang W, Yang M, He Z, Feng J. On-Site Welding Research for High-Strength S690 Steel. Buildings. 2025; 15(22):4102. https://doi.org/10.3390/buildings15224102

Chicago/Turabian StyleZou, Xiaokang, Yang Zhang, Jiang Huang, Jun Shi, Zhen Zhao, Wenjie Lu, Weiliang Qiang, Minghan Yang, Zhongcai He, and Jingwei Feng. 2025. "On-Site Welding Research for High-Strength S690 Steel" Buildings 15, no. 22: 4102. https://doi.org/10.3390/buildings15224102

APA StyleZou, X., Zhang, Y., Huang, J., Shi, J., Zhao, Z., Lu, W., Qiang, W., Yang, M., He, Z., & Feng, J. (2025). On-Site Welding Research for High-Strength S690 Steel. Buildings, 15(22), 4102. https://doi.org/10.3390/buildings15224102