1. Introduction

Fiber-reinforced polymer (FRP) composites have been widely adopted for the strengthening and rehabilitation of reinforced concrete (RC) structures owing to their high tensile strength, low weight, and excellent corrosion resistance [

1,

2,

3,

4]. The overall performance of FRP-strengthened systems is fundamentally governed by the bond behavior at the FRP–concrete interface, which controls the efficiency of stress transfer and, consequently, dictates the load-bearing capacity and long-term durability of the strengthened member [

5,

6]. However, when exposed to aggressive service environments, the integrity of the FRP–concrete interface can deteriorate significantly. In cold or seasonally fluctuating regions, repeated freeze–thaw (FT) cycles represent one of the most severe environmental stressors, progressively degrading the interfacial bond performance and consequently reducing structural integrity and service life [

7].

Extensive research has been conducted to explore the degradation of the FRP–concrete bond under FT exposure. Jiang et al. [

8] experimentally demonstrated that repeated FT cycles led to significant reductions in bond strength and interfacial stiffness due to microcrack accumulation in the interfacial transition zone (ITZ). Zhang et al. [

9] further revealed that sulfate–FT coupling accelerated interfacial degradation and reduced the effective bonding area, while Zhang et al. [

10] confirmed that both static and dynamic bond capacities declined markedly with increasing FT cycles. Wang and Petrů [

11] observed that ice-induced stresses severely reduced the fracture energy and shifted the failure mode toward adhesive debonding. Although these studies provide valuable insights, the mechanisms of FT-induced interfacial degradation remain insufficiently clarified and often lack a consistent modeling framework. In addition, recent works have explored performance-based predictive models for FRP-strengthened systems under harsh environmental conditions [

12,

13], but most of these focus solely on ultimate bond strength, neglecting the evolution of key bond–slip parameters such as peak shear stress, slip capacity, and fracture energy. Furthermore, current models are often built on limited datasets and simplified assumptions, resulting in reduced reliability when applied under coupled environmental–mechanical conditions.

In recent years, machine learning (ML) techniques have been increasingly adopted in concrete engineering to enhance predictive accuracy, computational efficiency, and model interpretability [

14,

15,

16,

17,

18]. For FRP–concrete systems, data-driven models have demonstrated strong potential in capturing nonlinear relationships among geometric, material, and environmental factors, often outperforming traditional empirical formulations. Zhou et al. [

19] developed an explicit neural network model trained on a large experimental dataset, achieving high accuracy and generalizability in predicting interfacial bond strength. Chen et al. [

20] proposed an ensemble learning framework to improve robustness and minimize prediction errors across diverse test conditions. Similarly, Zhang et al. [

21] constructed ML-based regression models capable of accurately estimating ultimate bond strength, fracture energy, and stiffness. Kumar et al. [

22] further introduced a user-friendly graphical interface based on ML, enabling efficient bond strength prediction under variable exposure conditions. Su et al. [

23] evaluated multiple ML algorithms and optimized model selection for FRP–concrete bond strength prediction, while Zhu et al. [

24] employed SHAP-based explainable ML methods to quantify the relative importance of input variables and enhance interpretability. In addition, Qu et al. [

25] proposed a GAN–ANN hybrid model to address small-sample limitations in FRP–concrete datasets, providing a viable solution for rare-condition modeling. Ge et al. [

26] utilized metaheuristic algorithm-optimized ML frameworks, demonstrating superior performance in bond strength prediction under high-temperature environments. Despite these advancements, most existing studies remain limited to predicting the ultimate bond strength, lacking comprehensive modeling of the full bond–slip evolution at the FRP–concrete interface, and failing to adequately account for the coupled degradation effects under environmental exposures, particularly freeze–thaw cycles.

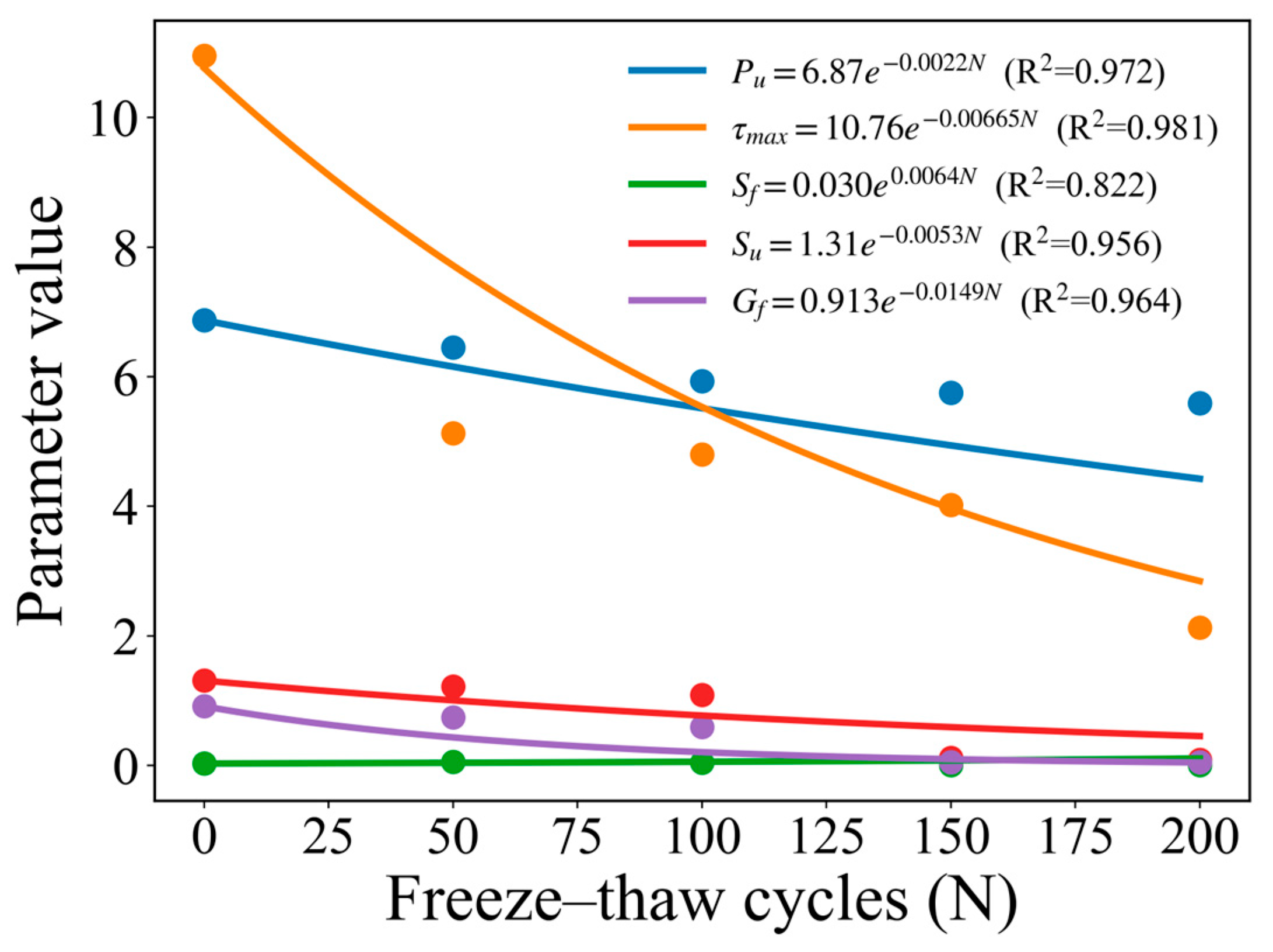

Most existing models, whether empirical or data-driven, focus solely on predicting ultimate bond strength under ambient conditions, without capturing the evolution of bond–slip behavior or the degradation of key interfacial parameters under FT exposure. The environmental sensitivity of peak shear stress, slip capacity, and fracture energy remains insufficiently quantified, limiting accurate durability assessments. To address this gap, the present study integrates experimental investigation and machine learning (ML) modeling to systematically evaluate and predict the degradation of FRP–concrete interfacial properties under FT cycles. A series of single-lap shear tests were conducted to quantify changes in bond strength, slip response, and fracture energy across different FT cycles, enabling a comprehensive understanding of bond deterioration trends. Based on the experimental dataset, interpretable ML models were developed to predict key bond–slip parameters and to identify the relative influence of geometric, material, and environmental variables. Unlike previous studies that emphasize only ultimate strength, this work establishes a generalized, data-driven framework for assessing and forecasting the environmental sensitivity of interface performance in cold-region applications.

2. Experimental Program

2.1. Material Properties and Specimen Setup

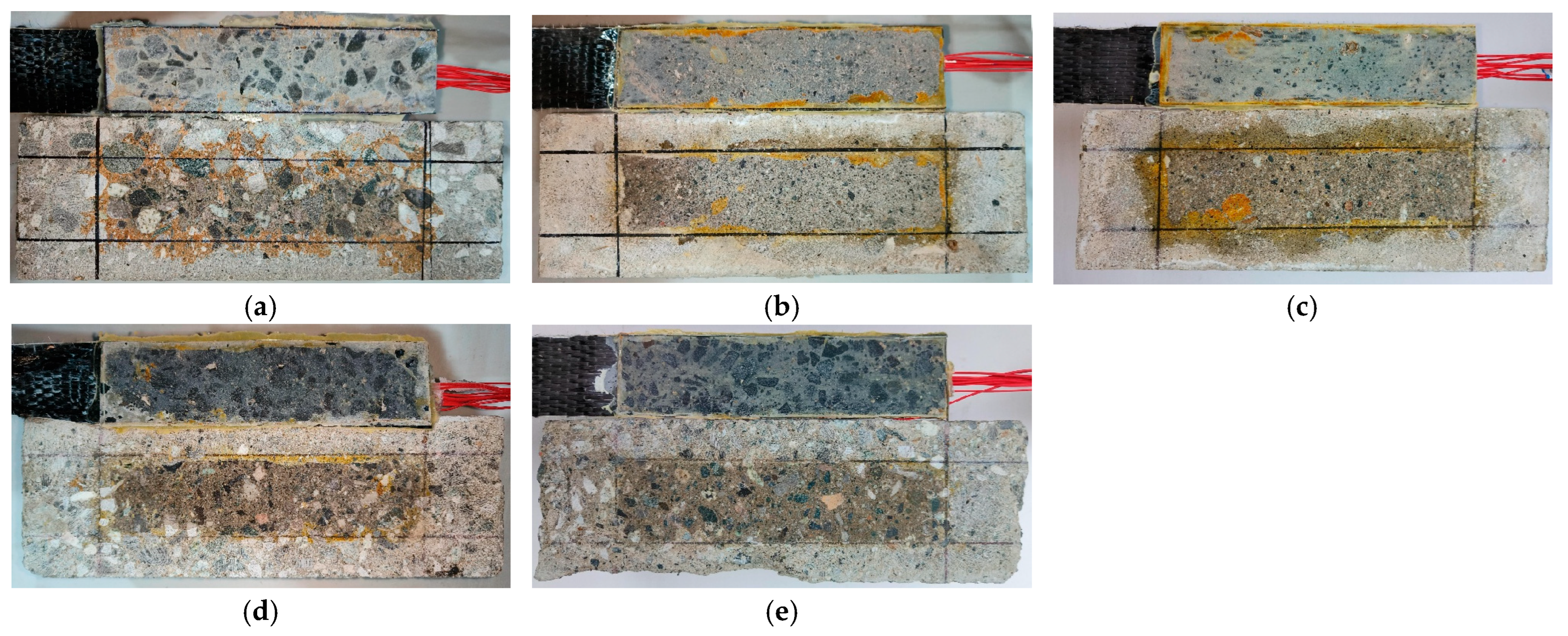

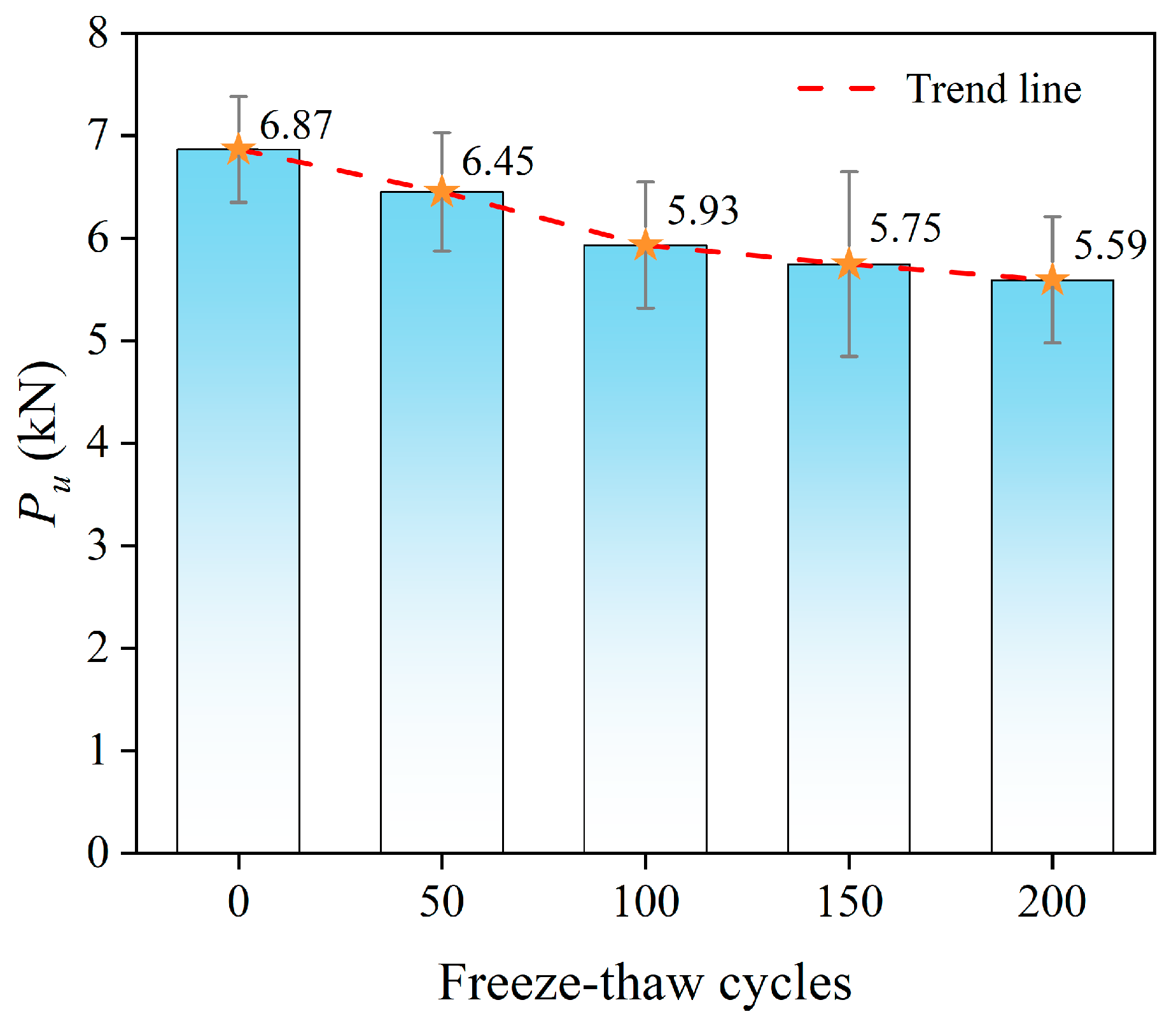

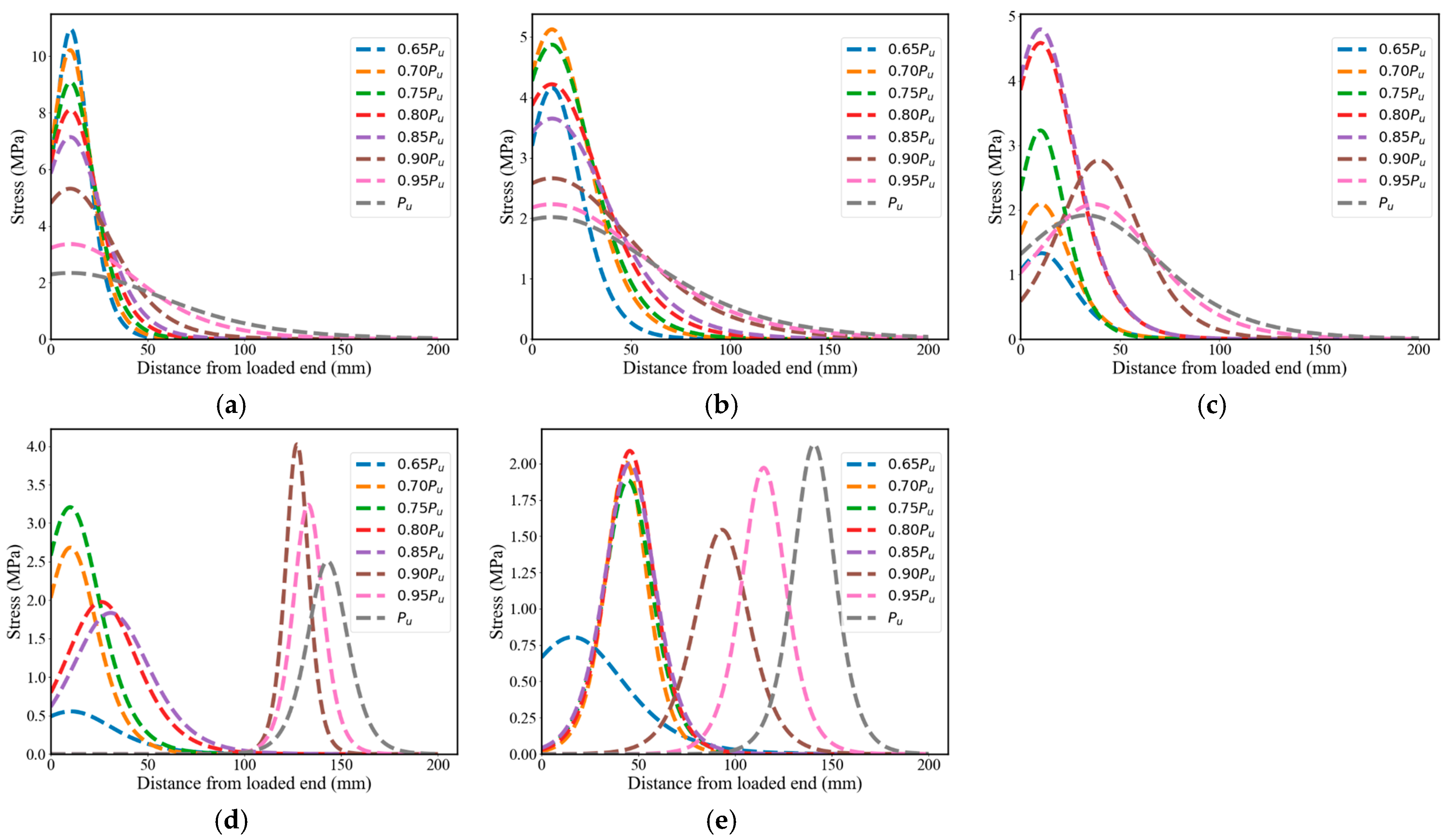

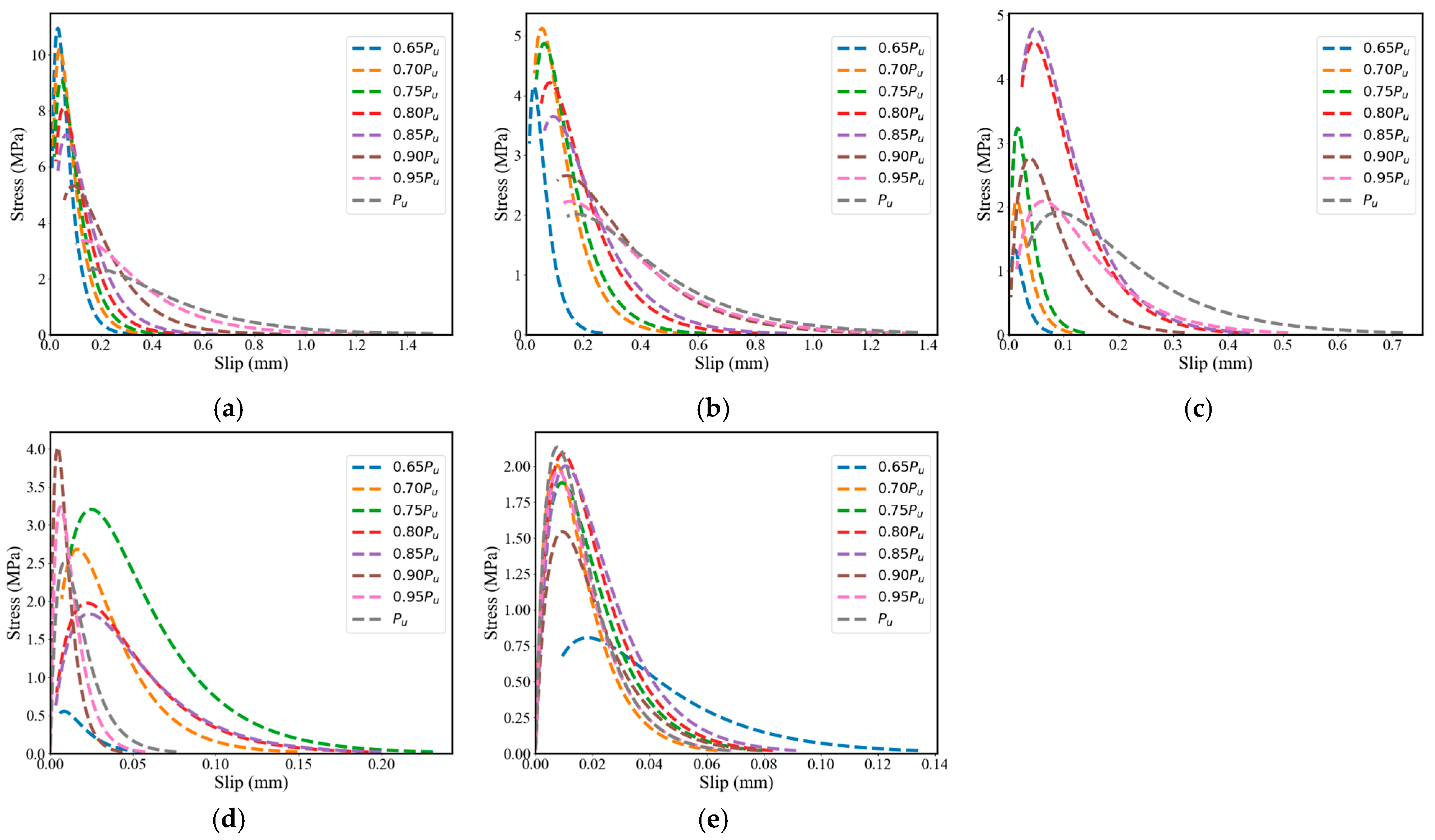

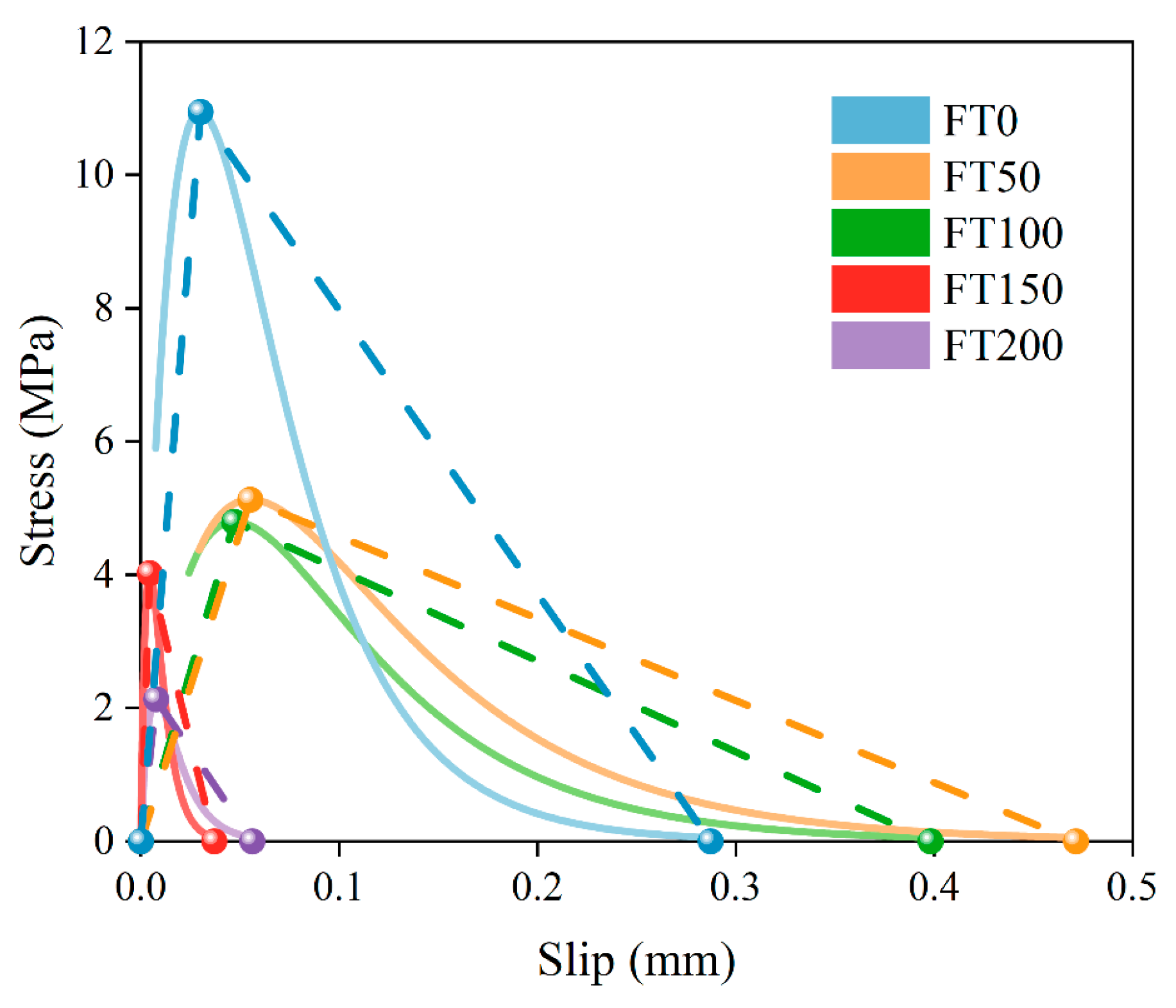

This study systematically investigated the evolution of bond performance at the FRP–concrete interface under the influence of freeze–thaw cycles, using concrete with an average 28-day compressive strength of 55.5 Mpa as the substrate. To perform single-lap shear tests, standard concrete prism specimens were designed and fabricated with dimensions of 100 mm (width) × 100 mm (height) × 300 mm (length). The interface was strengthened using unidirectional carbon fiber-reinforced polymer (CFRP) sheets, which exhibited a tensile strength of 3731.0 Mpa, an elastic modulus of 238 GPa, and a nominal thickness of 0.167 mm. The structural adhesive was a two-component epoxy resin used as the CFRP impregnation adhesive, prepared by mixing component A (resin) and component B (hardener) at a mass ratio of 2:1. After curing, the adhesive exhibited a tensile strength of 38.6 Mpa and an elastic modulus of 3.0 GPa. To ensure effective stress transfer and minimize boundary effects, the CFRP sheets were applied in a single unidirectional layer along the longitudinal axis of the specimen. The bonded width and effective bond length were 50 mm and 150 mm, respectively, while a 200 mm unbonded segment was reserved at the free end to avoid constraint effects. The bond-line thickness was controlled using 1.0 mm diameter steel wires as spacers, maintaining a uniform thickness of 1.0 ± 0.2 mm among all specimens. During specimen preparation, the concrete surface was mechanically ground to remove surface laitance and create a uniformly roughened substrate. The CFRP sheets were then applied at ambient temperature. After bonding, all specimens were cured in a well-ventilated environment for no less than 7 days to ensure complete curing of the epoxy resin and the development of stable interfacial properties. The specimens were divided into five groups, labeled FT0, FT50, FT100, FT150, and FT200, corresponding to 0 (control group), 50, 100, 150, and 200 freeze–thaw cycles, respectively. To ensure adequate statistical representation and experimental repeatability, specimens were prepared in groups of 3 for each freeze–thaw condition, leading to a total of 15 specimens for testing.

2.2. Freeze–Thaw Cycle Test

The freeze–thaw cycling procedure was conducted in accordance with the rapid freezing method specified in GB/T 50082-2009 [

27]. Each cycle lasted 4 h, consisting of a freezing phase at −18 ± 2 °C and a thawing phase at 5 ± 2 °C, with a controlled temperature change rate of 3.0 ± 0.5 °C/min. Prior to testing, all FRP–concrete specimens were immersed in water for 4 days to achieve full saturation and ensure consistent internal moisture conditions. During testing, all specimens were subjected to identical equipment settings and temperature-control procedures to guarantee environmental uniformity and reproducibility.

2.3. Single-Shear Test

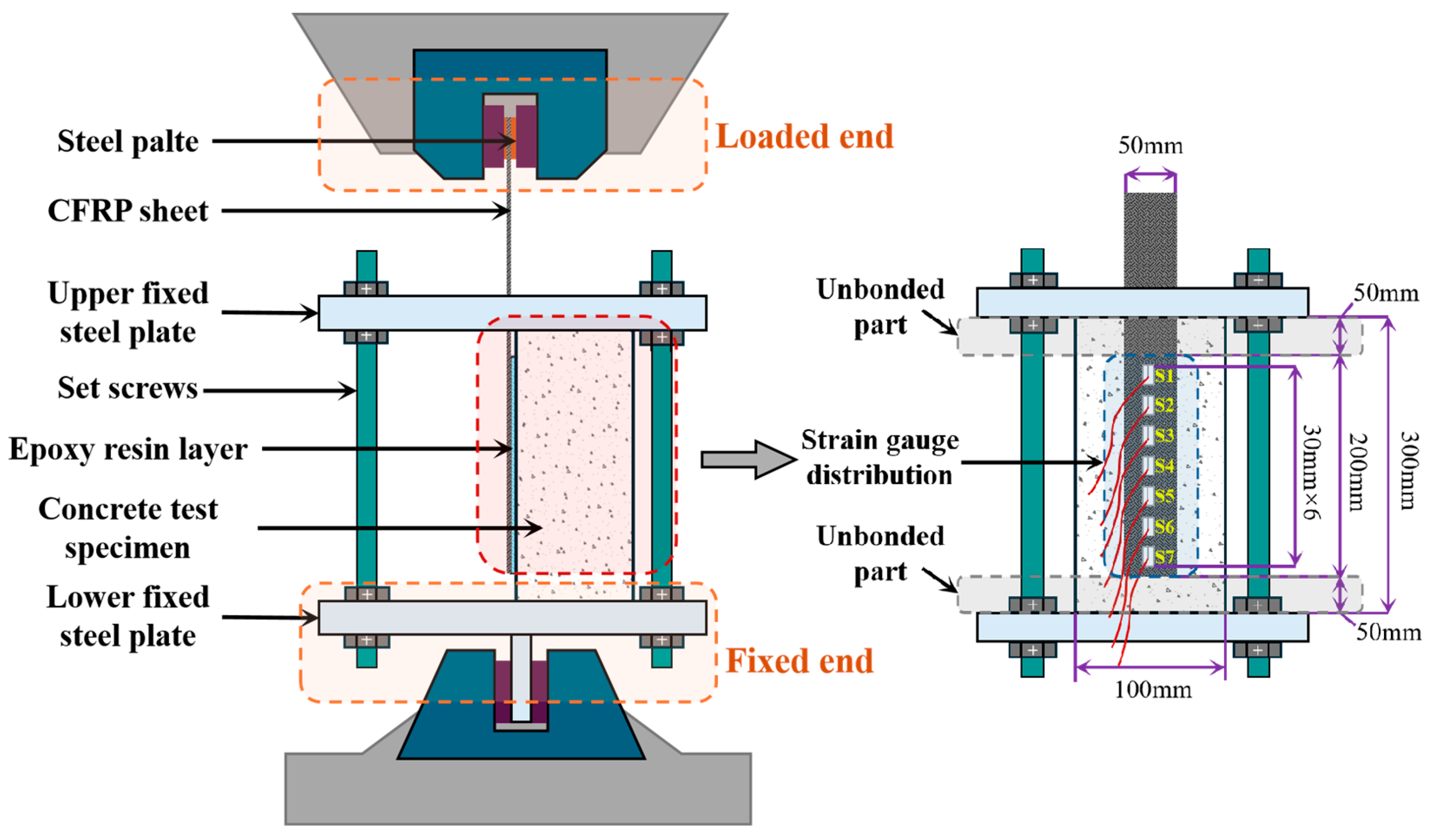

Figure 1 illustrates the customized test apparatus and instrumentation layout used to evaluate the bond performance at the CFRP–concrete interface. The concrete prism specimen was laterally confined by a steel frame and axially anchored to a rigid steel base using high-strength bolts at both the loaded and fixed ends, effectively restraining rotational and translational movement during loading. To prevent premature failure at the gripping zone, a 50 × 50 mm Q235 steel plate was bonded to the CFRP sheet at the loaded end using high-strength epoxy resin for local reinforcement. A universal testing machine applied a monotonic tensile load to the CFRP sheet at a constant displacement rate of 1 mm/min. As shown in the right view of

Figure 1, seven strain gauges labeled S1 through S7 were uniformly installed along the bonded length of the CFRP sheet to measure the strain distribution along the FRP–concrete interface. The data were collected in real time using a static strain acquisition system.

4. Prediction Based on Machine Learning Models

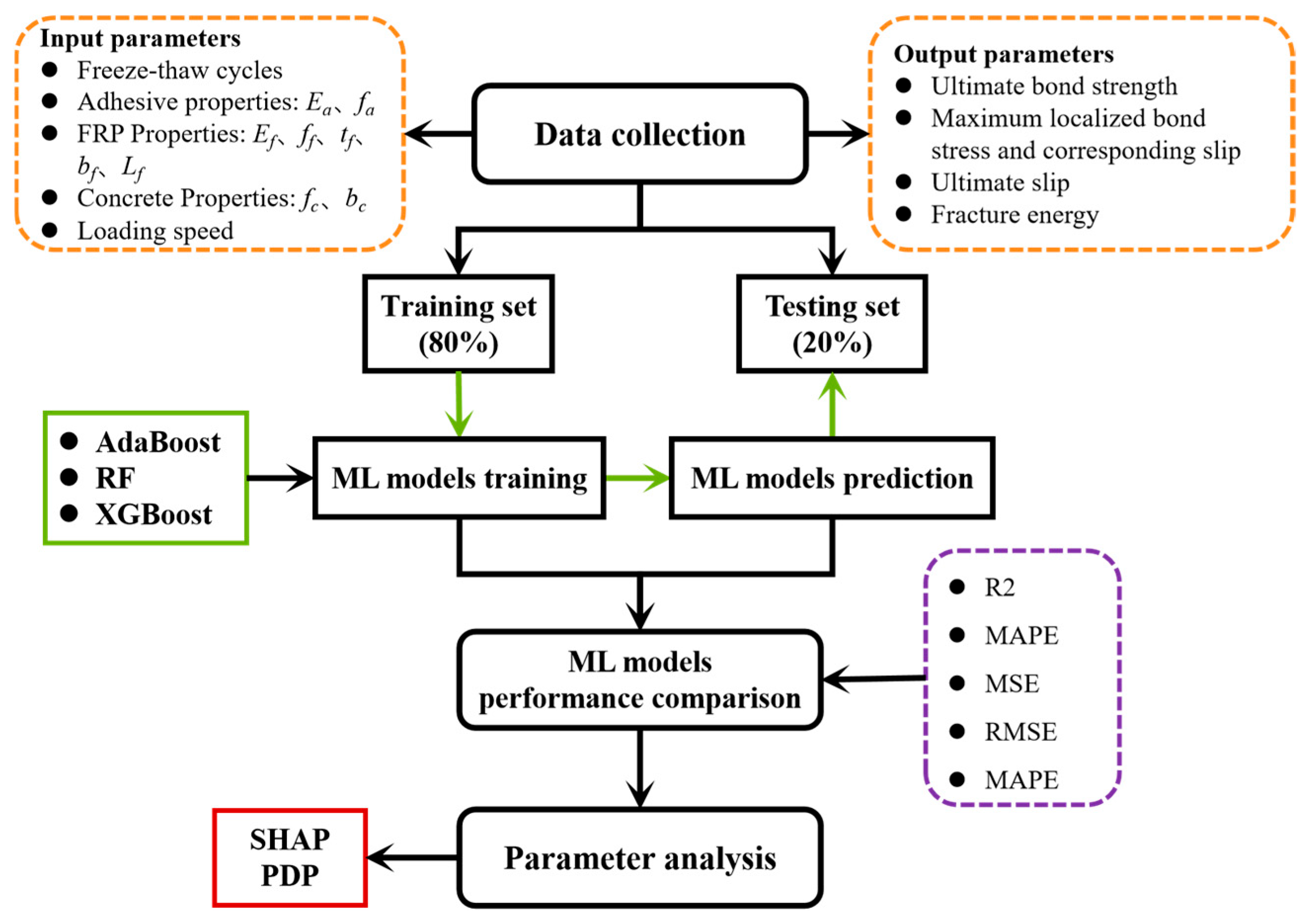

The workflow of the machine learning prediction process is illustrated in

Figure 9. First, data on the bond performance of FRP-concrete interfaces were collected from experimental results and relevant literature, followed by data preprocessing. Subsequently, machine learning models were employed to predict key bond performance parameters, and hyperparameters were tuned using optimization algorithms to enhance model performance. The predictive accuracy of different models was then compared using evaluation metrics to identify the optimal model. Finally, SHapley Additive exPlanations (SHAP) analysis was used to quantify the contribution of each input variable to bond performance, and partial dependence plots (PDPs) were employed to reveal the nonlinear influence trends of critical factors.

4.1. Data Collection and Pre-Processing

In this study, considering the limited availability of experimental data on FRP–concrete interfaces under FT conditions, a comprehensive dataset covering both ambient and FT exposure was established by integrating data from existing literature with experimental results obtained in this work. The key input parameters in the dataset included the number of FT Cycles, elastic modulus of the adhesive (Ea), tensile strength of the adhesive (fa), elastic modulus of the FRP (Ef), tensile strength of the FRP (ff), FRP thickness (tf), FRP width (bf), FRP bond length (Lf), compressive strength of the concrete (fc), concrete width (bc), and loading rate (v).

To ensure the integrity of the dataset, the Local Outlier Factor (LOF) method was employed for anomaly detection and data cleaning prior to model development. The LOF algorithm evaluates the local density deviation of each sample relative to its neighbors, effectively identifying points that are isolated in the multidimensional feature space. Samples with abnormally low local densities are considered outliers, as they often represent physically or statistically inconsistent data patterns. The parameters were set to n_neighbors = 20 and contamination = 0.1, following standard practice for medium-sized datasets. The LOF analysis was conducted before the dataset was divided into training and testing subsets. A total of 33 samples exhibiting low local density values were identified and removed, resulting in 299 valid samples for subsequent modeling. Notably, the samples detected as outliers did not show extreme deviations in individual features but rather displayed uncommon feature combinations, leading to sparse distributions in the multidimensional space that could introduce noise to regression training. The corresponding statistical characteristics are summarized in

Table 2. Detailed information on the dataset is provided in the

Supplementary Materials.

Moreover, to investigate the interrelationships among the variables in the dataset,

Figure 10 displays the Pearson correlation coefficient matrix between the input and output parameters. A higher absolute value of the coefficient indicates a stronger correlation between two variables. It was observed that, except for the correlation between

tf and

Ea, which exceeded 0.8 in absolute value, the correlation coefficients among the remaining parameters were all below 0.8, suggesting relatively low interdependencies.

4.2. Machine Learning Models

4.2.1. Adaptive Boosting (AdaBoost)

The AdaBoost model is an ensemble learning method that iteratively trains a series of weak classifiers, adjusting the weights of samples in each iteration to increase the model’s focus on misclassified instances [

34]. Ultimately, the predictions of all weak classifiers are combined through a weighted majority vote to form a strong classifier.

4.2.2. Random Forest (RF)

Random Forest (RF) is an ensemble learning technique that constructs multiple decision trees by training on different subsets of the original dataset generated through bootstrap sampling with replacement [

35]. For regression tasks, the RF model produces its final output by averaging the predictions from all individual decision trees.

4.2.3. Extreme Gradient Boosting (XGBoost)

XGBoost is an efficient gradient boosting framework based on the Gradient Boosted Decision Tree (GBDT) technique. It improves model performance by iteratively constructing tree models to minimize prediction residuals [

36].

4.3. ML Model Development

4.3.1. Performance Evaluation Indicators

To ensure a comprehensive and rigorous assessment of the predictive performance of different machine learning models, five evaluation metrics were adopted in this study: Mean Absolute Error (MAE), Mean Absolute Percentage Error (MAPE), Mean Squared Error (MSE), Root Mean Squared Error (RMSE), and the coefficient of determination (R

2). The corresponding mathematical formulations are provided in

Table 3. These metrics collectively assess the accuracy, magnitude of prediction errors, and the degree of data fitting. The use of these multidimensional evaluation criteria provides robust data support for model selection and optimization.

4.3.2. Model Training and Optimization

To accurately capture the distinct degradation patterns of different interfacial properties, a multi-task prediction framework was established, in which five independent sub-models were constructed to predict the key bond–slip parameters Pu, , Sf, Su, and Gf, respectively. Although these parameters are interrelated in the physical sense, their statistical distributions, magnitudes, and sensitivities to FT damage differ considerably. Therefore, training independent sub-models under a unified framework enables each model to specialize in learning its characteristic mapping relationship while maintaining consistency in data processing and evaluation.

The Optuna hyperparameter optimization framework was applied separately to each sub-model to determine the optimal parameter configuration. Optuna integrates Bayesian optimization with the Tree-structured Parzen Estimator (TPE) algorithm, allowing adaptive and efficient exploration of the hyperparameter search space to enhance predictive performance [

37]. To ensure comparability, all sub-models shared identical input features, optimization criteria, and search ranges, with 300 Optuna trials conducted for each model. The optimal configuration was selected based on the minimum mean squared error (MSE) obtained on the validation set.

Table 4 lists the unified hyperparameter search ranges and the optimal configurations determined for each sub-model under the Optuna optimization framework.

To evaluate the convergence behavior and generalization capability of the optimized models, learning curves were plotted based on the R

2 with increasing training sample proportions, as shown in

Figure 11. The solid lines with colored circular and triangular markers illustrate the evolution of training and test set results for different ML models, respectively. For all prediction tasks, the training R

2 values remained consistently high (>0.95), while the validation R

2 values exhibited a monotonic increase and gradually converged. When the training size was below 60 samples, large fluctuations and even negative validation R

2 values were observed, especially for

Sf and

Su. As the training data increased, the validation R

2 of all models progressively improved and stabilized within the range of 0.75–0.90, demonstrating that the models effectively captured the underlying feature–response relationships once sufficient data coverage was achieved. Among the three algorithms, XGBoost consistently exhibited the highest and smoothest convergence trend, with the smallest generalization gap between the training and validation curves, indicating its superior robustness and generalization performance.

In addition, to further verify the robustness and statistical consistency of the developed models, supplementary experiments were conducted under five different random seeds (0, 7, 42, 99, and 123). For each of the five output parameters, the mean and standard deviation of the R

2 and RMSE were calculated, and paired t-tests were performed based on R

2 to evaluate the statistical significance of inter-model differences. As shown in

Table A2, the XGBoost model consistently achieved high predictive accuracy across all outputs, with mean R

2 values ranging from 0.76 to 0.95 and relatively low RMSE and variance, indicating low sensitivity to random initialization and strong stability. In comparison, RF achieved comparable accuracy but with higher variability, whereas AdaBoost showed lower accuracy in

Pu and

Sf, indicating weaker adaptability. Although the paired

t-tests indicated that the inter-model differences were not statistically significant in most prediction tasks (

p > 0.05), XGBoost achieved the highest mean R

2 and lowest RMSE in four out of five outputs.

Overall, these results confirm that the optimized XGBoost model possesses superior stability and generalization capability across multiple prediction tasks.

4.4. ML Model Prediction Performance

This study analyzed the performance of three ML models in predicting the bond behavior at the FRP–concrete interface using multiple evaluation metrics. The models were compared based on their performance across five key output parameters. Detailed results of the evaluation metrics are presented in

Table A3, covering the training set, testing set, and the entire dataset.

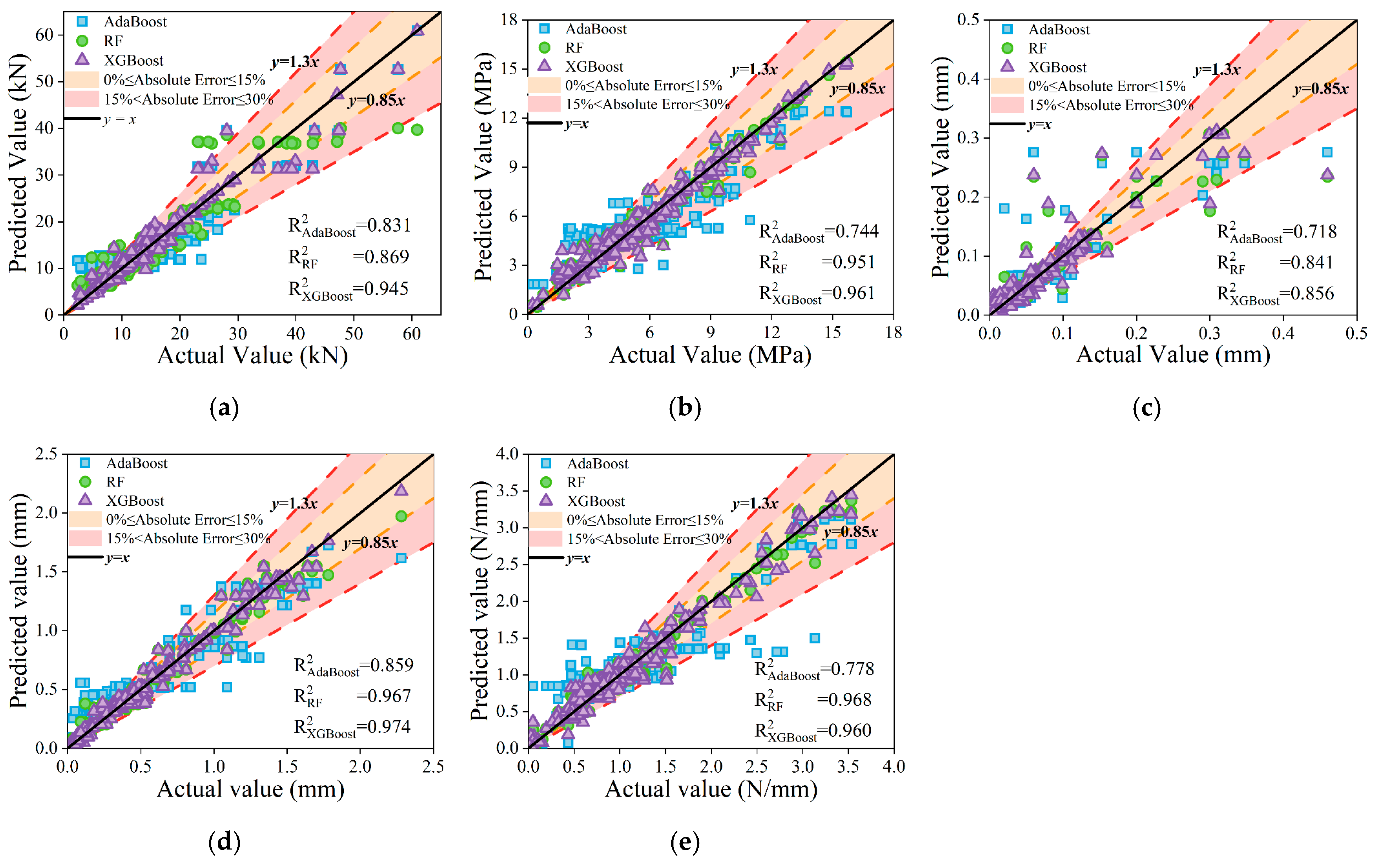

As illustrated in

Figure 12, notable differences were observed in the fitting performance between predicted and actual values across the entire dataset for the three ML models. Among them, the XGBoost model demonstrated particularly outstanding performance, especially in predicting the parameters

Pu,

,

Sf, and

Su, with corresponding R

2 values of 0.945, 0.961, 0.856, and 0.974, each exceeding those of the AdaBoost and RF models by more than 9%. In addition, for these four parameters, the RMSE values obtained by the XGBoost model were 1.995 kN, 0.558 MPa, 0.023 mm, and 0.070 mm, respectively, while the MAPE values were 6.01%, 10.46%, 24.11%, and 14.89%. These results further demonstrate the strong predictive capability of the XGBoost model for key indicators of FRP–concrete bond behavior. In comparison, although the overall predictive accuracy of the RF model was slightly inferior to that of XGBoost, it exhibited superior performance in predicting the

Gf, achieving an R

2 value of 0.967, which was higher than XGBoost’s 0.960. This slight advantage suggests that the RF model may be better suited for capturing the characteristics associated with interfacial fracture energy. Among all the models, AdaBoost demonstrated the weakest performance, with R

2 values consistently lower than those of both XGBoost and RF across all prediction tasks. This indicates that AdaBoost struggles to accurately model the complex nonlinear behavior of the FRP–concrete interface.

Overall, the XGBoost model demonstrated outstanding fitting accuracy and generalization ability across all prediction tasks. It consistently exhibited lower prediction errors on the training set, testing set, and the entire dataset. Therefore, XGBoost can be considered the most effective machine learning model for predicting the bond performance at the FRP–concrete interface.

4.5. Analysis of Input Features

4.5.1. SHAP Analysis

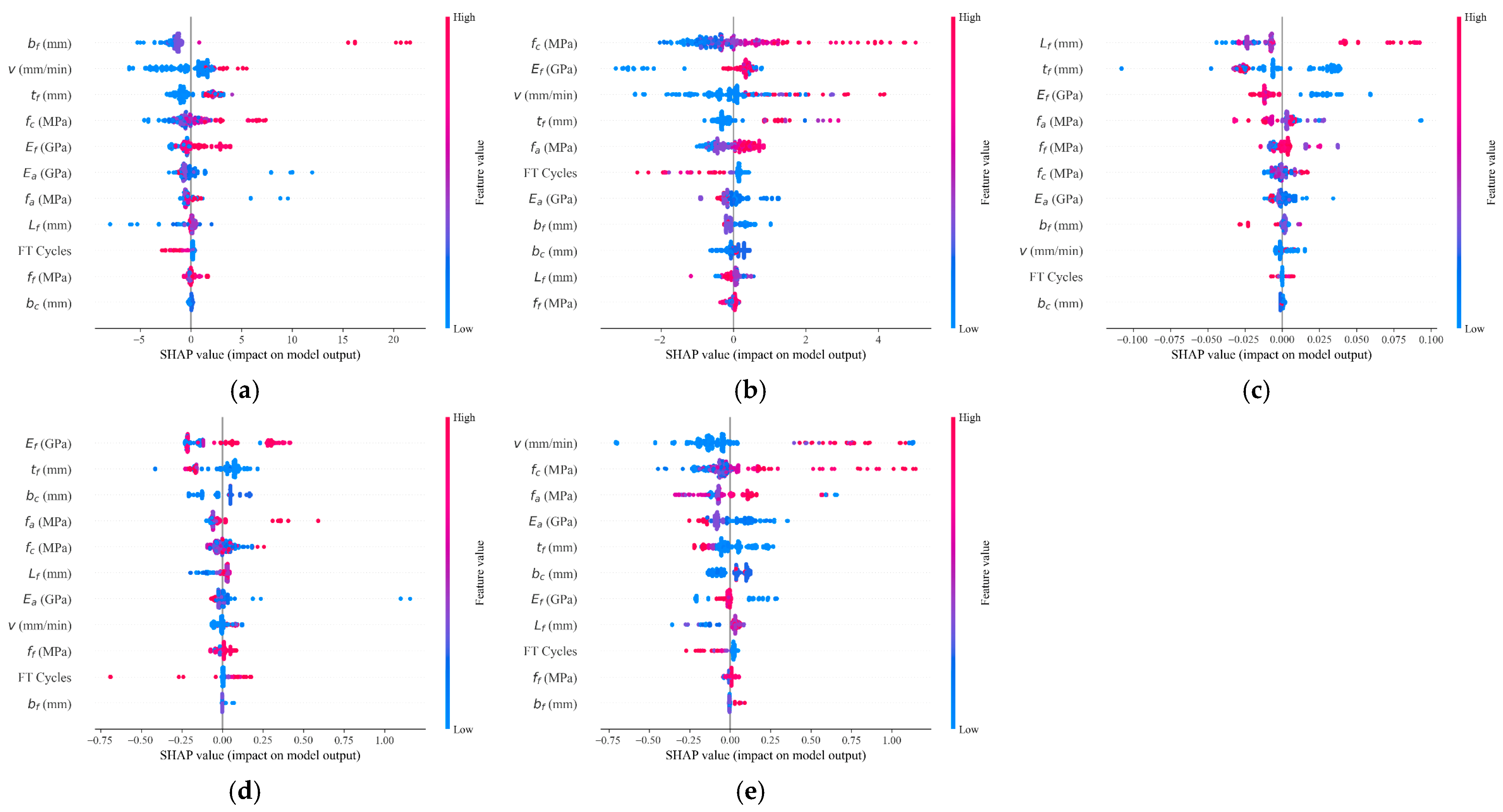

In this study, the XGBoost machine learning model was employed in conjunction with the SHAP (Shapley Additive Explanations) analysis method to investigate the influencing factors governing the bond performance at the FRP–concrete interface. The SHAP approach enables a quantitative assessment of the contribution of each input variable to the model’s predictions, thereby revealing the key factors affecting the interfacial behavior between FRP sheets and concrete.

Table 5 summarizes the overall SHAP-based feature importance rankings, highlighting the varying contributions of input variables across different output parameters.

Figure 13 further visualizes the distribution of local SHAP values, providing insights into the individual influence of each feature on the model predictions.

In the prediction of the

Pu, the

bf was identified as the most influential factor, accounting for 25.1% of the total feature importance. As shown in

Figure 13a, an increase in the

bf significantly enhanced the load-bearing capacity of the bond interface. Additionally, the

v and

tf contributed 16.8% and 13.1% to the model’s predictions. A higher

v was found to accelerate the attainment of

Pu, while an increase in

tf contributed to an overall improvement in the structural integrity of the interface.

For the , the fc had the most significant influence, with a feature importance of 20.2%, indicating that high-strength concrete plays a critical role in enhancing . The Ef and the v contributed 15.7% and 15.5%, respectively, highlighting the notable impact of both material properties and loading conditions on shear performance.

The slip behavior at the FRP–concrete interface was primarily governed by the mechanical properties and geometric dimensions of the FRP material. In the prediction of the slip corresponding to the Sf, the Lf and tf were identified as the key influencing factors, with feature importance values of 26.5% and 25.1%, respectively. For the Su, the most significant factor was the Ef, with a feature importance of 31.7%, followed by the tf at 14,7%. Materials with higher elastic modulus can effectively improve the interfacial bond stiffness by enhancing constraint at the interface.

In the prediction of Gf, the v was the dominant factor, with a feature importance of 24.0%. An increase in v tends to intensify brittle failure at the bond interface, thereby reducing the Gf. In addition, the fc and fa had feature importance values of 14.1% and 13.7%, respectively. These material parameters play a critical role in enhancing the energy accumulation and load-bearing capacity of the bonded interface.

Although experimental results indicated that FT cycles had a significant impact on the and Su, their feature importance in the XGBoost model was relatively low. This is primarily due to the high degree of coupling between the effects of FT cycles and other variables, such as concrete compressive strength and the elastic modulus of the FRP, rather than FT cycles acting as an independent determining factor. While FT degradation does contribute to the deterioration of bond performance, within the analyzed dataset, the influence of material properties—particularly concrete strength and FRP stiffness—was more prominent, thereby reducing the apparent direct contribution of FT cycles in the model.

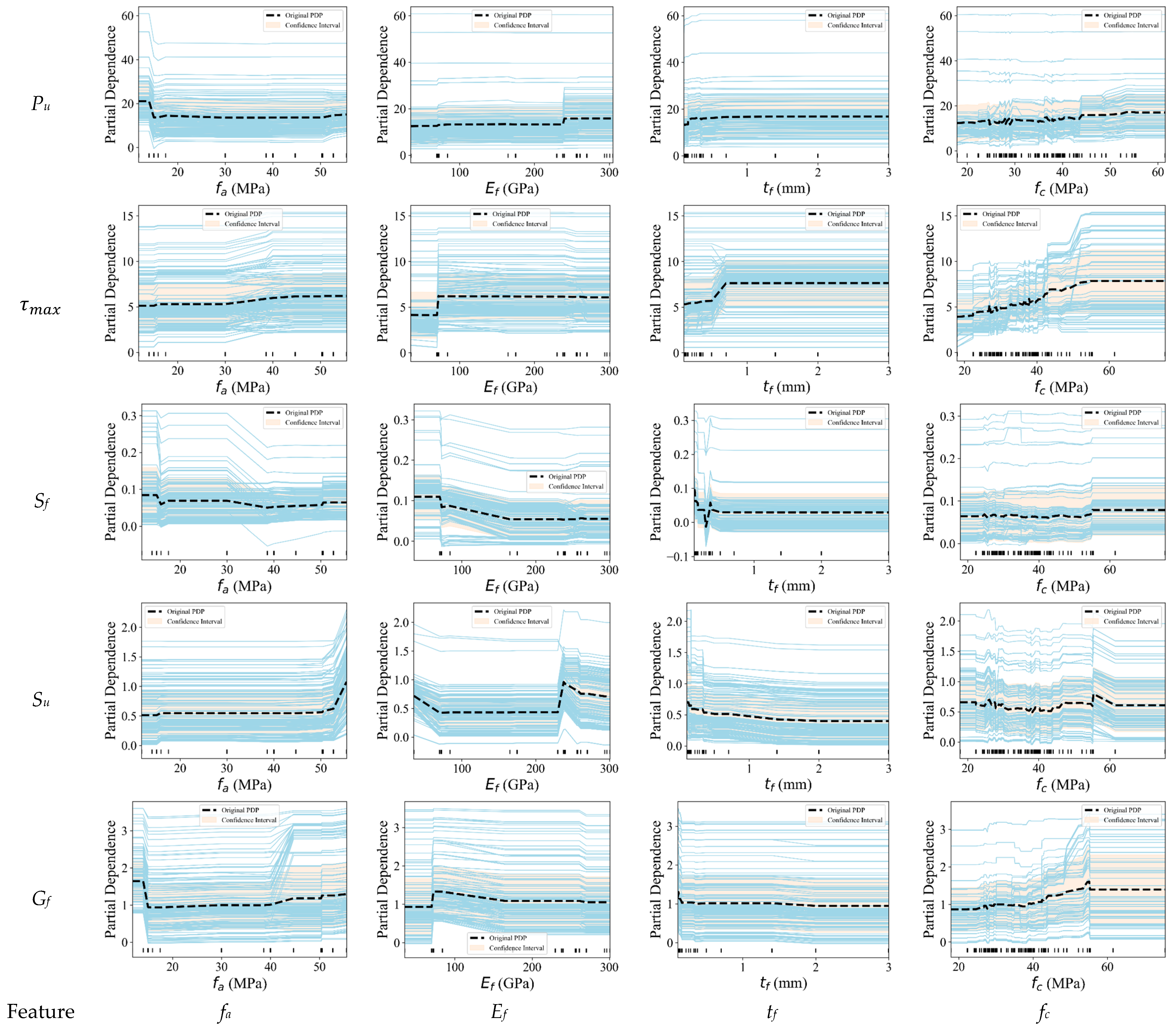

4.5.2. PDP Analysis

In this study, the application of the SHAP method revealed that the tensile strength of the adhesive layer (

fa), elastic modulus of the FRP (

Ef), fiber thickness (

tf), and concrete compressive strength (

fc) exert significant influence on the bond performance at the FRP–concrete interface. These parameters not only demonstrated high feature importance across multiple output variables, but also played a central role in interfacial stress transfer, deformation behavior, and failure modes. However, while SHAP analysis effectively identified the importance and directionality of these features, it did not provide detailed insights into the specific trends of their influence on model outputs or the optimal value ranges. To address this limitation, Partial Dependence Plots (PDPs) were further employed to investigate the influence patterns of these key variables on the predicted outcomes. As shown in

Figure 14, the blue PDP curves illustrate the average effect of each feature on the model output. The black vertical lines at the bottom indicate the distribution of sample points across the feature range, and the black dashed line represents the smoothed trend fitted from the PDP, revealing the nonlinear relationship between the feature and the predicted response.

A detailed analysis of

Figure 14 identified the optimal range for the

fa to be 15–25 MPa. Within this range,

fa not only enhances the interfacial resistance to debonding, but also avoids the reduction in energy dissipation capacity and the risk of brittle failure caused by excessive adhesive stiffness. For the

Ef and

tf of the FRP, the recommended optimal ranges are 70–140 GPa and 1.1–2.0 mm, respectively. Parameters within these intervals contribute to improved stress transfer efficiency and interfacial load-bearing capacity, while reducing premature debonding due to stress concentration. The optimal range for

fc was found to be 30–50 MPa. This range not only enhances the load-bearing capacity of the concrete substrate, but also improves interfacial performance under large slip conditions, enabling greater energy accumulation under high-stress environments. By precisely adjusting these key parameters, the bond performance at the FRP–concrete interface can be significantly improved, thereby optimizing both the overall structural performance and long-term durability.