Research on the Impact Performance of Polypropylene Fiber-Reinforced Concrete Composite Wall Panels

Abstract

1. Introduction

2. Mechanical Property Tests of Concrete with Hybrid Polypropylene Fibers

2.1. Experimental Procedures

2.1.1. Raw Materials

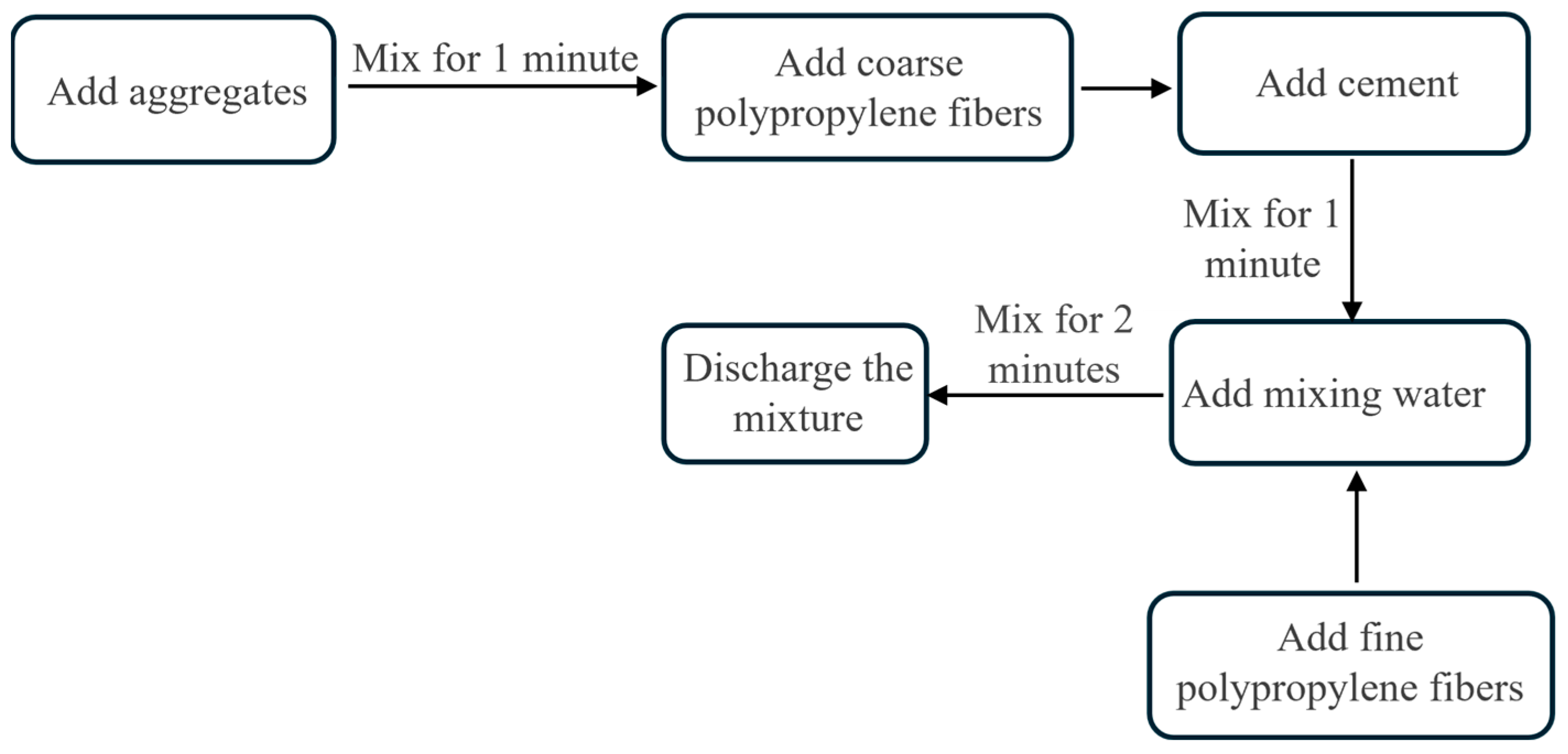

2.1.2. Mix Proportion, Casting Procedures, and Specimen-Making

2.1.3. Testing Procedure

2.2. Test Results and Analysis

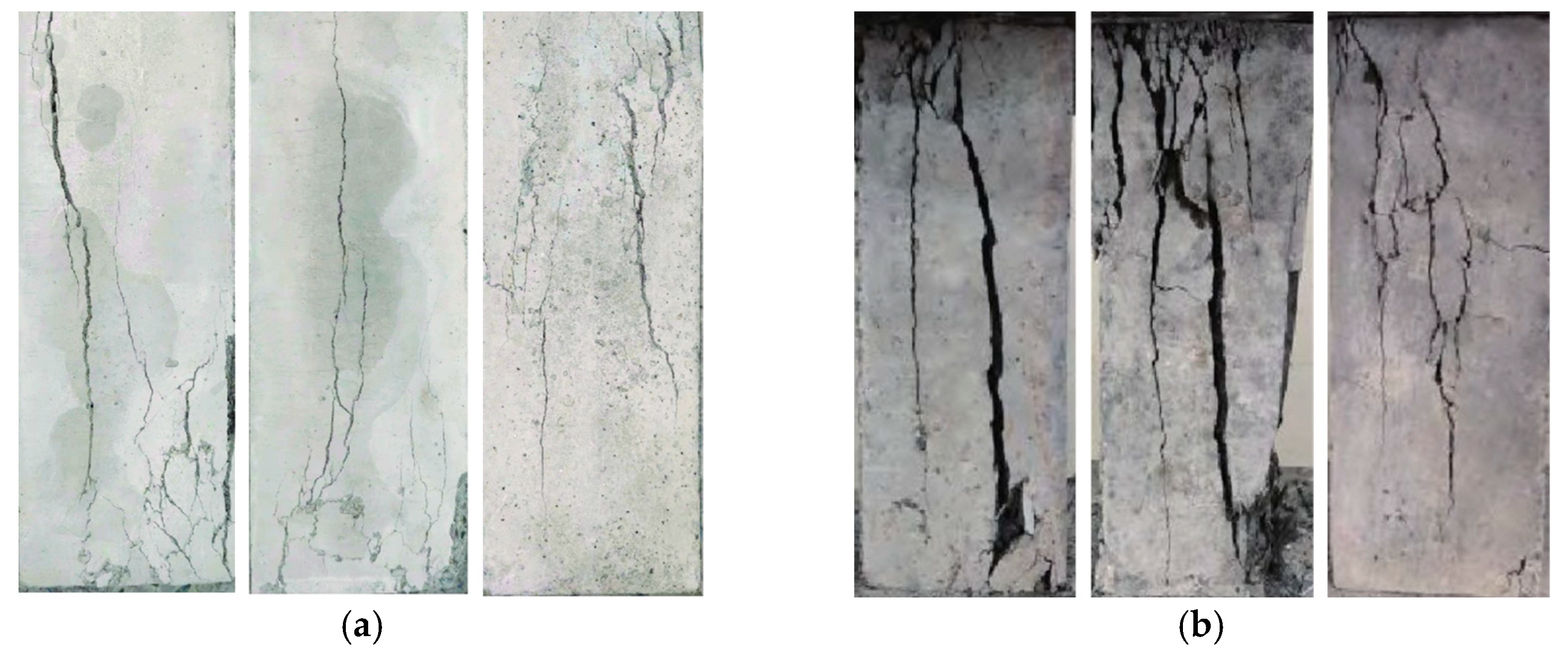

2.2.1. Failure Mode Analysis

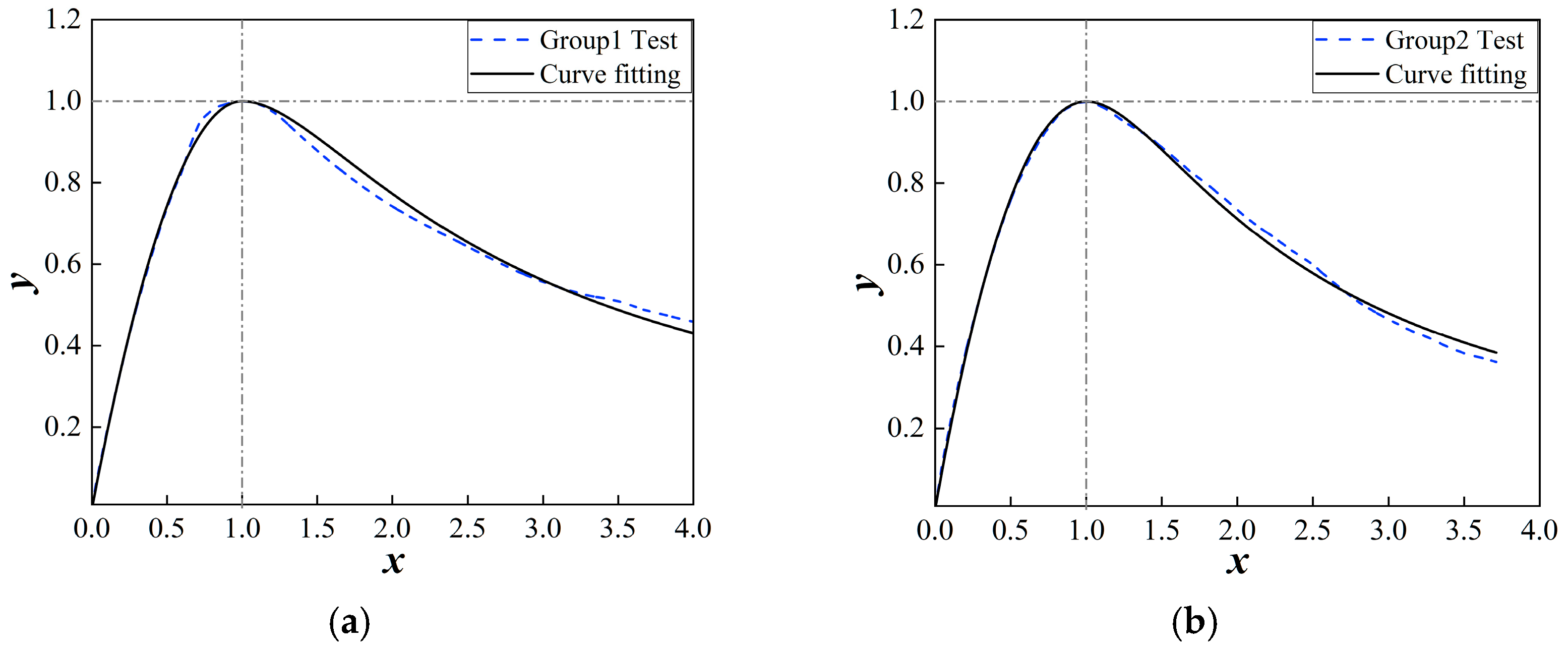

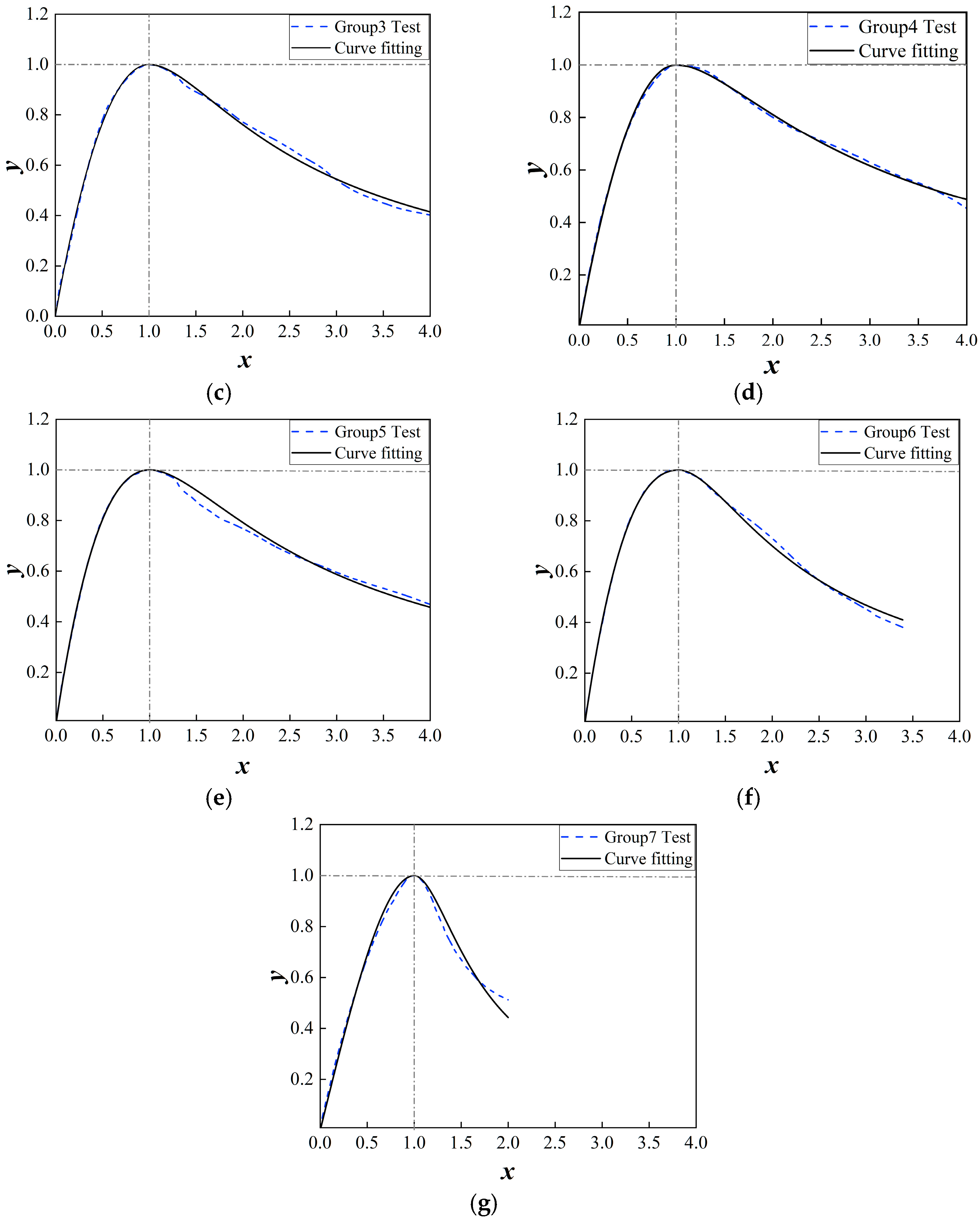

2.2.2. Stress–Strain Curve Analysis

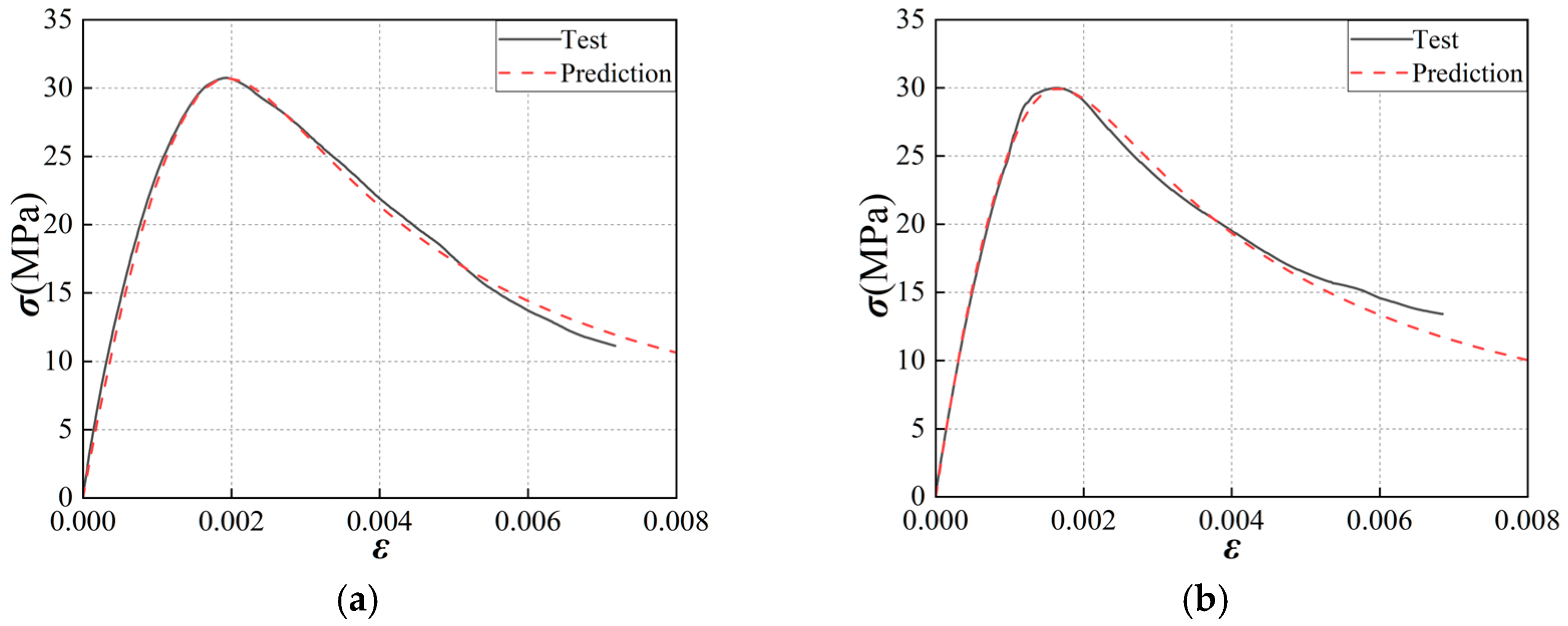

2.2.3. Stress–Strain Curve Fitting

3. Finite Element Model Development and Validation

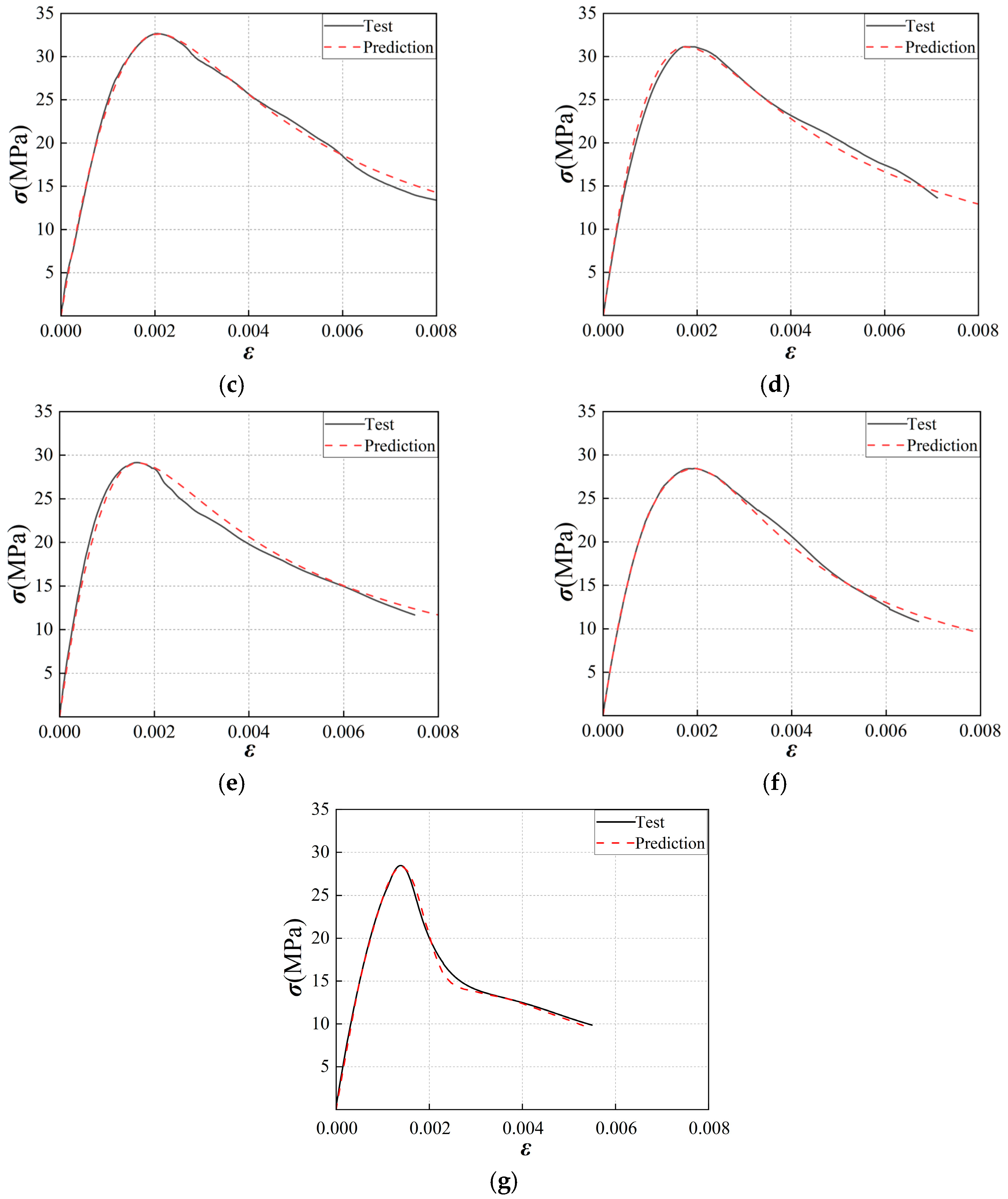

3.1. Wall Panel Design

3.2. Material Constitutive Relationships

3.2.1. Fiber-Reinforced Concrete

3.2.2. Steel Truss and Glass Fiber Mesh

3.2.3. Insulation Material

3.3. Element Types and Meshing

3.4. Contact Interactions and Boundary Conditions

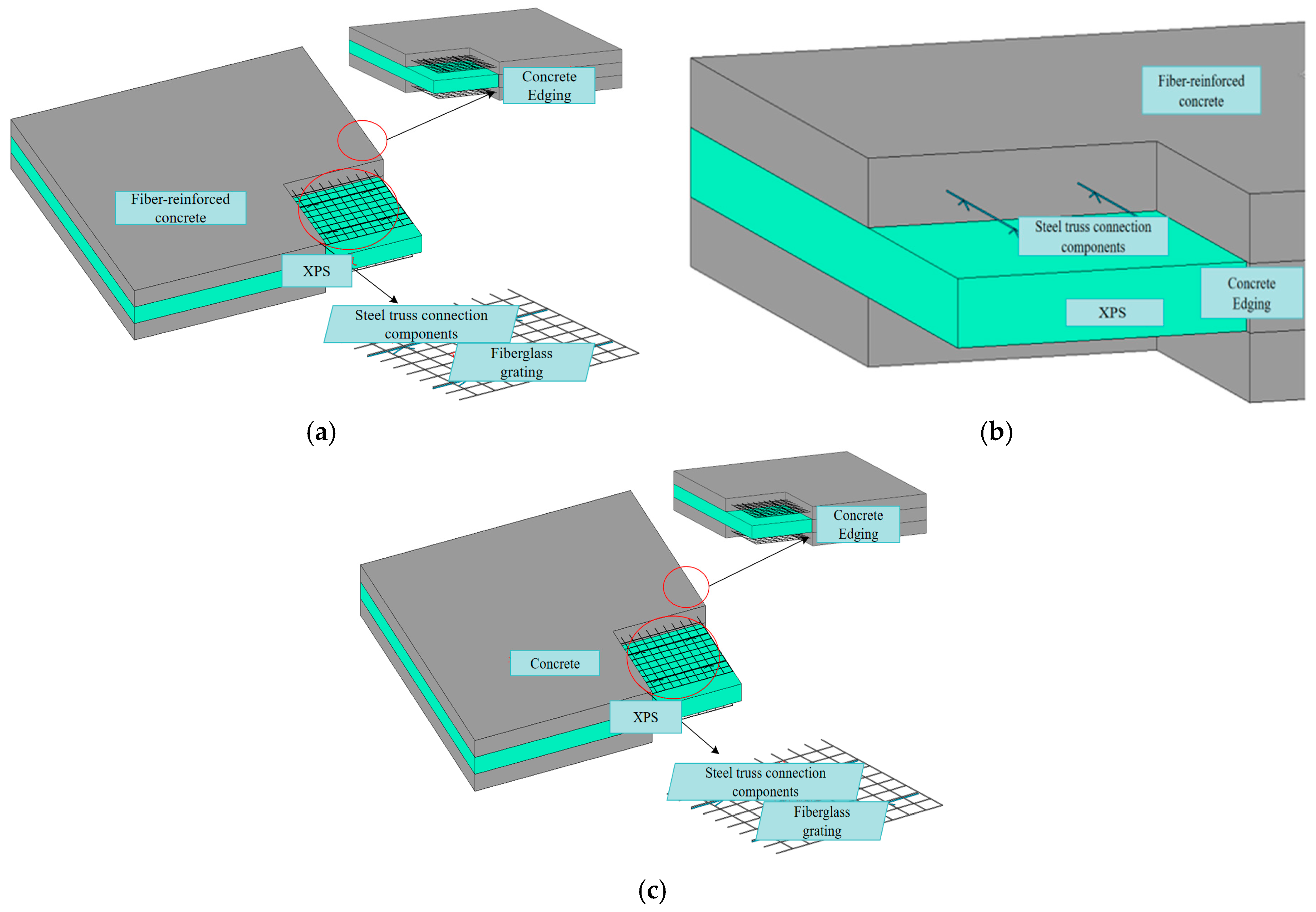

3.5. Model Validation

4. Analysis of Simulation Results

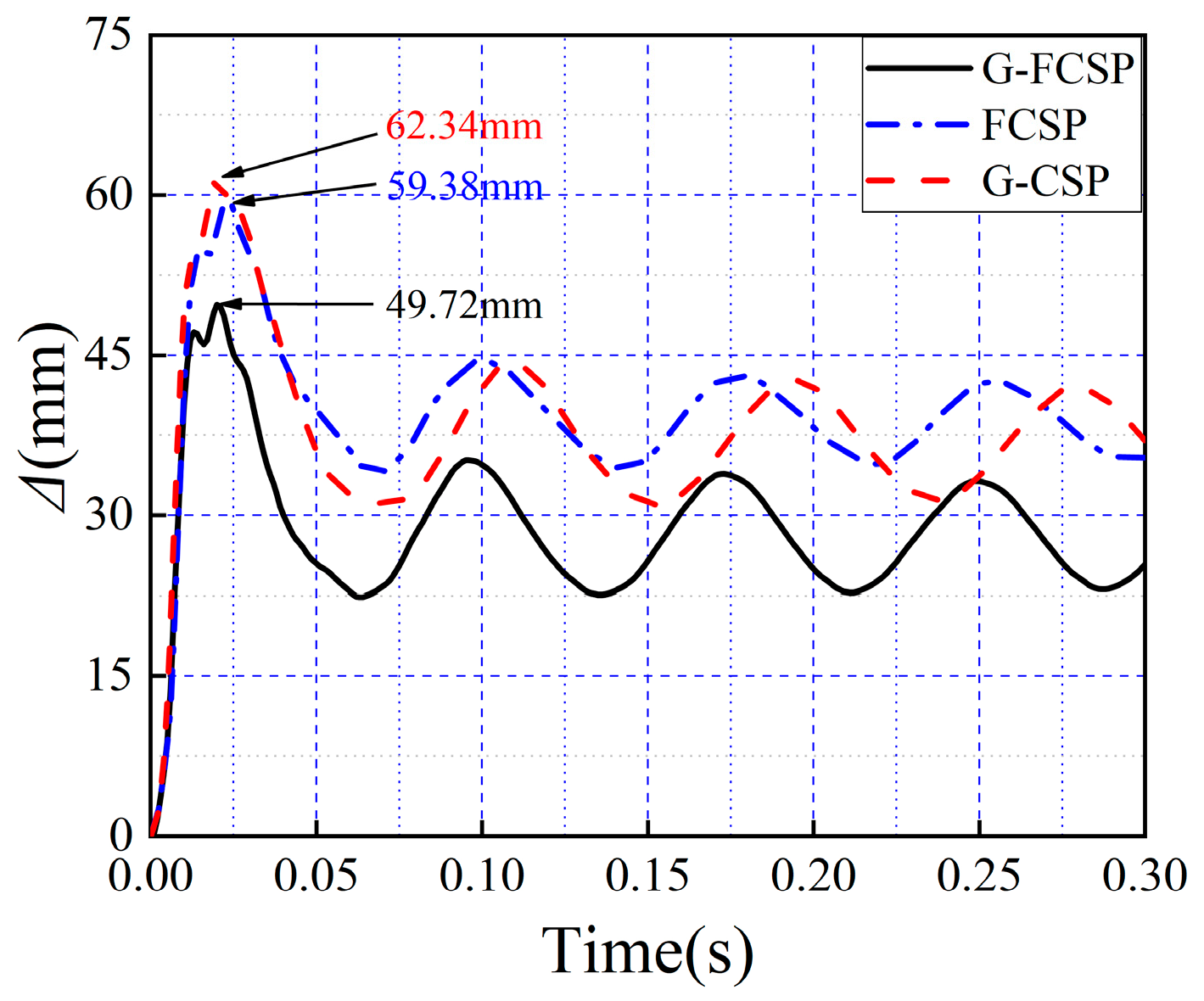

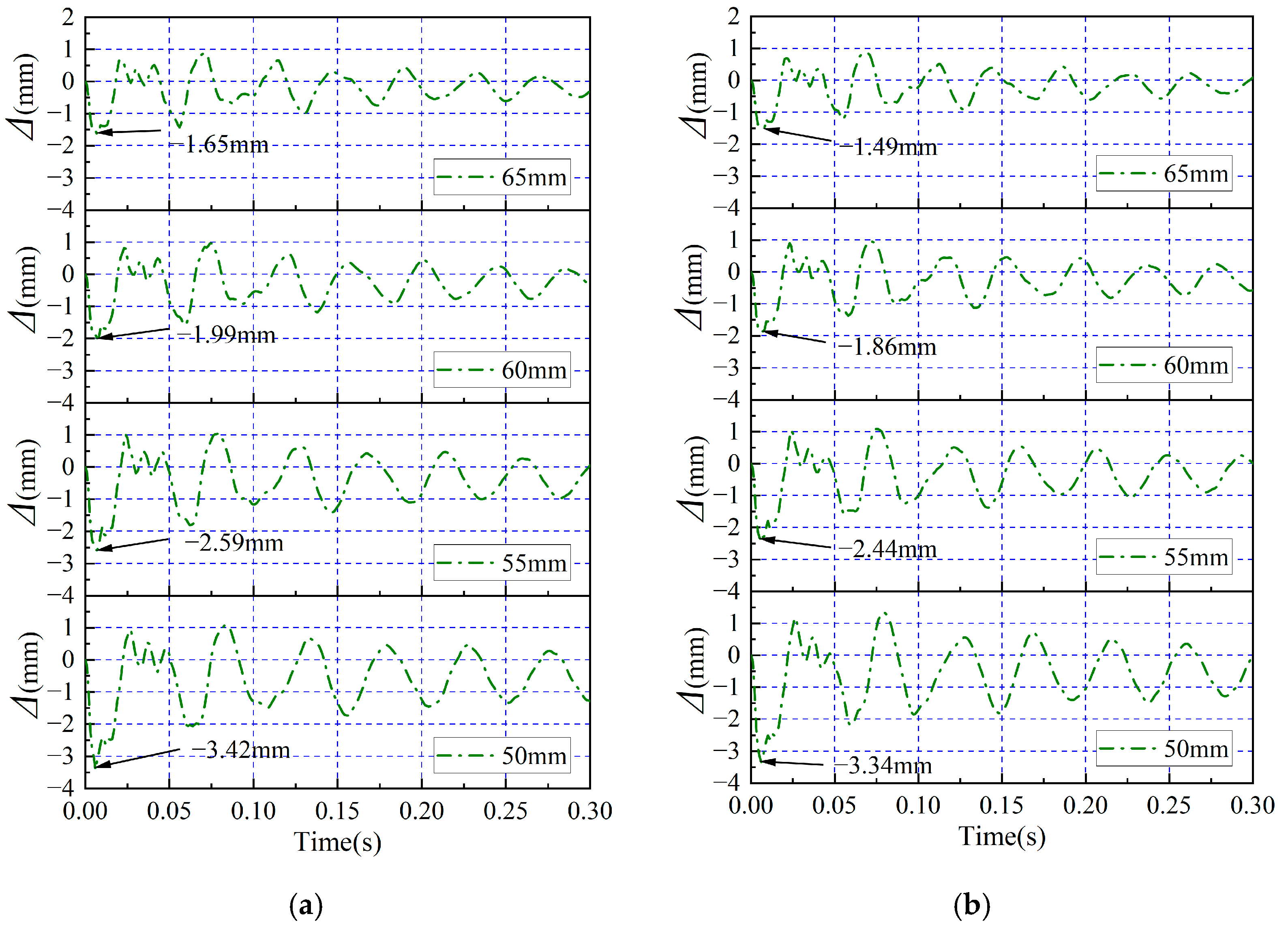

4.1. Displacement-Time History Curves

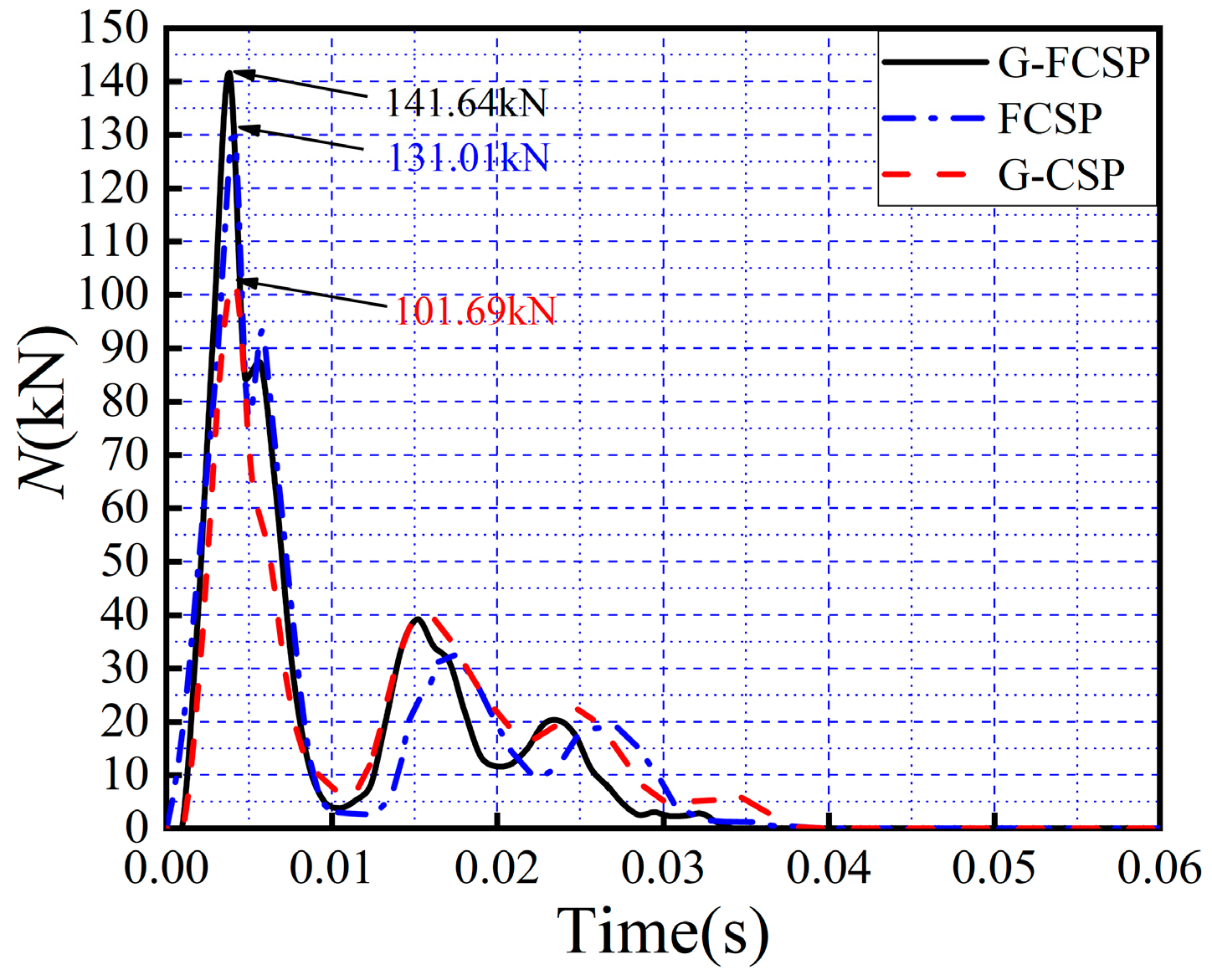

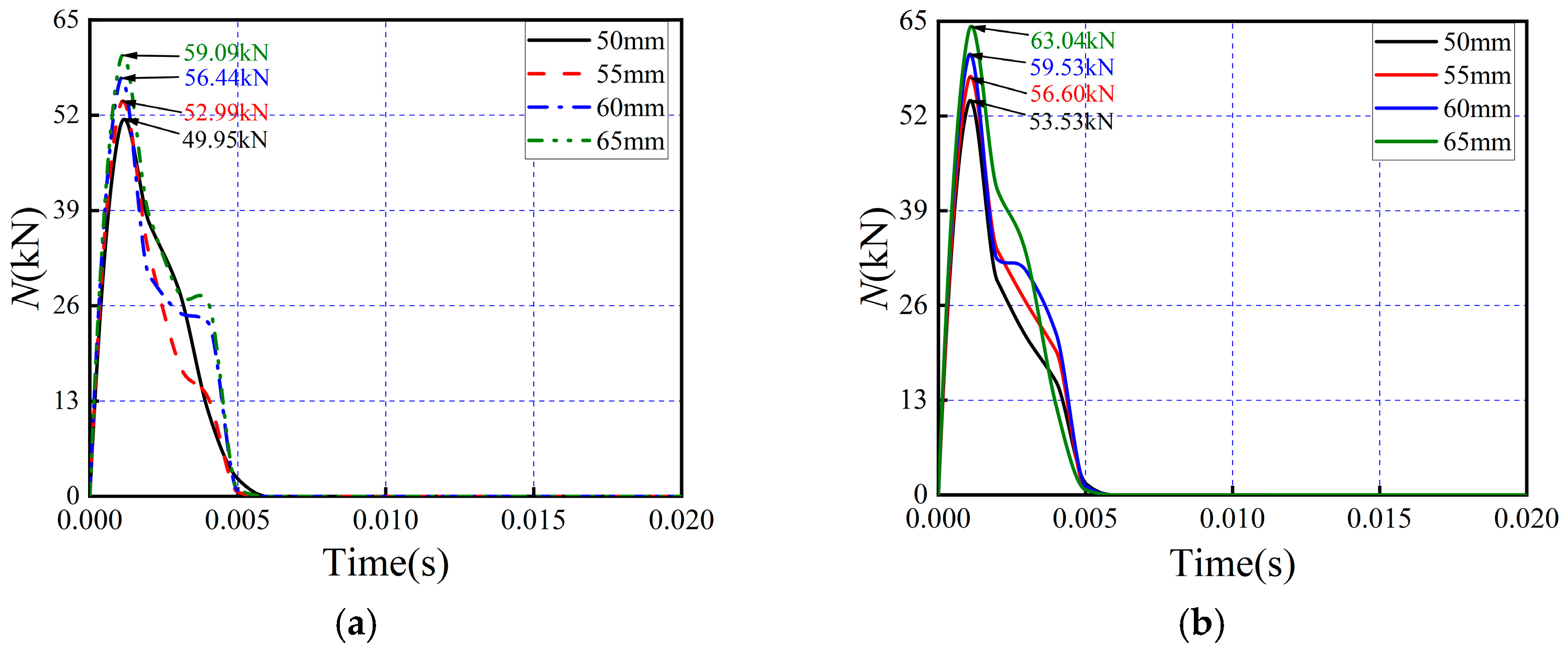

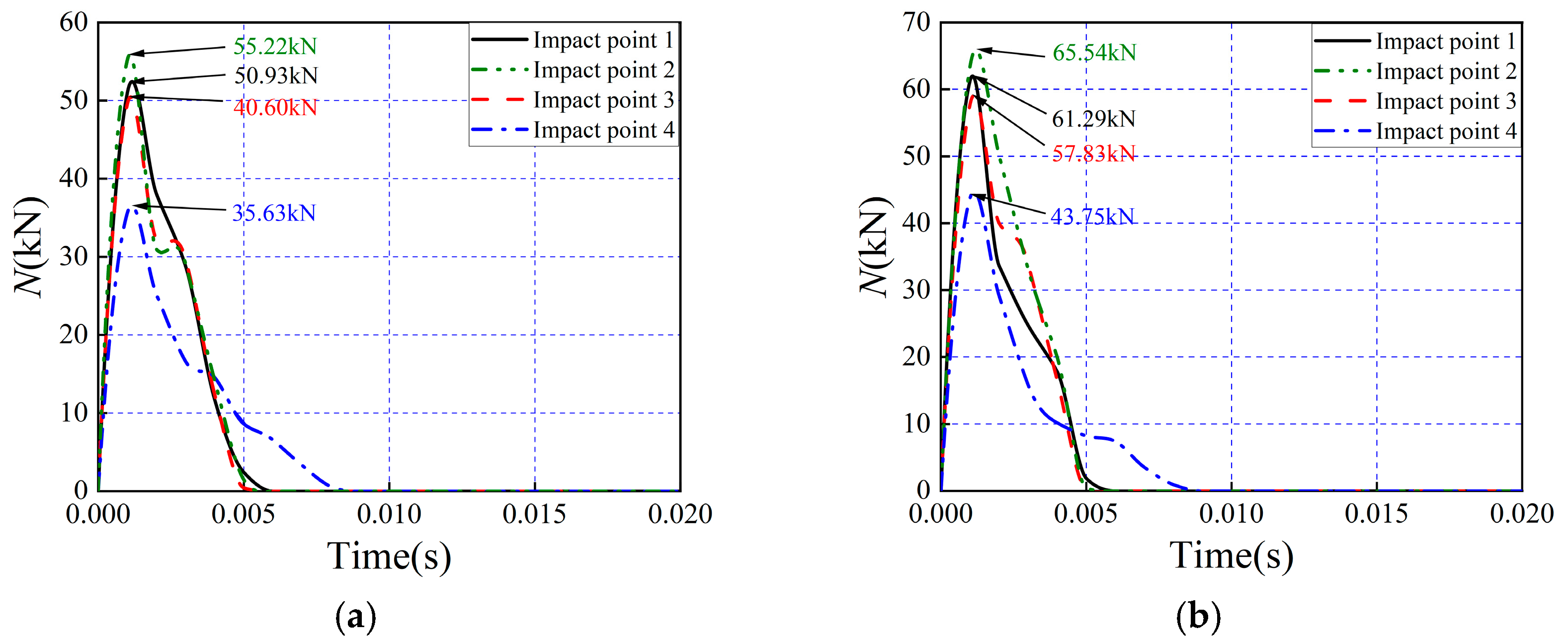

4.2. Impact Force–Time History Curves

4.3. Damage Contours

5. Parametric Analysis

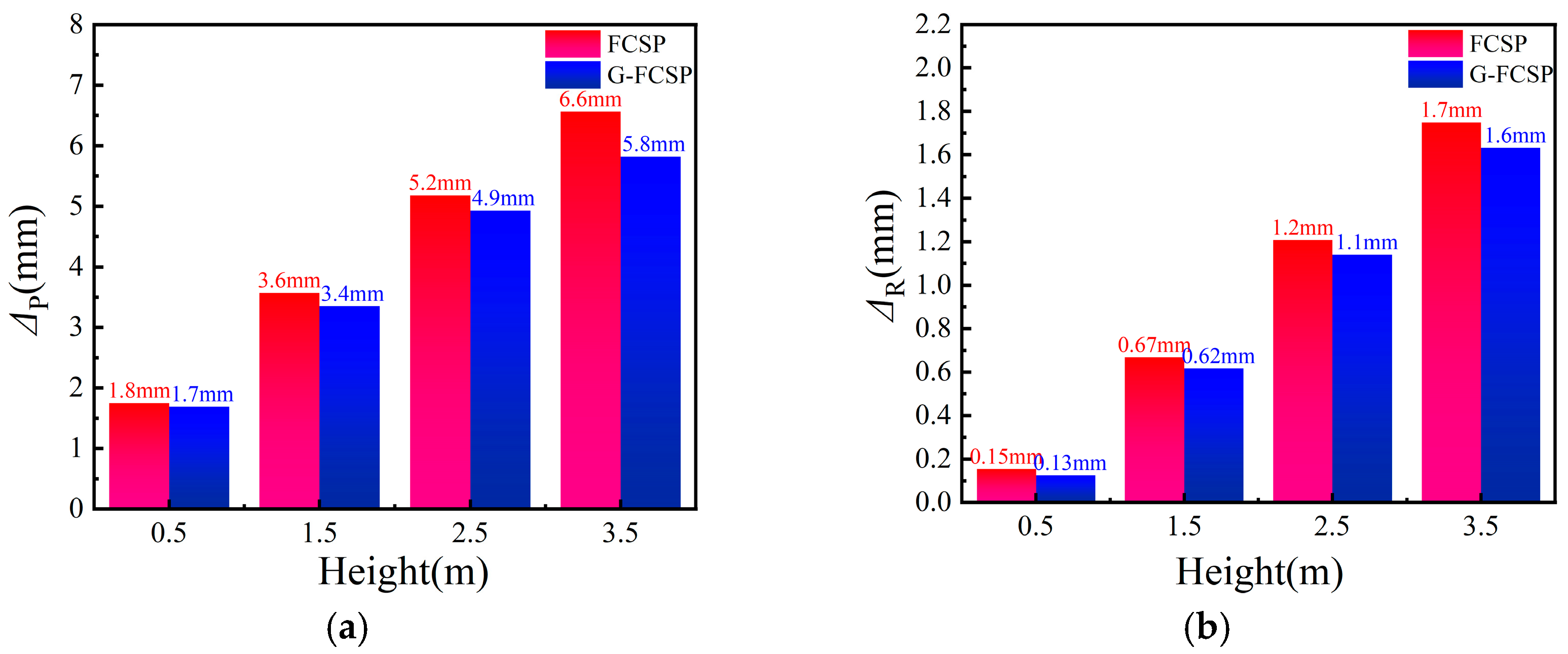

5.1. Effect of Impact Height (Impact Energy) on Panel Impact Response

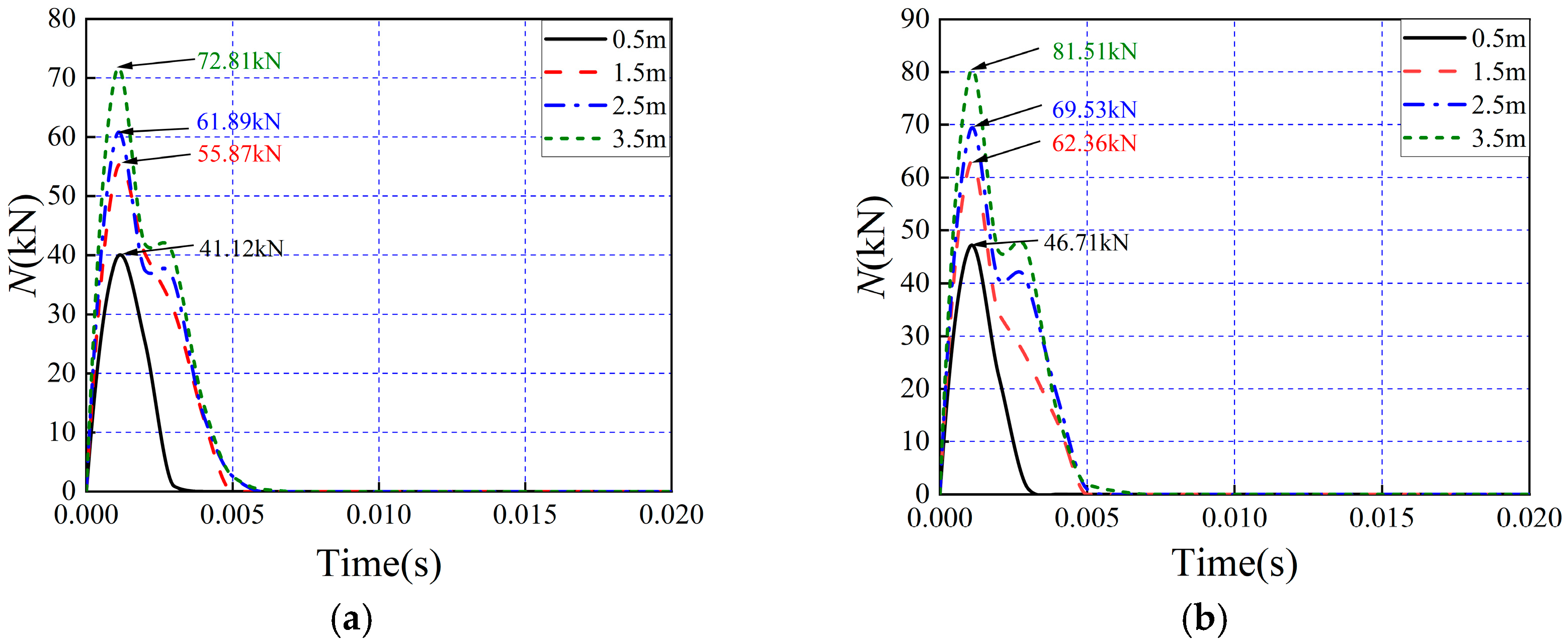

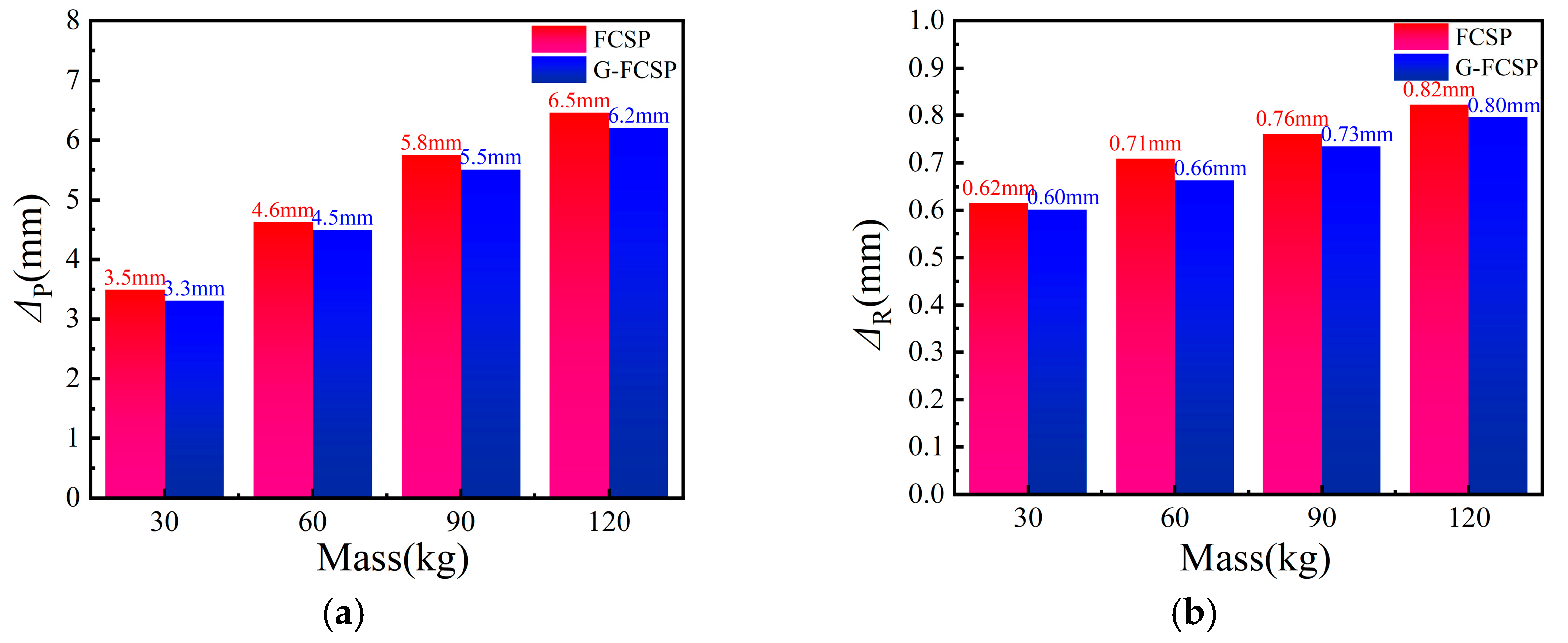

5.2. Effect of Impactor Mass on Panel Impact Response

5.3. Effect of Concrete Wythe Thickness on Panel Impact Response

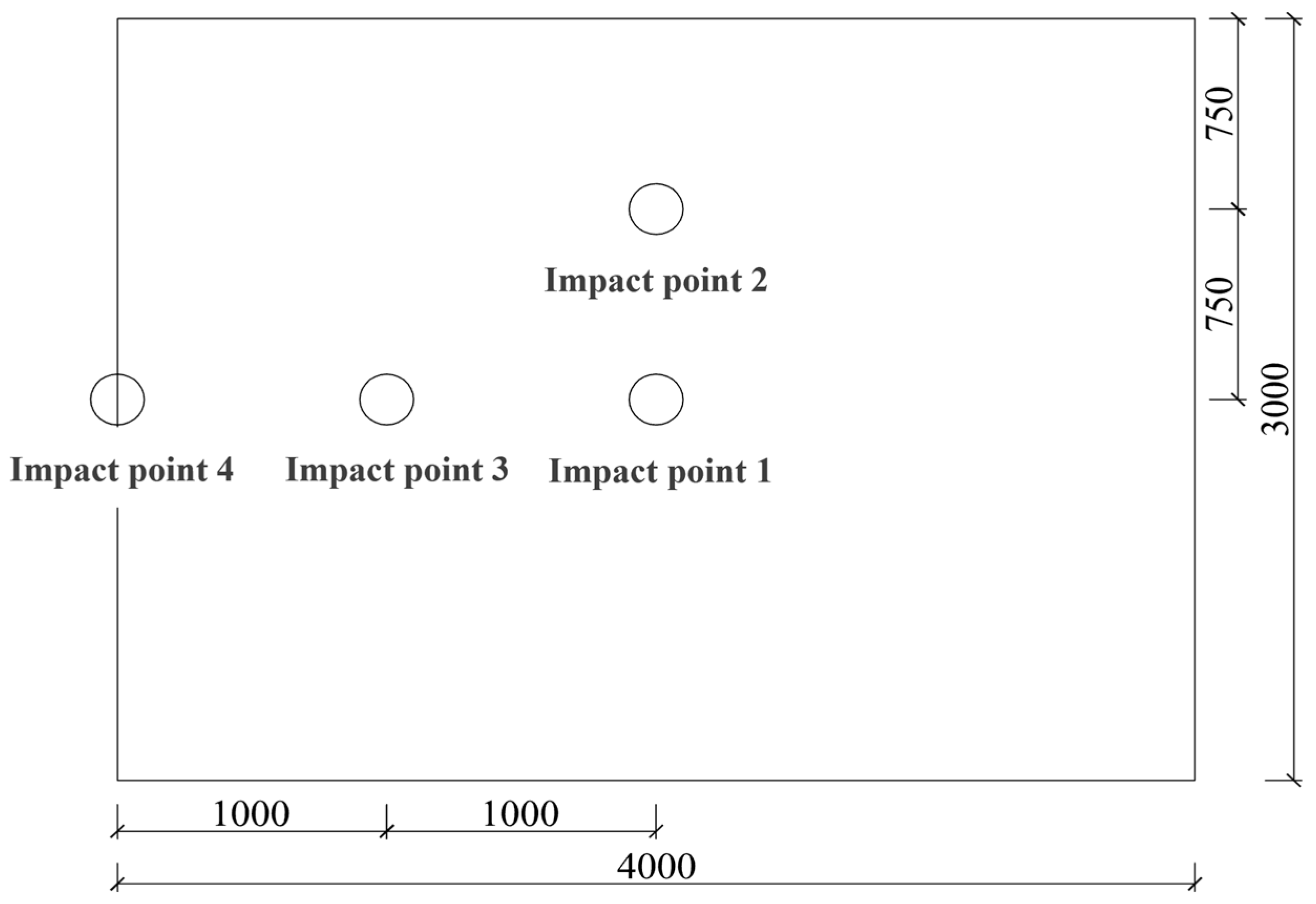

5.4. Effect of Impact Location on Panel Impact Response

6. Conclusions

- In axial compression tests, the descending branch of the fiber-reinforced concrete stress–strain curve was significantly smoother, indicating that fiber addition can substantially improve the ductile and tough properties of concrete. As the coarse fiber content increased, the concrete strength initially rose and then decreased. The peak strength of the specimens was highest (32.66 MPa) at a coarse fiber content of 1% and a fiber length of 30 mm.

- Utilizing the concrete constitutive model proposed by Guo Zhenhai, a stress–strain curve equation for concrete under compression, suitable for the steel fiber hybrid method employed in this study, was established. This equation was then compared and validated against experimental stress–strain curves, showing an error within 5% and a good agreement. The proposed shape parameter formula and the corresponding stress–strain equation can accurately predict the mechanical response of polypropylene fiber-reinforced concrete.

- Under the same impact energy, compared to G-CSP, the peak displacement of G-FCSP decreased by 16.5%, and the residual displacement decreased by 27.9%. (There is a slight repetition in the original text, corrected here for flow). The impact energy capacity of G-FCSP was enhanced by 7.2% and 27.8% compared to FCSP and G-CSP, respectively.

- Under varying impact heights, the incorporation of glass fiber grids effectively enhances the resistance to impact of composite wall panels. As the impact height increases, G-FCSP demonstrates reductions in peak displacement of 3.4%, 6.2%, 5.1%, and 11.3%, respectively, compared to FCSP. Similarly, under different impact mass conditions, when subjected to a 30 kg impact mass, G-FCSP exhibits 5.4% and 3.2% reductions in peak and residual displacements relative to FCSP. With a 120 kg impact mass, the corresponding reductions reach 4.5% and 2.4%. Increasing concrete panel thickness also improves the impact resistance and deformation capacity of composite wall panels, though this enhancement effect remains limited: for G-FCSP, a 15 mm increase in panel thickness results in merely 10.7% and 8.0% reductions in peak and residual displacements, while increasing peak impact force by 12.1%. Both G-FCSP and FCSP exhibit inferior impact resistance, reduced stiffness, and compromised deformation capacity at their edge regions. In contrast, the quarter-height location of the panels shows exceptionally high peak impact force. Practical engineering applications should therefore consider implementing special reinforcement measures for the edge zones of wall panels.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Bibora, P.; Drdlová, M.; Prachař, V.; Sviták, O. The impact of various types of steel fibres on the strength parameters and blast resistance of high–performance concrete. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tatry Mountains, Slovakia, 14 August 2019; IOP Publishing: Bristol, UK, 2019; Volume 596, p. 012018. [Google Scholar]

- Esaker, M.; Thermou, G.E.; Neves, L. Impact resistance of concrete and fibre-reinforced concrete: A review. Int. J. Impact Eng. 2023, 180, 104722. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J.; Xu, Z.; Li, S. Experimental study of compressive behavior of polypropylene-fiber-reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr. Build. Mater. 2019, 194, 216–225. [Google Scholar] [CrossRef]

- Ahmed, T.W.; Aljubory, N.H.; Zidan, R.S. Properties and performance of polypropylene fiber reinforced concrete: A review. Tikrit J. Eng. Sci. 2020, 27, 82–97. [Google Scholar] [CrossRef]

- Lakshmi, A.; Pandit, P.; Bhagwat, Y.; Nayak, G. A review on efficiency of polypropylene fiber-reinforced concrete. Sustain. Trends Chall. Civ. Eng. Sel. Proc. CTCS 2020, 2021, 799–812. [Google Scholar]

- Saini, R.; Chaturvedy, G.K.; Pandey, U.K. Examining the effects of nano iron oxide on physical and mechanical characteristics of rubberized concrete. Innov. Infrastruct. Solut. 2024, 9, 180. [Google Scholar] [CrossRef]

- Chaturvedy, G.K.; Pandey, U.K.; Mohan, G. Impact of nano-silica and multi-walled carbon nanotubes on the fire resistance performance of rubberized concrete. J. Build. Pathol. Rehabil. 2025, 10, 161. [Google Scholar] [CrossRef]

- Chaturvedy, G.K.; Kothari, P.K.; Pandey, U.K. Analyzing the effect of reduced graphene oxide on the physical, mechanical, and long-term durability performance of rubberized concrete. Fuller. Nanotub. Carbon Nanostruct. 2025, 33, 946–964. [Google Scholar] [CrossRef]

- Nguyen, C.T.; Pham, P.N.; Nam, H.P.; Nguyen, P. Factors affecting compressive strength of steel slag concrete: A systematic literature review. J. Build. Eng. 2025, 100, 111686. [Google Scholar] [CrossRef]

- Cao, J.; Zou, Z.; Zeng, P. Mechanical properties of fly ash concrete after the coupling effects of sustained load and sulphate erosion. Constr. Build. Mater. 2025, 460, 139866. [Google Scholar] [CrossRef]

- Li, Y.L.; Liu, F.Q.; Yu, P.; Du, T. A review of the application of steel slag in concrete. Structures 2024, 63, 106352. [Google Scholar] [CrossRef]

- Mohanta, N.R.; Murmu, M. A Review on the Utilization of Steel Slag as Alternative Coarse Aggregate in Concrete: Transforming Waste into Wealth. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025, 1–36. [Google Scholar] [CrossRef]

- Zhang, P.; Qin, Z.; Gao, Z.; Wang, F.; Lai, C. Research progress on impact resistance of fiber-reinforced concrete—A review. J. Build. Eng. 2025, 112, 113982. [Google Scholar] [CrossRef]

- Li, P.; Huang, M.; Shang, Y.; Kuang, Y.; Xiong, G.; Tang, X. Study on Mechanical Properties of Coarse-Fine Polypropylene Fiber Blended Concrete. Buildings 2025, 15, 2971. [Google Scholar] [CrossRef]

- Khaloo, A.; Daneshyar, A.; Rezaei, B.; Fartash, A. Fiber bridging in polypropylene—Reinforced high—Strength concrete: An experimental and numerical survey. Struct. Concr. 2022, 23, 457–472. [Google Scholar] [CrossRef]

- Wei, X.; Qin, Z.; Wang, S.; Ma, S.; Shi, M.; Fa, J.; Li, G. Experimental study on dynamic impact mechanical properties and fracture resistance mechanism of polypropylene fiber reinforced concrete. J. Build. Eng. 2025, 112, 113654. [Google Scholar] [CrossRef]

- Shang, Y.; Li, P.; Tang, X.; Xiong, G. Numerical Analysis of Impact Resistance of Prefabricated Polypropylene Fiber-Reinforced Concrete Sandwich Wall Panels. Buildings 2025, 15, 3015. [Google Scholar] [CrossRef]

- Youm, K.; Moon, J. Experimental study on impact behavior of concrete panel with and without polypropylene macrofibers. Buildings 2023, 13, 303. [Google Scholar] [CrossRef]

- Xu, H.; Mindess, S.; Duca, I.J. Performance of plain and fiber reinforced concrete panels subjected to low velocity impact loading. In Proceedings of the RILEM Conference on Fiber Reinforced Concrete, BEFIB, Varenna, Italy, 20–22 September 2004; pp. 1257–1268. [Google Scholar]

- Hossain, M.T.; Shahid, M.A.; Mahmud, N.; Habib, A.; Rana, M.M.; Khan, S.A.; Hossain, M.D. Research and application of polypropylene: A review. Discov. Nano 2024, 19, 2. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Klomranok, T.; Su, Q. Assessment of the use of polypropylene fiber reinforced foam concrete as a subgrade material for the China railway track system (CRTS) III slab ballastless tracks. Transp. Res. Rec. J. Transp. Res. Board 2021, 2675, 641–654. [Google Scholar] [CrossRef]

- Raj, A.; Nagarajan, P.; Pallikkara, S.A. Application of fiber-reinforced rubcrete in fencing posts. Pr. Period. Struct. Des. Constr. 2020, 25, 04020037. [Google Scholar] [CrossRef]

- Rehman, A.; Ali, M. Optimization of hybrid fiber-reinforced concrete for controlling defects in canal lining. Materials 2024, 17, 4000. [Google Scholar] [CrossRef]

- Blazy, J.; Blazy, R. Polypropylene fiber reinforced concrete and its application in creating architectural forms of public spaces. Case Stud. Constr. Mater. 2021, 14, e00549. [Google Scholar] [CrossRef]

- Einea, A.; Salmon, D.C.D.C.; Tadros, M.K.; Culp, T. A new structurally and thermally efficient precast sandwich panel system. PCI J. 1994, 39, 90–101. [Google Scholar] [CrossRef]

- Mastali, M.; Valente, I.; Barros, J.A. Flexural performance of innovative hybrid sandwich panels with special focus on the shear connection behavior. Compos. Struct. 2017, 160, 100–117. [Google Scholar] [CrossRef]

- Gombeda, M.J.; Naito, C.J.; Quiel, S.E. Flexural performance of precast concrete insulated wall panels with various configurations of ductile shear ties. J. Build. Eng. 2021, 33, 101574. [Google Scholar] [CrossRef]

- Ahmad, A.; Singh, Y. Flexural behavior of Expanded Polystyrene core Reinforced Concrete Sandwich Panels with different construction methods and end conditions. Structures 2021, 34, 2900–2911. [Google Scholar] [CrossRef]

- Zhai, X.; Wang, Y.; Wang, X. Thermal performance of precast concrete sandwich walls with a novel hybrid connector. Energy Build. 2018, 166, 109–121. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Y.; Wang, D.; Ma, C.; Liu, J. Theoretical, experimental and numerical study on the influence of connectors on the thermal performance of precast concrete sandwich walls. J. Build. Eng. 2022, 57, 104886. [Google Scholar] [CrossRef]

- Zhang, Z.; Hou, Y.; Wang, Y. Research on Thermal Performance of Polypropylene Fiber-Reinforced Concrete Wall Panels. Buildings 2025, 15, 2199. [Google Scholar] [CrossRef]

- Kasapgil, S.M.; Binici, B.; Canbay, E. Seismic behavior of AAC infill walls insulated with cementitious lightweight panels in reinforced concrete frames. Eng. Struct. 2021, 248, 113215. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, Q. Dynamic performance of prestressed concrete panel under impact loads. Structures 2025, 71, 108157. [Google Scholar] [CrossRef]

- Al-Rousan, R.Z.; Alhassan, M.A.; Al-Salman, H. Impact resistance of polypropylene fiber reinforced concrete two-way slabs. Struct. Eng. Mech. 2017, 62, 373–380. [Google Scholar] [CrossRef]

- Nili, M.; Afroughsabet, V. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete. Constr. Build. Mater. 2010, 24, 927–933. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, L.; Zheng, K.; Bakura, T.J.; Jibrin, T.; Totakhil, P.G. Research on compressive impact dynamic behavior and constitutive model of polypropylene fiber reinforced concrete. Constr. Build. Mater. 2018, 187, 584–595. [Google Scholar] [CrossRef]

- GB 175-2023; Common Portland Cement. Standards Press of China: Beijing, China, 2023. (In Chinese)

- GB/T 14684-2022; Sand for construction. Standards Press of China: Beijing, China, 2022. (In Chinese)

- JGJ/T 221-2010; Technical Specification for Application of Fiber-Reinforced Concrete. China Architecture and Building Press: Beijing, China, 2010. (In Chinese)

- JGJ 55−2019; Specification for Mix Proportion Design of Ordinary Concrete. China Construction Industry Press: Beijing, China, 2019. (In Chinese)

- Sohaib, N.; Seemab, F.; Sana, G.; Mamoon, R. Using polypropylene fibers in concrete to achieve maximum strength. In Proceedings of the Eighth International Conference on Advances in Civil and Structural Engineering, Kuala Lumpur, Malaysia, 24 June 2018; pp. 36–42. [Google Scholar]

- Gao, H.; Xu, L.H.; Yu, M.; Long, Y.; Yu, C.L.; Huang, L.; Chi, Y. Cyclic compressive behavior of high-performance hybrid fiber reinforced recycled aggregate concrete: Degradation law and acoustic emission features. Constr. Build. Mater. 2024, 431, 136412. [Google Scholar] [CrossRef]

- GB/T 50081−2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Architecture and Building Press: Beijing, China, 2019. (In Chinese)

- Guo, Z.H. Strength and Constitutive Relation of Concrete-Principle and Application; China Architecture and Building 541 Press: Beijing, China, 2004. (In Chinese) [Google Scholar]

- Zhao, X.; Liang, H.; Lu, Y.; Zhao, P. Size effect of square steel tube and sandwiched concrete jacketed circular RC columns under axial compression. J. Constr. Steel Res. 2020, 166, 110534. [Google Scholar] [CrossRef]

- Federation International du Beton (FIB). Model Code 2010-First Complete Draft; Fédération Internationale du Béton, Bulletin 56: Lausanne, Switzerland, 2010; Volume 1, pp. 763–777. [Google Scholar]

- Cowper, G.R.; Symonds, P.S. Strain-Hardening and Strain-Rate Effects in the Impact Loading of Cantilever Beams; Brown University: Providence, RI, USA, 1957. [Google Scholar]

- Barabanshchikov, Y.; Belyaeva, S.; Avdeeva, A.; Perez, M. Fiberglass reinforcement for concrete. Appl. Mech. Mater. 2015, 725, 475–480. [Google Scholar] [CrossRef]

- Li, Z.-X.; Zhang, X.; Shi, Y.; Wu, C.; Li, J. Predication of the residual axial load capacity of CFRP-strengthened RC column subjected to blast loading using artificial neural network. Eng. Struct. 2021, 242, 112519. [Google Scholar] [CrossRef]

- Ochola, R.; Marcus, K.; Nurick, G.; Franz, T. Mechanical behaviour of glass and carbon fibre reinforced composites at varying strain rates. Compos. Struct. 2004, 63, 455–467. [Google Scholar] [CrossRef]

- Yan, P.P. Mechanical and Thermal Properties of Composite Wallboard with Mixed Recycled Coarse Aggregate Concrete; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2023. (In Chinese) [Google Scholar]

- Zhao, W.Y.; Guo, Q.Q. Study on behavior of double-skin steel-concrete composite walls subjected to low-velocity impact. J. Civ. Eng. 2018, 51, 88–94. (In Chinese) [Google Scholar]

| Type | Length /mm | Diameter /um | Mass Density/ (g/cm3) | Tensile Strength/MPa | Elastic Modulus/GPa | Elongation at Break/% |

|---|---|---|---|---|---|---|

| Coarse | 30 | 1000 | 0.91 | 627.9 | 10 | 6.3 |

| Coarse | 50 | 1000 | 0.91 | 627.9 | 10 | 6.3 |

| Fine | 12 | 27 | 0.91 | 625 | 5.2 | 22 |

| Specific Surface Area/m2·kg−1 | Setting Time/min | Compressive Strength/MPa | Flexural Strength/MPa | |||

|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3d | 28d | 3d | 28d | |

| 350 | 95 | 150 | 28.5 | 49.3 | 5.6 | 7.9 |

| Test Group | Coarse Fiber Volume Fraction/(%) | Fine Fiber Volume Fraction/(%) | Fine Fiber Length/(mm) | Coarse Fiber Length/(mm) |

|---|---|---|---|---|

| 1 | 0.5 | 0.1 | 30 | 12 |

| 2 | 0.5 | 50 | ||

| 3 | 1 | 30 | ||

| 4 | 1 | 50 | ||

| 5 | 1.5 | 30 | ||

| 6 | 1.5 | 50 | ||

| 7 | / | / | / | / |

| Specimen Name in Reference [54] | Drop Hammer Height/(m) | Impact Velocity/(m/s) |

|---|---|---|

| H15 | 1.5 | 5.42 |

| H30 | 3 | 7.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, X.; Shi, Y.; Lu, H.; Hao, R.; Zhang, H.; Chen, W.; Liu, Y. Research on the Impact Performance of Polypropylene Fiber-Reinforced Concrete Composite Wall Panels. Buildings 2025, 15, 3983. https://doi.org/10.3390/buildings15213983

Zou X, Shi Y, Lu H, Hao R, Zhang H, Chen W, Liu Y. Research on the Impact Performance of Polypropylene Fiber-Reinforced Concrete Composite Wall Panels. Buildings. 2025; 15(21):3983. https://doi.org/10.3390/buildings15213983

Chicago/Turabian StyleZou, Xuan, Yanran Shi, Hao Lu, Ruifu Hao, Haichen Zhang, Wenting Chen, and Yuanping Liu. 2025. "Research on the Impact Performance of Polypropylene Fiber-Reinforced Concrete Composite Wall Panels" Buildings 15, no. 21: 3983. https://doi.org/10.3390/buildings15213983

APA StyleZou, X., Shi, Y., Lu, H., Hao, R., Zhang, H., Chen, W., & Liu, Y. (2025). Research on the Impact Performance of Polypropylene Fiber-Reinforced Concrete Composite Wall Panels. Buildings, 15(21), 3983. https://doi.org/10.3390/buildings15213983