Abstract

Construction sites present intrinsically hazardous conditions characterized by dynamic and complex operational environments which persistently contribute to elevated rates of occupational injuries. While conventional safety management emphasizes controls during the execution phase, addressing safety considerations during the earliest phases of a project is more effective. In this work, a Nonlinear Multifactor Safety Index (NMF-SI) is developed to quantify activity-level occupational risk for use in project planning. The index synthesizes multiple risk factors, including accident probability, task severity, exposure duration, workforce size, and contextual variables, such as weekday effects, and site conditions, like waste accumulation. Additionally, it incorporates a structured questionnaire to capture the implementation of safety measures on site. Its nonlinear formulation reflects interactions among factors, penalizes temporal clustering of high-risk tasks, and prioritizes temporal distribution and proactive planning. To produce risk-aware schedules, a hybrid optimization framework that couples a tree-based constructive heuristic with the marine predators algorithm is introduced, maximizing NMF-SI subject to project-duration, precedence, and resource constraints. In simulation, the optimized schedules achieve higher NMF-SI values and a smoother risk profile over time than baseline plans. These results translate into a quantitative, data-driven contribution to safety by design, offering a practical decision-support tool for intelligent, risk-aware construction scheduling.

1. Introduction

Construction sites are inherently hazardous environments due to their dynamic and rapidly changing conditions [1], resulting in accident rates that exceed those in other sectors. Mitigating these risks and reducing their severity is a global priority considering the large workforce involved. According to some studies, construction represents around 7% of global employment but contributes to 30–40% of fatal occupational injuries each year, underscoring the sector’s risks and the urgent need for improved safety strategies [2,3].

While many safety initiatives emphasize the use of personal protective equipment (PPE), training, and supervision during site execution, an increasing number of publications highlight the importance of integrating safety considerations during the planning phase of construction projects [4,5,6]. Studies have shown that construction accidents could be mitigated or prevented with better pre-construction planning [7]. This concept, often referred to as Prevention through Design (PtD) [8], advocates for integrating safety measures into the early stages of a project lifecycle.

Recent advances in digital construction strategies, such as Building Information Modelling (BIM), 4D simulation, digital twins and AI-based scheduling, have enabled more proactive and data-driven approaches to construction safety planning [9,10]. Researchers have developed safety-risk prediction models using machine learning, context-aware systems to monitor real-time conditions, and algorithms to simulate safe work consequences [11,12].

Despite these advancements, a significant gap still exists in integrating safety metrics directly into the scheduling and optimization processes of construction planning. Most digital tools remain focused on cost, time, and resource efficiency, without considering safety as a measurable optimization objective [13,14,15].

This research aims to bridge this gap by exploring how safety can be quantitatively assessed and integrated into construction planning processes. It examines the factors that most significantly impact occupational risk on construction sites, including task severity, exposure duration, and workforce size. Furthermore, it proposes the development of a scheduling optimization framework designed to minimize safety risks while considering project constraints such as duration, precedence, and resource limitations.

The main objectives of this research are to develop the NMF-SI, a quantitative measure of occupational risk for construction planning, and to integrate this index into a hybrid optimization framework that generates risk-aware schedules. Additionally, this study aims to validate the effectiveness of the proposed index and optimization framework through simulations, comparing risk profiles from optimized schedules with baseline plans. The NMF-SI provides a quantitative and schedule-aware measure of occupational risk by integrating accident probability and severity with worker exposure (e.g., working hours) and contextual factors such as weekday effects [16,17]. Its nonlinear mapping penalizes the temporal clustering of hazardous activities and normalizes results to enable project-level comparisons. Furthermore, the index incorporates a structured on-site safety-compliance questionnaire to calibrate planned safety levels with real site conditions.

Using this index as a benchmark, a systematic approach has been applied to improve the planned tasks, with the goal of reducing occupational hazards. This process involves a thorough analysis and adjustment of procedures to ensure a safer working environment for everyone involved.

By providing a clear, numerical representation, the NMF-SI enables project managers to identify high-risk periods and take proactive measures to mitigate these risks. Additionally, this score allows for comparison between different schedules, facilitating systematic improvements in the planning of the tasks and reducing occupational hazards. Furthermore, a hybrid optimization approach is proposed, combining a constructive heuristic based on tree search with a metaheuristic algorithm for solution refinement, enabling the automatic evaluation of alternative schedules to maximize the NMF-SI while considering worker availability and task dependencies.

This study advances existing research by introducing a nonlinear, concurrency-sensitive safety index that simultaneously captures probabilistic, exposure-based, and contextual factors—dimensions that are rarely modelled together in construction scheduling. Unlike previous studies that integrate safety as a linear or aggregate objective, the proposed NMF-SI explicitly accounts for the interaction of concurrent activities and temporal variations (weekday and waste-related effects) within the schedule. In addition, its integration into a two-phase optimization process—with a fixed project duration—demonstrates how safety improvements can be achieved without increasing the total project time. Together, these features represent a practical step forward in embedding safety-by-design principles directly into construction planning and optimization workflows.

2. Methodology

This study applies a structured methodology to better understand and enhance safety in construction projects. The process brings together three key elements: a review of accident determinants, the development of a safety index, and a scheduling model that balances risk with practical constraints. Combined, these steps offer clearer insight into how accidents arise, provide a consistent way to measure safety, and support planners in making informed decisions to reduce risks on site.

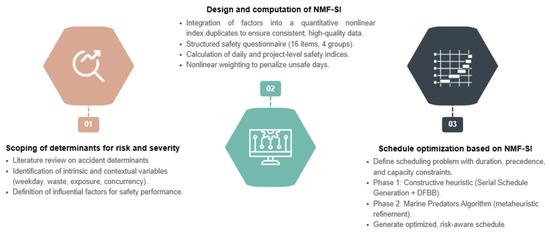

A schematic representation of the research methodology is presented in Figure 1. The process comprises three main stages: (1) identification of accident determinants, (2) development and computation of the Nonlinear Multifactor Safety Index (NMF-SI), and (3) optimization of construction schedules using a hybrid heuristic–metaheuristic approach. This integrated framework connects theoretical risk factors with a practical optimization tool for safety-aware project planning.

Figure 1.

Research methodology.

2.1. Scoping of Determinants for Risk and Severity

The first step focuses on reviewing recent studies to identify determinants of accident likelihood and severity in construction. The aim was to uncover variables that significantly influence occupational accidents, including those external to the specific technical risks associated with individual construction tasks. Similar approaches have been reported in the literature [1,3] which analysed occupational risk assessment models and safety management trends in the construction sector. By synthesizing these elements, this paper supports a more unified understanding of the operational context in which accidents occur and reinforces the need for safety assessment models that account for both intrinsic and contextual risk drivers [4,18]. This insight is essential in advancing the development of more robust and context-sensitive tools for risk assessment and safety management on construction sites [5,7,19,20].

The analysed literature consistently highlights several determinants that extend beyond the intrinsic hazards of specific activities and include contextual and environmental elements that shape overall accident dynamics. One of the most commonly reported factors is the day of the week [16,21], as studies have shown that accident frequency and severity can vary depending on the specific day, with certain days exhibiting a higher incidence of safety-related events [22]. This temporal variability has been linked to changes in workforce fatigue, scheduling patterns, and environmental conditions, as highlighted in a study for modelling and forecasting occupational accidents of different severity levels in Spain [23].

Another critical factor is waste generation, which has been associated with increased disorder and a higher likelihood of hazards arising in the work environment [16,17]. High levels of waste correlate with decreased mobility, reduced visibility, and greater physical obstructions, all of which contribute to a more hazardous site [24,25,26]. Exposure variables such as the number of workers present and the duration of their daily activities further compound risk by increasing the probability of an incident occurring within a given timeframe [15,27,28].

In addition, the concurrent execution of multiple tasks introduces complex interactions that do not follow predictable or linear relationships when analysed by risk-aware schedules, a situation further compounded by varying levels of manager supervision. As reported by the literature, overlapping activities can generate dynamic conditions, where the risk associated with one task may be amplified by the presence or requirements of another [1,3]. These interdependencies create compounded safety challenges that must be considered in any risk assessment, a point also emphasized in planning frameworks based on good practices [29,30,31,32].

Another key element is the effective implementation of safety measures, whose impact can be assessed through structured tools, such as validated questionnaires. An earlier investigation [33] demonstrated that such instruments allow for the quantification of current safety practices, providing valuable insight into how well preventive strategies are applied on site. Previous studies have also shown that consistent enforcement of these measures has a measurable impact on reducing accident probability [7,9,34]. The degree to which such measures are consistently implemented and maintained has a direct influence on overall risk levels.

Taken together, this comprehensive perspective on internal and external risk factors, supported by empirical evidence from diverse contexts, provides a foundation for developing more accurate, responsive, and context-aware safety evaluation methodologies in the construction sector.

2.2. NMF-SI Design

In order to move from the identification of risk determinants toward a practical application, it is necessary to establish a framework that can synthesize diverse factors into a single, comparable measure. Relying solely on qualitative evaluations often proves insufficient to capture the complexity of construction projects, where overlapping tasks, contextual conditions, and varying levels of safety compliance interact in nonlinear ways. The review of safety measures and the available instruments for assessing their implementation provides the conceptual framework upon which the development of more robust and responsive indices is grounded. To address this challenge, the NMF-SI is proposed as a quantitative and adaptive tool that integrates the previously identified factors in a structured manner, offering a mechanism that overcomes the limitations of purely qualitative approaches and enables a more objective and adaptable assessment at both the daily-activity and overall project-schedule levels. In doing so, it translates complex site dynamics into an interpretable metric that supports more objective decision-making in safety planning and management.

The NMF-SI is designed as a quantitative, schedule-aware safety index on [0, 1], where higher values indicate safer plans. Its purpose is to assess the safety at the daily-activity level and for the project schedule, replacing qualitative or subjective judgments with structured, data-driven evaluation, in line with previous studies [1,3]. This approach follows the logic of activity-based risk-assessment models [15] and probabilistic safety-evaluation frameworks [18,20,27,35] that have demonstrated their ability to translate task-specific risks into measurable indicators.

The NMF-SI is computed from the set of planned activities, their schedule, and a structured on-site safety questionnaire which captures the degree of implementation and maintenance of preventive measures. For each day, a daily safety index is obtained by combining the likelihood of accidents and their potential severity associated with the scheduled activities, considering the determinants identified in the previous section. The schedule plays a major role, since modelling of days with multiple concurrent activities is critical to capture interactions under spatial and managerial constraints, which can amplify or attenuate risk [24,32,33]. Accordingly, a nonlinear specification is adopted to reflect this effect. The specific influence of each variable on the NMF-SI will be detailed in Section 2.2.1.

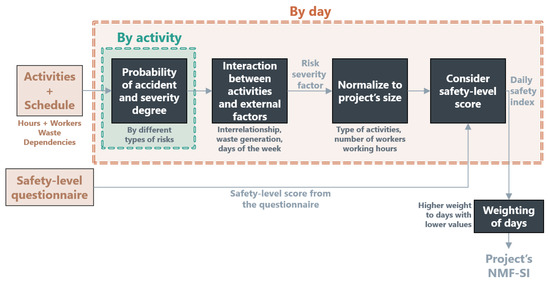

Figure 2 illustrates the NMF-SI diagram, representing the steps to calculate all the elements involved. First, activity-level accident probabilities and severities are estimated and aggregated into a daily risk-severity factor. This factor is then normalized to a common project scale and adjusted by the on-site safety-compliance score derived from the questionnaire, yielding the daily safety indices. Finally, these indices are weighted and aggregated to obtain the project-level NMF-SI.

Figure 2.

NMF-SI diagram.

By quantifying these diverse factors, the NMF-SI enables planners and safety managers to identify high-risk periods, evaluate the effectiveness of current safety protocols, and make informed decisions to mitigate hazards. This mirrors the preventive design principles outlined by existing studies [7,9,34] where quantitative metrics guide proactive interventions. Ultimately, this index aims to support proactive safety management by translating complex site conditions and planning structures into a single, interpretable value that guides continuous improvement in construction safety performance.

2.2.1. Safety Measures and Best Practices on Construction Sites

In this step, a quantification of the extent of implementation and ongoing maintenance of safety measures on construction sites was undertaken using a structured questionnaire developed from established safety-management frameworks. Specifically, the questions and grouping procedure were directly adapted from the study “An occupational safety risk method at construction sites using fuzzy sets” by Gürcanli and Müngen [20], as this work was identified in the state of the art review as the most comprehensive and methodologically appropriate reference for assessing construction site safety performance through structured questionnaires. This assessment instrument draws on recognized operational standards and integrates best practice principles [21]. Accordingly, the questionnaire items and their organization into groups follow the same structure proposed by Gürcanli and Müngen [21], which operationalizes the implementation of recommended safety practices on construction sites and assigns a score that contributes to the overall NMF-SI.

The assessment consists of 16 items that collectively cover critical dimensions of construction-site safety. Items 1–3, gathered in Group 1, address signalling and personnel competence, specifically the adequacy of equipment for flaggers, high-visibility apparel, and operator licensing and record control. Items 4–6, classified as Group 2, concern equipment identification and intrinsic safeguards, namely posting of load and speed limits, safe positioning or blocking of implements when idle or under maintenance, and the presence and upkeep of service, emergency, and parking brake systems. Items 7–13, forming Group 3, target site-wide operational safety: compliance of off-highway vehicle operations with standards, correct application of parking brakes and chocking on inclines, availability of audible warnings and backup alarms for machines with obstructed rear visibility, provision of rollover protective structures for relevant equipment, prevention of unauthorized access to hazardous work zones, roadway condition and traffic organization within the site, and measures that prevent rollovers on inclined or unstable surfaces. Items 14–16, identified as Group 4, are crane-specific controls, covering bearing capacity and stability of crane footings, exclusion of personnel from the crane’s slewing radius, and adherence to manufacturer specifications and load-handling controls [19,21].

Each item is rated on a 1 to 10 scale reflecting current on-site conditions; responses are then transformed into a single continuous indicator via weighted normalization that emphasizes higher priority controls [18] and remains robust to occasional missing answers provided that at least one item has been completed.

Let if item has a valid response and otherwise, with per-item weights and group weights for (and group membership ). Equation (1) expresses the total effective weight of all answered items (S). In this formulation, indicates whether an item was answered, represents the weight of the group to which item belongs, and corresponds to the relative importance of each item.

To capture the weighted compliance total, Equation (2) combines item weights with normalized response scores. Here, the normalized score expresses the fractional compliance of each answered item, ensuring comparability across the 1–10 rating scale.

The normalized questionnaire index is then obtained in Equation (3), defined as the ratio of weighted performance to effective weight mass; if no items are answered, a small constant is returned.

Group membership and group weights are

Per-item weights reflecting the relative criticality of each control are

This implementation yields a normalized, interpretable score that increases with better safety performance and assigns disproportionately larger penalties to low compliance with high-priority items. The value of will influence the final computation of the NMF-SI as detailed in subsequent sections. Because the mapping from the safety-practice score to the NMF-SI is nonlinear, ensures that noncompliance with critical safety measures is penalized more severely, reinforcing its role in capturing overall safety performance [21].

The proposed NMF-SI framework is conceived primarily for the planning phase of construction projects, supporting decision-making during schedule generation and optimization before execution begins. This aligns with the Prevention through Design (PtD) philosophy, embedding safety as a measurable design parameter. Nevertheless, the on-site compliance questionnaire enables calibration of the model using field data, facilitating a feedback loop during the execution phase.

2.2.2. Daily Risk and Severity Assessment of the Activities

This subsection details the computation of the daily safety index , which represents the steps shown in Figure 2. It is defined as be the set of activities, as the set of calendar days in the project, and as the set of possible accidents on the construction site, following previous studies [15,19]. For each day , let denote the activities scheduled on . Each scheduled activity has workers involved , assigned working hours (otherwise is not considered on ), and waste generated . Moreover, each activity is categorized by type , which determines the possible accident types , their accident rates per worker-hour and the severity associated with each , consistent with [19].

Step 1: Probability of accident occurrence and severity. In this step, a value is computed that combines the probability of at least one accident of type r on day d for activity i with its associated severity. The probability of at least one event is obtained via a Poisson model through Equation (6), where is the rate of the distribution [11,12]:

where

This probability combined with the severity associated in Equation (7) to that type of accident yields the risk-severity factor for each activity and date:

Step 2: Interaction between activities and external factors. A representative daily factor is obtained that summarizes interactions between activities and external drivers. First, aggregation by the worst case (maximum) across risk-severity factors is used in Equation (8) to define risk-severity factor for the day :

Then, external influences are computed using Equations (9) and (10): a weekday factor to capture the variability in accident frequency and severity on certain days of the week, with some days being prone to undesired events [14,15], and a waste factor reflects higher risk on high-waste days [14]:

where is the ISO weekday index of day d (1 = Mon, …, 7 = Sun).

where is the maximum waste generated by any activity in the project .

Finally, these factors are incorporated multiplicatively through Equation (11) to obtain an adjusted risk-severity factor :

Step 3: Normalization to project size. In this step, the adjusted risk-severity factor is normalized with respect to the project, adjusting it according to the type of activities, the number of workers, and the scope of the project. The normalization constant is defined in Equation (12) from the worst risk-severity factor for any of the activities performed in the project, nominal daily hours, total workforce, and maximum severity:

where

- represents the nominal daily working hours;

- is the total number of workers involved in the project;

The normalized daily risk-severity factor is then computed through Equation (13), where is also clipped to prevent it from distorting the subsequent mapping to the daily safety index:

On this scale, represents the highest daily risk-severity ceiling compatible with the project size and smaller values indicate proportional fractions of that ceiling.

Step 4: Accounting for safety measures on-site. The daily safety index is computed through Equation (14), considering the safety-level score obtained in the questionnaire defined in the previous section. This formula applies a nonlinear mapping that penalizes low safety measures or high risk-severity factors:

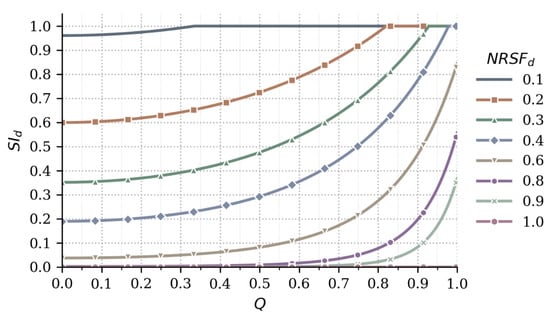

Figure 3 illustrates the joint effect of and on the daily safety index . With inadequate protocols (low ), remains low even for a modest . Conversely, strong measures (high ) maintain high with relatively high values of . Nevertheless, a high normalized risk-severity factor prevents the safety index from being near 1, even when adequate protocols are applied (high ).

Figure 3.

Daily safety index as a function of the questionnaire’s score across varying levels of normalised risk-severity factor . Each curve represents a different , illustrating how safety performance improves with higher compliance with safety protocols.

2.2.3. Weighting of Days and Overall Score

The project-level NMF-SI is computed through the aggregated daily safety levels . However, to prioritize safety improvements, the index was designed to penalize unsafe days more strongly. A weighted average is implemented, with higher weights assigned to smaller . First, a preliminary weight, is computed as described in Equation (15):

Subsequently, the weights are normalized through Equation (16) to ensure a proportional contribution to the overall score, ensuring that the sum of all normalized weights over the evaluation period equals 1:

The weighted daily safety index for each day is then given by Equation (17):

Finally, the global NMF-SI of the project is computed as the sum of the weighted daily safety indices, Equation (18):

2.3. Schedule Optimization Based on NMF-SI

Once the NMF-SI was formalized as a quantitative index of project-schedule safety, planning task can be cast as an optimization problem. Given the complexity of the scheduling space and the nonlinear behaviour of the NMF-SI, particularly due to its emphasis on high-risk periods, a tailored optimization algorithm was designed to efficiently explore alternative scheduling configurations. The objective is to maximize the NMF-SI in the space of feasible schedules, while ensuring compliance with constraints such as task dependencies and workforce availability across subcontracted teams. The result sets a schedule with reasonable project duration, where the nonlinear behaviour of the index, placing greater emphasis on low-safety days, promotes activity shifts that equalize safety across the project, thus mitigating high-risk periods.

Throughout this section, is the set of subcontracted teams . Each activity has a fixed duration in days and resource demands by team and each team has a capacity . Moreover, precedence relations are defined only for a subset of ordered pairs so that if activity can start only after finishes. It may also include a minimum time lag between the activities .

The aim, defined in Equation (19), is to maximize the NMF-SI by selecting the start days considering that activity occupies the consecutive block of days :

Subject to

- Precedence: for every the start of must satisfy

- Team capacities: for each day and team ,

The vector of the start days induces a full schedule, denoted by . Partial schedules used in the constructive phase of the optimization algorithm are denoted by with . In addition, the total completion of any complete schedule is written as and will be computed following Equation (20):

To prevent artificial stretching of the schedule when optimizing the NMF-SI, the project duration is fixed to the constructive baseline total schedule length, denoted by. This baseline is the minimal feasible duration when scheduling under precedence and team-capacity constraints, without considering the NMF-SI, and is computed through Equation (21), subject to the same constraints mentioned above:

This value will be a hard constraint when maximizing the NMF-SI because without this bound the index would tend to favour longer schedules that spread high-risk tasks more evenly, an outcome misaligned with realistic industrial timelines. Therefore, ensures the schedule is both operationally viable and temporally bounded.

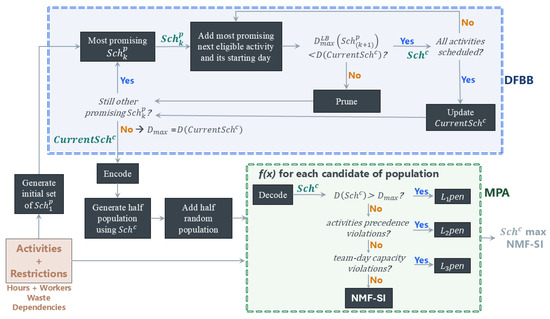

To address the problem efficiently, a hybrid optimization strategy was adopted, as shown in Figure 4, which is a simplified flowchart of the optimization process, combining a constructive heuristic with a metaheuristic refinement phase. In phase 1, a Serial Schedule Generation Scheme (SSGS) is applied within the heuristic to obtain a complete schedule that minimizes project duration. The search follows a Depth-First Branch-and-Bound (DFBB) exploration, where each node represents a partial schedule (with activities) and carries a lower bound on the overall project duration, denoted as , estimated from (i) the current fixed placements, (ii) precedence with lags, (iii) residual team capacities, and (iv) remaining activities.

Figure 4.

Simplified flowchart of the optimization process.

In DFBB, an incumbent full schedule , together with its duration , is defined and maintained after the initial depth-first descent from the root that reaches the first complete schedule. Branches are expanded by fixing the next eligible activity at its earliest feasible start that preserves precedence and day-wise team capacities, producing multiple new nodes with . Nodes are pruned whenever the lower bound duration carried in the node is greater than or equal to that duration ≥ . Whenever a newly completed schedule has a smaller duration, the incumbent is updated. The DFBB search continues until all branches are discarded, guaranteeing optimality. Finally, the maximum duration of the project is established as .

The outcome is a minimal-duration and operationally viable schedule . Importantly, NMF-SI is not optimized in this phase to avoid biasing the baseline toward stretched timelines; instead, is enforced as a hard duration cap in phase 2, and the resulting schedule is used as a reference to guide the initial steps of the metaheuristic search, thereby reducing the computational time.

In phase 2, the metaheuristic refines the start times of the activities to improve the NMF-SI, while preserving and satisfying all operational constraints. The chosen metaheuristic algorithm is the Marine Predators Algorithm (MPA) [36], introduced in 2020 and recognized in recent literature for its strong performance in complex, constraint-laden optimization problems [37]. MPA is selected here because it requires very few hyperparameters, which simplifies tuning and avoids it becoming an optimization problem itself [38].

The method is applied in a decoder-based manner well suited to discrete, constraint-laden scheduling. Each candidate solution is encoded as a start-day vector over all the activities, and feasibility is enforced by decoder checks, which flags them as infeasible. To steer the search effectively, fitness is designed as a penalized objective, where feasible schedules are scored by their NMF-SI (bounded in [0, 1]), whereas infeasible candidates receive a hierarchical penalty that yields a strictly negative score. Penalty is defined following the recommendation of literature [39,40] and experience from previous work, using ordered levels with continuous severities that quantify “distance from feasibility”. In decreasing importance, the levels are as follows: (L1) violation of the duration established in phase 1 to drive the algorithm to place all tasks within the restricted horizon; (L2) activities precedence violations to ensure dependencies are respected; and (L3) team-day capacity violations. The continuous component is computed as follows: for L1 and L2, the total number of violating days; for L3, the aggregated worker-day overload required to realize the schedule. Hierarchy is enforced via scaling coefficients , such that any candidate violating the most important criteria is ranked below every candidate that satisfies it, and any precedence-violating candidate is ranked below every candidate that satisfies precedence, regardless of capacity surplus. Given that MPA is not gradient-based, the selection of these scaling factors is irrelevant, as long as the previous condition is satisfied.

As search operators, a moderate population size of 50 is selected to balance exploration and runtime, and the termination criterion is set to 500 epochs, which was sufficient to reach convergence in all tested instances. The initialization of population includes the baseline of phase 1 together with (i) jittered random variants in its neighbourhood and (ii) fully random solutions generated using standard initialization procedures described in the foundational works of the algorithm. The additional random solutions may include infeasible candidates, retained for diversity, which will be penalized through the decoder-based fitness.

Fixing prior to metaheuristic refinement sharply reduces the search space faced by the metaheuristic: instead of exploring schedules over an unbounded time horizon, the search is confined to rearrangements within a fixed planning horizon, which lowers dimensionality, curbs combinatorial blow-up, and accelerates convergence. This design also prevents the metaheuristic from “gaming” the objective by stretching the timeline to dilute risk, ensuring that safety improvements arise from better temporal allocation rather than longer projects. Moreover, seeding with the constructive baseline provides an immediately feasible anchor that guides early iterations and shortens time to quality. In practice, the hybrid scheme couples the speed and feasibility guarantees with the global search capability of MPA, yielding robust, computationally efficient optimization under realistic industrial constraints.

3. Results and Discussion

The design of the NMF-SI, particularly its nonlinear response to safety violations and its heavier weighting of high-risk days, appears well aligned with the objectives identified in the literature regarding risk reduction in construction scheduling [12]. The index not only reflects the relative safety of a schedule but also encourages planning behaviours aligned with PtD principles. In this regard, the NMF-SI functions not merely as an indicator but as a decision support tool that structurally discourages risky clustering patterns, fostering better temporal distribution of hazardous tasks.

A comparative analysis of different planning scenarios, including those generated through the optimization algorithm, revealed that the nonlinear formulation of the NMF-SI effectively penalizes clusters of high-risk tasks. This behaviour discourages the concentration of hazardous activities in short timeframes and results in smoother risk profiles. Managers can thereby identify and target high-risk periods more easily, enabling a more focused application of mitigation strategies.

In addition, we applied hybrid optimization to compare a conventional time-focused baseline with a schedule optimized for NMF-SI during the planning phase for a real renovation project. The scenario involved a total of 37 workers distributed across 5 subcontractors, executing 10 main activities of different types, including window replacement, replacement of ceiling insulation, and excavation for the installation of geothermal plants. The mean crew size per activity was 5.1 workers, and the mean activity duration was 20.3 days. Two groups of activities exhibited cascading dependencies, requiring careful sequencing to be performed correctly. In addition, the safety questionnaire yielded a score of 8, indicating a high current safety level, albeit with room for improvement.

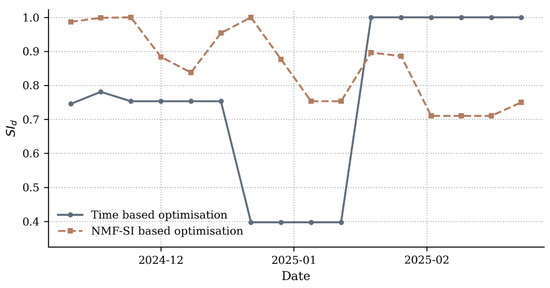

The results are shown in Figure 5: the time-based schedule (blue line) resulted in a highly variable daily NMF-SI, with values dropping below 40 during critical phases of the project. This uneven distribution is due to activity clusters in high-risk periods without adequate mitigation strategies. By contrast, the schedule generated by the safety-based optimization (orange line) not only raised the average NMF-SI significantly, from 35.2 to 71.4, but also led to a more balanced distribution of risk over time. Days with low scores were minimized, contributing to a higher global safety factor due to the greater penalty applied to such days in the weighting model. These results validate the effectiveness of the optimization framework in identifying more favourable task sequences while still satisfying all temporal and resource constraints.

Figure 5.

Comparison of the weekly NMF-SI between time-based and safety-based optimizations in a real-world renovation scenario.

At the planning level, the algorithm suggests delaying the execution of three activities, while always respecting dependencies and the overall project deadline, so that they do not overlap with others of higher risk due to the nature of the tasks, the number of workers involved, and the amount of waste generated. In this way, the proposed schedule may appear less straightforward, but it helps reduce the associated risks without extending the total project duration.

The constructive heuristic proved efficient in producing an initial baseline schedule aligned with operational requirements. However, its tendency to focus on project duration without directly considering safety led to suboptimal results in terms of risk exposure. The metaheuristic refinement through MPA was able to exploit this initial solution space and reallocate tasks to safer time windows. This refinement step was essential, as a direct heuristic approach based on the NMF-SI would have unrealistically extended the project duration, which is not acceptable in real industrial contexts.

The outcomes demonstrate that incorporating the NMF-SI as an explicit objective in the planning phase can substantially improve occupational safety without compromising project duration. One of the key findings is that risk-aware scheduling can lead to more uniform safety conditions, preventing dangerous peaks of activity clustering, particularly during high-risk periods such as late project stages or waste-intensive phases.

It is also important to highlight that ensuring safety in construction environments remains a complex, multi-variable challenge, influenced by human, technical, and environmental factors. Nonetheless, the NMF-SI proposed here can represent a first step toward the use of quantitative, data-driven methods to support safer planning practices.

4. Conclusions

This study introduces a novel, quantifiable methodology for safety-aware planning in building construction projects. By formalizing the NMF-SI as a nonlinear index of occupational safety and integrating it into a hybrid optimization algorithm, the proposed approach enables systematic evaluation and improvement of task schedules with respect to occupational safety.

The NMF-SI provides a valuable step forward in enhancing safety management in the construction sector. By quantifying daily potential risks, it allows project managers to detect high-risk periods early and take proactive mitigation actions. Additionally, the global score facilitates comparative evaluation between alternative schedules, enabling more informed decision-making during the planning phase.

Importantly, the nonlinear nature of the index, particularly its penalization of low-scoring days, incentivizes both better task distribution and the reinforcement of on-site safety measures. The improved score observed after optimization reflects not only scheduling refinement but also the potential for driving safety-conscious behaviours at the management level.

Although several scenarios have been analysed and the variation of the NMF-SI has been demonstrated in a real renovation project, the present work remains primarily theoretical and should be further validated through its application to full-scale construction projects. This limitation stems from the complexity and variability inherent in on-site operations, including contractors’ differing capacities to replan tasks, shared resource constraints, and the influence of external factors, such as costs or environmental conditions. Furthermore, the availability of detailed input data, such as time or resource buffers, may restrict the practical deployment of the proposed method, particularly in smaller-scale projects.

Future research should focus on validating the proposed methodology under real conditions and extending the optimization framework to include additional constraints and objectives. These could encompass contractors’ flexibility limits, cost and time penalties, or even multi-objective formulations to integrate safety with broader project performance indicators.

Author Contributions

Conceptualization, D.A., M.Á.C.-L., F.T.-L. and J.A.; methodology, D.A., M.Á.C.-L., F.T.-L. and J.A.; software, D.A., M.Á.C.-L. and F.T.-L.; validation, D.A., M.Á.C.-L. and F.T.-L.; formal analysis, D.A., M.Á.C.-L., F.T.-L. and J.A.; investigation, D.A., M.Á.C.-L. and F.T.-L.; data curation, D.A., M.Á.C.-L. and F.T.-L.; writing—original draft, D.A., M.Á.C.-L., F.T.-L. and J.A.; Writing—review and editing, D.A., M.Á.C.-L., F.T.-L. and J.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by European Union as part of the InCUBE project (an InClUsive toolBox for accElerating and smartening deep renovation), under Grant Agreement no. 101069610.

Institutional Review Board Statement

The questionnaire referenced in the manuscript consists exclusively of general questions and does not include any that are personal in nature.

Informed Consent Statement

No information of any kind regarding the individuals completing the questionnaire has been collected.

Data Availability Statement

The datasets presented in this article are not readily available because they are subjected to a confidentiality contract between the project partnersRequests to access the datasets should be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pinto, A.; Nunes, I.L.; Ribeiro, R.A. Occupational Risk Assessment in Construction Industry—Overview and Reflection. Saf. Sci. 2011, 49, 616–624. [Google Scholar] [CrossRef]

- Sunindijo, R.; Zou, P. Political skill for developing construction safety climate. J. Constr. Eng. Manag. 2012, 138, 605–612. [Google Scholar] [CrossRef]

- Zhou, Z.; Goh, Y.M.; Li, Q. Overview and Analysis of Safety Management Studies in the Construction Industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Salzano, A.; Cascone, S.; Zitiello, E.P.; Nicolella, M. Construction Safety and Efficiency: Integrating Building Information Modeling into Risk Management and Project Execution. Sustainability 2024, 16, 4094. [Google Scholar] [CrossRef]

- Benjaoran, V.; Bhokha, S. An Integrated Safety Management with Construction Management Using 4D CAD Model. Saf. Sci. 2010, 48, 395–403. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial Intelligence and Smart Vision for Building and Construction 4.0: Machine and Deep Learning Methods and Applications. Autom. Constr. 2022, 141, 104440. [Google Scholar] [CrossRef]

- Gangolells, M.; Casals, M.; Forcada, N.; Roca, X.; Fuertes, A. Mitigating Construction Safety Risks Using Prevention through Design. J. Saf. Res. 2010, 41, 107–122. [Google Scholar] [CrossRef] [PubMed]

- Jabbarani Torghabeh, Z.; Shahab Hosseinian, S. Designing for Construction Workers’ Safety. Int. J. Adv. Eng. Technol. 2012, 4, 373–382. [Google Scholar]

- Zhang, S.; Teizer, J.; Lee, J.K.; Eastman, C.M.; Venugopal, M. Building Information Modeling (BIM) and Safety: Automatic Safety Checking of Construction Models and Schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Liu, J.; Luo, H.; Liu, H. Deep Learning-Based Data Analytics for Safety in Construction. Autom. Constr. 2022, 140, 104302. [Google Scholar] [CrossRef]

- Chukwuma, O.I.; Cheng, P.L.; Varianou-Mikellidou, C.; Dimopoulos, C.; Boustras, G. Machine Learning for Occupational Accident Analysis: Applications, Challenges, and Future Directions. J. Saf. Sci. Resil. 2025, 7, 100250. [Google Scholar] [CrossRef]

- Armenteros-Cosme, P.; Arias-González, M.; Alonso-Rollán, S.; Márquez-Sánchez, S.; Carrera, A. Advancements in Artificial Intelligence and Machine Learning for Occupational Risk Prevention: A Systematic Review on Predictive Risk Modeling and Prevention Strategies. Sensors 2025, 25, 5419. [Google Scholar] [CrossRef]

- Panthi, A.; Hussain, A. Integrated optimization of construction schedules: A five-objective approach for time, cost, quality, safety, and environmental sustainability using OBNSGA-III. Asian J. Civ. Eng. 2025, 1–20. [Google Scholar] [CrossRef]

- Arar, E.; Halicioglu, F.H. Understanding Artificial Neural Networks as a Transformative Approach to Construction Risk Management: A Systematic Literature Review. Buildings 2025, 15, 3346. [Google Scholar] [CrossRef]

- Gurcanli, G.E.; Bilir, S.; Sevim, M. Activity Based Risk Assessment and Safety Cost Estimation for Residential Building Construction Projects. Saf. Sci. 2015, 80, 1–12. [Google Scholar] [CrossRef]

- Abuelaish, R.; Toğan, V. Integration of Lean Construction and Buffer Management—A Systematic Literature Review. Lean Constr. J. 2024, 85–107. [Google Scholar] [CrossRef]

- Xia, N.; Zou, P.X.; Liu, X.; Wang, X.; Zhu, R. A Hybrid BN-HFACS Model for Predicting Safety Performance in Construction Projects. Saf. Sci. 2018, 101, 332–343. [Google Scholar] [CrossRef]

- Perkins, E.J.; Ashauer, R.; Burgoon, L.; Conolly, R.; Landesmann, B.; Mackay, C.; Murphy, C.A.; Pollesch, N.; Wheeler, J.R.; Zupanic, A. Building and Applying Quantitative Adverse Outcome Pathway Models for Chemical Hazard and Risk Assessment. Environ. Toxicol. Chem. 2019, 38, 1850–1865. [Google Scholar] [CrossRef]

- Tsai, T.C.; Yang, M.L. Risk Assessment of Design-BID-Build and Design-Build Building Projects. J. Oper. Res. Soc. Jpn. 2010, 53, 20–39. [Google Scholar] [CrossRef][Green Version]

- Ogunsanmi, O.E. Risk Classification Model for Design and Build Projects. CJRBE 2015, 3, 54–76. [Google Scholar][Green Version]

- Gürcanli, G.E.; Müngen, U. An Occupational Safety Risk Analysis Method at Construction Sites Using Fuzzy Sets. Int. J. Ind. Ergon. 2009, 39, 371–387. [Google Scholar] [CrossRef]

- Asanka, W.A.; Ranasinghe, M. Study on the Impact of Accidents on Construction Projects. In Proceedings of the 6th International Conference on Structural Engineering and Construction Management, Kandy, Sri Lanka, 11–13 December 2015. [Google Scholar]

- Carmen Carnero, M.; José Pedregal, D. Modelling and Forecasting Occupational Accidents of Different Severity Levels in Spain. Reliab. Eng. Syst. Saf. 2010, 95, 1134–1141. [Google Scholar] [CrossRef]

- Leino, A.; Heinonen, R.; Kiurula, M. Improving Safety Performance Through 5S Program. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, IGLC-22, Oslo, Norway, 25–27 June 2014. [Google Scholar]

- Yılmaz, H.; Gümüşburun Ayalp, G. Determination of Criteria for Preventing Construction Waste in Construction Projects at the Architectural Design Stage. Int. J. Mater. Eng. Technol. 2025, 8, 1–15. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Ding, G.; Feng, Z. Developing a Quantitative Construction Waste Estimation Model for Building Construction Projects. Resour. Conserv. Recycl. 2016, 106, 9–20. [Google Scholar] [CrossRef]

- Kale, Ö.A.; Baradan, S. Identifying Factors That Contribute to Severity of Construction Injuries Using Logistic Regression Model. Tek. Dergi Tech. J. Turk. Chamb. Civ. Eng. 2020, 31, 9919–9940. [Google Scholar] [CrossRef]

- Badawy, M.; Alqahtani, F.; Hafez, H. Identifying the Risk Factors Affecting the Overall Cost Risk in Residential Projects at the Early Stage. Ain Shams Eng. J. 2022, 13, 101586. [Google Scholar] [CrossRef]

- Xing, W.; Hao, J.L.; Qian, L.; Tam, V.W.; Sikora, K.S. Implementing Lean Construction Techniques and Management Methods in Chinese Projects: A Case Study in Suzhou, China. J. Clean Prod. 2021, 286, 124944. [Google Scholar] [CrossRef]

- Liang, H.; Zhang, S.; Su, Y. The structure and emerging trends of construction safety management research: A bibliometric review. Int. J. Occup. Saf. Ergon. 2020, 26, 469–488. [Google Scholar] [CrossRef]

- Rehacek, P.; Bazsova, B. Risk Management Methods in Projects. JEERBE 2018, 2018, 790198. [Google Scholar] [CrossRef]

- Muneeswaran, G.; Manoharan, P.; Awoyera, P.O.; Adesina, A. A Statistical Approach to Assess the Schedule Delays and Risks in Indian Construction Industry. Int. J. Constr. Manag. 2020, 20, 450–461. [Google Scholar] [CrossRef]

- Larios, J.A.; Sanz, A.; Pellicer, E.; Catalá, J. Construction Health and Safety from a Lean Production Approach. In Proceedings of the XVI Congreso Internacional de Ingeniería de Proyectos, Valencia, Spain, 11–13 July 2012. [Google Scholar]

- Guo, S.; He, J.; Li, J.; Tang, B. Exploring the Impact of Unsafe Behaviors on Building Construction Accidents Using a Bayesian Network. Int. J. Environ. Res. Public Health 2020, 17, 221. [Google Scholar] [CrossRef]

- Bilir, S.; Gürcanli, G.E. A Method for Determination of Accident Probability in Construction Industry. Tek. Dergi Tech. J. Turk. Chamb. Civ. Eng. 2018, 29, 8537–8561. [Google Scholar] [CrossRef]

- Faramarzi, A.; Heidarinejad, M.; Mirjalili, S.; Gandomi, A.H. Marine Predators Algorithm: A Nature-Inspired Metaheuristic. Expert Syst. Appl. 2020, 152, 113377. [Google Scholar] [CrossRef]

- Camino López, M.A.; Ritzel, D.O.; Fontaneda, I.; González Alcantara, O.J. Construction Industry Accidents in Spain. J. Saf. Res. 2008, 39, 497–507. [Google Scholar] [CrossRef] [PubMed]

- Alorf, A. A Survey of Recently Developed Metaheuristics and Their Comparative Analysis. Eng. Appl. Artif. Intell. 2023, 117, 105622. [Google Scholar] [CrossRef]

- Homaifar, A.; Qi, C.X.; Lai, S.H. Constrained Optimization Via Genetic Algorithms. Simulation 1994, 62, 242–253. [Google Scholar] [CrossRef]

- Richardson, J.T.; Palmer, M.R.; Liepins, G.E.; Hilliard, M.R. Some Guidelines for Genetic Algorithms with Penalty Functions. In Proceedings of the 3rd International Conference on Genetic Algorithms, Fairfax, VA, USA, 1 June 1989; Morgan Kaufmann Publishers Inc.: San Francisco, CA, USA, 1989; pp. 191–197. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).