An Investigation into the Role of 3D Printing in Residential Buildings: An Emirati Housing Case Study

Abstract

1. Introduction

2. Case Study and Methods

Simulation Scenarios

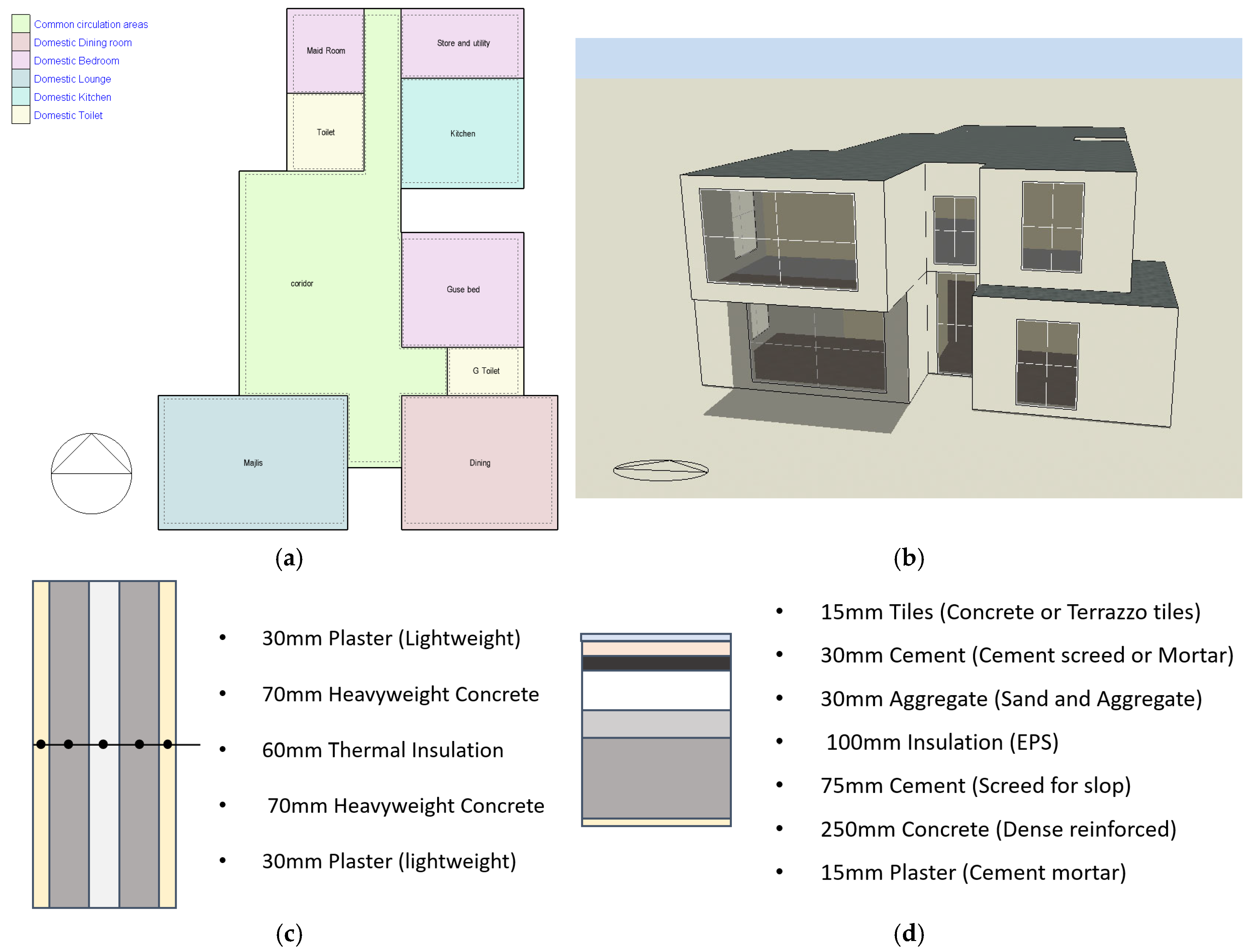

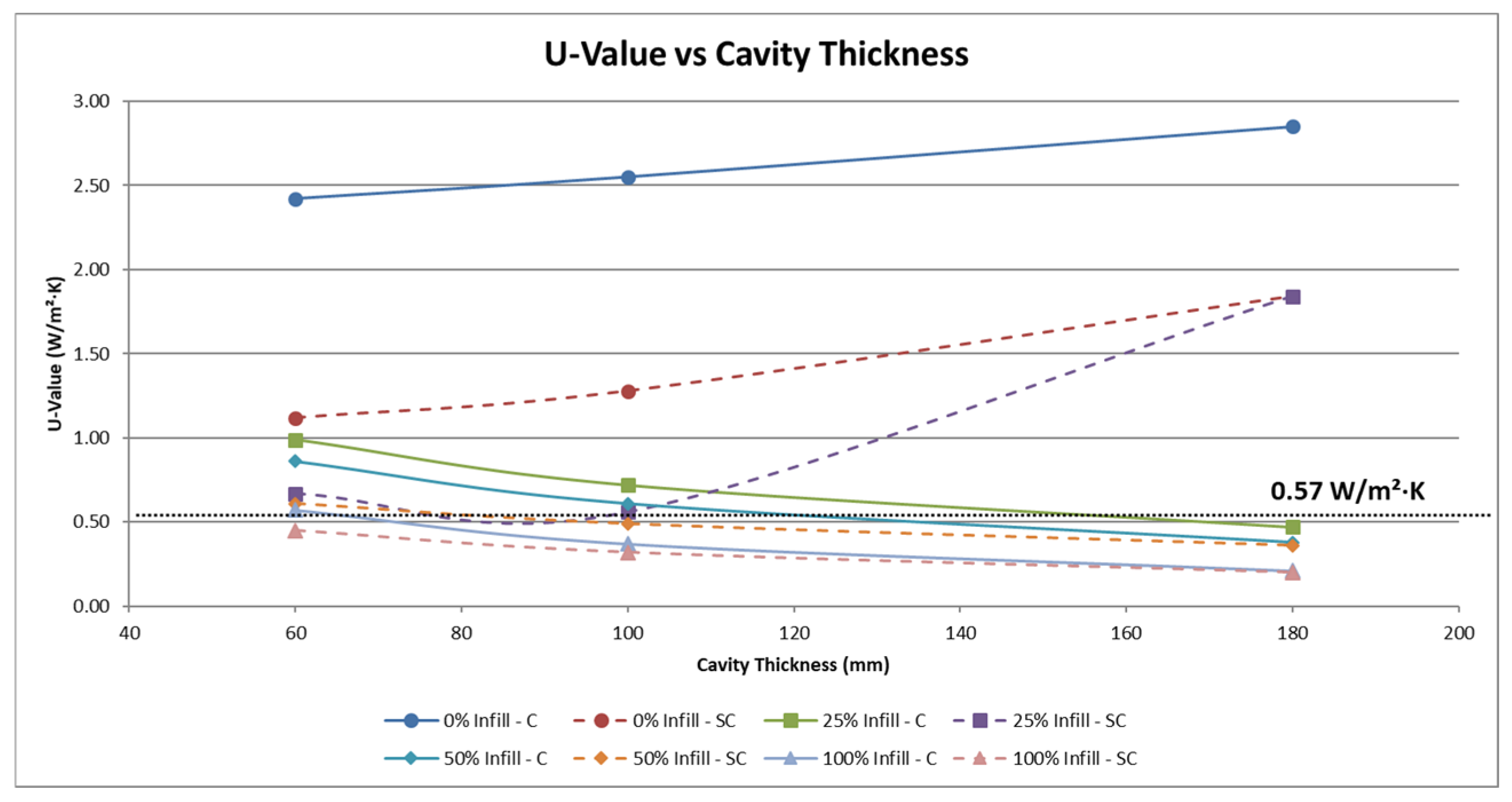

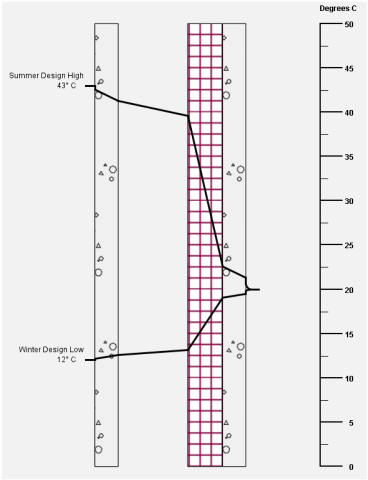

- Scenario 1 involved altering the type and thickness of the 3D-printed concrete layers. Two types of concrete mix were tested, conventional concrete and sulfur concrete, with specifications provided in Table 3. The sulfur concrete mix followed the formulation proposed by Bretz [42] and recently applied in 3D-printed wall simulation research [32]. Additionally, the size of the printing nozzle was assumed to be the standard 4 cm, 8 cm, and 10 cm, the type of printing concrete was varied, and the size of the internal cavity was adjusted to 18 cm, 10 cm, and 6 cm, respectively. The total wall thickness was thus 26 cm, which matches the case study villa’s actual external wall thickness (Figure 1c).

- Scenario 2 examined various filling levels of insulation for each of the internal cavities that were outlined in Scenario 1, and insulation fill was set to 25%, 50%, and 100% of the cavity space.

| 3D Material Specifications | Density (kg/m3) | Thermal Conductivity (W/m·K) | Specific Heat (J/g·K) |

|---|---|---|---|

| General Concrete Mix (C) | 2240 | 1.95 | 0.900 |

| Sulfur Concrete Mix (SC) | 1.254 | 0.367 | 0.803 |

| Expanded Polystyrene (EPS) | 15 | 0.04 | 1.45 |

3. Results

3.1. Analysis of U-Value Variations Based on 3D Printing Materials and Insulation Levels

3.2. Cooling Load Analysis for 3D Printing Materials and Insulation Levels

3.3. Cooling Energy Consumption Analysis for 3D-Printed Materials and Insulation Levels

3.4. Optimal Selections for Satisfying the Baseline Condition

3.5. Overall Simulation Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tu, H.; Wei, Z.; Bahrami, A.; Ben Kahla, N.; Ahmad, A.; Özkılıç, Y.O. Recent advancements and future trends in 3D concrete printing using waste materials. Dev. Built Environ. 2023, 16, 100187. [Google Scholar] [CrossRef]

- Kreiger, M.; Kreiger, E.; Mansour, S.; Monkman, S.; Delavar, M.A.; Sideris, P.; Roberts, C.; Friedell, M.; Platt, S.; Jones, S. Additive construction in practice—Realities of acceptance criteria. Cem. Concr. Res. 2024, 186, 107652. [Google Scholar] [CrossRef]

- Habibi, A.; Buswell, R.; Osmani, M.; Aziminezhad, M. Sustainability principles in 3D concrete printing: Analysing trends, classifying strategies, and future directions. J. Build. Eng. 2024, 98, 111354. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive manufacturing: Technology, applications, markets, and opportunities for the built environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Lee, D.; Kim, H.; Sim, J.; Lee, D.; Cho, H.; Hong, D. Trends in 3D Printing Technology for Construction Automation Using Text Mining. Int. J. Precis. Eng. Manuf. 2019, 20, 871–882. [Google Scholar] [CrossRef]

- Aghimien, D.; Aigbavboa, C.; Aghimien, L.; Thwala, W.D.; Ndlovu, L. Making a case for 3D printing for housing delivery in South Africa. Int. J. Hous. Mark. Anal. 2020, 13, 565–581. [Google Scholar] [CrossRef]

- Raza, M.H.; Besklubova, S.; Zhong, R.Y. Economic analysis of offsite and onsite 3D construction printing techniques for low-rise buildings: A comparative value stream assessment. Addit. Manuf. 2024, 89, 104292. [Google Scholar] [CrossRef]

- Es-Sebyty, H.; Igouzal, M.; Ferretti, E. Improving stability of an ecological 3D-printed house -a case study in Italy. J. Achiev. Mater. Manuf. Eng. 2022, 111, 18–25. [Google Scholar] [CrossRef]

- Giacomobono, L.; Argenti, M.; Ferretti, E.; Paparella, G. Three-Dimensional Printing with Earthen Materials: A Settlement-Scale Design Experience. Buildings 2024, 14, 2721. [Google Scholar] [CrossRef]

- De Rubeis, T.; Ciccozzi, A.; Giusti, L.; Ambrosini, D. On the use of 3D printing to enhance the thermal performance of building envelope—A review. J. Build. Eng. 2024, 95, 110284. [Google Scholar] [CrossRef]

- Rahemipoor, S.; Hasany, M.; Mehrali, M.; Almdal, K.; Ranjbar, N.; Mehrali, M. Phase change materials incorporation into 3D printed geopolymer cement: A sustainable approach to enhance the comfort and energy efficiency of buildings. J. Clean. Prod. 2023, 417, 138005. [Google Scholar] [CrossRef]

- Capêto, A.P.; Jesus, M.; Uribe, B.E.B.; Guimarães, A.S.; Oliveira, A.L.S. Building a Greener Future: Advancing Concrete Production Sustainability and the Thermal Properties of 3D-Printed Mortars. Buildings 2024, 14, 1323. [Google Scholar] [CrossRef]

- Government of the United Arab Emirates. Dubai 3D Printing Strategy; Government of the United Arab Emirates: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- Dubai Municipality. Dubai Green Building Regulations and Specifications (GBRS): Energy—Thermal Transmittance Requirements for External Walls; Dubai Municipality: Dubai, United Arab Emirates, 2014. [Google Scholar]

- Abu Dhabi Urban Plnning Council. The Pearl Rating System for Estidama Public Realm Rating System Design & Construction; Abu Dhabi Urban Plnning Council: Abu Dhabi, United Arab Emirates, 2016. [Google Scholar]

- Harold, J.; Lyons, S.; Cullinan, J. The determinants of residential gas demand in Ireland. Energy Econ. 2015, 51, 475–483. [Google Scholar] [CrossRef]

- Rasuli, M.A.; Torii, S. Energy consumption comparison at various insulation scenarios: Mid-rise residential buildings, Kabul city. E3S Web Conf. 2023, 405, 02001. [Google Scholar] [CrossRef]

- Fang, M.; Fang, T.; Chen, J.; Yu, Z. Impact Analysis of the Thickness of Wall Insulation on Indoor Comfort in Hot Summer and Cold Winter Area. Appl. Mech. Mater. 2012, 193–194, 1069–1074. [Google Scholar] [CrossRef]

- Kabundu, E.; Mbanga, S.; Botha, B.; Ayesu-Koranteng, E. Relative comparison of the benefits of wall envelope insulation materials in the South African energy zones, subject to the new national building energy efficiency standards. Front. Built Environ. 2023, 9, 1305029. [Google Scholar] [CrossRef]

- Chandrasiri, D.; Gatheeshgar, P.; Ahmadi, H.M.; Simwanda, L. Numerical Study of Thermal Efficiency in Light-Gauge Steel Panels Designed with Varying Insulation Ratios. Buildings 2024, 14, 300. [Google Scholar] [CrossRef]

- Martins, C.; Santos, P.; Da Silva, L.S. Lightweight steel-framed thermal bridges mitigation strategies: A parametric study. J. Build. Phys. 2016, 39, 342–372. [Google Scholar] [CrossRef]

- Bodalal, A.; Mashite, S.; Aladouli, O.; Ihdash, A. Calculation of Annual Heating and Cooling Energy Requirements for Residential Building in Different Climate Zones in Libya. Innov. Energy Res. 2017, 6, 161. [Google Scholar] [CrossRef]

- Mitterpach, J.; Hroncová, E.; Ladomerskỳ, J.; Štefko, J. Quantification of Improvement in Environmental Quality for Old Residential Buildings Using Life Cycle Assessment. Sustainability 2016, 8, 1303. [Google Scholar] [CrossRef]

- Kuan, S.-C.; Chan, C.-C.; Shu, C.-M. A study of BIPV net-zero energy building. Int. J. Smart Grid Clean Energy 2014, 3, 64–69. [Google Scholar] [CrossRef]

- Petrou, G.; Hutchinson, E.; Mavrogianni, A.; Milner, J.; Macintyre, H.; Phalkey, R.; Hsu, S.C.; Symonds, P.; Davies, M.; Wilkinson, P. Home energy efficiency under net zero: Time to monitor UK indoor air. BMJ 2022, 377, e069435. [Google Scholar] [CrossRef]

- Lingard, J. Residential retrofit in the UK: The optimum retrofit measures necessary for effective heat pump use. Build. Serv. Eng. Res. Technol. 2021, 42, 279–292. [Google Scholar] [CrossRef]

- Wang, X.; Lin, Q.; Li, J. Energy saving technology of wall insulation of harbor building based on energy cost analysis. Therm. Sci. 2021, 25, 4003–4010. [Google Scholar] [CrossRef]

- Wu, C.; Evans, P. An Integrated System for Improving 3D Concrete Printing Process. In Proceedings of the Eleventh National Conference of IBPSA-USA, Denver, CO, USA, 21–23 May 2024. [Google Scholar]

- Abouzeid, T.M.; Tarek, Z.M.; Sayad, E.L.; Ragheb, R.A. 3D Printing Technology as a Sustainable Solution for Mitigation of Energy Consumption in the Face of the Climate Crisis. In Proceedings of the IASTEM International Conference, Dubai, United Arab Emirates, 26–27 February 2024; pp. 2394–2827. [Google Scholar]

- Torcellini, P.; Pless, S.; Deru, M.; Crawley, D. Zero Energy Buildings: A Critical Look at the Definition. In Proceedings of the ACEEE Summer Study Pacific Grove, Pacific Grove, CA, USA, 14−18 August 2006. [Google Scholar]

- Alkhalidi, A.; Hatuqay, D. Energy efficient 3D printed buildings: Material and techniques selection worldwide study. J. Build. Eng. 2020, 30, 101286. [Google Scholar] [CrossRef]

- Chamatete, K.; Yalçınkaya, Ç. Numerical Evaluation on Thermal Performance of 3D Printed Concrete Walls: The Effects of Lattice Type, Filament Width and Granular Filling Material. Buildings 2024, 14, 926. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef] [PubMed]

- AlZahrani, A.A.; Alghamdi, A.A.; Basalah, A.A. Computational optimization of 3D-printed concrete walls for improved building thermal performance. Buildings 2022, 12, 2267. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Upasiri, I.; Gatheeshgar, P.; Poologanathan, K.; Nagaratnam, B.; Santos, P.; Rajanayagam, H. Energy Performance of 3D-Printed Concrete Walls: A Numerical Study. Buildings 2021, 11, 432. [Google Scholar] [CrossRef]

- Dziura, P.; Maroszek, M.; Góra, M.; Rudziewicz, M.; Pławecka, K.; Hebda, M. Influence of the In-Fill Pattern of the 3D Printed Building Wall on Its Thermal Insulation. Materials 2023, 16, 5772. [Google Scholar] [CrossRef]

- Pessoa, S.; Jesus, M.; Rangel, C.; Guimarães, A.S.; Lucas, S.S.; Simões, N. Preliminary study of the application of thermal mortar in 3D printed concrete walls. J. Phys. Conf. Ser. 2023, 2654, 012081. [Google Scholar] [CrossRef]

- Volpe, S.; Sangiorgio, V.; Petrella, A.; Coppola, A.; Notarnicola, M.; Fiorito, F. Building Envelope Prefabricated with 3D Printing Technology. Sustainability 2021, 13, 8923. [Google Scholar] [CrossRef]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P.; Baryś, M. The Potential of 3D Printing in Thermal Insulating Composite Materials—Experimental Determination of the Impact of the Geometry on Thermal Resistance. Materials 2024, 17, 1202. [Google Scholar] [CrossRef] [PubMed]

- Department of Municipal Affairs. Abu Dhabi International Energy Conservation Code (ADIECC); Government of Abu Dhabi: Abu Dhabi, United Arab Emirates, 2013. [Google Scholar]

- Bretz, T.J. Properties of Sulfur Concrete; U.S. Bureau of Mines: Washington, DC, USA, 1979. [Google Scholar]

| Actual Building | DesignBuilder | |

|---|---|---|

| Roof (U-value: W/m2 K) | 0.31 | 0.31 |

| External Wall (U-value: W/m2 K) | 0.57 | 0.54 |

| Windows (U-value: W/m2 K) | 2.2 (SHGC: 0.4) | 2.2 (SHGC: 0.39) |

| Cooling Load (kW) | 72.3 | 71.9 |

| AC Type and COP | PTHP and 3.5 | PTHP and 3.5 |

| Scenarios | 3D-Printed Concrete Layers | Variation of the Parameters | |||

|---|---|---|---|---|---|

| 1. Thickness of concrete layers + internal cavity + concrete layer | General Concrete Mix | 4 cm + 18 cm + 4 cm | 8 cm + 10 cm + 8 cm | 10 cm + 6 cm + 10 cm | |

| Sulfur Concrete Mix | |||||

| 2. Filling levels of insulation internal cavity | General Concrete Mix | 25% | 7.2 cm | 4 cm | 2.4 cm |

| Sulfur Concrete Mix | 50% | 9 cm | 5 cm | 3 cm | |

| 100% | 18 cm | 10 cm | 6 cm | ||

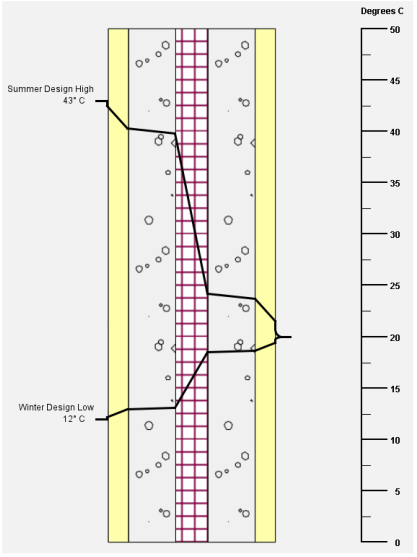

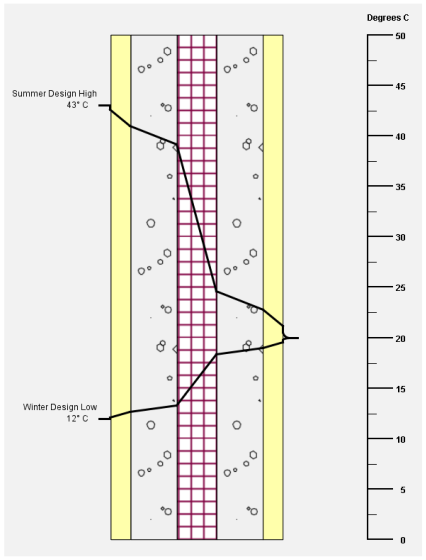

| Type of Walls | ① Baseline Wall | ② Baseline Wall with Sulfur Concrete | ③ 3D-Printed Sulfur Concrete Wall: 4 cm + (12 cm + 6 cm EPS) + 4 cm |

|---|---|---|---|

|  |  | |

| Walls properties | |||

| Total Thickness (mm) | 260 | 260 | 260 |

| R-value (m2K/W) | 1.77 | 2.37 | 2.03 |

| U-value (W/m2 K) | 0.57 | 0.421 | 0.493 |

| Time Lag (h) | −9.84 | −1.69 | −0.15 |

| Baseline Model | CASE I | CASE II | CASE III | CASE IV | |

|---|---|---|---|---|---|

| External Wall Details | Plaster (3 cm) Concrete (7 cm) EPS (6 cm) Concrete (7 cm) Plaster (3 cm) | General Concrete (4 cm) EPS (9 cm) Cavity (9 cm) General Concrete (4 cm) | General Concrete (4 cm) EPS (18 cm) General Concrete (4 cm) | Sulfur Concrete (4 cm) EPS (18 cm) Sulfur Concrete (4 cm) | General Concrete (8 cm) EPS (10 cm) General Concrete (8 cm) |

| U-value (W/m2 K), | 0.57 | 0.38 | 0.21 | 0.20 | 0.37 |

| Cooling Load (kW), | 72.3 | 71.3 | 69.0 | 72.0 | 69.3 |

| Cooling Energy per unit (kWh/m2) | 199.2 | 193.0 | 187.3 | 182.7 | 193.5 |

| Wall Type | Units | Infill Insulation (%) | |||

|---|---|---|---|---|---|

| 0 | 25 | 50 | 100 | ||

| 4 cm Concrete Mix (C) | U-value (W/m2 K) | 2.85 | 0.47 | 0.38 | 0.21 |

| Cooling Load (kW) | 103.9 | 72.4 | 71.3 | 69 | |

| Cooling Energy per unit (kWh/m2) | 254.1 | 195.4 | 193 | 187.3 | |

| 4 cm Sulfur Concrete (SC) | U-value (W/m2 K) | 1.84 | 0.43 | 0.36 | 0.2 |

| Cooling Load (kW) | 94.2 | 74.3 | 73.7 | 72 | |

| Cooling Energy per unit (kWh/m2) | 226.6 | 189.5 | 187.4 | 182.7 | |

| 8 cm Concrete Mix (C) | U-value (W/m2 K) | 2.55 | 0.72 | 0.61 | 0.37 |

| Cooling Load (kW) | 94.1 | 73.3 | 72.1 | 69.3 | |

| Cooling Energy per unit (kWh/m2) | 253.6 | 205.3 | 201.4 | 193.5 | |

| 8 cm Sulfur Concrete (SC) | U-value (W/m2 K) | 1.28 | 0.56 | 0.49 | 0.32 |

| Cooling Load (kW) | 86.9 | 76.1 | 75.3 | 73.2 | |

| Cooling Energy per unit (kWh/m2) | 213.4 | 193.5 | 191.5 | 186.3 | |

| 10 cm Concrete Mix (C) | U-value (W/m2 K) | 2.42 | 0.99 | 0.86 | 0.57 |

| Cooling Load (kW) | 91.1 | 75.8 | 74.3 | 72.1 | |

| Cooling Energy per unit (kWh/m2) | 251.9 | 214.1 | 210.2 | 200.6 | |

| 10 cm Sulfur Concrete (SC) | U-value (W/m2 K) | 1.12 | 0.67 | 0.61 | 0.45 |

| Cooling Load (kW) | 84.4 | 77.8 | 76.8 | 74.6 | |

| Cooling Energy per unit (kWh/m2) | 209.3 | 196.7 | 195 | 190.2 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.K.; Scoppa, M.; Haddad, M. An Investigation into the Role of 3D Printing in Residential Buildings: An Emirati Housing Case Study. Buildings 2025, 15, 3933. https://doi.org/10.3390/buildings15213933

Kim YK, Scoppa M, Haddad M. An Investigation into the Role of 3D Printing in Residential Buildings: An Emirati Housing Case Study. Buildings. 2025; 15(21):3933. https://doi.org/10.3390/buildings15213933

Chicago/Turabian StyleKim, Young Ki, Martin Scoppa, and Madhar Haddad. 2025. "An Investigation into the Role of 3D Printing in Residential Buildings: An Emirati Housing Case Study" Buildings 15, no. 21: 3933. https://doi.org/10.3390/buildings15213933

APA StyleKim, Y. K., Scoppa, M., & Haddad, M. (2025). An Investigation into the Role of 3D Printing in Residential Buildings: An Emirati Housing Case Study. Buildings, 15(21), 3933. https://doi.org/10.3390/buildings15213933