1. Introduction

Reinforced concrete walls (RC walls) are widely used in civil air defence, transportation, and nuclear island engineering fields. These projects are in complex environments and may be threatened by high-mass, low-velocity impact loads, such as vehicles and falling rocks. Therefore, the impact resistance performance and effective protection methods of key RC walls in various fields hold research significance. However, current research on the out-of-plane, high-mass, low-velocity collision of RC walls is relatively limited, and there is an urgent need for targeted protection of key RC walls to enhance their impact resistance performance.

To improve the impact resistance of RC walls, scholars have conducted some re-search on the use of carbon fibre, aramid fibre, and other reinforcement methods, as well as measures such as spraying polyurea and other elastomers [

1]. Both of these methods can effectively improve the impact resistance of RC walls, reduce the impact acceleration and stress peak, and decrease the impact damage of RC walls. There is little research on the impact resistance and protection measures of RC walls. Due to the larger size of the RC wall surface and the smaller width of the beam surface, the research on impact protection of RC walls can also refer to the research on impact protection of RC slabs.

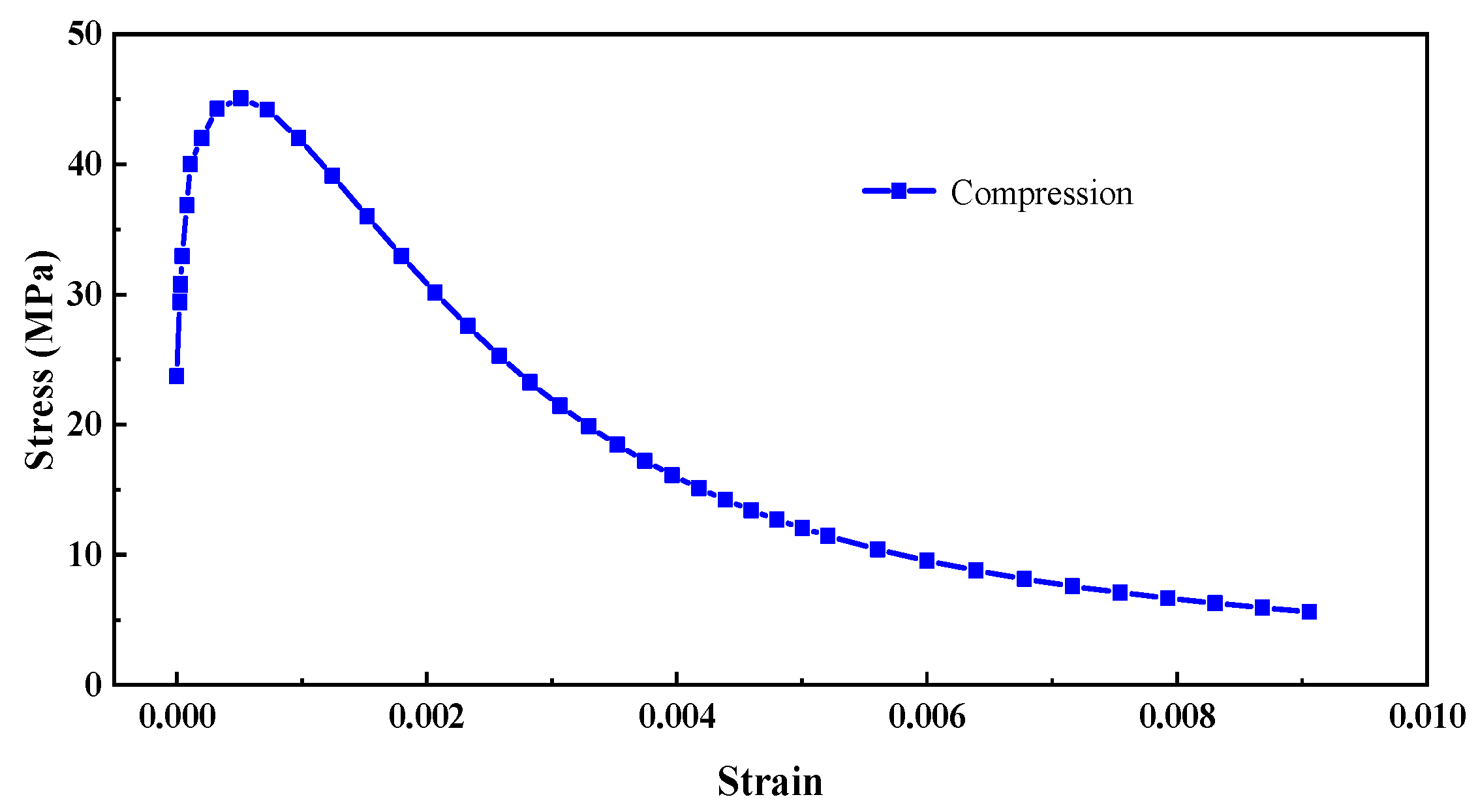

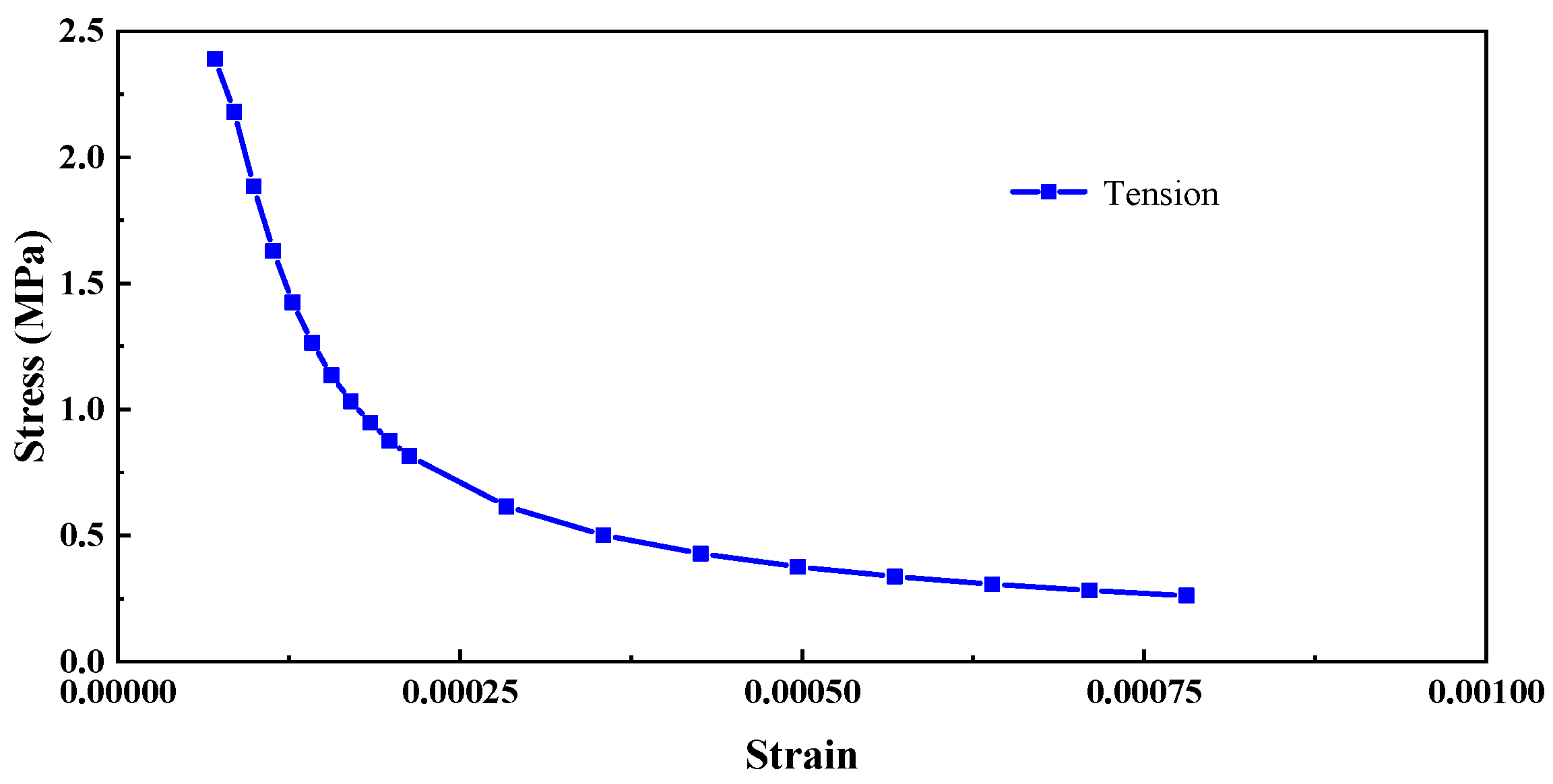

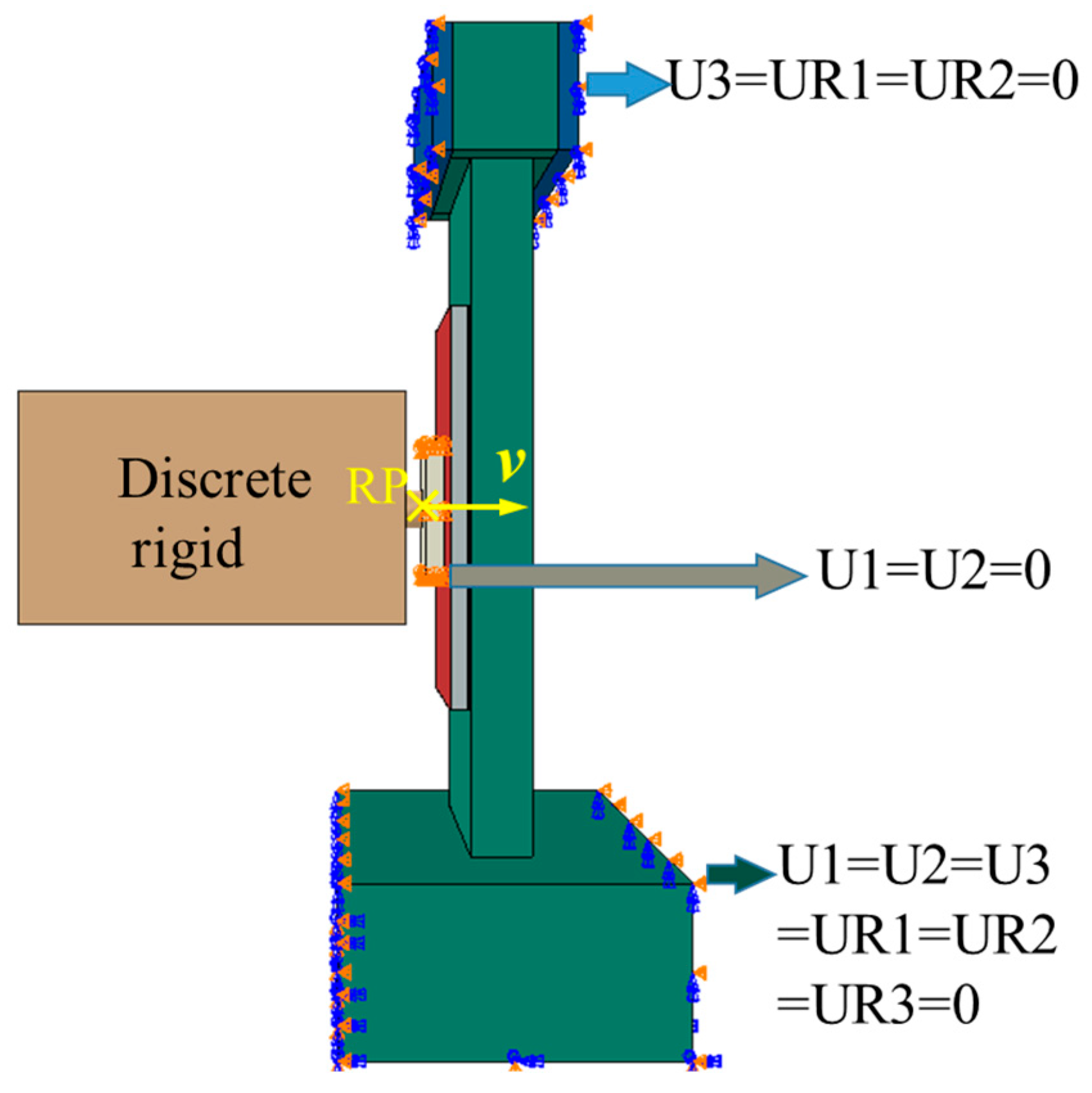

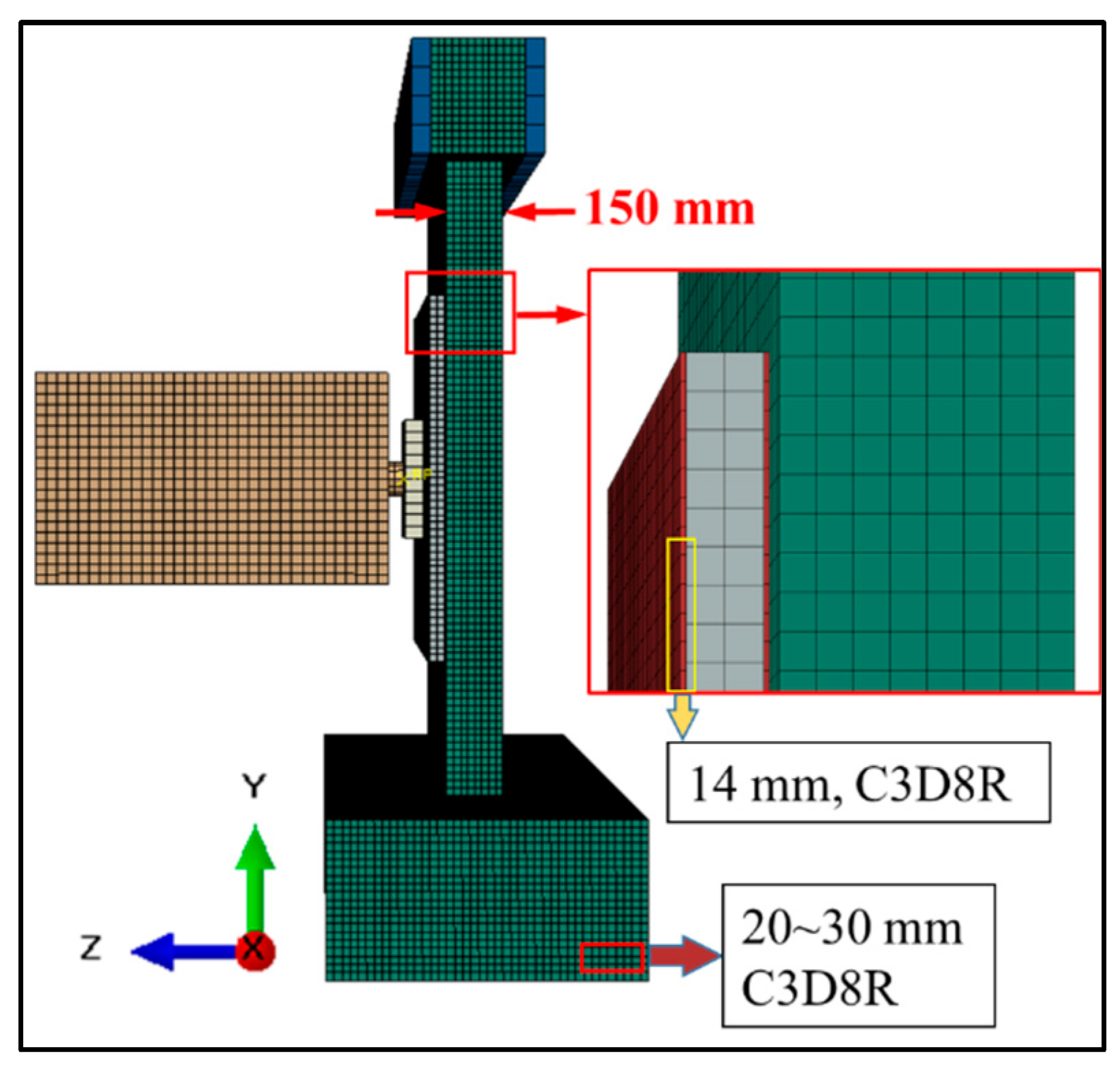

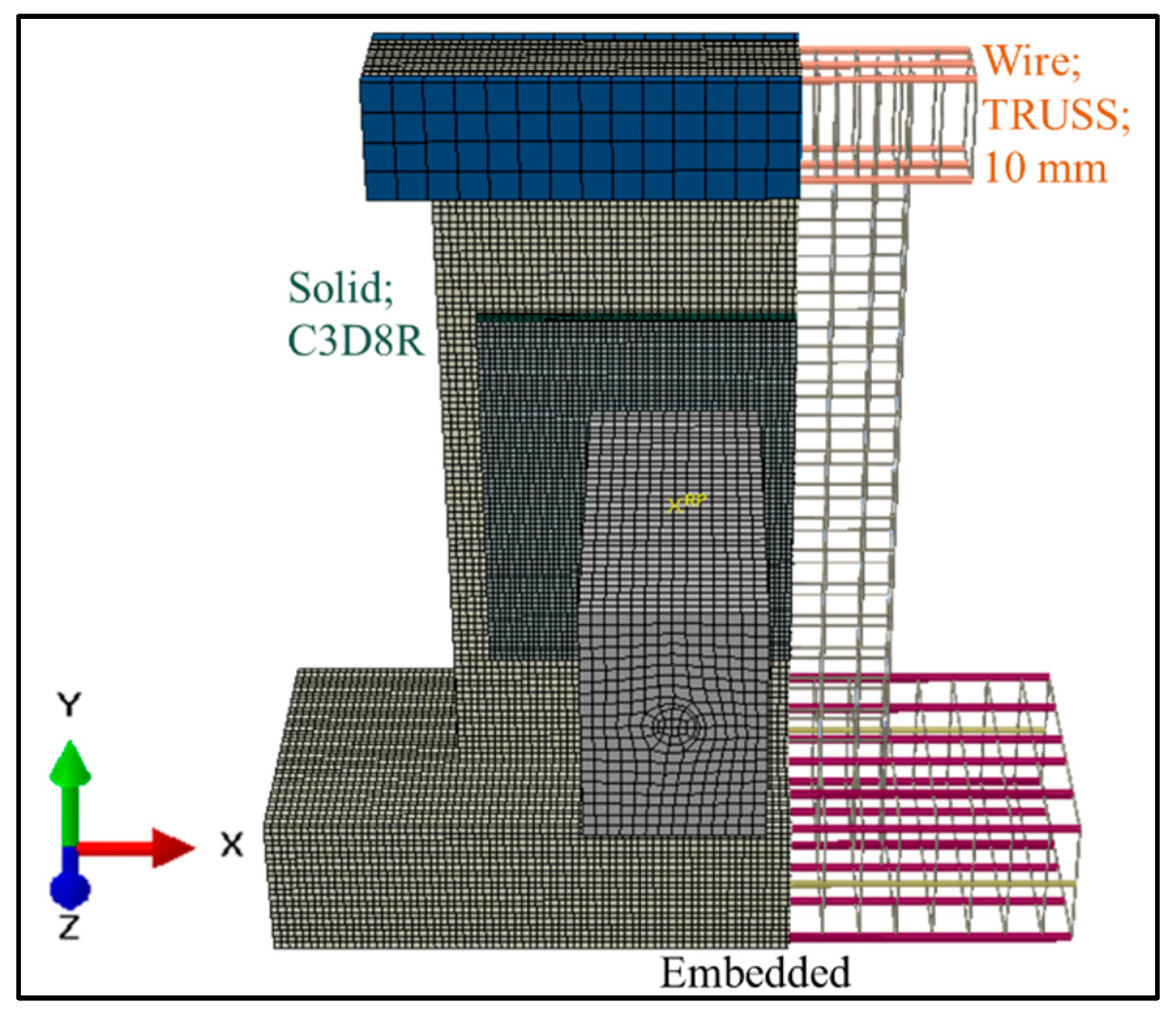

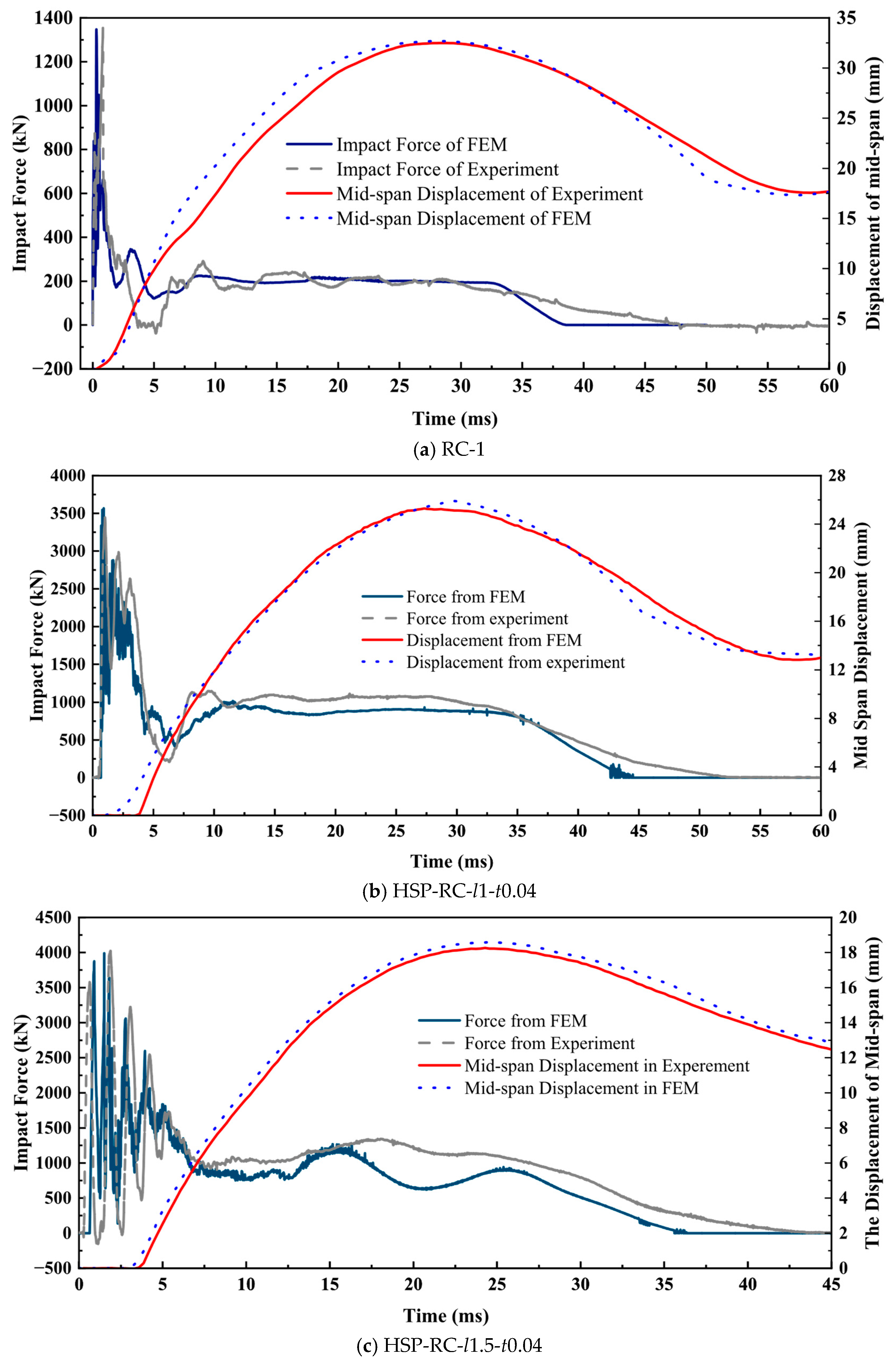

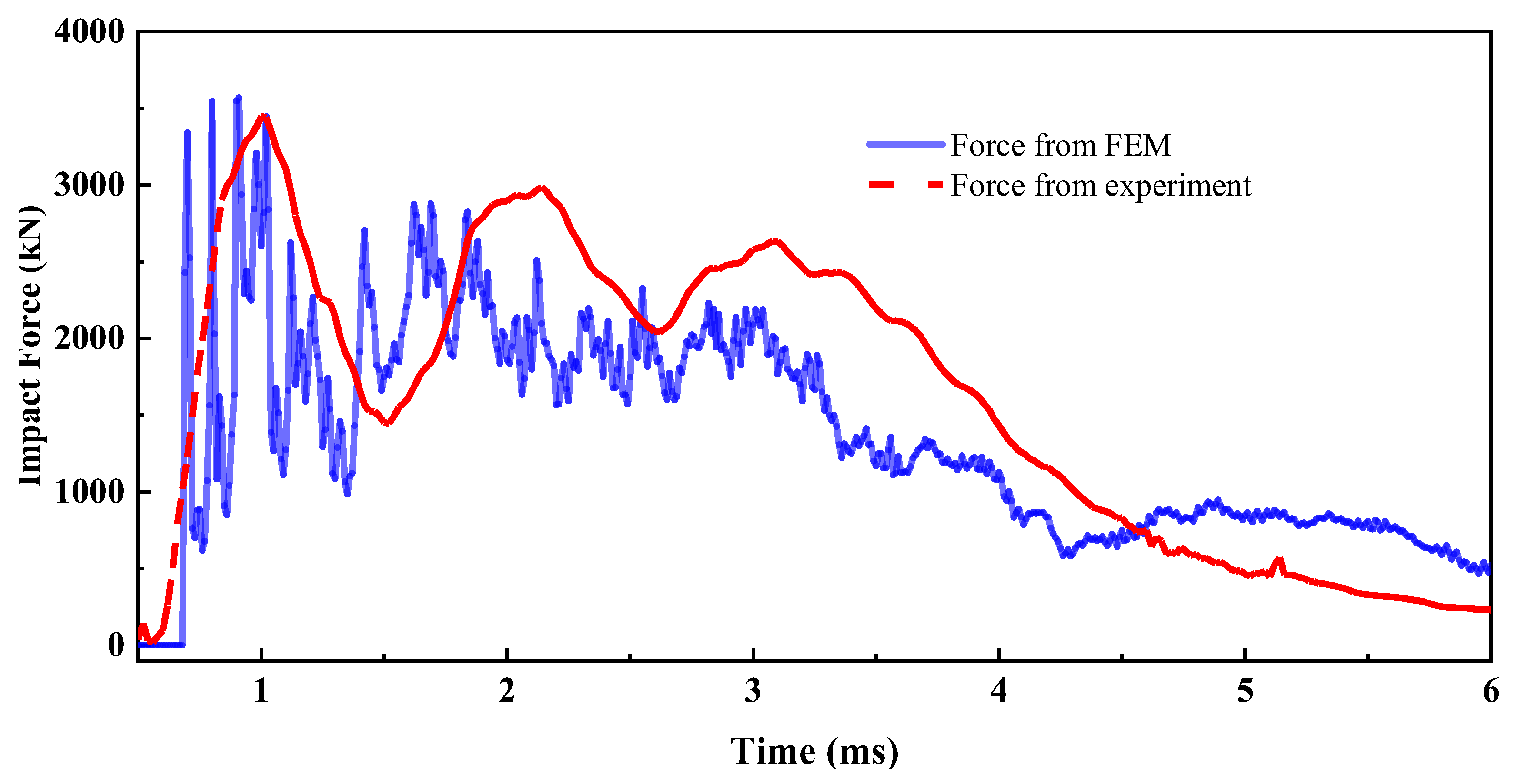

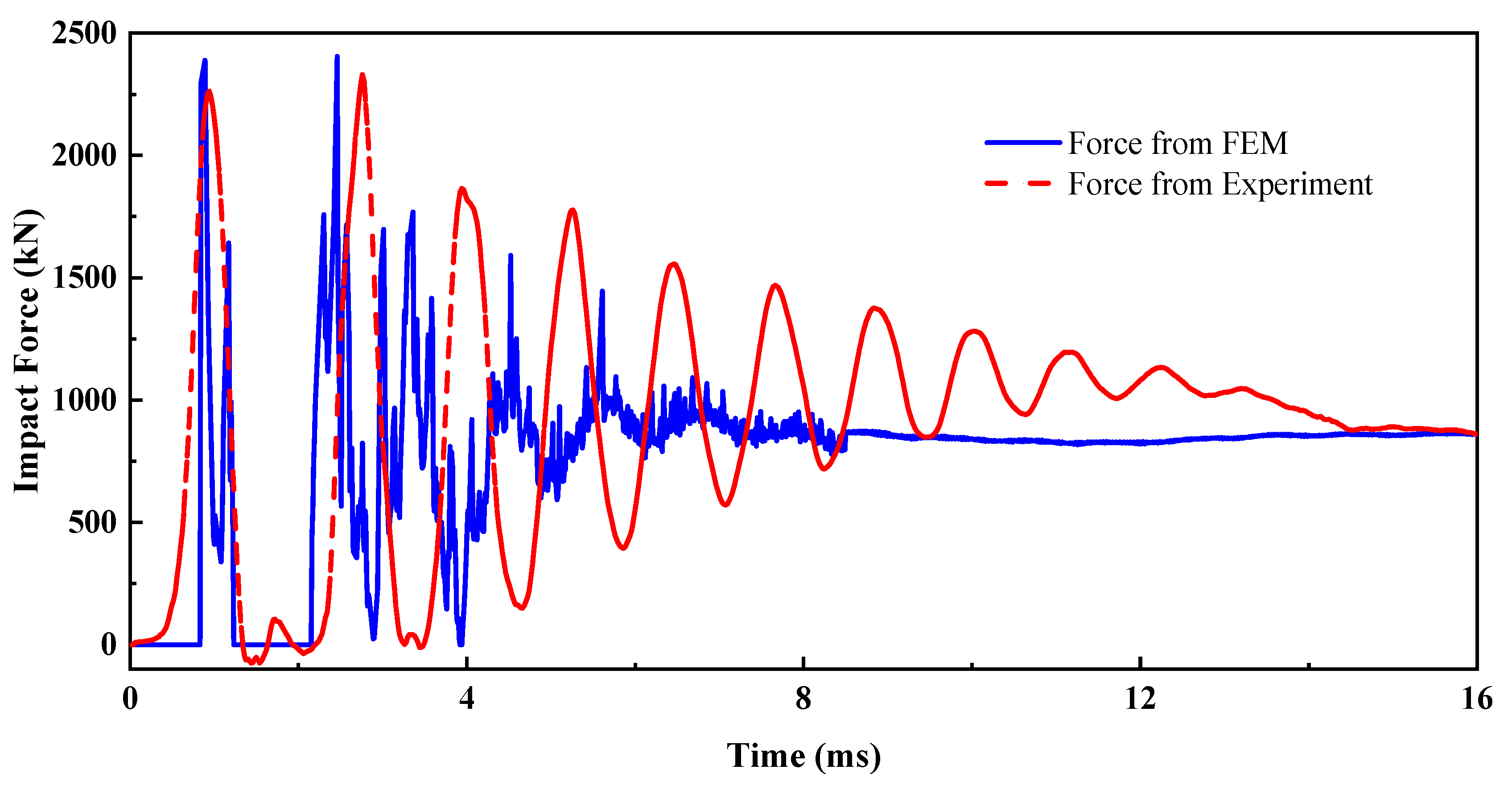

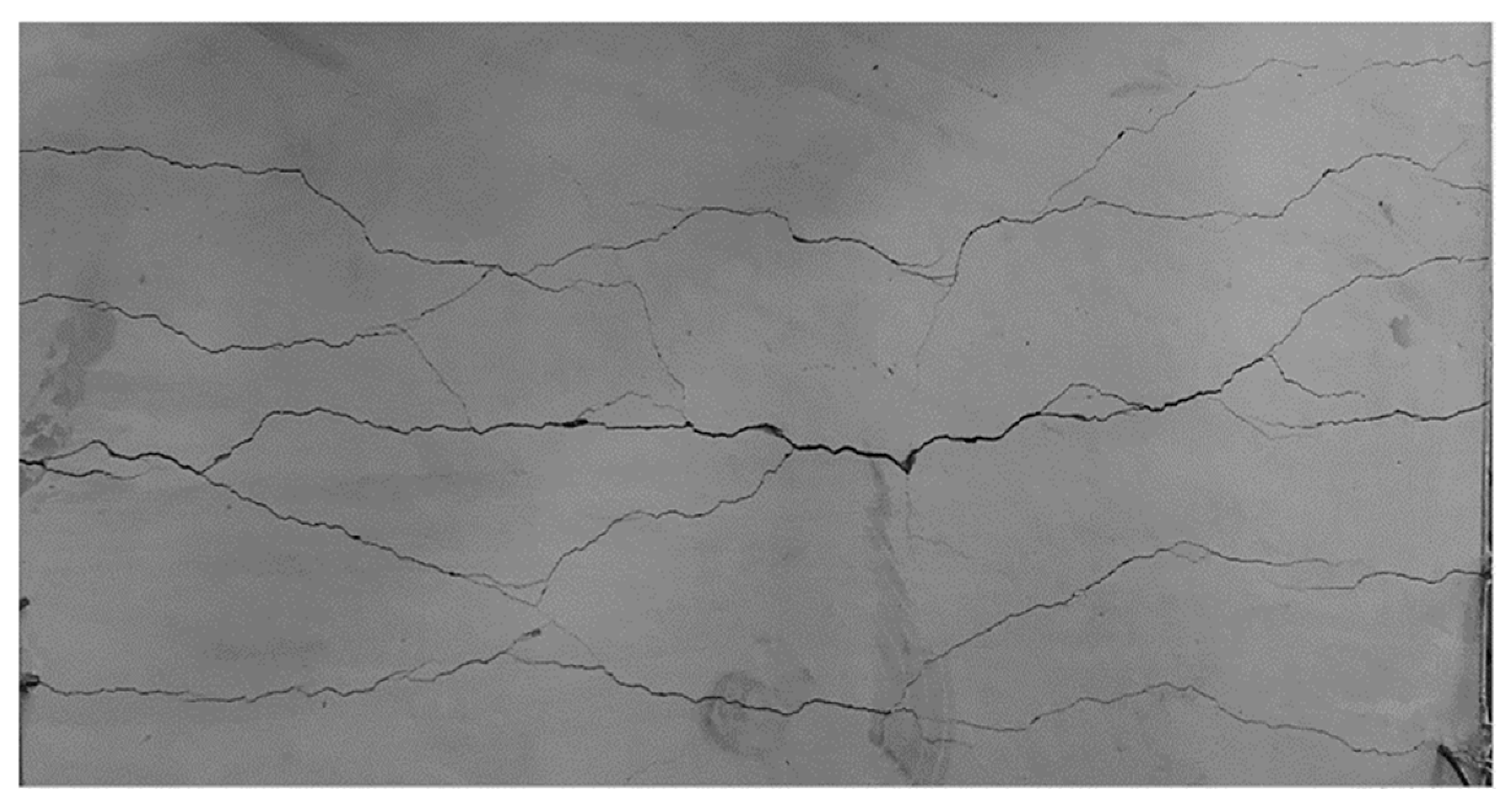

The study of the impact resistance performance of RC slabs mainly relies on two methods: experiments and numerical simulation. The experiments include the drop hammer test, pendulum test, etc. Although experimental research is intuitive and reliable, capturing dynamic responses under extreme conditions is costly, complex, and sometimes challenging. Therefore, numerical simulation techniques have been widely applied. Researchers simulate the impact process by establishing detailed finite element models (FEMs), including concrete, steel bars, reinforcement materials, and impactors, then introducing material constitutive models that consider strain rate effects (such as the KCC model for concrete and the Cowper–Symonds model for steel). After experimental verification, these FEMs can be effectively used for parametric analysis and structural impact dynamic response prediction.

In addition to measures such as improving concrete strength [

2,

3], changing reinforcement materials [

4,

5], and altering rebar arrangement and reinforcement ratio [

6,

7,

8], current research on enhancing the impact resistance of RC slabs mainly focuses on external bonding reinforcement materials such as CFRP [

9], GFRP [

4], steel plates, polyurea [

10,

11], and reinforcing mesh protective layers [

12] to enhance their performance. Among them, CFRP is one of the most essential reinforcement materials studied. Research [

13] has shown that CFRP reinforcement can significantly improve the ballistic ultimate velocity (by 9.4% to 18%) and penetration resistance of RC slabs, reduce the range of front peeling and back collapse, and effectively suppress the scattering of concrete fragments. CFRP reinforcement mainly enhances the structure’s overall integrity, delaying the propagation of cracks and structural failure. Polyurea-coated concrete exhibits a significant strain rate effect. When polyurea is coated on the end face of the concrete specimen, the peak strain increases significantly, and the brittleness improves.

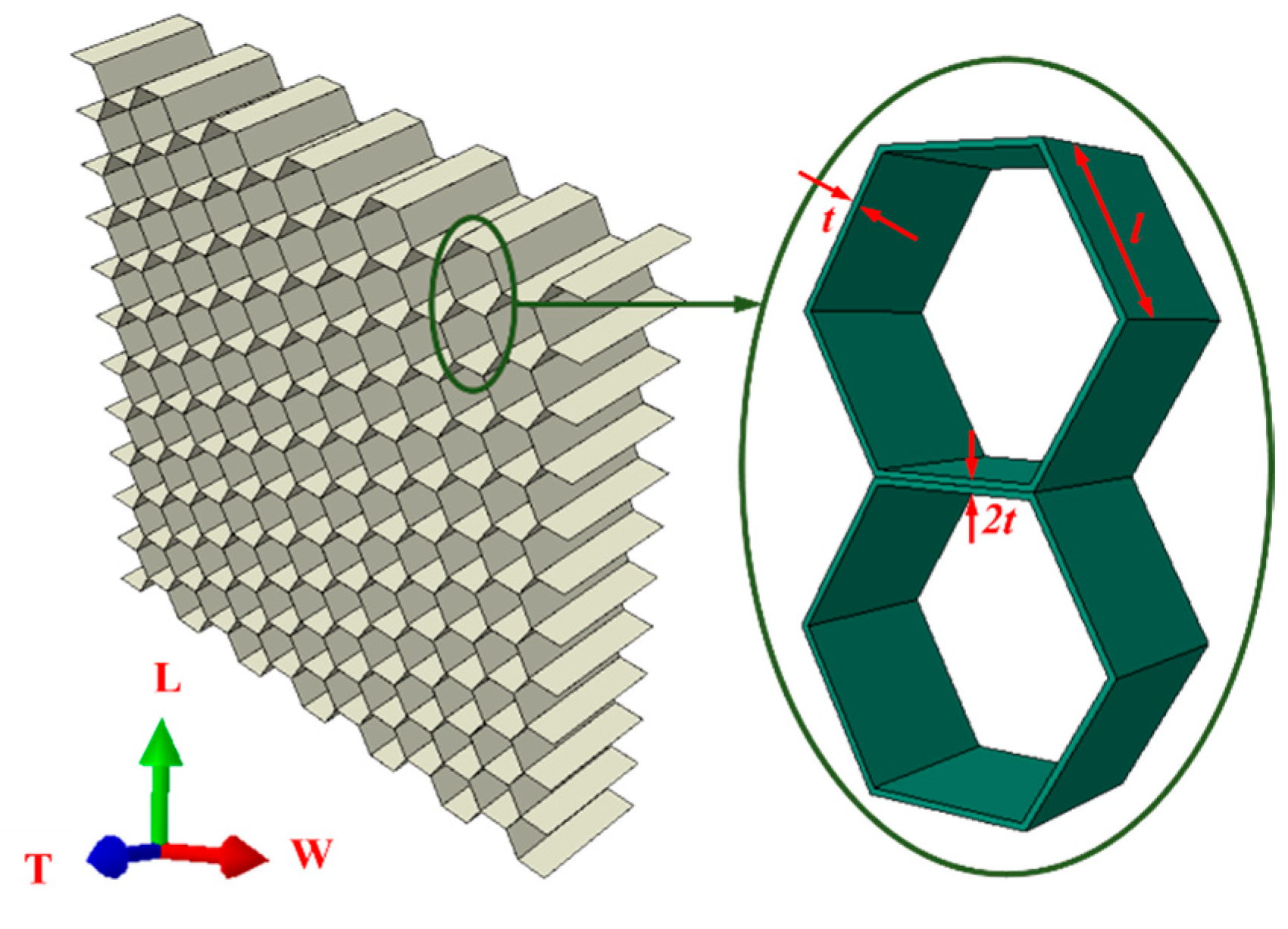

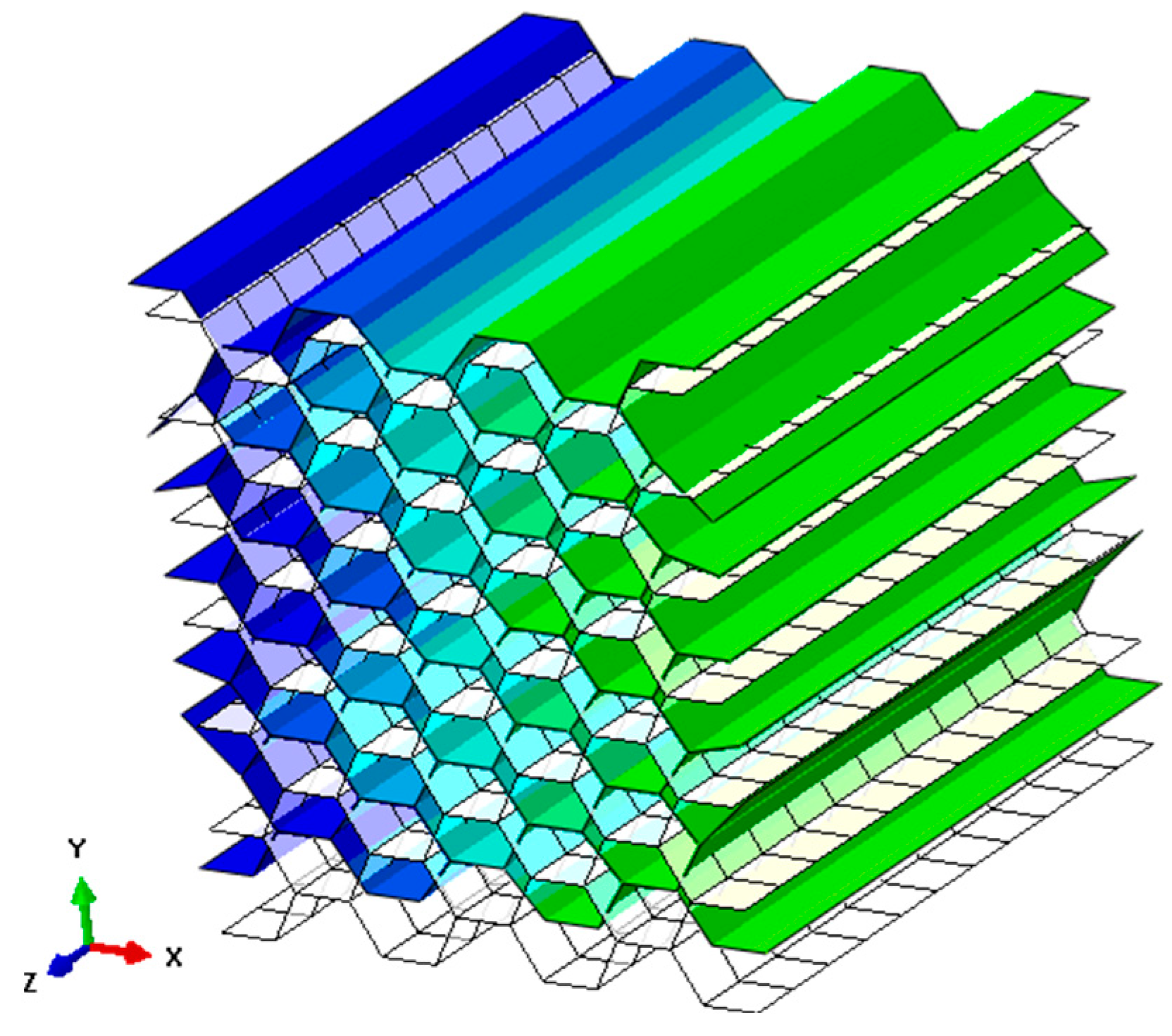

Honeycomb, a thoroughly researched and processed energy-absorbing material, has excellent properties under impact loads [

14,

15,

16]. Honeycomb can absorb energy through plastic deformation, thereby controlling the damage range and reducing the impact energy transfer during an accident. Therefore, the local deformation characteristics of honeycomb composite structures under impact loads can be applied to control the damage range and provide safety protection in civil structures. The earliest applications of classic honeycomb aluminium as an energy-absorbing device and protective material are mostly in aerospace [

17,

18], vehicles, submarine and ship shock wave protection, etc. Research has shown that improving the honeycomb structure [

19,

20], matrix [

21,

22], honeycomb pore cross-section, etc., can enhance its energy absorption efficiency and impact protection capability. For example, Mohammadiha and Beheshti et al. [

19] conducted optimisation analysis on collision avoidance boxes using functional hierarchical honeycomb. Collision avoidance boxes are widely used in the transportation industry between the chassis and bumper of vehicles to reduce the transmission of impact energy to other parts of the car in collision accidents and ensure the safety of different front parts. Galehdari and Khodarahmi [

20] used a hierarchical honeycomb structure as an aircraft seat shock absorber to absorb energy, avoid passenger injuries caused by emergency collisions, and reduce the harm to passengers in accidents.

In civil engineering, the primary use of honeycomb aluminium is not for the impact protection of buildings. The application scenarios of honeycomb sandwich panels alone include being used as exterior walls of buildings, etc. Since 2020, the construction industry’s application of honeycomb beam structures, honeycomb steel beam structures, honeycomb sandwich floor systems, wall panels, and other honeycomb structures has received widespread attention. Generally, honeycomb structures are mainly applied to form composite structural beams with honeycomb and reinforced concrete, while there is little research on the impact of adding honeycomb aluminium as an energy absorption device on the protection of structures.

However, in the research on the impact protection of RC structures, some cover layer materials are consistent with the energy absorption principle of honeycomb sandwich panels. Jin Pan et al. [

21,

22] designed a new U-shaped steel plate composite energy-absorbing device filled with GFRP honeycomb for bridge piers. The energy absorption characteristics of the honeycomb structure were applied to protect the bridge piers under low-speed impact. The protective effect of the honeycomb energy-absorbing device was analysed through experiments and finite element methods, which showed that the protective effect for bridge piers was good. In addition to the mass and velocity of the impact load, the stiffness and contact area of the impact body were important parameters affecting energy absorption. Xu et al. [

23] studied the impact resistance and dynamic response of square regular-strength concrete (R–NSC) and ultra-high-performance concrete (R–UHPC) under the protection of closed-cell foam aluminium using a drop weight test and finite element model. They compared them with columns without a closed-cell foam aluminium protective layer (CCAF). The research results indicate that the CCAF layer can reduce impact force and absorb much impact energy, effectively protecting R-NSC and R-UHPC columns. After the foam aluminium layer is used to protect the RC column, the impact force between the column and the impactor decreases, preventing the rebound and secondary impact phenomenon after the drop hammer impacts the RC column, reducing the deflection of the RC column and effectively improving the safety. Similarly, R-UHPC columns exhibit better impact resistance than R-NSC columns, especially those with CCAF layers, showing the best impact resistance. The author also predicted the dynamic behaviour of foam aluminium in R-NSC and R-UHPC specimens through the finite element model and studied the energy absorption of each part. Song et al. [

24] designed a Metal Hollow Sphere Structure (MHSS) as an energy-absorbing device for bridge piers to provide impact protection under impact loads. Through finite element modelling research, it was found that MHSS can effectively protect bridge piers under vehicle impact.

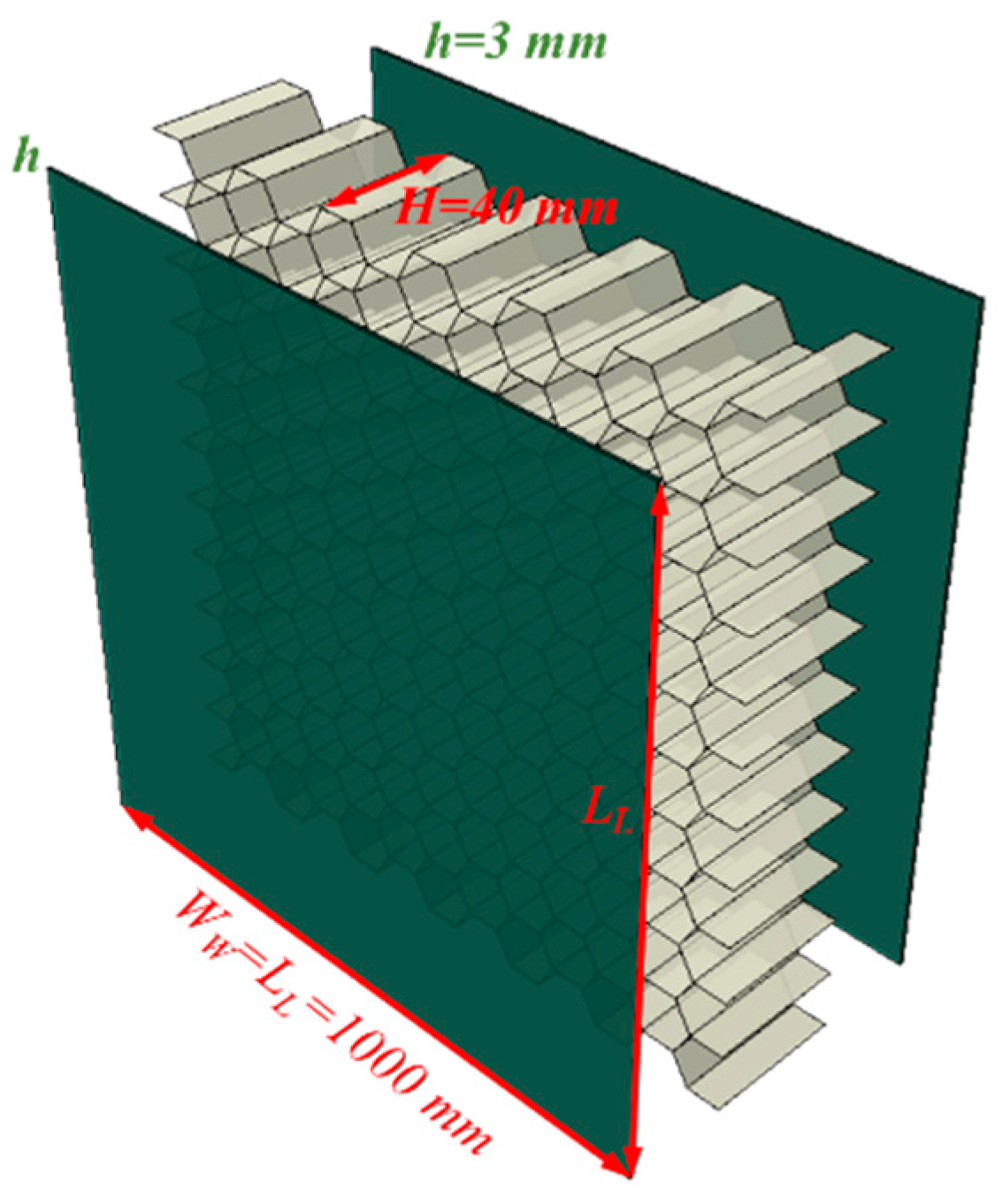

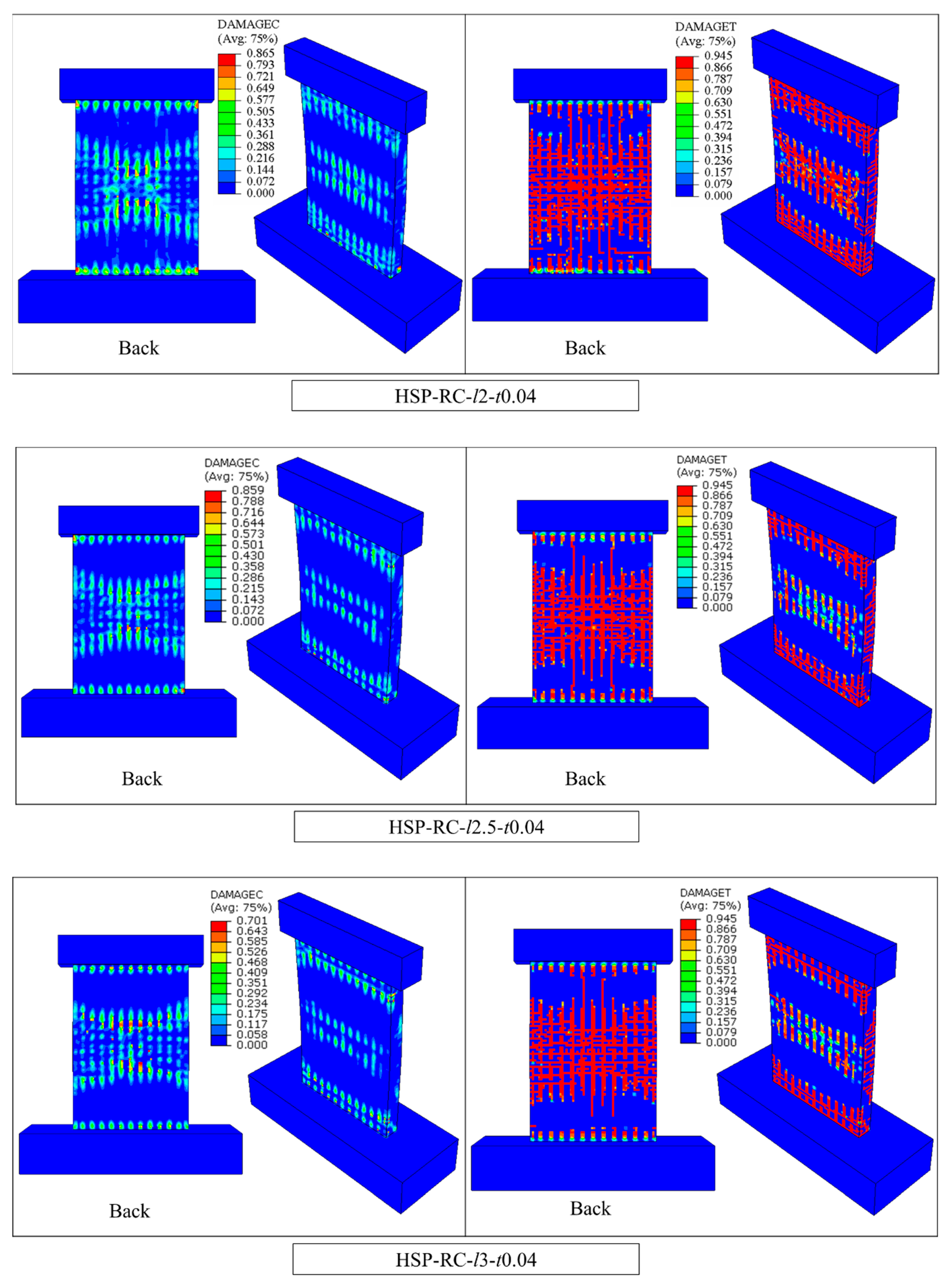

The above impact protection research can verify that honeycomb and other porous materials control the damage range and impact energy transfer during accident impacts through energy absorption. The local deformation characteristics of honeycomb under impact loads can be applied to civil structures for damage range control and safety protection. Based on the advantages of honeycomb sandwich structures and the author’s previous research on the impact resistance of RC walls [

25], as well as the pendulum impact experiments of RC walls under the protection of honeycomb sandwich structures [

26], this paper establishes a finite element model of pendulum impact on HSP-RC walls to study the dynamic behaviour and impact damage of HSP-RC walls, characterise the impact protection performance of honeycomb sandwich panels on RC walls, quantify their protection effect, and lay the foundation for further analysis of the influence of various structural parameters on the impact protection performance of honeycomb sandwich panels in the future.