Multiscale Analysis of Styrene–Butadiene Latex Modified Rubber Concrete

Abstract

1. Introduction

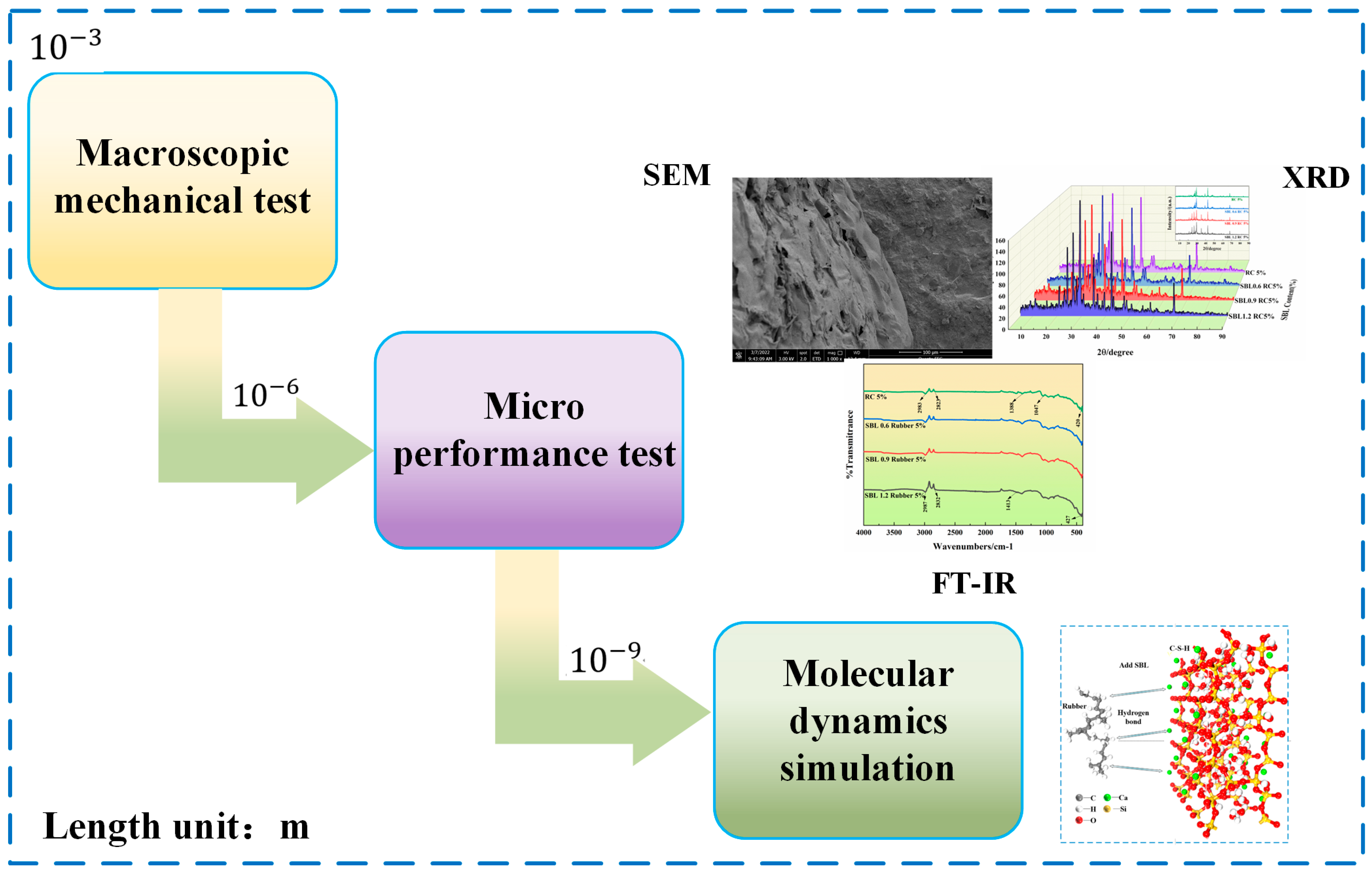

2. Measure

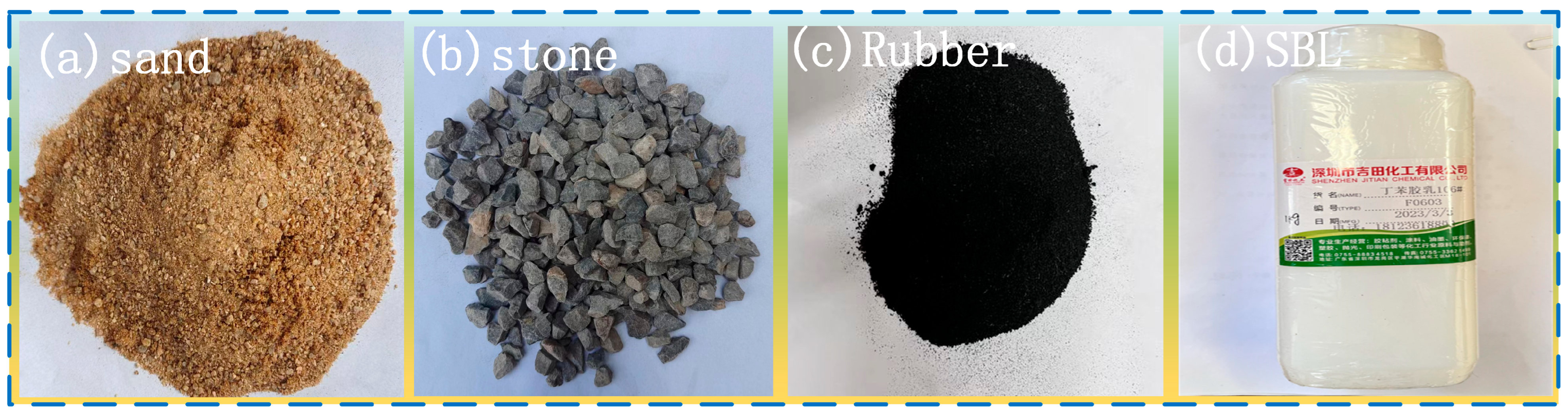

2.1. Primary Materials

2.2. Treatment Method and Mechanism

2.3. Mix Ratio Design

2.4. Specimen Preparation

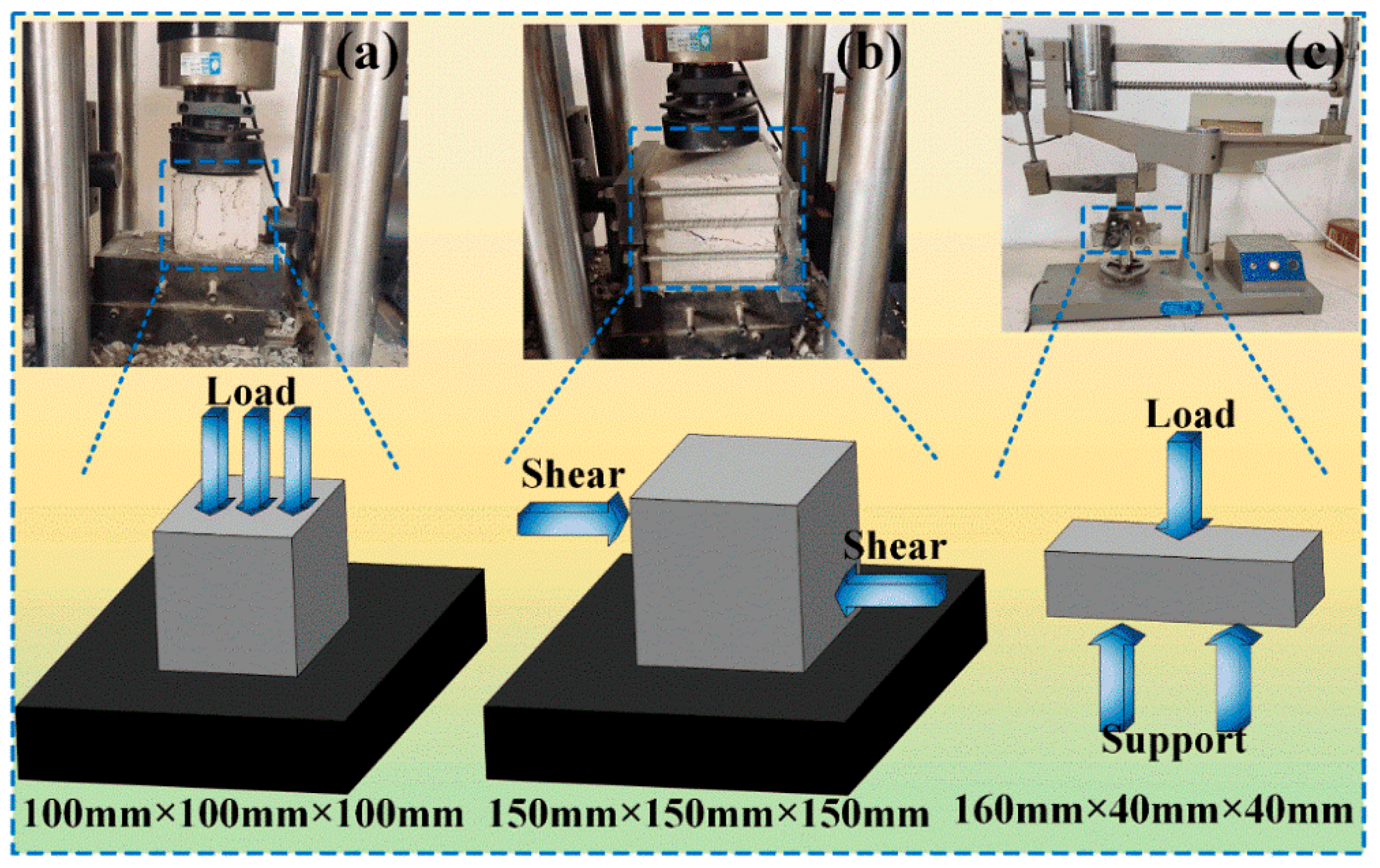

2.5. Mechanical Testing

3. Microanalysis

3.1. Scanning Electron Microscope (SEM)

3.2. X-Ray Diffraction (XRD)

3.3. Fourier Transform Infrared Spectrometer (FT-IR)

4. Molecular Simulation

4.1. Computational Model

4.2. Force Field Simulation Details

5. Results and Discussion

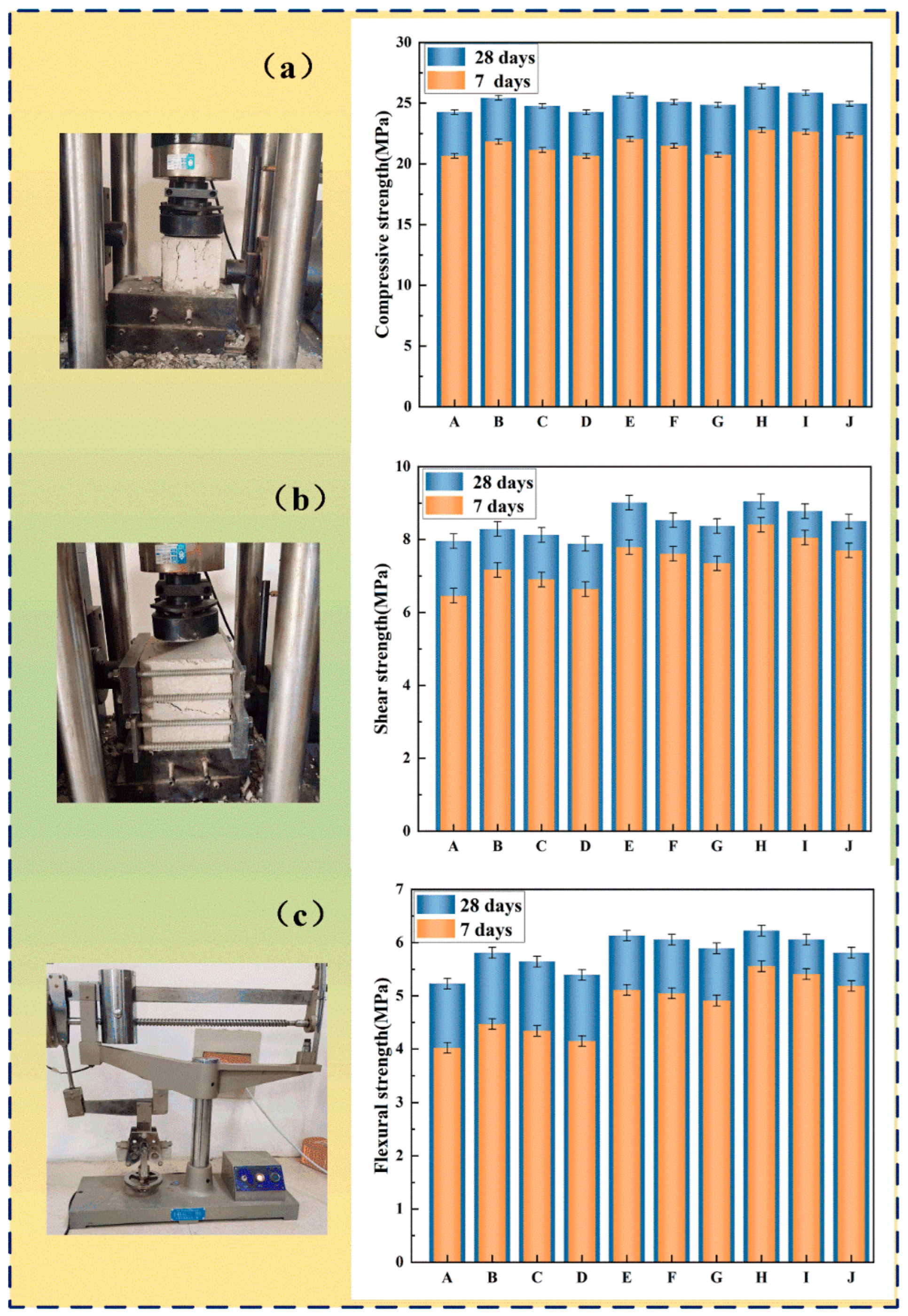

5.1. Mechanical Test Result

5.2. Microscopic Test Result

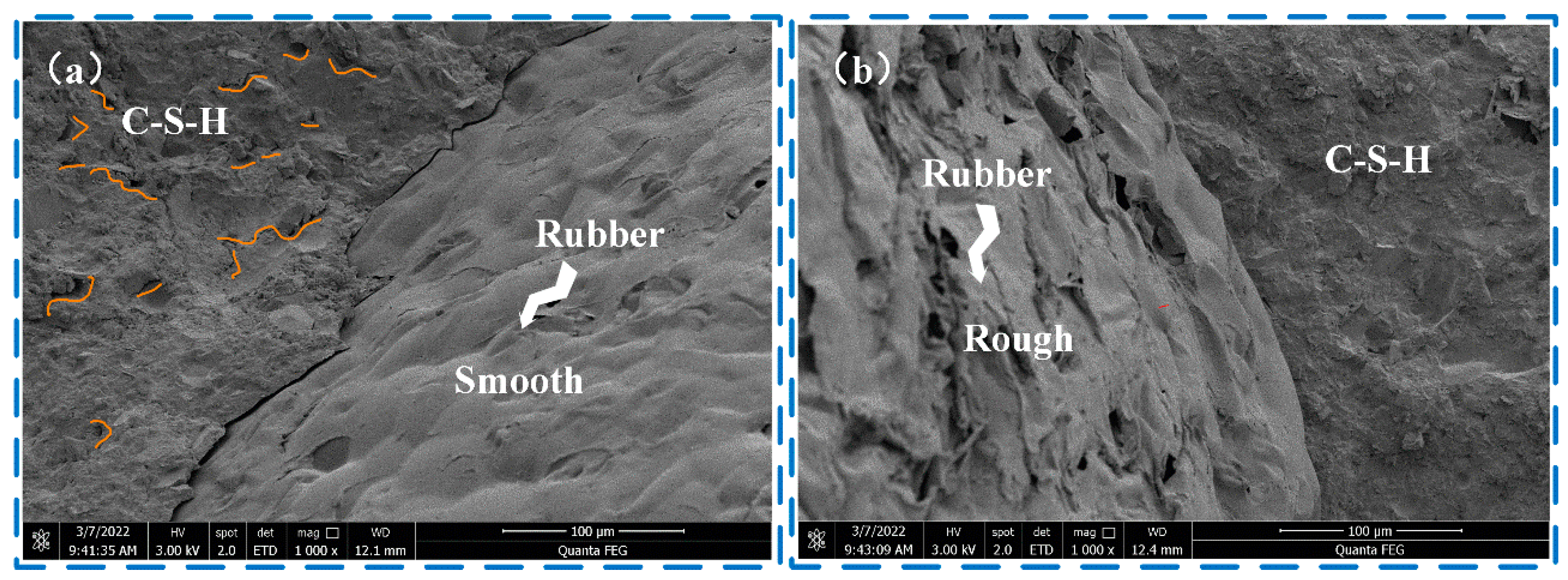

5.2.1. SEM

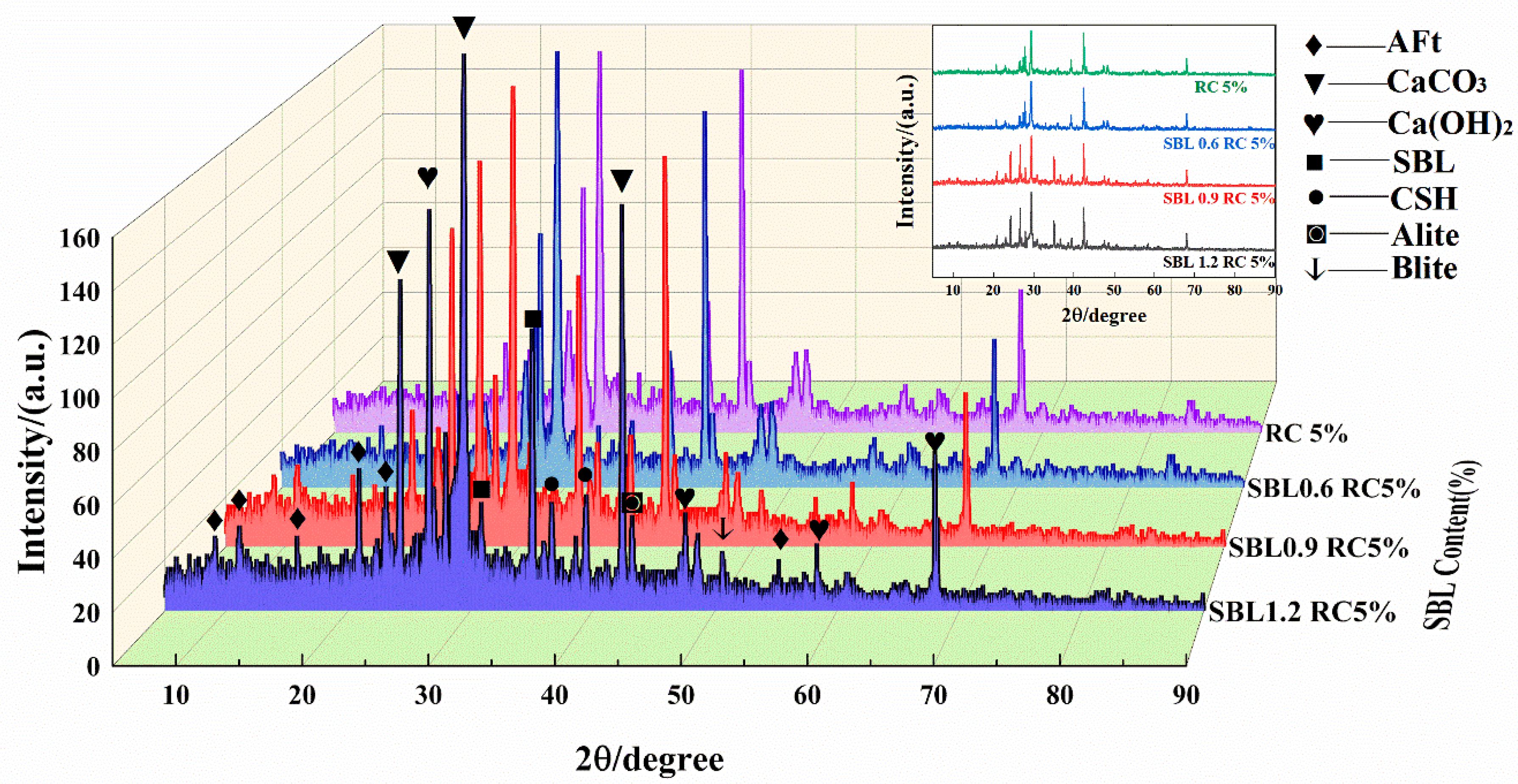

5.2.2. XRD

5.2.3. FT-IR

5.3. Molecular Results

5.3.1. Binding Energy

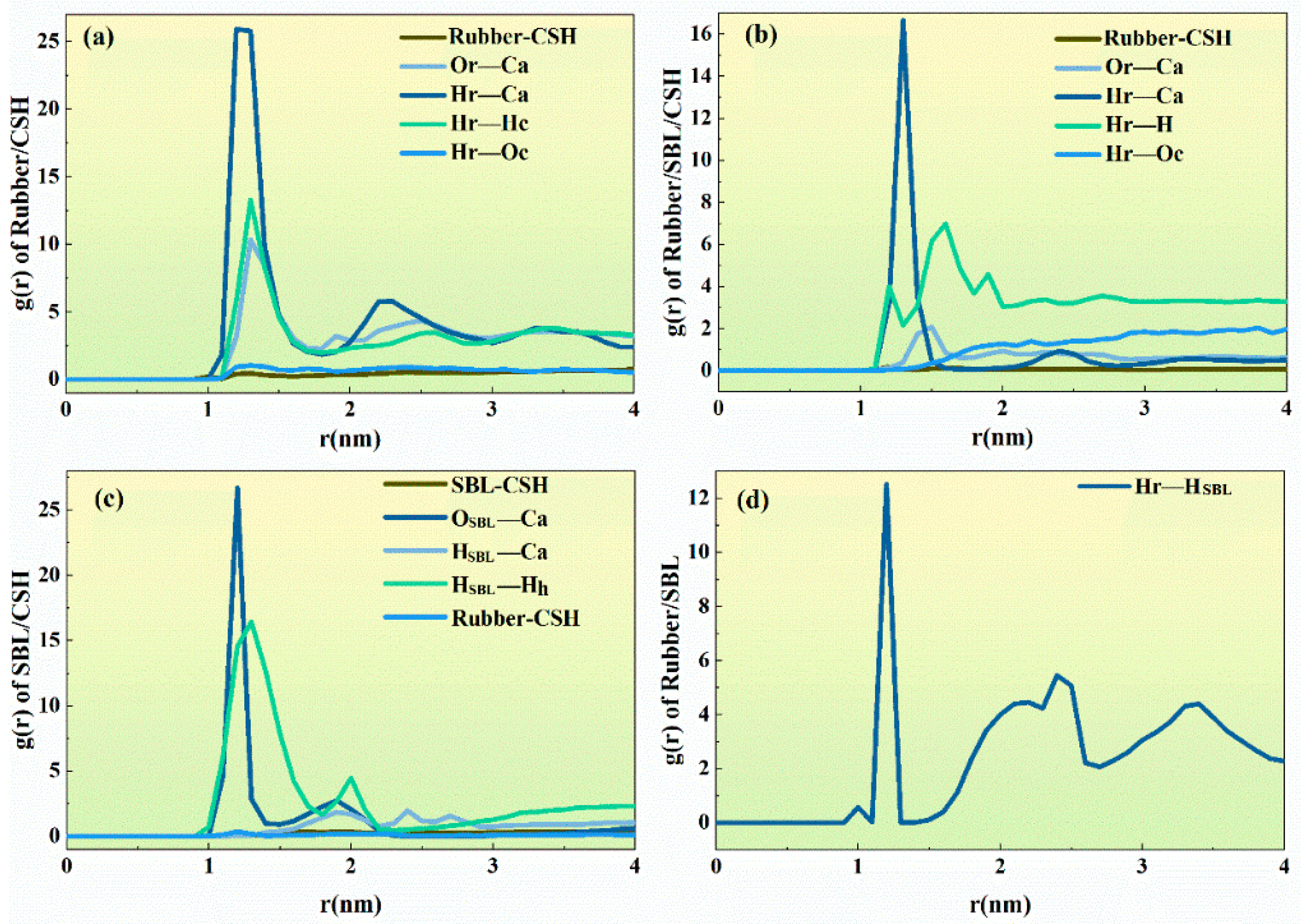

5.3.2. Radial Distribution Function (RDF)

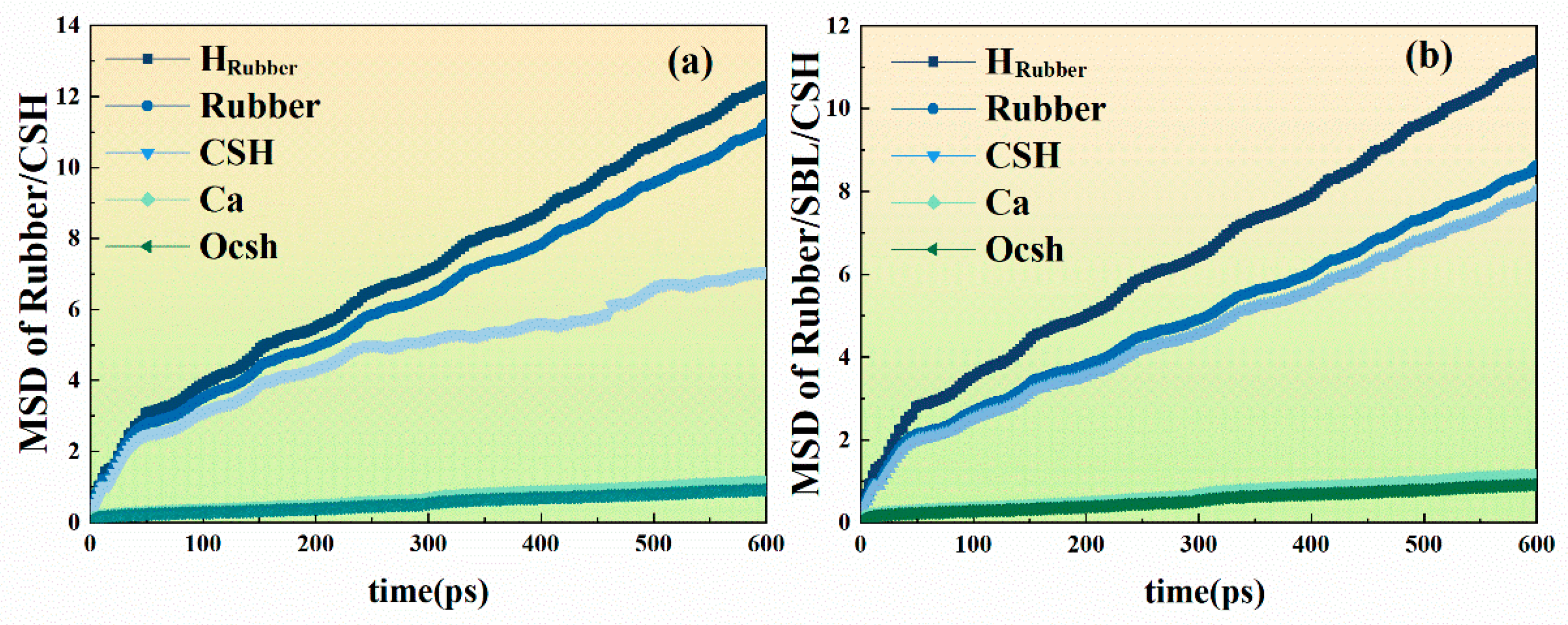

5.3.3. Mean Square Displacement (MSD)

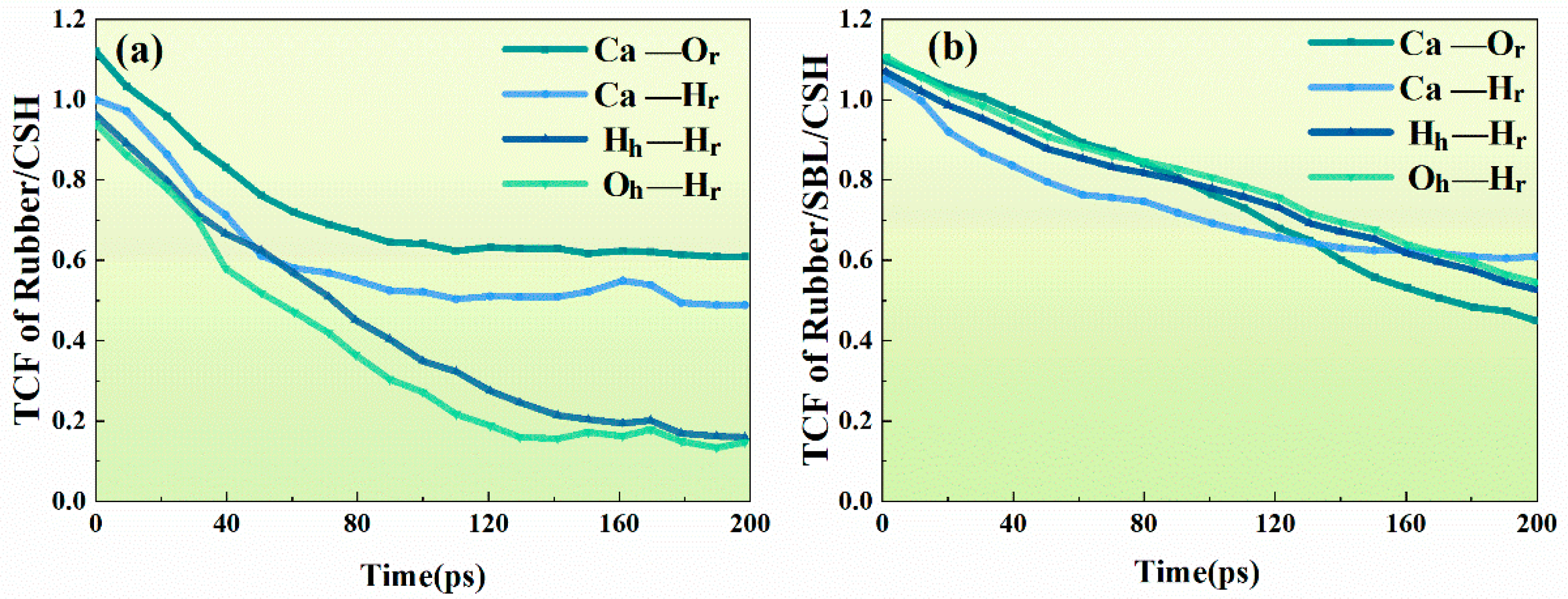

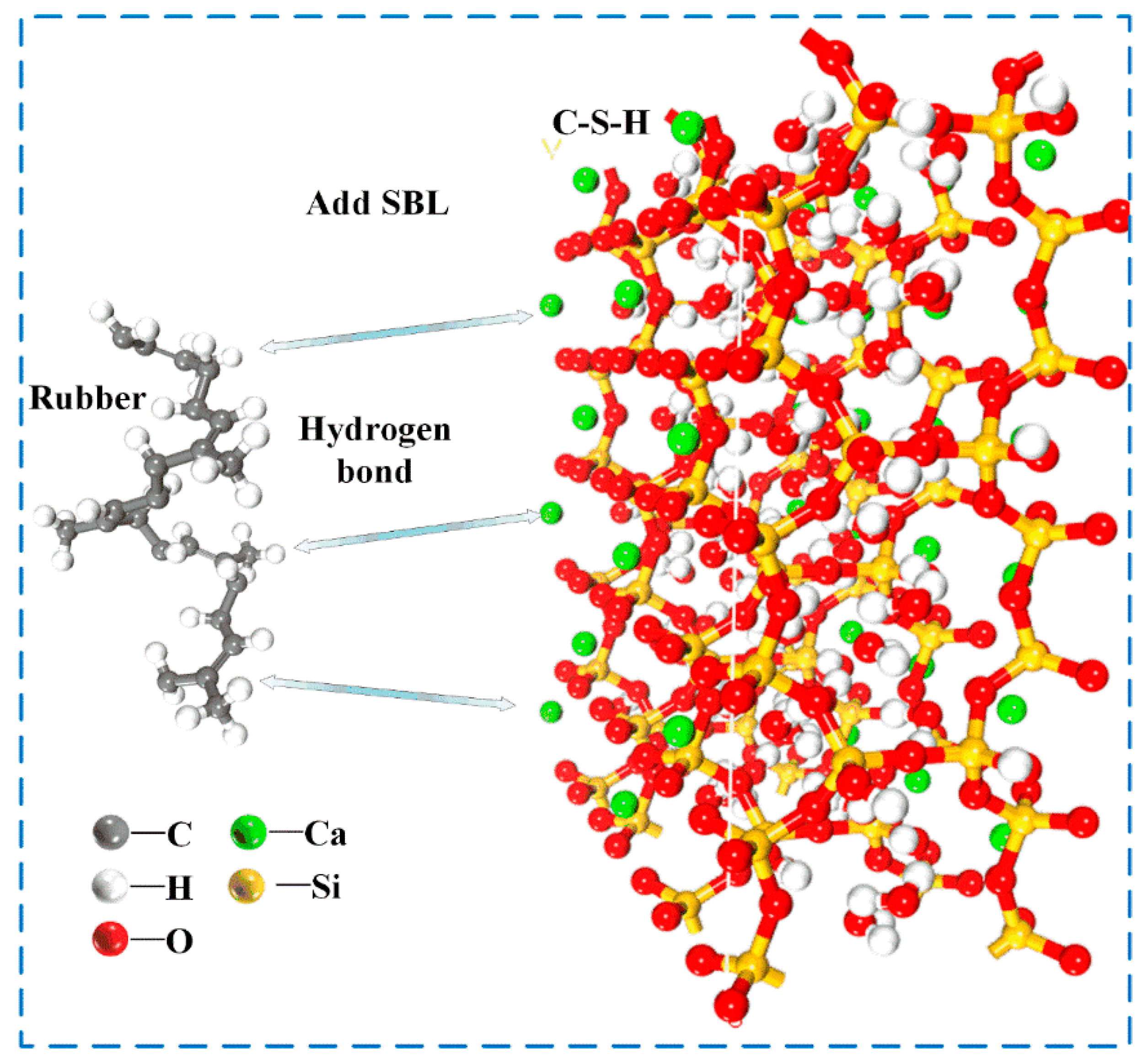

5.3.4. Time Correlation Function (TCF)

6. Multiscale Analysis

6.1. Mechanism for Macroscopic Enhancement

6.2. Mechanism for Microscopic Enhancement

6.3. Mechanism for Nano Enhancement

7. Conclusions

- Macroscopic mechanical tests reveal a significant increase in flexural strength, shear strength, and compressive strength of the composite concrete upon the introduction of SBL and rubber. Specifically, the compressive strength improved by 8.8%, shear strength by 13.7%, and flexural strength by 18.9% at 28 days.

- Based on SEM observations, it is evident that incorporating SBL enhances the density of the cementitious matrix and addresses the inadequate adhesion between rubber and cement, thereby augmenting the cohesion between rubber and concrete and ultimately enhancing the mechanical properties of the concrete.

- XRD and FTIR analyses show that SBL delays cement hydration, increases the quantity of gel, and optimizes the composition of interface cement hydration products, thereby enhancing the overall strength of rubber concrete.

- Molecular dynamics simulations revealed that styrene–butadiene latex promotes the creation of enduring H bonds between rubber’s hydrogen atoms and cement’s calcium ions, effectively linking rubber with the matrix, thereby bolstering interface bonding strength.

- Multiscale analysis shows that SBL significantly enhances rubber concrete’s performance and compactness, promoting high durability and performance. However, molecular dynamics currently only analyzes surface interactions and cannot accurately assess the impact of different parameters.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mei, J.; Xu, G.; Ahmad, W.; Khan, K.; Amin, M.N.; Aslam, F.; Alaskar, A. Promoting sustainable materials using recycled rubber in concrete: A review. J. Clean. Prod. 2022, 373, 133927. [Google Scholar] [CrossRef]

- Garcia-Troncoso, N.; Acosta-Calderon, S.; Flores-Rada, J.; Baykara, H.; Cornejo, M.H.; Riofrio, A.; Vargas-Moreno, K. Effects of Recycled Rubber Particles Incorporated as Partial Sand Replacement on Fresh and Hardened Properties of Cement-Based Concrete: Mechanical, Microstructural and Life Cycle Analyses. Materials 2022, 16, 63. [Google Scholar] [CrossRef]

- Ehsan, M.; Mahdi, K. Recycling of landfill waste tyre in construction materials: Durability of concrete made with chipped rubber. Constr. Build. Mater. 2023, 409, 134114. [Google Scholar] [CrossRef]

- Pei, X.; Huang, X.; Li, H.; Cao, Z.; Yang, Z.; Hao, D.; Min, K.; Li, W.; Liu, C.; Wang, S.; et al. Numerical Simulation of Fatigue Life of Rubber Concrete on the Mesoscale. Polymers 2023, 15, 2048. [Google Scholar] [CrossRef]

- Xu, Y.; Wang, J.; Zhang, P.; Guo, J.; Hu, S. Enhanced effect and mechanism of colloidal nano-SiO2 modified rubber concrete. Constr. Build. Mater. 2023, 378, 131203. [Google Scholar] [CrossRef]

- Liu, K.; Liu, H.X.; Liu, B.B.; Liu, Y.N. Mechanical performance and carbonation resistance of basalt fiber—Polypropylene fiber rubber concrete. Front. Mater. 2023, 10, 1229629. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, W.; Wang, S.; Niu, Z.; Li, L. Multi-scale analysis of mechanical properties of KH-560 coupling agent modified PVA fiber-rubber concrete. Compos. Interfaces 2023, 30, 983–1010. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, X.; Huang, Q.; Shiau, J.; Liang, J.; Zhang, B.; Zheng, J.; Fahimizadeh, M.; Sabri, M.M. Effects of particle size on properties of engineering muck-based geopolymers: Optimization through sieving treatment. Constr. Build. Mater. 2025, 492, 142967. [Google Scholar] [CrossRef]

- Muslum, M.M. Experimental behavior of injected geopolymer grout using styrene-butadiene latex for the repair and strengthening of masonry walls. Adv. Struct. Eng. 2021, 24, 2484–2499. [Google Scholar] [CrossRef]

- Xiong, Z.; Tang, Z.; He, S.; Fang, Z.; Chen, Z.; Liu, F.; Li, L. Analysis of mechanical properties of rubberised mortar and influence of styrene–butadiene latex on interfacial behaviour of rubber–cement matrix. Constr. Build. Mater. 2021, 300, 124027. [Google Scholar] [CrossRef]

- Khaleel, B.A.; Abed, J.M.; Abed, H.S. Enhancement of bonding efficiency between overlay and substrate concrete using styrene-butadiene rubber latex and different surface roughness methods. Eng. Appl. Sci. Res. 2021, 48, 33–39. [Google Scholar]

- Dong, F.; Mingkai, Z.; Deyong, J.; Qing, L. Investigation on the relationship between flexural strength, flexural toughness and impact toughness of styrene–butadiene rubber latex-modified cement concrete. Mater. Res. Innov. 2015, 19, S8-849–S8-854. [Google Scholar] [CrossRef]

- Aviral, S.; Sumit, S. Recent advances in experimental and molecular dynamics study of graphene-oxide/natural rubber composites: A review. J. Reinf. Plast. Compos. 2023, 42, 110–130. [Google Scholar]

- Li, L.; Wang, W.; Xu, Z.; Niu, Z.; Li, X.; Wang, Q. Mechanical Property Test and Finite Element Simulation Analysis of KH-560 Coupling Agent-Modified PVA Rubber Concrete. Geofluids 2022, 2022, 2839755. [Google Scholar] [CrossRef]

- Zhang, N.; Mao, Z.; Sun, Q.; Luo, Y.; Zhang, P.; Wang, Q.; Yang, R.; Zhang, M.; Wang, D. The influence of polymer powder on the ion transportation and antierosion mechanism of cement mortar: From experiments to molecular dynamics simulation. Constr. Build. Mater. 2023, 409, 134171. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, Q.; Xu, W.; Han, Z.; Luo, Q.; Chen, G.; Yuan, J.; Zhang, Q.; Sabri, S.M.M. Study on the interaction between pile and soil under lateral load in coral sand. Geomech. Energy Environ. 2025, 42, 100674. [Google Scholar] [CrossRef]

- Maria da Silva, F.; Batista, L.S.; Gachet, L.A.; Lintz, R.C. The Effect of Tire-Rubber Pretreatment on the Physical–Mechanical Properties and Durability of High-Performance Concrete. J. Mater. Civ. Eng. 2022, 34, 04022354. [Google Scholar] [CrossRef]

- Youssf, O.; Swilam, A.; Tahwia, A.M. Performance of crumb rubber concrete made with high contents of heat pre-treated rubber and magnetized water. J. Mater. Res. Technol. 2023, 23, 2160–2176. [Google Scholar] [CrossRef]

- Shahzad, K.; Zhao, Z. Experimental study of NaOH pretreated crumb rubber as substitute of fine aggregate in concrete. Constr. Build. Mater. 2022, 358, 129448. [Google Scholar] [CrossRef]

- Jia, Y. Discussion on the revision significance of JGJ55-2011 “Ordinary Concrete Mix Design Regulations”. New Build. Mater. 2013, 40, 27–30. [Google Scholar]

- Yuan, B.; Liang, J.; Huang, X.; Huang, Q.; Zhang, B.; Yang, G.; Wang, Y.; Yuan, J.; Wang, H. Eco-efficient recycling of engineering muck for manufacturing low-carbon geopolymers assessed through LCA: Exploring the impact of synthesis conditions on performance. Acta Geotech. 2024, 20240915. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, Q.; Li, L.; Ma, Y.; Li, X. Multiscale analysis of silane coupling agent modified rubber-fiber concrete interfaces. Mater. Today Commun. 2023, 35, 105960. [Google Scholar] [CrossRef]

- Wang, X.; Xie, W.; Ren, J.; Zhu, J.; Li, L.-Y.; Xing, F. Interfacial Binding Energy between Calcium-Silicate-Hydrates and Epoxy Resin: A Molecular Dynamics Study. Polymers 2021, 13, 1683. [Google Scholar] [CrossRef]

- Kim, G.; Im, S.; Jee, H.; Suh, H.; Cho, S.; Kanematsu, M.; Morooka, S.; Koyama, T.; Nishio, Y.; Machida, A.; et al. Effect of magnesium silicate hydrate (M-S-H) formation on the local atomic arrangements and mechanical properties of calcium silicate hydrate (C-S-H): In situ X-ray scattering study. Cem. Concr. Res. 2022, 159, 106869. [Google Scholar] [CrossRef]

- Tavakoli, D.; Tarighat, A. Molecular dynamics study on the mechanical properties of Portland cement clinker phases. Comput. Mater. Sci. 2016, 119, 65–73. [Google Scholar] [CrossRef]

- Alkhateb, H.; Al-Ostaz, A.; Cheng, A.H.-D.; Li, X. Materials Genome for Graphene-Cement Nanocomposites. J. Nanomechanics Micromechanics 2013, 3, 67–77. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, X.; Li, R.; Luo, Q.; Shiau, J.; Wang, Y.; Yuan, J.; Sabri, S.M.M.; Huang, S.; Liao, C. Dynamic behavior and deformation of calcareous sand under cyclic loading. Soil Dyn. Earthq. Eng. 2025, 199, 109730. [Google Scholar] [CrossRef]

- Feng, Y.; Qin, D.; Zhao, C.; Li, Y. Multiscale Enhancement Mechanisms of EVA on EPS-Cement Composites. J. Mater. Civ. Eng. 2023, 35, 04023102. [Google Scholar] [CrossRef]

- Li, F.; Yang, Y.; Tao, M.; Li, X. A cement paste-tail sealant interface modified with a silane coupling agent for enhancing waterproofing performance in a concrete lining system. RSC Adv. 2019, 9, 7165–7175. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Cao, J. Interfacial heat transfer behavior of graphene-based filler and calcium-silicate-hydrate in cement composites. Int. J. Heat Mass Transf. 2021, 176, 121165. [Google Scholar] [CrossRef]

- Yu, C.; Hu, K.; Yang, Q.; Wang, D.; Zhang, W.; Chen, G.; Kapyelata, C. Analysis of the Storage Stability Property of Carbon Nanotube/Recycled Polyethylene-Modified Asphalt Using Molecular Dynamics Simulations. Polymers 2021, 13, 1658. [Google Scholar] [CrossRef]

- Feng, Y.; Li, Y.; Zhao, C.; Qin, D.; Wang, C.; Wang, P. Nano-CaCO3 enhances PVA fiber-matrix interfacial properties: An experimental and molecular dynamics study. Mol. Simul. 2022, 48, 1378–1392. [Google Scholar]

- Yu, C.; Hu, K.; Yang, Q.; Chen, Y. Multi–scale observation of oxidative aging on the enhancement of high–temperature property of SBS–modified asphalt. Constr. Build. Mater. 2021, 313, 125478. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Diffusion and interaction mechanism of rejuvenating agent with virgin and recycled asphalt binder: A molecular dynamics study. Mol. Simul. 2018, 44, 1433–1443. [Google Scholar] [CrossRef]

- Zhao, C.; Li, L.; Li, X.; Chen, W.; Li, Y. Multi-scale analysis of the synergistic strengthening effect of silane coupling agent on PVA and cement interface. Front. Mater. 2023, 10, 1276785. [Google Scholar] [CrossRef]

- Lu, Z.; Yu, J.; Yao, J.; Hou, D. Experimental and molecular modeling of polyethylene fiber/cement interface strengthened by graphene oxide. Cem. Concr. Compos. 2020, 112, 103676. [Google Scholar] [CrossRef]

- Wang, W.; Feng, Y.; Li, X. EVA/KH560 synergistically modified recycled concrete mechanical properties—Experiment and molecular dynamics simulations. J. Mol. Graph. Model. 2024, 126, 108641. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Wang, W.; Wang, S. PVA fiber/cement-based interface in silane coupler KH560 reinforced high performance concrete—Experimental and molecular dynamics study. Constr. Build. Mater. 2023, 395, 132184. [Google Scholar] [CrossRef]

- Feng, Y.; Qin, D.; Zhao, C. The synergistic strengthening effect of silane coupling agent on the interface between PVA/EPS and cement: Experiment and molecular simulation. Compos. Interfaces 2023, 30, 21–41. [Google Scholar] [CrossRef]

- Yuan, B.; Liang, J.; Zhang, B.; Chen, W.; Huang, X.; Huang, Q.; Li, Y.; Yuan, P. Optimized reinforcement of granite residual soil using a cement and alkaline solution: A coupling effect. J. Rock Mech. Geotech. Eng. 2025, 17, 509–523. [Google Scholar] [CrossRef]

| Rubber Type | Dimension (mm) | Mesh Number (Mesh) | Density (g/cm3) |

|---|---|---|---|

| particles | 0.4–0.6 | 40 | 1.93 |

| Type | Solids Content/% | PH | Stickiness (25 °C) /(mPa-s) Vitrification | Temperature/°C | Styrene Mass fraction/% |

|---|---|---|---|---|---|

| White liquid | 49 | 8 | 190 | −25–20 | 64 |

| Test Number | Materials | Admixtures | |||||

|---|---|---|---|---|---|---|---|

| Cement | Water | Coarse Aggregate | Fine Aggregate | Styrene–Butadiene Latex % | Rubber% | Water Reducer | |

| A | 375 | 150 | 1164 | 572 | 0 | 5 | 0.01 |

| B | 375 | 150 | 1164 | 572 | 0.6 | 5 | 0.01 |

| C | 375 | 150 | 1164 | 534 | 0.6 | 10 | 0.01 |

| D | 375 | 150 | 1164 | 504 | 0.6 | 15 | 0.01 |

| E | 375 | 150 | 1164 | 572 | 0.9 | 5 | 0.01 |

| F | 375 | 150 | 1164 | 534 | 0.9 | 10 | 0.01 |

| G | 375 | 150 | 1164 | 504 | 0.9 | 15 | 0.01 |

| H | 375 | 150 | 1164 | 572 | 1.2 | 5 | 0.01 |

| I | 375 | 150 | 1164 | 534 | 1.2 | 10 | 0.01 |

| J | 375 | 150 | 1164 | 504 | 1.2 | 15 | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Feng, Y.; Feng, J. Multiscale Analysis of Styrene–Butadiene Latex Modified Rubber Concrete. Buildings 2025, 15, 3881. https://doi.org/10.3390/buildings15213881

Wang W, Feng Y, Feng J. Multiscale Analysis of Styrene–Butadiene Latex Modified Rubber Concrete. Buildings. 2025; 15(21):3881. https://doi.org/10.3390/buildings15213881

Chicago/Turabian StyleWang, Weiming, Yong Feng, and Jingjie Feng. 2025. "Multiscale Analysis of Styrene–Butadiene Latex Modified Rubber Concrete" Buildings 15, no. 21: 3881. https://doi.org/10.3390/buildings15213881

APA StyleWang, W., Feng, Y., & Feng, J. (2025). Multiscale Analysis of Styrene–Butadiene Latex Modified Rubber Concrete. Buildings, 15(21), 3881. https://doi.org/10.3390/buildings15213881