Seismic Performance of Corroded RC Bridge Piers Strengthened with UHPC Shells

Abstract

1. Introduction

2. Corrosion and Material Properties

2.1. The Starting Time of the Corrosion

2.2. Deterioration of Steel Bars

2.3. Deterioration of Concrete

2.4. Material Properties of UHPC

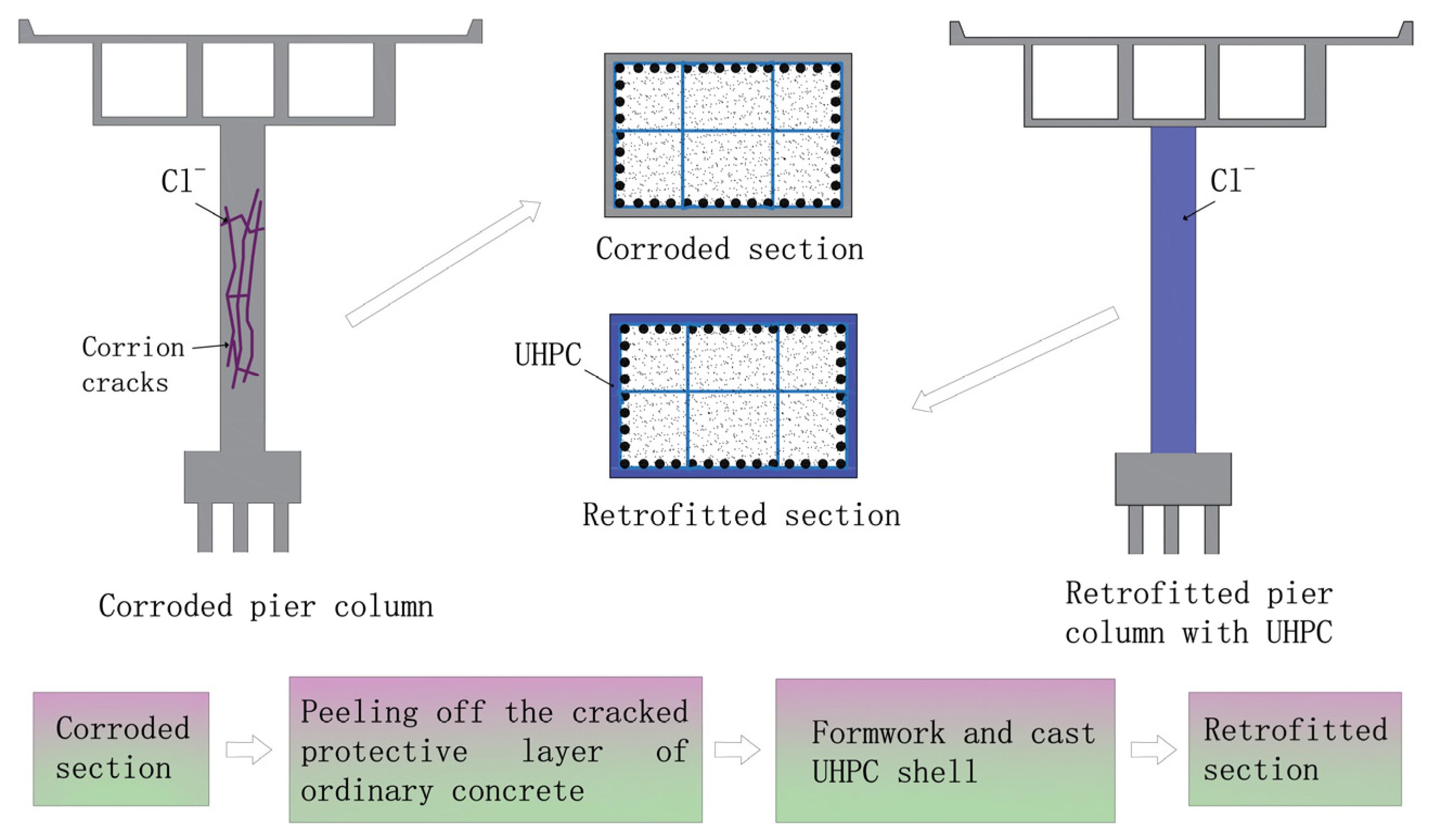

3. Illustrative Example of a Corroded Bridge Pier Retrofitted with a UHPC Shell

3.1. Description of the Bridge Pier

3.2. Numerical Model of the Bridge Pier Under Cyclic Loading

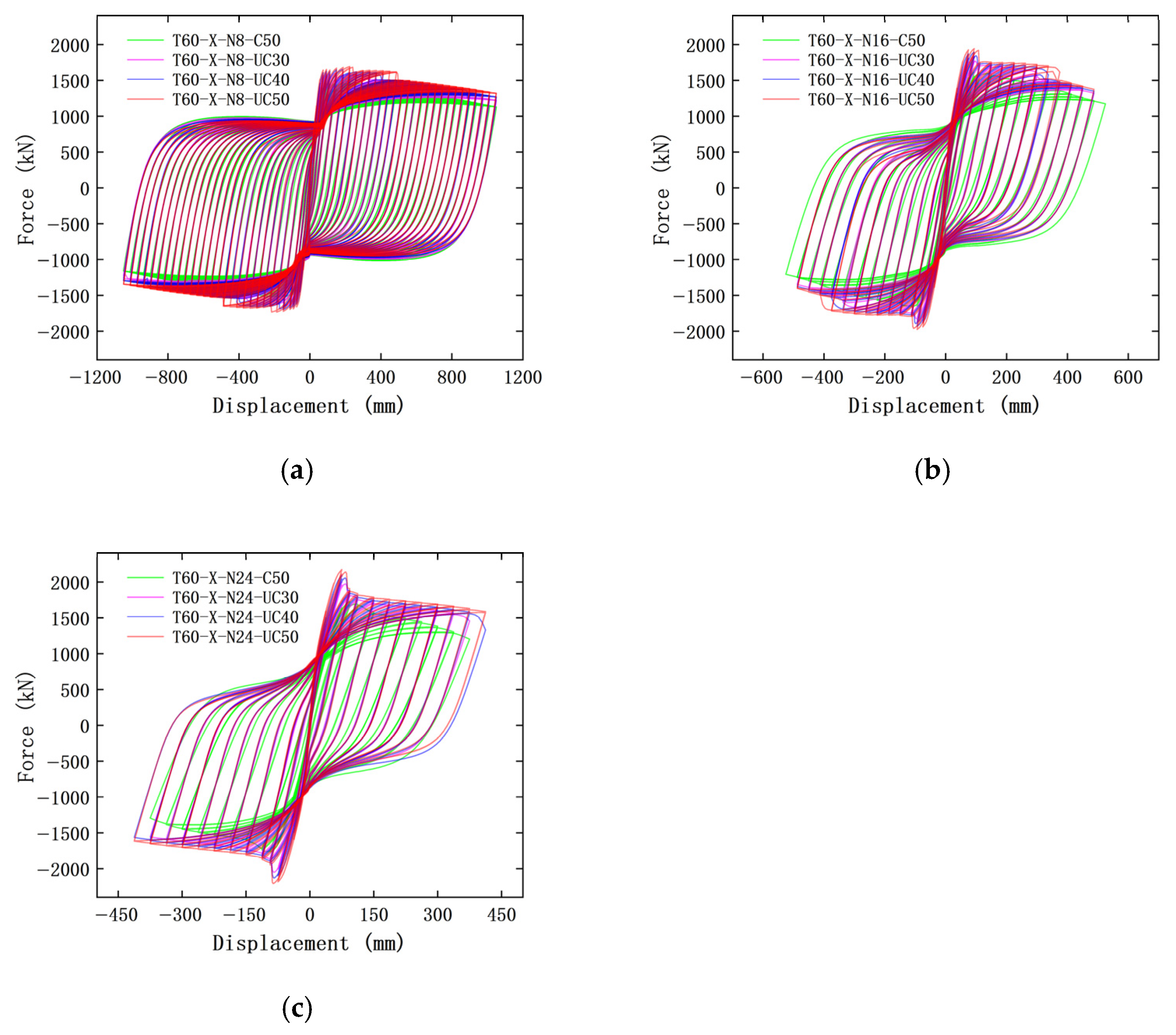

3.3. Hysteresis Curves

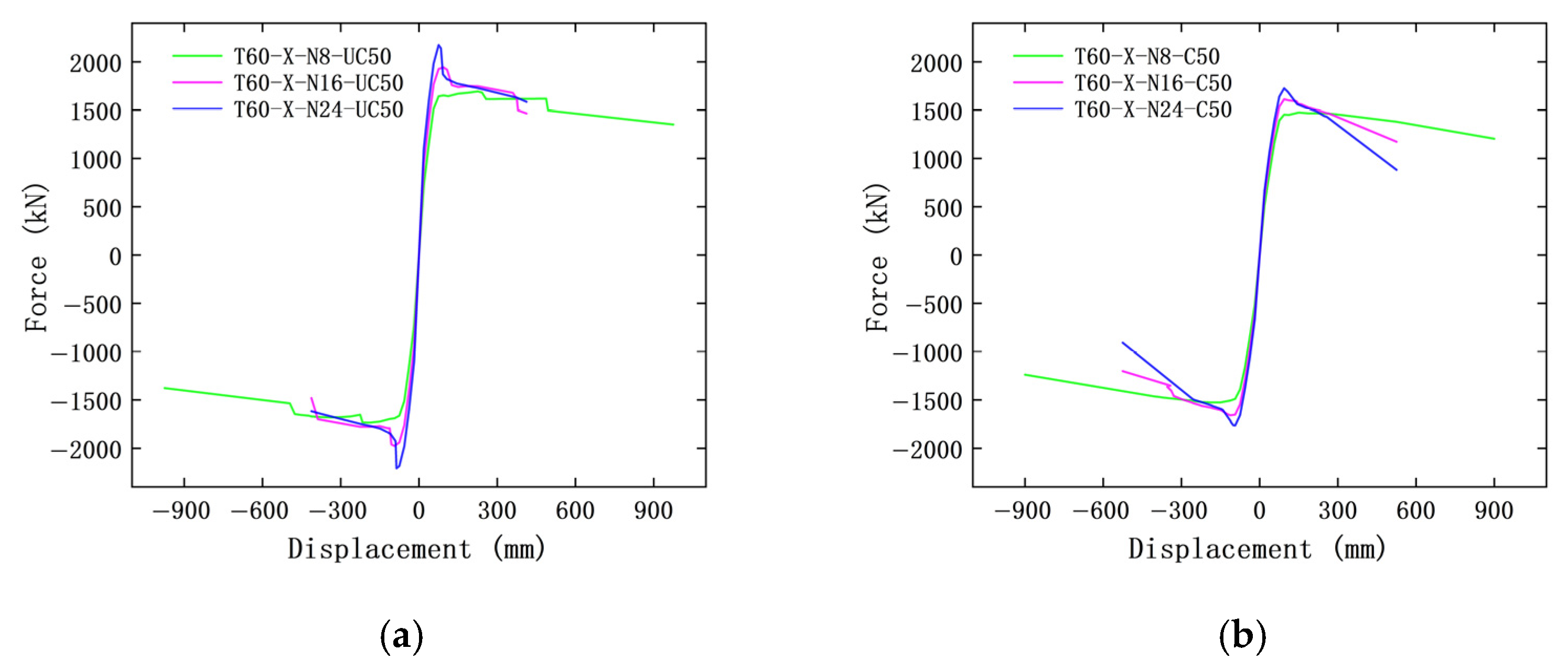

3.4. Strength and Deformation Capacity

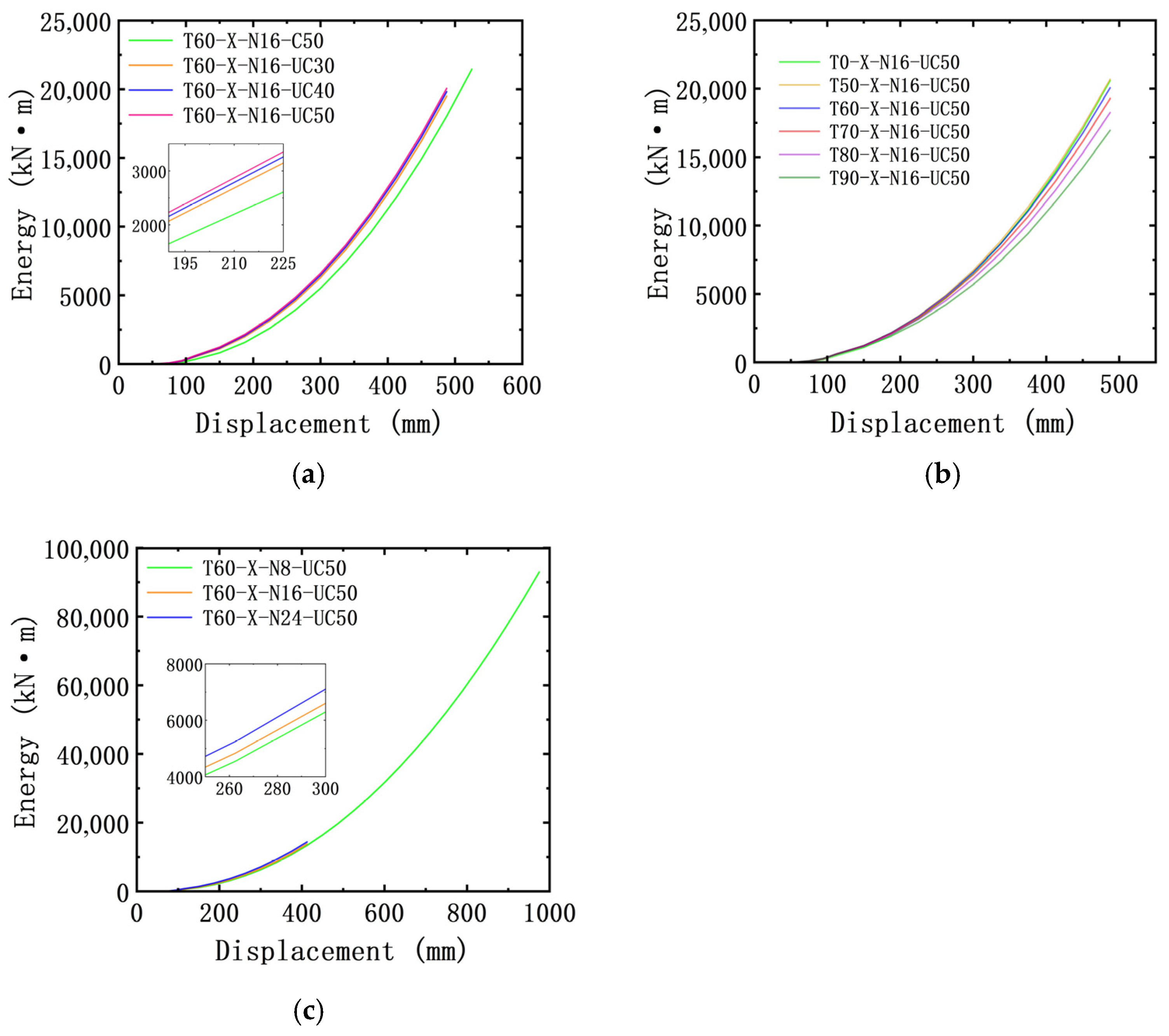

3.5. Energy Dissipation Capacity

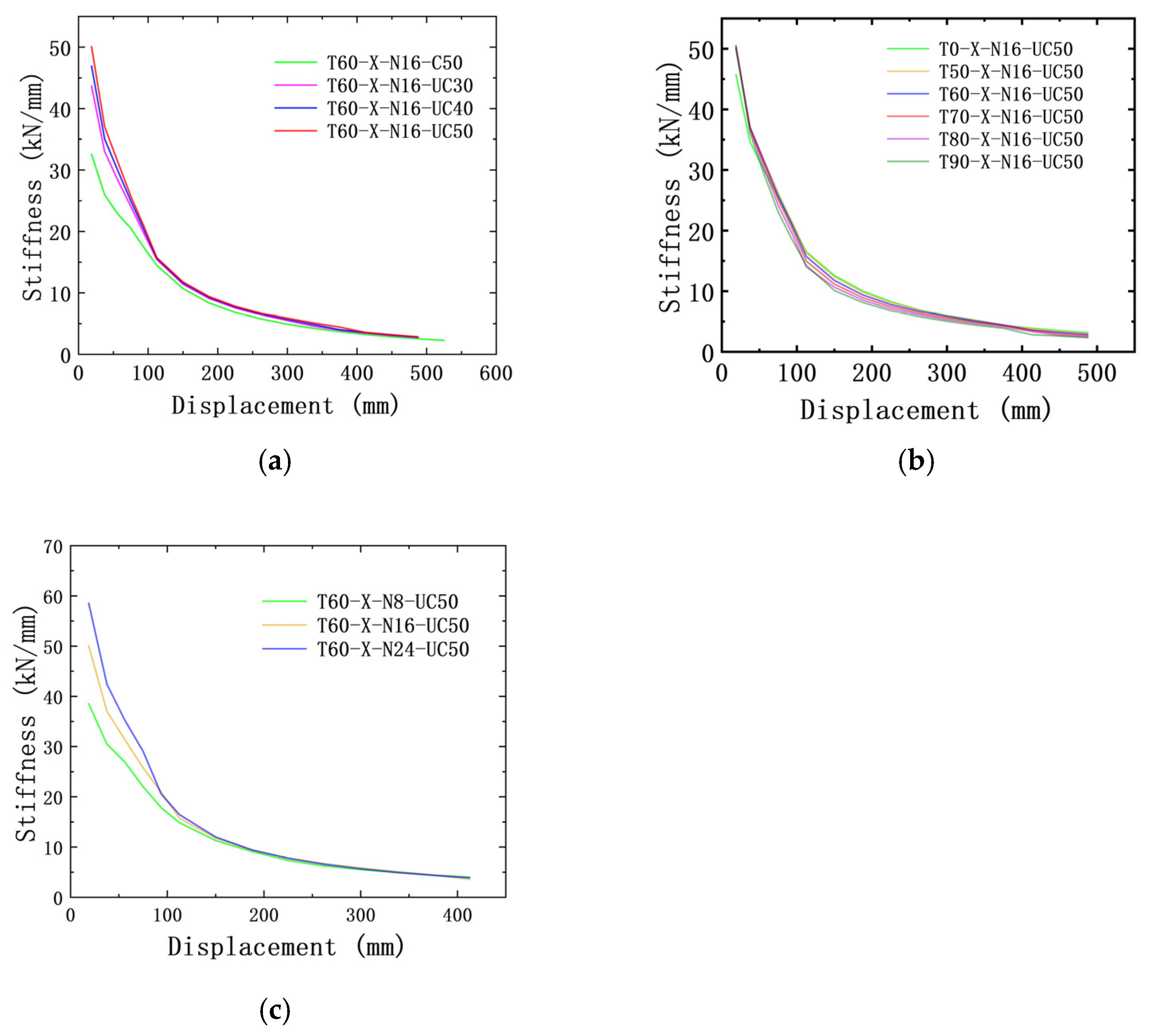

3.6. Stiffness

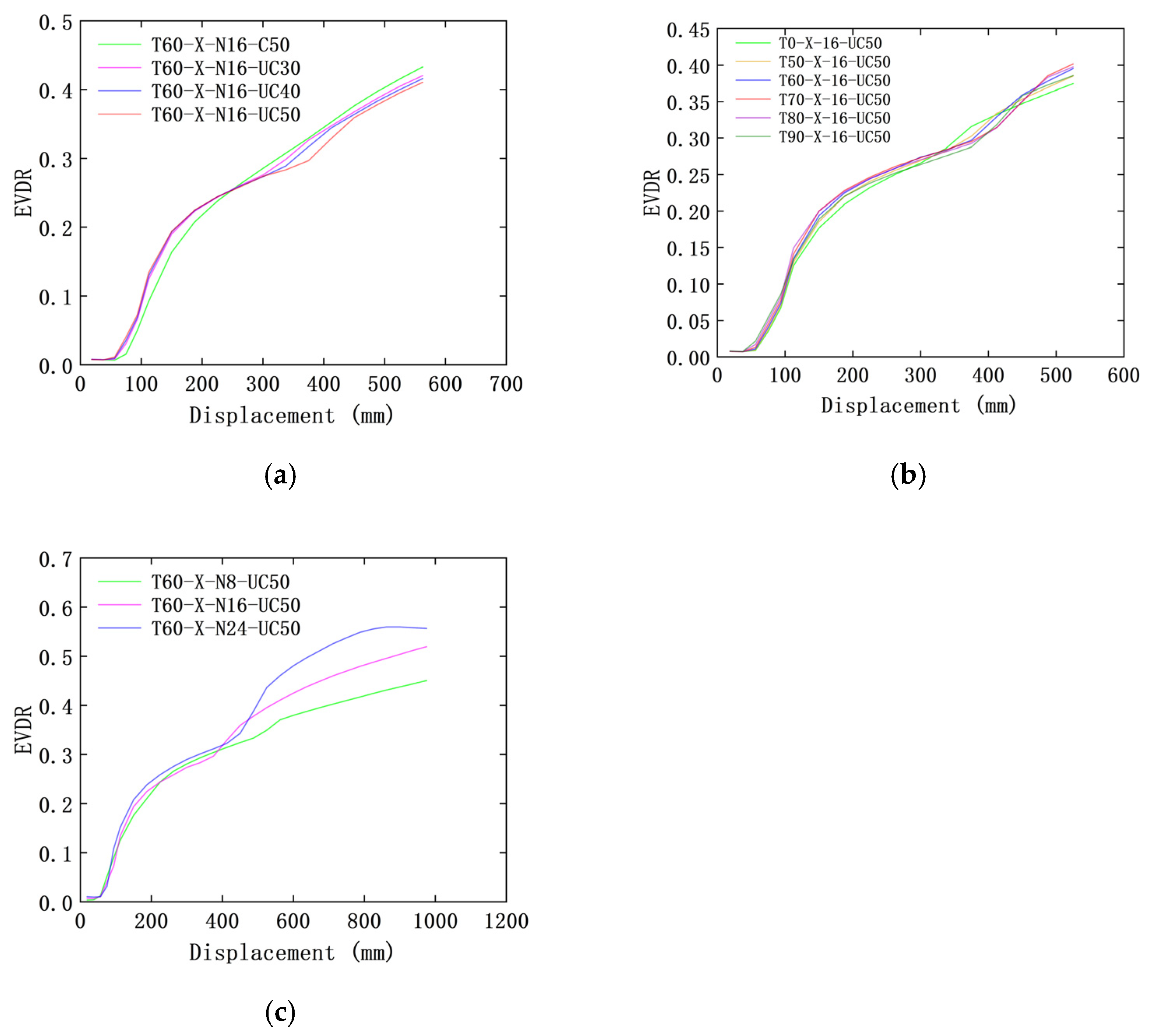

3.7. Equivalent Viscous Damping Coefficient

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cairns, J.; Du, Y.; Law, D. Influence of corrosion on the friction characteristics of the steel/concrete interface. Constr. Build. Mater. 2005, 21, 190–197. [Google Scholar] [CrossRef]

- Zhou, H.J.; Liang, X.B.; Zhang, X.L.; Lu, J.L.; Xing, F.; Mei, L. Variation and degradation of steel and concrete bond performance with corroded stirrups. Constr. Build. Mater. 2017, 138, 56–68. [Google Scholar] [CrossRef]

- Yuan, W.T.; Fang, Q.H.; Dong, Z.X. Evaluation of Biaxial Strength Deterioration for Coastal Bridge Piers under Non-uniform Corrosion. KSCE J. Civ. Eng. 2021, 26, 1329–1343. [Google Scholar] [CrossRef]

- Cheng, H.; Wang, D.S.; Li, H.N.; Yan, X.C.; Yu, S. Transfer time of the MDP and its effect on the time-dependent lateral deformation capacity of coastal bridge piers. Structures 2021, 34, 3196–3205. [Google Scholar] [CrossRef]

- Vu, N.S.; Li, B. Seismic Performance Assessment of Corroded Reinforced Concrete Short Columns. J. Struct. Eng. 2018, 144, 04018018. [Google Scholar] [CrossRef]

- Yuan, W.T.; Wang, Y.R.; Zhou, P.; Yuan, W.; Yao, Y. Effect of Biaxial Loading Path on Seismic Performance of RC Bridge Piers with Corrosion Damage. KSCE J. Civ. Eng. 2023, 27, 5243–5255. [Google Scholar] [CrossRef]

- Wang, X.; Tong, T.; Liu, Z.; Bairán, J.M.; Wang, T.; Li, X. Experimental study on the seismic performance of precast and cast-in-place hollow circular piers under chloride-induced corrosion. Eng. Struct. 2025, 335, 120387. [Google Scholar] [CrossRef]

- Wu, X.T.; Yuan, W.T.; Guo, A.X. Experimental study on seismic performance of precast bridge piers with corrosion-damaged grouted sleeve connections. Structures 2025, 75, 108699. [Google Scholar] [CrossRef]

- Yuan, W.; Guo, A.X.; Li, H. Experimental investigation on the cyclic behaviors of corroded coastal bridge piers with transfer of plastic hinge due to non-uniform corrosion. Soil Dyn. Earthq. Eng. 2017, 102, 112–123. [Google Scholar] [CrossRef]

- Domaneschi, M.; De Gaetano, A.; Casas, J.; Cimellaro, G.P. Deteriorated seismic capacity assessment of reinforced concrete bridge piers in corrosive environment. Struct. Concr. 2020, 21, 1823–1838. [Google Scholar] [CrossRef]

- Yuan, W.T.; Guo, A.X.; Li, H. Equivalent elastic modulus of reinforcement to consider bond-slip effects of coastal bridge piers with non-uniform corrosion. Eng. Struct. 2020, 210, 110382. [Google Scholar] [CrossRef]

- Kashani, M.M.; Moodley, H.; Aminulai, H.O.; Afshan, S.; Crump, D. Experimental Investigation of Nonlinear Cyclic Behavior of Circular Concrete Bridge Piers with Pitting Corrosion. J. Bridge Eng. 2024, 29, 04024048. [Google Scholar] [CrossRef]

- Bagheri, M.; Jamkhaneh, M.E.; Samali, B. Effect of Seismic Soil–Pile–Structure Interaction on Mid- and High-Rise Steel Buildings Resting on a Group of Pile Foundations. Int. J. Geomech. 2018, 18, 04018103. [Google Scholar] [CrossRef]

- Crespi, P.; Zucca, M.; Valente, M.; Longarini, N. Influence of corrosion effects on the seismic capacity of existing RC bridges. Eng. Fail. Anal. 2022, 140, 106546. [Google Scholar] [CrossRef]

- Zhou, Y.W.; Wang, X.H.; Hu, B.; Sui, L.; Yuan, F. Seismic Retrofit of Nonuniformly Corroded Coastal Bridge Piers with FRP and Engineered Cementitious Composite Overlays. J. Compos. Constr. 2023, 27, 04022088. [Google Scholar] [CrossRef]

- Jia, J.F.; Zhao, L.Y.; Wu, S.W.; Bai, Y.; Wei, Y. Experimental investigation on the seismic performance of low-level corroded and retrofitted reinforced concrete bridge columns with CFRP fabric. Eng. Struct. 2020, 209, 110225. [Google Scholar] [CrossRef]

- Fu, T.; Li, Y.; Xu, L.W.; Wang, G.; Meng, L.; Sun, Z.; Xu, Y. Seismic performance and calculation method for plastic hinge length of RC pier reinforced with UHPC. Structures 2024, 69, 107569. [Google Scholar] [CrossRef]

- Zhang, J.W.; Li, Z.F.; Wang, F.; Zhuo, S.; Wang, T. Seismic Resilience Study of Piers Enhanced by Ultrahigh-Performance Concrete Jackets Based on Cyclic Loading Test and Static Push-Over Curves. Sci. Adv. Mater. 2022, 14, 1679–1691. [Google Scholar] [CrossRef]

- Yuan, W.T.; Wang, X.T.; Dong, Z.X.; Zhou, P.; Wang, Q. Cyclic loading test for RC bridge piers strengthened with UHPC jackets in the corrosive environment. Soil Dyn. Earthq. Eng. 2022, 158, 107290. [Google Scholar] [CrossRef]

- Yuan, W.T.; Wang, X.T.; Guo, A.X.; Li, C.; Dong, Z.; Wu, X. Cyclic performance of RC bridge piers retrofitted with UHPC jackets: Experimental investigation. Eng. Struct. 2022, 259, 114139. [Google Scholar] [CrossRef]

- Bhargava, K.; Mori, Y.; Ghosh, A.K. Time-dependent reliability of corrosion-affected RC beams. Part 3: Effect of corrosion initiation time and its variability on time-dependent failure probability. Nucl. Eng. Des. 2010, 241, 1395–1402. [Google Scholar] [CrossRef]

- Val, D.V. Deterioration of Strength of RC Beams due to Corrosion and Its Influence on Beam Reliability. J. Struct. Eng. 2007, 133, 1297–1306. [Google Scholar] [CrossRef]

- Du, Y.G.; Clark, L.A.; Chan, A.H.C. Residual capacity of corroded reinforcing bars. Mag. Concr. Res. 2005, 57, 135–147. [Google Scholar] [CrossRef]

- Finozzi, I.; Saetta, A.; Budelmann, H. Structural response of reinforcing bars affected by pitting corrosion: Experimental evaluation. Constr. Build. Mater. 2018, 192, 478–488. [Google Scholar] [CrossRef]

- Coronelli, D.; Gambarova, P. Structural Assessment of Corroded Reinforced Concrete Beams: Modeling Guidelines. J. Struct. Eng. 2004, 130, 1214–1224. [Google Scholar] [CrossRef]

- Biondini, F.; Vergani, M. Damage modeling and nonlinear analysis of concrete bridges under corrosion. In Bridge Maintenance, Safety, Management, Resilience and Sustainability, Proceedings of the Sixth International Conference of Bridge Maintenance, Safety and Management (IABMAS 2012), Stresa, Italy, 8–12 July, 2012; CRC Press: Boca Raton, FL, USA, 2012; pp. 949–957. [Google Scholar]

- Mander, J.; Priestley, M. Theoretical Stress-Strain model for confined concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Silva, M.L.d.; Prado, L.P.; Félix, E.F.; Sousa, A.M.D.d.; Aquino, D.P. The Influence of Materials on the Mechanical Properties of Ultra-High-Performance Concrete (UHPC): A Literature Review. Materials 2024, 17, 1801. [Google Scholar] [CrossRef]

- Mangalathu, S.; Soleimani, F.; Jeon, J. Bridge classes for regional seismic risk assessment: Improving HAZUS models. Eng. Struct. 2017, 148, 755–766. [Google Scholar] [CrossRef]

- Stewart, M.G.; Wang, X.; Nguyen, M.N. Climate change impact and risks of concrete infrastructure deterioration. Eng. Struct. 2011, 33, 1326–1337. [Google Scholar] [CrossRef]

- Duprat, F. Reliability of RC beams under chloride-ingress. Constr. Build. Mater. 2006, 21, 1605–1616. [Google Scholar] [CrossRef]

- Vu, K.A.T.; Stewart, M.G. Structural reliability of concrete bridges including improved chloride-induced corrosion models. Struct. Saf. 2000, 22, 313–333. [Google Scholar] [CrossRef]

- Yuan, W.; Li, X.; Pang, X.; Tian, C.; Li, Z.; Zhou, P.; Wang, Y. Cyclic Behavior of Rectangular Bridge Piers Subjected to the Coupling Effects of Chloride Corrosion and Bidirectional Loading. Buildings 2023, 13, 425. [Google Scholar] [CrossRef]

- Mazzoni, S.; McKenna, F.; Scott, M.H.; Fenves, G.L. OpenSees Command Language Manual; (Open System for Earthquake Engineering Simulation—Home Page); University of California: Berkeley, CA, USA, 2007. [Google Scholar]

- Asgari, A.; Bagheri, M.; Hadizadeh, M. Advanced seismic analysis of soil-foundation-structure interaction for shallow and pile foundations in saturated and dry deposits: Insights from 3D parallel finite element modeling. Structures 2024, 69, 107503. [Google Scholar] [CrossRef]

- Rodrigues, H.; Varum, H.; Arêde, A.; Costa, A. A comparative analysis of energy dissipation and equivalent viscous damping of RC columns subjected to uniaxial and biaxial loading. Eng. Struct. 2012, 35, 149–164. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Yuan, W.; Chang, J.; Zhao, B. Seismic Performance of Corroded RC Bridge Piers Strengthened with UHPC Shells. Buildings 2025, 15, 3863. https://doi.org/10.3390/buildings15213863

Li Y, Yuan W, Chang J, Zhao B. Seismic Performance of Corroded RC Bridge Piers Strengthened with UHPC Shells. Buildings. 2025; 15(21):3863. https://doi.org/10.3390/buildings15213863

Chicago/Turabian StyleLi, Yixue, Wenting Yuan, Jianmei Chang, and Bingjie Zhao. 2025. "Seismic Performance of Corroded RC Bridge Piers Strengthened with UHPC Shells" Buildings 15, no. 21: 3863. https://doi.org/10.3390/buildings15213863

APA StyleLi, Y., Yuan, W., Chang, J., & Zhao, B. (2025). Seismic Performance of Corroded RC Bridge Piers Strengthened with UHPC Shells. Buildings, 15(21), 3863. https://doi.org/10.3390/buildings15213863