Evaluation of the Consistency of Rock Joint Surface Morphology Based on Grayscale Surface-Differential Box Counting and Mechanical Tests

Abstract

1. Introduction

2. Methods for Verifying the Consistency of Joint Surface Morphology

2.1. Acquisition of Real Joint Surface Morphology

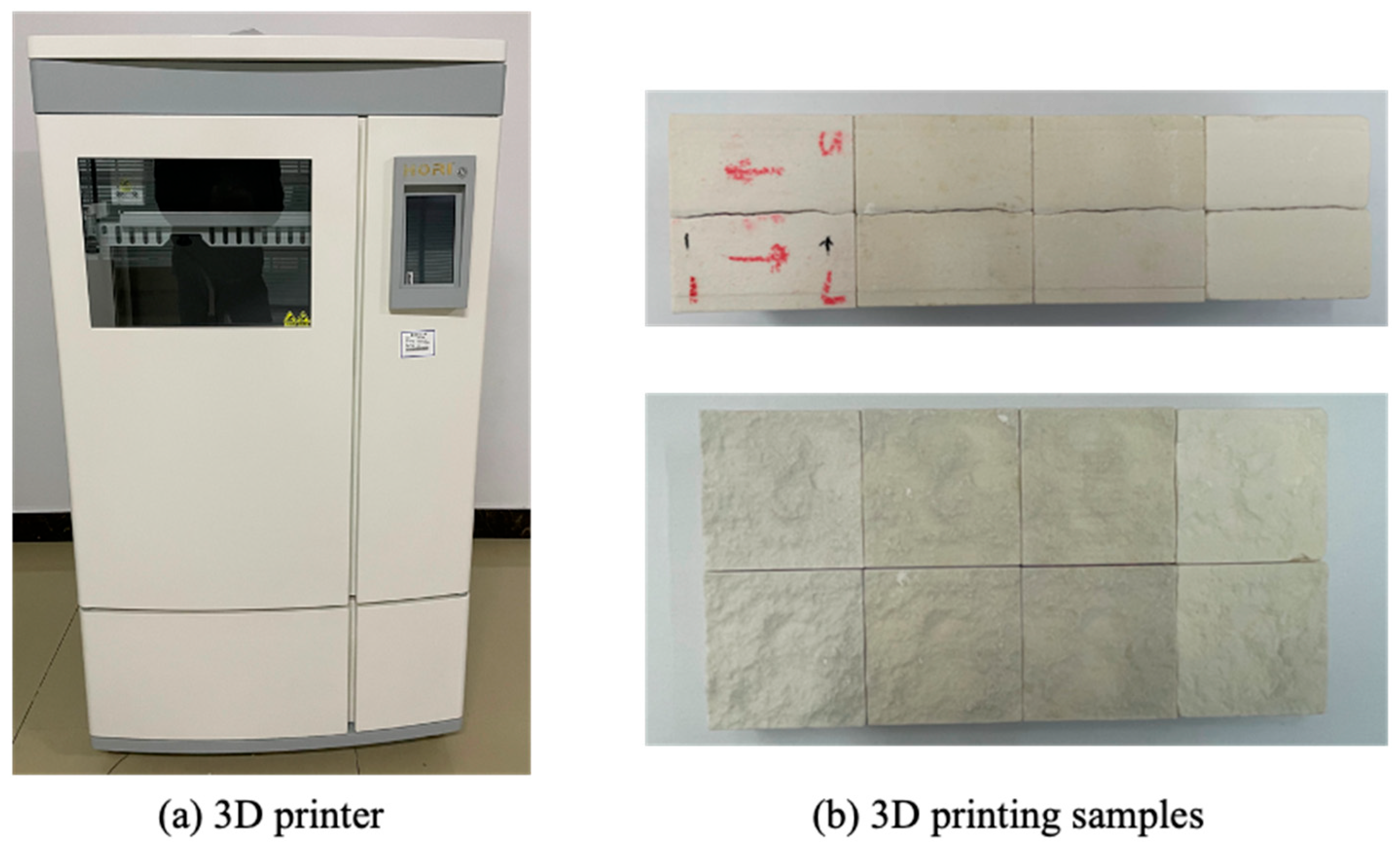

2.2. Reproduction of Joint Surface Morphology

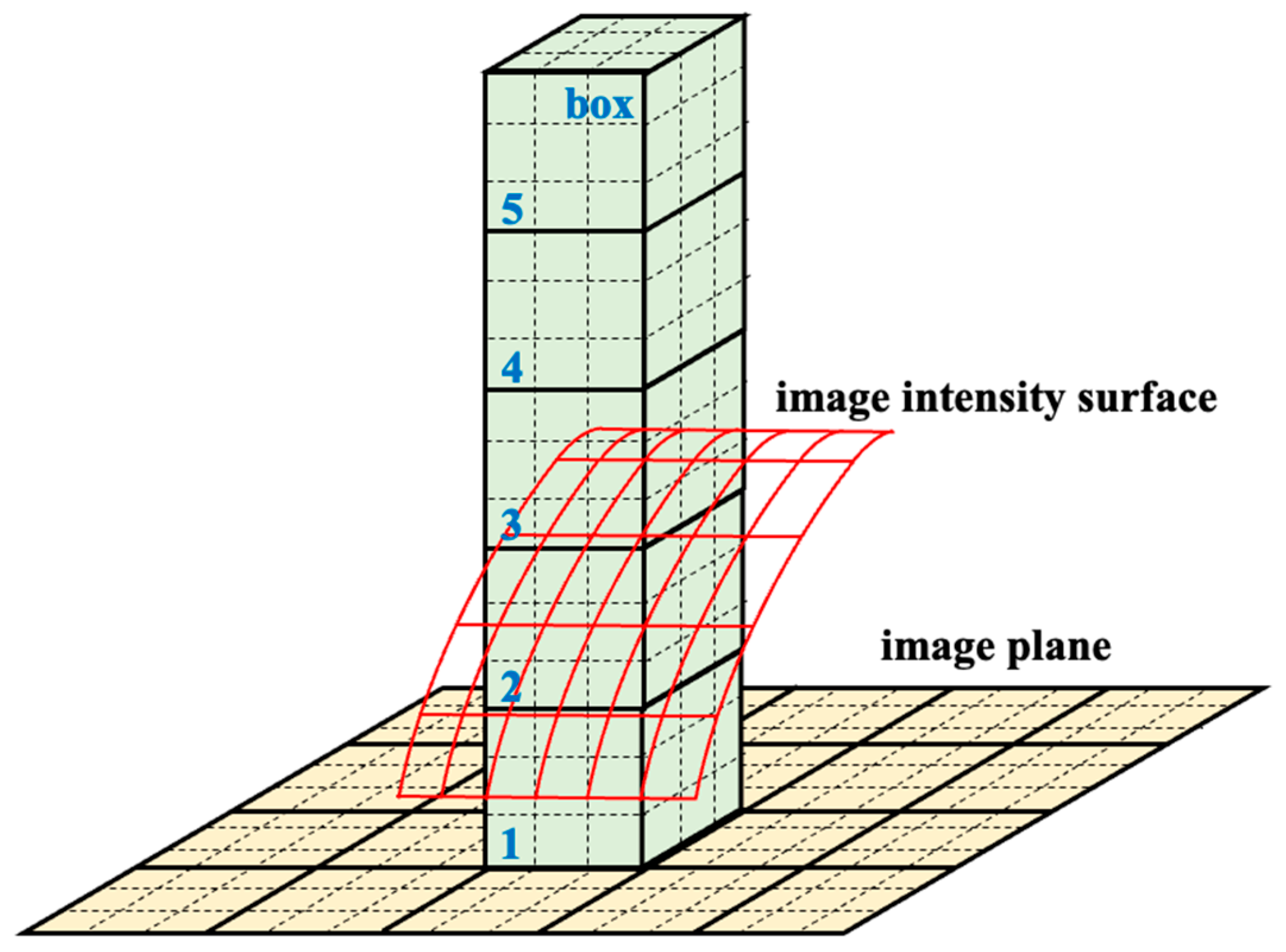

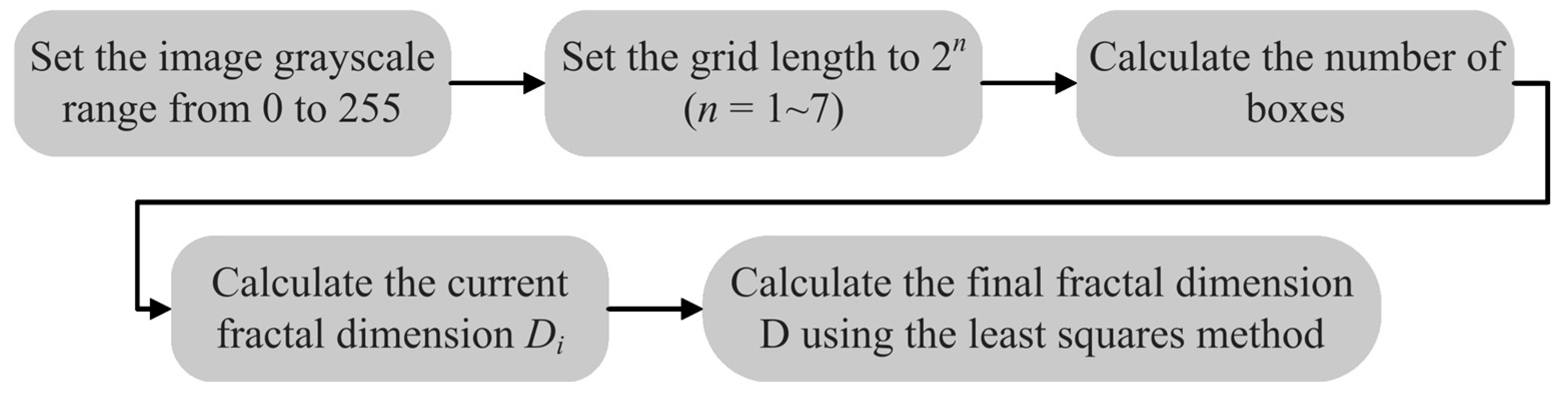

2.3. Fractal Dimension Identification Method Based on Grayscale Surface and Differential Box-Counting

2.4. Consistency Verification

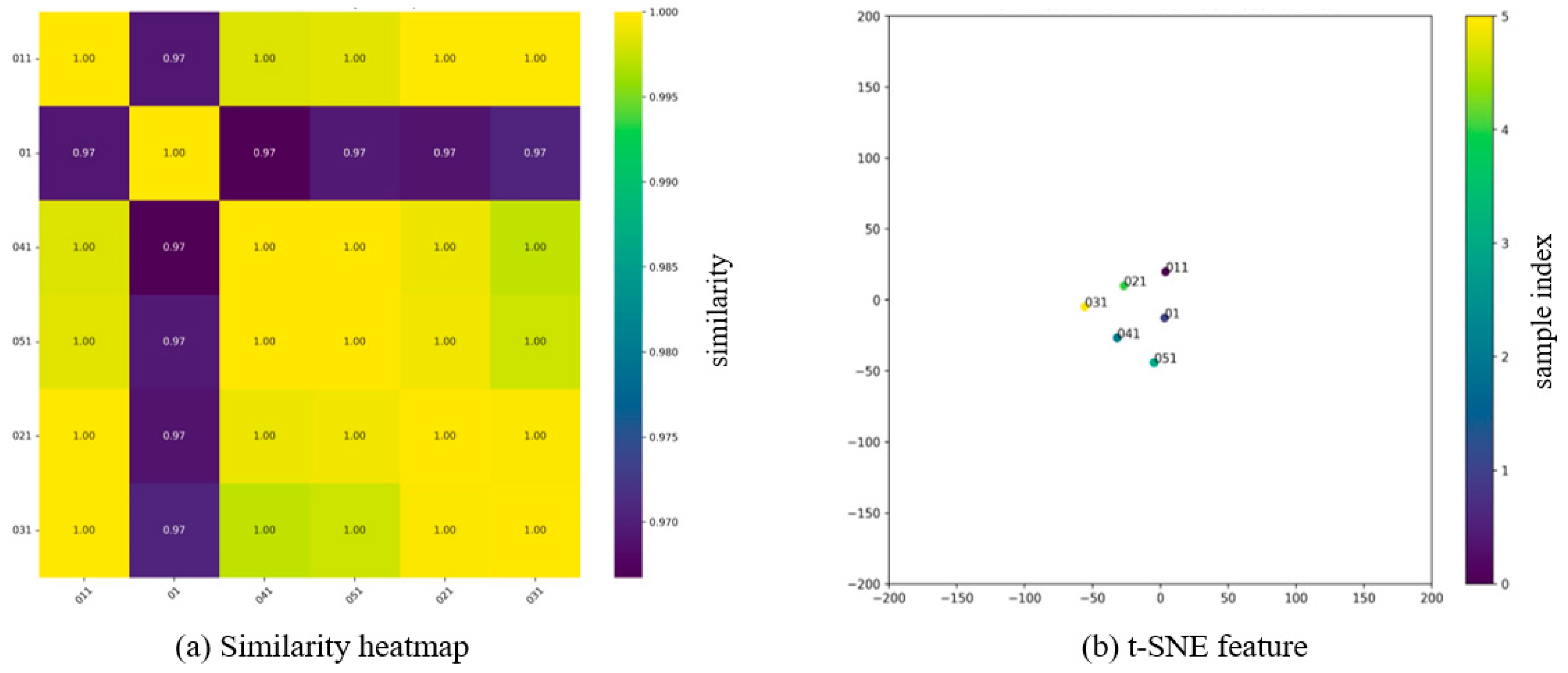

3. Verification of CNN Feature Extraction

3.1. CNN Model Construction

3.2. Image Consistency Verification

4. Mechanical Experiment Verification

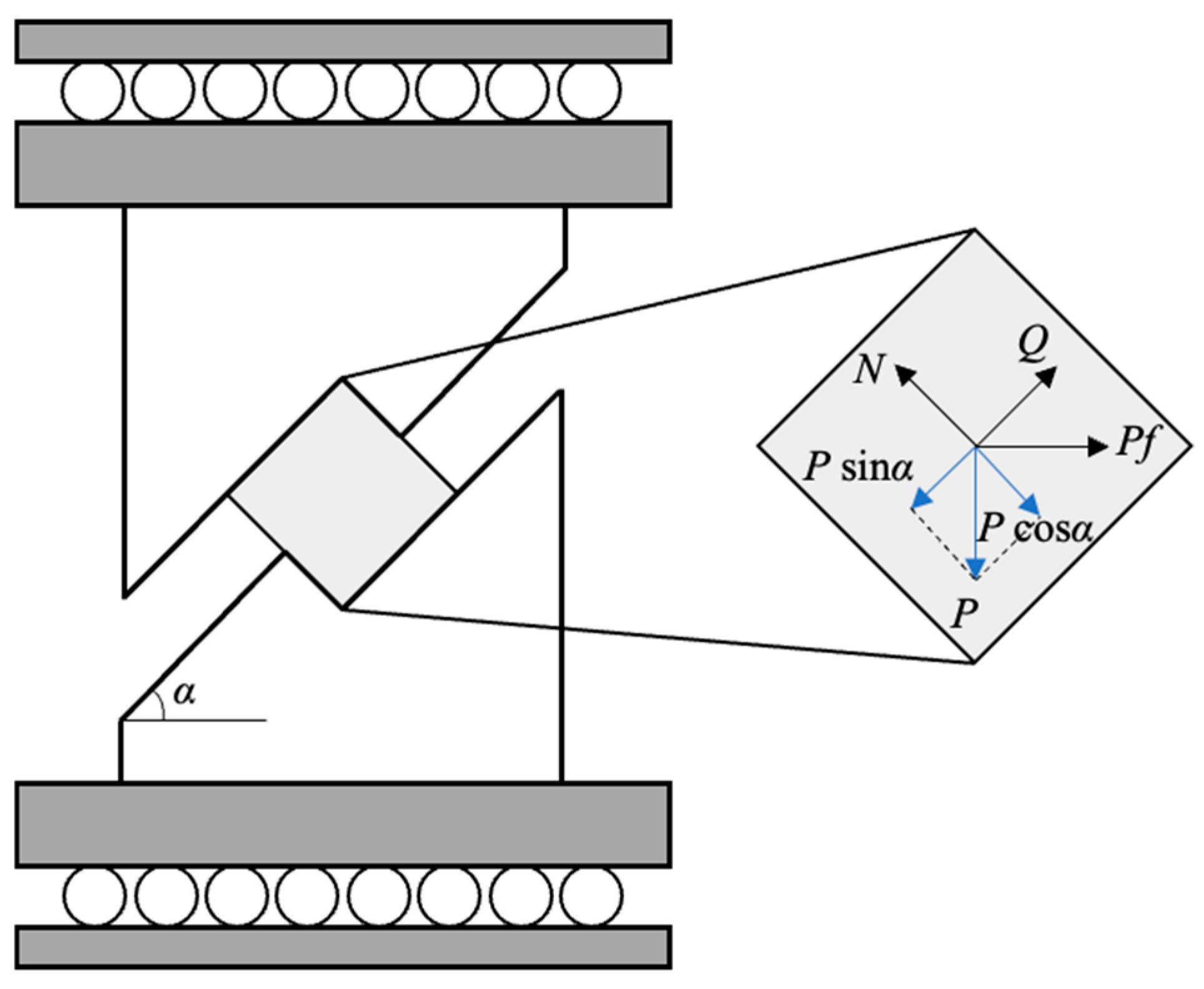

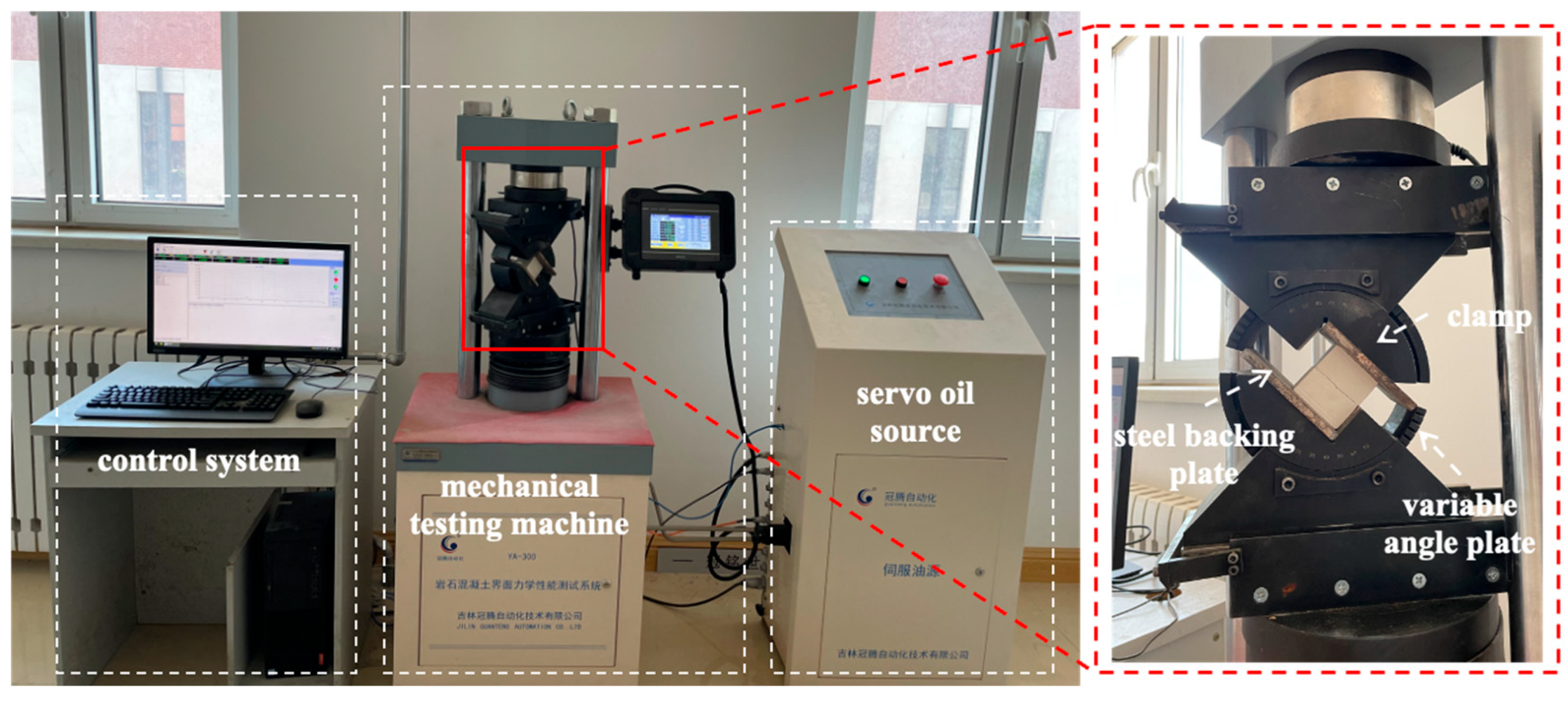

4.1. Experimental System

4.2. Experimental Procedure

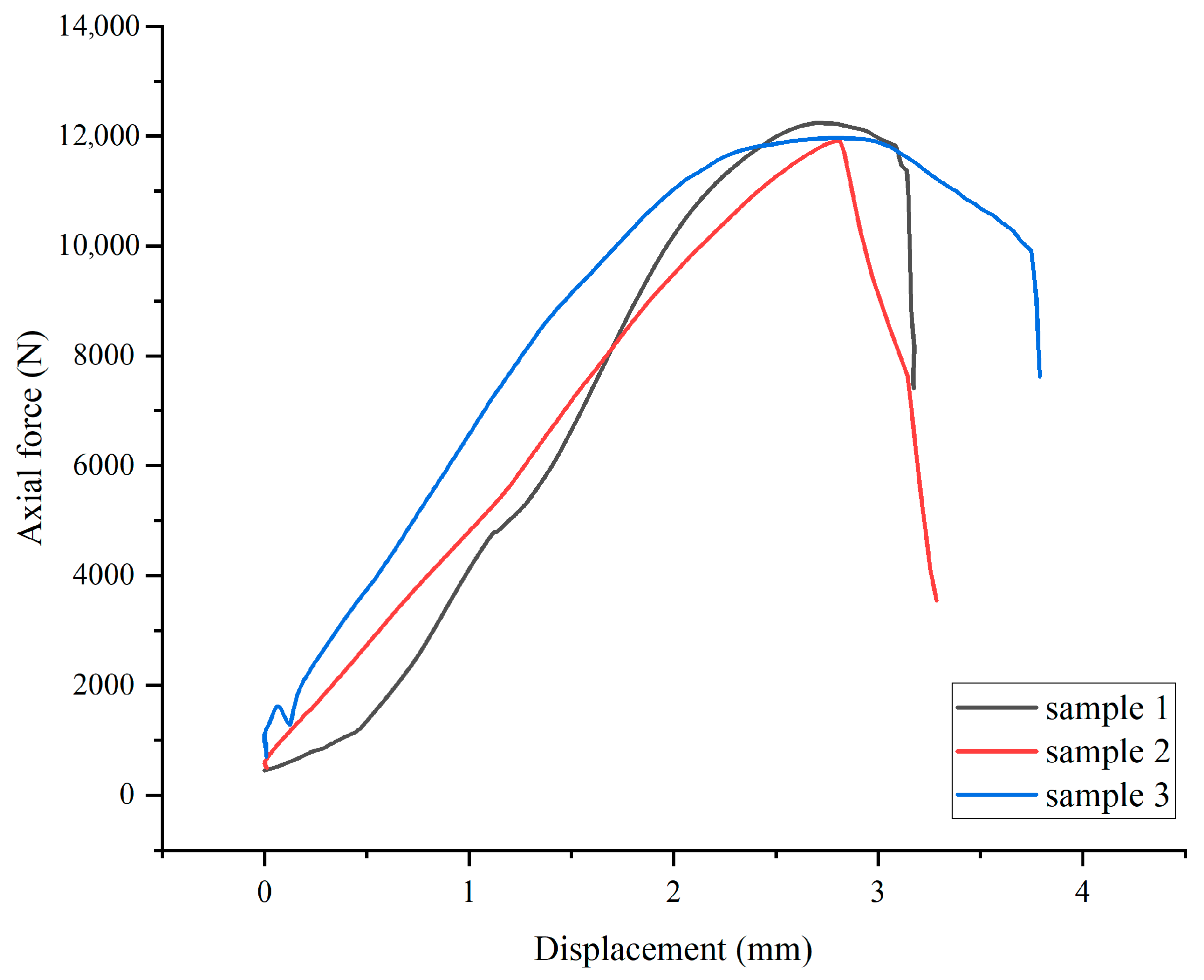

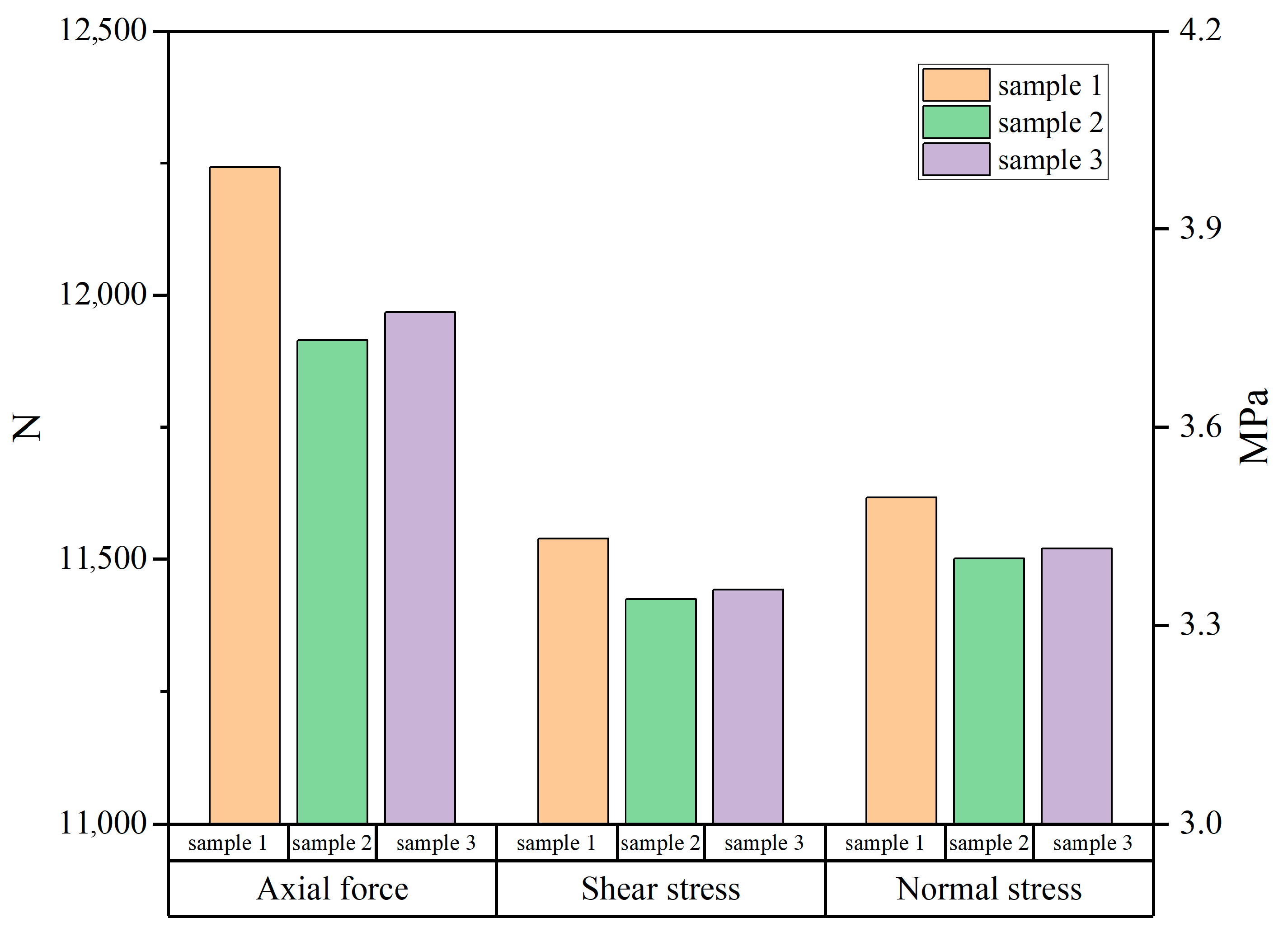

4.3. Experimental Results

5. Conclusions

- (1)

- By conducting red sandstone splitting tests, the real shear surfaces of red sandstone were obtained manually as joint surfaces. The joint surface morphology was reproduced using 3D printing technology, resulting in 3D printed samples based on the real joint surface morphology.

- (2)

- An automatic identification method for the fractal dimension of joint surfaces based on grayscale surface and differential box-counting was proposed, and a program was developed to automatically identify the fractal dimension of joint surface roughness. The fractal dimensions of the real red sandstone joint surface morphology and the 3D printed sample joint surface morphology were quantitatively identified, with average identification errors of 8.58% for the upper part and 7.10% for the lower part.

- (3)

- A CNN feature extraction method was employed to perform a feature similarity analysis on images of the original red sandstone joint surface morphology and the 3D-printed joint surface morphology at the image scale. The validation results indicated that the consistency of the joint surfaces in the upper half was lower than that in the lower half, which aligned with the joint surface consistency errors obtained from fractal dimension calculations. Additionally, the similarity distribution of each sample point’s distance to centers 01 and 02 was consistent with the fractal dimension calculation results.

- (4)

- The mechanical performance of the joint surfaces of the samples was tested using variable-angle shear tests. From the perspective of mechanical performance, the consistency of the joint surface morphology of the samples was reflected. The load–displacement curves, maximum load, normal stress, and shear stress on the shear surface of the samples all exhibited high convergence characteristics. Therefore, the proposed automatic fractal dimension identification method can effectively evaluate the true consistency of joint surfaces.

- (5)

- Applying this validated workflow to a wider range of natural joint surfaces with varying roughness, lithologies, and genetic origins represents a crucial and vital direction for our future research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jafari, M.K.; Amini Hosseini, K.; Pellet, F.; Boulon, M.; Buzzi, O. Evaluation of shear strength of rock joints subjected to cyclic loading. Soil Dyn. Earthq. Eng. 2003, 23, 619–630. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Taghichian, A.; Li, W.C. Effect of asperity order on the shear response of three-dimensional joints by focusing on damage area. Int. J. Rock Mech. Min. Sci. 2010, 47, 1012–1026. [Google Scholar] [CrossRef]

- Zhao, J. Joint surface matching and shear strength part A: Joint matching coefficient (JMC). Int. J. Rock Mech. Min. Sci. 1997, 34, 173–178. [Google Scholar] [CrossRef]

- Wang, L.C.; Zhu, L.; Cao, Z.Z.; Liu, J.; Xue, Y.; Wang, P.S.; Cao, X.S.; Liu, Y. Thermo-mechanical degradation and fracture evolution in low-permeability coal subjected to cyclic heating-cryogenic cooling. Phys. Fluids 2025, 37, 14. [Google Scholar] [CrossRef]

- Fathi, A.; Moradian, Z.; Rivard, P.; Ballivy, G.; Boyd, A.J. Geometric Effect of Asperities on Shear Mechanism of Rock Joints. Rock Mech. Rock Eng. 2016, 49, 801–820. [Google Scholar] [CrossRef]

- Wang, J.A.; Wang, Y.X.; Cao, Q.J.; Ju, Y.; Mao, L.T. Behavior of microcontacts in rock joints under direct shear creep loading. Int. J. Rock Mech. Min. Sci. 2015, 78, 217–229. [Google Scholar] [CrossRef]

- Li, H.H. Mechanical Responses of Rock Joints With Regular Asperities Under Various Shear Rates Investigated by Double Shear Test. J. Test. Eval. 2017, 45, 470–483. [Google Scholar] [CrossRef]

- Kwon, T.H.; Hong, E.S.; Cho, G.C. Shear behavior of rectangular-shaped asperities in rock joints. Ksce J. Civ. Eng. 2010, 14, 323–332. [Google Scholar] [CrossRef]

- Tang, Z.C.; Wong, L.N.Y. New Criterion for Evaluating the Peak Shear Strength of Rock Joints Under Different Contact States. Rock Mech. Rock Eng. 2016, 49, 1191–1199. [Google Scholar] [CrossRef]

- Xu, B.; Liu, X.R.; Zhou, X.H.; Xie, Y.K.; Suliman, L.; Liu, X.L.; Lin, G.Y.; Huang, J.H. Investigation on the macro-meso fatigue damage mechanism of rock joints with multiscale asperities under pre-peak cyclic shear loading. Soil Dyn. Earthq. Eng. 2021, 151, 16. [Google Scholar] [CrossRef]

- Barton, N. Review of a new shear-strength criterion for rock joints. Eng. Geol. 1973, 7, 287–332. [Google Scholar] [CrossRef]

- Barton, N.; Choubey, V. The shear strength of rock joints in theory and practice. Rock Mech. 1977, 10, 1–54. [Google Scholar] [CrossRef]

- Zhang, X.B.; Zhu, X.; Yao, C.; Ouyang, S.; Yang, J.H.; Jiang, Q.H. Investigation on the Shear Behavior of Rough Rock Joints Prepared by Three- Dimensional Engraving Technique. J. Test. Eval. 2022, 50, 1425–1440. [Google Scholar] [CrossRef]

- Bao, H.; Zhang, G.B.; Lan, H.X.; Yan, C.G.; Xu, J.B.; Xu, W. Geometrical heterogeneity of the joint roughness coefficient revealed by 3D laser scanning. Eng. Geol. 2020, 265, 9. [Google Scholar] [CrossRef]

- Babanouri, N.; Nasab, S.K.; Baghbanan, A.; Mohamadi, H.R. Over-consolidation effect on shear behavior of rock joints. Int. J. Rock Mech. Min. Sci. 2011, 48, 1283–1291. [Google Scholar] [CrossRef]

- Li, X.L.; Ren, Z.Y.; Cao, Z.Z.; Hao, R. Study on coal drawing parameters of deeply buried hard coal seams based on PFC. Sci. Rep. 2025, 15, 16. [Google Scholar] [CrossRef] [PubMed]

- Ju, Y.; Xie, H.P.; Zheng, Z.M.; Lu, J.B.; Mao, L.T.; Gao, F.; Peng, R.D. Visualization of the complex structure and stress field inside rock by means of 3D printing technology. Chin. Sci. Bull. 2014, 59, 5354–5365. [Google Scholar] [CrossRef]

- Ju, Y.; Wang, L.; Xie, H.P.; Ma, G.W.; Zheng, Z.M.; Mao, L.T. Visualization and Transparentization of the Structure and Stress Field of Aggregated Geomaterials Through 3D Printing and Photoelastic Techniques. Rock Mech. Rock Eng. 2017, 50, 1383–1407. [Google Scholar] [CrossRef]

- Liu, P.; Ju, Y.; Ranjith, P.G.; Zheng, Z.; Wang, L.; Wanniarachchi, A. Visual representation and characterization of three-dimensional hydrofracturing cracks within heterogeneous rock through 3D printing and transparent models. Int. J. Coal Sci. Technol. 2016, 3, 284–294. [Google Scholar] [CrossRef]

- Jiang, C.; Zhao, G.F. A Preliminary Study of 3D Printing on Rock Mechanics. Rock Mech. Rock Eng. 2015, 48, 1041–1050. [Google Scholar] [CrossRef]

- Jiang, C.; Zhao, G.F.; Zhu, J.B.; Zhao, Y.X.; Shen, L.M. Investigation of Dynamic Crack Coalescence Using a Gypsum-Like 3D Printing Material. Rock Mech. Rock Eng. 2016, 49, 3983–3998. [Google Scholar] [CrossRef]

- Jiang, Q.; Feng, X.T.; Song, L.B.; Gong, Y.H.; Zheng, H.; Cui, J. Modeling rock specimens through 3D printing: Tentative experiments and prospects. Acta Mech. Sin. 2016, 32, 101–111. [Google Scholar] [CrossRef]

- Head, D.; Vanorio, T. Effects of changes in rock microstructures on permeability: 3-D printing investigation. Geophys. Res. Lett. 2016, 43, 7494–7502. [Google Scholar] [CrossRef]

- Chen, F.; Yu, H.M.; Yang, Y.L.; Wu, D.Y. Influences of Roughness Sampling Interval and Anisotropy on Shear Failure Mechanism of Rock Joint Surface. Energies 2021, 14, 6902. [Google Scholar] [CrossRef]

- Magsipoc, E.; Zhao, Q.; Grasselli, G. 2D and 3D Roughness Characterization. Rock Mech. Rock Eng. 2020, 53, 1495–1519. [Google Scholar] [CrossRef]

- Magsipoc, E.; Grasselli, G. A local surface roughness mapping method for post-failure interpretation of brittle fracture propagation. Int. J. Rock Mech. Min. Sci. 2023, 172, 16. [Google Scholar] [CrossRef]

- Tatone, B.S.A.; Grasselli, G. Quantitative Measurements of Fracture Aperture and Directional Roughness from Rock Cores. Rock Mech. Rock Eng. 2012, 45, 619–629. [Google Scholar] [CrossRef]

- Tatone, B.S.A.; Grasselli, G. A new 2D discontinuity roughness parameter and its correlation with JRC. Int. J. Rock Mech. Min. Sci. 2010, 47, 1391–1400. [Google Scholar] [CrossRef]

- Tatone, B.S.A.; Grasselli, G. An Investigation of Discontinuity Roughness Scale Dependency Using High-Resolution Surface Measurements. Rock Mech. Rock Eng. 2013, 46, 657–681. [Google Scholar] [CrossRef]

- Turk, N.; Greig, M.J.; Dearman, W.R.; Amin, F.F. Characterization of rock joint surfaces by fractal dimension. In Proceedings of the 28th U.S. Symposium on Rock Mechanics (USRMS), Tucson, AZ, USA, 29 June–1 July 1987. [Google Scholar]

- Lee, Y.H.; Carr, J.R.; Barr, D.J.; Haas, C.J. The fractal dimension as a measure of the roughness of rock discontinuity profiles. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1990, 27, 453–464. [Google Scholar] [CrossRef]

- Wakabayashi, N.; Fukushige, I. Experimental study on the relation between fractal dimension and shear strength. In Fractured and Jointed Rock Masses; CRC Press: Boca Raton, FL, USA, 1995; pp. 119–124. [Google Scholar]

- Xie, H.P. Fractal Description of Rock Joints. Chin. J. Geotech. Eng. 1995, 17, 18–23. [Google Scholar]

- Li, Y.R.; Huang, R.Q. Relationship between joint roughness coefficient and fractal dimension of rock fracture surfaces. Int. J. Rock Mech. Min. Sci. 2015, 75, 15–22. [Google Scholar] [CrossRef]

- Mandelbrot, B. How Long Is the Coast of Britain? Statistical Self-Similarity and Fractional Dimension. Science 1967, 156, 636–638. [Google Scholar] [CrossRef]

- Falconer, K. Fractal Geometry: Mathematical Foundations and Applications; John Wiley: Chichester, UK, 1990. [Google Scholar]

- Wu, Y.; Verdú, S. Rényi information dimension: Fundamental limits of almost lossless analog compression. IEEE Trans. Inf. Theory 2010, 56, 3721–3748. [Google Scholar] [CrossRef]

- Grassberger, P.; Procaccia, I. Measuring the strangeness of strange attractors. Phys. D Nonlinear Phenom. 1983, 9, 189–208. [Google Scholar] [CrossRef]

- Schleicher, D. Hausdorff dimension, its properties, and its surprises. Am. Math. Mon. 2007, 114, 509–528. [Google Scholar] [CrossRef]

- Sarkar, N.; Chaudhuri, B.B. An efficient differential box-counting approach to compute fractal dimension of image. IEEE Trans. Syst. Man Cybern. 1994, 24, 115–120. [Google Scholar] [CrossRef]

- Ban, L.R.; Qi, C.Z.; Chen, H.X.; Yan, F.Y.; Ji, C.M. A New Criterion for Peak Shear Strength of Rock Joints with a 3D Roughness Parameter. Rock Mech. Rock Eng. 2020, 53, 1755–1775. [Google Scholar] [CrossRef]

| No. | Parts | Fractal Dimension | Relative Error (%) | Average Error (%) | Maximum Error (%) | Minimum Error (%) |

|---|---|---|---|---|---|---|

| 011 | top | 2.2833 | 7.98 | |||

| 021 | top | 2.2634 | 8.79 | |||

| 031 | top | 2.2486 | 9.38 | 8.58 | 9.38 | 7.40 |

| 041 | top | 2.2500 | 9.33 | |||

| 051 | top | 2.2977 | 7.40 | |||

| 01 | top | 2.4777 | ||||

| 012 | bottom | 2.3140 | 6.61 | |||

| 022 | bottom | 2.2632 | 8.66 | |||

| 032 | bottom | 2.2743 | 8.21 | 7.10 | 8.66 | 5.76 |

| 042 | bottom | 2.3351 | 5.76 | |||

| 052 | bottom | 2.3228 | 6.25 | |||

| 02 | bottom | 2.4814 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Zhang, Y.; Wang, Y. Evaluation of the Consistency of Rock Joint Surface Morphology Based on Grayscale Surface-Differential Box Counting and Mechanical Tests. Buildings 2025, 15, 3861. https://doi.org/10.3390/buildings15213861

Li M, Zhang Y, Wang Y. Evaluation of the Consistency of Rock Joint Surface Morphology Based on Grayscale Surface-Differential Box Counting and Mechanical Tests. Buildings. 2025; 15(21):3861. https://doi.org/10.3390/buildings15213861

Chicago/Turabian StyleLi, Mingfei, Yongjun Zhang, and Yan Wang. 2025. "Evaluation of the Consistency of Rock Joint Surface Morphology Based on Grayscale Surface-Differential Box Counting and Mechanical Tests" Buildings 15, no. 21: 3861. https://doi.org/10.3390/buildings15213861

APA StyleLi, M., Zhang, Y., & Wang, Y. (2025). Evaluation of the Consistency of Rock Joint Surface Morphology Based on Grayscale Surface-Differential Box Counting and Mechanical Tests. Buildings, 15(21), 3861. https://doi.org/10.3390/buildings15213861