Dynamic Response Analysis of Infilled RC Frames with Openings Under Instantaneous Column Removal Scenarios

Abstract

1. Introduction

2. Finite Element Modelling and Validation

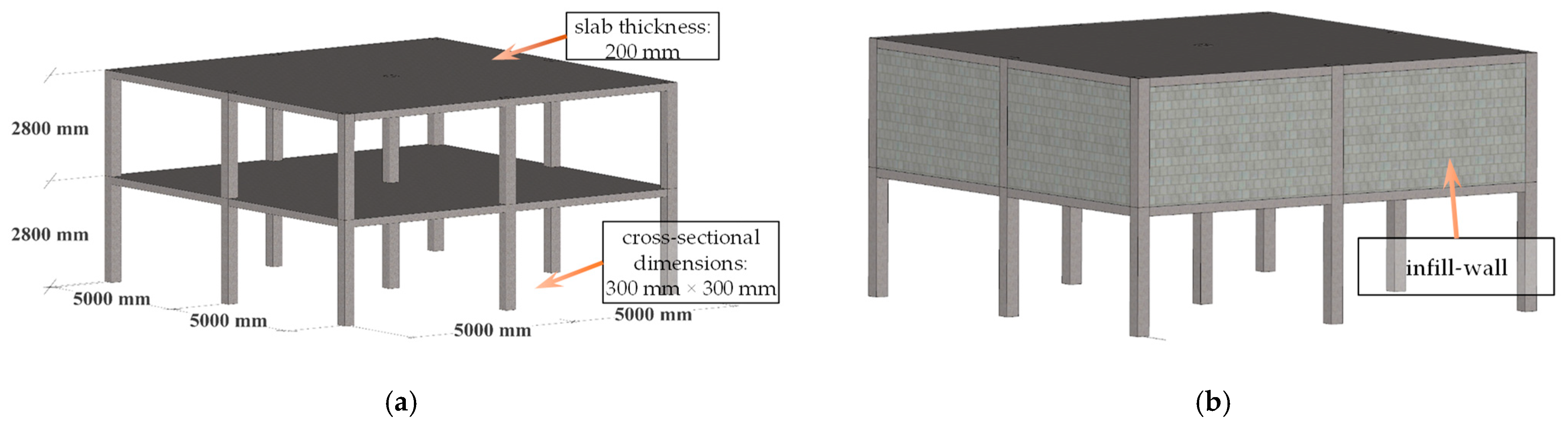

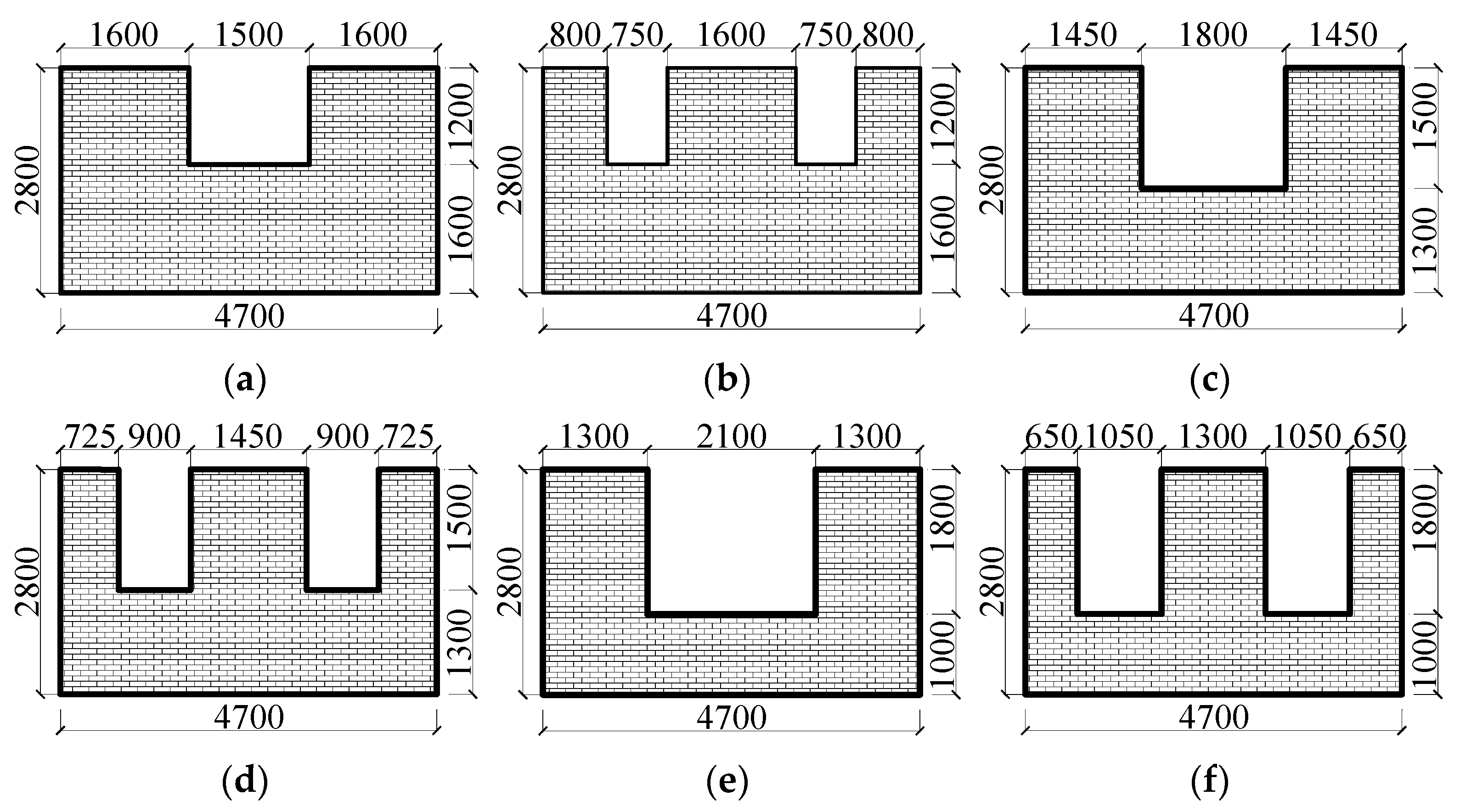

2.1. General Situation

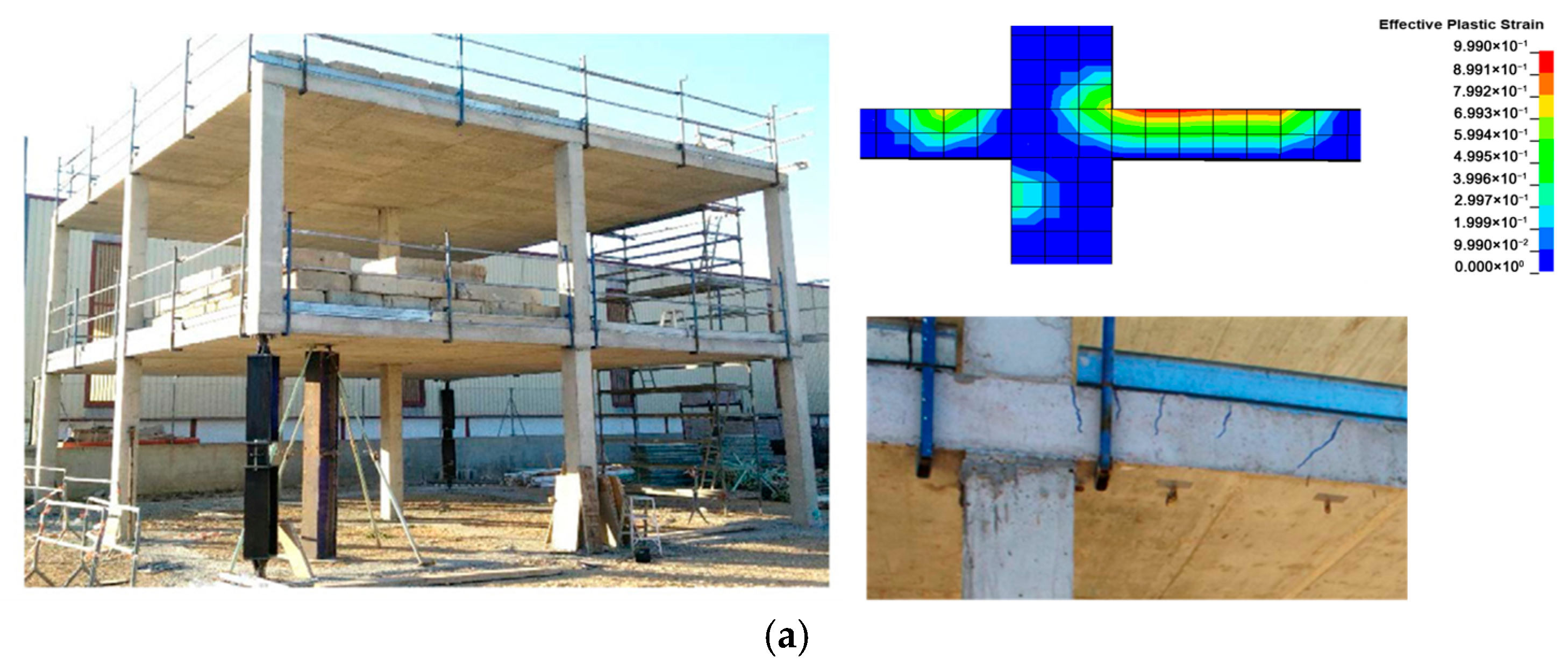

2.1.1. Test Introduction

2.1.2. Load Arrangement and Column Removal Devices for Test

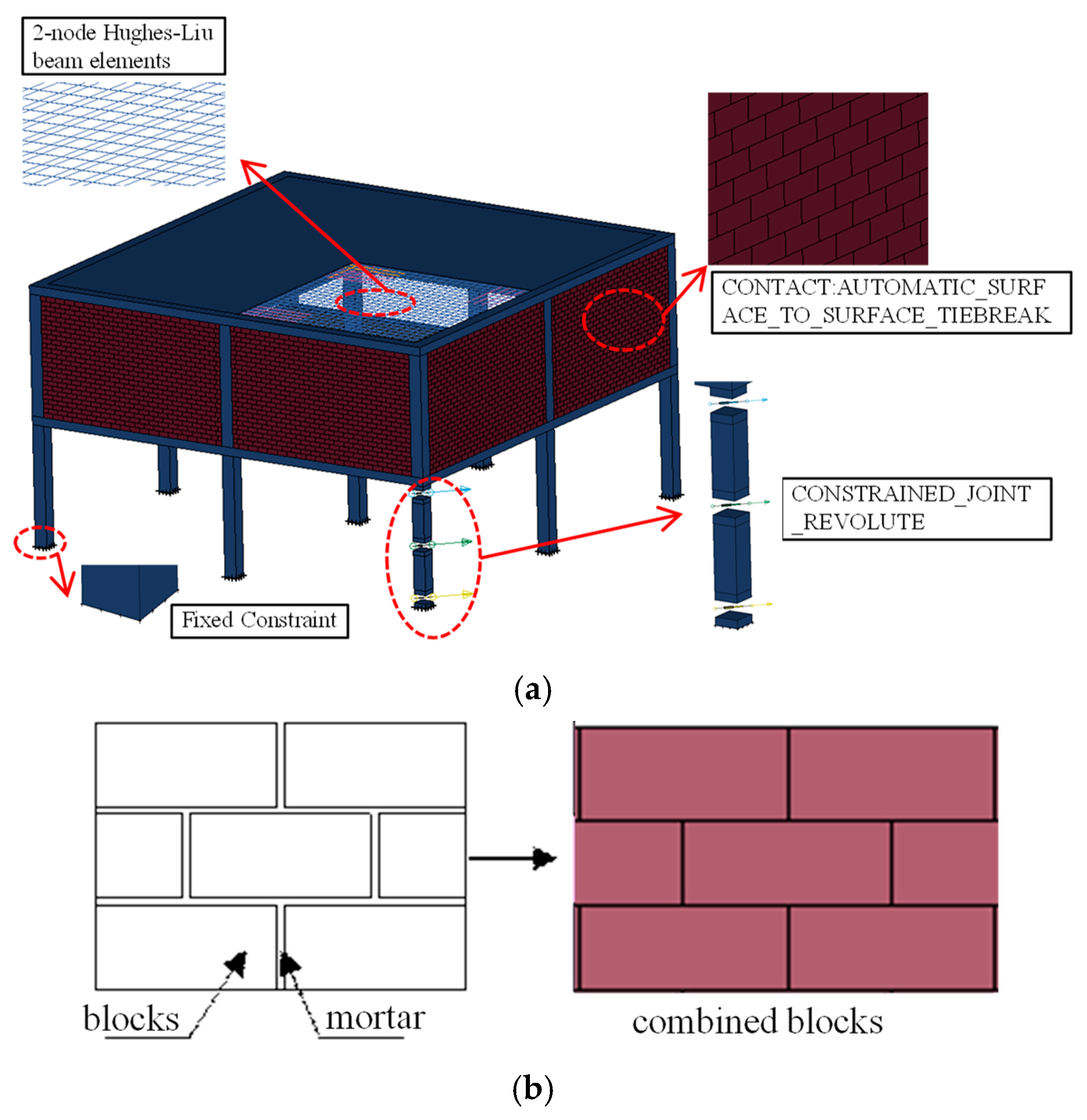

2.2. Finite Element Modelling

2.2.1. Selection of Elements and Materials

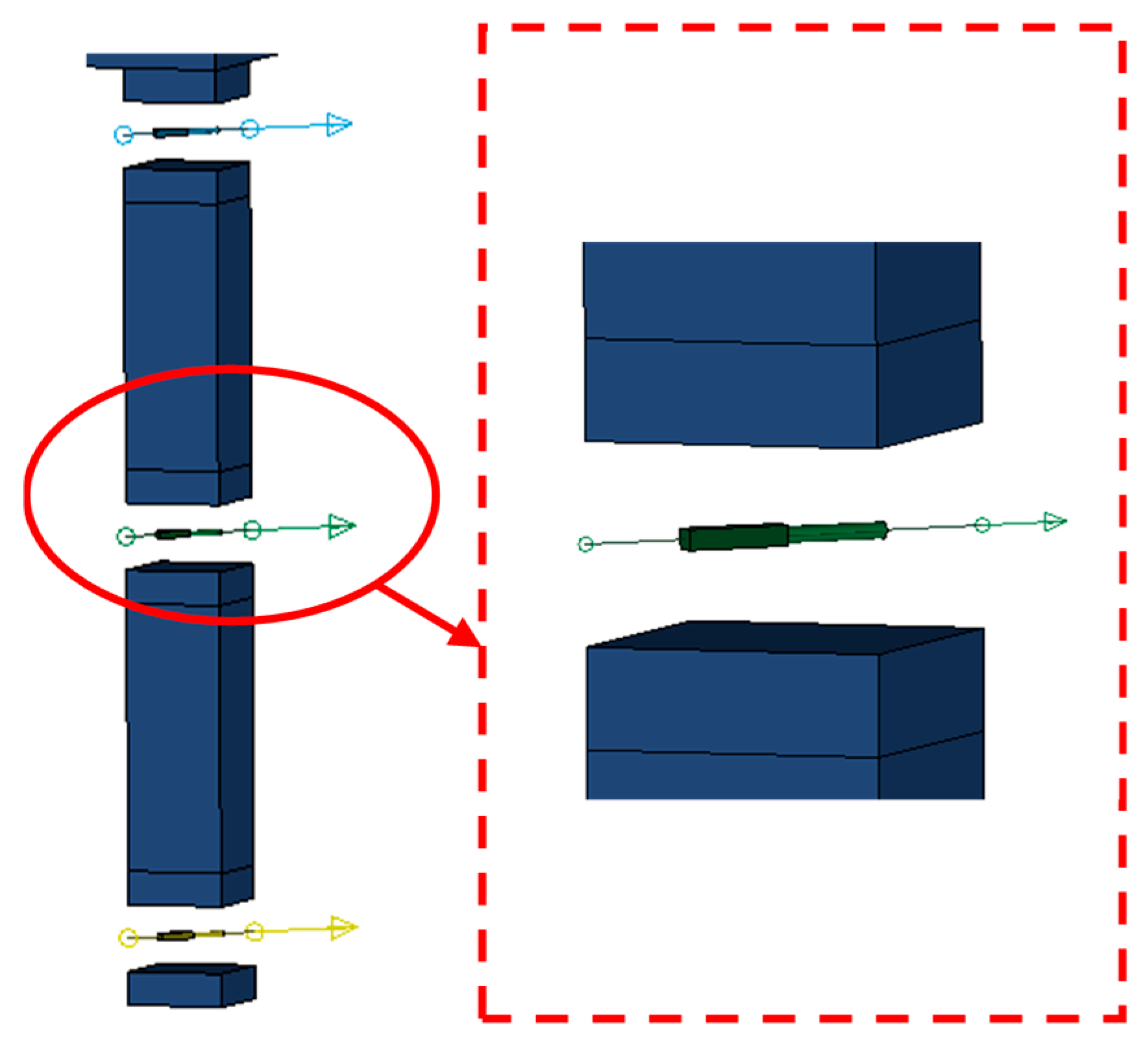

2.2.2. Load Arrangement and Column Removal Devices

2.2.3. Masonry and Mortar Contact Mode

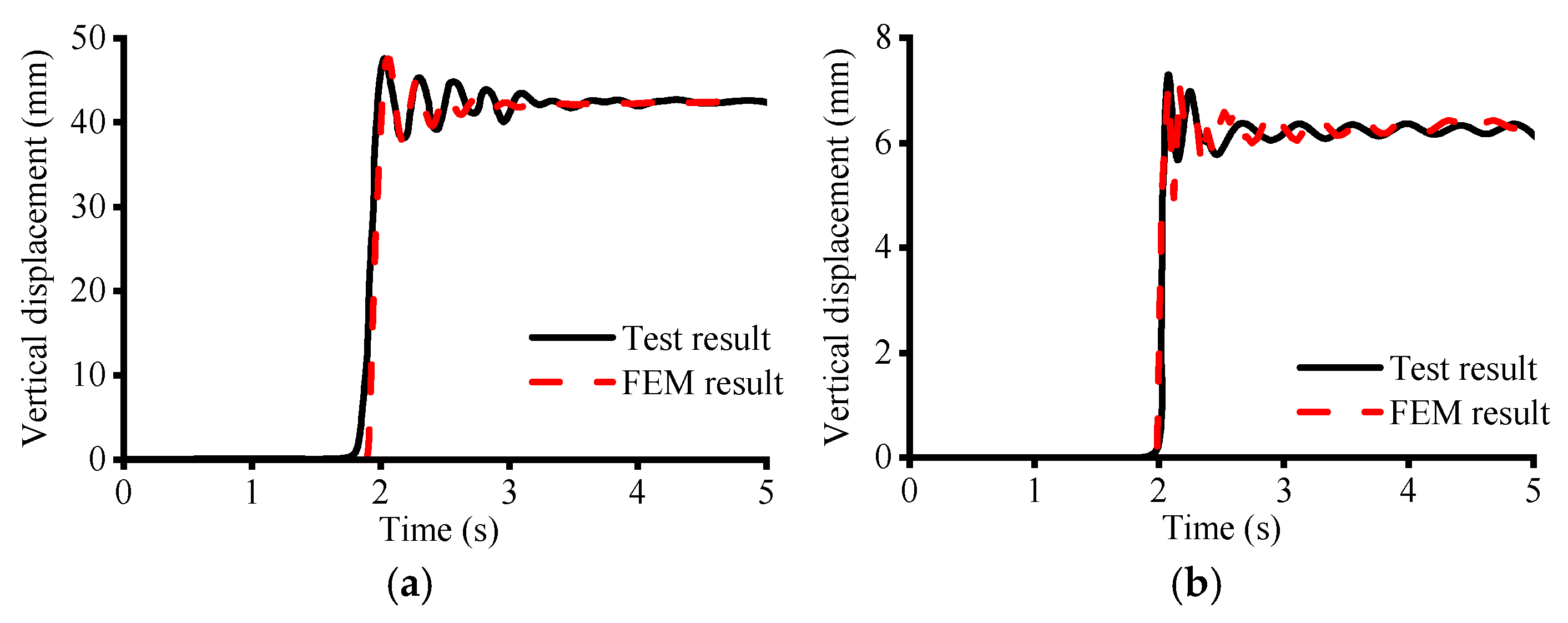

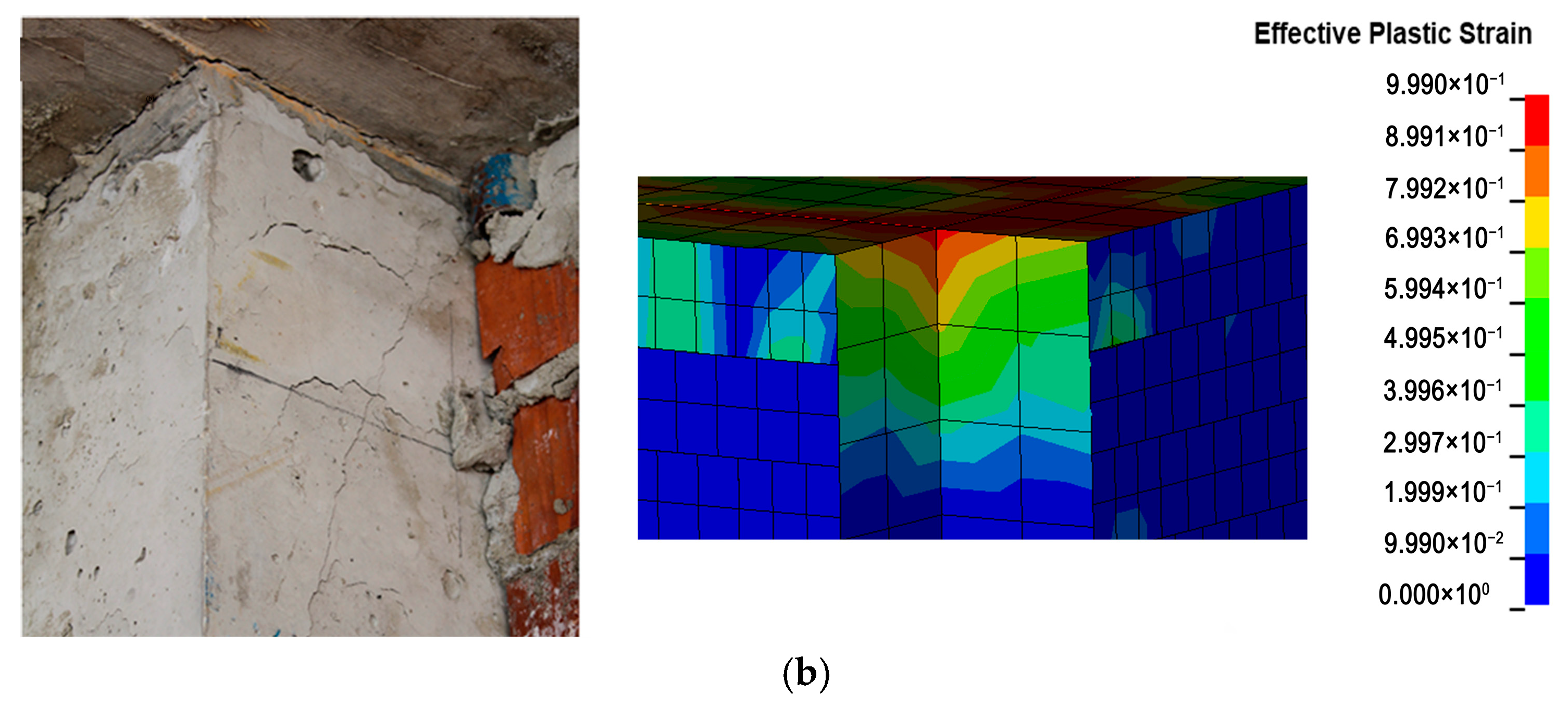

2.3. Validation of Finite Element Models

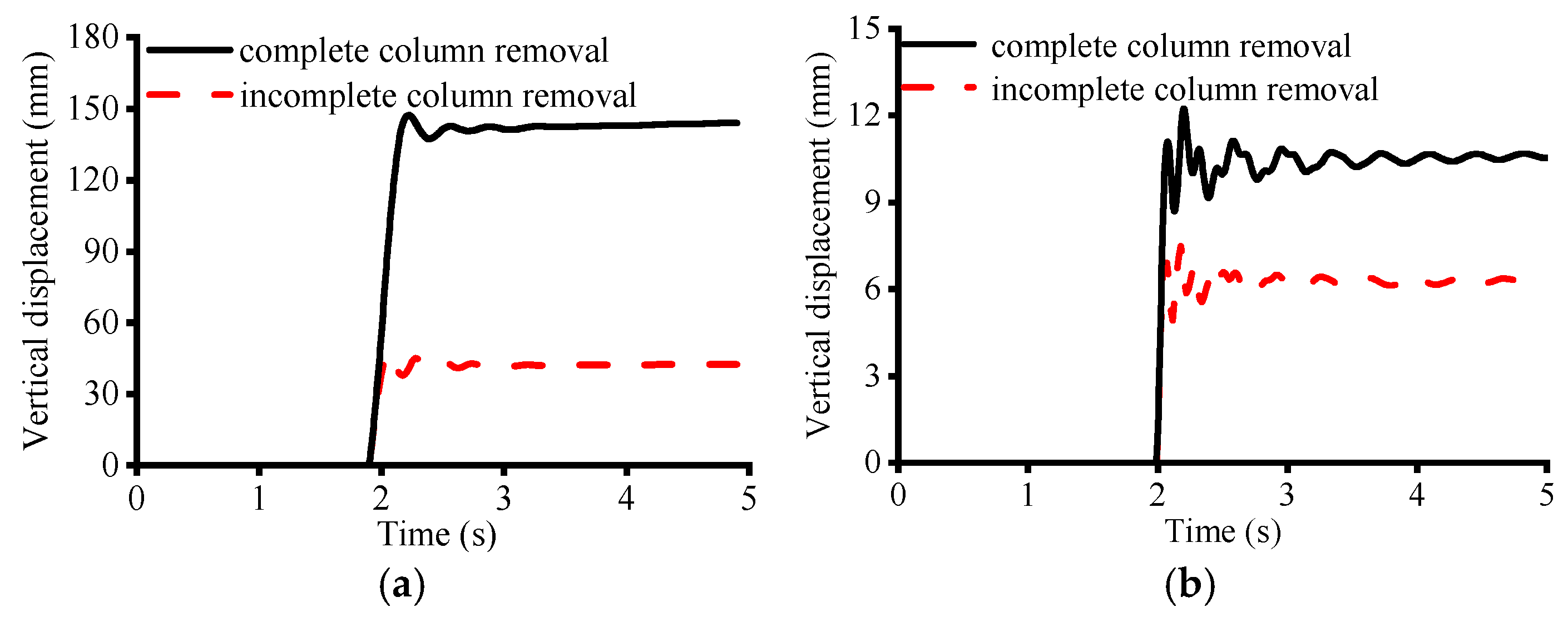

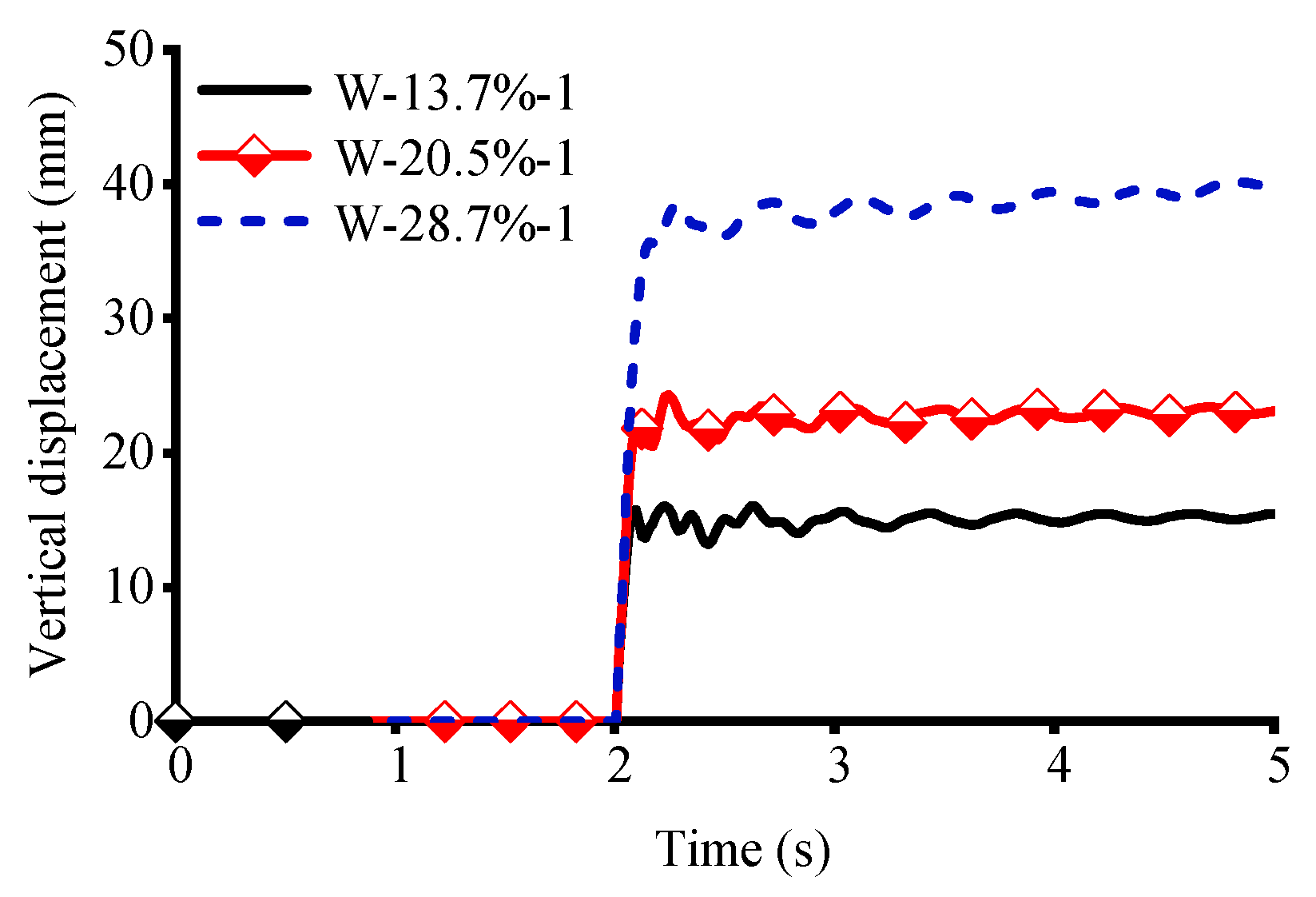

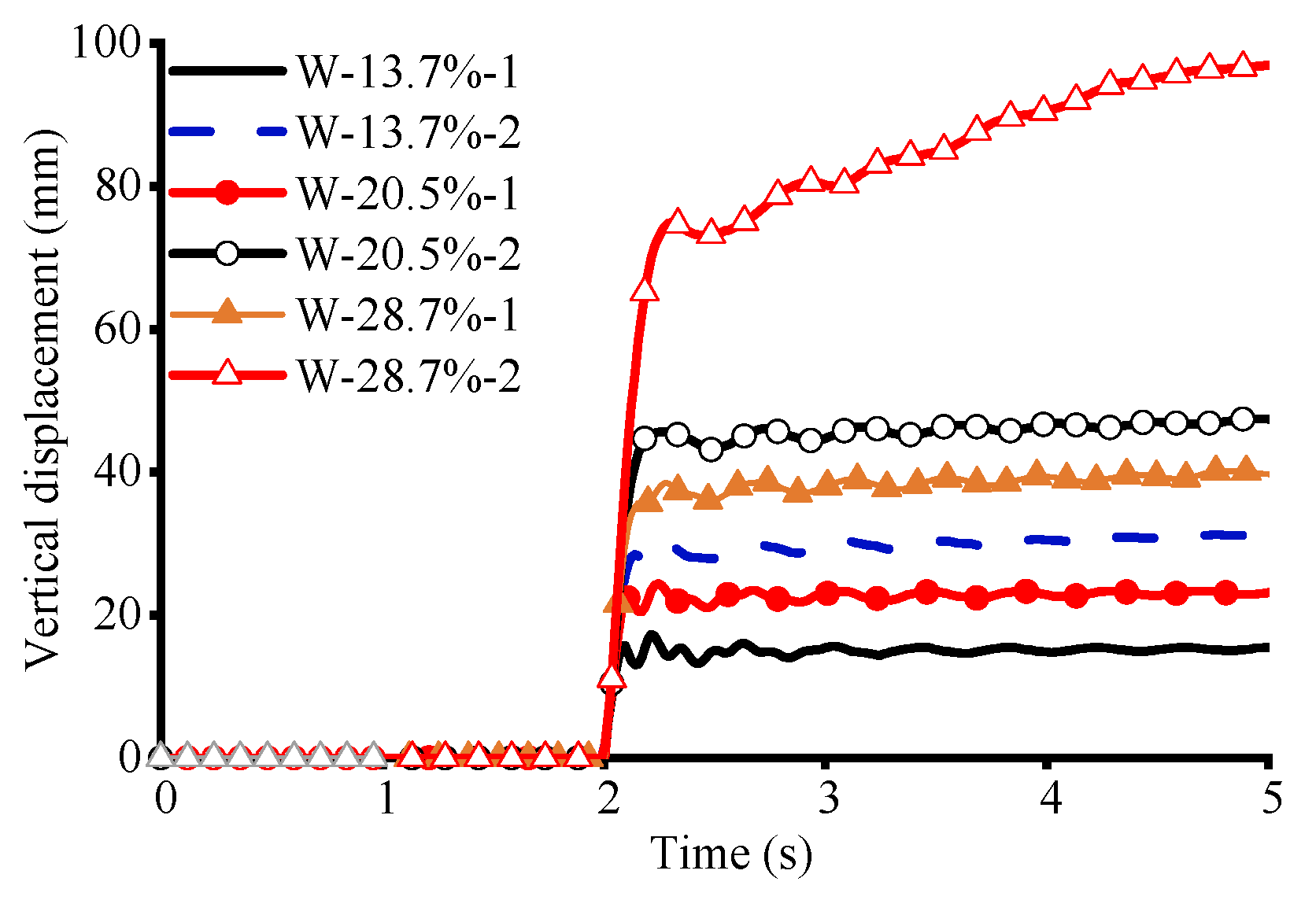

2.3.1. Comparison of Time–Displacement Curves

2.3.2. Comparison of Damage Modes

3. Influence of Column Removal Devices

4. Effect of Infill Wall Openings on Collapse Resistance of RC Space Frame Structures

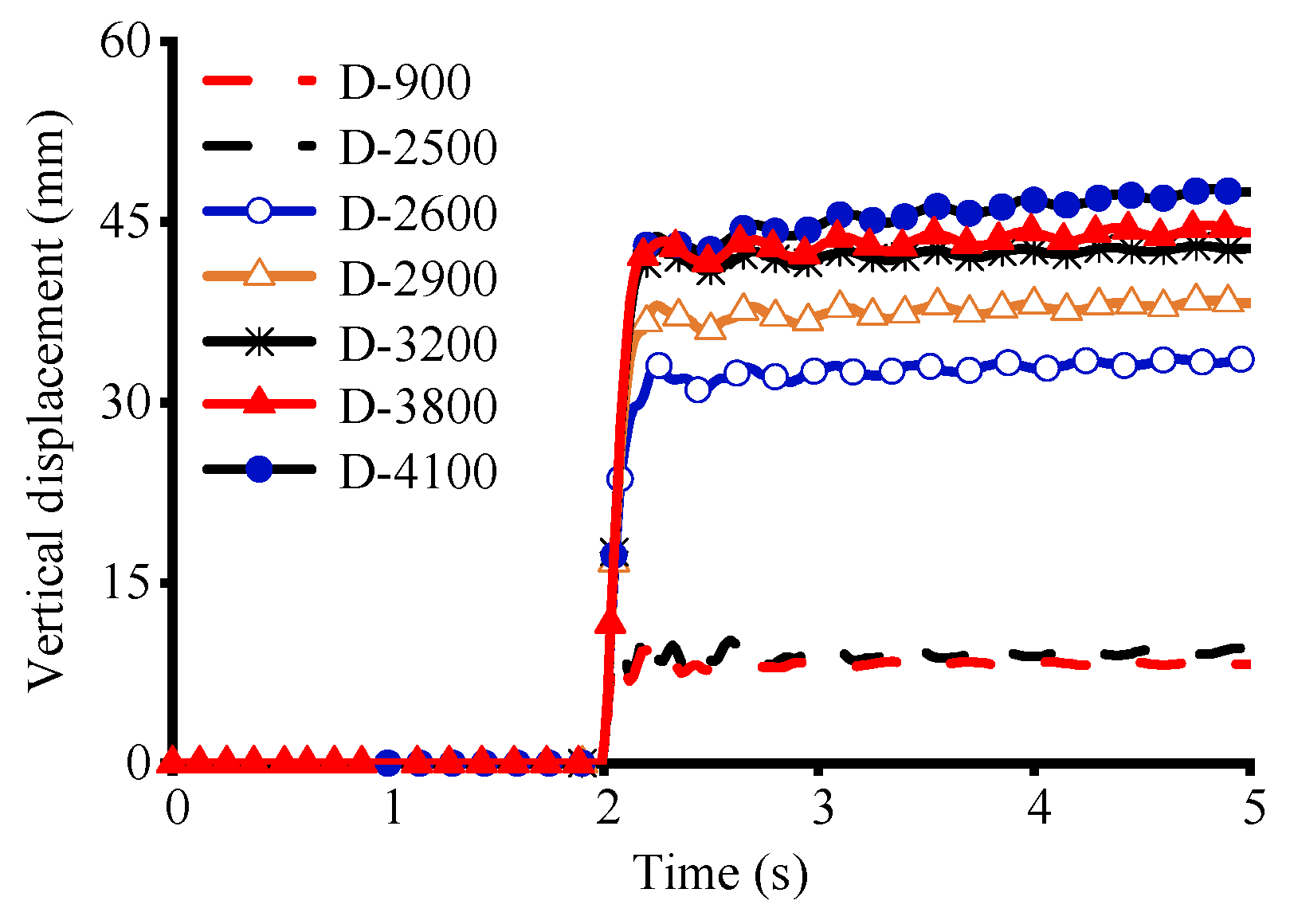

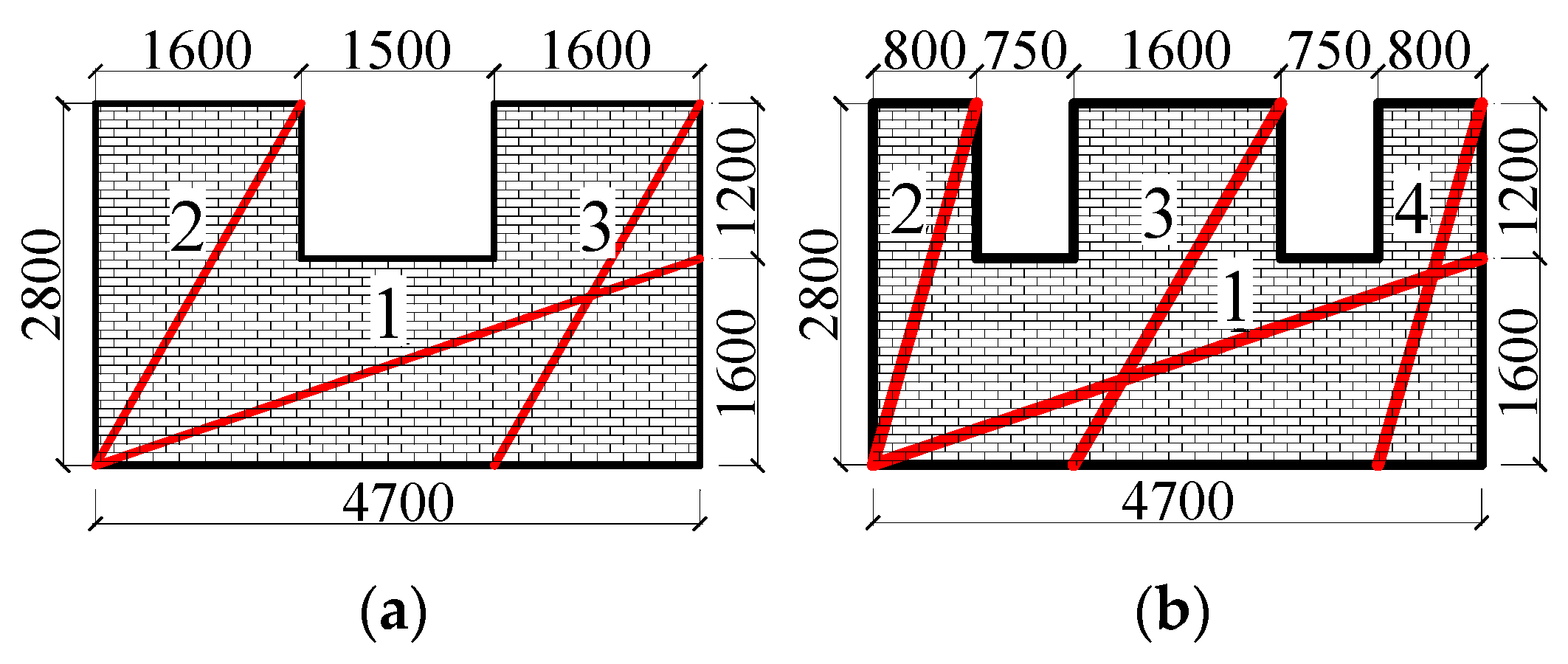

4.1. Effect of Doorway Location on Resistance to Progressive Collapse

4.2. Effect of Opening Rate and Number of Openings on Resistance to Progressive Collapse

5. Conclusions

- A comparative analysis of refined finite element models with complete and incomplete column removal demonstrates that the simulation method exerts a non-negligible influence on the structural response. This effect is particularly pronounced for the pure RC frame, where the incomplete removal method significantly overestimates structural stiffness, leading to non-conservative and potentially unsafe predictions;

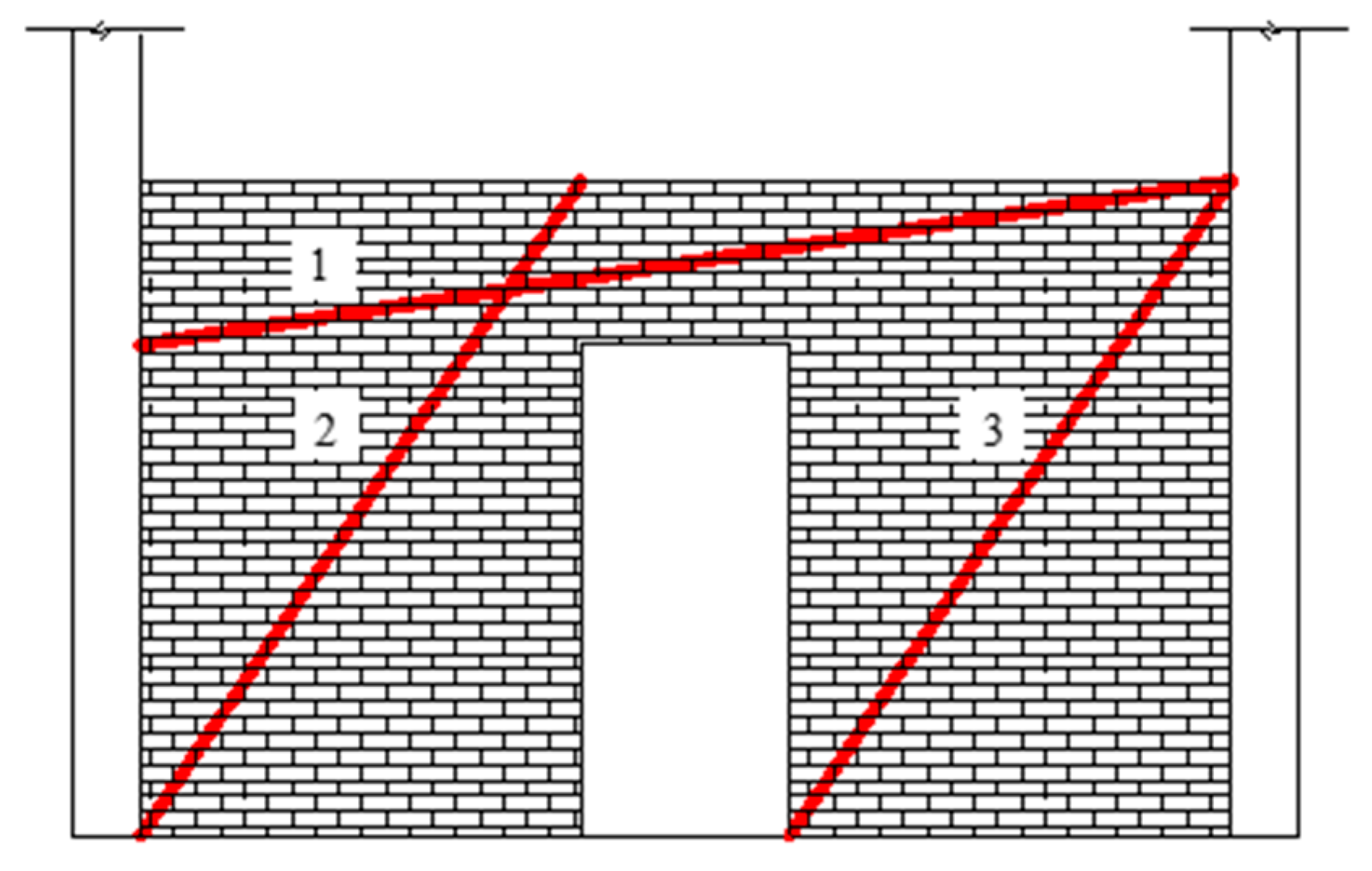

- After the removal of corner columns in the infill wall with openings, diagonal struts will be formed in the corresponding area to transfer the load. The strength of the struts near the fixed end has the most significant effect on the structural stiffness and plays a controlling role. With the increase in the distance from the doorway to the failure column, the increase in the opening rate, and the increase in the number of openings, the effective area of the struts near the fixed end decreases, the strength of the struts decreases, and the structural stiffness is weakened. The value of the structural stiffness decreases by up to 78.2%;

- The closer the door-opening position is to the fixed end, the more significantly the structural stiffness is weakened. When the position of the doorway moves from the centre of the wall length to the fixed end (2500 mm < L < 2600 mm), the structural stiffness decreases the most significantly. When it continues to move further towards the fixed end, the rate of decrease in structural stiffness slows down;

- The analysis reveals that for opening ratios below 8%, structural stiffness is more sensitive to the number of discrete openings than to the overall opening ratio, highlighting the importance of opening dispersion.

6. Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zucca, M.; Tattoni, S.; Di Castri, M.; Simoncelli, M. On the collapse of a post-tensioned reinforced concrete truss bridge during the construction phases. Eng. Fail. Anal. 2024, 158, 107999. [Google Scholar] [CrossRef]

- Abdelwahed, B. A review on building progressive collapse, survey and discussion. Case Stud. Constr. Mater. 2019, 11, e00264. [Google Scholar] [CrossRef]

- Russell, J.M.; Sagaseta, J.; Cormie, D.; Jones, A.E.K. Historical review of prescriptive design rules for robustness after the collapse of Ronan Point. Structures 2019, 20, 365–373. [Google Scholar] [CrossRef]

- Marjanishvili, S.M. Progressive analysis procedure for progressive collapse. J. Perform. Constr. Facil. 2004, 18, 79–85. [Google Scholar] [CrossRef]

- Yu, J.; Tan, K.H. Analytical model for the capacity of compressive arch action of reinforced concrete sub-assemblages. Mag. Concr. Res. 2014, 66, 109–126. [Google Scholar] [CrossRef]

- Kang, S.B.; Tan, K.H. Analytical Model for Compressive Arch Action in Horizontally Restrained Beam-Column Subassemblages. ACI Struct. J. 2016, 113, 813–826. [Google Scholar] [CrossRef]

- Yi, F.; Yi, W.J.; Sun, J.M.; Zhou, Y.; Zhang, W.X.; He, Q.F. Experimental study on progressive collapse behavior of frame structures triggered by impact column removal. Eng. Struct. 2024, 321, 119022. [Google Scholar] [CrossRef]

- Qian, K.; Geng, S.Y.; Liang, S.L.; Fu, F.; Yu, J. Effects of loading regimes on the structural behavior of RC beam-column sub-assemblages against disproportionate collapse. Eng. Struct. 2022, 25, 1113470. [Google Scholar] [CrossRef]

- Sasani, M.; Sagiroglu, S. Gravity load redistribution and progressive collapse resistance of 20-story reinforced concrete structure following loss of interior column. ACI Struct. J. 2010, 107, 636–644. [Google Scholar] [CrossRef]

- Sasani, M.; Kazemi, A.; Sagiroglu, S.; Forest, S. Progressive Collapse Resistance of an Actual 11-Story Structure Subjected to Severe Initial Damage. J. Struct. Eng. 2011, 137, 893–902. [Google Scholar] [CrossRef]

- Qian, K.; Li, B. Dynamic performance of RC beam-column substructures under the scenario of the loss of a corner column—Experimental results. Eng. Struct. 2012, 42, 154–167. [Google Scholar] [CrossRef]

- Yu, J.; Luo, L.Z.; Fang, Q. Structure behavior of reinforced concrete beam-slab assemblies subjected to perimeter middle column removal scenario. Eng. Struct. 2020, 208, 110336. [Google Scholar] [CrossRef]

- Ma, F.; Gilbert, B.P.; Guan, H.; Xue, H.; Lu, X.; Li, Y. Experimental study on the progressive collapse behaviour of RC flat plate substructures subjected to corner column removal scenarios. Eng. Struct. 2019, 180, 728–741. [Google Scholar] [CrossRef]

- Adam, J.M.; Buitrago, M.; Bertolesi, E.; Sagaseta, J.; Moragues, J.J. Dynamic performance of a real-scale reinforced concrete building test under a corner-column failure scenario. Eng. Struct. 2020, 210, 110414. [Google Scholar] [CrossRef]

- Sasani, M.; Werner, A.; Kazemi, A. Bar fracture modeling in progressive collapse analysis of reinforced concrete structures. Eng. Struct. 2011, 33, 401–409. [Google Scholar] [CrossRef]

- Pham, A.T.; Lim, N.S.; Tan, K.H. Investigations of tensile membrane action in beam-slab systems under progressive collapse subject to different loading configurations and boundary conditions. Eng. Struct. 2017, 150, 520–536. [Google Scholar] [CrossRef]

- Qian, K.; Cheng, J.F.; Weng, Y.H.; Fu, F. Effect of loading methods on progressive collapse behavior of RC beam-slab substructures under corner column removal scenario. J. Build. Eng. 2021, 44, 103258. [Google Scholar] [CrossRef]

- Tsai, M.H.; Huang, T.C. Progressive collapse analysis of an RC building with exterior partially infilled walls. Struct. Des. Tall Spec. Build. 2011, 22, 327–348. [Google Scholar] [CrossRef]

- Kong, J.; Zhai, C.; Wang, X. In-plane behavior of masonry infill wall considering out-of-plane loading. Period. Polytech.- Civ. Eng. 2016, 60, 217–221. [Google Scholar] [CrossRef]

- Qian, K.; Lan, D.Q.; Fu, F.; Li, B. Effects of infilled wall opening on load resisting capacity of RC frames to mitigate progressive collapse risk. Eng. Struct. 2020, 223, 111196. [Google Scholar] [CrossRef]

- Qian, K.; Li, B. Effects of Masonry Infill Wall on the Performance of RC Frames to Resist Progressive Collapse. J. Struct. Eng. 2017, 143, 04017118. [Google Scholar] [CrossRef]

- Brodsky, A.; Yankelevsky, D.Z. Resistance of reinforced concrete frames with masonry infill walls to in-plane gravity loading due to loss of a supporting column. Eng. Struct. 2017, 140, 134–150. [Google Scholar] [CrossRef]

- Stinger, S.M.; Orton, S.L. Experimental Evaluation of Disproportionate Collapse Resistance in Reinforced Concrete Frames. ACI Struct. J. 2013, 110, 521–529. [Google Scholar]

- Shan, S.D.; Li, S.; Xu, S.Y.; Xie, L.L. Experimental study on the progressive collapse performance of RC frames with infill walls. Eng. Struct. 2016, 111, 80–92. [Google Scholar] [CrossRef]

- Baghi, H.; Oliveira, A.; Valençac, J.; Cavaco, E.; Neves, L.; Júlio, E. Behavior of reinforced concrete frame with masonry infill wall subjected to vertical load. Eng. Struct. 2018, 171, 476–487. [Google Scholar] [CrossRef]

- Li, S.; Shan, S.; Zhai, C.; Xie, L. Experimental and numerical study on progressive collapse process of RC frames with full-height infill walls. Eng. Fail. Anal. 2016, 59, 57–68. [Google Scholar] [CrossRef]

- Buitrago, M.; Bertolesi, E.; Sagaseta, J.; Calderón, P.A.; Adam, J.M. Robustness of RC building structures with infill masonry walls: Tests on a purpose-built structure. Eng. Struct. 2021, 226, 111384. [Google Scholar] [CrossRef]

- Yu, J.; Gan, Y.P.; Wu, J.; Wu, H. Effect of concrete masonry infill walls on progressive collapse performance of reinforced concrete infilled frames. Eng. Struct. 2019, 191, 179–193. [Google Scholar] [CrossRef]

- Qian, K.; Wang, D.F.; Huang, T.; Weng, Y.H. Initial damage and residual behavior of RC beam-slab structures following sudden column removal—Numerical study. Structures 2022, 36, 650–664. [Google Scholar] [CrossRef]

- Shan, S.; Li, S.; Wang, S. Effect of infill walls on mechanisms of steel frames against progressive collapse. J. Constr. Steel Res. 2019, 162, 105720. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.-L.; Zou, Y.; Liu, H.; Wu, Y.; Li, Z.; Xue, T.-Q. Dynamic Response Analysis of Infilled RC Frames with Openings Under Instantaneous Column Removal Scenarios. Buildings 2025, 15, 3778. https://doi.org/10.3390/buildings15203778

Wang J-L, Zou Y, Liu H, Wu Y, Li Z, Xue T-Q. Dynamic Response Analysis of Infilled RC Frames with Openings Under Instantaneous Column Removal Scenarios. Buildings. 2025; 15(20):3778. https://doi.org/10.3390/buildings15203778

Chicago/Turabian StyleWang, Jia-Liang, Yu Zou, Huan Liu, You Wu, Zhi Li, and Tian-Qi Xue. 2025. "Dynamic Response Analysis of Infilled RC Frames with Openings Under Instantaneous Column Removal Scenarios" Buildings 15, no. 20: 3778. https://doi.org/10.3390/buildings15203778

APA StyleWang, J.-L., Zou, Y., Liu, H., Wu, Y., Li, Z., & Xue, T.-Q. (2025). Dynamic Response Analysis of Infilled RC Frames with Openings Under Instantaneous Column Removal Scenarios. Buildings, 15(20), 3778. https://doi.org/10.3390/buildings15203778