An Experimental Evaluation of Steel Beam-HSST/CFSST Column Connection with Varying Joint Configurations

Abstract

1. Introduction

2. Experiment Design

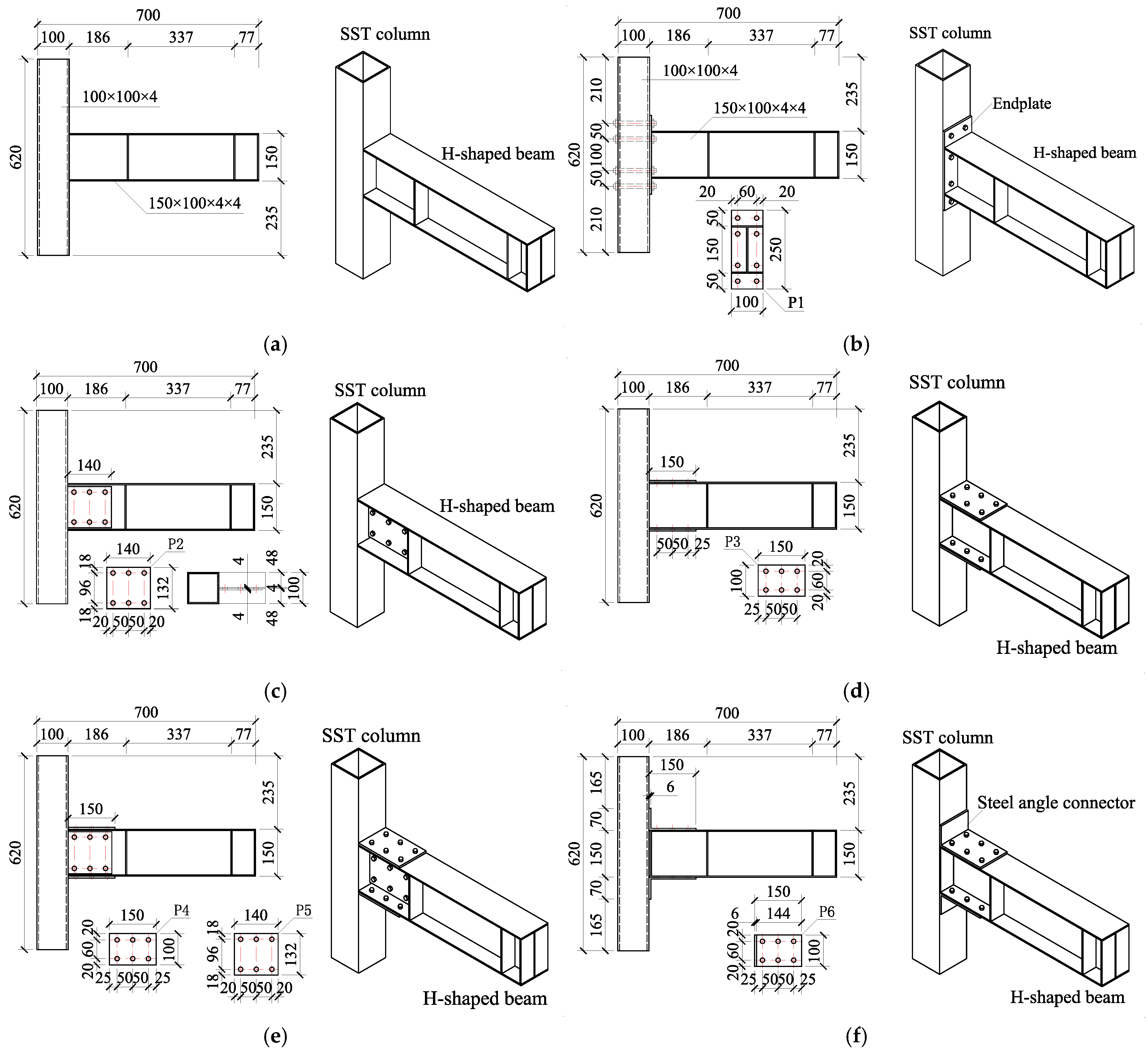

2.1. Specimens

2.2. Material Properties

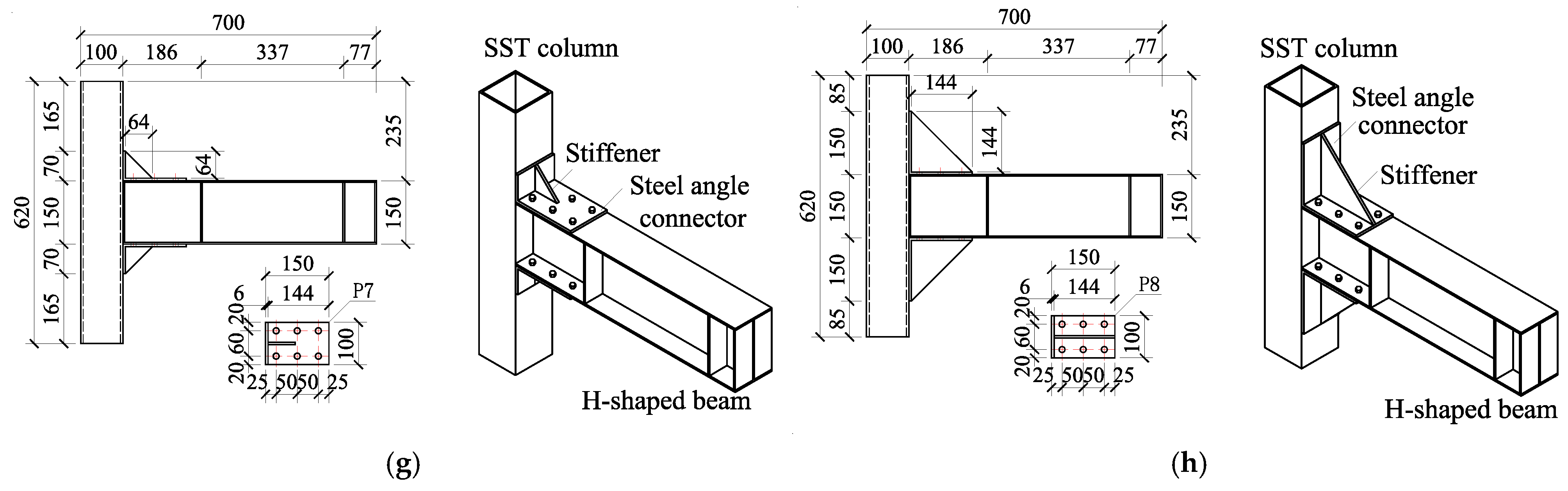

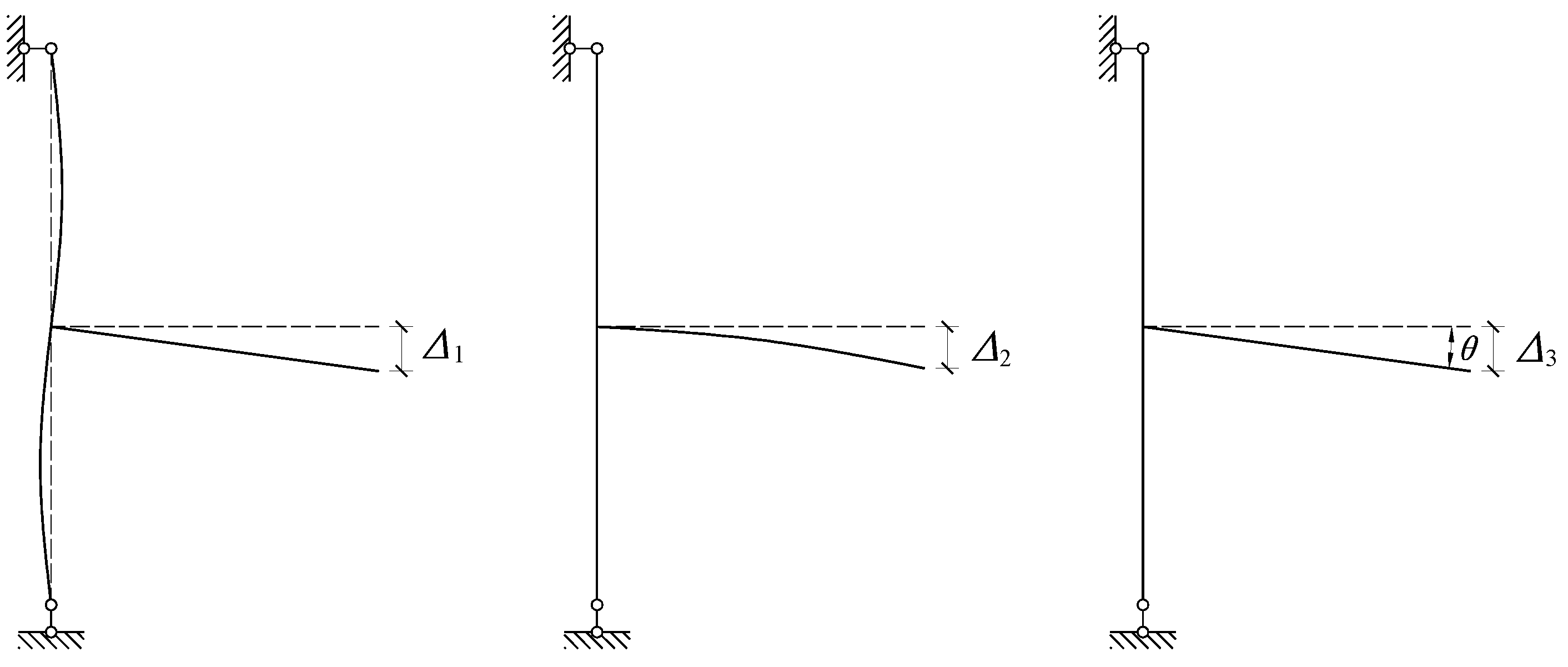

2.3. Loading Schemes

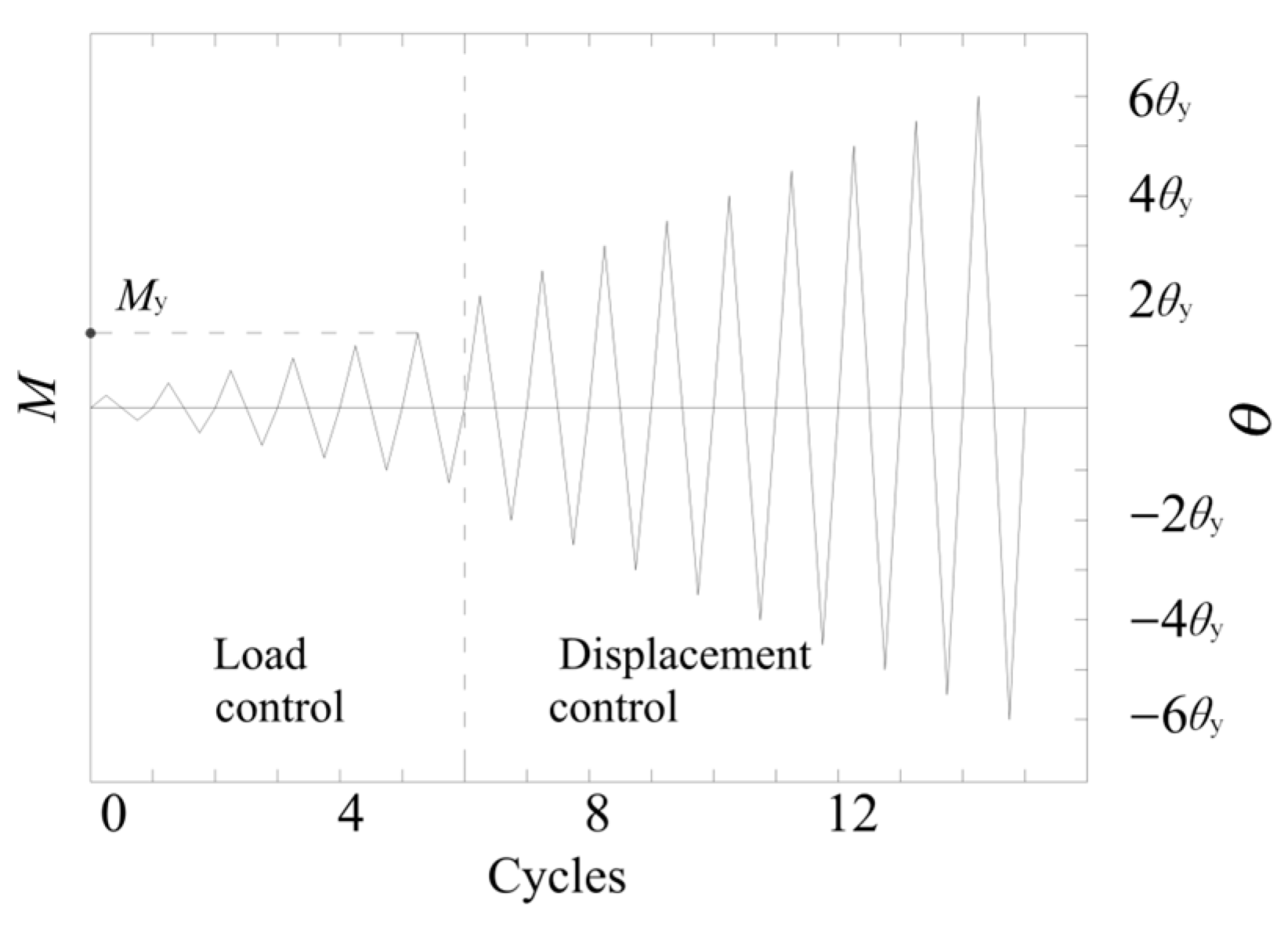

2.4. Data Collection

3. Results and Analysis

3.1. Failure Modes

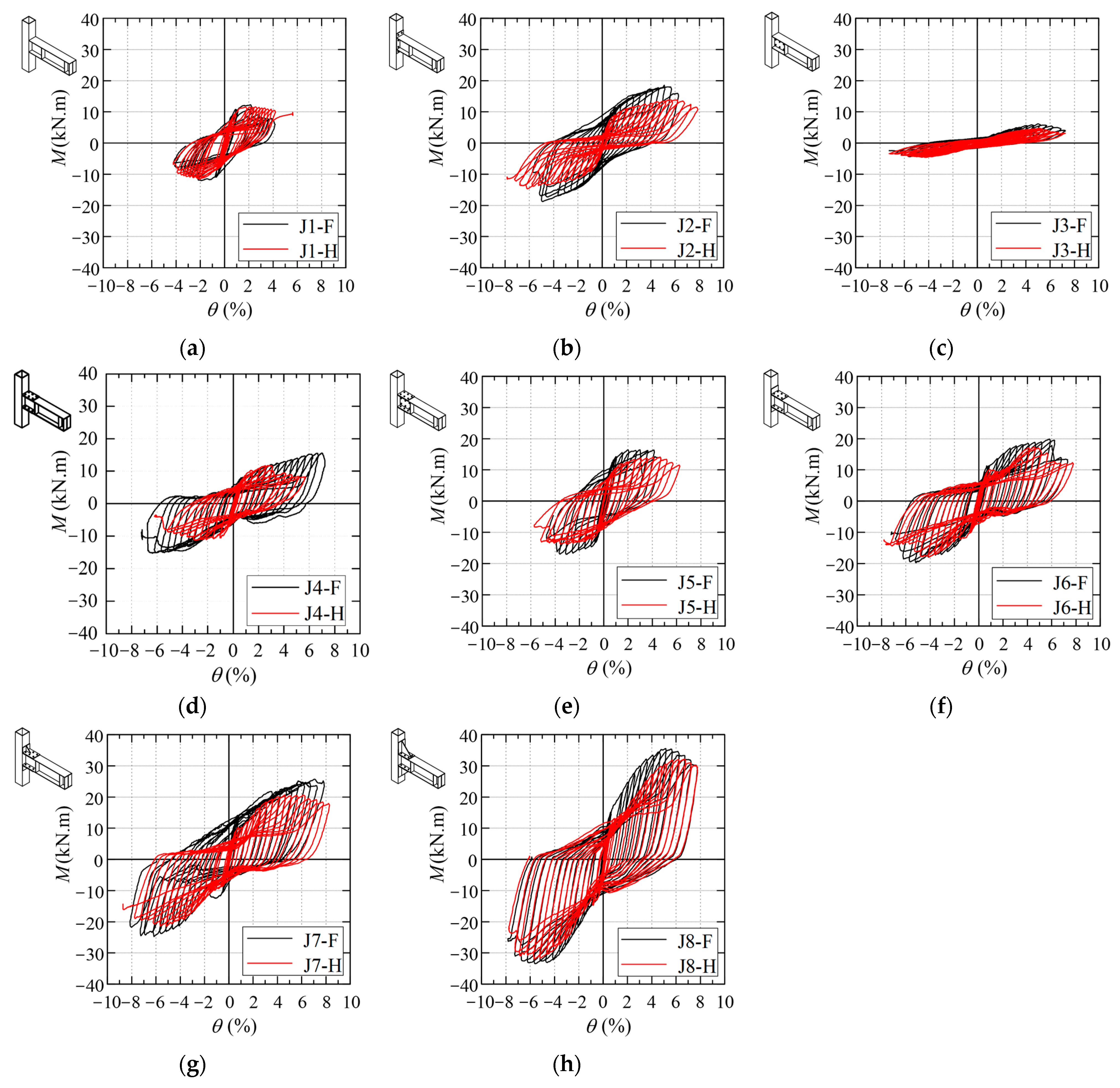

3.2. Hysteresis Curve

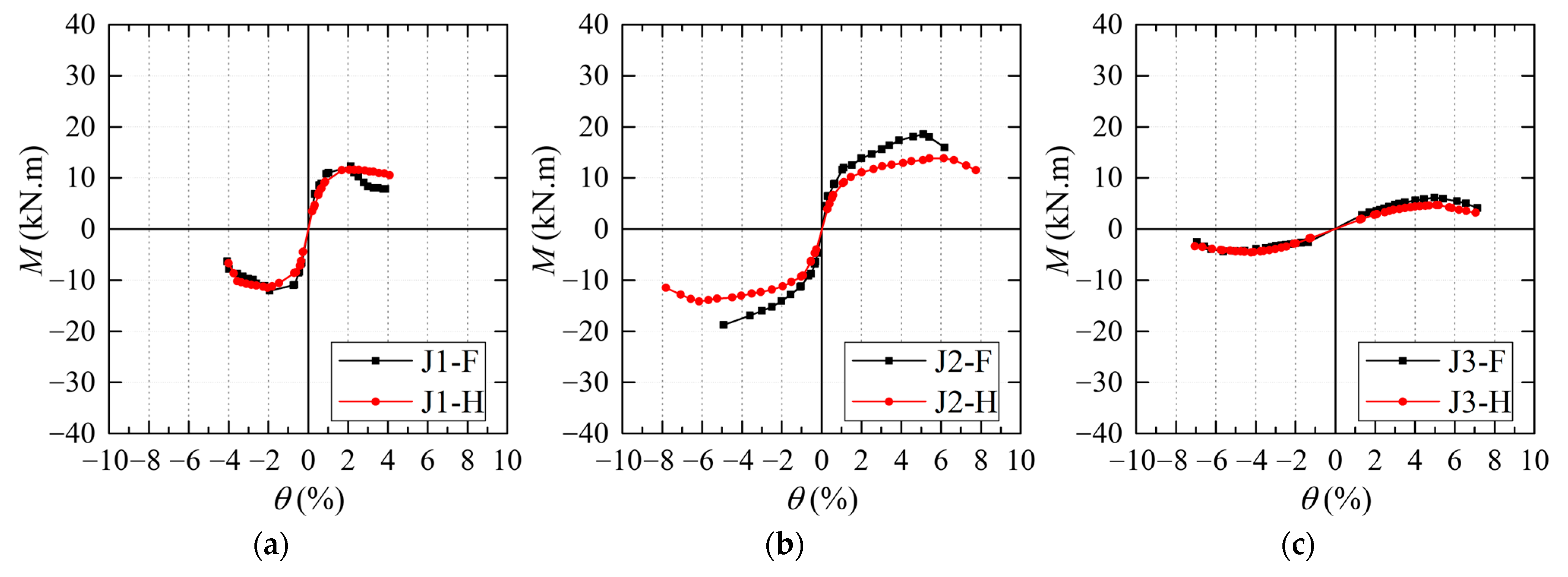

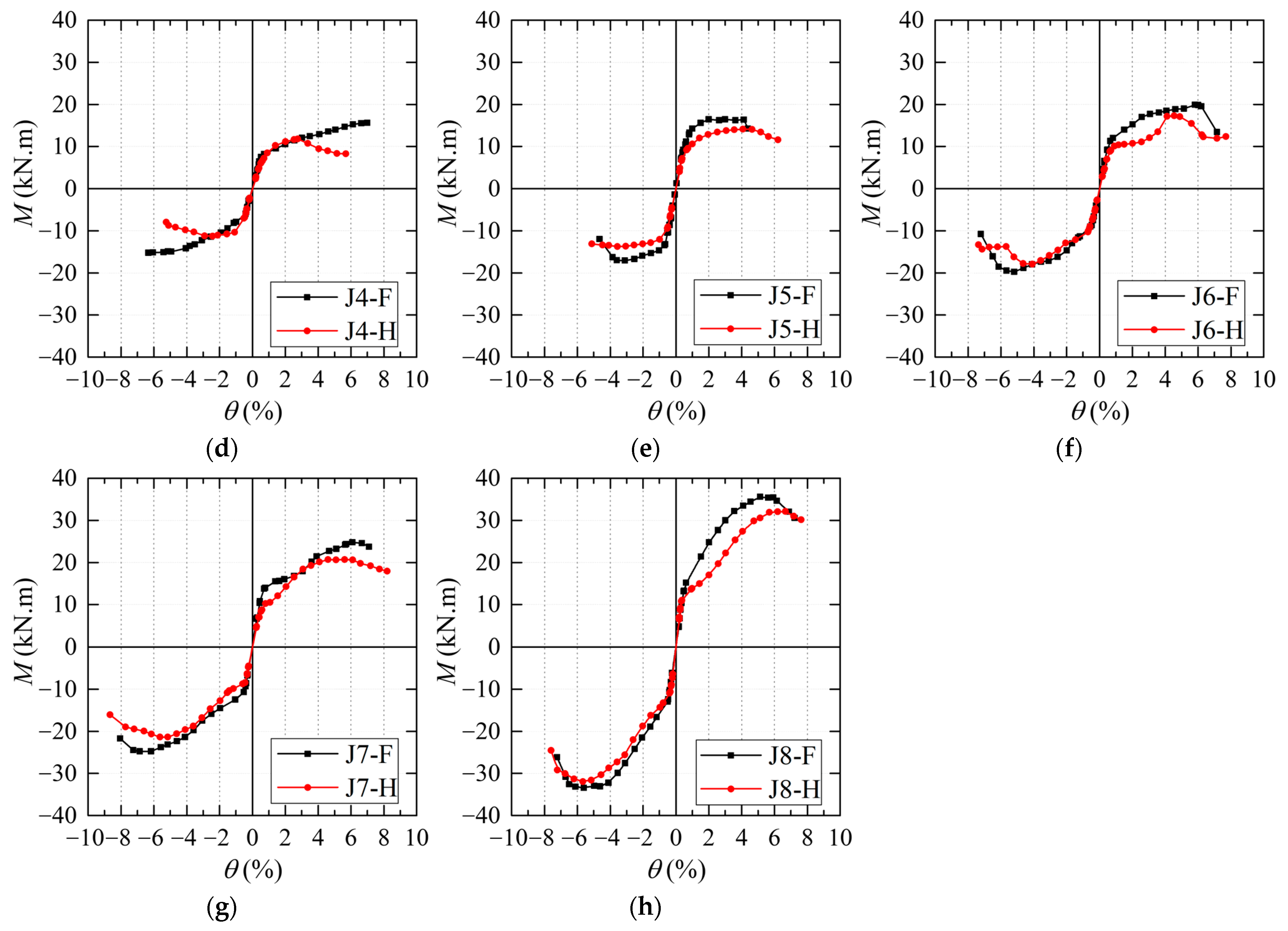

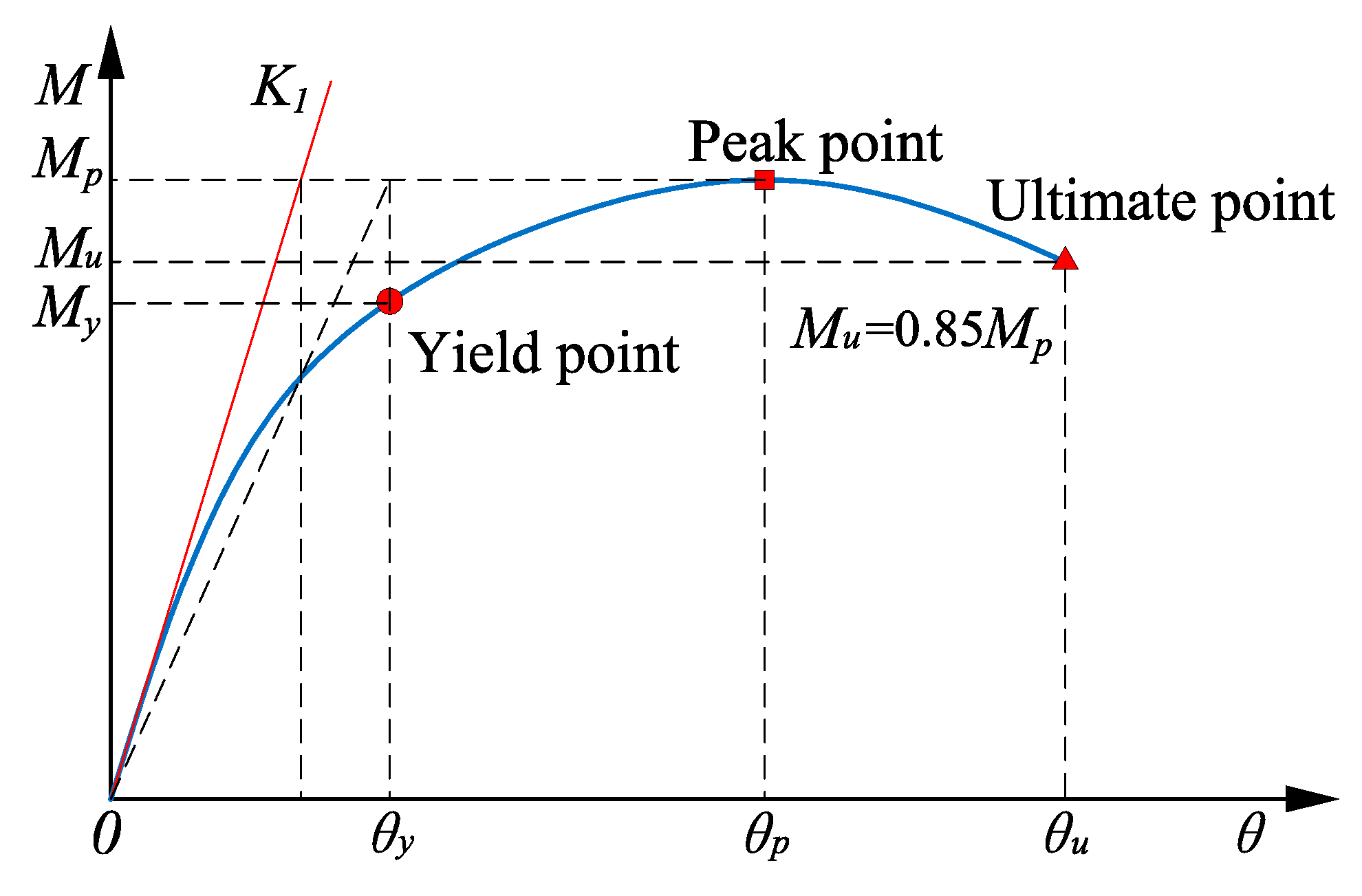

3.3. Skeleton Curves and Feature Points

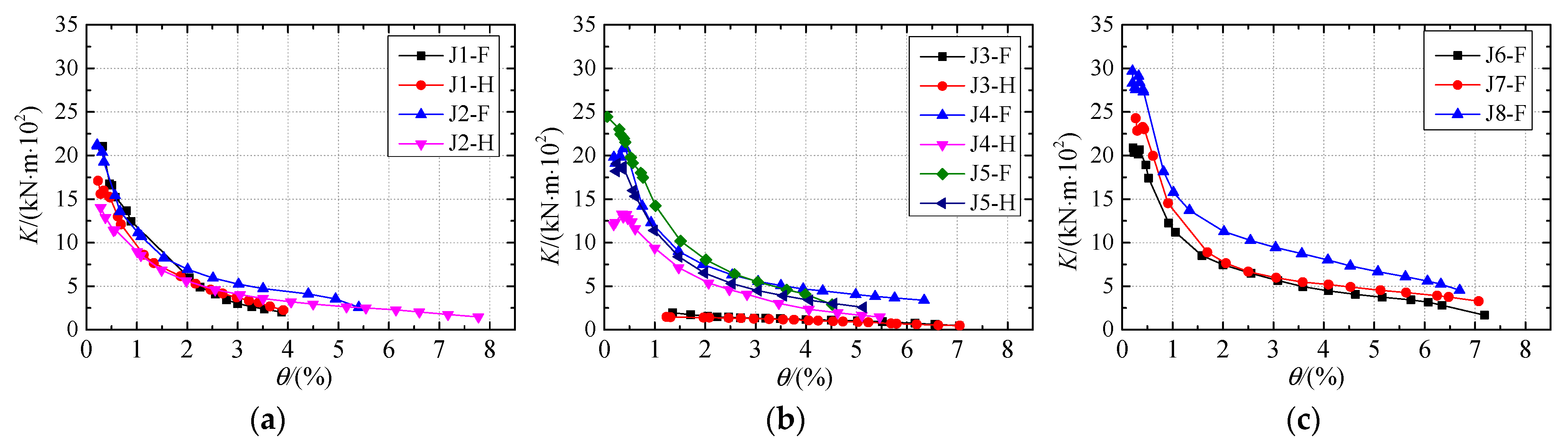

3.4. Stiffness Degradation

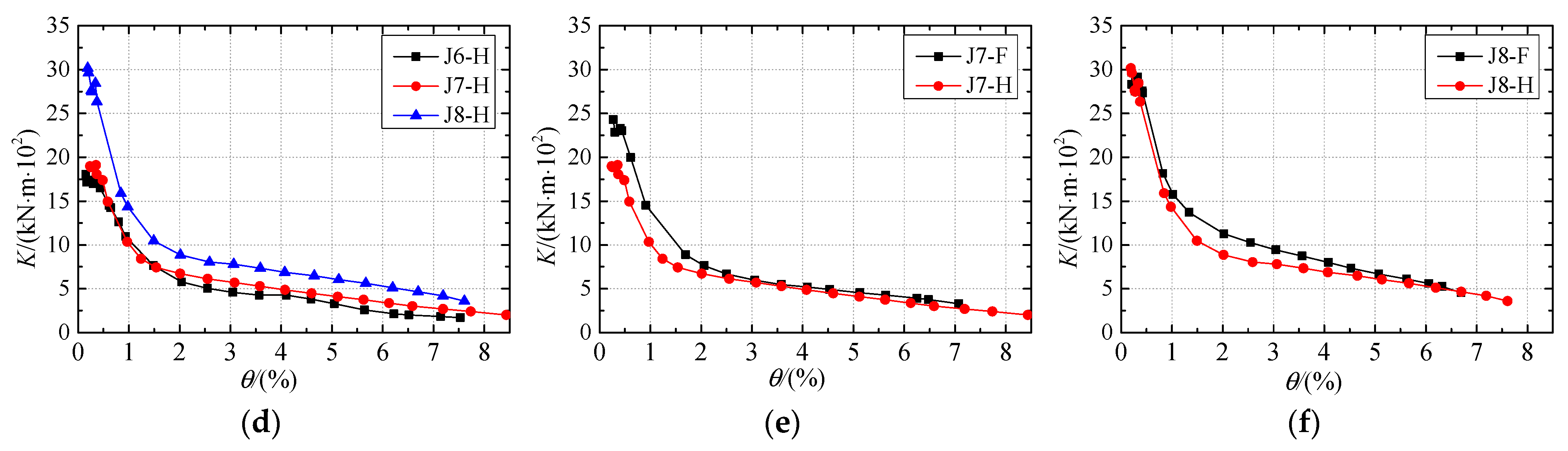

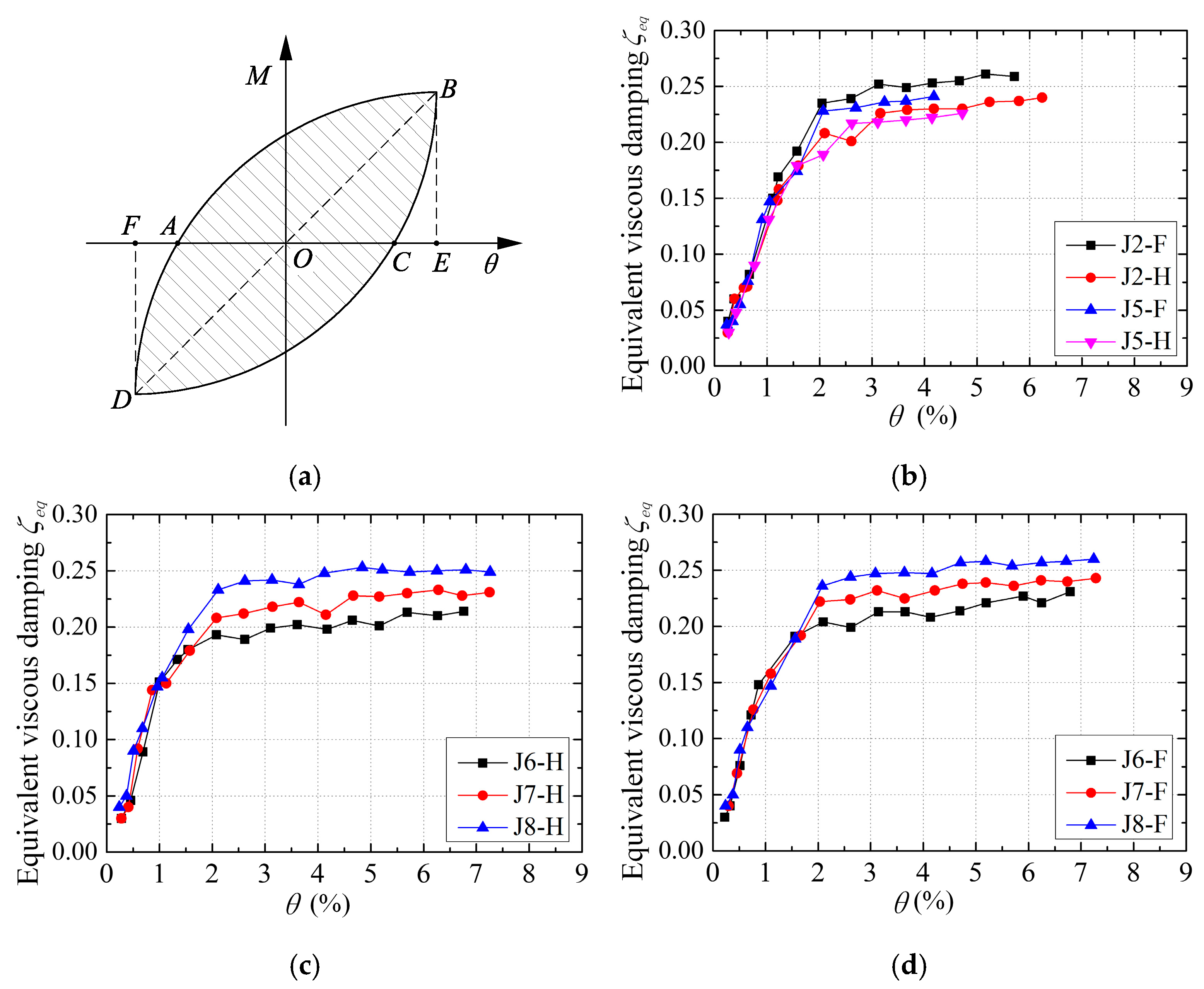

3.5. Energy Dissipation

3.6. Joint Classification

3.7. Comprehensive Evaluation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| SST | Square steel tube |

| HSST | Hollow square steel tube |

| CFSST | Concrete-filled square steel tube |

| CFST | Concrete-filled steel tube |

| SQC | Steel quantity for connection |

| DT | Displacement transducer |

| DG | Dial gauge |

References

- Derakhshan, H.; Shekastehband, B. Seismic performance of bolted T-stub Beam-to-Box column connection. Structures 2023, 56, 104873. [Google Scholar] [CrossRef]

- Han, L.-H.; Li, W.; Bjorhovde, R. Developments and advanced applications of concrete-filled steel tubular (CFST) structures: Members. J. Constr. Steel Res. 2014, 100, 211–228. [Google Scholar] [CrossRef]

- Rong, B.; Zhang, Y.; Sun, J.; Zhang, R. Experimental and numerical research on hysteretic behavior of CFST frame with diaphragm-through connections. J. Build. Eng. 2022, 45, 103529. [Google Scholar] [CrossRef]

- Kassem, M.M.; Nazri, F.M.; Farsangi, E.N.; Ozturk, B. Development of a uniform seismic vulnerability index framework for reinforced concrete building typology. J. Build. Eng. 2022, 47, 103838. [Google Scholar] [CrossRef]

- Kassem, M.M.; Nazri, F.M.; Farsangi, E.N.; Ozturk, B. Improved vulnerability index methodology to quantify seismic risk and loss assessment in reinforced concrete buildings. J. Earthq. Eng. 2022, 26, 6172–6207. [Google Scholar] [CrossRef]

- Doung, P.; Sasaki, E. Load-deformation characteristics and performance of internal diaphragm connections to box columns. Thin-Walled Struct. 2019, 143, 106221. [Google Scholar] [CrossRef]

- Doung, P.; Leelataviwat, S.; Sasaki, E. Tensile strength and failure mechanism of internal diaphragms in wide flange beam-to-box column connections with concrete filling. J. Build. Eng. 2021, 34, 102037. [Google Scholar] [CrossRef]

- Zhang, N.; Jiang, S.; Chen, X.; Bao, L.; Zhou, F.; Zhao, H.; Shi, G. Experimental study on seismic behaviour of thick-flange steel beam to square CFST column joints with internal diaphragms. Eng. Struct. 2024, 319, 118792. [Google Scholar] [CrossRef]

- Chen, C.-C.; Lin, C.-C.; Tsai, C.-L. Evaluation of reinforced connections between steel beams and box columns. Eng. Struct. 2004, 26, 1889–1904. [Google Scholar] [CrossRef]

- Tong, L.; Huang, J.; Wu, H.; Wang, K.; Dong, B. Experimental behavior of steel-beam to flat rectangular CFST column connections with small-sized external diaphragms. J. Constr. Steel Res. 2022, 198, 107520. [Google Scholar] [CrossRef]

- Tong, L.; Zheng, J.; Wu, H.; Wang, K.; Dong, B.; Liu, B. Parametric study of steel-beam to flat-rectangular CFST column connections with small-size diaphragms. J. Constr. Steel Res. 2023, 211, 108156. [Google Scholar] [CrossRef]

- Xu, P.; Wang, Z.; Mou, B.; Gao, D. Seismic performance of CFST column to steel beam joint with outer annular stiffener. J. Build. Eng. 2022, 54, 104679. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, Y.; Wang, Z.; Lin, Y.; Shu, C.; Zhang, F. Experimental study of through diaphragm bolted joint between H-beam to CFST column. J. Constr. Steel Res. 2021, 182, 106647. [Google Scholar] [CrossRef]

- Lin, Y.; Ye, Q.; Wang, Y.; Shu, C.; Zhang, F.; Zhang, Y.; Zhao, Y.; Cao, H. Seismic behaviour of diaphragm-through bolted-welded joints between CFST column to steel beam. J. Constr. Steel Res. 2023, 200, 107651. [Google Scholar] [CrossRef]

- Wang, J.; Wang, J.; Wang, H. Seismic behavior of blind bolted CFST frames with semi-rigid connections. Structures 2017, 9, 91–104. [Google Scholar] [CrossRef]

- Thai, H.-T.; Uy, B.; Yamesri; Aslani, F. Behaviour of bolted endplate composite joints to square and circular CFST columns. J. Constr. Steel Res. 2017, 131, 68–82. [Google Scholar] [CrossRef]

- Waqas, R.; Uy, B.; Thai, H.-T. Experimental and numerical behaviour of blind bolted flush endplate composite connections. J. Constr. Steel Res. 2019, 153, 179–195. [Google Scholar] [CrossRef]

- Wang, P.; Sun, L.; Liu, M.; Zhang, B.; Hu, X.; Yu, J. Experimental studies on thread-fixed one-side bolted connection of beam to hollow square steel tube under static bending moment. Eng. Struct. 2020, 214, 110655. [Google Scholar] [CrossRef]

- Zhang, B.; Yuan, H.; Xia, C.; Liu, X.; Liu, M.; Liu, F.; Wang, P. Seismic behavior of thread-fixed one-side bolted endplate connection of steel beam to hollow square column. J. Build. Eng. 2021, 43, 102557. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, B.; Liu, Q.; Liu, Y.; Tang, L.; Zhang, W.; Liu, F.; Wang, P. Experimental studies on thread-fixed one-side bolted endplate connection with internal strengthening structure. Eng. Struct. 2021, 246, 112977. [Google Scholar] [CrossRef]

- Sun, L.; Liang, Z.; Cai, M.; Liu, L.; Bai, Y.; Geng, Z.; Cheng, Y.; Wang, P.; Liu, M. Seismic behaviour of I-beams bolted CFST column connection using extended TSOBs. Structures 2023, 48, 882–900. [Google Scholar] [CrossRef]

- Cai, M.; Liu, X.; Wang, Q.; Gu, H.; Wang, P.; Liu, Y.; Liu, F. Seismic performance of thread-fixed one-side bolts bolted extended endplate connection to HSST column with internal strengthening components. J. Build. Eng. 2022, 45, 103615. [Google Scholar] [CrossRef]

- Liu, X.C.; Cui, F.Y.; Zhan, X.X.; Yu, C.; Jiang, Z.Q. Seismic performance of bolted connection of H-beam to HSS-column with web end-plate. J. Constr. Steel Res. 2019, 156, 167–181. [Google Scholar] [CrossRef]

- Zhan, X.-X.; Liu, X.-C.; Feng, S.; Yu, C. Seismic performance of a square HSS column to H-section beam bolted connection with double cover plate. Eng. Struct. 2021, 231, 111729. [Google Scholar] [CrossRef]

- Cho, Y.; Wang, F.; Seo, S.-Y.; Lee, K.; Kim, T. Experimental and numerical investigation of through-diaphragm in H-shaped steel beam to CFST column connections. Thin-Walled Struct. 2024, 199, 111852. [Google Scholar] [CrossRef]

- Lee, H.-J.; Choi, I.-R.; Oh, M.-W. Vertical diaphragms for moment connection of thin-walled CFT column to steel beam. J. Build. Eng. 2024, 97, 110607. [Google Scholar] [CrossRef]

- Ahmadi, M.M.; Mirghaderi, S.R. Experimental studies on through-plate moment connection for beam to HSS/CFT column. J. Constr. Steel Res. 2019, 161, 154–170. [Google Scholar] [CrossRef]

- Paul, S.; Deb, S.K.; Rangoonwala, A.H. Seismic performance of bidirectional bolted drilled cut RBS-CFT connections under cyclic loads. J. Build. Eng. 2023, 77, 107185. [Google Scholar] [CrossRef]

- Cao, S.; Shu, G.; Lin, K.; Qin, Y. Experimental seismic behaviour of bottom-through-diaphragm and top-ring connection to SST columns. J. Constr. Steel Res. 2018, 150, 249–260. [Google Scholar] [CrossRef]

- Xu, X.; Cheng, R.; Yang, P.; Yu, Y. Experimental and numerical investigations on square CFST column to U-shaped steel-concrete composite beam joints with internal T-shaped diaphragms. J. Build. Eng. 2022, 60, 105172. [Google Scholar] [CrossRef]

- Habibi, A.; Fanaie, N.; Shahbazpanahi, S. Experimental and numerical investigation of I-beam to concrete-filled tube (CFT) column moment connections with pipe-stiffened internal diaphragm. J. Constr. Steel Res. 2023, 200, 107648. [Google Scholar] [CrossRef]

- Ding, C.; Bai, Y.; Yang, K.; Zhang, J. Cyclic behaviour of prefabricated connections for steel beam to concrete filled steel tube column. J. Constr. Steel Res. 2021, 176, 106422. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Qin, X.; Chen, Y.; Li, L. Performance of practical beam-to-SHS column connections against progressive collapse. Eng. Struct. 2016, 106, 332–347. [Google Scholar] [CrossRef]

- Wang, W.; Fang, C.; Chen, Y.; Wang, M. Seismic performance of steel H-beam to SHS-column cast modular panel zone joints. Eng. Struct. 2016, 117, 145–160. [Google Scholar] [CrossRef]

- Fanaie, N.; Moghadam, H.S. Experimental study of rigid connection of drilled beam to CFT column with external stiffeners. J. Constr. Steel Res. 2019, 153, 209–221. [Google Scholar] [CrossRef]

- Rezaifar, O.; Younesi, A. Experimental study discussion of the seismic behavior on new types of internal/external stiffeners in rigid beam-to-CFST/HSS column connections. Constr. Build. Mater. 2017, 136, 574–589. [Google Scholar] [CrossRef]

- GB 50936-2014; Technical Code for Concrete Filled Steel Tubular Structures. China Architecture & Building Press: Beijing, China, 2014.

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. China Planning Press: Beijing, China, 2021.

- JGJ 82-2011; Technical Specification for High Strength Bolt Connections of Steel Structures. China Planning Press: Beijing, China, 2011.

- GB 50011-2010; Code for Seismic Design of Buildings, 2016 ed. China Architecture & Building Press: Beijing, China, 2016.

- JGJ/T 101-2015; Specification for Seismic Test of Buildings. China Architecture & Building Press: Beijing, China, 2015.

- EN 1993-1-8; Eurocode 3: Design of Steel Structures—Part 1.8: Design of Joints. CEN: Brussels, Belgium, 2005.

- Koloo, F.A.; Badakhshan, A.; Fallahnejad, H.; Jamkhaneh, M.E.; Ahmadi, M. Investigation of Proposed Concrete Filled Steel Tube Connections under Reversed Cyclic Loading. Int. J. Steel Struct. 2018, 18, 163–177. [Google Scholar] [CrossRef]

| Specimen | Fabrication Process | On-Site Process | SQC (kg) |

|---|---|---|---|

| J1-H & J1-F | None | Beam flanges and webs are welded to the column | 0 |

| J2-H & J2-F | The beam flange and web are welded to the end plate P1 | End plate P1 and the column are connected with bolts | 2.62 |

| J3-H & J3-F | Connecting plate P2 is welded to the column | The beam, web, and the connecting plate P2 are connected with bolts | 0.97 |

| J4-H & J4-F | Connecting plate P3 is welded to the column | The upper and lower flanges of the beam are connected to the connecting plate P3 with bolts | 2.19 |

| J5-H & J5-F | Connecting plates P4 and P5 are welded to the columns | The upper and lower flanges of the beam are connected to the connecting plate P4 with bolts. The beam, web, and the connecting plate P5 are connected with bolts | 3.16 |

| J6-H & J6-F | Angle connector plate P6 is welded to the column | The upper and lower flanges of the beam are connected to the angle connector plate P6 with bolts | 2.80 |

| J7-H & J7-F | Angle connector plate P7 is welded to the column | The upper and lower flanges of the beam are connected to the angle connector plate P7 with bolts | 2.99 |

| J8-H & J8-F | Angle connector plate P8 is welded to the column | The upper and lower flanges of the beam are connected to the angle connector plate P8 with bolts | 3.77 |

| Material | t (mm) | (Mpa) | (Mpa) | δ (%) | E (Gpa) |

|---|---|---|---|---|---|

| Beam webs, beam flanges, column webs | 4 | 373 | 444.3 | 21.5 | 214 |

| column flange | 6 | 346 | 429.1 | 19.2 | 202 |

| End plates, L-shaped connecting plates, stiffening ribs | 6 | 355 | 423.8 | 19.7 | 202 |

| Specimens | Loading Direction | My (kN·m) | (%) | Mp (kN·m) | (%) | Mu (kN·m) | (%) | μ | Ω |

|---|---|---|---|---|---|---|---|---|---|

| J1-H | Forward | 10.94 | 1.76 | 11.60 | 2.35 | 10.16 | 4.08 | 2.32 | 1.08 |

| Negative | 9.98 | 1.31 | 11.52 | 2.04 | 9.79 | 3.83 | 2.92 | ||

| J1-F | Forward | 10.40 | 1.05 | 12.24 | 2.15 | 10.49 | 2.29 | 2.18 | 1.13 |

| Negative | 10.75 | 0.94 | 12.04 | 1.94 | 10.23 | 2.46 | 2.62 | ||

| J2-H | Forward | 11.61 | 2.68 | 13.85 | 6.14 | 11.78 | 7.05 | 2.63 | 1.19 |

| Negative | 11.32 | 2.80 | 14.15 | 6.15 | 12.03 | 6.73 | 2.40 | ||

| J2-F | Forward | 14.11 | 2.54 | 18.54 | 5.11 | 15.97 | 6.18 | 2.43 | 1.26 |

| Negative | 14.64 | 2.59 | 18.77 | 4.91 | 18.77 | 4.91 | 1.90 | ||

| J3-H | Forward | 4.16 | 4.08 | 4.65 | 5.08 | 3.95 | 6.09 | 1.49 | 1.14 |

| Negative | 3.81 | 3.07 | 4.56 | 4.23 | 3.88 | 6.06 | 1.97 | ||

| J3-F | Forward | 5.26 | 4.04 | 6.15 | 4.99 | 5.23 | 6.14 | 1.52 | 1.28 |

| Negative | 3.62 | 4.02 | 5.38 | 5.62 | 4.57 | 6.26 | 1.56 | ||

| J4-H | Forward | 9.62 | 1.54 | 11.78 | 2.76 | 10.01 | 3.19 | 2.07 | 1.19 |

| Negative | 9.01 | 0.84 | 11.29 | 2.41 | 9.60 | 4.03 | 4.80 | ||

| J4-F | Forward | 11.68 | 2.19 | 15.57 | 7.01 | 15.57 | 7.01 | 3.20 | 1.32 |

| Negative | 11.13 | 2.17 | 15.22 | 6.33 | 15.22 | 6.33 | 2.92 | ||

| J5-H | Forward | 11.70 | 1.56 | 14.09 | 4.08 | 11.98 | 6.11 | 3.92 | 1.14 |

| Negative | 12.13 | 1.18 | 13.74 | 3.55 | 13.10 | 5.21 | 4.42 | ||

| J5-F | Forward | 14.12 | 1.15 | 16.87 | 2.01 | 14.34 | 4.39 | 3.82 | 1.15 |

| Negative | 14.58 | 1.27 | 17.07 | 3.62 | 14.51 | 4.55 | 3.58 | ||

| J6-H | Forward | 12.13 | 2.31 | 17.31 | 4.54 | 14.71 | 5.92 | 2.56 | 1.33 |

| Negative | 13.33 | 2.19 | 17.92 | 4.09 | 15.23 | 5.56 | 2.54 | ||

| J6-F | Forward | 16.08 | 1.94 | 19.91 | 5.81 | 16.92 | 6.46 | 3.33 | 1.25 |

| Negative | 15.15 | 2.09 | 19.74 | 5.18 | 16.78 | 6.31 | 3.02 | ||

| J7-H | Forward | 17.26 | 2.25 | 20.64 | 4.60 | 17.54 | 8.11 | 3.60 | 1.31 |

| Negative | 14.38 | 2.17 | 21.36 | 5.63 | 18.16 | 7.89 | 3.64 | ||

| J7-F | Forward | 17.25 | 2.01 | 24.74 | 6.09 | 23.68 | 7.10 | 3.53 | 1.47 |

| Negative | 15.29 | 2.08 | 24.78 | 6.85 | 21.74 | 8.02 | 3.86 | ||

| J8-H | Forward | 18.83 | 2.22 | 32.13 | 6.69 | 30.11 | 7.32 | 3.30 | 1.59 |

| Negative | 19.67 | 2.14 | 32.66 | 5.65 | 27.76 | 7.59 | 3.55 | ||

| J8-F | Forward | 25.87 | 2.16 | 35.57 | 5.21 | 30.23 | 7.07 | 3.27 | 1.34 |

| Negative | 24.64 | 2.29 | 33.49 | 5.67 | 28.47 | 7.95 | 3.47 |

| Specimen | K1 | Increase (%) | Ka | Increase (%) |

|---|---|---|---|---|

| J1-H | 17.09 | 14.76 | ||

| J1-F | 21.06 | 23.23 | 16.63 | 12.67 |

| J2-H | 14.02 | 11.79 | ||

| J2-F | 21.21 | 51.28 | 16.58 | 40.63 |

| J3-H | 1.47 | —— | ||

| J3-F | 1.95 | 32.65 | —— | —— |

| J4-H | 12.08 | 12.63 | ||

| J4-F | 19.79 | 63.82 | 17.18 | 36.03 |

| J5-H | 18.19 | 16.98 | ||

| J5-F | 24.44 | 34.36 | 20.20 | 18.96 |

| J6-H | 17.06 | 15.77 | ||

| J6-F | 20.88 | 22.39 | 18.10 | 14.77 |

| J7-H | 19.38 | 17.01 | ||

| J7-F | 24.19 | 24.82 | 21.93 | 28.92 |

| J8-H | 29.16 | 23.55 | ||

| J8-F | 29.69 | 1.82 | 25.63 | 8.83 |

| Specimens | R0 (kN·m/rad) | Mu (kN·m) | EIb/lb (kN·m) | R0lb/EIb | Mu/Mbp | Joint Classification |

|---|---|---|---|---|---|---|

| J1-H | 1708.7 | 9.83 | 1791.86 | 0.95 | 0.34 | Semi-rigid, partial-strength |

| J1-F | 2105.8 | 10.36 | 1791.86 | 1.18 | 0.36 | Semi-rigid, partial-strength |

| J2-H | 1402.3 | 11.91 | 1791.86 | 0.78 | 0.41 | Semi-rigid, partial-strength |

| J2-F | 2121.1 | 17.37 | 1791.86 | 1.18 | 0.60 | Semi-rigid, partial-strength |

| J3-H | 147.5 | 3.92 | 1791.86 | 0.08 | 0.14 | Nominal pinned, nominal pinned |

| J3-F | 195.3 | 4.91 | 1791.86 | 0.11 | 0.17 | Nominal pinned, nominal pinned |

| J4-H | 1207.9 | 9.81 | 1791.86 | 0.67 | 0.34 | Semi-rigid, partial-strength |

| J4-F | 1979.8 | 15.39 | 1791.86 | 1.10 | 0.53 | Semi-rigid, partial-strength |

| J5-H | 1819.5 | 12.54 | 1791.86 | 1.02 | 0.43 | Semi-rigid, partial-strength |

| J5-F | 2444.3 | 14.37 | 1791.86 | 1.36 | 0.50 | Semi-rigid, partial-strength |

| J6-H | 1805.6 | 14.97 | 1791.86 | 1.01 | 0.52 | Semi-rigid, partial-strength |

| J6-F | 2088.1 | 16.85 | 1791.86 | 1.17 | 0.58 | Semi-rigid, partial-strength |

| J7-H | 1897.7 | 18.04 | 1791.86 | 1.06 | 0.62 | Semi-rigid, partial-strength |

| J7-F | 2428.9 | 22.71 | 1791.86 | 1.36 | 0.78 | Semi-rigid, partial-strength |

| J8-H | 2957.2 | 29.68 | 1791.86 | 1.65 | 1.03 | Semi-rigid, full strength |

| J8-F | 2969.4 | 29.99 | 1791.86 | 1.66 | 1.04 | Semi-rigid, full strength |

| Specimens | J1-H | J2-H | J3-H | J4-H | J5-H | J6-H | J7-H | J8-H |

|---|---|---|---|---|---|---|---|---|

| S value | 0.571 | 0.509 | 0.330 | 0.437 | 0.494 | 0.684 | 0.822 | 1.240 |

| Specimens | J1-F | J2-F | J3-F | J4-F | J5-F | J6-F | J7-F | J8-F |

| S value | 0.482 | 0.564 | 0.255 | 0.601 | 0.507 | 0.642 | 0.844 | 1.247 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Chen, L.; Cai, L.; Li, Y.; Yusoff, Z.M. An Experimental Evaluation of Steel Beam-HSST/CFSST Column Connection with Varying Joint Configurations. Buildings 2025, 15, 3774. https://doi.org/10.3390/buildings15203774

Zhang Z, Chen L, Cai L, Li Y, Yusoff ZM. An Experimental Evaluation of Steel Beam-HSST/CFSST Column Connection with Varying Joint Configurations. Buildings. 2025; 15(20):3774. https://doi.org/10.3390/buildings15203774

Chicago/Turabian StyleZhang, Zongmin, Lanhua Chen, Ling Cai, Yanchun Li, and Zaharah Mohd Yusoff. 2025. "An Experimental Evaluation of Steel Beam-HSST/CFSST Column Connection with Varying Joint Configurations" Buildings 15, no. 20: 3774. https://doi.org/10.3390/buildings15203774

APA StyleZhang, Z., Chen, L., Cai, L., Li, Y., & Yusoff, Z. M. (2025). An Experimental Evaluation of Steel Beam-HSST/CFSST Column Connection with Varying Joint Configurations. Buildings, 15(20), 3774. https://doi.org/10.3390/buildings15203774