Experimental and Numerical Study on Ultra-High Performance Concrete Repair of Uniformly Corroded Reinforced Concrete Pipes

Abstract

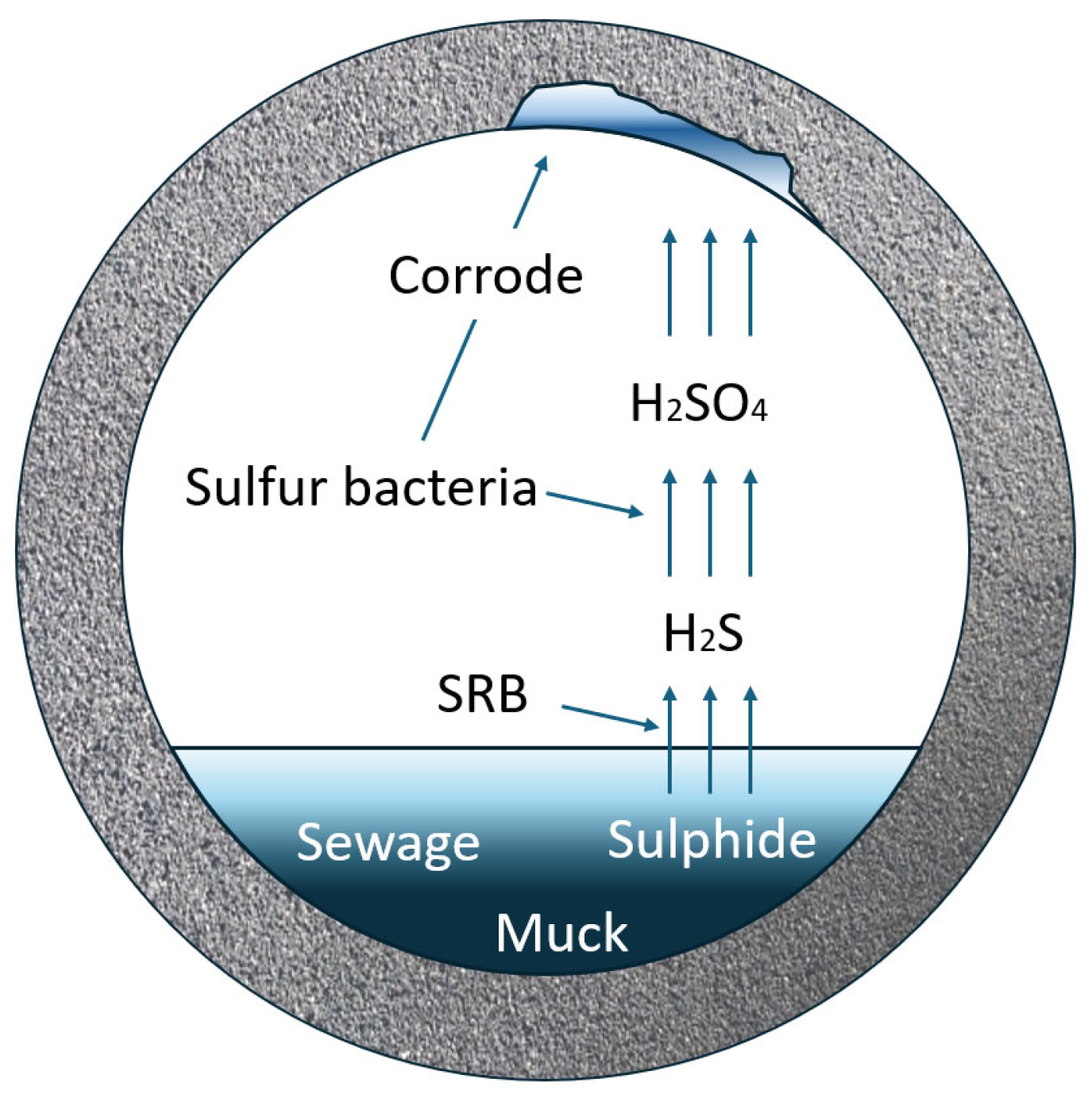

1. Introduction

2. Experiments

2.1. Experimental Scheme

2.2. Material Properties

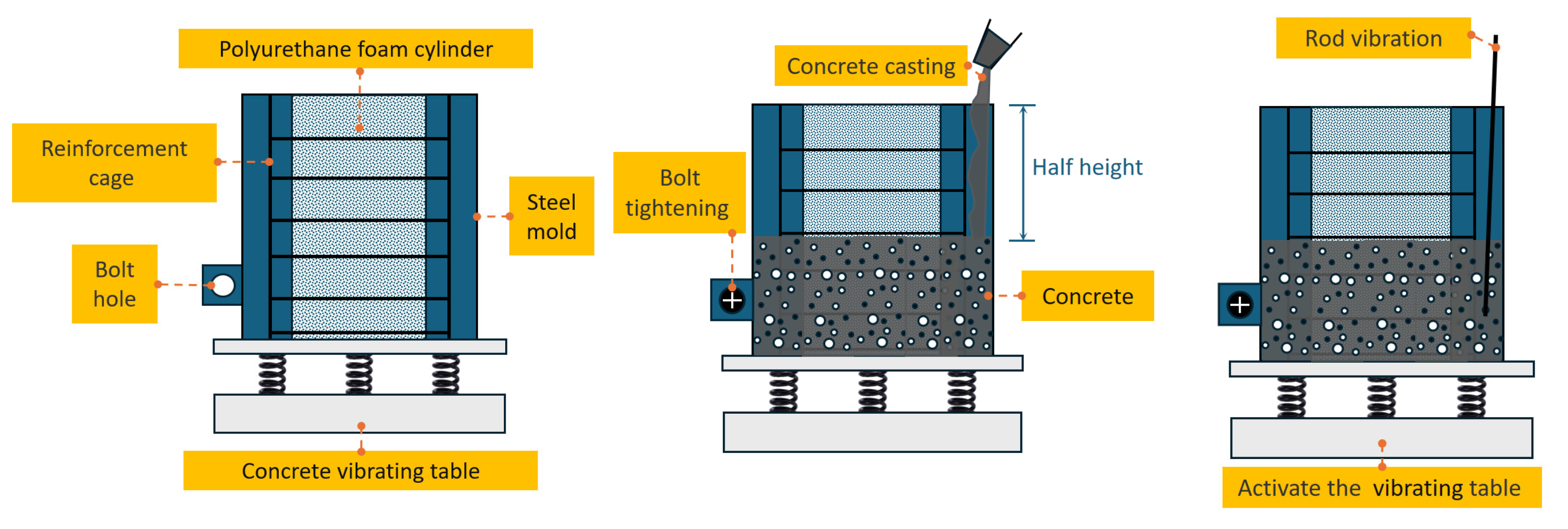

2.3. Specimen Preparation

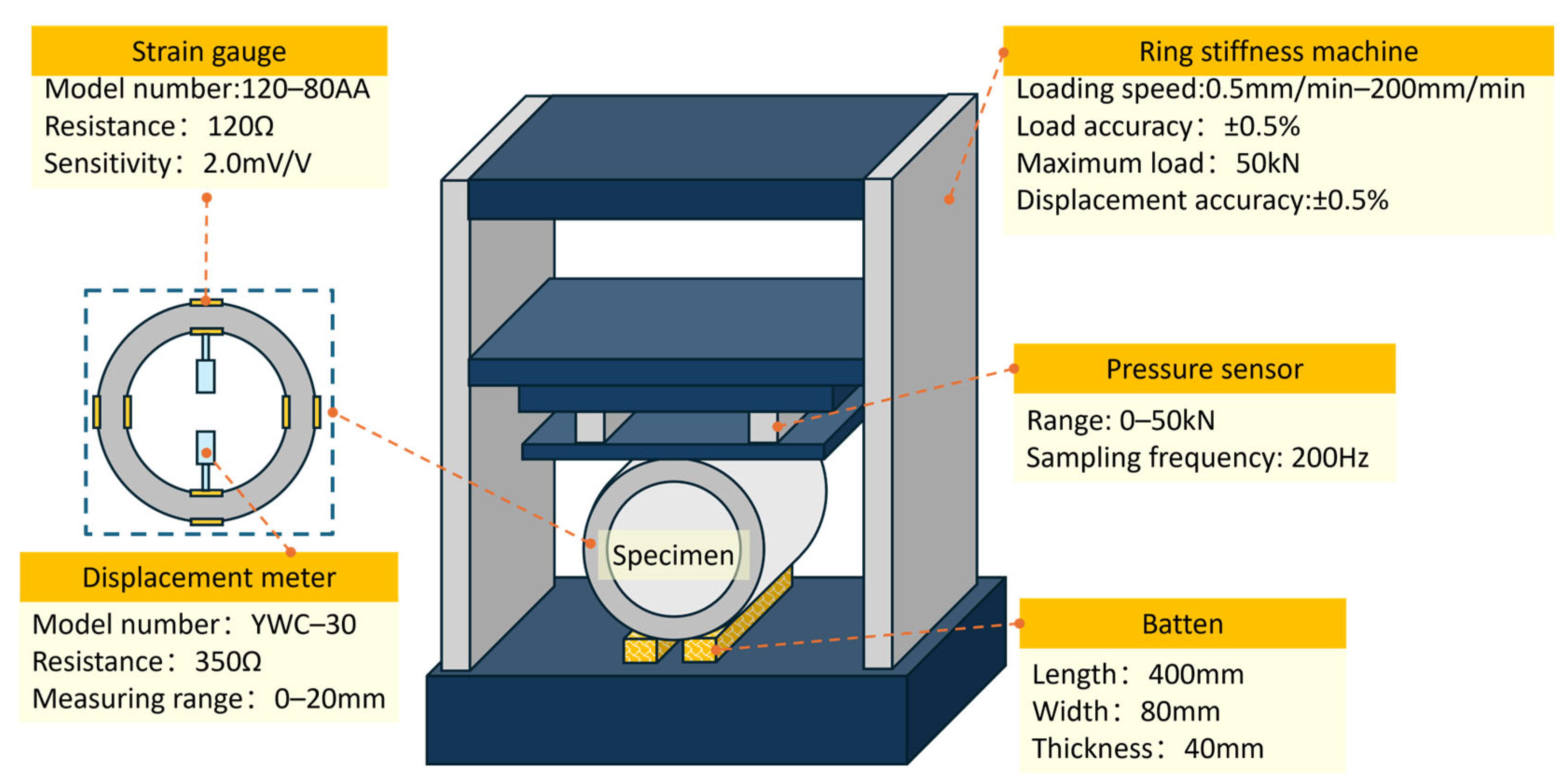

2.4. Three-Edge Bearing Test

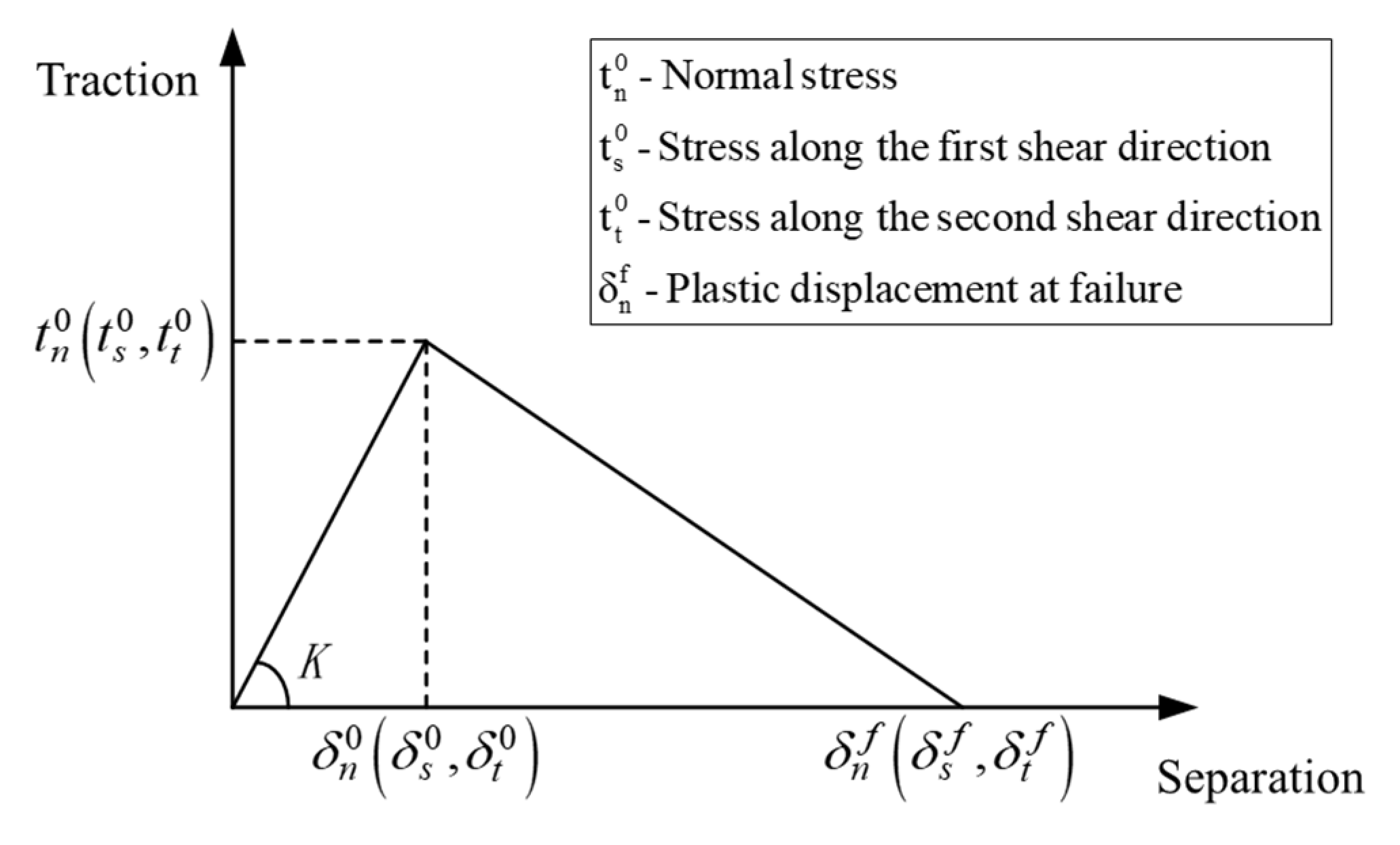

3. Numerical Simulations

4. Results and Analysis

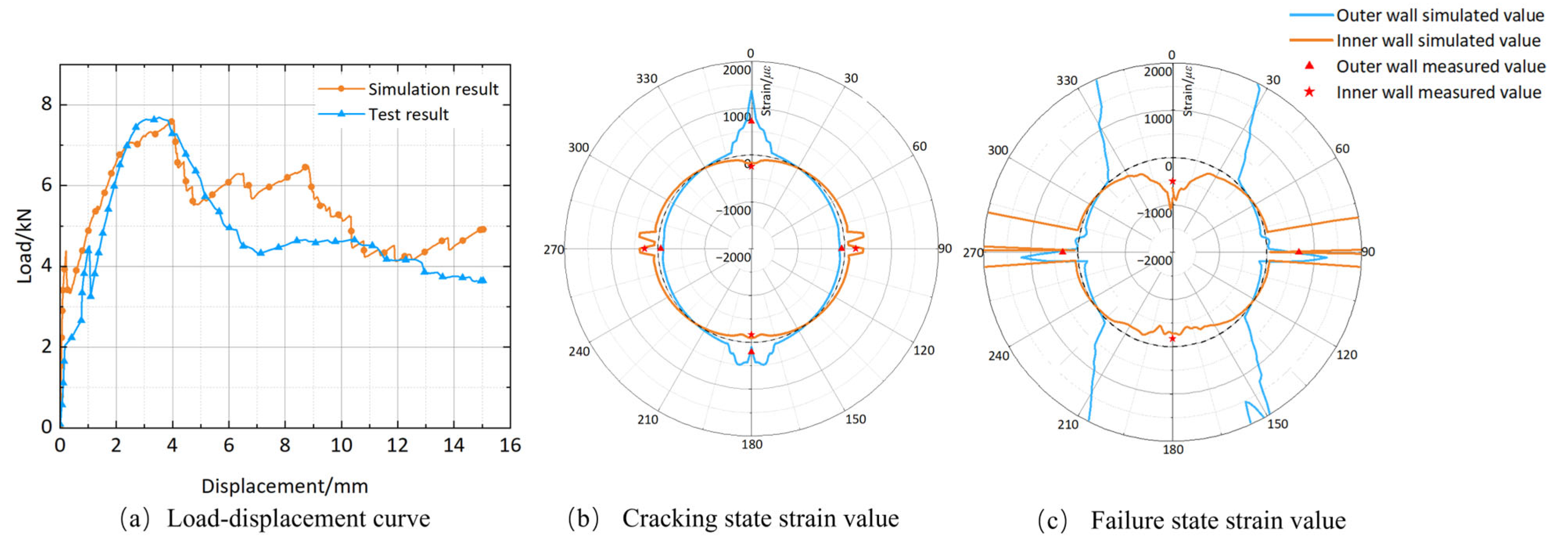

4.1. Model Validation

4.2. Effect of Corrosion Thickness on Load-Bearing Capacity

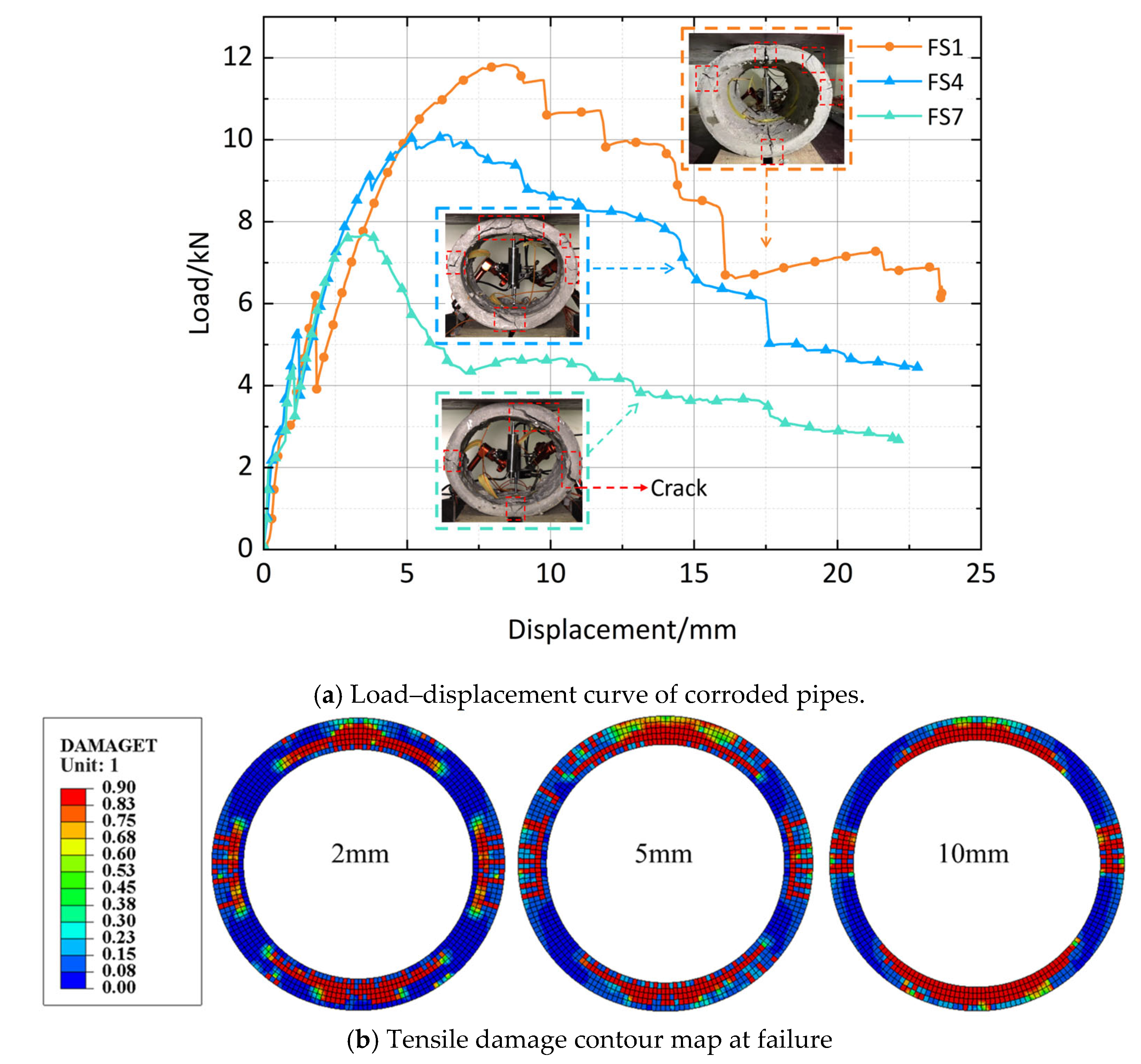

4.2.1. Effect on Unrepaired Pipes

- Elastic Stage: a linear correlation between load and displacement is observed from the onset of loading until crack initiation. During this phase, short vertical cracks are formed in high-stress regions, specifically at the crown, invert, and springlines.

- Crack growth Stage: From crack initiation to failure load, cracks propagate to critical widths, causing concrete failure and a sharp load drop due to brittle capacity loss. Re-inforcing bars remain unyielding, supporting the load increase. Vertical cracks at the crown and invert develop into bending-shear diagonal fractures, tapering from wider bases to narrower tips at a 45° inclination toward the load point.

- Yield Stage: Post-reinforcement yield, the pipe fails with gradual load decline and ac-celerated deformation, marked by widespread structural degradation.

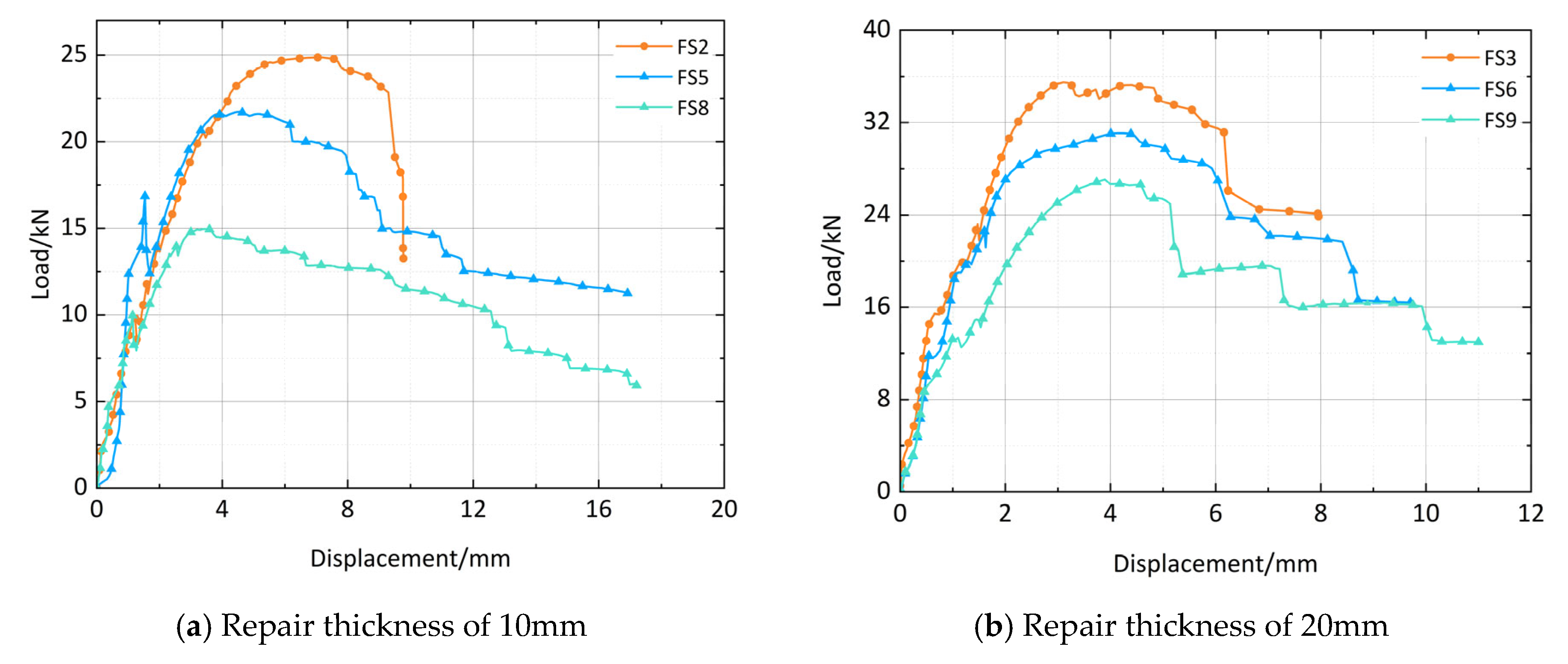

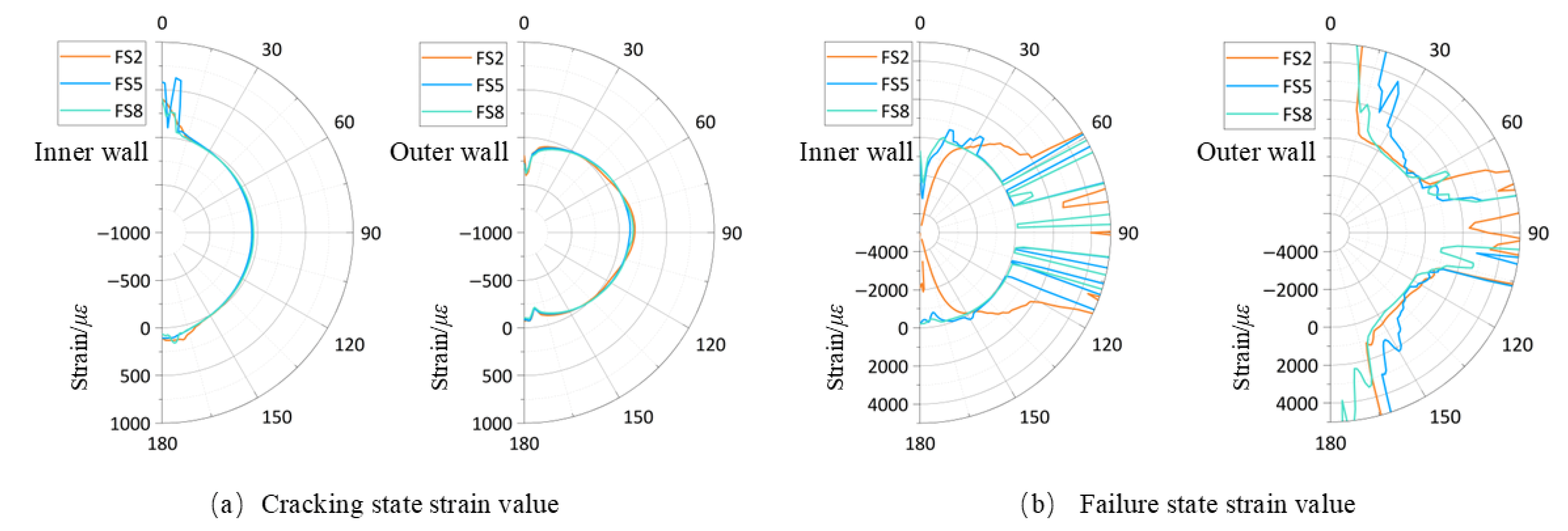

4.2.2. Effect on the Repaired Pipes

- Before crack initiation, repaired pipes exhibit a near-linear load–displacement response, reflecting strong elastic compatibility between the UHPC lining and host pipe, with a consistent equivalent elastic modulus

- At crack onset, repaired pipes experience less load reduction than unrepaired ones, with the reduction decreasing as UHPC lining thickness increases, owing to the lining’s sustained post-cracking strength and enhanced flexural capacity.

- During yielding, repaired pipes show an extended yield plateau, indicating improved ductility. The UHPC lining’s high stiffness limits localized deformation, while fiber pullout restricts crack growth, allowing greater plastic strain and delaying buckling, shifting failure from brittle to ductile.

- With progressive loading and crack propagation, the equivalent elastic modulus gradually declines, especially in pipes with a corrosion thickness of 10 mm. Increased corrosion reduces the host pipe’s load-bearing capacity, transitioning the structure to a UHPC-dominated load-carrying system, with reduced interfacial friction accelerating modulus decline.

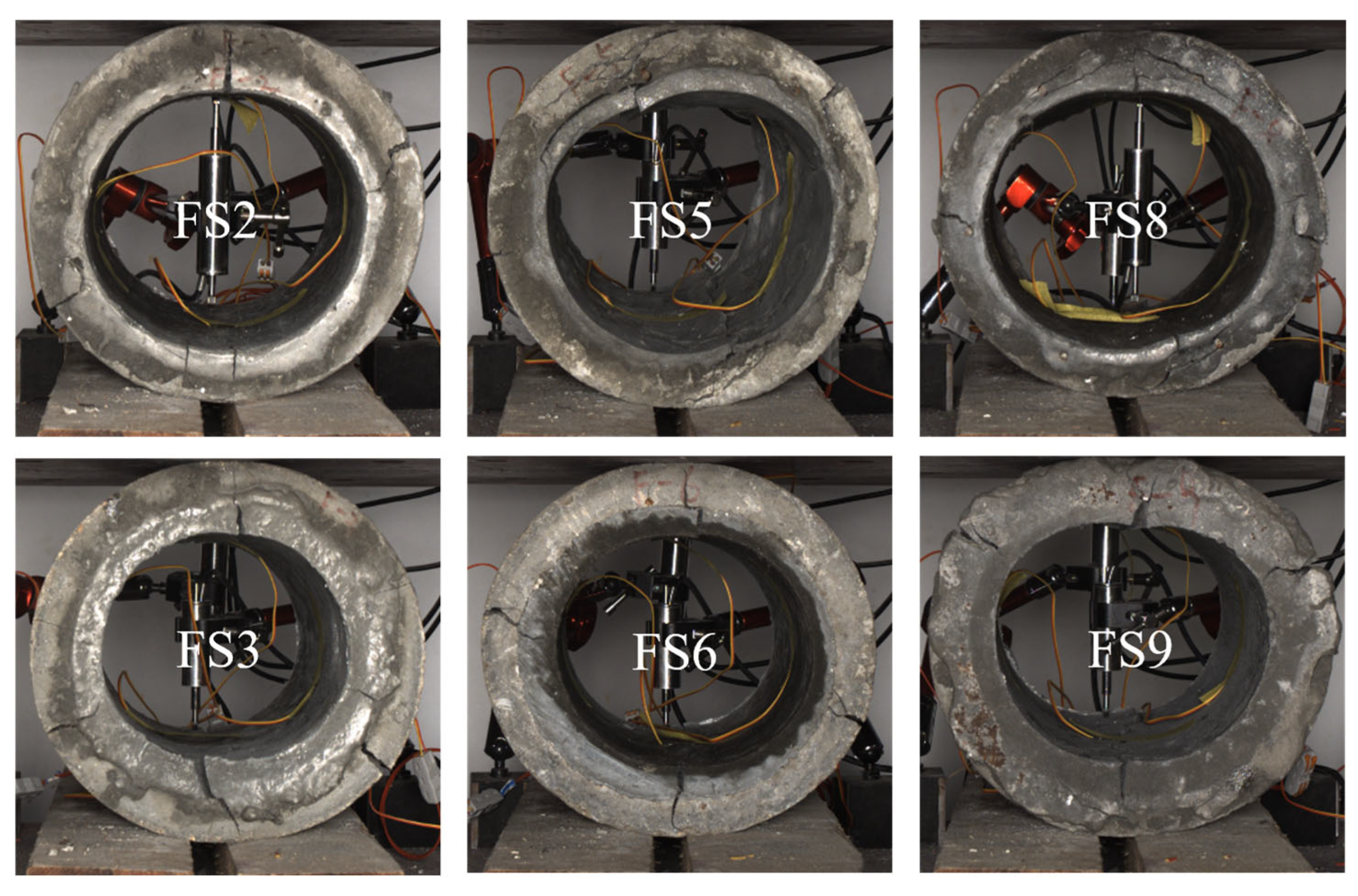

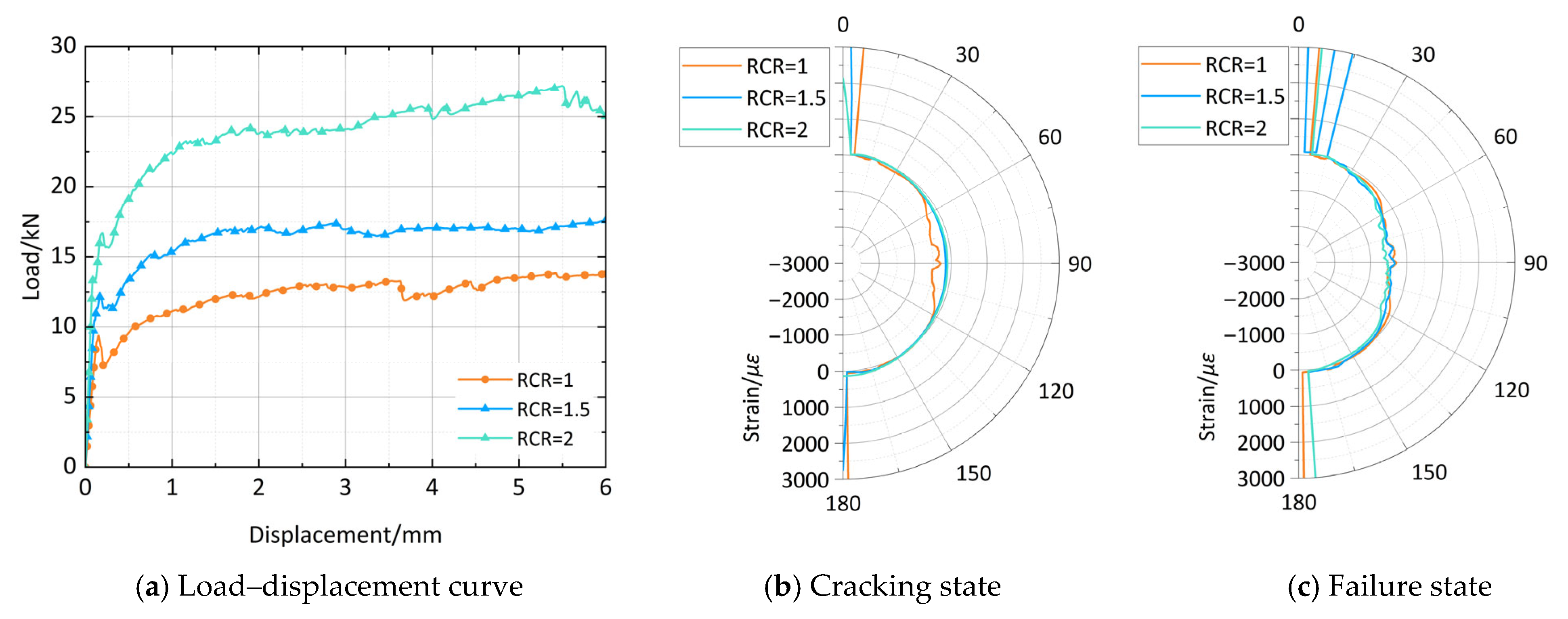

4.3. Effect of Repair Thickness on Load-Bearing Capacity

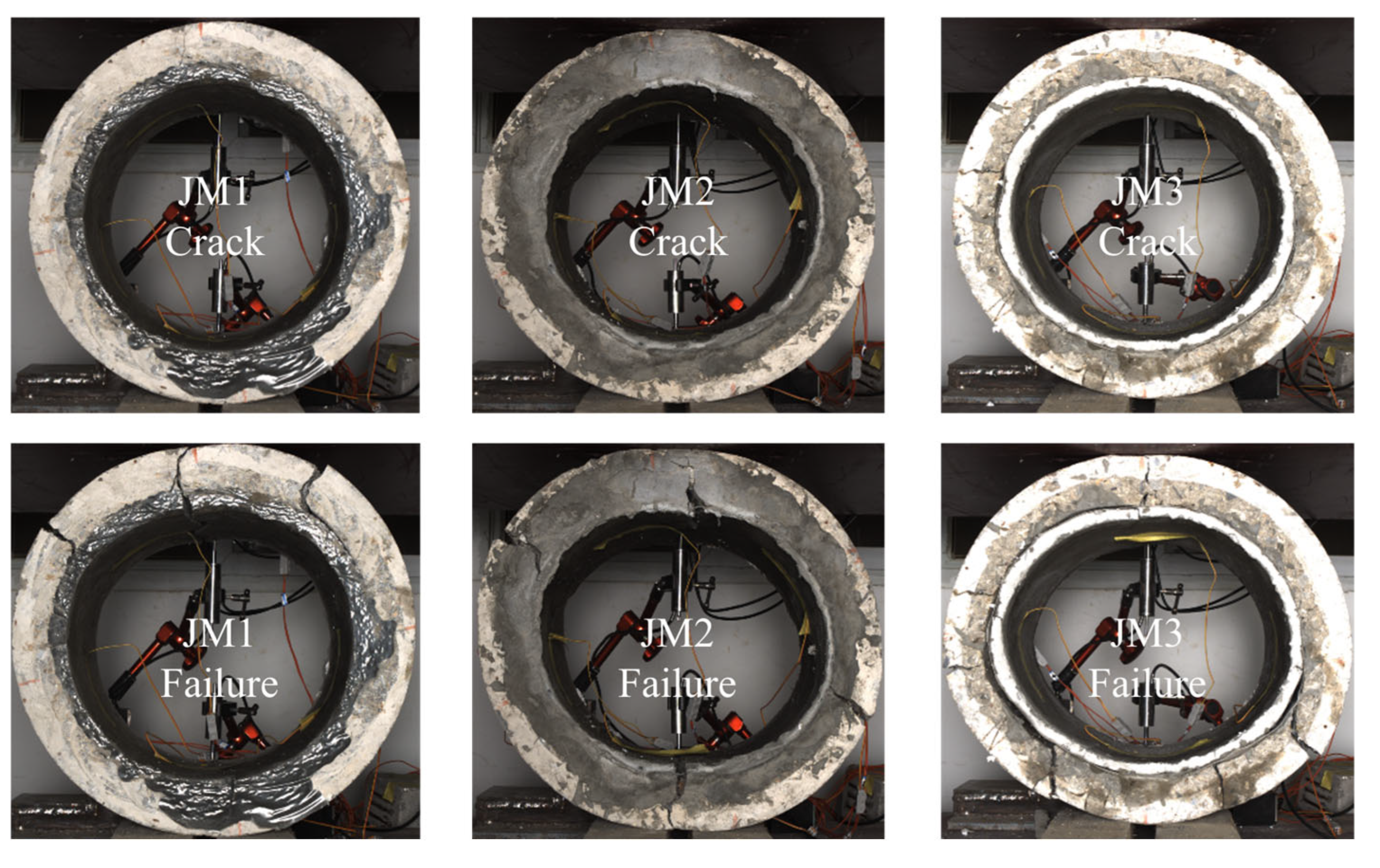

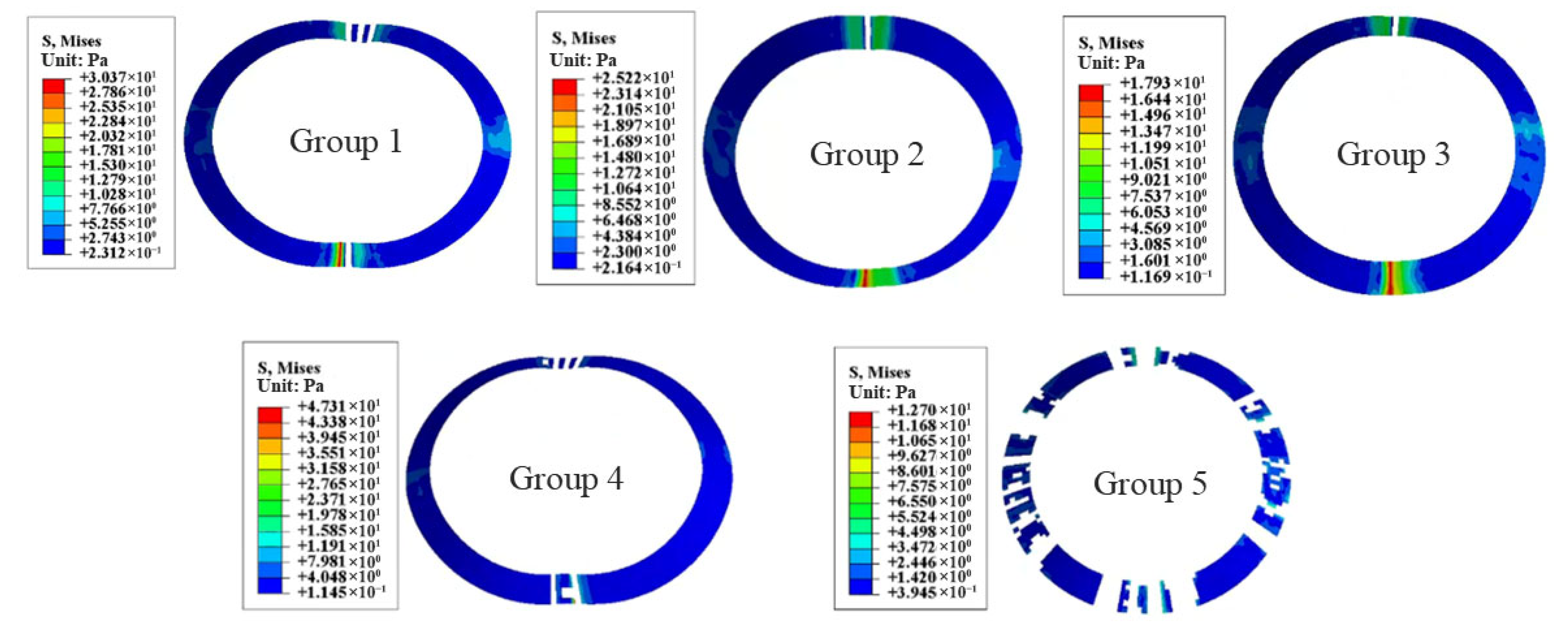

4.4. Effect of Interface Type on Load-Bearing Capacity

5. Conclusions

- Load–displacement response includes elastic, crack propagation, and yield phases. UHPC linings reduce crack-induced load drops, delay buckling, enhance yield capacity, and shift failure from brittle to ductile.

- The residual load-bearing capacity of corroded pipes exhibits a linear decrease with increasing corrosion depth, while it improves with greater repair thickness, enhancing both crack resistance and deformation capacity. Specifically, for each 5 mm increase in UHPC lining thickness, the load-bearing capacity of pipes with 2 mm, 5 mm, and 10 mm corrosion depths rises by 48.78%, 49.92%, and 70.49%, respectively.

- Interface shear strength and fracture energy significantly affect repaired pipe capacity. Higher fracture energy minimizes debonding, while lower shear strength increases sliding, impacting capacity fivefold more than debonding. Independent damage in composite systems reduces capacity compared to fully bonded structures. Interface design should optimize shear strength.

- Nail embedding enhances shear strength, increasing capacity by 2.91 times over natural bonding and preventing debonding. Unitized systems with polyethylene films reduce load-sharing due to sliding, lowering failure load by 15.67%. Localized shear reinforcement, such as nail embedding, is recommended for high-stress zones, with continuous monitoring of interfacial sliding for durability. Future research is advisable to optimize UHPC composition and investigate diverse interface treatments, including roughening and varied steel nail configurations, to further elucidate their impact on pipeline load capacity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| RCPs | Reinforced concrete pipes |

| SRB | Sulfate-reducing bacteria |

| UHPC | Ultra-high performance concrete |

| NC | Normal concrete |

| TEBT | Three-Edge Bearing Test |

| CDP | Concrete damage plasticity |

References

- Wang, M.; Wang, Y.; Tan, Z. Exploration on the Comprehensive Utilization of Underground Space in China’s Smart City. Beijing Jiaotong Univ. 2016, 40, 1–8. [Google Scholar]

- Liu, H.; Liu, J.B.; Zhu, Z.H.; Zhao, Y.H.; Wang, Z.G.; Qiao, L.X.; Luan, Q.X.; Zhang, P. Influence of Corrosion-Induced Concrete Thinning on the Bearing Capacity of Reinforced Concrete Pipes. Civ. Eng. Manag. 2022, 39, 62–75. [Google Scholar]

- Wang, F. Theoretical Analysis and Experimental Study on Stress Characteristics of Damaged Concrete Pipes Repaired by In-Situ Spraying. Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2022. [Google Scholar]

- Kong, Y. Study and Application of Cast In-Situ Method for Pipeline and Manhole Trenchless Rehabilitation. Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2017. [Google Scholar]

- Lin, S.; Huang, Q.; Chen, B.; Chen, Y. Design of U-RC Composite Pier of Sea-Crossing Bridge. Traffic Transp. Eng. 2017, 17, 55–65. [Google Scholar]

- Wang, C. Global Structure Analysis and Optimal Design of the Pier in T-Type Rigid Bridge Constructed with Rotation Method. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2017. [Google Scholar]

- Hu, Y. The Axial Compressive Performance Study of a Reactive Powder Concrete Precast Tube Concrete Composite Columns. Ph.D. Thesis, Hunan University, Changsha, China, 2015. [Google Scholar]

- Bolina, F.L.; Poleto, G.; Carvalho, H. Proposition of parametric data for UHPC at high temperatures. J. Build. Eng. 2023, 76, 107222. [Google Scholar] [CrossRef]

- Bolina, F.L.; München, R.M.; Lago, B.D.; Kodur, V. A comparative study between ultra-high-performance concrete structures and normal strength concrete structures exposed to fire. Structures 2024, 68, 107197. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B.; Su, J.; Xu, G.; Zhang, D.; Zhou, J. Effects of fibers on the mechanical properties of UHPC: A review. J. Traffic Transp. Eng. Engl. Ed. 2022, 9, 363–387. [Google Scholar] [CrossRef]

- Shi, C.J.; He, W.; Wu, Z.; Wu, L.; Zhu, D.; Huang, Z. Influence of Fibers on Mechanical Properties of UHPC. Bull. Chin. Ceram. Soc. 2015, 34, 2227–2247. [Google Scholar]

- Yuan, C.; Xu, S.; Raza, A.; Wang, C.; Wang, D. Influence and Mechanism of Curing Methods on Mechanical Properties of Manufactured Sand UHPC. Materials 2022, 15, 6183. [Google Scholar] [CrossRef]

- Wu, T.R. Durability of UHPC-Normal Concrete Bond Interface under Marine and Freeze-Thaw Conditions. Ph.D. Thesis, Guangdong University of Technology, Guangdong, China, 2025. [Google Scholar]

- Yang, Y.B.; Yue, X.D.; Zheng, F.B.; Liu, F.C.; Guo, W.Y.; Wang, H.C. Research on sewage corrosion resistance of ultra high performance concrete. Ind. Constr. 2020, 50, 82–87. [Google Scholar]

- Cheng, X.Y. Study on Durability of UHPC in Sulfuric Acid Environment. Ph.D. Thesis, Guangdong University of Technology, Guangzhou, China, 2024. [Google Scholar]

- Liu, J.; Wei, J.; Li, J.; Su, Y.; Wu, C. A comprehensive review of ultra-high performance concrete (UHPC) behaviour under blast loads. Cem. Concr. Compos. 2024, 148, 105449. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, J.; Shao, X.; Hou, C. Experiment on Interfacial Shear Properties Between Ultra-High Performance Concrete and Normal Strength Concrete. China Civ. Eng. J. 2021, 54, 81–89. [Google Scholar]

- Liao, Z. Experimental Research on Bond Strength of UHPC-NC Interface. Ph.D. Thesis, Hunan University, Changsha, China, 2018. [Google Scholar]

- Buda-Ozog, L.; Skrzypczak, I.; Kujda, J. Cracks Analysis in the Reinforced Concrete Pipes. Balt. Road Bridge Eng. 2017, 12, 88–93. [Google Scholar] [CrossRef]

- Silva, J.D.; Debs, M.K.; Beck, A.T. Reliability Evaluation of Reinforced Concrete Pipes in Crack Opening Limit State. Rev. IBRACON Estrut. Mater. 2008, 1, 314–330. [Google Scholar] [CrossRef]

- Shi, Z.; Masaki, N.; Yoshifumi, T. Structural Analysis and Renovation Design of Ageing Sewers; De Gruyter Open: Berlin, Germany, 2016. [Google Scholar]

- Zhang, H.F. Theoretical and Experimental Study on Structural Performance of the Sprayed-on Cement Mortar Liners Rehabilitating Precast Concrete Drainage Pipe. Ph.D. Thesis, China University of Geosciences, Wuhan, China, 2019. [Google Scholar]

- GB/T 50080-2016; Standard for Test Method of Performance on Ordinary Fresh Concrete. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2016.

- GB/T 17671-2021; Test Method of Cement Mortar. State Administration for Market Regulation: Beijing, China, 2021.

- GB/T 16752-2017; Test Methods of Concrete and Reinforced Concrete Sewer Pipes. General Administration of Quality Supervision, Inspection and Quarantine of China: Beijing, China, 2017.

- Fang, H.; Tan, P.; Du, X.; Li, B.; Yang, K.; Zhang, Y. Mechanical Response of Buried HDPE Double-Wall Corrugated Pipe Under Traffic-Sewage Coupling Load. Tunn. Undergr. Space Technol. 2021, 108, 103664. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. Ministry of Housing and Urban-Rural Development of China: Beijing, China, 2010.

- Li, Q.; Kuang, Y.; Guo, W. CDP Model Parameters Calculation and Value Method Verification. Zhengzhou Univ. Eng. Sci. 2021, 42, 43–48. [Google Scholar]

- Alfarah, B.; Lopez-Almansa, F.; Oller, S. New Methodology for Calculating Damage Variables Evolution in Plastic Damage Model for RC Structures. Eng. Struct. 2017, 132, 70–86. [Google Scholar] [CrossRef]

- Demir, A.; Ozturk, H.; Dok, G. 3D Numerical Modeling of RC Deep Beam Behavior by Nonlinear Finite Element Analysis. Disaster Sci. Eng. 2016, 2, 13–18. [Google Scholar]

- Darabnoush Tehrani, A. Finite Element Analysis for ASTM C-76 Reinforced Concrete Pipes with Rebar Steel Cage. Ph.D. Thesis, University of Texas Arlington, Arlington, TX, USA, 2016. [Google Scholar]

- Zhang, G.; Su, J. Nonlinearity Analysis of Reinforced Concrete Based on ABAQUS. Sci. Technol. Eng. 2008, 20, 5620–5624. [Google Scholar]

- Oyang, N.; Deng, S. Study on the Interfacial Properties of UHPC-NC Composite Component. Chongqing Univ. 2021, 44, 63–74. [Google Scholar]

- Yang, J.; Fang, Z. Research on Stress-Strain Relation of Ultra High Performance Concrete. Concrete 2008, 7, 11–15. [Google Scholar]

- Zhang, Z.; Shao, X.D.; Li, W.G.; Zhu, P.; Chen, H. Axial Tensile Behavior Test of Ultra High Performance Concrete. China J. Highw. Transp. 2015, 28, 50–58. [Google Scholar]

| Design Indicators | Value | ||

|---|---|---|---|

| DN200 | DN400 | ||

| Size | Wall thickness/mm | 30 | 40 |

| Cover thickness/mm | 10 | ||

| Length/mm | 300 | ||

| Circumferential reinforcement | Diameter/mm | 3 | 5 |

| Inner diameter of the ring/mm | 221 | 427 | |

| Number of rings | 18.5 | 20.6 | |

| Pitch/mm | 54.1 | 48.5 | |

| Longitudinal tendon | Diameter/mm | 5 | |

| Number | 6 | ||

| Diameter | Group | Corrosion Thickness/mm | Repair Thickness/mm |

|---|---|---|---|

| DN200 | FS0 | 0 | 0 |

| FS1 FS2 FS3 | 2 | 0 10 20 | |

| FS4 FS5 FS6 | 5 | 0 10 20 | |

| FS7 FS8 FS9 | 10 | 0 10 20 |

| Diameter | Group | Structure Type | Processing Method | Repair Thickness/mm |

|---|---|---|---|---|

| DN400 | JM0 | Composite | Natural bonding | 0 |

| JM1 | Natural bonding | 25 | ||

| JM2 | Steel nail embedding | 25 | ||

| JM3 | Unitized | PE film adhesion | 25 |

| Group | Fluidity/mm | Curing Time/d | Flexural Strength/MPa | Compressive Strength/MPa |

|---|---|---|---|---|

| 1 | 184 | 1 | 6.0 | 55.7 |

| 2 | 181 | 7 | 10.4 | 64.3 |

| 3 | 185 | 28 | 17.9 | 84.7 |

| Corrosion | Diameter/mm | Repair/mm | Diameter/mm |

|---|---|---|---|

| 2 | 204 | 10 | 184 |

| 20 | 164 | ||

| 5 | 210 | 10 | 190 |

| 20 | 170 | ||

| 10 | 220 | 10 | 200 |

| 20 | 180 |

| Element | Parameter | Value |

|---|---|---|

| C30 concrete | Dilation angle, Ψ * | 36° |

| Elastic modulus, Ec | 30,000 MPa | |

| Poisson’s ratio, ν | 0.2 | |

| Eccentricity, e | 0.1 | |

| Ratio of biaxial to uniaxial compressive strength, fb0/fc0 | 1.16 | |

| Ratio of second stress invariants, kc | 0.667 | |

| Viscosity parameter, μ | 0.0001 | |

| Reinforcing steel | Elastic modulus, Ecr | 200,000 MPa |

| Poisson’s ratio, νr | 0.3 |

| Knn | Kss/Ktt | Gc | ||

|---|---|---|---|---|

| 2887 | 73 | 9.3 | 16.1 | 0.9 |

| Group | Corrosion Thickness/mm | TEBT | Numerical Simulations | ||

|---|---|---|---|---|---|

| Crack Load/kN | Failure Load/kN | Crack Load/kN | Failure Load/kN | ||

| FS0 | 0 | 7.50 | 12.57 | 5.65 | 12.52 |

| FS1 | 2 | 6.19 | 11.83 | 6.29 | 11.39 |

| FS4 | 5 | 5.36 | 10.12 | 5.17 | 10.02 |

| FS7 | 10 | 4.51 | 7.69 | 4.38 | 7.61 |

| Group | Corrosion Thickness/mm | Failure Load/kN | Error | |

|---|---|---|---|---|

| TEBT | Numerical Simulation | |||

| FS2 | 2 | 24.87 | 25.24 | 1.49% |

| FS5 | 5 | 21.73 | 20.79 | −4.33% |

| FS8 | 10 | 14.96 | 14.21 | −5.01% |

| Group | Crack Load/kN | Failure Load/kN |

|---|---|---|

| FS1 | 6.19 | 11.83 |

| FS2 | 9.80 | 24.87 |

| FS3 | 15.41 | 35.64 |

| FS4 | 5.36 | 10.12 |

| FS5 | 16.85 | 21.73 |

| FS6 | 22.83 | 31.08 |

| FS7 | 4.51 | 7.69 |

| FS8 | 9.97 | 14.96 |

| FS9 | 13.37 | 27.09 |

| Group | /MPa | Gc/(N/mm) | Failure Load/kN | |

|---|---|---|---|---|

| 1 | 9.3 | 16.1 | 0.1 | 17.77 |

| 2 | 9.3 | 16.1 | 0.5 | 17.42 |

| 3 | 9.3 | 16.1 | 0.9 | 17.57 |

| 4 | 3.3 | 4.5 | 0.9 | 16.46 |

| 5 | 0.33 | 0.45 | 0.9 | 15.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Gong, C.; Zhang, P.; Zeng, C. Experimental and Numerical Study on Ultra-High Performance Concrete Repair of Uniformly Corroded Reinforced Concrete Pipes. Buildings 2025, 15, 3772. https://doi.org/10.3390/buildings15203772

Wang D, Gong C, Zhang P, Zeng C. Experimental and Numerical Study on Ultra-High Performance Concrete Repair of Uniformly Corroded Reinforced Concrete Pipes. Buildings. 2025; 15(20):3772. https://doi.org/10.3390/buildings15203772

Chicago/Turabian StyleWang, Dongting, Chenkun Gong, Peng Zhang, and Cong Zeng. 2025. "Experimental and Numerical Study on Ultra-High Performance Concrete Repair of Uniformly Corroded Reinforced Concrete Pipes" Buildings 15, no. 20: 3772. https://doi.org/10.3390/buildings15203772

APA StyleWang, D., Gong, C., Zhang, P., & Zeng, C. (2025). Experimental and Numerical Study on Ultra-High Performance Concrete Repair of Uniformly Corroded Reinforced Concrete Pipes. Buildings, 15(20), 3772. https://doi.org/10.3390/buildings15203772